Page 1

Operator’s Manual

S

ERIES

8000

COMPACT TRACTOR

MODEL 8404

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com ]

PRINTED IN U.S.A. FORM NO. 769-00707

ECO

(03/03)

Page 2

TABLE OF CONTENTS

TO THE OWNER .................. ...... ....... ...... ....... ...... ....... ............................................. ...... ...... .. 2

CALLING SERVICE INFORMATION ...................................................................................... 2

RECORDING MODEL AND SERIAL NUMBER INFORMATION ........................................... 3

IMPORTANT SAFE OPERATION PRACTICES ..................................................................... 4

SAFETY LABELS ................................................................................................................. 10

SECTION 1: CONTROLS AND FEATURES ........................................................................ 12

SECTION 2: OPERATION .................................................................................................... 20

SECTION 3: ADJUSTMENTS .............................................................................................. 30

SECTION 4: TRACTOR MAINTENANCE ............................................................................ 34

SECTION 5: TROUBLESHOOTING ..................................................................................... 50

SECTION 6: SPECIFICATIONS ........................................................................................... 54

WARRANTY ......................................................................................................................... 56

TO THE OWNER

This Operator’s Manual is an important part of your new tractor. The information contained in this

manual has been prepared in detail to help you better understand the features, correct operation,

adjustments, and mainten ance of your tractor. The performance and dep endability of this tr actor rely

greatly on the manner in which it is operated and maintained. Theref ore, it is recommended that all

operators of the tracto r carefully read this manua l and fully understand its ope ration. Also keep the

manual available for reference to ensure proper operation, and that maintenance procedures are

performed as scheduled to assure the tractor’s optimal mechanical condition.

NOTE: All references to LEFT, RIGHT, FRONT, and REAR, unless specifically stated otherwise,

indicate that relative position on the tractor when facing forward while seated in the operator’s seat.

Your authorized Cub C adet dea ler is i ntere sted in the perfo rmance y ou re ceiv e from yo ur tr actor, an d

with the maintenance needed to ensure the satisfactory operation of your tractor. The dealer has

trained service personnel familiar with the latest servicing information, is equipped with the latest

tools, and has a comple te line of genuine Cub Cadet s ervice parts which a ssure proper fit and hig h

quality.

CALLING SERVICE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance,

power-rating, and specifications.

If you have difficulties with the tractor and/or eq uipment; have any q uestions regarding th e operation

or maintenance of t his equipment; or desire addi tional information not fou nd in this manual, contact

your dealer. If you need assistance in locat ing a dealer in your area, contact the Customer Dealer

Referral Line by calling:

1-877-282-8684

Before calling your deal er, make sure that you have y our model number(s) and manufa cturing date

available for the dealer.

2

Page 3

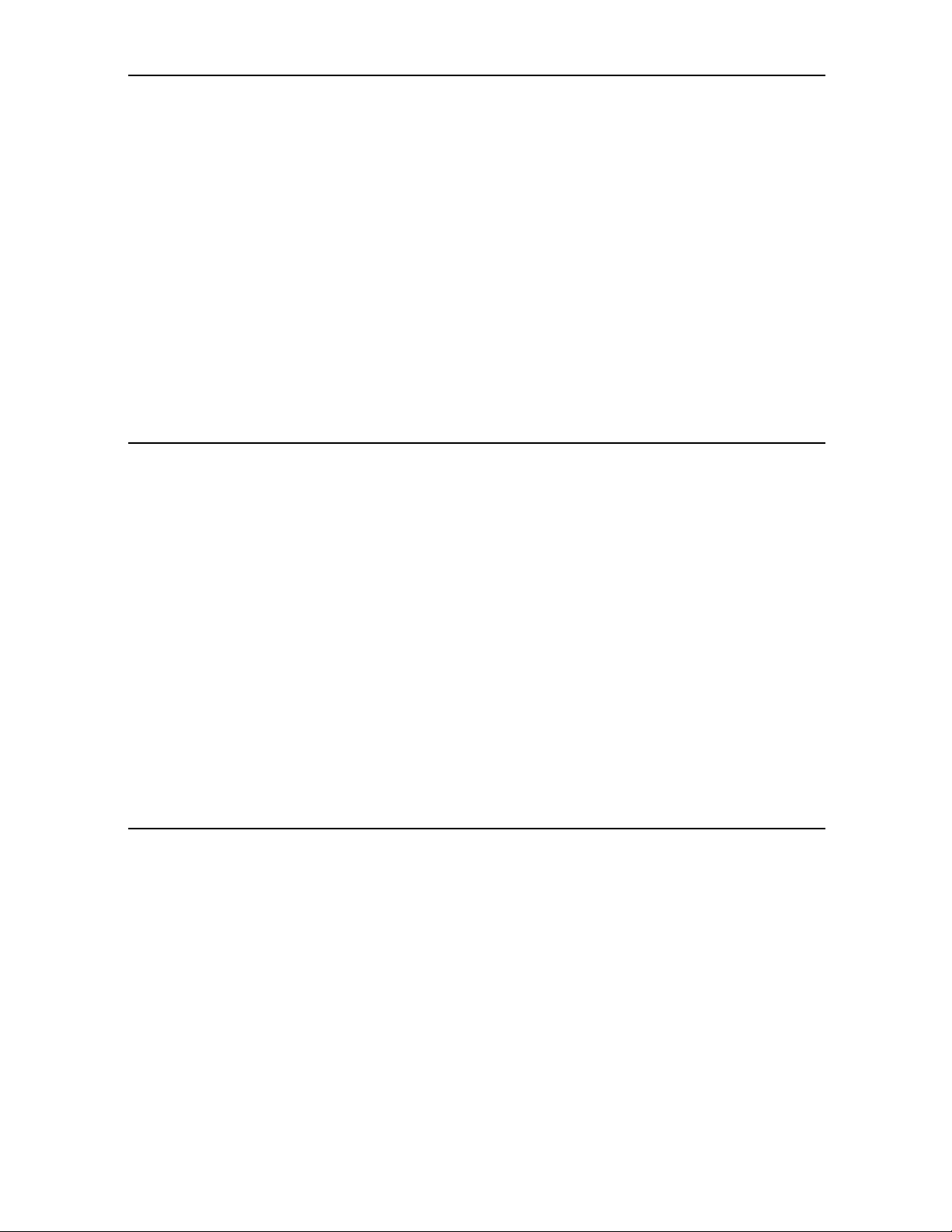

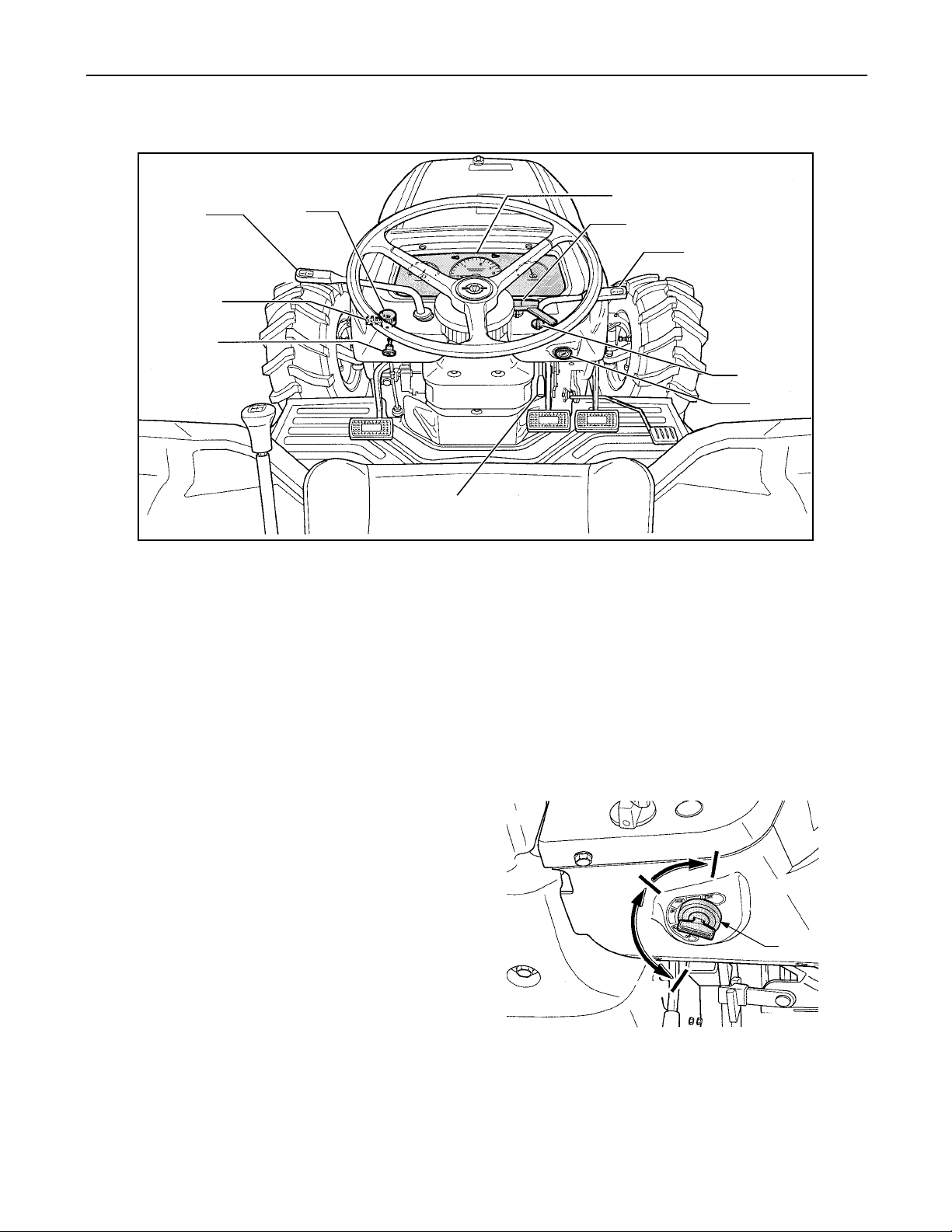

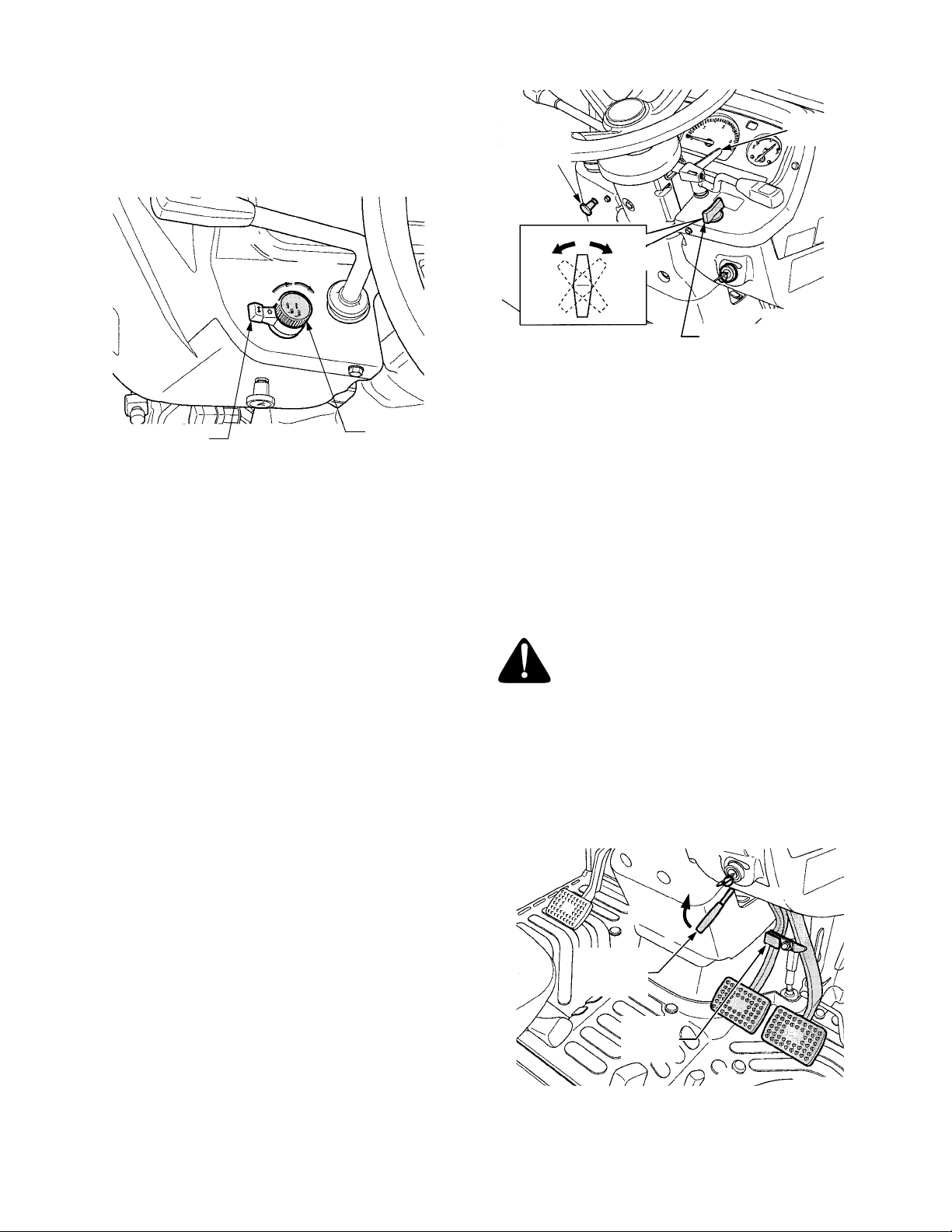

RECORDING MODEL AND SERIAL NUMBER INFORMATION

Product identification plates are provided for major components of your tractor. The numbers on these

plates are importa nt if your tractor sh ould requi re deale r servi ce, or if you need a dditional in formatio n

on your tractor. Prior to usin g your tracto r for the fir st time, r ecord the nu mbers from the ident ificatio n

plates in the appropriate spaces provided below.

• The tractor model plate is located on the transmission housing on the left side of the tractor.

• The engine serial number is located on the right side of the engine crankcase.

• The transmission serial num ber is located on the left side of the transmission case nea r the left

brake case.

• The ROPS information plate is located on the ROPS.

Tractor Model Plate:

Model Number Serial Number

Engine Information:

Engine Serial No.

Transmission Information:

Transmission Serial No.

ROPS Information:

TRACTOR

MODEL

PLATE

ROPS Serial No.

TRANSMISSION

SERIAL NO.

ENGINE

SERIAL NO.

3

Page 4

IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL,

HEED ITS WARNING.

