Page 1

Professional Shop ManualProfessional Shop Manual

RT 75 Rear Tine Tiller

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accura te as possible at the time of publication. However, du e to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2013 MTD Products Inc. All Rights Reserved

Page 2

Page 3

Table of Contents

Chapter 1: Introduction

About the text format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Understanding model and serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

The RT 75 Series Tiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2: Belts

Belt Removal/replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3: Cables

Forward Drive Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reverse Drive Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 4: Engine

Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 5: Transmission Removal

Transmission removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 6: Transmission Overhaul

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Transmission Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 7: Tines

Tines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Chapter 8: Swivel Handle

Handle bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Swivel Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

I

Page 4

II

Page 5

Introduction

! WARNING! WARNING

! DANGER! DANGER

! CAUTION! CAUTION

CHAPTER 1: INTRODUCTION

Professional Service Manual Intent: This manual is intended to provide service dealers with repair and overhaul

procedures for the RT&% series tiller.

Disclaimer: The information contained in this manual is co rrect at the time of writing. Both the product and the infor-

mation about the product are subject to change without notice.

About the text format

Certain flags and key words are used to indicate the nature of the text that accompanies them. They are as follows:

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result

in minor or moderate injury. It may also be used to alert against unsafe practices.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could

result in death of serious injury.

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result

in death or serious injury. This signal word is to be limited to the most extreme situa

tions.

NOTE: “NOTE” is used to point-out helpful information that may not fit as a step in a procedure.

1. Numbered steps indicate specific things that should be done, and the order in which they should be done .

1a. Sub steps will be lettered and nested within steps. Two or more sub steps may be combined to describe

the actions required to complete a step.

• Bullet points: Indicate sub-steps or points of interest, without implying order or relative importance.

Disclaimer: This manual is intended for use by trained, professional technicians.

• Common sense in operation and safety is assumed.

-

If the person using this manual is uncomfortable with any procedures they encounter, they should seek the help

of a qualified technician.

• In no event shall MTD be liable for poor text interpretation, or poor execution of the procedures described

in the text.

1

Page 6

RT 75

• Be prepared in case of emergency:

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very ser ious

harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

• Lift and support heavy objects sa fely and securely.

• Be aware of your surroundings and potential h azards that are inhe rent to all power

equipment. All the labels in the world cannot protect a technician from an in stant of

carelessness.

! CAUTION! CAUTION

• Grooming and attire:

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection ................................ while working around any machinery

Protective gloves ..................................... where necessary

Armored footwear.................................... when working around any machinery

Hearing protection ................................... in noisy environments

Chemically resistant gloves..................... when working with chemicals or solvents

Respirator................................................ when working with chemical or solvents

Appropriate tinted eye protection............. when cutting or welding

Flame resistant headgear, jacket, chaps. when cutting or welding

! WARNING! WARNING

• Exhaust fumes from running engines contain carbon monoxide (CO). Carbon

monoxide is a colorless odorless gas that is fatal if inhaled in sufficient quantity.

Only run engines in well ventilated areas. If running engines indoors, use an

exhaust evacuation system with adequate make-up air ventilated into the shop.

! DANGER! DANGER

2

Page 7

Introduction

Fasteners

• The fasteners used on the equipment described in this manual, and the engine that powers it are a co mbination of metric and fractional inch. For this reason, wrench sizes are frequently identified in the text, and

measurements are given in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of releasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners, like cotter pins, are single-use items that are not to be reused. Other fasteners, such as:

lock washers, retaining rings, and internal cotter pins (hairpin clips), may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

Assembly instructions

• Torque specifications may be noted in the part of the text that covers assembly. They may be summarized in tables along with special instructions regarding locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-by-step procedure guide that does not require the user to hunt for information.

• Lubricant quantity and specification may be noted in the part of the text that covers maintenance, and

again in the section that covers assembly. They may also be summarized in tables along with special

instructions. Whichever method is more appropriate will be used. In many cases, the information will be

found in several places in the manual so that the manual is handy as a quick-r eference g uide as we ll as a

step-by-step procedure guide that does not require the user to hunt for information.

• The level of assembly instructions provided will be determined by the complexity of reassembly, and by

the potential for damage or unsafe conditions to arise from mistakes made in assembly.

• Some instructions may refer to other parts of the manual for subsidiary procedures. This avoids repeating

the same procedure two or three times in the manual.

3

Page 8

RT 75

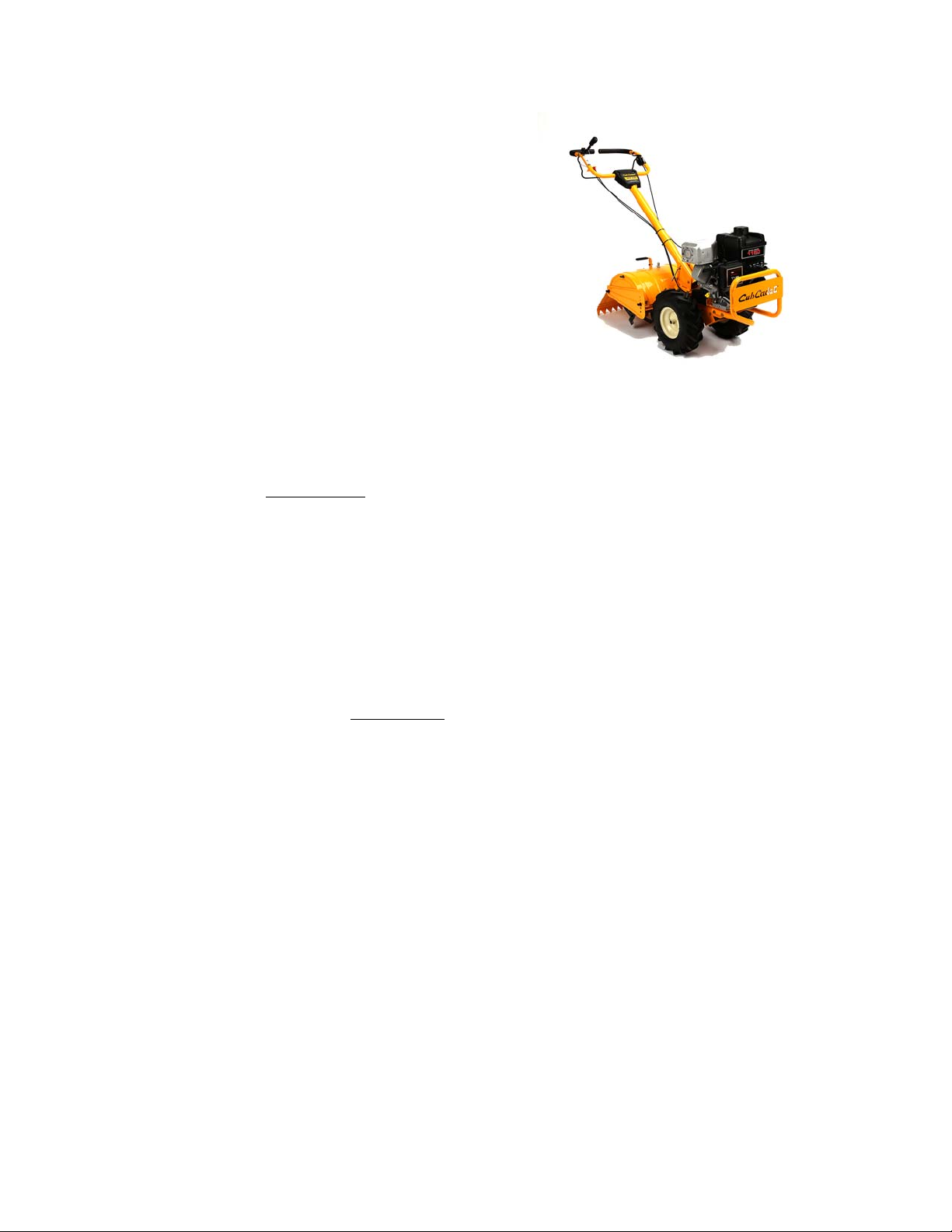

Figure 1.1

The RT 75 series tiller

The RT 75 tiller is a new tiller line that was introduced

for the 2014 model year . This is a r ear tine, coun ter rot ating

tiller that features:

• Ball bearings on the wheel and tine shafts

• Bronze worm gears.

• A neutral lever to disengage the transmission.

Understanding model and serial numbers

The model number of the RT 75 tiller described in this manual is 21AC482R710.

The break down of what the model number

• 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . indicates that this is a tiller

means is as follows:

• . . A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . indicates the sales revision

• . . . . C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . indicates the tire size

• . . . . . . 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . indicates this is a 400 series tiller

• . . . . . . . 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . indicates th e a swin g ha ndle (48 0 tra n sm issio n)

• . . . . . . . . . 2R. . . . . . . . . . . . . . . . . . . . . . . . . indicates the engine

• . . . . . . . . . . . . .710 . . . . . . . . . . . . . . . . . . . . . indicates the customer

The serial number is 1J053P10005. The serial number

• 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . engineering level

• . J. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .month of production (J = October)

• . . .05 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .day of the month

• . . . . . 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .last digit of the year

• . . . . . . .P. . . . . . . . . . . . . . . . . . . . . . . . . . . . .plant it was built in

• . . . . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . .assembly line number

• . . . . . . . . . . 0005 . . . . . . . . . . . . . . . . . . . . . .number of unit built

Additional technical and service information may also be available to our company authorized service center personnel through our company corporate offices, regional parts distributors and regional service center field support

personnel. Please contact the designated support office in your area or our corporate offices directly should further

service information be needed.

reads as follows:

