Page 1

Service Manual

RZT Zero Turn Rider

NOTE: These materials are prepared for use by trained technicians who are experienced in the service and repair of equipment of the

kind described in this publication, and are not intended for use by untrained or inexperienced individuals. Such individuals should seek

the assistance of an authorized service technician or dealer. Read, understand, and follow all directions when working on this equipment. This includes the contents of the Operators Manual, which came with your equipment. No liability can be accepted for any inaccuracies or omission in this publication, although every care has been take to make it as complete and accurate as possible. The right

is reserved to make changes at any time to this document without prior notice and without incurring an obligation to make such

changes to previously published documents. All information contained in this publication is based on product information available at

the time of publication. Photographs and illustrations used in this publication are for reference use only and may not depict actual

model and component parts.

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-01636

12/2004

Page 2

Page 3

TABLE OF CONTENTS

Cub Cadet RZT

Deck Leveling ............................................................................................................... 1

PTO / Deck Belt Replacement ...................................................................................... 2

Deck Removal ............................................................................................................... 2

Drive Belt Replacement ................................................................................................ 3

Servicing Electric PTO Clutch ....................................................................................... 3

Transmission Replacement .......................................................................................... 4

Steering Linkage: Adustment ........................................................................................ 6

Pivot Bar ....................................................................................................................... 9

Seat Removal ............................................................................................................. 10

Console Removal ........................................................................................................ 11

Battery Removal ......................................................................................................... 13

Fuel Tank Removal ..................................................................................................... 14

Control Shaft Replacement ......................................................................................... 15

Deck Lift Shaft Replacement ...................................................................................... 17

Electrical System Components ................................................................................... 20

Page 4

Page 5

Cub Cadet RZT 22

617AA5A7P710

1D224G20073

2004 is the first year for the RZT. There are two models RZT17 and RZT22. Now for the ‘05 model year is

Kohler Command 19 HP model witha 50” deck.

This series of riders has the unique feature of not having to reset the PTO switch if the end users tries to

mow in reverse. Once one lapbar is moved in to neutral

or forward the PTO will turn back on.

The “RZT 17” has a 17 HP Briggs & Stratton Intek

which is a single cylinder engine with full pressure lubrication. The engine drives the dual hydrogear EZT

Hydrostatic transmissions and the electric PTO. The

PTO runs the 3-in-1blades on the 42” twin blade

stamped deck. On the front of the stamped frame is a

large pivoting front axle. All this with the 3 gallon fuel

tank will provide many hours of fun and relaxing mowing.

1. DECK LEVELING

1.1. To adjust the deck pitch, front to back, loosen or

tighten the jam nuts located on the front stabilizer bracket using a 15/16” socket and a 15/16”

wrench. The correct deck pitch should be 1/8” to

1/4” lower in the front than in the back, as measured from the blade tips. See Figure 1.1.

Front deck hanger bracket

Figure 1.1

1.2. To level the deck, side to side, loosen the screw

on the left side adjustment gear using a 1/2”

socket. Using a 3/4” wrench, run the gear up or

down as necessary until each outside blade tip

is the same distance from the ground.

See Figure 1.2.

Deck hanger rod

The “RZT 22” is very similar to the RZT 17 except for

the twin cylinder, 22 HP Briggs & Stratton Intek. There

are also 4 wheels, instead of 2, on the 50” triple blade

stamped deck.

All versions of the Cub Cadet RZT (and White ZT) are

bagger capable.

Deck adjustment gear

Figure 1.2

1

Page 6

2. PTO / DECK BELT REPLACEMENT

3. DECK REMOVAL

2.1. Insert a 1/2” breaker bar into the square hole in

the tensioner arm located on top of the deck.

See Figure 2.1.

Idler arm

1/2” Breaker bar

Figure 2.1

2.2. Pivot the tensioner arm and pulley to slacken the

belt.

3.1. Release the deck J pins from the rear hanger

arms. See Figure 3.1.

Deck hanger rod

Deck adjustment gear

Figure 3.1

3.2. Slide the deck forward until the front stabilizer

bar can be lifted away from the front mounting

bracket.

2.3. Remove the belt from the two stationary idler

pulleys and spindle pulleys.

NOTE: The spindle covers do not need to be

removed.