WARNING:

contain or emit che micals known to the State o f California to cause can cer, birth defects or other

reproductive harm.

WARNING:

or near any unimproved for est-covered, brush-covered or grass-co vered land unless the engine’s

exhaust system is eq uipped with a spark a rrester meeti ng applic able local o r state law s (if any). If a

spark arrester is used, it should be maintained in effective working order by the operator. In the

State of California the above is required by law (Section 4442 of the California Pub lic Resources

Code). Other states m ay hav e sim il ar la ws. F ede ra l la ws app ly on f ede ra l l and s. A spar k arr est er for

the muffler is available throug h your neares t engine authoriz ed service d ealer or contact the service

department, P.O. Box 361131Cleveland, Ohio 44136-0019.

DANGER:

manual. As with any ty pe of power equip ment, car elessn ess or er ror o n the p art of the op erator can

result in serio us injury. To help preven t accidents, read and take the following precautions before

operating this tractor. Failure to observe the following safety instructions could result in serious

injury or death.

The engine exhaust, some of its constituents, and certain vehicle components

This unit is equip ped with an inter nal combustion engine and should not be u sed on

Your tractor wa s built to be operated accordi ng to the rules for safe op eration in this

1. GENERAL OPERATION

• Read, understand, and follow all instructions i n

the operator’s manual and on the machine

before starting. Keep this manual in a safe

place for future and regular reference.

• Use the handholds and step plates when

getting on and off the tractor to help prevent

accidental falls. Keep the steps and running

boards clear of mud and debris.

• Before driving the tractor in reverse, check to

see that there are no people or obstacles

around.

• Only allow responsi ble individuals familiar with

the instructions to operate the machine. Know

controls and how to stop the machine quickly .

• Pay special attention to the warning and

caution labels affixed to the tractor.

• Keep all safety decals clean and readable.

Replace any missing, illegible, or damaged

safety decals.

• Watch where you are going at all times. Watch

for and avoid all obstacles. Be alert at row

ends, near trees and other obstructions.

4

Page 5

• Never operate the machine while under the

influence of alcohol or drugs, or while fatigued.

• When working in cooperation with others, let

them know in advance what you are doing.

• Always sit in the tractor seat when starti ng the

engine or operating controls. Do not start the

engine or operate controls while standing

beside the tractor.

• Do not allow anyone but the operato r to ride o n

the tractor unless a passenger seat is fitted.

Keep bystanders away from the tractor during

operation.

• Never leave a running machine unattended.

Always engage the pa rking brake, lower implements to the ground, stop the engine and

remove the key before dismounting.

• Do not modify or alter, o r permit an yone else t o

modify or alter, any tractor components or any

tractor functions.

• Before starting the engine, sit in the seat,

disengage the clutch, and place the shift leve rs

in the neutral position.

• Use the ROPS (Roll O ver Protective Structure)

and seat belt for safe operation. Overturning

the tractor without a ROPS, or with a ROPS

and the seat belt unfastened, can result in

injury or death.

• Always use the seat belt when the tractor is

equipped with a ROP S. Never us the seat belt

when the tractor is not equipped with a ROPS.

• Whenever possible, adjust the rear wheels to

their maximum tread width to improve stability

of the tractor during operation.

• Engage the parking brake, place the position

control lever in the down position, and place the

transmission levers in neutral before starting

the tractor.

• Avoid accidental contact with control pedals

while the engine is runni ng, as this can cause

unexpected movement of the tractor.

• Shut off the engine and PTO, and engage the

parking brake before getting off the tractor.

5

Page 6

• Never try to get on or off a moving tractor.

• Never park the tractor on a steep incline.

• Do not run the engine in an enclosed building

without adequate ventilation. Exhaust fumes

can cause death.

• Use the 3-point hitch only with equipment

designed for 3-point hitch usage.

• Do not operate near embankments, ditches,

holes, or other terrain features which may collapse under the tractor’s weight. The tractor

could suddenly turn over if a wheel goes over

the edge of a cliff or ditch, or if an edge caves in.

• Driving forward out of a ditch or mired condition, or up a steep slope, inc reases the risk of

the tractor flipping ov er backward. Use reverse

to free the tractor in these situations.

• Check overhead clearance carefully before

driving under power lines, wi res, bridges or low

hanging tree branches, before entering or

leaving buildings, or in any other situation

where the operator and/or roll bar may be

struck, which could result in serious injury.

• Pull only from the drawbar. Make certain the

drawbar pin is locked i n place. Pulling from th e

rear axle of the t ra ctor or any point above the

axle could cause the tractor to overturn.

• Maintain the weight balance of the tractor.

Install front end weights to counterbalance

heavy implements attached to the three point

hitch. Do not operate the tractor with a light

front end.

• Check all connections, and tigh ten if necessary,

before starting the engine or pressurizing lines.

• Do not leave equipment in the raised position

when the vehicle is stopped or unattended.

• Use only accessories approved for this

machine by the manufacturer. Read, understand and follow all instructions provided with

the approved access ory. Know your equipment

and its limitations.

• Remember that your tractor , if abused or incorrectly used, can be dangerous and become a

hazard both to the op erator and to bystanders.

Do not overload, or operate with attached

equipment which is unsafe, not designed for

the particular task, or is poorly maintained.

• Lock the brake pedals t ogether when traveling

at road speeds. Brake both wheels simultaneously when making an emergency stop.

Uneven braking at road speeds could cause

the tractor to tip over.

• Watch for traffic when operating near or

crossing roadways. If local laws permit road

travel, use the h ead li ghts, flashing hazard li ghts

and SMV signs when traveling on public

roadways.

• Do not engage the differential lock while

traveling at road speeds. Difficulty steering

could cause you to lose control of the tractor.

• Avoid sudden motions of t he steering wheel as

they can lead to a dangerous loss of stability.

The risk is especia lly great when the tractor is

traveling at road speeds.

6

Page 7

• Always slow the tractor down before turning.

Turning at high speed may tip the tractor over.

• To avoid upsets, drive the tractor with care and

at a safe speed. Use extra caution when

operating over rough ground, when crossing

ditches or slopes, and when turning corners.

• Wear sturdy work shoes. Never operate the

tractor in bare fe et , sand als, o r sne akers.

• Do not wear loose fitting clothes or jewelry.

They can be caught in moving parts.

• When towing equipment, u se safety c hains and

place an SMV emblem on the equipment.

• Any towed vehicle with a tota l wei ght exceeding

that of the tractor should be equipped with its

own braking system that is oper ational from th e

tractor seat.

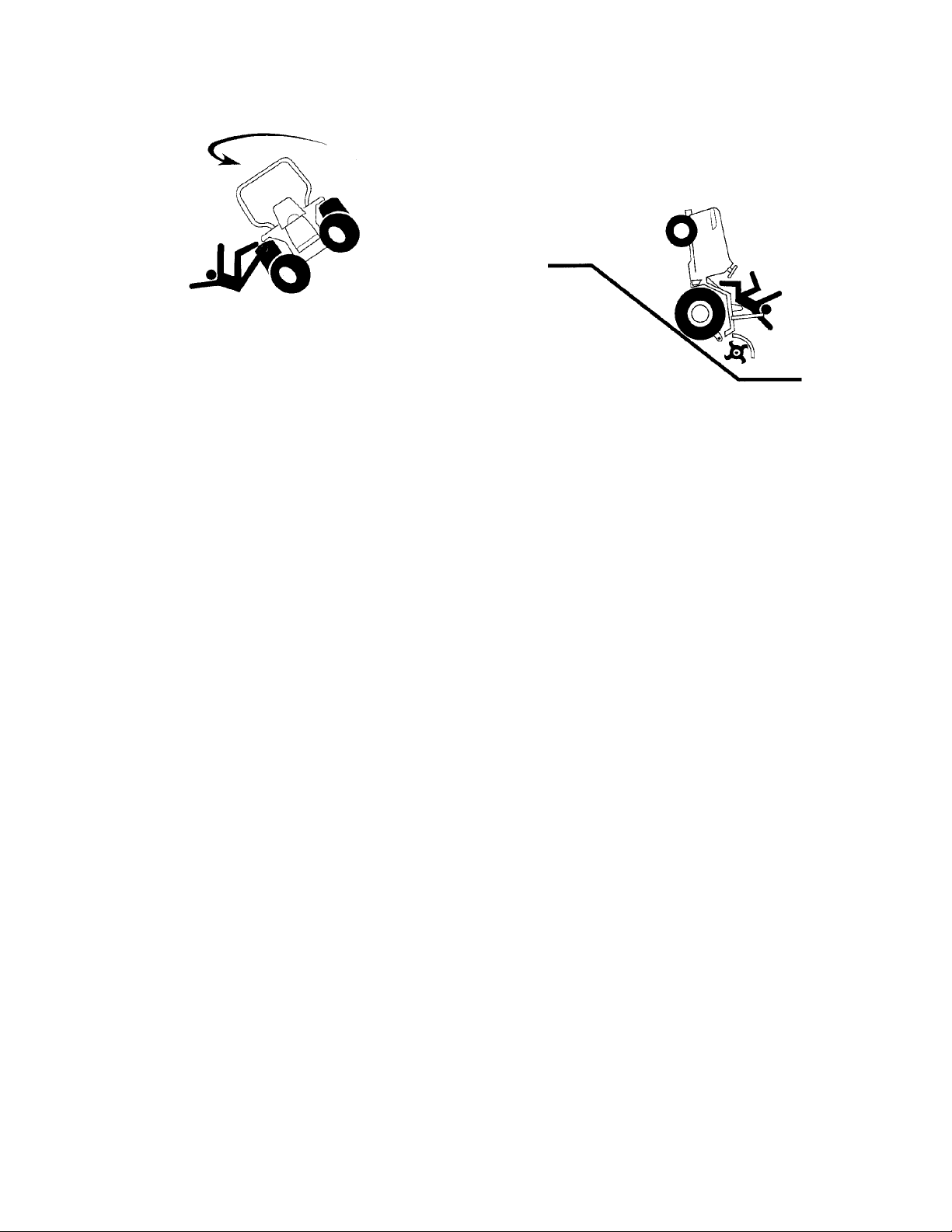

2. SLOPE OPERATION

Slopes are a major factor rel ated to loss of control

and tip-over accidents which can result in severe

injury or death. All slopes require extra caution. If

you cannot back up the slope or if you feel uneasy

on it, do not operate this unit on tha t area or serious

injury could result.

DO:

• Operate up and down slopes, not across.

• Remove obstacles such as rocks, limbs, etc.

• Watch for holes, rut s or bumps. Uneven terrain

could overturn the m achin e. Tall g rass can h ide

such obstacles.

• Place the transmission in the low range. when

climbing or descending slopes. Always keep

machine in gear when going down slopes to

take advantage of engine braking action.

• Follow the manufacturers rec ommendations for

counterweights to improve stability.

• Keep all movement on the slopes slow and

gradual. Do not make sudden changes in

speed or direction. Rapid engagement or

braking could cause the front of the mac hine to

lift and rapidly flip ov er backwards which could

cause serious injury.

• Avoid starting or stopping on a slope. If tires

lose traction, disen gage the PTO and proceed

slowly straight down the slope.

DO NOT:

• Do not turn on slopes unles s necessary; then,

turn slowly and gradually downhill, if possible.

• Never "free-wheel". Disengaging the clutch or

shifting into neutral while descending a slope

could lead to a loss of control.

3. CHILDREN

• Tragic accidents ca n occu r if the oper ator is no t

alert to the presence of children. Children are

often attracted to the machine. Never assume

children will remain where you last saw them.

• Keep children out of the operating area and in

watchful care of an adult other than the

operator.

• Be alert and turn machine off if children enter

the area.

• Before and when backing, look behind and

down for small children.

• Never carry children. They ma y fall off and be

seriously injured or interfere with safe machine

operation.

• Never allow children to operate the machine.

• Use extra care when approaching blind corners, shrubs, trees or other objects that may

obscure your vision of a child or other hazard.

• Remove key when machine is unattended to

prevent unauthorized operation.

7

Page 8

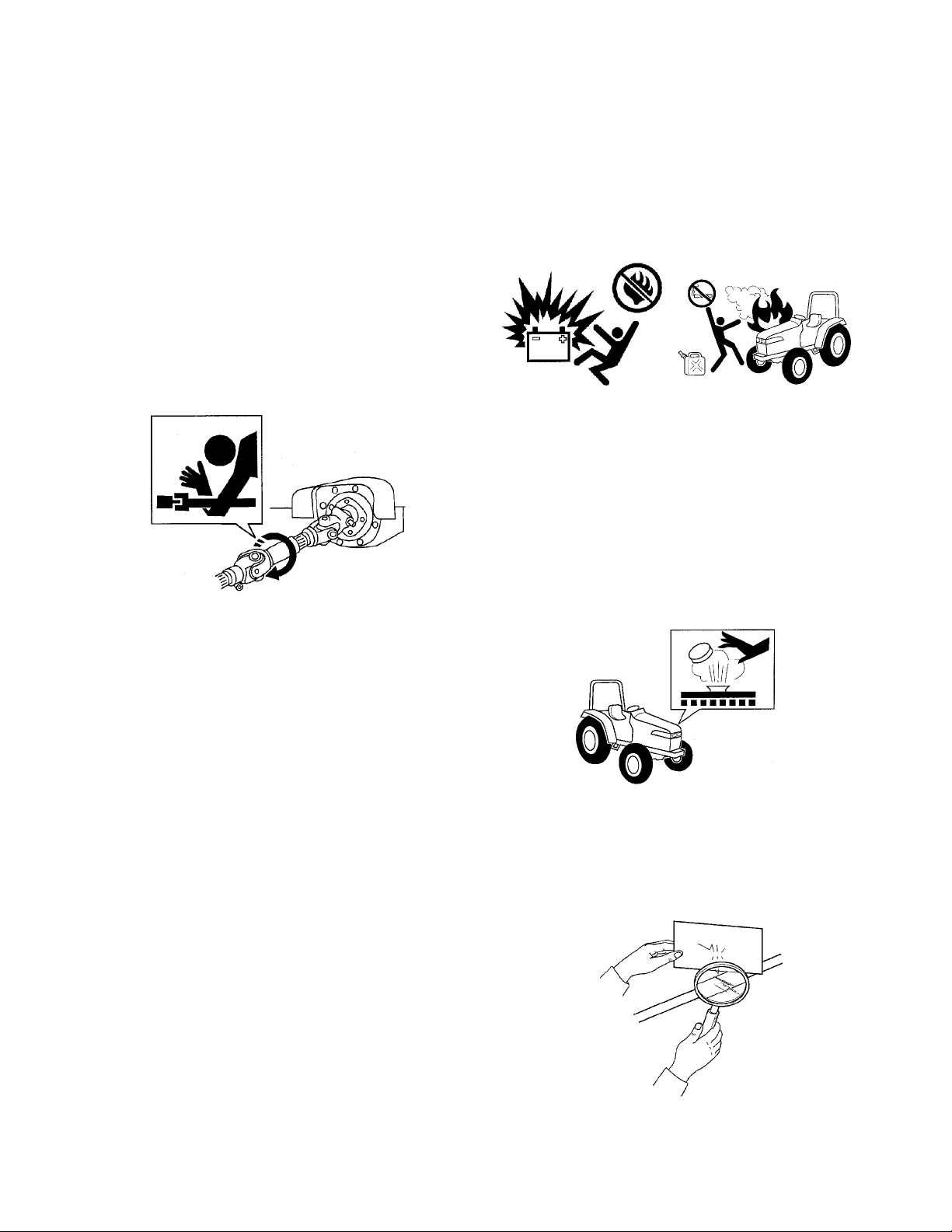

4. OPERATING THE PTO

• Disengage the PTO, stop the engine, and wait

until all moving components have completely

stopped before dismounting the tractor and

connecting, disconnecting, adjusting, cleaning,

or servicing any PTO driven equipment.