MTD Products LLC

P.O. Box 368022

Cleveland, OH 44136

Telephone: (800) 800-7310

www.mtdproducts.com

4

Page 9

Maintenance chart

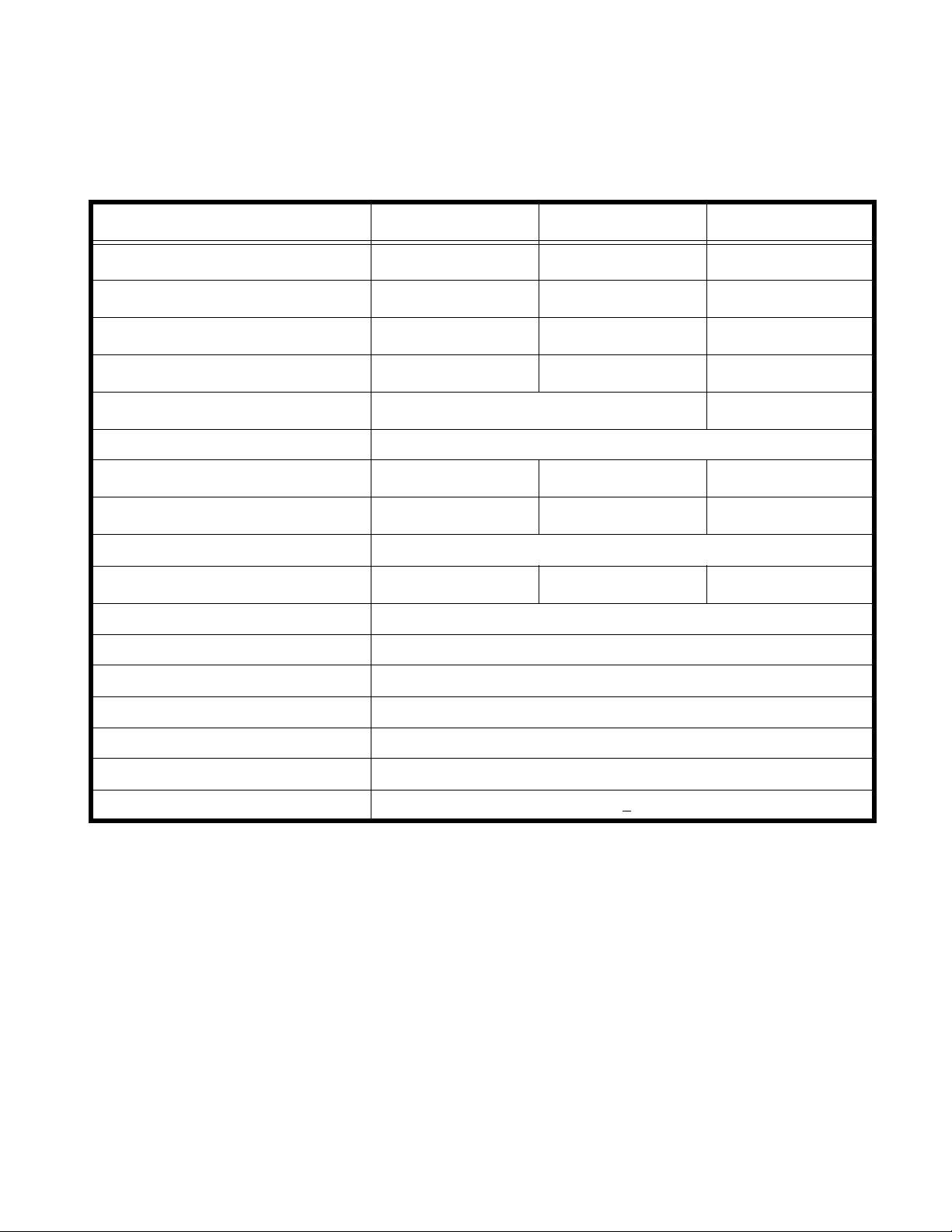

Maintenance item Each use Each 25 hrs. use Each 50 hrs. use

Introduction

Check engine oil

Check air filter

Check transmission oil

Check for loose/broke tines

Check & gap spark plug Replace if worn

Check cooling fins After prolonged storage

Check/clean spark arrestor

Change oil

Note on oil: Change oil after first 5 hrs of use and before prolonged storage

Change air filter

Note on air filter Air filter and pre-filter life vary dramatically with operating conditions

