Page 1

Professional Shop Manual

Medium Frame 2 & 3 Stage Snow Throwers

(500, 600 and 700 series)

2005 to present

NOTE: These materials are for use by trained technician s who are experi enced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not inte nded for use by untrained or inexperienced ind ividuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experie nced and trained prof essional. Read, understand, a nd follow all

instructions and use common sense when working on powe r e quip ment. T his includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as comple te and accu rate as possible at the time of publ ication. However , due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2013 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

Page 2

Page 3

Table of Contents

Chapter 1: Introduction

Professional Service Manual Intent .......................................................................1

Safety ....................................................................................................................1

Fasteners .............................................................................................................. 3

Assembly Instructions ........................................................................................... 3

Identifying Snow Thrower Series........................................................................... 3

Understanding Model And Serial Numbers ...........................................................4

Chapter 2: Belts And Cables

Auger Belt .............................................................................................................7

Drive Belt .............................................................................................................10

Auger Control Cable ...........................................................................................11

Drive Clutch Control Cable ..................................................................................13

Auger and Drive Cable Adjustments (500, 600 and 3-wheel Track Drives) ........14

Auger Cable Adjustments (2-wheel Track Drives) ..............................................15

Speed Selector Cable .........................................................................................16

Speed Selector Rod ............................................................................................18

Auger and Drive Lever Interlock.......................................................................... 20

Chapter 3: 500 Series Drive System

Axle Assemblies ..................................................................................................23

Hex Drive Shaft ...................................................................................................26

Planetary Gears...................................................................................................27

Friction Wheel Replacement............................................................................... 29

Chapter 4: 600 Series Drive System

Axle Assemblies ..................................................................................................31

Hex Drive Shaft Assembly ...................................................................................33

Friction Wheel Replacement............................................................................... 35

Chapter 5: 700 Series 2-Wheel Track-Drive System

Track Adjustment ................................................................................................37

Track and Track Wheels ..................................................................................... 38

Hex Drive Shaft ...................................................................................................39

Friction Wheel Replacement............................................................................... 43

Axle Shaft ............................................................................................................44

Planetary Gears and Shaft ..................................................................................46

Steering Trigger Cables ...................................................................................... 51

I

Page 4

Chapter 6: 700 Series 3-Wheel Track-Drive System

Track Removal/replacement ............................................................................... 53

Track Drive Assembly ......................................................................................... 58

Drive Axle Assemblies .........................................................................................59

Hex Drive Shaft and Planetary Gears................................................................. 60

Friction Wheel Replacement ...............................................................................63

Idler Hold Down Tools .........................................................................................64

Chapter 7: Auger Housing and Gear Box

Skid Shoes.......................................................................................................... 67

Skid Shoe Adjustment......................................................................................... 67

Shave Plate .........................................................................................................68

Auger Housings ...................................................................................................69

Auger Assemblies ............................................................................................... 71

2-Stage Gear Boxes ............................................................................................74

3-Stage Gear Boxes ............................................................................................78

Chapter 8: Discharge Chute and Controls (Manual Crank)

Remote Pitch Control Head (Plastic Chutes) ......................................................83

Remote Pitch Control Head (Steel Chutes)......................................................... 86

Discharge Chute (Manual Crank, Cork Screw Style).......................................... 89

Discharge Chute (with Remote Head)................................................................. 90

Manual Crank, Cork Screw Style ........................................................................ 92

Chute Bracket Adjustment ..................................................................................92

Remote Head ......................................................................................................93

Chapter 9: Discharge Chute and Controls (Joystick, Cable Style)

Remote Pitch Control Head (Plastic Chutes)...................................................... 97

Discharge Chute (with Remote Head) ...............................................................100

Joystick (Cable Style) ........................................................................................102

Chapter 10: Discharge Chute and Controls (Joystick, Hex Shaft)

Remote Pitch Control Head (Plastic Chutes).................................................... 105

Remote Head (Joystick, Hex Shaft) ..................................................................108

Joystick (Hex Shaft) ..........................................................................................114

Chapter 11: Discharge Chute and Controls (Electric)

Remote Pitch Control Head (Plastic Chutes) ....................................................119

Remote Pitch Control Head (Steel Chutes) .......................................................122

Discharge Chute ...............................................................................................125

Electric Chute Control .......................................................................................130

Electric Joystick and Harness ........................................................................... 131

Electric Joystick Bracket ....................................................................................132

Chute Control Assembly ....................................................................................136

Chute Control Motors

........................................................................................137

Electric Chute Control Pitch Cables ..................................................................140

Schematics ........................................................................................................143

II

Page 5

Introduction

Caution is used to point out potential danger to the technician, operator, bystanders, or surrounding property.

! CAUTION! CAUTION

Warning indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury.

! WARNING! WARNING

! DANGER! DANGER

Danger indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations

CHAPTER 1: INTRODUCTION

Professional Service Manual Intent

This Manual is intended to provide service dealers with an introduction to the mechanical aspects of medium

frame two and three stage snow throwers.

NOTE: Please refer to the engine’s service manual for all maintenance and repair procedures.

Disclaimer: The information contained in this manual is correct at the time of writin g. Both the prod u ct an d th e inf or -

mation about the product are subject to change without notice.

About the text format:

NOTE: is used to point out information that is relevant to the procedure, but does not fit as a step in the proce-

dure.

• Bullet points: indicate sub-steps or points.

1. Numbered steps

1a. Substeps

the actions required to complete a step.

Disclaimer: This manual is intended for use by trained, professional technicians.

• Common sense in operation and safety is assumed.

• In no event shall MTD or Cub Cadet be liable for poor text interpretation or poor execution of the proce-

dures described in the text.

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician or Cub Cadet Technical Support.

Safety

This Service Manual is meant to be used along with the Operator’s Manual. Read the Operator’s Manual and

familiarize yourself with the safety and operational instructions for the equipment being worked on. Keep a copy of

the Operator’s Manual for quick reference. Operator’s manuals may be viewed for free at the Cub Cadet website. It

will be necessary to have the complete model and serial number for the equipment.

indicate specific things that should be done, and the or der in which they should be done.

will be lettered and nested within steps. Two or more substeps may be combined to describe

1

Page 6

Medium Frame 2 & 3 Stage Snow Throwers

• Be prepared in case of emergency:

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

! CAUTION! CAUTION

• Grooming and attire:

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection ................................ while working around any machinery

Protective gloves ..................................... where necessary

Armored footwear.................................... when working around any machinery

Hearing protection ................................... in noisy environments

Chemically resistant gloves..................... when working with chemicals or solvents

Respirator................................................ when working with chemical or solvents

Appropriate tinted eye protection............. when cutting or welding

Flame resistant headgear, jacket, chaps. when cutting or welding

! WARNING! WARNING

! CAUTION! CAUTION

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very serious

harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

• Lift and support heavy objects safely and securely.

• Be aware of your surroundings and potential hazards that are inherent to all power

equipment. All the labels in the world cannot protect a technician from an instant of

carelessness.

2

Page 7

Introduction

Figure 1.1

500 Series

Fasteners

• Most of the fasteners used on these snow throwers have SAE thread sizes.The engines have metric

thread sizes. For this reason, wrench sizes are frequently identified in the text, and measurements are

given in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of releasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners, like cotter pins, are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

Assembly Instructions

• Torque specifications may be noted in the part of the text that covers assembly. They may be summa-

rized in tables along with special instructions regarding locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-by-step procedure guide that does not require the user to hunt for information.

• Lubricant quantity and specification may be noted in the part of the text that covers maintenance, and

again in the section that covers assembly. They may also be summarized in tables along with special

instructions. Whichever method is more appropriate will be used. In many cases, the information will be

found in several places in the manual so that the manua l is hand y as a quick-reference guide a s well a s a

step-by-step procedure guide that does not require the user to hunt for information.

• The level of assembly instructions provided will be determined by the complexity of reassembly, and by

the potential for damage or unsafe conditions to arise from mistakes made in assembly.

• Some instructions may refer to other parts of the manual for subsidiary pr ocedures. Th is avoid s repe ating

the same procedure two or three times in the manual.

Identifying Snow Thrower Series

NOTE: Medium frame two stage snow throwers are available as a 500, 600 or 700 series.

The 500 series features:

• Steerable drive wheels

• Auger housing width of 22” - 30”

• 2 stage and 3 stage augers available.

3

Page 8

Medium Frame 2 & 3 Stage Snow Throwers

Figure 1.2

600 Series

Figure 1.3

700 Series

Figure 1.4

The 600 series features:

• Solid drive wheel axles

• Auger housing width of 22” - 30”

• 2 stage augers

The 700 series features:

• Track drive (2 and 3 wheel versions)

• Auger housing width of 24” - 30”

• 2 stage and 3 stage augers available.

Understanding Model And Serial Numbers

The model and serial numbers are located on a white

sticker with a bar code. The sticker is located at the back of

the machine, below and to the left of the speed selector

shaft.

4

Page 9

Introduction

The model number is 31AH64FG795. The break down of what the model number

• 31 - - - - - - - - - - - - - - - - - - - - - - - - Indicates that this is a snow thrower.

• - - A- - - - - - - - - - - - - - - - - - - - - - - - Sales level

• - - - H- - - - - - - - - - - - - - - - - - - - - - - Starter (M = 110v electric starter with a 3A/5A split alternator)

• - - - - - 6 - - - - - - - - - - - - - - - - - - - - - Frame series

• - - - - - - 4 - - - - - - - - - - - - - - - - - - - - Engine (T = 277 cc Cub Cadet engine)

• - - - - - - - F- - - - - - - - - - - - - - - - - - - Handle panel style

• - - - - - - - - -G - - - - - - - - - - - - - - - - - Auger housing

• - - - - - - - - - - 795 - - - - - - - - - - - - - - Customer number

The serial number is 1H072B30186. The serial number

• 1 - - - - - - - - - - - - - - - - - -Engineering level

• - H - - - - - - - - - - - - - - - - -Month of production (H = August)

• - - - 07- - - - - - - - - - - - - - - -Day of the month

• - - - - - 2 - - - - - - - - - - - - - - -Last digit of the year

• - - - - - - B - - - - - - - - - - - - - -Plant it was built in

• - - - - - - - - 3 - - - - - - - - - - - - -Assembly line number

reads as follows:

means is as follows:

• - - - - - - - - - -0186 - - - - - - - - - -Number of unit built

Additional technical and service information may also be available to our company authorized service center personnel through our company corporate offices, regional parts distributors and regional service center field support

personnel. Please contact the designated support office in your area or our corporate offices directly should further

service information be needed.

Cub Cadet LLC

P.O. Box 368022

Cleveland, OH 44136

Telephone: (330) 273-8669

www.cubcadet.com

5

Page 10

Medium Frame 2 & 3 Stage Snow Throwers

6

Page 11

Auger Belt

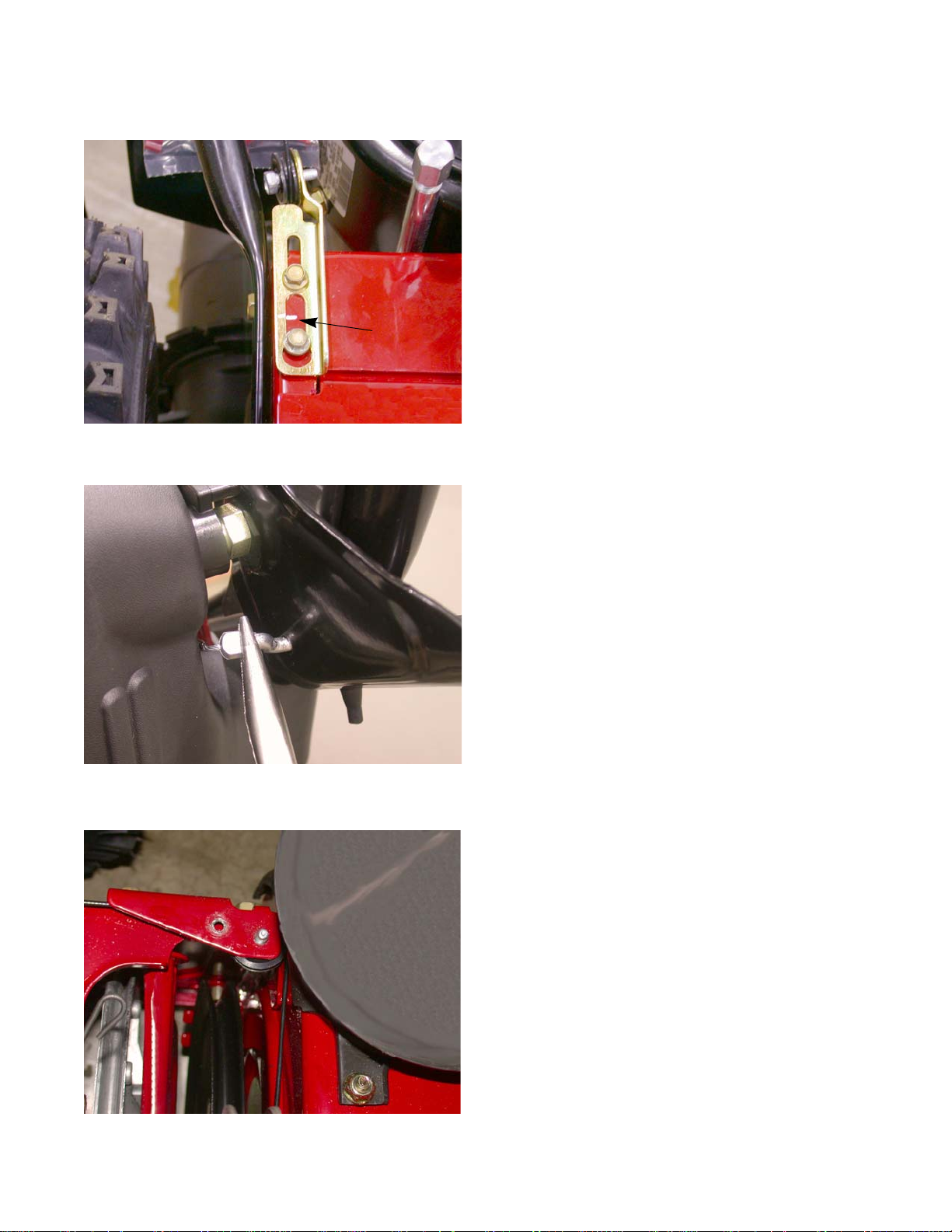

Figure 2.1

3/8”

Hex Screws

Figure 2.2

Belts and Cables

Chapter 2: Belts And Cables

To remove/replace the Auger Belt:

NOTE: Prior to servicing or replacing any belts stop the

engine and allow it to cool. Then disconnect spark

plug and ground it to the engine

NOTE: If the unit is throwing the Auger Belt, inspect the

round part of the Auger Housing that the impeller

spins in. If there is a buckle or a crease in it, the

Auger Housing is bent and must be replaced

before replacing the belt.

1. Remove the two screws that secure the belt cover

using a 3/8” wrench. See Figure 2.1.

2. Lift the belt cover off of the unit.

NOTE: Some units have a belt guide. The belt guide can

be removed by removing the two screws, by the

arrows in Figure 2.2., using a 1/2” wrench.

