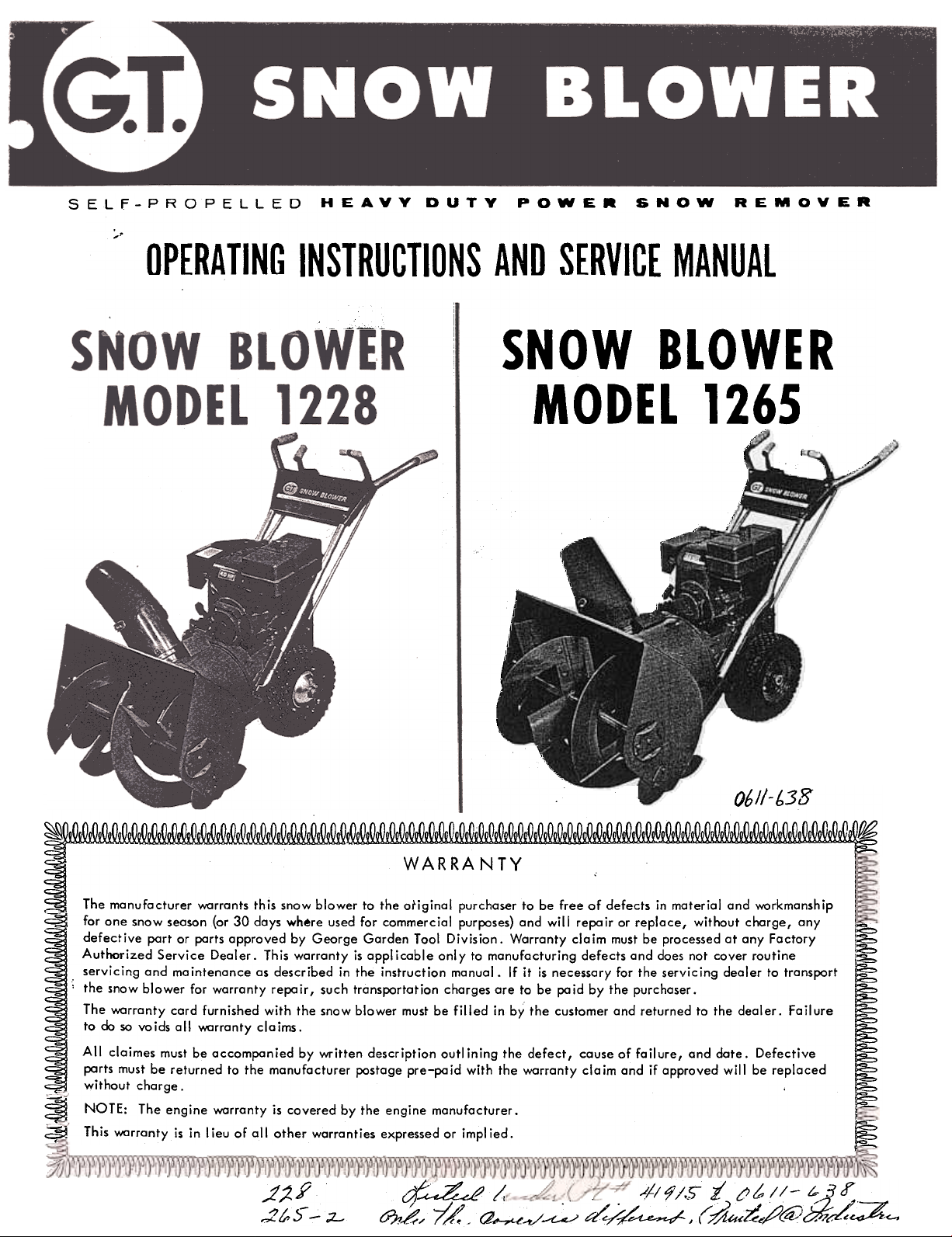

Page 1

HEAVY DUTY POWER SNOW REMOVER

;..

OPERATING INSTRUCTIONS AND SERVICE MANUAL

.' ~~

~ -SNOW BLOWER

MODEL 1265

~/ I

(- r \ (

=-

( r

)---"" /

"'

\

"""