Drain or preserve fuel Before prolonged storage

Fog or lube cylinder Before prolonged storage

*

*

*

*

*

*

*

*

Rotate engine to TDC Before prolonged storage

Remove wheels and lube wheel shaft Once a year

Remove tines and lube tine shaft Once a year

Engine RPM 3500 +

100

5

Page 10

RT 75

6

Page 11

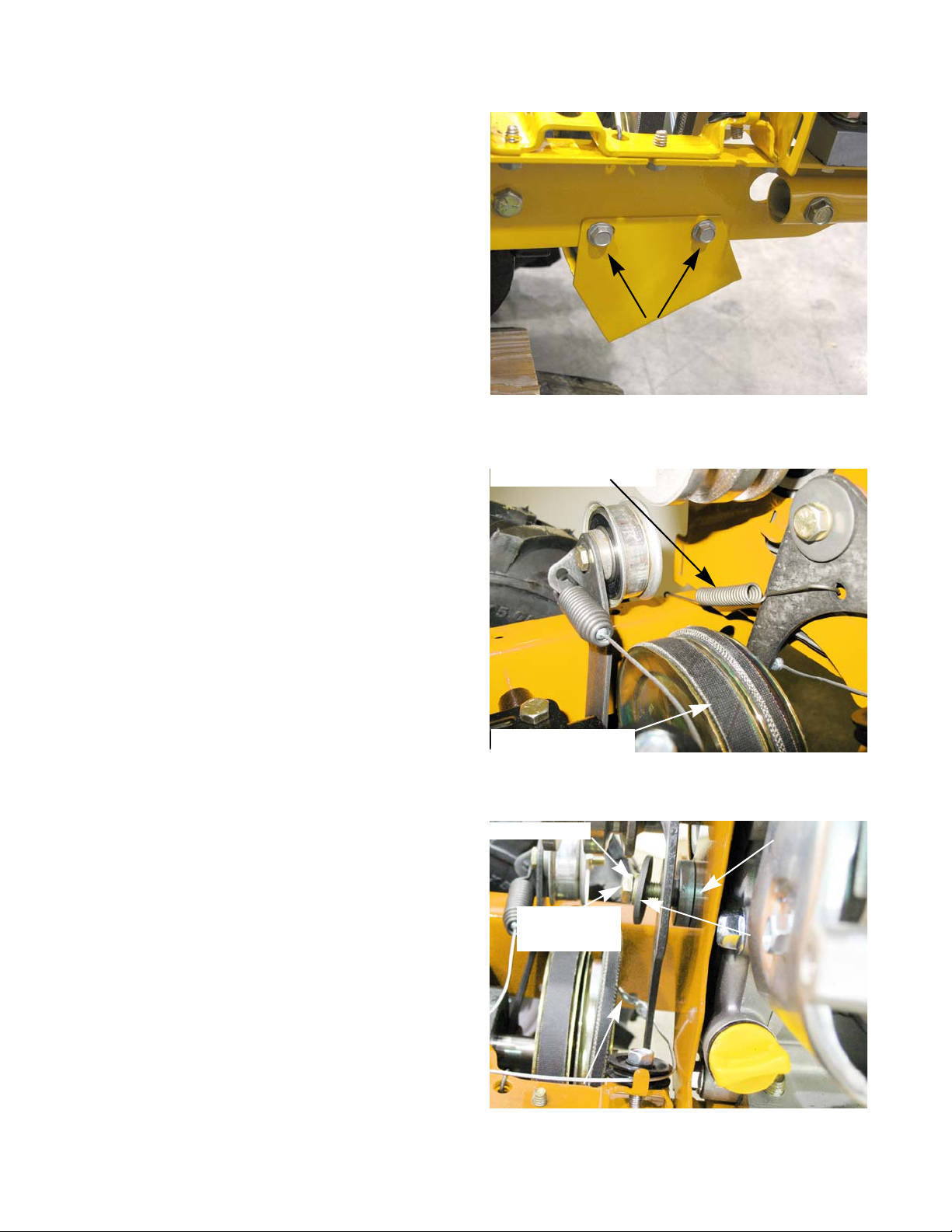

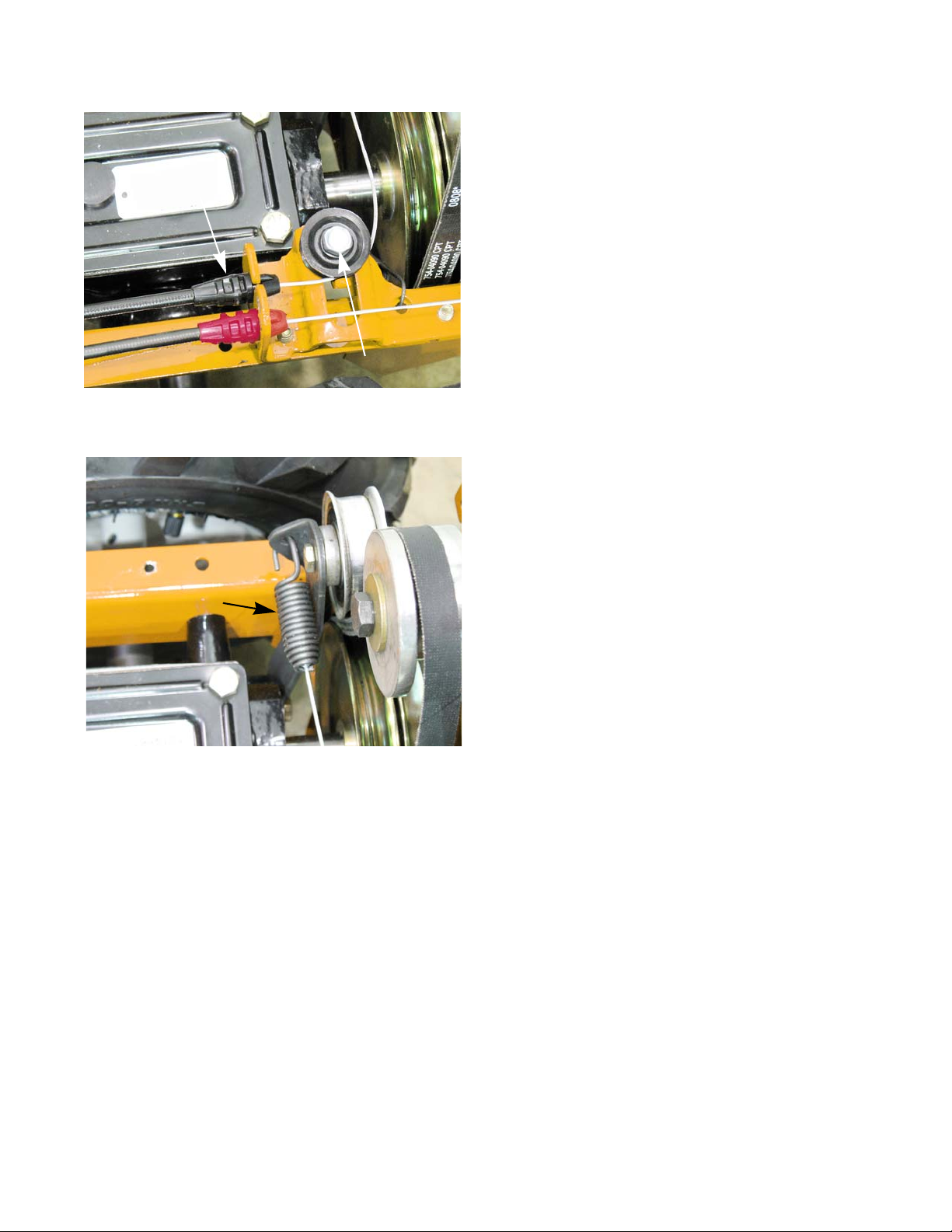

Figure 2.1

screws

Figure 2.2

reverse idler

pulley

CHAPTER 2: BELTS

The RT 75 tiller has two belts; a forward drive belt and a

reverse belt. Both belts have to come off together. MTD

recommends replacing both belts at the same time.

To remove/replace the belts:

1. Disconnect and gr ound the spark plug wire.

2. Remove the two screws that secure the belt cover.

See Figure 2.1.

Belts

3. Swing the belt cover up and off of the tiller.

4. Slide the forward drive belt off of the engine pulley.

5. Loosen the nut and bolt that secure the reverse idler

pulley to the idler bracket using a pair of 7/16”

wrenches.

6. Slide the reverse belt past the belt guards and off of

the idler pulley.

See Figure 2.2.

7

Page 12

RT 75

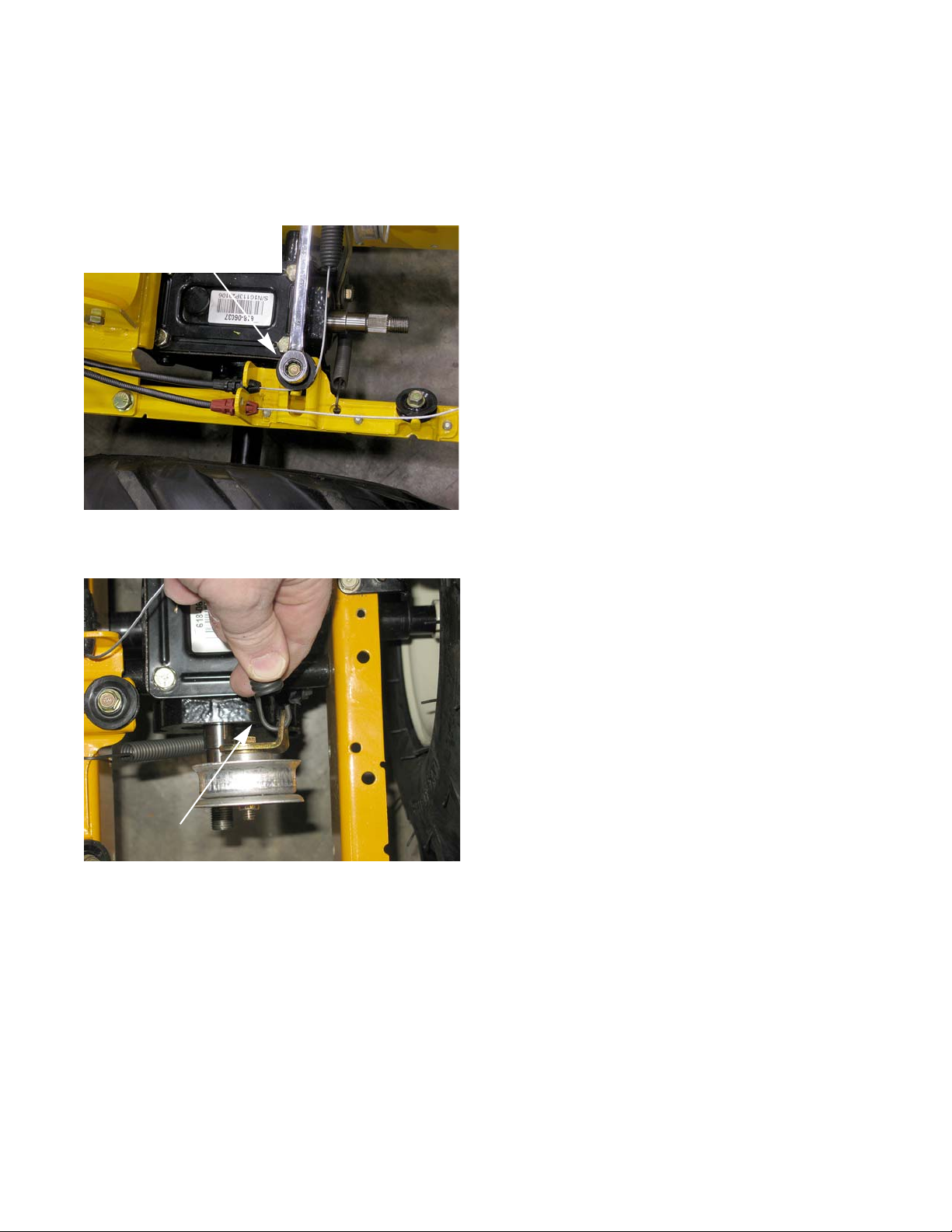

Figure 2.3

screws

Figure 2.4

reverse idler spring

belts pushed down

Figure 2.5

fender washer

shoulder

lock washer

spacer

Z-fitting

remove this

screw

7. Remove the four screws that secure the transmission pulley shield using a 3/8” wrench.

See Figure 2.3.

NOTE: The tire was removed for this picture. It is

not required to remove the tire to remove the

belts.

8. Push both belts down onto the transmission pulley.

See Figure 2.4.

9. Unhook the reverse idler spring. See Figure 2.4.

10. Unhook the rever se cable Z-fitting from the reverse

idler bracket.

11. Remove the reverse idler bracket using a 1/2”

wrench.

See Figure 2.5.

8

Page 13

Belts

Figure 2.6

7/8” nut

Figure 2.7

forward drive belt

reverse belt

hub

12. Remove the nut that secures the transmission pulley

using a 7/8” socket and an impact wrench.

See Figure 2.6.

13. Slide the transmission pulley and both belts off

together.

14. Position the new belts on the transmission pulley.

See Figure 2.7.

15. Install the belts by following steps 1 through 13 in

reverse order.

NOTE: The transmission pulley has a star shaped center

hole. When installing the pulley, the star must fit

over the raised star on the hub.

16. Test run the tiller in a safe area before returning it to

service.

See Figure 2.7.

