Page 1

FORM NUMBER 769-00902

88335544//88440044 SSEERRVVIICCEE M

MAANNUUAALL

MTD Products, LLC Product Training and Education Department

Page 2

Page 3

CONTENTS

CHAPTER 1 GENERAL INFORMATION..........................................................................................1-1

1. TRACTOR VIEW............................................................................................................................................... 1-3

2. TIGHTENING T ORQUE FOR STANDARD BOLTS AND NUTS ................................................................. 1-4

2.1 TIGHTENING TORQUE.......................................................................................................................... 1-4

3. SPECIFICATIONS............................................................................................................................................ 1-6

4. IDENTIFICATION ............................................................................................................................................. 1-8

4.1 ENGINE NUMBER................................................................................................................................... 1-8

4.2 CHASSIS NUMBER OF THE TRACTOR(CHASSIS NUMBER OF THE MACHINE)....................... 1-8

5. CAUTION BEFORE REPAIR .......................................................................................................................... 1-9

5.1 BEFORE REP AIR OR INSPECTION..................................................................................................... 1-9

5.2 ASSEMBLY AND DISASSEMBLY ........................................................................................................... 1-9

5.3 PARTS TO BE REPLACED..................................................................................................................... 1-9

5.4 PARTS ....................................................................................................................................................... 1-9

5.5 ASBESTOS PARTS................................................................................................................................ 1-10

5.6 ELECTRICAL SYSTEM ......................................................................................................................... 1-10

5.7 TUBES AND RUBBERS ........................................................................................................................ 1-11

5.8 LUBRICANT ............................................................................................................................................ 1-11

6. REGULAR CHECK LIST............................................................................................................................... 1-12

7. OIL & WATER SUPPL Y LIST........................................................................................................................ 1-13

CHAPTER 2 ENGINE SYSTEM.........................................................................................................2-1

1. GENERAL......................................................................................................................................................... 2-3

1.1 APPEARANCE.......................................................................................................................................... 2-3

1.2 SPECIFICATIONS .................................................................................................................................... 2-4

1.3 PERFORMANCE CURVE ....................................................................................................................... 2-5

1.4 DIMENSIONS ........................................................................................................................................... 2-6

1.5 GENERAL WARNING.............................................................................................................................. 2-6

2. STRUCTURE AND FUNCTION ..................................................................................................................... 2-7

2.1 BODY ......................................................................................................................................................... 2-7

2.2 LUBRICATING SYSTEM........................................................................................................................ 2-11

2.3 COOLING SYSTEM................................................................................................................................ 2-13

2.4 FUEL SYSTEM ....................................................................................................................................... 2-15

3. DISASSEMBLING AND SERVICING ...........................................................................................................2-24

3.1 TROUBLESHOOTING...........................................................................................................................2-24

3.2 SERVICING SPECIFICATIONS............................................................................................................ 2-27

3.3 CHECKING, DISASSEMBLING AND SERVICING ............................................................................ 2-33

CHAPTER 3 CLUTCH .........................................................................................................................3-1

1. DISASSEMBLY AND ASSEMBLY.................................................................................................................... 3-3

1.1 DISASSEMBLY OF PANEL FRAME........................................................................................................ 3-3

1.2 DISASSEMBLY OF FENDER AND STEPLADDER ASSEMBLY ......................................................... 3-6

Page 4

2. CLUTCH............................................................................................................................................................ 3-8

2.1 CHARACTERISTICS ............................................................................................................................... 3-8

2.2 LINK STRUCTURE AND CONTROL..................................................................................................... 3-9

2.3 TROUBLESHOOTING........................................................................................................................... 3-10

2.4 SPECIFICATION .................................................................................................................................... 3-11

2.5 TIGHTENING TORQUE ........................................................................................................................ 3-11

2.6 DISASSEMBLY, MAINTENANCE .........................................................................................................3-12

CHAPTER 4 TRANSMISSION ...........................................................................................................4-1

1. STRUCTURE ................................................................................................................................................... 4-3

2. POWER TRANSMISSION ............................................................................................................................... 4-4

2.1 MAIN TRANSMISSION............................................................................................................................. 4-4

2.2 SHUTTLE.................................................................................................................................................. 4-7

2.3 HI-LO SHIFT ............................................................................................................................................. 4-8

2.4 MID PTO .................................................................................................................................................... 4-9

2.5 REAR PTO ................................................................................................................................................ 4-9

2.6 CREEPER SPEED (IF APPLICABLE )................................................................................................. 4-10

2.7 FRONT WHEEL DRIVE......................................................................................................................... 4-10

3. TRANSMISSION SHIFT LINK STRUCTURE ... .... ...................................................................................... 4-11

3.1 MAIN SHIFT.......................................................................................................................................... 4-11

3.2 SHUTTLE SHIFT .................................................................................................................................4-11

3.3 HI-LO SHIFT......................................................................................................................................... 4-12

3.4 PTO SHIFT ...........................................................................................................................................4-12

3.5 CREEPER SPEED ..............................................................................................................................4-12

3.6 MID PTO SHIFT ...................................................................................................................................4-13

3.7 FRONT WHEEL DRIVE SHIFT .......................................................................................................... 4-13

4. PTO CLUTCH................................................................................................................................................. 4-14

4.1 CHARACTERISTICS........................................................................................................................... 4-14

4.2 HYDRAULIC CIRCUIT........................................................................................................................4-14

4.3 OIL FLOW ............................................................................................................................................. 4-15

5. DIFFERENTIAL GEAR ..................................................................................................................................4-16

5.1 STRUCTURE ....................................................................................................................................... 4-16

5.2 OPERATION ......................................................................................................................................... 4-17

6. TROUBLESHOOTING ................................................................................................................................... 4-19

7. MAINTENANCE SPECIFICATION................................................................................................................4-20

8. TIGHTENING TORQUE ................................................................................................................................4-21

9. CLUTCH HOUSING ......................................................................................................................................4-22

9.1 TRANSMISSION OIL DRAINING ........................................................................................................ 4-23

9.2 CLUTCH HOUSING GROUP DISASSEMBLY ................................................................................. 4-23

10.CLUTCH HOUSING DISASSEMBLY..................................................................................................

10.1 FIRST ST AGE (DISCONNECTION OF MAIN TRANSMISSION COVER)..................................... 4-28

10.2 SECOND STAGE (DISCONNECTION OF PROPULSION SHAFT CASE)................................... 4-29

............. 4-28

Page 5

10.3 THIRD STAGE (DISASSEMBLY OF 25 GEAR SHAFT AND PROPULSION SHAFT 1)...........................4-30

10.4 FOUR TH STAGE (DISASSEMBLY OF BEARING COVER ASSEMBLY) .......................................... 4-30

10.5 FIFTH STAGE (DISCONNECTION OF TRANSMISSION FORK).....................................................4-31

10.6 SIXTH STAGE (DISASSEMBLY OF 22 GEAR SHAFT)...................................................................... 4-32

10.7 SEVENTH STAGE (DISASSEMBLY OF MAIN TRANSMISSION COUNTER SHAFT) ...................4-33

10.8 MAINTENANCE ......................................................................................................................................4-35

11.INTERMEDIATE CASE .................................................................................................................................. 4-37

11.1 DISASSEMBLY, ASSEMBLY.................................................................................................................. 4-38

11.2 MAINTENANCE ......................................................................................................................................4-43

12.TRANSMISSION CASE ................................................................................................................................. 4-46

12.1 DISASSEMBL Y , ASSEMBL Y.................................................................................................................. 4-46

12.2 MAINTENANCE ......................................................................................................................................4-56

CHAPTER 5 REAR AXLE ...................................................................................................................5-1

1. STRUCTURE ................................................................................................................................................... 5-3

2. TIGHTENING TORQUE .................................................................................................................................. 5-4

3. SERVICE SPECIFICA TION ............................................................................................................................ 5-5

4. DISASSEMBL Y , ASSEMBLY ........................................................................................................................... 5-6

4.1 DISCONNECTION OF REAR AXLE GROUP ....................................................................................... 5-6

4.2 DISASSEMBLY OF REAR AXLE ............................................................................................................. 5-8

5. MAINTENANCE ................................................................................................................................................ 5-9

5.1 BEARING CHECK ................................................................................................................................... 5-9

5.2 GEAR CHECK.......................................................................................................................................... 5-9

5.3 CLEARANCE CHECK OF PLANET AR Y GEAR AND PLANETARY GEAR SHAFT........................... 5-9

5.4 CHECK THRUST COLLAR FOR WORN.............................................................................................. 5-9

CHAPTER 6 BRAKE ...........................................................................................................................6-1

1. STRUCTURE ................................................................................................................................................... 6-3

2. OPERATION...................................................................................................................................................... 6-4

3. TROUBLESHOOTING ..................................................................................................................................... 6-5

4. MAINTENANCE SPECIFICATION.................................................................................................................. 6-6

5. TIGHTENING TORQUE .................................................................................................................................. 6-6

6. BRAKE PEDAL................................................................................................................................................. 6-7

6.1 DISASSEMBLY, MAINTENANCE ........................................................................................................... 6-7

6.2 MAINTENANCE ........................................................................................................................................ 6-8

7. BRAKE CASE ................................................................................................................................................... 6-9

7.1 DISASSEMBLY AND ASSEMBL Y............................................................................................................ 6-9

7.2 OPERATION CHECK OF BRAKE CAM LEVER ................................................................................. 6-12

CHAPTER 7 FRONT AXLE.................................................................................................................7-1

1. STRUCTURE ................................................................................................................................................... 7-3

2. WHEEL ALIGNMENT....................................................................................................................................... 7-4

3. TROUBLESHOOTING ..................................................................................................................................... 7-5

4. MAINTENANCE SPECIFICATION.................................................................................................................. 7-6

Page 6

5. TIGHTENING TORQUE .................................................................................................................................. 7-7

6. DISASSEMBLY, MAINTENANCE ................................................................................................................... 7-8

6.1 STRUCTURE............................................................................................................................................ 7-8

7. DISCONNECTION OF FRONT AXLE GROUP ...........................................................................................7-10

7.1 DISASSEMBLY , ASSEMBL Y.................................................................................................................. 7-10

8. DISASSEMBL Y OF FRONT AXLE ................................................................................................................7-12

8.1 FIRST STAGE (DISCONNECTION OF FRONT AXLE CASE AND BEVEL GEAR CASE) ................................. 7-12

8.2 SECOND STAGE (DISASSEMBLY OF FRONT AXLE) ...................................................................... 7-12

8.3 THIRD STAGE (DISASSEMBLY OF FRONT AXLE CASE)................................................................7-13

8.4 FOURTH STAGE (DISASSEMBLY OF FRONT AXLE SUPPORT)................................................... 7-14

8.5 FIFTH STAGE (DISASSEMBLY OF FRONT AXLE SUPPORT)......................................................... 7-15

8.6 SIXTH STAGE (DISASSEMBLY OF BEVEL PINION SHAFT) ........................................................... 7-16

8.7 SEVENTH STAGE (DISASSEMBLY OF DIFFERENTIAL GEAR) ..................................................... 7-17

9. MAINTENANCE .............................................................................................................................................. 7-18

9.1 CLEARANCE CHECK BETWEEN CENTER PIN, FRONT AXLE SUPPORT BOSS AND

FRONT AND REAL BRACKETS .............................................................................................................. 7-18

9.2 CHECK FOR BACKLASH AND TOOTH CONTACTED IN FRONT AXLE CASE............................ 7-18

9.3 CHECK FOR BEVEL GEAR BACKLASH AND TOOTH CONTACTED IN BEVEL GEAR CASE ..7-19

9.4 CHECK FOR SHIM BETWEEN AXLE CASE SUPPORT AND FRONT AXLE CASE ............................... 7-19

9.5 CHECK FOR BACKLASH AND TOOTH CONT ACTED BETWEEN BEVEL PINION SHAFT

AND SPIRAL BEVEL GEAR.................................................................................................................. 7-20

9.6 CLEARANCE CHECK BETWEEN DIFFERENTIAL PINION SHAFT AND

DIFFERENTIAL PINION........................................................................................................................ 7-21

9.7 CLEARANCE CHECK BETWEEN FRONT DIFFERENTIAL CASE, DIFFERENTIAL CASE COVER

AND DIFFERENTIAL SIDE GEAR....................................................................................................... 7-21

9.8 CHECK FOR BACKLASH AND TOOTH CONTACTED BETWEEN DIFFERENTIAL PINION AND

DIFFERENTIAL SIDE GEAR ............................................................................................................... 7-22

CHAPTER 8 STEERING SYSTEM....................................................................................................8-1

1. CHARACTERISTICS ....................................................................................................................................... 8-3

2. HYDRAULIC CIRCUIT OF POWER STEERING SYSTEM......................................................................... 8-4

3. GEAR PUMP..................................................................................................................................................... 8-5

3.1 PUMP CHARACTERISTICS ................................................................................................................... 8-5

3.2 MAJOR SPECIFICATION......................................................................................................................... 8-5

3.3 STRUCTURE OF GEAR PUMP.............................................................................................................. 8-5

3.4 OPERATION.............................................................................................................................................. 8-6

4. POWER STEERING UNIT.............................................................................................................................. 8-7

4.1 MAJOR SPEC. .......................................................................................................................................... 8-7

4.2 STRUCTURE AND OPERATION ........................................................................................................... 8-7

5. STEERING CYLINDER................................................................................................................................... 8-8

5.1 STRUCTURE............................................................................................................................................ 8-8

5.2 MAJOR SPECIFICATION......................................................................................................................... 8-8

Page 7

6. OIL FLOW ......................................................................................................................................................... 8-9

6.1 IN NEUTRAL........................................................................................................................................... 8-9

6.2 TURNING TO THE RIGHT.................................................................................................................... 8-9

6.3 TURNING TO THE LEFT..................................................................................................................... 8-10

6.4 MANUAL STEERING............................................................................................................................ 8-10

7. TROUBLESHOOTING ................................................................................................................................... 8-11

8. DISASSEMBLY, MAINTENANCE ................................................................................................................. 8-12

8.1 GEAR PUMP ......................................................................................................................................... 8-12

8.2 POWER STEERING UNIT...................................................................................................................8-14

8.3 STEERING CYLINDER ....................................................................................................................... 8-21

CHAPTER 9 HYDRAULIC SYSTEM.................................................................................................9-1

1. HYDRAULIC CIRCUIT DIAGRAM.................................................................................................................. 9-3

2. STRUCTURE ................................................................................................................................................... 9-4

3. HYDRAULIC CIRCUIT DIAGRAM OF 3-POINT HYDRAULIC SYSTEM............................................................ 9-5

4. HYDRAULIC PUMP ......................................................................................................................................... 9-6

4.1 STRUCTURE OF HYDRAULIC PUMP .................................................................................................. 9-6

4.2 OPERATION.............................................................................................................................................. 9-6

5. OI L FILTER ....................................................................................................................................................... 9-7

