Page 1

Service Manual

Commercial MMZ Rider

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow

all instructions and use common sense when working on power equipment. This includes the contents of the product’s

Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication, although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to the variety of outdoor power equipment and continuing product changes that occur over time, updates will be

made to these instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing

or repairing a product. The company reserves the right to make changes at any time to this publication without prior notice

and without incurring an obligation to make such changes to previously published versions. Instructions, photographs and

illustrations used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2005 MTD Products Inc. All Rights Reserved

MTD Products Inc - Product Training and Education Department

FORM NUMBER - 769-01760

3/2005

Page 2

Page 3

SECTION 1

Cub Cadet Commercial M60 Tank - 2002 and prior years

PTO Belt Removal ......................................................................................................1

Cutting Deck Removal ................................................................................................3

Cutting Deck Drive Belt Removal ...............................................................................5

Spindle Removal and Disassembly ............................................................................6

Hydrostatic Drive Belt Removal ..................................................................................7

Electric PTO Clutch Removal .....................................................................................9

Electric PTO Clutch Specifications ...........................................................................10

Hydrostatic Drive Assembly Removal ......................................................................11

Hydrostatic Pump / Transmission Removal .............................................................15

Left Transmission Disassembly and Inspection .......................................................18

Left Transmission Shimming and Assembly ........................................................22

Shimming Procedures ..............................................................................................24

Inner Housing ...........................................................................................................24

Outer Housing ..........................................................................................................24

Preparation ...............................................................................................................29

Lap Bar Adjustment ..................................................................................................29

Neutral Control Adjustment ......................................................................................29

Creep Adjustment .....................................................................................................30

Parking Brake Adjustment ........................................................................................33

Preliminary Setup .....................................................................................................35

Lift Adjustment Rods ................................................................................................35

Side to Side Adjustment ...........................................................................................35

Mower Deck Leveling ...............................................................................................35

Front to Back Adjustment .........................................................................................37

SECTION 2

Cub Cadet Commercial M60 Tank - 2003/4 Update

Changes for 03/04.......................................................................................................1

Drive System Adjustment ............................................................................................1

Testing Hydro Pump Output........................................................................................4

Replacing the Hydro Pump .........................................................................................6

Replacing the Hydro Motor........................................................................................10

Brake Linkage Adjustment ........................................................................................13

M72 Update...............................................................................................................16

Other Tank Features .................................................................................................19

1

Page 4

2

Page 5

Cub Cadet Commercial M60 Tank - 2002 and prior years

Service Manual

Cub Cadet Commercial M60 Tank - 2002 and prior years

PTO Belt Removal

1. Pivot the seat assembly forward.

2. Remove the lock nut and hex bolt securing the

negative battery cable to the negative battery terminal using a 7/16” socket and a 7/16” wrench.

3. Remove the sparkplug wires from the sparkplugs

on the engine.

4. Lower the cutting deck to the lowest position.

5. Grasp the floor panel assembly and raise it to the

fully open position.

6. Unlatch the PTO belt release lever and slowly

pivot it away from the unit. See Figure 1.

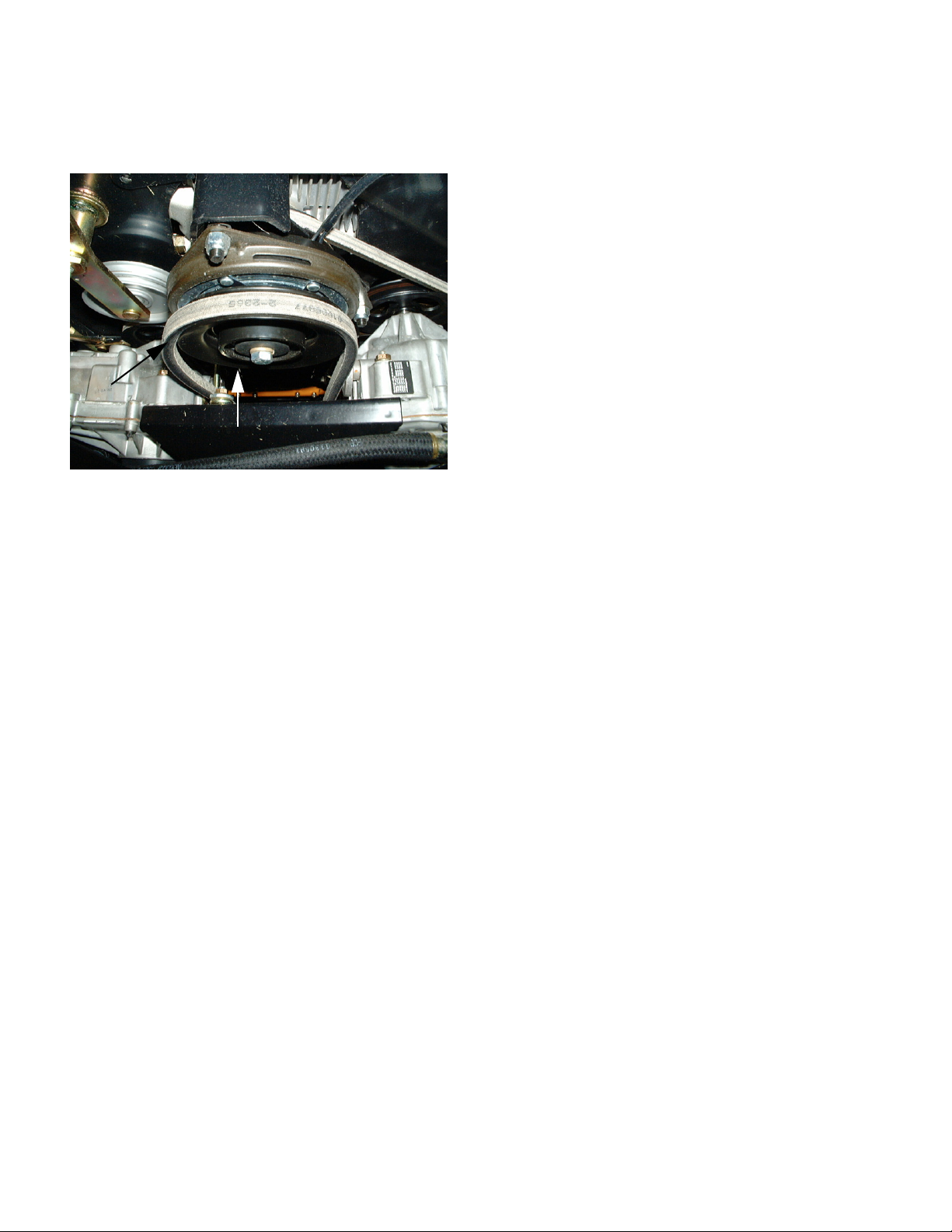

7. Grasp the idler pulley and pull outward while rolling the PTO belt off. See Figure 2.

Idler Pulley

Pull Outward

PTO Belt

Figure 2

8. Roll the PTO belt off of the upper portion of the

double stack pulley. See Figure 3.

Release Lever

Figure 1

PTO Belt

Double Stack Pulley

Figure 3

1

Page 6

Cub Cadet Commercial M60 Tank - 2002 and prior years

9. Remove the PTO belt from the electric clutch pulley. See Figure 4.

PTO Belt

Electric Clutch Pulley

Figure 4

10. Inspect the V-belt for damage or wear.

11. Install the PTO belt in the reverse order above.

2

Page 7

Cub Cadet Commercial M60 Tank - 2002 and prior years

Cutting Deck Removal

NOTE: Prior to performing this section, the PTO

Belt Removal section must be performed.

1. Make certain the cutting deck is at the lowest

position. See Figure 1.

Deck Lift Handle

Clevis Pin

Hairpin

4. Pull the front mounting rod to the right several

inches until the left frame strut and lift brace are

free. See Figure 3.

Frame Strut

Above

To

Here

From

Here

Below

Lowest Position

Figure 1

2. Remove the hairpin and clevis pin from below

the deck lift handle, and install them above the

deck lift handle.

NOTE: This step must be performed to make

certain the deck lift handle is restrained and will

not spring back up during cutting deck removal.

3. Remove all six linch pins securing the cutting

deck to the deck link eye bolts and front mounting rod. See Figure 2.

Right

Front Mounting Rod

Lift Brace

Figure 3

5. Pull the front mounting rod to the left until the

right frame strut and lift brace are free.

6. Remove all four of the lift link eye bolts from the

deck lift pins. See Figure 4.

Eyebolt

Cutting

Deck

Eye Bolts

Figure 2

Deck Lift

Pins

Figure 4

7. Push the lift handle down (against the spring tension) and remove the hairpin and clevis pin from

above it.

8. Slowly raise the lift handle all the way up.

NOTE: The lift handle can swing up quickly if

care is not taken to hold it back.

3

Page 8

Cub Cadet Commercial M60 Tank - 2002 and prior years

9. Install the clevis pin and hairpin below the lift

handle.

10. Slide the cutting deck assembly out from below

the unit. See Figure 5.

Cutting Deck

Figure 5

11. Install the cutting deck in the reverse order

above.

4

Page 9

Cub Cadet Commercial M60 Tank - 2002 and prior years

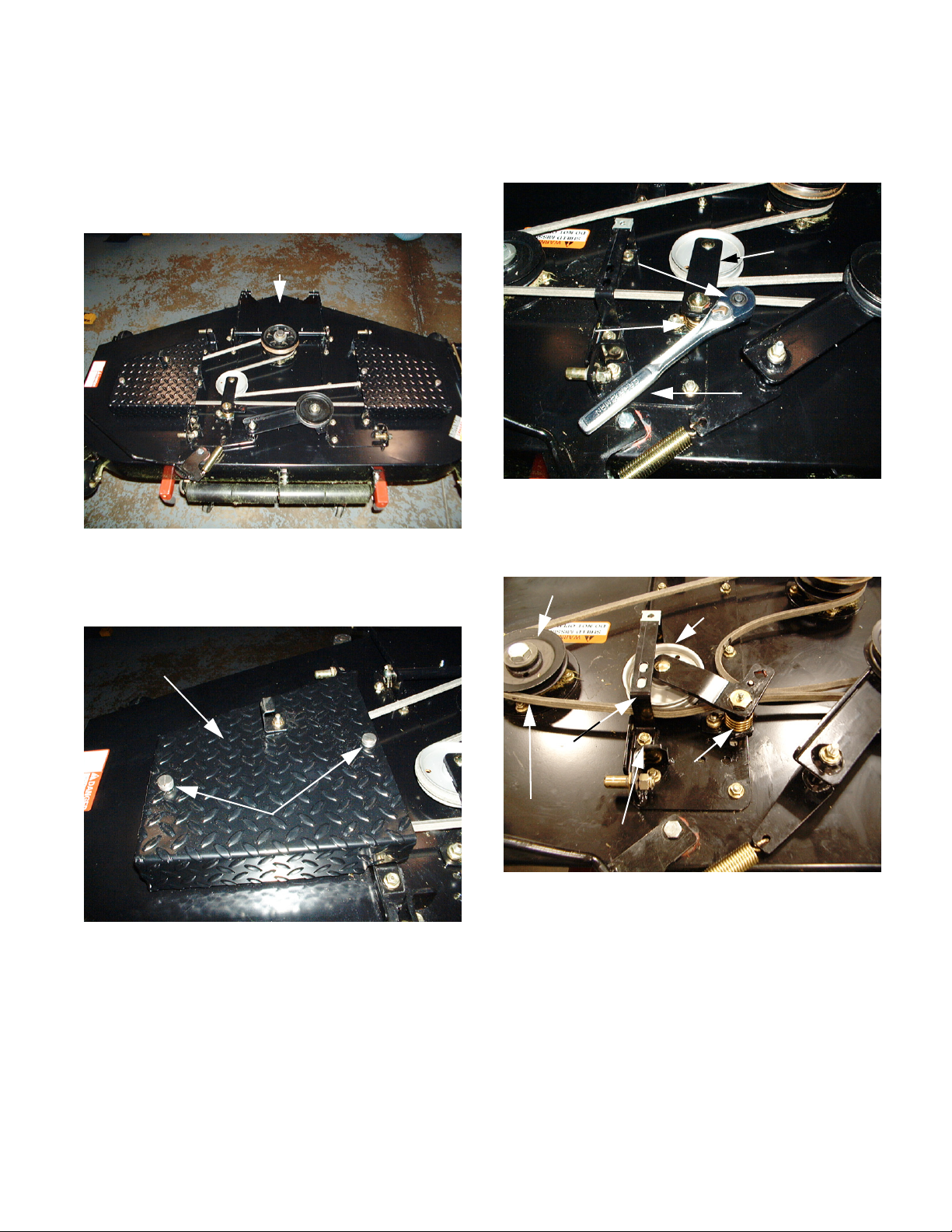

Cutting Deck Drive Belt Removal

NOTE: Prior to performing this section, the PTO

Belt Removal and Cutting Deck Removal sections must be performed.