• Do not wear loose fitting clothing when

operating the PTO or when near rotating

equipment.

• Keep the PTO shaft co ver in place at all times .

Replace the PTO shaft cap when the shaft is

not in use.

• When operating stationary PTO driven equipment, always apply the tractor parking brake

and place chocks behind and in front of the rear

wheels. Stay clear of all rotating parts.

• Replace fuel cap securely and wipe off any

spilled fuel before st arting the engine as it may

cause a fire or explosion.

• Do not smoke w hen wo rking around the b attery

or when refueling. K eep all sparks and flames

away from the battery and fuel tank. The

battery presents an explosive hazard because

it gives off hydrogen and oxygen... especially

when recharging.

• Never store the fuel container or machine

inside where there is an open flame or spark,

such as a gas hot water heater, space heater

or furnace.

• The cooling system is under pressure. Never

remove the radiator cap when the system is

hot. Slowly turn the cap the to the fi rst stop to

release pressure before removing the cap. If

the tractor has a coolant recovery tank, add

coolant there instead of to the radiator.

5. SAFETY FRAME (ROPS)

Your tractor is equipped with a rollover protective

structure (ROPS) which must be maintained in a

fully functional condition. Use care when driving

through doorways or spaces with a low overhead.

• Never modify the ROPS in any way.

• Never attempt to straig hten or reweld any part

of the main frame or retaining brackets that

have been damaged. Doing so may weaken

the structure and endanger your safety.

• Never secure any parts on the main frame or

attach the safety frame wi th a ny thing othe r tha n

the special fasteners specified.

• Never attach ropes, chains, or cables to the

ROPS for pulling purposes.

• Although the ROPS provides you the maximum

protection possible, never take unnece ssary risks.

6. SERVICE

• Use extreme care in handling fuels. They are

extremely flammable and the vapors are

explosive. Use only an approved container.

• Never remove fuel cap or add fuel with the

engine running.

• Escaping hydraulic fluid under pressure can

penetrate the skin. If fluid is injected into the

skin, seek immedia te medical attention. Do no t

use your hand to check for lea ks. Use a piece

of cardboard or paper.

8

Page 9

• Engine components become hot during

operation and can caus e a burn. Allow to cool

down before touching.

• Before "jump starting " a dead batter y, read and

follow all of the instructions.

• Do not attempt to mount a tire on the rim. This

should be done by a qualified person with

proper equipment.

• Always maintain the correct tire pressure. Do

not inflate tires above the recommended

pressure shown in the operator’s manual.

• Securely support the tractor when changing

wheels or the wheel tread width.

• Make sure that wheel bolts have been

tightened to the specified torque.

• To avoid sparks from arcing, always disconnect the battery’s negative cable first and

connect it last.

• Disconnect negative cable from battery before

working on or near electrical components.

• To reduce fire hazard, keep the tractor free of

any debris build-up. Clean up oil or fuel spillage.

• Before cleaning, repairing or inspecting, make

certain all moving parts have stopped. Keep all

nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

• Never tamper w ith safety devi ces. Check their

proper operation regularly.

• Check brake operation frequently. Adjust and

service as required.

• Observe proper di sposal laws and regulations.

Improper disposal of fluids and materials can

harm the environment and the ecology.

• Prior to disposal, determi ne the proper method

to dispose of waste from your local

Environmental Protection Agency. Recycling

centers are established to properly dispose of

materials in an environmentally safe fashion.

• Use proper contai ners when drainin g fluids. Do

not use food or beverage containers that may

mislead someone into drinking from them.

Properly dispose of the conta iners immediately

following the draining of fluids.

• DO NOT pour oil or oth er fl ui ds into th e g r ound ,

down a drain or into a stream, pond, lake or

other body of water. Observe Environmental

Protection Agency regulations when disposing

of oil, fuel, coolant, brak e fluid, filters, b atteries,

tires and other harmful waste.

• We do not recommend the use of a pressure

washer or garden hose to cl ean your unit. T hey

may cause damage to electrical components;

spindles; pulleys ; bearings; or the engine. The

use of water will result in shortened life and

reduce serviceabi li ty.

WARNING:

read, understand and follow the warnings and instructions in this manual and on the machine.

- YOUR RESPONSIBILITY:

Restrict the use of this power machine to persons who

9

Page 10

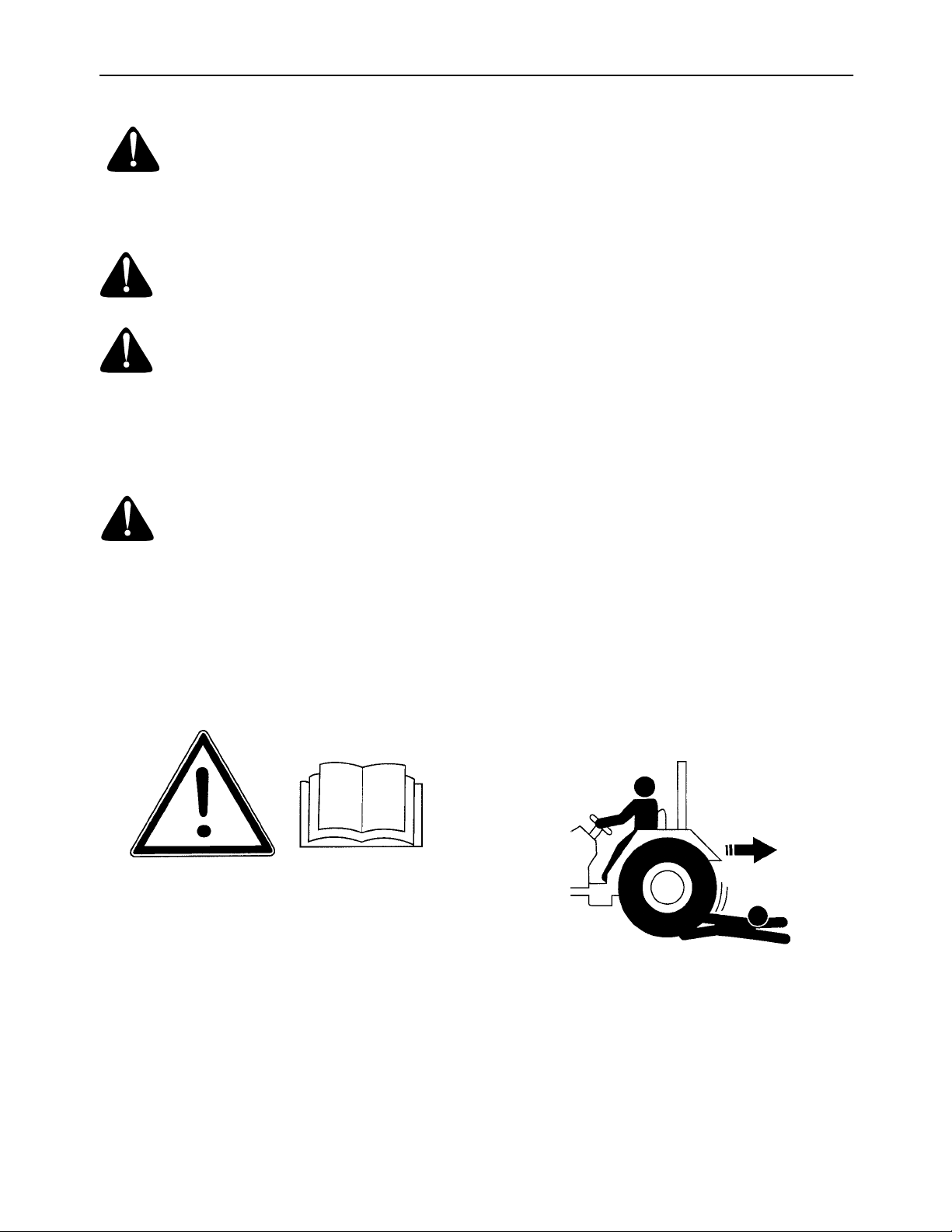

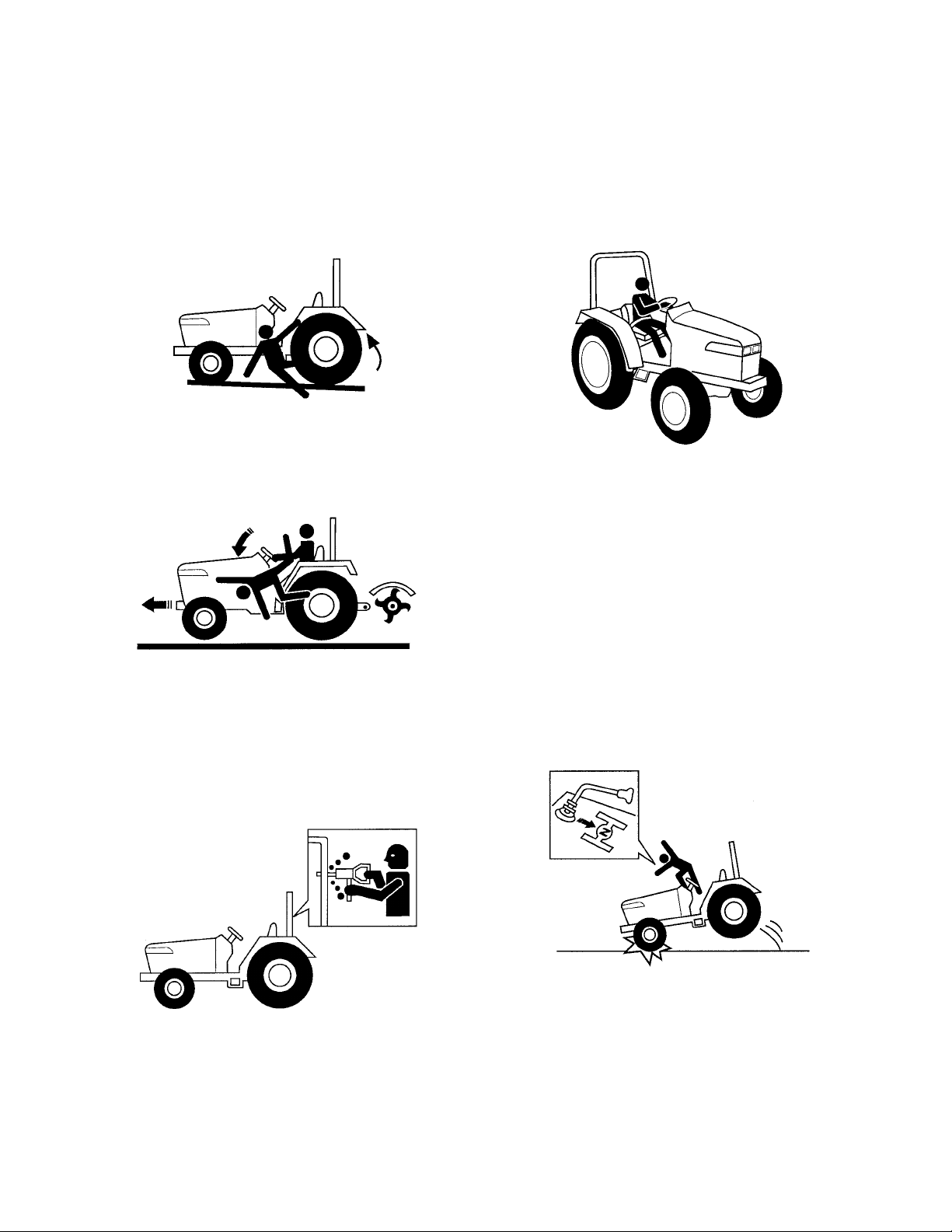

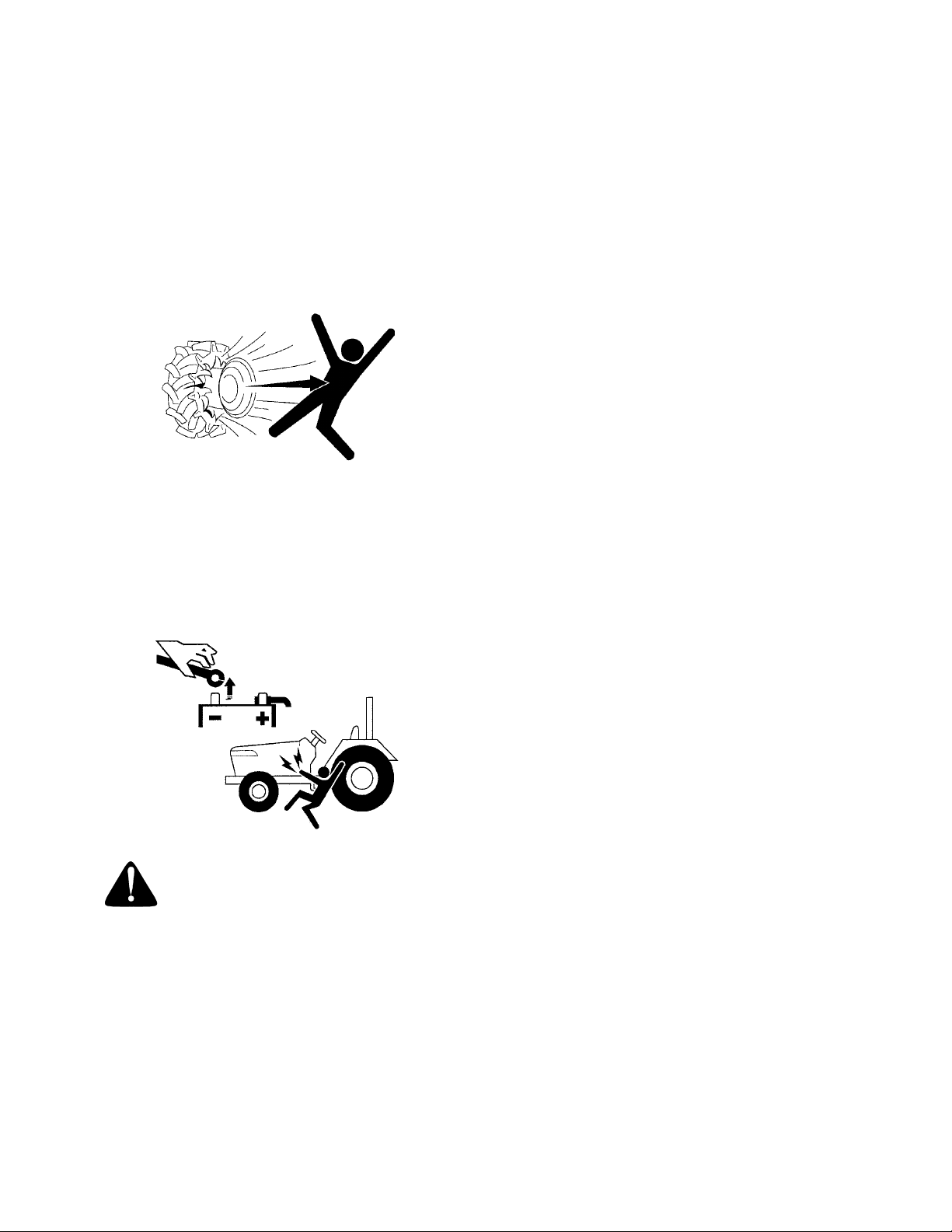

SAFETY LABELS

4

1. DD-T2325-50512

1

7

6

5

2

3

3. DD-T2325-50724

2. DD-T2325-50743

4. DD-T2241-50702

10

Page 11

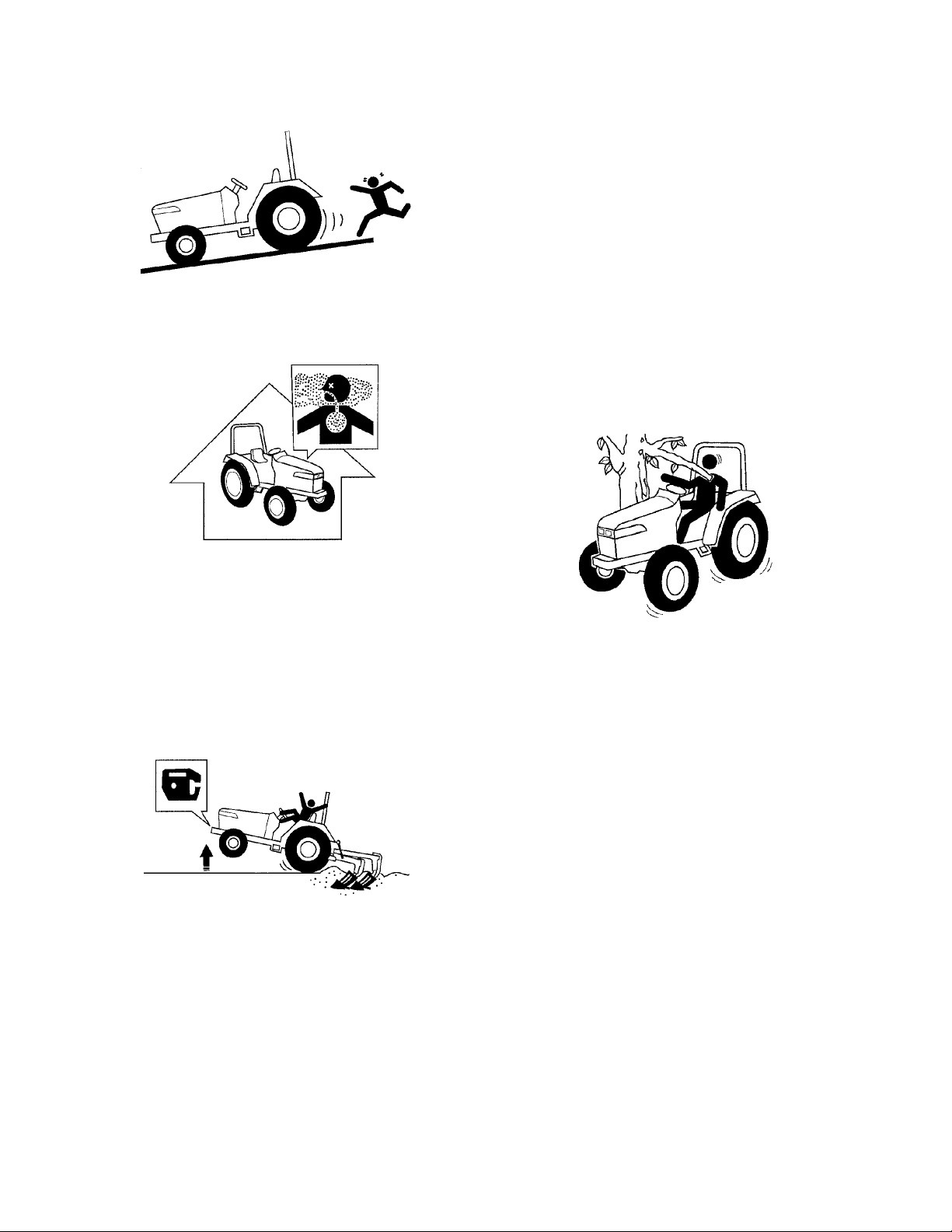

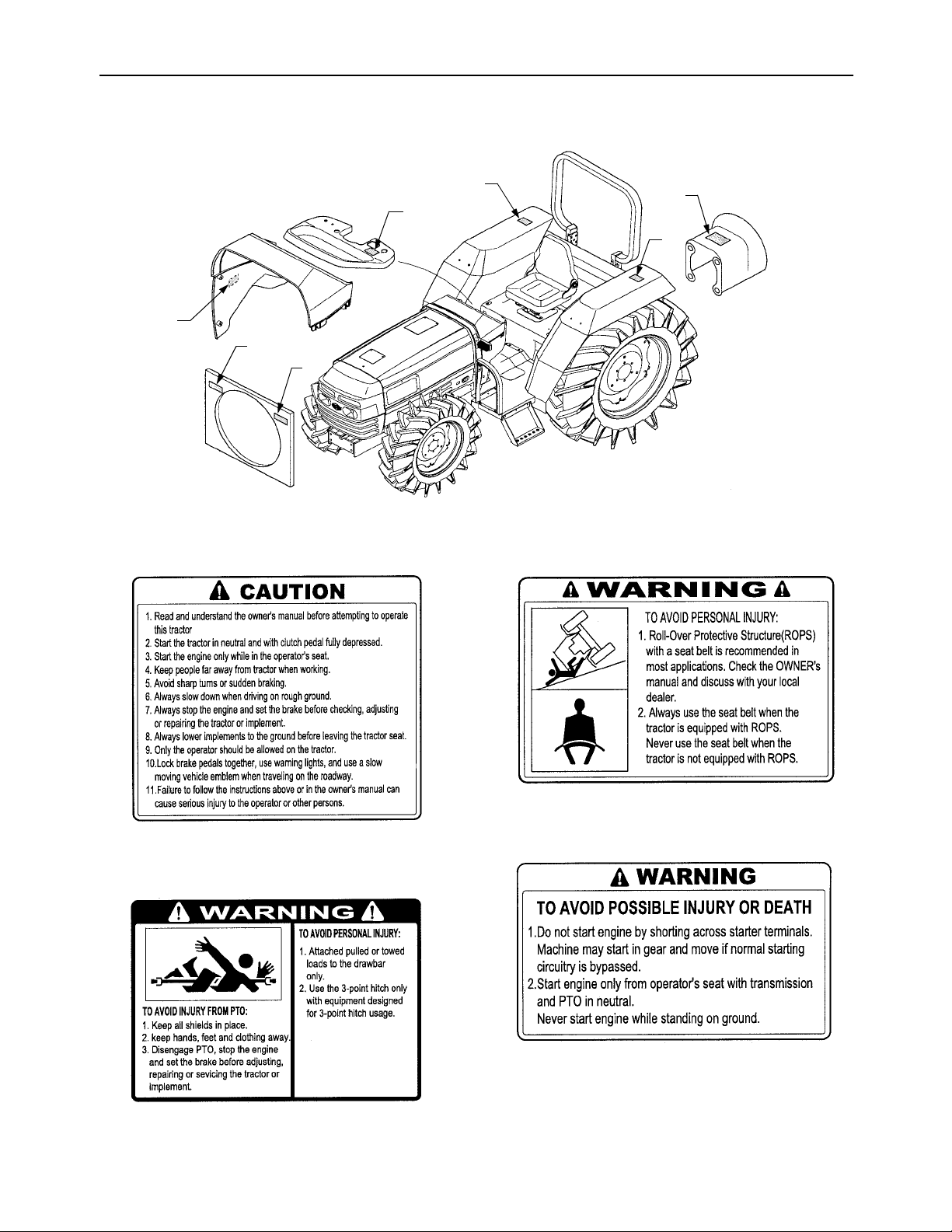

SAFETY LABELS (Cont.)

5. DD-T4625-52361

6. DD-T4625-52351

7. DD-T4625-53191

11

Page 12

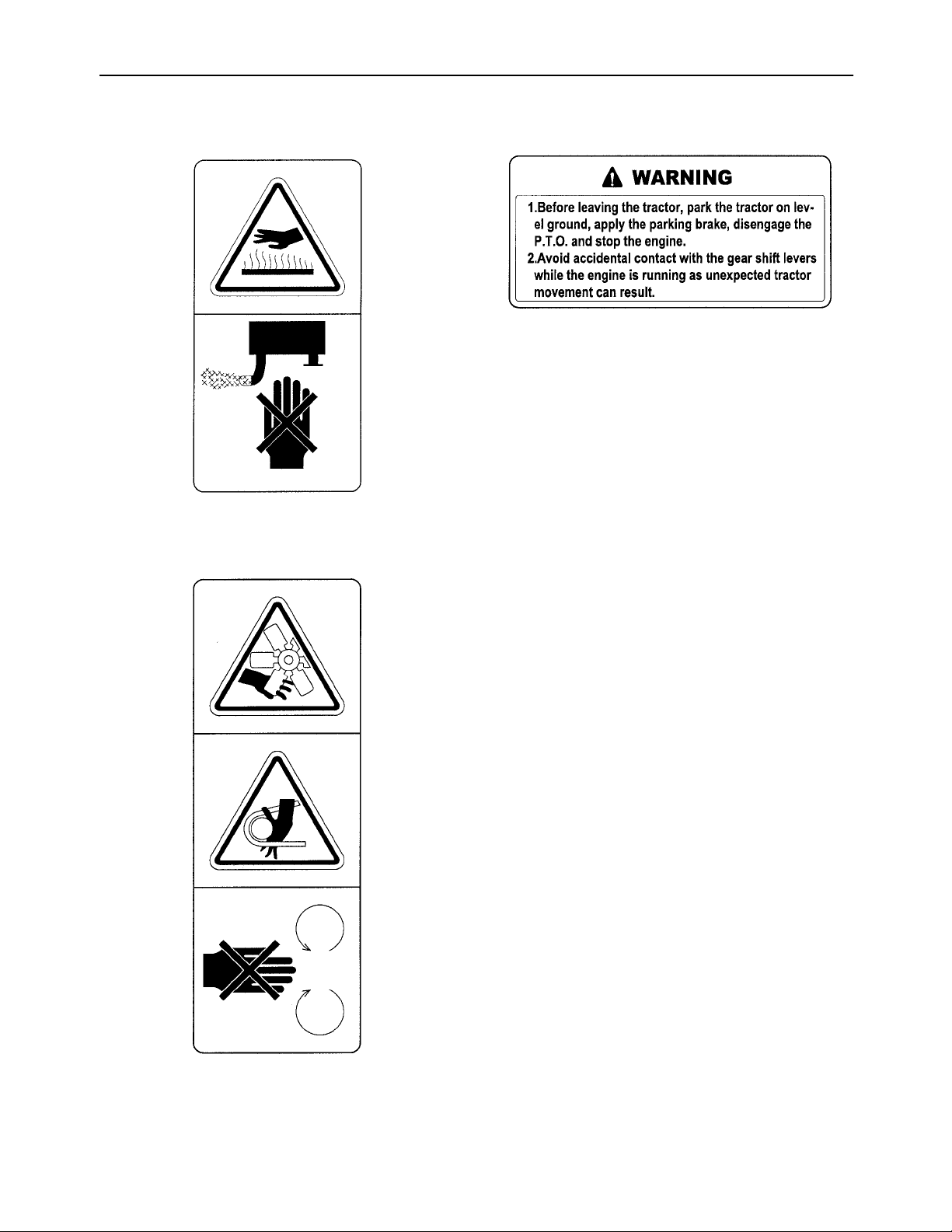

SECTION 1: CONTROLS AND FEATURES

SWITCHES AND DASH MOUNTED CONTROLS

H

C

D

B

G

J

F

I

E

A

Ignition Switch

A.

Light Switch

B.

Turn Signal Switch

C.

Hazard Lamp Switch

D.

PTO Switch

E.

A. Ignition Switch

NOTE: To prevent accidental starting and/or battery

discharge, remove the key from the ignition switch

when the tractor is not in use.

The ignition switch has four positions turning

clockwise as follows (Refer to Figure 2):

OFF - The engine and electrical system is turned off.

ACC - Energizes the accessory circuit.

ON/HEAT - Energizes the tractor’s electrical system.

Warning lamps on the instrument panel are

momentarily illuminating to test the system. Engine

glowplugs are also energized to preheat the

combustion chamber.

START - Activates the starte r motor to turn over and

start the engine. When the en gine starts release the

key immediately and it will return to the ON position.

Figure 1

NOTE: The s afety circuit will pre vent the starter from

turning if the clutch pedal is not depressed.

F.

Steering Tilt Lock Lever

G.

Parking Brake Lever

H.

Forward/Reverse Shift Leve r

I.

Hand Throttle Lever

J.

Instrument Panel

On/Heat

Start

IGNITION

SWITCH

Off

Figure 2

12

Page 13

B. Light Switch

Turn the light switch one click clockwise to illuminate

the low beam headlights and the taillights.

Turn the light switch one more click clockwise to

illuminate the high beam headlights. See Figure 3.

