Page 1

Owner’s Man ual

¨SET-UP ¨OP ER A TION ¨MAIN TE NANCE

IMPORTANT: Read Safety Rules and In struc tions Care fully

PRINTED IN CANADA OGST-3305

Page 2

CALLING CUS TOMER SUP PORT

XXX-XXXXXX

XXXXXXXXXXX

CUB CADET CANADA

KITCHENER, ON N2G 4J1

Model Number

Numéro de modèle

Serial Number

Numéro de série

• LO CATE YOUR MODEL NUMBER AND SE RIAL NUMBER which ap pears on your unit

and re cord the in for ma tion in the space pro vided be low.

IM POR TANT: You must have these num bers, along with the date and proof of

pur chase to re ceive war ranty or ser vice.

• If you are hav ing dif fi culty as sem bling this prod uct or if you have any ques tions re gard ing

the con trols, op er a tion or main te nance of this unit, please call an au tho rized dealer.

• Please have your model num ber and se rial num ber ready when you call.

NOTE: Al though both num bers are im por tant, you will be asked to en ter only

your se rial num ber be fore your call can be pro cessed.

This is where your model num ber will be,

re cord Model Num ber here:

This is where your se rial num ber will be,

re cord Se rial Num ber here:

This unit has been in spected against the man u fac tur ers qual ity check list. In case of

a dis crep ancy, please call us. We will make ev ery ef fort to ship the part(s) by cou rier

within one work ing day of your call.

IM POR TANT SAFE OP ER A TION PRAC TICES

WARNING: This sym bol points out im por tant safety in struc tions which, if not

fol lowed, could en dan ger the per sonal safety and/or prop erty of your self and

oth ers. Read and fol low all in struc tions in this man ual be fore at tempt ing to

op er ate this ma chine. Fail ure to com ply with these in struc tions may re sult in

per sonal in jury. When you see this sym bol—heed its warn ing.

DANGER: This ma chine was built to be op er ated ac cord ing to the rules for safe

op er a tion in this man ual. As with any type of power equip ment, care less ness or

er ror on the part of the op er a tor can re sult in se ri ous in jury. This ma chine is ca pa ble of am pu tat ing hands and feet and throw ing ob jects. Fail ure to ob serve the

fol low ing safety in struc tions could re sult in se ri ous in jury or death.

TRAINING

1. Read, un der stand, and fol low all in struc tions on the ma chine and in the

man ual(s) be fore at tempt ing to as sem ble and op er ate. Keep this man ual in a

safe place for fu ture and reg u lar ref er ence and for or der ing re place ment

parts.

2. Be fa mil iar with all con trols and their

proper op er a tion. Know how to stop

the ma chine and dis en gage them

quickly.

3. Never al low chil dren un der 14 years old

to op er ate this ma chine. Children 14

years old and over should read and un der stand the op er a tion in struc tions and

safety rules in this man ual and should

be trained and su per vised by a par ent.

4. Never al low adults to op er ate this ma chine with out proper in struc tion.

5. Thrown ob jects can cause se ri ous per sonal in jury. Plan your snow throw ing

pat tern to avoid dis charge of ma te rial

to ward roads, by stand ers and the like.

2

Page 3

6. Keep by stand ers, help ers, pets and chil dren at least 75 feet from the ma chine

while it is in op er a tion. Stop ma chine if

any one en ters the area.

7. Ex er cise cau tion to avoid slip ping or

fall ing, es pe cially when op er at ing in re verse.

PREP A RA TION

1. Thor oughly in spect the area where the

equip ment is to be used. Re move all

door mats, news pa pers, sleds, boards,

wires and other for eign ob jects which

could be trip ped over or thrown by the

au ger/im pel ler.

2. Al ways wear safety glasses or eye

shields dur ing op er a tion and while

per form ing an ad just ment or re pair to

pro tect your eyes. Thrown ob jects

which ric o chet can cause se ri ous in jury

to the eyes.

3. Do not op er ate with out wear ing ad e quate win ter outer gar ments. Do not

wear jew elry, long scarves or other

loose cloth ing which could be come en tan gled in mov ing parts. Wear foot wear

which will im prove foot ing on slip pery

sur faces.

4. Use a grounded three wire ex ten sion

cord and re cep ta cle for all units with

elec tric start en gines.

5. Ad just col lec tor hous ing height to clear

gravel or crushed rock sur faces.

6. Dis en gage all clutch le vers be fore start ing the en gine.

7. Never at tempt to make any ad just ments

while en gine is run ning, ex cept where

spe cif i cally rec om mended in the op er a tor’s man ual.

8. Let en gine and ma chine ad just to out door tem per a ture be fore start ing to

clear snow.

9. To avoid per sonal in jury or prop erty

dam age use ex treme care in han dling

gas o line. Gas o line is ex tremely flam ma ble and the va pors are ex plo sive.

Se ri ous per sonal in jury can oc cur when

gas o line is spilled on your self or your

clothes which can ig nite. Wash your

skin and change clothes im me di ately.

a. Use only an ap proved gas o line con -

tainer.

b. Ex tin guish all cig a rettes, ci gars,

pipes and other sources of ig ni tion.

c. Never fuel ma chine in doors.

d. Never re move gas cap or add fuel

while the en gine is hot or run ning.

e. Al low en gine to cool at least two min -

utes be fore re fu el ing.

f. Never over fill fuel tank. Fill tank to no

more than ½ inch be low bot tom of

filler neck to pro vide space for fuel

ex pan sion.

g. Re place gas o line cap and tighten se -

curely.

h. If gas o line is spilled, wipe it off the

en gine and equip ment. Move ma chine to an other area. Wait 5

min utes be fore start ing the en gine.

I. Never store the ma chine or fuel con -

tainer in side where there is an open

flame, spark or pi lot light (e.g. fur nace, wa ter heater, space heater,

clothes dryer etc.).

j. Al low ma chine to cool at least 5 min -

utes be fore stor ing.

OP ER A TION

1. Do not put hands or feet near ro tat ing

parts, in the au ger/ im pel ler hous ing or

dis charge chute. Con tact with the ro tat ing parts can am pu tate hands and feet.

2. The au ger/im pel ler clutch le ver is a

safety de vice. Never by pass its op er a tion. Doing so, makes the ma chine

un safe and may cause per sonal in jury.

3. The clutch le vers must op er ate eas ily in

both di rec tions and au to mat i cally re turn

to the dis en gaged po si tion when re leased.

4. Never op er ate with a miss ing or dam aged dis charge chute. Keep all safety

de vices in place and work ing.

5. Never run an en gine in doors or in a

poorly ven ti lated area. En gine ex haust

con tains car bon mon ox ide, an odor less

and deadly gas.

6. Do not op er ate ma chine while un der the

in flu ence of al co hol or drugs.

7. Muf fler and en gine be come hot and can

cause a burn. Do not touch.

8. Ex er cise ex treme cau tion when op er at ing on or cross ing gravel sur faces. Stay

alert for hid den haz ards or traf fic.

