Page 1

Page 2

Page 3

INTRODUCTION

Welcome to the World of Cub Cadet Yanmar Tractor

Thank you for purchasing our tractor product that has been designed and

manufactured based on our state-of-the-art technology and rich expertise in

developing and manufacturing tractor products.

Handle your tractor correctly by following the instructions contained in this

Operator’s Manual so that it provides you long years of reliable and faithful

service.

This manual constitutes an indispensable part of your Cub Cadet Yanmar tractor

product. Always keep the manual readily accessible.

Carefully study this manual to get familiar with the instructions and information

contained in it. These instructions and information are helpful in using your

tractor correctly and safely, and avoiding personal injury and other accidents

during operation and servicing of the tractor.

When using any implement together with your tractor, also carefully study its

operation manual so that you can use it safely, correctly and efficiently.

This manual is organized with sections arranged in a particular order so that you

can better understand the safety messages and the controls on your tractor to

help you operate your tractor correctly and safely. This manual will also help you

answer questions about operation and servicing. An index is available at the end

of this manual to assist you in quickly finding necessary information.

The machine shown in this manual may somewhat differ from your actual

machine. However, this manual will still assist you in understanding the

instructions associated with your tractor.

Before delivery of your machine, your Cub Cadet Yanmar dealer has performed

a pre-delivery check to ensure that your tractor can long remain problem-free.

1

Sc2400 Operator’s Manual

Page 4

TABLE OF CONTENTS

1. SAFETY PRECAUTIONS ................................................................................... 1-1

1. About This Manual .................................................................................................................. 1-1

2. Safety-Alert Symbols............................................................................................................... 1-2

3. Precautions before Operating Your Tractor ............................................................................ 1-3

4. Safe Practices for Operating Your Tractor .............................................................................. 1-4

5. Operating Your Tractor on Slopes........................................................................................... 1-6

6. Traveling on a Road................................................................................................................ 1-7

7. Safe Practices for Parking Your Tractor.................................................................................. 1-7

8. Operating the Power Take Off (PTO)...................................................................................... 1-8

9. Using the 3-Point Hitch............................................................................................................ 1-8

10.Safety Frame (Roll-Over Protective Structure) (ROPS) Precautions ...................................... 1-8

11.Safe Practices for Servicing Your Tractor ............................................................................... 1-9

12.Understanding the Tractor Safety Decals ............................................................................. 1-11

Safety-Alert Symbols ...........................................................................................................................................1-11

Care of DANGER, WARNING and CAUTION Decals.........................................................................................1-11

2. SERVICING THE TRACTOR .............................................................................. 2-1

3. SPECIFICATIONS............................................................................................... 3-1

1. Specifications Table ................................................................................................................ 3-1

2. Traveling Speeds .................................................................................................................... 3-2

4. IMPLEMENT CAPACITIES................................................................................. 4-1

5. NAMES AND FUNCTIONS OF COMPONENTS ................................................ 5-1

1. Appearance............................................................................................................................. 5-1

2. Operator Station Controls........................................................................................................ 5-2

3. Instrument Panel, Switches and Hand Controls...................................................................... 5-3

6. PRE-OPERATION CHECK ................................................................................. 6-1

1. Pre-Operation Check............................................................................................................... 6-1

2. Precautions before the Operation ........................................................................................... 6-1

3. Routine Check......................................................................................................................... 6-1

4. Prevent Damage to the Plastic Surfaces and Painted Surfaces ............................................. 6-1

7. OPERATING THE ENGINE ................................................................................ 7-1

1. Starting the Engine.................................................................................................................. 7-1

Opening / Closing the Fuel Shut-Off Valve............................................................................................................7-1

Adjusting the Operator's Seat................................................................................................................................7-2

Fastening the Retractable Seat Belt......................................................................................................................7-2

Engaging the Parking Brake ..................................................................................................................................7-3

Checking the Lights on the Instrument Panel ........................................................................................................7-6

Warming Up the Engine in Cold Weather..............................................................................................................7-7

2. Stopping the Engine................................................................................................................ 7-8

3. Restarting a Stalled Engine..................................................................................................... 7-9

Sc2400 Operator’s Manual

2

Page 5

TABLE OF CONTENTS

8. OPERATING THE TRACTOR............................................................................. 8-1

1. Operating a New Tractor......................................................................................................... 8-2

2. Operation of the Tractor .......................................................................................................... 8-3

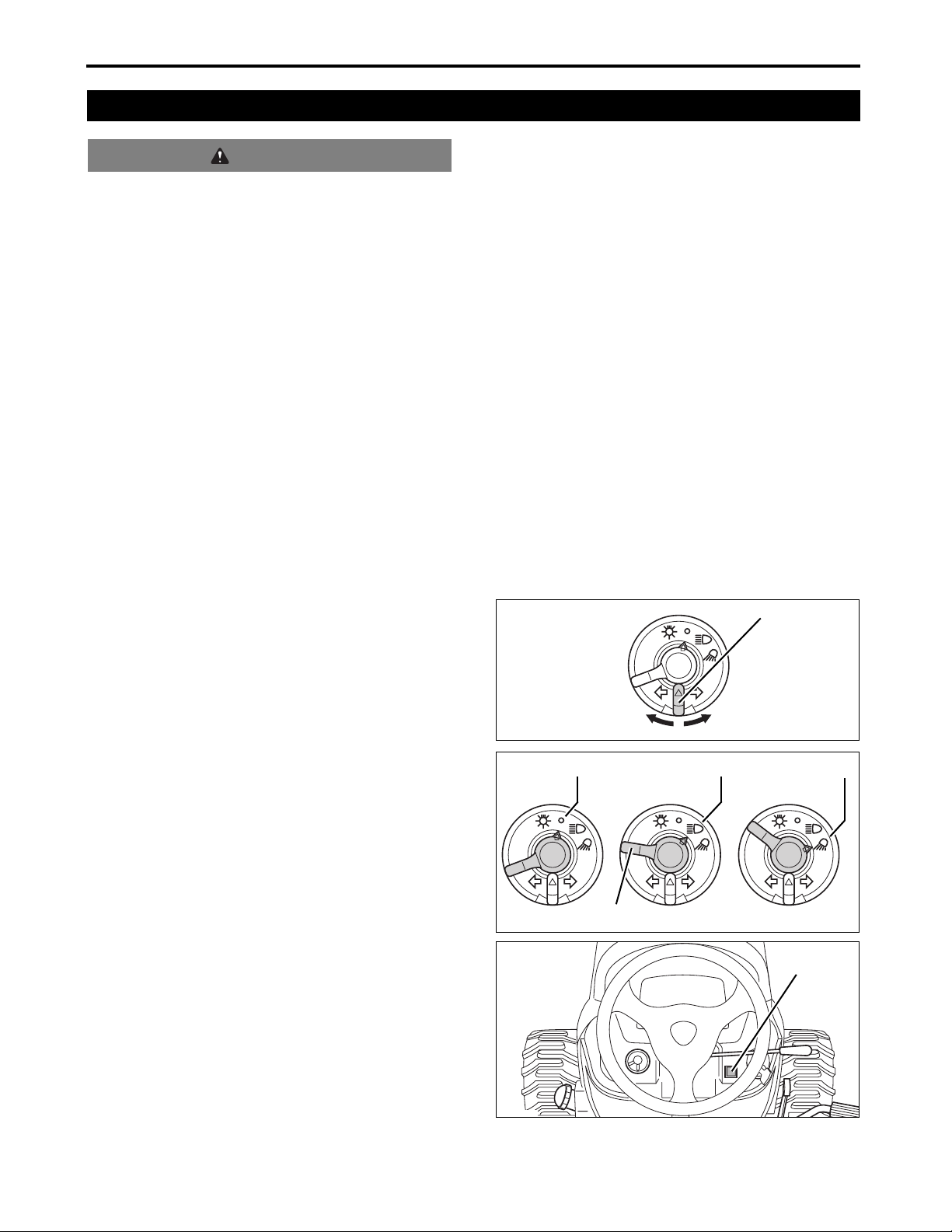

Turn Signals ..........................................................................................................................................................8-3

Headlights / Work Lights........................................................................................................................................8-3

Hazard Lights ........................................................................................................................................................8-3

Range Shift Lever..................................................................................................................................................8-4

4-Wheel Drive Lever..............................................................................................................................................8-4

Throttle Control Lever............................................................................................................................................8-5

Forward and Reverse Drive Pedal ........................................................................................................................8-6

Engaging the Cruise Control .................................................................................................................................8-7

Disengaging the Cruise Control.............................................................................................................................8-7

3. Stopping Travel of the Tractor................................................................................................. 8-8

Emergency Stop Procedure ..................................................................................................................................8-8

4. Parking the Tractor.................................................................................................................. 8-9

Applying the Parking Brake ...................................................................................................................................8-9

Releasing the Parking Brake .................................................................................................................................8-9

5. Safe Practices for Operation ................................................................................................. 8-10

Engaging the Differential Lock.............................................................................................................................8-10

Disengaging the Differential Lock........................................................................................................................8-10

Hydro Static Transmission (HST) pressure release lever....................................................................................8-13

Uphill / Downhill ...................................................................................................................................................8-16

Steep Downhill.....................................................................................................................................................8-16

9. POWER TAKE OFF (PTO) ................................................................................. 9-1

1. Operating the Power Take Off (PTO)...................................................................................... 9-1

Rear- Power Take Off (PTO) .................................................................................................................................9-2

Mid- Power Take Off (PTO)...................................................................................................................................9-2

Engaging the Power Take Off (PTO).....................................................................................................................9-2

Disengaging the Power Take Off (PTO)................................................................................................................9-4

2. Installing an Implement to the Power Take Off (PTO) Drivelines............................................ 9-5

3. Operating the Power Take Off (PTO) while the Tractor is Traveling

in the Reverse Direction (Reverse Override Function)............................................................ 9-5

10.3-POINT HITCH ................................................................................................ 10-1

1. Adjusting the 3-Point Hitch.................................................................................................... 10-1

Right Lift Link.......................................................................................................................................................10-2

Top Link...............................................................................................................................................................10-2

Sway Link ............................................................................................................................................................10-2

Hitch ....................................................................................................................................................................10-2

11.HYDRAULIC SYSTEM...................................................................................... 11-1

1. 3-Point Hitch Control System ................................................................................................ 11-1

Operating the 3-Point Hitch Control / Cutting Height Adjustment Lever to Raise or Lower the 3-Point Hitch .....11-1

Hydraulic Flow Control / Stop Knob.....................................................................................................................11-2

2. Controlling the Implement Control Valve (Option)................................................................. 11-3

Implement Control Valve (Option) .......................................................................................................................11-3

Implement Control Lever (Option) .......................................................................................................................11-4

Implement Lock Lever (Option) ...........................................................................................................................11-4

Connecting the Implement Hydraulic Hoses .......................................................................................................11-5

3

Sc2400 Operator’s Manual

Page 6

TABLE OF CONTENTS

12.TIRES, WHEELS AND BALLAST .................................................................... 12-1

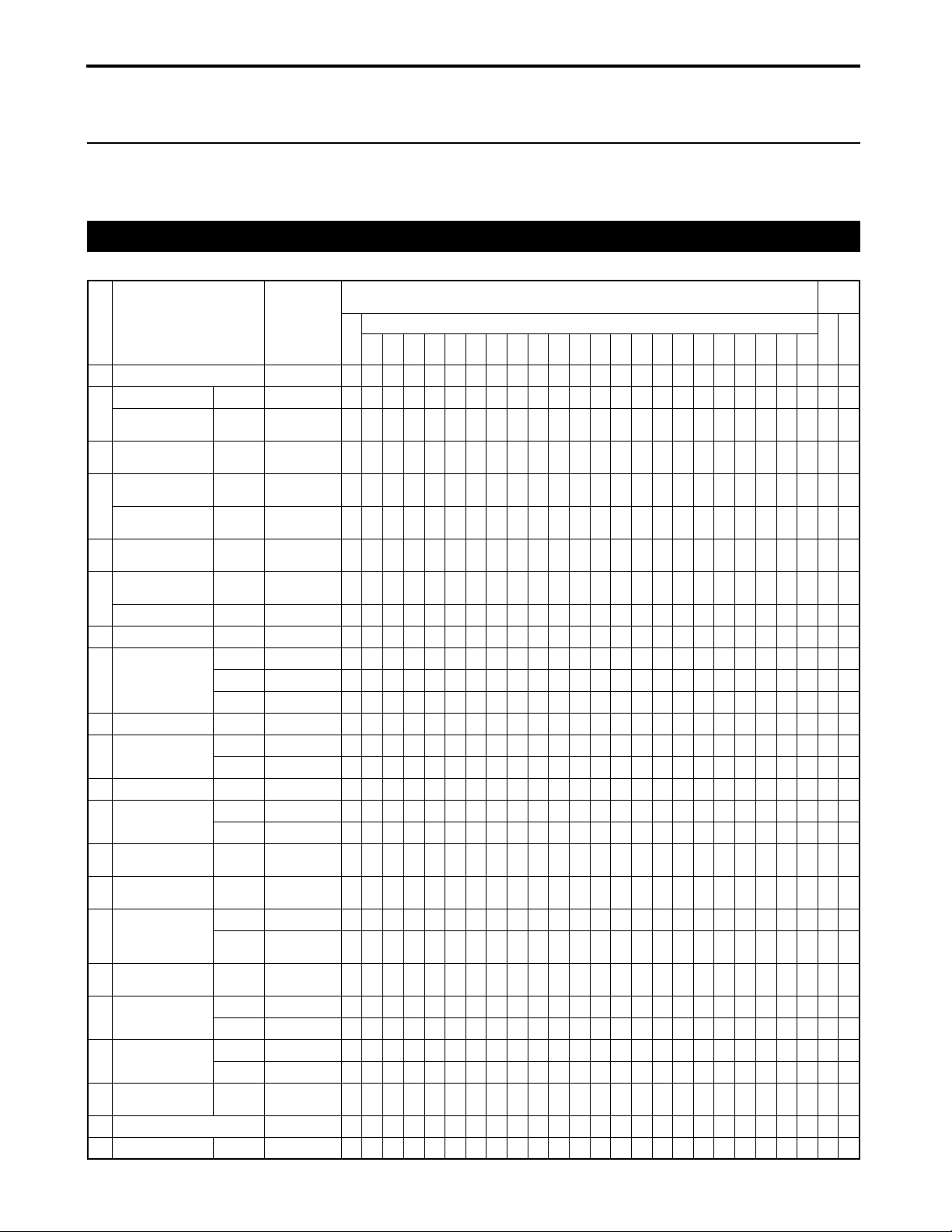

1. Tires ...................................................................................................................................... 12-1

Inflation Pressure.................................................................................................................................................12-2

Wheel Bolt Tightening Torque .............................................................................................................................12-2

2. Ballast.................................................................................................................................... 12-3

Front Ballast ........................................................................................................................................................12-3

Maximum Weight .................................................................................................................................................12-4

Using Liquid Weight for the Tires ........................................................................................................................12-4

13.MAINTENANCE ................................................................................................ 13-1

1. Maintenance Check List ........................................................................................................ 13-1

2. Lubricants.............................................................................................................................. 13-2

3. Replacement Parts................................................................................................................ 13-3

14.PERIODIC SERVICE ........................................................................................ 14-1

■ Warranty and Repair of the Engine....................................................................................... 14-1

1. Opening / Closing the Hood .................................................................................................. 14-2

Opening the Hood ...............................................................................................................................................14-2

Closing the Hood .................................................................................................................................................14-2

2. Daily Checks ......................................................................................................................... 14-3

Refilling the Fuel Tank .........................................................................................................................................14-3

Checking the Engine Oil Level ............................................................................................................................14-5

Checking the Transmission Oil Level ..................................................................................................................14-6

Checking the Radiator Hoses and Clamps..........................................................................................................14-7

Cleaning the Radiator Cooling Fins and Screen .................................................................................................14-7

Cleaning the Rear Grille Screen ..........................................................................................................................14-8

Checking the Cooling System .............................................................................................................................14-9

Checking the Fuel Line ......................................................................................................................................14-10

Checking the Intake Air Hoses and Clamps ......................................................................................................14-10

Checking the Safety Interlock System...............................................................................................................14-11

Checking and Adjusting the Brake ....................................................................................................................14-13

Checking the Seat Belt and Roll-Over Protective Structure (ROPS).................................................................14-13

Checking the Wheel Bolt Tightening Torque .....................................................................................................14-14

Checking the Inflation Pressure.........................................................................................................................14-14

Checking the Light Bulbs ...................................................................................................................................14-15