2.4. Remove the belt from the clutch.

3.3. Slide the deck out from underneath the unit.

2

Page 7

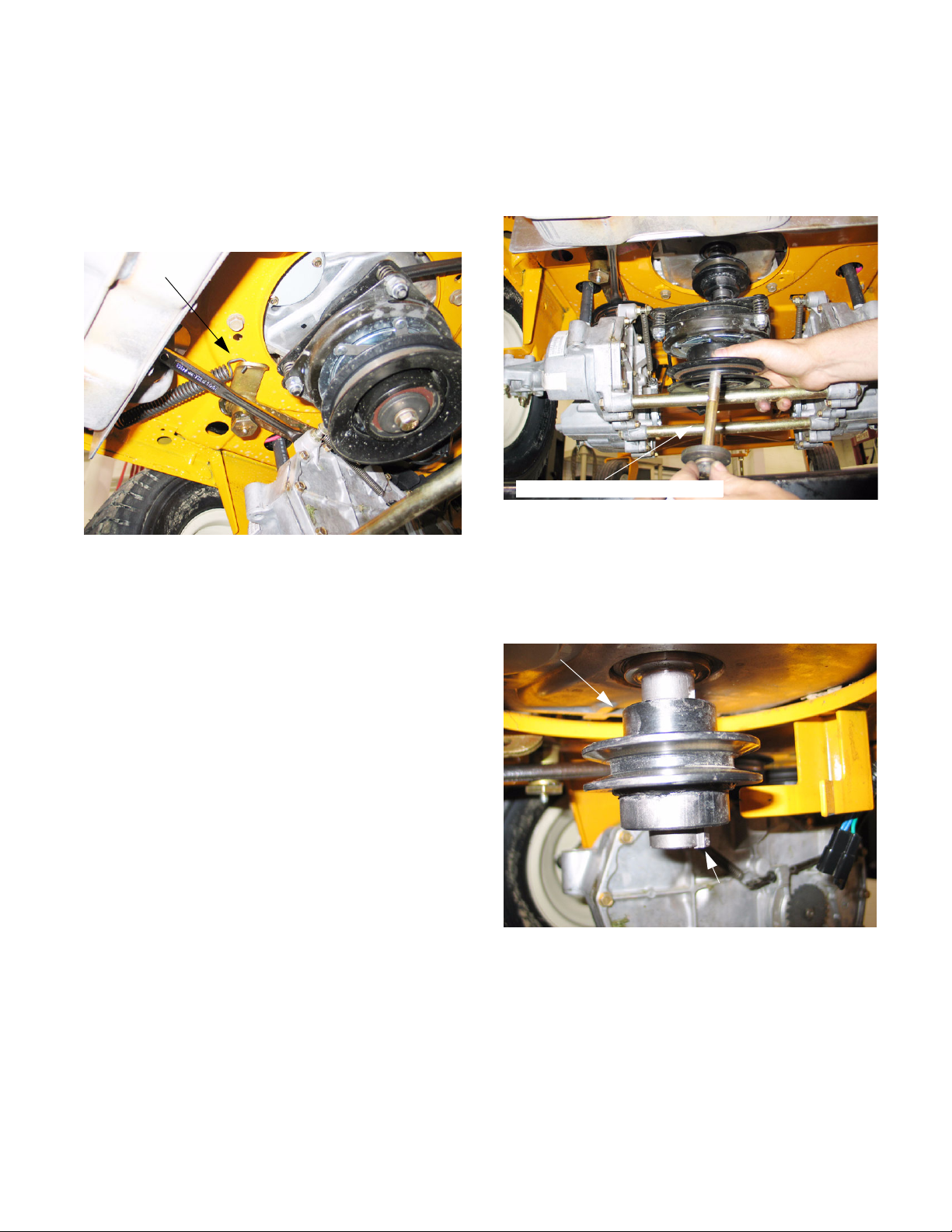

4. DRIVE BELT REPLACEMENT

5. SERVICING ELECTRIC PTO CLUTCH

4.1. Insert a 1/2” breaker bar into the square hole on

the tensioner arm.

4.2. Pull the breaker bar to the right until it can be

braced in position at the pivot point of the tensioner arm. See Figure 4.2.

Idler arm

Figure 4.2

4.3. Remove the belt from the transmission pulleys,

tensioner pulley and the crankshaft pulley.

5.1. Unplug the clutch.

5.2. Using a 9/16” socket and an impact wrench,

remove the clutch bolt. See Figure 5.2.

7/16-20 x 4.0 Hex cap screw

Figure 5.2

5.3. Lower the clutch off of the crankshaft.

5.4. Remove the crankshaft key.

5.5. Remove the crankshaft pulley. See Figure 5.5.

Crankshaft pulley

Key

Figure 5.5

3

Page 8

5.6. Use a 9/16” socket to adjust the air gap on the

clutch to between.010” and.015”.

See Figure 5.6.

.012 Feeler gage

6. TRANSMISSION REPLACEMENT

6.1. Insert a 1/2” breaker bar into the square hole on

the tensioner arm.

6.2. Pull the breaker bar to the right until it can be

braced in position at the pivot point of the tensioner arm.

