Page 1

OPERATOR’S MANUAL

SERIES 7000

COMPACT TRACTOR

Model Numbers

7530

7532

IMPORTANT:

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A. FORM NO. 769-01060

(1/04)

Page 2

Manufacturer Statem

issio

ntr

Off-Road Diesel Engine

Emission Control System Warranty Statement

Emission Related System Defect Warranty

Manufacturer Statement

Mitsubishi Heavy Industries, ltd. (MHI) will give a warranty condition, required by the

U.S. Environmental Protection Agency(EPA) and the California Ai r R esource

Board(CA RB) to Original Equipment Manufacturers (OEMs) for small off-road engines

purchased in 1997 and later which are used in U.S.A.

It is the OEMs responsibility to give the following warranty to the end-users for small

off-road engines purchased in 1997 and later which are used in U.S.A.

The manufacturer of MHI small off-road engines has authorized equipment

manufacturers to be the direct contact for all warranty and service related questions

and/or repairs. All inquiries should be direct ed to equipment manufacturers only.

Em issio

Applicable only to engines purchased in U.S.A. in 1997 and thereafter which are used

in U.S.A. .

EPA emission control defects warranty statement – Your (Customer) defects warranty

rights and obligations:

EPA and Mitsubishi Heavy Industries, Ltd. are pleased to explain the emission control

system warranty on your 1997 and later small off-road engine. In U.S.A., new small

off-road engines must be designed, built and equipped to meet the EP A stringent

anti-smog s t andards. Mitsubishi Heavy Industries, Ltd. must warrant the emission

control system on your small off-road engine for the periods of time listed below,

pr ovided there has been no abuse, neglect or imp r oper maintenance of your small

off-road engine.

Where a warrantable condition exists, the (OEMs) will repair your small off-road

engine at no cost t o you including diagnosis, parts and labor .

n CoControl Warranty Statement

A

Page 3

Manufacture

r

s warra

n

ecific W

anted Parts

Manufacturer

Applicable only to engines purchased in U.S.A. in 1997 and thereafter which are used

in U.S.A.

Emission control systems warranty coverage.

The small off-road engines are warranted as to emission control parts defects for a

period, which is prescribed by US EPA CFR Part 89, subject to provisions as set forth

hereafter . If any covered part on your engine is defective, the part will be repaired by

(OEMs).

’s Emission Control Warranty Coverage

Owner ’s warran

As the sma ll off-road engine owner , you are responsible for the performance of the

required maintenance listed in your owner ’s manual. (OEMs) recommends that you

retain all receipts covering maintenance on your small off-road engine. But (OEMs)

cannot deny warranty solely for the lack of re ceipts or for your failure to ensure t he

performance of all scheduled maintenance.

As the small off-road engine owner, you should be aware, howe ver, that OEMs may

deny you warranty coverage if your small off-road engine or a part has failed due to

abuse, neglect, i mproper maintenance or un appr oved modifications.

You are responsible for pr esenting y our small off-road engine to an authorized service

dealer (authorized by OEMs) of small off-road engines as soon as a problem exists. The

undisputed warranty repairs should be completed in a reasonable amount of time, not

to exceed 30 days. If you have any questi on regarding your warranty rights and

responsibilities, you should contact (CUB CADET) at

warranty is a defects warranty. Defects are jud ged on normal engine perf ormanc e.

The warranty is not rela ted to an in-use emission test.

Specific W

ty responsibility

arranty Provisions

1-330-273-4550. The emission

The following are specific provisions relative to your emissions control systems

warranty coverage.

Warrrranted Parts

Coverage under this warranty extends only t o the parts listed below (the emission

control systems parts) to the extent these parts were present on the engine purchased.

B

Page 4

Length of Coverage

No Charge

Claims an

Coverage Exclus

Fuel injection system

Fuel injection pump

Fuel inj ectors

Inlet system

Intake manifold

Exhaust system

Exhaust manifold

Turbocharger system

Turbocharger (it equipped)

Miscellaneous items used in above systems

Cylinder Head Gasket

Valve Stem Seal

Length of Coverage

MHI warrants to the initial owner and each subsequent purchaser that the warranted

parts shall be free from defects in materials and workmanship which cause the failure

of the warranted part(s) for a period, which is prescribed by US EP A CFR Part 89,

from the date the engin e is delivered to a retail purchaser.

For all engines rated under 19kW and for constant speed engines rated under 37kW

with rated speeds greater than or equal to 3,000 rp m, the warranty period is

3,000 hours or 5 years of use, whichever first occurs.

For all other engines rated at or above 19kW, the warranty period is 5,000 hours or 7

years of use, whichever first occurs.

No Charge

Repair or replacement of any warranted part will be performed at no charge to the

owner, including diagnostic labor which leads to the determination that a warrant ed

part is defective, if the diagnostic work is perfor med at an authorized service dealer of

small off-road engines to whom OEM s would sell engines.

Claims an

Warranty claims shall be filled in accordance with the provisions of the OEMs engine

warranty policy . Warranty coverage shall be excluded for fail ures of warranted parts

d Coverage Exclus

ions

C

Page 5

Maintenance

Conse

uential Coverage

which are not original OEMs parts or because of abuse, neglect or impr oper

maintenance as s et forth in the OEMs engi ne warranty policy . OEMs is not liable to

cover failures of warranted parts caused by the use of add-on, non-original, or modified

parts.

Maintenance

Any warranted part which is not scheduled for rep l acement as required maintenance

or which is scheduled only for regular inspection to the effect of “repair or replace as

necessary” shall be warranted as to defects for the warranty period. Any warranted

part which is scheduled for replacement as required maintenance shall be warranted

as to defects only of the period of time up to t he first scheduled replacement for that

part. Any replacement part that is equivalent in performance and durability may be

used in the performance of any maintenance or repairs. The owner is responsible for

the p erfor mance of all required main tenance, as defined in t he MHI owner’s manual.

Conse

quential Coverage

Coverage hereunder sha ll extend to the failure of any engine components caused by

the failure of any warranted part still under warranty.

D

Page 6

INTRODUCTION

INTRODUCTION

This instruction manual contains information on the operation, lubrication

and maintenance of your tractor. The information contained is

comprehensive and essential, and is designed to assist you, even if

unexperienced, in utilizing your tractor.

How well your tractor continues to give satisfactory performance depends

greatly upon the manner in which it is operated. It is, therefore, requested

that this manual be read carefully and kept ready for use so that the

operation and maintenance service will properly be carried out in order to

keep the tractor in top mechanical condition at all times.

Should any information as to your tractor be required, consult your local

dealer or distributor stating the machine and engine serial numbers of the

tractor concerned. We are sure you will be happy with your tractor.

NOTE: Expressions such as LEFT, RIGHT, FRONT, or REAR used in this

manual should be understood in accordance with following rules:

FRONT means the front grill end while REAR means the lifting arm end of

the tractor. LEFT or RIGHT means the left or right hand side of the tractor

looking forward from operator’s seat.

REAR

RIGHT

TURN RIGHT TURN LEFT

LEFT

FRONT

I

Page 7

SERIAL NUMBERS

SERIAL NUMBERS

Write your machine Model Name and Serial Numbers of major components

on the lines provided. If needed, give these numbers to your dealer when

you need parts or information for your machine.

1. TRACTOR MODEL NAME

2. TRACTOR SERIAL NUMBER

3. ENGINE SERIAL NUMBER

4. ROPS SERIAL NUMBER

SERIAL NUMBER LOCATIONS

ROPS SERIAL NUMBER PLATETRACTOR MODEL NUMBER AND

SERIAL NUMBER PLATE

ENGINE SERIAL NUMBER

II

Page 8

GENERAL TABLE OF CONTENTS

Safety/Decals 1~13

Specifications 14~18

Instruments/Controls 19~35

Operating Instructions 36~54

Field Operation 55~64

Tires/Wheels/Ballast 65~75

Lubrication/Filters/Fluids 76~103

Maintenance/Adjustments 104~109

Electrical System 110~116

Storage 117~118

III

Page 9

SAFETY/DECALS

SAFETY PRECAUTIONS

REMEMBER: “SAFETY” IS ONLY A WORD UNTIL IT IS PUT INTO

PRACTICE

Improper handling of the tractor could cause an accident. Prior to the

operation of the tractor, be sure to read this Manual carefully and have

a thorough understanding of all of the contents. In particular, the instructions

given in this section entitled “Safety Precautions” must be strictly followed.

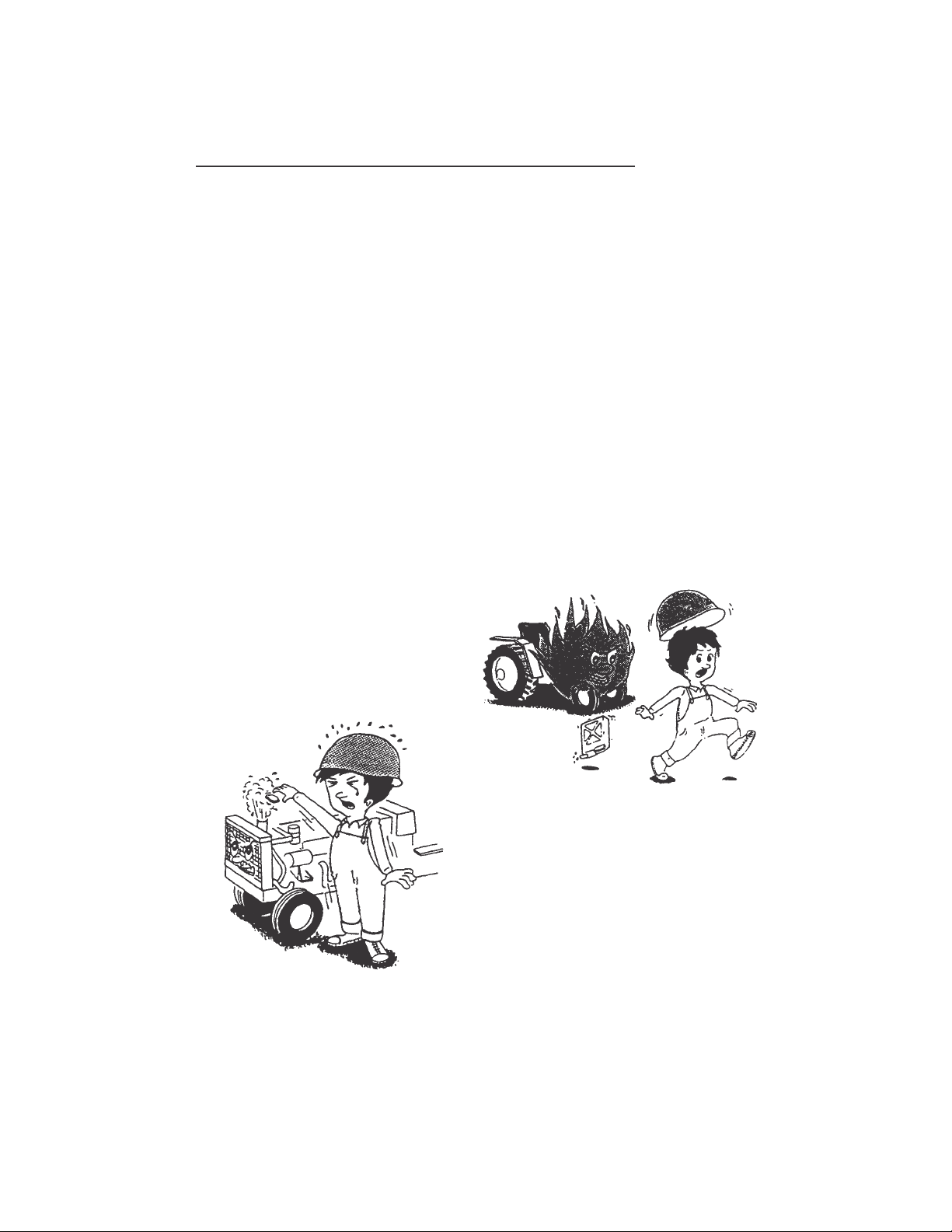

A. GENERAL OPERATING

SAFETY PRECAUTION

1. Observe all the safety

precautions in this manual

when operating the tractor.

2. Operate the tractor while

wearing tight clothing that

allows easy movement.

Avoid loose jackets, mufflers, ties,

scarves, or loose shirt

sleeves to prevent from being

caught by moving parts.

3. Always work when you are in

good physical condition by

taking sufficient rest to avoid

overwork.

4. Do not allow children or adults

having no knowledge of the

tractor or tractor operation,

to operate the tractor.

5. Never allows riders on the

tractor, linkage drawbar or

attachment while traveling

and operating them.

B. BASIC SAFETY REQUIREMENTS

FOR MAINTENANCE

Always follow these maintenance

instructions before operating

the tractor:

1. Immediately repair the head

lights and work lamps required

to conform to traffic regulations

where the tractor is operated.

2. Keep tractor steps clean to

avoid accidents due to

slippage.

1

Page 10

SAFETY/DECALS

3. Cover the PTO shaft with a guard

when not using.

4. Be sure to engage the brake and

lower any attachment or implement

before disassembling any part.

5. Never adjust or service the tractor

when it is in motion or while the

engine is running. Always adjust

the brake or clutch properly in

accordance with the adjusting

procedure in the instruction book.

6. Do not remove the radiator cap

while the engine is running.

Shut down the engine and wait

until it cools sufficiently. For

removal, turn the cap to the first

stop to relieve pressure.

To replace the coolant, use the

coolant recovery tank.

7. Hydraulic oil or fuel escaping

under pressure can penetrate

the skin, causing serious injury.

Before disconnecting oil or fuel

lines, be sure to relieve all pressure.

Before restoring pressure after

repair, be sure all connections are

tight and all hydraulic components

are in normal condition. If injured

by leaked fluid, see a doctor

immediately for proper treatment.

8. When refueling, be particularly

careful first to stop the engine

completely to prevent the fuel

from igniting. Never refuel in the

presence of an open flame or

while smoking.

2

Page 11

SAFETY/DECALS

9. Before starting any work on

electrical equipment or work that

may cause you to touch the

electrical parts accidentally, first

disconnect the battery cables.

Never remove the rubber cap

cover at the positive terminal of

the battery cable end. Before

connecting the battery to the

charger, make sure that the

charger switch is in “OFF” position.

Be sure to connect the charger to

the correct terminals on the battery

(positive to positive, negative to

negative).

A great amount of hydrogen gas is

generated by the battery when it is

being charged. Take precautions

against fire: Do not have any

exposed flame in the area where

you are working.

Be sure not to cause any leakage

of the electrolyte, since it will

corrode the skin or clothing.