9. Ex er cise cau tion when chang ing di rec tion and while op er at ing on slopes.

3

Page 4

10. Plan your snow throw ing pat tern to avoid

dis charge to wards win dows, walls, cars

etc. To avoid prop erty dam age or per sonal in jury caused by a ric o chet.

11. Never di rect dis charge at chil dren, by stand ers and pets or al low any one in front

of the ma chine.

12. Do not over load ma chine ca pac ity by at tempt ing to clear snow at too fast of a

rate.

13. Never op er ate this ma chine with out good

vis i bil ity or light. Al ways be sure of your

foot ing and keep a firm hold on the han dles. Walk, never run.

14. Dis en gage power to the au ger/im pel ler

when trans port ing or not in use.

15. Never op er ate ma chine at high trans port

speeds on slip pery sur faces. Look down

and be hind and use care when in re verse.

16. If the ma chine should start to vi brate ab nor mally, stop the en gine, dis con nect the

spark plug and ground it against the en gine. In spect thor oughly for dam age.

Re pair any dam age be fore start ing and

op er at ing.

17. Dis en gage all clutch le vers and stop en gine be fore you leave the op er at ing

po si tion (be hind the han dles). Wait un til

the au ger/im pel ler co mes to a com plete

stop be fore un clog ging the dis charge

chute, mak ing any ad just ments, or in spec tions.

18. Never put your hand in the dis charge or

col lec tor open ings. Al ways use the

clean-out tool pro vided to un clog the dis charge open ing. Do not un clog

dis charge chute while en gine is run ning.

19. Use only at tach ments and ac ces so ries ap proved by the man u fac turer (e.g. wheel

weights, tire chains, cabs etc.).

20. If sit u a tions oc cur which are not cov ered

in this man ual, use care and good judg ment. Con tact the cus tomer sup port

de part ment.

MAIN TE NANCE AND STOR AGE

1. Never tam per with safety de vices. Check

their proper op er a tion reg u larly. Re fer to

the main te nance and ad just ment sec tions

of this man ual.

2. Be fore clean ing, re pair ing, or in spect ing

ma chine dis en gage all clutch le vers and

stop en gine. Wait un til the au ger/im pel ler

come to a com plete stop. Dis con nect

the spark plug wire and ground against

the en gine to pre vent un in tended start ing.

3. Check bolts, and screws for proper tight ness at fre quent in ter vals to keep the

ma chine in safe work ing con di tion. Also,

vi su ally in spect ma chine for any dam age.

4. Do not change the en gine gov er nor set ting or over-speed the en gine. The

gov er nor con trols the max i mum safe op er at ing speed of the en gine.

5. Snowthrower shave plates and slide shoes

are sub ject to wear and dam age. For

your safety pro tec tion, fre quently check

all com po nents and re place with orig i nal

equip ment man u fac turer’s (OEM) parts

only. “Use of parts which do not meet

the orig i nal equip ment spec i fi ca tions may

lead to im proper per for mance and com pro mise safety!”

6. Check clutch con trols pe ri od i cally to ver ify

they en gage and dis en gage prop erly and

ad just, if nec es sary. Re fer to the ad just ment sec tion in this op er a tor’s man ual for

in struc tions.

7. Main tain or re place safety and in struc tion

la bels, as nec es sary.

8. Ob serve proper dis posal laws and reg u la tions for gas, oil, etc. to pro tect the

en vi ron ment.

9. Prior to stor ing, run ma chine a few min utes to clear snow from ma chine and

pre vent freeze up of au ger/im pel ler.

10. Never store the ma chine or fuel con tainer

in side where there is an open flame,

spark or pi lot light such as a wa ter heater,

fur nace, clothes dryer etc.

11. Al ways re fer to the op er a tor’s man ual for

proper in struc tions on off-sea son stor age.

OWNER'S

MAN UAL

SAFETY LA BEL

WARNING - Your Re spon si bil ity:

Re strict the use of this power ma chine to per sons who

read, un der stand and fol low the warn ings and in struc tions in this man ual and on the ma chine.

4

Page 5

ASSEMBLY INSTRUCTIONS

NOTE: The snowthrower is

shipped with oil and WITH OUT

GAS O LINE. Af ter as sem bly, re fer to

sep a rate en gine man ual for proper

fuel and en gine oil rec om men da tions.

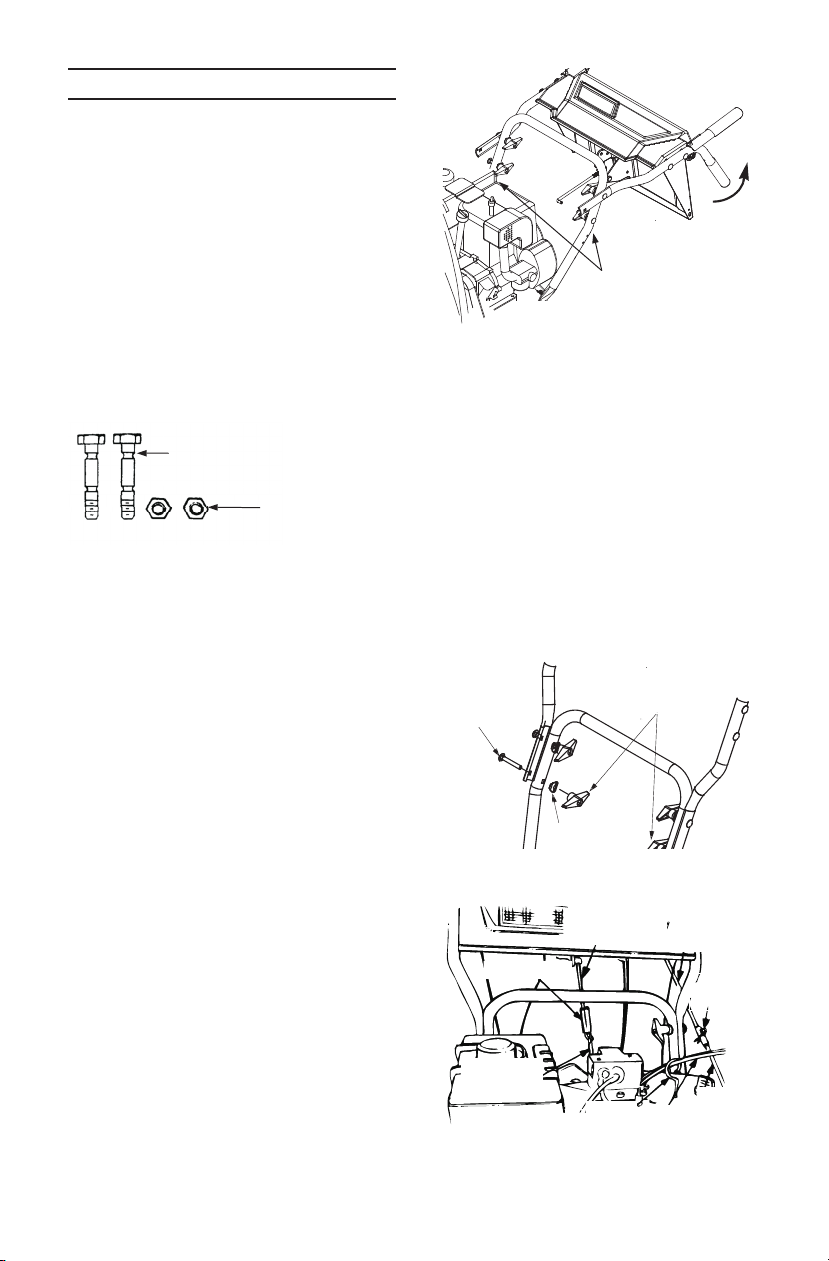

AUGER SHEAR BOLTS

The au gers are se cured to the spi ral

shaft with two shear bolts and hex

flange locknuts. Two re place ment hex

bolts and hex flange locknuts have

been pro vided for your con ve nience.