I, 06//-b3S

~~~

WARRANTY

The manufacturer v.1:Irrants this snow blower to the original purchaser to be free of defects in material and v.1:Irkmanship

for one snow season (or 30 days where used for commercial purposes) and will repair or replace, without charge, any

~

defective part or parts approved by George Garden Tool Division. Warranty claim must be processed at any Factory

Authorized Service Dealer. This warranty is applicable only to manufacturing defects and does not cover routine

.servicing and maintenance as described in the instruction manual. If it is necessary for the servicing dealer to transport

..the snaw blower for warranty repa ir, such transportation charges are to be po id by the purchaser.

The v.1:Irranty card furnished with the snow blower must be filled in by the customer and returned to the dealer. Fail ure

to do so voids all v.1:Irranty claims.

All claimes must be accompanied by written description outlining the defect, cause of failure, and date. Defective

parts must be returned to the manufacturer postage pre-pa id with the v.1:Irranty cia im and if approved will be replaced

without charge.

~ NOTE: The engine v.1:Irranty is covered by the engine manufacturer.

~ This v.1:Irranty is in I ieu of all other warranties expressed or impl ied.

-

~

SELF-PROPELLED~~~

I

.)'

;2. Y

,;Z to ~ -;;L-

&J?1~~t:~./~ d/~-~ (~u:Z;;~gj:::z.:c-.

Page 2

PAGE

PAGE

r

,-over

Table of Contents. ..

1 Snowblower and Model 265-2

Transmission Unit Parts Diagram. ...

...2

Parts List.

Section I, Assembly Instructions for

Models 228 and 265-2 2,3,4 Parts List (con't), Continuation of

Operating Instructions.

Section II, Pre-Starting Instructions. .: .4

Section V f Lubrication. ..

Section III, Rules for Safe Operation. ..4-5

Section VI, Adjustment, Repair or

Section IV I Operating Instruction.

.5 and 9

Replacement.

SECTION

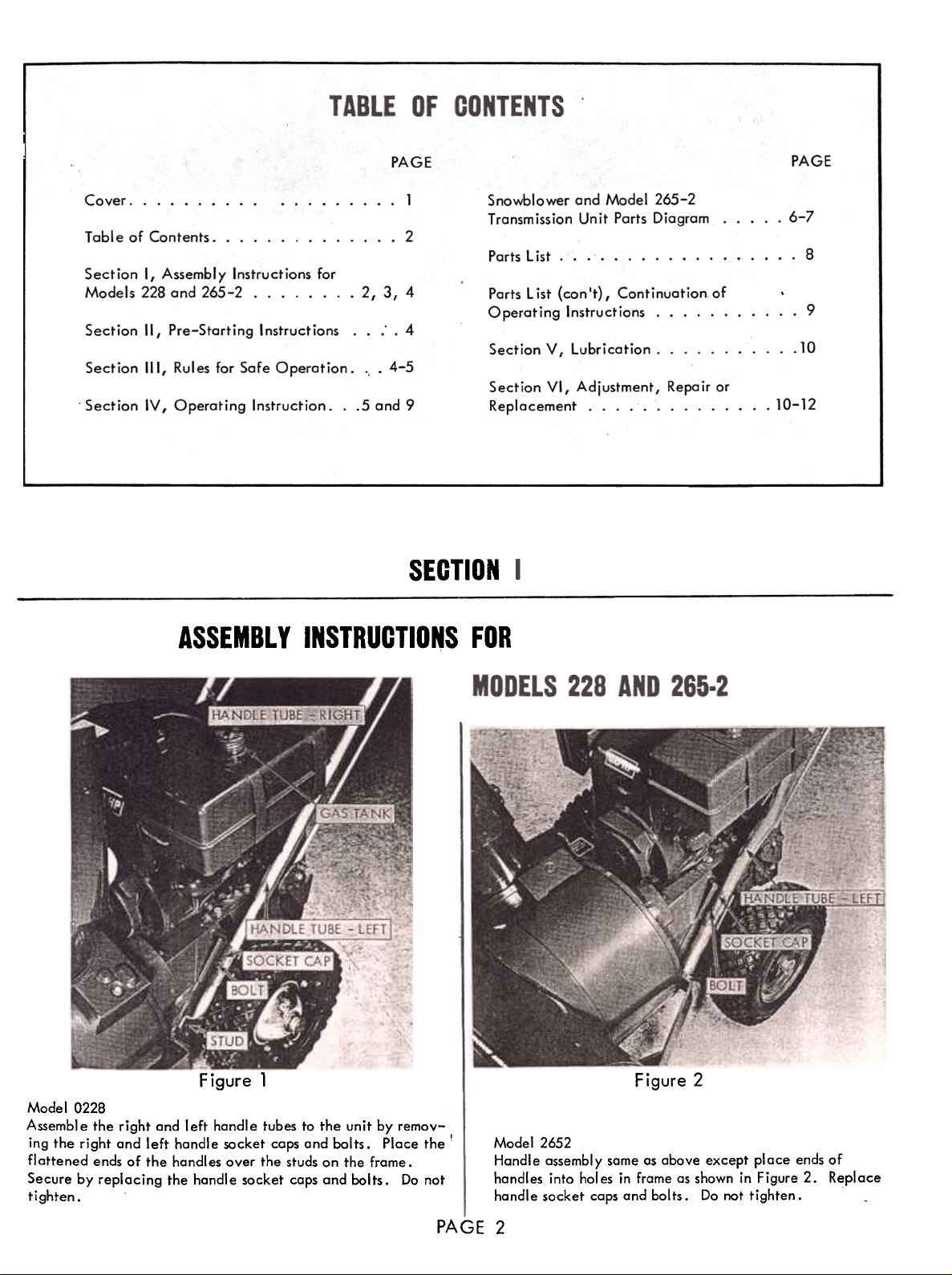

ASSEMBLY INSTRUCTIONS FOR

6-7

8

9

10

.10-12

Figure 1

Model 0228

Assemble the right and left handle tubes to the unit by remov-

ing the right and left handle socket caps and bolts. Place the!

flattened ends of the handles over the studs on the frame.

Secure by replacing the handle socket caps and bolts. Do not

tighten.

Figure 2

Model 2652

Handle assembly same as above except place ends of

handles into hol es in frame as shown in Figure 2. Replace

handle socket caps and bolts. Do not tighten.

PAGE 2

Page 3

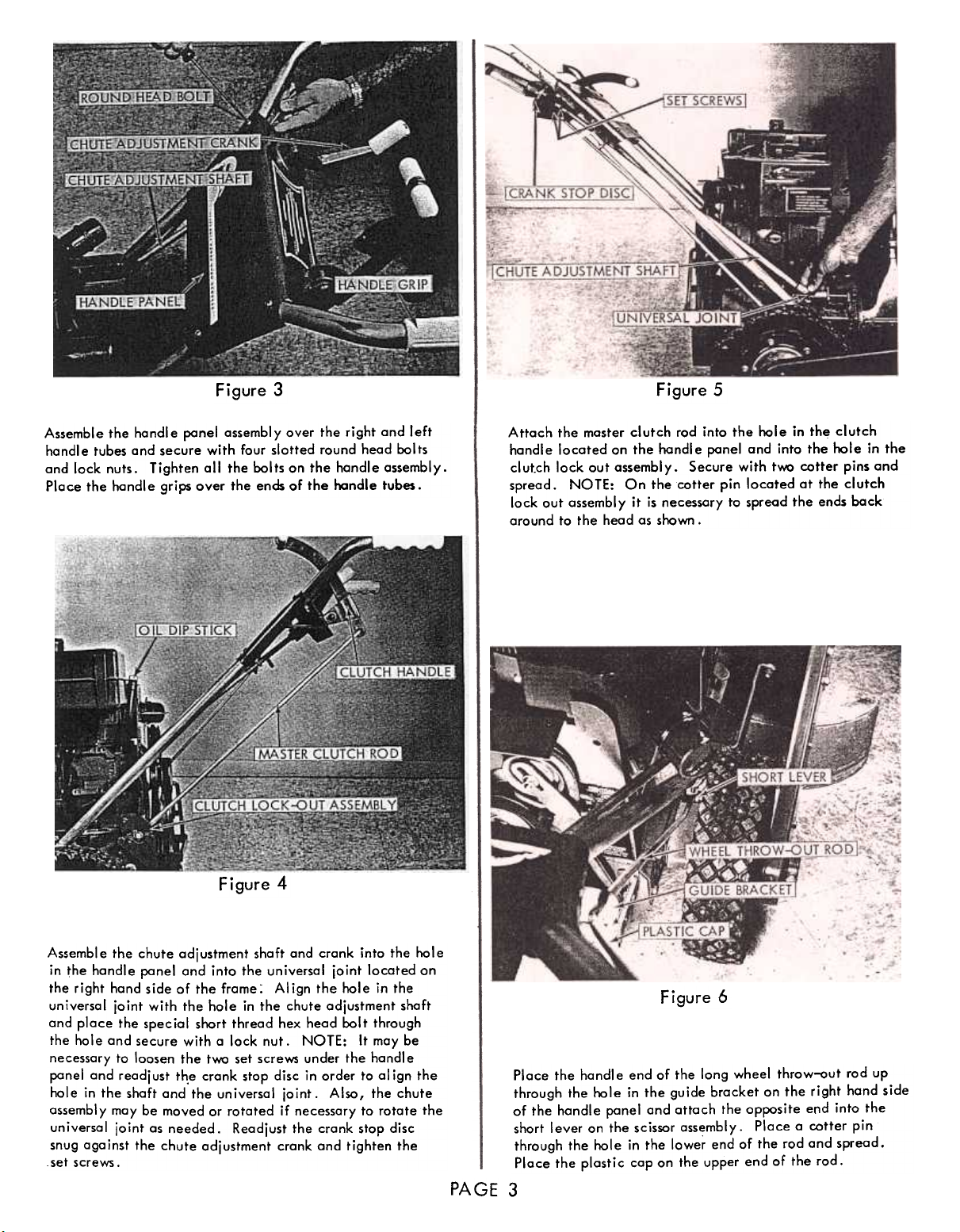

Figure 3 Figure 5

Assemble the handle panel assembly over the right and left

handle tubes and secure with four slotted round head bolts

and lock nuts. Tighten all the bolts on the handle assembly.

Place the handle grips over the ends of the handle tubes.

Figure 4

Attach the master clutch rad into the hale in th~ clutch

handle located on the handle panel and into the hale in the

clutch lock aut assembly. Secure with two cotter pins and

spread. NOTE: On the cotter pin located at the clutch

lock out assembly it is necessary to spread the ends back

around to the head as shawn .

Assemble

Figure

PAGE

the chute adjustment shaft and crank into the hole

in ~he handle ponel and into the universal joint located on

the right hand side of the frame: AI ign the hole in the

universal joint with the hole in the chute adjustment shaft

and place the special short thread hex head bolt through

the hole and secure with a lock nut. NOTE: It may be

necessary to loosen the two set screws under the handle

ponel and readjust th.e crank stop disc in order to al ign the

hole in the shaft and the universal joint. Also, the chute

