Page 1

READ ALL INSTRUCTIONS BEFORE OPERATING

SAFETY BASICS

• Carefully read and understand the operator's manual of the battery that powers this unit.

• Be thoroughly familiar with the controls and the proper use of the unit. Know how to stop the unit and

disengage the controls quickly.

• Stay alert! Do not operate the unit when tired, ill or under the influence of alcohol, drugs or medication.

• Never allow children to operate the unit. Never allow adults to operate the unit without proper instruction.

• Do not allow the unit to be used as a toy.

• Make sure that all guards and safety attachments are properly installed before operating the unit.

• Keep these instructions. Refer to them often and use them to instruct other users. If loaning someone this

unit, also loan them these instructions.

PRELIMINARY SAFETY PRECAUTIONS

• DO NOT rely exclusively upon the safety devices built into the unit.

• Keep bystanders, especially children and pets, at least 50 feet (15 m) away. If anyone enters the

work area, stop the unit!

• Keep the work area clean. Cluttered areas invite injuries. Do not start cutting until the work area is clear

and free from obstructions, there is secure footing and a planned retreat path from falling branches.

• Always wear appropriate eye and ear protection when operating this unit. Wear safety goggles, or

safety glasses with side shields, that are marked as meeting ANSI Z87.1-1989 standards. Failure to

do so could result in serious eye injury caused by thrown or falling objects. If the operation is dusty,

wear a face mask or dust mask. When operating the unit over the head, use a hardhat or other type

of safety helmet.

• Dress appropriately, wear heavy, snug-fitting clothes (long pants and a long sleeve shirt), non-slip

protective gloves and steel-toed safety boots. Do not wear loose clothing, jewelry, short pants,

sandals or go barefoot. Secure hair above shoulder level to prevent entanglement in moving parts.

• Only use the unit in daylight or good artificial light.

• Only use the unit for the purpose intended.

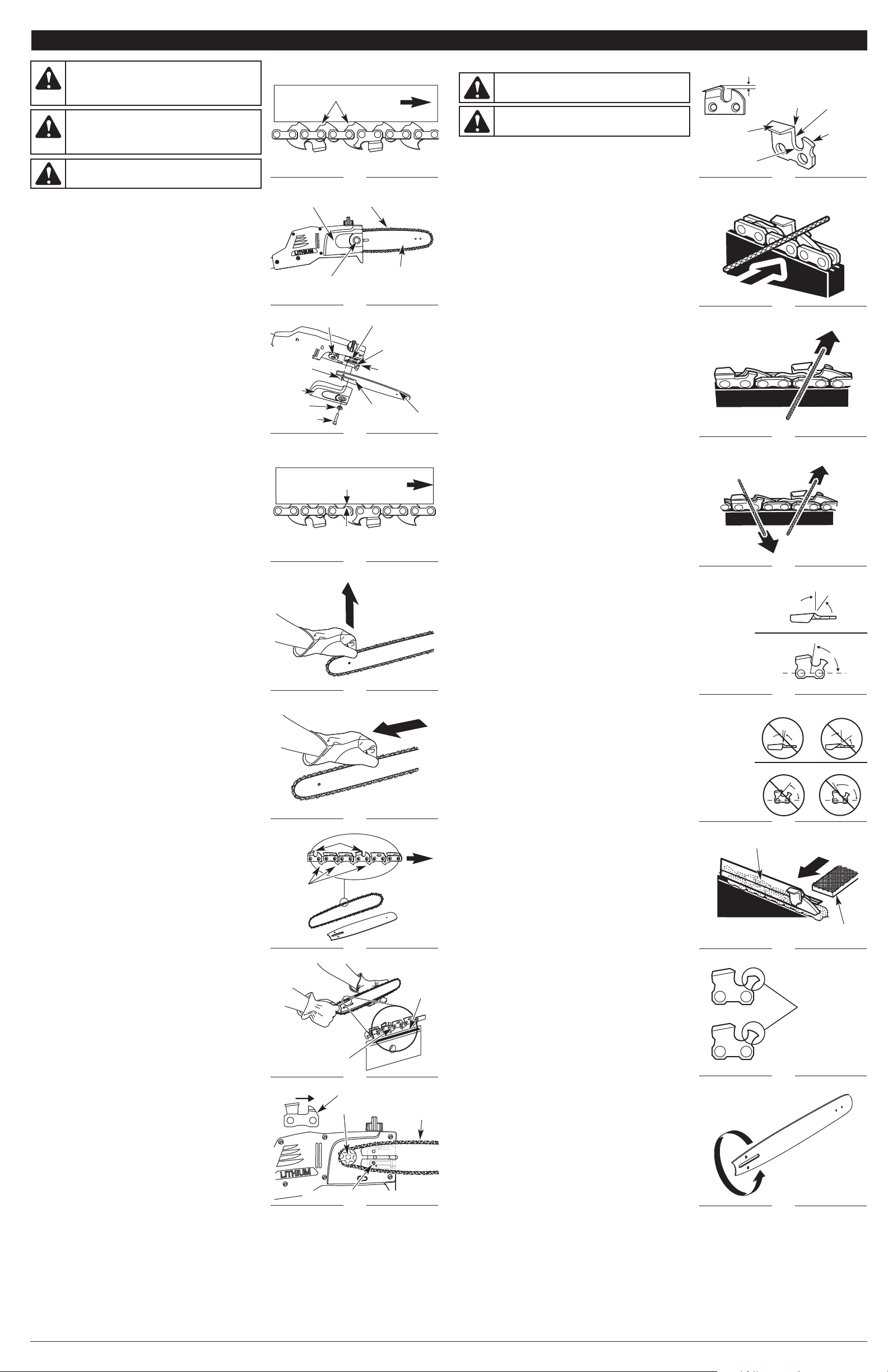

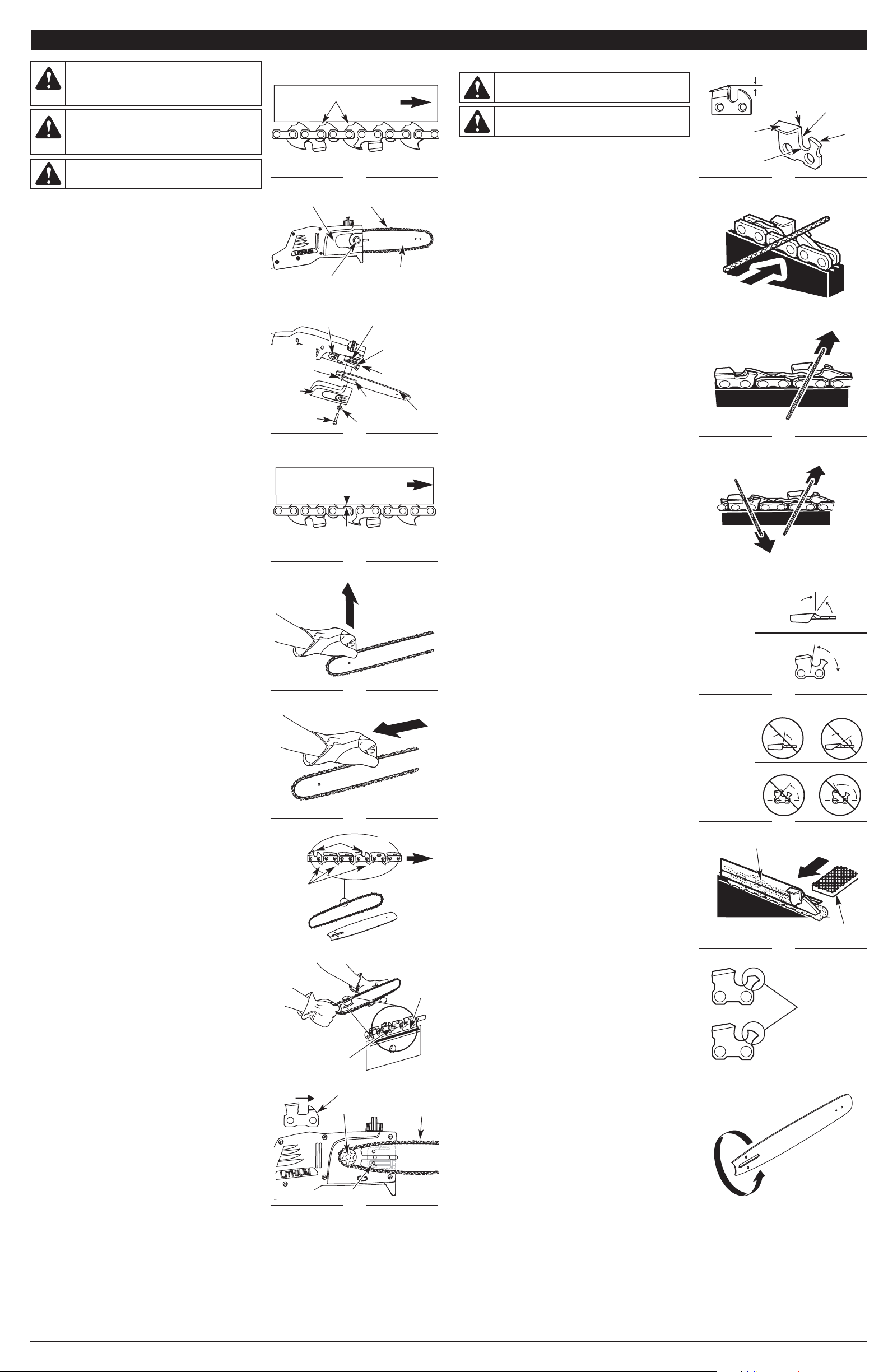

UNDERSTANDING KICKBACK

• Rotational Kickback can happen when the upper tip of

the guide bar contacts an object while the chain is

moving (Fig. 1 & 2). This can cause the chain to dig into

the object and momentarily stop moving. The guide bar

is then kicked up and back toward the operator in a

lightning-fast reverse reaction.

• Pinch Kickback can happen when the wood on either

side of a cut closes in and pinches the moving saw chain

along the top of the guide bar. This can cause the chain

to instantly stop. The chain force is then reversed,

causing the saw to move in the opposite direction,

sending the saw straight back toward the operator.

• Pull-In can happen when the moving chain on the

bottom of the guide bar hits a foreign object inside

the wood. This can cause the chain to suddenly stop.

The saw is then pulled forward and away from the

operator, which could potentially result in the loss of

control of the saw.

KICKBACK SAFETY PRECAUTIONS

• DO NOT over reach.

• DO NOT make cuts with the tip of the guide bar.

• DO NOT let the tip of the guide bar contact any object,

such as a log, branch, ground or other obstruction.

Remove or avoid any obstructions that might impact the

tip of the guide bar while cutting.

• DO NOT cut more than one branch at a time.

• DO NOT twist the saw when removing the guide bar from an undercut.

• Never start the saw when the guide bar is inside an existing cut. Be extremely careful when re-entering

a cut.

• Grip the unit firmly with both hands when the motor is running. Keep the right hand on the handle and the

left hand on the pole shaft at a position that provides adequate support. Use a firm grip with thumbs and

fingers encircling the handle and pole shaft. Stand slightly to the left of the unit to avoid being in the direct

line of the saw chain. Follow all instructions in the Operating Instructions section.

• Keep proper footing and balance at all times.

• When starting the unit, always allow the motor to achieve full speed before beginning a cut. Fully squeeze

the switch trigger and maintain a steady cutting speed. Slower speeds increase the chance of kickback.

Keep the saw housing pressed firmly against the wood.

• Watch for shifting logs, branches, or other objects that might pinch, or fall onto, the chain while cutting.

769-06477 P02 06/11

Operator’s Manual

20 Volt Lithium-Ion

Battery-Powered Pole Saw

PS59L

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Starting and Stopping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED FOR

WARRANTY SERVICE.