Low

Beam

High

Beam

HAZARD

LAMP

SWITCH

Auto.

TILT LOCK

LEVER

Off

Manual

PTO SWITCH

Figure 4

TURN SIGNAL

SWITCH

LIGHT

SWITCH

Figure 3

C. Turn Sign al Sw itch

Use the switch lever to activate one of the rear ambe r

lights and haza rd lights in a blinki ng mode to i ndicate

a turn in that direction. Refer to Figure 3.

Lever downward — Left light flashes

Lever upward — Right light flashes

D. Hazard Lamp Switch

Use to turn on the tw o a mbe r haz ar d lig hts lo ca ted on

top of the rear fender in the flashing mode. Refer to

Figure 4.

• Pull the switch outward to activate amber lights.

• Push in to turn off.

E. PTO Switch

Use this switch to engage and disengage the 540

RPM rear PTO shaft. See Figure 4.

The PTO switch has three positions as follows:

OFF Position — Center pos ition of switch . Stops the

rotation of the rear PTO shaft.

NOTE: The PTO switch must be placed in the OFF

position before st arti ng th e engi ne . Th e eng ine s tarte r

motor will not engage if th e PTO switch is not in the

OFF position.

AUTOMATIC Position — Turn top of switch to left.

The PTO will oper ate only w hen the 3-poin t hitch and

its mounted implement a re lowered u sing the p osition

control lever.

MANUAL Position — Tur n top of switch to r ight. The

PTO will operate continuously until the switch is

returned to the OFF position.

F. Steering Tilt Lock Lever

Use this lever to lock the steering wheel in the tilt

position selected by the operator. See Figure 4.

To reposition the steering wheel proceed as follows:

• Grasp the handle of the lever and push inward.

• Rotate the lever counterclockwise to loosen.

• Adjust the position of the steering wheel.

• Push the handle inwa rd and rotate cl ockw ise until

tight to lock the steering wheel.

• Pull the handle outward.

WARNING: Make sure the steering wheel

is locked before driving t he tr ac tor . Neve r

adjust the steering wheel while in motion.

G. Pa rki ng Brak e Lever

Use this lever, located below the dash panel to the

right of the steering column, to set the parking brake

before dismounting the tractor. See Figure 5.

Engage

PARKING

BRAKE

LEVER

Brake

Pedals

Locked

Figure 5

13

Page 14

To set the parking brake proceed as follows:

• Lock the right and left brake pedals together

using the brake lock. Refer to Brake Lock in

Floorboard and Fender Mounted Controls later

in this section.

• Fully depress and hold the brake pedals.

• Pull the brake lock lever upward and hold while

while releasing the brake pedals. If properly

engaged, both the leve r and the brak e pedals will

lock in their present position.

• Depress the brake pedals again to release the

parking brake.

H. Forward/Reverse Shift Lever

Use this lever to set the tractor’s direction of travel.

WARNING: Never shift the forward/

reverse lever without first disengaging

the tractor’s clutch by depressing the

clutch pedal. Failure to do so will result

in severe damage to the transmission.

To change the direction of travel, proceed as follows:

• Fully depress the clutch pedal.

• Shift the lever into one of three positions (See

Figure 6).

Forward position — The tractor will drive in the

forward direction.

Center position — Tractor in neutral.

Rearward position — The tractor will drive in the

reverse direction.

• Slowly and evenly release the clutch peda l.

I. Hand Throttle Lever

When the hand throttle is pushed forward, the engine

speed will increase. When pulled rearward, the

engine speed will decrease.

Fast

Slow

HAND

THROTTLE

Figure 7

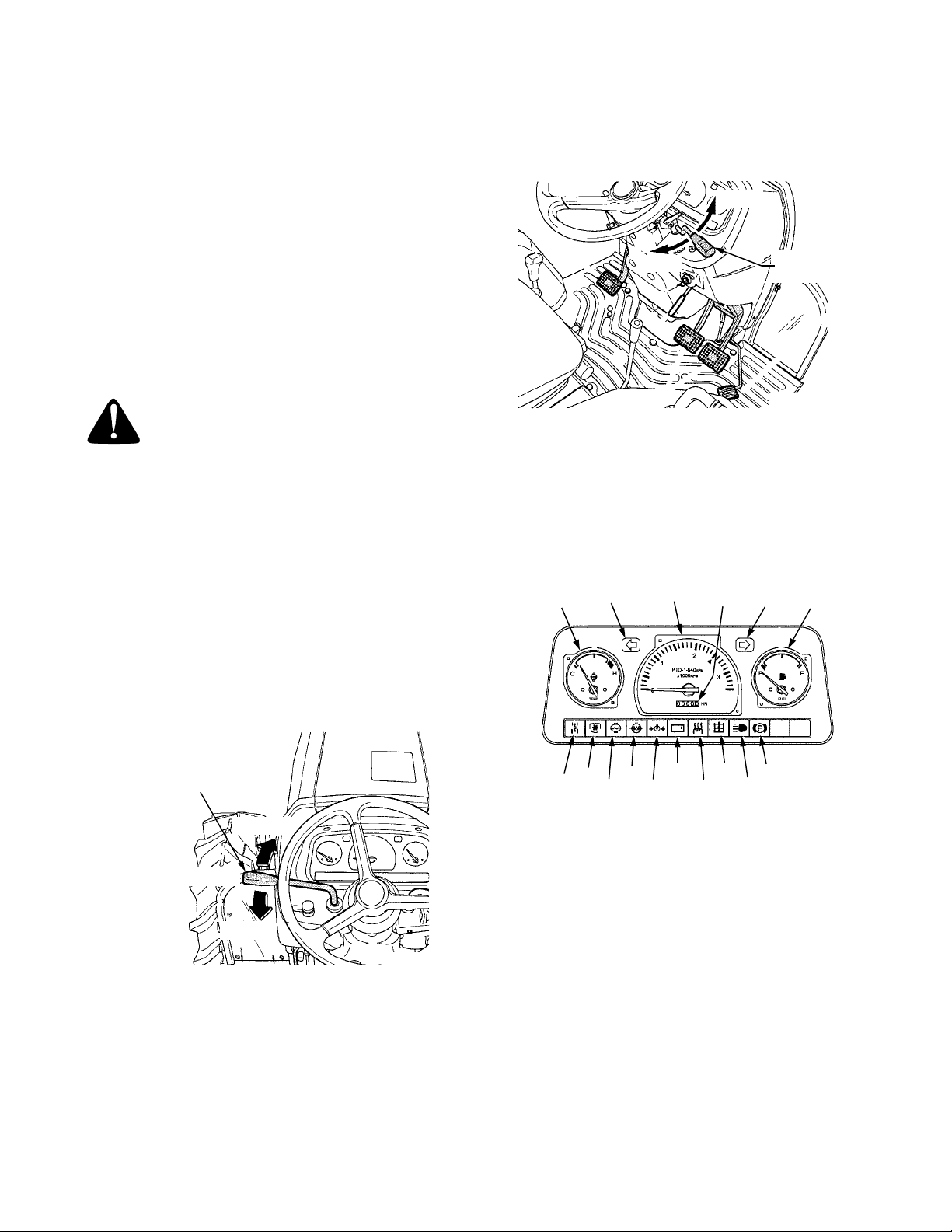

J. Instrument Panel

The instrument panel contains the following gauges

and indicator lights to inform the operator of tractor

conditions (See Figure 8):

15

4

1

2

15

3

FORWARD/REVERSE

SHIFT LEVER

Forward

Neutral

Reverse

Figure 6

11

12

14

13

5

9

7

10

8

6

Figure 8

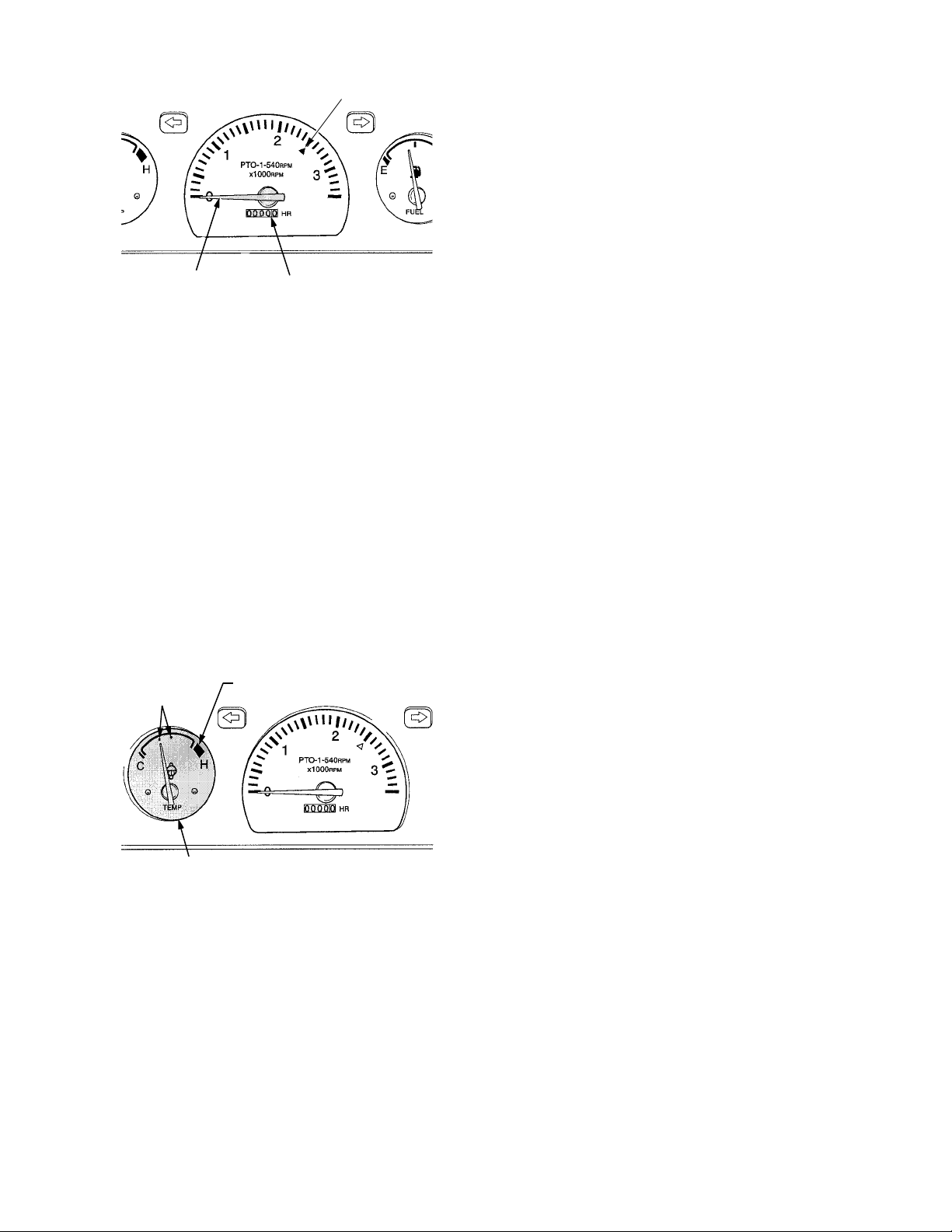

1. Tachometer - Indicates the engine speed in

revolutions per minute (RPM). When operating

PTO driven equipment, adjust the engine speed

so that the tachomete r needle is at the 540 PTO

rpm mark, unless otherwise specified in the

equipment owner’s manual. See Figure 9.

14

Page 15

PTO Mark

TACHOMETER

HOURMETER

Figure 9

2. Hour meter (In Tachometer) - This meter shows

the number of hours the tractor has been operated at rated engine RPM. The right-most digit

(white background) indicates tenths of an hour.

Monitor the hour meter to ensure all maintenance procedures are c om ple ted a ccor di ng to the

maintenance schedule. Refer to Figure 9.

3. Coolant Temperature Gauge - Indicates the

temperature of the engine coolant. Monitor the

gauge to allow the engine to warm up when first

starting the tractor. Do not operate the tractor

under load before the temperature gauge

indicates the proper temperature. Monitor the

gauge to protect against overheating the engine

(the red section on the temperature gauge

indicates overheating). See Figure 10.

Normal

Operating

Range

COOLANT TEMP. GAUGE

Overheat Range

Figure 10

4. Fuel Gauge - Indicates the volume of fuel in the

fuel tank.

5. 4WD Indicator - Illuminates when the front drive

lever has been engaged.

6. PTO Indicator - Illuminates when the PTO is

engaged.

7. Coolant Level Lamp - Illuminates if the engine

coolant leve l falls below a prescribed level. Stop

the tractor and refill the cooling system.

8. Differential Lock In dicator - Illuminates when the

differential lock pedal has been engaged.

9. Engine Oil Pressure Warning Lamp - Illuminates

when the ignition switch is turned on to assure

the light is fu nctioning properly. The light sh ould

go off after the e ngine starts. If the light remains

on, stop the engine immediately and inspect for

the cause or contact your Cub Cadet dealer.

10. Battery Charge Wa rning La mp - Illumi nates when

the ignition switc h is turned on and should go off

as the engine sta rts. I f the lamp continues to glo w

above idle speeds, indicating the battery is being

discharged, stop th e tractor and have the electrical system checked for the cause.

11. Glow Plug Indicator - L ights for approxima tely 10

seconds after the glow p lugs are energized , then

turns off to indicat e the comb ustion chamb ers ar e

preheated. NOTE: Alt hough the lamp turns off, it

normally takes approximately 20 seconds for the

glow plugs to fu lly heat a cold engine . The lower

the ambient temperatures, the longer the preheating time needed.

12. Hydraulic Filt er Warning Lamp - Illu mination indicates a problem with hydraulic oil flow through

the filter.

13. High Beam Lamp - Illuminates when the headlight switch is turned to high beam position.

14. Parking Brake Indicator - Illuminates when the

parking brake is engaged.

15. Turn Signal Indi cators - One of the lamps light in

a flashing mode to indicate that turn signal has

been activated with the turn signal switch.