Checking the Tie-rod Rubber Boots ..................................................................................................................14-15

Checking the Hydraulic Hoses ..........................................................................................................................14-16

3. First 50 Hours...................................................................................................................... 14-18

Changing the Engine Oil....................................................................................................................................14-18

Replacing the Engine Oil Filter ..........................................................................................................................14-18

Changing the Transmission Oil .........................................................................................................................14-18

Replacing the Transmission Oil Filter ................................................................................................................14-18

4. Every 50 Hours.................................................................................................................... 14-18

Checking the Front Axle Oil Level .....................................................................................................................14-18

Checking the Fuel / Water Separator ................................................................................................................14-19

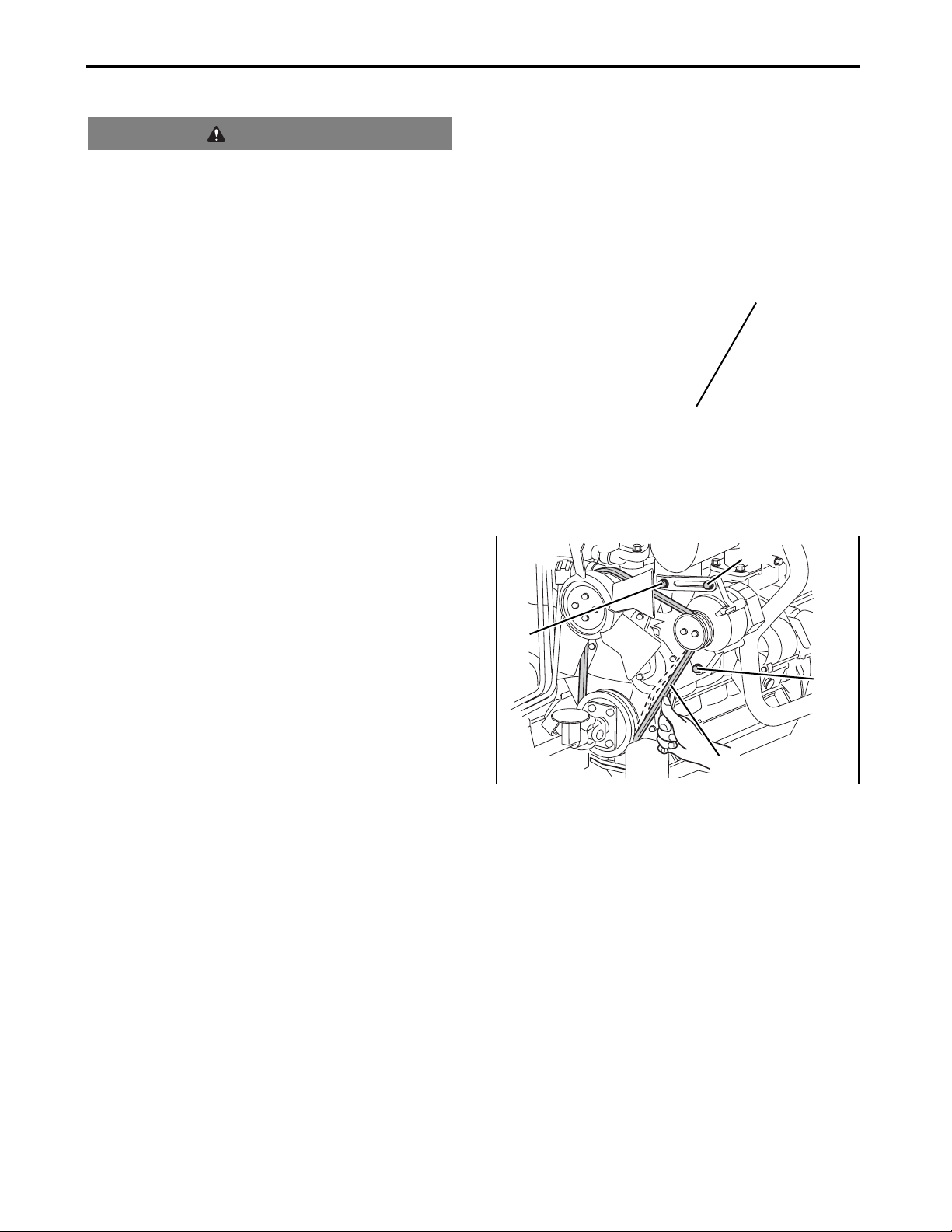

Adjusting the Fan Belt .......................................................................................................................................14-20

Greasing and Lubricating ..................................................................................................................................14-21

5. Every 100 Hours.................................................................................................................. 14-23

Engine Oil ..........................................................................................................................................................14-23

Changing the Engine Oil....................................................................................................................................14-23

Cleaning the Fuel / Water Separator .................................................................................................................14-24

Cleaning the Air Cleaner Element .....................................................................................................................14-25

Sc2400 Operator’s Manual

4

Page 7

TABLE OF CONTENTS

6. Every 200 Hours.................................................................................................................. 14-27

Replacing the Engine Oil Filter ..........................................................................................................................14-27

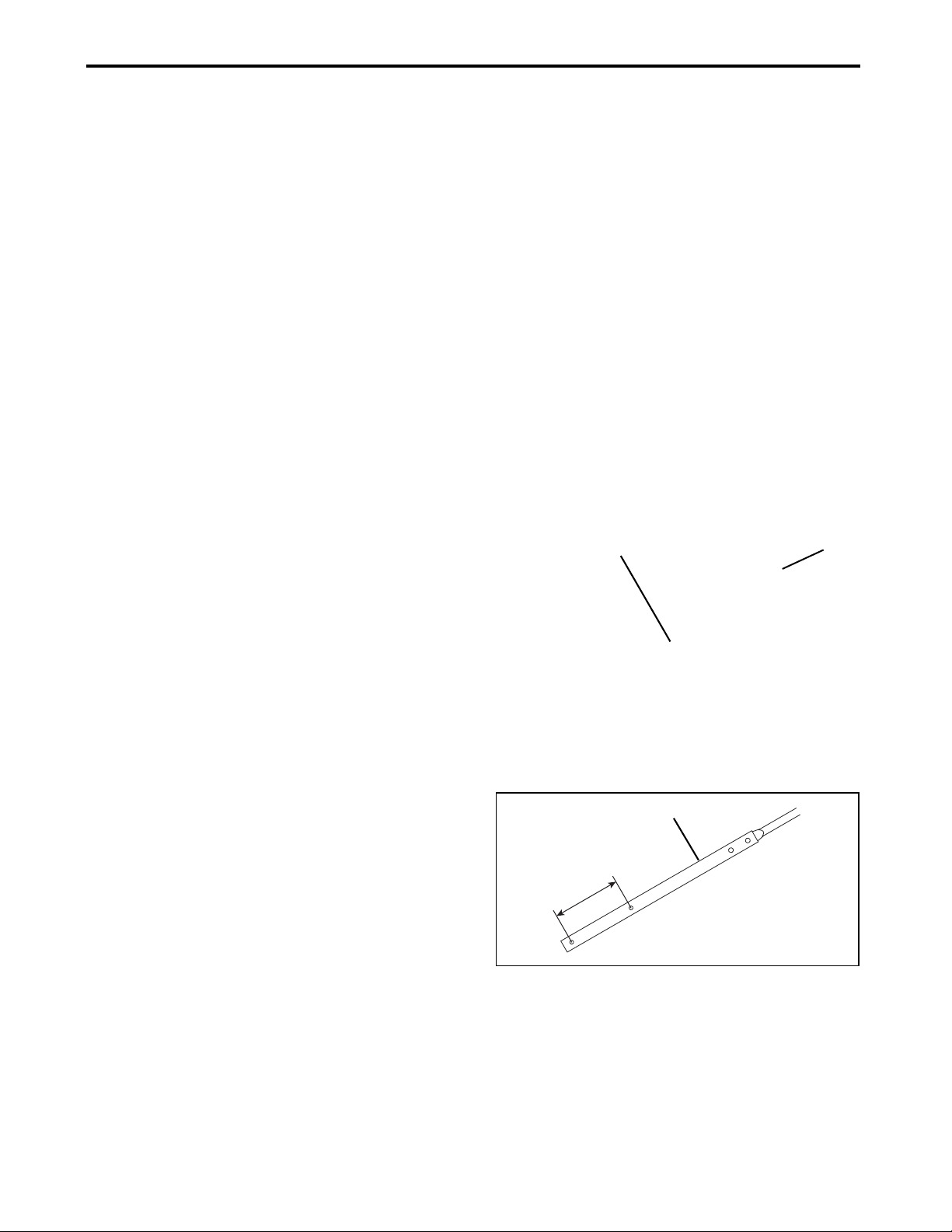

Adjusting the Toe-in...........................................................................................................................................14-28

7. Every 300 Hours.................................................................................................................. 14-28

Transmission Oil................................................................................................................................................14-28

Changing the Transmission Oil and Replacing the Transmission Oil Filter.......................................................14-29

8. Every 500 Hours.................................................................................................................. 14-30

Front Axle Case Oil ...........................................................................................................................................14-30

Changing the Front Axle Case Oil .....................................................................................................................14-30

Replacing the Fuel Filter Element (in the Fuel / Water Separator) ....................................................................14-31

Replacing the Fuel Filter....................................................................................................................................14-31

9. Every 1000 Hours................................................................................................................ 14-32

Coolant ..............................................................................................................................................................14-32

Flushing the Cooling System .............................................................................................................................14-33

Changing the Coolant ........................................................................................................................................14-35

Adjusting the Engine Valve Clearance ..............................................................................................................14-35

Checking the Fuel Injection Nozzle Injection Pressure .....................................................................................14-35

Checking the Fuel Injection Pump .....................................................................................................................14-35

10.Every 1 Year........................................................................................................................ 14-36

Replacing the Air Cleaner Element ...................................................................................................................14-36

Flushing the Cooling System .............................................................................................................................14-36

Changing the Coolant ........................................................................................................................................14-36

11.Every 2 Years...................................................................................................................... 14-36

Replacing the Radiator Hoses and Clamp ........................................................................................................14-36

Replacing the Fuel Line .....................................................................................................................................14-36

Replacing the Intake Air Hose ...........................................................................................................................14-36

Replacing the Hydraulic Hoses .........................................................................................................................14-36

15.SERVICING THE ELECTRICAL SYSTEM ....................................................... 15-1

1. Battery ................................................................................................................................... 15-1

Special Note for the Battery.................................................................................................................................15-1

Servicing the Battery Safely ................................................................................................................................15-2

Inspecting the Battery..........................................................................................................................................15-3

Removing and Installing the Battery ....................................................................................................................15-3

Cleaning the Battery and Terminals ....................................................................................................................15-4

Using a Booster Battery.......................................................................................................................................15-5

2. Fuses..................................................................................................................................... 15-6

Replacing the Accessory Fuses ..........................................................................................................................15-6

Checking the Alternator Fuse and the Main Fuse ...............................................................................................15-6

3. Bulb ....................................................................................................................................... 15-7

Replacing the Headlight Bulb ..............................................................................................................................15-7

Replacing the Work Light Bulb ............................................................................................................................15-8

Replacing the Tail Light Bulb...............................................................................................................................15-9

Replacing the Turn Signal / Hazard Lights Bulb ..................................................................................................15-9

Replacing the Instrument Panel Light Bulb .......................................................................................................15-10

4. Headlights ........................................................................................................................... 15-10

Adjusting the Headlights ....................................................................................................................................15-10

5

Sc2400 Operator’s Manual

Page 8

TABLE OF CONTENTS

16.STORAGE......................................................................................................... 16-1

1. Safe Practices for Storage .................................................................................................... 16-1

Fuel......................................................................................................................................................................16-2

Engine .................................................................................................................................................................16-2

2. Preparing the Stored Tractor for Operation........................................................................... 16-3

17.TROUBLESHOOTING ...................................................................................... 17-1

1. How to Use the Troubleshooting Table................................................................................. 17-1

18.INDEX................................................................................................................ 18-1

Sc2400 Operator’s Manual

6

Page 9

1. SAFETY PRECAUTIONS

1. SAFETY PRECAUTIONS

1. About This Manual

This Operator’s Manual presents you messages that

help you remain aware of potential hazards and

possible machine damage in operating and servicing

your machine. Carefully study all the information in it

so that you can positively avoid personal injury and

damaged properties.

NOTE:

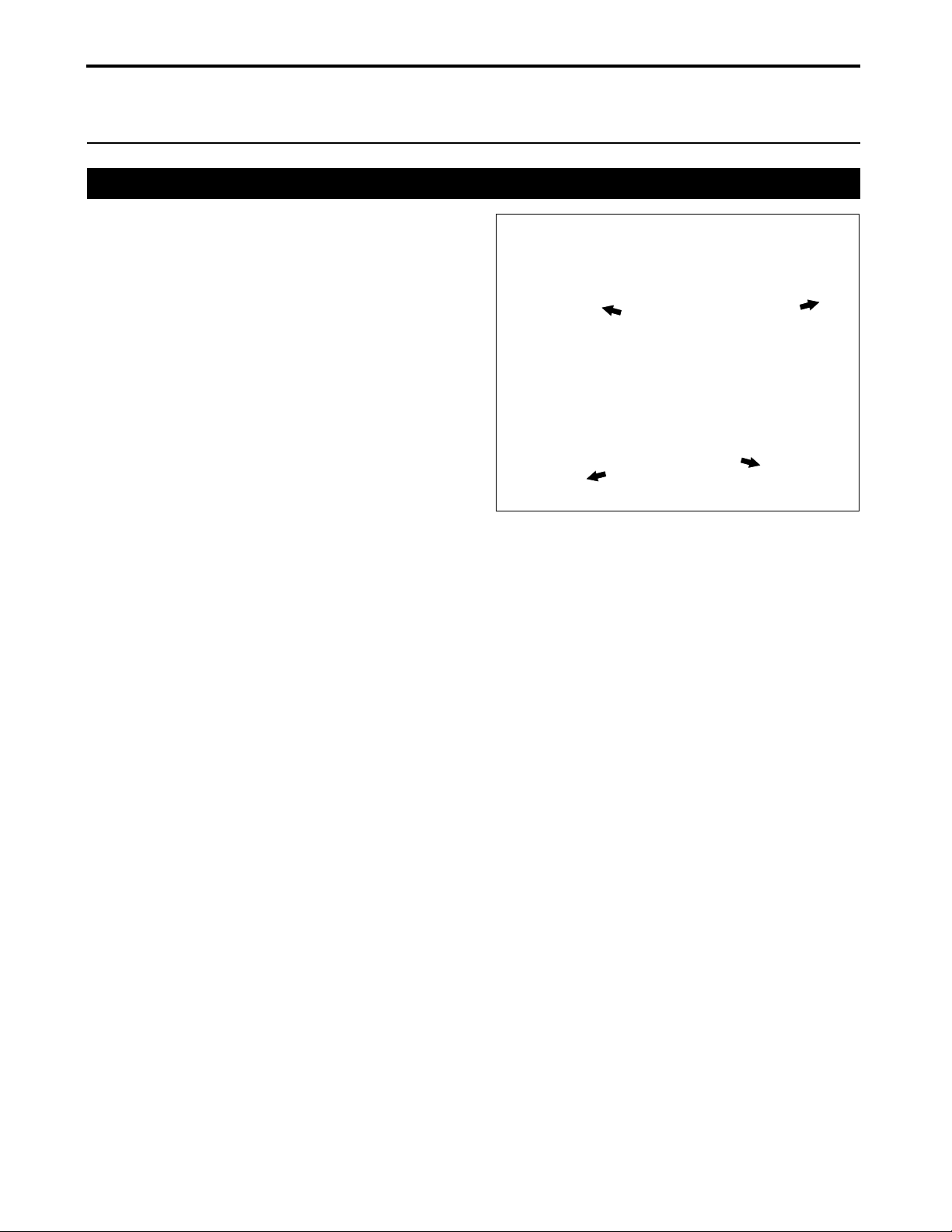

●Unless otherwise stated, the expressions–righthand side, left-hand side, front side, and rear side,

used throughout this manual refer to the sides

relative to the direction of forward movement with

the tractor.

P3014903

RIGHT

FRONT

REAR

LEFT

1-1

Sc2400 Operator’s Manual

Page 10

2. Safety-Alert Symbols

1. SAFETY PRECAUTIONS

The safety-alert symbols appear with

most safety statements. It means

attention, become alert, your safety is

involved!

Please read and strictly observe the

message that follows the safety-alert

symbols.

DANGER

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

WARNING: READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE

ATTEMPTING TO OPERATE YOUR TRACTOR. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

WARNING: The engine exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer, birth defects or other

reproductive harm.