9

Page 14

RT 75

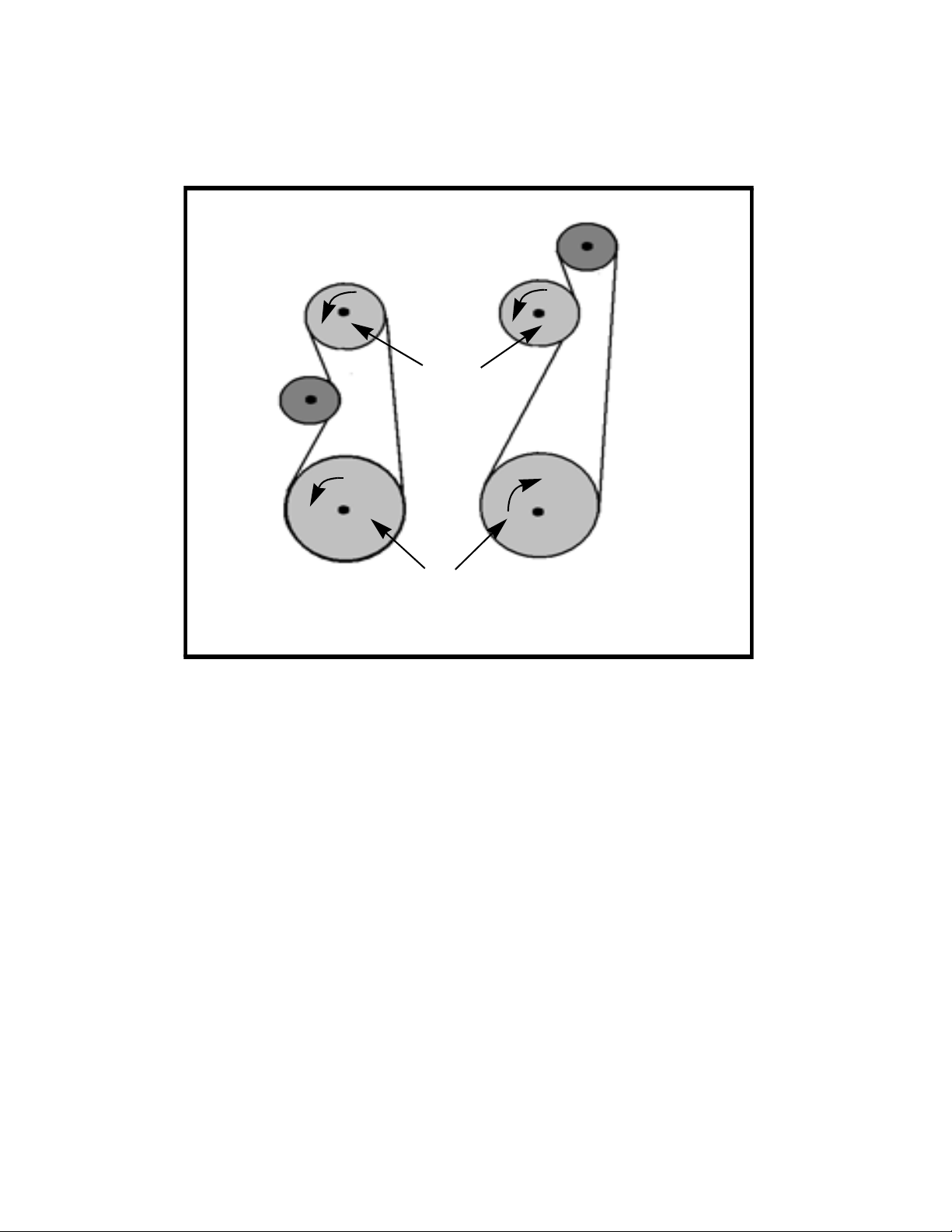

Belt Routing

Forward drive belt

Reverse drive belt

Transmission pulley

Engine

Pulley

10

Page 15

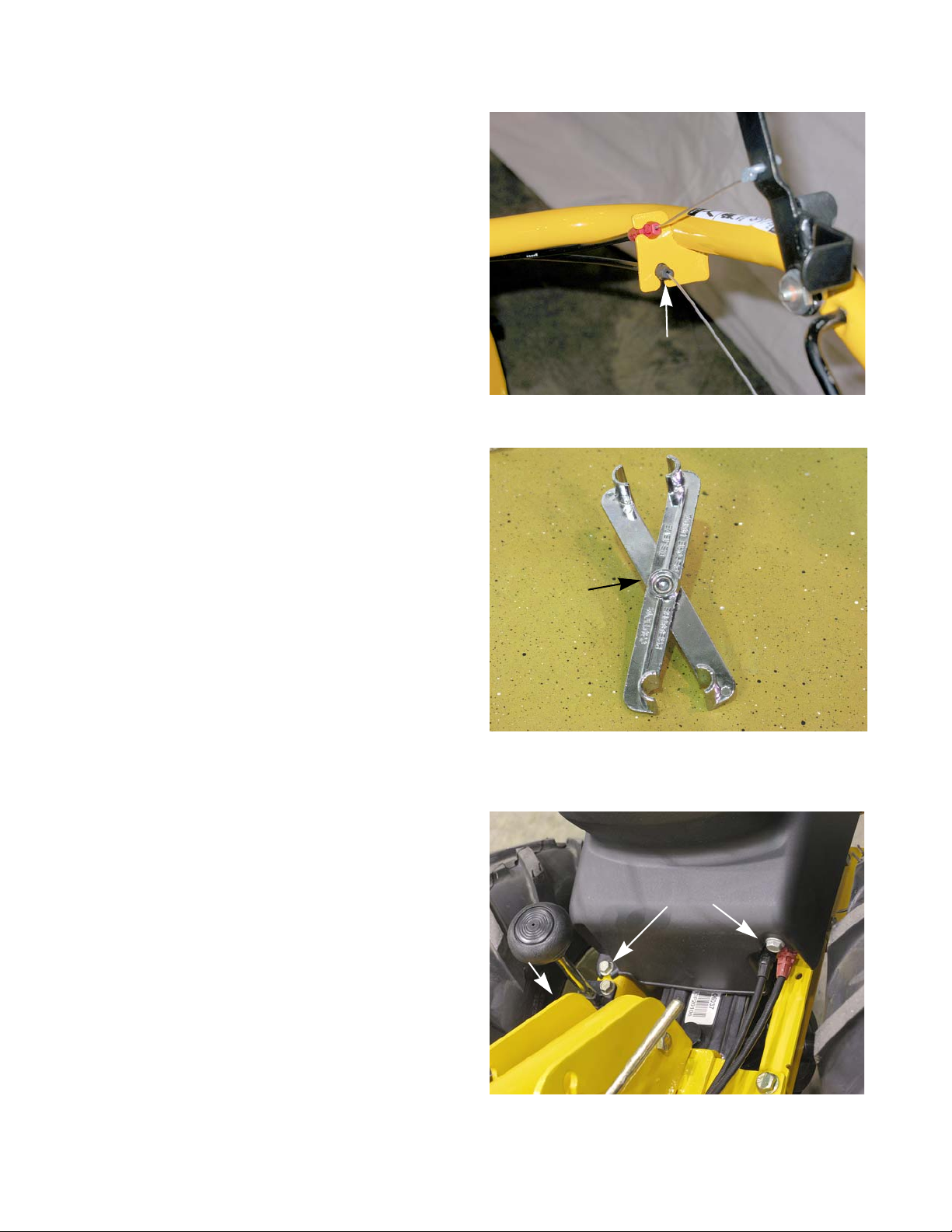

Figure 3.1

reverse lever

forward drive bail

Figure 3.2

Reverse lever hitting

the drive bail

CHAPTER 3: CABLES

The RT 75 tiller has a forward drive cable and a reverse drive cable. The forward drive cable is actuated by a bail

that the operator squeezes. The reverse drive cable is actuated by a lever.

See Figure 3.1.

Cables

The shape of the drive bail and reverse lever will help prevent the operator from engaging the reverse lever while

in the forward mode. As the reverse lever is engaged, the bend on the bottom of it hits the drive bail making it ne ces

sary to release the drive bail. See Figure 3.2.

-

11

Page 16

RT 75

Figure 3.3

Disconnect the

cable fitting

Figure 3.4

Ford fuel

line tool

Figure 3.5

Remove these

screws

washer

Forward drive cable

To remove/replace the forward drive cable:

1. Disconnect and ground the spark plug wire.

2. Disconnect the black cable fitting from the handle bar

bracket.

NOTE: A ford fuel line tool is useful to compress the

See Figure 3.3.

ears on the cable fitting while removing it.

See Figure 3.4.

3. Unhook the Z-fitting from the forward drive bail.

4. Remove the two screws that secure the belt cover.

See Figure 3.5.

5. Swing the belt cover up and off of the tiller.

12

Page 17

Cables

Figure 3.6

Loosen this screw

Disconnect

this cable

Figure 3.7

Disconnect cable

6. Loosen, but do not remove, the screw securing the

cable pulley.

7. Slip the cable off of the pulley.

8. Disconnect the black cable fitting from the cable

bracket.

9. Unhook the spring end of the cable from the forward

idler bracket.

See Figure 3.6.

See Figure 3.6.

See Figure 3.7.

NOTE: The spring end of the cable is to help prevent over

tensioning of the drive belt.

10. Install the cable by following the previous steps in

reverse order.

11. Test run the tiller in a safe area before returning it to

service.

13

Page 18

RT 75

Figure 3.8

Disconnect the

cable fitting

Figure 3.9

Remove these

screws

Figure 3.10

Loosen this screw

Z-fitting

Reverse drive cable

To remove the reverse drive cable:

1. Disconnect and ground the spark plug wire.

2. Disconnect the red cable fitting from the handle bar

bracket.

3. Unhook the Z-fitting from the reverse drive lever.

4. Remove the two screws that secure the belt cover.

See Figure 3.9.

See Figure 3.8.

NOTE: The left screw has a washer to prevent the

slot in the cover from opening up as the screw

is tightened.

5. Swing the belt cover up and off of the tiller.

6. Slide the forward drive belt off of the engine pulley.

7. Slide the reverse belt off of the idler pulley.

7a. Loosen the nut and bolt that secures the idler

pulley to the idler bracket.

7b. Slide the belt past the belt guides.

8. Loosen, but do not remove, the screw securing the

cable pulley.

See Figure 3.10.

14

Page 19

Cables

Figure 3.11

Disconnect

this cable

9. Disconnect the red cable fitting from the cable

bracket.

10. Disconnect the cable Z-fitting.

11. Install the reverse cable by following the previous

steps in reverse order.

12. Test run the tiller in a safe area before returning it to

service.

See Figure 3.11.

15

Page 20

RT 75

16

Page 21

Figure 4.1

Remove these

screws

Figure 4.2

throttle cable clamp

CHAPTER 4: ENGINE

At the time this manual was written, a Briggs and Stratton engine was the only engine option for the RT 75 tiller.

If a different brand of engine is used, the removal/replacement procedures will be essentially the same.

Engine removal

To remove/replace the engine:

1. Disconnect and gr ound the spark plug wire.

2. Remove the two screws that secure the belt cover.

See Figure 4.1.

3. Swing the belt cover up and off of the tiller.

Engine

4. Set the throttle to the full throttle position.

5. Remove the throttle cable clamp using a flat headed

screwdriver.

6. Disconnect the throttle cable from the throttle lever.

See Figure 4.2.

17

Page 22

RT 75

Figure 4.3

reverse idler

pulley

Figure 4.4

Unhook spring

Belts pushed down

Figure 4.5

screws

7. Slide the forward drive belt off of the engine pulley.

8. Loosen the nut and bolt that secures the reverse

idler pulley to the idler bracket, using a pair of 7/16”

wrenches.

9. Slide the reverse belt past the belt guards a nd of f of

the idler pulley.

10. Unhook the reverse idler spring. See Figure 4.4.

See Figure 4.3.

11. Unhook the reverse cable Z-fitting from the reverse

12. Remove the four screws, two on each side, that

13. Remove the four engine mounting screws, using a

14. Lift the engine off of the tiller and place it in a safe

idler bracket.

secure the front bumper to the frame, using a 1/2”

wrench.

1/2” wrench.

work area.

NOTE: If replacing the engine, continue to the next

18

step.

Page 23

Engine

Figure 4.6

motor cover plate

reverse idler bracket

engine

pulley

Figure 4.7

Spot welds must face away from

the idler bracket

Figure 4.8

cable pulley

screw

bumper

cover

plate

15. Transfer the engine pulley, reverse idler bracket and

the motor cover plate to the new engine.