Store in a safe place un til needed.

Shear Bolts

5/16-18 x 1.75" Lg.

(710-0891)

Hex Flange

Locknuts

5/16-18 Thread

FIG URE 1

NOTE: Ref er ence to right hand or

left hand side of ma chine are ob served from the op er at ing po si tion.

IM POR TANT: Check the ad just ments

as in structed on page 10, and make

any fi nal ad just ments nec es sary

be fore op er at ing your snow thrower.

Fail ure to fol low the in struc tions may

cause dam age to the snow thrower.

• Re move sta ples or break glue on the

top flaps of the car ton. Re move any

loose parts in cluded with unit (i.e.,

owner’s man ual, etc.).

• Cut along dot ted lines and lay end of

car ton down flat. Re move pack ing ma te rial.

• Roll unit out of car ton. Check car ton

thor oughly for loose parts or lit er a ture.

• Re move the lower two plas tic wing

nuts, cupped wash ers and car riage

bolts from each side of the lower han dle. See Fig ure 2.

• Raise the up per han dle as sem bly un til it

locks over the lower han dle. See Fig ure

2 and 3.

(712-04063)

Wing Nuts,

Washers

and Bolts

FIG URE 2

• Se cure the up per han dle and lower

han dle with the two plas tic wing nuts,

cupped wash ers and car riage bolts pre vi ously re moved. See Fig ure 3.

• Slide the shift rod con nec tor down over

the end of the lower shift rod. See Fig ure 4. Tap the con nec tor un til it locks

on the lower shift rod.

NOTE: If the con nec tor is not prop erly as sem bled, the shift rod will

pivot and you will not be able to

shift gears or change di rec tions.

Carriage

Bolt

Wing Nuts

Washer

FIG URE 3

Upper Shift

Rod

Connector

Upper

Chute

Crank

Hairpin

Clip

Lower

Shift Rod

Cable

Guide

Chute

Cable

Lower

Chute

Crank

FIG URE 4

5

Page 6

• Re move the hair pin clip from the end of

the up per chute crank. Slide the up per

chute crank into the lower chute crank.

Align the holes, and se cure with hair pin

clip. See Fig ure 4.

• The ca ble ties nor mally are loosely in -

stalled on each side of the lower han dle

at the fac tory. Pull the ca ble ties tight to

se cure. Trim ex cess from the ends of

ca ble ties.

• If not al ready at tached, slip the ca bles

that run from the han dle panel to the

chute into the ca ble guide lo cated on

top of the en gine. See Fig ure 4.

FINAL ASSEMBLY AND ADJUSTMENTS

Slide Shoe Adjustment

The space be tween the shave plate and

the ground can be ad justed. For close

snow re moval, place slide shoes in the

low po si tion. Use mid dle or high po si tion when area to be cleared is un even.

See Fig ure 5.

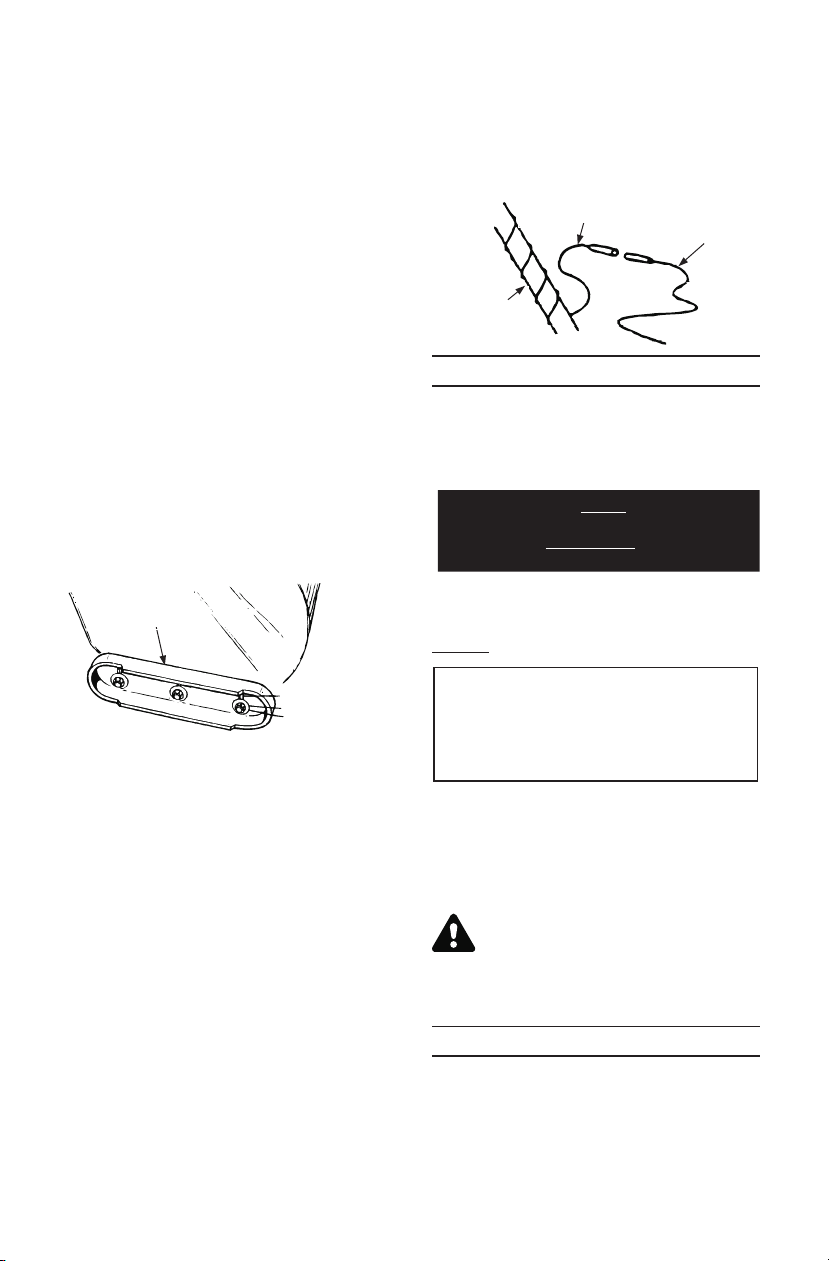

LAMP WIRING CONNECTION

(optional)

• Wrap the wire from the lamp down the

right han dle un til the wire can be

plugged into the al ter na tor lead wire un der the fuel tank.