In case of accident as described

below, immediately seek first aid,

and see a doctor immediately for

proper treatment.

c) If diluted sulfuric acid has gotten

on the skin of clothing: Wash away

the diluted sulfuric acid completely

with a lot of clean running water and

neutralize with soap solution.

Then rinse with water.

d) If the diluted sulfuric acid is spilled:

Wash away with a lot of water or

neutralize with slacked lime or

bicarbonate of soda.

10. Stop the engine and make sure

the PTO shift lever is in Neutral

before performing any of the

following services, including.

a) Removal of the propeller shaft

between PTO and any attachment.

b) Adjustment of PTO drive train

and hitch.

c) Adjustment or cleaning of PTO

driven attachment.

a) If the diluted sulfuric acid from

the battery has gotten into

the eyes:

Cleanse the eyes with a lot of

clean running water for more

than 15 minutes, while opening

the eyes widely.

b) If diluted sulfuric acid from the

battery has been swallowed:

Rinse the mouth with clean

water immediately and drink

a lot of raw eggs or milk. Lie

down quietly.

11.The steering wheel always has

built-in play to some extent, which

is required for smooth meshing

of sector gear and pinion gear.

Always inspect the amount of

the play. Do not operate the

tractor if there is too much or

too little play in the steering.

3

Page 12

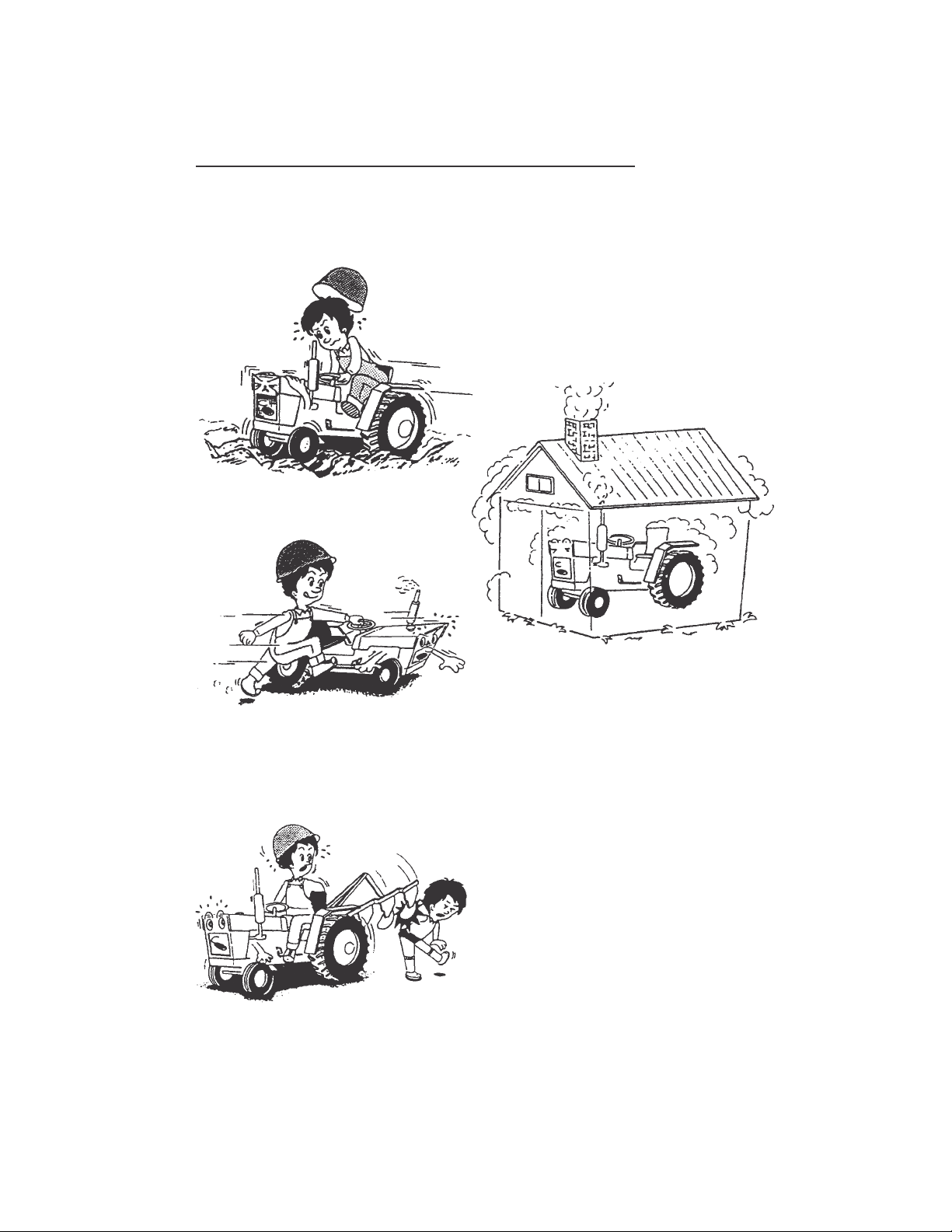

C. OPERATION OF THE TRACTOR

Before driving the tractor,

follow these rules:

C-1. Before starting and Driving

the Tractor

Operate the tractor only when

seated properly in operator’s seat

and keep a firm grip on the

steering wheel at all times.

Never attempt to perform any

operation of the tractor from

anywhere else, on or off the tractor.

Always wear a “hard hat” when

operating the tractor.

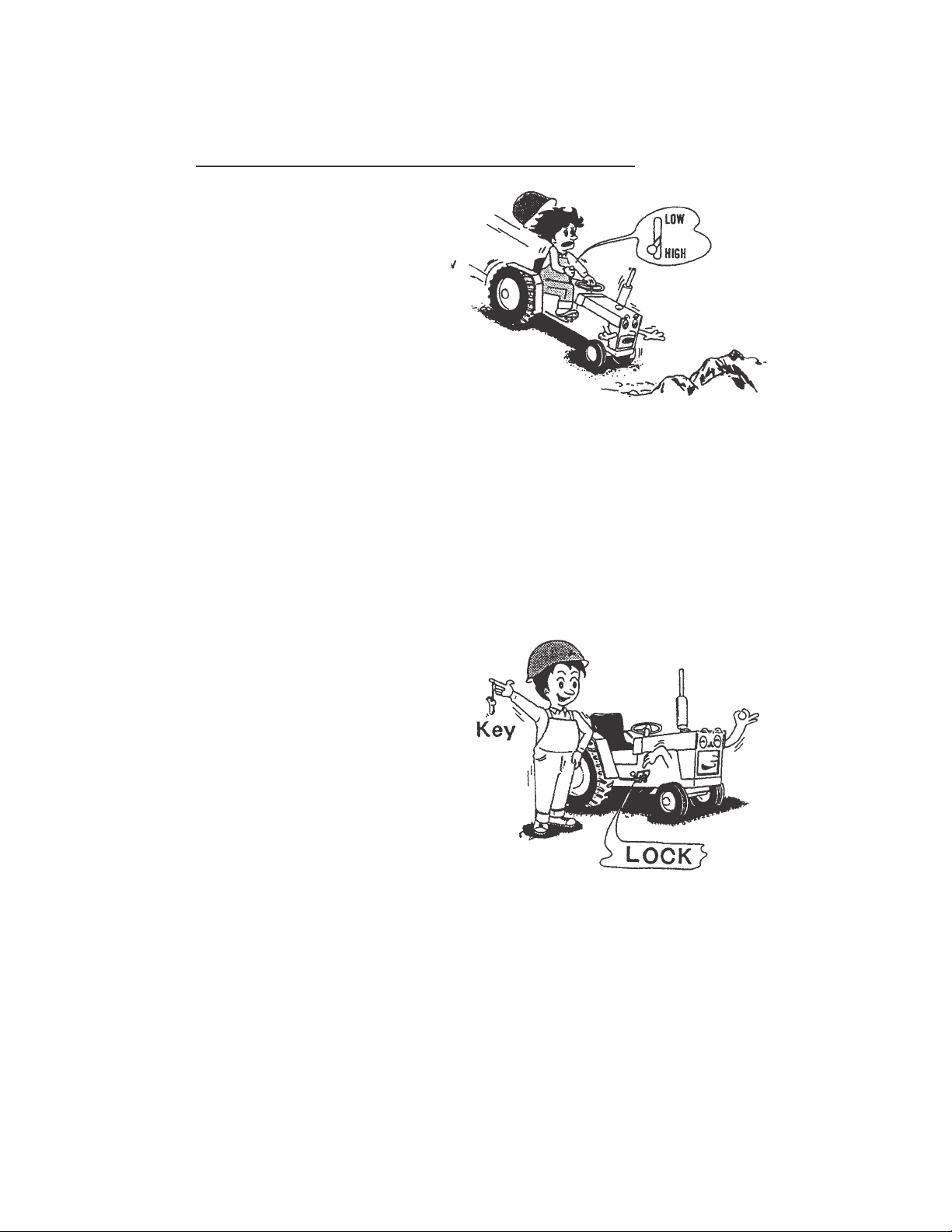

C-2. Starting and Driving the Tractor

Always operate the tractor at the

proper speeds which enable you

to keep the tractor in complete

control.

SAFETY/DECALS

To start traveling, lower the

engine speed and release the

clutch pedal slowly.

Before leaving the tractor, stop

the engine, remove the key,

apply the parking brake and

make sure that the engine has

come to a complete stop, and

any attachment is completely

touching the ground.

4

Page 13

SAFETY/DECALS

Slow down when operating the

tractor on rough ground.

Never attempt to jump on or off

a moving tractor.

When starting the engine in an

enclosed area or building, ensure

proper ventilation by opening the

doors and/or windows to prevent

carbon monoxide inhalation.

Mount the extension exhaust pipe

on the tractor which has a cabin.

When starting the tractor,

operating any attachment or

engaging the PTO make sure

that no one is in the way,

especially children.

5

Page 14

SAFETY/DECALS

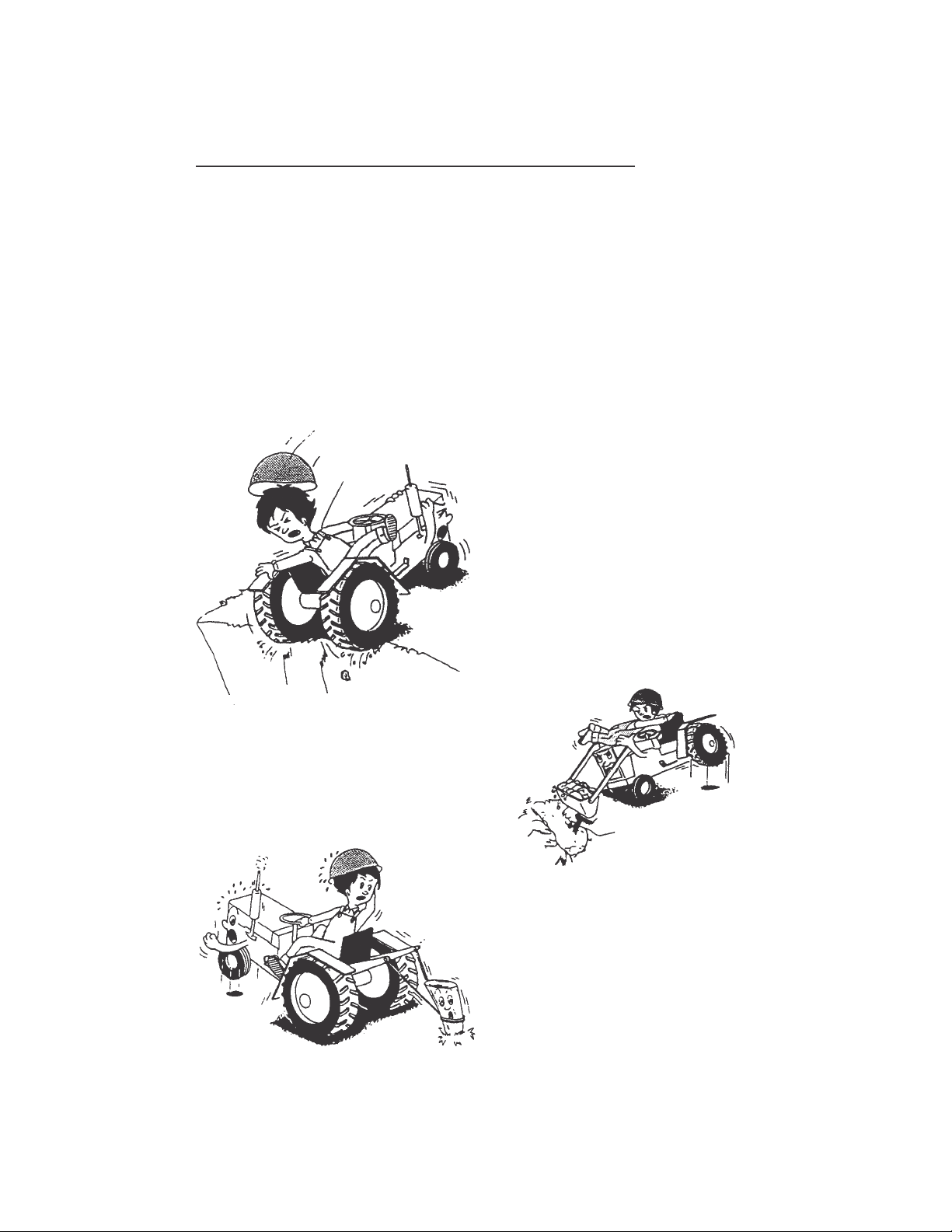

C-3. Traveling on Roads and Streets

For traveling on roads and streets

be sure to lock both brake pedals

together before driving to prevent

either brake from acting

independently.

Never operate the differential lock

while driving at high speed or

traveling on the road. For driving

the 4-WD tractor on the road,

be sure to place the 4-WD shift

lever in OFF position.

C-4. Steering and Turning the

Tractor

Slow down your tractor and

disengage the differential lock

before going into a turn, being

careful to prevent any attachments

mounted on the front or rear from

hitting anyone or anything

C-5. Towing and Operating

on Hills

For towing work on downward

slope, place the shift lever in low

speed and use engine brake.

Never try to reduce the speed with

brake only.

Towing a heavy object on a hill is

highly hazardous.

Widen the tread of the tractor and

mount the wheel weight or chassis

weight to increase the stability

and operate with extra precaution.

6

Page 15

SAFETY/DECALS

When operating the tractor on

either a steep slope or flat ground,

be sure not to suddenly steer,

brake, clutch or operate

attachments.

Do not operate the tractor at the

edge of cliff or slope. Be

particularly careful right after the

rain when soil is soft and may

give way easily.

Avoid operating the tractor on

an extreme slope that appears

hazardous, when forced to

operate on such slope, use extra

care. Driving forward out of a ditch

or mired condition or up a steep

slope could cause tractor to tip

over rearward.

