Page 1

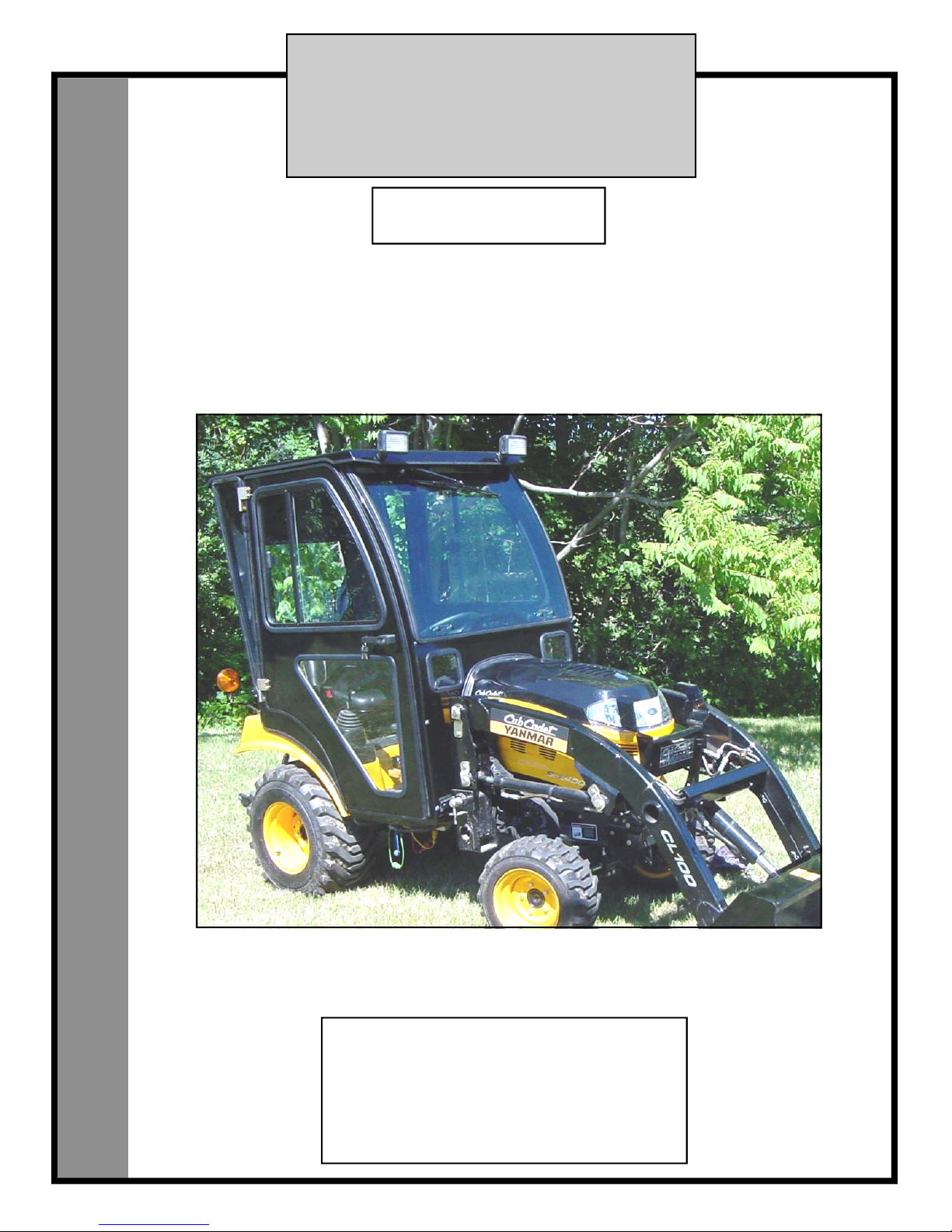

CUB CADET Sc SERIES

cab kit with hard doors

and soft rear curtain

Rev. -, p. 1 of 19

p/n 59A40056727

An optional Hard Rear Panel

can be purchased separately.

The contents of this envelope are the property of the owner.

Be sure to leave with the owner when installation is complete.

APPROXIMATE INSTALLATION TIME: 2 to 3 HOURS

(excluding accessories)

Shown with optional work lights and optional sliding door windows.

Additional options available are: heater, hard rear pa nel , an d rear win d ow wi per.

Note: a front windshield wiper comes standard with this cab kit.

INSTALLATION & OWNER’S MANUAL

WARNING: FOR STABILITY,

A 100 POUND BALLAST

WEIGHT IS REQUIRED IN

REAR BALLAST BOX.

(revised: 10/23/2008)

Page 2

NOTICE

Cabs, blades, and general accessories add

additional weight to the base vehicle.

Deduct the accessory’s total weight from

the vehicle’s rated capacity including

driver and passenger.

Exposure to Carbon Monoxide can

Never operate vehicle if suspicious of Carbon Monoxide. Inspect

exhaust system for leaks monthly. Leaks can result from loose

connections, corrosion, cracks or other damage to the exhaust

manifold. If leaks are found, repair or replace exhaust system.

Do not use vehicle until repair or replacement is complete.

Cause illness, serious injury or death.

CAB INSTALLATION

BEFORE YOU START

HELPFUL HINTS:

A. Refer to parts diagram toward the back of this manual

to help identify parts during the assembly process.

B. To assist with the cab installation, leave all bolts

loose for later adjustment unless otherwise specified.