5.1 STRUCTURE OF OIL FILTER ................................................................................................................ 9-7

5.2 FUNCTION AND OPERATION................................................................................................................ 9-7

6. CONTROL VALVE (MLS V AL VE)..................................................................................................................... 9-8

6.1 STRUCTURE............................................................................................................................................ 9-8

6.2 CIRCUIT DIAGRAM .................................................................................................................................9-8

6.3 OPERATION PRINCIPLE........................................................................................................................ 9-9

7. RELIEF VALVE (HYDRAULIC BLOCK) .......................................................................................................9-12

8. HYDRAULIC CYLINDER .............................................................................................................................. 9-13

9. STRUCTURE AND OPERATION .................................................................................................................. 9-14

9.1 STRUCTURE .......................................................................................................................................... 9-14

9.2 OPERATION............................................................................................................................................ 9-14

10.OUTSIDE HYDRAULIC EXTRACTION ....................................................................................................... 9-18

10.1 HYDRAULIC BLOCK ............................................................................................................................. 9-18

10.2 ACTING VALVE .......................................................................................................................................9-19

10.3 QUICK COUPLER ................................................................................................................................. 9-19

1 1.TOP LINK BRACKET DEVICE ..................................................................................................................... 9-20

11.1 STRUCTURE.......................................................................................................................................... 9-20

11.2 OPERATION............................................................................................................................................ 9-20

12.TROUBLESHOOTING...................................................................................................................................9-21

13.MAINTENANCE SPECIFICATION................................................................................................................9-22

13.1 3-POINT SYSTEM HYDRAULIC PUMP ..............................................................................................9-22

13.2 RELIEF VALVE .......................................................................................................................................9-22

13.3 LINK CONTROL..................................................................................................................................... 9-22

13.4 HYDRAULIC CYLINDER ......................................................................................................................9-23

Page 8

14.TIGHTENING TORQUE ................................................................................................................................ 9-24

15.DISASSEMBL Y , ASSEMBL Y ......................................................................................................................... 9-25

15.1 GEAR PUMP...........................................................................................................................................9-25

15.2 MAINTENANCE ......................................................................................................................................9-27

15.3 RELIEF VALVE ....................................................................................................................................... 9-27

15.4 HYDRAULIC CYLINDER ......................................................................................................................9-28

15.5 CHECK AND ADJUSTMENT................................................................................................................. 9-34

CHAPTER 10 ELECTRIC SYSTEM ............................................................................................... 10-1

1. ELECTRONIC INSTRUMENTATION........................................................................................................... 10-3

1.1 INSTRUMENT GAUGE..........................................................................................................................10-3

1.2 INDICA TORS AND WARNING LIGHTS...............................................................................................10-4

2. TROUBLE SHOOTING..................................................................................................................................10-6

3. SERVICING SPECIFICATIONS ................................................................................................................... 10-8

4. MECHANISM...................................................................................................................................................10-9

4.1 STARTING SYSTEM .............................................................................................................................. 10-9

4.2 CHARGING SYSTEM.......................................................................................................................... 10-12

4.3 PREHEATING SYSTEM...................................................................................................................... 10-14

4.4 FUSE .................................................................................................................................................... 10-15

4.5 GAUGE AND SENSORS .................................................................................................................... 10-16

5. MAIN CIRCUIT DIAGRAM .......................................................................................................................... 10-17

Page 9

CHAPTER 1

GENERAL INFORMATION

Page 10

Page 11

1. TRACTOR VIEW

GENERAL INFORMA TION

D615-W02 May-2003

615W101A

1-3

Page 12

CHAPTER 1 8354/8404

2. TIGHTENING TORQUE FOR STANDARD BOLTS AND NUTS

2.1 TIGHTENING TORQUE

Screws, bolts and nuts whose tightening torques are not specified in this workshop manual should be tightened

according to the table below.

A . TIGHTENING TORQUE FOR ST ANDARD BOLTS AND NUTS

Grade No grade 4T 7T 9T

Unit

Nominal

Diameter

M 6

(6 mm, 0.24 in.)

M 8

(8 mm, 0.31 in.)

M 10

(10 mm, 0.39 in.)

M 12

(12 mm, 0.47 in.)

M 14

(14 mm, 0.55 in.)

M 16

(16 mm, 0.63 in.)

M 18

(18 mm, 0.71 in.)

M 20

(20 mm, 0.79 in.)

N·m

7.85

~

9.30

17.7

~

20.5

39.2

~

45.0

62.8

~

72.5

108

~

125

167

~

191

245

~

284

334

~

392

Kgf·m

47 9

lbf·ft

9.1

~

10.5

21.7

~

25.3

44.9

~

52.1

76.0

~

86.8

123

~

144

192

~

224

254

~

297

362

~

420

0.80

~

0.95

1.8

~

2.1

4.0

~

4.6

6.4

~

7.4

11.0

~

12.8

17.0

~

19.5

25.0

~

29.0

34.0

~

40.0

lbf·ft

5.79

~

6.87

13.0

~

15.2

29.0

~

33.2

46.3

~

53.5

79.6

~

92.5

123

~

141

181

~

210

246

~

289

N·m

9.80

~

11.2

23.6

~

27.4

48.1

~

55.8

77.5

~

90.1

124

~

147

196

~

225

275

~

318

368

~

431

Kgf·m

1.00

~

1.15

2.4

~

2.8

4.9

~

5.7

7.9

~

9.2

12.6

~

15.0

20.0

~

23.0

28.0

~

32.5

37.5

~

44.0

lbf·ft

7.24

~

8.32

17.4

~

20.2

35.5

~

41.2

57.2

~

66.5

91.2

~

108

145

~

166

203

~

235

272

~

318

N·m

12.3

~

14.2

29.4

~

34.3

60.8

~

70.5

103

~

117

167

~

196

260

~

303

343

~

401

490

~

568

Kgf·m

1.25

~

1.45

3.0

~

3.5

6.2

~

7.2

10.5

~

12.0

17.0

~

20.2

26.5

~

31.0

35.0

~

41.0

50.0

~

58.0

* The figures on the table above are indicated the top of screw of bolt.

1-4

D615-W02 May-2003

Page 13

B. TIGHTENING TORQUE FOR STUDS

GENERAL INFORMA TION

M8

M10

M12

11.7 ~ 15.7 N·m

24.5 ~ 31.4 N·m

34.3 ~ 49.0 N·m

1.2 ~ 1.6 kgf·m

2.5 ~ 3.2 kgf·m

3.4 ~ 5.0 kgf·m

C. TIGHTENING TORQUE FOR HIGH PRESSURE HOSE UNION NUTS

Hose Size

(Inside Diameter: Inches)

Screw Size (PF)

Tightening (N·m)

Torque (kgf·m)

(lbf·ft)

1/8″ 3/16″ 1/4″ 5/16″ 3/8″ 1/2″ 5/8″, 3/4″ 1″

1/8″

9.8

1

7.2

1/4″

24.5

2.5

18.0

1/4″

24.5

2.5

18.0

3/8″

49.0

5

36.1

3/8″

49.0

5

36.1

8.6 ~ 11.5 lbf·ft

18.0 ~ 23.1 lbf·ft

25.3 ~ 36.1 lbf·ft

1/2″

58.8

6

43.3

3/4″

117.7

12

86.8

1″

137.3

14

101.2

D615-W02 May-2003

1-5

Page 14

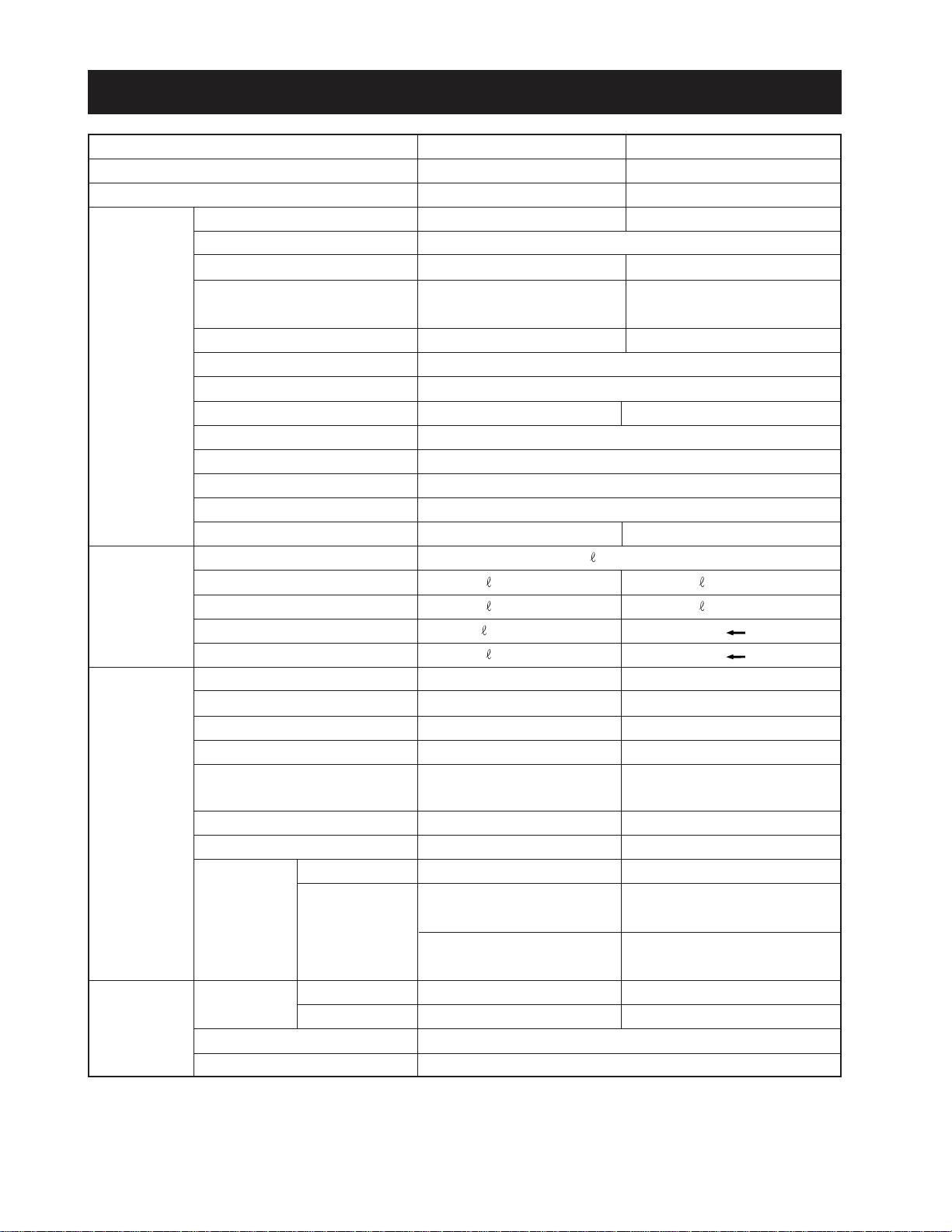

CHAPTER 1 8354/8404

3. SPECIFICATIONS

Maximum PTO power

Engine GROSS power

Engine

Capacities

Dimensions

(with std.

Tires)

Traveling

system

Model

Type

Number of cylinders

Bore and stroke

Total displacement

Rated revolution

Injection timing

Injection order

Compression ratio

Lubricating system

Cooling system

Alternator

Weight (Dry)

Fuel tank

Engine crankcase

Engine coolant

Transmission case

Front axle case

Overall length (without 3p)

Overall length (with 3p)

Overall width (minimum tread)

Overall height (Top of ROPS)

Overall height

(Top of steering wheel)

Wheelbase

Ground clearance

Tread Front

Tire size

(Std. tires)

Clutch

Steering

Model

Rear

Front

Rear

8354

28.3 HP

33.5 HP

3A165D

Indirect injection, vertical, water-cooled, 4-cycle diesel

3

87 × 92.4 mm

(3.425 × 3.637 in.)

1,647

2,700 rpm

18° before T.D.C.

1-2-3

22 : 1

Forced lubrication by trochoidal pump

Pressurized radiator, Forced circulation with water pump

12 V , 50 AMPS

179 kg

40 (10.6 U.S.gal.)

5.8

(1.5 U.S.gal.)

(1.9 U.S.gal.)

7.0

44

(11.6 U.S.gal.)

(2.0 U.S.gal.)

7.5

3,357 mm (132.2 in.)

3,468 mm (136.5 in.)

1,440 mm (56.7 in.)

2,445 mm (96.5 in.)

1,530 mm

(60.2 9n.)

1,668 mm (65.7 in.)

239 mm (9.4 in.)

1,235mm (48.4 in.)

1,166 mm

(45.9 in.)

1,077 ~ 1,387 mm

(42.4 ~ 54.6 in.)

7-16

12.4-24

Dry single stage

Hydrostatic steering system

8404

33.4 HP

40.4 HP

4A200

4

83 × 92.4 mm

(3.268 × 3.637 in.)

1,999

1-3-4-2

205 kg

7.0

(1.9 U.S.gal.)

(2.4 U.S.gal.)

8.9

3,365 mm (132.5 in.)

3,550 mm (139.8 in.)

1,505 mm (59.3 in.)

2,465 mm ( 97.0 in.)

1,545 mm

(60.8 in.)

1,780 mm (70 in.)

257 mm (10.1 in.)

1,235 mm (48.4 in.)

1,158 mm

(45.6 in.)

1,158 ~ 1,467 mm

(45.6 ~ 57.8 in.)