CAUTION

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

Indicates a situation which can cause damage to the

machine, personal property and/or the environment

or cause the equipment to operate improperly.

IMPORTANT: Means that implement or

property damage could occur if instructions are

ignored.

NOTE: Provides useful information.

DANGER: Your tractor was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. To help prevent accidents, read and take the following precautions before

operating this tractor. Failure to observe the following safety instructions could result in serious

injury or death.

Sc2400 Operator’s Manual

1-2

Page 11

1. SAFETY PRECAUTIONS

3. Precautions before Operating Your Tractor

1. Understand the performance and limitations of

your tractor. Carefully study this Operator’s

Manual and learn the instructions in it before

operating or servicing your tractor. Keep the

Operator’s Manual in an easily accessible place.

2. Strictly follow the statements given in the

DANGER, CAUTION and WARNING safety

decals attached to the tractor.

3. For operator safety, always install the Roll-Over

Protective Structure (ROPS).

Keep the seat belt fastened while operating the

tractor with the Roll-Over Protective Structure

(ROPS). This practice will reduce the possibility

of injury or death in the event of roll-over

accident.

If the Roll-Over Protective Structure (ROPS) has

been removed for any reason, be sure to reinstall

all the associated parts before operating the

tractor.

Do not alter the Roll-Over Protective Structure

(ROPS). The altered Roll-Over Protective

Structure (ROPS) may fail to provide the

designed protection.

Replace the damaged Roll-Over Protective

Structure (ROPS) immediately. Contact your

local Cub Cadet Yanmar dealer for technical

assistance.

NEVER alter or repair the Roll-Over Protective

Structure (ROPS). Welding, bending, drilling,

grinding, or cutting may weaken the Roll-Over

Protective Structure (ROPS). Contact your local

Cub Cadet Yanmar dealer for technical

assistance.

4. Always fasten the seat belt while operating the

tractor with the Roll-Over Protective Structure

(ROPS).

Check the seat belt for any damage. Replace the

damaged seat belt immediately. Contact your

local Cub Cadet Yanmar dealer for technical

assistance.

Do not use the seat belt if the tractor does not

have the Roll-Over Protective Structure (ROPS).

5. Check overhead clearance carefully before

driving under power lines, wires, bridges or low

hanging tree branches, before entering or leaving

building, or in any other situation where the

operator and/or Roll-Over Protective Structure

(ROPS) may be struck, which could result in

serious injury.

6. Make sure that any person (other than a usual

operator) who will operate the tractor studies this

Operator’s Manual before operation. Know the

controls and how to stop the machine quickly.

7. Make sure that any person or obstacle is not

under or around the tractor before and during

operation. Be sure to maintain sufficient

overhead clearance above the tractor.

8. Do not operate your tractor and/or implement

installed to it while you are under the influence of

alcohol, drug, medicine or controlled

substance(s) or when you are not fit for operation

of your tractor.

9. For operation, wear close-fitting clothing. When

operating the tractor or working around the

tractor, do not wear loose-fitting clothes or

jewelry, or baggy or damaged clothing. When

caught by a moving part of the tractor, an

accident can result. Cut-off pants or shorts do not

provide protection against flying debris. Never

operate the tractor in bare feet, sandals, or

sneakers. Wear additional protections including

non-slip safety boots or shoes, and safety

goggles and gloves, etc. as appropriate or

required by currently applicable local laws and

regulations. Wear ear protection in a noisy

environment to prevent hearing damage and

reduce operator fatigue.

10. NEVER allow a passenger on any portion of the

tractor.

11. Remain seated in the operator’s station when

operating the tractor.

12. Make sure that the brakes, clutch and other

mechanical components are free from

misadjustment and excessive wear. Replace any

excessively worn or damaged component

immediately. At regular intervals, check that all

the nuts, bolts and screws are appropriately

tightened. (For details, see “MAINTENANCE”)

1-3

Sc2400 Operator’s Manual

Page 12

1. SAFETY PRECAUTIONS

13. Always keep your tractor clean. Dust, grease or

grass clippings accumulated on your tractor can

lead to fire accidents or personal injury.

14. Use the handholds and running board steps

when getting on and off the tractor to help prevent

accidental falls. Keep the running boards clear of

mud and debris.

15. Only use the implements that satisfy the

requirements in this manual or are approved by

your Cub Cadet Yanmar dealer. (See “4.

IMPLEMENT CAPACITIES”)

16. When using front or rear mounted implements,

install an appropriate weight(s) to the front or rear

of your tractor to prevent upsetting of the tractor.

If you choose to use the front loader, mount an

implement or ballast to the 3-point hitch in order

to get the tractor to stabilize. Observe the

instructions about safety in the manual for the

implement to be used.

17. Do not attempt to modify your tractor.

Modification can deteriorate the performance

and/or safety of your tractor, possibly leading to

personal injury or property damage.

4. Safe Practices for Operating Your Tractor

1. Starting Your Tractor

1. Remain seated in the operator’s station when

starting the engine, or actuating the levers or

controls. Do not start the engine or operate

controls while standing beside the tractor.

2. Before starting the engine, make sure that the

forward and reverse drive pedal are in the neutral

positions, the parking brake is engaged, and the

Power Take Off (PTO) is disengaged.

3. Always keep the seat belt fastened around your

waist whenever the tractor has the Roll-Over

Protective Structure (ROPS).

4. Start the engine of your tractor only by using the

starter key switch. Do not attempt to start the

engine by short-circuiting across the starter

solenoid terminals with a jumper wire, or by

bypassing the safety start switch. This defeats

the safety interlock circuit and the tractor may

begin to move and/or the Power Take Off (PTO)

shafts may begin to rotate, possibly leading to

personal injury or property damage.

5. Do not run or idle the engine in a confined area

that is poorly ventilated or not ventilated at all.

The engine emits carbon monoxide gas that is

colorless, odorless and can cause death.

6. Before operation, check that all the safety

features are functioning correctly. Never tamper

with safety devices. Check their proper operation

regularly. Contact your Cub Cadet Yanmar dealer

if safety devices malfunction.

7. Avoid accidental contact with control pedals while

the engine is running, as this can cause

unexpected movement of the tractor.

8. Never leave a running machine unattended.

Sc2400 Operator’s Manual

1-4

Page 13

1. SAFETY PRECAUTIONS

2. Working with Your Tractor

1. Make sure that all the covers and guards are in

correct position. Replace any missing or

damaged cover immediately.

2. Before turning or when traveling on a rough

terrain, or before stopping, decrease the tractor

speed in order to prevent upsetting.

3. Use extra caution when operating over rough

ground, when crossing ditches or slopes, and

when turning corners.

4. Do not attempt to turn with the differential lock

engaged. Attempting to turn the tractor while the

differential lock is engaged can lead to a roll-over.

5. Stay clear of ditches, holes, embankments or

ponds. A hazard of tractor upset can occur more

easily if the ground is soft or wet. Before entering

an area covered with tall grass, walk the area to

detect any obstacles.

6. Always watch where you are going, especially at

blind corners, trees, or other objects that can

obscure your vision. Remain alert when you are

approaching the end of a row, trees or any

obstacle.

7. When two or more people are working in one

area, always keep in good communication with

each other.

8. Do not get on or off a moving tractor.

9. Make certain all tractor lights are illuminated

when operating at night.

3. Considerations for Safety of Children

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine. They do not understand the

dangers. Never assume they will remain where you

last saw them.

1. Keep children out of the operating area and in the

watchful care of an adult other than the operator.

2. Be alert if a child enters the work area, stop your

tractor immediately.

3. Never allow a child to ride on the tractor. They

may fall off and be seriously injured or interfere

with safe machine operation.

4. Never allow children under 16 years old to

operate the machine. Children 16 years and over

should only operate machine under close

parental supervision and proper instruction.

5. Be extremely careful when backing the tractor.

Before and during backing, look back and

downward. A child may be in your path.

6. Use extra care when approaching blind corners,

shrubs, trees or other objects that may obscure

your vision of a child or other hazard.

7. Never allow a child to play on the tractor or

implement.

8. Keep children away from hot or running engines.

They may suffer burns.

9. Park your tractor on a solid, flat and level place.

Engage the parking brake securely, remove the

key from the starter key switch to prevent

unauthorized operation. If parking on a slope is

unavoidable, park the tractor across the slope

and chock the wheels.

1-5

Sc2400 Operator’s Manual

Page 14

1. SAFETY PRECAUTIONS

5. Operating Your Tractor on Slopes

On a slope, the tractor is less stable and more prone

to tip-over, possibly leading to serious injury or death.

Remain very cautious when your tractor is on any

slope.

A2019005

DO:

●Operate up and down slopes, not across.

●Remove obstacles such as rocks, limbs, etc.

●Watch for holes, ruts or bumps. Uneven terrain

could overturn the machine. Tall grass can hide

such obstacles.

●Place the transmission in the slow range when

climbing or descending slopes.

●Keep all movement on the slopes slow and

gradual. Do not make sudden changes in speed or

direction. Rapid engagement or braking could

cause the front of the machine to lift and rapidly flip

over backwards which could cause serious injury.

●Avoid starting or stopping on a slope. If tires lose

traction, disengage the Power Take Off (PTO) and

proceed slowly straight down the slope.

●To avoid upset, move backward up a steep slope.

If backing on the slope is not comfortable, do not

attempt to continue. Avoid an extremely steep

slope.

●When moving forward to escape from a ditch, or

deep mud, or when traveling on a steep slope, the

risk of the tractor upsetting backward is high.

Always move backward to escape these situations.

In the four-wheel drive mode, special caution is

needed to avoid false confidence in the tractor’s

ability to climb slopes.

DO NOT:

●Do not mow near drop-offs, ditches or

embankments. The mower could suddenly turn

over if a wheel goes over the edge of a cliff or ditch,

or if an edge caves in.

WARNING

●Before approaching a slope, select an

appropriate speed setting. Be sure to run the

tractor at a lower speed on slopes.

●Suddenly starting the tractor on an uphill can

cause the front wheels to jump off the ground,

and this situation poses an extreme danger. To

avoid this problem, run the engine at a lower

speed, and gently start the tractor.

●Do not park the tractor on a slope. If parking on

a slope is unavoidable, chock the tires, and

engage the parking brake securely.

Sc2400 Operator’s Manual

1-6

Page 15

6. Traveling on a Road

1. SAFETY PRECAUTIONS

1. Disengagement of the 4-wheel drive is

recommended.

2. Remember that the braking characteristics differ

between the two and four wheel drive modes. Be

aware of the current drive mode and use

carefully.

3. Before turning, always slow down the tractor.

High-speed turn may cause the tractor to tip over.

4. When traveling on a road, be sure that the Slow

Moving Vehicle (SMV) emblem is on the tractor

and is clearly visible. Use the hazard lights and

turn lights as required by the currently effective

local laws or regulations.

5. Strictly observe all the currently effective local

traffic and safety laws and regulations.

6. Turn ON the headlights as required by the

currently effective local laws or regulations.

7. Always travel at a speed that allows you to

8. Avoid engaging differential lock while traveling on

9. While traveling on a road, do not suddenly turn

10. While on a road, do not attempt to operate an

7. Safe Practices for Parking Your Tractor

1. Disengage the Power Take Off (PTO), lower the

implement to the ground, set the forward and

reverse drive pedal in the neutral positions,

engage the parking brake securely, stop the

engine and remove the key from the starter key

switch.

2. Before leaving your tractor, be sure the tractor is

completely stopped.

3. Do not park on a steep slope. Rather, park on

4. Allow the tractor to cool at least 5 minutes before

maintain control of the tractor.

a road. It may cause the operator to lose control

of the tractor.

the steering wheel. Such an action can lead to

loss in the stability of the tractor, and can cause

an extremely dangerous situation.

implement. During transportation, put the 3-point

hitch control / cutting height adjustment lever in

its raised position and lock it with the position

stop knob. Do not fully close the hydraulic flow

control / stop knob.

solid, flat, level ground whenever possible. If

parking on a slope is unavoidable, park the

tractor across the slope, and lower the implement

to the ground and chock the wheels.

storing.

1-7

Sc2400 Operator’s Manual

Page 16

1. SAFETY PRECAUTIONS

8. Operating the Power Take Off (PTO)

1. Before getting off the tractor, connecting/

disconnecting an implement, adjusting, cleaning

or servicing a Power Take Off (PTO)-driven

implement, make sure that all the moving

components are at a standstill.

2. Ensure that the Power Take Off (PTO) shaft

cover is always in place. Replace the Power Take

Off (PTO) shaft cap only when the shaft is at a

standstill.

9. Using the 3-Point Hitch

3. Before installing or operating Power Take Off

(PTO)-driven implement, carefully study the

manufacturer’s Operator’s Manual and the safety

decals on the implement.

4. When installing the Power Take Off (PTO)- driven

implements, engage the parking brake securely

and chock the four wheels. Do not approach or

access any rotating component.

1. Use the 3-point hitch only in conjunction with the

implement that is specifically designed for use

with the 3-point hitch.

2. Before using a 3-point hitch mounted implement,

the appropriate counterbalance may need to be

installed on the front of the tractor.

10. Safety Frame (Roll-Over Protective Structure) (ROPS) Precautions

Your tractor is equipped with a Roll-Over Protective

Structure (ROPS) which must be maintained in a fully

functional condition. Check overhead clearance

carefully before driving under power lines, wires,

bridges or low hanging branches, before entering or

leaving buildings, or in any other situation where the

operator and/or Roll-Over Protective Structure

(ROPS) may be stuck, which could result in serious

injury.

1. Never modify the Roll-Over Protective Structure

(ROPS) in any way.

2. Never attempt to straighten or reweld any part of

the main frame or retaining brackets that have

been damaged. Doing so may weaken the

structure and endanger your safety.

3. Never secure any parts on the main frame or

attach the safety frame with anything other than

the special fasteners specified.

4. Never attach ropes, chains, or cables to the RollOver Protective Structure (ROPS) for pulling

purposes.

5. Although the Roll-Over Protective Structure

(ROPS) provides the operator the maximum

protection possible, never take unnecessary

risks.

Sc2400 Operator’s Manual

1-8

Page 17

1. SAFETY PRECAUTIONS

11. Safe Practices for Servicing Your Tractor

Before starting any servicing work, park your tractor

on solid, level ground, engage the parking brake

securely, disengage the Power Take Off (PTO),

lower the implement to the ground, set the forward

and reverse drive pedal to the neutral position, stop

the engine and remove the key from the starter key

switch.

1. Always keep a first-aid kit and a fire extinguisher

readily available.

2. Before accessing the engine, muffler, radiator or

other possibly hot components, wait until the

tractor has fully cooled off.

3. Use extreme care in handling diesel fuels. They

are extremely flammable and the vapors are

explosive. Use only an approved container.

4. Be sure to stop the engine before refueling. After

refueling, replace fuel cap securely and wipe off

any spilled fuel before starting the engine as it

may cause a fire or explosion.

5. Do not smoke while refueling. Keep any spark or

open flame away from the fuel tank.

6. Never refuel the machine indoors because fuel

vapors will accumulate in the area.

7. Never store the fuel container or machine inside

where there is an open flame or spark, such as a

gas hot water heater, space heater or furnace.