7

Page 12

Medium Frame 2 & 3 Stage Snow Throwers

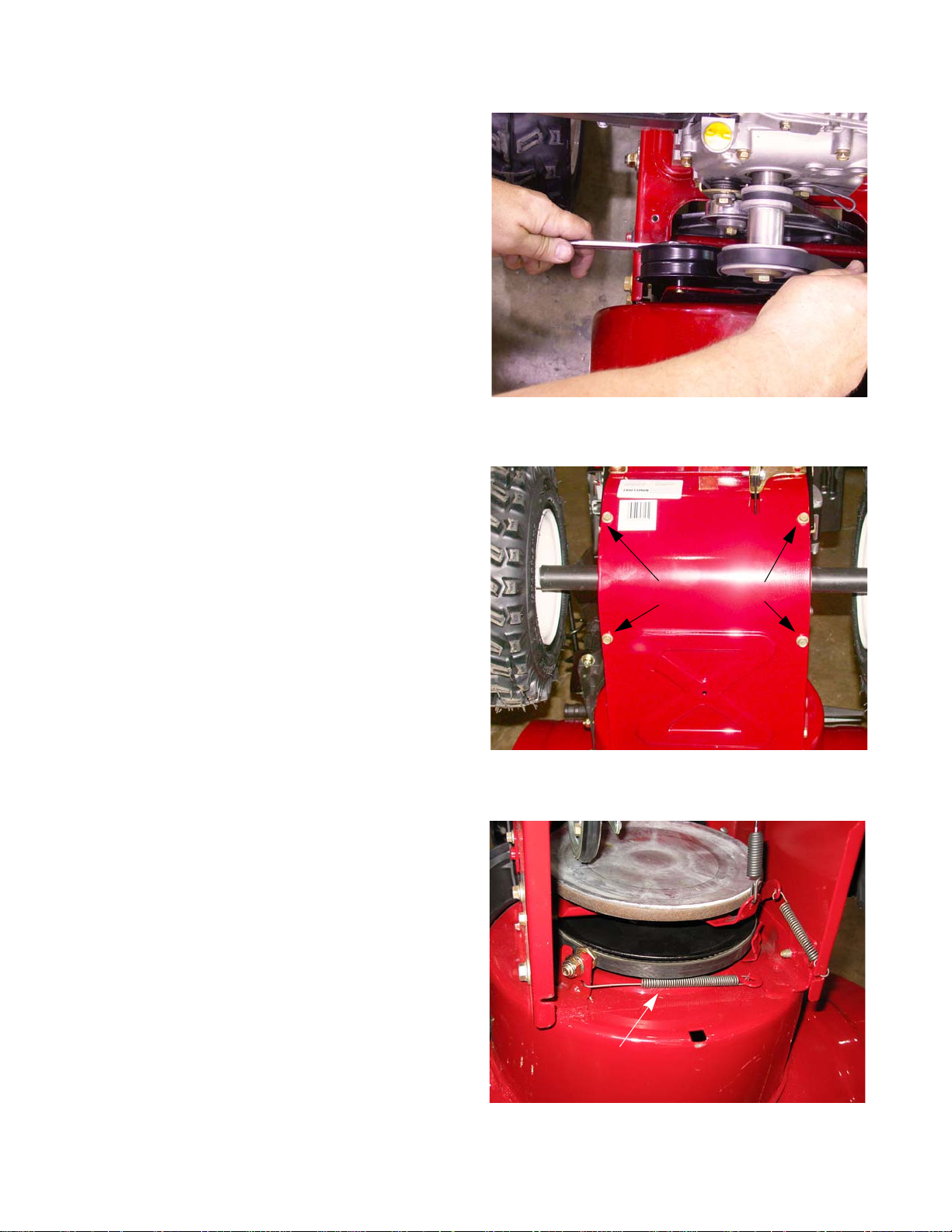

Figure 2.3

Figure 2.4

3/8” wrench

Figure 2.5

Return Spring

3. Loosen the idler pulley enough for the belt to cl ear it

using a 1/2” wrench.

4. Slip the belt off of the engine pulley.

5. Drain the fuel into an approved container.

6. Carefully tip the snow thrower forward so it rests on

the auger housing.

7. Remove the bottom access panel. See Figure 2.4.

8. Remove the belt guide (the shoulder bolt) with a 3/

4” wrench and a 9/16” wrench. See Figure 2.5.

9. Unhook the idler bracket return spring.

8

Page 13

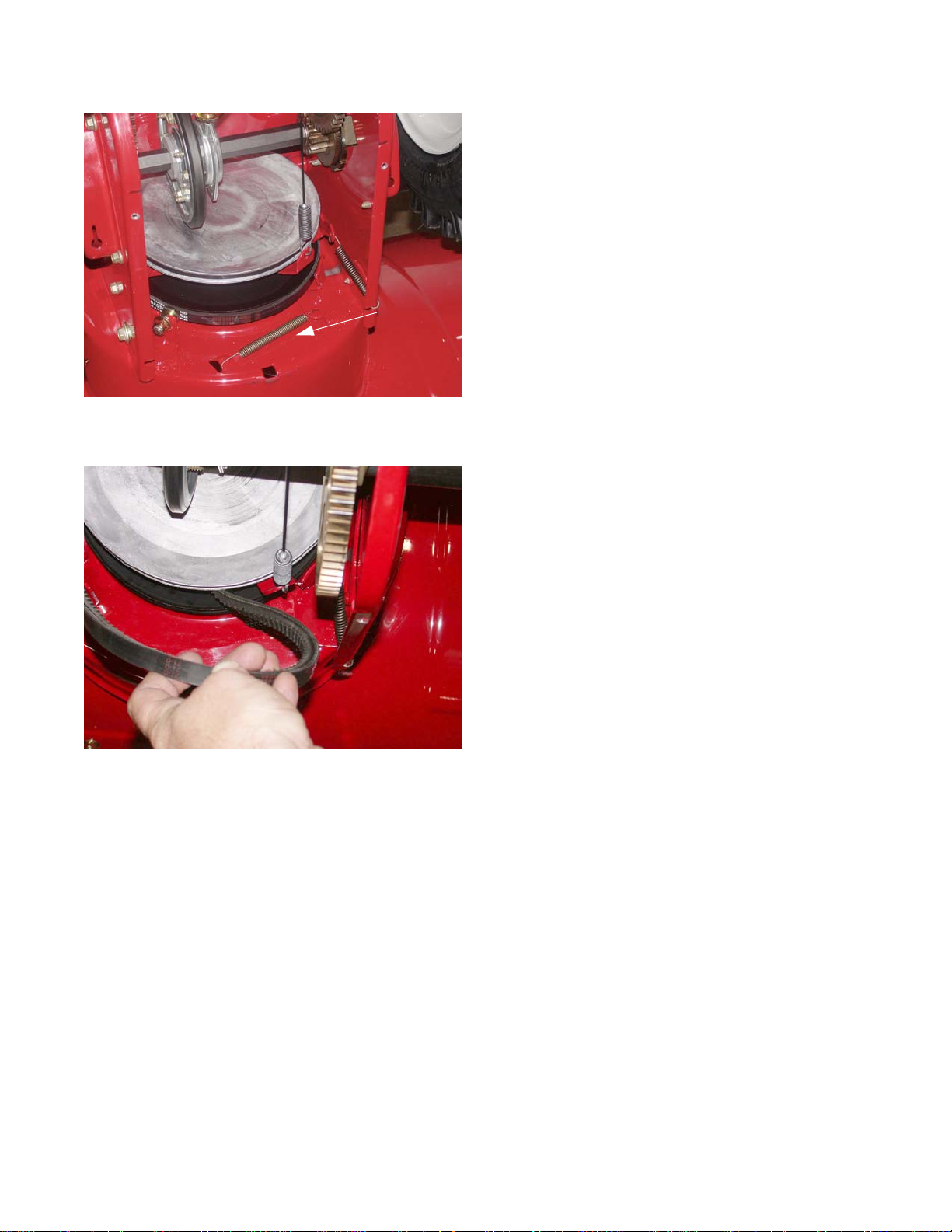

Belts and Cables

Figure 2.6

Return

Spring

Figure 2.7

NOTE: On 2005 through 2007 model years, the Return

Spring hooked into a hole in the impeller housing.

See Figure 2.6.

NOTE: The idler bracket has a tab that acts as a brake,

pressing against the Auger Belt whenever the

Auger Control Lever is released.

10. Pull the belt down past the Auger Pulley. See Figure

2.7.

11. Install the belt by following the previous steps in

reverse order.

12. Start the engine.

13. Engage and disengage the Auger Control Lever a

few times.

14. With the Auger Control Lever disengaged, move to

the front of the unit and verify that the augers are not

moving.

NOTE: If the Augers are moving, adjust the cable tension

and repeat steps 12 through 14.

15. Test run the snow thrower in a safe area before

returning it to service.

9

Page 14

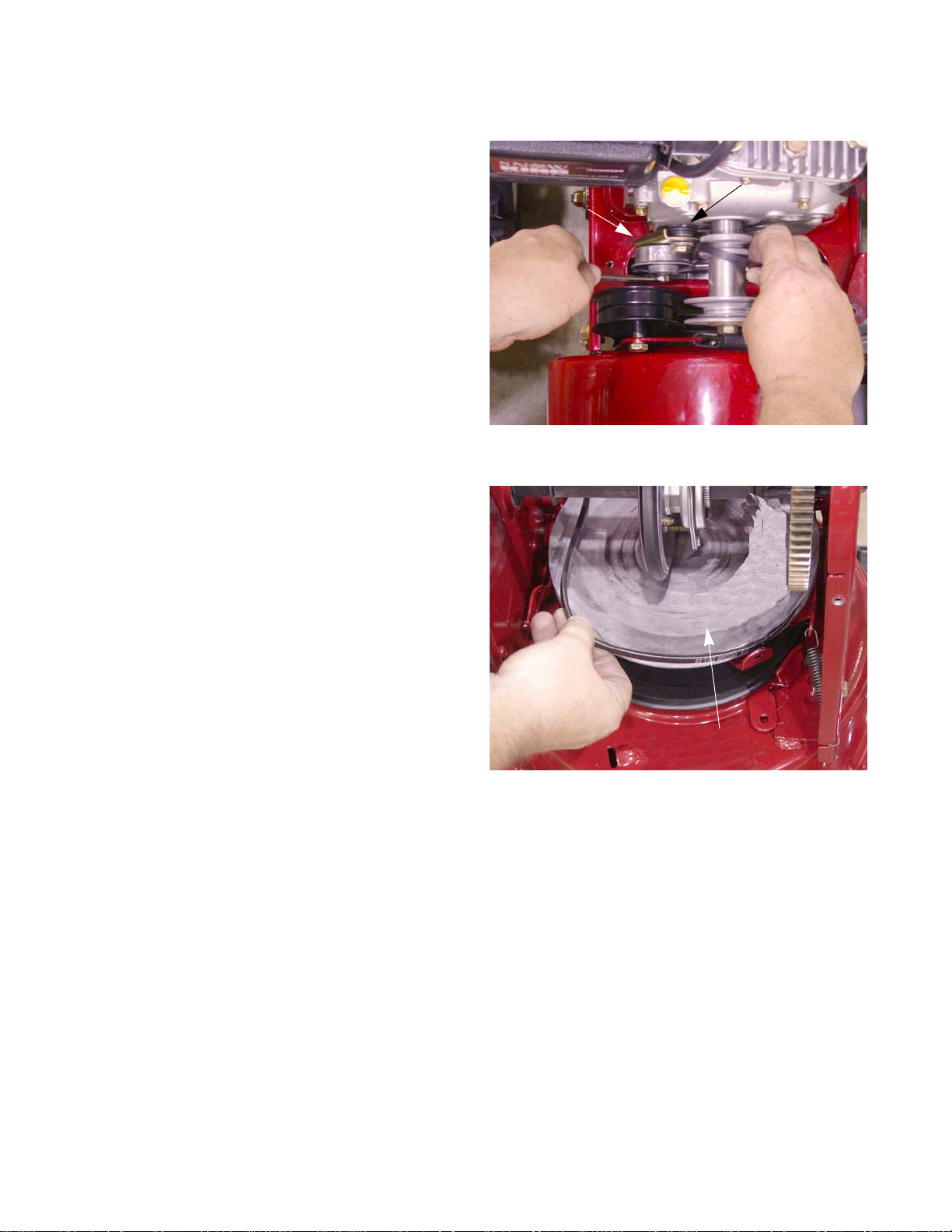

Medium Frame 2 & 3 Stage Snow Throwers

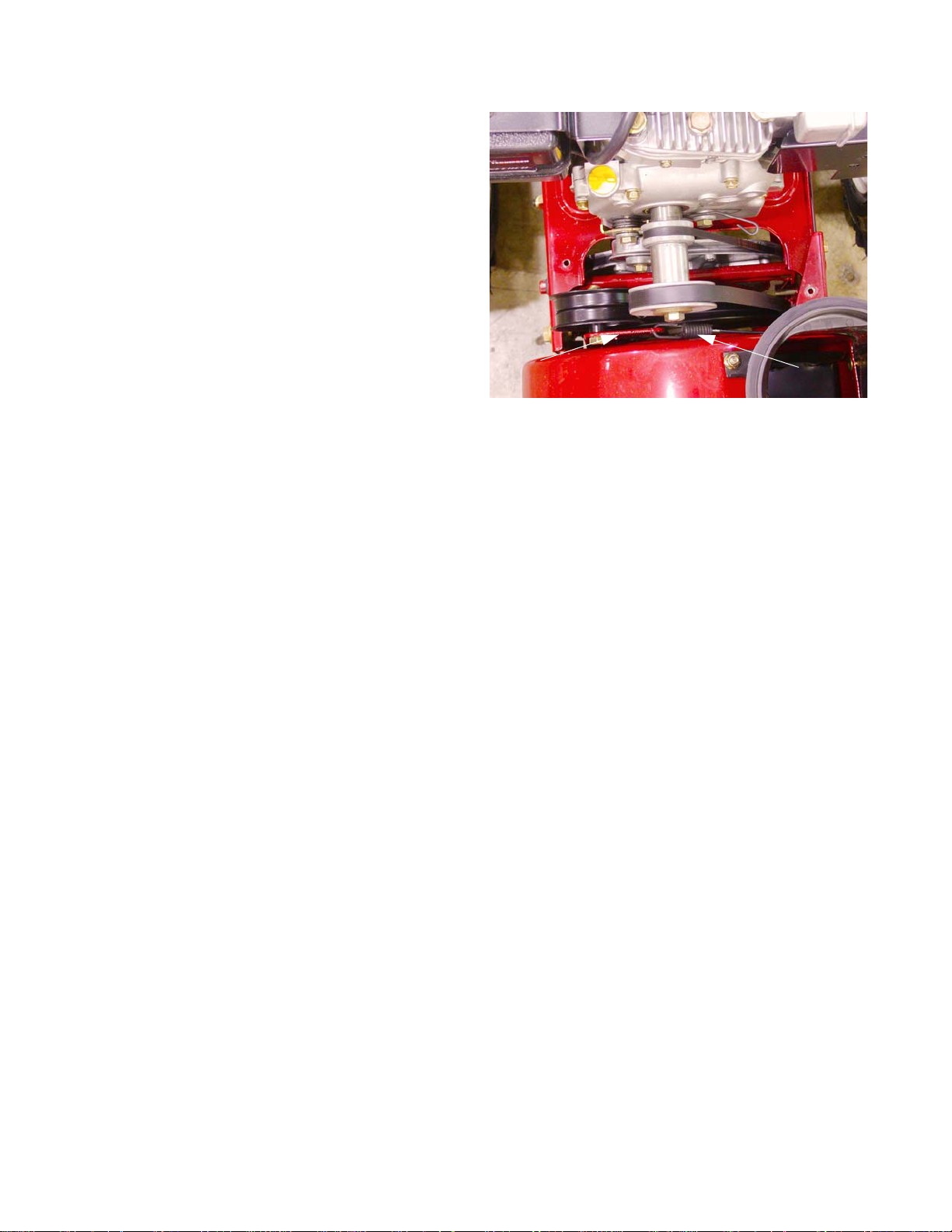

Figure 2.8

Drive

Idler Bracket

Torsion

Spring

Figure 2.9

Drive Platter

Drive Belt

To remove/replace the drive belt:

NOTE: Prior to servicing or replacing any belt s, stop

the engine and allow it to cool. Then disconnect spark plug and ground it to the engine

1. Remove Auger Belt as described on the Auger Belt

section of this chapter.