assembl y may be moved or rotated if necessary to rotate the

universal joint os needed. Readjust the crank stop disc

snug against the chute adjustment crank and tighten the

setscrews.

6

Place the handle end of the long wheel throw-out rod up

through the hole in the guide bracket on the right hand side

of the handle panel and attach the opposite end into the

short lever on the scissor assembly. Place a cotter pin

through the hole in the lowe~ end of the rod and spread.

Place the plast i c cap on the upper end of the rod.

3

Page 4

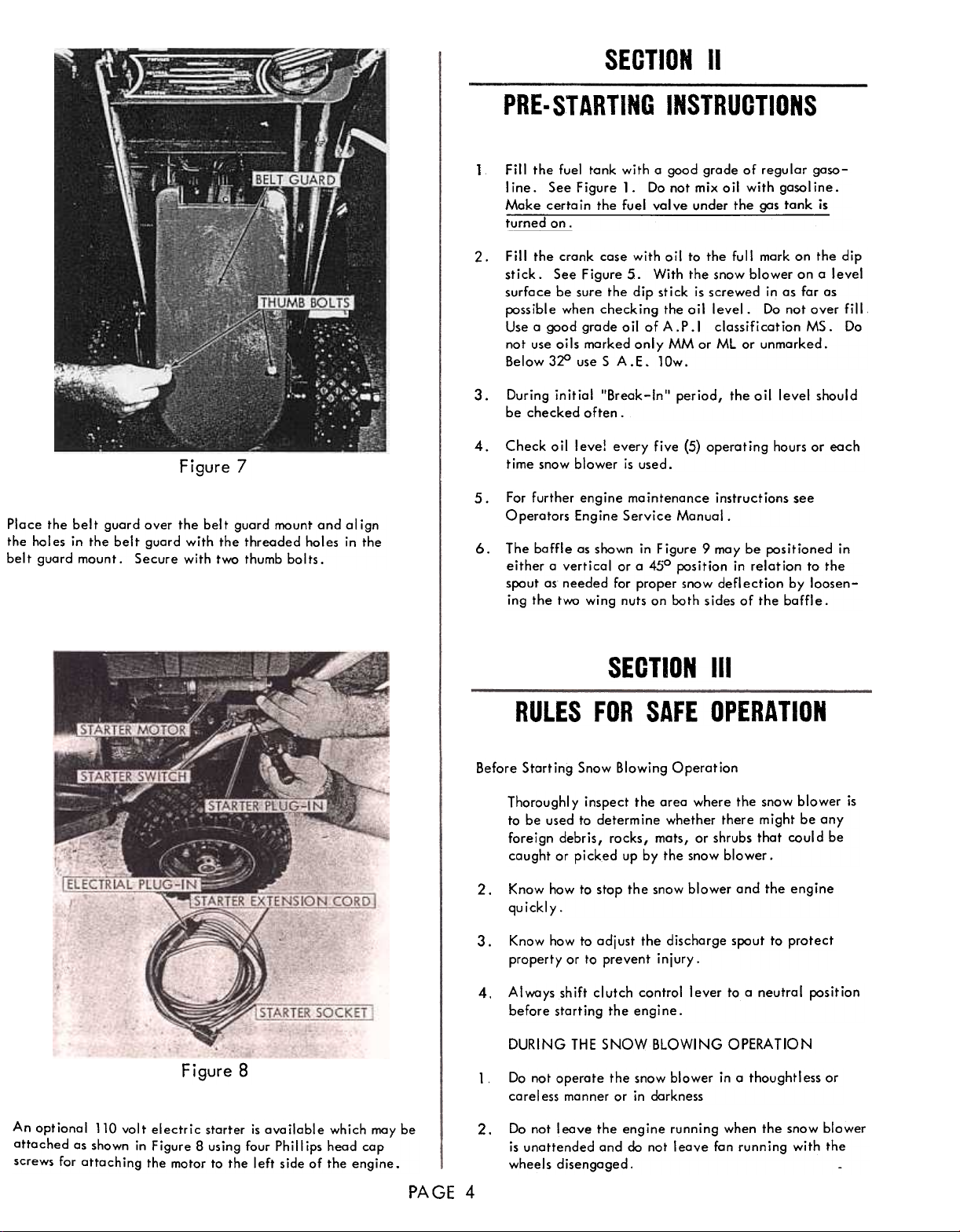

Figure 7

Place the belt guard over the belt guard mount and align

the holes in the belt guard with the threaded holes in the

bel t guard mount. Secure with two thumb bol ts.

SECTION II

PRE. STARTING INSTRUCTIONS

Fill the fuel tank with a good grade of regular gaso-

1

line. See Figure 1. Do not mix oil with gasoline.

Make certain the fuel valve under the gas tank is

turned on.

Fill the crank case with ail to the full mark an the dip

stick. See Figure 5. With the snow blower on a level

surface be sure the dip stick is screwed in as for as

possible when checking the oil level. Do not over fill

Use a good grade oil of A.P.I classification MS. Do

not use oils marked only MM or ML or unmarked.

Below 3~ use S A.E. lOw.

During initial "Break-In" period, the oil level should

3.

be checked often.

oil leve! every five (5) operating hours or each

time snow blower is used.

For further engine mointenance instructions see

Operators Engine Service Monual.

baffle as shawn in Figure 9 may be positianed in

either a vertical or a 450 position in relation to the

spout as needed for proper snow deflection by loosen-

ing the two wing nuts on both sides of the baffl e.

Figure 8

An optional 110 volt electric starter is available which may be

attached as shown in Figure 8 us ing four Ph i II ips head cap

screws for attaching the motor to the left side of the engine.

SECTION III

RULES FOR SAFE OPERATION

Before Storting Snow Blowing Operation

Thoroughl y inspect the area where the snow blower is

to be used to determine whether there might be any

foreign debris, rocks, mats, or shrubs that could be

caught or picked up by the snow blower.

Know how to stop the snow blower and the engine

quickly.

Know how to odjust the discharge spout to protect

property or to prevent injury.

Always shift clutch control lever to a neutral position

before starting the engine.

THE SNOW BLOWING OPERATION

Do not operate the snow blower in a thought I ess orcarel

1

ess manner or in darkness

Do not leave the engine running when the snow blower

is unattended and do not leave fan running with thewheels

disengaged.

2.

Check

4.

5.

6.The

2.3.

4.DURING

2.PAGE

4

Page 5

Never over-speed the engine. Excessive operoting speed

or tompering with the governor on the engine con be

dangerous.

4.

Stop snow blowing operation when onother person

opproaches the discharge side or comes near the intake

snow reel. Also, be constantly alert as to the direction

of the snow discharge to prevent damage to autos,

buildings, etc.

Never put hands or feet near rotating parts, using

special caution to keep away from intake reel, blower

fan, belts, chains, and pulleys. Never work on the

snow blower while the engine is running. Disconnect

the spark plug wire before doing ony work on the snow

blower.

Use extreme coution when using the snow blower on

slopes or inclines.

Never fill the gasoline tank while the engine is runn-

ing or while the engine is hot. Wipe off any spilled