For assistance regarding the assembly, controls, operation or maintenance of the unit, please call the

Customer Support Department: 1-877-282-8684 (U.S.) or 1-800-668-1238 (Canada).

Additional information about the unit can be found on our website: www.cubcadet.com (U.S.) or

www.cubcadet.ca (Canada).

Please call the Customer Support Department for replacement parts. When servicing, use only identical

replacement parts.

SAFETY INFORMATION

SAVE THESE INSTRUCTIONS

All information, illustrations and specifications in this manual are based on the latest product information

available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2011 MTD SOUTHWEST INC, All Rights Reserved.

SERVICE INFORMATION

Use 20V Lithium-Ion Battery A59 LBTY (sold separately)

Use 20V Lithium-Ion Battery Charger A59LCHGR (sold separately)

• IMPORTANT SAFETY INSTRUCTIONS •

WARNING:Please read the entire operator’s manual carefully before

attempting to assemble, operate or maintain the unit. Follow all safety instructions. Failure

to do so can result in property damage or serious injury to yourself and/or others.

DANGER:

Kickback may occur when the nose or tip of the guide bar touches an

object, or when the wood closes in and pinches the saw chain in the cut. In some cases, tip contact

may cause a lightening-fast reverse action, kicking the guide bar rapidly back towards the operator.

Pinching the saw chain along the top of the guide bar may push the guide bar rapidly back towards

the operator. Either of these reactions may cause a loss of control over the saw, which could result in

serious injury to the user. Contact with foreign objects within the wood can also induce a loss of chain

saw control.

Fig. 2

Kickback Danger Zone

Fig. 1

Rotational

Kickback

CALIFORNIA PROPOSITION 65

WARNING:Battery posts, terminals and certain finished components contain

lead, lead compounds and chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm. Wash hands after handling.

DANGER:Signals an EXTREME hazard.

Failure to obey a safety DANGER signal WILL result in serious injury or death to yourself or

to others.

WARNING:

Signals a SERIOUS hazard.

Failure to obey a safety WARNING signal CAN result in serious injury to yourself or to others.

CAUTION:

Signals a MODERATE hazard.

Failure to obey a safety CAUTION signal MAY result in property damage or injury to

yourself or to others.

IMPORTANT! Signals special mechanical information.

NOTE: Signals additional important general information.

SYMBOL MEANING

• SAFETY ALERT SYMBOLS •

Safety alert symbols are used to draw your attention to possible dangers. These symbols, and their

explanations, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures. These safety instructions are not meant to cover every

possible condition that may occur. If questions arise, please call the Customer Support

Department at 1-877-282-8684 (U.S.) or 1-800-668-1238 (Canada).

Page 2

SAFETY INFORMATION

2

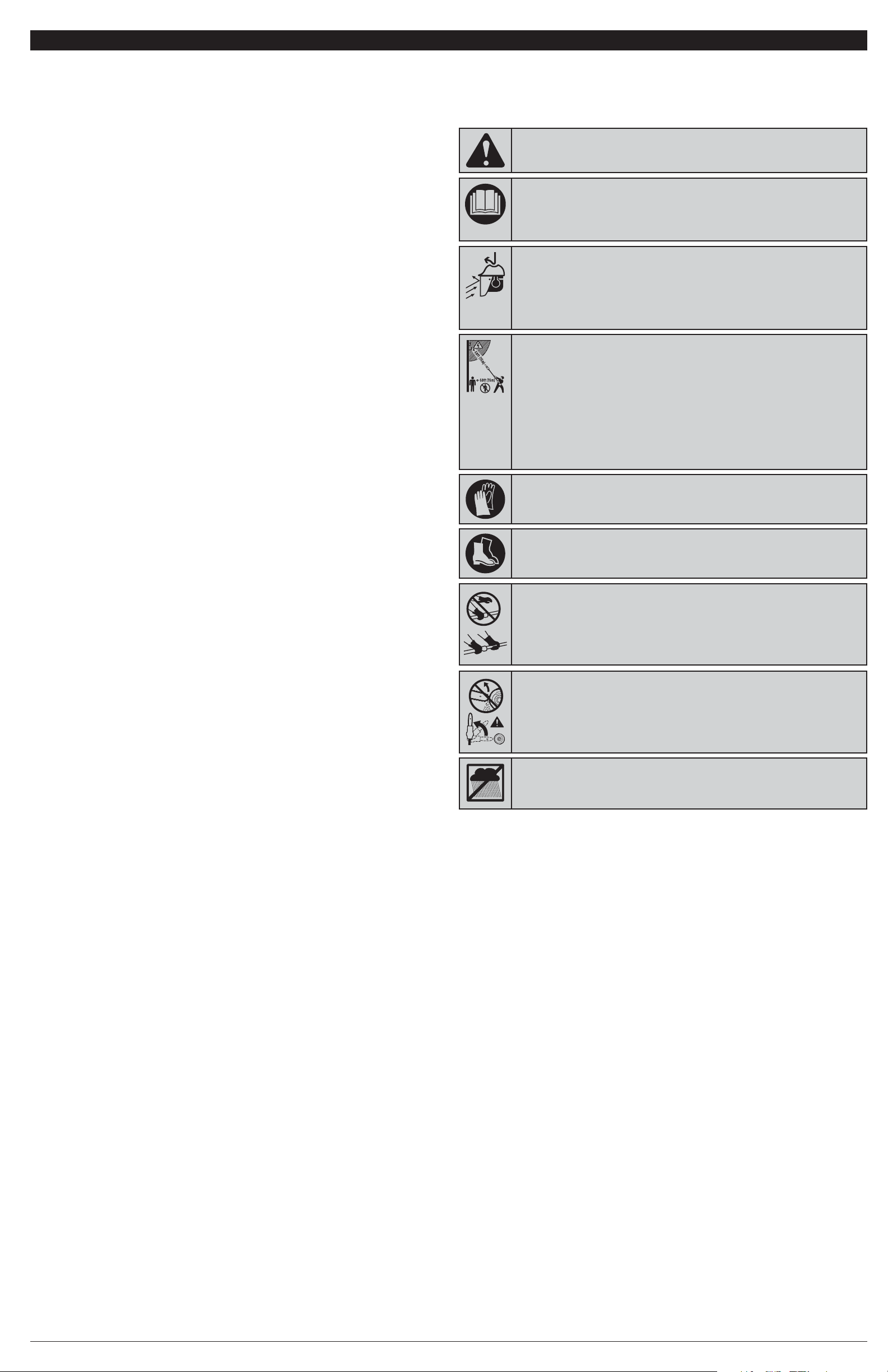

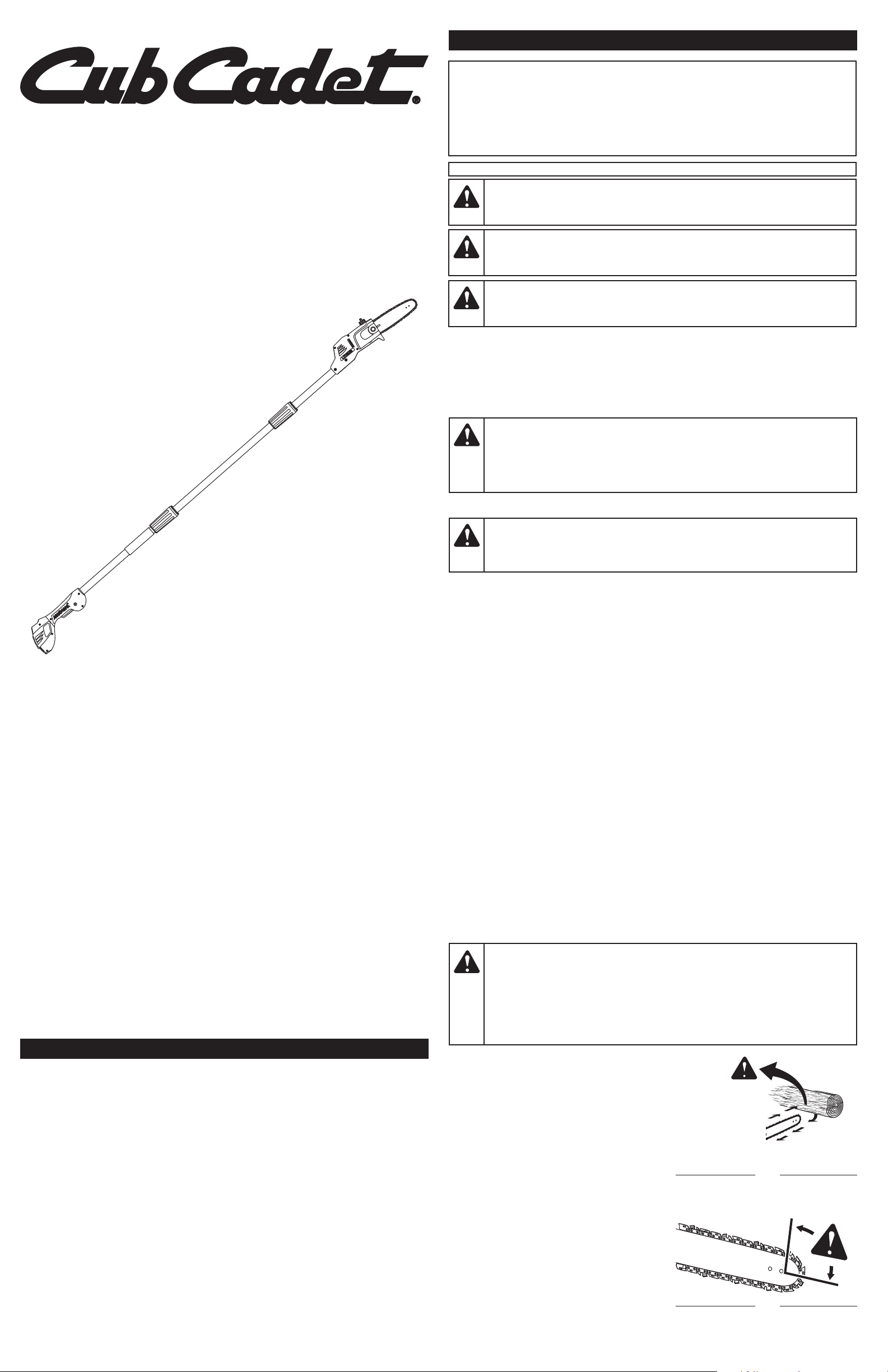

• SAFETY AND INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that

may appear on this product. Read the operator's manual for complete safety, assembly,

operating, maintenance and repair information.

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other

symbols or pictographs.

• READ OPERATOR'S MANUAL

WARNING:R

ead the operator’s manual(s) and follow all warnings

and safety instructions. Failure to do so can result in serious injury to the operator

and/or bystanders.

• WEAR HEAD, EYE AND HEARING PROTECTION

WARNING:Thrown objects and loud noise can cause severe eye

injury and hearing loss. Wear eye protection meeting ANSI Z87.1-1989

standards and ear protection when operating this unit. Wear head protection

when operating this unit; falling objects can cause severe head injury. Use a

full face shield when needed.

SYMBOL MEANING

• WEAR SAFETY FOOTWEAR

Wear non-slip safety footwear when using this equipment.

•

WEAR SAFETY GLOVES

Wear non-slip, heavy-duty protective gloves when handling the unit.

• DO NOT USE IN THE RAIN

WARNING:Avoid dangerous environments. Never operate your

unit in the rain, or in damp or wet conditions. Moisture is a shock hazard.

• KICKBACK WARNING

Contact of the guide bar tip with any object should be avoided. Tip contact

may cause the guide bar to move suddenly upward and backward, which

may cause serious injury.

• KEEP BYSTANDERS AWAY

WARNING:Keep all bystanders, especially children and pets, at

least 50 feet (15 m) from the operating area. If anyone enters the work area, stop

the unit!