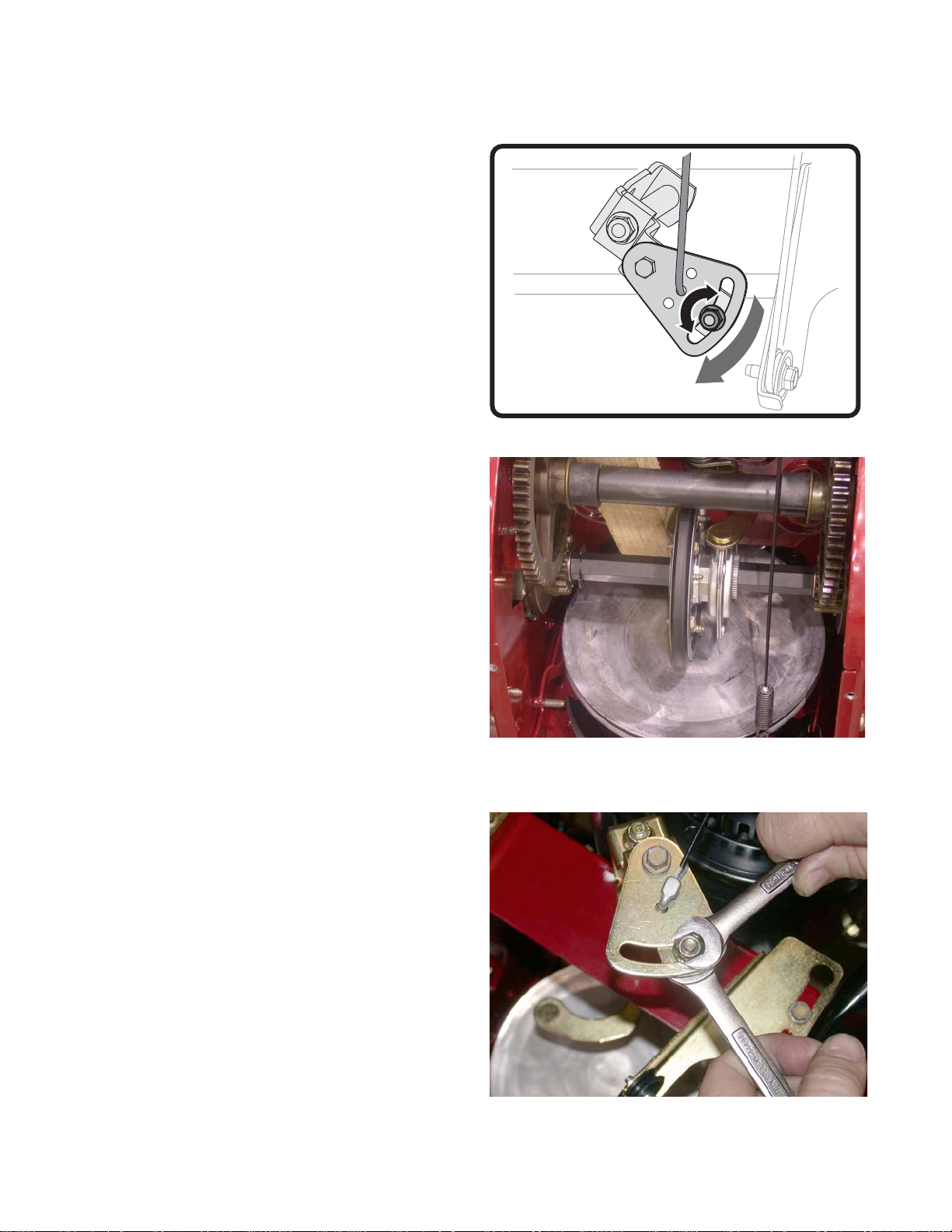

2. Using a 3/8” wrench, rotate the Drive Idler Bracket

enough slip the belt off of the engine pulley. See

Figure 2.8.

3. Work the belt off the bottom of the Drive Platter.

4. Slip the belt between the Friction Wheel and Drive

5. Pull the belt up through the top of the housing.

6. Install the belt by following the previous steps in

7. Test run the snow thrower in a safe area before

Platter. See Figure 2.9.

reverse order.

returning it to service.

10

Page 15

Auger Control Cable

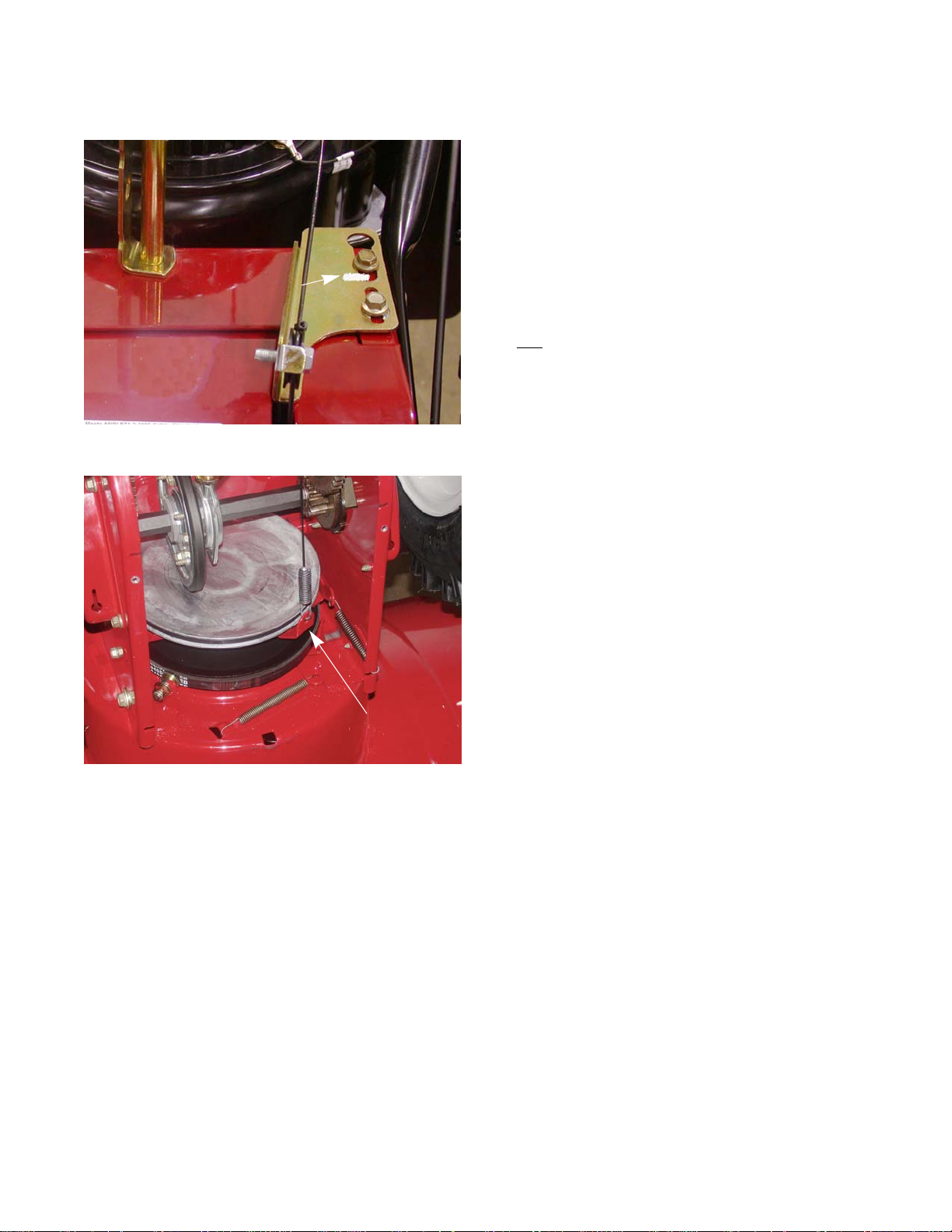

Figure 2.10

Alignment mark

Figure 2.11

Figure 2.12

Belts and Cables

To remove/replace the Auger Control Cable:

NOTE: The auger control is on the left side of the handle

bars.

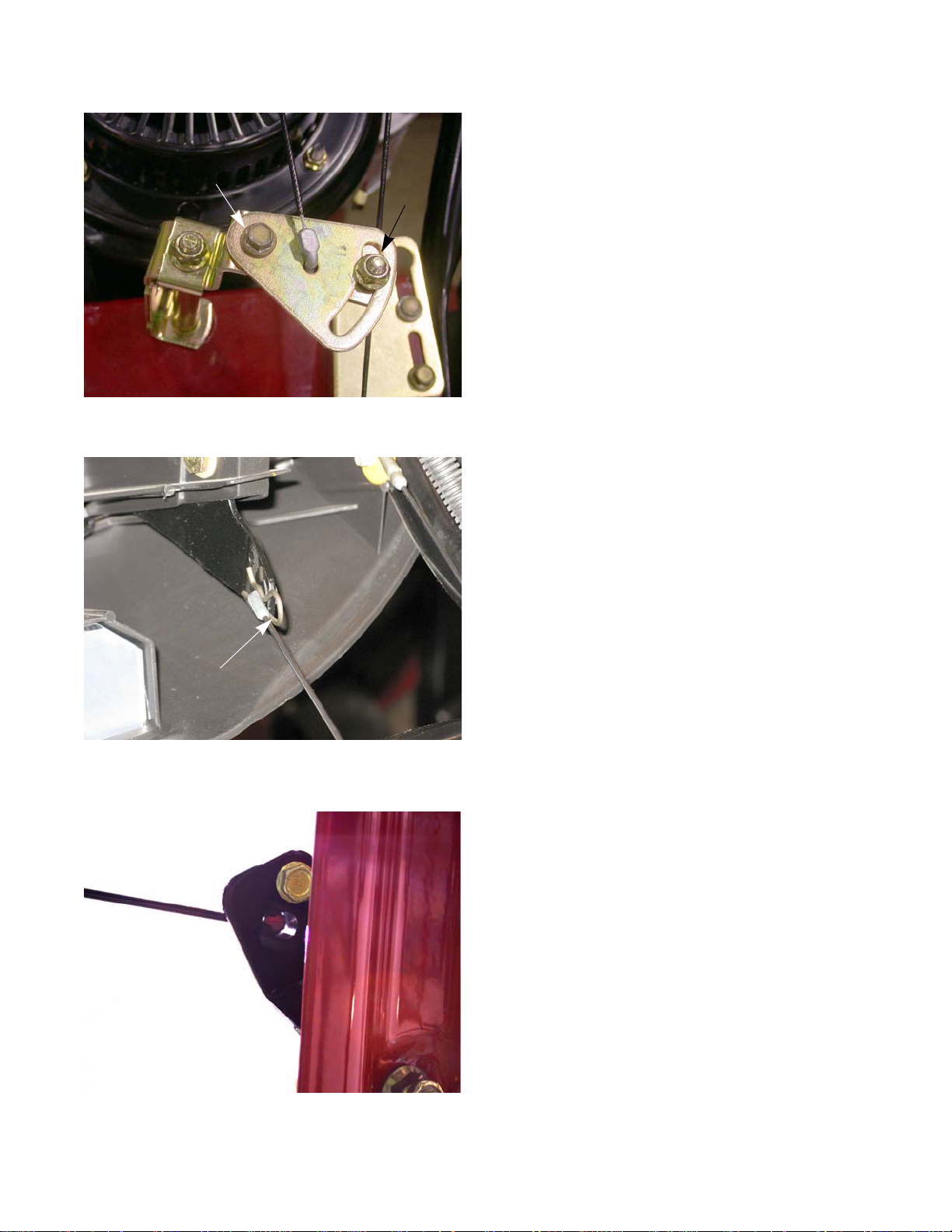

1. Place an alignment mark on the adjustment bracket

and the frame. See Figure 2.10.

2. Loosen the hex screws securing the adjustment

bracket to release tension off of the cable.

3. Detach the cable from the control handles. See Figure 2.11.

NOTE: On units with threaded Z-fittings:

• Loosen the jam nut.

• Unthread the cable from the Z-fitting.

4. Loosen the cable guide pulley on the adjustment

bracket and slip the cable out of the pulley groove.

5. Remove the belt cover.

6. Loosen the second cable guide pulley and slip the

cable out of the pulley groove. See Figure 2.12.

11

Page 16

Medium Frame 2 & 3 Stage Snow Throwers

Figure 2.13

Idler Pulley Bracket

Auger Cable

7. Detach the spring end of the cable from the Idler

Pulley Bracket. See Figure 2.13.

8. Install the cable by following the previous steps in

reverse order.

NOTE: When attaching he spring end of the cable,

the open side of the spring faces the engine.

9. Test run the snow thrower in a safe area before

returning it to service.

12

Page 17

Drive Clutch Control Cable

Figure 2.14

alignment mark

Figure 2.15

Drive platter support bracket

Belts and Cables

To remove/replace the Drive Control Cable:

NOTE: The drive control is on the right handle.

1. Stop the engine and allow it to cool. Disconnect the

spark plug wire and ground it to the engine.

2. Drain the fuel into an approved container.

3. Carefully tip the snow thrower forward so it rests on

the auger housing opening.

4. Place an alignment mark on the adjustment bracket

and

the frame. See Figure 2.14.

5. Detach the cable from the engagement handle.

NOTE: On units with threaded Z-fittings:

• Loosen the jam nut.

• Unthread the cable from the Z-fitting.

6. Remove the bottom access panel.

7. Unhook the spring end of the cable from the Drive

Platter Support Bracket. See Figure 2.15.

8. Unhook the cable from the pulley on the adjustment

bracket.

9. Install the cable by following the previous steps in

reverse order.

10. Test run the snow thrower in a safe area before

returning it to service.