8-16

13.6-24

1-6

D615-W02 May-2003

Page 15

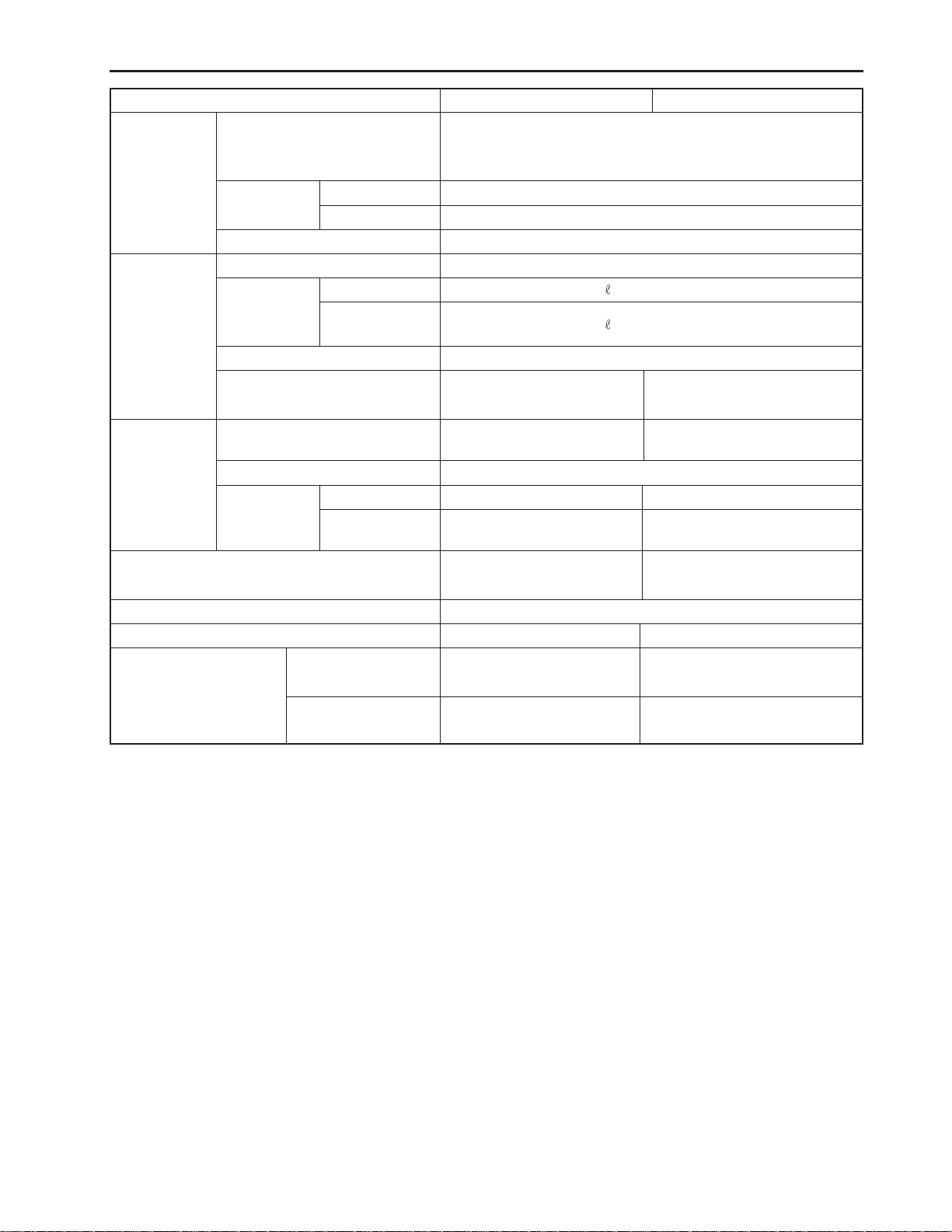

GENERAL INFORMA TION

Traveling

system

Hydraulic

system

PTO

Model 8354

Transmission

Brake Traveling

Parking

Differential

Hydraulic lift control system

Pump

capacity

Three point hitch

Maximum lifting capacity

(the end of lower ling)

No. of Remote control valve

ports(Option)

PTO shaft

Revolution

(independent PTO)

Main pump

Power steering

pump

MID PTO

Rear PTO

1,650 kg (3,638 lb)

2,000 (2,542 rpm)

540 (2,451 rpm)

8404

Synchronized shuttle and transmission

8 forward and 8 reverse speeds

(CR: 16 forward and 16 reverse speeds)

Wet disc type

Connected with the traveling brake

Bevel gear

Position, Draft and Mixed control

29.7 /min (7.8 U.S.gal.)

/min (4.7 U.S.gal.)

17.8

SAE Category l

1,550 kg (3,417 lb)

2 or 4

SAE 1-3/8, 6 splines

2 or 4

2,000 (2,542 rpm)

540 (2,451 rpm)

Min. turning radius (without brake)

Traction system

Weight (with ROPS)

Traveling speed

(at 2700 engine speed

with Std. tires)

Forward (creeper)

Reverse (creeper)

3,100 mm

(112.7 in.)

Swing Draw-Bar

1,515 kg

1.6 (0.21) ~ 23.2 km/h

0.99 (0.13) ~ 14.41 mph

1.55 (0.20) ~ 21.4 km/h

0.96 (0.12) ~ 13.30 mph

3,125 mm

(123 in.)

1,665 kg

1.7 (0.21) ~ 23.4 km/h

1.06 (0.13) ~ 14.54 mph

1.56 (0.20) ~ 21.6 km/h

0.97 (0.12) ~ 13.42 mph

D615-W02 May-2003

1-7

Page 16

CHAPTER 1 8354/8404

4. IDENTIFICATION

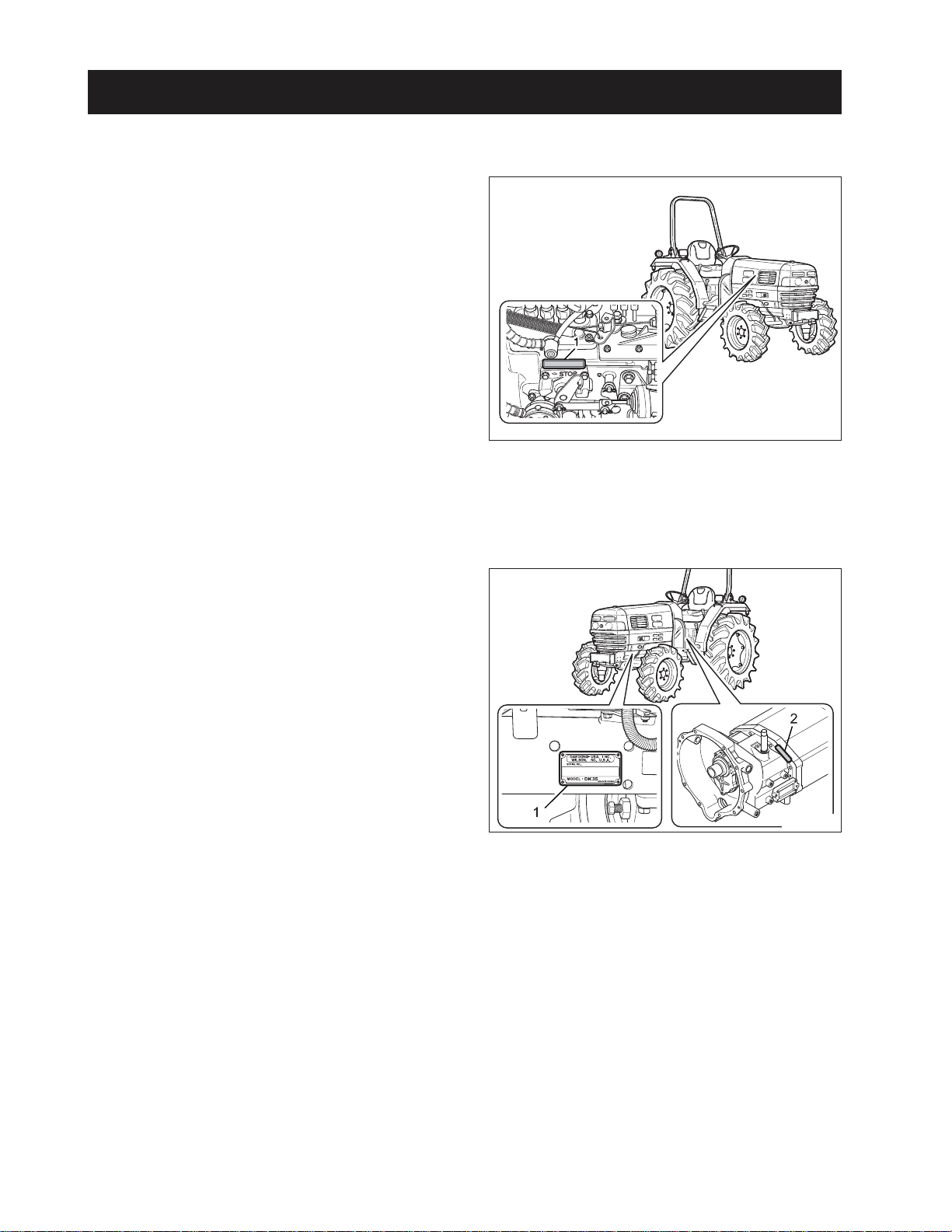

4.1 ENGINE NUMBER

The engine serial number is stamped on the left side

of the cylinder block as shown in the figure. Engine

serial number provides important information.

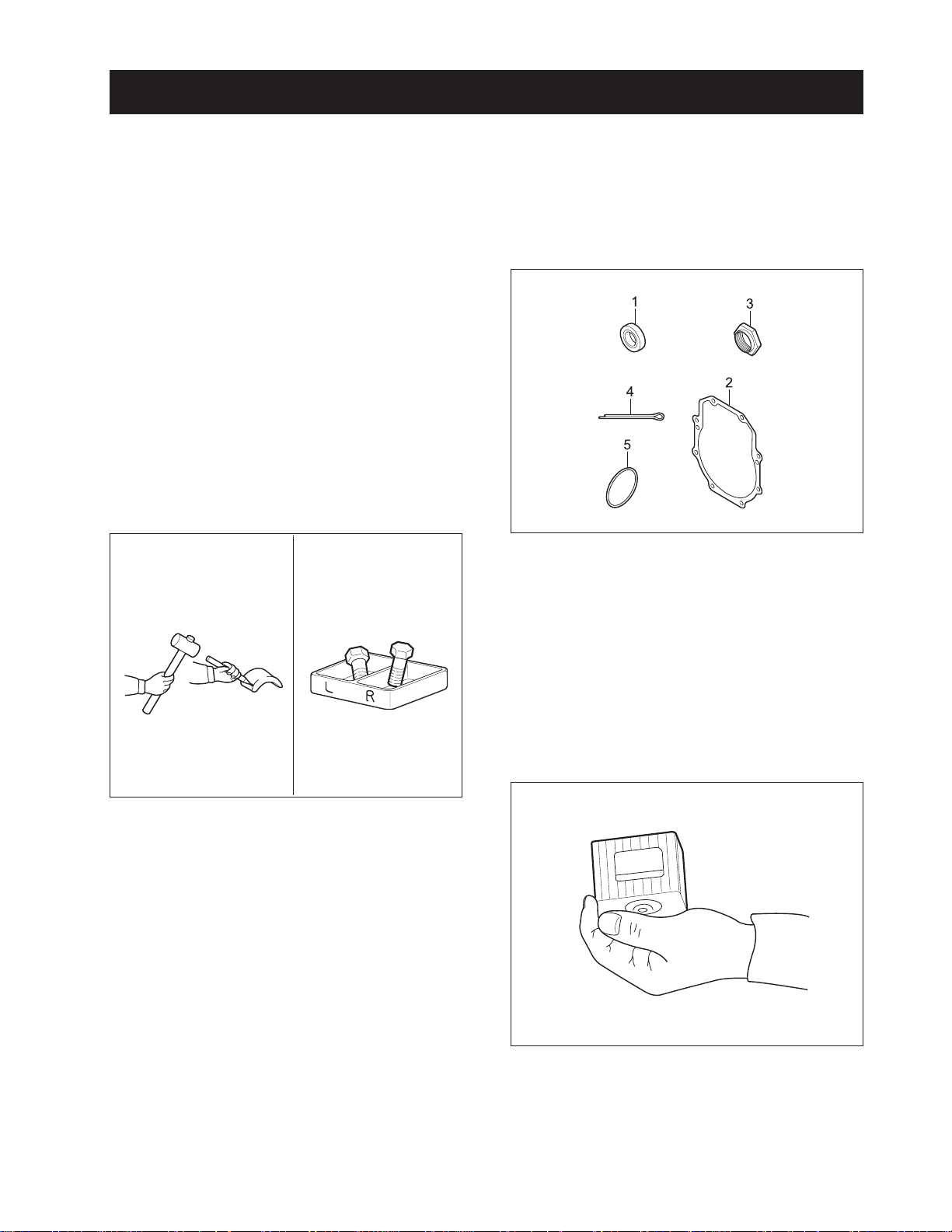

4.2 CHASSIS NUMBER OF THE

TRACTOR (CHASSIS NUMBER OF

THE MACHINE)

615W102A

(1) Engine Serial Number

The chassis serial number of the tractor is stamped

on the left side of the front axle frame as shown in the

figure.

615W103A

(1) Manufacture Plate

(2) Transmission Serial Number

1-8

D615-W02 May-2003

Page 17

5. CAUTION BEFORE REP AIR

C C

GENERAL INFORMA TION

5.1 BEFORE REPAIR OR INSPECTION

1. In case of repair or inspection, locate the tractor

on the flat ground and pull the parking brake on.

2. Except for the items to be checked while the engine is running, be sure to stop the engine prior to

the work.

3. When washing parts, use parts washing solvent

for industrial use (avoid using gasoline so to prevent environmental pollution). For the hydraulic

parts, apply designated hydraulic oil in washing.

4. When disassembling and assembling of the hydraulic apparatus, pay special attention not to allow dust or foreign substance to be attached or

intermixed.

5.2 ASSEMBLY AND DISASSEMBLY

To check a failure, try to find out its underlying cause. If

assembly or disassembly is needed, perform the work

in regular sequence as specified in this repair manual.

7. Finish assembly within 20 minutes after applying

sealant, after that, wait approx. 30 minutes later

before filling with oil.

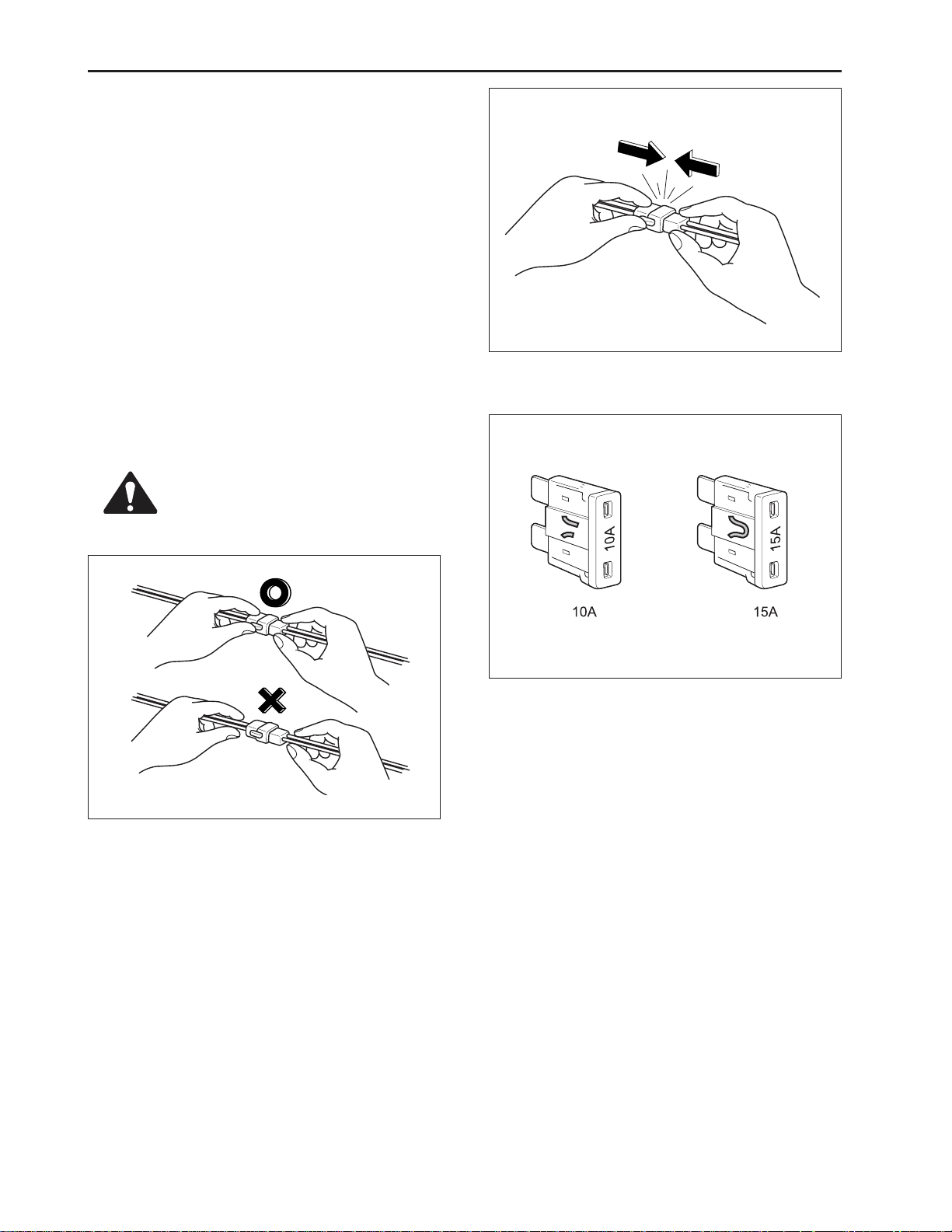

5.3 PARTS TO BE REPLACED

615W105A

The following parts should be replaced with new ones

when removed.