• POWER LINES CAN CAUSE SEVERE INJURY

WARNING:Do not operate this unit near power lines. Contact

with a power line may cause serious injury or damage to the unit. Maintain a

clearance of at least 50 feet (15 m) between the pole saw (including any

branches it is contacting) and any electrical line.

• If using wedges, only use wedges made of plastic or wood. Do not use metal to hold a cut open.

• Follow the manufacturer’s sharpening and maintenance instructions for the saw chain.

• Use only replacement bars and chains specified by the manufacturer or the equivalent.

• Use devices, such as low-kickback chains, guide bar nose guards, chain brakes and special guide bars,

which reduce the risks associated with kickback. There are no other replacement components for

achieving kickback protection in accordance with CSA Z62.3.

•

Low-kickback saw chain is chain that has met the kickback performance requirements of ANSI B175.1-1991

and is in accordance with CSA Z62.3. Do not use other replacement chain unless it has met these

requirements for the specific model. As saw chains are sharpened, some of the low kickback qualities are

lost and extra caution should be used.

OTHER SAFETY PRECAUTIONS

• DO NOT operate the unit with one hand! Serious injury to the operator, helpers or bystanders may result

from one-handed operation. This unit is intended for two-handed use.

• DO NOT handle the unit with wet hands.

• DO NOT

operate a

pole

saw in a tree or on a ladder unless specifically trained to do so.

• DO NOT expose the unit to rain. Do not use the unit in damp or wet locations or conditions.

• DO NOT

operate the unit on wet surfaces.

• DO NOT use the unit in the presence of flammable liquids or gases.

• DO NOT operate a unit that is damaged, improperly adjusted or not completely and securely assembled.

Be sure that the unit stops when the trigger is released. Do not use the unit if the switch does not turn the

unit on and off properly or if the switch lock does not work.

• DO NOT attempt operations beyond the operator’s capacity or experience.

• DO NOT cut near electrical cables or power lines.

• DO NOT force the pole saw, especially near the end of a cut. It will do a better, safer job when used at

the intended rate.

• To reduce the risk of electric shock, avoid body contact with grounded conductors, such as metal pipes

or wire fences.

• Keep all body parts away from the saw chain when the motor is operating. Before starting the saw, make

sure the saw chain is not contacting anything.

• Always stop the motor when operation is delayed, before setting down the unit or when walking from one

location to another. Make sure the chain comes to a complete stop.

•

To avoid accidental starting, never carry the unit with fingers on the switch trigger.

•

Always carry the pole saw with the battery removed, finger off the switch trigger and the guide bar and saw

chain sheathed in the scabbard and positioned to the rear.

•

Always make sure the lock-off button is in the locked or OFF position before installing or removing the battery.

• Cut wood only. Do not use the pole saw for purposes for which it was not intended.

•

When cutting a limb that is under tension, be alert for spring back, which may cause the operator to

be struck when the tension of the wood fibers is released.

• Use extreme caution when cutting small-sized brush and saplings, as slender material may catch the

saw chain and be whipped toward the operator or pull the operator off balance.

•

This unit is intended for infrequent use by homeowners, cottagers and campers, and for general

applications such as limbing, pruning, etc. It is not intended for prolonged use. If the intended use

involves prolonged periods of operation, this may cause circulatory problems in the user’s hands due

to vibration. It may be appropriate to use a saw having an anti-vibration feature.

MAINTENANCE AND STORAGE SAFETY

• DO NOT perform

maintenance

procedures other than those described in this manual. Do not

attempt to repair; there are no user serviceable parts inside.

• Follow all maintenance instructions in this manual.

• Before inspecting, servicing, cleaning, storing, transporting or replacing any parts on the unit:

1.

Make sure all moving parts have stopped.

2. Allow the unit to cool.

3. Make sure the lock-off button is in the locked or OFF position.

4. Remove the battery.

• Never remove, modify or make inoperative any safety device furnished with the unit.

• For safer, more effective performance, make sure the bar and chain are properly cleaned, lubricated,

tightened and sharpened. Check the bar and chain at frequent intervals for proper adjustment.

• Frequently inspect the unit for damage.

Before further use, any damaged part should be carefully checked

to determine that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts and any other conditions that may affect its operation.

Damaged parts should be properly repaired or replaced.

• Use only original manufacturer replacement parts and accessories, which are designed specifically to

enhance the performance and maximize the safe operation of the product. Failure to do so may cause

poor performance and possible injury. Use only the chain and guide bar supplied with this product.

• Remove the battery from the unit when not in use.

• Be sure to secure the unit while transporting.

• Always use the scabbard on the bar and chain during transportation and storage.

• When not in use, store the unit in a locked-up and dry, or high and dry, place to prevent unauthorized use

or damage. Keep out of the reach of children.

• Keep the handle and grip dry, clean and free from debris, oil and grease. Clean the unit after each use.

Never douse or squirt the unit with water or any other liquid. Do not use solvents or strong detergents.

• If dropped in water, do not use the unit.

• USE BOTH HANDS

Always use both hands while operating the pole saw. Never use only one

hand to operate the unit.

SAVE THESE INSTRUCTIONS

Page 3

This unit requires assembly. The saw chain may be loose on the guide bar; refer to Adjusting the Chain Tension in the Maintenance and

Repair Instructions section.

UNPACKING

• Carefully remove the product and any accessories from the box.

• Inspect the product carefully to make sure no breakage or damage occurred during shipping.

• Do not discard the packing material until you have carefully inspected and satisfactorily operated the product.

• If any parts are damaged or missing, please call 1-877-282-8684

(U.S.) or 1-800-668-1238 (Canada) for assistance.

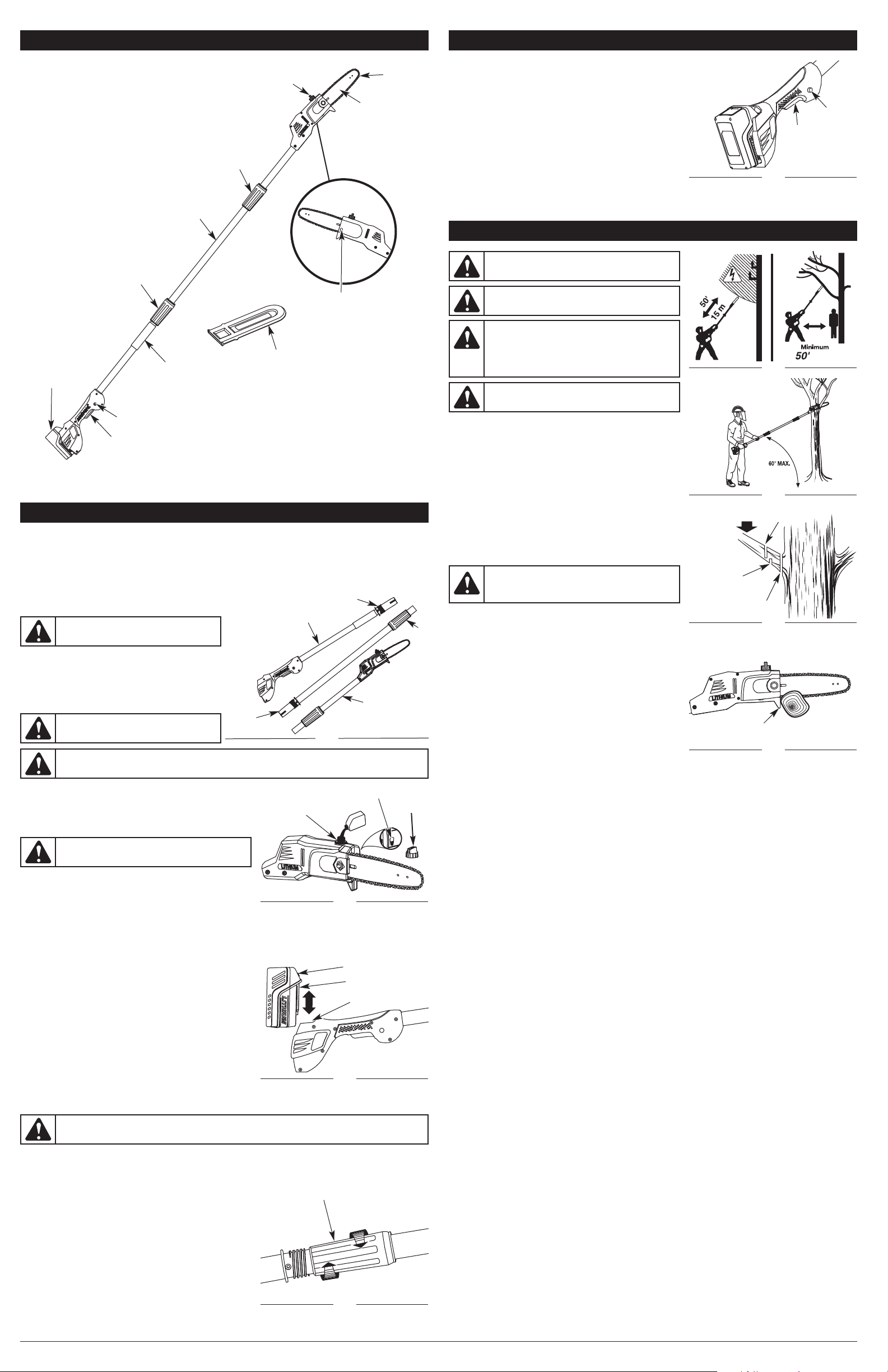

ASSEMBLING THE POLES

There should be three poles (Fig. 3).

1. Insert the extension pole into the handle pole and slide them

together. The tubes are egg-shaped and will only install one way.

2. Lower the collar on the extension pole to the threaded base on the

handle pole and rotate the collar to the right to tighten (Fig. 6).

3. Repeat this process to attach the extension pole to the

powerhead pole.

ADDING BAR AND CHAIN LUBRICANT

Only use bar and chain oil that is formulated to perform over a wide range of

temperatures with no diluting required in the oil reservoir. Do not use motor oil or

any other petroleum-based oil.

NOTE: This pole saw comes from the factory with the bar lube reservoir empty. Use

the bottle of bar and chain oil that is included with the unit.

1. Remove the bar lube reservoir cap (Fig. 4).

2. Carefully pour the bar and chain oil into the bar lube reservoir.

3. Replace the oil cap and tighten securely.

4. Wipe off excess oil.

5. The unit is ready for use.

NOTE: Because bar lube reservoirs are designed to keep oil slowly flowing onto the chain, be sure to check the oil level after every 15

minutes of operation and refill the bar lube reservoir as needed.

NOTE: Do not use dirty, used or otherwise contaminated oils. Damage may occur to the guide bar or chain.

IMPORTANT! Please dispose of oil properly. Consult your local waste authority for information regarding available disposal options.

INSTALLING AND REMOVING THE BATTERY

Follow these instructions in order to avoid injury and to reduce the risk of electric

shock or fire:

• Verify that the lock-off button is in the locked or OFF position before installing

or removing the battery. Refer to Starting and Stopping Instructions.

• Verify that the battery is removed and the lock-off button is in the locked or

OFF position before inspecting, adjusting or performing maintenance on any

part of the unit.

Installing the Battery

1. Align the tongue of the battery with the handle cavity (Fig. 5).

2. Grasp the pole saw firmly.

3. Push the battery into the handle cavity until the latch locks into place.

4.

Do not use force when inserting the battery. It should slide into position and “click.”

Removing the Battery

1. Press the latch button on the battery down and hold (Fig. 5).

2. Grasp the pole saw firmly and pull the battery out of the handle cavity.

NOTE: The battery fits into the handle cavity snugly in order to prevent accidental dislodging. It may require a strong pull to remove it.