13

Page 18

Medium Frame 2 & 3 Stage Snow Throwers

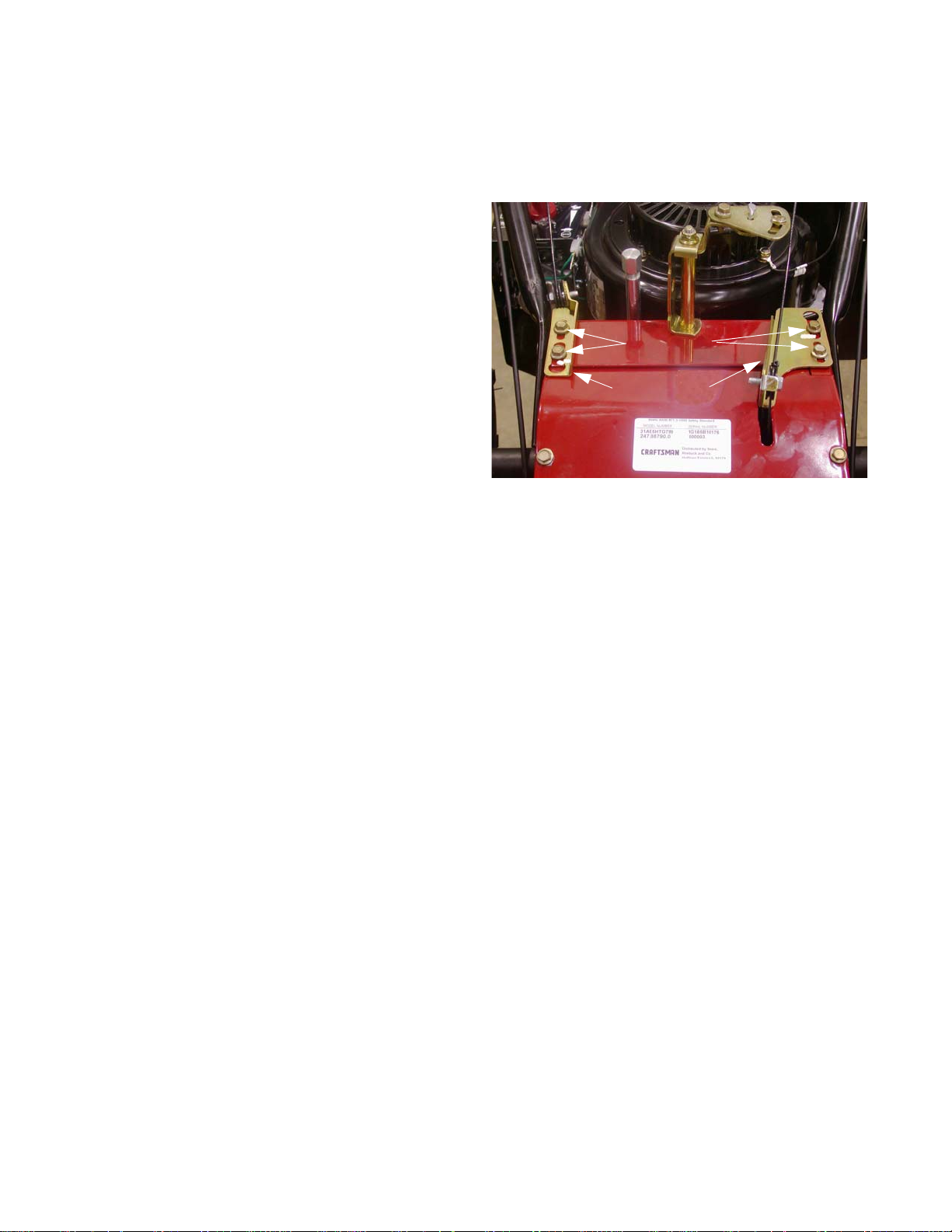

Figure 2.16

Hex Screws

Adjustment

Brackets

Auger and Drive Cable Adjustments (500, 600 and 3-wheel Track Drives)

NOTE: Prior to servicing or replacing any belt s, stop

the engine and allow it to cool. Then disconnect spark plug and ground it to the engine

1. Loosen the hex screws that secure the bracket that

guides the cable needing adjustment using a 3/8”

wrench. See Figure 2.16.

2. Slide the bracket up to add slack to the cable or

down to add tension to the cable.

NOTE: The cables should be straight, without ten-

sion when the handle is not engaged.

NOTE: If either bracket reaches the end of its travel

without achieving correct adjustment, use a

straight-edge to confirm that the handle bars

are not bent.

3. When adjusted correctly, the cables should not have

any slack. They should also not be under tension

while in the disengaged position.

NOTE: The speed selector sho uld be able the travel

through its full range of travel without binding.

IMPORTANT: Creep in the drive or auger systems

is unacceptable and must be fixed

before returning to service.

4. Test run the unit in a safe area before returning it to

service.

14

Page 19

Belts and Cables

Figure 2.17

Auger Cable Adjustments (2-wheel Track Drives)

Check the adjustment of the auger control:

1. When the Auger Control Lever is released, in the

disengaged or “up” position, the cable should have

very little slack. It should not be tight.

2. In a well-ventilated area, start the snow thrower

engine.

3. While standing in the operator’s position, behind the

snow thrower, engage the auger.

4. Allow the auger to remain engaged for approximately ten seconds before releasing the auger control. Repeat this several times.

5. With the throttle control in the FAST (rabbit) position

and the auger control in the disengaged or “up”

position, walk to the front of the machine.

6. Confirm that the auger has completely stopped

rotating and shows no signs of motion.

IMPORTANT: If the auger shows any signs of rotating, return to the operator’s position and shut of f the engine

and wait for all moving parts to stop before readjusting the auger control.

To adjust the Auger Control Cable:

1. Loosen the hex jam nut on the Auger Control Cable “Z” fitting. See Figure 2.17.

2. Without turning the cable, thread the ferrule up or down the “Z” fitting u ntil there is no slack in the cable without pulling on the auger idler pulley..

• Hold the flats on the ferrule with pliers and tighten the jam nut against the ferrule.

• Do not over-tighten the cable.

3. Repeat steps 2 through 6 above until proper adjustment has been achieved.

Drive Cable Adjustments (2-wheel Track Drives)

Check the adjustment of the drive control by:

1. With the Drive Control Lever released, in the disengaged or “up” position, push the snow thrower gently forward. The unit should roll freely.

2. Engage the drive control and gently attempt to push the sno w thrower forward. T he tr acks shou ld not tur n and

the unit should not roll freely.

3. Release the drive control and move the shift lever back and forth between the R2 positio n an d the F6 po sition

several times. The shift lever should move easily.

If any of the above tests failed, the drive cable is in need of adjustment. Proceed as follows:

1. To adjust the drive, loosen the hex jam nut on the auger control cable “Z” fitting. See Figure 2.17.

2. Thread the ferrule without turning the cable onto the “Z” fitting until there is no slack in the cable.

• Hold the flats on the ferrule with pliers and tighten the jam nut against the ferrule.

• Do not over-tighten the cable.

3. Rotate the coupling end of the cable counterclockwise to loosen the tension or clockwise to increase the tension on the cable.

4. Tighten the hex jam nut.

5. Re-check the adjustment of the Drive Control Cable, as described above, to verify proper a djustment has been

achieved.

15

Page 20

Medium Frame 2 & 3 Stage Snow Throwers

Figure 2.18

Figure 2.19

Figure 2.20

Speed Selector Cable

To adjust the Speed Selector Cable:

NOTE: Inspect the drive platter and friction wheel

before adjusting the speed sector cable.

Ensure that the friction wheel can freely

travel through the whole range of positions.

NOTE: A damaged or binding friction wheel can

mimic a speed selector cable that is out of

adjustment.

1. Place the shift lever in the fastest forward speed

position.

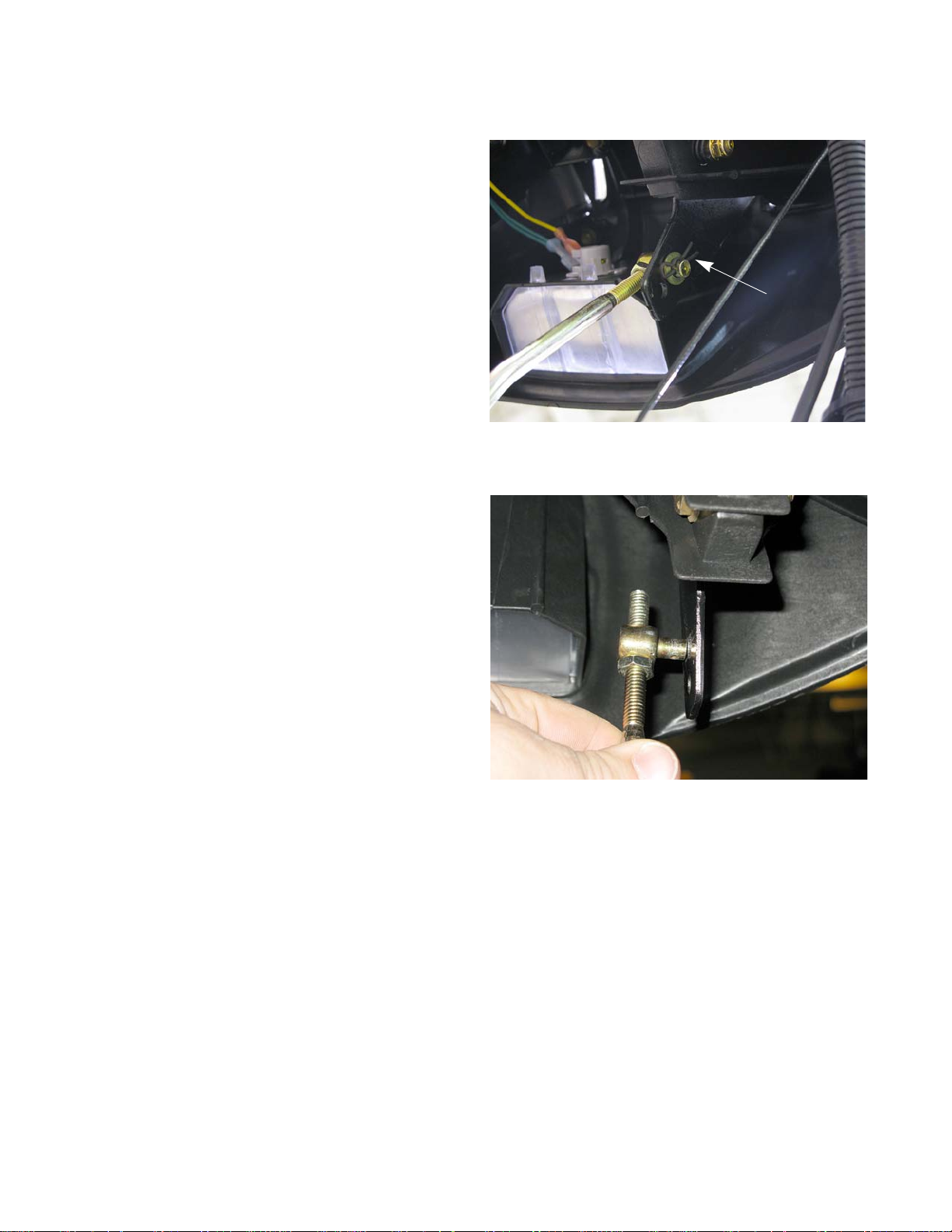

2. Loosen the hex nut on the Shift Cable Index Bracket

and pivot the bracket downward until the slack in the

cable is gone. See Figure 2.18.

3. Tighten the hex nut.

To remove/replace the Speed Selector Cable:

1. Stop the engine and allow it to cool. Disconnect the

spark plug wire and ground it to the engine.

2. Drain the fuel into an approved container.

3. Carefully tip the snow thrower forward so it rests on

the auger housing opening.

4. Remove the bottom access panel.

5. Place a block of wood on the left side of the drive

wheel to hold the shifter arm stationary. See Figure

2.19.

6. Release the tension on the Speed Selector Cable

with two 7/16” wrenches. See Figure 2.20.

NOTE: Older production units only have one hole

for the speed selector cable, as seen in Figure 2.20. Current production models have

three holes. The extra holes were added to

expand the adjustment range to the cable.

16

Page 21

Belts and Cables

Figure 2.21

Screw

Nut

Figure 2.22

Hair pin clip

Figure 2.23

7. Loosen the cable screw and nut enough to free the zfitting from the from the Speed Control Pivot Bracket.

See Figure 2.21.

8. Remove the hair pin clip from the cable end. See Figure 2.22.

NOTE: Early production units have a hex screw securing

the barrel side of the cable to the shifter handle.

NOTE: The bracket securing the cable to the shift lever is

two pieces

9. Install the cable by following the previous steps in

reverse order.

10. Adjust the cable by following the procedures

described in the Speed Control Cable adjustment

section of this chapter.

11. Test run the snow thrower in a safe area before

returning it to service.

17

Page 22

Medium Frame 2 & 3 Stage Snow Throwers

Figure 2.24

Hair Pin Clip

Figure 2.25

Speed Selector Rod

To adjust the Speed Selector Rod:

NOTE: Inspect the drive platter and friction wheel

before adjusting the Speed Selector Cable.

Ensure that the friction wheel can freely

travel trough the whole range of positions.

NOTE: A damaged or binding friction wheel can

mimic a speed selector cable that is out of

adjustment.

1. Place the Speed Selector Lever in the fastest forward speed position.

2. Remove the hair pin clip and washer from the upper

end of the selector rod. See Figure 2.24.

3. Slide the ferrule out of the speed selector leve r.

4. Loosen the jam nut.

5. Adjust the ferrule until the ferrule lines up with the

hole in the speed selector lever without pulling on

the rod. See Figure 2.25.

NOTE: When adjusted, the rod needs to be parallel

with the axis of the snow thrower.

6. Reinstall the washer and hair pin clip.

7. Test run the unit in a safe area before returning it to

service.

18

Page 23

Belts and Cables

Figure 2.26

Figure 2.27

Ball Joint

To remove/replace the Speed Selector Rod:

1. Place the shift lever in the fastest forward speed position.

2. Remove the hair pin clip and washer from the upper

end of the Selector Rod. See Figure 2.26.

3. Slide the ferrule out of the Speed Selector Lever.

4. Remove the nut that secures the ball joint on the end

of the selector rod to the selector assembly, using a

1/2” wrench. See Figure 2.27.

5. Slide the ball joint out of the Selector Assembly.

6. Install the Selector Shaft by following the previous

steps in reverse order.

NOTE: The ball joint is a wear item. MTD recommends

replacing the ball joint when installing the Speed

Selector Shaft.

7. Adjust the shaft by following the procedures

described in the previous section of this chapter.

8. Test run the unit in a safe area before returning it to

service.

19

Page 24

Medium Frame 2 & 3 Stage Snow Throwers

Figure 2.28

Alignment marks

Figure 2.29

”

3/4””

Wrench

1/2”

Wrench

Figure 2.30

“D” hole

Auger and Drive Lever Interlock

To remove/service the Auger And Drive Lever Interlock:

1. Loosen, but do not remove the two screws ho lding

the auger cable using a 3/8” socket. See Figure

2.28.

NOTE: Place an alignment mark on the adjustment

bracket and the frame for reassembly.

2. Remove the Z-fitting from the Auger Control Lever

with a pair of needle nose pliers.

3. Remove the shoulder bolt using a 3/4” wrench and a

1/2” wrench. See Figure 2.29.

4. Carefully release the tension from the torsion spring

as the bolt is withdrawn.

5. Repeat the previous step on the drive control lever.

6. Detach the pivot rod from the Clutch Lock Cam. See

Figure 2.30.

NOTE: The flats at each end of the pivot rod fit into

the “D” hole in the cam lock.

7. Slide the rod out of the handle panel.

20

Page 25

Belts and Cables

Figure 2.31

Powdered metal end

Nail headed

Figure 2.32

Clutch Lock Cam

Shoulder nut

Hex key

NOTE: The pivot rod for early production models were nail

headed. Current production models have a powered medal end. See Figure 2.31.

NOTE: The shoulder nuts are attached to the clutch lock

cams with a socket head screw. The screw can be

removed using a 3/16” hex key.

NOTE: If the socket head screw is over torqued, the screw

head will sink into the plastic material of the Clutch

Lock Cam. The socket head screw will also prevent the shoulder bolt from threading into the

shoulder bolt all the way.

NOTE: If the socket head screw is too loose, the Clutch

Cam Lock will not operate the Auger Control

Lever.

8. Install the interlocks by following the previous procedures in reverse order.

9. Test run the unit in a safe area before returning it to

service.

21

Page 26

Medium Frame 2 & 3 Stage Snow Throwers

22

Page 27

Axle Assemblies

Figure 3.1

Axle Support

Tube

Axle Shafts

Figure 3.2

Hex drive shaft

Axle

500 Series Drive System

Chapter 3: 500 Series Drive System

NOTE: Units with steerable drive wheels have a split axle

to allow each wheel to be driven independently of

each other. See Figure 3.1.