(1) Oil Seal

(2) Gasket

(3) Lock Nut

(4) Split Pin

(5) O-Ring

615W104A

1. Disassembled parts shall be arranged orderly.

2. Sort out the parts to be replaced from the ones to

be reused.

3. Be sure to use standard bolts and nuts that are

designated.

4. When assembling snap rings or spring pin types,

take care of assembling direction.

5. Split pin shall be spread surely not to escape when

installed.

6. When using sealant (such as gasket bond) on the

assembled surfaces, apply it evenly and consistently in a height of 3 ~ 5 mm (0.12 ~ 0.2 in.) on the

contact surface after removing the old bond and

cleaning the sealing surface with solvent. Apply

sealant on the center of the contact surface for the

space between the bolt holes of the contact

surface, and on the more inner side than the bolt

hole for the bolt area.

D615-W02 May-2003

5.4 PARTS

615W106A

When replacing parts, use only genuine Cub Cadet parts.

1-9

Page 18

CHAPTER 1 8354/8404

5.5 ASBESTOS PARTS

Since dust out of asbestos fibrous parts is extremely

dangerous to your health, be sure to clean such parts

carefully, do not use compressed air.

5.6 ELECTRICAL SYSTEM

1. Check electrical wiring every year for any damage

or short circuit at the connections. In addition, have

your dealer inspection the electric system regularly.

2. Do not modify or reorganize the wiring of the electric field parts.

3. When disconnecting the battery cable, disconnect

negative cable first, reinstall the positive cable first

when reinstalling.

Disconnect battery negative terminal

• Be sure to turn the starting key OFF

when connecting or disconnecting the

cable.

CAUTION

615W108A

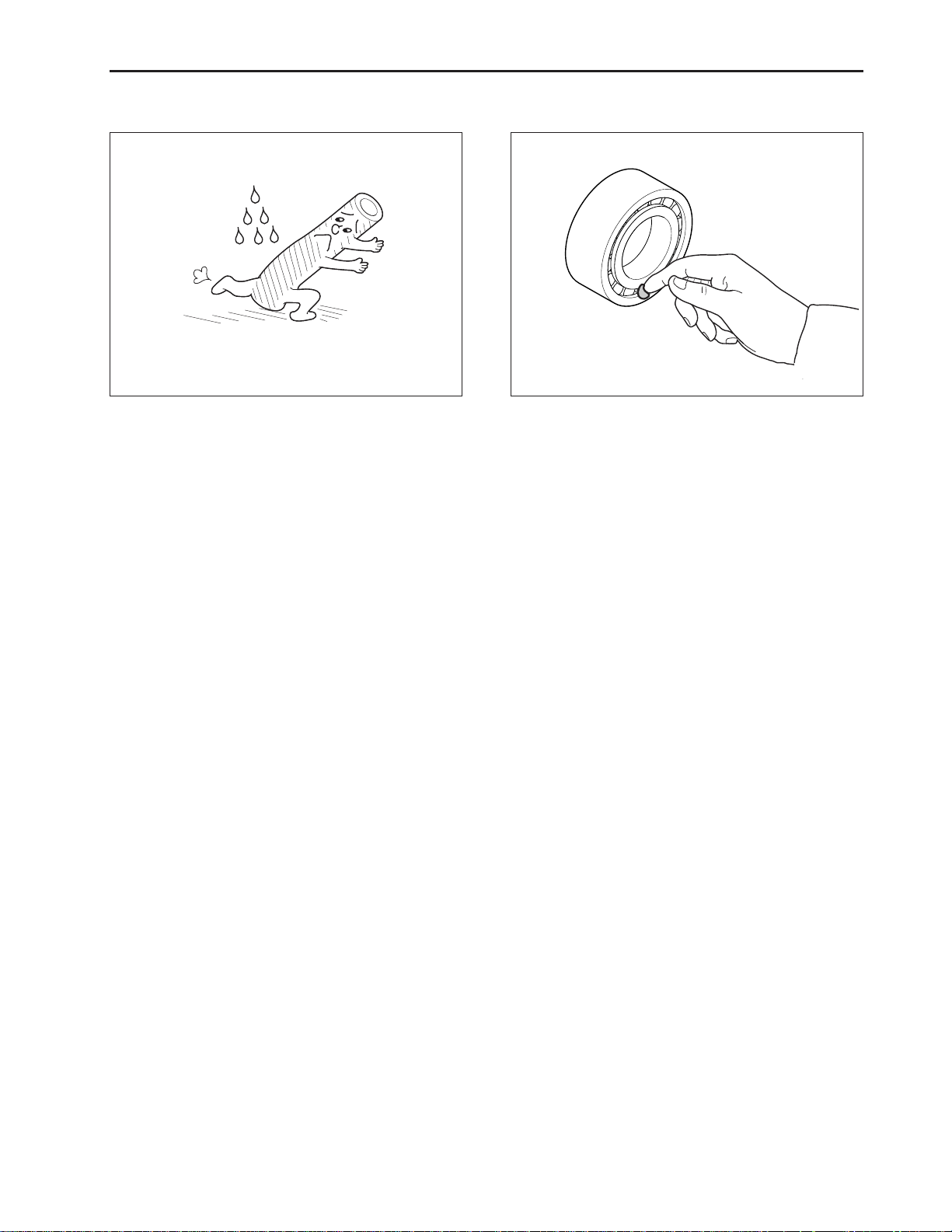

5. When connecting the connector, insert it until it

snaps.

615W107A

4. Remove the connector by pulling the plastic

section, not the wiring.

615W109A

6. Be sure not to drop sensors and relays which are

fragile.

7. When replacing a broken fuse with a new one, be

sure to use the fuse of capacity as specified.

1-10

D615-W02 May-2003

Page 19

5.7 TUBES AND RUBBERS 5.8 LUBRICANT

GENERAL INFORMA TION

615W112 A615W11 1 A

Be cautious of oil or other petroleum products on the

hoses and rubber parts, this may cause damage.

When assembling and fixing, apply designated lubricant where specified in accordance with this repair

manual.

D615-W02 May-2003

1-11

Page 20

CHAPTER 1 8354/8404

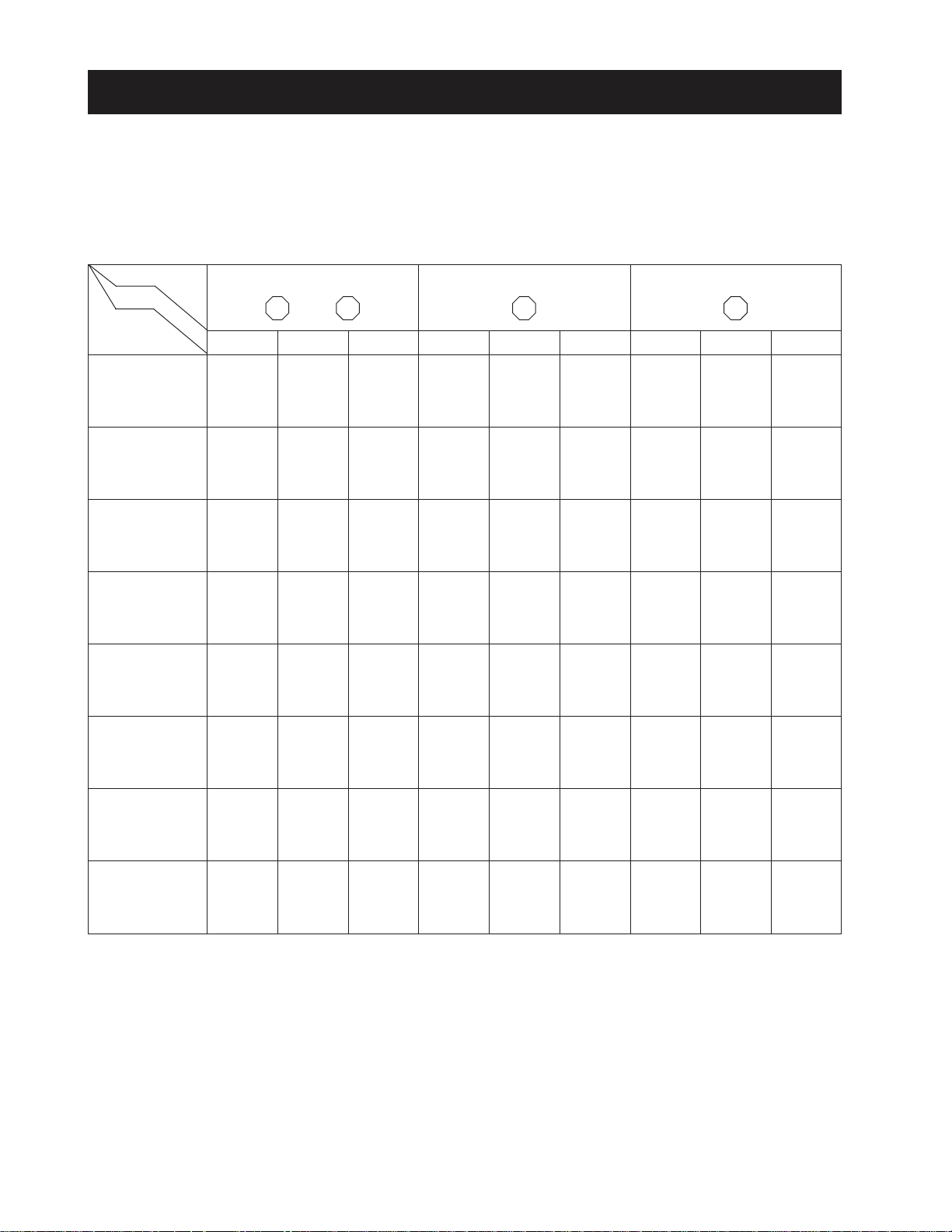

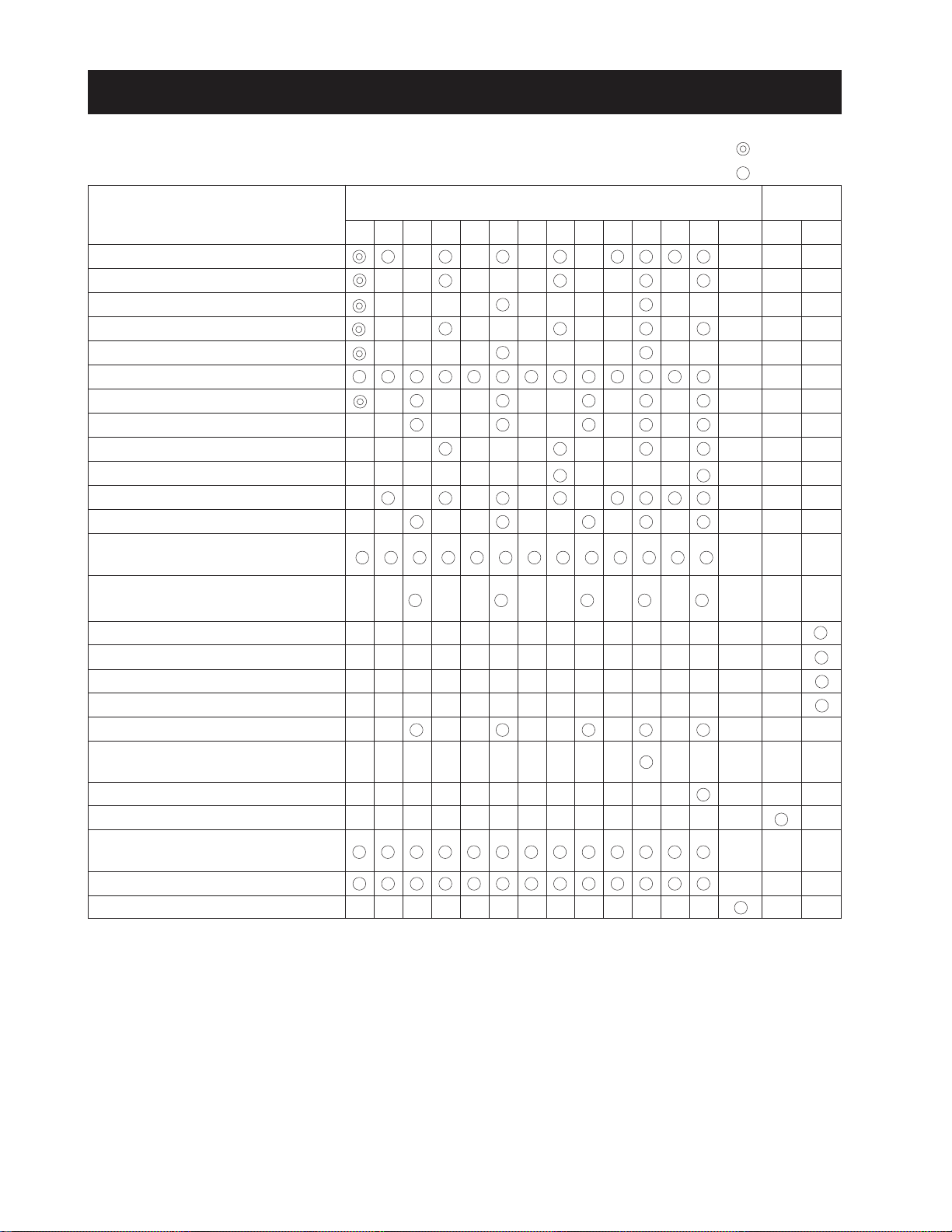

6. REGULAR CHECK LIST

Check Items

Engine oil change

Engine oil filter cartridge change

Transmission oil change

Hydraulic oil filter change

Front axle oil change

Applying grease

Clutch pedal deflection

Brake pedal deflection

Fan belt tension

Fuel filter element change

Air cleaner element change

Battery electrolyte

Oil pressure fuel pipe’s inlet screw

if loosened

Radiator hose’s inlet bands if

loosened

Fuel pipe change

Radiator hose change

Hydraulic pipe joint change

Steering hose change

Toe-in

Deflection adjustment in front and

rear of the front axle

Direction control section

Bolt, nuts and pins of each part

Battery positive code adjustment &

change

Bleeding water in clutch housing

Check injection nozzle*

Indicated Hours By Hour Meter

The first

Periodically

Since

Purchased

80070060050045040035030025020015010050

1500hr

1yr 2yr

* Maintenance intervals in basis on the EPA instructions.