IMPORTANT! The battery is equipped with an internal circuit breaker that will automatically shut off power to the unit if the battery is

overloaded during heavy use. Once cooled, the battery will reset itself. Follow these steps if an overload occurs:

1. Release the switch trigger and then restart the unit. Refer to Starting and Stopping Instructions.

2. The battery may need to be removed for approximately 1 minute, allowed to cool and then reinstalled.

ADJUSTING THE POLE LENGTH

1. Remove the battery from the handle cavity (Fig. 5).

2. Rotate the collar(s) to the left to loosen (Fig. 6).

3. Remove the extension pole to shorten the pole, or add the extension pole to

lengthen the pole.

4. When the desired length is achieved, rotate the collar to the right to tighten.

NOTE: Extend the pole only to the length required to reach the limb being cut.

NOTE: Adjust hand placement on the shaft of the pole saw to keep proper

balance. Do not attempt to use the pole saw at a length that does not allow

for proper footing and balance at all times.

3

KNOW YOUR UNIT

ASSEMBLY INSTRUCTIONS

Scabbard

Lock-off Button

Extension Pole

Quick-view Oil Indicator

Powerhead Pole

Handle Pole

Threaded Base

Collar

Extension

Pole

Fig. 3

APPLICATIONS

This unit may be used for the purposes listed below:

• Cutting Small Limbs

• General Tree Pruning

Bar Lube

Reservoir Cap

Collar

Collar

Battery

(Sold Separately)

WARNING:

Do not install the battery until the

assembly is complete. Failure to comply could result in

accidental starting and possible serious personal injury.

WARNING:

Failure to lock the powerhead pole

as directed could result in serious injury or death.

WARNING:

Do not use any attachments or accessories not recommended by the manufacturer of this product. The

use of attachments or accessories not recommended can result in serious personal injury.

Bar Lube

Reservoir

Fig. 4

Quick View Oil Indicator

Bar Lube

Reservoir

Cap

WARNING:

Make sure the bar lube reservoir is always

filled. Failure to fill the bar lube reservoir will cause irreparable

damage to the unit.

Latch Button

Fig. 5

Tongue

Handle Cavity

Loosen

Fig. 6

Collar

Tighten

OPERATING INSTRUCTIONS

STARTING AND STOPPING INSTRUCTIONS

STARTING THE MOTOR

To help prevent accidental start-ups, this unit has a lock-off button and a switch

trigger that must be used together to start the unit.

1. Fit the battery into the handle cavity (Fig. 5). Refer to Installing the Battery.

2. Place your thumb on the lock-off button and push it completely in (Fig. 7).

3. While holding the lock-off button in, press and hold the switch trigger.

4. Release the lock-off button and continue to squeeze the switch trigger for

continued operation.

STOPPING THE MOTOR

1. Release the switch trigger.

NOTE: It is normal for the chain to coast to a stop once the switch trigger is released.

NOTE: Upon release of the switch trigger, the lock-off button will automatically reset

to the locked position.

PREPARATION FOR CUTTING

• To prevent electrocution, do not operate within 50 feet (15 m) of overhead

electrical lines (Fig. 8).

• Keep everyone – helpers, bystanders, children and animals – at least 50 feet

(15 m) away from the work area (Fig. 8). If anyone enters the work area, stop

the unit!

• Wear non-slip gloves for maximum grip and protection.

• Be certain the collars are fully tightened before operating the unit; check them

periodically for tightness during use to avoid serious injury.

• Maintain a proper grip on the unit whenever the motor is running. Hold the

unit firmly with both hands. Firmly grip the handle with the right hand and the

pole shaft with the left hand (Fig. 9).

• The operator should be to the left of the chain line. Never use a left-handed

(cross-handed) grip, or any stance that places any body part across the chain

line (Fig. 9).

• Never stand directly under the limb being cut.

PRUNING

This unit is designed for trimming small branches and limbs up to 6 inches (15.2 cm)

in diameter. For best results, observe the following precautions.

• Do not use the pole saw for cutting down trees.

• Plan the cut carefully. Be aware of the direction in which the branch will fall.

• Branches may fall in unexpected directions. Do not stand directly under the

branch being cut (Fig. 9).

• The most typical cutting application is to position the unit at an angle of 60°

or less, depending on the specific situation (Fig. 9). As the angle of the pole

saw shaft to the ground increases, the difficulty of making the first cut (from

the underside of the limb) increases.

• Remove long branches in several stages.

• Cut lower branches first to allow the top branches more room to fall.

• Work slowly, keeping both hands on the unit with a firm grip. Maintain secure

footing and balance

• Do not cut from a ladder; this is extremely dangerous. Leave this operation for

professionals.

• Do not make the flush cut next to the main limb or trunk until the limb has

been cut further out to reduce the weight.

BASIC CUTTING PROCEDURE

Follow the steps below to prevent stripping the bark from the main member of the tree or shrub. Do not use a back-and-forth sawing motion.

1. Make a shallow first cut (1/4 of the limb’s diameter) on the underside of the limb close to the main limb or trunk (Fig. 10).

2. Make a second cut from the top side of the limb outboard from the first cut. Continue the cut through the limb until the limb separates

from the tree. Be prepared to balance the weight of the tool when the limb falls.

3. Make a final cut close to main limb or trunk.

NOTE: For second and final cuts (from the top of the limb or branch), hold the front cutting guide against the limb being cut (Fig. 11). This will

help steady the limb and make it easier to cut. Allow the chain to do the cutting; only exert light downward pressure. If the cut is forced,

damage to the bar, chain or motor may result.

4. Release the trigger as soon as the cut is completed. Failure to follow proper cutting procedures will result in the bar and chain binding

and becoming pinched or trapped in the limb. If this should happen:

• Stop the motor and remove the battery from the pole saw.

• If the limb can be reached from the ground, lift the limb while holding the saw. This should release the “pinch” and free the saw.

• If the saw is still trapped, call a professional for assistance.

WARNING:

If any parts are damaged or missing, do not

operate the unit until the parts are replaced. Failure to heed this

warning could result in serious personal injury.

Switch

Trigger

Fig. 7

Lock-off

Button

Load

Fig. 10

Second Cut

Cutting

Guide

Fig. 11

Fig. 9

Fig. 8

First Cut

1/4 Diameter

Final Cut

WARNING:

Do not allow familiarity with this unit to

promote carelessness. Remember that a careless fraction of a

second is enough to inflict serious injury.

Switch Trigger

Guide Bar

Chain

CAUTION:

When the battery is not installed in the unit, keep it away from paper clips, coins, keys, nails, screws or

other metal objects that could make a connection from one terminal to another. Shorting the battery terminals together

may cause sparks, burns or a fire.

WARNING:

Always wear appropriate eye and ear

protection when operating this unit. Wear safety goggles, or

safety glasses with side shields, that are marked as meeting

ANSI Z87.1-1989 standards. Failure to do so could result in

serious eye injury caused by thrown objects. If the operation is

dusty, wear a face mask or dust mask. When operating the unit

over the head, use a hardhat or other type of safety helmet.

Foam Grip

WARNING:

Use caution when pruning heavy branches.

Falling branches can cause serious injury. Always wear head

protection, plan a safe exit from the path of falling limbs and

stay alert.

WARNING:

Wear non-slip gloves for maximum grip and

protection. Refer to the Safety Information section for

appropriate safety equipment.

NO TOOLS REQUIRED!

(15 m)

Page 4

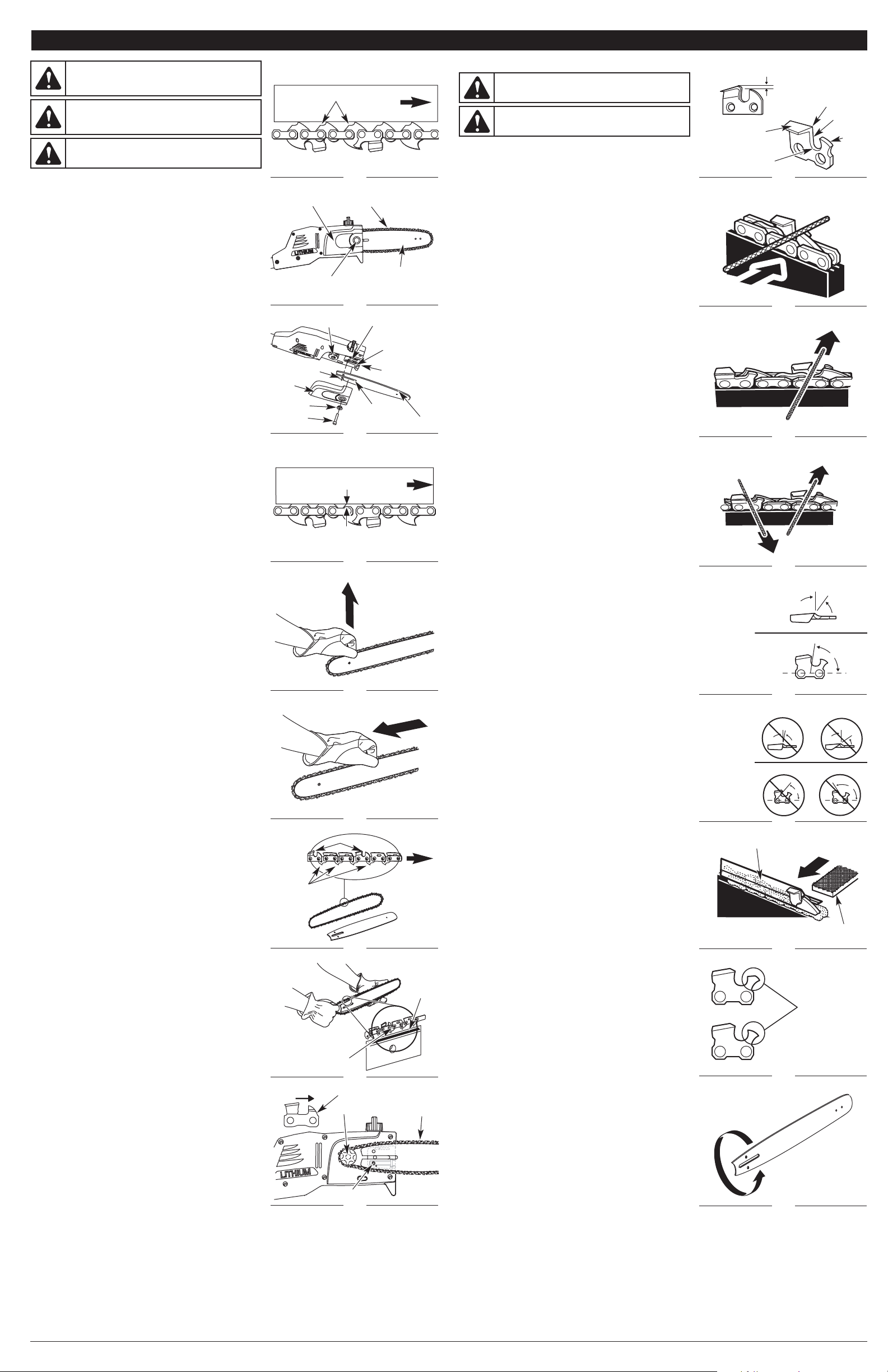

CHAIN MAINTENANCE

For smooth and fast cutting, the chain needs to be maintained properly. The

following conditions indicate that the chain requires sharpening:

• Wood chips are small and powdery.

• The chain must be forced through the wood during cutting.

• The chain cuts to one side.

During maintenance of the chain, consider the following:

• The depth gauge (or raker clearance) setting determines the height at which the

cutter enters the wood and the size of the wood chip that is removed (Fig. 21).

Too much clearance increases the potential for kickback. Too little clearance

decreases the size of the wood chip, thus decreasing the chain's cutting ability.

• If the cutter teeth have hit hard objects, such as nails and stones, or were

abraded by mud or sand on the wood, have a service dealer sharpen the chain.