To remove the axles:

1. With the engine stopped and allowed to cool, disconnect the spark plug wire and ground it to the engine.

2. Drain the fuel into an approved container.

3. Carefully tip the snow thrower forward, so it rests on

the auger housing opening.

4. Remove the bottom access panel. See Figure 3.2.

23

Page 28

Medium Frame 2 & 3 Stage Snow Throwers

Figure 3.3

Figure 3.4

Spacer

Bushing

Hex

Figure 3.5

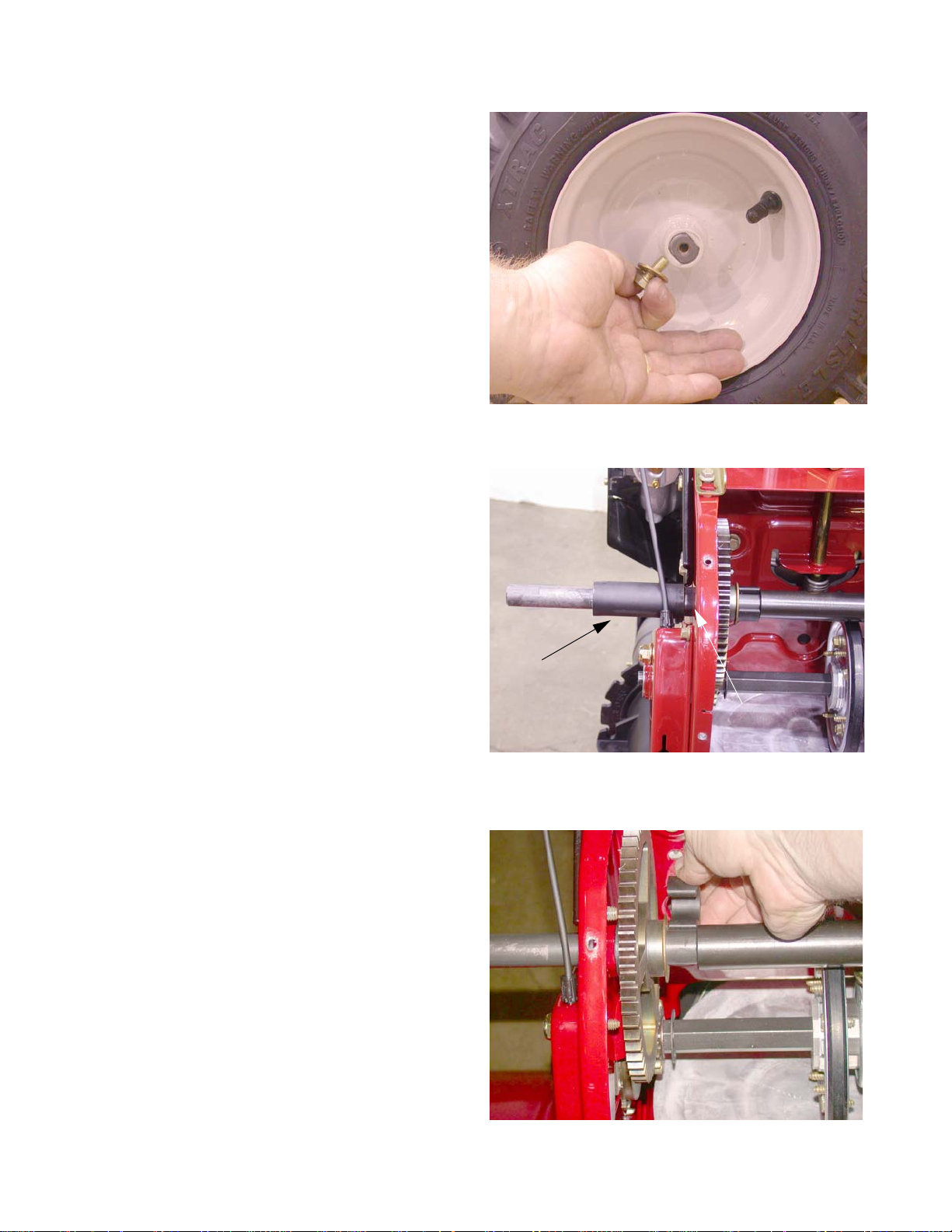

5. Remove the wheels using a 1/2” wrench.

NOTE: The ends of the axle shafts ar e a double -D.

See Figure 3.3.

6. Slide the spacers off of the axle. See Figure 3.4.

7. Carefully pry the 2 split bushings from the axle. See

Figure 3.5.

24

Page 29

500 Series Drive System

Figure 3.6

56 tooth gear

Spacer

Woodruff

key

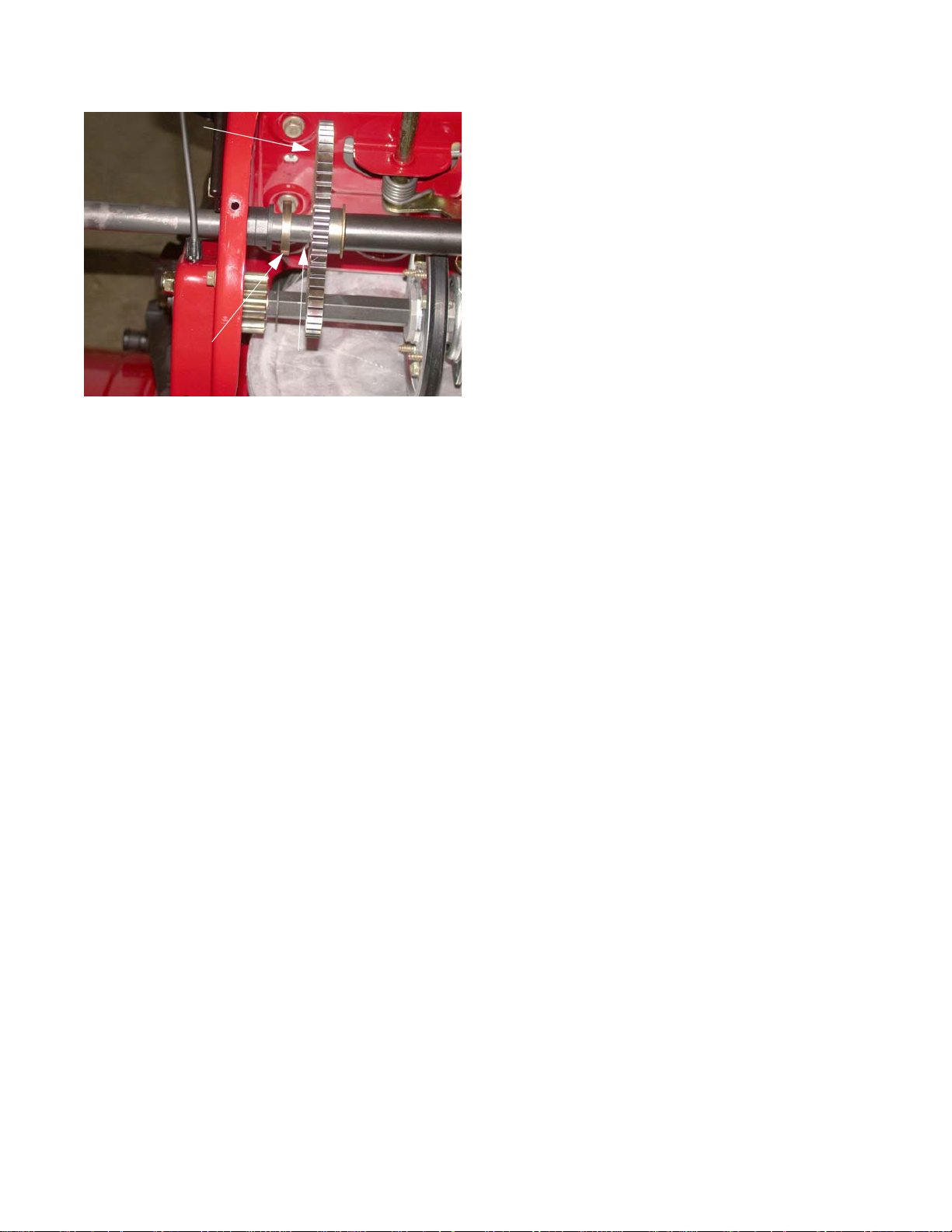

8. Slide one of the large 56T gears inward, while gently

pulling the axle outward enough to expose the key

that engages the gear. See Figure 3.6.

9. Remove the key.

10. Hold the axle support tube and pull the shaf t from the

housing.

11. Repeat steps 8 through 10 for the opposite axle.

NOTE: Examine the removed parts: If failed because of

something other than normal wear, identify and

correct the cause before returning the snow

thrower to service

12. Install the axle assemblies by following the previous

steps in reverse order.

13. Test run the snow thrower in a safe area before

returning it to service.

25

Page 30

Medium Frame 2 & 3 Stage Snow Throwers

Figure 3.7

Figure 3.8

Figure 3.9

Planetary Gear Sets

Drive Gears

Hex Drive Shaft

To remove/replace a Hex Drive Shaft:

1. Stop the engine and allow it to cool, disconnect the

spark plug wire and ground it to the engine.

2. Drain the fuel into an approved container.

3. Carefully tip the snow thrower forward, so it rests on

the auger housing opening.

4. Remove the access panel using 3/8” wrench.

5. Remove both wheels using a 1/2” wrench.

6. Remove the axle assembly by following the procedure described in the previous section of this cha pter.

7. Remove the four screws that hold the right side

Shaft Retainer Housing. See Figure 3.7.

NOTE: In order to remove the housing, it may be

necessary to squeeze the steering trigger to

release the dog assembly from the planetary

ring gear.

8. Rotate the entire Friction Wheel Assembly backwards to it from the Shifter Assembly.

9. Maneuver the entire drive assembly to the left,

enough for the right side to clear the frame, then

remove. See Figure 3.8.

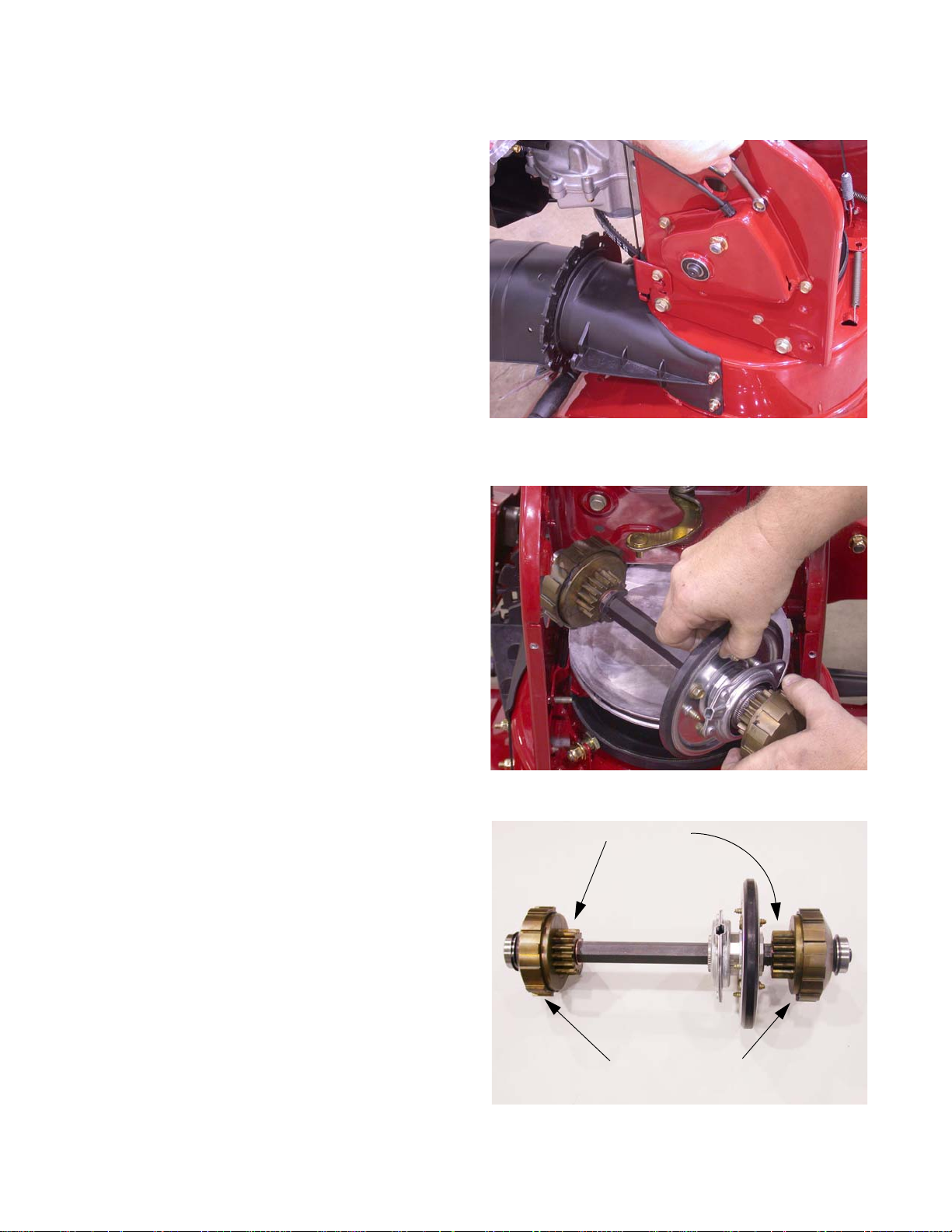

10. The complete drive assembly has two housings on

each side, commonly referred to as the planetary

gear sets. See Figure 3.9.

NOTE: Each drive gear drives one half of the split

11. Install the hex drive shaft by following the previous

steps in reverse order.

axle.

12. Test drive the snow thrower in a safe area before

returning it to service.

26

Page 31

Planetary Gears

Figure 3.10

Figure 3.11

Snap Ring

Shims

Figure 3.12

500 Series Drive System

1. To inspect or repair the planetary gears. it is not necessary to completely remove the drive assembly from

the snow thrower.

2. Stop the engine and allow it to cool, disconnect the

spark plug wire and ground it to the engine.

3. Drain the fuel into an approved container.

4. Carefully tip the snow thrower forward so it rests on

the auger housing opening.

5. Remove the wheel using a 1/2” wrench.

6. Remove the Planetary Gear Housing from the snow

thrower using a 3/8” wrench. See Figure 3.10.

7. Remove the bearing and spacer (if equipped).

8. Remove the snap ring and shims off of the shaf t. See

Figure 3.11.

NOTE: Starting with the 2013 production year, the snap

ring was changed to an E-ring.

9. Carefully remove the ring gear from the planetary

gear set. See Figure 3.12.

NOTE: The planetary gears and sun gear will slide off eas-

ily.

NOTE: Any time the carrier is taken of f o f the dr ive assem-

bly check the grease and add some Arctic Grease

(737-0318-CRTG).

27

Page 32

Medium Frame 2 & 3 Stage Snow Throwers

Figure 3.13

Ring Gear

Sun Gear

Planetary gears

Planetary gear carrier

Figure 3.14

Washer/spacer

Shims

10. Inside of each planetary gear set is a series of planetary gears that rotate aro und a sun gear and rotate

inside of the ring gear. See Figure 3.13.

NOTE: The groves are grease grooves.

11. Although the planetary gears rarely have any service issues, a good working knowledge is important.

• The hex shaft transfers torque from the rubber

drive disc to the sun gear on each end of the

hex drive shaft.

• The sun gear drives the planetary gears.

• When unlatched (trigger squeezed) the ring

gear is allowed to spin freely.

• When the ring gear spins freely it will not drive

the planetary gear carrier.

• When the trigger is released and the ring gear

is latched (prevented from rotating). The plan et

gears drive the carrier in the opposite direction

of the sun gear, but at greater speed.