6.3. Remove the belt from the transmission pulleys,

tensioner pulley and the crankshaft pulley.

6.4. Remove the four lug nuts securing the rear

wheel to the axle hub.

NOTE: Insure the lap bar control rods and brake

rods are not rubbing against the frame.

6.5. Remove the cotter pin securing the bypass rod

to the transmission bypass arm. Remove the

bypass rod. See Figure 6.5.

Figure 5.6

NOTE: Clutch adjustment can be done with the

clutch in the unit. If a new clutch is being put in

the adjustment can be done on the bench.

Bypass rod

Neutral

adjustment

plate

Figure 6.5

4

Page 9

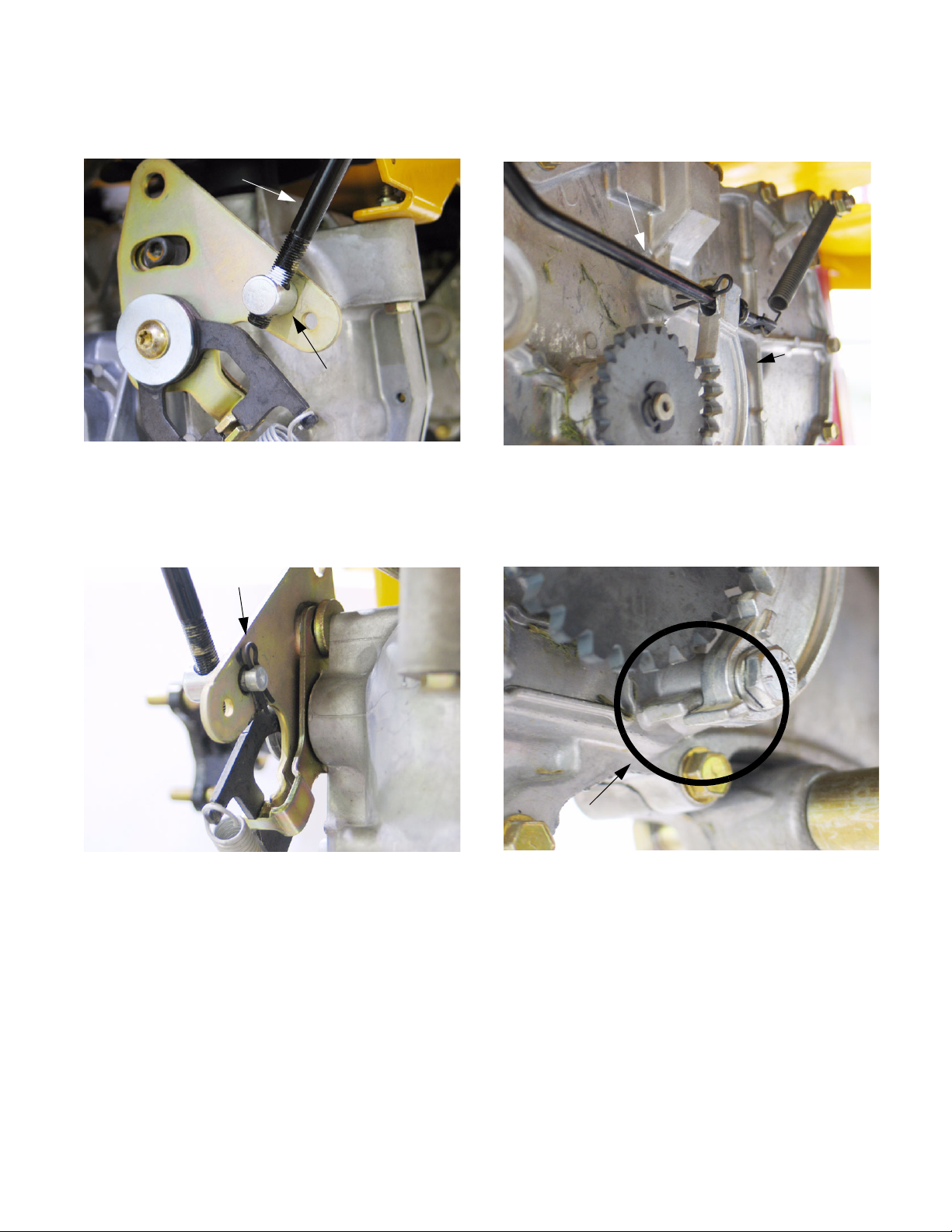

6.6. Mark the lap bar control rod threads near the clevis pin. See Figure 6.6.

6.8. Disconnect the brake return spring from the

brake arm. See Figure 6.8.

Lap bar control rod

Ferrule

Figure 6.6

6.7. Remove the hairpin securing the lap bar control

rod to the transmission return assembly.

See Figure 6.7.