NOTE: Inspect the drive sprocket for wear or damage when replacing the chain.

If signs of wear or damage are present, do not use the unit.

NOTE: If you do not fully understand the correct procedure for sharpening the

cutters after reading the instructions that follow, have the saw chain

sharpened by an authorized service center or replace the chain with a

recommended low-kickback chain.

SHARPENING THE CUTTERS

Be careful to file all cutters to the specified angles and to the same length. Fast

cutting can be obtained only when all cutters are uniform.

• Tighten the chain tension enough so that the chain does not wobble. Do all of

the filing at the midpoint of the guide bar. Wear gloves for protection.

• Use a round file and holder.

• Keep the file level with the top plate of the tooth (Fig. 22). Do not let the file

dip or rock.

• Using light but firm pressure, stroke towards the front corner of the tooth (Fig. 23).

Lift the file away from the cutter before returning the file to the beginning of the

sharpening stroke.

• Put a few firm strokes on every tooth. File all left hand cutters in one direction

(Fig. 24). Then move to the other side and file the right hand cutters in the

opposite direction. Occasionally remove filings from the file with a wire brush.

Top Plate Filing Angle

• CORRECT (30°) – File holders are marked with guide marks to align the file

properly and produce the correct top plate angle (Fig. 25).

• INCORRECT (LESS THAN 30°) – For cross cutting (Fig. 26).

• INCORRECT (MORE THAN 30°) – This creates a feathered edge that dulls quickly.

Side Plate Filing Angle

• CORRECT (80°) – This is produced automatically if the correct diameter file is

used in the file holder (Fig. 25).

• INCORRECT (HOOK) – This causes the chain to “grab” and dull quickly,

increasing the potential for kickback. A hook is caused by using a file with too

small a diameter or a file held too low (Fig. 26).

• INCORRECT (BACKWARD SLOPE) – This causes a need for too much feed

pressure, producing excessive wear to the bar and chain. A backward slope

is caused by using a file with too large a diameter or a file held too high.

MAINTAINING DEPTH GAUGE CLEARANCE

• Maintain the depth gauge at a clearance of 1/32 inch (0.6 mm) (Fig. 21). Use a

depth gauge tool for checking the depth gauge clearances.

• Every time the chain is filed, check the depth gauge clearance.

• Use a flat file and a depth gauge jointer to lower all gauges uniformly (Fig. 27).

Use a 1/32 inch (0.6 mm) depth gauge jointer. After lowering each depth

gauge, restore the original shape by rounding the front (Fig. 28). Be careful

not to damage adjoining drive links with the edge of the file.

• Depth gauges must be adjusted with the flat file in the same direction the

adjoining cutter was filed with the round file.

• Use care not to contact the cutter face with the flat file when adjusting depth

gauges.

MAINTAINING THE GUIDE BAR

After every week of use, rotate the guide bar on the saw to distribute the wear for

maximum guide bar life (Fig. 29). Frequently check the guide bar for damage.

Feathering and burring of the guide bar rails (the ridges on either side of the bar

groove) is a normal process of guide bar wear. Such faults should be smoothed

with a file as soon as they occur.

A guide bar with the following faults should be replaced:

• Wear inside the guide bar rails that permits the chain to lay sideways.

• Bent guide bar.

• Cracked or broken rails.

• Spread rails.

4

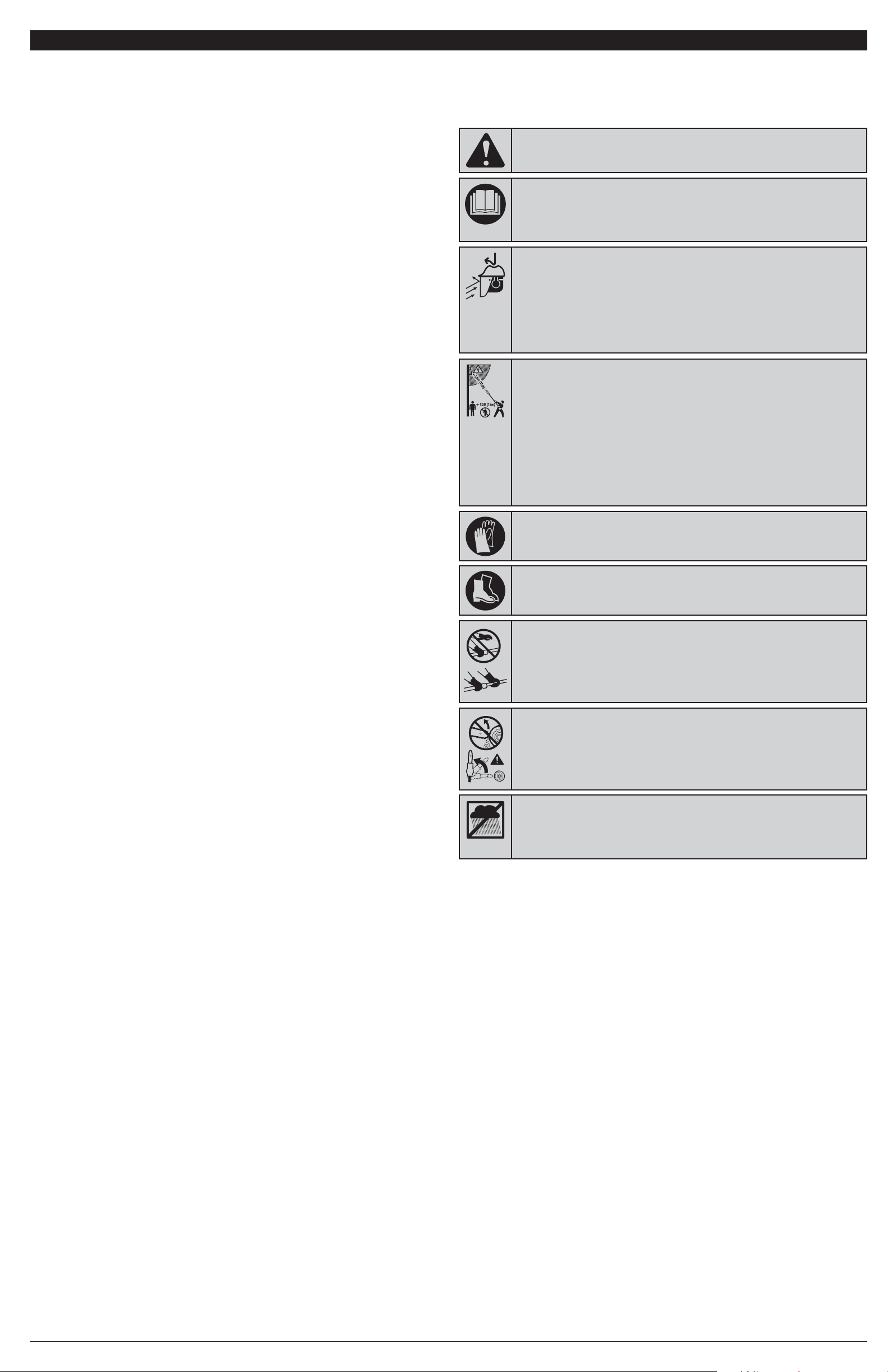

ADJUSTING THE CHAIN TENSION

The chain must be tensioned whenever the flats on the drive links hang out of the

bar groove (Fig. 12). Check for proper chain tension before starting the unit and

periodically during operation.

NOTE: A new chain tends to stretch. Check the chain tension frequently and

tighten as required.

1. Stop the motor, make sure the lock-off button is in the locked or OFF

position and remove the battery from the unit. Refer to Removing the Battery

in the Assembly Instructions section.

2. Slightly loosen the bar cover bolt (Fig. 13).

3. Rotate the chain-tensioning bolt (Fig. 14) clockwise with a hex wrench (Allen

wrench) to tension the chain. The desired tension depends on the

temperature of the chain:

• Cold Chain Tensioning - A cold chain is correctly tensioned when there is

no sag on the underside of the guide bar and the chain seats snugly

against the guide bar with the drive links in the bar groove.

• Warm Chain Tensioning - During normal operation, the temperature of the

chain will increase. The drive links of a correctly tensioned warm chain will

hang approximately 1/16 inch (1.3 mm) out of the bar groove (Fig. 15).

4. Once adjusted, lift the tip of the guide bar up to check for proper tension

(Fig. 16). If the chain is still too loose, release the tip of the guide bar and turn

the chain-tensioning bolt 1/2 turn clockwise. Repeat this process until the

desired tension is achieved.

NOTE: If the chain is too tight, it will not rotate. To loosen the chain, turn the

chain-tensioning bolt 1/4 turn counterclockwise. Ensure that the chain can be

turned by hand without binding (Fig. 17).

5. Hold the tip of the guide bar up and rotate the bar cover bolt clockwise to secure.

REMOVING/REPLACING THE GUIDE BAR AND CHAIN

Use only a low-kickback chain on this saw. This fast-cutting chain provides

kickback reduction when properly maintained.

NOTE: When replacing the guide bar and chain, use only manufacturer

suggested replacement parts. The use of any other parts may create a hazard

or cause product damage and will VOID the warranty.

Removing the Old Guide Bar and Chain

1. Make sure the lock-off button is in the locked or OFF position and remove

the battery from the unit.

2. Rotate the bar cover bolt counterclockwise and remove the bar cover bolt,

sleeve and bar cover (Fig. 14).

3. Remove the guide bar and chain from the mounting surface.

4. Remove the old chain from the guide bar.

Installing the New Guide Bar and Chain

1. Lay out the new saw chain in a loop and straighten any kinks. The cutters on

the top of the guide bar should face toward the guide bar tip in the direction

of chain rotation (Fig. 18). If they face backward, turn the loop over.

2. Place the chain drive links into the bar groove as shown (Fig. 19).

NOTE: Make sure the chain is correctly installed and the cutters are facing in the

correct direction (Fig. 18).

3. Position the chain so there is a loop at the back of the guide bar.

4. Hold the chain in position on the guide bar and place the loop around the

drive sprocket.

5. Fit the guide bar flush against the mounting surface so that the bar stud is in

the

bar stud slot

.

NOTE: When placing the guide bar on the bar stud, ensure that the chain-

tensioning pin is in the chain tension pin hole (Fig. 20).

6. Replace the bar cover, sleeve and bar cover bolt. To tighten, rotate the bar

cover bolt clockwise with a hex wrench (Allen wrench).

NOTE: Tighten the bar cover bolt to finger tightness only. The guide bar should

still be free to move for chain tension adjustment.

7. Adjust the chain tension. Refer to the Adjusting the Chain Tension

instructions above.

MAINTENANCE AND REPAIR INSTRUCTIONS

Chain Rotation

Fig. 20

Drive Sprocket

Chain

WARNING:

A dull or improperly sharpened chain can

cause excessive motor speed during cutting, which may result

in severe motor damage.

WARNING:

Improper chain sharpening increases the

potential of kickback. Failure to replace or repair a damaged

chain can cause serious injury.

Top Plate

Fig. 21

Cutting Corner

Gullet

Fig. 22

Fig. 23

Left Hand

Cutters

Fig. 24

Right Hand

Cutters

Chain Tensioning Pin

Depth

Gauge

Raker Clearance

1/32” (0.6 mm)

Side Plate

Fig. 27

Fig. 28

Fig. 29

Flat File

Depth Gauge Jointer

Restore Original

Shape by Rounding

the Front

Filing Height

Filing Angle

Fig. 25

Fig. 26

Top Plate

Less than 30˚

More than 30˚

30˚

Incorrect

Filing Angles

Hook

Backward Slope

80˚

Correct

Filing Angles

Top Plate

Side Plate

Side Plate

Fig. 18

Chain Drive

Links

Chain

Rotation

Cutters

Approx. 1/16”

(1.3 mm)

Fig. 15

Bar Tip

WARNING:

Before inspecting, cleaning or servicing the

unit, stop the motor, wait for all moving parts to stop and

remove the battery. Failure to follow these instructions can

result in serious personal injury or property damage.