Back out of such situation if possible.

If the situation does not permit you

to back out, use the front wheel

weight or the chassis weight for

balancing the tractor lengthwise.

Also in case any extra-heavy rear

mounting attachment is used, try

to obtain better balance in this

manner.

C-6. Using Attachment

To mount or operate attachment,

follow the instruction manual for

the particular attachment for safe

operation.

For towing, be sure to use the

drawbar only. Set the hitch point

below the center line of the rear axle.

When using a chain, never try to

move forward abruptly.

When using agricultural

chemicals with an attachment

on the tractor, always follow the

instructions in the manual for

the attachment as well as the

instructions provided by the

chemical manufacturer.

7

Page 16

SAFETY/DECALS

DECALS

IMPORTANT: Install new decals if the old decals are destroyed, lost,

painted over or can not be read. When parts are replaced that have decals,

make sure you install a new decal with each new part.

NOTE: New decals are available from your Dealer.

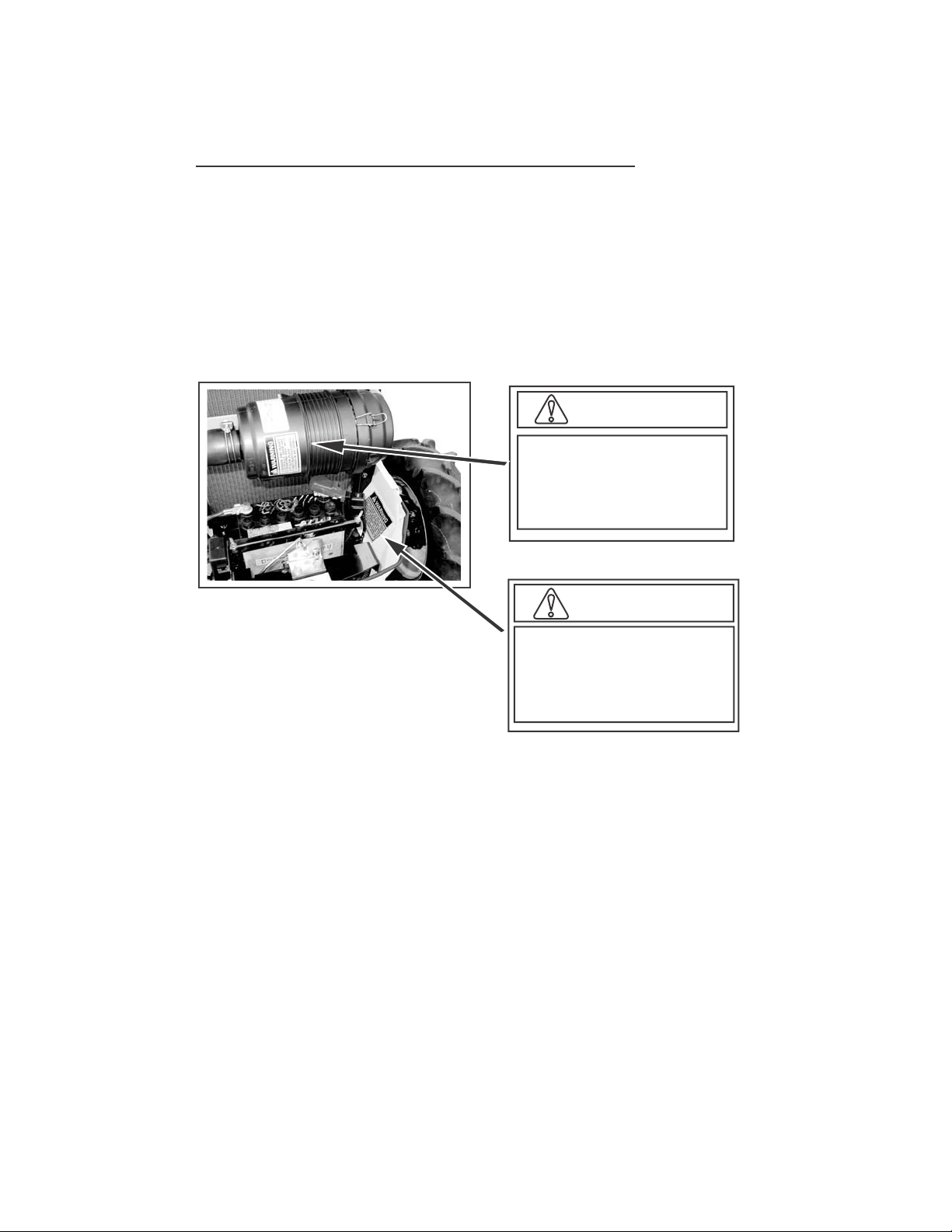

WARNING

EXPLOSION AND INJURY

CAN RESULT FROM USE

OF STARTING AIDS WITH

HOT GLOW PLUGS.

DO NOT INJECT GASOLINE

OR ETHER IN AIR INTAKE.

WARNING

BATTERIES CONTAIN ACID AND EXPLOSIVE

GAS. EXPLOSION CAN RESULT FROM

SPARKS,FLAMES, OR WRONG CABLE CONNECTIONS. TO CONNECT JUMPER CABLES

OR CHARGER, SEE MANUAL(S) FOR THE

CORRECT PROCEDURE. FAILURE TO

FOLLOW THE ABOVE INSTRUCTIONS CAN

CAUSE SERIOUS PERSONAL INJURY OR

DEATH

321-6714

8

Page 17

SAFETY/DECALS

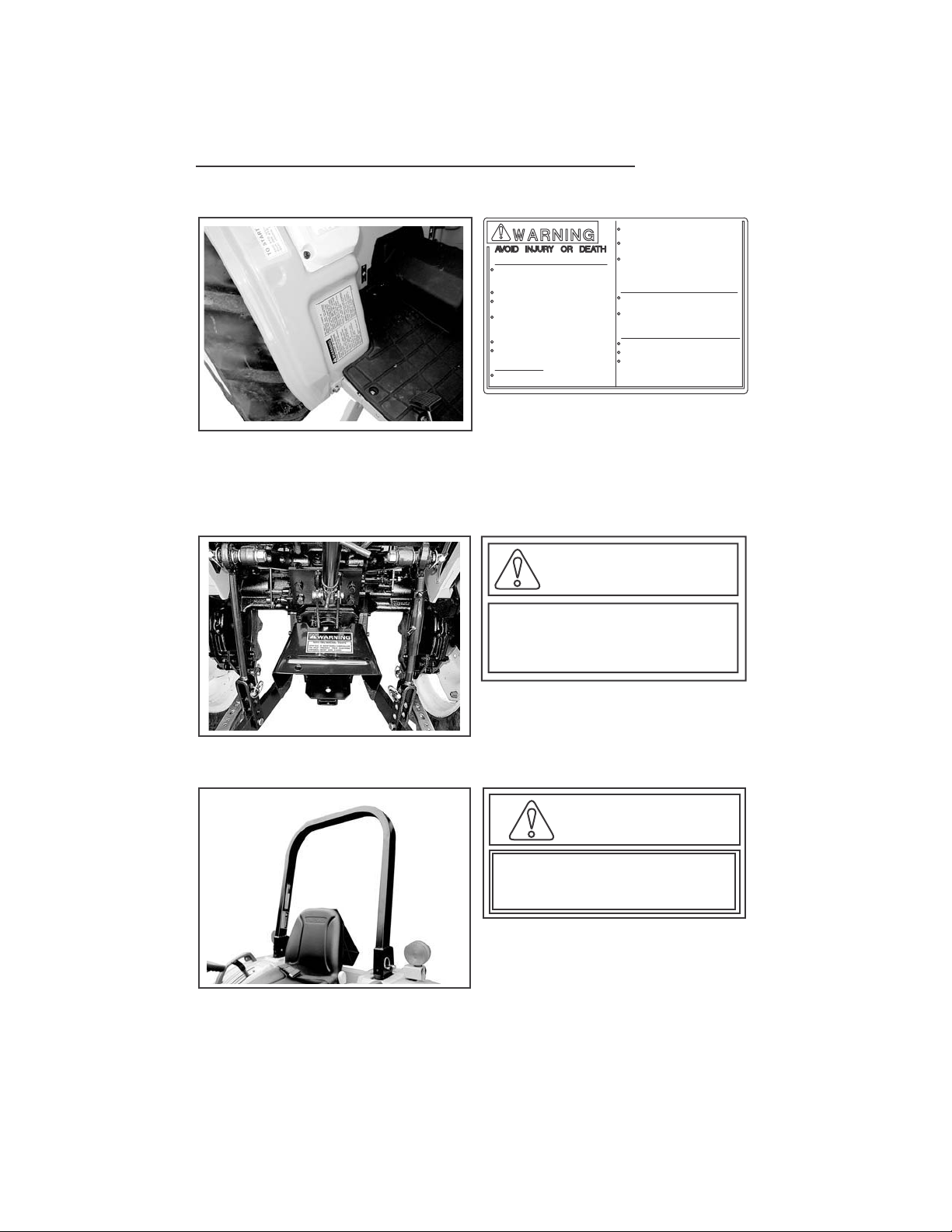

WARNING

ROTATING MACHINE PARTS

STAY CLEAR,KEEP SHIELDS INSTALLED

TO HELP PROTECT FROM CLOTHING

ENTANGLEMENT AND INJURY.

321-3710

WARNING

When improperly operated,this tractor can rollover or upset.Use of ROPS

and seat belt minimize the possibility of injury or death if rollover or

upset occurs.For low clearance use only,the ROPS can be lowered.NO

protection is provided in this position and the seat belt should not be

fastened.For all other uses.secure ROPS in upright position and fasten

seat belt.

9

1991603C1

Page 18

SAFETY/DECALS

Tractor Roll Over

ROPS is a special safety unit. After an accident the ROPS must be

replaced so that you will get the same protection as a new ROPS.

ROPS, the seat, the seat belts and all the mounting, accessories and

wiring inside the operator’s protective area must be carefully checked

after a tractor accident and all parts with damage should be replaced

immediately. DO NOT TRY TO MAKE REPAIRS OR WELD ROPS.

Safety Rules

1. Do not make modification to the ROPS. Example, welding an accessory

to the ROPS, or drilling a hole in the ROPS.

2. Special fasteners are used to install the operator protective parts.

Replacement parts must be the same as given in the Parts Catalog

for your tractor.

ROPS Label

1. ROPS is equipped with a ROPS label.

2. The label contains the ROPS serial number and applicable standards.

10

Page 19

SAFETY/DECALS

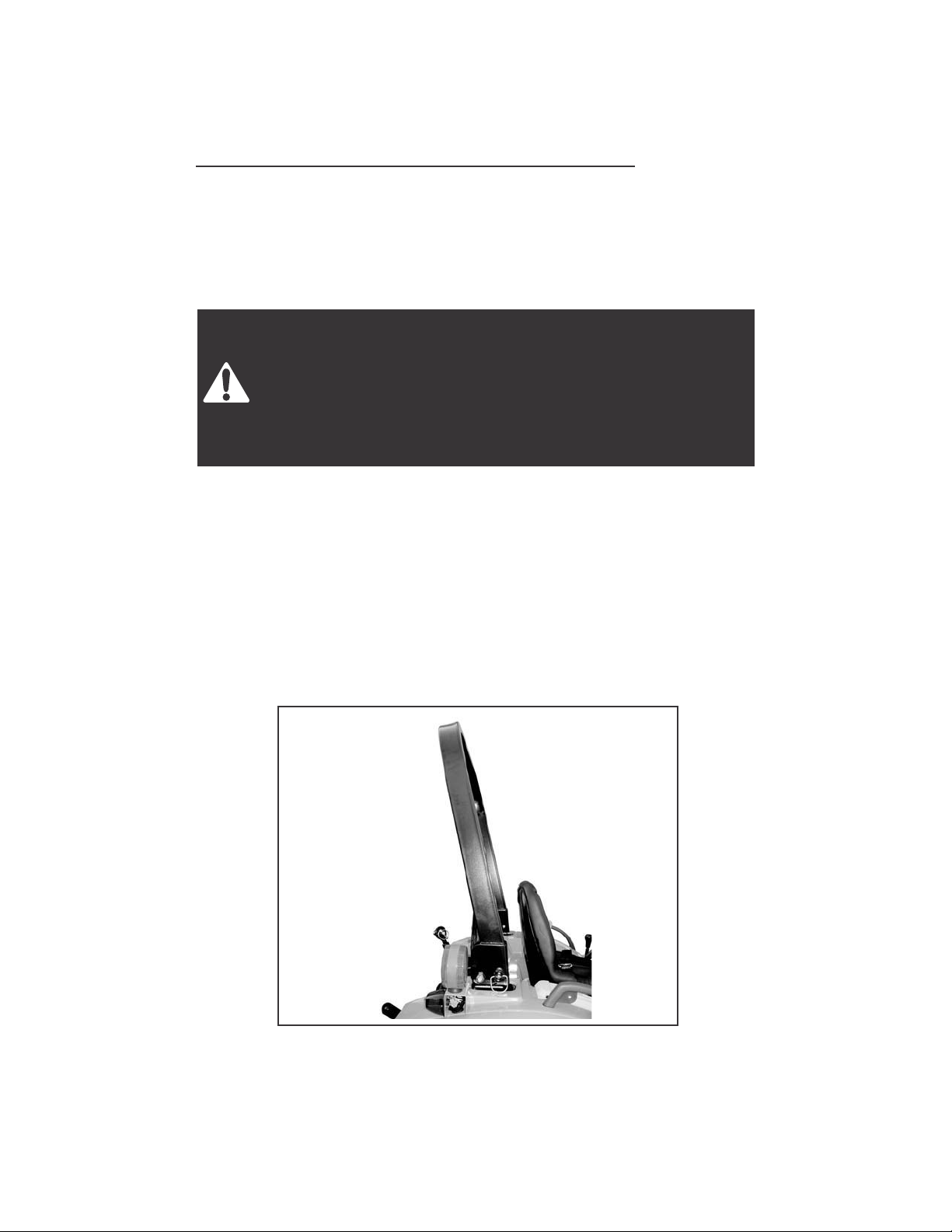

ROLL OVER PROTECTIVE STRUCTURE (ROPS)

Foldable ROPS Frame

When improperly operated, this tractor can roll over or upset.

Use of the ROPS and seat belt minimize the possibility of injury

or death if rollover or upset occurs. For low clearance use only,

the ROPS can be lowered. No protection is provided in this

position and the seat belt should not be fastened. For all other

uses, secure the ROPS in the upright position and the fasten

the seat belt.

ROPS is foldable so that the tractor can be operated in places such as

orchards where the height is restricted. See Folding the ROPS in this manual.