Hair pin

Brake rod

Brake arm

Figure 6.8

6.9. Remove the bolt securing the brake arm to the

transmission using a 7/16” socket.

See Figure 6.9.

Figure 6.7

Note proper installation

Figure 6.9

NOTE: A spacer is located between the brake

arm and transmission housing.

NOTE: During installation, the bottom ridge of

the brake arm needs to be below the embossment on the transmission housing. Improper

installation will prevent the brake from engaging.

6.10. Remove both bolts securing the tubular transmission brace using a 5/8” socket.

NOTE: When installing the brace bolts use loctite 242.

5

Page 10

6.11. Remove the front transmission mounting bolt

using a 1/2” wrench and a 1/2” socket.

NOTE: Secure the transmission or use another

technician to support the transmission while performing the next step.

6.12. Remove both transmission mounting bolts

securing the transmission to the mounting

bracket using two 1/2” wrenches.

See Figure 6.12.

Transmission Mounting Bolts

Figure 6.12

6.13. Rotate the transmission out and down until the

fan is clear of the front transmission mounting

bracket, and remove it from the frame.

7. STEERING LINKAGE: ADJUSTMENT

7.1. Begin to adjust the steering by confirming that

both EZTs are correctly adjusted for neutral control. See Figure 7.1.

Neutral

adjustment

plate

Figure 7.1

7.2. Lift and safely support the rear of the mower.

7.3. Disconnect the ferrule at the EZT end of each

lap bar control rod from the neutral return

assembly on each of the EZTs. The ferrules are

secured to the neutral return assemblies with

hairpin clips. See Figure 7.3.

6.14. Installation notes:

• Lift transmission into place and start all threaded

fasteners before tightening any individual fasteners.

• The remainder of the installation process consists of reversing the removal process.

• Tighten the lug nuts to a torque of 350-500 inlbs.

• Tighten the center wheel hub nut to a torque of

100-160 ftlb.

Ferrule

Figure 7.3

NOTE: In the course of normal service, it is very

unusual for the neutral return assemblies to

require adjustment unless someone has previously tampered with it. It is necessary to check

the adjustment because the rest of the proce-

6

Page 11

dure counts on the neutral control being correctly adjusted.

7.4. Start the engine. With the control rods disconnected, the EZT should self-center to neutral.

The wheels should not rotate. If either wheel

rotates, the neutral return assembly on the EZT

that drives that wheel needs to be adjusted.

7.5. To adjust the neutral return assembly, loosen

the socket head cap screw that holds the centering bracket in position on the housing using a 1/

4” allen wrench. See Figure 7.5.

Neutral adjustment screw

7.7. Align the post on the ferrule with the hole that it

seats into on the neutral return assembly.

Thread the ferrule up or down the length of the

control rod to center the lap bar in the neutral

recess in the control console. See Figure 7.7.

Right lap bar

Figure 7.7

7.8. When each ferrule is in the correct position,

secure it to the neutral control assembly with a

hairpin clip.

Figure 7.5

7.6. Rotate the assembly in whichever direction

causes the wheels to stop rotating. The point

where the wheels do not rotate with the engine

at full throttle is true neutral. Tighten the socket

head cap screw at true neutral.

7.9. Lower the machine to the ground. Test the operation of the hydros in a safe space.

7.10. Adjust the stop bolts so that it tracks as straight

as possible with both lap bars pushed to the full

forward position. See Figure 7.10.

Stop bolt

Figure 7.10

7

Page 12

7.11. The socket head cap screws that secure the

neutral return assemblies to the EZTs act as a

travel stop at the EZT end of the linkage. The lap

bar pivot brackets should contact the stop

screws before the socket head cap screw contacts the end of the slot on the neutral bracket.

See Figure 7.11.

Neutral adjustment screw

Figure 7.11

NOTE: With one lap bar in the reverse position,

and the PTO turned on, the PTO clutch should

turn off as soon as the second lap bar crosses

the threshold from neutral into reverse. Repeat

test for each side.

NOTE: When at least one lap bar is in the neutral or forward position, the PTO clutch will operate. There is not a relay to re-set by cycling the

PTO switch off and on again, as is the case with

Cub Cadet front engine residential equipment.

7.14. If the reverse safety switch adjustment is not

correct, loosen the reverse safety switch bracket

using a 3/8” wrench. Pivot the bracket and

switch to a position that results in correct operation, then tighten the bracket. See Figure 7.14.

7.12. If the lap bars are not aligned with each-other,

they may be adjusted using the slotted mounting

where they connect to the lap bar pivot brackets.

See Figure 7.12.

Lap bar adjustments

Figure 7.12

7.13. After final adjustment, test the operation of the

reverse safety switches. They should turn the

PTO clutch off whenever both lap bars are in the

reverse position.