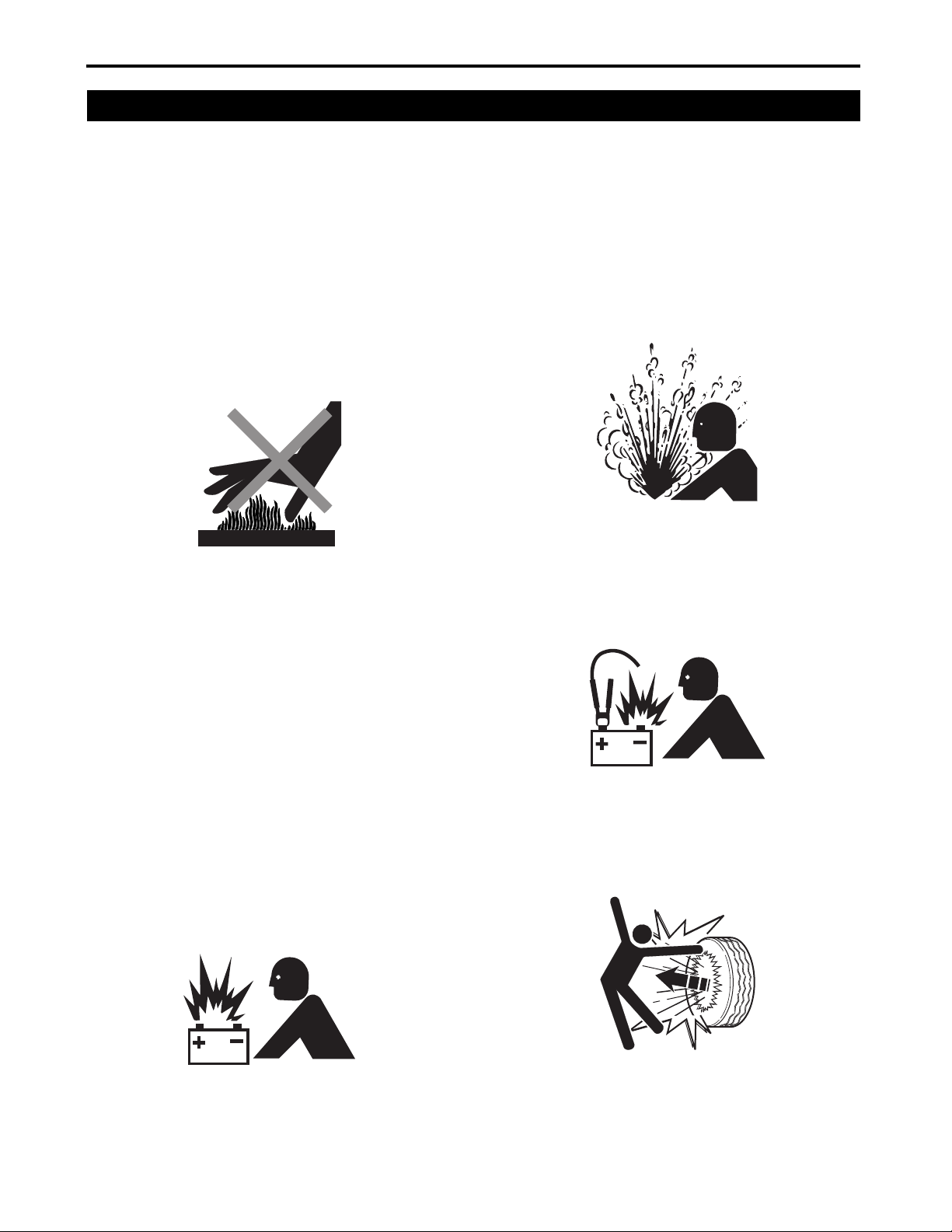

8. Do not smoke while working around the battery.

Keep any spark or open flame away from the

battery. The battery emits hydrogen and oxygen

gas, in particular, during recharging and can pose

a hazard of explosion.

9. Prior to “jump starting” a tractor that has a fully

depleted battery, read and follow all the

instructions in the “7. OPERATING THE

ENGINE”.

10. Carefully loosen the radiator cap to the first stop,

and allow excessive pressure to escape, and only

then remove the radiator cap. If the tractor is

equipped with a coolant reserve tank, add coolant

or water to the reserve tank, not to the radiator

(See “Checking the Cooling System”).

11. Before working on or around electric

components, first disconnect the battery ground

cable.

12. To prevent a spark occurring from short-circuit,

disconnect the battery grounding (–) terminal first

and reconnect last.

13. The operator must not mount a tire onto a rim.

Only qualified personnel should do this task.

14. Always keep the tires at a correct pressure level.

Do not exceed the recommended tire pressure

specified in the Operator’s Manual.

15. Keep the tractor securely supported while

changing the wheels or adjusting the wheel tread

width. Be sure to tighten the wheel bolts at the

specified tightening torque.

1-9

Sc2400 Operator’s Manual

Page 18

1. SAFETY PRECAUTIONS

16. Avoid working under any hydraulically supported

devices. Such devices can settle, suddenly leak

down, or be accidentally lowered. If working

beneath the tractor, or an implement, is

unavoidable, be sure to support the tractor or

implement with appropriate stands or lift

apparatus.

17. High pressure hydraulic fluid, when released, can

penetrate human skin, possibly leading to serious

personal injury. Before disconnecting any

hydraulic line, fully release the internal pressure.

Before exerting a pressure to the hydraulic

system, make sure that all connections are tight

and all the lines, pipes and hoses are free from

fissure/crack or any other damage.

18. Check brake operation frequently. Adjust and

service as required.

19. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds

are dangerous.

20. Observe proper disposal laws and regulations.

Prior to disposal, determine the proper method to

dispose of waste from your local Environmental

Protection Agency. Recycling centers are

established to properly dispose of materials in an

environmentally safe fashion.

21. Use proper containers when draining fluids. Do

not use food or beverage containers that may

mislead someone into drinking from them.

Properly dispose of the containers immediately

following the draining of fluids.

22. DO NOT pour oil or other fluids into the ground,

down a drain or into a stream, pond, lake or other

body of water. Observe Environmental Protection

Agency regulations when disposing of oil, fuel,

coolant, brake fluid, filters, batteries, tires and

other harmful waste.

23. We do not recommend the use of a pressure

washer or garden hose to clean your unit. They

may cause damage to electrical components;

spindles; pulleys; bearings; or the engine. The

use of water will result in shortened life and

reduce serviceability.

WARNING: YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions in this manual and on the

machine.

Sc2400 Operator’s Manual

1-10

Page 19

1. SAFETY PRECAUTIONS

12. Understanding the Tractor Safety Decals

■ Safety-Alert Symbols

The tractor safety decals illustrated in this section are

provided in critical areas on the tractor so that people

including the operator can remain always aware of

potential hazards.

The tractor safety decals contain the words DANGER,

WARNING and CAUTION together with the safety-alert

symbols. DANGER and WARNING stand for the most

serious hazards.

The Operator’s Manual also contains special safety

messages that explain potential hazards about which the

operator must remain cautious. These messages are

presented together with the word CAUTION and the

safety-alert symbols.

■ Care of DANGER, WARNING and CAUTION Decals

1. Always keep all the danger, warning and caution

decals clean and clearly legible.

2. Clean the danger, warning and caution decals with

soap water, and wipe dry with clean soft cloth.

3. Replace damaged or missing danger, warning and

caution decals with new decals available from your

local Cub Cadet Yanmar dealer.

4. If a component having a danger, warning or caution

decals is replaced with a new one, make sure that a

new decal is on the same location as on the old

component.

5. Affix a new danger, warning or caution decals flat on a

clean, dry surface, squeezing out trapped air.

1-11

Sc2400 Operator’s Manual

Page 20

1. SAFETY PRECAUTIONS

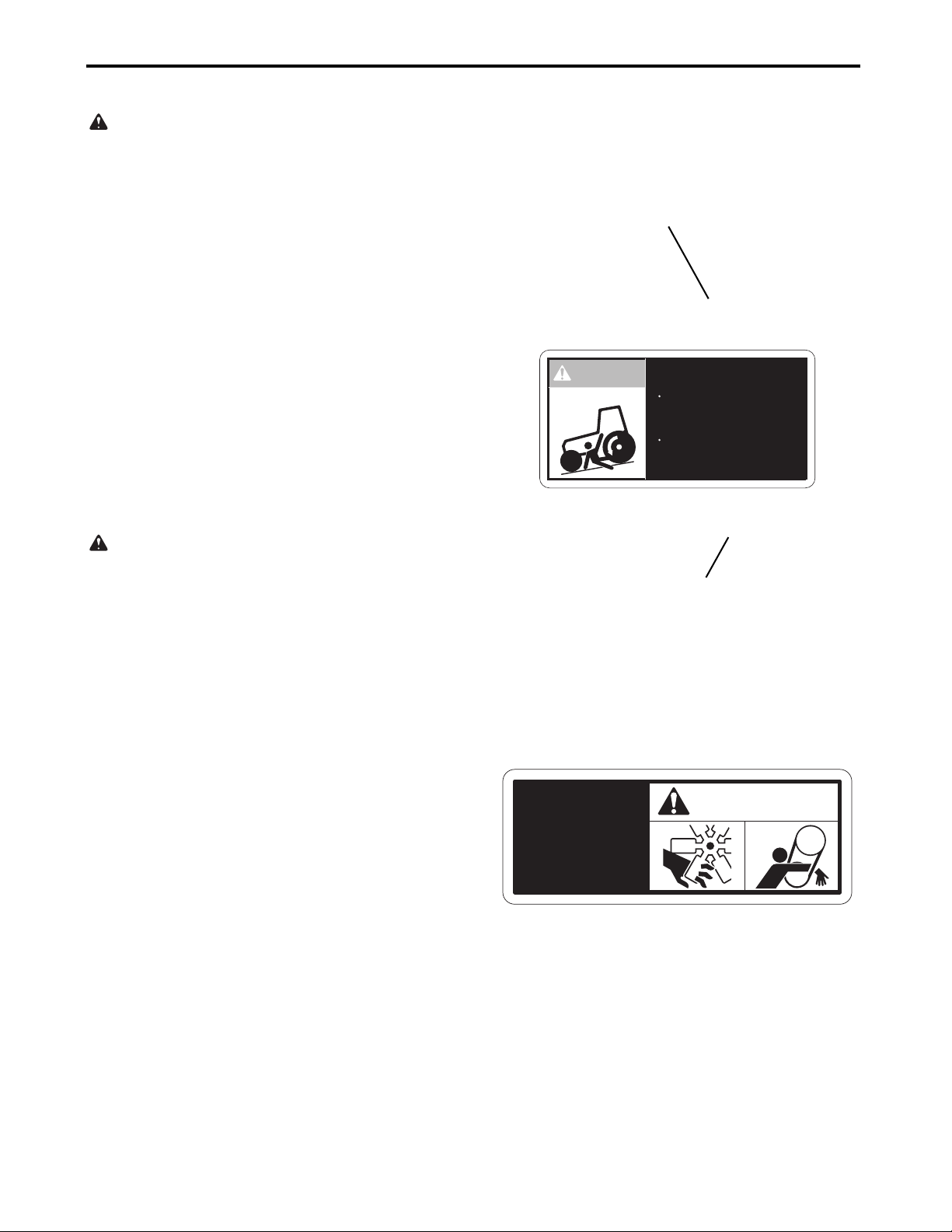

(A) CY1A8160-65300

DANGER

TO AVOID INJURY OR DEATH:

●Do not start engine by shorting across starter

terminals or bypassing safety start switch.

●Start engine only from seat with transmission and

PTO OFF.

(A)

P3014902

(B) CY1A7880-65620

WARNING

STAY CLEAR OF ENGINE FAN AND FAN BELT

P3014961

STAY CLEAR OF

ENGINE FAN

AND FAN BELT

DANGER

TO AVOID INJURY OR DEATH:

Do not start engine by

䇭shorting across starter

䇭terminals or bypassing

䇭safety start switch.

Start engine only from

䇭seat with transmission

䇭and PTO OFF.

1A8160-65300

(B)

WARNING

Sc2400 Operator’s Manual

㪈㪘㪎㪏㪏㪇㪄㪍㪌㪍㪉㪇

1-12

Page 21

1. SAFETY PRECAUTIONS

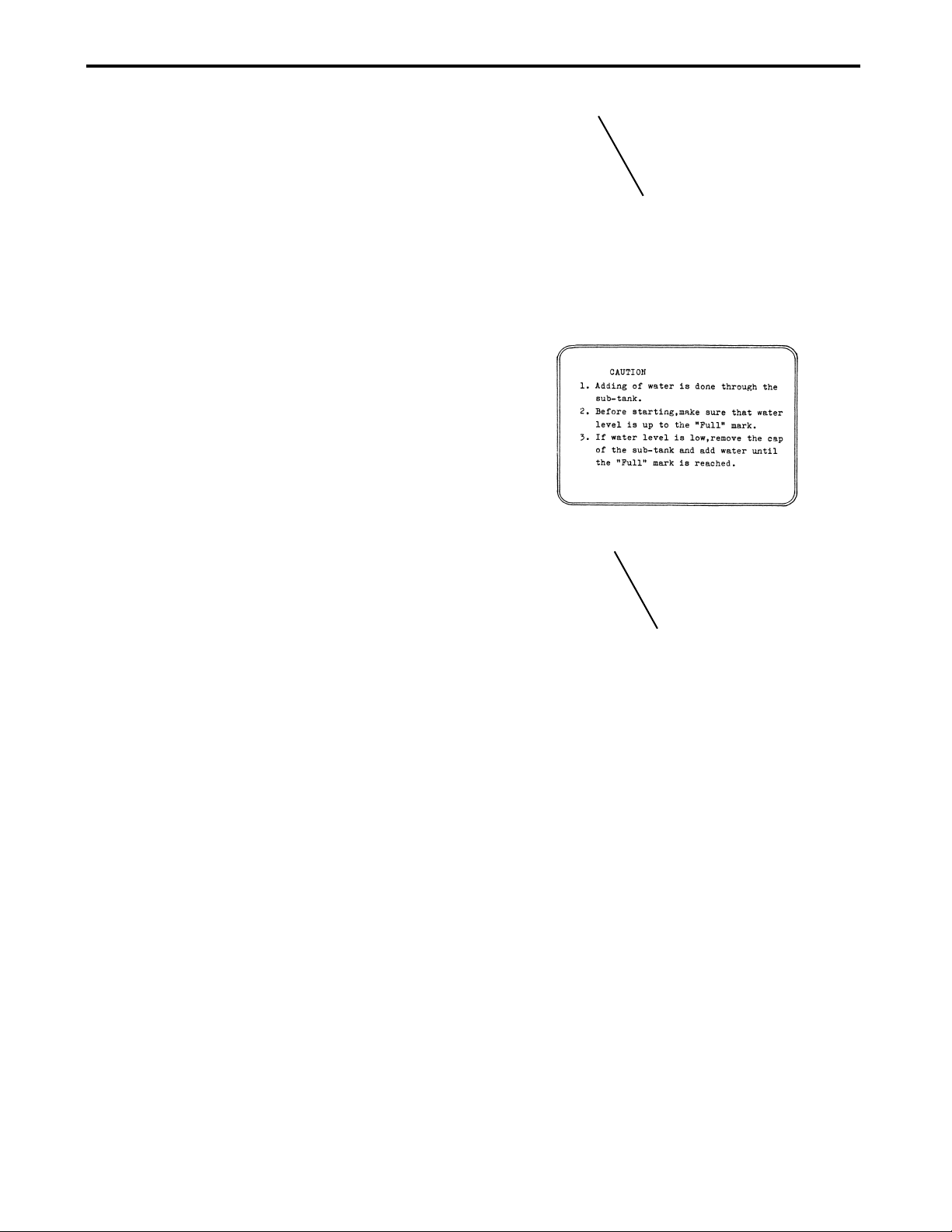

(C) CY124764-44810

CAUTION

1. Adding of water is done through the sub-tank.

2. Before starting, make sure that water level is up

to the "Full" mark.

3. If water level is low, remove the cap of the sub-

tank and add water until the "Full" mark is

reached.

(D) CY1A8160-51520

DANGER/POISON (ENGLISH)

●SHIELD EYES: EXPLOSIVE GASES CAN CAUSE

BLINDNESS OR INJURY.

●NO SPARKS, FLAMES, SMOKING.

●SULFURIC ACID CAN CAUSE BLINDNESS OR

SEVERE BURNS.

●FLUSH EYES IMMEDIATELY WITH WATER.

SEEK MEDICAL HELP RIGHT AWAY.

●KEEP OUT OF REACH OF CHILDREN. DO NOT

TIP.

●KEEP VENT CAPS TIGHT AND LEVEL.

(C)

P3014947

(D)

P3014933

1-13

P3013722a

Sc2400 Operator’s Manual

Page 22

1. SAFETY PRECAUTIONS

(E) CY1A7880-65600

WARNING

READ OPERATOR'S MANUAL

1. Do not operate the machine without guards

shields and safety devices in place and working.

2. Keep all riders off tractor during operation.

3. Make certain everyone is clear of machine before

starting engine or operation.

4. Keep hands, feet and clothing away from power-

driven parts.

5. Use seat belt.

6. Reduce speed when turning or operating around

hazards, on rough ground or steep slopes.

7. Do not allow operation of the machine by

untrained personnel.

8. Stop engine, lower implement to ground and lock

park brake before dismounting.

9. Wait for all movement to stop before servicing

machinery.

10. Remove key if leaving tractor unattended.

11. Securely support tractor and implements before

working underneath.

12. On public roads use SMV emblem and hazard

lights.

13. Do not jump if machine tips.

(E)

P3014940

WARNING

R

E

A

D

O

P

E

R

A

T

O

R

'

M

A

N

U

A

1

.

D

o

s

h

i

e

w

o

r

2

.