Normal Operating Position

For normal operation, including transport, always use the foldable ROPS

in the secured upright position with a fastened seat belt for full rollover

protection.

11

Page 20

SAFETY/DECALS

Low Clearance Positions

For low clearance operation, such as operating in buildings, orchards or

vineyards, the ROPS can be lowered and secured in the down position.

No rollover protection is provided in the lowered positions and the seat

belt should not be fastened. When the low clearance operation is

completed, return the ROPS to the secured upright position for all other

tractor uses and transport.

IMPORTANT: When the ROPS frame is in the lowered position, make

sure there is clearance between the frame and hitch mounted equipment.

Slowly raise the hitch to maximum height to check for necessary clearance.

For drawbar attached and/or PTO driven equipment, check for clearance

including turning corners.

12

Page 21

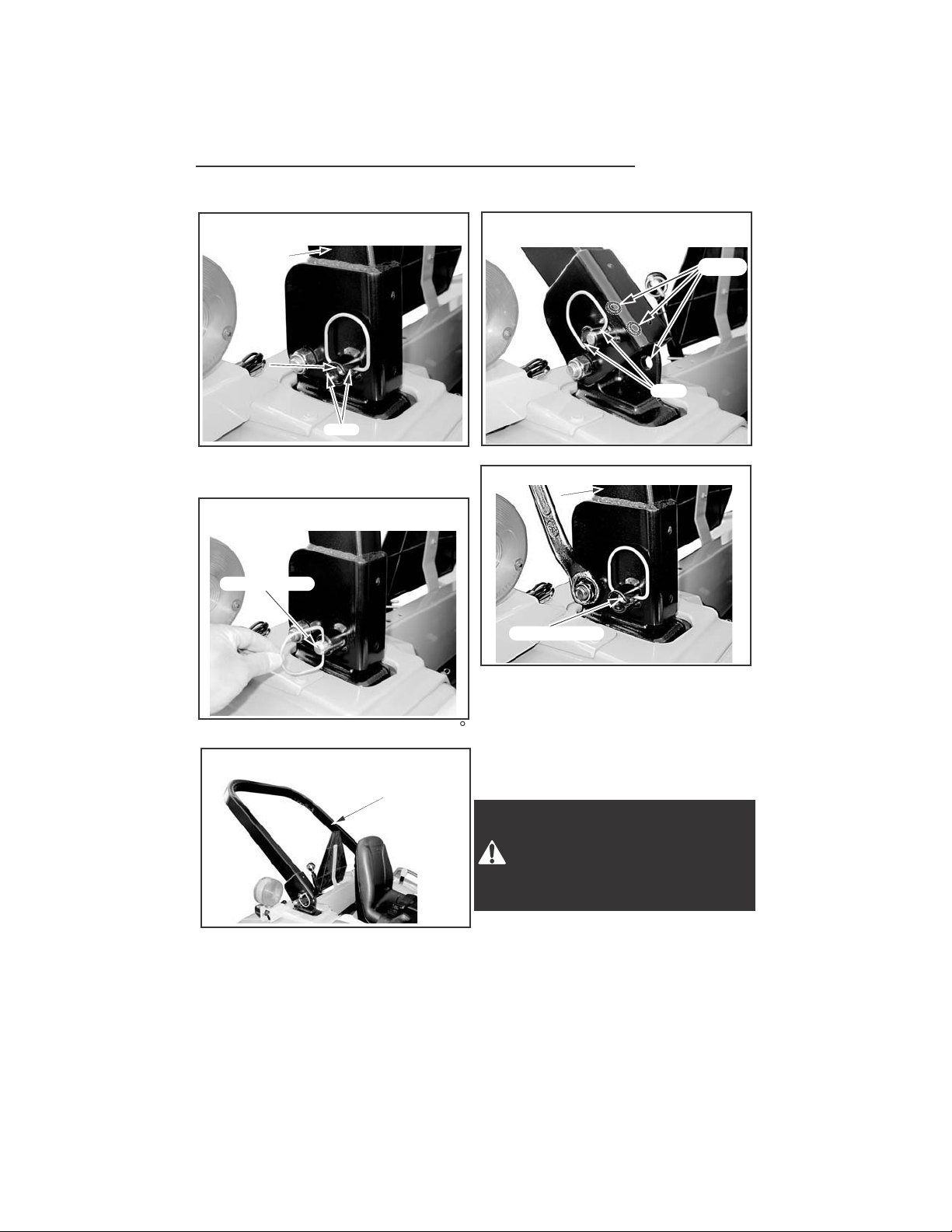

SAFETY/DECALS

POSITION

PIN

ROPS BAR

NORMAL

OPERATING

ROPS BAR

UPRIGHT

STEP 1

ROPS BAR

ROPS BAR

NORMAL

NORMAL

OPERATING

OPERATING

(

(

POSITION

POSITION

POSITION

PIN

While holding the ROPS bar.

CAREFULLY pull the position pins.

STEP 2

POSITION PIN

(

(

SLIT

STEP 4

STEP 5

ROPS BAR

ROPS BAR

UPRIGHT

UPRIGHT

(

(

POSITION

POSITION

POSITION PIN

HOLE

SLIT

((

((

And then Rotate position pin to (90 ).

STEP 3

ROPS BAR

CAREFULLY move the ROPS bar

to the desired position.

Rotate position pin and insert GUIDE

to SLIT. In this state, move ROPS bar

up and down and position pin is

installed completely ROPS bar can

set at three position.

13

Adjustment of Foldable ROPS.

If you feel less friction when the ROPS

is in the upright position, tighten the

nut untill you feel the right friction

in the movement.

Rollover protection is provided

only with proper assembly. Lock

pins, must be in place. Correct

parts may be obtained from your

dealer.

Page 22

General

Type

SPECIFICATIONS

DIESEL ENGINE

Three Cylinders, Four Stroke Cycle,

Valve in Cylinder Head, Cross

Flow Porting

Firing Order

Bore

Stroke

Piston Displacement

Compression Radio

Governor Engine Speed without Load

Rated Engine Speed

Engine Idle Speed

Maximum Horsepower (Per SAE J816b & J245)

7530

7532

Valve Clearance (Intake and Exhaust Cold Engine)

IMPORTANT: Valve clearance adjustment must be made when the

engine is not running and is cold.

1496cm (91.29 Cubic inch)

84mm (3.307 inch)

90mm (3.543 inch)

3

2670 to 2730 RPM

1005 to 1055 RPM

30 HP at 2500 RPM

32 HP at 2500 RPM

0.25 mm (0.010 inch)

1-3-2

18.0 to 1

2500 RPM

Engine Lubrication System

Oil Pressure

Fuel System

Fuel Injection Pump

Injection Pump Timing

Fuel Injectors

296 to 441kPa (43 to 64 PSI) at 2500

Engine RPM with 20 W Oil at

93.3 C (200 F)

BOSCH M Plunger In Line

NIPPONDENSO ND – PFR

11Degrees Before Top Dead Center (BTDC)

Hole Type, NIPPONDENSO, ND – DLLA150P

14

Page 23

Air Intake System

Type

Cooling System

Type

Radiator

SPECIFICATIONS

Dry Type Air Cleaning System

with 2nd Filter

Pressure System, Thermostat

Controlled Bypass, Impeller Type Pump

Corrugated and Wave Fin Type

Thermostat

Pressure Cap

Water Temperature

Tractor Brakes

Type

Operation

Parking Brakes

Transmission

Type

Gear Drive

Hydrostatic Drive

Gear Selection

Gear Drive

Start to Open at Approx.82 C (180 F)

Fully Open at 95 C (203 F)

88.3kPa (12.8PSI)

Thermometer on Instrument Panel

POWER TRAIN

Wet Disk Plate Type

Mechanical

Hand Operating Lock Type

Synchromesh on shuttle shift

(forward-reverse section) and main

Gear Shift of constant mesh with

two Ranges of Selective Sliding Gears

Hydrostatic Transmission with Three

Ranges of Selective Sliding Gears

8 Speeds Forward and 8 Speeds Reverse

Hydrostatic Drive

Shift Control

Gear Drive

Hydrostatic Drive

Oil Cooler

3 Speed ranges in Forward and Reverse

with Variable Speeds.

Actuated by Two Shift Levers on the LH

Fender and shuttle lever on the column.

Actuated by Pedal on the RH Step and

lever on the LH Fender

Hydrostatic Drive only

15

Page 24

SPECIFICATIONS

Clutch

Type, Diameter

Gear Drive

Hydrostatic Drive

Operation Mechanical

Dry, Single Disc, Diaphragm Type,

215mm (8.46 Inch)

Dry, Single Disc, Diaphragm Type,

215mm (8.46 Inch)

Mechanical Front Drive (MFD)

Front Axle Spiral Bevel Gear Type Differential

with Bevel Gear Reductions

Differential Lock

Type

Gear Drive

Hydrostatic Drive

Controlled by Pedal on the RH Step

and Mechanically Actuated

Controlled by Pedal on the LH Step

and Mechanically Actuated

Steering

Type of Steering Hydrostatic Type

Hitch System

Type Three Point, Category

Type Control

Type Valve

Lifting Capacity at 24”behind Lift Point (Per ASAE S349.1)

Type of Cylinder

Three Positions, Lift, Hold and lower

16

Position Control

780kg (1720lbs)

Single Acting Type

Page 25

Hydraulic System

SPECIFICATIONS

Hydraulic Pump Type

Capacity

Pump for Three Point Hitch

Pump for Power Steering

Maximum System Pressure 15200kPa (2204PSI)

Auxiliary Connector Front Hydraulic Block

Connector Size 9.5mm (3/8 inch)

Front Mounted, Engine Driven,

Pressure Loading Gear Type

27.2 l/min (7.2GPM)

at 2500 Engine RPM

12.3 l/min (3.3GPM)

at 2500 Engine RPM

Rear Power Takeoff (PTO)

PTO Type

Gear Drive Independent PTO

Hydrostatic Drive Live PTO

Location

Rotation

Shaft Size

Speed

34.9 mm (1.375 Inch) Diameter, 6Splines

At the rear of transmission

Clockwise from rear of tractor

540 RPM at 2376 Engine RPM

Mid Power Takeoff (PTO) OPTION

PTO Type

Gear Drive Independent PTO

Hydrostatic Drive Live PTO

Location

Rotation

Shaft Size

Speed

25.4mm (1 Inch) Diameter, 15Splines

At the Bottom of Transmission

Clockwise from Rear of Tractor

2000 RPM at 2632 Engine RPM

Drawbar

Type

Distance from Hitch Hole to the End of PTO Shaft

358mm (14.092 inch)

Maximum Vertical Load on Drawbar

17

Fixed Type

440Kgf (969Lb)

Page 26

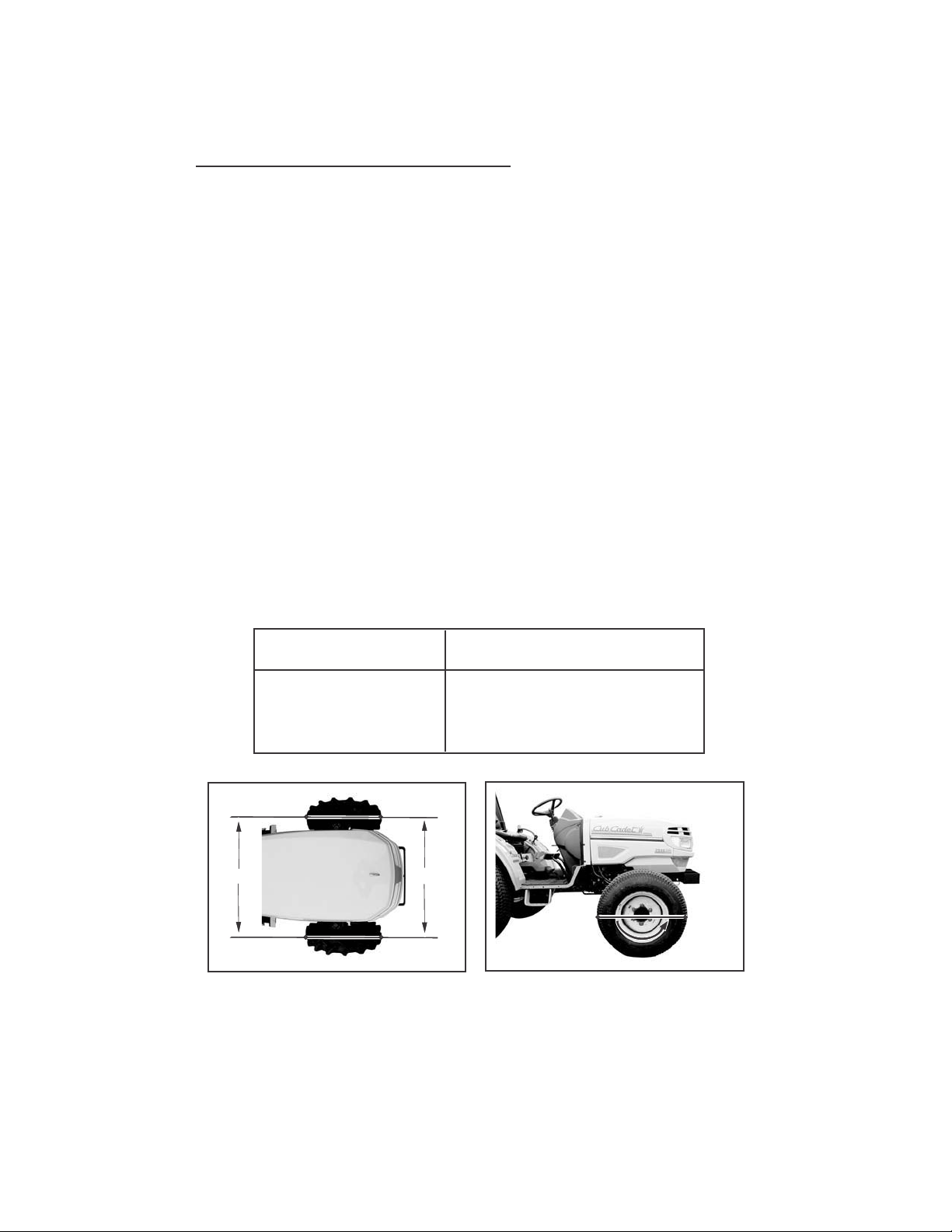

SPECIFICATIONS

Overall length (To end of Lower link)

3080 mm (121 inch)

Overall width (To end of tire)

7530

7532

1360 mm (53.5 inch)

1365 mm (54 inch)

Height (To top of ROPS)

7530

7532

2110 mm (83 inch)

2140 mm (84.3 inch)

Wheel base

7530 1710 mm (67 inch)

Ground Clearance

7530 370 mm (15 inch)

7532 325 mm (12.8 inch)

Turning Radius (with Brake Assistance)