C. Read and understand all instructions before beginning.

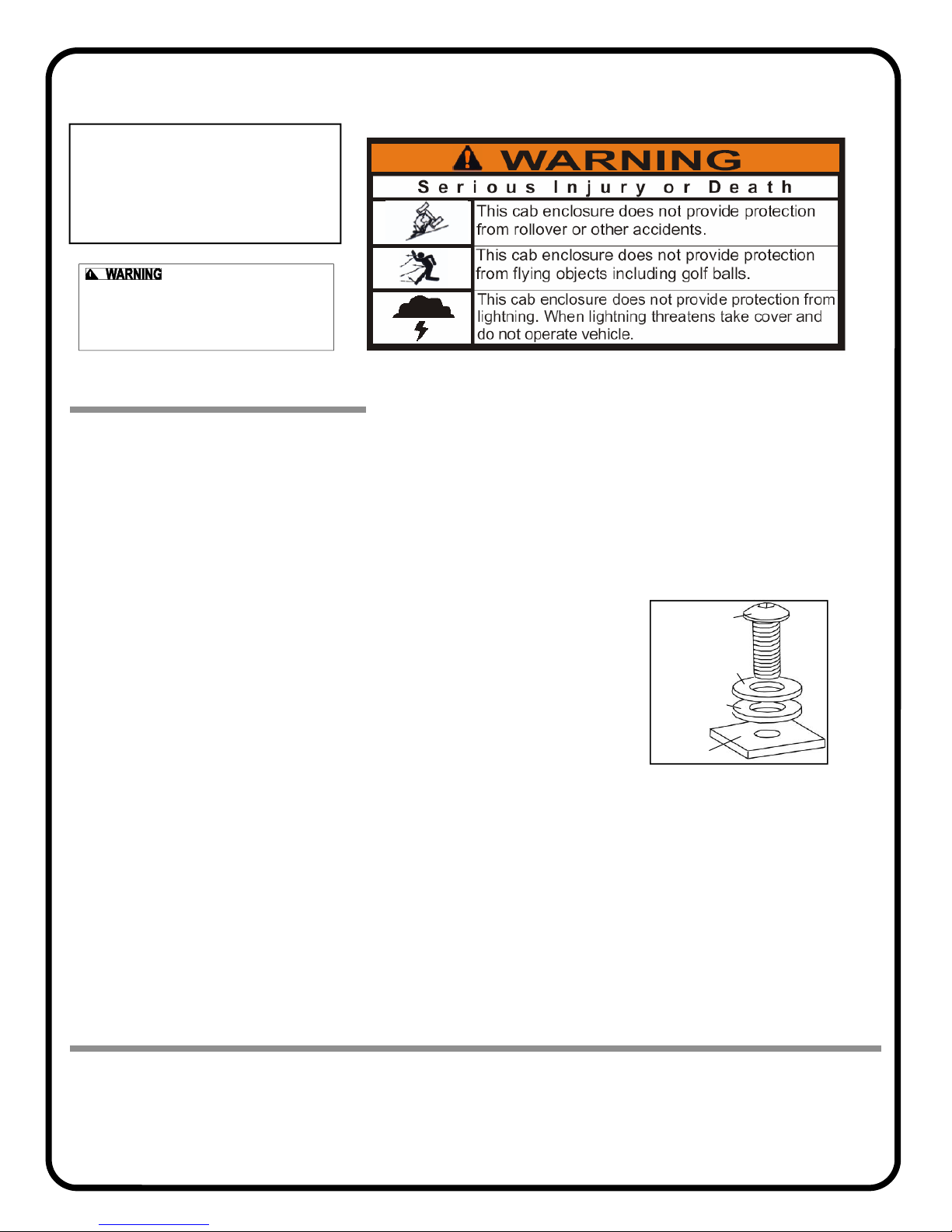

D. Plastic washers have been supplied to provide a

weather seal under the heads of all exterior bolts.

The plastic washer should be installed under each

bolt head directly against the outside cab surface.

Care should be taken not to over tighten the fast eners and damage the plastic washer. Also use

steel washers as required. See diagram.

E. Apply a clear silicone sealant to seal any minor

gaps that may occur due to vehicle variations.

F. Use caution to avoid damaging the factory installed

threaded inserts. Begin the bolt engagement by hand

to guard against potential cross threading.

TOOLS REQUIRED:

Set of standard and metric sockets

Set of standard and metric open end wrenches

Scissors

One Phillips Head and one Flat Screwdriver

One 3/8” Drive Ratchet

One 3/16” Allen Wrench (preferably “T” handle type)

One 5mm Allen Wrench (preferably “T” handle type)