gasoline before starting the engine.

Never operate the snow blower engine without proper

ventilation.

Check all screws, nuts and bolts at frequent intervals

9.

to be sure thot the snow blower is in a safe operating

condition.

SECTION IV

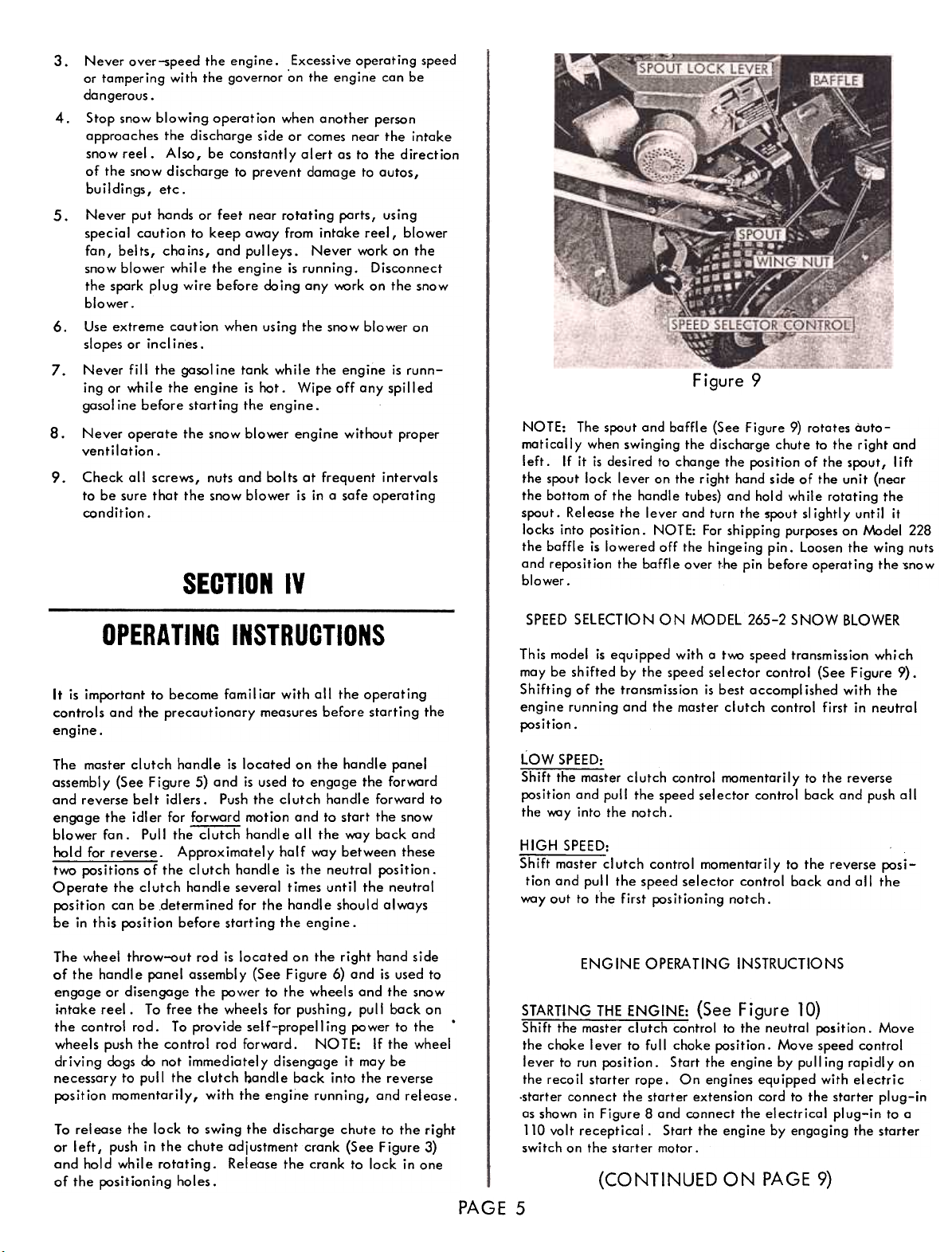

Figure 9

NOTE: The spout and baffle (See Figure 9) rotates automotically when swinging the dischorge chute to the right ond

left. If it is desired to change the position of the spout I lift

the spout lock lever on the right hand side of the unit (near

the bottom of the handle tubes) and hold while rotating thespout.

Rei eose the I ever and turn the spout sl ightl y unt il it

locks into position. NOTE: For shipping purposes on ,'.;.odel 228

the baffle is lowered off the hingeing pin. Loosen the wing nutsand

reposition the baffle over the pin before operating the ~now

blower.

SELECTION ON MODEL 265-2 SNOW BLOWER

INSTRUCTIONS

This model is equipped with a tv.\:> speed transmission which

moy be shifted by the speed selector control (See Figure 9).

It is important to became familiar with all the operating

controls and the precautionary measures before starting the

engine.

The master clutch handle is located on the handle panel

assembly (See Figure 5) and is used to engage the forward

and reverse belt idlers. Push the clutch handle forward to

engage the idl er for forward motion and to start the snow

blower fan. Pull the clutch handle all the way back and

hold for reverse. Approximately half way between these

twa positions of the clutch handle is the neutral position.

Operate the clutch handle several times until the neutral

position can be determined for the handle should always

be in this position before starting the engine.

The wheel throw-out rod is located on the right hand side

of the handl e panel assembl y (See Figure 6) and is used to

engage or disengage the pav{er to the wheels and the snow

i~take reel. To free the wheels for pushing, pull back on

the control rod. To provide self-propelling pawer to the'

wheels push the control rod forward. NOTE: If the wheel

driving dogs do not immediately disengage it may be

necessary to pull the clutch ~andle back into the reverse

position momentarily, with the engine running, and release.

To release the lock to swing the discharge chute to the right

or left, push in the chute adjustment crank (See Figure 3)

and hold while rotating. Release the crank to lock in one

of the positioning holes. (CONTINUED ON PAGE 9)

Shifting of the tronsmission is best accompl ished with the

engine running and the master clutch control first in neutral

position.

LOW SPEED:

Shift the master clutch control momentarily to the reverse

position ond pull the speed selector control bock and push all

the way into the notch.

HIGH SPEED:

Shift master clutch control momentarily to the reverse posi-

tion and pull the speed selector control back and all the

way out to the first positioning notch.

ENGINE OPERATING INSTRUCTIONS

STARTING THE ENGINE: (See Figure 10)

Shift the master clutch control to the neutral position. Move

the choke lever to full choke position. Move speed control

lever to run position. Start the engine by pull ing rapidly on

the recoil starter rope. On engines equipped with electric

-starter connect the starter extens ion cord to the starter pi ug-in

as shown in Figure 8 and connect the electrical plug-in to a

110 volt receptical. Start the engine by engaging the starter

switch on the starter motor.

3.

5.6.7.

8.

SPEED

OPERATING

PAGE 5

Page 6

Page 7

~ ~ 1-""--8

.t 143~ ~~, "'8

"'

)