Lamp Wire

Al ter na tor

Lead

Right

Han dle

BE FORE STARTING

NOTE: The crank case has been

filled with oil and fac tory tested.

Paint on the muf fler may have burnt

due to test ing.

AT TEN TION: YOU MUST CHECK OIL

LEVEL BE FORE OP ER A TION. LEVEL

MUST BE AT FULL MARK ON DIP STICK

BE FORE ENGINE IS STARTED.

Slide

Shoe

High

Middle

Low

FIG URE 5

• Ad just slide shoes by loos en ing the hex

nuts, wash ers and car riage bolts and

mov ing slide shoes to de sired po si tion.

Make cer tain the en tire bot tom sur face

of slide shoe is against the ground to

avoid un even wear on the slide shoes.

Tighten bolts se curely.

CHUTE CLEAN-OUT TOOL

The chute clean-out tool is con ve niently

fas tened to the rear of the au ger hous ing with a mount ing clip. Use the

clean-out tool to clear snow and ice

which may lodge in the dis charge chute

dur ing op er a tion. Re fer to the Op er a tion

sec tion for more de tailed in for ma tion re gard ing the chute clean-out tool.

Fail ure to fol low this pro ce dure may re sult in se ri ous en gine dam age which

will not be cov ered by war ranty.

Your unit may be equipped with a

plas tic fuel plug at the open ing of the

fuel tank. Please re move and dis card

the plug be fore fill ing your unit with

gas or be fore putt ing the unit into

op er a tion.

GAS AND OIL FILL-UP

Ser vice the en gine with gas o line and oil

as in structed in the sep a rate en gine

man ual packed with your snowthrower.

Read in struc tions care fully.

WARNING: Never fill fuel tank

in doors. Never fill fuel tank with

en gine run ning or while en gine

is hot. Do not smoke when fill ing fuel tank.

OP ER A TION

TO START ENGINE

• Make cer tain the metal loop on the end

of the spark plug wire (in side the boot)

is fas tened se curely over the metal tip

on the spark plug. See Fig ure 6.

6

Page 7

• Make cer tain the au -

Disengaged

ger and drive clutch

le vers are in the dis en gaged (re leased)

po si tion.

• Move throt tle con trol

up to FAST po si tion. In sert ig ni tion

key into slot. See Fig ure 7. Be cer tain it

snaps into place. Do not turn key.

Elec tric Starter (Op tional)

WARNING: The op tional elec tric

starter is equipped with a

three-wire power cord and plug,

and is de signed to op er ate on

120 volt AC House hold cur rent.

It must be prop erly grounded at

all times to avoid the pos si bil ity

of elec tric shock which may be

in ju ri ous to the op er a tor.

Fol low all in struc tions care fully. De ter mine

that your house wir ing is a three wire

grounded sys tem. Ask a li censed elec tri cian if you are not cer tain. If your house

wir ing sys tem is not a three-wire grounded

sys tem, do not use this elec tric starter un der any con di tions. If your sys tem is

grounded and a three hole re cep ta cle is

not avail able at the point your starter will

nor mally be used, one should be in stalled

by a li censed elec tri cian.

When con nect ing the power cord, al ways con nect cord to starter on en gine

first, then plug the other end into a

three-hole grounded re cep ta cle.

When dis con nect ing the power cord, al ways un plug the end from the

three-hole grounded re cep ta cle first.

• Ro tate choke knob to FULL choke po si tion.

• Push primer but ton two or three times

as in structed in the sep a rate en gine

man ual. See Fig ure 7.

NOTE: Al ways cover vent hole in

primer but ton when push ing. Ad di tional prim ing may be nec es sary

for first start if tem per a ture is be low

15oF (-9oC).

• Con nect power cord to switch box on

en gine. Plug the other end of power

cord into a three-hole, grounded 120

volt AC re cep ta cle.

Metal

Loop on

Spark

Plug Wire

Rubber Boot

FIG URE 6

ENGINE WILL NOT START

UN LESS IG NI TION KEY IS

IN SERTED INTO IG NI TION

SLOT IN CAR BU RE TOR

COVER. DO NOT TURN

IG NI TION KEY.

Spark Plug

Switch Box

Starter

Button

Rope

Starter

Handle

Muffler

Primer

Ignition

Key

Choke

Throttle

Control

FIGURE 7 - Your engine may be slightly

different from the engine shown .

CHOKE OFF

• Push starter but ton to crank en gine. See

FULL CHOKE

Fig ure 7.

• When en gine starts, re lease starter but -

ton, and move choke grad u ally to OFF. If

en gine fal ters, move choke im me di ately

to FULL and then grad u ally to OFF.

Re coil Starter:

• Ro tate choke knob to FULL choke po si -

tion (cold en gine start).

If en gine is warm, place choke in OFF

po si tion in stead of FULL.

• Push primer but ton two or three times

as in structed in the sep a rate en gine

man ual. See Fig ure 7.

If en gine is warm, push primer but ton

once only.

7

Page 8

NOTE: Al ways cover vent hole in

primer but ton when push ing. Ad di tional prim ing may be nec es sary for

first start if tem per a ture is be low 15°F.

• Grasp starter han dle (see Fig ure 7) and

pull rope out slowly, un til it pulls slightly

harder. Let rope re wind slowly.

• Pull starter han dle rap idly. Do not al low

han dle to snap back. Al low it to re wind

slowly while keep ing a firm hold on the

starter han dle. Re peat un til en gine

starts.

• As en gine warms up and be gins to op -

er ate evenly, ro tate choke knob slowly

to OFF po si tion. If en gine fal ters, re turn

to FULL choke, then slowly move to

OFF po si tion.

TO STOP ENGINE

• Run en gine for a few min utes be fore

stop ping to help dry off any mois ture on

the en gine.

• To help pre vent pos si ble freeze-up of

starter, pro ceed as fol lows:

Op tional Elec tric Starter: Con nect

power cord to switch box on en gine,

then to 120 volt AC re cep ta cle. With the

en gine run ning, push starter but ton and

spin the starter for sev eral sec onds. The

un usual sound made by spin ning the

starter will not harm en gine or starter.

Dis con nect the power cord from re cep ta cle first, and then from switch box.

Re coil Starter: With en gine run ning,

pull starter rope with a rapid, con tin u ous full arm stroke three or four times.

Pulling the starter rope will pro duce a

loud clat ter ing sound, which is not

harm ful to the en gine or starter.

• To stop en gine, re move the ig ni tion key.