Pliers

Rev. -, p. 2 of 19

Fastener

Steel Washer

Plastic Washer

Cab Surface

Page 3

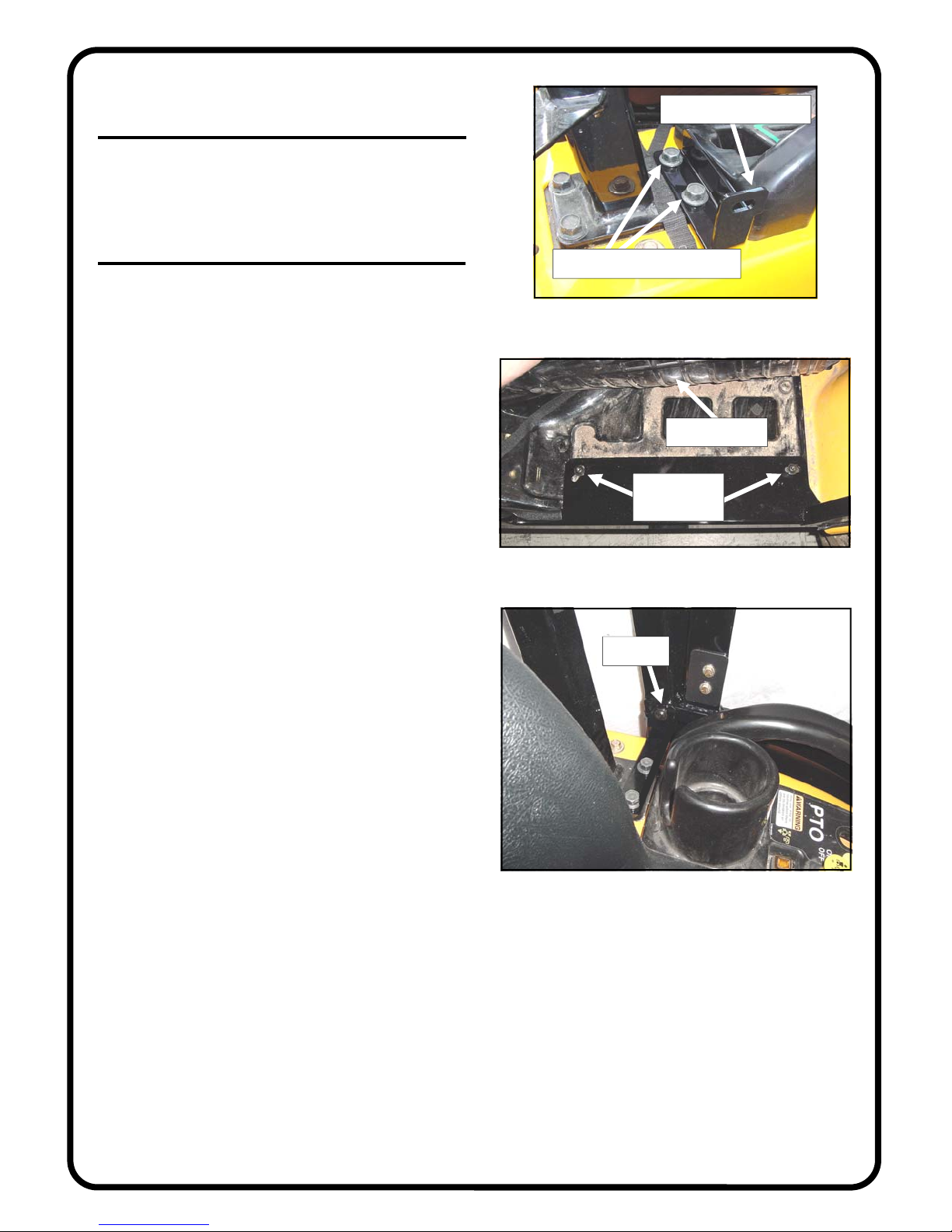

1. VEHICLE PREP.

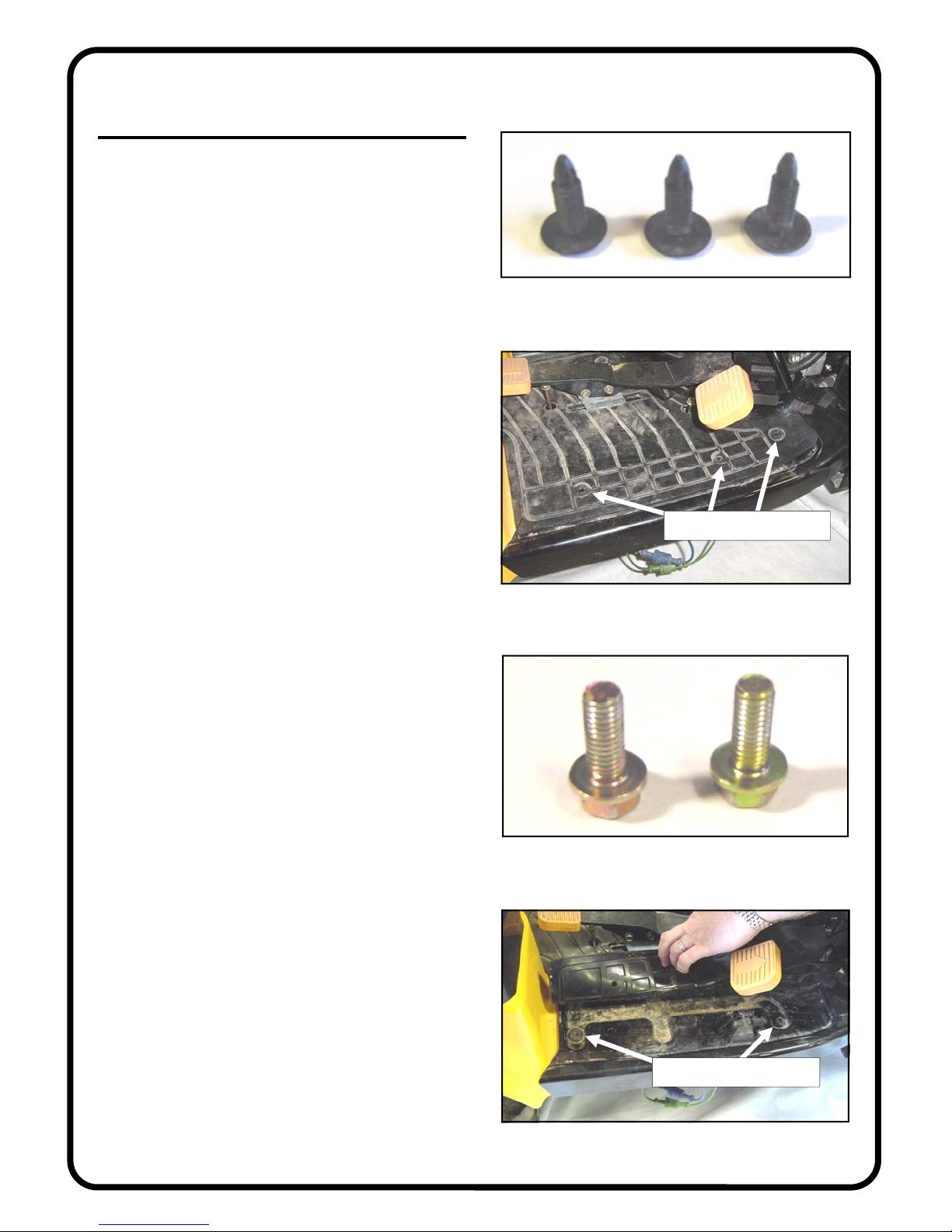

1.1 Per figures 1.1 and 1.1.1, use a flat screwdriver

and pliers to remove three (3) plastic pine tree clips from

the rubber mat on top of the floorboard on each side of

the tractor. Repeat for opposite side. Discard all six. Six

new clips will be installed in step 18.3.