Cutting Deck

Figure 1

3. Release the spring tension being applied to the

deck drive belt by installing a 1/2" ratchet in the

square hole of the idler arm assembly and pulling

outward. See Figure 3.

1/2” Ratchet

in Square

Hole

Spring

Ten si on

Pull

Figure 3

4. Roll the deck drive belt off of the idler pulley. See

Figure 4.

Idler Arm

Assembly

1. Loosen both knobs securing each belt cover to

the deck assembly. See Figure 2.

Belt Cover

Knobs

Figure 2

2. Remove the belt covers.

Spindle Pulley

Idler Pulley

Spindle

Cover

Bracket

Deck Drive Belt

Lock Nut

5. Slowly retract the 1/2" ratchet and release the

compression spring tension.

6. Remove the deck drive belt from all three spindle

pulleys.

7. Remove both hex flange lock nuts securing the

left inner spindle cover bracket to the deck using

a 9/16” socket and a 9/16” wrench.

Compression

Spring

Figure 4

8. Inspect the deck drive belt for damage or wear.

9. Install the deck drive belt in the reverse order

above.

5

Page 10

Cub Cadet Commercial M60 Tank - 2002 and prior years

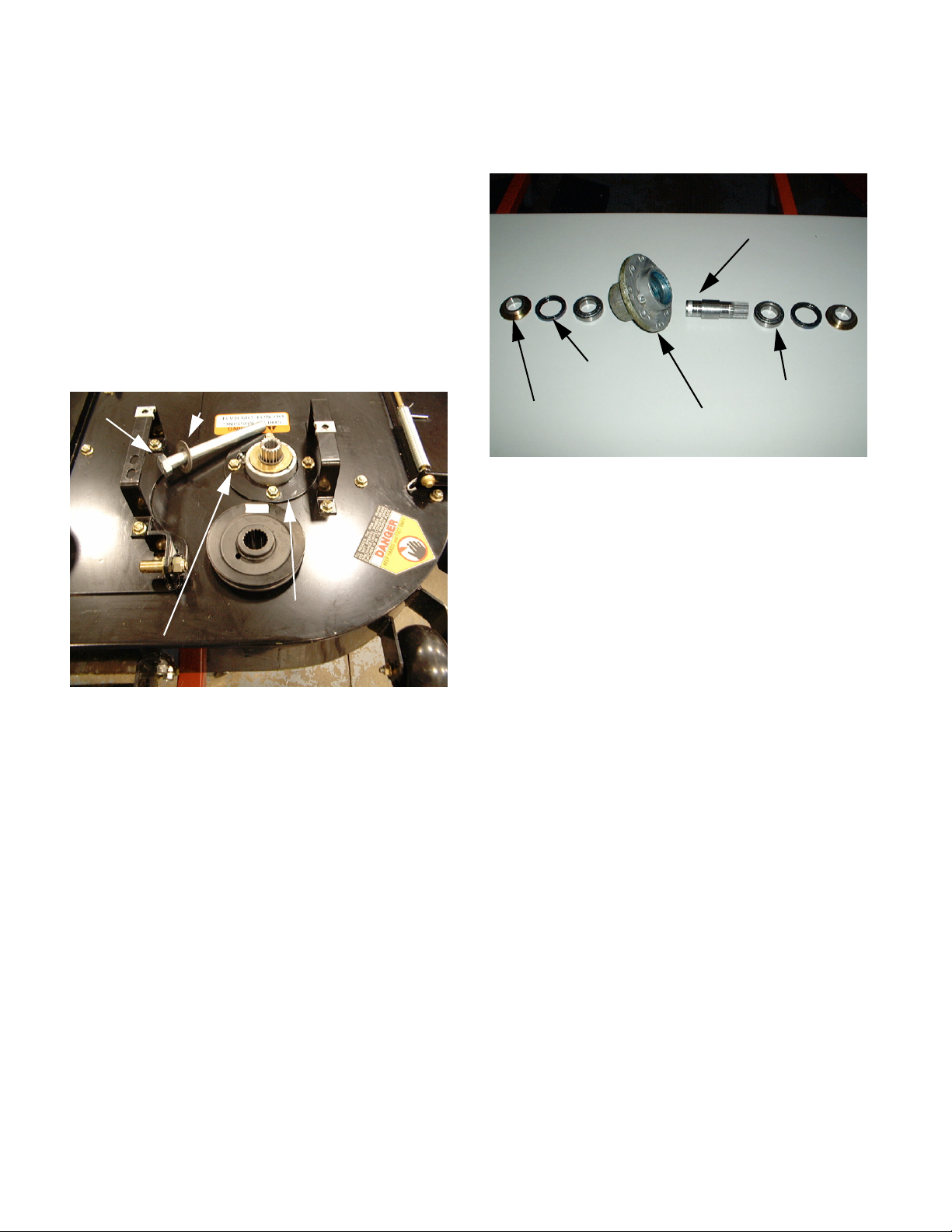

Spindle Removal and Disassembly

NOTE: Prior to performing this section, the Cut-

ting Deck Drive Belt Removal section must be

performed.

1. Remove the hex flange lock nut securing the

blade assembly together using a 1-1/8” socket

and a 1-1/8” wrench.

2. Remove the blade and spacer from the large hex

cap screw.

3. Remove the large hex cap screw and washer.

See Figure 1.

Large hex cap screw and washer

5. Press all of the spindle components apart and

inspect for wear or damage. See Figure 2.

Shaft Blade Spindle

Ring Seal

Cone Bearing

Oil Seal

NOTE: The bearings will be damaged by the

force of the press. New bearings should be

heated and set into position.

Spindle Housing

Figure 2

Spindle Housing

Spindle Hex Cap Screws and Lock Nuts

Figure 1

4. Remove all four hex cap screws and hex flange

lock nuts securing the spindle housing to the

deck assembly using a 9/16” socket and a 9/16”

wrench.

6. Assemble the spindle in the reverse order above.

6

Page 11

Cub Cadet Commercial M60 Tank - 2002 and prior years

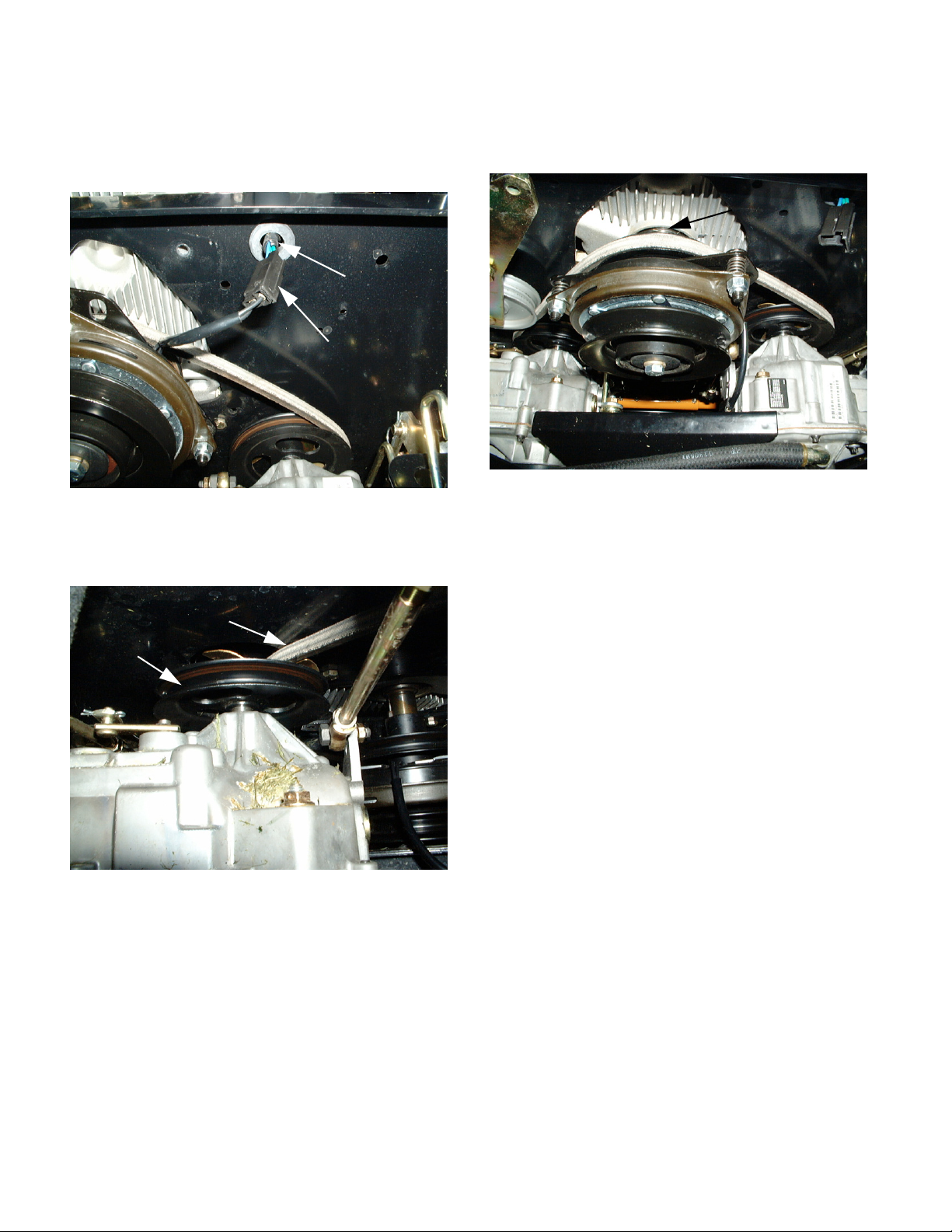

Hydrostatic Drive Belt Removal

1. Pivot the seat assembly forward.

2. Remove the lock nut and hex bolt securing the

negative battery cable to the negative battery terminal using a 7/16” socket and a 7/16” wrench.

3. Remove the sparkplug wires from the sparkplugs

on the engine.

4. Remove the hex insert lock nuts and flat washers

from the input shafts of the right and left hydrostatic pump assemblies using a 3/4" socket. See

Figure 1.

Access Holes

Lock Nut

Input Shaft

Figure 1

Flat Washer

5. Remove the idler arm extension spring from the

left frame rail using vice grips. See Figure 2.

Idler Arm

Extension Spring

Frame Rail

Figure 2

NOTE: Make certain the orientation of the spring

is recorded.