~~~ ~~l ~ ~~;;$

~ /0' /11' \1r ~ ~~=~~~---<§

"'W

/

35 " "D ".. J~~~~~~ 8

~~~~~: ~~ @

\~-7-- -~ I ..-~ -13 7

-~~~ ~

I

/'~

I

~5 I ~2:

IS! -~~

150 153] 1 :: §

~7 44 1,--':4"2'

.:~~--:::~~

f--t48\e

~~--::::~.e.

~ / .

/. .~

f ~~

(

~-;T-

~~-I -@

"-

"@

/~Q

/ ~

"@~(

~

@

@'(§) <

(

(i5) ,

~~.

~- -

..~ ~~@

~T,

--:-\t-- -

~

cr

1

!~

0

J

,

~~:::==:~~ ~

"""~V

9

"'"

"e

~~~~

~_.

Page 8

PARTS LIST

Ref.

No.

10

11

12

13

14

15

16

17

18

18

19

20

21

22

23

24

25

26

27

27

28

29

30

31

32

32

33

33

34

35 40468

35 40201

36 60693

37 40066

37 40150

38 60718

39 40031

39 40490

40 40069

41 20123

42 40072

Port

No.

40441

1

2

61758

61449

3

4

21668

40112

5

41144

6

7

40021

40153

8

9

20521

60799

40151

60046

60026

40081

40041

40033

40032

22171

22193

40052

40079

40156

40035

20533

50045

40148

40065

40062

40225

40442

20116

40435

40056

40105

40155

60670

60764

40042

43 40071

44 40050

45 ' 40073

46 ! 40299

47

I 40040 48 22173

49 40004

50 40047

51 40245

52 40048

53 40076

60053

54

40097

55

56

20100

57

40149

60765

58

40085

59

40087

60

61

61111

61

60149

Thumb Bolt 5/16 x 3/4 (Pltd.)

Belt Guard

Belt Guard t.'.)unt

Belt Guard t.'.)unt Bond

Hex. Hd. Bolt 5/16 x 5/8

Whizlack (Pltd.)

Bolt, 1;'4-28 x 3/8

Belt, 4L-360 (Special)

Lacknut, Rev. (Pltd.)

Farward Belt Restrictar

Boll Bearing Idler

Hex Hd. t.'.)chine Bolt

5/16 x 5/8 (Pltd.)

Reverse Arm Retainer

Reverse Arm

Carriage Bolt 5/16 x 1-3/4 Sh.

Sq. Neck (Pltd.)

Belt, 4L-400 (Special)

Pulley, 8" "'V" Type

Pulley, 7-1/2 Flat Type

Shaft, 20 M M Fan

Shaft, Fan

Spring Pin 5/16 x 1-1/2

Hex Head Machine Bolt 5/16 x

1-3/4 (Pltd.)

S.A.E. Washer, 5/16 (Pltd.)

Cotter Pin 1/8 x 1 (Pltd.)

Axle Collar (Pltd.)

Spring Pin 1/4 x 1-1/2

Std. Wrought Washers 5/16 (Pltd.

Nylack Nuts 1/4 (Pltd.)

Round Heod Stave Bolts 1/4.x

1-1/2 (Pltd.)

Raund Head Stove Bolts 1/4 x

1-3/4 (Pltd.)

Shear Bol t

Shear Bolt Collar.

Bushing Chain Guard

Hex Head Bolt 1/4 x 1/2 (Pltd.)

Lackwcsher 1/4 Spring Type

Lackwcsher 1/4 Spring Type

Chain Guard with Bushing

Long Choin Guard

Carriage Bolt 1/4 x 1/2 Sh. Sq.

Neck (Pltd.)

Chain '40-108 P

Chain with Repoir Link '40-118P

Rear Chain Protector

Hex Nut 1/4"

Hex Nut 1/4" (Pltd.)

20 T. Sprocket with Hub

Wheels

Wheel, Right Pneumatic

Taathed Wheel Bushing

Clutch Dog Caver (Right)

Clutch Dog Sleeve

Clutch Dag, Sliding

Spring Pin, 5/16 x 2

Clutch Dags, Pinned

Oil Seal 1 x 1-7/16

Idler Spring

Belt Guard Plate

Engine Pulley

Set Screw

Lockwasher 5/16 Ext. Shake

Spring Pin 1/4 x 1

Hex Head Machine Bolt 5/16 x

1-1/2 (Pltd.)