Flats

Fig. 12

Bar Cover Bolt

Fig. 13

WARNING:

To avoid possible serious injury, never touch or

adjust the chain while the motor is running. The saw chain is

very sharp; always wear protective gloves when performing

maintenance on the chain.

CAUTION:

A chain tensioned while warm, may be too tight

upon cooling. Check the “cold tension” before the next use.

Bar Tip

Drive Sprocket

Fig. 14

Chain-tensioning

Pin

Bar Stud

Bar Cover

Chain

Guide Bar

Bar Stud Slot

Bar Groove

Bar Cover

Bolt

Bar

Cover

Chain-tensioning

Pin Hole

Chain-tensioning

Bolt

Sleeve

Fig. 19

Fig. 16

Fig. 17

Bar Groove

Chain Drive

Links

Page 5

CAUSE SOLUTION

The battery lacks sufficient charge Charge the battery

5

CLEANING INSTRUCTIONS

NOTE: It is normal for oil to seep from the unit when it is not in use. Please take this into consideration when storing the unit.

• Remove the battery from the unit.

• Slacken the chain if it was retensioned at operating temperature during cutting work. The chain contracts as it cools down. If it is not

slackened, it may damage the gearbox and bearings.

• Wipe the unit down with a damp cloth. Do not douse the unit with water. Do not use solvents or strong detergents. If preparing the unit

for long-term storage (three months or more), remove the chain and guide bar, then clean the unit thoroughly with a damp cloth. A firmbristled, non-wire, brush can be used to remove debris from the bar groove and assembly. When finished, reassemble the unit. Refer to

Removing/Replacing the Guide Bar and Chain.

• Spray the guide bar and chain with corrosion inhibiting oil.

STORAGE INSTRUCTIONS

• Follow the Cleaning Instructions listed above.

• Attach the scabbard to the guide bar and chain.

• Store the unit in a dry, high and/or locked location, out of the reach of children and other unauthorized persons.

WARNING:

Do not let brake fluids, gasoline, petroleum-based products, penetrating oils, etc., come in contact with plastic

parts. These chemicals may damage, weaken and destroy plastic, which may result in serious personal injury.

SPECIFICATIONS*

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at

any time without notice.

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cordless, Battery-powered

Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 V

Motor Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 rpm

Bar Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 inches (20.3 cm)

Chain Pitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8 inch (9.5 mm)

Chain Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-inch Chain

Guide Bar Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-inch Bar

Chain speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.68 ft./s (6 m/s)

Bar Lube Reservoir Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 oz (45 ml)

Weight (with Battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 lb (5 kg)

CLEANING AND STORAGE

The chain is dull Sharpen the chain

The chain is on backwards Reverse the direction of the chain

TROUBLESHOOTING

NOTE: For maintenance beyond the minor adjustments listed above, or for replacement parts, please call the Customer Support

Department at 1-877-282-8684 (U.S.) or 1-800-668-1238 (Canada).

The chain tension is too tight Adjust the chain tension

The bar lube reservoir is empty Refill the bar lube reservoir

The chain tension is too tight Adjust the chain tension

The guide bar and chain are assembled incorrectly Refer to Removing/Replacing the Guide Bar and Chain

The guide bar and chain are damaged Inspect the guide bar and chain for damage

The drive assembly is damaged Refer to Service Information

THE CHAIN DOES NOT ROTATE WHILE THE MOTOR IS RUNNING

THE CHAIN ROTATES, BUT DOES NOT CUT

ACCESSORIES (SOLD SEPARATELY)

Model #

A59 LBTY . . . . . . . . . . . . .

A59LCHGR . . . . . . . . . . . .

Description

20V Lithium-ion Battery

20V Lithium-ion Battery Charger

Part #

753-06579 . . . . . . .

753-06580 . . . . . . .

THE MOTOR OPERATES SLOWLY OR WILL NOT OPERATE

NOTES

REPLACEMENT PARTS

Description

8-inch Chain

8-inch Bar

Part #

753-06628. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

753-06630. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THE BAR AND CHAIN ARE RUNNING HOT AND SMOKING OR STUCK

Page 6

6

NOTES

Page 7

LIRE TOUTES LES INSTRUCTIONS AVANT UTILISATION

PRÉCAUTIONS DE SECURITÉ ÉLEMENTAIRES

• Lisez attentivement et assurez-vous de bien comprendre le manuel de l’utilisateur de la batterie qui

alimente cet appareil.

• Familiarisez-vous avec les commandes et la marche à suivre pour une utilisation correcte de cet appareil.

Apprenez à rapidement couper le moteur de l’appareil et à mettre les commandes en position neutre.

• Restez attentif. N’utilisez pas cet appareil lorsque vous êtes fatigué, malade, ou sous l’influence de

l’alcool, de drogues, ou de médicaments.

• Ne laissez jamais les enfants utiliser cet appareil. Ne laissez jamais des adultes utiliser cet appareil

sans qu’ils aient reçu une formation appropriée.

• Ne pas laisser l'unité à être utilisé comme un jouet.

• Assurez-vous que toutes les protections et tous les dispositifs de sécurité ont été correctement

installés avant d’utiliser l’appareil.

• Conservez ces instructions. Consultez-les régulièrement et utilisez-les pour donner des consignes

aux autres utilisateurs. Si vous prêtez cet appareil à quelqu’un, prêtez-lui également ces instructions.

PRÉCAUTIONS DE SECURITÉ AVANT L’UTILISATION

• NE vous fiez PAS exclusivement aux protections de sécurité incorporées dans l’appareil.

• Faites reculer les personnes se trouvant à proximité, en particulier les enfants et les animaux, d’au

moins 50 pieds (15 m). Si quelqu’un s’approche de la zone de travail, arrêtez l’appareil !

• Veillez à ce que la zone de travail soit dégagée. Les zones encombrées favorisent les accidents. Ne

commencez pas à couper avant d’avoir nettoyé la zone de tous débris, d’avoir une position parfaitement

stable, et de vous être assuré qu’il y a suffisamment d’espace pour reculer en cas de chute de branches.

• Portez toujours des protections oculaires et auditives lorsque vous utilisez cet appareil. Portez des

lunettes de sécurité ou une visière dotée de protections latérales conformes aux normes ANSI

Z87.1-1989. Le non-port de ces protections peut entraîner de graves lésions oculaires suite à la

projection ou la chute d’objets. Si la tâche est poussiéreuse, portez un masque anti-poussière.

Lorsque vous utilisez l'appareil au delà de votre tête, portez un casque de sécurité.

• Habillez-vous de manière adéquate, portez de vêtements épais et près du corps (pantalon et

chemise à manches longues), des gants et des bottes de travail antidérapants. Ne portez pas de

vêtements amples, de bijoux, de pantalons courts, de sandales et ne soyez pas pieds nus.

Attachez-vous les cheveux au dessus du niveau des épaules pour éviter qu’ils ne se prennent dans

les parties en mouvement de l’appareil.

• Utilisez l’appareil uniquement à la lumière du jour ou sous un éclairage artificiel satisfaisant.

• N’utilisez pas cet appareil pour des fonctions pour lesquelles il n’a pas été prévu.

COMPRENDRE L’EFFET DE REBOND

•Un rebond rotatif peut se produire lorsque la partie

supérieure de la pointe du guide heurte un objet alors

que la chaîne est en mouvement (Fig. 1 & 2). La

chaîne peut en conséquence s’enfoncer dans l'objet

et s’arrêter momentanément de tourner. Le guide est

alors propulsé vers le haut à toute vitesse et se

retourne vers l'utilisateur dans un mouvement inverse

ultra-rapide.

•Un effet de rebond par coincement peut se

produire lorsque le bois se referme de chaque côté

d'une coupe et coince la chaîne en mouvement au

niveau du haut du guide. Ceci peut caler la chaîne

net. La force de la chaîne est ainsi renversée, ce qui

provoque un retour instantané et soudain de la

tronçonneuse vers l’utilisateur.

•Un effet de calage peut se produire lorsque la chaîne

en mouvement sur la partie inférieure du guide heurte

un objet étranger dans le bois. Ceci peut caler la

chaîne net. La tronçonneuse est alors propulsée en

avant et s’écarte de l’utilisateur, qui pourrait

potentiellement en perdre le contrôle.

PRÉCAUTIONS DE SECURITÉ POUR ÉVITER L’EFFET

DE REBOND

• N’essayez PAS d’atteindre des espaces trop éloignés.

• N’effectuez PAS de coupes avec la pointe du guide.

• Veillez à ce que la pointe du guide n’heurte aucun

objet tel qu’une bûche, une branche, le sol ou tout autre élément gênant. Retirez ou évitez les

éléments gênants susceptibles de butter contre l'extrémité du guide lors de la coupe.

Manuel de l’utilisateur

Tronçonneuse sur perche

à batterie lithium-ion 20 Volts

PS59L

TABLE DES MATIÈRES

Informations sur l’entretien et le service après-vente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Informations sur la sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Familiarisez-vous avec votre appareil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Instructions d’assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Instructions de démarrage et d’arrêt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Instructions d’utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Entretien et réparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Nettoyage et rangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Résolution des problèmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

INFORMATIONS SUR LA SECURITÉ

Utilisez une batterie lithium-ion 20V A59 LBTY (vendue séparément)

Utilisez un chargeur de batterie lithium-ion 20V A59LCHGR (vendu séparément)

• CONSIGNES DE SÉCURITÉ IMPORTANTES •

AVERTISSEMENT :Veuillez lire ce manuel de l’utilisateur

attentivement et dans sa totalité avant d’essayer de monter, d’utiliser ou d’entretenir

l’appareil. Conformez-vous à toutes les consignes de sécurité. Le non respect de ces

consignes peut entraîner des dégâts matériels ou des blessures graves pour vous-même

et/ou pour les autres.

DANGER :

Un effet de rebond peut se produire lorsque le nez ou la pointe du guide

touche un objet, ou lorsque le bois se referme et coince la chaîne lors de la coupe. Dans certains

cas, un contact avec l'extrémité de l’outil peut causer un effet de rebond extrêmement rapide,

retournant ainsi le guide instantanément vers l'utilisateur. Coincer la chaîne coupante sur le haut

du guide risque de retourner rapidement le guide vers l'utilisateur. L’une et l’autre de ces réactions

peuvent provoquer une perte de contrôle de la tronçonneuse, ce qui peut entraîner des blessures

graves pour l'utilisateur. Si la tronçonneuse heurte ou se prend dans un objet étranger dans le

bois, cela peut également provoquer une perte de contrôle de la chaîne coupante.

Fig. 1

Rebond

rotatif

769-06477 P02 06/11

NE RAMENEZ PAS CET APPAREIL CHEZ LE DÉTAILLANT. UNE PREUVE D’ACHAT SERA EXIGÉE

POUR TOUTE PRISE EN CHARGE DANS LE CADRE DE LA GARANTIE.

Si vous éprouvez des difficultés à assembler ce produit ou si vous avez des questions sur les commandes,

l’utilisation ou l’entretien de cet appareil, veuillez contacter le service à la clientèle : 1-877-282-8684 (aux

États Unis) ou 1-800-668-1238 (au Canada).

Des informations supplémentaires sont disponibles sur notre site web : www.cubcadet.com (aux États

Unis) ou www.cubcadet.ca (au Canada).

Veuillez appeler le service à la clientèle pour obtenir des renseignements sur les pièces de rechange. Lors

de l’entretien, utilisez uniquement des pièces de rechange identiques.

CONSERVEZ CES INSTRUCTIONS

L’ensemble des informations, illustrations et caractéristiques sont basées sur les toutes dernières

informations disponibles sur le produit à l’impression de ce guide. Nous nous réservons le droit

d’effectuer des modifications à tout moment sans notification préalable.