Do not turn key. Dis con nect the spark

plug wire from the spark plug to pre vent ac ci den tal start ing while equip ment

is un at tended.

NOTE: Do not lose ig ni tion key.

Keep it in a safe place. En gine will

not start with out the ig ni tion key.

• Wipe all snow and mois ture from the

car bu re tor cover in the area of the con trol le vers. Also, move con trol le vers

back and forth sev eral times.

CONTROLS

Con trol po si tions and in for ma tion mark ings, on your ma chine are in

in ter na tional sym bols, as ex plained.

Calls your at ten tion to in struc tions con cern ing per sonal safety.

AUGER CLUTCH GRIP

Lo cated on left hand han dle.

Squeeze to en gage. Re lease

to stop.

DRIVE CLUTCH GRIP

Located on right hand han dle. Squeeze to en gage. Re lease to stop.

Keep by stand ers, help ers,

pets and chil dren at least 75

feet from the ma chine while

it is in op er a tion.

Avoid in jury from ro tat ing au ger – keep hands, feet and

cloth ing away.

Never put hand in chute.

Contact with ro tat ing parts

can am pu tate fin gers and

hands. Use clean-out tool to

un clog dis charge chute.

TO ENGAGE DRIVE

• With the en gine run ning near top

speed, move shift le ver into one of the

pos si ble FOR WARD or RE VERSE po si tions. Se lect a speed ap pro pri ate for the

snow con di tions that ex ist. Use the

slower speeds un til you are fa mil iar with

the op er a tion of the snowthrower.

• Squeeze the left hand au ger clutch grip

and en gage it.

• While the left hand au ger clutch grip is

en gaged, en gage the right hand drive

clutch grip.

8

Page 9

• Re lease the left hand au ger clutch grip

only. The in ter lock mech a nism should

keep the left hand clutch en gaged un til

the right hand clutch is re leased.

NOTE: Never move shift le ver with out first re leas ing the drive clutch.

CHUTE CLEAN-OUT TOOL

WARNING: Stop the en gine by

re mov ing the ig ni tion key and

wait for ALL mov ing parts to

stop, be fore us ing the clean-out

tool.

The chute clean-out tool is con ve niently

fas tened to the rear of the au ger hous ing with a mount ing clip. Should snow

and ice lodge it self in the dis charge

chute dur ing op er a tion, pro ceed as fol lows to safely clean the chute and

chute open ing:

• Re lease both au ger and drive clutch

grips.

• Stop the en gine by re mov ing the ig ni -

tion key.

• Re move the clean-out tool from the clip

which se cures it to the rear of the au ger

hous ing.

• Use the shovel-shaped end of the

clean-out tool to dis lodge and scoop

any snow and ice which has formed in

and near the dis charge chute.

WARNING: Never use your

hands to clean snow and ice

from the dis charge chute or au ger hous ing.

• Refasten the clean-out tool to the

mount ing clip on the rear of the au ger

hous ing, re in sert the ig ni tion key and

start the snow thrower’s en gine.

• While stand ing in the op er a tor’s po si -

tion (be hind the snow thrower), en gage

the au ger clutch le ver for a few sec onds

to clear any re main ing snow and ice

from the dis charge chute.

TRIGGER LEVERS (optional)

The trig ger le vers are lo cated on the

un der side of the han dles and used to

steer your snowthrower. See Fig ure 8.

To turn right, squeeze the right trig ger

le ver and guide the snowthrower to the

Trigger Assembly

FIGURE 8

right. Squeeze and guide the left le ver

to turn left. These con trols should be

used while op er at ing your snowthrower

in open ar eas un til you be come fa mil iar

with their op er a tion.

Squeeze both trig gers to free wheel or

to trans port unit.

TIRE PRESSURE

Pneu matic tires only. Tires are over-in flated for ship ping pur poses. Cor rect

tire pres sure is 10-15 psi.

OPERATING TIPS

NOTE: Al low the en gine to warm

up for a few min utes as the en gine

will not de velop full power un til it

reaches op er at ing tem per a ture.

WARNING: Tem per a ture of muf fler and sur round ing ar eas may

ex ceed 150°F. Avoid these ar eas.

• For most ef fi cient snow re moval, re -

move snow im me di ately af ter it falls.

• Dis charge snow down wind when ever

pos si ble. The dis tance snow is thrown

can be ad justed by ad just ing the an gle

of the chute as sem bly. The sharper the

an gle, the shorter the dis tance snow is

thrown. Slightly over lap each pre vi ous

swath.

• Set the slide shoes 1/4" be low the

scraper bar for nor mal us age. The slide

shoes may be ad justed up ward for

hard-packed snow. Ad just down ward

when us ing on gravel or crushed rock.

• Be cer tain to fol low the pre cau tions

listed un der pre vi ous sec tion, “To Stop

En gine” to pre vent pos si ble freeze up.

• Clean the snowthrower thor oughly af ter

each use.

9

Page 10

ADJUSTMENTS

WARNING: NEVER at tempt to

clean chute or make any ad just ments while en gine is run ning.

REMOTE CHUTE ASSEMBLY

ADJUSTMENT

The re mote chute con trol ca bles have

been pre-ad justed at the fac tory. Move

the re mote chute le ver on the con trol

panel back and for ward to ad just an gle

of the chute as sem bly.

CARBURETOR ADJUSTMENT

Mi nor car bu re tor ad just ment may be

re quired to com pen sate for dif fer ences in fuel, tem per a ture, al ti tude

and load.

Re fer to the sep a rate en gine man ual

packed with your unit for car bu re tor ad just ment in for ma tion.

NOTE: Fail ure to com ply with sug gested main te nance and lu bri ca tion

spec i fi ca tions will void war ranty.

CHECK ADJUSTMENT OF CLUTCH

CABLES

Proper ad just ment is achieved by slid ing

the spring up the ca ble and thread ing

the nut in or out. Cor rect ad just ment on

ca bles is min i mal slack but not tight.

AUGER BELT ADJUSTMENT

Pe ri odic ad just ment of the belt ten sion

may be re quired due to nor mal stretch

and wear on the belt. In crease belt ten sion if the au gers hes i tate while the

au gers are en gaged or de crease ten sion

if the the au gers con tinue to turn when

the au gers are dis en gaged. To ad just,

dis con nect fer rule from the brake

bracket as sem bly (Fig ure 16) and thread

fer rule in (to wards idler) to in crease ten sion on belt, out to de crease ten sion.

SHIFT ROD ADJUSTMENT

• To ad just the shift rod, re move the cot ter

pin which se cures the fer rule to the shift

le ver.

• Place the shift le ver in the fast est for -

ward po si tion. Push the shift rod down

Ferrule

Flat Washer

Cot ter Pin

Upper

Shift Rod

FIGURE 9

sharply, as far as it will go, to put the

drive into the fast est for ward po si tion.

Thread the fer rule in or out on the shift

rod as nec es sary un til the fer rule lines

up with the up per hole in the shift le ver.