Reverse safety switch

Figure 7.14

NOTE: It is not necessary to remove either con-

trol console to reach the reverse safety switches,

but it may be necessary to temporarily disconnect the blue wires in order to reach the mounting screws for the brackets.

8

Page 13

8. PIVOT BAR

8.1. Safely lift and support the front of unit.

8.2. Disconnect the - (negative) lead to the battery.

8.5. Lightly grease the wheel spacers during re

assembly. Using a grease gun fill the rest of the

cavity AFTER the wheel assembly has been

mounted.

8.3. Using two 9/16” wrenches remove wheel assembly from caster bracket. See Figure 8.3.

Grease fitting

Figure 8.3

NOTE: Be careful not to drop spacers on both

sides of wheel assembly.

8.4. Remove center wheel spacer and inspect all

spacers for damage. See Figure 8.4.

8.6. Remove both caster wheel assemblies using a

9/16” wrench. See Figure 8.6.

Caster

wheel

bracket

Figure 8.6

8.7. Inspect flange bearing on top and bottom of

pivot axle. Replace if damaged. See Figure 8.7.

Wheel spacer

Figure 8.4

NOTE: Be sure to use a good quality grease

during reassembly.

NOTE: There are none replaceable 3/4” roller

bearing in the wheel hub.

.79 x .347

Spacer

Flat washer

Figure 8.7

NOTE: Assure proper order during reassembly.

From the top down in this order: hex head cap

screw, lock washer, flat washer, flange bearing,

pivot axle, flange bearing, flat washer, and

caster bracket.

NOTE: Be sure to use a good quality grease

during reassembly.

9

Page 14

8.8. Using a grease gun, fill the rest of the cavity

AFTER final assembly. Filling before final

assembly will allow the flange bearings to be

pushed out.

8.9. Remove both hex cap screws securing the axle

shaft to the frame. This will be done with a 3/4”

wrench. See Figure 8.9.

1/2-13 x 1.25 hex cap screws

9. SEAT REMOVAL

9.1. Disconnect the - (negative) lead to the battery.

9.2. Flip the seat forward. Keep one hand on back of

seat to prevent seat from trying to bite back.

See Figure 9.2.

Wing knobs

Figure 9.2

Figure 8.9

NOTE: Use removable threadlocking compound

such as “Loctite 242” during reassembly.

8.10. The axle shaft may be removed and inspected

for wear.

8.11. Inspect the flange bearing on each side of the

pivot axle for wear. Replace as needed.

See Figure 8.11.

Flange bearing

9.3. Remove both wing knobs from under seat. Keep

track of washers and spacers. See Figure 9.3.

Seat spacer

Figure 9.3

9.4. Slide seat forward to align seat spacers with

large hole in seat mounting bracket. Carefully lift

the seat out.

Figure 8.11

8.12. AFTER reassembly use a good quality grease to

fill the axle shaft chamber.

10

Page 15

9.5. Disconnect wires from the seat safety switch.

See Figure 9.5.

Seat safety switch

Figure 9.5

NOTE: Failure to reconnect seat safety switch

will cause unit not to run.

10. CONSOLE REMOVAL

The console needs to be removed to do many of the

following procedures. Removing the right and left console are very similar.

Under or attached to the left side console there is the

neutral switch, starter solenoid, three relays, 20 amp

fuse, choke knob (if applicable), hour meter, throttle

lever and reverse safety switch.

Under or attached to the right side console there is

neutral switch, key switch, reverse safety switch, and

pto switch.

LEFT SIDE CONSOLE

RIGHT SIDE CONSOLE

11

Page 16

10.1. Disconnect the - (negative) lead to the battery.

10.2. Using a 1/2” wrench, remove the three screws

securing the console to the seat frame.

See Figure 10.2.

5/16-18 x .625 screws

10.5. The two other screws are located under the console mounting bracket. See Figure 10.5.

#12-16 x .500 screws

Figure 10.5

Figure 10.2

10.3. From underneath remove the four #12-16 selftapping hex head screws. This can be accomplished by using a 5/16” socket with an extension.

10.4. There are two screws hidden in the tubular

frame at the front end of the console and the

rear of the console. See Figure 10.4.

#12-16 x .500 screw

NOTE: If the console mounting bracket is slotted, where it is attached to the seat frame box, it

may be easier to loosen the mounting screws

from the seat frame and leave bracket mounted

to the console.

10.6. Using two 1/2” wrenches remove the screw connecting the lapbar pivot bracket to control hub.

See Figure 10.6.

Lap bar pivot screw

Figure 10.4

Figure 10.6

10.7. Remove the lapbar and set to the side in a clean

safe area.

NOTE: Unscrew fuel cap when removing the left

side.