4.6.

NOTE: If the idler pulley was removed from the idler

bracket, it must be reassembled so that the spot

welds face away from the idler bracket to ensure

proper belt alignment.

See Figure 4.7.

See Figure

Engine Installation

16. Set the engine, with the motor cover plate installed,

on the tiller.

NOTE: The motor cover plate must sit between the cable

pulley bracket and the screw securing the cable

pulley bracket.

17. Tip the engine to the rear of the tiller and slide the

bumper between the engine and the frame.

18. Install the four engine mounting screws, using a 1/2”

wrench.

19. Follow steps 1 through 13 in the previous section in

reverse order.

20. Test run the tiller in a safe area before the tiller is

returned to service.

NOTE: The engine RPM should be set to 3500 RPMs for

proper operation.

See Figure 4.8.

19

Page 24

RT 75

20

Page 25

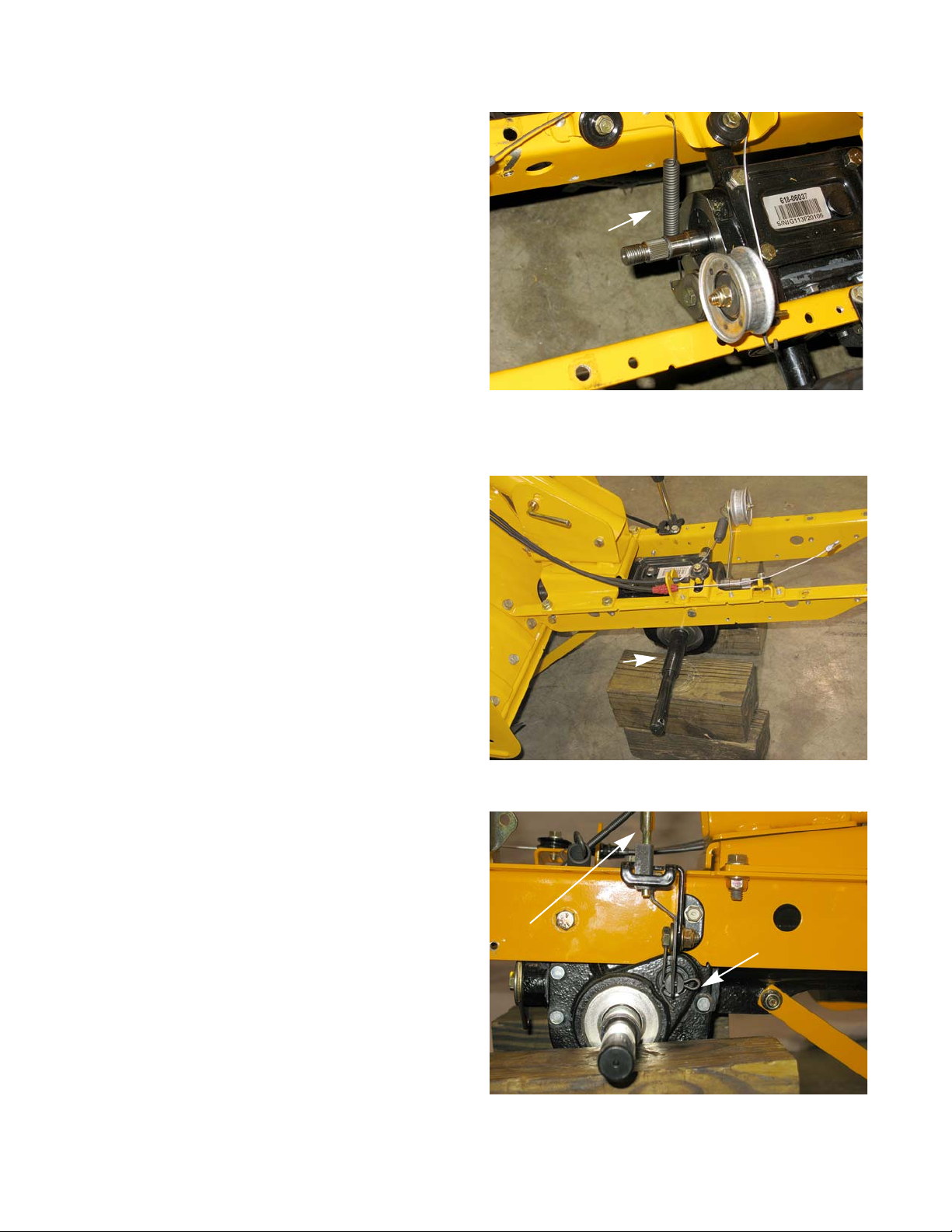

Transmission removal

Figure 5.1

Loosen screw and slide

cable off of the pulley

Figure 5.2

Unhook the cable

Transmission Removal

CHAPTER 5: TRANSMISSION REMOVAL

1. Remove the belts by following the procedures

described in Chapter 2: Belts.

2. Remove the engine by following the steps described

in Chapter 4: Engine Removal.

3. Loosen the forward drive cable pulley, using a 3/8”

wrench, and slide the cable off of the pulley.

See Figure 5.1.

4. Unhook the cable. See Figur e 5.2.

21

Page 26

RT 75

Figure 5.3

idler bracket

spring

Figure 5.4

Support the

wheel shafts with

wood blocks

Figure 5.5

cotter pin

Neutral lever

5. Unhook the idler bracket spring. See Figure 5.3.

6. Remove the wheels.

7. Support the wheel shafts with wood blocks.

See Figure 5.4.

NOTE: Any time the wheels are removed, or once a

year, the wheel shafts should be coated with antiseize or grease.

8. Remove and discard the cotter pin that holds the

neutral lever to the transmission shifter fork.

See Figure 5.5.

22

Page 27

Transmission Removal

Figure 5.6

Drag bar

Remove nut

and bolt

Figure 5.7

screws

handle mount nuts and bolts

Figure 5.8

Remove these screws

9. Disconnect the front of the drag bar, using a 5/8”

wrench and a 1/2” wrench.

10. Remove the four screws that hold the frame rails to

the transmission, using a 1/2” wrench.

See Figure 5.7.

See Figure 5.6.

11. Loosen, but dot remove, the handle mount nuts and

bolts.

12. Remove the two screws that hold the depth bar

bracket to the rear of the transmission, using a 1/2”

wrench.

See Figure 5.8.

23

Page 28

RT 75

Figure 5.9

Figure 5.10

Bow tie clip

Figure 5.11

Direction of rotation

Front of tiller

Curve of the tine

13. Lift the frame, handle bar and tine shield off as one

unit.

See Figure 5.9.

14. Remove the tines:

14a. Remove the bow tie clip and clevis pin.

See Figure 5.10.

14b. Slide the tines off of the shaft.

NOTE: Any time the tines are removed, or once a

year, the tine shafts should be coated with

anti-seize or grease.

NOTE: When installing the tines, make sure the

curve of the tine is facing the direction of

rotation.

See Figure 5.11.

24

Page 29

Transmission Removal

Figure 5.12

idler bracket

15. Remove the idler bracket, using a 1/2” wrench.

See Figure 5.12.

16. Install the transmission by following the previous

steps in reverse order.

17. Test run the tiller in a safe area before returning it to

service.

25

Page 30

RT 75

26

Page 31

Transmission Overhaul

Figure 6.1

Front

Transmission

Cover

Fill plug

Figure 6.2

Oil Seal

CHAPTER 6: TRANSMISSIO N OVERHAUL

The 460 series transmission is equipped with a neutral feature that will disengage the wheel shaft from the transmission. This allows the tiller to be pushed without the engine driving it. The neutral mechanism is a dog clutch that is

splined to the wheel shaft. When the neutral lever is moved to the engaged position, the dog clutch slides into the

worm gear, allowing the transmission to drive the wheel shaft. When the lever is moved to the neutral position, the

dog clutch slides out of the worm gear, allowing the wheel shaft to rotate freely.

Transmission disassembly

NOTE: The drive shaft and the wheel shaft cannot be removed from the transmission separately.

1. Remove the transmission from the tiller by following the steps described in Chapter 5: Transmission Removal.

2. Drain the transmission.

2a. Remove the four hex flange screws securing

the front transmission cover to the transmission

housing using a 1/2” wrench.

2b. Wedge a sharp 5-in-1 painters tool or putty

knife in between the cover and the transmission

housing.

See Figure 6.1.

2c. Pry the cover off.

2d. Turn the transmission over and drain the oil into

a suitable container.

2e. Allow all of the gear oil to drain from the trans-

mission.

NOTE: The front cover has a fill plug.

3. Secure the transmission in a soft jawed vise.

4. Clean the gasket fr om the front transmission housing

and cover, using a scraper.

5. Clean the rust and dirt off of the tine and wheel

shafts.

6. Remove the left and right tine wheel oil seals from

the transmission housing.

NOTE: Use of the Thexton seal removal tool kit #TWX-

4006 is the preferred method of removing the

seals.

For information on purchasing this tool kit contact:

Thexton Toolworx

1157 Valley Park Drive. Suite 150

Shakopee, MN 55379

800-328-6277

• Instructions on how to use this tool kit can be found in manual number 769-02093 available from MTD

Publications.

NOTE: Make certain the transmission oil seal bores are not damaged during removal.

27

Page 32

RT 75

Figure 6.3

Alignment pins

Side cover

Figure 6.4

Figure 6.5

Snap ring

Shift fork oil seal

Wheel shaft bearing

7. Remove the retaining ring that secures the right

wheel shaft bearing, using a pair of snap ring pliers.

8. Remove the eight screws that secure the side cover

to the transmission housing, using a 3/8” wrench.

See Figure 6.3.

NOTE: It is not necessary to remove the snap ring

and the left wheel shaft bearing. They will

come off with the side cover.

9. Gently pry the side cover off of the transmission.

See Figure 6.4.

NOTE: There are two alignment pins that go

through the side cover into the transmission

housing.

10. Push the wheel shaft to th e right, forcing the right

wheel shaft bearing out of the transmission housing.