7530

7532

2300 mm (78.8 inch)

2300 mm (78.7 inch)

Weight

7530

1060 kg (2370 lbs)

7532

1115 kg (2456 lbs)

18

Page 27

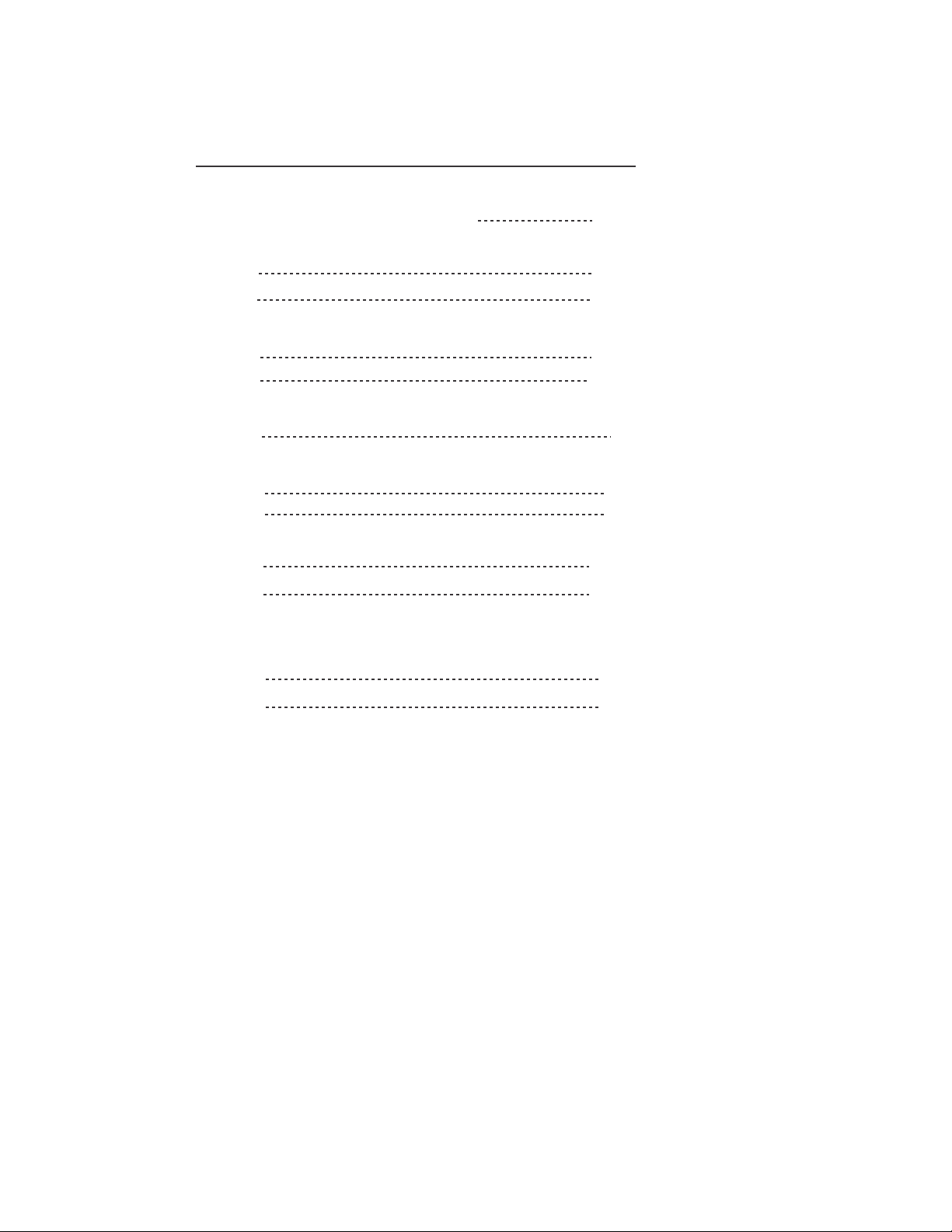

INSTRUMENTS/CONTROLS

INSTRUMENTS AND INDICATORS

1. TACHOMETER AND HOURMETER

Yellow line [A] shows the 540 rpm of the Rear

[A]

[B]

PTO speed.

Yellow line [B] shows the 2000 rpm of the MID

PTO speed.

The tachometer shows the

engine speed in revolutions per

minute (RPM). A symbol on the

face indicates the correct Power

Takeoff (PTO) operating speed.

The hour meter shows the hours

and tenths of hours that the engine

has operated at an average RPM.

19

Page 28

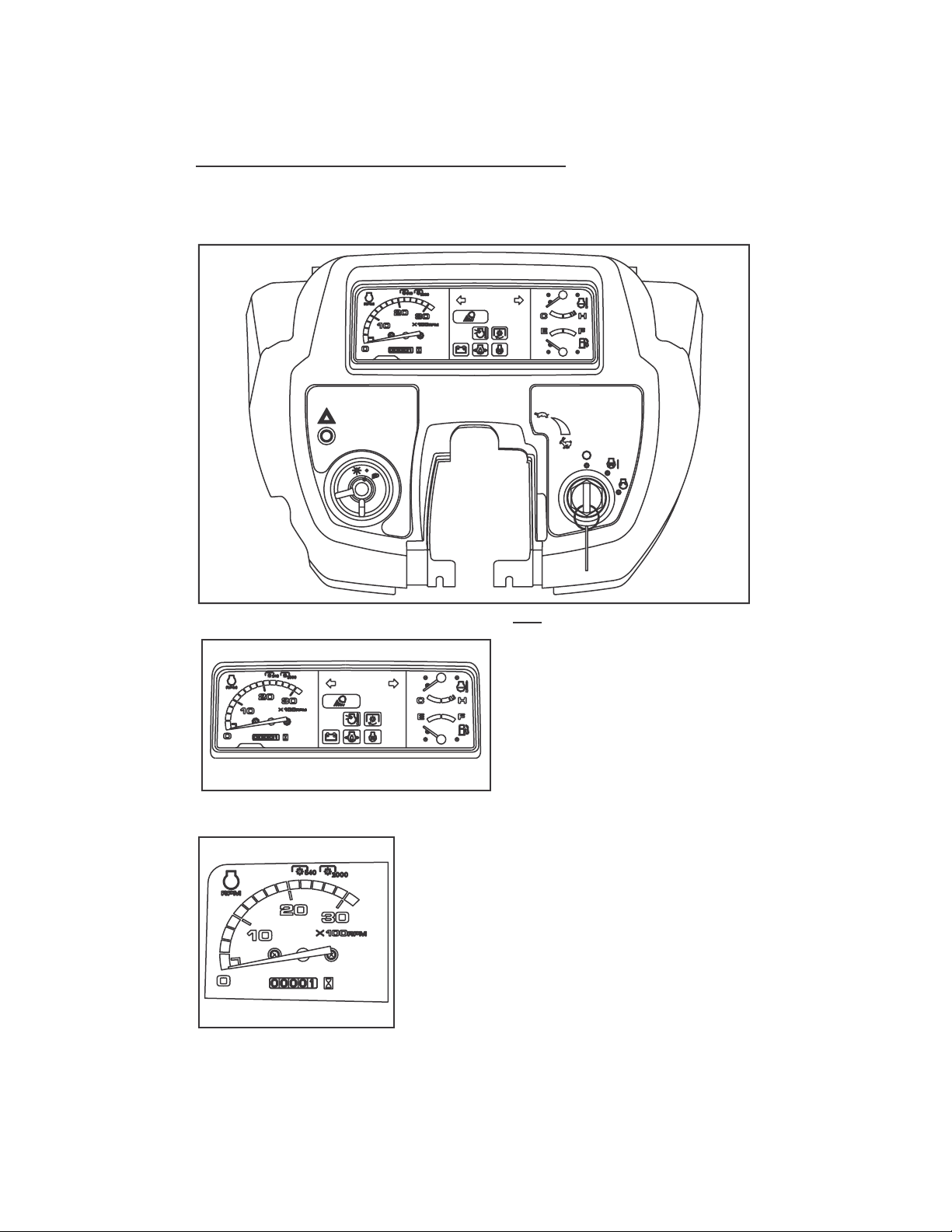

2. ENGINE COOLANT TEMPERATURE GAUGE

The gauge indicates the coolant

temperature when the starter key

switch is in ON position.

If the engine overheats, the pointer

moves right into H position area.

In this case, run the engine at

1500 RPM without load until the

pointer moves left out from H

position area. If the pointer still

stays in the H position area, stop

the engine immediately and check

for the cause.

INSTRUMENTS/CONTROLS

3. FUEL GAUGE

The meter shows how much fuel is in the tank.

NOTE: The pointer can be in

any position when the starter

key switch is in the OFF position.

4. TURN SIGNAL INDICATORS The LH indicator on the

TACHOMETER will operate when

the turn signal switch is turned to

the left. The RH indicator will

operate when the switch is turned

to the right. Both indicators will

operate ON and OFF when Hazard

switch is pushed down.

20

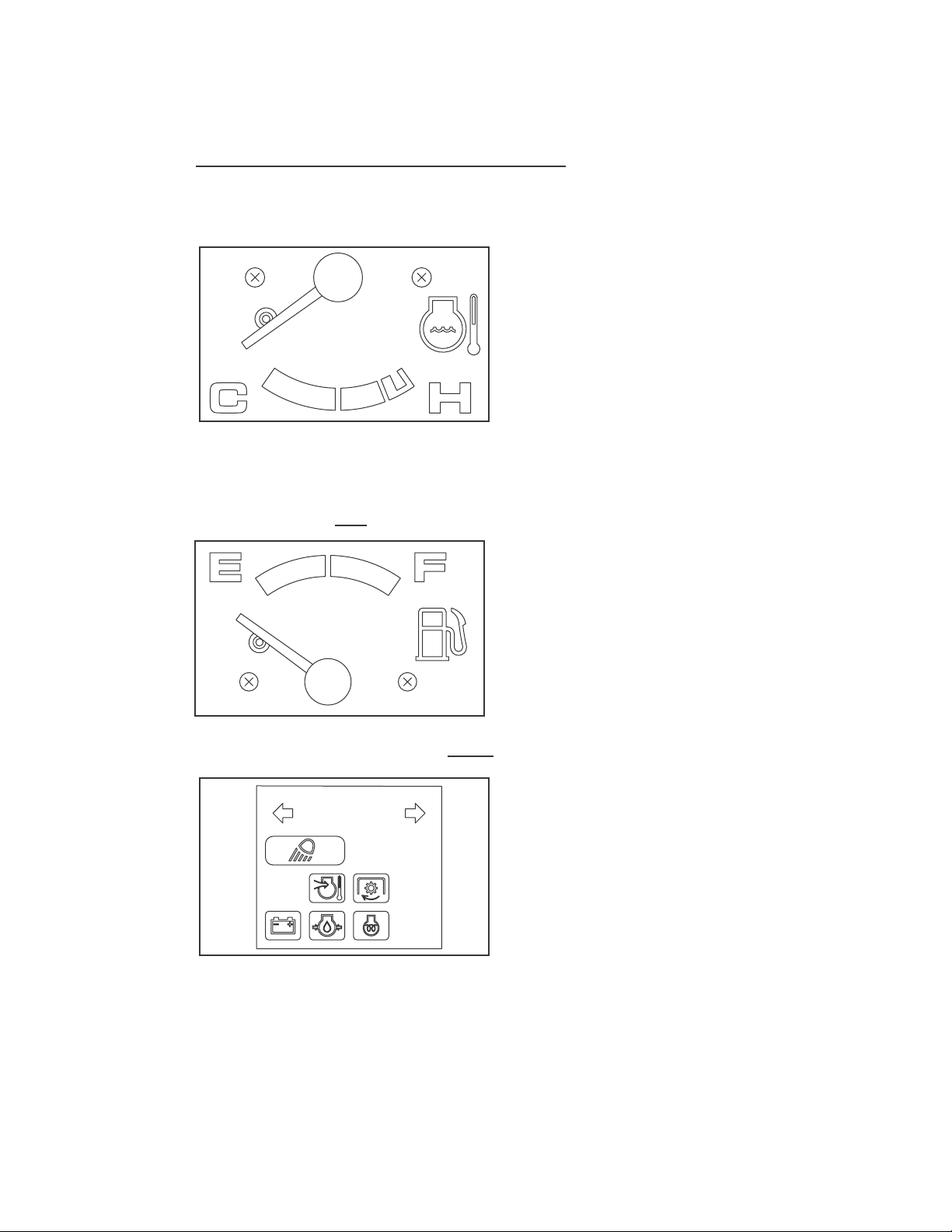

Page 29

5. ENGINE GLOW PLUG INDICATOR

This signal indicates the correct functioning

of the glow plug circuit. When the glow plugs have

reached the correct temperature for engine starting,

the glow plug indicator lamp will be put out.

INSTRUMENTS/CONTROLS

6. CHARGE INDICATOR

The charge indicator indicates the battery is

being discharged. If the lamp illuminates during

operation, stop the engine and check for the cause.

7. ENGINE OIL PRESSURE INDICATOR

The engine oil pressure indicator indicates

low engine oil pressure. If the engine oil pressure

drops below its normal pressure, the engine oil

pressure indicator will come on. Shut off the

engine immediately. Check for the cause.

8. INDEPENDENT PTO CLUTCH INDICATOR(GEAR DRIVE ONLY)

This signal indicates the INDEPENDENT

PTO CLUTCH is ON or OFF.