10.8. Carefully remove console from unit.

12

Page 17

10.9. If any electrical connections are present disconnect or remove switch from console.

See Figure 10.9.

Relays

PTO switch

Solenoid

Key switch

Reverse

switch

11. BATTERY REMOVAL

The battery can be removed two different ways.

Depending on the final out come of the work that needs

to be preformed is which technique you will use.

When just replacing a battery the fuel pump needs to

be removed.

If for any reason the right side control console has to

be removed in conjunction with removal of the battery,

the fuel pump will NOT have to be removed.

NOTE: THE FOLLOWING STEPS ARE FOR

BATTERY REMOVAL WITH OUT THE

REMOVING THE RIGHT SIDE CONSOLE.

11.1. Disconnect the - (negative) lead to the battery.

11.2. Disconnect the + (positive) lead to the battery.

11.3. Disconnect the battery strap from frame.

Figure 10.9

NOTE: The throttle cable and choke knob does

not need to be removed. The console can be

flipped up on the unit and secured safely.

NOTE: There is different throttle and choke

cable routing for the different models.

NOTE: Not all models have a choke knob.

11.4. Using a 3/8” wrench remove the two screws

securing the fuel pump to the engine. The hoses

don’t need to be removed. See Figure 11.4.

Fuel pump

Figure 11.4

NOTE: When reinstalling the battery make sure

strap is hooked under the seat box before placing battery in the unit.

11.5. Battery can be pulled up and to the side to

remove.

NOTE: THE FOLLOWING STEPS ARE FOR

BATTERY REMOVAL WITH THE REMOVAL

OF THE RIGHT SIDE CONSOLE.

11.6. Disconnect the - (negative) lead to the battery.

11.7. Disconnect the + (positive) lead to the battery.

11.8. Disconnect the battery strap from frame.

13

Page 18

11.9. Remove right side console as per “CONSOLE

REMOVAL” of this manual.

11.10. With the right side console removed the battery

will slip out the side easily. See Figure 11.10.

Battery strap

Figure 11.10

12. FUEL TANK REMOVAL

12.1. Perform the “SEAT REMOVAL” section of this

manual.

12.2. Remove the battery per “BATTERY REMOVAL”

section.

NOTE: The right side console does NOT need to

be removed.

12.3. Remove the two screws securing the fuel tank

mounting wire to the frame using a 1/2” socket.

See Figure 12.3.

Fuel tank mounting screws

Figure 12.3

12.4. Remove fuel tank mounting wire and set off to

the side.

12.5. Disconnect electrical connector between the

tank and the engine to allow room for the tank to

slide out. See Figure 12.5.

Electrical connector

14

Figure 12.5

Page 19

12.6. Remove the left console as described in the

“CONSOLE REMOVAL” section of this manual.

12.7. Rotate tank upward and slide out toward the

side. See Figure 12.7.

Fuel tank

Figure 12.7

13. CONTROL SHAFT REPLACEMENT

13.1. Disconnect the - (negative) lead to the battery.

13.2. Remove appropriate side console. refer to

“CONSOLE REMOVAL” section of this manual.

13.3. Disconnect the ferrule from the return to neutral

assembly. See Figure 13.3.

Control arm

12.8. Disconnect the fuel line from the fuel pump and

carefully remove fuel tank from unit.

NOTE: Make sure to clean up any spilled fuel.

NOTE: During reassembly be certain to recon-

nect electrical connector and fuel line.

NOTE: This would a good time to change the

fuel filter.

Figure 13.3

13.4. Remove hex head cap screw and flat washer

securing the control hub to the control shaft.

See Figure 13.4.

Control hub

Figure 13.4

13.5. Remove hair pin securing the lapbar control rod

to the control hub.

15

Page 20

13.6. While rotating the control hub forward the lapbar

control rod can be disconnected and removed.

See Figure 13.6.

Hair pins

Lap bar control rod

Figure 13.6

13.7. Pull the control hub off the control shaft.

See Figure 13.7.

Control shaft

13.9. The control shaft can be removed from underneath the seat frame box. See Figure 13.9.

Control shaft

Brake switch

Figure 13.9

13.10.Inspect hex flange bearing and control shaft.

Replace as needed.

NOTE: Applying anti-seize compound to the

double “D” end of the control shaft will aid in

future removal of the shaft.

NOTE: Undertaking the “DECK REMOVAL”

section of this manual will make this procedure a

little less painful but, is not necessary.

Reverse safety switch

Figure 13.7

13.8. Remove outboard hex flange bearing. Inspect

and replace as needed.