12. Install the gears by following the previous steps in

13. Apply a generous coating of Arctic Grease (737-

14. Repeat on opposite side.

15. Test drive the snow thrower in a safe area before returning it to service.

• The drive gear attached to the carrier transfers

power each side of the split axle.

NOTE: Examine all the gears: If one or more of the

gears failed because of something other

than normal wear, identify and correct the

cause before returning the snow thrower to

service.

NOTE: Starting with the 2013 production year, the

needle bearings in the ring gear, were

replaced with ball bearings. Seals were also

added.

reverse order

0318-CRTG) to the inside of the ring and planetary

gears.

NOTE: When installing the bearing, remember that

the wide side faces outward. See Figure 3.14.

28

Page 33

Friction Wheel Replacement

Figure 3.15

Figure 3.16

Figure 3.17

1

2

3

4

500 Series Drive System

To remove/replace the Friction Wheel:

1. Remove the Hex Drive Shaft by following the procedures described in the Hex Drive Shaf t section of this

chapter.

2. Remove the bearing from one side of the Hex Drive

Shaft.

3. Remove the snap ring that holds the planetary gear

set to the Hex Drive Shaft.

4. Slide the planetary gear set off of the Hex Drive

Shaft.

5. Slide the Friction Wheel Assembly off of the hex

shaft.

6. Remove the four screws that hold the Friction Wheel

Assembly together using a 1/2” wrench.

NOTE: Earlier production units require 3/8” wr en ch for the

four screws.

7. Separate the friction wheel assembly.

8. Examine the removed parts.

NOTE: If it failed because of something other than normal

wear, identify and correct the cause before returning to service. See Figure 3.16.

9. Inspect the parts for damage or wear.

10. Install the rubber Friction Wheel following the previous steps in reverse order.

NOTE: Tighten the screws to in a star pattern. See Figure

3.17.

NOTE: The torque for the 1/4”-20 screws is 72 - 108 in lbs

(8 - 12 Nm).

NOTE: The torque for the 5/16”-18 screws is 115 - 145 in

lbs (13 - 16 Nm)

NOTE: Make sure the rubber ring is secure within the

wheel assembly before installing it in the unit.

NOTE: Place a small amount of 3-in-,1 or similar oil, on a

rag. Wipe a light coating of oil on the hex shaft.

11. Test run the snow thrower before returning it to service.

29

Page 34

Medium Frame 2 & 3 Stage Snow Throwers

30

Page 35

Axle Assemblies

Figure 4.1

Figure 4.2

600 Series Drive System

Chapter 4: 600 Series Drive System

1. With the engine stopped and allowed to cool, disconnect the spark plug wire and ground it to the engine.

2. Drain the fuel into an approved container.

3. Carefully tip the snow thrower forward, so it rests on

the auger housing opening.

4. Remove the bottom access panel. See Figure 4.1.

5. Remove the wheels using a 1/2” wrench.

NOTE: The ends of the axle shaft are double D.

31

Page 36

Medium Frame 2 & 3 Stage Snow Throwers

Figure 4.3

Spacer

Washers

Bushing

Hex

Figure 4.4

Woodruff Key

E-ring groove

Figure 4.5

6. Slide the spacers and washers off of the axle. See

Figure 4.3.

NOTE: There are usually 2 washers on the left side

and only 1 on the right side.

7. Remove the E-rings from the axle shaft.

NOTE: Starting in 2013, the E-rings were removed

and replaced with a 7” long split spacer.

8. Slide the axle to the left until the woodruff key in the

axle is fully exposed. See Figure 4.4.

9. Remove the woodruff key.

10. While holding the large drive gear, remove the axle

shaft from the left side.

NOTE: The washers will drop as the axle is

removed.

11. Lift the large drive gear and washers out of the

machine. See Figure 4.5.

12. Remove the hex flange bushings.

NOTE: Anytime it is necessary to remove bushings,

13. Install the axle by following the previous step in

reverse order.

14. Test run the snow thrower before returning it to service.

32

carefully inspect them for normal wear and

replace them if the wear is excessive.

Page 37

Hex Drive Shaft Assembly

Figure 4.6

Figure 4.7

13/16” Wrench

9/16”

Wrench

Figure 4.8

Drive shaft

600 Series Drive System

To remove/replace the Hex Drive Shaft Assembly:

1. Remove the Axle Assembly as described in Axle

Assemblies section of this chapter.

2. Remove the E-ring from the left side of the drive shaft

assembly. See Figure 4.6.

3. Remove the bolt or nut, depending on production

date, from the end of the hex shaft using a 9/16”

wrench while holding the shaft with a 13/16” wrench.

See Figure 4.7.

NOTE: Some units may have a 3/4” hex shaft.

NOTE: On single speed units, the drive shaf t is round. See

Figure 4.8.

33

Page 38

Medium Frame 2 & 3 Stage Snow Throwers

Figure 4.9

Collar

4. Rotate the friction wheel assembly until the collar is

free from the pin on the shift assembly.

5. Maneuver the shaft part ially through the wheel drive

frame, then tilt the assembly forward to free it from

the housing. See Figure 4.9.

6. Examine the removed parts: if any failed because o f

something other that normal wear, identify and correct the cause before returning the snow thrower to

service.

7. Install the drive shaft assembly by following the previous step in reverse order.

NOTE: Place a small amount of 3-in-1, or similar oil,

on a rag. Wipe a light coating of oil on the

hex shaft.

8. Test run the snow thrower before returnin g it to service.

34

Page 39

Friction Wheel Replacement

Figure 4.10

Roll pin

Figure 4.11

600 Series Drive System

1. Remove the drive shaft by following the procedures

described in the Hex Drive Shaft Assembly section of

this chapter.

2. Remove the bearing from one end of the shaft.

3. Slide the Friction Wheel Assembly off of the shaft.

NOTE: On the single speed models, drive out the roll pin

holding the friction wheel to the hex shaft.

4. Remove the four screws that hold the Friction Wheel

Assembly together using a 1/2” wrench.

NOTE: Earlier production units require 3/8” wr en ch for the

four screws.

5. Separate the Friction Wheel Assembly. See Figure

4.11.

35

Page 40

Medium Frame 2 & 3 Stage Snow Throwers

Figure 4.12

1

2

3

4

6. Inspect the parts for damage or wear.

7. Install the rubber Friction Wheel by following the

previous steps in reverse order.

NOTE: Tighten the screws in a star pattern. See

Figure 4.12.

NOTE: The torque for the 1/4”-20 screws is 72 - 108

in lbs (8 - 12 Nm).

NOTE: The torque for the 5/16”-18 screws is 115 -

145 in lbs (13 - 16 Nm)

NOTE: Make sure the rubber ring is secure within

the wheel assembly before installing it in the

unit.

NOTE: Place a small amount of 3-in-1 or similar oil

on a rag. Wipe a light coating of oil on the

hex shaft.

8. Test run the snow thrower before returnin g it to service.

36

Page 41

Track Adjustment

Figure 5.1

J-bolt

Front of snow thrower

Bottom of track

Note the direction

of the Track Tread

Pattern.

700 Series 2-Wheel Track-Drive System

Chapter 5: 700 Series 2-Wheel Track-Drive System

To adjust track:

1. Disconnect the spark plug wire from the spark plug

and ground against engine.

2. Drain fuel from fuel tank.

NOTE: The tension on the tracks of the snow thrower can

be adjusted. There are track adjusters on each

side of the unit. It is important that each track is

adjusted equally.

3. Tip the snow thrower forwa rd so that it rests on the

auger housing opening.

4. Loosen the front wheel nuts, using a 3/4” wrench

5. Adjust the track tension by loosening or tightening

the hex nut on J-bolts at the front of track side plates.

See Figure 5.1.

NOTE: When properly adjusted, there should be approxi-

mately 1/2” of deflection in the track with 15 lbs of

pressure applied to the track between the idler

wheel and the drive wheel assemblies.

6. Tighten the nut on the front wheels

7. Test run the unit in a safe area before returning to

service.

37

Page 42

Medium Frame 2 & 3 Stage Snow Throwers

Figure 5.2

Drive wheel

Figure 5.3

Figure 5.4

Track and Track Wheels

To remove/replace the Track and Track Wheels:

NOTE: The Track and Track Wheels are removed

and installed as one assembly.

1. Disconnect spark plug wire from spark plug and

ground it against the engine.

2. Drain the fuel tank.

3. Tip the snow thrower forward, so that it rests on its

auger housing opening.

4. Remove the nut and washer from the drive wheel

using a 3/4” wrench. See Figure 5.2.

5. Remove the nut and washer from the idler wheel

using a 3/4” wrench. See Figure 5.3.

6. Loosen the Tensioning J-bolt nuts.

7. Slide the Track and the Track Wheels off of the unit.

8. Slip the wheels out of the Track.

9. Install the Track and Track Wheels by following the

previous steps in reverse order.

NOTE: The Tracks are directional. There is an

arrow molded on the inside of the Track. The

arrow points in the direction of rotation for

forward travel. See Figure 5.4.

NOTE: The arrow was highlighted with a white paint

pen to make it visible in the photograph.

10. Adjust the track tension by following the procedures

described in the Track Adjustment section of this

chapter.

11. Test run the unit in a safe area before returning it to

service.

38

Page 43

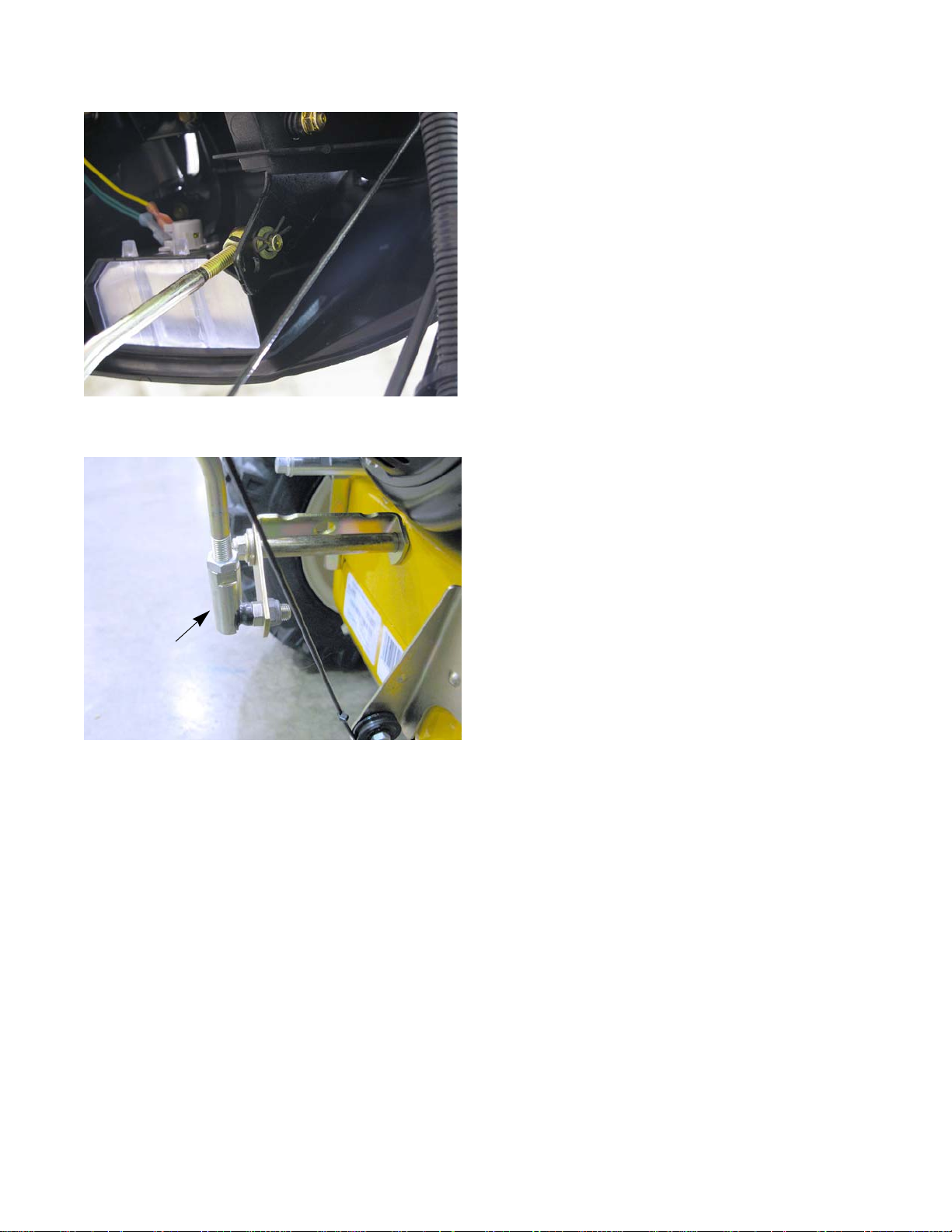

Hex Drive Shaft

Figure 5.5

Figure 5.6

Figure 5.7

Patch bolt

700 Series 2-Wheel Track-Drive System

To remove/replace the Hex Drive Shaft:

1. Stop the engine and allow it to cool, disconnect the

spark plug wire and ground it to the engine.

2. Drain the fuel tank into an approved container.

3. Carefully tip the snow thrower forward so it rests on

the auger housing opening.

4. Remove the access panel using 3/8” wrench. See

Figure 5.5.

5. Hold the Hex Drive Shaft with a 3/4” wrench. See Figure 5.6.

NOTE: Some units may have a 7/8” hex shaft.

6. Remove the Patch Bolt and washer that secures the

right Hex Drive Shaft Bearing. See Figure 5.7.

7. Remove the bearing.

39

Page 44

Medium Frame 2 & 3 Stage Snow Throwers

Figure 5.8

Patch bolt

Figure 5.9

Figure 5.10

Shifter Arm

Pin

8. Remove the Patch Bolt and washer that secures the

left Hex Drive Shaft Bearing. See Figure 5.8.

9. Remove the bearing and spacer.

10. Slide the Hex Drive Shaft out of the unit from the

right side. See Figure 5.9.

NOTE: The Friction Wheel Assembly is now free.

Inspect and replace the Friction Wheel if

there are any signs of wear or damage.

To install the Hex Drive Shaft:

11. Verify that the Friction Wheel Assembly is engaged

with the pin on the Shifter Arm. See Figure 5.10.

40

Page 45

700 Series 2-Wheel Track-Drive System

Figure 5.11

Figure 5.12

Sprocket

Figure 5.13

Spacer

12. Slide the Hex Drive Shaft into the frame from the righ t

side, passing it through the Friction Wheel Assembly.

NOTE: The side without the E-ring goes in first.

13. Align the Hex Drive Shaft with the sprocket.

14. Pass the Hex Drive Shaft through the sprocket until

the E-ring on the shaft rests against the Fr iction

Wheel. See Figure 5.12.

15. Install the spacer on the left side of the Hex Drive

Shaft. See Figure 5.13.

16. Install the left bearing.

17. Hold the Hex Drive Shaft with a 3/4” wrench.

18. Install the washer and patch bolt.

41

Page 46

Medium Frame 2 & 3 Stage Snow Throwers

Figure 5.14

Right bearing

19. Install the bearing on the right side. See Figure

5.14.

20. Install the Patch Bolt and washer.

21. Place a small amount of 3-in-1, or similar oil, on a

rag. Wipe a light coating of oil on the Hex Drive

Shaft.

22. Install the access panel.

23. Test run the unit in a safe area before returning it to

service.

42

Page 47

Friction Wheel Replacement

Figure 5.15

Shift Arm

Figure 5.16

Figure 5.17

1

2

3

4

700 Series 2-Wheel Track-Drive System

To remove/replace the Friction Wheel:

1. Remove the Hex Drive Shaft by following the procedures described in the Hex Drive Shaf t section of this

chapter.