6. Remove the extension spring from the idler arm

and set it aside.

7. Remove both hex cap screws and flange lock

nuts securing the PTO clutch retension bracket

to the frame using a 1/2" socket and a 1/2"

wrench. See Figure 3.

NOTE: There are two 4” holes above each

hydrostatic pump assembly to access the lock

nuts.

PTO Bracket

Hex Cap Screws

Clutch Retension

Bracket

Figure 3

7

Page 12

Cub Cadet Commercial M60 Tank - 2002 and prior years

8. Disconnect the PTO clutch connector from the

wiring harness connector using a small flat-blade

screw driver. See Figure 4.

Wiring Harness

PTO Clutch Connector

Figure 4

9. Roll the drive belt up and off of the right transmission pulley. See Figure 5.

12. Remove the drive belt from the engine drive pulley. See Figure 6.

Engine Drive

Pulley

Figure 6

13. Inspect the drive belt for damage or wear.

14. Install the hydrostatic drive belt in the reverse

order above.

Drive Belt

Transmission

Pulley

Figure 5

10. Push the drive belt up and over the right hydrostatic input shaft, hydro pulley fan and transmission pulley.

11. Push the drive belt up and over the left hydrostatic input shaft, hydro pulley fan and transmission pulley.

8

Page 13

Cub Cadet Commercial M60 Tank - 2002 and prior years

Electric PTO Clutch Removal

NOTE: Prior to performing this section, the

Hydrostatic Drive Belt Removal section must be

performed.

1. Remove the hex lock nut securing the negative

cable to the right front engine mounting bolt

using a 1/2" wrench. See Figure 1.

Lock Nut

Negative Cable

Figure 1

3. Loosen the front engine mounting bolts and hex

flange lock nuts securing the engine to the frame

using a 1/2" socket and a 1/2" wrench.

See Figure 3.

Engine Mounting Bolts

Figure 3

4. Remove the hex cap screw, lock washer and flat

washer securing the electric PTO clutch to the

engine crankshaft using a 5/8” socket.

See Figure 4.

2. Remove the hex lock nut securing the ground

wires to the left front engine mounting bolt using

a 1/2" wrench. See Figure 2.

Lock Nut

Ground Wires

Figure 2

Electric

PTO

Clutch

Flat Washer

Lock

Washer

Hex Cap Screw

Figure 4

9

Page 14

Cub Cadet Commercial M60 Tank - 2002 and prior years

5. Lift the rear of the engine slightly and remove the

electric PTO clutch from the engine crankshaft.

See Figure 5.

Electric PTO Clutch

Figure 5

6. Inspect and test the electric PTO clutch.

7. Install the electric PTO clutch in the reverse

order above.

Electric PTO Clutch Specifications

• Ogura part #520038

• Bore of 1-1/8", keyway for 1/4"x 1/4" square key

• Forged steel rotor

• E-coated metal parts

• Epoxy coated coil

• Sealed bearings with high temperature, long life

grease

• Static torque rating of 110 lb.-ft.

• Minimum "pull-in" voltage is 8 VDC

• Consumption of 50 watts (6 amps) at 12 VDC

• Coil resistance is 3 to 4 ohms at 70 F.

• Air gap (re-setting) between 0.013" (minimum)

and 0.015"

10

Page 15

Cub Cadet Commercial M60 Tank - 2002 and prior years

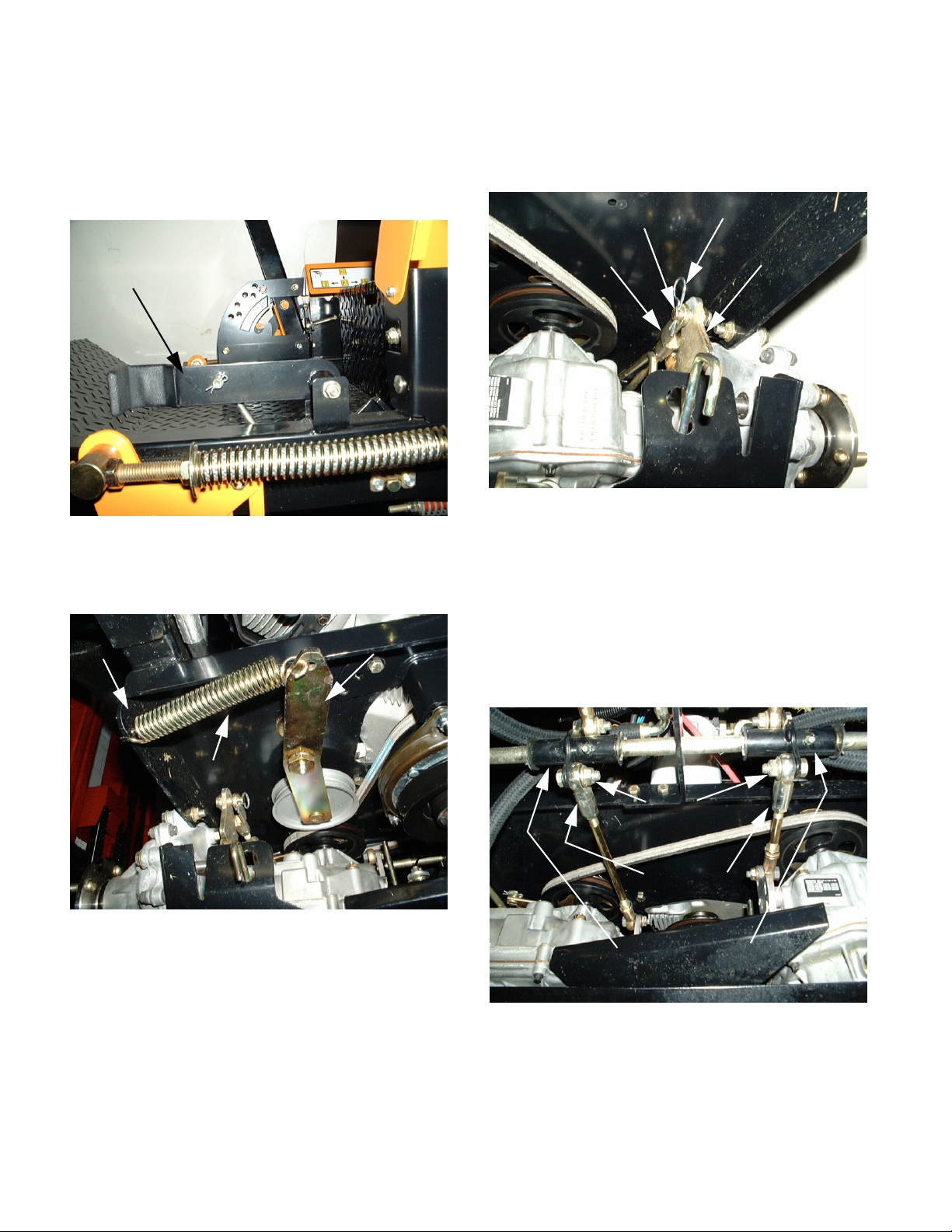

Hydrostatic Drive Assembly Removal

NOTE: The following section was performed with

a lift. Make certain the front castor wheels are

rotated rearward for maximum stability.

1. Pivot the seat assembly forward.

2. Remove the lock nut and hex bolt securing the

negative battery cable to the negative battery terminal using a 7/16” socket and a 7/16” wrench.

3. Remove the sparkplug wires from the sparkplugs

on the engine.

4. Place suitable hydrostatic fluid drain containers

under each hydrostatic pump and the hydrostatic

reservoir. See Figure 1.

6. Remove the drain caps from both hydrostatic

pumps, and the drain plug from the hydrostatic

reservoir using a 5/8” socket and an 11/16”

socket. See Figure 2.

Drain

Plug

Drain Caps

Figure 2

7. Allow all of the hydrostatic fluid to drain from the

system.

Hydrostatic Fluid

Drain Containers

Figure 1

5. Remove the fill cap from the hydrostatic reservoir.

8. Install all three oil drain plugs using a 5/8” socket

and an 11/16” socket.

9. Raise the rear of the unit until the rear wheels

are off the ground.

10. Remove all four lug nuts securing each rear tire

assembly using a 3/4" socket. See Figure 3.

11

Figure 3

Page 16

Cub Cadet Commercial M60 Tank - 2002 and prior years

11. Support the bottom of the skid plate assembly

from below.

12. Make certain the parking brake is released. See

Figure 4.

Parking Brake

Figure 4

13. Remove the idler arm extension spring from the

left frame rail using vice grips. See Figure 5.

15. Remove both hairpins and clevis pins securing

the brake rod yokes to the brake actuation arms.

See Figure 6.

Clevis Pin

Brake Rod

Yoke

Figure 6

16. Engage the parking brake lever.

NOTE: The brake rod yokes will be pulled

forward and out of the way.

Hairpin

Brake Actuation

Arm

Left Frame Rail

Extension Spring

Figure 5

NOTE: Make certain the orientation of the spring

is recorded.

14. Remove the extension spring from the idler arm

and set it aside.

Idler Arm

17. Remove the hex flange lock nuts and shouldered

hex screws securing both connecting rod ball

joints to the center belle crank assemblies using

a 9/16” socket and a 9/16” wrench. See Figure 7.

Flanged Lock Nuts

and Hex Screws

Ball Joints

Center Bell Crank

Assemblies

Figure 7

12

Page 17

Cub Cadet Commercial M60 Tank - 2002 and prior years

18. Remove the hairpin and clevis pin from below

the deck lift lever.

19. Push the deck lift lever down as far as it will go

and place the clevis pin and hairpin above it. See

Figure 8.

Hairpin

Clevis Pin

Lift Lever

Figure 8

21. Remove both of the hex bolts, flat washers and

lock nuts securing the right and left hydrostatic

pumps to the frame using a 9/16” socket and a

9/16” wrench. See Figure 10.

Hex Bolts

and

Flat Washers

Skid Plate

Figure 10

22. Lower the skid plate assembly slightly.

NOTE: This keeps the deck links down.

20. Remove both hex lock nuts and carriage bolts

securing the skid plate frame struts to the mid

frame of the unit using a 9/16” socket.

See Figure 9.

Hex Lock Nuts and

Carriage Bolts

Frame

Struts

Deck Links Down

Figure 9

23. Remove the drive belt from both of the hydrostatic transmission pulleys.

24. Pull the drive belt rearward and out of the way.

NOTE: The drive belt is still secured around the

electric clutch.

25. Mark and record all of the hydrostatic line connections to the hydrostatic pumps.

See Figure 11.

Hydrostatic Lines

Hydrostatic Pumps

13

Figure 11

Page 18

Cub Cadet Commercial M60 Tank - 2002 and prior years

26. Make certain the hydrostatic fluid drain containers are below the skid plate assembly.

27. Remove all four of the hydraulic line connectors

from both hydrostatic pumps using a 3/4" wrench

and a 7/8” wrench.

28. Slowly lower the skid plate assembly and remove

it from the unit. See Figure 12.

Skid Plate

Assembly

Figure 12

29. Install the hydrostatic drive assembly in the

reverse order above.