NOTE: The bearing is a slip fit. It may take several

tries of pushing the wheel shaft to the right,

while wiggling it, to walk the bearing out of

the transmission housing.

11. Remove the bearing and washer from th e r igh t sid e

of the wheel shaft.

12. Remove the snap ring from the side cover.

13. Remove the wheel shaft bearing from the side

cover.

See Figure 6.5.

14. Remove the shift fork oil seal from the side cover.

28

Page 33

Transmission Overhaul

Figure 6.6

Rear transmission cover

Figure 6.7

Thexton seal removal tool

Figure 6.8

Snap ring

15. Remove the four hex flange screws holding the rear

transmission cover to the transmission housing,

using a 1/2” wrench.

16. Wedge a sharp 5-in-1 painters tool or putty knife in

between the cover and the transmission housing.

17. Pry the cover off.

18. Clean the gasket from the rear transmission housing

and cover.

NOTE: The rear cover does not have a fill plug.

19. Remove the tine shaft oil seals from the transm ission

housing .

See Figure 6.7.

See Figure 6.6.

20. Remove the snap rings that secure the tine shaft

bearings, using a pair of snap ring pliers.

See Figure 6.8.

21. Push the tine shaft to the right, forcing the right tine

shaft bearing out of the transmission housing.

NOTE: The bearing is a slip fit. If it is stuck, use a block of

wood and a large hammer.

NOTE: The washer will be damaged by the Hi-Pro key.

22. Remove the bearing and washer from the right side

of the tine shaft.

23. Slide the tine shaft back into the housing until the HiPro key contacts the tine shaft worm gear.

24. Rotate the tine shaft until the Hi-Pro key slides into

the worm gear keyway.

29

Page 34

RT 75

Figure 6.9

Rear Bearing Cap

Place punch

here

Figure 6.10

Shim

Bearing cap

25. Drive the tine shaft to the left, forcing the left tine shaft bearing out of the transmission housing.

26. If the bearing is stuck, use a block of wood and a large hammer.

NOTE: The washer will be damaged by the Hi-Pro key.

27. Remove the tine shaft.

28. Remove the remaining lower hex flange screw

securing the rear bearing cap, using a 1/2” wrench.

See Figure 6.9.

NOTE: The top two screws were removed with the

depth bar bracket.

29. Using a brass punch and hammer, rotate the rear

bearing cap to break the seal.

30. Once the rear bearing cap is rotated enough to

allow access to one of the corners, use the bras s

punch to drive the cover off.

See Figure 6.9.

31. Clean the sealant fr om the rear of the transmission

32. Remove the rear bearing cap shim(s).

housing and the bearing cap.

See Figure 6.10.

30

Page 35

Transmission Overhaul

Figure 6.11

Figure 6.12

Rear bearing

Front bearing

Figure 6.13

33. Measure the overall thickness of the rear bearing

shims using a dial caliper.

34. Record the measurement for future reference.

35. Inspect the rear tapered roller bearing assembly for

damage or wear.

See Figure 6.11.

36. Thoroughly clean the exposed portion (front) of the

drive shaft.

37. Slowly push the drive shaft assembly rearward and

out of the transmission assembly.

NOTE: The front tapered roller bearing should come out

with the drive shaft. If it did not, remove it from the

transmission housing.

NOTE: Inspect the front tapered roller bearin g for we ar or

damage.

• Inspect the drive shaft.

• Check the operation of the one way clutch.

38. Remove the tine shaft worm gear.

39. Remove the wheel shaft, worm gear, and neutral

assembly from the left side of the transmission.

Figure 6.13.

See

31

Page 36

RT 75

Figure 6.14

Shifter fork

Clutch collar

Spring

Washer

Snap ring

Worm gear

Snap ring

Snap ring

Figure 6.15

Front drive shaft oil seal

40. Slide the shifter fork out of the dog clutch collar.

41. Remove the snap ring that retains the spring and

washer, using a pair of snap ring pliers.

42. Slide the washer, spring, and the dog clutch collar

off of the wheel shaft.

43. Remove the two snap rings that secure the worm

gear to the wheel shaft.

44. Remove the front drive shaft oil seal, using a flat

blade screwdriver.

45. Remove the front inter nal snap ring, using snap ring

pliers.

46. Remove the front tapered roller bearing race by

lightly tapping on the perimeter, using a blunt ended

punch and a hammer or a bearing driver.

47. The race should be ge ntly pushed into the center of

the transmission housing for ease of removal.

48. Clean and inspect all of the parts for signs of wear

or damage.

32

Page 37

Trans mission assembly

Figure 6.16

Dial Caliper

Washers

Figure 6.17

Bearing race

Snap ring

Figure 6.18

Worm gear

Transmission Overhaul

1. Thoroughly clean the entire transmission housing.

2. Clamp the transmission housing in a soft jawed vice.

3. Make certain all the drive shaft components are

accounted for.

4. Locate both hex flang e screws that were securing the

hood bracket to the transmission assembly.

5. Locate two sets of flat washers that would equal

approximately 0.120” in thickness (the thickness of

the hood bracket).

NOTE: Measure the thickness of both washers using a

dial caliper.

See Figure 6.16.

6. Install the front snap r ing using snap ring pliers.

7. Lubricate and install the front tapered roller bearing

race into the front of the transmission housing. It

should seat up against the front retaining ring.

Figure 6.17.

NOTE: The front race is installed from inside the transmis-

sion housing.

8. Install a new front oil seal.

9. Place the tine shaft worm gear in the transmission

housing.

See Figure 6.18.

See

33

Page 38

RT 75

Figure 6.19

Snap ring grooves

Dog clutch side

Worm gear bearing surface

Figure 6.20

Dog clutch

Figure 6.21

Dogs

Dog clutch collar

10. Assemble the wh eel sh af t and the neutr al assembly.

10a. In the middle of the wheel shaft there is a sec-

tion that is splined. On one side of the splines

there are two snap ring grooves. On that side,

install a snap ring in the grove closest to the

splines.

10b. Slide the worm gear onto the wheel shaft so

that it rests against the snap ring, on the side

opposite of the splines.

See Figure 6.19.

NOTE: The dog clutch side of the worm gear must

face the splines when it is installed.

See Figure 6.20.

10c. Install a snap ring in the groove next to the

worm gear.

10d. Slide the dog clutch collar onto the spline side

of the wheel shaft, with the dogs facing the

worm gear.

See Figure 6.21.

34

Page 39

Transmission Overhaul

Figure 6.22

Spring

Washer

Clutch collar

Snap ring

Figure 6.23

Shifter fork

Figure 6.24

shifter fork oil seal

10e. Slide the spring onto the wheel shaft so that it

is next to the clutch collar.

10f. Slide the washer onto the wheel shaft so that it

is against the spring.

10g. Install the third snap ring while compressing the

spring and washer.

1 1. Slide the shift fork into the groove in the clutch collar .

See Figure 6.23.

See Figure 6.22.

12. Slide the wheel shaft assembly into the transmission

housing.

NOTE: Do not install the wheel shaft bearings at this time.

13. Install the tapered roller bearings onto both ends of

the drive shaft.

14. Slide the drive shaft into the transmission housing

from the rear opening.

15. Apply a 3/16” (4.75mm) bead of Threebond® 1 217H,

Permatex

on the side cover..

16. Install the side cover. Tighten the screws to a torque

of 110 - 125 in lbs (12 - 14 Nm).

17. Install the left side wheel shaft bearing.

® Ultra Black #82180 or equivalent sealant

18. Install the snap ring that retains the lef t wheel bearing

using a pair of snap ring pliers.

19. Install the right wheel shaft bearing.

20. Install the snap ring that retains the right wheel bearing using a pair of snap ring pliers.

21. Install a new shift fork oil seal. See Figure 6.24.

35

Page 40

RT 75

Figure 6.25

Snap ring

Figure 6.26

bearing race

22. Install the tine shaft. It will pass through the bearing

bore, through the tine shaft worm gear and out the

other side of the transmission.

23. Slide the Hi-Pro key into the tine shaft worm gear.

24. On each side, slide the washer over the tine shaft.

25. Insert the tine shaft bearings over the tine shaft until

they pass the snap ring grooves in the transmission

housing.

NOTE: A bearing installation tool can be made

using a 1” I.D. PVC pipe by 7” long.

26. Install both of the snap rings that retain the tine

shaft bearing in the transmission housing using a

pair of snap ring pliers.

27. Slide th e drive sha ft assembly into the front tapered

roller bearing race.

See Figure 6.25.

28. Position the re ar bea rin g race over th e r ear tapered

roller bearing.

29. Set the rear bearing cap in position.

NOTE: Do not put sealant on the bearing cap.

30. Fasten the rear bearing cap to the transmission

housing with the hex flange screws, using a 1/2”

wrench.

NOTE: The washers from step five go on the top

31. Tighten the hex screws to a torque of 100 in lbs. (1 1

Nm).

NOTE: The drive shaft rides in a pair of tape re d ro ller bea rin gs. Tapered roller bearings have low fr ictio n, a lot

See Figure 6.26.

two screws.

of surface area and they bear thrust loads very well. The worm drive system used in this tiller is very

sturdy, but it generates high thrust loads on the drive shaft. If the end-play is too tight, the bearings will

overheat as they are jammed into their races. When the end play is too loose, the bearings will move

around in their races. This will cause damage to the rollers, the cages, and will put dimples in the

races.

36

Page 41

Transmission Overhaul

Figure 6.27

Drive Shaft

Dial Indicator

Magnetic Base

Figure 6.28

Wheel shaft

Tine shaft

32. Shim the rear drive shaft bearing to set the drive

shaft end play to 0.005” - 0.015” (0.13 -. 038 mm).

32a. Set up a dial indicator at the front of the drive

shaft.

See Figure 6.27.

32b. Rotate the tine shaft towards the rear of the

transmission to seat the drive shaft into the rear

bearing cap.

NOTE: A screwdrivers or punch can be inserted into the

shaft for leverage to rotate it.