2. Slide the Friction Wheel Assembly off of the pin on

the Shift Arm. See Figure 5.15.

3. Remove the four screws that hold the Friction Wheel

Assembly together, using a 1/2” wrench.

NOTE: Earlier production units require a 3/8” wrench for

the four screws.

4. Separate the Friction Wheel Assembly.

5. Examine the removed parts.

NOTE: If it failed because of something other than normal

wear, identify and correct the cause before returning to service. See Figure 5.16.

6. Inspect the parts for damage or wear.

7. Install the rubber Friction Wheel following the previous steps in reverse order.

NOTE: Tighten the screws in a star pattern. See Figure

5.17.

NOTE: The torque for the 1/4”-20 screws is 72 - 108 in lbs

(8 - 12 Nm).

NOTE: The torque for the 5/16”-18 screws is 115 - 145 in

lbs (13 - 16 Nm)

NOTE: Make sure the rubber ring is secure within the

wheel assembly before installing it in the unit.

NOTE: Place a small amount of 3-in-1, or similar oil, on a

rag. Wipe a light coating of oil on the Hex Drive

Shaft.

8. Test run the snow thrower before returning it to service.

43

Page 48

Medium Frame 2 & 3 Stage Snow Throwers

Figure 5.18

Figure 5.19

Figure 5.20

Axle Shaft

To remove/replace an Axle Shaft:

1. Remove the Track and T rack Wheels of the affected

axle by following the procedures described in the

Track and Track Wheels section of this chapter.

2. Remove the bottom access panel.

3. Remove the eight screws that hold the rear aluminum housing in place, using a 1/2” wrench. See Figure 5.18.

4. Lift the housing out of the snow thrower.

5. Remove the two screws that hold the axle tube in

place, using a 1/2” wrench.

6. Move the axle so that the sprocket teeth on the axle

are beside the teeth on the Planet ary Gear Set. See

Figure 5.20.

7. Work the chain off of the sprockets.

8. Slide the axle out of the axle tube.

9. Remove the two nuts, bolts and fender washers,

that secure the axle tube to the side plate using a 1/

2” wrench and a 5/8” wrench.

10. Inspect the axle and the axle tube for signs of damage or wear. If any are found, replace the affected

component.

44

Page 49

700 Series 2-Wheel Track-Drive System

Figure 5.21

Figure 5.22

Figure 5.23

Fender washers

11. Drive out the old bushings using a drift punch. See

Figure 5.21.

12. Install new bushings in the axle tube.

13. Set the axle tube in place.

14. Slip the chain over the axle tube.

15. Slide the axle into the axle tube.

16. With the teeth of the sprocket gears next to each

other, slip the chain onto both sprockets.

17. Install the two screws that hold the axle tube in place.

18. Install the two nuts, bolts and fender washers that

secure the axle tube to the side plate using a 1/2”

wrench and a 5/8” wrench. See Figure 5.23.

19. Install the rear housing.

20. Install the access panel.

21. Install the Track and Track Wheels by following the

procedure described in the Tra ck and Track Wheel

section of this chapter.

22. Test drive the unit in a safe area befor e returning it to

service.

45

Page 50

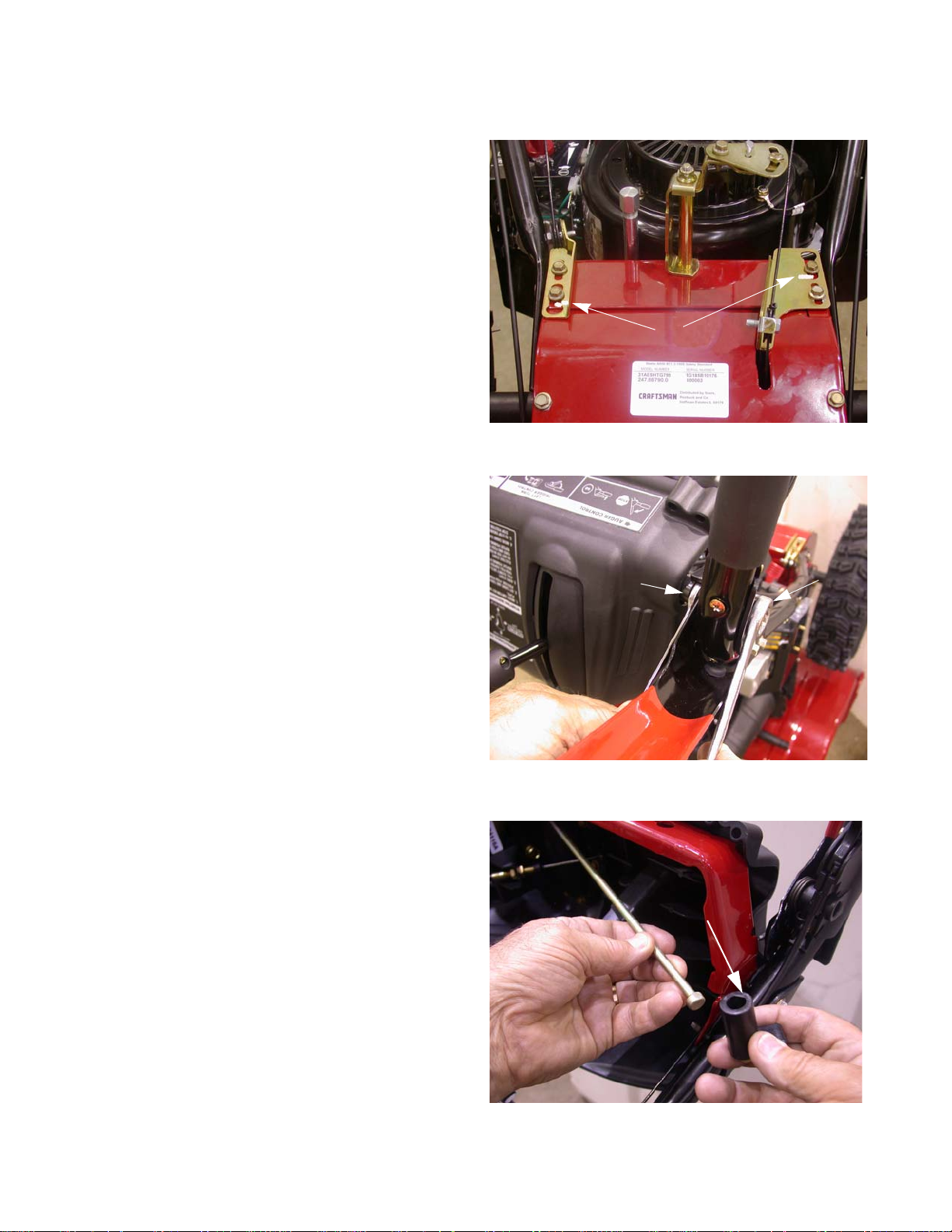

Medium Frame 2 & 3 Stage Snow Throwers

Figure 5.24

Triggers

Figure 5.25

Figure 5.26

Planetary Gears and Shaft

To remove/replace the planetary gears and shaft:

1. Slip the chains off of both axles by following the procedures described in the Axle Shaft section of this

chapter.

2. Clamp down both steering triggers. See Figure

5.24.

3. Drive out the roll pin using a 5/32” pin punch. See

Figure 5.25.

4. Remove the nut and washer on each end of the

Planetary Shaft. See Figure 5.26.

5. Remove the Hex Flange Bushing from each end of

the shaft.

46

Page 51

700 Series 2-Wheel Track-Drive System

Figure 5.27

Figure 5.28

Figure 5.29

Shim Washers

6. Slide the Planetary Shaft to the right enough for it to

clear the transmission housing. See Figure 5.27.

7. Slip the drive chain off of the sprocket on the end of

the shaft.

8. Remove the Planetary Shaft Assembly from the

transmission box.

9. Set the shaft on the work bench. See Figure 5.28.

10. Slide the sprocket off of the shaf t.

11. Remove both chains.

12. Remove the shim washers.

13. Slide the left Planetary Gear carrier off of the shaft.

See Figure 5.29.

47

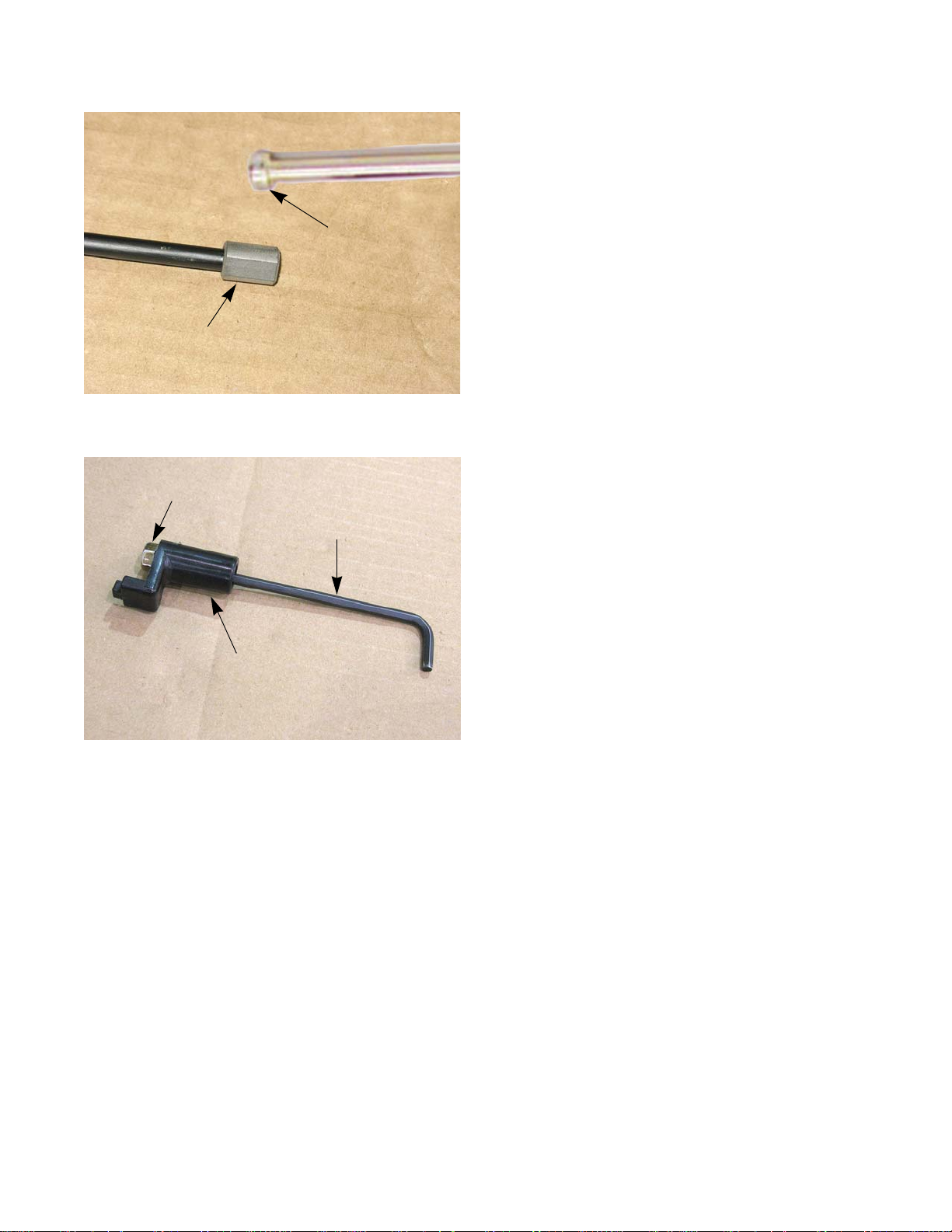

Page 52

Medium Frame 2 & 3 Stage Snow Throwers

Figure 5.30

Sun Gear

Ring Gear

Planetary Gears

Figure 5.31

Snap Ring

Figure 5.32

14. Remove the Sun Gear. See Figure 5.30.

15. Remove the Ring Gear and washer.

16. Remove the snap ring from the right Planetar y Gear

Set. See Figure 5.31.

17. Remove the shim washers.

18. Slide the right Planetary Gear Carrier off of the

shaft.

19. Remove the Sun Gear.

20. Remove the Ring Gear and washer.

21. Clean and inspect all of the components.

NOTE: If any of the Planet ary Gear Set components

show signs of wear or damage, the whole

gear set must be replaced.

22. Grease the needle bearings and the inside of the

ring gear with Arctic Grease (737-0318-CRTG).

See Figure 5.32.

NOTE: Use a liberal amount of grease. Any excess

will work its way out of the gear set.

48

Page 53

700 Series 2-Wheel Track-Drive System

Figure 5.33

Figure 5.34

Splines

Figure 5.35

Drive sprocket

23. Grease the needle bearing and the planetary gear

posts on the carrier with Arctic Grease (73 7-0318CRTG). See Figure 5.33.

24. Install the planetary gears on the carrier.

NOTE: The grooves on the planeta ry gears are for grease.

They are not timing marks.

25. Slide the washer , from behind the ring gears, onto the

shaft.

26. Grease the splines and the part of the shaft where

the needle bearings ride with Arctic Grease (7370318-CRTG). See Figure 5.34.

27. Install a Ring Gear on the right side of the shaft.

NOTE: The right side of the shaft is the side with the snap

ring groove.

NOTE: The ring gears and planetary carrier are the same

part number for each side.

28. Install a carrier with the Planetary Gears.

29. Install shim washers.

30. Install the snap ring.

31. Slide a ring gear on to the left side of the shaft.

32. Install a carrier with the planetary gears.

33. Install shim washers.

34. Slide the drive sprocket on to the left side of the shaf t.

35. Install the roll pin into drive sprocket. See Figure

5.35.

49

Page 54

Medium Frame 2 & 3 Stage Snow Throwers

Figure 5.36

36. Measure the free travel of each Planetary Gear Set

using a feeler gauge.

NOTE: There should be 0.010” - 0.030” travel.

NOTE: If there is too much travel, add a 0.020”

shim, part number 936-0502. If there is not

enough travel remove a shim.

37. Remove the roll pin, but leave the sprocket on the

shaft.

NOTE: Installing the drive chain, with the roll pin in

place, is very difficult.

38. Install the Planetary Shaft Assembly by following

step 1 - 8 in reverse order.

39. Test run the unit in a safe area before returning it to

service.