16

Page 21

14. DECK LIFT SHAFT REPLACEMENT

14.1. The following section of this manual need to be

accomplished:

DECK REMOVAL

SEAT REMOVAL

14.5. Carefully lift the fuel tank and remove the hex

head cap screw under the rear of the fuel tank

securing the seat box frame to the frame. Using

a 1/2 “wrench will help immensely

NOTE: The fuel tank does NOT need to be

taken out.

CONSOLE REMOVAL, RIGHT AND LEFT SIDE

BATTERY REMOVAL

NOTE: THE DECK LIFT SHAFT ALSO DOU-

BLES AS THE FULCRUM POINT FOR THE

PARKING BRAKE ROD AND HANDLE.

14.2. Remove the two screws securing the fuel tank

mounting wire to the frame using a 1/2” socket.

See Figure 14.2.

Fuel tank mounting screws

Figure 14.2

14.6. Using the same 1/2” wrench remove the other

eight screws hold down the seat box frame.

There area total two in the rear, two on each

side and three in the front for a tally of nine.

See Figure 14.6.

5/16-18 x .625 hex head washer screws

Figure 14.6

14.7. Disconnect the lapbar control rods from the

return to neutral brackets. See Figure 14.7.

Lapbar control rod

14.3. Remove fuel tank mounting wire and set off to

the side.

14.4. Disconnect the electrical connection between

the fuel tank and the engine. This will allow room

for the fuel tank to be moved to get a wrench

underneath.

Figure 14.7

17

Page 22

14.8. Using two 9/16” wrenches remove the bolt, nut,

and spring on the brake handle on the left handle side of the deck lift shaft. See Figure 14.8.

Brake handle

14.10.Remove the only large hairpin going through the

center of the deck lift shaft on the left side of the

shaft. See Figure 14.10.

Deck

Deck

lift

shaft

Large hairpin

Figure 14.8

NOTE: When reassembling tighten screw.030

past flush to end of screw.

14.9. Remove the hairpins securing the deck lift

cables the deck lift shaft. See Figure 14.9.

Deck lift cable

Figure 14.9

Figure 14.10

NOTE: By removing this hairpin it will allow the

concentric brake cross shaft to slide to the right

to disconnecting the brake rods.

14.11. Remove the hairpin keeping the brake rods connected to the concentric brake cross shaft.

14.12.Slide the concentric brake cross shaft to the right

allowing the brake rods to come out of the hole

in the shaft. See Figure 14.12.

Brake rod

Figure 14.12

14.13.Remove rubber handle from the deck lift rod.

18

Page 23

14.14.Carefully release the tension on the deck lift

handle torsion spring. See Figure 14.14.

Torsion spring

Figure 14.14

14.17.Place a piece of 2 x 4 or something equivalent

under the front, left side of the seat box frame.

This will allow enough clearance for deck lift

assembly to slip out the back easily.

See Figure 14.17.

2 x 4 or equivalent

NOTE: Putting the deck lift handle in the lowest

cutting position will make this task much easier.

14.15.Remove the E-clips on the ends of the deck lift

shaft. See Figure 14.15.

Deck lift shaft

Figure 14.15

14.16.Remove both hex flange bearings.

Figure 14.17

14.18.Shuffle the deck lift assembly to the left till the

right side falls out of the seat box.

14.19.From this point the deck lift shaft and deck lift

handle will slip of the rear of the unit where the

battery was. See Figure 14.19.

Deck lift shaft

Figure 14.19

19

NOTE: The outer hex flange bearing on the deck

lift shaft can be replaced with out removing the

shaft.

NOTE: The split flange bearing on the deck lift

handle can be replaced with out removing the

deck lift shaft or deck lift handle.

Page 24

15. ELECTRICAL SYSTEM COMPONENTS

This section is intended to help technicians identify the

location and function of specific components on the

RZT electrical system.

15.1. The SEAT SAFETY SWITCH is located under

the seat assembly. See Figure 15.1.

-The contacts on the switch are normally closed. This

is indicated with the initials N.C.on the side of the

spades.

-When the seat is unoccupied this will energize relay #

1 & 2.

NOTE: The seat safety switch has nothing to do

with the starting circuit.

Seat safety switch

15.2. The PARKING BRAKE SWITCH is located

under the seat box frame. See Figure 15.2.

-Both sets of contacts are normally open (N.O.).

-When the switch is activated the red wire supplies

power to the seat switch. The red/white wire is for an

indicator light on the hour meter. An orange wire goes

to the starter solenoid. The orange/white wire goes to

the PTO switch.

Brake switch

Figure 15.1

Figure 15.2

NOTE: The brake switch is part of the start cur-

cuit.

20

Page 25

15.3. The NEUTRAL SWITCHES are in the console

on each side of the unit. They are normally open/

normally closed switches. See Figure 15.3.

15.4. The REVERSE SWITCHES are located just

under the lapbars in the console.