15

Page 16

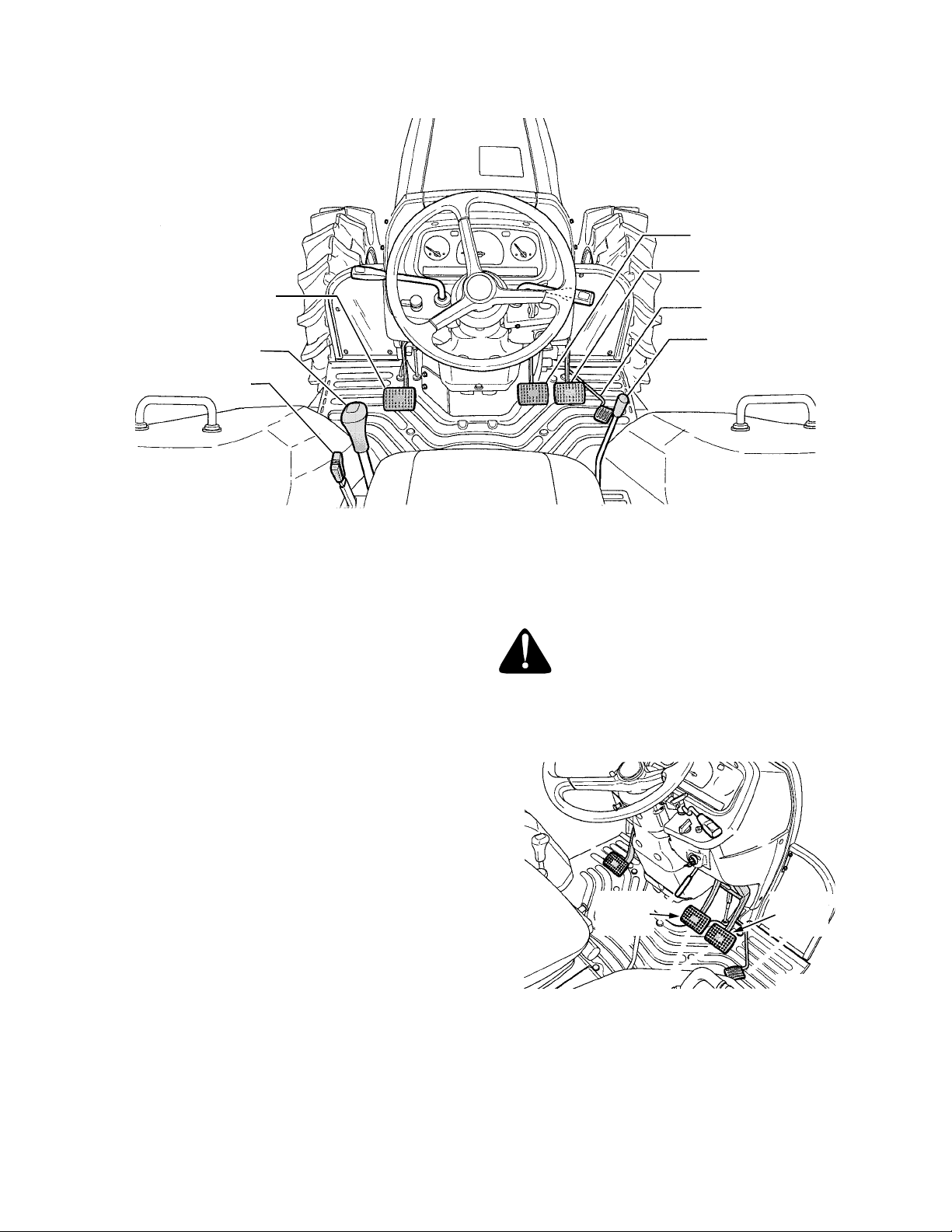

FLOOR BOARD AND FENDER MOUNTED CONTROLS

A

B

B

C

D

E

A.

Clutch Pedal

B.

Brake Pedals

C.

Foot Throttle

Figure 11

A. Clutch Pedal

When the clutch pedal is fully depres sed, th e tractor ’s

drive clutch is di sengaged. Fully and ra pidly depress

the clutch pedal before shifting the main shift lever,

the Hi-Lo Range lever, or the forward/reverse shift

lever. Gradually release the clutch pedal after shifting.

IMPORTANT: The clutch pedal should be rapidly

depressed, but s lowly a nd even ly released to prevent

damage to the clutch plates. Never operate the

tractor with your foot resting on the clutch pedal.

Doing so may contribute to premature clutch wear.

D.

Main Shift Lever

E.

Hi-Lo Range Shift Lever

F.

Auxiliary Hydraulics Lever

WARNING: Always lock the brake pedals

together before driving the tractor on

roadways or at high transport speeds.

Engaging only one brake under these

operating conditions could cause a

dangerous accident.

F

B. Brake Pedals (Right and Left)

• The right (outer) brake pedal engages only the

right brake assembly. Refer to Figure 12.

• The left (inner) brake pedal engages only the left

brake assembly. Refer to Figure 12.

Use the individual brake pedals to assist in making

sharp turns while operating the tractor in the field.

Depress the brake pedal corresponding to the

direction of the turn.

16

LEFT

BRAKE

PEDAL

RIGHT

BRAKE

PEDAL

Figure 12

Page 17

C. Foot Throttle

The foot throttle is interlocke d with the hand throttle.

Depressing the foot throttle increases the engine

speed. Full engine speed control can be obtained

with the foot throttle if th e hand throttle is in the full

rearward (slow) position. The foot throt tle may also be

used to temporaril y increase the engine s peed above

the hand throttle setting.

D. Main Shift Lever

WARNING: Never shift the main shift

lever without first disengaging the

tractor’s clutch by depressing the clutch

pedal. Failure to do so will result in

severe damage to the transmission.

The main shift lever allows you to shift the tractor’s

transmission into any of fou r gear sets. Each gear set

represents a change in tractor spee d, with 1 being the

slowest speed and 4 the fastest. The synchromesh

type gearbox allows you to change gears without

stopping by just fully depressing the clutch pedal.

The shift pattern is in the form of an "H " with the center position being neutral. See Figure 13.

MAIN SHIFT LEVER - SHIFT PATTERN

1st Speed

3rd Speed

HI-LO RANGE SHIFTER

Low Range

Neutral

High Range

Figure 14

Use in combination with the main shift lever and forward/reverse lever to obtain eight speeds in forward

and eight speeds in reverse

F. Auxiliary Hydraulics Lever

Use this lever to control the cylinder positions of

optional impleme nts attached to the remote hy draulic

outlets of the tractor.

IMPORTANT: Do not hold the lever in the "Pull" or

"Push" position on ce the remo te cyl inder ha s reache d

the end of its stroke. Doing so will force oil through

the relief valve, and over a prolonged period cause

the hydraulic oil to overheat.

Neutral

2nd Speed

4th Speed

Figure 13

E. Hi-Lo Range Shift Lever

WARNING: Never shift the Hi-Lo range

shift lever without first disengaging the

tractor’s clutch by depressing the clutch

pedal. Failure to do so will result in

severe damage to the transmission.

The Hi-Lo range shift lever allows you to shift the tractor’s transmission into either of two ranges. To shift

into High or Low range, completely stop the tractor

and fully depress the clutch pedal. See Figure 14.

• Push the lever forward to shift into the Low

(slower) range.

• Pull the lever rearward to shift into the High

(faster) range.

• Move the lever to the center posit ion to place in

neutral.

Front Wheel Drive Lever

The front wheel drive lever is located in the

floorboard, below and to the left of the seat.

Use the front wheel mechanism only whe n additional

traction is needed to drive the tractor. For example:

when operating grou nd engaging equipment suc h as

a front end loader; when climbing slopes; or when

operating in wet, sandy or loose soil conditions.

• To engage the front wheel drive mechanism,

depress the clutch pedal and push the front

wheel drive lever downward. See Figure 15.

• To disengage the front wheel drive, depress the

clutch pedal and pull the lever upward.

FRONT WHEEL

DRIVE LEVER

Disengaged

Engaged

Figure 15

17

Page 18

Differential Lock Pedal

Located at the rear of the right floor board, the differential lock is used to gain additional traction when

operating the tractor on wet or loose soil. When the

pedal is depressed t he rear wheels of the tractor are

prevented from rotating independently of one another.

See Figure 16.

DIFFERENTIAL

LOCK PEDAL

Engage

Figure 16

WARNING: When operating with the

differential lock engaged, the tractor will

be difficult to steer. To prevent loss of

control of the tractor, do not drive the

tractor on roadways or at speeds above 5

MPH with the differential lock engaged.

• To engage the diffe rential l ock, ligh tly ste p on the

differential lock pedal with your heel.

• To disengage, simple release the pedal.

Hydraulic Control Levers

The hydraulic control levers , cons istin g of the pos ition

control and draft control levers, are located on the

right fender. See Figure 17.

Use these control levers to control the w orking depth

and pull of implements attached to the three point

hitch as follows:

• Using Position Control — This will control the

working depth of 3-point implements regardless

of the amount of pull required. Push the draft

control lever forward to the lowest position and

set the implement working depth by moving the

position control lever to the desired position.

• Using Draft Control — This will con trol the pull o f

the 3-point im plement. As the pull on the 3-point

hitch changes due to various soil conditions, the

draft control system automatically responds to

these changes by either raising or lowering the

implement slightly to maintain a constant pull.

Push the position control lever forward to the

lowest position and set the implement pull by

moving the draft control lever to the desired

setting.

• Using Mixe d Control — In dra ft control , when draft

decreases, the im plement automatically lowers to

increase draft. However, the implement sometimes lowers too much. To limit the degree the

implement ca n be lower ed, s et the pos ition c ontrol

lever at the lowest working depth desired for the

implement; t hen lower the dra ft cont rol lev er to the

point where the implement is at the desired depth.

This stops the implement from going too deep and

also controls the pull to prevent loss of traction and

ground speed.

Brake Pedal Lock

The brake pedal lock is located on the right brake

pedal. Flip the lock counterclockwise so it engages

the bracket on the left brake pedal to interlock both

brake pedals. See Figure 18.

Lower

Raise

Lower

POSITION

CONTROL

LEVER

Figure 17

Raise

DRAFT

CONTROL

LEVER

18

Engage

Figure 18

Disengage

BRAKE

PEDAL

LOCK

Page 19

Seat Adjustment Lever

The seat adjustm ent lever is located beneath the left

side of the seat. This lever is used to adjust the seat

forward or backward to the desired operating position.

See Figure 19.

SEAT ADJUSTMENT LEVER

Mid PTO Lever

The tractor’s Mid PTO is used power implements

designed to be operated at 2000 RPM.

The mid PTO le ver is located in the pane l below the

right side of the seat. See Figure 21.

• Turn the PTO switch to the manual position.

• Pull the lever upward to engage the Mid PTO.

• Push the lever down to disengage the Mid PTO.

WARNING: To avoid possible personal

injury or damage to the tractor, make

sure the Mid PTO is disengaged (lever

down) when not in use.

Engage

Figure 19

PTO Safety Switch

Located on the right fender. To stop the PTO in an

emergency, depress th e switch. The switch must be

pressed a second time (switch button in the up

position) to re-engage the PTO. See Figure 20.

ON

OFF

- On

- Off

PTO

SAFETY

SWITCH

Figure 20

Disengage

MID PTO

LEVER

Figure 21

19

Page 20

SECTION 2: OPERATION

ROLLOVER PROTECTIVE STRUCTURE (ROPS)

This tractor is equipped with a foldable Rollover

Protection Structure (ROPS) and seat belts. When

used together they are effectiv e in reducin g injurie s to

the operator in the event of an accidental tractor

rollover. The safety provided by the ROPS is

minimized if the seat belt is not properly adjusted

AND buckled.

WARNING: Always wear the seat belt

when operating the tractor equipped with

a ROPS. However, if the ROPS is in the

folded position or has been re-moved, the

seat belt must not be used.

Use the following guidelines when using a tractor

equipped with a ROPS:

• Be aware of overhead clearances in the area of

operation. Check for clearance of door (or gate)

openings and other overhead objects such as

utility lines and tree branches. Overhead objects

could catch the ROPS and upset the tractor.

• Do not modify the ROPS by drilling holes for, or

welding accessories to the structure.

• Do not use the ROPS to pull objects with the

tractor. Use ONLY the tractor drawbar for pulling.

• In the event of an accident, have the ROPS

carefully inspected and, if neces sary, repl aced by

your Cub Cadet dealer. Do not attem pt to repair

the ROPS.

FUELING THE TRACTOR

Fill the fuel tank with only clean, fresh, diesel fuel. To

ensure the freshness of the fuel, purchase fuel in a

quantity that can be used within 30 days.

NOTE: DO NOT USE KEROSENE OR GASOLINE in

your diesel engine. Damage to the engine will occur.

Generally a good grade Number Two Diesel Fuel

should be used in your diesel engine. However, in

extremely cold temperatures a quality Number One

Diesel Fuel, or a blend o f Number One and Number

Two Diesel fuels should be used. In most areas,

diesel fuel is properly blended for seasonal use as

ambient temperatures change. Therefore, it is

important to monitor fuel pur chases so that seasonal

grade fuels are not carried over after the average

ambient temperature has changed.

WARNING: Never fill the fuel tank to the

top of the filler neck. Expansion could

result in overflow through the vents in

the cap.

• Do not smoke while refueling the tractor.

• Do not fill the fuel tank when the engine is

running or while the engine is hot.

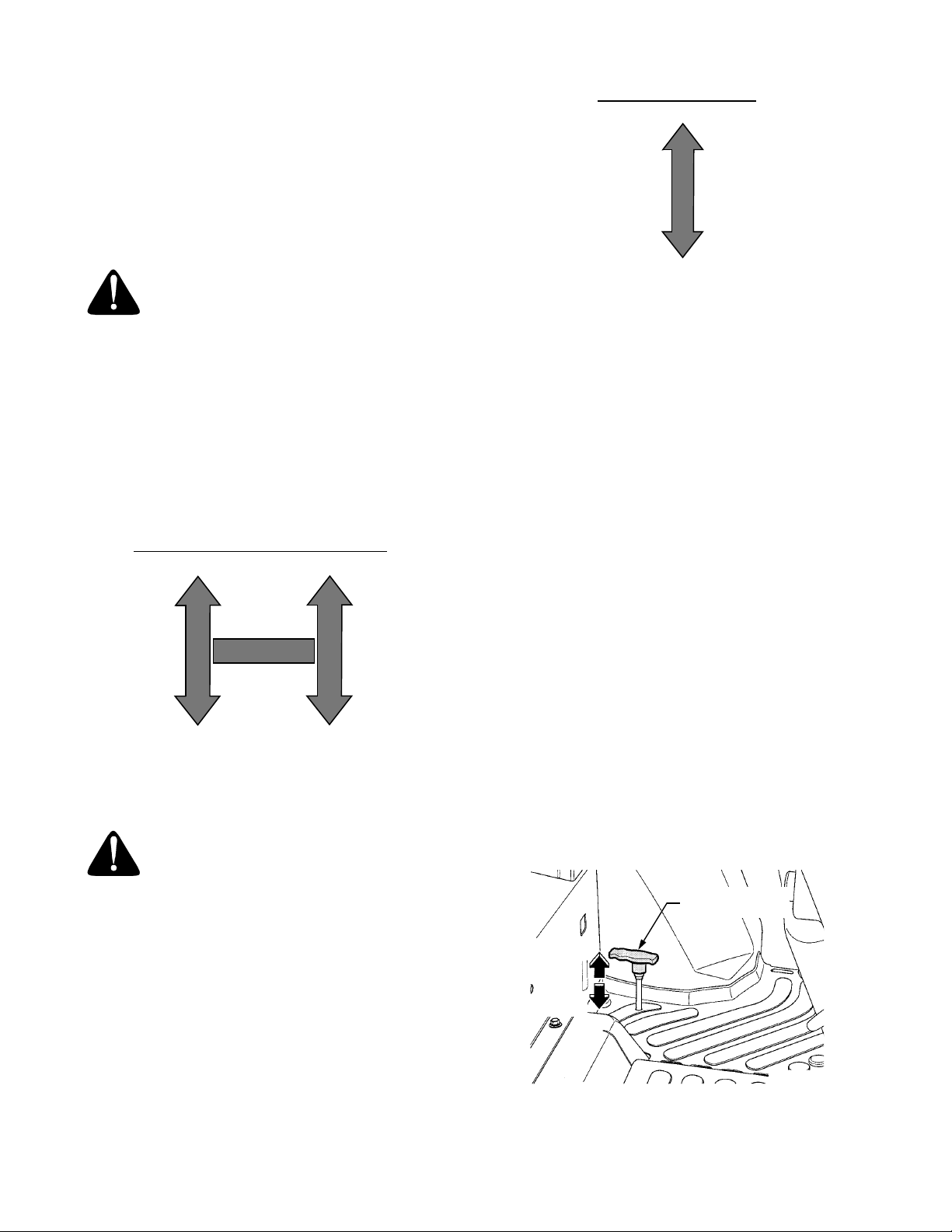

• The fuel fill cap is located beneath the small

access door in the rearward end of the hood.