Copyright© 2011 MTD SOUTHWEST INC, Tous droits réservés.

INFORMATIONS SUR L’ENTRETIEN ET LE SERVICE APRES-VENTE

PROPOSITION DE LOI 65 DE CALIFORNIE

AVERTISSEMENT :

Les bornes de batterie, les cosses et certains

composants finis contiennent du plomb, des éléments à base de plomb et des produits

chimiques connus de l’État de Californie comme étant à l’origine de cancers, de

malformations congénitales ou autres anomalies de la reproduction. Lavez-vous les mains

après manipulation.

DANGER :Signale un risque EXTREME.

Le non respect d’une consigne de sécurité relative à un signal de DANGER entraînera des

blessures graves ou mortelles pour vous-même ou pour les autres.

AVERTISSEMENT :Signale un risque GRAVE.

Le non respect d’un AVERTISSEMENT de sécurité PEUT entraîner des blessures graves

pour vous-même ou pour les autres.

ATTENTION :Signale un risque MOYEN.

Le non respect d’une consigne de signal d’ATTENTION PEUT entraîner des dégâts

matériels ou des blessures graves pour vous-même ou pour les autres.

IMPORTANT ! Signale une information technique spécifique.

REMARQUE : Signale une information générale importante supplémentaire.

SYMBOLE SIGNIFICATION

• SYMBOLE D’ALERTE DE SECURITÉ •

L’objectif de ces symboles d’alerte de sécurité est d’attirer votre attention sur les dangers possibles.

Vous devez être attentifs aux symboles de sécurité, et à leurs explications. Les avertissements de

sécurité en eux-mêmes n’éliminent pas le danger. Les consignes ou avertissements de sécurité ne

se substituent pas aux mesures appropriées de prévention des accidents. Ces consignes de sécurité

ne sauraient couvrir toutes les éventualités susceptibles de se produire. Si vous avez des questions,

veuillez appeler le service à la clientèle au 1-877-282-8684 (E.U.) ou 1-800-668-1238 (Canada).

Fig. 2

Zone de danger présentant

un risque de rebond

Page 8

8

INFORMATIONS SUR LA SECURITÉ

• SYMBOLES INTERNATIONAUX ET DE SECURITÉ •

Ce manuel de l’utilisateur décrit les symboles et pictogrammes de sécurité et internationaux

qui peuvent apparaître sur ce produit. Lisez ce manuel de l’utilisateur pour obtenir une

information complète sur la sécurité, l’assemblage, l’utilisation l’entretien et les réparations.

• SYMBOLE D’ALERTE DE SECURITÉ

Indique le danger, l’avertissement ou la prudence. Peut être utilisé

conjointement avec d’autres symboles ou pictogrammes.

• LISEZ LE MANUEL DE L’UTILISATEUR

AVERTISSEMENT :Lisez le(s) manuel(s) de l’utilisateur

et suivez toutes les consignes de sécurité et de prévention. Tout

manquement peut entraîner des blessures graves pour les utilisateurs et/ou

pour les personnes à proximité de l’appareil.

• PORTEZ UN CASQUE, DES LUNETTES DE SECURITÉ ET DES

BOUCHONS ANTI-BRUITS

AVERTISSEMENT :Les objets projetés et le bruit peuvent

entraîner des lésions oculaires et des pertes auditives. Portez des

protections oculaires conformes aux normes ANSI Z87.1-1989 et des

protections auditives lorsque vous utilisez cet outil. Le port du casque est

obligatoire lors de l’utilisation de cet appareil ; la chute d'objets peut

entraîner de graves blessures à la tête. Utilisez une protection pour le visage

si nécessaire.

SYMBOLE SIGNIFICATION

• PORTEZ DES CHAUSSURES DE SECURITÉ

Portez des chaussures de sécurité antidérapantes lorsque vous utilisez cet

appareil.

•

PORTEZ DES GANTS DE PROTECTION

Portez des gants de protection antidérapants lorsque vous manipulez

l’appareil.

• N’UTILISEZ PAS CET APPAREIL SOUS LA PLUIE

AVERTISSEMENT :Évitez les environnements

dangereux. N’utilisez jamais cet appareil sous la pluie ou dans des conditions

atmosphériques humides. L’humidité est un risque d’électrocution.

• AVERTISSEMENT RELATIF A L’EFFET DE REBOND

Il faut absolument éviter que le bout du guide entre en contact avec tout

autre objet. Si le bout du guide heurte un objet, le guide peut brusquement

être propulsé vers le haut ou vers l'arrière et causer des blessures graves.

• ÉLOIGNEZ LES PERSONNES SE TROUVANT À PROXIMITÉ

AVERTISSEMENT :Faites reculer les personnes se

trouvant à proximité, en particulier les enfants et les animaux, d’au moins 50

pieds (15 m) de la zone de travail. Si quelqu’un s’approche de la zone de

travail, arrêtez l’appareil !

• LES LIGNES ÉLECTRIQUES PEUVENT CAUSER DES BLESSURES GRAVES

AVERTISSEMENT : N’utilisez pas cet appareil à

proximité de lignes électriques. Tout contact avec une ligne électrique peut

provoquer des blessures graves ou endommager l’appareil. Maintenez une

distance d'au moins 50 pieds (15 m) entre la tronçonneuse sur perche (y

compris les branches avec lesquelles l’outil est en contact) et toute ligne

électrique.

• NE coupez PAS plus d’une branche à la fois.

• NE tordez PAS la tronçonneuse lorsque vous retirez le guide d’une entaille.

• Ne démarrez jamais la tronçonneuse lorsque le guide se trouve dans une entaille. Soyez

extrêmement prudent lorsque vous recoupez dans une entaille.

• Tenez l’appareil fermement des deux mains lorsque le moteur tourne. Gardez la main droite sur la

poignée et la main gauche sur la perche de manière à ce que votre position procure un soutien

suffisant. Gardez une prise ferme avec les doigts et le pouce bien autour de la poignée et de la

perche. Tenez-vous un peu sur la gauche de l’appareil pour éviter d’être dans la ligne directe de la

chaîne coupante. Suivez toutes les instructions indiquées dans la section Instructions d'utilisation.

• Assurez-vous de garder constamment une position stable et un bon équilibre.

• Lorsque vous démarrez la tronçonneuse, attendez toujours que le moteur tourne à plein régime

avant de commencer la coupe. Enfoncez complètement l’interrupteur à gâchette et maintenez une

vitesse de coupe constante. Les vitesses réduites sont plus propices aux effets de rebond.

Maintenez le corps de la tronçonneuse fermement appuyé contre le bois

• Veillez à ce qu’aucune bûche, branche instables, ou autre objet ne se coince ou heurte la chaîne

lors de la coupe.

• Si vous utilisez des coins d’abattage, utilisez uniquement des modèles en plastique ou en bois.

N’utilisez jamais d’objet métallique pour maintenir une coupe ouverte.

• Suivez les instructions du fabriquant concernant l’affûtage et l’entretien de la chaîne coupante.

• N’utilisez que des guides et chaînes de remplacement recommandés par le fabricant ou de qualité

équivalente.

• Utilisez des dispositifs tels que des chaînes à faible rebond, des protections pour nez de guide, des

freins de chaîne et des guides spécifiques, qui permettent de réduire les risques associés aux

effets de rebond. Il n'existe pas d'autres composants de remplacement conformes à la norme CSA

Z62.3 permettant de se prémunir des rebonds.

• Une chaîne coupante à faible rebond est une chaîne qui répond aux exigences de performance de

la norme ANSI B175.1-1991 et qui est conforme à la norme CSA Z62.3. N’utilisez pas de chaîne de

remplacement d’un autre type, sauf si celle-ci répond aux exigences du modèle spécifique.

Certaines des qualités de faible rebond pouvant disparaître avec l’affûtage des chaînes, il est

recommandé de redoubler de prudence.

AUTRES PRÉCAUTIONS DE SÉCURITÉ

• N’utilisez PAS l’appareil d’une seule main. Cela pourrait entraîner des blessures sérieuses pour

l’utilisateur, ses assistants, ou les personnes se trouvant à proximité. Cet appareil est conçu pour

être utilisé avec les deux mains.

• N’utilisez PAS l’appareil avec des mains mouillées.

• N’utilisez PAS une tronçonneuse sur perche dans un arbre ou sur une échelle à moins que vous

n’ayez été formé spécifiquement pour cela.

• NE laissez PAS l’appareil sous la pluie. N’utilisez pas l'appareil dans des conditions ou des

endroits humides ou mouillés.

• N’utilisez PAS l'appareil sur des surfaces mouillées.

• N’utilisez PAS l'appareil en présence de liquides inflammables ou de gaz.

• N’utilisez PAS cet appareil lorsqu’il est endommagé, mal réglé, ou mal assemblé. Assurez-vous

que l’appareil s’arrête lorsque vous relâchez la gâchette. N’utilisez PAS l’appareil si l’interrupteur ne

parvient pas à démarrer ni à arrêter correctement l’appareil ou si l’interrupteur de sécurité ne

fonctionne pas.

• N’effectuez PAS de tâches qui vont au delà des capacités ou de l’expérience de l’utilisateur.

• NE coupez PAS à proximité de câbles électriques.

• NE forcez PAS la tronçonneuse sur perche, en particulier à la fin d’une coupe. L’outil sera plus

efficace et plus sûr si vous l’utilisez à la vitesse pour laquelle il a été conçu.

• Pour réduire le risque d’électrocution, évitez tout contact avec des conducteurs de mise à la terre,

tels que des tuyaux métalliques ou des grillages.

• Gardez la chaîne coupante bien éloignée de votre corps lorsque le moteur est en marche. Avant de

démarrer la tronçonneuse, assurez-vous que la chaîne coupante n’est en contact avec rien.

• Arrêtez toujours le moteur lorsque le fonctionnement est interrompu, avant de déposer l’appareil ou

lorsque vous vous déplacez vers une autre aire de coupe. Assurez-vous que la chaîne s’arrête

complètement.

• Pour éviter les démarrages accidentels ne portez jamais l’appareil avec vos doigts sur l’interrupteur

à gâchette.

• Portez toujours la tronçonneuse sur perche avec la batterie retirée, sans vos doigts sur l’interrupteur

à gâchette, avec le guide et la chaîne coupante rangés dans le fourreau et dirigés vers l’arrière.

• Assurez-vous toujours que le bouton de verrouillage est sur la position ARRÊT ou verrouillé avant

d’installer ou de retirer la batterie.

• Coupez uniquement du bois. N’utilisez pas la tronçonneuse sur perche pour des travaux pour

lesquels elle n’a pas été prévue.

• Lorsque vous coupez une branche maîtresse sous tension, faites attention au risque de rebond. La

branche peut en effet frapper l’utilisateur lorsque la tension des fibres du bois se relâche.

• Faites attention lorsque vous coupez des petits taillis ou de jeunes arbres car les branches fines

peuvent se prendre dans la chaîne coupante et se projeter vers l’utilisateur ou le déséquilibrer.

• Cet appareil est destiné à un usage domestique et peu fréquent pour l’entretien du jardin d’une

maison, d’un chalet ou d’un mobile-home, et pour l’élagage, la taille, etc. Il n'est pas conçu pour

une utilisation prolongée. En cas d'utilisation prolongée, des problèmes circulatoires peuvent

survenir au niveau des mains de l'utilisateur en raison des vibrations. Dans ce cas, il peut s’avérer

opportun d'utiliser une tronçonneuse munie d'une fonction anti-vibration.

PRÉCAUTIONS CONCERNANT L’ENTRETIEN ET LE RANGEMENT

• N’effectuez PAS de procédures d’entretien autres que celles décrites dans ce manuel. N’essayez

pas de réparer vous-même l’appareil ; il ne contient aucune pièce remplaçable par l’utilisateur.