K

e

e

L

n

o

t

o

p

e

r

a

t

e

t

h

e

m

a

c

l

d

s

a

n

d

s

k

i

n

g

.

p

a

l

l

r

i

d

e

r

h

a

f

e

t

y

d

e

v

i

c

e

s

o

f

f

t

r

a

c

t

o

r

S

i

n

e

w

i

t

h

o

u

t

s

i

n

p

l

a

c

e

a

d

u

r

i

n

g

o

p

e

r

3

.

M

a

k

e

c

e

r

t

a

i

n

e

v

e

r

y

o

n

e

i

s

b

e

f

o

r

e

s

t

a

r

t

i

n

4

.

K

e

p

o

5

.

U

s

6

.

R

g

u

n

d

a

t

i

o

e

a

r

d

s

a

r

o

s

l

o

7

.

D

o

n

u

.

n

t

g

e

p

h

a

n

d

s

,

f

w

p

r

e

e

r

-

d

r

i

v

e

n

p

e

s

e

a

t

b

e

l

t

.

d

u

c

e

s

p

e

e

d

u

n

d

h

a

z

a

r

d

s

e

s

.

n

o

t

a

l

l

o

w

o

p

a

i

n

e

d

p

e

r

s

o

c

e

n

g

i

n

e

o

r

o

e

t

a

n

d

c

l

o

t

h

a

r

t

s

.

w

h

e

n

t

u

r

n

i

n

,

o

n

r

o

u

g

h

g

e

r

a

t

i

o

n

o

f

t

h

n

n

e

l

.

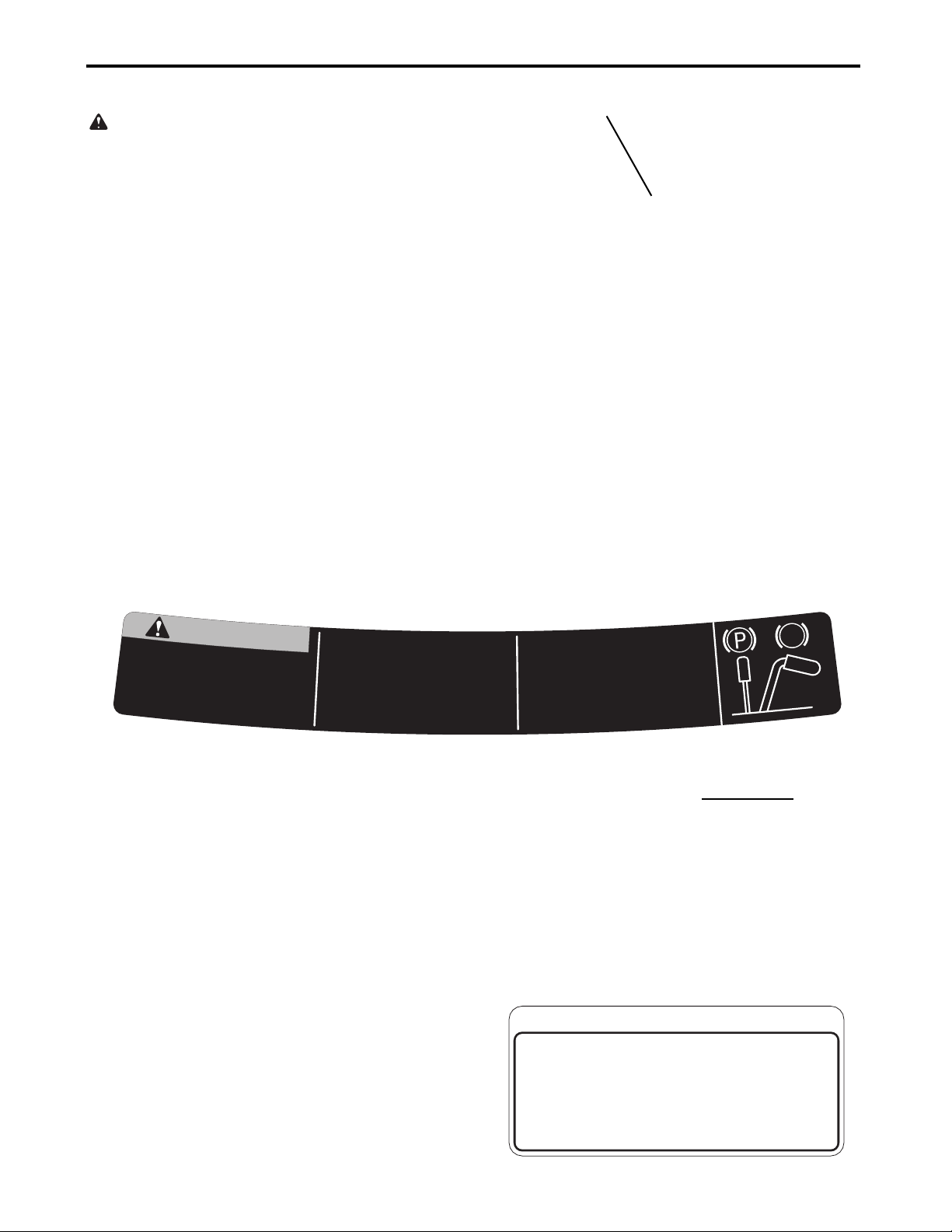

(F) CY1A7880-65630

IMPORTANT

12V DC OUTLET

1. DO NOT CONNECT A LIGHT OR LOAD OF

MORE THAN 120 WATTS.

2. DO NOT USE AS A CIGARETTE LIGHTER.

3. REMOVE PLUG FROM SOCKET WHEN NOT IN

USE.

4. DO NOT USE WHEN WET.

l

e

a

r

e

o

f

n

i

m

h

a

c

p

e

r

.

a

t

n

i

o

i

n

g

a

w

a

y

r

f

g

o

r

o

p

e

r

t

a

r

o

u

n

d

o

r

t

s

e

m

a

c

h

i

n

e

S

.

8

a

m

o

W

.

9

s

.

0

1

.

1

1

g

n

i

p

e

e

.

2

1

y

b

3

1

,

e

n

i

g

n

e

p

o

t

l

d

n

t

i

a

c

i

v

r

e

m

e

R

c

e

S

o

f

e

b

n

O

z

a

h

o

D

.

a

r

b

k

r

a

p

k

c

o

e

v

o

m

l

l

a

r

o

f

n

i

h

c

a

m

g

n

i

l

f

i

y

e

k

e

v

o

o

p

p

u

s

y

l

e

r

u

g

n

i

k

r

o

w

e

r

s

d

a

o

r

c

i

l

b

u

p

.

s

t

h

g

i

l

d

r

a

m

f

i

p

m

u

j

t

o

n

d

e

r

o

f

e

b

e

k

p

o

t

s

o

t

t

n

e

m

.

y

r

e

e

r

u

o

t

c

a

r

t

g

n

i

v

a

d

n

a

r

o

t

c

a

r

t

t

.

h

t

a

e

n

r

e

d

n

e

V

M

S

e

s

u

s

p

i

t

e

n

i

h

c

a

.

g

n

i

t

n

u

o

m

s

i

e

r

o

f

e

b

u

r

m

i

b

m

.

.

d

e

d

n

e

t

t

a

n

s

t

n

e

m

e

l

p

d

n

a

m

e

l

5600

6

0-

1A788

d

n

u

o

r

g

o

t

t

n

e

m

e

l

p

m

i

r

e

w

o

l

(F)

P3014958

IMPORTANT

12V DC OUTLET

1.DO NOT CONNECT A LIGHT OR LOAD OF MORE

THAN 120 WATTS.

2.DO NOT USE AS A CIGARETTE LIGHTER.

3.REMOVE PLUG FROM SOCKET WHEN NOT IN USE.

4.DO NOT USE WHEN WET.

1A7880-65630

Sc2400 Operator’s Manual

1-14

Page 23

1. SAFETY PRECAUTIONS

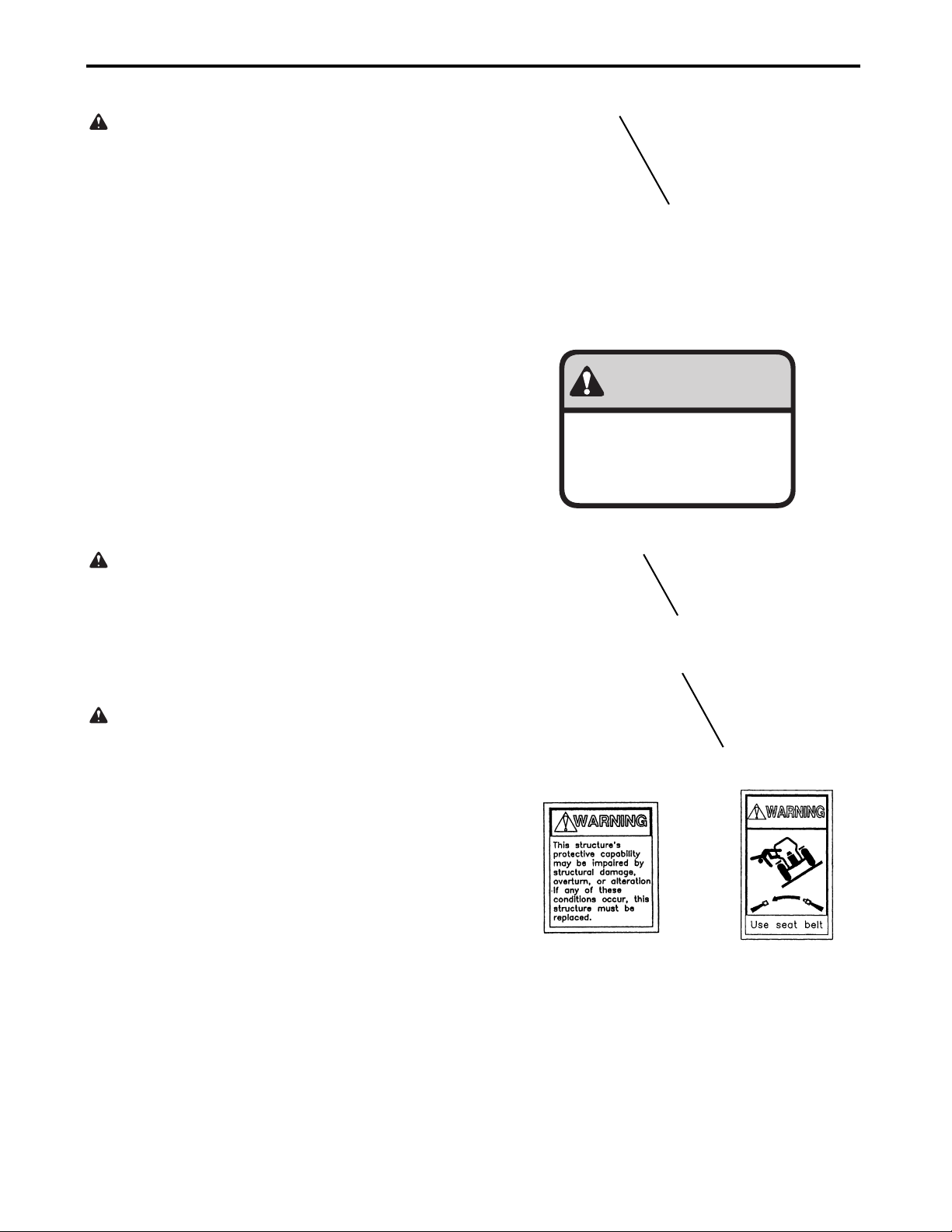

(G) CY1A7880-65350

WARNING

Only use PTO in reverse when there are no children

or others around

(H) CY1A7880-85170

WARNING

This structure's protective capability may be impaired

by structural damage, overturn, or alteration.

If any of these conditions occur, this structure must

be replaced.

(G)

P3014940

WARNING

Only use PTO in

reverse when there

are no children or

others around

(H)

(I) CY1A7880-85180

WARNING

Use seat belt

P3014939

( I )

(H) ( I )

1-15

Sc2400 Operator’s Manual

Page 24

(J) CY198220-65621

WARNING

AVOID INJURY FROM PTO

●Keep all shields in place

●Keep hands, feet and clothing away

●Operate only with 540 RPM

1. SAFETY PRECAUTIONS

(K) CY1A8160-65310

WARNING

TO AVOID INJURY:

Before leaving or servicing machine,

●Stop engine.

●Set parking brake.

●Park on level ground.

●Lower all implements to the ground.

●Remove key.

P3014938

P3014959

(J)

WARNING

AVOID INJURY FROM PTO

Keep all shields in place

Keep hands,feet and

clothing away

Operate only with 540

RPM

(K)

Sc2400 Operator’s Manual

1-16

Page 25

2. SERVICING THE TRACTOR

2. SERVICING THE TRACTOR

Your Cub Cadet Yanmar dealer wants to remain

committed to the tractors our customers have

purchased and intends to support our customers in

fully developing the performance of their Cub Cadet

Yanmar tractors. After carefully studying this manual,

the customers themselves will be able to do a certain

portion of the regular maintenance work.

When parts / components or major service work is

needed, contact your local Cub Cadet Yanmar dealer

for technical assistance.

For information about the service work, contact your

local Cub Cadet Yanmar dealer. When ordering a

part / component, inform your local Cub Cadet

Yanmar dealer of the tractor and engine serial

numbers. Find both serial numbers and enter them in

the following table.

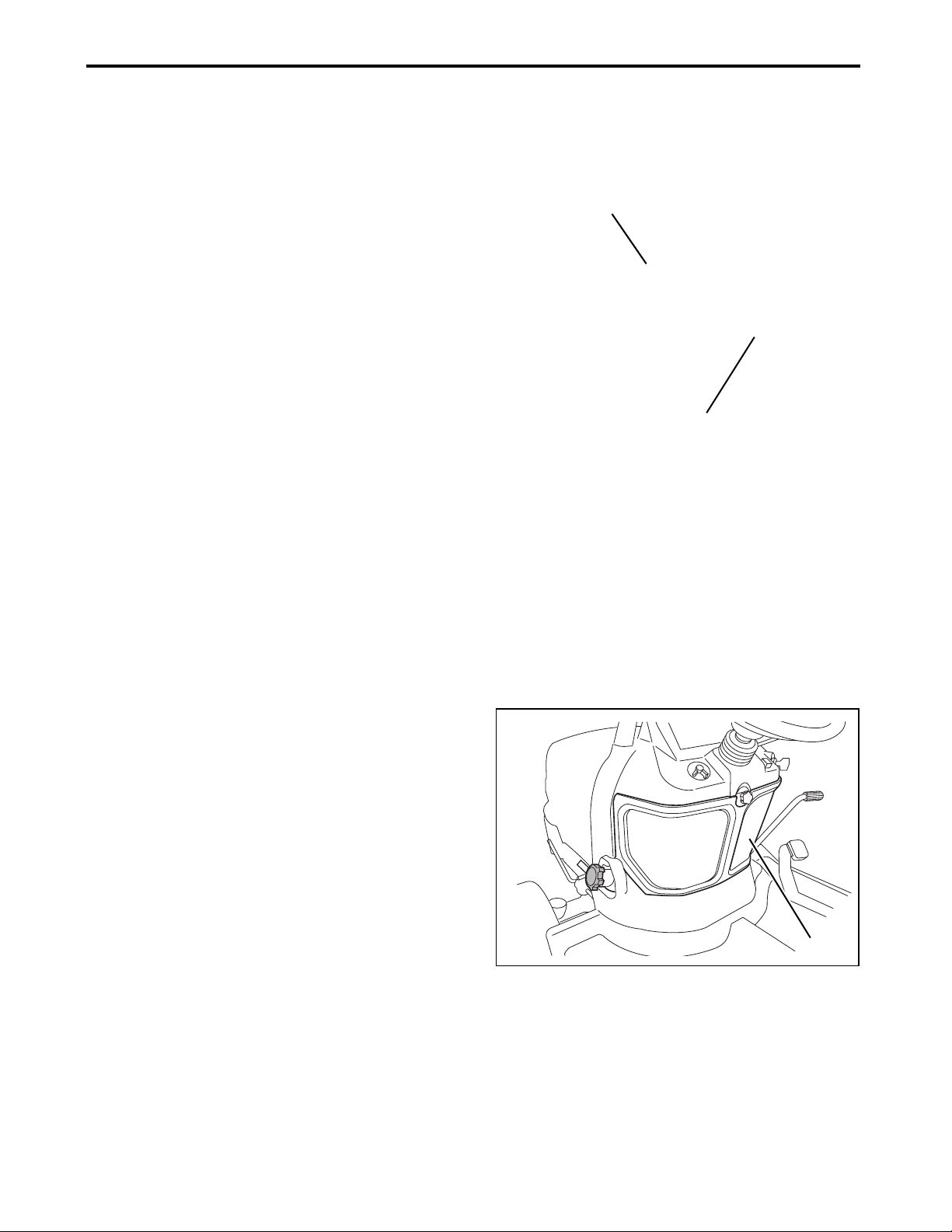

P3014902

(A)

Type Serial No.