32c. Zero the dial indicator when the drive shaft is

seated.

32d. Rotate the tine shaft towards the front of the

transmission.

32e. Read the dial indicator.

NOTE: This is the end play.

32f. Subtract 0.010” (0.38 mm) from the total shaft

end play measurement. This is the thickness of

the stack of shims that should be used between

the rear bearing cap and the bearing race.

32g. Remove the rear bearing cap and install the stack of shims described in step 32f.

32h. Fasten the rear bearing cap to the tr ansmission housing with the hex flange screws, using a 1/2” wrench.

32i. Tighten the hex screws to a torque of 100 in lbs (11 Nm).

32j. Repeat step 32a. through step 32e. The end play should be 0.000 to 0.010 at this point.

NOTE: The drive shaft needs to be over shimmed by 0.005” (0.13 mm) to make up for the sealant that will be

added to the bearing end cap.

See Figure 6.28.

33. Apply a 3/16” (4.75mm) bead of Threebond® 1217H, Permatex® Ultra Black #82180 or equivalent sealant

on the rear bearing cap.

37

Page 42

RT 75

34. Secure the rear bearing cap to the transmission assembly with the hex flange screws with the washers used

earlier, using a 1/2” wrench.

NOTE: Tighten the hex screws to a torque of 100 in lbs (11 Nm).

NOTE: Leave the two top screws in place until the sealant has cured. Then they should be removed.

35. Verify the end pla y is bet we e n 0.005” - 0.015” by repeating step 32a. through step 32e.

36. Install both of the wheel shaft seals.

37. Install both of the tine shaft seals.

38. Fill the transmission with 30 oz (0.9 L) of 85W-140 gear lube.

39. Install the transmission covers using new gaskets.

40. Install the transmission in the tiller.

41. Test run the tiller in a safe area before returning it to service.

38

Page 43

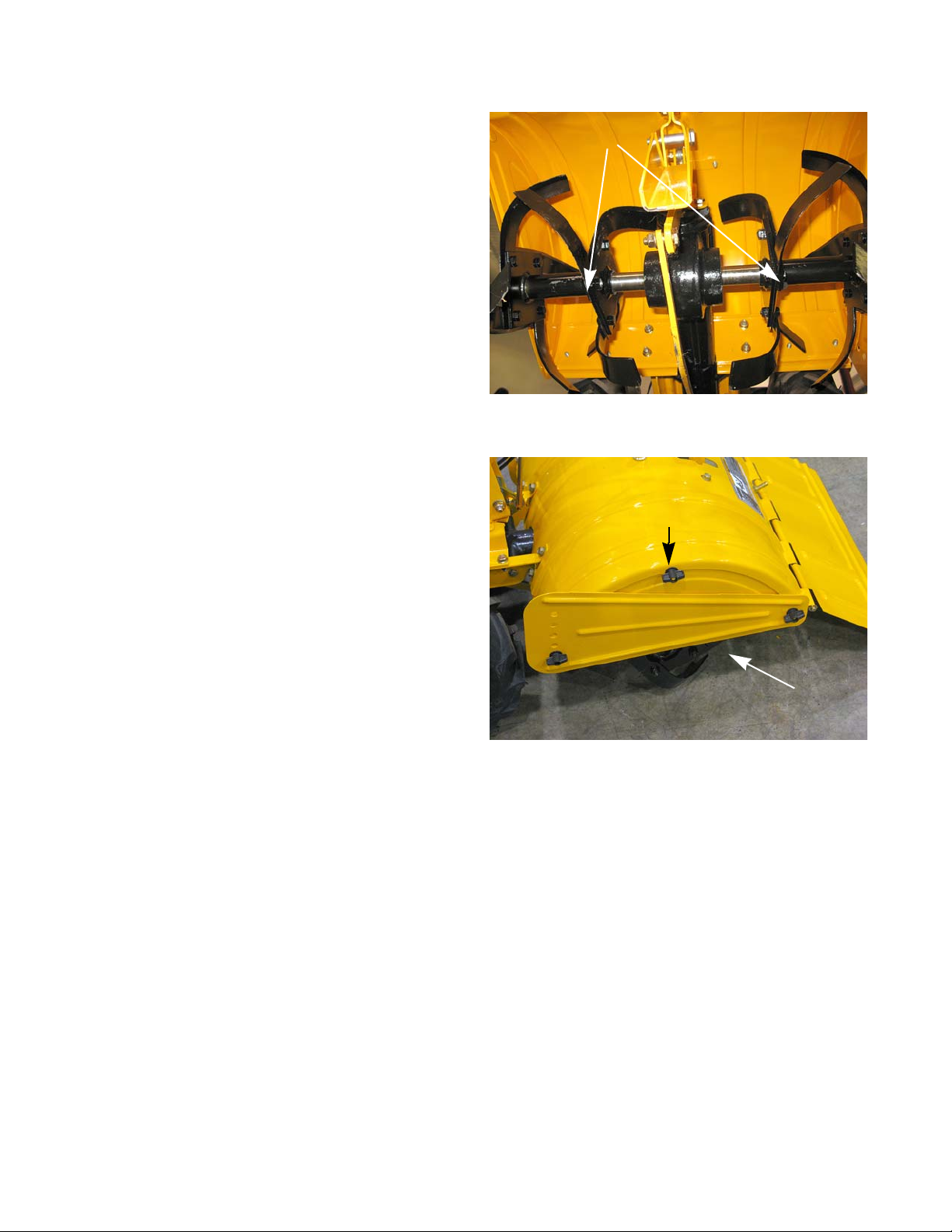

Tines

Figure 7.1

Euro tines

Figure 7.2

New

Worn

Sharp point

CHAPTER 7: TINES

The RT 75 tiller is a counter rotating tiller equipped with

Euro tines. If the tines are properly installed, the tines will

cut into the ground and break up the soil. If the tines are

installed backwards, the tines will “hammer” the ground,

making the machine hard to control and will not till the soil.

See Figure 7.1.

Tines

As the tines dig through the ground, the grin ding action

of the soil will put a sharp edge on the tines. Once the tine

has been ground to a sharp point, it must be replaced.

See Figure 7.2.

39

Page 44

RT 75

Figure 7.3

Figure 7.4

bow tie clip

Clevis pin

Figure 7.5

1/2” wrenches

1. Remove the tine hood end cover and the side

shield.

See Figure 7.3.

2. Remove the tine assemblies by removing the clevis

pin and bow tie clip that secures the tine assemblies

to the tine shaft on the transmission.

See Figure 7.4.

NOTE: Replace the nut and bolt if they show signs

of wear or damage.

3. Slide the assemblies off of the tine shaft.

NOTE: If the hub assemblies are frozen to the tine

shaft, a hub puller can be used to remove

them.

4. Remove the old tines from the tine assembly. with a

pair of 1/2” wrenches.

See Figure 7.5.

40

Page 45

Tines

Left Hand Tine

Right Hand Tine

Hold with the sharp edge facing you

Figure 7.6

Left Hand Tine

Right Hand Tine

Hold with the sharp edge facing you

Left Hand Tine

Right Hand Tine

Hold with the sharp edge facing you

Figure 7.7

clevis pin hole

,EFTHANDTINEASSEMBLY

Figure 7.8

Shoulder

end

NOTE: When installing the tines, it is important that the

correct tines are used and they are installed in the

proper orientation.

5. To determine which tine is right or left:

5a. Hold the tines with the cutting edge towards

you.

See Figure 7.6.

5b. If the tine curves to the left, it is a left handed

tine.

5c. If the tine curves to the right, it is a right handed

tine.

NOTE: The right and left tine holders are the same part

number.

NOTE: The end of the tine holder with the clevis pin hole

slides onto the tine shaft first.

6. Install two left hand tines and two right hand tines to

the flange closest to the shoulder end.

See Figure 7.8.

7. Install four right hand tines on the outside flange of

the left hand tine assembly.

8. Install fou r left ha nd tines on the out side flange of the

right hand tine assembly.

See Figure 7.7.

NOTE: The inside of the curve of the tine should face the

center of the flange.

NOTE: Tighten the nuts and bolts to a torque of 35 ft lbs

(47 Nm)

41

Page 46

RT 75

Figure 7.9

clevis pin

Figure 7.10

Side shield

center wing nut

9. Apply anti-seize to the tine shaft.

10. Installing the assembly.

11. When correctly installed:

• The end of the tine holder with the clevis pin

hole should face towards the transmission.

• The outside tines should curve inward

• The tines should be bolted to the outboard side

of the plate on the tine holder. See Figure 7.9.

12. Insert the tine hood end panel. Secure it with the

center wing nut.

13. Install the side shield. Secure it with the remaining

wing nuts.

14. Test the tiller in a safe area before returning it to

service.

42

Page 47

Handle bar

Figure 8.1

throttle lever

Figure 8.2

swivel rod knob

CHAPTER 8: SWIVEL HANDLE

To remove/replace the handle bar:

1. Disconnect the forward and reverse cables from the

handle bar , by following the procedures described in

Chapter 3: Cables.

2. Remove the nut and bolt that secures the throttle

lever to the handle bar, using a pair of 7/16”

wrenches.

See Figure 8.1.

Swivel Handle

3. Unthread the swivel ro d knob. See Figure 8.2.

43

Page 48

RT 75

Figure 8.3

cable ties

Figure 8.4

inner cotter pin

outer cotter pin

washer

Figure 8.5

handle adjustment crank

handle mounting bolt

4. Remove and discard both of the cable ties from the

handle bar.

See Figure 8.3.

5. Remove and discard the outer cotter pin that

secures the swivel rod to the swivel latch.

ure 8.4.

NOTE: Do not remove the inner cotter pin.

6. Remove the swivel rod and washer.

7. Remove the handle adjustment crank. See Figure

8.5.

See Fig-

44

Page 49

Swivel Handle

Figure 8.6

nut retension bracket

NOTE: There is a nut retension bracket on the left side of

the handle bar swivel mount. When the handle

mounting nut and bolt is removed, the bracket and

the upper nut will fall off.