In sert fer rule from the right side of the

snowthrower into up per hole in shift le ver and se cure with flat washer and

in ter nal cot ter pin. See Fig ure 9.

SLIDE SHOE ADJUSTMENT

The space be tween the shave plate and

the ground can be ad justed. Re fer to

“Fi nal As sem bly and Ad just ment".

LUBRICATION

WHEELS

Oil or spray lu bri cant into bear ings at

wheels at least once a sea son. Re move

wheels, clean and coat ax les with a

multi-pur pose au to mo tive grease.

CHAINS AND SHIFTING MECHANISM

Re move rear cover. Oil all chains.

sprock ets, bear ings, the hex ag o nal

shaft, round shaft and shift ing mech a nism at least once a sea son. Use

en gine oil or a spray lu bri cant. Avoid

get ting oil on rub ber fric tion wheel and

alu mi num drive plate.

CHUTE CRANK WORM

The worm gear on the chute di rec tion

crank should be greased with multi-pur pose au to mo tive grease.

AUGER SHAFT

Re move au ger bolts on au ger shaft, see

See Fig ure 11. Oil or spray lu bri cant in side shaft.

10

Page 11

ENGINE

Re fer to en gine man ual for en gine lu bri ca tion in struc tions.

WARNING: When fol low ing in struc tions in sep a rate en gine

man ual for drain ing oil, be sure

to pro tect frame to avoid oil

drip ping onto trans mis sion

parts.

HEX SHAFT

Lu bri cate the gear (hex) shaft with a light

weight cold weather lu bri cant at lease

once a sea son or af ter ev ery 25 hours of

op er a tion.

IM POR TANT: Keep all grease and oil off

of the rub ber fric tion wheel and alu mi num

drive plate.

If for any rea son your trans mis sion was

dis as sem bled and the au ger ca ble dis con nected, re as sem ble rout ing the ca ble

so it does not in ter fere with any mov ing

parts when pulled tight.

MAIN TE NANCE and

LU BRI CA TION

CHECK LIST

Check en gine oil level • •

Change en gine oil • •

Tighten all screws and nuts •

Check spark plug •

Lu bri cate chute open ing •

Lu bri cate wheel axle •

Lu bri cate wheel bear ings •

Lu bri cate chains, bear ings, • •

and hex shaft

Check wear on fric tion wheel

rub ber •

Check au ger pul ley(s) and

au ger drive belts •

no saeS hcaE gni nni geB

sruoH 2 tsriF re tfA

sruoH 5 re tfA

yltneu qerF

eg arotS ero feB

MAINTENANCE

WARNING: Dis con nect the

spark plug wire and ground

against the en gine be fore per form ing any re pairs or main te nance

AUGERS

The au gers are se cured to the spi ral shaft

with two shear bolts and hex locknuts.

See Fig ure 11. If you hit a for eign ob ject

or ice jam, the snowthrower is de signed

so that the shear bolts will shear.

If the au gers will not turn, check to see if

the hex bolts have sheared. Two re place ment hex bolts and hex lock nuts have

been pro vided with the snowthrower.

When re plac ing bolts, spray an oil lu bri cant into shaft be fore in sert ing new bolts.

SHAVE PLATE AND SLIDE SHOES

The shave plate and slide shoes on the

bot tom of the snowthrower are sub ject to

wear. They should be checked pe ri od i cally and re placed when nec es sary.

Shift Arm

Au ger

Bracket

As sem bly

Drive

Bracket

Hex Bolt

and

Cupped

Washer

Hex

Shaft

Fric tion

Wheel

FIG URE 10

NOTE: Some mod els are equipped

with re vers ible slide shoes.

To re move slide shoes, re move the

car riage bolts, cupped wash ers and hex

nuts which at tach them to the

snowthrower. Re as sem ble new slide

shoes with the car riage bolts, cupped

wash ers (cupped side goes against

slide shoes) and hex nuts.

11

Page 12

Au ger

Shaft

Hex Shear

Bolt

Dis charge

Chute

As sem bly

Hex Cap

Screw

Shave Plate

Hex Centre Locknut

FIGURE 11

To re move shave plate, re move slide

shoes as pre vi ously in structed, re move

the car riage bolts, cupped wash ers

and hex nuts which at tach it to the

snowthrower hous ing. Re as sem ble new

shave plate, mak ing sure heads of the

car riage bolts are to the in side of the

hous ing. Tighten se curely.

BELT RE MOVAL AND RE PLACE MENT

WARNING: Re move the spark

plug wire from the spark plug

and ground. Drain gas o line

from the fuel tank, or place a

piece of plas tic film un der neath

the gas cap to pre vent gas o line

from leak ing.

Auger Drive Belt

To re move and re place ei ther the au ger

drive belt or the drive belt, pro ceed with

the fol low ing in struc tions.

• Dis con nect chute crank as sem bly at the

dis charge chute by re mov ing the cot ter

pin and flat washer. See Fig ure 12.

Flat Washer

Chute

Crank

Plastic

Bushing

Hex

Locknut

Chute Flange

FIG URE 13

Keeper

Belt

Cover

Self-Tapping Screw

Flat Washer

FIG URE 14

• Re move the chute as sem bly by

removing the hex cap screws, chute

flange keep ers and hex locknuts. See

Fig ure 13.

• Re move the plas tic belt cover on the

front of the en gine by re mov ing three

self-tap ping screws and flat wash ers.

See Fig ure 14.

En gine

Pul ley

Large

Shoul der

Bolt

Cotter Pin

Chute Crank

Bracket

FIGURE 12

Hex Nuts

FIG URE 15

12

Page 13

• Re move the large shoul der bolt and

washer on the left hand side of the en gine pul ley with an ad just able wrench.

See Fig ure 15.

NOTE: Ref er ence to right hand or

left hand side of ma chine are ob served from the op er at ing po si tion.

• Re move the cot ter pin and washer from

the fer rule in or der to dis con nect the

au ger idler rod from the brake bracket

as sem bly as shown in Fig ure 16.

FIG URE 17

Frame

As sem bly

Au ger

Housing

Re move

Screw

and Lock

Washer

Au ger

Idler

Rod

Fer rule

Cotter

Pin and

Brake

Washer

Bracket

As sem bly

“Z”

Fitting

Ca ble Roller Guide

FIG URE 16

• Slip the au ger drive belt (the front belt)

off the en gine pul ley. See Fig ure 18.

• Pull the brake bracket as sem bly to -

wards the ca ble guide roller and

un hook the au ger ca ble “Z” fit ting. See

Fig ure 16.

• Re move the top screws and

lockwashers which at tach the au ger

hous ing as sem bly to the frame as sem bly. A 9/16" wrench is re quired. See

Fig ure 17.

• Sep a rate the au ger hous ing from the

frame as sem bly by tilt ing the hous ing

for ward and pull ing up the han dles.

• Rest the han dle as sem bly on the

ground and tip the re main ing half for ward to rest on the hous ing.