Tractor

Engine

Date of Purchase

Name of Dealer

(A) Tractor identification plate with tractor serial

number

(B) Engine serial number

(B)

P3014901

2-1

Sc2400 Operator’s Manual

Page 26

3. SPECIFICATIONS

3. SPECIFICATIONS

1. Specifications Table

Model Sc2400

Power Take Off (PTO) Power hp (kW) 16.5 (12.3)

Maker YANMAR

Model 3TNV72

Type

Number of Cylinders 3

Bore and Stroke in. (mm) 2.834 × 2.913 (72 × 74)

Total Displacement cu. in. (L) 55.1 (0.903)

Engine

Capacities

Dimensions

Weight (with Roll-Over Protective Structure (ROPS) and R4 Tires) lb (kg) 1279 (580)

Gross Power hp (kW) 24.0 (17.9)

Net Power hp (kW) 20.4 (15.0)

Rated Revolution rpm 3300

High Idle Speed rpm 3470

Low Idle Speed rpm 1150

Maximum Torque ft•lb (N•m) 38.3 (52.3)

Battery 12V BP24 , CCA: 540 A

Fuel Diesel Fuel No.1-D , No.2-D

Fuel Tank US gal (L) Approximately 5.8 (22)

Engine Oil US qt (L) Approximately 2.5 (2.4)

Engine Coolant US qt (L) Approximately 3.4 (3.2)

Transmission Oil US gal (L) Approximately 2.0 (7.5)

Overall Length (without 3-Point Hitch) in. (mm) 82.7 (2100)

Overall Length (with 3P) in. (mm) 95.5 (2425)

Overall Width (with R4 Tires) in. (mm) 44.5 (1130)

Overall Height (with Roll-Over Protective Structure

(ROPS), R4 Tires)

Overall Height (with R4 Tires)

(Top of Steering Wheel)

Wheel Base in. (mm) 55.1 (1400)

Min. Ground Clearance (with R4 Tires) in. (mm) 7.5 (190)

Tread (with R4)

Front in. (mm) 34.6 (879)

Rear in. (mm) 32.2 (820)

in. (mm) 71.5 (1817)

in. (mm) 49.9 (1267)

Indirect Injection, Vertical,

Water-Cooled, 4 Cycle Diesel

Sc2400 Operator’s Manual

3-1

Page 27

3. SPECIFICATIONS

Traveling

System

Hydraulic Unit

Power Take Off

(PTO)

Ag (R1)

Tire

Clutch –

Steering Power Steering

Transmission

Drive Selected 4WD

Brake Wet plates

Minimum Turning Radius ft (m) 7.2 (2.2)

Differential Lock Foot Pedal Control

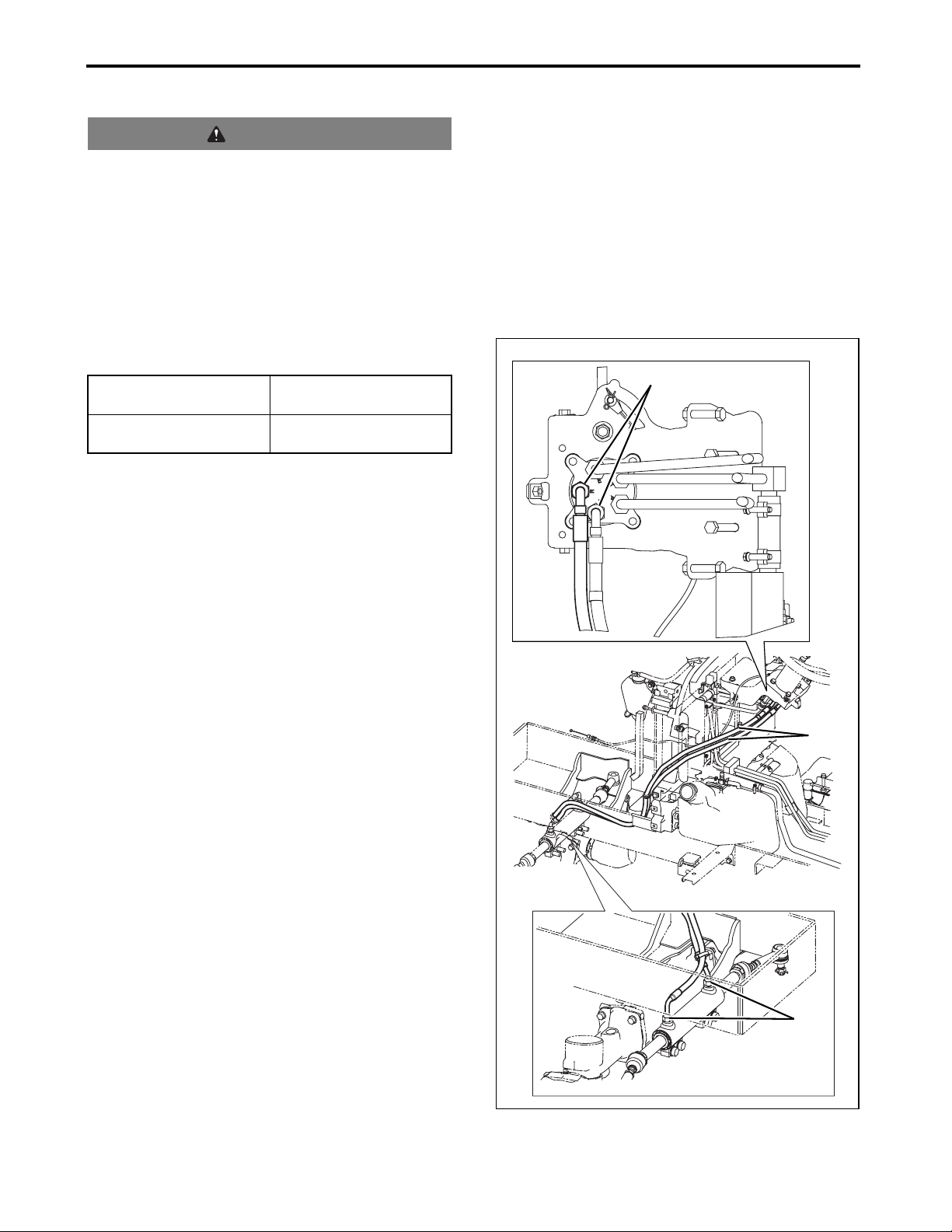

Hydraulic Control System Type Position Control

Pump Capacity (main)

Pump Capacity (steering)

3-Point Hitch Limited Category I

Max. Lift Force

System Pressure psi (MPa) 1813 (12.5)

Type Electric Clutch

Rear

Mid

Turf (R3)

Industrial (R4)

Lift Point lb. (kg) 1036 (470)

24 in. Behind Lift Point lb. (kg) 661 (300)

Shaft Size SAE 1-3/8, 6-Splines

Type Independent

Speed / Engine rpm 540 / 3111

Shaft Size SAE 16/32, 15-Splines

Type Independent

Speed / Engine rpm 2100 / 3338

Front 18 × 8.50-10

Rear 26 × 12.00-12

Front 18 × 8.50-10

Rear 26 × 12.00-12

Front 18 × 8.50-10

Rear 26 × 12.00-12

Hydrostatic Transmission,

2 Range Speeds

US gal/min

(L/min)

US gal/min

(L/min)

Approximately 3.4 (13.2)

Approximately 3.4 (13.2)

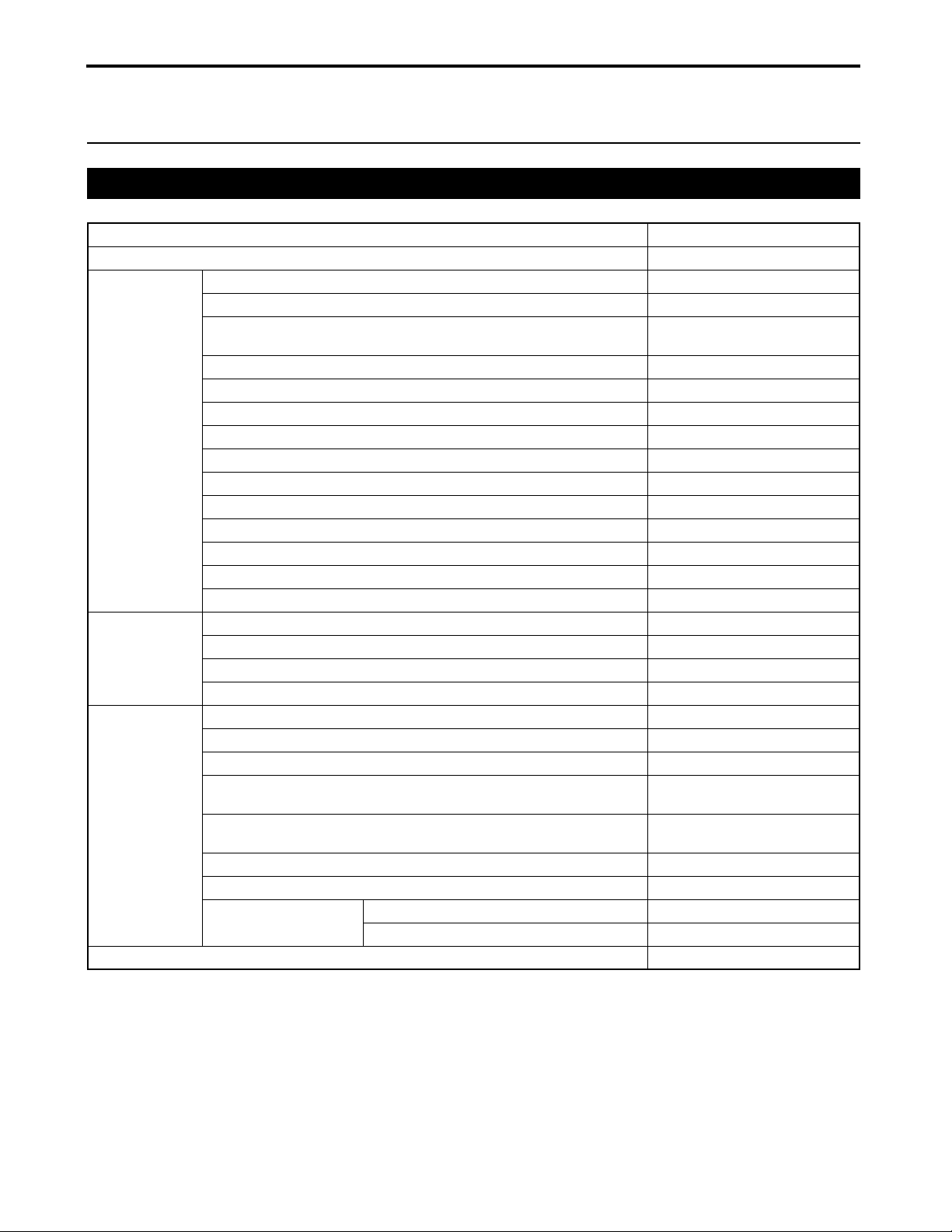

2. Traveling Speeds

Model Sc2400

Forward

Reverse

Range Shift Lever mph km/h

Slow 0-6.0 0-9.7

Fast 0-9.3 0-15

Slow 0-3.6 0-5.8

Fast 0-5.6 0-9

3-2

Sc2400 Operator’s Manual

Page 28

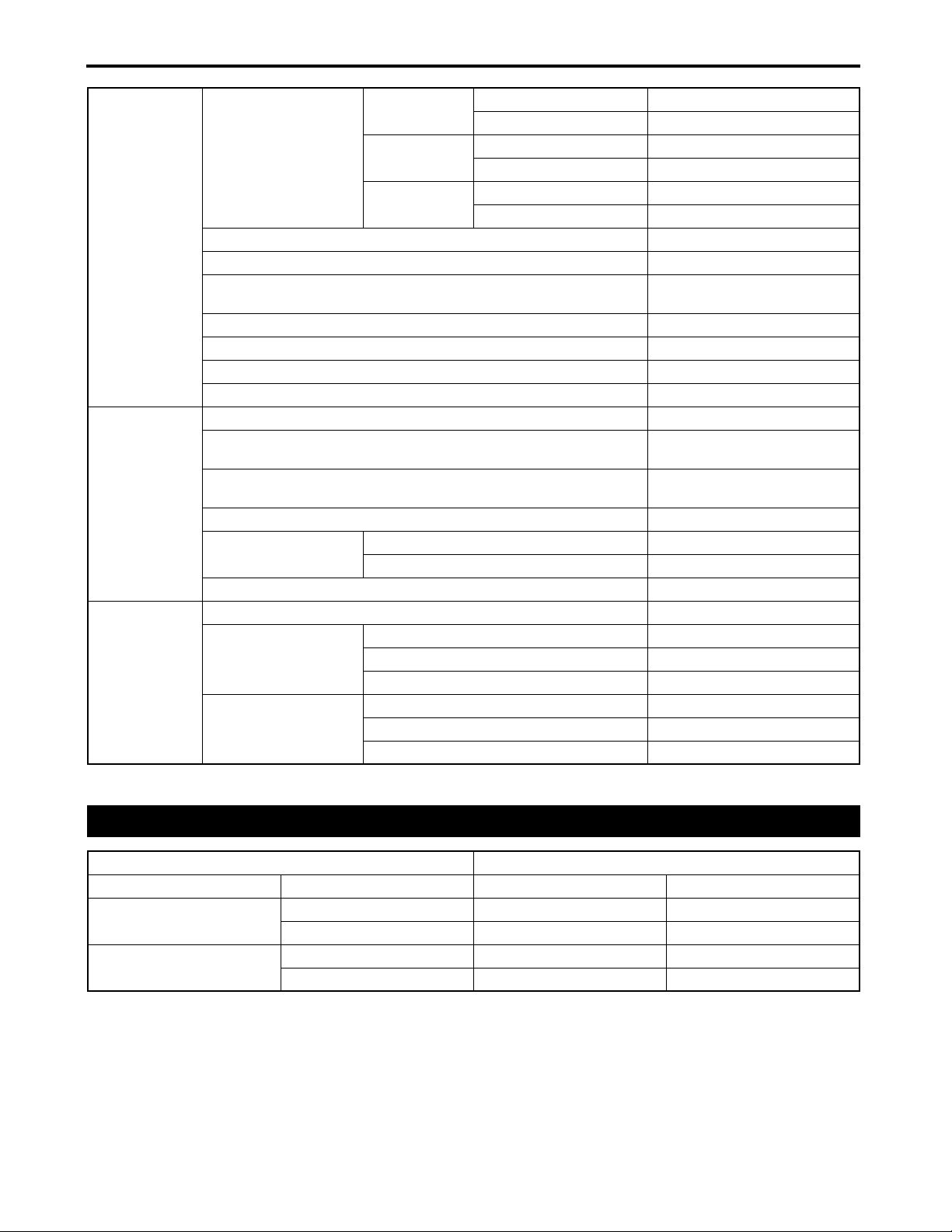

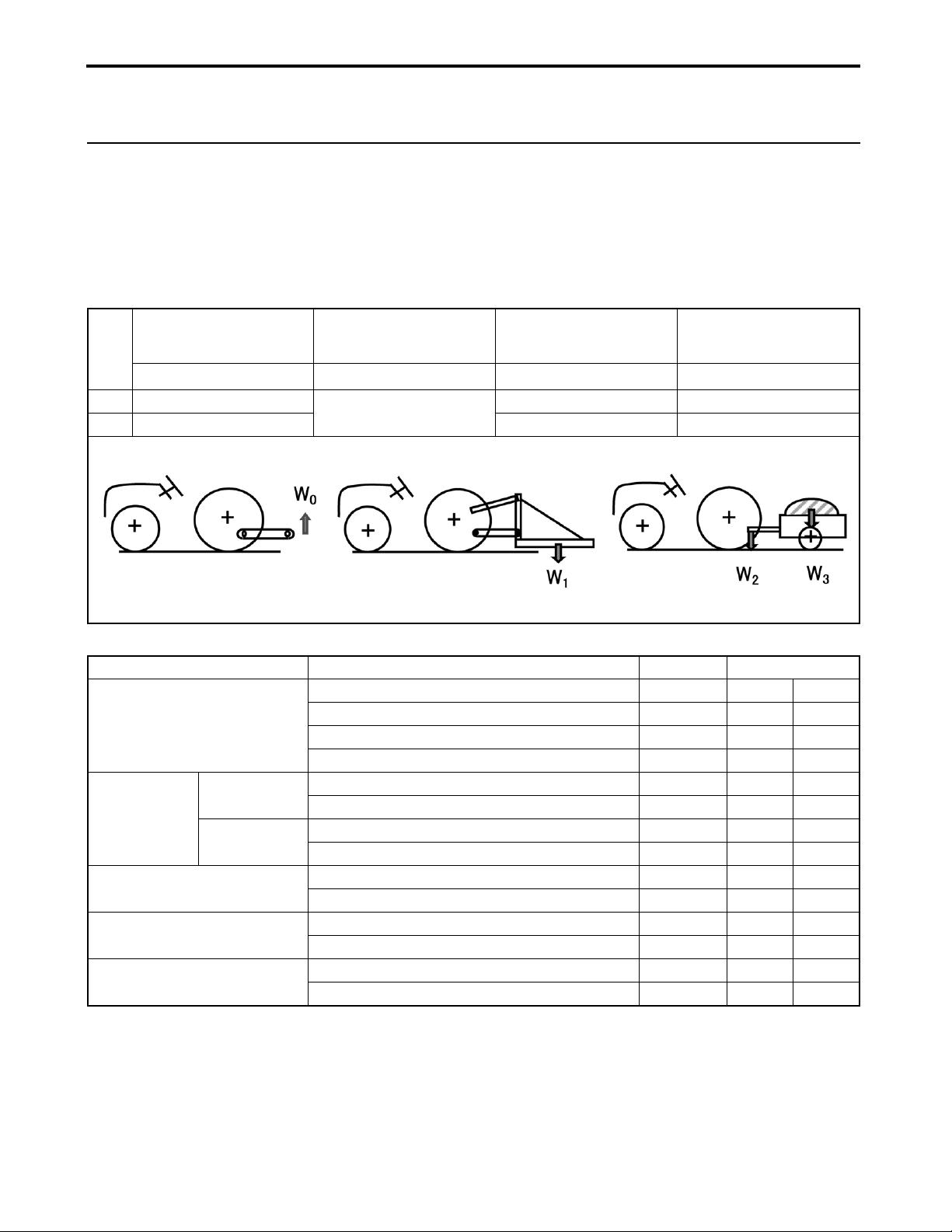

4. IMPLEMENT CAPACITIES

4. IMPLEMENT CAPACITIES

The Cub Cadet Yanmar tractor has been carefully tested in the configuration equipped with implements sold or