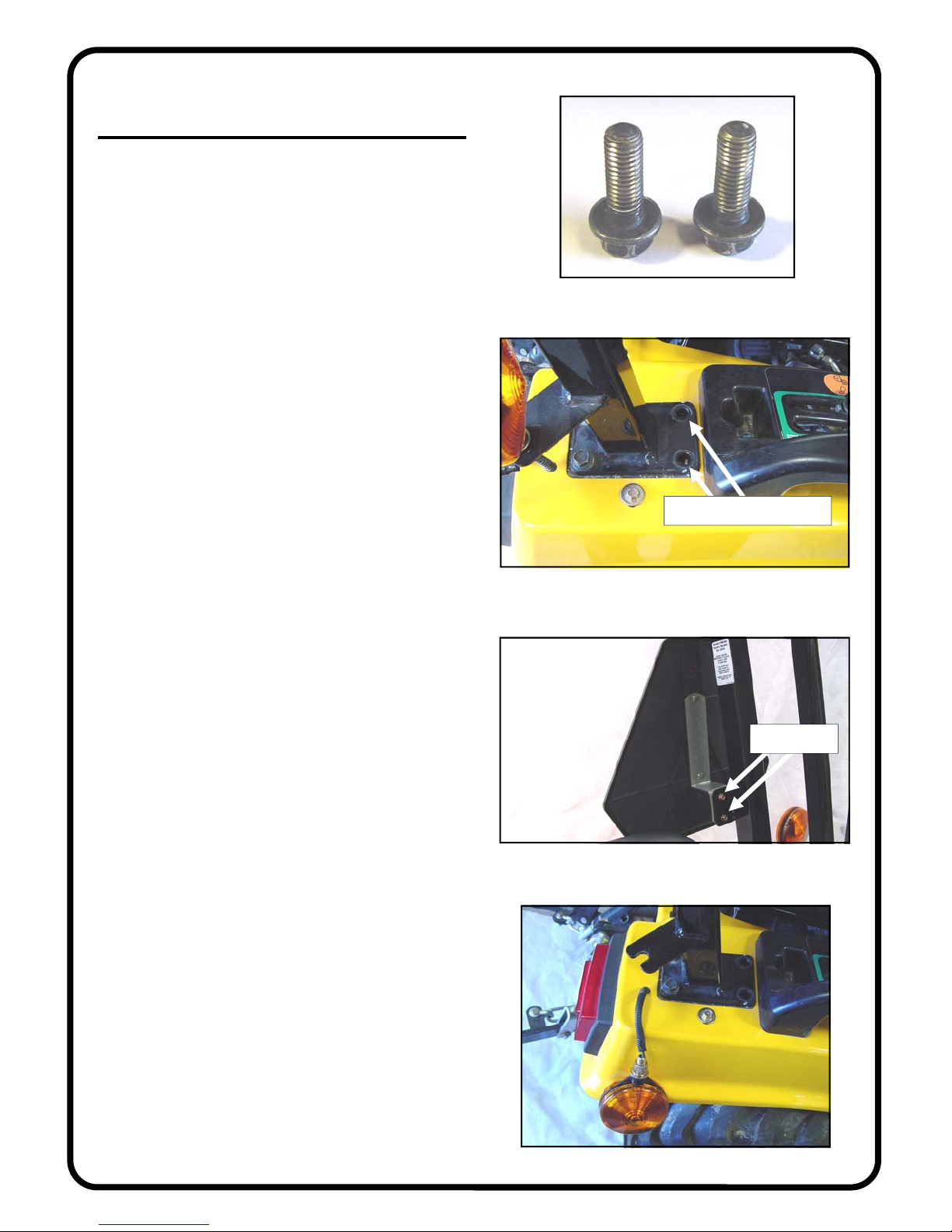

1.2 Per figures 1.2 and 1.2.1, remove two (2) M8 bolts

from underneath the rubber mat per side of the tractor.

Repeat for opposite side. Discard these short bolts. New,

longer M8 button head bolts are supplied in the hardware

bag.

Rev. -, p. 3 of 19

Fig. 1.1 (plastic pine tree clips)

remove 3 clips from here

Fig. 1.1.1 (view from right side)

Fig. 1.2 (two M8 bolts)

remove 2 bolts from here

Fig. 1.2.1 (view from right side)