Chain Oper. Chute Pulley

Tarsian Spring

Handle Socket Caps

5/16 Lackwcsher (Pltd.)

Cable Oper. Chute Pulley

Coble Hald Down Washer

1/4 x 1/2 Carriage Bolt (Pltd.)

Spout Tube Assembly

Spout Tube Assembly

aly.

02282652

2

1

1

1

7

4

1

12

10

1

2

4

1

8

8

1

2

6

7

4

5

1

2

2

2

2

2

2

2

1

1

1

5

2

2

9

1

2

12

1

1

Ref.

No.

'2

1

1

1

8

4

1

1

2

4

1

1

\

4

7

8

I

2

6

7

4

~

1

2

1

2

2

2

2

2

1

1

1

5

2

2

iO

1

2

13

1

1

1

Part

No

21272

62

62

20185

40100

63

64

60044

60181

64

40091

65

60038

66

60010

67

60\48

67

60009

68

60\47

68

2\269

69

20273

69

60004

70

71

40084

419\9

72

73

4006\

400\8

74

20087

75

20\90

75

40027

76

77

60728

':i)143

17

78

40118

20030

79

40098

80

40089

81

40024

82

40019

83

60015

86

86

60154

20030

88

20108

89

60180

89

90

20505

91

40160

92

60005

92

60144

93

40495

94

20110 Coble Roller

95

40108 Coble Roller Bushing

96

60051 Coble Roller Tightening Bracket 1

97

60014 Blower Housing and Chute Assembly 1

97

61762 Blower Housing and Chute Assembly

98

40142 Special Hex Key 1

99

20266 Coble

99

20263 Coble

61757 Engine Bose and Frome Assembly

100

61568 Engine Bose and Frome Assembly

100

20150 Worm R. H. 1 T.

101

20644 WarmR. H. 3T.

101

40068 Bolt Hex Head 5/16 x 3/4 (Pltd.)

102

103

60056 Clutch lockout Assembly

40163 Thrust Washers

104

105

40023 Boll Bearing

60045 Engine Bose Bock Plate

106

107

20514 Axle (1")

107

20163 Axle (1")

108

40474 Gear Housing

108

40184 Gear Housing

40025 Oil Seal 20 M M x 1-1/8

109

40060 Plugl/4N.P.T.F.SquareHead

110

20124 C:lutch Dog Cover (left)

111

112

20114 left Wheel Collar

113

40164 Thrust Bearing

114

20162 Worm Gear 28 T. (1 T.)

114

60185 Worm Gear with Bushing

40099 Worm Spacer

115

115

40193 Worm Spacer

116

40467 Gasket, Gear Housing

116

40186 Gasket, Gear Housing

117

40475 Gear Housing lid

Description

Baffle

Boffle

Carriage Bolt 5/16 xl Sh. Sq.

Neck (Pltd.)

Chute Collar

Chute Collar

Stove Bolt 1/4 x 5/8 Round

Head (Pltd.)

Special Wing Nut

Reel Shaft Assembly

Reel Shaft Assembly

Scoop Assembly

Scoop Assembly

Front Chain Cover

Front Chain Cover

Sprocket Guard

Washer, 25/32 x 1-1/4 x 1/32

Bal t, Special Step

Press in Oiler

Fan Costing, Top

Reel Paddle

Reel Paddle

Bushing Oilite 3/4 x 1-1/32 x

1-1/8

Reel

Reel

Special Step Bolt (Pltd.) 1

Reel Adjusting Plate 1

Flanged Wizlack I-Jut 5/16 (Pltd.) 16

Felt Wick 1

Bushing, Oilite 20 M M x 1-1/32

x3/4l. 2

Fan Costing Bottom 1

Disc Wheel 2

Disc Wheel

Disc Wheel Adjusting Plate (l)

Coble Roller Cover

Coble Roller Cover

Skids

Carriage Bolt 5/16 x 3/4

Fan Assembly

Fan Assembly

Screw, Hex Head Machine

.5/16 xl

aty. Gty.

02282652Description

i

2

1

j

2

2

2

1

2

12

2

7

1

2

2

2

2

2

2

2

1

1

2

16

I

2

2

1

1

2

12

7

1

/~,

2

4

1

1

2

1

1

1

1

aly.

""'

1

~

PAGE 8

Page 9

PARTS LIST

Ref.

No.

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

135

136

136

137

137

138

139

140

141 i

150

141

142

143

144

145

146

148

149

151

Port

No.

40185

20097

60033

60018

40039

60055

60019

60016

41917

40165

40110

40139

40140

40070

60326

20265

22179

22190

40044

40217

41911

41920

41912

41921

41913

41316

22230

41916

41938

22176

61576

40132

40078

60343

40198

40341

61752

40320

Description

Gear Housing Lid

Clutch Scissor Link

Right Hand Clutch Yake

Clutch Scissor Arm (Right)

dutch Scissor Spring

Left Hand dutch Yake

Clutch Scissor Arm (Left)

dutch Scissor Bar Assembly

Chute Adjusting Chain

Chain Connecting Link

Chain Mounting Bolt

Chute Chain Connecting Pin

Hair Pin Cotter,

Flartged Whizlack Bolt 1/4 x

1/2 (Pltd.)

Double Spring Pin Assembly

Key, 3/16 Sq. x 1-1/2

Wheel Thra""ut Rod

Master dutch Rod

Handle Grips 1"

Handle Grips 1-1/4"

Handle L. H.

Handle L. H.

Handle R. H.

Handle R. H.

Cap, Plastic 5/16 x 2-1/2

Screw, Self Tapping Slatted Head

Universal Joint

Engine 4 H. P. Tecumseh Lauson

Model 'H40

Engine 6 H. P. Tecumseh Lauson

Model 'H60

Chute Adjusting Shaft (Pltd.)

Crank Stop Disc Assembly

Push Nut

Plastic Handle

Chute Adjusting Crank

Crank Pivot Tube and Plate

Compression Spring (Pltd.)

Chute Adjusting Sprocket Assembly

Handle Caps, Plastic

Oty. Oty.

0228 2652

3

1

1

1

1,

2

1

2

1

1

1

1

1

1

1

1

1

2

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

Part'

No.

40250

40480

22181

22184

41362

61753

61574

40489

40173

40248

40220

40251

20228

60218

40177

40183

41302

40179

40180

40045

22194

41304

40181

61397

20164

60076

20156

40236

20157

21673

40226

40249

40496

Description

Spring Pin 1/8 x 3/8

Special Bolt 1-1/4 (Pltd.)

Chute Chain Caver

Sprocket Spacer Bushing

Sintered Bronze Bushing

Handle Panel Assembly

Handle Panel Assembl y

Wheel Complete (l. H.)