approved by Cub Cadet Yanmar and has proved to perform properly. Do not use any implement that has not

been sold or recommended by a Cub Cadet Yanmar dealer, or that fails to satisfy the specified values given

below. Never mount an implement that is not approved for the Cub Cadet Yanmar tractor. Using unapproved

implements could result in malfunction, failure, and damage to the tractor and/or implement, and increase the

possibility of injury to the operator or other people. The Cub Cadet Yanmar warranty does not cover any

malfunction or failure that results from use of an unapproved implement.

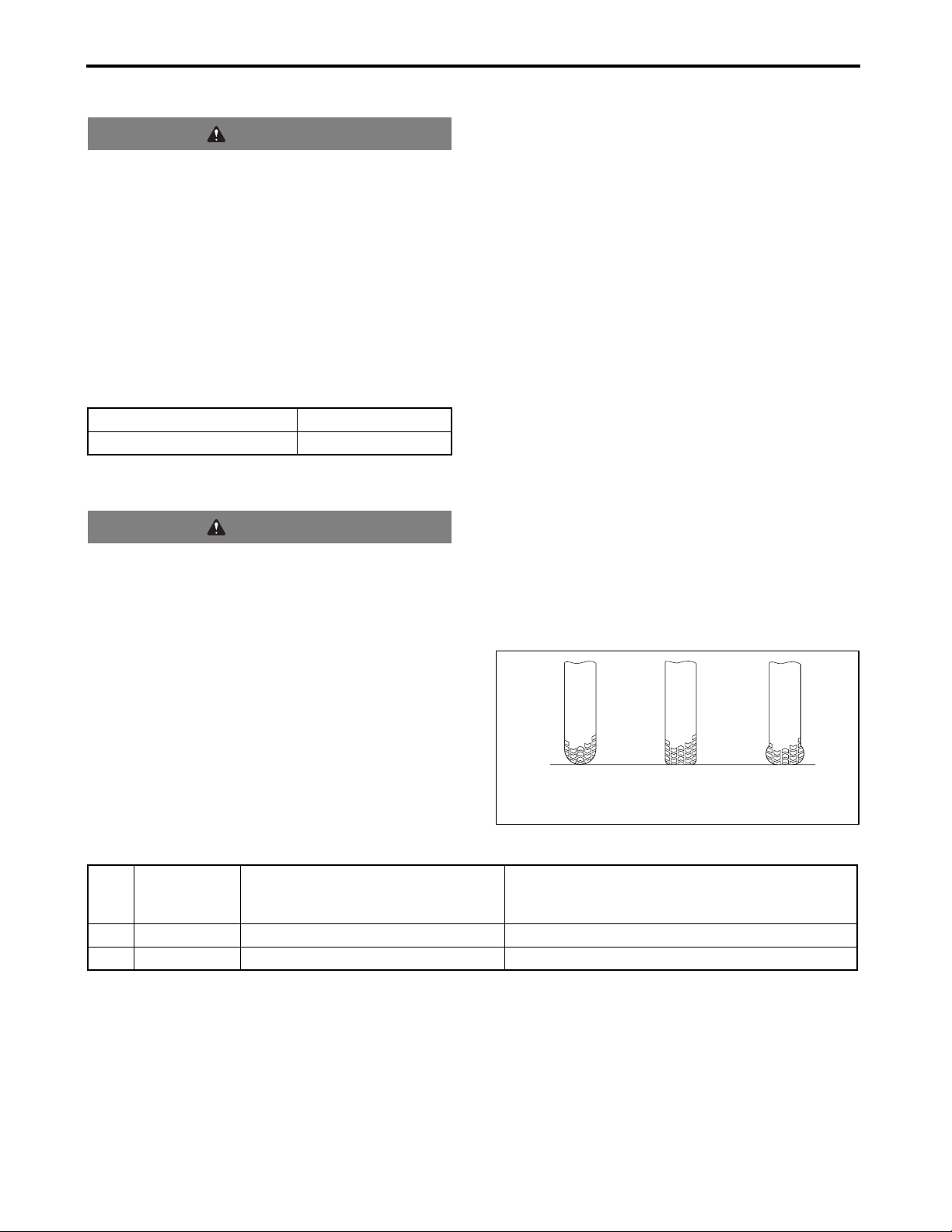

24in. Behind Lift Point

Maximum

Lifting Capacity

W

0

lb 661

kg 300 150 300

A3013714a

Implement Remarks Unit Amount

Front - End Loader

Mid - Mount

Mower

Rear - Mount

Rotary Tiller

Box Scraper (Box Blade)

Rear Blade

Implement Weight

W

1

As specified in the list

Maximum Lift Capacity (at Pivot) lb (kg) 700 317

Maximum Overhang (Pivot - Front Tire Center) in. (mm) 40 1022

Maximum Weight lb (kg) 441 200

Maximum Oil Pressure psi (MPa) 1885 13

Maximum Cutting Width in. (mm) 60 1524

Maximum Weight lb (kg) 254 115

Maximum Cutting Width in. (mm) 48 1219

Maximum Weight lb (kg) 351 159

Maximum Tilling Width in. (mm) 42 1067

Maximum Weight lb (kg) 342 155

Maximum Cutting Width in. (mm) 48 1219

Maximum Weight lb (kg) 254 115

Maximum Cutting Width in. (mm) 60 1524

Maximum Weight lb (kg) 176 80

below.

Maximum Vertical

Hitch Load

W

2

331 661

Towing Capacity

Maximum

W

3

NOTE:

●Backhoes cannot be attached.

Sc2400 Operator’s Manual

4-1

Page 29

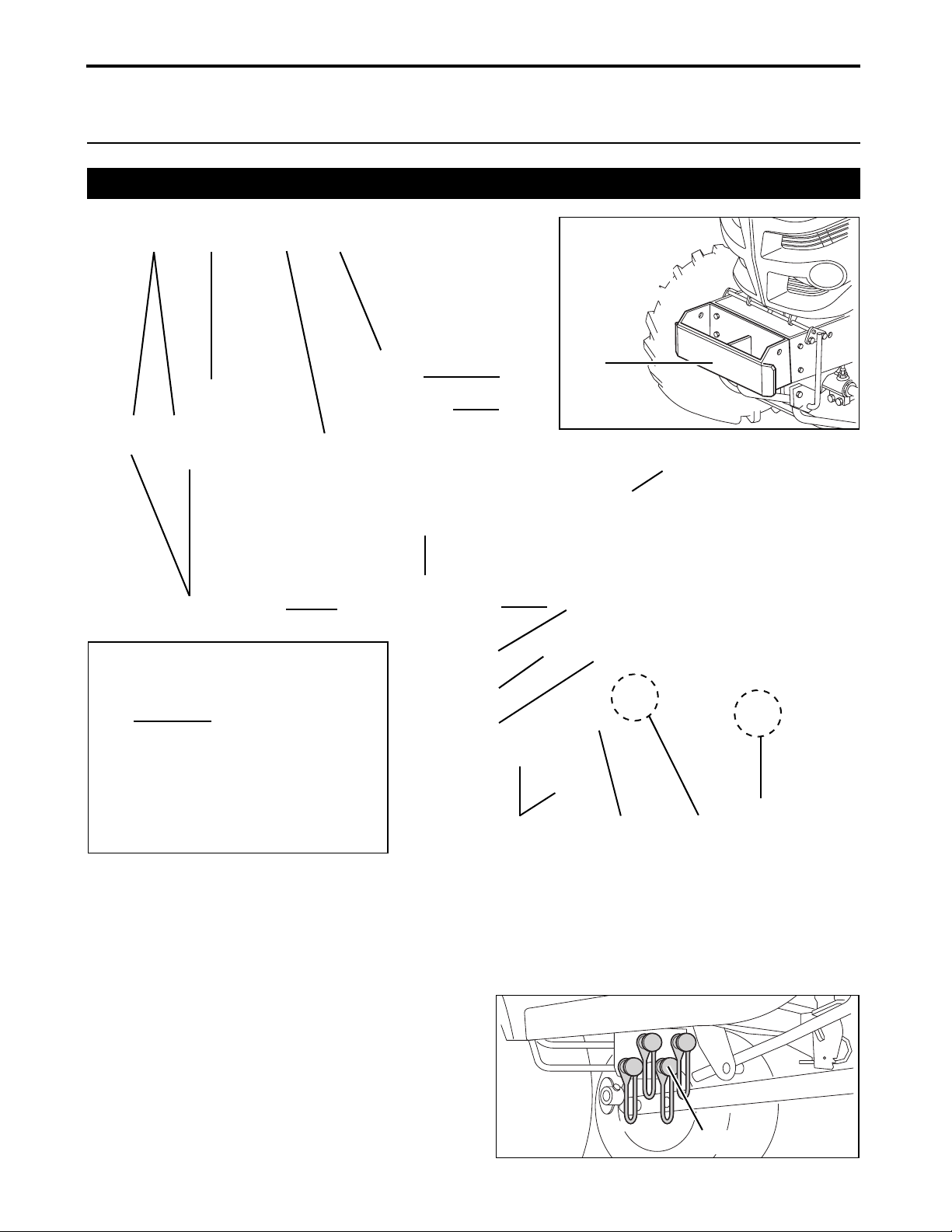

5. NAMES AND FUNCTIONS OF COMPONENTS

5.

NAMES AND FUNCTIONS OF COMPONENTS

1. Appearance

(1)

(2)

(3)

(4)

(5)

(6)

(10)

3014925a

(11)

P3014903

(9)

(8)

(20)

P3014904

(1) Headlights

(2) Hood

(3) Fuel inlet

(4) Seat

(5) Seat belt

(6) Fender

(7) Rear tires

(8) Front tires

(9) Work lights

(10) Front weight hitch (Option)

(11) Roll-Over Protective Structure (ROPS)

(12) Hydraulic quick couplers (Option)

(13) 12V DC outlet (for additional rear work light)

(14) Rear Power Take Off (PTO) shaft

(7)

(19)

(18)

(17)

(16)

P3014905

(15)

(15) Lower links

(16) Top link retainer

(17) Tail lights

(18) Top link

(19) Turn signal / Hazard lights

(20) Slow Moving Vehicle (SMV) emblem

3014906

(14)

5-1

(13)

(12)

Sc2400 Operator’s Manual

(12)

Page 30

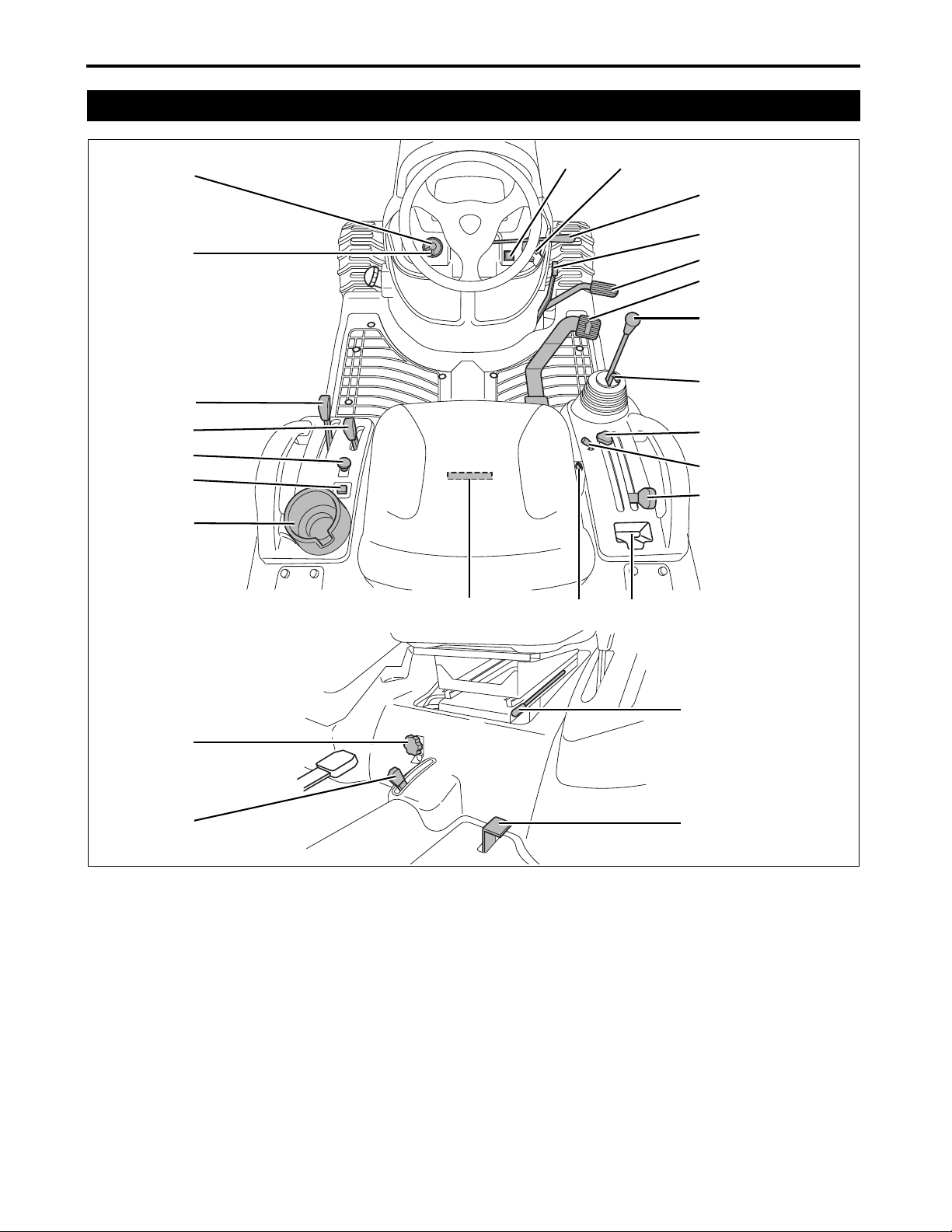

5. NAMES AND FUNCTIONS OF COMPONENTS

2. Operator Station Controls

(21)

(20)

(19)

(18)

(17)

(16)

(15)

3014903

(14)

(1)

(13)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(25)

(24)