1-12

D615-W02 May-2003

Page 21

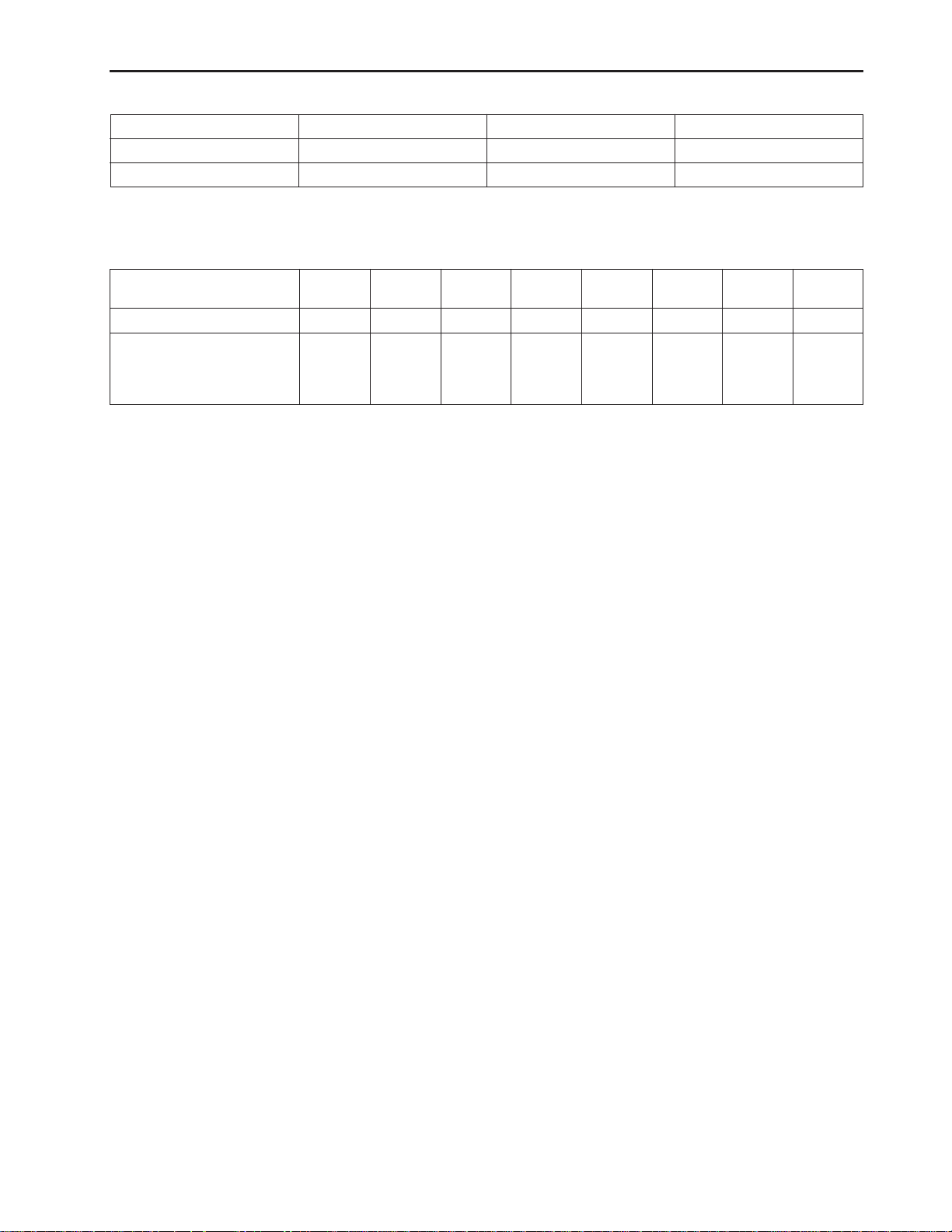

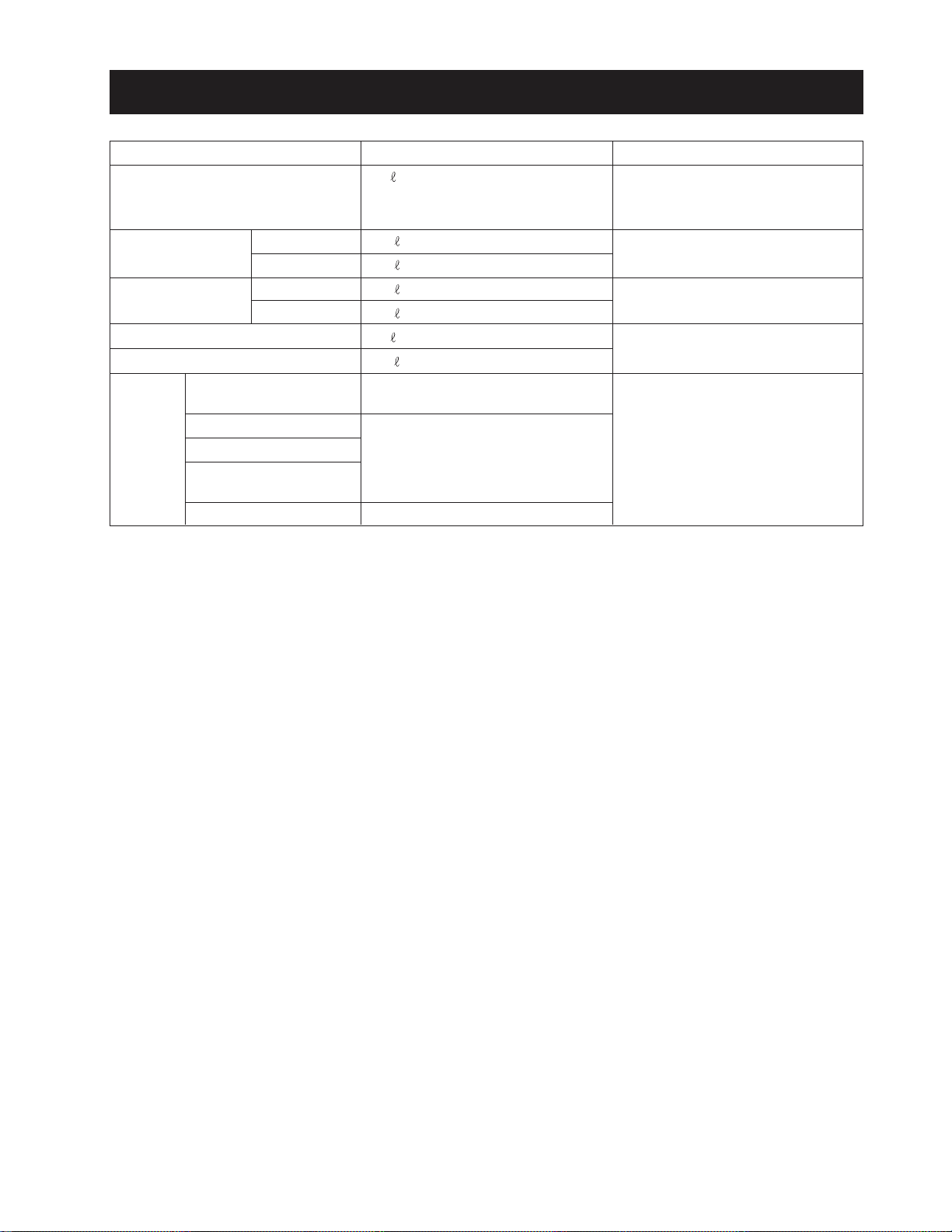

7. OIL & WATER SUPPLY LIST

GENERAL INFORMA TION

Supply Items

Fuel

Coolant

Engine Oil

Transmission Oil

Front Axle Section

Hydraulic control lever

shaft section

Applying

Grease

3 point link section

Brake pedal link section

Bracket section in front

and rear of the front axle

Clutch release hub

3A165D

4A200B

3A165D

4A200B

Capacity

(42.3 U.S.gal.)

40

(1.85 U.S.gal.)

7.0

8.9

(2.35 U.S.gal.)

(1.45 U.S.gal.)

5.5

7.0

(1.85 U.S.gal.)

44

(11.6 U.S.gal.)

(2.0 U.S.gal.)

7.8

Small quantity

Until grease exits

Supply when removed

Recommended Spec.

No. 2 - D diesel fuel

No. 1 - D diesel fuel if temperature

is below - 10 °C (14 °F)

Fresh clean water with antifreeze

SAE 15 W - 40

Universal tractor/transmission

hydraulic oil

SAE multi - purpose type grease

D615-W02 May-2003

1-13

Page 22

Page 23

CHAPTER 2

ENGINE SYSTEM

Page 24

Page 25

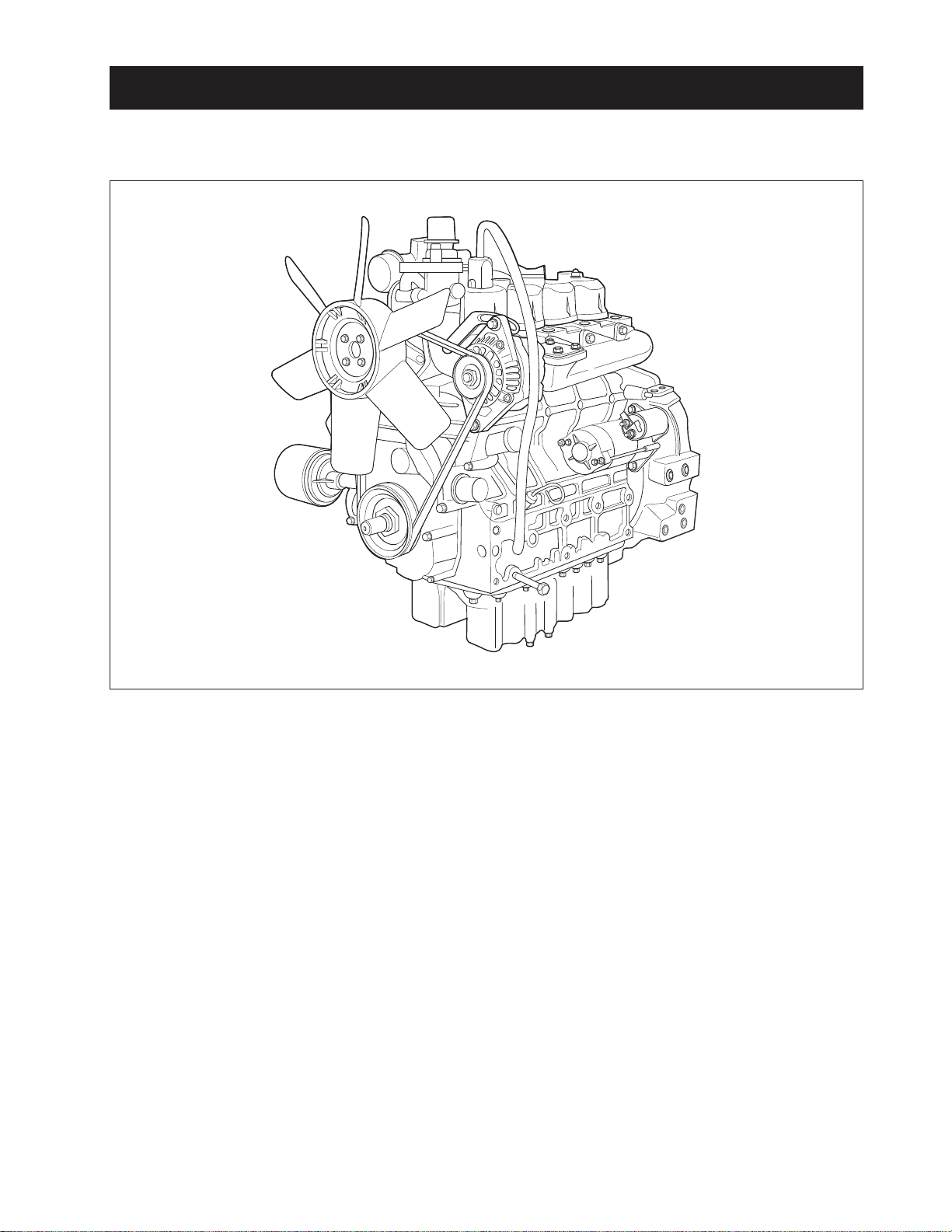

1. GENERAL

1.1 APPEARANCE

ENGINE SYSTEM

The DAEDONG A series engines are vertical, watercooled, 4-cycle, three or four cylinders diesel engines,

they concentrate DAEDONG’s foremost technologies.

With swirl combustion chamber, bosch K type fuel injection pump, well-balanced designs, they feature

greater power, low fuel consumption, less vibration and

noise, and low emission.