Page 4

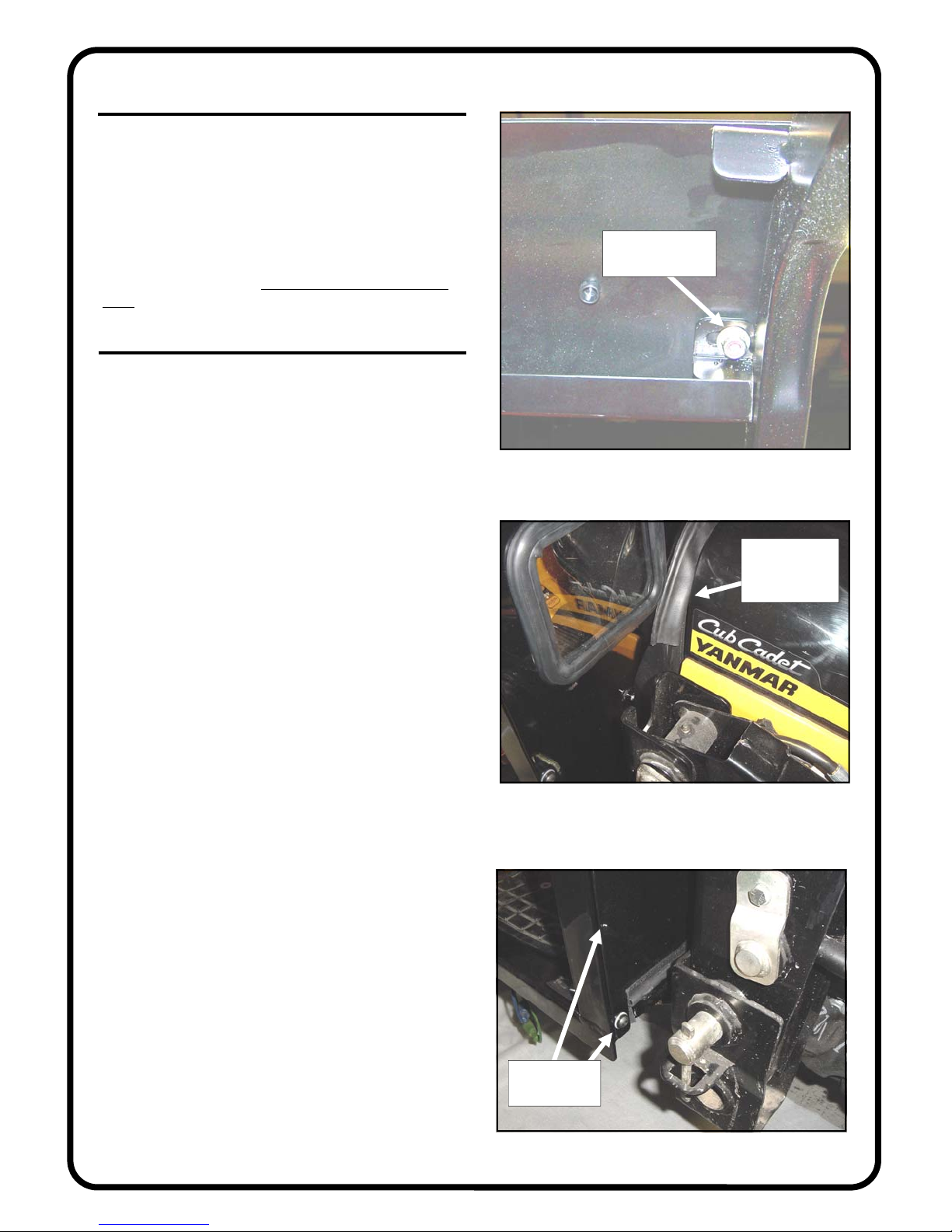

1. VEHICLE PREP. (cont’d.)

1.3 Per figures 1.3 and 1.3.1, remove two (2) M12

bolts from the bottom front area of the ROPS structure as

shown. Repeat for opposite side of tractor. Discard all

four bolts. New, longer hardware is supplied.

1.4 Per fig. 1.4, remove two (2) bolts from behind the

SMV sign (slow moving vehicle sign). Save these two

bolts for re-installation in step 18.6.

1.5 Per fig. 1.5, loosen the large hex nut on the rear

flasher lights, slide the assembly out the open ended slot

in the bracket, and temporarily rest the flasher assembly

against the side of the fender as shown. Repeat for opposite side.

Rev. -, p. 4 of 19

Fig. 1.3 (two M12 bolts)

remove 2 bolts from here

Fig. 1.3.1 (view from right side)

these 2 bolts

Fig. 1.4 (view from inside cab)

Fig. 1.5 (view from right side)

Page 5

2. REAR MOUNT BRACKET

2.1 Per fig. 2.1, install the right side rear mount

bracket as shown with the notch pointing forward. Use

the two new, longer M12 bolts supplied. Leave bolts

loose. Repeat for opposite side..

Rev. -, p. 5 of 19

notch to point forward

3. SIDE FRAMES

3.1 For ease of handling, remove the door from the

side frame by lifting up and off the pin hinges that are

bolted to the side frame.

3.2 See fig. 3.2. With assistance, install the right side

frame to the tractor. The floorboard of the side frame is

to be underneath the rubber mat. Use a 5mm Allen

wrench and the following hardware per side: two M8

button head bolts and two steel washers. Note: these

thread into the original equipment weldnuts under the

tractor floorboard. Use caution to avoid cross threading

the weldnuts. Begin the thread engagement by hand.

Leave bolts loose. Repeat for opposite side.

3.3 Per fig. 3.3, install the following hardware through

the rear mount bracket and into factory installed threaded

inserts in the lower rear corners of the side frames: one

5/16-18 x 3/4” long button head bolt and one steel

washer. Leave bolt loose. Repeat for opposite side.

install two new, longer bolts

Fig. 2.1 (view from right side)

lift rubber mat

2 bolts and

washers here

Fig. 3.2 (view from right side)

bolt here

Fig. 3.3 (view from inside the cab)

Page 6

4. WINDSHIELD SUPPORT

4.1 Per fig. 4.1, install the windshield support to the

top front corner of the side frames. Orient the windshield

support so the bent flanges are down and the decals are

legible. Use the following hardware in the lower hole on

each side (note: the remaining holes will receive hardware when the roof is installed): one 5/16- 1 8 x 3/ 4” l on g

button head bolt, one plastic washer, two steel washers,

and one locknut. Locknuts to be on the inside of the cab.

Repeat for opposite side. Tighten these two bolts at this

time.

5. COWL

5.1 Per fig. 5.1, install the cowl with the bent flanges up

top and towards the inside of the cab. The arched piece

of bulb rubber sits in the gap between the hood and the

console as shown.