14

Page 19

Cub Cadet Commercial M60 Tank - 2002 and prior years

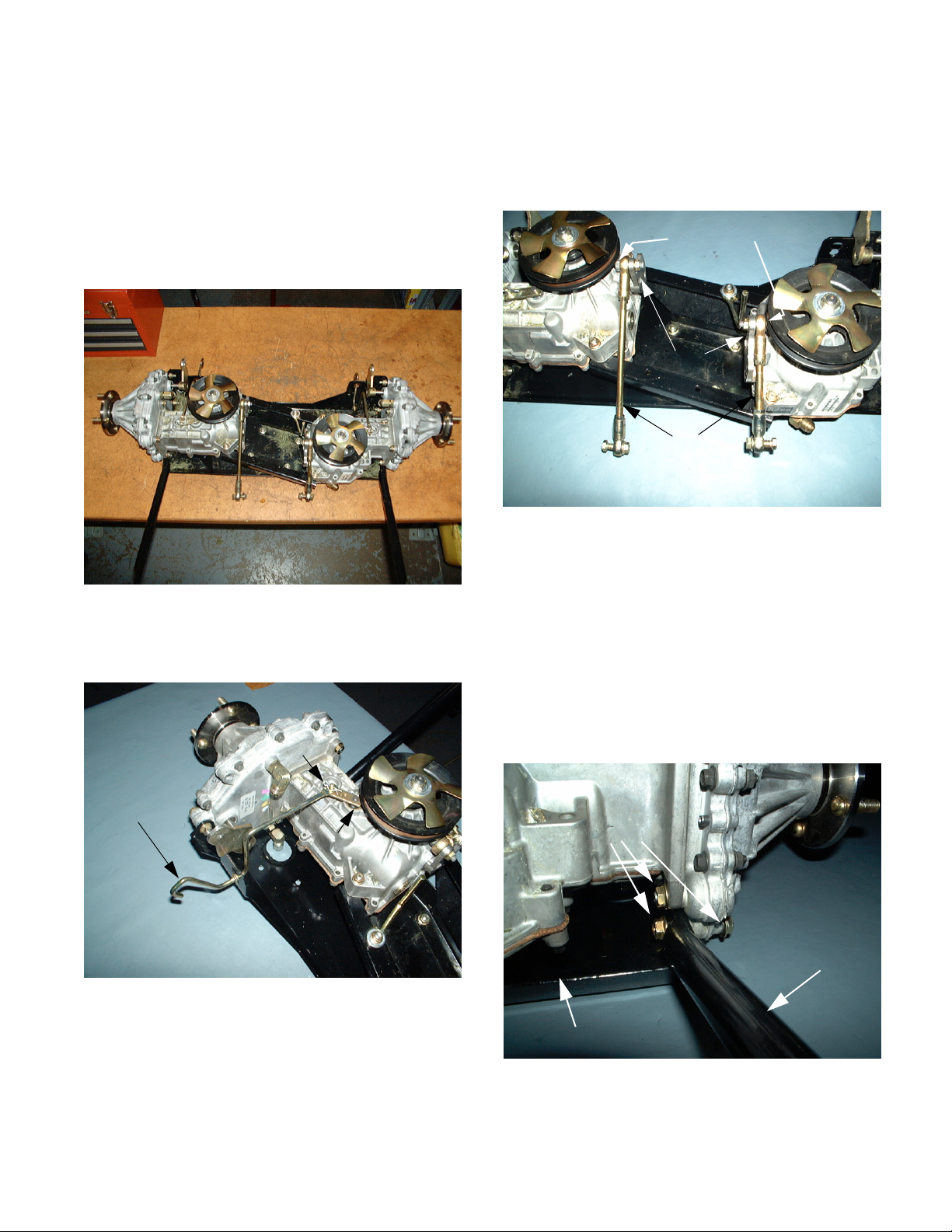

Hydrostatic Pump / Transmission Removal

NOTE: The following section has been written for

training and includes multiple steps for both the

left and right hydrostatic pump / transmission

assemblies. Prior to performing this section, the

Hydrostatic Drive Assembly Removal section

must be performed.

.

3. Remove both hex bolts and flange lock nuts

securing the short connecting rods to the neutral

return plates using a 1/2" socket and a 9/16”

wrench. See Figure 3.

Hex Bolts and

Lock Nuts

Neutral Return

Plates

Connecting

Rods

Figure 3

4. Remove both short connecting rods and set

them aside.

Figure 1

1. Remove both hairpins securing the pump

release rods to the bypass valves. See Figure 2.

Hairpin

Pump Release

Rod

Bypass

Valve

Figure 2

2. Remove both pump release rods.

NOTE: Record the orientation of the connecting

rods to the neutral return plates on both hydrostatic transmissions.

5. Remove the hex cap screw, flat washer and hex

flange lock nut that secure each frame strut to

the skid plate assembly using a 9/16” socket and

a 9/16” wrench. See Figure 4.

Hex Cap Screws,

Flat Washers, and

Hex Flange Lock Nuts

Frame Strut

Skid Plate

15

Figure 4

Page 20

Cub Cadet Commercial M60 Tank - 2002 and prior years

6. Remove all four hex cap screws and flange lock

nuts that secure the hydrostatic pump assemblies to the center pump support brackets using a

1/2" socket and a 1/2" wrench. See Figure 5.

Center Pump Support

Brackets

Hex Cap Screws

and Lock Nuts

Hydrostatic Pump Assembly

NOTE: The thick flat washers are used to make

up the difference between the hydrostatic pump

assembly housings and the skid plate assembly,

at the upper rear mounting hole (closest to the

dump valve lockout holes). See Figure 7.

Thick Flat

Washers

Figure 5

7. Remove all four remaining hex cap screws, flat

washers and flange lock nuts securing the hydrostatic pump assemblies to the skid plate assembly using a 1/2" socket and a 1/2" wrench. See

Figure 6.

Hydrostatic

Pump

Hex Cap Screws,

Flat Washers, and

Lock Nuts

Figure 6

Skid Plate

Figure 7

8. Remove both hydrostatic pump assemblies from

the skid plate assembly. See Figure 8.

Skid Plate

Figure 8

9. Assemble the hydrostatic pump/transmission

assembly in the reverse order above.

16

Page 21

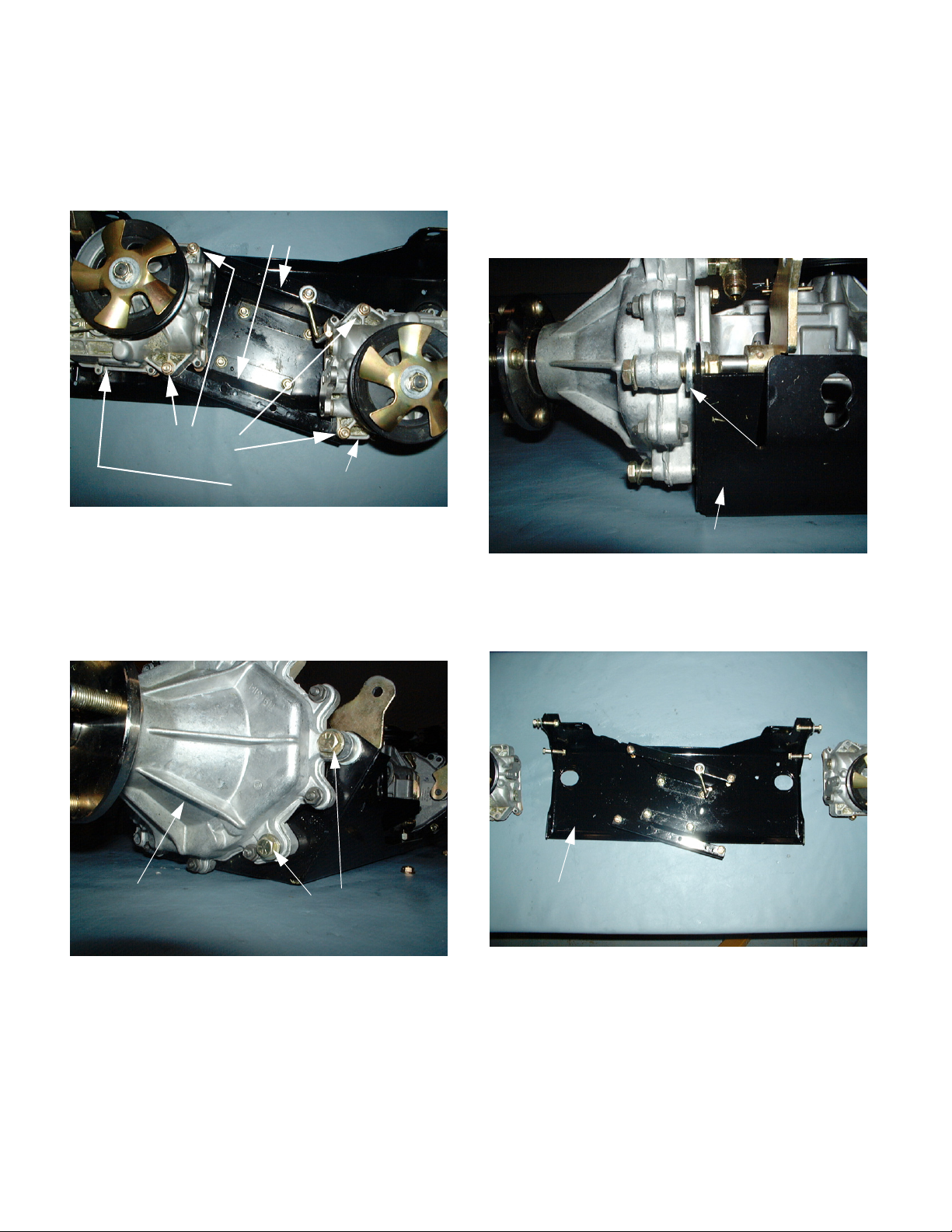

Cub Cadet Commercial M60 Tank - 2002 and prior years

NOTE: When assembling the transmissions to

the skid plate assembly, tighten and then torque

the bolts in numerical succession. (outside to

inside) See Figure 9.

14/15

1

2

91011

6

5

12

13

Figure 9

16/17

8

7

4

3

Bolt Torque Specifications:

Part# Bolt # Size Description Torque

00002528 1-4 3/8-16 x

Mounts transmission motor to skid plate 33 ft. lbs.

2.00 Gr 5

00013198 5-8 5/16-18 x

Mounts transmission pump to brackets 19 ft. lbs.

2.00 Gr 5

01000372 9-12 3/8-16 x

.750 Gr 5

01005852 13 5/16-18 x

1.00 Gr 5

Mounts bracket to skid plate 33 ft. lbs.

Mounts belt guide to bracket 19 ft. lbs.

Strut bolts 33 ft. lbs.

Pump to final drive 22 ft. lbs.

17

Page 22

Cub Cadet Commercial M60 Tank - 2002 and prior years

Left Transmission Disassembly and

Inspection

Figure 1

1. Remove the hex insert lock nut and flat washer

securing the hydrostatic fan and pulley to the

hydrostatic input shaft using a 3/4" socket. See

Figure 2.

3. Remove all four hex flange lock nuts securing the

hydrostatic pump assembly to the transmission

assembly using a 1/2" socket and a 1/2" wrench.

See Figure 3.

Transmission

Hydrostatic

Pump

Hex Flange

Lock Nuts

Figure 3

NOTE: Use Loctite 271 during assembly.

4. Slowly separate the hydrostatic pump assembly

from the transmission assembly. See Figure 4.

Hex Insert Lock Nut

Fan

Pulley

Figure 2

NOTE: This step is not necessary if the hydro-

static pump assembly is not in question.

2. Remove the hydrostatic fan and pulley from the

input shaft.

NOTE: The fan blades point down.

Orientation of fittings

“O” Ring

14 Tooth

Hydrostatic

Pump

NOTE: Make certain the 14T spur gear on the

output shaft of the hydrostatic pump assembly

does not fall into the transmission assembly.