9. AIR HEATER INDICATOR This signal indicates AIR HEATER is ON.

21

Page 30

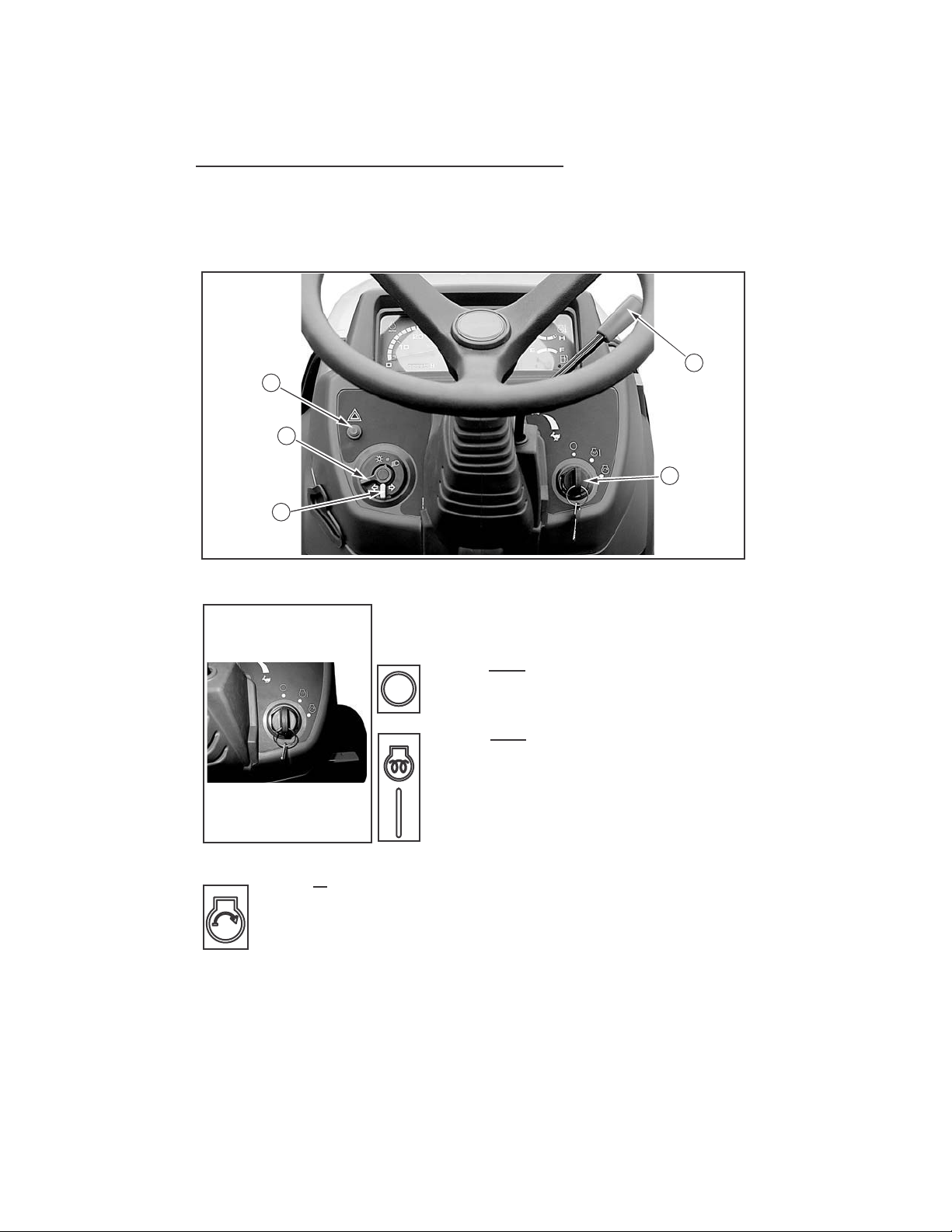

OPERATING CONTROLS

Control Switches

4

3

5

1. STARTER KEY SWITCH

The starter key switch can be removed with

the switch in the OFF position. Four position

switch as follows:

INSTRUMENTS/CONTROLS

2

1

position

(OFF)

Position

(HEAT)

&

(ON)

The fuel gauge and temperature gauge will show correct values.

position

(START)

NOTE: To prevent operation by persons not authorized and the possible

discharge of the battery, remove the starter key when you leave the tractor.

IMPORTANT: Do not keep the starter key switch in the ON position for

a long period of time when the engine is not operating.

Turn the key fully clockwise against the force of the

spring in the switch. The starter motor will turn the engine.

Release the key immediately when engine starts.

Engine and all lamps except

the turn signal and flasher lamps

are turned off.

First position clockwise from

OFF. In this position (Engine not

running) energizes the glow plugs.

The charge indicator, glow plug

indicator and oil pressure indicator

will illuminate.

22

Page 31

LAMP

INCREASE

INSTRUMENTS/CONTROLS

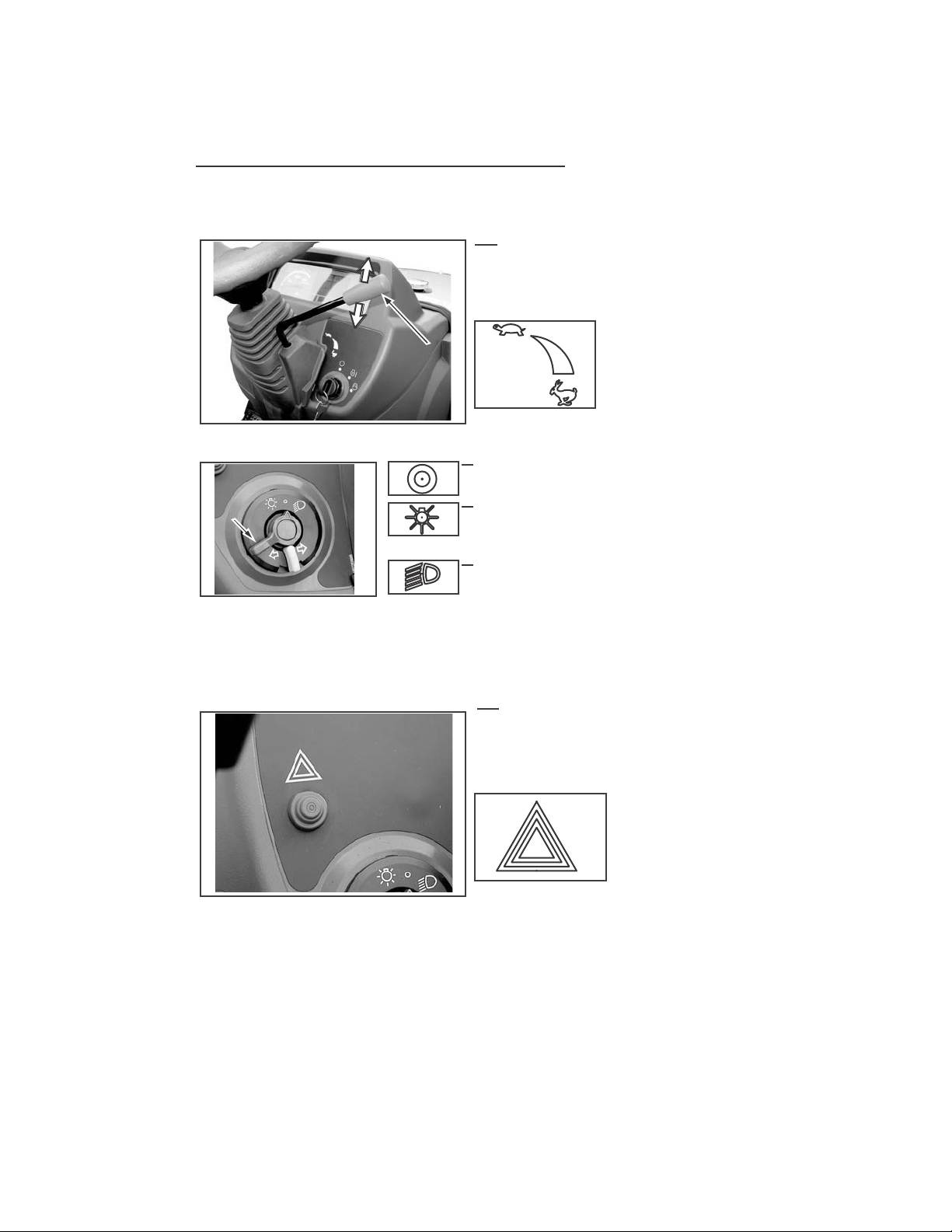

2. ENGINE SPEED CONTROL LEVER

DECREASEDECREASE

Move the engine speed control lever

to the rear to increase engine speed.

Move the engine speed control lever

forward to decrease engine speed.

INCREASE

INCREASE

ENGINE

ENGINE

CONTROL

CONTROL

LEVER

LEVER

3. LAMP SWITCH Three position switch as follows:

ALL lamps are OFF. (Turn signal and

LAMP

LAMP

SWITCH

SWITCH

flasher lamps can be turned on.)

First position clockwise illuminates

instrument panel lamp and rear red

lamp.

Second position clockwise illuminates

headlamps, instrument panel and

rear red lamp.

Use dimmer switch to dim or brighten

the headlamps.

4. FLASHER CONTROL BUTTON

To flash the Flasher Lamps

whenever the tractor is operated or

traveling onroads.

Push the button to energize the lamps.

23

Page 32

INSTRUMENTS/CONTROLS

5. TURN SIGNAL SWITCH To indicate that you are going

to turn the tractor to the RIGHT, move

the turn signal switch to right . To indicate

that you are going to turn the tractor to

the LEFT, move the turn signal switch

TURN

TURN

SIGNAL

SIGNAL

SWITCH

SWITCH

to left . Center position is OFF.

24

Page 33

Control Levers and Pedals

(Gear Drive)

(Hydrostatic Drive)

INSTRUMENTS/CONTROLS

3

1

3

1. ACCELERATOR PEDAL (GEAR DRIVE ONLY)

Use this pedal when operating

the tractor on the road. Push the

pedal down to increase engine

speed.

NOTE: The engine speed control

lever must be set to give the slowest

engine speed when the throttle

ACCELERATOR

ACCELERATOR

PEDAL

PEDAL

pedal is used.

25

2

Page 34

INSTRUMENTS/CONTROLS

BRAKE PEDAL

(LEFT SIDE)

BRAKE PEDAL

(RIGHT SIDE)

2. SPEED RATIO CONTROL PEDAL (HYDROSTATIC DRIVE ONLY)

The control pedal is spring loaded to

the center or neutral position. Push down

on the front of the pedal to increase

forward speed. Push down on the rear

of the pedal to increase reverse speed.

2

3. BRAKE PEDALS The pedals when locked together,

provides braking to both rear wheels

for stopping the tractor. When the brake

3

pedals are unlocked, the pedals are

used for individual braking of the rear

wheels to aid in turning the tractor

in soft soil conditions.

Push the RH brake pedal down to slow

or stop the RH rear tractor wheel, push

the LH brake pedal down to slow or slow

or step the LH rear wheel. The tractor

will turn in the direction of the wheel

that is slowed or stopped.

4. BRAKE PEDAL LOCK The brake pedal lock is located at

the brake pedal arms and is used to

LOCKLOCK

BRAKE PEDAL

BRAKE PEDAL

(LEFT SIDE)

(LEFT SIDE)

4

REMOVEREMOVE

BRAKE PEDAL

BRAKE PEDAL

(RIGHT SIDE)

(RIGHT SIDE)

lock the two brake pedals together so

that both brakes are applied.

CAUTION: Brake pedals must be locked together for road travel.

This will insure uniform brake application and maximum stopping

ability.

WARNING: Extra weight and bad traction conditions such as mud

or ice increase your stopping distance. Remember that liquid in the

tires, weight on the machine or wheels, tank filled with fertilizer,

herbicides or insecticides - all these add weight and increase

the distance you need in which to stop.

26

Page 35

INSTRUMENTS/CONTROLS

PARK BRAKE

(GEAR Drive)

(Hydrostatic Drive)

ON

BRAKE PEDAL

5

7

5. PARK BRAKE LEVER 1. The park brake must be on to prevent

movement of the tractor during stationary

power takeoff work or when the tractor

is parked. To engage the park brake,

lock the brake pedals together, push

down on the brake pedals and move

the park brake lever downward. Push

the brake pedal down to release the

park brake.

5

PARK BRAKE

2. Before getting off the tractor,

disengage the PTO, lower all implements

to the ground, place all control levers

in their neutral positions,set the parking

brake, stop the engine and remove

the key.

3. If it is necessary to park on an incline,

be sure to check the wheels to prevent

accidental rolling of the machine.

(HYDROSTATIC DRIVE)

It is free on engine brake with the

range lever engaged, be sure set

the parking brake.

27

Page 36

INSTRUMENTS/CONTROLS

6. SPEED LOCK LEVER (Hydrostatic Drive only)

To keep a constant forward travel speed,

move the lever fully upward, while holding

the speed ratio control pedal at the desired

6

speed. It does not work in reverse.

7. CLUTCH PEDAL

The clutch must be disengaged when starting the engine, stopping the

tractor, storing the tractor and operating the following levers, gear shift lever,

rear PTO lever, MID PTO lever If EQUIPED, MFD lever, shuttle lever.

7-1. SINGLE CLUTCH (7532)

1. Pedal completely released – Transmission and PTO engaged.

2. Pedal completely depressed – Transmission and PTO disengaged.

7-2. SINGLE CLUTCH (7530)

1. Pedal completely released – Transmission engaged

2. Pedal completely depressed – Transmission disengaged

8. CLUTCH LOCK LATCH For long term storage, lock the clutch

pedal in the disengaged position. This will

prevent the clutch disc from sticking to the

engine flywheel.

7

28

Page 37

Control Levers

(Gear Drive)

(Hydrostatic Drive)

INSTRUMENTS/CONTROLS

3

1

2

3

1.GEAR SHIFT LEVER (Gear Drive only)

The gear shift lever is used to shift the

transmission gears into any of four speeds.

29

2

Page 38

INSTRUMENTS/CONTROLS

2. RANGE SHIFT LEVER

Move the range shift lever forward

to place the transmission in H range.

Move the lever rear ward to place

the transmission in L range.

Move the range shift lever forward

to place the transmission in H range.

Move the lever to the rearward to

place the transmission in M or L range.

The center position between M and

L or H and M places the transmission

in N.

NOTE: Be sure the range shift lever

is in N (Engine start) slot when starting

the engine.

3-1. SHUTTLE SHIFT LEVER The shuttle shift lever is used to

(GEAR DRIVE ONLY)

shift the transmission gear into

forward of reverse position. Move

the shuttle shift lever forward

(F position) to the forward position.

Move the shuttle shift lever rearward

(R position) to the reverse position.

The center position between F and

R places the transmission in N position.

(neutral)

NOTE: Be sure the shuttle shift lever

is in N (Engine start) position when

starting the engine.

3-2. REAR PTO CONTROL LEVER Move the lever forward to engage

the REAR PTO. Move the lever

rearward to disengage the Rear

PTO.

NOTE: Be sure the Rear PTO

control lever is in OFF slot when

starting the engine.

30

Page 39

INSTRUMENTS/CONTROLS

4. MID PTO CONTROL LEVER (IF EQUIPPED)

Move the lever forward to

engage the Mid PTO. Move the lever

rearward to disengage the Mid PTO.

NOTE: Be sure the Mid PTO

control lever is in OFF slot when

starting the engine.

NOTE:

1. The Rear and Mid PTO shaft can be operated at the same time.

2. When not using the Mid PTO shaft, cover the shaft with the Mid PTO cover.

PTO SWITCH

PTO switch is used to engage or

disengage the Independent PTO

clutch. Turn right to engage push

to disengage.

(stop the turning of PTO shaft)

PTO indicator lamp in the meter

panel is illuminating when PTO is

in ON position.

PTO indicator lamp is not illuminating

when PTO is in OFF position.

NOTE: Be sure the PTO switch is

in OFF position when starting the

engine.