5.2 Per fig. 5.2, use the following hardware per side:

three 5/16-18 x 3/4” long button head bolts, three plastic

washers, and three steel washers. Leave loose. Repeat for

opposite side.

Rev. -, p. 6 of 19

steel washer and

locknut inside

Fig. 4.1 (view from right rear side of tractor)

bulb rubber to

be in this gap

as shown

Fig. 5.1 (view from right front side of tracto r )

use plastic

washers here

Fig. 5.2 (view from right front side of tracto r )

Page 7

6. ROLL BAR BRACKET

6.1 If installing an optional hard rear panel at this

time, skip to step 7 on the next page. (Note: the steel rear

mount shown in fig. 6.2 is not used with the optional

hard rear panel).

6.2 Per fig. 6.2, install the supplied rubber vibration

mount to the rear mount using the following hardware:

1/4-20 x 1” long button head bolt, one steel washer, and

one locknut. The head of the bolt is to be inside the recess in the rubber. The washer is to be used on the locknut side. Repeat for the other rear mount. Tighten these

bolts.

6.3 Per fig. 6.3, attach the rear mount to the back of

the side frame using the following hardware per side: two

5/16-18 x 3/4” long button head bolt and two steel wash ers into factory installed threaded inserts in the rear middle of the side frames. The rubber vibration mount is to

be up against the front face of the ROPS tubing. Leave

bolts loose. Repeat for the opposite side.

6.4 Per fig. 6.4, assemble the roll bar bracket to the

rear mount as shown. Use the following hardware: two

5/16-18 x 1” long button head bolts, 4 steel washers, and

two locknuts. The head of the bolts are to be towards the

rear of the tractor. Leave bolts loose. Repeat for opposite

side.

Rev. -, p. 7 of 19

Fig. 6.2 (rear mount)

Fig. 6.3 (view from left rear side)

head of bolt

Fig. 6.4 (view from rear right side)

Page 8

7. OPTIONAL REAR LEGS

7.1 Per fig. 7.1, install the supplied rubber vibration

mount to the rear leg using the following hardware: 1/420 x 1” long button head bolt, one steel washer, and one

locknut. The head of the bolt is to be inside the recess in

the rubber. The washer is to be used on the locknut side.

The vibration mount is to be on the same side as the bent

flange as shown. Repeat for the other rear leg. Tighten

these bolts.

7.2 Per fig. 7.2, install the right side rear leg (see fig–

ure 7.1) to the back of the side frame oriented so the rubber vibration mount is up against the front face of the

ROPS tubing and the long bent flange is inboard and

pointing towards the rear. Use the following hardware

per side: six 5/16-18 x 3/4” long button head bolts, six

plastic washers, and six steel washers. These thread into

factory installed threaded inserts. Leave bolts loose. Repeat for opposite side.

7.3 Per fig. 7.2, attach the roll bar bracket to the rear

leg using the following hardware per side: two 5/16-18 x

1” long button head bolts, two plastic washers, four steel

washers, and two locknuts. The heads of the bolts to be

outboard towards the rear of the tractor. Leave bolts

loose. Repeat for opposite side.

8. OPTIONAL HARD REAR PANEL

8.1 Per fig. 8.1, attach the hard rear panel to the rear

legs oriented so the large window is down and the upper

bent flange is pointing towards the front of the tractor.

Position the hard rear panel so the left and right bent

flanges are outboard

following hardware per side: three 5/16-18 x 3/4” long

button head bolts, 6 steel washers, 3 plastic washers, and

3 locknuts. Locknuts to be on the inside surface. Repeat

for opposite side. Leave bolts loose.

of the rear leg bent flanges. Use the

Rev. -, p. 8 of 19

bent flanges

are shown

up in this view

this is the right

side rear leg

Fig. 7.1 (rear legs)

step 7.2

(side frame bolts)

step 7.3

(roll bar bracket bolts)

head of bolt, plastic

and steel washers

Fig. 8.1 (view from right rear side of tractor)

Fig. 7.2 (view from right rear side)

Page 9

9. WINDSHIELD

9.1 See fig. 9.1. Have the following items ready: four

5/16-18 x 1 3/4” long flat head bolts, 4 steel washers, 4

locknuts, and 2 plastic spacer blocks. With assistance,

install the windshield hinges to the windshield support

with the two spacer blocks between the hinge and the

windshield support. Attach windshield latches to windshield latch receivers on the cowl by squeezing tabs to

retract spring loaded pins. See fig. 9.1.1. Lift up on bottom of windshield and close latches. Check alignment of

windshield with side frames and tighten hinge hardware.

CAUTION: hinges are plastic components. Do not

overtighten hardware. Torque to 7 foot-pounds max..

10. ROOF

10.1 If an optional hard rear panel was installed, the six

soft rear curtain snaps pre-assembled onto the back surface of the roof can be left in place or removed and discarded at the installer’s discretion.

10.2 Use a Phillips head screwdriver to punch a hole

through the headliner at all of the covered bolt hole locations (10 places). Punch holes from the inside out to

avoid having the headliner pull away from its glued surface.

10.3 With assistance, install the roof oriented so the

reflectors are towards the rear of the tractor. If installing

an optional hard rear panel, the back of the roof must go

over the tops of the rear legs and rear panel so they are

contained. Per figure 10.3, use the following hardware in

the front corners: one 5/16-18 x 1” long button head bolt,

two steel washers, one plastic washer, and one locknut

(locknuts on the inside surface). Install the bolt through

the roof, windshield support, and mounting tab. Leave

loose.

10.4 The bolt hole locations over the left and right side

frames use the following hardware per side: two 5/16-18

x 3/4” long button head bolts, two steel washers, an d tw o

plastic washers. These bolts are installed into factory

installed threaded inserts in the top of each side frame.