See Figure 15.4.

-The two inner terminals are N.C. They have a yellow/

white wire which supply a ground to center set of

spades on the PTO switch and spade 87 on the brake

relay.

-The two outer terminals are N.O. The left switch has a

yellow/white wire which goes to the key switch and a

orange that goes to the right neutral switch. The right

neutral switch has the orange wire and a orange/black

wire which leads to the PTO switch.

Neutral switch

-There are two of these switches.

-These are normally closed switches (N.C.).

-The switches need to be set-up in a way that when the

lapbar(s) are pulled to the rear the switch opens the circuit and eliminates power to the PTO from that switch.

-One lapbar can be pulled back at a time but, if both

are pulled back that will cut power to the PTO. Returning one or both lapbars to neural will reengage the

PTO. This is done by wiring the switches in parallel

-If the reverse safety switch adjustment is not correct,

loosen the reverse safety switch bracket using a 3/8”

wrench. Pivot the bracket and switch to a position that

results in correct operation, then tighten the bracket.

Reverse safety switch

Figure 15.3

NOTE: These switches are part of the starting

circuit.

Figure 15.4

NOTE: It is not necessary to remove either con-

trol console to reach the reverse safety switches,

but it may be necessary to temporarily disconnect the blue wires in order to reach the mounting screws for the brackets.

21

Page 26

15.5. The PTO switch is located on the right console

behind the key switch. This switch is part of the

start circuit, PTO run circuit, and reverse safety

circuit.

See Figure 15.5.

- The first set of terminals are in the start circuit. The

orange/white wire connects to the brake switch and the

orange/black wire goes to the neutral switches. The

PTO switch needs to be in the off position to start the

unit.

-The second set of terminals are part of the reverse

safety circuit. They consists of yellow/black wire connecting to the terminal “30” of the PTO relay and the

yellow/white wire which connects to terminal “87” on

the brake relay and neutral switches.

-The third and final set of terminals, PTO run circuit,

consists of blue wire from the reverse safety switches

and a red wire from the run line.

NOTE: If you are checking for power at the PTO

switch, you should have 12 volts at the red wire

and no voltage at the blue wire with the PTO

switch turned off. With the PTO switch on you

will have 12 volts at both the blue and red wires.

Be sure all other condition are being meet for the

PTO to run properly.

15.6. The KEY SWITCH is located on right console in

front of the PTO switch.

-There was a midyear change to the key switch. Units

with serial number before 1F014G20062 should have

key switch 725-04019 (Delta switch number 6900-31P)

and Harness 725-04170. When the old key switch is

turned to the start position it doesn’t energize the fuel

shut off solenoid. This will not allow fuel to flow to the

carburetor while the engine is cranking. To correct this,

there is a new key switch (725-04228) and a harness

adapter (725-04229). This is available in kit 759-04058

(service advisory CC-451)

-A new wiring harness 759-04170A should be on all

models with serial numbers above 1F224G20001.

These models will NOT need the harness adapter

(759-04058) and will already have the proper key

switch.

-To check for the proper key switch perform the follow-

ing test.

NOTE: A multimeter or continuity tester will be

need for this section.

Turn key to OFF position and check for continuity you

should have continuity between G and M only.

PTO switch

Key switch

Figure 15.5

Neutral switch

Turn key to the RUN you should have continuity

between L and B.

Turn and hold key in the Start position you should have

continuity between L, B, and S.

-If this is the case then you have the most current

switch. The old key switch is usually identical to the

new switch. The difference being that the old switch

when turned to START would have continuity between

B and S only.

22

Page 27

-The BRAKE RELAY should have a consistent ground

(terminal 86) and will receive power (terminal 85) when

the brake switch is activated.

Brake relay

15.7. There are three RELAYS in the electrical system

of the RZT. They are located under the right side

console toward the rear. See Figure 15.7.

-The relays are assessable from under the rear of the

console

-To replace a relay, the console does not need to be

removed.

Seat relay

15.8. The STARTER SOLENOID is located under the

right console just to the right of the relays.

See Figure 15.8.

- Be certain that there is a good path to ground by mak-

ing sure there is a star washer under the mounting tab

on the starter solenoid.

PTO relay

Figure 15.7

-When testing by feel a click should be felt when activated.

-Starting from the left they should be in the order of

SEAT, PTO, and, BRAKE

-The SEAT RELAY should have a consistent ground

(terminal 86) and will receive power (terminal 85) when

the seat switch is activated.

-The PTO RELAY should have a consistent ground

(terminal 86) and will also receive power (terminal 85)

when the seat switch is activated.

23

Page 28

Starter solenoid

Figure 15.8

24

Page 29

25

Page 30

26

Loading...

Loading...