Press downward on the rea r of the door to open.

See Figure 22.

PRE-STARTING CHECKS

Perform the followin g checks every day before starting and operating the tractor.

• Check the air pressures and general condition of

the tires.

• Check under the tr actor for any indications of oil

or water leakage.

• Check that all lamps and lights work properly.

• Walk around the tractor and inspect for loose

fasteners.

• Check the transmission oil level.

• Check the engine oil level.

• Check the engine coolant level.

• Check that the air cleaner is free of obstructions

and excessive dirt.

• Check the fuel supply.

• Check operation of the clutch and brake pedals.

• Check operation of the parking brake.

ACCESS

DOOR

FUEL CAP

Figure 22

IMPORTANT: Use of a strai ner when refuel ing i s rec-

ommended to prevent impurities from entering the

fuel system and causing contamination of the injection pump.

• Unscrew the fuel cap and fill tank from an

approved container. Do not fill the fuel tank to

capacity. Allow room for expansion.

20

Page 21

• Tighten the fuel cap securely, and immediately

wipe up any spilled fuel.

• To minimize conden sation, keep the fuel tank a s

full as possible without filling to capacity. It is a

good practice to fill the fue l tank at the end o f the

day to reduce overnight condensation.

• Do not allow the fuel tank to run dry. Running out

of fuel requires bleedin g air and priming the fuel

system.

WARNING: Fuel in the engine injection

system is under high pressure. If not a

qualified mechanic, do not attempt to

service the fuel injectio n system. Do not

use your hand to check for leaks.

NEW TRACTOR BREAK-IN PROCEDURES

A new tractor is built with high tolerance, well fitted

components, but various parts require a break-in

period before being subjected to severe work loads.

The manner in which the tractor is handled during the

"break-in" period greatly affects the life of the tractor.

Therefore, to obtain the maximum performance and

longest service life from the tractor, it is very

important to properly b re ak-i n th e trac tor . C ar e shou ld

be taken during the first 100 hours of operation to

operate the tractor at slower speeds and to avoid

excessive work loads. In handling a new tractor the

following precautions should be observed.

• Do not operate the tractor at full speed for the

first 100 hours.

• Do not start quickly or apply the brakes suddenly.

• Never operate a new engine immediately under

full load. Allow the engine to warm up.

STARTING THE ENGINE

WARNING: Always sit in the operator’s

seat when starting the tractor, Never

attempt to start the engine while

standing beside the tractor.

WARNING: Never use a starting fluid,

such as ether, as a starting aid. Using a

starting fluid could cause severe engine

damage or a fire, and will void the e ngine

warranty.

• Sit in the oper ator’s seat, adj ust the seat posi tion

(see ADJUSTMENTS), and fasten the seat belt

(only if a ROPS is installed and in the up

position).

• Engage the parking brake. See Figure 23.

Engage

PARKING

BRAKE

LEVER

Depress

Brake

Pedals

Figure 23

• Place the main gear shi ft lever, Hi-Lo range shift

lever, and the PTO switch in the neutral position.

• Place the position control lever in the lowest

position. See Figure 24.

• Avoid operating the engine for prolonge d periods

at either high or low speeds with no load.

• Use the transmission’s low speed range for

heavy loads to avoid lugging down the engine

due to overload.

• Closely monitor the engine oil and coolant levels,

and keep filled to the recommended levels.

• As parts "break-in", minute particles of material

may break away, and could cause wear to the

component. Therefore, it is very important to

perform all break-in maintenance procedures

found in the MAINTENANCE section.

Position Control

Lowest Position

Figure 24

21

Page 22

• Set the throttle lever in approximately the midd le

position (40hp). See Figure 25.

Throttle Lever

to Mid Position

On/Preheat

Position

PTO Switch

In Neutral

Figure 25

• Turn the ignition switch to the "ON/Preheat"

position. Refer to Figure 25.

NOTE: Some of the instrument panel lamps will

light momentarily to indicate they are functio ning.

The oil pressure an d b a tte ry c ha rg e lamps should

remain on until the tractor is started.

• Observe the glow plug indicator light on the

instrument panel — i t shoul d go out aft er approx imately 10 seconds, indicating the combustion

chamber has been preheated. Howev er, allowing

the glow plugs to preheat an additional 10 seconds (or longer in colder ambient temperatures)

is recommended.

NOTE: It is not normal ly n ece ssar y to preh eat the

engine when restarting after its been warmed up.

• Fully depress the clutch pedal.

• Turn the ignition key to the “START” p osition and

release it as soon as the engine s tarts; however,

do not crank the engine continuously for more

than 10 seconds at a time. If the engine does not

start within this time, turn the key to “OFF” and

wait at least 30 seconds to allow the engine’s

starter motor to cool. Try again after waiting.

STOPPING THE ENGINE

• Reduce the engin e speed to idle using the hand

throttle lever and apply even foot pressure on

both brake pedals.

• Depress the clu tch pedal a nd place th e m ain s hift

lever and Hi-Lo range shift lever in neutral.

• Turn the PTO switch to the neutral (OFF)

position.

• Use the position control lever to lower equipment.

• Allow the engine to idle for a short peri od of time.

NOTE: Stopping a hot engi ne at high spe ed may

cause internal engine damage.

• Interlock the br ake pedals using the brake p edal

lock and set the parking brake using the parking

brake lever.

• Turn the ignition switch counterclockwise to the

OFF position to stop the engine.

WARNING: To prevent unauthorized

operators from starting the tractor,

always remove the key from the ignition

switch when leaving the tractor.

DRIVING THE TRACTOR

WARNING: Always allow the engine to

warm up before applying load. Avoid

sudden starts, e xcessive speed and su dden stops.

WARNING: Always look behind and

down for bystanders or obstacles before

operating the tractor in the reverse

direction

• If transporting the tractor to a job site or traveling

on roadways, make certain the two brak e pedals

are interlocked. See Figure 26.

Engage

• Slowly release the clutch pedal and allow the

engine to run at medium speed for 5 to 10

minutes (depending on ambient tem peratures) to

warm the tractor before operating under load.

IMPORTANT: The engine oil pressure and battery

charge lights should turn off. If they do not, stop the

engine immediately and check for the cause or

contact your Cub Cadet dealer.

BRAKE

PEDAL

LOCK

Figure 26

22

Page 23

• Fully depress the clutch pedal and proceed as

follows:

- Shift the Fo rwar d/ Reve rse Sh ift Leve r to desir ed

direction. See Figure 27.

Depress

Clutch

Pedal

Throttle Up Using

Hand or Foot

Throttle

Forward

Reverse

Figure 27

- Shift the Main Shift Lever to desired gear speed.

See Figure 28.

- Shift the Hi-Lo Range Shift Lever to desired

range. See Figure 28.

Hi

Lo

Select

Gear

Speed

Disengage

Parking Brake

Figure 29

• Slowly release the clu tch pe dal to start the tr actor

moving.

NOTE: If operating power driven equipment running

off the PTO, the throttle must be in crease d to the 540

PTO mark unless otherwise specified in the

equipment operator’s manual. Use the gear shift

levers to select a safe travel speed. Proper travel

speed will depend on t he type of equipment and the

condition of the terrain.

IMPORTANT: Do not drive with your foot resting on

the clutch pedal. P artial enga gement of the clutc h will

cause clutch slipp age and resu lt in p rematu re wea r of

clutch components.

STOPPING THE TRACTOR

• Reduce the engine speed by pulling the hand

throttle rearward and remove your foot from the

foot throttle.

Figure 28

• Pull the position control lever rearward to raise the

attachment.

• Momentarily depress the brake pedals to disengage the parking brake. Refer to Figure 29.

• Throttle up the engine to a moderate speed using

either the hand throttle or foot throttle. See Figure

29.

• Evenly depress both brake pedals to stop the

tractor.

• Depress the clu tch pedal a nd place th e m ain s hift

lever and Hi-Lo shift lever in neutral.

• Push the position control lever forward to lower

equipment to the ground.

• Interlock the brak e pedals ; then ful ly depress and

hold the brake pedals.

• Pull the brake lock lever upward and hold while

releasing the brake peda ls to engage the parkin g

brake.

23

Page 24

• If leaving the tractor, turn the ignition key to the

OFF position and remove the key.

• If parking on an incline, chock the wheels to

prevent accidental rolling of the tractor.

TURNING THE TRACTOR

WARNING: Turning the tractor while

traveling at a fast speed may cause the

tractor to overturn.

NOTE: The tracto r is equipped with hydraulic power

steering. If front mounted equipment is installed on

the tractor and the eng ine is r unning at a slow spe ed,

it may take increased steering effort to turn the

tractor.

IMPORTANT: When the steering wheel is turned

completely and held in this position, the hydraulic

system may emit a high pitched sound from the relief

valve being actuate d. Avoid prolonged turns wi th the

tractor’s steering wheel held in the co mpletely turned

position.

• Always slow down the tractor by reducing throttle

speed and/or downshifting the transmission

before turning the tractor.

• Engagement of the differential lock will prevent

proper steering and could cause loss of tractor

control when turning. Always release the

differential lock pedal and make the certain it is

disengaged before turning the tract or.

• Use the individual wheel brakes to assist turning

ONLY when the tractor is wo rking in the fi eld and

operating at slower speeds.

WARNING: Sudden application of one

brake while traveling at high speed or

while making fast turns could cause the

tractor to roll over.

DRIVING ON SLOPES

WARNING: When climbing or descending

a hill, do not shift the transmission into

the neutral position or disengage the

clutch.

• Interlock the brake pedals before operating the

tractor on a slope. Never use the individual wheel

brakes when operating on a slope.

• Operate the tractor up and down slopes, never

across slopes. Do not drive so that the tractor

may tip over sideways.

• Prior to going uphill, sh ift the transmission into a

low enough gear to allow the tr actor to climb the

hill without lugging down the engine.

• Prior to going downhil l, reduce the engine speed

and shift the transmission into a lower gear to

take advantage of the braking action of the

engine.

• Before operating the t ractor on a slope, walk th e

slope to look for possible hazards s uch as rocks,

mounds, stumps, or surface irregularities which

could cause the tractor to be upset.

• Back the tractor with attac hment up the steepest

portion of each slope you intend to work. If the

tractor cannot ne gotiate the slope in reverse, the

slope is too steep to be worked.

• Avoid turns when driving on a slope. If a turn

must be made, turn down the slope. Turning up a

slope greatly increases the chance of a roll over.

• Avoid stopping when driving up a slope. If it is

necessary to stop wh ile driving up a slope, start

up smoothly and carefully to reduce the

possibility of flipping the tractor over backward.

DRIVING ON ROADWAYS

WARNING: Ensure proper weighting of

the tractor, and travel at a safe speed

when driving with a rear mounted implement in the raised position. Bouncing of

the implement while traveling at higher

speeds could momentarily rai se the front

end of the tractor and result in loss of

steering and control of the tractor.

• Make certain the left and right brake pedals are

interlocked before driving on public roads.

• Attach an SMV (slow moving vehicle) sign in a

visible location on the back of the trac tor or rear

mounted equipment.

• Reduce the speed of the t ractor when turning on

sharp curves.

• Downshift the transmis sion and use th e engine to

brake when descending steep slopes.

• Use the turn signal to ale rt other vehicles of your

intentions when making turns.

• If driving after dusk or before dawn, turn on all the

tractor lights - in cludi ng the flashing hazar d lights .

Dim the headlig hts to onco ming t raffic if using th e

high beams.

• Pay close attention for low shoulders on the side

of the road. Dropping the tracto r’s wheels off the

road onto a low shoulder could upset the tractor.

• Obey all traffic laws and allow faster moving

vehicles to pass. Do not block the road.

24

Page 25

CHECK WHILE OPERATING

While operating the tractor, regularly check the

gauges and warning lights on the instrum ent panel to

ensure the tractor is functioning properly.

Coolant Temperature Light

Regularly check that the gauge needle is within the

normal operating r ange. If the needle moves into the

red section (overh eat) of the gauge, stop the tractor

immediately and check for the following causes:

WARNING: After the engine has been

running for a short period, the radiator,

muffler, engine block, and any metal

surface in close proximity to the engine

will be HOT. Allow these areas to cool

and use extreme caution to avoid

burning yourself.

WARNING: Do not remove the radiator cap

until the coolant temperature is below its

boiling point. Then carefully loosen the

cap to its first stop to relieve any pressure

before completely removing the cap .

• Check the coolant level. If coolant is low check for

possible cause, such as a ra di at or o r hose le ak.

• Check for debris on the screen in front of the

radiator. Also check the passages between the

radiator cooling fins for accumulations of dust,

dirt, or debris.

• Check for a loose fan drive belt.

• Check for internal radiator blockage.

Engine Oil Pressure Lamp

The oil pressure lamp alerts the operator that the

engine oil pressure is below the prescribed level. If

the lamp should light during operation, stop the

engine immediately.