615W201A

D615-W02 May-2003

2-3

Page 26

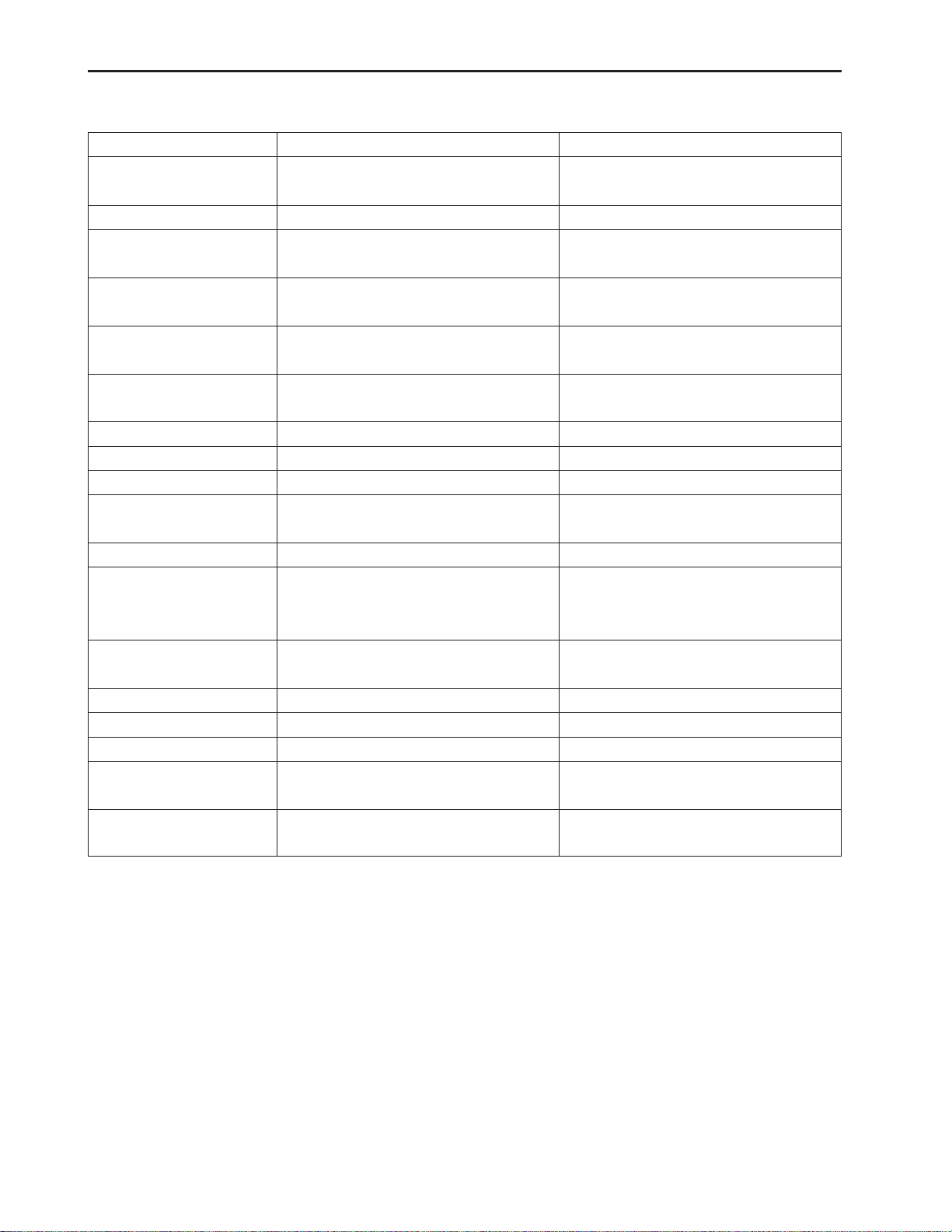

CHAPTER 2 8354/8404

1.2 SPECIFICATIONS

Model

Type

Number of cylinder

Bore and stroke

Total Displacement

Combustion

Chamber

Gross power

Maximum idling speed

Minimum idling speed

Order of firing

Direction of rotation

Injection pump

Injection pressure

Injection timing

(Before T.D.C)

Compression Ratio

Fuel

Lubricant

Dimensions

(length x width x height)

Dry weight

3A165D

Vertical, water-cooled,

4-cycle diesel engine

3

87 x 92.4 mm

3.43 x 3.64 in.

1,647 cc

100.5 in

3

Spherical type

33.5/2,700 HP/rpm

30.0/2,700 kW/rpm

2,900 rpm

850 ~ 900 rpm

1 - 2 - 3

Counterclockwise

(viewed from flywheel side)

Bosch K TYPE mini pump

140 ~ 150 kgf/cm²

13.73 ~ 14.71 MPa

1,991 ~ 2,133 psi

18 °

22 : 1

Diesel fuel

Engine oil SAE 15W-40

722.3 x 488.1 x 729.9 mm

28.4 x 19.2 x 28.7 in.

179 kg

395 lbs.

4A200B

Vertical, water-cooled,

4-cycle diesel engine

4

83 x 92.4 mm

3.27 x 3.64 in.

1,999 cc

122.0 in

3

Spherical type

40.4/2,700 HP/rpm

36.2/2,700 kW/rpm

2,900 rpm

850 ~ 900 rpm

1 - 3 - 4 - 2

Counterclockwise

(viewed from flywheel side)

Bosch K TYPE mini pump

140 ~ 150 kgf/cm²

13.73 ~ 14.71 MPa

1,991 ~ 2,134 psi

18 °

22 : 1

Diesel fuel

Engine oil SAE 15W-40

817.3 x 488.1 x 735.8 mm

32.2 x 19.2 x 29.0 in.

183 kg

403 lbs.

* NOTE: Change of parts are not subject to advance notice.

2-4

D615-W02 May-2003

Page 27

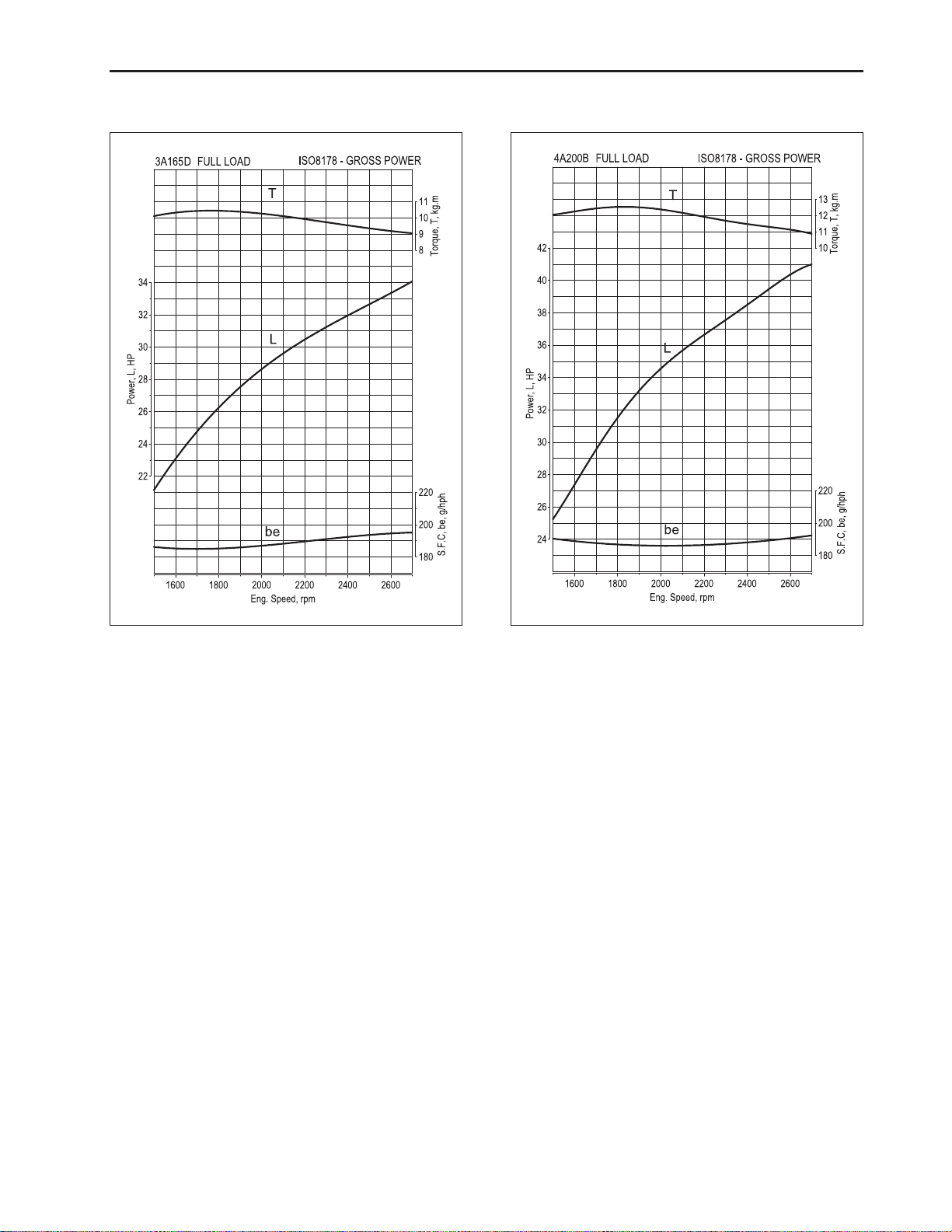

1.3 PERFORMANCE CURVE

ENGINE SYSTEM

615W204A615W203A

D615-W02 May-2003

2-5

Page 28

CHAPTER 2 8354/8404

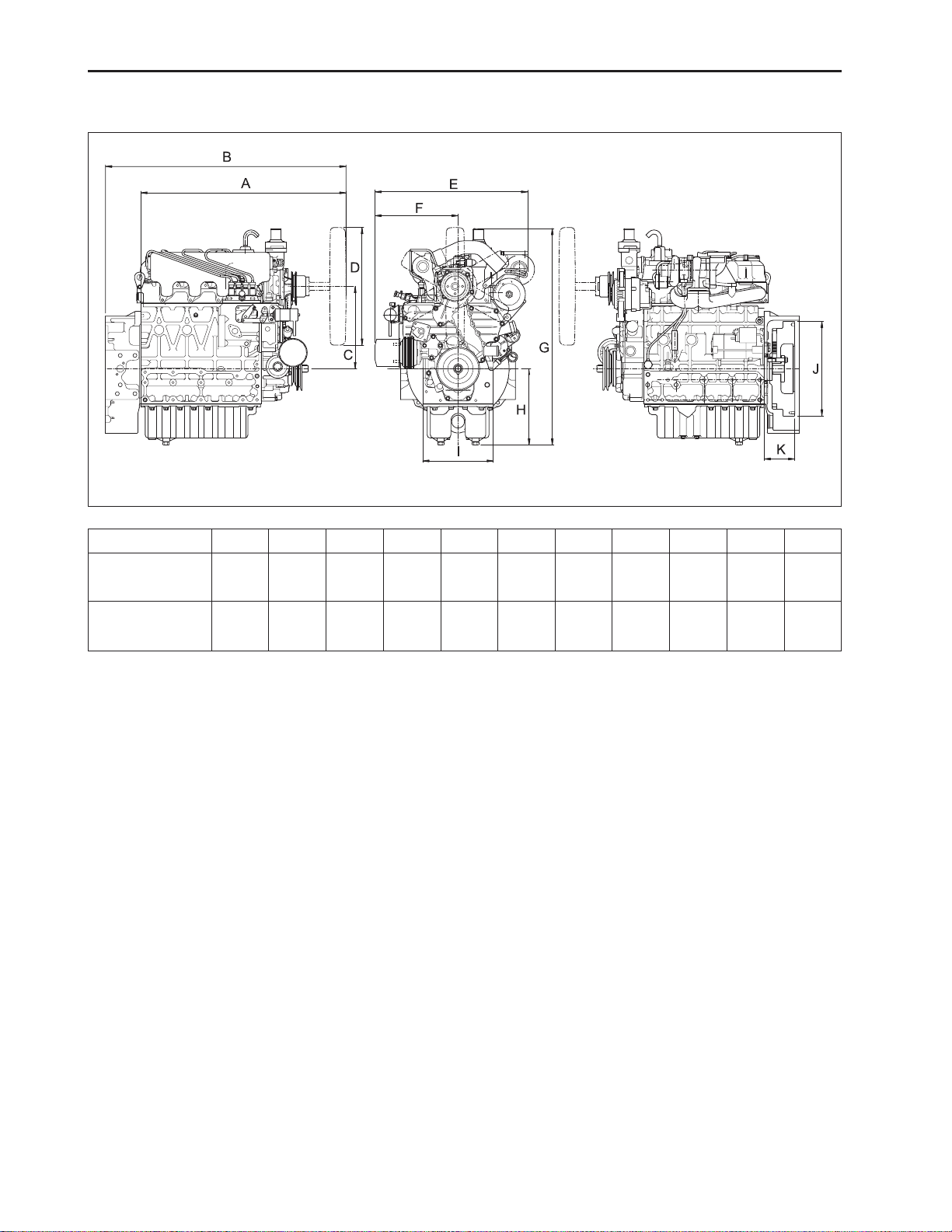

1.4 DIMENSIONS

615W206A

3A165D (mm)

(in.)

4A200B (mm)

(in.)

A

602.3

23.71

697.3

27.45

B

722.3

28.44

817.3

32.18

C

280.0

11.02

280.0

11.02

D

400.0

15.75

400.0

15.75

1.5. GENERAL WARNING

• When disassembling, arrange each part on a clean

place. Do not mix them up. Replace bolts and nuts

where they were.

• When servicing electrical parts or connecting instruments to electrical equipment, first disconnect the

battery negative terminal.

• Replace gaskets or O-rings with new ones when

reassembling, and apply grease on a O-ring and

the oil seal when reassembling.

• When exchanging parts, use Cub Cadet parts to

maintain engine performance and safety.

• To prevent oil and water leakage, apply non-drying

adhesive to the gaskets according to this manual

before reassembling.

• When hoisting up the engine, use the hook provided on the cylinder head.

• When reinstalling the engine, use the hook provided

on the cylinder head.

• When installing external cir-clips or internal cir-clips,

direct corner end to the non-loosening direction.