NOTE

: use caution to avoid damaging the internal

threads on the factory installed threaded inserts. Leave

loose.

10.5 The remaining four holes use the following hardware: four 5/16-18 x 3/4” long button head bol t s, 8 steel

washers, 4 plastic washers, and 4 locknuts. Locknuts to

be on the inside surface. Note: the two middle rear bolts

are used for both hard or soft rear panels. When installing

the standard soft rear panel, the two middle rear bolts

serve only as weather plugs in the existing roof holes.

Rev. -, p. 9 of 19

sandwich the

plastic spacer

block here

Fig. 9.1 (view from left front side of tractor )

latch receiver

Fig. 9.1.1 (view from right rear side of tractor)

1” long bolt here

1” long bolt here

Fig. 10.3 (view from right front side of tractor)

Page 10

11. TIGHTEN ALL BOLTS

11.1 Before and during bolt tightening, measure and

offset the side frames symmetrical to the ROPS tubing on

the rear of the tractor. Shift and/or push cab as necessary

before tightening all bolts. Tighten all bolts including

those under the floor mats, etc.. NOTE: torque the large

M12 bolts on the lower front of the ROPS tubing back to

the original equipment specifications to ensure full safety

standards.

12. AIR INTAKE SHIELD

12.1 Install the shield using two supplied hand knobs

per side (see figures 12.1). Note: hand knobs are used so

the shield is easily removable for operator access to the

battery and the front of the radiator for clean-outs.

12.2 Per figures 12.2 and 12.2.1, orient and install the

shield so the half circle relief is up top as shown.

Rev. -, p. 10 of 19

Fig. 12.1 (hand knobs)

relief up top

Fig. 12.2 (view from rear of tractor)

hand knobs

Fig. 12.2.1 (view from right front side of tractor)

Page 11

13. VINYL FILLERS (qty.: 4)

13.1 Per fig. 13.1, raise the seat and install the smaller

of the two rectangular vinyl fillers as shown. Note: the

slightly larger rectangular filler is for the air intake

shield.

13.2 Fig. 13.2 shows the filler temporarily peeled back

to show the application of the narrow 5/8” wide PSA

(pressure sensitive adhesive) hook velcro. Only three (3)

edges of the rectangle will receive mating velcro. As

shown, do not install the velcro underneath the forward

most edge of the filler so the decal will not be obstructed

and this will allow easier grasping and opening of the

filler for servicing. Note: make sure the surfaces of the

tractor are clean, dry, and at room temperature for best

adhesion of the velcro.

13.3 Per figures 13.3 through 13.3.4, install the larger

underseat filler. Photos continued on the next page. Dry

fit the filler in place to determine where all the flaps fit

best then install the narrow 5/8” wide PSA hook velcro

onto the mating velcro on the filler. Peel back the protective strip and adhere on to the tractor to suit. Reminder:

make sure the surfaces of the tractor are clean, dry, and at

room temperature for best adhesion of the velcro.

Rev. -, p. 11 of 19

seat shown tilted up 90 degrees

rectangular filler

Fig. 13.1 (view from left side of tractor)

do not

apply

hook

PSA

velcro

here

large underseat filler

Fig. 13.3.1 (view from right side of tractor w/ seat up)

Fig. 13.2 (view from left side of tractor)

Fig. 13.3 (underseat vinyl fillers)

Page 12

13. VINYL FILLERS (cont’d.)

13.4 Install the filler to suit. Note: the narrow front portion pointed out in fig. 13.3.2 has mating velcro strips for

connection onto each other for closure. Note: the rear

portion of this filler will either connect to the bottom of a

soft rear curtain or an optional hard rear panel as the installation continues.

13.5 Per fig. 13.5 and the photos on the next page, install this vinyl filler shown to the very bottom of the air

intake shield.

Rev. -, p. 12 of 19

velcro the

left onto

the right

large underseat filler

Fig. 13.3.2 (view from left side of tractor)

large underseat filler

Fig. 13.3.3 (view from left side of tractor)

large underseat filler

Fig. 13.3.4 (view from right side of tractor)

Fig. 13.5 (lower filler for air intake shield)

Page 13

13. VINYL FILLERS (cont’d.)

13.6 Orient the filler so the pocket for the fuel fill cap

is on the left side where required. Per figures 13.6

through 13.6.3, apply narrow 5/8” wide PSA hook velcro

to the very bottom horizontal edge of the air intake

shield. Apply narrow 5/8” wide PSA hook velcro on the

plastic tractor cowl (above the decals

remainder of the filler to suit.

). Fit and install the

Rev. -, p. 13 of 19

position the

velcro above

the decal

ref.: pocket for

fuel fill cap

Fig. 13.6 (view from left side of tractor)

fuel cap is under here

position the

velcro above

the decal

Fig. 13.6.1 (view from right side of tractor)

the filler velcros onto itself here

Fig. 13.6.3 (view from left side of tractor)

Fig. 13.6.2 (view from right side of tractor)

Page 14

13. VINYL FILLERS (cont’d.)

13.7 Per fig. 13.7, apply narrow 5/8” wide PSA hook

velcro along four sides of the rectangular air flow openings as shown.

13.8 Per fig. 13.8, install the final rectangular filler

over the air flow openings onto the newly installed velcro. Note: the air shield filler is the larger of the two rectangular pieces provided. This filler is used in cooler

weather to help keep heat in the cab. In warmer weather,

the filler can be removed for increased air flow to the

radiator.

14. SOFT REAR CURTAIN

14.1 If not installing a soft rear curtain, skip to step 15

on the next page.

14.2 Snap the rear curtain to the factory installed snaps

on the inside surface of the back of the roof (6 snaps).