Washer 51/64 x 1-1/8 x .015

Side Caps

Spring Pin 5/16 x 1-3/4

Gasket, Cap

4OT. Gear, 20MMBore

Heavy Duty, Spring Pin

Spline Shaft

lack Ring External (1-1/8")

Cluster Gear

Spring, Cluster Gear

Steel Ball, 3/16" Dia.

Plastic Knob

Arm, Shift

Spring, Ext. (Shift Arm)

Hairpin Cotter

Upper Shift Arm Assembly

Inside Shift Collar (lever)

Inside Shift lever

Shifting Block

Bushing, Oilite

30 T. Spur Gear

39 T. Spur Gear -I" Bore

Washer (TRE-1625)

Bolt 1/4-28 T. x 1/2 Hex Head

Screw, Hex Head Type-B 5/16

Oty. Oty.

0228 2652

2 2

1 1

1 1

1

1 1

1

1 1

1

1

2

1

2

1

2

1

1

1

1

1

1

1

1

2

1

1

1

6

Ref.

No.

1

1

1

1

1

1

1

1

1

1

1

1

3

152

153

154

155

156

157

157

2

1

1

2

x 1-1/2"

* 39

*158

* 39

*

2

61577

61578

61579

61,500

OptionQI Equipment ot Additionol Cost

Wheel with Tire Stud.

Wheel with Tire Stud. L. H

Wheel with Tire Stud. R. H

Starter Matar Kit 110 Valt

2

(CONTINUED FROM PAGE 5

Figure 10

SECTION IV

OPERATING INSTRUCTIONS

,. ,

NOTE: The three-prong electrical plug-in on the extension

cord is to be used with a grounded circuit electrical outlet.

If no grounded three-prong outlet is available use the two-

prong adapter provided the ground wire on the adapter is

properly grounded. As the engine starts and begins to worm

up gradually return the choke lever to the "No Choke"

position.

NOTE: If the temperature is below + 100 F. depress and

hold the black button (primer) on the carburetor and pull

the engine over slowly with the starter rope. Release the.

button and start the engine as outlined above.

STOPPING THE ENGINE:

~

To stop the engine move the speed control lever to the stop

position or close the fuel shut-off valve under the gasoline

tank. The spork pi ug wire may also be removed to prevent

accidental starting while unattended.

PAGE 9

Page 10

V

LUBRICATION

LUBRICATE THE PARTS PERIODICALLY AS ILLUSTRATED IN

FIGURES 11,12 and 13.

LUBRICATION POINTS:

The following points are to be lubricated every five hours

of operation with S.A.E., 20 weight I ight duty oil, unless

otherwise noted.

Clutch Lock-out Assembly

1 .

2.

Reverse. Arm

3.

Wheel Clutch Dogs

4.

Clutch Yokes

Wheels

5.

6.

Discharge Spout

7.

Blower Housing.

8.

Reel Chain

9.10.

Chute Adjustment Cha in

Chain Guard Bushing

11 .12.13.14.

Universal Joint

Reel and Shaft Bearings

Cable Rollers

Gear Housing- With the belt guard removed turn the

holes in the pulleys to the bottom to expose the gear

housing fill plug. The oil level in the gear housing

should be kept at or above this fill plug. Drain and

refill with heavy duty GX-90 Gear Lubricating Oil

once each season or approximatel y 25 hours use.

Figure 12

SECTION

Figure 1

Figure 13

SECTION VI

ADJUSTMENT,

REPAIR OR REPLACEMENT

REEL DRIVE CHAIN ADJUSTMENT:.

Check periodically for undue looseness. To tighten the

chain, first loosen the t~ nuts at each end of the reel,

holding the reel shaft plates. Slide the snow intake reel

forward by rotating the plate near the sprocket end of the

reel with a punch or rod. Hold in the tightened position

and tighten the reel shaft plate bolts and nuts. IMPORTANT:

Adjust both ends of the reel equally to keep the fan shaft

casting in al ignment. Do not tighten the chain too tig~tly.PAGE

10

Page 11

DEPTH ADJUSTMENT:

accessible. Tighten the adjustment nut ta tighten the chain.

CAUTION: Chain should nat be tightened taa tightly.

CABLE ADJUSTMENT:

See Figure 13. Remove cable roller cover. Loosen the

locking bolt on top of the cable roller bracket and tighten

the adjustment bolt on the side.

CAUTION: The cable should not be adjusted too tightly,

but should allow the spout to rotate freely. Retighten the

lacking bait and replace the cable roller caver.

Figure 14

The adjustable shoes may be set lower to prevent picking up

loose stones and foreign material. Also, the disc wheels on

the inside of the scoop may be adjusted to help lift the

scraper blade over small obstructions or may be adjusted to

allow the snow reel to sl ightl y touch the ground for addi-

tional pulling power.

Figure 16

REPLACING SAFETY SHEAR BOLT:

If the intake snow reel should jam causing the safety shear

bolt to shear it may be replaced with a new bolt, furnished

in the parts bag, after removing the broken pieces in the

shaft. NOTE: Always align the hole in collar with the

al ignment grooves on the end of the sprocket sl eeve and

shaft before driving out the broken pin and'replacing the

new bolt.

Figure 15

.Q!UTE CHAIN AND ADJUSTMENT:

To tighten the chute position chain rotate the chute until

the spout is in the straight up position. Tilt the snow blower

forward until the adjustment bolt as shawn in Figure 15 is

CHUTE

PAGE

BELT AND IDLER WHEEL ADJUSTMENT:

CAUTION: For belt adjustment the engine should be stopped

and the spark plug wire removed.

After the machine has been aperated a short time it may be

necessary to readjust the idl ers for proper bel t tension. The

following steps should also be carefully followed when install ing replacement belts.

11

Page 12

.FORWARD BELT IDLER ADJUSTMENT:

With the master clutch control in the forward position

the edge of the reverse orm should be 01 igned with

line "B". As the belts become stretched or in the

installation of the new belt it may be necessary to

readjust the forward belt idler in its adjustment slot to

bring the reverse arm to line "B", in the forward

running position. For adjustment, return the clutch

control lever to the neutral position and loosen the

nut holding the forward belt idler and move the idler

in small steps to the right, and tighten the nut. Again

move the clutch control lever to the forward position

and check for al ignment with line "B". Repeat the

above steps until the proper idler position is accomp-

lished. NOTE: When retightening the nut on the

forward belt idler care should be taken to position the

forward belt restrictor to clear the belt at all points when

the idler pulley is engaged in the running position and it

should also clear the large pulley as shown in Figure 18.

Figure 17REVERSE

ARM ADJUSTMENT:

Remove the belt guard. A belt replacement decal is

located on the ponel behind the reverse arm which is

used to properly position the reverse arm and the idlers.