8. Remove the handle mounting nut and bolt.

9. Remove the handle bar from the machine.

10. If replacing the handle bar:

10a. Remove the forward drive bail.

10b. Remove the reverse lever.

10c. Remove the front cover and swivel rod bracket.

11. Install the handle bar by following the previous steps

in reverse order.

12. Test run the unit in a safe area before returning it to

service.

See Figure 8.6.

45

Page 50

RT 75

Figure 8.7

upper jam lock nut

Figure 8.8

flat washer

Figure 8.9

lower nut

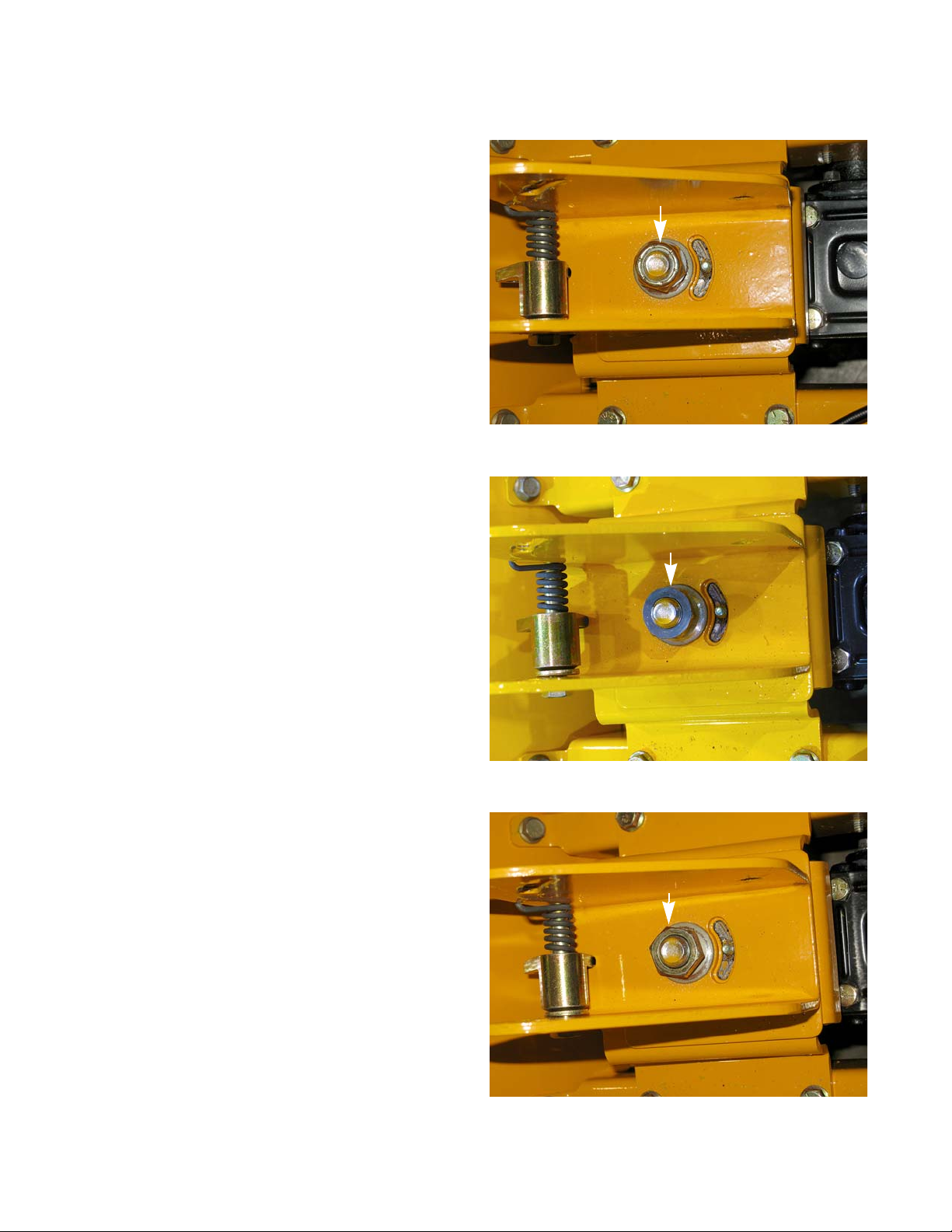

Swivel Bracket

To rebuild the swivel assembly:

1. Remove the handle bar assembly, by following the

procedures described in the previous section of this

chapter.

NOTE: It is advisable to rebuild the swivel assembly

on the machine. Having the lower bracket

mounted to the frame provides stability while

torquing the lower nut.

2. Remove the upper jam lock nut from the swivel

assembly, using a 15/16” wrench.

3. Remove the flat washer. See Figure 8.8.

See Figure 8.7.

4. Remove the lower nut, using a 15/16” wrench. See

Figure 8.9.

46

Page 51

Swivel Handle

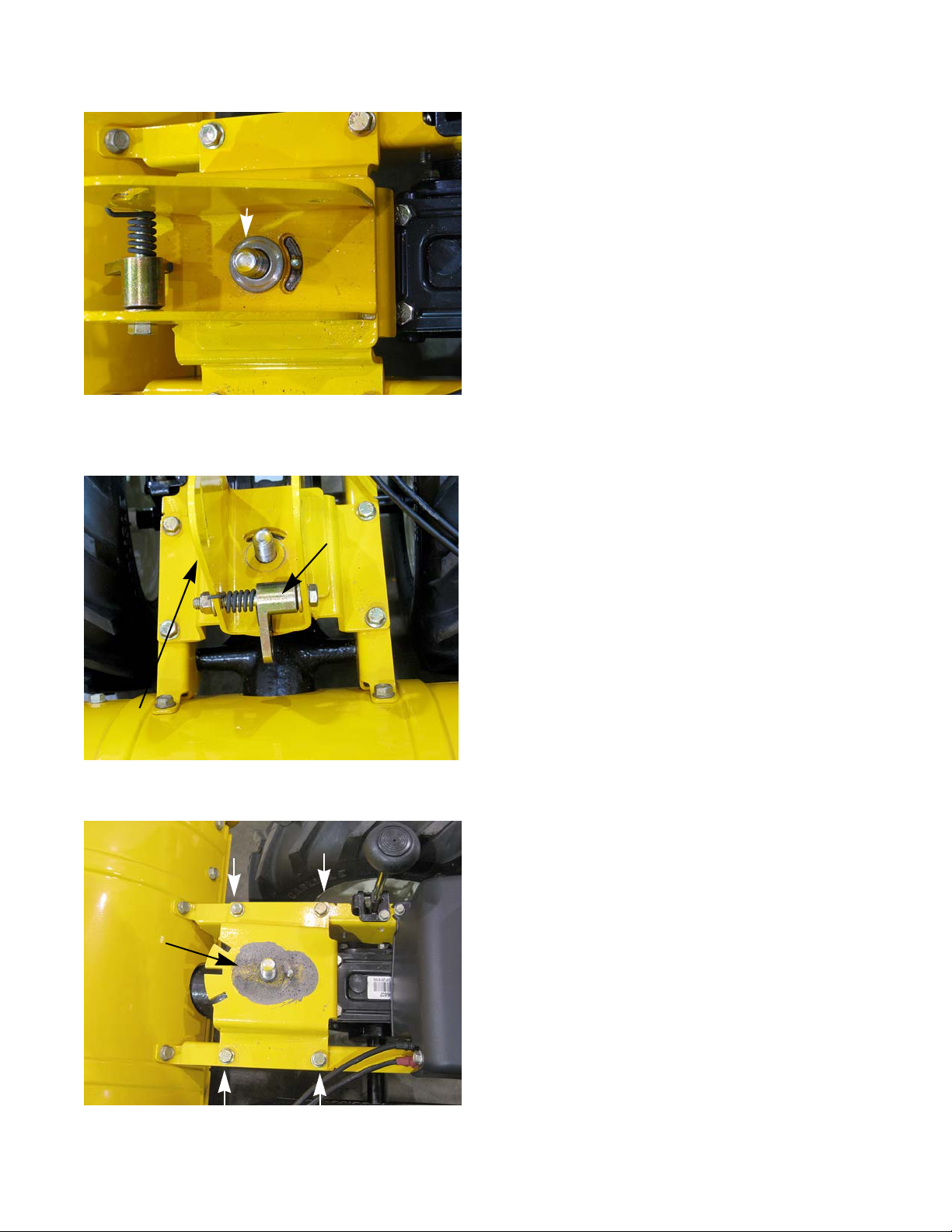

Figure 8.10

Belleville washer

Figure 8.11

swivel latch

upper swivel bracket

Figure 8.12

anti-seize

5. Remove the Belleville washer. See Figure 8.10.

6. Remove the nut and bolt that the swivel latch and

spring pivot on, using a pair of 9/16” wrenches.

Figure 8.11.

See

7. Remove the swivel latch and spring.

8. Lift the upper swivel latch bracket off of the machine.

9. If the lower bracke t is dama ged or worn, r emove and

replace it by removing the four nuts and bolts that

hold it down, using a pair of 1/2” wrenches.

ure 8.12.

To reassemble the swivel bracket assembly:

10. If removed, install the lower bracket assembly.

11. Apply a generous coating of anti-seize compound to

the lower bracket assembly where the upper and

lower brackets make contact.

See Fig-

47

Page 52

RT 75

Figure 8.13

Torque to

240 - 270 in lbs

Belleville

washer

locking jam nut

12. Install the upper swivel bracket.

13. Install the swivel latch and spring.

14. Install the Belleville washer.

15. Inst all the lo wer nu t an d tig hten it to a torque of 240

- 270 in lbs (27 - 31 Nm).

16. Inst all the flat washer.

17. Install the upper locking jam nut.

18. Install the handle bar by following the procedures

described in the previous section of this chapter.

19. Test run the unit in a safe area before returning it to

service.

See Figure 8.13.

48

Page 53

Page 54

MTD Products Inc - Product Training and Education Department

FORM NUMBER - 769-09590-00

12/2013

Loading...

Loading...