Brake Bracket

As sem bly

Au ger Drive

Belt

Pul ley

Auger Pulley

Mounting

Bolt

Belt Keeper (5)

Lockwasher (5)

FIG URE 18

To Re move the Au ger Drive Belt:

a. Using a 9/16" wrench re move the five

belt keep ers and lockwashers from

around the au ger pul ley. See Fig ure 18.

b. Re move and re place au ger drive

belt.

c. Re place lockwashers and belt keep ers.

NOTE: The au ger pul ley mount ing

bolt has chem i cal patch which sets

af ter bolt is as sem bled. If the bolt

is re moved for any rea son it must

be re placed.

NOTE: The brake puck in the brake

bracket as sem bly must al ways be

firmly seated in the pul ley groove

when the au ger clutch le ver is in

the dis en gaged po si tion.

13

Page 14

Belt Cover

1

2

3

4

Support

Bracket

Idler

Pulley

Drive

Belt

FIG URE 19

NOTE: See Ad just ment sec tion for

"Au ger Belt Ad just ment".

To Remove the Drive Belt:

a. Pull idler pul ley away from belt. See

Fig ure 19.

b. Re move drive belt from the en gine

pul ley and bot tom drive pul ley.

c. Re place belt and re as sem ble in re -

verse or der.

• Re as sem ble the two halves of the unit

hook ing the lower por tion of the au ger

hous ing over the sta tion ary shoul der

bolts in the frame as sem bly.

• Se cure the two halves with the two

screws and lockwashers.

• At tach the “Z” fit ting of the ca ble into

the brake bracket as sem bly. See Fig ure

16.

• Slip the au ger drive belt over en gine

pul ley.

• In sert fer rule on au ger idler rod into

bracket bracket as sem bly and se cure with

flat washer and cot ter pin.

• Re as sem ble the large shoul der bolt and

lockwasher as shown in Fig ure 15.

• Re as sem ble belt cover, chute as sem bly

and chute crank.

Changing the Friction Wheel

The rub ber on the fric tion wheel is sub ject to wear and should be checked

af ter 25 hours of op er a tion, and pe ri od i cally there af ter. Re place the fric tion

wheel rub ber if any signs of wear or

crack ing are found.

Bonded fric tion

wheel rub ber

Hex

self-tap ping

screws

FIG URE 20

Pin

Shift Rod

As sem bly

Fric tion

Spacer

Sprocket

Wheel

Shaft

Sup port Bracket

FIG URE 21

• Drain the gas o line from the

snowthrower, or place a piece of plas tic

un der the gas cap.

• Tip the snowthrower up and for ward, so

that it rests on the hous ing.

• Re move six self-tap ping screws from

the frame cover un der neath the

snowthrower and re move cover.

• Re move the wheels from the axle.

• Using a 7/8" wrench hold the hex shaft

and re move the hex bolt and cupped

washer and bear ing from left side of the

frame. See Fig ure 10. Hold the fric tion

wheel as sem bly, and slide the hex shaft

out of the unit to ward the right hand

side.

• Re move the four screws from the fric -

tion wheel as sem bly and re move the

bonded fric tion wheel.

• Re as sem ble new bonded fric tion wheel

rub ber to the fric tion wheel as sem bly,

turn each screw ap prox i mately 2 turns

in or der shown in Figure 20 un til screws

are tight. It is im por tant for the rub ber

to be as sem bled sym met ri cally.

14

Page 15

• Po si tion the fric tion wheel as sem bly up

onto the pin of the shift rod as sem bly

and slide the shaft through the fric tion

wheel. See Fig ure 21.

• Slide the hex shaft into the hex I.D. of

the sprocket, the spacer and the left

ball bear ing and se cure with the

cupped washer and hex bolt.

• Re move plas tic film from gas cap.

NOTE: Make sure the pin from the

shift arm as sem bly is as sem bled to

the new fric tion wheel as sem bly.

CAUTION: Check engine and

snowthrower frequently for loose

nuts, bolts, etc. and keep these items

tightened.

STORAGE INSTRUCTIONS

NEVER STORE ENGINE WITH

FUEL IN TANK IN DOORS OR IN

EN CLOSED, POORLY VEN TI LATED EN CLO SURES, WHERE

FUEL FUMES MAY REACH AN

OPEN FLAME OR SPARK.

If unit is to be stored over 30 days, pre pare for stor age as in structed in the

sep a rate en gine man ual packed with

your unit.

NOTE: Fail ure to com ply with sug gested main te nance and

lu bri ca tion spec i fi ca tions will void

war ranty.

15

Page 16

TROU BLE SHOOTING

PROB LEM POS SI BLE CAUSE(S) COR REC TIVE AC TION

En gine fails to start 1. Fuel tank empty, or stale fuel.

2. Blocked fuel line.

3. Choke not in the FULL po si tion.

4. Faulty spark plug.

5. Safety key not in ig ni tion switch

on en gine.

6. Spark plug wire dis con nected.

7. Primer but ton not be ing used

prop erly.

8. Fuel shut-off valve closed.

En gine runs er ratic 1. Unit run ning on CHOKE.

2. Blocked fuel line or stale fuel.

3. Wa ter or dirt in the fuel sys tem.

Loss of power 1. Spark plug wire loose.

2. Gas cap vent hole plugged.

Ex ces sive vi bra tion 1. Loose parts or dam aged au ger. 1. Stop the en gine im me di ately and dis -

Unit fails to drive prop erly 1. Drive con trol ca ble in need of

Unit fails to

dis charge snow

Heated grips are not

cre at ing heat

ad just ment.

2. Drive belt loose or dam aged.

1. Dis charge chute clogged.

2. Shear bolt sheared.

3. For eign ob ject lodged in au ger.

4. Au ger con trol ca ble in need of

ad just ment.

5. Au ger belt loose or dam aged.

1. Unit is not run ning.

2. Loosen elec tri cal con nec tions.

3. Blown Fuse.

4. Faulty grip. If one heated grip

fails, both grips will not func tion.

1. Fill tank with clean, fresh gas o line.

Fuel be comes stale af ter thirty days.

2. Clean the fuel line.

3. Move switch to the FULL po si tion.

4. Clean, ad just gap or re place.

5. In sert the key fully into the switch.

6. Con nect spark plug wire.

7. Re fer to the en gine man ual.

8. Open fuel shut-off valve.

1. Move the choke le ver to OFF po si tion.

2. Clean the fuel line; fill the tank with

clean, fresh gas o line.

3. Drain the fuel tank and car bu re tor.

Re fill with fresh fuel.

1. Con nect and tighten spark plug wire.

2. Re move ice and snow from gas cap.

Be cer tain vent hole is clear.

con nect the spark plug wire. Tighten

all bolts and nuts. If vi bra tion con tin ues, have the unit ser viced by an

au tho rized ser vice dealer.

1. Ad just drive con trol ca ble. Re fer to

Ad just ment Sec tion of this man ual.