With the master clutch control in the neutral position

the right hand edge of the reverse arm should be al igned

with line "A" on the decal. The two bolts on the clutch

lock out arm may be loosened to allow adjustment of the

arm up or down as needed to position the reverse arm

to line "A".

REVERSE IDLER ADJUSTMENT:

With the clutch control in the forword running position

check to see that the reverse belt is tight when pulled

up on the rim of the reverse belt idler wheel. Loosen

the bolt on the reverse idler and slide it up or down to

obtain the proper tension. Return the cl utch cont;ol

to the neutral position and position the reverse belt in

the center of the idl er. Check to see thot there is

approximatel y 1/8 inch clearance between the lorge

pulley and the pulley band.

END OF SEASON STORAGE:~--

In the event the engine is to be stored for any length of time

(30 days or more) or at the end of the snow blowing season,

prepare it as outlined in the following steps.

1

Drain gas tank completely by removing fuel line atthe

carburetor or fuel tank, whichever is easier.

Drain the carburetor by pressing up~rd on the bowl

2.

drain.

To protect the engine when storing, remove the spark

plug and inject one ounce of S.A.E. 10 weight oil

through the spark plug hole into the cylinder. Crank

the engine (without starting) several times to spread theoil

over the cylinder walls.

2.

3.

3.

Figure 18

4.

Lubricate ailiubricatian points as outlined in Section 5.

Page 13

CHUTE CABLE

REPLACEMENTAND

REPAIR FOR MODEL

228 AND

265-2

NOTE:

The reference numbers referred to in the following instructions may be found in the parts list

and the exploded view.

REMOVE THE BLOWER HOUSING FROM THE SNOW

BLOWER.

A. Remove the safety shear bait (Ref. No. 28), chain

guard (Ref. No. 33), and disconnect the reel drive

chain (Ref. No. 35) at the chain connecting link.

B. Remove the faur carr~age baits (Ref. No. 91)

fasten the scoop (Ref. No. 58) to the frame. Remo':'e the scoop and reel assembl y intact.

C. Remove the spring pin (Ref. No. 19) and remove

the fan (Ref. No. 92).

D. Remove the set screw which holds the chain pulley

(Ref. No. 54) in place and slide the chain pulley

off the blower housing tube.

E. Remove the blower housing (Ref. No. 97) from the

unit.

CABLE WASHER

CABLE BOLTII

I

"

"

CABLE TRACK

FIGURE A

2. REMOVE THE WORN CABLE.

A. Place the blower housing on a bench with the

cable pulley (Ref. No. 58) exposed as shown in

Figure E.

B. Remove the cable roller cover (Ref. No. 89) and

remove the bolt from the chute collar (Ref. No.

64). See Figure C.

C. Loosen the lock bolt on top o( the cable roller

bracket and adjust the cable adjusting bolt and

cable roller in as far os possible (See Figures C

and D).

D. Remove the special hex key (Ref. No. 98) from

the tube protruding from the blower housing and

slide the cable pulley oway from the blower hous-

ing approximately 3 inches.

E. Loosen the cable mounting bolt (Ref. No. 31)

Figure E and remove the cable ends from the cable

pulley.

F. Pry the chute collar apart (Ref. No. 64) Figure B

ond remove the upper spout assembly (Ref. No. 61)

from the blower housing.

G. Loosen the nut on the cable mounting bolt (Ref.

No. 60) Figure B which fastens the cable to the

upper spout assembly and remove the worn cable.

REPLACE NEW CABLE.

A. Start both ends of the cable through the hol e in

the top of the cabl e track on the upper spout

assembly, (See Figure A). Pull both ends of the

cable through and fasten the loop under the cable

washer (Ref. No. 59) making certain that both ends

of the cable are even.

3.

~

CABLE

FIGURE

UPPER SPOUT ASSEMBLY

-{=~~~

0

CABLE TRACK

/"

7 ,ncc," ,

CHUTE COLLAR

CABLE MOUNTING BOLT

FIGURE B

MODEL 228

CHUTE COLLAR BOLT r

CHUTE COLLAR

DOUBLE ROLLERI

--.0 I~LE ROLLER

CABLE ROLLER BRACKET

ADJUSTMENT BOLT

CABLE LOCK BOLT

C

Page 14

MO DEL

265-2

FIGURE D

CABLE PULLEY

CABLE BOLT

BLOWER HOUSING

FIGURE E

B. With the cable crossed wrap each end of the coble

oround the upper spout in the direction as shown in

Figure B.

C. Start the cable through the holes in the chute

collar from the inside and sl ip the collar aver the

cable track as shown in Figure B. The cable coming from the left side of the spout should enter

through the left hole in the collar. The cable com-

ing from the right side of the spout should enter

through the right hole in the collar. Make certain the cable stays in the track when the chute

collar is replaced.

D. Replace the upper spout assembly onto the blower

housing, slipping the collar over the flanged ring,

and fasten with the chute collar bolt.

PLACING THE CABLE OVER THE CABLE ROLLERS.

A. Rotate the upper spout assembly with the open side

in the opposite direction from the cable pulley side

of the blower housing assembl y. See Figure C and

D.

B. For Model 0228.

Extend the cable from the right side of the spout

assembly over the inside groove of the double

roller (See Figure C) and through the left hole and

the top of the blower housing and down the left

side of the cable pulley. Extend the cable from

the left side of the upper spout across the roller

nearest the chute collar around the inside and

around the cable adjusting roller, over the double

roller to the right, and down through the hale in

the blower housing and along the side of the cable

pulley.

B. For Model 265-2

Extend the cable from the left side of the upper

spout assembly over the roller on the right side of

the cable roller bracket (See Figure D) and through

the right cable hol e in the top of the blower hous-

ing. Extend the cable from the right side of the

spout assembly across the center cable roller, back

and around the cable adjustment roller and over the

cable roller on the left side of the cable roller

bracket and down to the left hole in the top of the

blower housing.

C. Turn the cable pulley with the cable bolt (Ref: No.

31) toward the bottom of the blower housing (See

Figure E).

D. Put the ends of the cabl e up through the hol es in

the bottom of the cabl e pulley and cross the ends

up and over the cabl e bolt and under the washer.

The right cable extends up through the left hole.

Pull the cable tight and tighten the cable bolt and

nut I mak ing sure the cabl e rema ins in the track

around the cable pulley.

E. Replace special hex key and slide cable pulley

back into place.

F. Tighten cable with adjusting cable roller.

REPLACE THE BLOWER HOUSING.

A. Reverse the steps outl ined in Step 1 to replace the

blower housing and parts to the snow blower.

4.

5.

GEORGE GARDEN TOOLS DIVISION, 811 So. HAMILTON, SULLIVAN, ILLINOIS

Loading...

Loading...