31

Page 40

(Gear Drive)

5

(Hydrostatic Drive)

INSTRUMENTS/CONTROLS

5

5. HITCH CONTROL LEVER Use this lever to control the position of

the hitch. Move the lever forward to lower

the hitch to the required depth. Move the

lever to the rear to raise the hitch to the

required height.

32

Page 41

(Gear Drive)

3

1

(Hydrostatic Drive)

INSTRUMENTS/CONTROLS

2

3

1

1. DIFFERENTIAL LOCK PEDAL

Push the pedal down to engage the differential lock. A spring inside the

differential lock will push it out of engagement when pedal is released.

GEAR DRIVE

33

HYDROSTATIC DRIVE

2

Page 42

INSTRUMENTS/CONTROLS

NOTE: When engaging the differential lock, push the clutch pedal down

or bring speed ratio control pedal to Neutral, to stop the wheels that are

rotating, then push the differential lock pedal. Do not engage the differential

lock pedal while the wheels are rotating.

Do not drive on roads, or at high speed anywhere, with the

differential lock engaged. Difficult steering will occur, and can result

in an accident. In field operation, use the differential lock for traction

improvement, but release for turning at row ends.

2. MFD CONTROL LEVER To engage the MFD (Mechanical

Front Drive), move the MFD control

2WD

2WD

lever downward. Move the lever upward

to disengage MFD (drive to the rear

wheels only).

IMPORTANT: The clutch pedal

must be pushed down to operate the

MFD

MFD

MFD lever.

3. HYDRAULIC FLOW CONTROL KNOB

Use the hydraulic flow control knob to adjust the hitch lowering speed.

Adjust the lowering speed to provide smooth operation of the hitch with

the implement being used. Turn the knob fully clockwise to lock the hitch

in position. See Hitch Lowering Speed Adjustment in this manual for

more information.

34

Page 43

INSTRUMENTS/CONTROLS

COLMN TILT

SEAT

OPERATORS SEAT

The seat can be adjusted in 5 fore/aft position by the lever located under

the RH side of the seat.

The seat is adjustable fore and aft by moving a lever.

1. Move the lever upward.

2. Move the seat rearward or forward to

the required position then release the

lever.

3. Push the seat rearward to make sure

SEAT

SEAT

ADJUSTING

ADJUSTING

LEVER

LEVER

that the lock is engaged.

STEERING

STEERING

COLMN TILT

COLMN TILT

LEVER

LEVER

STEERING COLUMN TILT

The steering wheel angle can be adjusted

in three positions by the lever located under

the steering column.

To adjust the position of the steering wheel,

use following procedure.

1. Move the lever fully downward to

disengage the latch from the column.

2. Move the steering wheel rearward of

forward to the required position, then

return the lever upward to lock the

steering column.

3. Make sure that the lock is engaged.

35

Page 44

OPERATING INSTRUCTION

BEFORE STARTING THE ENGINE

Before starting your tractor for the first time and before each operating

period after that, make these checks:

1. Make sure all persons who operate or do maintenance on the tractor

understand that clean fuel is important.

2. Check all lubrication fittings for grease as given in the Lubrication Chart.

3. Check the oil level in the engine crankcase. Check the fluid level in the

transmission.

4. Check the tractor fuel tank is filled with clean fuel that has the

specifications given in this manual.

NOTE: Clean around the fuel tank cap before you remove cap.

5. Check the fuel system, cooling system and engine oil pan for leaks.

6. Check the fan belt is adjusted correctly.

7. Remove any water or sediment from the fuel filter cup.

8. Check the air pressure of the tires.

9. Make sure the PTO safety guard is installed.

10. Check the coolant level in the radiator and reservoir bottle.

Add water and ethylene glycol coolant as needed.

36

Page 45

OPERATING INSTRUCTION

RUN – IN PROCEDURE

If run-in instructions for a new engine are not followed, you can cause

damage to piston rings and cylinder walls.

LOAD

Never operate an engine immediately under full load. Allow the engine to

warm up before operating it at full load. Run-in the engine carefully as

shown in the table.

Engine Speed

Period Load

1st Hour

2nd

Through

5th Hour

NO LOAD

Do not run the engine at idle speed. When not operating the engine with

a load, you can keep the correct engine operating temperature if you run

the engine at approximately 1500 RPM.

Control Lever

Position

Fully

advanced

Fully

advanced

Maintain engine speed

100 RPM above full load

governed speed

Full load governed

speed with occasional

short periods of lighter load

REAR WHEEL BOLTS

After the first 10 hours of operation, check the rear wheel bolts. Tighten

all wheel bolts to the torque give in the Wheel Mounting Torques in this

manual.

FRONT WHEEL BOLTS

After the first 10 hours of operation, check the front wheel bolts. Tighten

the bolts to the torques shown in the Wheel Mounting Torques in this

manual.

FRONT FRAME BOLTS

After the first 10 hours of operation, check the front frame bolts. Tighten

the bolts to the torque shown below.

Front Frame Mounting Torques

Side (M12x35), 12Bolts (6LH and 6RH) … 83 to 93 Nm (61 to 69 lb ft)

LOWER LINK BRACKET BOLTS

After the first 10 hours of operation, check the Lower Link Bracket bolts.

Tighten the bolts to the correct tightening 39 to 44 Nm (29 to 33 lb ft).

37

Page 46

OPERATING INSTRUCTION

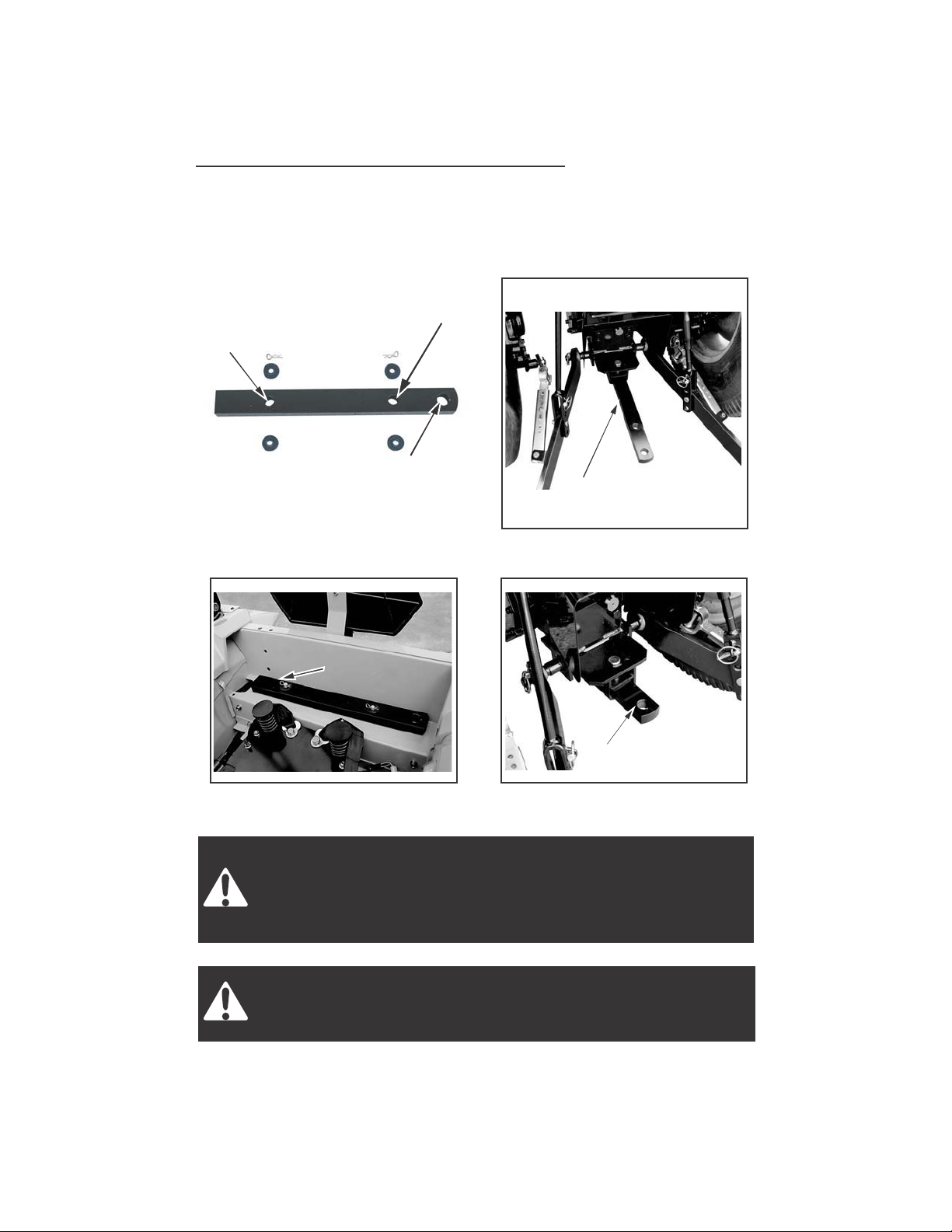

FUEL SHUT-OFF VALVE

NORMAL STARTING PROCEDURE

IMPORTANT: It is very important that enough lubricant reaches the engine

parts before operating the engine at rated speed.

Operate controls only when seated in the operators seat.

Engine can start with transmission in gear when neutral or safety

start switch is by-passed:

1. Do not connect across terminals on starter.

2. Attach a booster battery by connecting the positive terminal of

the booster battery to the “positive terminal” provided or to the

positive terminal of the machine battery. Connect the negative

terminal of the booster battery to the “negative terminal” provided

or to the chassis of the machine.

Then use recommended starting procedures from operators seat.

3. When necessary, repair electrical system components promptly

so that “jump starting” will not be attempted.

Machine run-away can cause injury or death to operator and

bystanders.

STEP 1

Make sure the fuel shut-off valve

is open. The valve is located at the

bottom RH side of the fuel tank.

Before starting the engine, be sure all operating controls are in

neutral or park lock position. This will eliminate accidental

movement of the machine or start up of power driven equipment.

FUEL SHUT-OFF VALVE

FUEL SHUT-OFF VALVE

OPEN

STEP 2

NEUTRAL

POSITION

Put the gear shift lever in the

Neutral position (Gear Drive) or

the Speed Lock Lever to be released

(Hydrostatic Drive).

38

Page 47

OPERATING INSTRUCTION

STEP 3

OFF

OFF

POSITION

POSITION

Put the REAR PTO and MID PTO

control levers in the OFF

(Engine start) position.

STEP 4

STEP 5

ENGINE

ENGINE

SPEED

SPEED

CONTROL

CONTROL

LEVER

LEVER

Put the engine speed control lever

at the middle position.

STEP 6

Put the SHUTTLE lever in the N

(Engine start) slot (Gear Drive).

HST control pedal in the N position

CLUTCH pedal (HST Drive)

Turn the starter key switch to the

heat & ON position.

Wait until the glow plug indicator lamp

is put out.

(Approximately 1 to 3 seconds.)

39

Page 48

OPERATING INSTRUCTION

CLUTCH PEDAL

STEP 7

Push the clutch pedal down.

CLUTCH PEDAL

CLUTCH PEDAL

STEP 8

START

Turn key switch to start position until

engine starts, but no more than

10 seconds, then release the key.

Run engine for two minutes at

1500 RPM.

STEP 9

When the engine starts, check the

oil pressure indicators stay on, stop

the engine and find out what is wrong.

NOTE: If the oil pressure indicator stays on after the engine starts,

stop the engine and check the oil level in the crankcase. Add oil if necessary.

Start the engine, if the indicator is still on, do not operate the engine.

Operating the engine without oil pressure will damage engine bearings and

other engine parts. See your dealer.

IMPORTANT:

1. If the engine starts and then stops, wait for the starting motor to stop

turning before you turn the key switch to START position again.

2. Do not use the starter motor for more than 10 seconds without stopping.

Wait one minute between starts so the starter motor can cool.

3. If engine stops when operating with a load, immediately start the engine

again to prevent overheating caused by stopping the flow of oil for cooling

and lubrication.

40

Page 49

OPERATING INSTRUCTION

4. If the charge indicator comes on during operation, determine and correct

the cause to avoid complete discharge of the battery and possible damage

to other components of the electrical system. See your Dealer.

5. If the coolant temperature indicator comes on, remove the load and

allow the engine to run at 1500 rpm until the indicator goes out.

If the indicator does not go out within one minute, stop the engine and

determine the cause.

Starting Procedure for Hydrostatic Drive Tractors

After Transporting on Truck or Flatcar

IMPORTANT: Hydrostatic transmission can jump into gear without warning,

if the fluid leaks out of the control system. This can occur due to vibration

if the tractor is transported on a truck or rail car. It can also happen if

the transmission is drained or if the tractor sits still for very long periods.

If any of these have happened, start the tractor as follows:

1. Put the range shift control lever into the N (Engine start) slot and release

the speed lock lever to permit the speed ratio control pedal to return to

N (Neutral) position.

2. Lock the brake pedals together, press down on the brake pedals.

3. Pull the engine speed control lever and start the engine. Set the engine

speed to about 1000 RPM.

4. Slowly move the range shift lever to H range for high speed engagement.

If gear clash is obvious the engine should be shut off immediately and

the tractor unloaded by other means. Tow the tractor with the range

shift lever in N(Neutral) to an area where the transmission can be checked

by your Dealer. Refer to Towing the Tractor in this manual.

If there is no obvious gear clash, drive the tractor in the normal manner.

41

Page 50

OPERATING INSTRUCTION

STOP

PTO

STOPPING THE ENGINE

IMPORTANT: When stopping the engine after operating under heavy load,

run the engine at 1500 RPM for a short period of time. This will allow the

engine temperature to decrease gradually.

STEP 1

STOP

STOP

Move the engine speed control

lever to run engine at idle speed

for three to five minutes to decrease

the temperature of engine.

STEP 2

STEP 3

OFF

Turn the key switch to OFF position.

Remove the key.

REAR

REAR

PTO

PTO

REVER

REVER

Put the REAR PTO control lever,

MID PTO control lever and the

range shift lever in the OFF or N

(neutral) position.

42

Page 51

OPERATING INSTRUCTION

COLD TEMPERATURE OPERATION

To start and operate your tractor during cold ambient temperatures, use

these procedures:

1. BATTERY – Must have a full charge.

2. FUEL – Must be clean and with no water. See Fuel Specifications in

this manual.

3. ENGINE OIL – Must have the correct viscosity for the ambient

temperature range.

4. TRANSMISSION HYDRAULIC FLUID – Use Cub Cadet Hydraulic

Transmission fluid.

5. COOLING SYSTEM – Must have ethylene glycol solution for protection.

6. TIRES – If there is liquid in the tires, the tires must have protection

against temperatures below 0 C(32 F). See your Dealer.