E

488.1

19.22

488.1

19.22

F

251.6

9.91

251.6

9.91

G

729.9

28.74

735.8

28.97

H

259.7

10.00

259.7

10.22

I

240.0

9.45

240.0

9.45

J

315.0

12.40

321.0

12.64

K

95.0

3.74

92.0

3.62

2-6

D615-W02 May-2003

Page 29

2. STRUCTURE AND FUNCTION

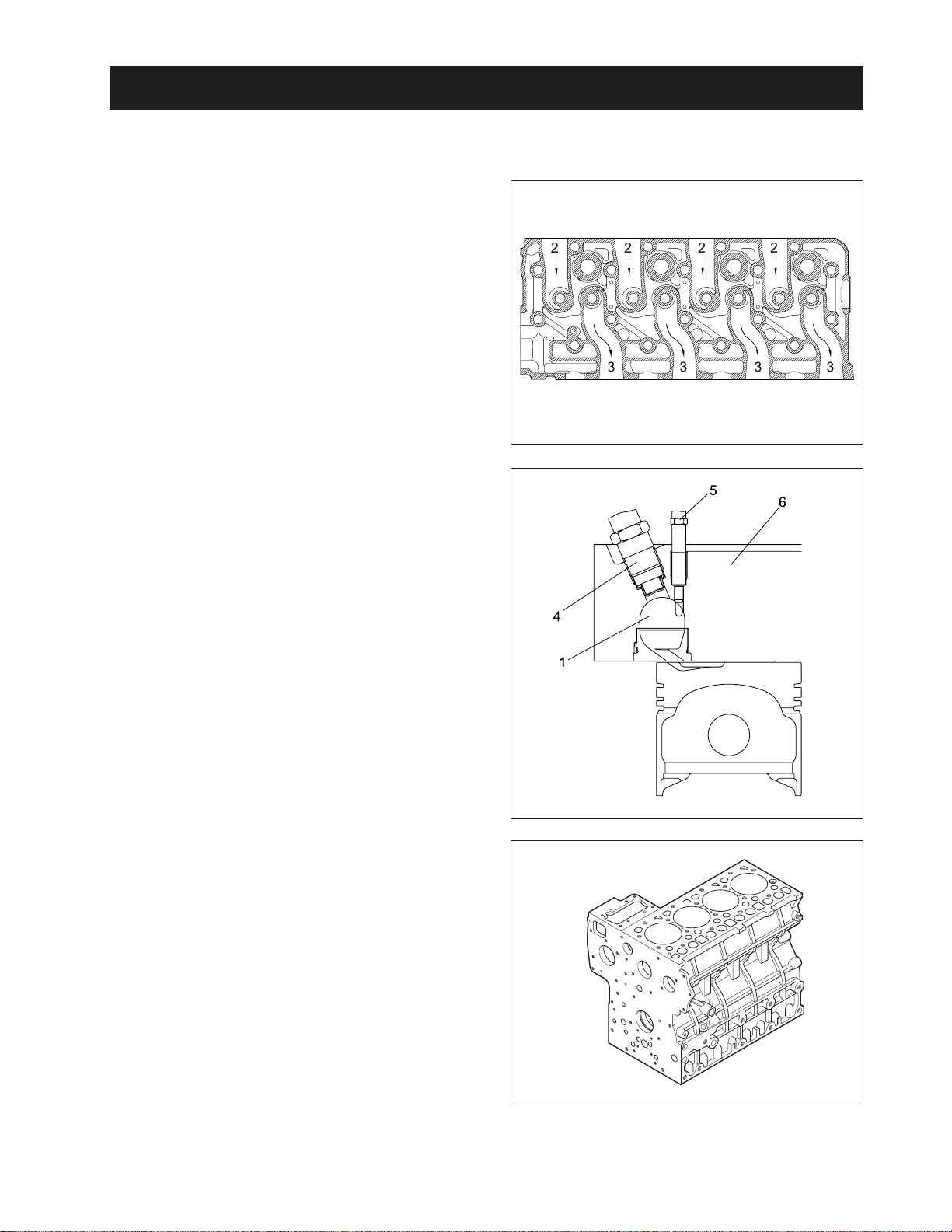

2.1 BODY

A . CYLINDER HEAD

The cylinder head is made of special alloy cast iron

which can resist high temperature and pressure

caused by combustion. The inlet and exhaust ports are

arranged cross-flow type to get high combustion efficiency by protecting the suction air from being heated

and expanded by heated exhaust air.

The DAEDONG vortex type combustion chamber is designed for high combustion efficiency and reducing fuel

consumption. The glow plug assures easier than ever

engine starts even at -15 °C (5 °F).

(1) Combustion Chamber

(2) Inlet Port

(3) Exhaust Port

(4) Injection Nozzle

(5) Glow Plug

(6) Cylinder Head

ENGINE SYSTEM

615W207A

B. CYLINDER BLOCK

The engine has a high durability tunnel-type cylinder

block. Furthermore, liner less type, allows effective cooling, less distortion, and greater wear-resistance using

special material. The noise is reduced to a minimum

because each cylinder has its chamber.

D615-W02 May-2003

615W208A

615W209A

2-7

Page 30

CHAPTER 2 8354/8404

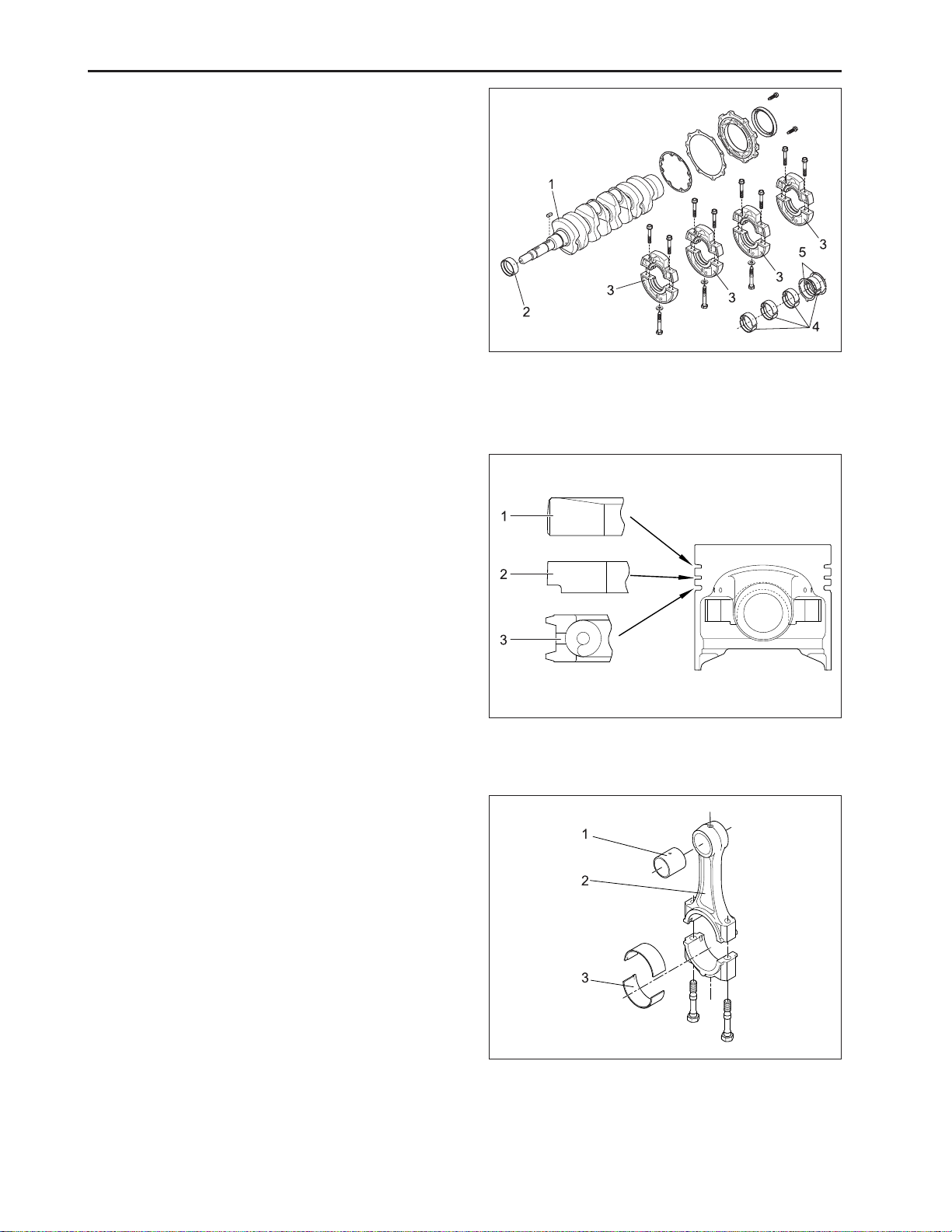

C. CRANKSHAFT

The crankshaft is made of forged steel and the journals,

the crankpins and the bearing surface for the oil seal

are induction-hardened to increase wear resistance.

Each crankshaft journal is supported by the main bearing case (3) having a bearing inside. The front bearingcrankshaft bearing (2) is a solid type bushing and rear

and intermediate bearings are a split type. The

crankshaft, crankshaft bearings have oil holes for lubricant flow.

D. PISTON AND PISTON RINGS

The piston is made of an aluminum alloy which is temperature and pressure resistant. Three rings are installed in the grooves of the piston. The top ring (1) is a

keystone type, which can withstand heavy loads, and

the barrel face on the ring fits well to the cylinder wall.

The second ring (2) is an undercut type, which prevents the oil from being carried up. The oil ring (3) has

chambered contact faces and an expander ring, which

increase the pressure of the oil ring against the cylinder wall to scrape the oil. The top ring is plated with

hard chrome to increase wear resistance (The ring of

4A200T engine is made of a special steel).

615W210A

(1) Crankshaft (4) Crankshaft Bearing 2

(2) Crankshaft Bearing 1 (5) Thrust Bearing

(3) Main Bearing Case

E. CONNECTING ROD

The connecting rod (2), which converts the reciprocating motion of the pistons caused by the fuel combustion into the rotating motion of the crankshaft, is made

of hard forged steel. The connecting rod has bearings

at both ends. The small end has a solid type bearing

(small end bushing (2)) and the big end has a split

type bearing (crankpin bearing (3)).

615W211A

(1) Top Ring (3) Oil Ring

(2) Second Ring

615W212A

(1) Small End Bushing (3) Crankpin Bearing

(2) Connecting Rod

2-8

D615-W02 May-2003

Page 31

F. CAMSHAFT

The camshaft (3) is made of forged steel and its journal and cams are hardened to increase wear

resistance. The cams on the camshaft open and close

the inlet and exhaust valves with the push rods and

rocker arms. The journals and their bearings are forcelubricated.

G. FUEL CAMSHAFT

This fuel camshaft is made of forged steel and its cams

are hardened and tempered to increase wear

resistance. The cams on the fuel camshaft (1) drive

the injection pump and the fuel transfer pump. The

governor balls are installed on the fuel camshaft to

control the engine speed.

ENGINE SYSTEM

615W213A

(1) Cam Gear (3) Camshaft

(2) Camshaft Stopper

H. ROCKER ARM ASSEMBL Y

The rocker arm assembly includes the rocker arms (1)

and an adjusting screw (3), which is at the end of rocker

arm and rests on the push rod, rocker arm brackets (4)

and rocker arm shaft (5). The rocker arms are activated

by the reciprocating motion of the push rods and open

or close the inlet and exhaust valves. The rocker arm

and other parts are lubricated through the drilled holes

of the brackets and the rocker arm shaft.

615W214A

(1) Fuel Camshaft (2) Injection Pump Gear

615W215A

(1) Rocker Arm (4) Rocker Arm Bracket

(2) Lock Nut (5) Rocker Arm Shaft

(3) Adjusting Screw

D615-W02 May-2003

2-9

Page 32

CHAPTER 2 8354/8404

I. INLET AND EXHAUST V AL VES

The valve and its guide of the inlet are different from

those for the exhaust. Other parts, such as the spring,

spring retainers, valve spring collets, valve stem seals

are the same for both the inlet and the exhaust. All

contact or sliding surfaces are hardened to increase

wear resistance.

J. TIMING GEARS

The crankshaft drives the oil pump and the idle gear

engaged fuel camshaft and camshaft. The timings for

opening and closing the valves is extremely important

to achieve effective air inlet and sufficient gas exhaust.

The appropriate timing can be obtained by aligning the

mark on the crankshaft gear (6) with one the idle gear

(5), idle gear with camshaft gear, idle gear with injection pump gear, when assembling.

615W216A

(1) Valve Spring Collet (4) Valve Stem Seal

(2) Valve Spring Retainer (5) Exhaust Valve

(3) Valve Spring (6) Inlet Valve

K. FLYWHEEL

The flywheel is installed on the rear end of the

crankshaft. Its inertia keeps the flywheel turning at a

constant speed, while the crankshaft tends to speed

up during the power stroke and to slow down during

other stokes. The flywheel has a ring gear (1), which

mesh with the drive pinion of the starter. The flywheel

has also marks “TC” and “FI” on its outer rim. The mark

TC shows the piston’s top dead center and the mark FI

shows the fuel injection timing, when they are aligned

with the mark of window on the clutch housing.

615W217A

(1) Injection Pump Gear (5) Idle Gear

(2) Fuel Camshaft (6) Crankshaft Gear

(3) Camshaft Gear (7) Crankshaft

(4) Camshaft

615W218A

(1) Ring Gear (3) Crankshaft

(2) Flywheel

2-10

D615-W02 May-2003

Page 33

2.2 LUBRICATING SYSTEM

A . FLOW OF LUBRICATING OIL

The lubricating oil is forced to each journal through the

oil passages of the cylinder block, cylinder head and

shafts. The oil, splashed by the crankshaft or thrown

off from the bearings, lubricates other engine parts

such as the push rods (11), tappets (12), camshaft

(14), and crankshaft (15).

ENGINE SYSTEM

B. OIL PUMP

The oil pump is a gear type. Whose rotors have trochoid lobes. The inner rotor (3) has 4 lobes and the

outer rotor (4) has 5 lobes, and they are eccentrically

engaged with each other. The inner rotor, which is driven

by the crankshaft through the gears, rotates the outer

rotor in the same direction, varying the space between

the lobes.

While the rotors rotate from (A) to (B), the space leading to the inlet port increases, which causes the oil to

flow through the inlet port.

When the rotors rotate to (C), the port to which the space

leads is changed from inlet to outlet.

At (D), the space decreases and oil is discharged

through the outlet port.

615W219A

(1) Piston (9) Rocker Arm Shaft

(2) Idle Gear (10) Rocker Arm

(3) Oil Pump (11) Push Rod

(4) Relief Valve (12) Tappet

(5) Strainer (13) Oil Pressure Switch

(6) Oil Filter Element (14) Camshaft

(7) Bypass Valve (15) Crankshaft

(8) Oil Pan

615W220A

(1) Inlet (3) Inner Rotor

(2) Outlet (4) Outer Rotor

D615-W02 May-2003

2-11

Page 34

CHAPTER 2 8354/8404

C. OIL FIL TER AND RELIEF V ALVE

The lubricating oil force-fed by the pump is filtered by

the filter cartridge, passing through the filter element

from the outside to the inside. When the filter element

accumulates dirt and the pressure difference between

the inside and the outside rises more than 98 kPa

(1.0 kgf/cm², 14 psi), the bypass valve (1) opens to

allow the oil to flow from the inlet line to outlet line,

bypassing the filter element. The relief valve ball (4) in

the inlet line allows oil to prevent damage to the lubricating system, when the oil pressure rises more than

441 kPa (4.5 kgf/cm², 64 psi).

615W221A

(1) Bypass Valve

(2) Bypass Adjusting Spring

(3) Filter Element

(4) Relief Valve Ball

(5) Relief Adjusting Spring

(a) To Idle Gear, Camshaft and Rocker Arm

(b) From Oil Pump

(c) To Crankshaft Journal Crankpin

(d) Drain of Relief Valve

D. OIL PRESSURE SWITCH

The oil pressure switch is installed on the cylinder

block and leads to the oil passage of the lubricating

oil. When the oil pressure falls below the specified

value, the contacts of the oil pressure switch closes to

turn on the warning lamp (1).