2. Re place drive belt. Re fer to Belt Re moval and Re place ment.

1. Stop en gine and dis con nect spark

plug wire. Clean dis charge chute and

in side of au ger hous ing with tool pro vided.

2. Re place shear bolt.

3. Stop en gine im me di ately and dis con nect spark plug wire. Re move ob ject

from au ger.

4. Ad just au ger con trol ca ble. Re fer to

Ad just ment sec tion of this man ual.

5. Re fer to Belt Re moval and Re place ment.

1. Start the unit

2. Un der the han dle panel, check con nec tions from the han dles to the

wir ing har ness.

3. Re place 5A fuse un der the han dle

panel near crank switch con nec tor.

4. Have the grips checked at an au tho rized ser vice dealer.

16

Page 17

THREE (3) YEAR LIMITED WAR RANTY

For three (3) years from the date of orig i nal pur chase of our prod ucts, we will ei ther re pair or

re place, at its op tion, free of charge, F.O.B. Fac tory or au tho rized ser vice firm, any part found to

be DE FEC TIVE IN MA TE RIAL and WORK MAN SHIP for the orig i nal pur chaser. all trans por ta tion

charges on parts sub mit ted for re place ment un der this war ranty must be paid by the pur chaser

un less re turn is re quested by the man u fac turer.

This war ranty DOES NOT ap ply to any part which has be come in op er a tive through mis use, ex ces sive use, ac ci dent, ne glect, im proper main te nance or al ter ations by un au tho rized per sons.

The lim ited war ranty does not ex tend to the re place ment of parts which are not de fec tive, but

where reg u lar us age has ex hausted the life of the part.

EN GINES, ELEC TRIC START KITS, PEER LESS TRANS MIS SIONS AND PEER LESS

TRANSAXLES ARE WAR RANTED BY THEIR RE SPEC TIVE MAN U FAC TURER. ALL CLAIMS

AGAINST THESE COM PO NENTS MUST BE HAN DLED THROUGH THE RE SPEC TIVE MAN U FAC TURER’S SER VICE DEAL ERS.

Belts, light bulbs, clutch parts (fric tion wheels), grass bags, tires, seats, rider deck wheels and

cut ting blades are cov ered by a 60 day lim ited war ranty.

Bat ter ies are cov ered by a 90 day lim ited war ranty.

Fuses, shear bolts and blade adapt ers are con sid ered con sum able items and as such are not

war ranted.

NOTE: Reg u lar main te nance re place ment parts and re lated in spec tions and ad just ments are

ex cluded from cov er age when made as part of nor mal main te nance ser vice.

TRAC TOR AT TACH MENT WAR RANTY

Mower decks in cluded with your prod uct, or sold sep a rately, as an at tach ment for your gar den

trac tors will be war ranted ac cord ing to the above terms of the man u fac turer three (3) year lim ited con sumer war ranty.

ALL OTHER AT TACH MENTS will be sold un der the same con di tion as above ex cept the war ranty will be ONE YEAR FROM DATE OF ORIG I NAL PUR CHASE.

PER SONAL USE

THE FORE GO ING PARA GRAPHS CON STI TUTE THE MAN U FAC TURER’S EN TIRE WAR RANTY WITH RE SPECT TO ANY PROD UCT PUR CHASED AND USED FOR PER SONAL

FAM ILY, HOUSE HOLD/RES I DEN TIAL PUR POSES, AS DIS TIN GUISHED FROM COM MER CIAL US AGE.

COM MER CIAL USE

ALL AP PLI CA TIONS OTHER THAN PER SONAL USE AS OUT LINED ABOVE, ARE CON SID ERED COM MER CIAL US AGE.

New prod ucts pur chased for com mer cial us age are war ranted in the same man ner and

to the same ex tend EX CEPT the term of war ranty will be 60 DAYS from date of pur chase,

90 days if your unit is equipped with an OHV en gine. “

WAR RANTY SER VICE CAN ONLY BE PER FORMED BY AN AU THO RIZED SER VICE

DEALER. ANY NON-ORIG I NAL EQUIP MENT RE PLACE MENT PART USED ON OR IN A

PROD UCT UN DER WAR RANTY WILL BE EX CLUDED FROM THAT WAR RANTY COV ER AGE,

AS WILL BE ANY RE LATED DAM AGED COM PO NENTS RE SULT ING FROM THE IN STAL LA TION OF A RE PLACE MENT PART FROM AN OTHER SOURCE OTHER THAN THE

MAN U FAC TURER.

17

Page 18

SUP PLE MENT SUP PLÉ MENT

IN STRUC TIONS FOR AT TACH ING

THE CHUTE AS SEM BLY

• Place chute as sem bly over chute

open ing, with the open ing in the

chute as sem bly fac ing the front of the

unit. Place chute flange keep ers be neath lip of chute as sem bly, with the

flat side of chute flange keeper fac ing

down ward.

• In sert hex cap screws up through

chute flange keeper and chute as sem bly as shown in Fig ure 1. Se cure

with hex flange locknuts. Tighten with

two 7/16" wrenches. Do not over

tighten.

• With the hex nuts loos ened on the

lower chute crank bracket (see Fig ure

2) ad just the bracket so that the spi ral

on the chute crank fully en gages the

teeth on the chute as sem bly. Tighten

the nuts on the lower chute crank

bracket se curely.

FIG URE 1

Flat Washer

Cotter Pin

Chute Crank

Bracket

FIGURE 2

Dis charge Chute

As sem bly

Hex Cap

Screw

(710-3015)

Hex Flange

Locknut

(712-3027)

Chute Flange

Keeper (731-0851A)

Chute

Crank

Plastic

Bushing

Hex Nuts

MONTAGE DE LA GOULOTTE

• Disposez la goulotte au-dessus de

l’ouverture en plaçant l’ouverture

d’éjection de la goulotte face à l’avant

de la ma chine. Positionnez les

garde-brides sous le rebord de la

goulotte, le côté plat des garde-brides

tourné vers le bas.

• Faites passer les vis à cha peau à tête

hex. à travers les garde-brides et la

goulotte, comme à la Fig ure 1.

Maintenez en place avec des

contre-écrous à embase. Serrez avec

deux clés de 7/16 po. Ne serrez pas

excessivement.

• Les écrous à six pans du sup port de

la manivelle de la goulotte étant

desserés, et ajustez celui-ci (voir la

Fig ure 2) de manière que la partie

hélicoïdale de la manivelle s’engrène

bien avec les dents de la goulotte.

Serrez les écrous sur les sup port de

la manivelle inférieure.

Garde-bride de la goulotte

(731-0851A)

FIGURE 1

Rondelle plate

Goupille

fendue

Support de la manivelle de

la goulotte

FIGURE 2

Assemblage de

la goulotte

Vis à chapeau

à tête hex.

(710-3015)

Contre-écrou à

embase

(712-3027)

Coussinet en

plastique

Manivelle de la

goulotte

Écrous à

six pans

OGST-3105A

6.25.04

1

Page 19

SUP PLE MENT

Loading...

Loading...