5. Remove and replace the large O-ring on the mating face of the transmission assembly.

Spur Gear

Transmission

Figure 4

18

Page 23

Cub Cadet Commercial M60 Tank - 2002 and prior years

6. Set the hydrostatic pump assembly aside.

7. Record the orientation of both hydraulic elbow fittings on the transmission assembly.

8. Remove both hydraulic fittings from the transmission assembly using an 11/16” wrench. See

Figure 5.

O Rings

Figure 5

9. Inspect and replace the O-ring on each fitting.

10. Remove the roll pin securing the brake actuation

arm to the brake shaft using a 5/32” punch. See

Figure 6.

11. Drive both centering roll pins into the inner case

halve using a punch. See Figure 7.

Inner Case

Half

Centering Roll

Pins

Perimeter Hex

Flange Lock nuts

and Hex Screws

Figure 7

12. Rotate the transmission assembly 90 degrees

and set it on the drive hub studs.

13. Remove all ten perimeter hex flange lock nuts

and hex washer head screws securing both case

halves to one another using a 3/8” socket and a

7/16” wrench.

14. Separate the case halves from one another

using a scraper. See Figure 8.

Brake Shaft

Brake Actuation

Arm

Roll Pin

Figure 6

Needle Bearing

Inner Housing Assembly

19

Case Halves

Figure 8

Page 24

Cub Cadet Commercial M60 Tank - 2002 and prior years

15. Remove the inner housing assembly.

16. Inspect the needle bearing in the inner housing.

NOTE: Remove and press in a new bearing if

needed.

17. Remove all of the shim washers from the top of

the reduction gear. See Figure 9.

Shim

Reduction Gear

Figure 9

Washers

19. Remove the brake assembly and inspect all of

the components. See Figure 11.

Brake Retaining

Dowel

Pins

Brake Shoe

Spring

Figure 11

NOTE: The brake shoe spring is slightly bent.

Make certain it is not distorted.

20. Inspect the brake retaining dowel pins.

See Figure 12.

Brake Shoes

Brake Shaft

18. Remove the reduction gear and inspect the

center needle bearing. See Figure 10.

Needle Bearing

Reduction Gear

Figure 10

Brake

Pins

Output Carrier

46T Ring Gear

Figure 12

21. Remove the 46T ring gear.

22. Remove all three 13T spur gears.

23. Remove the output carrier assembly.

13T Spur Gear

Assembly

20

Page 25

Cub Cadet Commercial M60 Tank - 2002 and prior years

24. Remove the center snap ring securing the axle

assembly in position using snap ring pliers. See

Figure 13.

Center Snap Ring

Axle Assembly

25. Press the axle assembly out of the outer ball

bearing. See Figure 14.

Internal Snap Ring

Ball Bearing

Figure 13

28. Inspect the outer oil seal and replace it if damaged or worn. See Figure 15.

Oil Seal

Figure 15

29. Inspect all components of the transmission

assembly.

30. Clean the mating surfaces of both halves of the

housing assembly and prepare them for assembly.

Axle Assembly

Snap Rings

Figure 14

26. Remove the internal snap ring securing the outer

ball bearing into the outer axle housing using

snap ring pliers.

27. Push the outer ball bearing out of the housing.

NOTE: The outer ball bearing can be damaged

by the press and should be replaced.

Ball Bearing

21

Page 26

Cub Cadet Commercial M60 Tank - 2002 and prior years

Left Transmission Shimming and

Assembly

1. Make certain both transmission mating faces are

clean.

2. If the outer oil seal was removed, press a new

one into the outer axle housing until it bottoms

out. See Figure 1.

Oil Seal

Outer Axle Housing

6. Secure the axle assembly in position with the

center snap ring using snap ring pliers.

7. Install the output carrier assembly, all three 13T

spur gears and the 46T ring gear onto the axle

assembly. See Figure 3.

Output Carrier

13T

46T Ring Gear

Figure 3

Spur Gear

Figure 1

3. Push the outer ball bearing into the outer axle

housing until it is firmly in position. See Figure 2.

Ball Bearing

Axle Assembly

Outer Axle Housing

Figure 2

4. Secure the outer ball bearing in position with the

large internal snap ring using snap ring pliers.

Large Internal

Snap Ring

Center Snap

Ring

8. Install the brake assembly. See Figure 4.

Brake Assembly

Figure 4

NOTE: Make certain the bend in the brake shoe

spring is flush up against the brake shaft.

5. Press the axle assembly into the outer ball bearing.

22

Page 27

Cub Cadet Commercial M60 Tank - 2002 and prior years

9. Install the reduction gear onto the axle assembly.

See Figure 5.

Axle Assembly

Figure 5

10. Make certain all of the gears turn smoothly without binding. See Figure 6.

Reduction

Gear

Figure 6

23

Page 28

Cub Cadet Commercial M60 Tank - 2002 and prior years

Shimming Procedures

NOTE: This section requires a measuring device

that can measure depth in thousands of an inch.

A dial caliper was used to perform this section.

Inner Housing

11. Locate a flat section of bar-stock and measure its

depth. This is bar-stock (1). See Figure 7.

A

Bar Stock (1)

14. Measure the distance from the top of bar-stock

(1) to the top of the center needle bearing boss.

15. Record the measurement._____ This is measurement (B).

16. Subtract measurement (B) from measurement

(A).

17. Record this measurement._____ This is measurement (C).

NOTE: Measurement (C) is the distance from the

mating surface of the inner housing to the top of

the center needle bearing boss.

NOTE: Example formula is ( A - B ) = C

Outer Housing

Locate two additional sections of bar-stock that are

identical in depth. These are bar-stocks (2) and (3)

18. Place both sections of identical bar-stock (2) and

(3) across the full width of the axle housing mating face.

19. Set bar-stock (1) across and on top of bar-stock

(2) and (3).

Figure 7

12. Record the measurement._____ This is measurement (A).

13. Place bar-stock (1) across the full width of the

inner housing mating face, next to the center

needle bearing boss. See Figure 8.

Bar Stock (1)

(B)

(A)

Inner Housing

Center Needle

Bearing Boss

20. Measure the distance from the top of bar-stock

(1) to the first shoulder of the axle shaft assembly. See Figure 9.

1

k

c

o

t

S

r

a

(D)

2

Bar Stocks 2 and 3

Figure 9

21. Record the measurement._____ This is measurement (D).

B

First shoulder of

the axle shaft

3

Figure 8

24

Page 29

Cub Cadet Commercial M60 Tank - 2002 and prior years

22. Measure the total distance of bar-stocks (1) and

(2). See Figure 10.

Bar Stock 1

(E)

Figure 10

23. Record the measurement._____ This is measurement (E).

24. Subtract measurement (E) from measurement

(D). See Figure 11 and 12.

Bar Stock 2

(D)

Figure 12

25. Record this measurement._____ This is measurement (F).

NOTE: Measurement (F) is the distance from the

mating surface of the outer axle housing to the

first shoulder of the axle shaft. This measurement should be greater than measurement (C).

NOTE: Example formula is ( D - E ) = F

26. Subtract measurement (C) from measurement

(F).

27. Record this measurement._____ This is measurement (Z).

(E)

Figure 11

NOTE: Example formula is ( F - C ) = Z

25

Page 30

Cub Cadet Commercial M60 Tank - 2002 and prior years

28. Shim the first shoulder of the axle assembly to

achieve a 5 to 20 thousands measurement of

(Z). See Figure 13.

NOTE: Z = 5 to 20 thousands.

Shim

Figure 13

NOTE: A 5 to 20 thousands measurement will

allow the unit to operated smoothly, without binding.

30. Place a bead of sealant around the outer

perimeter of the mating surface.

NOTE: Use Loctite 5999 or equivalent.

31. Set the inner housing on top of the outer axle

housing and align the centering roll pins by tapping them into place using a punch and a small

hammer.

32. Secure the inner housing to the outer axle housing with the ten hex washer head screws and hex

flange nuts removed earlier using a 3/8” socket

and a 7/16” wrench.

33. Make certain the centering roll pins are correctly

set in place.

34. Place the brake actuation arm onto the brake

shaft and drive the roll pin into place using a

5/32” punch. See Figure 15.

Brake Shaft

29. Drive the centering roll pins up using a punch.

See Figure 14.

Hex Washer

Head Screws

Inner Housing

Figure 14

Centering Roll

Pins

Brake Actuation

Arm

Roll Pin

Figure 15

26

Page 31

Cub Cadet Commercial M60 Tank - 2002 and prior years

35. Install both hydraulic elbow fittings to the correct

position using an 11/16” wrench. See Figure 16.

Loctite

Mounting

O Ring

14T Spur Gear

NOTE: Make certain the O-rings do not get damaged during installation.

36. Set the large O-ring onto the hydrostatic pump

assembly.

Hydraulic Elbow Fittings

Figure 16

Studs

40. Place the hydrostatic pulley and fan onto the

input shaft.

41. Secure the hydrostatic pulley and fan to the input

shaft with a flat washer and hex insert lock nut

using a 3/4" socket. See Figure 18.

Input Shaft

Flat Washer and

Hex Insert Lock Nut

Fan

Pulley

Figure 18

37. Set the 14T spur gear on the output shaft of the

hydrostatic pump assembly.

38. Loctite the hydrostatic mounting studs.

NOTE: Use Loctite 271

39. Place the transmission assembly over the hydrostatic assembly and secure it in position with four

hex flange lock nuts using a 1/2" socket and a

1/2" wrench. See Figure 17.

Transmission

Hydrostat

Hex Flange

Lock Nuts

Figure 17

27

Page 32

Cub Cadet Commercial M60 Tank - 2002 and prior years

3

4

7

1

16

18

5

8

5

17

21

5

5

18

6

REF.

NO.

PART

NO. DESCRIPTION

618-3110A Drive Ass’y Complete

1. 611-3012 Axle Assembly

710-0852 Ribbed Neck Stud

2. 618-3106 Carrier Assembly, Output

3. 618-3107 Gear Assembly, 51T Internal & 20T

4. 618-3109 Housing Ass’y

5. 710-1342 Hex Washer Screw 1/4-20 x 1-1/8

6. 711-1048 Brake Shaft

7. 712-3027 Hex Flange Lock Nut 1/4-20

8. 715-0156 Roll Pin

9. 715-0219 Dowel Pin

10. 715-3045 Bushing

11. 716-3015 Inverted Retaining Ring

12. 716-3018 Snap Ring

7

15

22

11

12

2

13

10

19

24

14

9

23

20

REF.

NO.

PART

NO. DESCRIPTION

13. 717-3395 Spur Gear 13T

14. 717-3397 Ring Gear 46T

15. 719-3114 Axle Outer Housing

16. 721-0381 Oil Seal

17. 721-0393 Oil Seal

18. 727-3124 Elbow Fitting

19. 732-0752 Brake Shoe Spring

20. 736-0351 Shim Washer .76 x 1.5 x .030

736-0492 Shim Washer .76 x 1.5 x .010

736-0493 Shim Washer .76 x 1.5 x .020

21. 741-0665 Needle Bearing

22. 741-3033A Ball Bearing

23. 741-3080 Needle Bearing

24. 761-3049 Shoe Brake

28

Page 33

Cub Cadet Commercial M60 Tank - 2002 and prior years

Neutral Control Adjustment

Preparation

1. Check the hydraulic fluid level and raise the rear

of the unit off the ground.

2. Remove all four lug nuts securing the right rear

wheel assembly to the right axle hub using a 3/4"

socket and extension.

3. Remove the right rear wheel assembly.

Lap Bar Adjustment

4. Lock both center belle crank assemblies into a

fixed position by sliding a 1/4" by 28” steel dowel

rod through the right frame alignment hole, both

center belle crank assemblies and out the left

frame alignment hole. See Figure 2.