615W222A

(A) At Lower Oil Pressure

(49 kPa (0.5 kgf/cm², 7 psi) or less)

(B) At Proper Oil Pressure

(1) Warning Lamp (6) Rubber Washer

(2 ) Battery (7 ) Oil Pressure

(3) Contact Movable (8) Cylinder Block

(4) Contact Cup (9 ) Pressure

(5) Diaphragm

2-12

D615-W02 May-2003

Page 35

2.3 COOLING SYSTEM

A. FLOW OF COOLING WATER

The cooling system consists of a radiator (5), a centrifugal water pump (7), a cooling fan (6) and a thermostat (2). The water is cooled as it flows through the

radiator core, and the fan behind the radiator pulls the

cooling air through the radiator core. The water pump

receives water from the radiator or from the cylinder

head and forces it into cylinder block. The thermostat

open or closes according to the water temperature.

When the water temperature is high, the thermostat

opens to allow the water to flow from the cylinder block

to the radiator. When the water temperature is low, the

thermostat closes and the flow stays within the block.

The opening temperature of the thermostat is approx.

71 °C (160 °F).

ENGINE SYSTEM

615W223A

(1) Water Return Pipe

(2) Thermostat

(3) Cylinder Head Water Jacket

(4) Cylinder Block Water Jacket

(5) Radiator

(6) Cooling Fan

(7) Water Pump

B. WA TER PUMP

The water pump is driven with the fan drive pulley, which

is on the water pump shaft and driven by the crankshaft

with a belt. The water pump sucks the cooled water,

forces into the cylinder block and draws out the hot

water to the radiator repeatedly. The mechanical seal

(3) prevents the water from entering the bearing (1).

615W224A

(a) From the Thermostat

(b) To the Cylinder Block

(c) From the Radiator

D615-W02 May-2003

(1) Bearing (3) Mechanical Seal

(2) Pump Body (4) Pump Impeller

2-13

Page 36

CHAPTER 2 8354/8404

C. THERMOSTAT

The thermostat is wax pellet type, which controls the

flow of the cooling water to the radiator to keep the

proper temperature. The case has a seat (1) and the

pellet has a valve (2). The spindle attached to the case

is inserted into the synthetic rubber in the pellet. The

pellet is charged with wax.

(A)At Low Temperature (Lower than 71 °C (160 °F)).

The valve (2) is seated by the spring (7) and the cool-

ing water circulates in the engine through the water

return pipe but does not enter the radiator.

(B)At High Temperature (Higher than 71 °C (160 °F)).

As the water temperature rises, the wax in the pellet (3)

turns liquid and expands, repelling the spindle.

The pellet lowers and the valve (2) opens to send the

cooling water to the radiator.

615W225A

(1) Seat (6) Wax (Solid)

(2) Valve (7) Spring

(3) Pellet (8) Leak Hole

(4) Spindle (9) Wax (Liquid)

(5) Synthetic Rubber

D. RADIATOR

The radiator core consists of water carrying tubes (2)

with fins (3) at a right angle to it. The water in the radiator is cooled by the air flowing through between the

tube wall and the fin.

E. RADIA TOR CAP

The pressure type cap is installed on the radiator, which

prevents the pressure difference between the inside

and the outside of the radiator from deforming the radiator.

(A) At High Pressure

(Higher than 88 kPa (0.9 kgf/cm², 13 psi)

When the water temperature rises and the pressure in

the radiator increases above the specified pressure,

the pressure valve (1) opens to reduce the internal

pressure.

(B) At Low Pressure.

When the water temperature falls and a vacuum is

formed in the radiator, the vacuum valve (2) opens to

allow the water to enter the radiator.

615W226A

(1) Cooling Water (3) Fin

(2) Tube

615W227A

(1) Pressure Valve (2) Vacuum Valve

2-14

D615-W02 May-2003

Page 37

2.4 FUEL SYSTEM

A. FLOW OF FUEL

The fuel is fed from the fuel tank (1) through the fuel

feed pump (7) to the injection pump (3) by the fuel filter

(2). The injection pump force-feds the fuel through the

injection nozzles (5), which inject the fuel into the cylinders for combustion. The excessive fuel from the injection pump to the injection nozzles (5), which inject the

fuel into the cylinders for combustion. The excessive

fuel from the injection pump to the injection nozzles is

collected in the fuel overflow pipes (6) and returns to

the fuel tank.

ENGINE SYSTEM

615W228A

(1) Fuel Tank (5) Injection Nozzle

(2) Fuel Filter (6) Fuel Overflow Pipe

(3) Injection Pump (7 ) Fuel Feed Pump

(4) Injection Pipe

B. FUEL FILTER

The fuel filter removes dirt and water with its fine filter

paper, which collects particles of 90 microns (0.0034 in.)

at 20 kPa (0.2 kgf/cm², 3 psi). The fuel from the fuel

feed pump is filtered by the filter element (6), while

flowing through the filter body (3) has an air vent (2) to

return the air tin the fuel to the fuel tank to prevent the

engine from stopping or running irregularly.

615W229A

(a) To Fuel Tank

(b) From Fuel Feed Pump

(c) To Injection Pump

(1) Cock (4) Retainer Ring

(2) Ai r Vent (5) Pot

(3) Filter Body (6) Filter Element

D615-W02 May-2003

2-15

Page 38

CHAPTER 2 8354/8404

C. FUEL FEED PUMP

The diaphragm (6) is linked to the tappet (3) with the

push rod (2). The tappet is reciprocated by the eccentric cam on the fuel camshaft (7).

(A)Inlet Stroke

When the diaphragm is pulled down by the spring,

vacuum in the chamber (5) causes the outlet valve (4)

to close and the atmospheric pressure in the fuel tank

to force the fuel into the chamber, opening the inlet

valve (1).

(B) Discharge Stroke

When the diaphragm is pushed up by the cam, the

pressure in the chamber causes the inlet valve to close

and forces out the fuel, opening the outlet valve.

615W230A

(a) From Fuel Tank

(b) To Fuel Filter

(1) Inlet Valve (5) Chamber

(2) Push Rod (6) Diaphragm

(3) Tappet (7) Fuel Camshaft

(4) Outlet Valve

D. FUEL INJECTION PUMP

The injection pump is Bosch K type mini injection

pump. It features a compact and light weight design.

615W240A

(a) To Injection Nozzle

(b) From Fuel Filter

(1) Delivery Valve Holder (5) Plunger

(2) Delivery Valve Spring (6) Control Rack

(3) Delivery Valve (7) Plunger Spring

(4) Cylinder (8) Tappet

2-16

D615-W02 May-2003

Page 39

a. Pump Element

The pump element (1) consists of a plunger (3) and

cylinder (2), their sliding surfaces are precision machined to maintain fuel tightness. The plunger (3) fits

in the control sleeve (5) at the driving surface (7). The

sleeve is engaged with the control rack, which rotate

the plunger in the cylinder to control the amount of fuel

delivery.

ENGINE SYSTEM

615W241A

b. Operation of Pump Element

(A)Before Delivery

As the taper lowers, the plunger (2) lowers and fuel is

drawn into the delivery chamber (1) through the feed

hole (4) from the fuel chamber (5).

(B) Beginning of Delivery

When the plunger is pushed up by the cam and the

head of the plunger closes the feed hole (4), the pressure in the delivery chamber (1) rises to push the delivery valve (3) open.

(C)Delivery

While the plunger (2) is rising, delivery of fuel continues.

(D) End of Delivery

When the plunger rises further and the control groove

(6) on its periphery meets the feed hole, the fuel returns to the fuel chamber (5) from the delivery chamber

(1) through the control groove (6) and the feed hole (4).

(1) Pump Element (5) Control Sleeve

(2) Cylinder (6) Control Groove

(3) Plunger (7) Driving Surface

(4) Feed Hole

D615-W02 May-2003

615W242A

(1) Delivery Chamber (4) Feed Hole

(2) Plunger (5) Fuel Chamber

(3) Delivery V alve (6) Control Groove

2-17

Page 40

CHAPTER 2 8354/8404

c. Amount of Fuel Delivery

(A)No Fuel Delivery

At the engine stop position of the control rack (3), the

lengthwise slot (1) on the plunger (2) aligns with the

feed hole (5). The delivery chamber (4) is led to the

feed hole during the entire stroke of the plunger. The

pressure in the delivery chamber does not build up

and no fuel is forced to the injection nozzle.

(B)Fuel Delivery

The plunger is rotated by the control rack and the feed

hole is not aligned with the lengthwise slot. When the

plunger is pushed up, the feed hole is closed by the

plunger. The pressure in the delivery chamber builds

up and forces the fuel to the injection nozzle until the

control groove (6) meets the feed hole. The amount of

the fuel to be forced into the nozzle corresponds to

distance A.

615W243A

d. Delivery Valve

The delivery valve prevents the fuel in the injection pipe

from flowing back into the delivery chamber and the

fuel in the injection nozzle from dribbling after injection.

(1) Slot (4) Delivery Chamber

(2) Plunger (5) Feed Hole

(3) Control Rack (6) Control Groove

2-18

615W244A

(1) Valve Spring (4) Fuel Chamber

(2) Valve (5) V alve Face

(3) Valve Seal (6) Relief Plunger

D615-W02 May-2003

Page 41

E. FUEL INJECTION NOZZLE

The nozzle is a throttle-type one. It features low fuel

consumption and works well with DAEDONG combustion chamber. The nozzle valve opening pressure is

about 13.7 to 14.7 MPa (140 to 150 kgf/cm², 1991 to

2134 psi), the pressure overcomes the counterforce of

nozzle valve spring, and push the valve up instantly, the

fuel is then injected in a proper quantity into the swirling air in the combustion chamber for combustion. Addition or reduction of adjusting can adjust the opening

pressure. A washer of 0.1 mm corresponds to 980 kPa

(10 kgf/cm², 142 psi) change in opening pressure. The

heat seal is employed to improve the durability and

reliability of the nozzle.

ENGINE SYSTEM

615W245A

F. GOVERNOR AND IDLE COMPENSA TING

a. Disassembled View

The governor serves to keep engine speed constant by

automatically adjusting the amount of fuel supplied to

the engine according to changes in the load. The engine employs an all-speed governor which controls

centrifugal force of the steel ball (13) weight, produced

by rotation of the fuel camshaft (9), and tension of the

governor spring 1 (2) and 2 (3) are balanced.

(1) Nozzle Holder Ass’y (6) Nozzle Body

(2) Adjusting Washer (7) Needle Valve

(3) Nozzle Spring ( 8) Heat Seal

(4) Push Rod (9) Packing

(5) Retaining Nut

615W246A

(1) Start Spring (8) Governor Lever

(2) Governor Spring 1 (9) Fuel Camshaft

(3) Governor Spring 2 (10) Governor Ball Case

(4) Fork Lever 1 (11) Steel Ball

(5) Fork Lever 2 (12) Governor Sleeve

(6) Fork Lever Shaft (13) Steel Ball

(7) Fork Lever Holder

D615-W02 May-2003

2-19

Page 42

CHAPTER 2 8354/8404

b. Operation of Governor

1) At start

The steel ball (13) has no centrifugal force. As the fork

lever 1 (4) is pulled by the start spring (1), the control

rack (14) moves to the maximum injection position. At

start, the sufficient injection of the fuel enables easy

starting.

615W247A

2) At idling

At the idling position of the speed control lever (15), the

governor spring 1 (2) is free and the governor spring 2

(3) does only act slightly. The governor sleeve (12) is

pushed leftward by a centrifugal force of steel ball (13).

Therefore, the fork lever 1 (4) and control rack (14) are

moved to the left by the governor sleeve (12) and then

the idling adjusting spring (16) is compressed by the

control rack (14). As a result, the control rack is kept at

a position here a centrifugal force of steel ball (13) and

forces start spring (1), governor spring 2 (3) and idling

limit spring are balanced, providing stable idling.

IMPORTANT:

• The idling speed has been factory-set. The idling

adjusting screw (20) and spring (16) should not be

disassembled and readjusted.

17

16

4

3

(1) Start Spring

(2) Governor Spring 1

(3) Governor Spring 2

(4) Fork Lever 1

(12) Governor Sleeve

(13) Steel Ball

(14) Control Rack

(15) Speed Control Lever

(16) Idle Adjusting Spring

(17) Idle Adjusting Screw

14

15

2

1

12

13

615W248A

2-20

D615-W02 May-2003

Page 43

3) At high speed running with overload

When an overload is applied to the engine running at a

high speed, the centrifugal force of steel ball (13) becomes small as the engine speed is dropped, and fork

lever 2 (5) is pulled to the right by the governor spring 1

(2) and 2 (3), increasing fuel injection. Though, fork

lever 2 becomes ineffective in increasing fuel injection

when it is stopped by the adjusting bolt (17). After that,

when the force of torque spring (18) becomes greater

than the centrifugal force of the steel ball, fork lever 1

(4) moves rightward to increase fuel injection, causing

the engine to run continuously at a high torque.

4) To stop engine

When the stop lever (19) is moved to the STOP position,

fork lever 1 (4) is moved leftward and the control rack

(14) is moved to the non-injection position, stopping

the engine.

ENGINE SYSTEM

615W249A

(2) Governor Spring 1 (13) Steel Ball

(3) Governor Spring 2 (17) Adjusting Bolt

(4) Fork Lever 1 (18) Torque Spring

(5) Fork Lever 2

D615-W02 May-2003

615W250A

(4) Fork Lever 1 (19) Stop Lever

(14) Control Rack

2-21

Page 44

CHAPTER 2 8354/8404

A . FLOW OF INT AKE AIR AND EXHAUST GAS

(a) Intake Air

(b) Exhaust Gas

(1) Intake Manifold

(2) Air Cleaner

(3) Cylinder Head

(4) Muffler

(5) Exhaust Manifold

B. AIR CLEANER

The air cleaner is dry-cyclone type and easy to maintain.

The air from the inlet port (2) circulates along the fin (3)

and around the air cleaner element (4) and the heavier

dust is carried to the evacuator (6), to the dust exhaust

port. The fine dust in the air is filtered with the air cleaner

element (4), and the filtered air flows to the outlet port

(1).

615W251A

C. MUFFLER

The exhaust noises are absorbed, while the gases are

passed through a series of holes on the inner tube

and glass wool of the muffler.

615W252A

(a) Inlet Air

(b) To Intake Manifold

(c) Heavier Dust

(1) Outlet Port (4) Air Cleaner Element

(2) Inlet Port (5) Body

(3) Fi n (6) Evacuator

615W253A

2-22

D615-W02 May-2003

Page 45

3. DISASSEMBLING AND SERVICING

3.1 TROUBLESHOOTING

ENGINE SYSTEM

Symptom Probable Cause

Engine Does Not Start

(Starter Does Not Run)

Engine Revolution is Not Smooth

• Not fuel

• Air in the fuel system

• Water in the fuel system

• Fuel pipe clogged

• Fuel filter clogged

• Excessively high viscosity of fuel

or engine oil at low temperature

• Fuel with low cetane number

• Fuel leak due to loose injection

pipe retaining nut

• Incorrect injection timing

• Fuel camshaft worn

• Injection nozzle clogged

• Injection pump malfunctioning

• Fuel transfer pump

malfunctioning

• Seizure of transfer pump