• Suivez toutes les instructions d’entretien décrites dans ce manuel.

• Avant de vérifier, d’entretenir, de nettoyer, de ranger, de transporter ou de remplacer une

quelconque pièce dans l'appareil :

1. Assurez-vous que toutes les pièces mobiles se sont arrêtées.

2. Laissez refroidir l’appareil.

3. Assurez-vous que le bouton de verrouillage est sur la position ARRÊT ou verrouillé.

4. Retirez la batterie.

• N’enlevez, ne modifiez ou ne désactivez jamais un dispositif de sécurité qui est fourni avec l’appareil.

• Pour renforcer la sécurité et obtenir des performances optimales, assurez-vous que le guide et la

chaîne sont parfaitement propres, graissés, resserrés et affûtés. Vérifiez régulièrement que le guide

et la chaîne sont correctement ajustés.

• Inspectez régulièrement l’appareil pour vous assurer qu’il n’est pas endommagé. Avant d’utiliser

l’appareil, toute pièce endommagée devrait être inspectée pour déterminer si elle fonctionnera

correctement et remplira sa fonction comme il se doit. Vérifiez l’alignement et la fixation de toutes

les pièces mobiles, assurez-vous qu’aucune pièce n’est brisée et qu’aucun autre problème n’est

susceptible d'affecter le fonctionnement de l’appareil. Les pièces endommagées devraient être

correctement réparées ou remplacées.

• N’utilisez que des pièces de rechange et accessoires de la marque du fabriquant qui sont

spécifiquement conçus pour améliorer les performances et maximiser la sûreté de fonctionnement

de l’appar

eil. À défaut, l’appareil risque de produire des performances médiocres et même des

blessures. Utilisez exclusivement la chaîne et le guide fournis avec le produit.

• Retirez la batterie lorsque vous n’utilisez pas l’appareil.

• Assurez-vous que l’appareil est sécurisé pour les transports.

• Utilisez toujours le fourreau sur le guide et la chaîne pendant le transport et lors du rangement.

• Quand l’appareil n’est pas utilisé, rangez-le dans un endroit sec et sous clé ou sec et en hauteur

pour éviter un usage non autorisé ou des dommages. Gardez toujours l’appareil hors de la portée

des enfants.

• Veillez à ce que la poignée reste sèche, propre et dépourvue d’huile et de graisse. Nettoyez

l’appareil après chaque utilisation. Ne trempez ou humidifiez jamais l’appareil avec de l’eau ou tout

autre liquide. N’utilisez pas de solvants ou de détergents agressifs.

• Si l’appareil est tombé à l’eau, ne l’utilisez pas.

• UTILISEZ VOS DEUX MAINS

Utilisez toujours vos deux mains pour travailler avec la tronçonneuse sur

perche. N’utilisez jamais l’appareil d’une seule main.

CONSERVEZ CES INSTRUCTIONS

Page 9

9

Cet appareil doit être assemblé. Il se peut que la chaîne coupante soit détendue sur le guide ; consultez Réglage de la tension de la chaîne

dans la section Entretien et réparations.

DÉBALLER

• Retirez soigneusement l’appareil et ses accessoires de la boîte.

• Inspectez attentivement l’appareil pour vous assurer qu’il n’a pas été endommagé pendant le transport.

• Ne jetez pas l’emballage tant que vous n’avez pas inspecté et testé l’appareil de façon satisfaisante.

• Si des pièces sont endommagées ou manquantes, veuillez appeler le 1-877-282-8684 (E.U.) ou le 1-800-668-1238 (Canada) pour obtenir

de l’aide.

ASSEMBLAGE DES PERCHES

L’outil est composé de trois perches (Fig. 3).

1. Insérez la perche extensible dans la perche à poignée et

assemblez-les en les faisant coulisser. Les tubes ont une forme

ovoïdale et ne peuvent s’installer que dans un sens.

2. Abaissez le collier sur la perche extensible vers la base à visser

sur la perche à poignée et tournez le collier vers la droite pour le

resserrer (Fig. 6).

3. Répétez cette procédure pour fixer la perche extensible à la

perche à tête motrice.

RAJOUTER DU LUBRIFIANT POUR LA CHAÎNE ET LE GUIDE

N’utilisez que de l’huile pour la chaîne et le guide qui résiste à une large plage de

températures et qu’il ne faut pas diluer dans le réservoir d’huile. N’utilisez pas

d'huile pour moteur ou toute autre huile à base de pétrole.

REMARQUE : Cette tronçonneuse sur perche est vendue avec le réservoir de

lubrifiant vide. Utilisez le flacon d’huile de lubrification pour la chaîne qui est livré

avec l’appareil.

1. Retirez le bouchon du réservoir de lubrifiant (Fig. 4).

2. Versez soigneusement l’huile pour chaîne dans le réservoir de lubrifiant.

3. Remettez le bouchon d'huile en place et serrez fermement.

4. Essuyez l'excès d'huile.

5. L’appareil est prêt à être utilisé.

REMARQUE : Le réservoir d’huile de lubrifiant pour chaîne est conçu de façon à ce que l’huile coule lentement mais continuellement sur la

chaîne, il est donc important de vérifier le niveau d’huile toutes les 15 minutes d’utilisation et de remplir le réservoir si nécessaire.

REMARQUE : N’utilisez jamais d’huile sale, usagée ou contaminée de quelque sorte que ce soit. Cela risque d’endommager le guide ou la chaîne.

IMPORTANT ! Jetez votre huile usagée conformément à la réglementation. Consultez l’organisme local chargé des déchets pour obtenir

des informations sur les options d'élimination disponibles.

INSTALLER ET RETIRER LA BATTERIE

Observez ces instructions pour éviter des blessures et réduire le risque

d’électrocution ou d’incendie :

• Assurez-vous que le bouton de verrouillage est sur la position ARRÊT ou

verrouillé avant d’installer ou de retirer la batterie. Consultez les instructions

de démarrage et d’arrêt.

• Assurez-vous que la batterie est retirée et que le bouton de verrouillage est

sur la position ARRÊT ou verrouillé avant de vérifier, d’ajuster ou d’entretenir

une quelconque partie de l’appareil.

Installer la batterie

1. Alignez la languette de la batterie avec la cavité de la poignée (Fig. 5).

2. Saisissez fermement la tronçonneuse à perche.

3. Poussez la batterie dans la cavité de la poignée jusqu’à ce que la glissière

soit correctement insérée.

4.

Ne forcez pas quand vous insérez la batterie. Vous devez la faire coulisser pour la mettre en place et entendre un “clic” une fois

parfaitement insérée.

Retirer la batterie

1. Faites glisser le bouton de la glissière de la batterie vers le bas et tenez-le (Fig. 5).

2. Saisissez fermement la tronçonneuse à perche et tirez la batterie hors de la cavité de la poignée.

REMARQUE : La batterie s’encastre parfaitement dans la cavité de la poignée pour éviter qu’elle ne se détache accidentellement. Vous

devrez peut-être tirer avec force pour la déloger.

IMPORTANT ! La batterie est équipée d’un disjoncteur interne qui coupera automatiquement le courant de l’appareil en cas de surcharge suite

à une utilisation intense. Une fois refroidie, la batterie se réinitialisera elle-même. Suivez les étapes ci-après lors d’une surcharge :

1. Relâchez l’interrupteur à gâchette, puis redémarrez l’appareil. Consultez les instructions de démarrage et d’arrêt.

2. Il est possible qu’il faille retirer la batterie pendant environ 1 minute pour la laisser se refroidir avant de la réinstaller.

FAMILIARISEZ-VOUS AVEC VOTRE OUTIL

INSTRUCTIONS D’ASSEMBLAGE

Fourreau

Bouton de verrouillage

Perche

extensible

Témoin rapide du

niveau d’huile

Perche à tête

motrice

Perche à poignée

Base à visser

Collier

Perche

extensible

Fig. 3

APPLICATIONS

Cet appareil peut être utilisé pour les tâches suivantes :

• Coupe de branches maîtresses de petite taille

• Taille et élagage général des arbres

Bouchon du réservoir

de lubrifiant pour chaîne

Collier

Collier

Batterie

(vendue séparément)

AVERTISSEMENT :

N’installez pas la batterie

avant d’avoir terminé l’assemblage. Dans le cas

contraire, vous risquez de provoquer un démarrage

accidentel et des blessures graves.

AVERTISSEMENT :

Le non respect du

verrouillage de la perche à tête motrice tel qu’indiqué

peut entraîner des blessures graves voire mortelles.

AVERTISSEMENT :

N’utilisez jamais de pièces ou d’accessoires non recommandés par le fabricant de ce produit,

au risque d’entraîner des blessures graves.

Réservoir de

lubrifiant

Fig. 4

Témoin rapide du niveau d’huile

Bouchon du

réservoir

d’huile pour la

lubrification

de la chaîne

AVERTISSEMENT :

Assurez-vous que le réservoir

d’huile de lubrification pour la chaîne est toujours bien rempli.

À défaut de remplir le réservoir de lubrifiant, vous risquez de

causer des dommages irréparables sur l’appareil.

Bouton de la glissière

Fig. 5

Languette

Cavité de la poignée

INSTRUCTIONS D’UTILISATION

INSTRUCTIONS DE DÉMARRAGE ET D’ARRÊT

DÉMARRER LE MOTEUR

Pour éviter les démarrages accidentels, cet appareil est muni d’un bouton de

verrouillage et d’un interrupteur à gâchette qui doivent être utilisés conjointement

pour démarrer l’appareil.

1. Insérez la batterie dans la cavité de la poignée (Fig. 5). Consultez la section

Installer la batterie.

2. Placez votre pouce sur le bouton de verrouillage et enfoncez-le

complètement (Fig. 7).

3. Tout en maintenant enfoncé le bouton de verrouillage, appuyez sur

l’interrupteur à gâchette et maintenez-le aussi enfoncé.

4. Relâchez le bouton de verrouillage et maintenez enfoncé l’interrupteur à

gâchette pour une utilisation continue.

ARRÊTER LE MOTEUR

1. Relâchez l’interrupteur à gâchette.

REMARQUE : Il est normal que la chaîne s’arrête dès que l’interrupteur à

gâchette est relâché.

REMARQUE : Lorsque vous relâchez l’interrupteur à gâchette, le bouton de verrouillage se verrouille automatiquement.

PRÉPARATION DE LA COUPE

• Pour éviter l'électrocution, n’utilisez pas l’outil à moins de 50 pieds (15 m) de

lignes électriques aériennes (Fig. 8).

• Faites reculer toutes les personnes se trouvant à proximité (assistants,

enfants, animaux ou autres) d’au moins 50 pieds (15 m) de la zone de travail

(Fig. 8). Si quelqu’un s’approche de la zone de travail, arrêtez l’appareil !

• Portez des gants antidérapants pour garantir une prise parfaite et votre sécurité.

• Assurez-vous que les colliers sont bien resserrés avant d'utiliser l'appareil ;

effectuez cette vérification régulièrement lors de l'utilisation pour éviter de

graves blessures.

• Tenez toujours fermement l’appareil lorsque le moteur tourne. Tenez

fermement l’appareil des deux mains. Saisissez fermement la poignée avec la

main droite et le manche de la perche avec la main gauche (Fig. 9).

• L’utilisateur doit se tenir à gauche de la ligne de coupe de la chaîne. Ne

jamais tenir la poignée de la main gauche (en traverse) ou adopter une autre

position susceptible de mettre une quelconque partie du corps à travers la

ligne de coupe de la chaîne (Fig. 9).

• Ne vous tenez jamais directement sous la branche que vous coupez.

ÉLAGAGE

Cette tronçonneuse est conçue pour la coupe de petites branches et branches