3014904

(1) Hazard lights button switch

(2) Starter key switch

(3) Throttle control lever

(4) Parking brake lever

(5) Brake pedal

(6) Forward and reverse drive pedal

(7) Implement control lever (Option)

(8) Implement lock lever (Option)

(9) Position stop knob

(10) Cruise control lever

(11) 3-point hitch control /

cutting height adjustment lever

(12) Storage compartment

(13) 12V DC outlet

Sc2400 Operator’s Manual

(22)

(23)

(14) Hydro Static Transmission (HST)

pressure release lever

(15) Cup holder

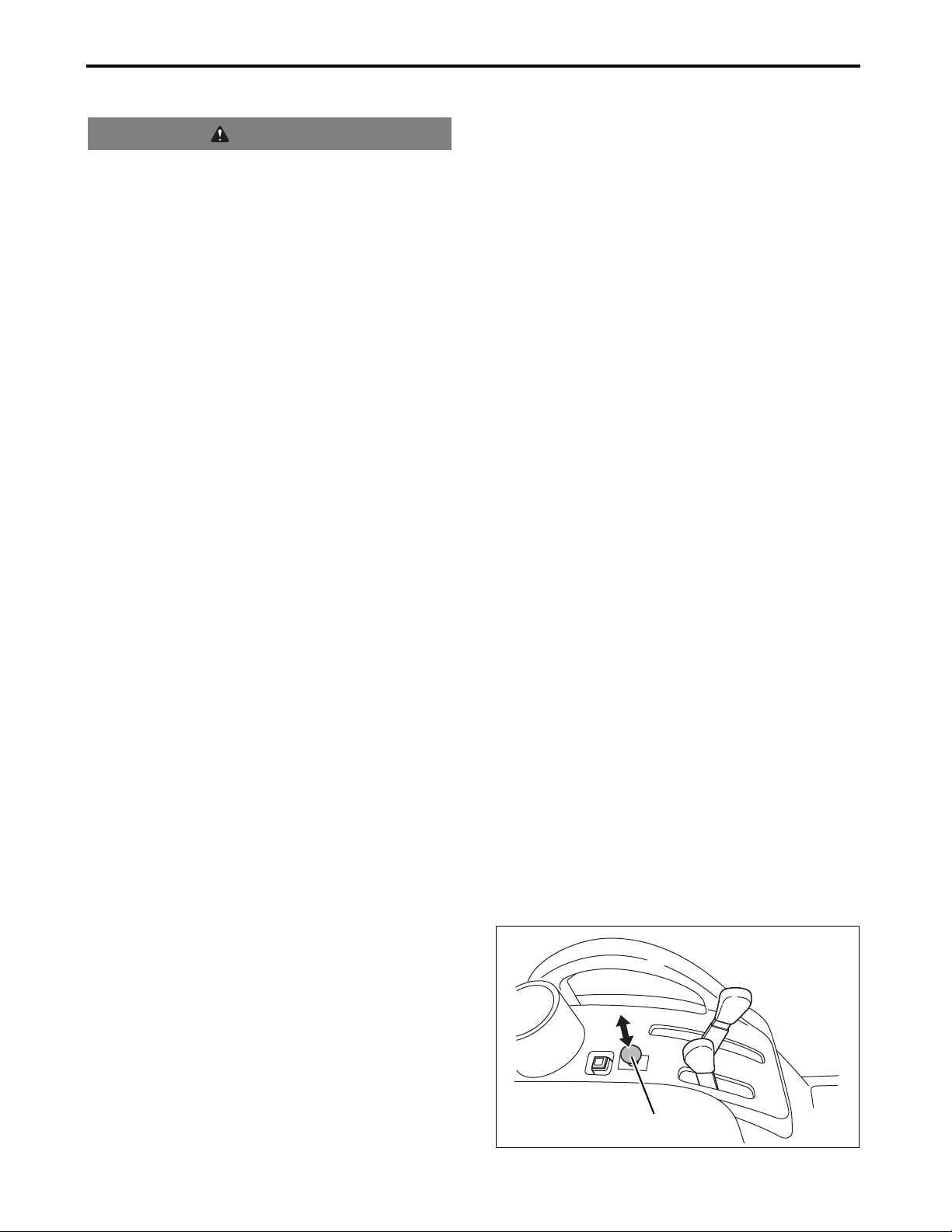

(16) Reverse - override - switch

(17) Power Take Off (PTO) switch

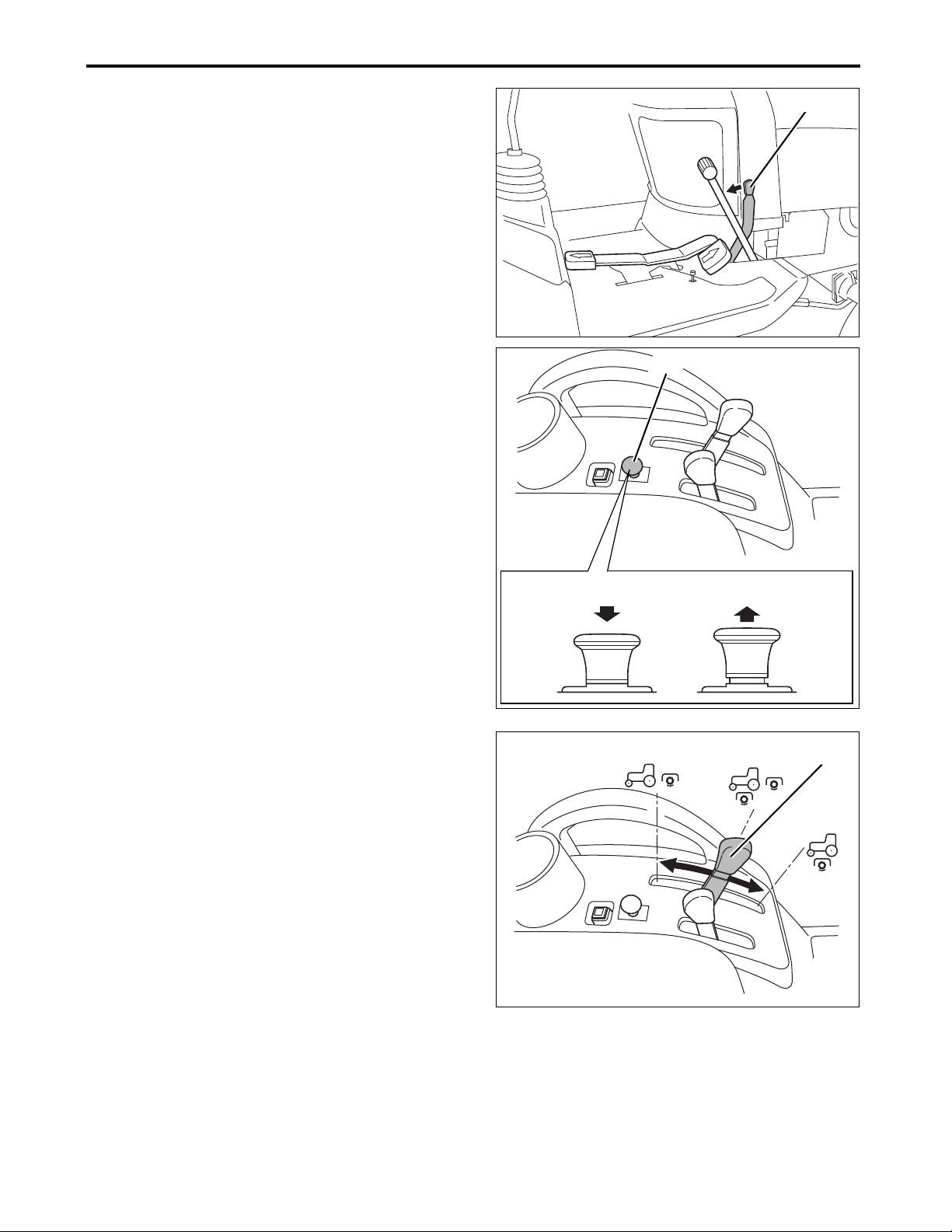

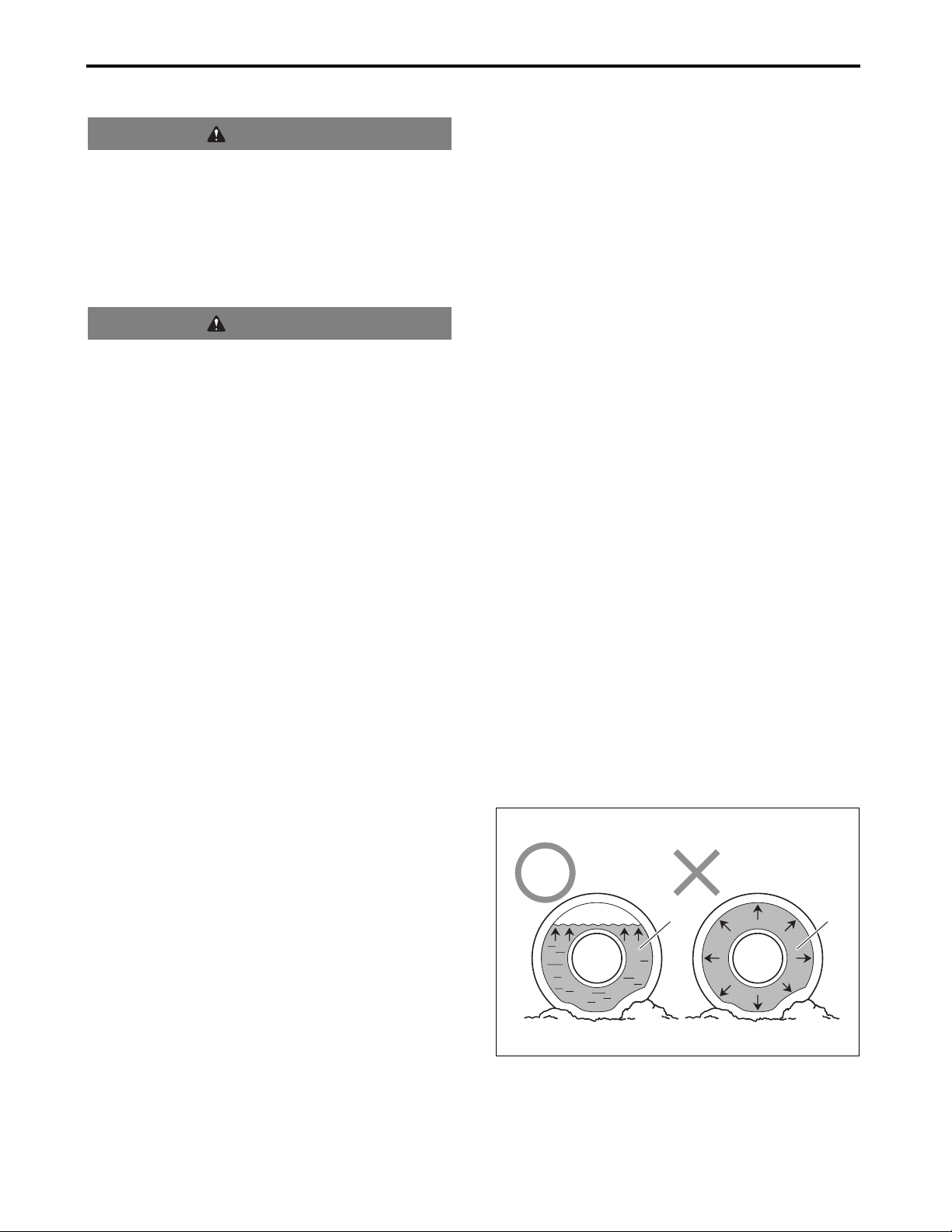

(18) Range shift lever

(19) Mid- / Rear-Power Take Off (PTO) select lever

(20) Turn signal switch

(21) Headlight / work light switch

(22) Seat adjustment lever

(23) Differential lock foot pedal

(24) 4-wheel drive lever

(25) Hydraulic flow control / stop knob

5-2

Page 31

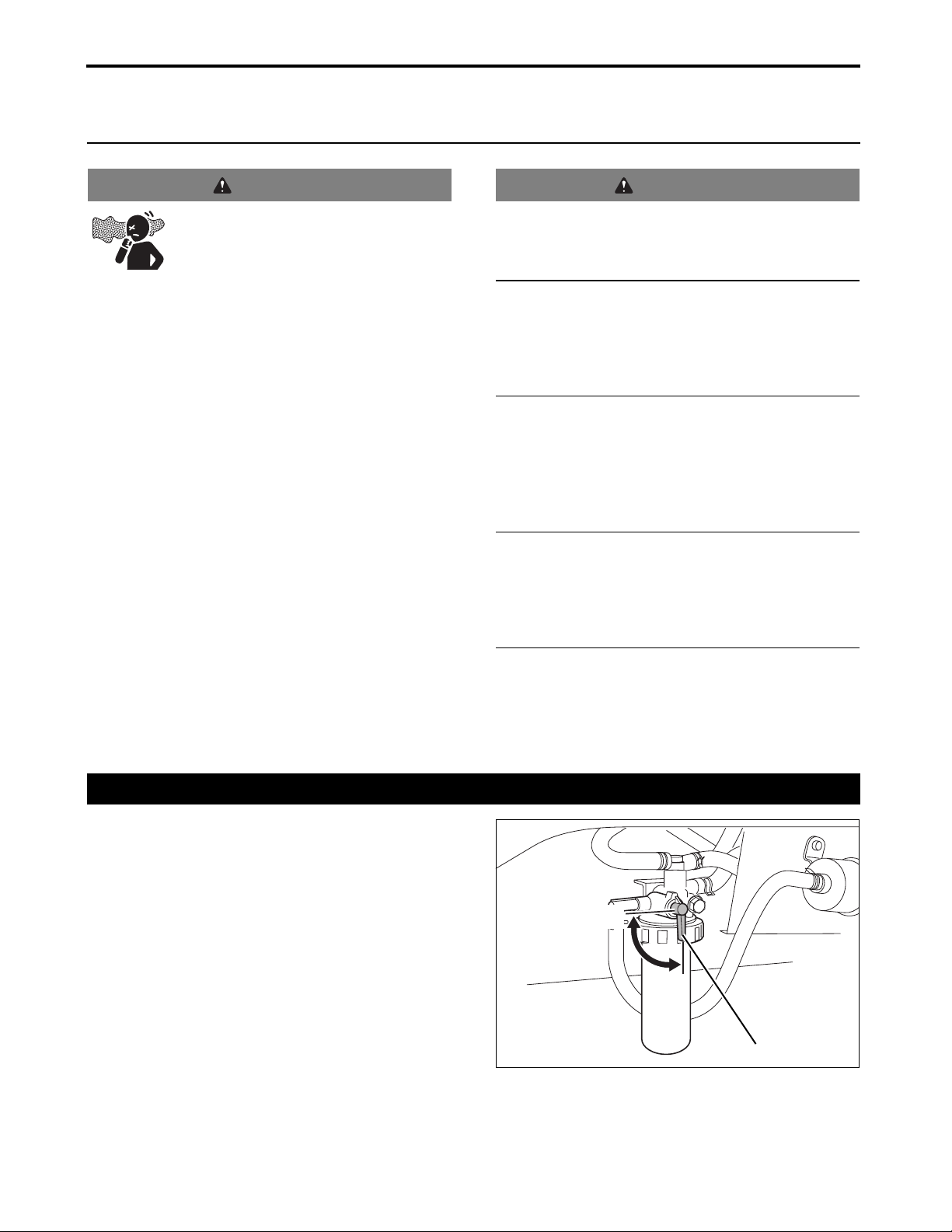

5. NAMES AND FUNCTIONS OF COMPONENTS

3. Instrument Panel, Switches and Hand Controls

(1)

(7)

(6)

(5)

(4)

3014905

(2)(3)

(1) Tachometer

This meter indicates the current engine speed in

increments of 100 rpm.

(2) Fuel Gauge

This gauge indicates level of fuel in the fuel tank,

while the starter key switch is in the ON position.

(3) Hour Meter

This meter indicates the total accumulated operating

hours. This indication is based on the assumption

that the engine runs at a speed of 3300 rpm.

(4) Alternator / Battery Charging Light

This light remains lit when the starter key switch is in

the ON position and the engine is OFF.

IMPORTANT:

●If this light illuminates while the engine is running,

the power generated by the alternator is too low.

Fully pull the throttle control lever backward and

increase the engine speed. If the light still remains

lit, immediately stop the engine and contact your

local Cub Cadet Yanmar dealer for technical

assistance.

(5) Engine Oil Pressure Warning Light

This light remains lit when the starter key switch is in

the ON position and the engine is OFF.

IMPORTANT:

●If this light illuminates while the engine is running,