• Check the engine oil level.

• If the oil level within the operating range, conta ct

your Cub Cadet dealer.

NOTE: If the engi ne is left runni ng at idle sp eed for a

prolonged period, the oil pressure lamp may light.

This does not indicate a problem with the engine, but

this situation should be avoided.

Battery Charge Lamp

The battery charge lamp aler ts the operator that the

alternator in not charging the battery. If the lamp

should light during operation, stop the engine

immediately.

• Loose wire connections at the alternator and

regulator.

• Loose wiring harness connections.

• Loose alternator drive belt.

• Loose or corroded connections at the battery.

Fuel Gauge

Regularly check the fuel gauge. Do not allow the fuel

tank to empty completely. If the tractor runs out of

fuel, air is allowed to enter the fuel system, which

could cause the engine to run poorl y after refuelin g. If

this happens, the f uel system should be ble d prior to

restarting the engin e (refer to MAINTENANCE i n this

manual).

Observed Problems

The engine should be stopped immediately and the

tractor checked if any of the following are observed

while operating the tractor.

• The engine suddenly slows down or speeds up.

• Unusual noises are suddenly heard.

• The engine exhaust suddenly and for no

apparent reason becomes very dark .

NOTE: The engine exhaust is nor mally colorless .

If the tractor is overloaded the exhaust may

become darker until the load is reduced. Try to

avoid this situation. Operating the tractor in a

prolonged overloaded condition may cause

damage to tractor components.

TRAVEL SPEEDS

Using combinations of shift positions for the main

shifter, Hi-Lo shifter, and forw ard/reverse shifter, the

tractor can be placed in any of eight speeds in

forward and eight speeds in reverse.

• Fully depress the clutc h pedal before shiftin g any

of the transmission shift levers.

• Do not shift the Hi-Lo range shifter while the

tractor is moving. Stop the tractor before shifting.

• At the rated engine speed (approx. 2600 RPM)

with standard tires, the approximate speeds are

as follows:

Fwd./Rev.

Position

Forward

Reverse

Hi-Lo

Position

Low

High

Low

High

Main Gear

Position

1 1.1 (1.8)

2 1.5 (2.4)

3 2.3 (3.8)

4 3.4 (5.5)

1 4.8 (7.7)

2 6.6 (10.7)

3 10.3 (16.6)

4 15.0 (24.3)

1 1.0 (1.6)

2 1.4 (2.3)

3 2.2 (3.5)

4 3.2 (5.1)

1 4.4 (7.1)

2 6.1 (9.9)

3 9.5 (15.3)

4 13.9 (22.4)

Approx. Speed

mph (kph)

25

Page 26

USING THE DIFFERENTIAL LOCK

Depressing the differential lock pedal engages a

mechanism in the transmission that locks the

differential. This prevents the rear wheels from

rotating independently of each other and provides

constant power to both rear wheels when additional

traction is needed.

IMPORTANT:

Do not engage the differential

lock when one of the rea r wheels is r otating. Stop

the wheel rotation and then engage the

differential lock.

WARNING: When operating with the differential lock engaged, the tractor will be

difficult to st eer. Do not drive the tr actor

on roadways or at high speeds with the

differential lock engaged.

• Using your heel, fully depress and hold the

differential lock pe dal to engage the transmission

differential lock. Rel ease the pedal to disengage

the differential lock. See Figure 30.

USING THE FRONT WHEEL DRIVE

Use the front wheel drive when the conditio ns require

the additional traction provided by all four wheels

driving the tractor.

For example:

• When operating ground engaging equipment,

such as a front end loader, that may cause the

rear wheels to break traction.

• When climbing slopes.

• When operating in wet, sandy or loose soil

conditions.

To engage the front wheel dr ive mechani sm, depress

the clutch pedal, stop the tract or, and push the front

wheel drive lever downward. See Figure 31.

Disengage

Engage

DIFFERENTIAL

LOCK PEDAL

Engage

Figure 30

• Apply the differential lock moderately. Limit its

use to situations where the trac tor is sto ppe d or is

unable to drive straight because one its rear

wheels has lost tracti on due to slippery or loose

soil.

• Do not engage the differential lock for prolonged

periods. Release the pedal when traction has

been restored.

NOTE: Because of the drive load on the internal

engagement mechani sm , r el easin g th e pedal may not

always disengage the differential lock even though

the pedal springs ba ck. It may be necessary to slow

the tractor, or engage the b rake pedal, to disengage

the differential lock.

Figure 31

To disengage the front wheel drive, depress the

clutch pedal and pull the lever upward.

USING THE POSITION CONTROL AND DRAFT

CONTROL LEVERS

• Use the positio n control lever to set the height of

a 3-point hitch mounted implement if drag on the

tractor is not a concern.

• Set the draft control l ever to control the drag on

the tractor when operating a 3-point hitch

mounted implemen t. Draft control will maintain a

constant drag on the tractor by co ntinually rais ing

and lowering the implement as different soil

conditions are experienced.

• Use a combination of the two levers to set the

height of the implement while also controlling the

drag on the tractor. Refer to Figure 32.

26

Page 27

Ground

Surface

soft soil

Penetration w/Draft

Control and Position

Control

hard soil

Penetration w/Draft

Control Only

Figure 32

Engage

Disengage

MID PTO

LEVER

• After determining a desired working position

using one, or both, controls, the stop bolts can be

used to ensure the levers are returned to their

selected positions. Loosen the wing screws and

slide the stop(s) again st one (or both levers) and

re-tighten the wing s crews. Once the stop bol t is

set, simply move the relevant hydraulic lever

forward until it contacts the stop. See Figure 33.

Position Control

Setting

Draft Control

Setting

Slide Stop Against

Control Lever

Wing Screw

Figure 33

IMPORTANT: Do not operate the hydraul ics until the

engine has warmed up. If operation is attempted

when the engine is still cold, the hydraulic system

may be damaged.

Figure 34

• Push the lever down to disengage the Mid PTO.

WARNING: To avoid possible personal

injury or damage to the tractor, make

sure the Mid PTO is disengaged (lever

down) when not in use.

USING THE DRAWBAR

WARNING: Never pull from the top link

of the 3-point hitc h, the rear axle, or a ny

point above the drawbar. Doing so could

cause the tractor to roll over rearward

causing personal injury.

Use only the drawbar for towing pull-behind equipment (carts, trailers, etc.) or dragging loads. See

Figure 35.

Raise the lower links of th e three point hitch to their

highest position to prevent interference with the

towed equipment.

3 POINT

LOWER LINKS

IMPORTANT: If noises are heard when the

implement is lifting after the hydraulic control lever

has been activated, the hydraulic mechanism may not

be adjusted properly. Contact your Cub Cadet dealer.

USING THE MID PTO

Use the Mid PTO to power implements, such as a

mower deck, that are connected to the mid PTO

shaft.

• Turn the PTO switch to the manual position.

• Pull the lever upward to engage the Mid PTO.

See Figure 34.

DRAWBAR

Figure 35

IMPORTANT:

When transporting pull-behind

equipment on public roadways, always use a safety

chain to supplement the connection between the

tractor and towed e quipment. The safety chain must

have a strength rating equal to or greater than the

gross weight of the equipment being towed.

27

Page 28

USING THE THREE POINT HITCH

WARNING: Always disengage the PTO,

stop the engine, and set the parking

brake before dismounting the tractor to

connect, disconnect, or adjust three

point hitch mounted implements. Never

stand between the rear wheels and the

implement when attaching and adjusting

the implement.

Use the 3-point hitch only with equipment designed

for 3-point hitch usage.

Top Link

• Use holes A or B in the top link hold er for the top

link when attaching non draft sensitive

implements.

• Use holes B or C in th e top li nk hold er for th e top

link when attaching draft sensitive implements.

• Use hole A for the top link when transporting

implements.

A

TOP LINK

HOLDER

B

C

• Following the information provided in the

implement owner’s manual, attach the l eft lift rod

to the lower link using one of the three holes

provided in the lift rod. Remove the internal cotter

pin and clevis pin to adjust the left lift rod. See

Figure 37.

LEFT

LIFT

LINK

Upper Hole

Middle Hole

Lower Hole

Figure 37

• Loosen the jam nut on the right lift rod and adjust

its length as necessary to level the two lower

links by turning the adjustment tube. Re-tighten

the jam nut. See Figure 38.

Jam Nut

Adjustment

Tube

Figure 36

• Adjust the length of the top link following the

information provided in the implement owner’s

manual.

• When an implement is not attached, pivot the

center link upwar d and store in the top lin k hook

on the tractor.

Lifting Rods

WARNING: Before disconnecting a lift

rod from the lower link, stop the engine

and lower the attached equipment to the

ground. Ensure the attached equipment

is safely supported and relieve any

residual pressure from the hydraulic

system by moving the hydraulic lift

control levers fully rearwa rd and forward

several times.

Check

Links

Check Link Pins

Figure 38

Check Links

Remove the pins and adjust the length of the check

links to limit, or increase, the side to sid e movement

of the lower links as suggested in the implement

owner’s manual. Refer to Figure 38.

WARNING: Keep the guard around the

PTO shaft in place at all times. Replace

the PTO shaft cap when the shaft is not in

use.

28

Page 29

USING REMOTE HYDRAULICS

The tractor is equipped with a remote hydraulic

system for powering hydraulically driven implements

that are approved for usage on the tractor.

WARNING: To avoid personal injury, stop

the tractor engine and relieve pressure

from the hydraulic system before

connecting or disconnecting lines. Do

not use your hand to check for leaks.

Connecting Implements

• Clean the hydraulic couplers on both the tractor

and implement.

• Remove dust plugs or caps from the couplers.

Refer to Figure 39.

Dust Cap

Auxiliary

Hydraulic

Couplers

(One Set)

Figure 39

• Insert the implement coupler into the tractor

hydraulic coupler.

• Pull slightly on the implement couplers to make

certain they are firmly connected to the tractor.

Disconnecting Implements

• Lower the implement to the ground to release

hydraulic pressure in the hoses.

• Relieve pressu re by moving the hydrauli c control

lever in each direction several times with the

engine shut off.

• Pull each implement hose coupler straight from

the hydraulic coupler to release it.

• Clean oil and dust from each couple r and rep lace

the dust plugs and/or caps.

Remote Control Valve Lever

Move the lever up or down a nd h old. Thi s will r aise or

lower the implement. The lever will return to neutral

when released.

IMPORTANT: Do not hold the lever in the "pull" or

"push" position once the re mote cylind er has rea ched

the end of its stroke. Doing so will force oil through

the relief valve, and over a prolonged period cause

the hydraulic oil to overheat.

IMPORTANT: When using the tractor hydraulic

system to power a front loader, do not operate the

boom and bucket cylinders simultaneously.

TRACTOR WEIGHTING

When implements are installed on either the front or

rear of a tract or, th e tr act or’s norma l bala nce is alt ered .

• As a rear mounted implement is raised to the

transport positio n, the balance po int of the trac tor

shifts rearward, which may result in a loss of

steering control and tractor stability.

• When a front mounted implement is raised, the

balance point shifts forward and may result in a

loss of traction and stability.

To counterbalance these weight shifts, weight should

be added to the tractor in the form of cast iron

weights or liquid ballast. However, only enough

weight should be added to obtain good traction, control, and stability . Excessive we ight will unneces sarily

load down the tractor’s engine and transmission.

NOTE: When adding wei ght to the tractor, it may be

necessary to increase inflation pressure in the tires.

Front Weights

To counterbalance three point hitch mounted

equipment, weight sh ould be adde d to th e fro nt of th e

tractor. Add enough ballast to maintain steering

control and prevent tip over. Remove the weight

when it is not ne eded. Front weights a re available at

your Cub Cadet dealer.

Follow the guidelines provided in the implement

Operator’s Manual to dete rmine how much weight is

needed to counterbalance the equipment. If

guidelines are not ava ilable, ball ast the tractor so that

a minimum of approximately 40% of the machine

weight is on the front wheels.

If necessary, contact your Cub Cadet dealer for help

in determining how much weight is needed for your

particular application.

Weighting the Rear of the Tractor

Add weight to the rear wheels if needed to improve

traction or for stability. The amount of rear ballast

should be matched to the job, and the ballast should

be removed when it is not needed. The most common

methods of addin g weight are filling the rear whee ls

with liquid ballast or mounting a rear weight box.

Liquid Ballast

Because special equip ment and a familiarity with the

practice is required, only a qualified tire technician

should perform this p rocedure. Cons ult with your Cub

Cadet dealer about having liquid ballast added to

your tires, and for any special maintenance

instructions after the procedure is performed.

Rear Weight Box

Consult with your Cub Cadet dealer about available

rear weight boxes. Your dealer can help in

determining the positioning of the box and the amount

of weight needed for your particular application.

29

Page 30

SECTION 3: ADJUSTMENTS

ADJUSTING THE SEAT

For the comfort of the operator, a single lever

adjustable seat is provided to set the fore to aft

position of the seat. Adjust the seat to the most

comfortable position that allows you to operate all

controls and pedals.

WARNING: Do not adjust the seat when

the tractor is moving, as this could cause

the operator to lose momentary control

of the tractor and result in an accident.

• To adjust the seat, pivot the seat adjustment

lever to the left and hold while repositioning the

seat to the desired position. See Figure 40.

SEAT

ADJUSTMENT

LEVER

t

a

e

S

e

d

i

l

S

Pivot Lever

to Left

Figure 40

• After repositioning the seat, release the lever to

lock the seat in position. Slide the seat either

slightly forward o r rearward to assu re it is locked

or until engagement of the lock is felt.

ADJUSTING FRONT WHEEL TOE-IN

The front wheel toe-in is s et at the facto ry and shou ld

maintain the proper setting. However, the toe-in

should be checked periodically and readjusted if

necessary.

A

JAM

NUT

TIE

ROD

B

JAM

NUT

Figure 41

• Distance ‘A’ should be .08" to .31" less than

distance ‘B’ if the toe-in is correct. If it is not,

adjust the toe-in.

READJUST THE TOE-IN AS FOLLOWS:

• Loosen the jam nuts a t both ends of the tie rod.

Refer to Figure 41.

• Turn the tie rod in either direction to adjust its

length.

- Shorten the tie rod to increase distance ‘A’ and

decrease the toe-in.

- Lengthen the tie rod to decrease distance ‘A’

and increase the toe-in.

• Adjust the tie rod as necessary to obtain the

correct toe-in, then tighten the jam nuts.

ADJUSTING FRONT AXLE

Looseness or play in the front axle may cause serious

trembling of the front wheels and vibration of the

steering wheel. Check and adjust the front axle as

follows:

• Raise and support the front of the tractor so that