1/4” by 28” Steel Dowel Rod

Center Belle Crank

Assemblies

Figure 2

NOTE: There are cotter pins on the center belle

crank assemblies that may need to be bent down

to allow the 1/4" by 28” dowel rod to pass by.

Figure 1

5. Loosen both hex jam nuts that secure each of

the lap bar connecting rods in position using a

9/16” wrench and channel locks. See Figure 3.

Connecting

Rods

Hex Jam Nuts

Figure 3

29

Page 34

Cub Cadet Commercial M60 Tank - 2002 and prior years

6. Rotate the connecting rods clockwise or counterclockwise until the corresponding lap bars are

directly over the neutral slots, and the lap bars

pivot out and back freely. See Figure 4.

Figure 4

7. Tighten both hex jam nuts that secure each of

the lap bar connecting rods in position using a

9/16” wrench and channel locks.

Creep Adjustment

NOTE: If the unit creeps in either direction after

the lap bars have been adjusted, and the 1/4" by

28” alignment dowel rod is in place, perform the

following steps:

1. Make certain that the rear of the unit is off the

ground.

2. Place both lap bars in the outward position

(Neutral).

3. Set the parking brake.

4. Raise the seat and remove the wiring harness

connector from the seat safety switch using a

small flat-blade screw driver. See Figure 1.

Seat Safety

Switch

8. Make certain the lap bars move out and back

freely. See Figure 5.

Figure 5

9. Start the unit and inspect for creep in the neutral

position.

Wiring Harness

Connector

Figure 1

NOTE: Make certain the seat safety switch is

connected to the wiring harness connector

before releasing the unit to the customer.

30

Page 35

Cub Cadet Commercial M60 Tank - 2002 and prior years

5. Make certain both hydrostatic pump release rods

are in the operate position. See Figure 2.

Pump Release Rod

Figure 2

6. Start the unit and release the parking brake. See

Figure 3.

7. With the rear of the unit off the ground, bring the

lap bars to the operate position. See Figure 4.

Figure 4

8. Identify the rear axle that is creeping.

NOTE: The hydraulic fluid must be brought to

operating temperature (130 degrees F.) to correctly test for creep. The engine must be run at

full RPM.

Figure 3

9. Lower the throttle to idle and shut the unit off.

10. Locate the adjustable hydrostatic connecting rod

that pivots the neutral return plate on the hydrostatic transmission assembly that is creeping.

See Figure 5.

Connecting Rods

Hex

Jam

Nuts

Neutral Return Plate

Figure 5

31

Page 36

Cub Cadet Commercial M60 Tank - 2002 and prior years

11. Loosen both hex jam nuts securing the hydrostatic connecting rod in position using a 1/2"

wrench and channel locks.

12. Start the unit.

13. Rotate the connecting rod clockwise or counterclockwise until all rear wheel motion has been

eliminated.

CAUTION: The unit will be running during this

procedure.

14. Shut the unit off.

15. Tighten both hex jam nuts using a 1/2" wrench

and channel locks.

16. Raise the seat and install the wiring harness connector to the seat safety switch. See Figure 6.

Seat Safety Switch

17. Remove the 1/4" by 28” alignment dowel rod.

See Figure 7.

1/4” by 28” Dowel Rod

Figure 7

18. Install the right rear wheel assembly and secure

it to the axle hub with four lug nuts removed earlier using a 3/4" socket.

Wiring Harness

Connector

19. Lower the unit to the ground.

20. Test the unit and make certain it remains in neutral.

Figure 6

32

Page 37

Cub Cadet Commercial M60 Tank - 2002 and prior years

Parking Brake Adjustment

NOTE: Perform the left parking brake adjustment

first.

1. Make certain the parking brake lever is fully disengaged. See Figure 1.

Parking Brake

Lever

(Disengaged)

Figure 1

2. Locate a 1/4" piece of bar-stock. See Figure 2.

3. Place the 1/4" bar-stock between the parking

brake lever and the top of the skid plate assembly (at the pump release rod lockout bracket).

See Figure 3.

1/4” piece of bar stock

Parking Brake Lever

Skid Plate Assembly

Figure 3

4. Locate the threaded portion of the front brake

connecting rod (past the front brake bracket

assembly) and identify the front nylon lock nut at

the very end of the rod. See Figure 4.

Figure 2

Threaded portion of the brake connecting rod

1/4” Bar Stock

Nylon Lock Nut

Figure 4

33

Page 38

Cub Cadet Commercial M60 Tank - 2002 and prior years

5. Apply light pressure rearward to the brake connecting rod, while turning the front nylon lock nut

clockwise or counter-clockwise until the parking

brake lever lightly contacts the top of the 1/4"

bar-stock using a 9/16” wrench. See Figure 3 on

the previous page.

NOTE: It is important to apply rearward pressure

to the brake connecting rod to make certain the

rod is fully retracted at all times.

6. Make certain the base of the large front brake

spring is flush with the front of the brake bracket.

See Figure 6.

Shoulder Nut

Rear Jam Nut

10. Engage the parking brake and inspect for binding. See Figure 7.

Figure 6

11. Perform the above procedure for the right parking brake adjustment.

Lightly touches

Large brake spring

flush with the brake bracket

Figure 5

7. Loosen the rear hex jam nut securing the rear

shoulder nut in position on the brake connecting

rod using a 9/16” wrench and a 3/4" wrench.

8. Rotate the shoulder nut clockwise or counterclockwise until the small rear compression spring

and flat washer are lightly touching the back of

the brake bracket assembly using a 3/4" wrench.

9. Secure the shoulder nut in position with the hex

jam nut using a 9/16” wrench and a 3/4" wrench.

34

Page 39

Cub Cadet Commercial M60 Tank - 2002 and prior years

Mower Deck Leveling

Preliminary Setup

1. Place the unit on level ground and remove the

ignition key.

2. Remove both spark plug wires from the engine.

3. Make certain the air pressure in all four tires is

set at 10 PSI.

Lift Adjustment Rods

NOTE: Inspect the lift adjustment rod assemblies

on both sides of the unit and make certain they

are set to the following specifications:

See Figure 1.

Hex Nuts

13 inches

3/4”

1/2”

Lift Ferrules

Side to Side Adjustment

1. Place the clevis pin and hairpin in the three inch

setting for the height of cut. See Figure 2.

Clevis pin in 3” height position

Figure 2

2. Lower the deck lift handle to the three inch setting. See Figure 3.

Deck lift handle lowered

Figure 1

1. The front face of the front hex jam nut should be

3/4" from the front end of the connecting lift rod.

2. The back face of the rear hex jam nut should be

1/2" from the rear face of the connecting lift rod.

3. Make certain the inner jam nuts are securing the

lift ferrules in position.

4. The lift compression spring should have a measurement of 13” from the inside of the front flat

washer to the inside of the rear flat washer (at

the frame bracket).

5. If any of the measurements are incorrect, adjust

the corresponding hex jam nuts to the correct

specifications using a 15/16” wrench.

Figure 3

35

Page 40

Cub Cadet Commercial M60 Tank - 2002 and prior years

3. Loosen both of the lower hex jam nuts securing

the deck mounting eye bolts to the left deck lift

links using two 15/16” wrenches. See Figure 4.

Jam Nuts

Figure 4

4. Loosen the upper hex jam nuts until the top face

is flush with the ends of the eye bolts using a

15/16” wrench.

5. Rotate the cutting blades until they are perpendicular to the frame of the unit.

6. Measure the distance of the right cutting blade to

the ground and record it._____

8. If the right and left measurements are not equal,

perform the following steps:

9. Mark the top of each upper hex nut for a reference point. See Figure 6.

Mark hex nut with reference point

Figure 6

10. Rotate both upper hex nuts (equally) until the

blade to ground measurements are the same for

both the right and left side using a 15/16”

wrench.

NOTE: The upper hex nuts should be rotated the

same number of rotations.

7. Measure the distance of the left cutting blade to

the ground and record it._____ See Figure 5.

Blade tip to ground measurement

Figure 5

11. Secure both eye bolts to the left lift links with the

lower hex jam nuts using a 15/16” wrench.

12. Raise and lower the deck several times and

make certain the measurements are equal.

36

Page 41

Cub Cadet Commercial M60 Tank - 2002 and prior years

Front to Back Adjustment

NOTE: For optimum cutting performance, it is

important that the cutting deck is level side to

side and pitched forward 1/8” to 1/4".

1. Make certain the deck lift handle is set at the

three inch setting. See Figure 7.

Deck lift lever at 3” setting

4. Measure the distance from the rear of the cutting

blade to the ground and record it._____

NOTE: The front blade measurement should be

1/8” to 1/4" lower than the back blade measurement. If not, continue performing the following

steps:

5. Mark both front hex jam nuts securing the front

lift ferrules in position. See Figure 9.

Front Ferrule

Mark both front jam nut positions

Figure 7

2. Rotate the cutting blades until the outer blades

are parallel with the frame of the unit.

3. Measure the distance from the front of the cutting

blade to the ground and record it_____

See Figure 8.

Measure rear blade tip to ground

Figure 9

6. Loosen the front hex jam nuts equally one rotation at a time.

7. Rotate the inner jam nuts (up against the front lift

ferrules) equally clockwise or counter-clockwise

to raise or lower the rear of the deck to the correct specifications.

NOTE: Tightening both inner jam nuts lowers the

rear of the deck, and loosening both inner jam

nuts raises the rear of the deck.

8. Secure the front lift ferrules in position with the

front jam nuts using a 15/16” wrench.

9. Raise and lower the deck several times and

make certain the measurements are correct.

Figure 8

37

Page 42

Cub Cadet Commercial M60 Tank - 2002 and prior years

Notes:

38

Page 43

mSECTION 2 - M48/M72 Tank - 2003/04 Update

M48 Tank

1. ABOUT THIS SECTION:

The M48 is part of the Cub Cadet Commercial Tank

Series. The 2004 model year M48 is very similar to

The 2001 model year Tank. Earlier versions of this

machine have been covered in the “2001 Cub Cadet

Commercial Technical Handbook”: Form #770-

10528.

2. CHANGES FOR ‘03 AND ‘04

• New hydro motor frame assembly

• New hydro motors

• New brakes and brake linkages

• Finer increments of height adjustment

• Different choice of engines

• Features of the 72” TANK

The content of this section is intended to detail

changes in service techniques that have occurred

since the introduction of the M Series.

3. DRIVE SYSTEM ADJUSTMENT

3.1. Prior to making any adjustments to the drive system, inspect the hydro control linkages, drive

belt, brake linkage, tires, fluid, and filter.

3.2. The hydraulic reservoir and filter are accessible

beneath the seat. See Figure 3.2.

RESERVOIR

OIL FILTER

BATTERY

3.3. The hydraulic fluid level should be at the second

hole in the filler neck of the reservoir.

See Figure 3.3.

FIRST HOLE

SECOND HOLEsection

FLUID LEVEL

Figure 3.3

NOTE: It is very important that the hydraulic oil

does not become contaminated. Clean the surrounding area thoroughly prior to opening any

part of the hydraulic system.

NOTE: The hydraulic drive system contains

roughly 3.25 gal. of SAE 20W50 motor oil having

an API rating of SJ-CD or better. Hydraulic

Drive System Fluid Plus (P/N: 737-3121 gal.)

is an acceptable premium alternative.

NOTE: Complete draining and filling instructions

are contained in the “Operator’s and Service

Manual”.

3.4. Tracking is effected by the circumference of the

rear tires, and the amount of drag produced by

the front tires.

• Rear tire pressure may be adjusted within the

range of 8-10 PSI to achieve equal rear tire circumference.

Figure 3.2

• Front tire pressure should be within the range

of 20-25 PSI.