14.3 Per fig. 14.3, apply large 1” wide PSA (pressure

sensitive adhesive) hook velcro to the back inside surface

of the vertical rear tube of the side frames. Continue the

hook velcro 90 degrees on to the yellow fender of the

tractor. Note: surfaces must be clean, dry, and at room

temperature for best adhesion.

14.4 Attach the loose rear edge of the underseat filler to

the bottom of the soft rear curtain and work the velcroed

flaps around the seatbelts to suit. See fig. 14.4.

Rev. -, p. 14 of 19

velcro all around perimeter

of rectangular vent opening

Fig. 13.7 (air shield vinyl filler)

filler installed

Fig. 13.8 (air shield vinyl filler)

soft rear

curtain

filler velcros

onto itself

around seatbelts

Fig. 14.4 (view from right side of tractor)

Fig. 14.3 (view from left rear side of tractor)

5/8” wide

velcro

1” wide

velcro

Fig. 14.3 (view from left rear side of tractor)

Page 15

15. DOORS

15.1 Apply grease to the pin hinges. With assistance, reinstall the doors onto the pin hinges. Work the doors back

and forth until the hinges are completely seated.

Specific adjustments can be made per steps 15.2 and 15.3.

Note: top of door should end up visually parallel with side of

roof. Note: the door latch is a rotary type with two positions

to close. Adjust door so that when fully closed door latch

clicks twice

15.2 Per fig. 15.2, the large striker bolt and nut can be loosened and reset higher or lower or forward or back for better

engagement in the door latch assembly if necessary. Use two

3/4” open end wrenches. Note: finger guard to end up being

centered and facing inward.

15.3 Per fig. 15.3, the 1/4-20 hex head bolts on the door

hinges can be loosened on the rear tube, or on the door itself,

or in both places, in order to slightly rotate the door up or

down as necessary for proper latch assembly and striker bolt

engagement. Note: an assistant will be needed for this step.

Keep the hinge sleeves fully seated on the pin hinges.

Tighten all hinge bolts using caution to not

Over tightening will crush (damage) the structural tubing.

Torque to 40 inch/pounds.

CAUTION:

WITH DOORS OPEN. MAKE SURE DOORS ARE

CLOSED AND PROPERLY LATCHED WHEN DRIVING.

for total engagement.

over tighten.

FOR SAFE OPERATION, DO NOT DRIVE

16. LUBRICATION

16.1 Once the doors are properly adjusted, lubrication

(preferably grease) can be applied to the striker bolts and

door latch assemblies. Re-apply periodically as needed (same

goes for the door pin hinges as necessary).

Rev. -, p. 15 of 19

Fig. 15.2 (striker bolt)

EXTERIOR

VIEW OF

RIGHT SIDE

DOOR

Fig. 15.3 (right side door)

Page 16

17. FLASHER LIGHT BRACKET

17.1 Per fig. 17.1, install the flasher light brackets using

the following hardware per side of the tractor: one 5/16-18 x

3/4” long button head bolt, two steel washers, and one locknut. Repeat for the opposite side. Tighten the bolts.

17.2 Per fig. 17.2, re-install the flasher light. Note: both

washers (flat and lock) to be on the bottom side of the

bracket along with the hex nut.

18. FINISHING TOUCHES

18.1 Install the gas shock to the frame and door with the

small piston end towards the door. Press the button on the

compression fastener to lock the gas shock to the ball stud.

18.2 Install the supplied 5/16” nut covers (qty.: 16) on the

interior hex locknuts by snapping over nut. Install the two

1/4” nut covers on the locknuts for the vibration mounts.

18.3 Install six (6) new plastic pine tree clips (3 per side)

through the rubber floor mats. Press in place by hand.

Rev. -, p. 16 of 19

open

ended

slot to be

outboard

Fig. 17.1 (view from right side of tractor)

Fig. 17.2 (view from right side of tractor)

install 3 pine tree

clips per side

Fig. 18.3 (view from right side of tractor)

Page 17

18. FINISHING TOUCHES (cont’d.)

18.4 If a soft rear curtain has been installed, install the following hardware into the factory installed threaded inserts in

the back of each of the side frames: four 5/16-18 x 3/4” long

button head bolts, four plastic washers, and four steel washers. See fig. 18.4. These will serve as weather plugs when an

optional hard rear panel is not installed.

18.5 If an optional hard rear panel has been installed, apply

PSA hook velcro to the lower inside surface and attach the

loose rear edge of the underseat filler. Work the velcroed

flaps around the seatbelts to suit. See fig. 18.5.

18.6 Re-install the SMV sign using the original equipment

hardware. See fig. 18.6.

18.7 Peel protective film from windows.

18.8 Note: extra hardware has been provided in case they

get lost. Discard extras such as washers, e t c.

18.9 Install the front windshield wiper per the installation

instructions included with the wiper kit.

18.10 Additional optional equipment available: Work

Lights, Heater, Hard Rear Panel, Sliding Door Windows, and

Rear Window

19. CARE AND MAINTENANCE

19.1 Check and tighten hardware after 40 hours of operation. Periodically inspect and tighten hardware for the remainder of the unit’s life.

19.2 Wash the painted surfaces of the unit with commercial automotive cleaning products.

19.3 Clean windows with glass cleaner.

19.4 Vinyl components should be washed with a mild solution of warm soapy water.

19.5 Clear vinyl can be easily scratched. Be careful cleaning frost or snow from rear curtain. Do not roll curtain in

cold weather. The curtain becomes stiff and may crack. Keep

curtain clean.

Rev. -, p. 17 of 19

fill threaded inserts

Fig. 18.4 (view from right rear side of tractor)

filler velcros

onto itself

around seatbelts

Fig. 18.5 (view from right side of tractor)

these 2 bolts

Fig. 18.6 (view from inside the cab)

Page 18

Page 19

Loading...

Loading...