50

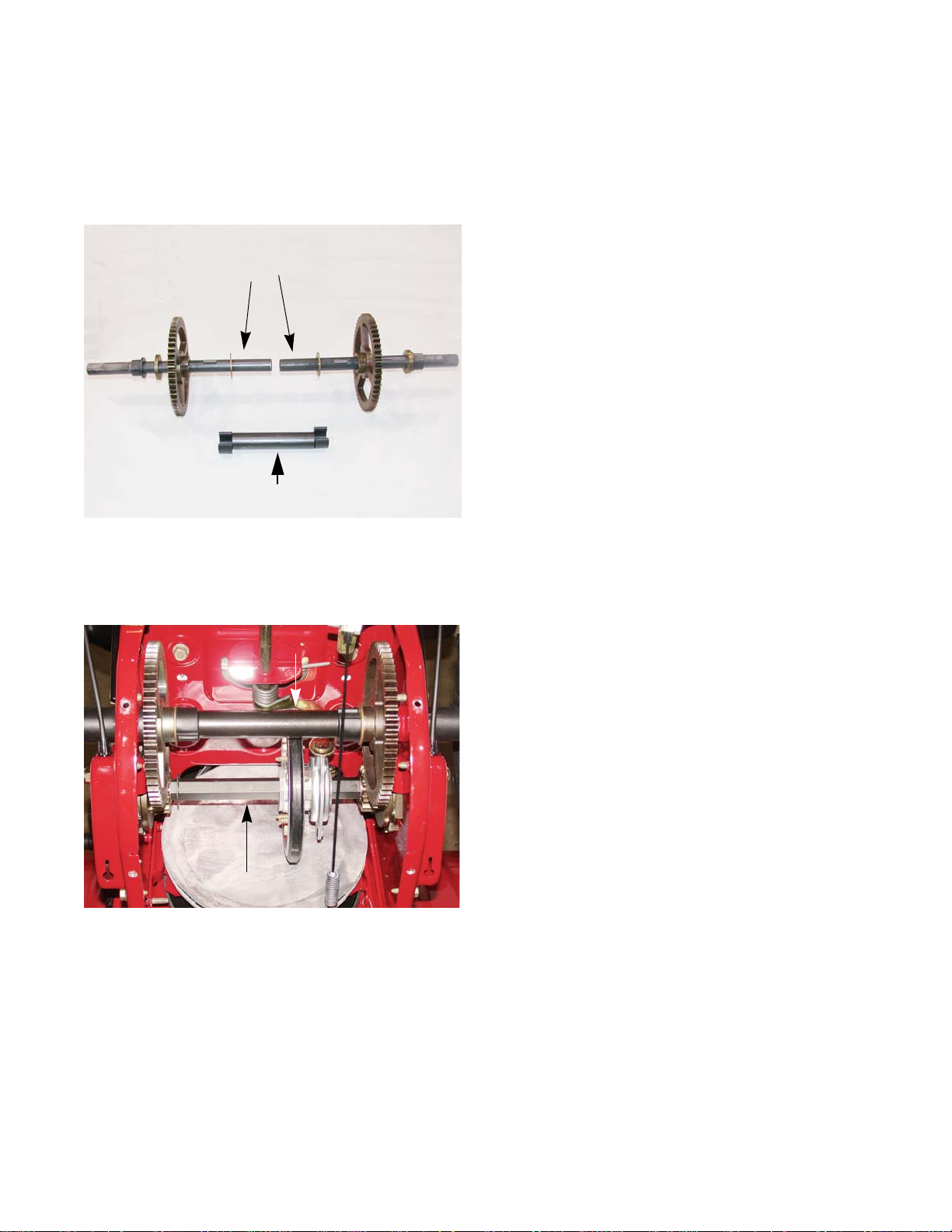

Page 55

Steering Trigger Cables

Figure 5.37

E-ring

Figure 5.38

Figure 5.39

Pull here

Do not pull here

700 Series 2-Wheel Track-Drive System

To remove/replace a steering trigger cable:

1. Disconnect the spark plug wire from spark pl ug and

ground it against the engine.

2. Drain the fuel tank into an approved container.

3. Tip the snow thrower forward so that it rests on its

auger housing opening.

4. Remove the E-ring that secures the steering trigger’s

Pivot Pin. See Figure 5.37.

5. Remove the Pivot Pin.

6. Unhook the trigger from the cable. See Figure 5.38.

7. Gently pry/pull the cable end out of the Trigger

Bracket.

NOTE: Do not pull on the cable jacket. It will separate from

the cable end, damaging the cable.

51

Page 56

Medium Frame 2 & 3 Stage Snow Throwers

Figure 3.40

Figure 5.41

Tabs

Planetary

pawl

Figure 5.42

Ford fuel line tool

8. Remove the bottom access panel.

9. Remove the eight screws that hold the rear aluminum housing in place, using a 1/2” wrench. See Figure 3.40.

10. Lift the housing out of the snow thrower.

11. Squeeze the tabs on the end of the cable. See Figure 5.41.

NOTE: A Ford fuel line tool is useful for squeezing

the tabs on the end of the cable. See Figure

5.42.

12. Pull the cable out of the rear plate.

13. Unhook the cable from the planetary pawls.

14. Install the cable by following the previous steps in

reverse order.

15. Test run the unit in a safe area before returning it to

service.

52

Page 57

Figure 6.1

Figure 6.2

Idler holding tool

Chapter 6: 700 Series 3-Wheel Track-Drive System

Track Removal/replacement

700 Series 3-Wheel Track-Drive System

To remove/replace the Tracks:

NOTE: There is a spring loaded idler on both tracks, that

will take up the slack in the Tracks as they stretch.

Both of the spring loaded idlers need to be held

down when doing any work or adjustments to the

Tracks. Instructions on how to build a set of tools

to hold the idlers down are located at the end of

this chapter. See Figure 6.1.

1. Drain the fuel tank into an approved container.

2. Drain the oil out of the engine.

3. Carefully tip the snow thrower forward until it rests on

the auger housing opening.

4. Install the tools to hold the idler wheel down.

NOTE: To use the tools:

• Insert the forked end of the tool over the idler arm,

between the spring and the idler wheel.

• Rotate the idler away from the Track enough for

the flange on the opposite end of the tool to hook

over the front wheel. See Figure 6.2.

• Push the tool in to fully seat it.

• Repeat on other side of the machine.

NOTE: Both Tracks must be serviced at the same time.

Failure to do so can result in non-parallel Tracks.

53

Page 58

Medium Frame 2 & 3 Stage Snow Throwers

Figure 6.3

Figure 6.4

Tensioning J-bolts

Figure 6.5

Retaining nut

5. Remove the four screws that hold the bottom

access panel in place using a 3/8” wrench.

6. Slide the panel out from under the top of the frame.

7. Rotate the panel until it is perpend icular to the frame

and slide it out of the slot in the frame. See Figure

6.3.

8. Remove the nuts from the tensioning J-bolt s using a

1/2” wrench. See Figure 6.4.

NOTE: The J-bolts will fall out when the Rear Wheel

retaining nuts are removed.

9. Remove the retaining nut from both Rear Wheels

using a 3/4” wrench. See Figure 6.5.

54

Page 59

700 Series 3-Wheel Track-Drive System

Figure 6.6

Rear Wheel

Figure 6.7

Rear Axle

Flange

Figure 6.8

Front

Bottom view

10. Slide the Rear Wheel off of the Rea r Axle. See Figure

6.6.

11. Remove the Rear Wheel.

12. Lift the Track off of the machine.

13. Repeat on the opposite side.

To install the tracks:

1. If the Rear Axle fell out, set the it on the machine so

that the flanges are inside the slots in the Track

Frame. See Figure 6.7.

2. With the idler hold-down tools still in place, set the

Track on the drive wheel and Front Wheel.

NOTE: Make sure the treads on the Tracks are facing the

right direction. See Figure 6.8.

55

Page 60

Medium Frame 2 & 3 Stage Snow Throwers

Figure 6.9

Groove

Figure 6.10

Quick Grip bar clamps

Figure 6.11

0.9”

3. Place the Rear Wheel into its groove in the Track.

4. Slide the Rear Wheel onto the Rear Axle with the

Track. See Figure 6.9.

5. Install the retaining nut a couple of threads deep.

IMPORTANT: Do not tighten the nut.

6. Repeat steps 2 through 5 on the opposite Track.

7. Lift the rear axle evenly to install the J-bolts.

NOTE: A pair of Quick Grip bar clamps in spreading

8. Install both J-bolt nuts a couple of thread deep.

IMPORTANT: Do not tighten the nuts at this time.

9. Remove the bar clamps.

10. Tighten both J-bolt nuts simultaneously, until the

ends of the J-bolts extend 0.9” from the frame. See

Figure 6.11.

mode work well for this. See Figure 6.10.

56

Page 61

700 Series 3-Wheel Track-Drive System

Figure 6.12

3/8” deflection

Pressure reading

11. Measure the Track tension:

NOTE: Track tension must be checked with the Tracks off

of the ground.

11a. Lay a straight edge across the section of Track

between the Drive Wheel and the Rear Wheel.

11b. With the idler hold-down tools installed, mea-

sure the amount of force required to cause 3/8”

deflection. See Figure 6.12.

• The reading should be 14 - 20 lbs.

• If the reading is too low , tighten both T racks evenly.

• If the reading is too high, loosen both Tracks

evenly.

NOTE: A spring loaded belt tensiometer is useful to mea-

sure the Track tension. The one shown in Figure

6.12. was purchased at: http://www.hmc-international.com/awi-i.htm

12. Tighten both Rear Wheels.

13. Install the bottom access panel.

14. Lower the unit onto the Tracks.

15. Fill the engine with oil.

16. Fill the fuel tank.

17. Test run the unit in a safe area before returning it to

service.

57

Page 62

Medium Frame 2 & 3 Stage Snow Throwers

Figure 6.13

Drive Wheel

Figure 6.14

Bearing Cup

Figure 6.15

Washer

Track Drive Assembly

To remove/replace the Track Drive Assembly:

1. Remove the Tracks by following the procedures

described in the Track remova l/replacement section

of this chapter.

2. Remove the screw that secures the Drive Wheel to

the drive axle using a 1/2” wrench.Figure 6.13.

NOTE: Engaging the Drive Control Lever will help

hold the axle while removing the screw that

secures the Drive Wheel.

3. Slide the Drive Wheel off of the axle.

4. Remove the idler holding tool.

5. Remove the three screws that secure the Drive Axle

Bearing Cup using a 3/8” wrench.Figure 6.14.

NOTE: The Track Drive Frame may drop down

when the screws are removed.

6. Remove the Bearing Cup and bearing.

7. Remove the washer that rides in the slot in the

Track Frame.

8. Lower the Track Frame until the back side of the

Front Axle clears the fork of the Height Adjusting

Arm.

9. Slip the frame off of the Rear and Drive Axles.

10. Install the Track Drive Assembly by following the

previous steps in reverse order.

11. Test run the unit in a safe area before returning it to

service.

58

Page 63

Drive Axle Assemblies

Figure 6.16

Split bushings

Figure 6.17

Key

Support Tube

Figure 6.18

Hex flange bushing

700 Series 3-Wheel Track-Drive System

To remove the Drive Axles:

1. Remove the Tracks by following the procedures

described in the Track removal/replacement section

of this chapter.

2. Remove the Track Drive As semblies by following the

procedures described in the Track Drive Assemblies

section of this chapter.

3. Remove the Split Bushings from the Drive Axle

4. Slide one of the large gears inward while gently pulling the axle outward enough to expose the key that

engages the gear. See Figure 6.17.

5. Remove the key.

6. Hold the large gear and pull the shaft from the housing.

NOTE: Keep track of the order of the washers for reas-

sembly.

7. Remove the large gear and washers.

8. Remove the Support Tube.

9. Repeat steps 4 through 7 for the opposite axle.

10. Remove the hex flange bushings. See Figure 6.18.

NOTE: Examine the removed parts. If failure was do to

something other than normal wear, identify and

correct the cause before returning the snow

thrower to service

11. Install the axle assemblies by following the previous

steps in reverse order.

12. Test run the snow thrower in a safe area before

returning it to service.

59

Page 64

Medium Frame 2 & 3 Stage Snow Throwers

Figure 6.19

Triggers

Figure 6.20

Shaft Retainer Housing

Figure 6.21

Pin

Hex Drive Shaft and Planetary Gears

To remove the Hex Drive Shaft:

1. Remove the Drive Axles by following the procedures described in the previous section of this chapter.

2. Clamp down both Steering Triggers. See Figure

6.19.

3. Remove the four screws that hold the left side

Retainer Housing. See Figure 6.20.

4. Rotate the entire Friction Wheel Assembly backwards to free the pin from the Shifter Arm.

5. Maneuver the entire drive assembly to the left

enough for the right side to clear the frame, then

remove. See Figure 6.21.

60

Page 65

700 Series 3-Wheel Track-Drive System

Figure 6.22

Bearing

Thick Washer

Thin Washer

Figure 6.23

E-ring

Figure 6.24

Thinest washer

6. Remove the bearing and washers.

NOTE: Keep track of the order of the washers for reas-

sembly. See Figure 6.22.

7. Carefully remove the E-ring that secures the Planetary Set. See Figure 6.23.

8. Slide the Planetary Gears Set off of the Hex Drive

Shaft.

9. Remove the washer that was behind the Gear Set.

NOTE: The washer behind the Gear Set is the thinnest of

the three washers. See Figure 6.24.

10. Slide the Friction Wheel Assembly off of the Hex

Drive Shaft.

11. Repeat steps 6 through 9 on the opposite side of the

Hex Drive Shaft.

61

Page 66

Medium Frame 2 & 3 Stage Snow Throwers

Figure 6.25

Ring Gear

Planetary Gears

Planetary Gear Carrier

Figure 6.26

Sun gear

Figure 6.27

Ring gear

12. Inside of each Planetary Gear Set is a series of

Planetary Gears that rotate around a Su n Ge ar and

rotate inside of the Ring Gear. See Figure 6.25.

NOTE: The groves are grease grooves.

13. Although the Planetary Gears rarely have any service issues, a good working knowledge is important.

• The Hex Drive Shaft transfers torque from the

Friction Wheel to the Sun Gear on each end of

the Hex Drive Shaft.

• The Sun Gear drives the Planetary Gears.

• When unlatched, trigger squeezed, the Ring

Gear is allowed to spin freely .

• When the Ring Gear spins freely it will not drive

the Planetary Gear Carrier.

• When the trigger is released and the Ring Gear

is latched, preventing it from rotating. The

Planet Gears drive the carrier in the opposite

direction of the Sun Gear, but at greater speed.

• The Drive Gear attached to the carrier transfers

power to the Axle Half.

NOTE: Inspect the component, replace/repair as

needed.

14. Slide the Friction Wheel Assembly onto the Hex

Drive Shaft so that the hole for the pin, on the shifte r

arm, is away from the E-ring on the shaft.

15. Install the thin washer and Planetary Carrier.

16. Install the Sun and Planetary Gears. See Figure

6.26.

17. Apply a generous coating of Arctic Grease (7370318-CRTG) to the inside of the Ring Gear and on

the gears.

18. Install the Ring Gear, E-ring, washers and bearing.

See Figure 6.27.

19. Repeat steps 15 through 18 on the opposite side.

20. Install the Hex Drive Shaft assembly by following

steps 1 through 5 in reverse order.

21. Coat the hex section of the Hex Drive Shaft with a

22. Test drive the snow thrower in a safe area before

62

generous coating an anti-seize compound.

returning it to service.

Page 67

Friction Wheel Replacement

Figure 6.28

Figure 6.29

Figure 6.30

1

2

3

4

700 Series 3-Wheel Track-Drive System

To remove/replace the Friction Wheel:

1. Remove the Hex Drive Shaft by following the procedures described in the Hex Drive Shaf t section of this

chapter.

2. Remove the bearing and washers from one side of

the Hex Drive Shaft.

3. Remove the E-ring that holds the Planetary Gear Set

to the Hex Drive Shaft.

4. Slide the Planetary Gear Set and washer off of the

Hex Drive Shaft. See Figure 6.28.

NOTE: The washer behind the gear set is the thinest of

the three washers. See Figure 6.24.

5. Slide the Friction Wheel Assembly off of the Hex

Drive Shaft.

6. Remove the four screws that hold the Friction Wheel

Assembly together using a 1/2” wrench.

7. Separate the Friction Wheel Assembly.

8. Inspect the parts for damage or wear. Replace parts

as needed

NOTE: If it failed because of something other than normal

wear, identify and correct the cause before returning to service. See Figure 6.29.

9. Install the rubber Friction Wheel following the previous steps in reverse order.

NOTE: Tighten the screws in a star pattern. See Figure

6.30.

NOTE: The torque for the 1/4”-20 screws is 72 - 108 in lbs

(8 - 12 Nm).