1

Page 44

M48 Tank

3.5. For complete brake adjustment procedures,

refer to the “Brake Adjustment” section of this

manual. For the purpose of tracking, insure that

the brake linkage bellcranks and rods are well

lubricated, not damaged, and work as intended.

See Figure 3.5.

BRAKE CONNECTING

ROD

Brake

Link

REAR BRAKE

ARM ASSEMBLY

BELLCRANK

MOUNTING

SHAFT

Figure 3.5

3.6. To check for brake drag, open the the relief valve

on each hydro pump. With the parking brake

released, both wheels should rotate with hand

pressure. See Figure 3.6.

3.7. If in doubt about the source of brake drag, disconnect the brake link rod from the actuator arm

on the brake assembly. The actuator arm

should return to center, releasing the brakes.

See Figure 3.7.

BRAKE LINK

BRAKE ACTUATOR

ARM

Figure 3.7

3.8. Check the condition of the belt tensioner and

belt that drives the hydro pumps. See Figure 3.8.

OPEN

HYDRO PUMP

HYDRO RELIEF VALVE

Figure 3.6

NOTE: Some hydraulic system drag will be

present, but a dragging brake will be immediately apparent.

DRIVE BELT

TENSIONER

Figure 3.8

3.9. Before making neutral control and tracking

adjustments, make sure the relief valves on both

hydro pumps are fully closed.

3.10. To check neutral control, safely lift and support

the rear wheels of the Tank.

3.11. Start the engine, and release the parking brake.

Do not move the lap bars from the neutral position. If either wheel rotates, neutral control

adjustment will be necessary. Turn off the

engine.

2

Page 45

M48 Tank

3.12. If adjustment is necessary, remove the cutting

deck.

3.13. Inspect the return to neutral cylinders, rods, and

bellcranks of the hydro control linkages.

• The bellcranks should pivot easily without too

much play.

• The rods should not be bent, and the rod ends

should not be loose.

NOTE: The rod end and jam nut at the rear of

each connector rod have left hand threads. A

lock washer is placed between the control input

arm on the hydro pump and the rod end.

NOTE: The rod end and jam nut at the front of

each connector rod have right hand threads. A

spacer fits between each control hub assembly

(bellcrank) and the front rod end that connects to

it.

• The return to neutral cylinders should both work

as advertised. See Figure 3.13.

3.14. Loosen the jam nuts at each end of the hydro

control link rods, and rotate the rods to lengthen

or shorten them. See Figure 3.14.

Figure 3.14

3.15. Start the engine and release parking brake to

test, then turn the engine off to make the adjustment.

3.16. Tighten the jam nuts against the rod ends when

adjustment is complete, and make a final test to

confirm.

RETURN TO NEUTRAL

CYLINDER (RIGHT)

Figure 3.13

NOTE: Remove the control console to gain

access to the return to neutral cylinder.

3.17. After neutral control is correctly adjusted, set the

travel stops to achieve correct tracking and

adjust the lap bars for operator comfort.

See Figure 3.17.

LAP BAR

MOUNTING

HANDLE

CLAMP

BOLTS

JAM

NUT

LAP BAR TRAVEL

STOP BOLT

Figure 3.17

NOTE: The clamp bolts for the lap bar mounting

handle can be used to adjust the amount of force

required to move the lap bars into or out of the

neutral slot.

3

Page 46

M48 Tank

3.18. If one side does not drive as effectively as the

other, test the output of the hydro pump to determine if the problem lies in the pump or the hydro

motor. By the process of elimination, if performance is lacking, brake drag is eliminated,

adjustment is correct, and the pump is O.K.,

then the problem is the motor. Pressure and

flow tests will be used to determine if the pump

is the the source of the problem.

4. TESTING HYDRO PUMP OUTPUT

NOTE: The log splitter hydraulic test kit is used

for this set of flow and pressure tests.

4.1. Safely lift and support the rear of the M48.

4.2. If the cutting deck is currently on the unit,

remove it.

4.3. Remove the rear wheels using a 3/4” socket.

See Figure 4.3.

4.4. Thoroughly clean the area surrounding any

hydraulic fittings to be loosened or removed.

4.5. If the unit has been run recently, allow it to cool

before doing loosening any hydraulic fittings.

WARNING: Hot hydraulic fluid can cause serious burns.

WARNING: Release of pressurized hydraulic

fluid can cause serious of fatal injury.

4.6. Open the relief valve on the hydro pump that is

to be tested. This will relieve any residual

hydraulic pressure.

4.7. Confirm that the hydraulic pressure has been

relieved by rotating the brake drum / hub assembly. If the it will not rotate, confirm that the brake

is released and that the brake linkage is not

bound.

4.8. Install a 1/2” JIC double male coupler in one end

of the 18” hydraulic line in the test kit. Install a

90 deg. 1/2” JIC double male elbow in the other

end. See Figure 4.8.

1/2” JIC COUPLER

VALVE

PRESSURE

GUAGE

FLOW

METER

18” HYDRAULIC

LINE

1/2” JIC

ELBOW

HIGH PRESSURE LINES:

TOP: in-forward / out-reverse

BOTTOM: out-forward / in-reverse

Figure 4.3

NOTE: The fittings on the lines that connect the

hydro pumps to the hydro motors are 1/2” JIC.

NOTE: 7/8” and 13/16” wrenches will be needed

for this test. A 1” wrench may be needed to hold

the connector that joins the JIC line connection

to the O ring connection on the hydro motor.

BRAKE DRUM

HYDRO MOTOR

Figure 4.8

4.9. Position a catch pan beneath the hydro motor.

Have the hydraulic pressure and flow test kit and

two 1/2” JIC plugs within reach.

NOTE: The fittings on the ends of the test kit are

all 1/2” JIC.

4.10. Disconnect the upper line from the hydro motor

and quickly install a 1/2” JIC plug in the line. It

only needs to be finger tight.

4

Page 47

NOTE: The test can be performed at either line

between the pump and the motor. The top line

on the motor is the in line from the pump when

driving forward. The linkage has more travel in

forward than it does in reverse, so the test is

most easily done on the top line of the pump,

driving the pump in the forward direction forward.

4.11. Connect the flow meter end of the test kit to the

hydro motor.

4.12. Remove the plug from the line coming from the

outboard port on the hydro pump. Use the 18”

test kit line to connect the pressure gauge end of

the hydraulic test kit to the line coming from the

hydro pump. See Figure 4.12.

M48 Tank

4.15. Remove the stop bolt that sets the end of the

travel of the lap bar that controls the hydro pump

to be tested. See Figure 4.15.

JAM NUT

STOP BOLT

Figure 4.15

Figure 4.12

4.13. Tighten all the fittings.

4.14. Insure that no unsafe conditions will result from

starting the engine and operating the drive system.

CAUTION: The technician will be exposed to

moving parts during this procedure. They

should not reach past or around any moving

parts during this test, nor should they place

themselves in any position where a loss of footing or balance might bring them into contact with

rotating components. Loose hair or garments

should be secured to avoid the possibility of

entanglement with rotating components.

4.16. Confirm that the valve on the test kit is fully

open.

4.17. Start the engine and purge the hydraulic sys-

tem as follows:

4.18. Cycle the lap bar from full forward to full reverse

5 times at 10 second intervals.

4.19. Close the relief valve on the hydro pump and

repeat the cycling process to purge any remaining air from the system.

4.20. Check for and repair any leaks.

4.21. Check the fluid level in the hydraulic reservoir.

Top it up if necessary.

4.22. Continue to operate the drive system to warm-up

the hydraulic fluid.

NOTE: Performing the test with cold fluid will

make a significant difference in the flow readings

obtained. The test will not be valid.

5

Page 48

M48 Tank

4.23. When the fluid is between 160-210 deg. f.

(71-90 deg. c.) apply full forward drive pressure

to the lap bar with the engine running at full

speed (3600 RPM) while an assistant closes the

valve to the point where pressure reaches 300

PSI (21 Bar.). See Figure 4.23.

CONTROL

CONSOLE INSET:

3600 RPM

SPINNING

FLOW

300 PSI

10 GPM

CLOSE VALVE TO

BUILD PRESSURE

Figure 4.23

4.27. Interpretation: flow droop greater than 1.5 GPM

indicates a pump that is not performing as well

as it should.

NOTE: A blocked filter may account for some

loss of performance.

4.28. Within the two year Cub Cadet Commercial warranty period, replace the pump if it does not perform as specified and all other factors have been

eliminated.

4.29. If a hydro pump requires repair, refer to HydroGear publication “BLN-51337” for complete service instructions.

4.30. If the hydro pump and all other factors are O.K.,

replace the hydro motor.

NOTE: The hydro motor is not serviceable.

Replace it as a unit if it fails.

NOTE: It may be necessary to over-shoot 300

PSI slightly, then open the valve to reduce pressure to 300 PSI.

4.24. Take note of the reading on the flow meter portion of the test kit when the pressure gauge

reads 300 PSI.

4.25. Continue closing the valve until the pressure

reading reaches 1,100 PS I (76 bar.). Take note

of the flow reading. See Figure 4.25.

9 GPM

1100 PSI

Figure 4.25

VALVE CLOSED

FURTHER

5. REPLACING THE HYDRO PUMP

5.1. If the cutting deck is currently on the unit,

remove it.

5.2. Safely lift and support the rear of the tank.

5.3. Remove the rear wheels using a 3/4” socket.

5.4. Tilt the seat up, and disconnect the negative battery cable.

5.5. Remove the screen that covers the opening over

the cooling fans on the hydro pump to be

removed using a 3/8” wrench. See Figure 5.5.

REMOVE DEBRIS SCREEN

4.26. Subtract the 1,100 PSI flow reading from the 300

PSI flow reading. The resulting figure is called

“flow droop”.

Figure 5.5

6

Page 49

M48 Tank

5.6. Remove the nut, washer, and cooling fan from

the hydro pump to be replaced, using a 9/16”

wrench. See Figure 5.6.

FAN

5.7. Use a 3/8” breaker bar to move the belt tensioner pulley arm, slipping the belt off of the pulley. See Figure 5.7.

NUT

WASHER

Figure 5.6

5.10. Use a small two-jaw puller to remove the pulley

from the tapered and keyed input shaft of the

hydro pump. See Figure 5.10.

PULLER

PULLEY

Figure 5.10

5.11. Disconnect the rod end on the back of the hydro

control rod from the control arm on the hydro

pump using a 9/16” wrench, and a 1/2” wrench.

See Figure 5.11.

SPRING

TENSIONER

PULLEY ARM

Figure 5.7

5.8. Unhook the spring that maintains tension on the

arm. This will provide more freedom of movement.

5.9. Slip the belt over the drive pulley of the hydro

pump to be removed.

NUT

ROD END

BOLT

LOCK WASHER

CONTROL ARM

Figure 5.11

NOTE: There is a lock washer positioned

between the rod end and the control arm.

5.12. Thoroughly clean the area surrounding any

hydraulic fittings to be loosened or removed.

5.13. If the unit has been run recently, allow it to cool

before doing loosening any hydraulic fittings.

WARNING: Hot hydraulic fluid can cause serious burns.

WARNING: Release of pressurized hydraulic

fluid can cause serious of fatal injury.

7

Page 50

M48 Tank

5.14. Open the relief valve on the hydro pump that is

to be tested. This will relieve any residual

hydraulic pressure. See Figure 5.14.

ELBOW

5.15. Confirm that the hydraulic pressure has been

relieved by rotating the brake drum / hub assembly. If the it will not rotate, confirm that the brake

is released and that the brake linkage is not

bound.

5.16. If there is any possibility of fluid contamination,

drain and flush the system, and replace the filter

before installing the new hydro pump.

5.17. Position a catch pan beneath the hydro pump to

be removed. Have four 1/2” JIC plugs and two

1/2” JIC caps within reach.

5.18. Disconnect the feed line that runs from from the

front of the hydro pump to the filter manifold

using a 7/8” wrench on the nut, and a 13/16”

wrench to hold the fitting on the hydro pump.

Plug the line, cap the fitting on the pump.

5.19. Disconnect the return line that runs from from

the outboard side of the hydro pump to the reservoir using a 7/8” wrench on the nut, and an 11/

16”” wrench to hold the fitting on the hydro

pump. Plug the line, cap the fitting on the pump.

See Figure 5.14.

RETURN LINE

FEED LINE

CLOSE

OPEN

RELIEF VALVE

Figure 5.14

5.20. Disconnect the two lines that connect the hydro

motor to the back of the hydro pump using a pair

of 7/8” wrenches. Plug the lines.

See Figure 5.20.

HYDRO

PUMP

5.21. Remove the two O ring to JIC adaptors from the

back of the hydro pump. Replace them with the

yellow shipping plugs from the replacement

hydro pump.

5.22. Remove the 90 deg. elbow fitting that the return

line was connected to using an 11/16” wrench

and a 3/4” wrench. Plug the port using a yellow

shipping plug removed from the replacement

pump.

5.23. Remove the O ring to JIC adaptor that the feed

line was connected using a 13/16” wrench. Plug

the port using a yellow shipping plug removed

from the replacement pump. See Figure

5.23.

PRESSURE LINES

BETWEEN PUMP

AND MOTOR

ADAPTORS

Figure 5.20

HYDRO

MOTOR

Figure 5.23

8

Page 51

M48 Tank

D

5.24. Remove the handle from the relief valve using a

7/16” wrench and a 3/16” allen wrench.

5.25. Remove the nuts from the carriage bolts that

hold the hydro pump to the hydro pump mounting plate. See Figure 5.25.

MOUNTING NUT

FITTINGS REMOVED

AND PLUGGED

Figure 5.25

5.26. Carefully lower and remove the hydro pump. If it

is to be returned to Cub Cadet, remove the yellow plugs and allow it to drain completely before

packing and shipping it.

5.27. Inspect all of the fittings and O rings prior to

installation in the replacement pump.

See Figure 5.27.

DEFORMED O RING

RELIEF VALVE

HANDLE REMOVE

GOOD O RING

5.29. Position the pulley over the opening in the hydro

pump support plate that the pump input shaft will

pass through.

5.30. Position the pump so that the two bolts that

secure it in position line-up with the two mounting ears on the pump, and the input shaft slips

into the pulley as the pump is raised up to the

hydro pump support plate. See Figure 5.30.

MOUNTING BOLT

PULLEY WITH KEY

NEW PUMP

Figure 5.30

5.31. Start both nuts that hold the pump onto their carriage bolts.

5.32. As the pump is tightened into position, rotate the

pulley to align the keyways, allowing the pulley

to seat on the input shaft.

5.33. Install the fittings and lines, working quickly to

minimize fluid loss.

NOTE: Use care not to over-tighten the O ring

fittings, damaging the O rings.

CHECK

THREADS

CHECK TAPERED SEATS

Figure 5.27

5.28. Prior to installation, pour oil directly into the

pump inlet and high-pressure ports, then transfer yellow plugs back to the replacement pump.

NOTE: The lines may be installed finger tight to

establish their positions, then tightened fully.

5.34. Install the belt, tension arm spring, steering linkage.

5.35. Install the fan, washer and nut to the input shaft.

Torque the nut to 240 inch/lbs.

5.36. Install the debris screen.

5.37. Check the fluid level in the reservoir, purge the

system as described in the test instructions.

5.38. If the hydraulic system has been drained and

flushed with 20W50, install a new filter and follow the instructions for refilling the hydraulic system in the “Operator’s and Service Manual”.

9

Page 52

M48 Tank

5.39. Install the wheels, lower the TANK to the ground,

and test run it in a safe area. Make any necessary adjustments before installing the cutting

deck.

6. REPLACING THE HYDRO MOTOR

6.1. If the cutting deck is currently on the unit,

remove it.

6.2. Safely lift and support the rear of the tank.

6.3. Remove the rear wheels using a 3/4” socket.

6.4. Tilt the seat up, and disconnect the negative battery cable.

6.5. Thoroughly clean the area surrounding any

hydraulic fittings to be loosened or removed.

6.6. If the unit has been run recently, allow it to cool

before doing loosening any hydraulic fittings.

WARNING: Hot hydraulic fluid can cause serious burns.

WARNING: Release of pressurized hydraulic

fluid can cause serious or fatal injury.

6.7. Open the relief valve on the hydro pump. This

will relieve any residual hydraulic pressure.

See Figure 6.7.

OPEN

Figure 6.7

6.8. Confirm that the hydraulic pressure has been

relieved by rotating the brake drum / hub assembly. If the it will not rotate, confirm that the brake

is released and that the brake linkage is not

bound.

10

Page 53

M48 Tank

6.9. If the brake assembly is to be transferred to the

new hydro motor: remove the cotter pin from the

castle nut that holds the hub to the axle.

6.10. Loosen, but do not remove the castle nut from

the axle using a 11/2” socket.

NOTE: It may be necessary to set the parking

brake while loosening the nut. Release the

parking brake afterward.

NOTE: The studs are pressed into the brake

drum. The brake drum effectively is the drive

hub. The drive hub mounts on an narrow taper.

6.11. Remove the hairpin clip that secures the brake

link to the brake arm. Pivot the arm out of the

way. See Figure 6.13.

HAIRPIN CLIP

BRAKE

ARM

HIGH

PRESSURE

LINES

CASTLE

NUT

BRAKE

LINK

COTTER

PIN

6.13. Disconnect the high pressure lines from the the

hydro motor one at a time using a 7/8” wrench.

A 1” wrench may be required to hold the fittings

on the hydro motor. Plug the lines.

See Figure 6.13.

DISCONNECT

Figure 6.13

6.14. Remove the four sets of nuts and bolts that hold

the hydro motor to the hydro motor frame

assembly using 3/4” wrenches.

6.15. Lift the motor slightly and carefully pull it out far

enough to remove the motor plate from the end

of the four bolts. See Figure 6.15.

MOUNTING

BOLTS

Figure 6.11

6.12. Place a catch pan under the hydro motor, and

have two 1/2” JIC plugs within reach.

MOTOR

PLATE

MOTOR SPACERS

Figure 6.15

NOTE: The hydro motor weighs nearly 50 lbs.

11

Page 54

M48 Tank

6.16. Withdraw the hydro motor, along with the three

motor spacers, and place them gently on a work

bench. See Figure 6.16.

Figure 6.16

6.17. If the brake is to be removed, remove the clip

that holds the brake arm on the splined shaft,

and mark the location of the brake arm on the

splined shaft.

6.19. Safely fixture the hydro motor and brake assembly in a minimum 20 Ton press so that the ram

presses against the end of the axle, and the

assembly is supported by the edge of the brake

drum. Press the drum off of the tapered shaft.

6.20. Remove the castle nut and brake drum from the

axle. See Figure 6.20.

ORIENTATION MARKS

(ARROW TO FITTINGS)

BRAKE

ASSEMBLY

Figure 6.20

6.21. Mark the orientation of the brake assembly on

the hydro motor.

BRAKE

DRUM

Figure 6.17

6.18. Remove the brake arm from the splined shaft.

NOTE: The Hydro motor can be ordered with or

without the brake assembly. If an appropriate

size press is not available, the dealer should

consider ordering hydro motor with the brake

assembly attached.

6.22. Remove the four socket head cap screws that

hold the brake assembly to the hydro motor

using a 1/4” allen wrench.

6.23. Transfer the four mounting bolts from the old

hydro motor to the new one. Replace any that

show signs of wear or damage.

6.24. Position the three motor spacers on the bolts,

and install the hydro motor in the TANK.

6.25. Place the motor plate over the end of the bolts,

apply Loctite 242 (blue) the the bolts, and install

the four nuts. Tighten the bolts to 450-550 in.lbs.

6.26. Inspect the brake assembly. If there are not

signs of significant wear or damage, install the

brake on the new hydro motor, using the match

marks to maintain the same orientation.

6.27. Use new lock washers and / or Loctite 242 (blue)

when installing the brake assembly. Torque the

socket head cap screws to 160-200 in.-lbs.

12

Page 55

M48 Tank

6.28. Install the brake arm and clip on the new hydro

motor. See Figure 6.28.

Figure 6.28

6.29. Transfer the O ring to flare adaptor fittings from

the old hydro motor to the new hydro motor,

using a 1” wrench. Inspect the fittings and O

rings. If there is any doubt about their condition,

replace them. Lightly lubricate the O rings with

oil on assembly.

6.30. Apply a small amount of anti-seize compound to

the taper of the brake drum, and install the brake

drum on the axle.

6.31. Install the castle nut on the axle, and lock it with

a fresh cotter pin.

6.32. Connect the brake linkage.

6.33. Install the rear wheels, and torque the lug nuts to

50-70 ft.-lbs.

6.34. Check the fluid level in the reservoir, purge the

system as described in the pressure and flow

test instructions.

NOTE: If the hydraulic system has been drained

and flushed with 20W50, install a new filter and

follow the instructions for refilling the hydraulic

system in the “Operator’s and Service Manual”.

6.35. Install the wheels, lower the TANK to the ground,

and test run it in a safe area. Make any necklaces adjustments before installing the cutting

deck.

7. BRAKE LINKAGE ADJUSTMENT

7.1. With the TANK parked on firm level ground, lift

and safely support the back of the unit.

7.2. Remove the hairpin clips that hold the floor panel

in position.

7.3. Lift the floor panel up using the grip opening at

the top rear edge, slide it to the left, and remove

it. See Figure 7.3.

Figure 7.3

7.4. Release the hydro relief valves and release the

parking brake.

7.5. Rotate each wheel to confirm that the brakes are

not dragging or binding.

7.6. Remove the rear wheels using a 3/4” socket.

NOTE: It may be necklaces to set the parking

brake while loosening the lug nuts.

13

Page 56

M48 Tank

7.7. Loosen the jam nut that locks the shoulder nut in

position on the brake connector rod using a

9/16” wrench and a 3/4” wrench. See Figure 7.7.

SHOULDER NUTS

JAM NUTS

BRAKE CONNECTOR RODS

Figure 7.7

7.8. Remove the hairpin clip that secures the brake

link rod to the brake arm on the brake assembly.

7.9. Repeat on other side.

7.10. Disconnect the brake link rods (left and right).

See Figure 7.10.

7.11. Remove the hairpin clip and clevis pin that

secures the clevis on the end of the brake connector rod to the rear brake arm assembly on

both sides. See Figure 7.11.

BRAKE

LINK

ROD

REAR BRAKE

ARM ASSEMBLY

Figure 7.11

7.12. Confirm that the rear brake arm assembly

moves freely on the rear bellcrank shaft, is sufficiently well lubricated, and is free from excessive

play caused by worn busings. See Figure 7.12.

REAR

BELLCRANK

SHAFT

BUSHING

BRAKE

CONNECTOR ROD

BRAKE LINK ROD

Figure 7.10

REAR BRAKE

ARM ASSEMBLY

Figure 7.12

NOTE: If rear brake arm assembly service is

needed, the rear bell crank shaft that the arms

pivot on can be easily removed by unbolting the

brake shaft holders, removing the cotter pins

and washers that locate the brake arm assemblies on the shaft.

NOTE: Both washers that fit next to each rear

brake arm go between the arm and the cotter

pin.

14