7. STOPPING THE ENGINE – Run the engine at idle speed for a short

period of time to permit the engine temperature to decrease before

stopping.

8. CONDENSATION IN FUEL TANK – To prevent condensation in the

fuel tank and water entering the fuel system, fill the fuel tank after each

operating day.

9. FUEL FILTER CUP – During cold ambient temperatures, make sure

you remove water from the fuel filter cup each day.

NOTE: Do not use ether as a cold temperature starting aid.

43

Page 52

OPERATING INSTRUCTION

IMPORTANT: During cold ambient temperatures, never run the engine

at low idle speed for long periods of time.

During cold ambient temperatures, if the engine will not heat to or keep the

rated operating temperatures can cause damage to the engine can occur.

Use the following procedures to warm the engine and transmission fluids,

and to keep the correct operating temperatures.

1. WARMING THE ENGINE AND TRANSMISSION.

A. To heat the transmission fluid to operating temperature, run the

engine at 1500 RPM for approximately five minutes.

IMPORTANT: Operating the tractor with cold transmission fluid can

cause rough tractor operation with possible injury to the operator.

2. KEEP ENGINE AT CORRECT OPERATING TEMPERATURE.

A. Never run the engine below 1500 RPM.

B. Put a cover in front of the grille to control the amount of air going

through the radiator.

3. STOPPING THE ENGINE

A. Run the engine at slow speed for a short period of time. This will

permit the engine temperature to decrease gradually before stopping

the engine.

44

Page 53

OPERATING INSTRUCTION

TOWING

When towing a tractor, follow these rules:

1. Never tow the tractor faster than a ground speed of 16 Km/h (10MPH).

2. Make sure all controls are in the neutral or OFF position.

3. Because of a possible loss of steering and brakes when the tractor engine

is not running, use only a rigid towing bar and safety chains to pull

the tractor.

Make sure that the weight of a trailed vehicle that is not equipped

with brakes, NEVER EXCEEDS the weight of the machine that is

towing the vehicle. Stopping distance increases with increasing

speed as the weight of the towed load increases, especially on

hills and slops.

HOW TO TRANSPORT TRACTOR

When you transport the tractor by truck or rail, follow these rules:

1. Hold the tractor with tie downs and block the wheels.

2. Gear Drive: Put the gear shift lever in 1 st position and put the range

shift lever in the L position and shuttle shift (over in F or R) position.

Hydrostatic Drive: Move the Speed Lock lever to OFF position and put

the range shift lever in the L position.

3. Lock the brake pedals together, push the brake pedals down and move

the park brake lever up to engage the park brake .

45

Page 54

OPERATING INSTRUCTION

GEAR DRIVE TRANSMISSION

The gear drive transmission has forward and a reverse gear section,

a four-speed main shift gear section, and a three-speed range section.

This arrangement gives 8 forward and 8 reverse speeds.

Transmission Operation

1. Push the clutch pedal and stop the tractor. Move the gear shift lever to

the gear needed.

2. Move the range shift lever to the position needed, H, L (The tractor

must be stopped before the range lever is operated.)

3. Move the shuttle lever to Forward or Reverse position.

4. Release the clutch pedal slowly.

NOTE: When shifting from fourth to another range, be careful not to run

the engine at more than 2700 RPM.

IMPORTANT: Before selecting a new range, push the clutch pedal halfway

and stop the tractor. Do not change range when the tractor is moving.

46

Page 55

OPERATING INSTRUCTION

SPEED RATIO

SPEED RATIO

(FORWARD)

HYDROSTATIC DRIVE TRANSMISSION

The Hydrostatic drive transmission has a forward/reverse hydrostatic section

and a three-speed range section. This arrangement gives three forward

and three reverse speeds ranges.

Transmission Operation

1. Push the clutch pedal fully and stop the tractor. Move the range shift

lever to the position needed, H, M or L.

2. Release the clutch pedal slowly.

3. Operate the speed ratio control pedal to move the tractor.

To shift from reverse to forward or from forward to reverse, move the

speed ratio control pedal without disengaging the clutch.

SPEED RATIO

SPEED RATIO

CONTROL

CONTROL

PEDAL

PEDAL

(FORWARD)

(FORWARD)

RANGE

RANGE

SHIFT

SHIFT

LEVER

LEVER

IMPORTANT: Before selecting a new range, stop the tractor and push

SPEED RATIO

SPEED RATIO

CONTROL

CONTROL

PEDAL

PEDAL

(REVERSE)

(REVERSE)

the clutch pedal. Do not change range when the tractor is moving.

Travel speed should be such that complete control and machine

stability is maintained at all times. Where possible, avoid operating

near ditches, embankments and holes. Reduce speed when turning,

crossing slopes, and on rough, slick, or muddy surfaces.

47

Page 56

LOCK PEDAL

LOCK PEDAL

DIFFERENTIAL

DIFFERENTIAL

LOCK PEDAL

LOCK PEDAL

OPERATING INSTRUCTION

DIFFERENTIAL LOCK

DIFFERENTIAL

DIFFERENTIAL

LOCK PEDAL

LOCK PEDAL

GEAR DRIVE

RIGHT SIDE of the transmission

HYDROSTATIC DRIVE

LEFT SIDE of the transmission

Your tractor has a differential lock that will make both rear wheels turn at

the same speed. The differential lock prevents loss of power when

one wheel does not have traction but the other wheel does have traction.

It also provides a straight in line steering aid when opening up the field

and to control implement overlap.

TO ENGAGE THE DIFFERENTIAL LOCK:

Depress and hold the differential lock pedal down.

IMPORTANT: Do not engage the differential lock while one rear wheel is

rotating and the other rear wheel is stopped. Always stop the wheel that is

rotating and then engage the differential lock.

IMPORTANT: When you engage or disengage the differential lock, the front

wheels must be in the straight forward position. Before turning the tractor,

disengage the differential lock.

TO DISENGAGE THE DIFFERENTIAL LOCK:

The differential lock will disengage when the differential lock pedal is

released. If the differential lock does not disengage easily, push down on

either brake pedal momentarily.

Do not drive on roads, or at high speed anywhere, with the

differential lock engaged. Difficult steering will occur, and can result

in an accident. In field operation, use the differential lock for

traction improvement, but release for turning at row ends.

48

Page 57

POWER TAKEOFF (PTO)

REAR PTO SHEFT

CLUTCH PEDAL

REAR PTO

CONTROL LEVER

PTO driven machinery can cause serious injury or death, usually due

to wrapped clothing. When required by the job to be in the

drive shaft area, stay clear of rotating parts. Before working on the

drive shaft, or servicing or clearing the driven machine, where

applicable on this tractor, put the PTO clutch lever in the DISENGAGE

position, the PTO lever in the NEUTRAL or OFF, and STOP the engine.

Rear PTO (HST)

The rear PTO is a 540 RPM with a

34.9 mm (1 3/8 inch) diameter 6

spline output shaft.

OPERATING INSTRUCTION

ENGAGE THE REAR PTO AS

REAR PTO SHEFT

REAR PTO SHAFT

FOLLOWS:

1. Push the clutch pedal fully.

2. Move the PTO control lever to the

ON position.

3. Release the clutch pedal slowly.

DISENGAGE THE REAR PTO

CLUTCH PEDAL

AS FOLLOWS:

CLUTCH PEDAL

1. Push the clutch pedal fully.

2. Move the PTO control lever to the

OFF (Engine Start) position.

NOTE : Keep the PTO control lever

in the OFF (Engine Start) position

when starting the engine and when

the PTO is not being used.

REAR PTO

REAR PTO

CONTROL LEVER

CONTROL LEVER

3. Release the clutch pedal slowly.

The following table shows the required speed to get the required Rear

PTO output shaft speed.

PTO Output

Shaft Speed

540 RPM

Required

Engine Speed

2376 RPM

49

Page 58

POWER TAKEOFF (PTO)

MID PTO

Mid PTO (OPTION)

The Mid PTO has a 25.4 mm

(1 inch) diameter 15 spline

output shaft.

ENGAGE THE MID PTO AS

FOLLOWS:

1. Push the clutch pedal fully.

2. Move the Mid PTO control

lever to the ON position.

3. Release the clutch pedal

slowly.

DISENGAGE THE MID PTO

AS FOLLOWS:

1. Push the clutch pedal fully.

OPERATING INSTRUCTION

CLUTCH

CLUTCH

PEDAL

PEDAL

2. Move the Mid PTO control

MID PTO

lever to the OFF (Engine Start)

position.

MID PTO

LEVER

LEVER

NOTE: Keep the Mid PTO

control lever in the OFF (Engine Start)

slot when starting the engine and when

the PTO is not being used.

3. Release the clutch pedal.

The following table shows the required engine speed to get the required

Mid PTO output shaft speed.

Mid PTO Output

Shaft Speed

2000 RPM

Required

Engine Speed

2526 RPM

50

Page 59

OPERATING INSTRUCTION

POWER TAKEOFF GUARDS

All tractors have a safety guard for the Rear PTO shaft and safety cover

for the Mid PTO shaft.

REAR PTO GUARD

Whenever a PTO driven machine is in operation, the PTO guard

must be in place for most operations to prevent injury to the operator

or bystanders. Where attachments, such as pumps, are installed on

the PTO shaft (especially if the tractor PTO guard is moved upward

or removed) extended shielding equivalent to the PTO guard must be

installed with the attachment. Install the PTO guard to its original

position immediately when the attachment is removed.

51

Page 60

OPERATING INSTRUCTION

PTO OPERATING SAFETY

For the safe operation of the PTO, follow these safe operating procedures.

Three Point Hitch Connecting Implements

1. Connect the implement to the hitch.

See THREE POINT HITCH SYSTEM in this manual.

2. Connect the implement driveline to the tractor.

3. Check the driveline for correct length and for free telescopic movement

by lifting and lowering hitch system. The correct length is important to

prevent the driveline from hitting bottom or from separating in any tractor

implement operating position.

Drawbar Connecting Implements

1. Connect the implement hitch to the drawer with a hardened steel pin.

Make sure the pin is securely held in place with a cotter pin or lock pin

and does not make contact with the implement driveline.

2. Connect the implement hitch to the tractor drawbar before connecting the

implement driveline to the PTO.

3. Connect the implement driveline to the tractor. Check the driveline for

correct length and for free telescopic movement. The correct length is

important to prevent the driveline from hitting bottom or from separating

in any tractor or implement operating position.

PTO driven machinery can cause serious injury. Before working on

or near the PTO shaft, or servicing or clearing the driven machine,

put the PTO lever in the DISENGAGE position and STOP the engine.

When doing stationary PTO work and dismounting from the tractor

with the PTO running, keep clear of all moving parts as they are

a potential safety hazard.

IMPORTANT: Follow the implement manufacturers recommendations in

adjusting and aligning the implement and implement driveline with the tractor.

52

Page 61

OPERATING INSTRUCTION

STORAGE POSITION

(WITH MID PTO)

DRAWBAR

Your tractor is equipped with a drawbar. Use the drawbar for connecting

all pull-behind implements.

STORAGE PIN HOLE

DRAWBAR HITCH

CONNECTING PIN HOLE

The drawbar must be in the storage position when using the three-point hitch.

WITHOUT MID PTO

IMPLEMENT CONNECTING

PIN HOLE

DRAWBAR

OPERATING

POSITION

WITH MID PTO WITHOUT MID PTO

Try to balance the load primarily on the implement wheels –as in

loading a trailer or spreader. Avoid overloading the drawbar. Add

front end weights for improved stability. Engage the clutch smoothly,

avoid jerking and use the brakes cautiously to avoid jackknifing.

Rear upset can result if pulling from wrong location on tractor.

Hitch only to the drawbar. Use 3 point hitch only with the implements

designed for its use – not as a drawbar.

STORAGE POSITION

STORAGE POSITION

(WITH MID PTO)

(WITH MID PTO)

STORAGE POSITION

(WITHOUT MID PTO)

53

Page 62

OPERATING INSTRUCTION

CONTROL BUTTON

WARNING LAMPS

FLASHER

FLASHER

CONTROL BUTTON

CONTROL BUTTON

TURN

TURN

SIGNAL

SIGNAL

SWITCH

SWITCH

The lamp switch has two positions. Turn the switch clockwise to

illuminate the headlamp, rear red lamp, and instrument panel lamps.

Push the flasher control button down to operate the amber warning lamps.

When the turn signal switch is moved upward to make a right turn,

the RH warning lamp will illuminate ON and OFF and the LH lamp will

illuminate continuously.

LAMP

LAMP

SWITCH

SWITCH

When the turn signal switch is moved downward to make a left turn,

the LH warning lamp will illuminate ON and OFF and the RH lamp will

illuminate continuously.

When the turn signal switch is returned to the center position, both

warning lamps will illuminate ON and OFF.

IMPORTANT: When towing an implement or wagon with the tractor,

the complete rear area warning system (amber warning lamps, rear

red lamp and SMV emblem) must be easily seen by any vehicle operator

coming near the tractor.

54

Page 63

FIELD OPERATION

REAR PTO SHAFT

CONNECTING IMPLEMENT TO DRAWBAR

The correct connection of the implement to the drawbar will prevent stress

on both the tractor and the implement.

To assure proper tractor operation and optimum implement performance,

the implement must be connected to the drawbar correctly.

1. Connect pull-behind implements to the drawbar only.

2. Use a hardened steel hitch pin

to connect the implement to

the drawbar. Make sure the pin

is held securely in place with

a lock pin.

3. When working with the drawbar,

raise the lower links as high as

possible to prevent interference

between the lower links and

the implement.

REAR PTO SHAFT

4. The drawbar provides the

REAR PTO SHAFT

standard hitch distance from

the end of the PTO shaft to

the centerline of the rear hole

in the drawbar. This is necessary

for safe PTO operation of trailing

DRAWBAR

type equipment.

PTO RPM

540

PTO SHAFT DIAMETER

1.375 In

(34.9 mm)

DIMENSION A

14 In

(358 mm)

IMPORTANT: The maximum fixed drawbar vertical load is 440 Kg

55

Page 64

FIELD OPERATION

SAFETY CHAIN

When towing equipment on a highway, use a safety chain as an auxiliary

connection between the tractor and the towed equipment. The safety chain

must have a rating greater than the gross load of the towed equipment.

Connect the chain to the tractor drawbar support and the towed equipment

as shown in the illustration. Check the adjustment of the safety chain by

turning the tractor completely to the right and left. Adjust the chain

as necessary.

56

Page 65

FIELD OPERATION

THREE POINT HITCH SYSTEM

The three point hitch system gives position control and draft control (If

equipped) of implements. This tractor is equipped with a category I hitch.

The three-point hitch dimensions are shown in the following table.

Implement Identification

Dimensions

A – Gap in top of implement mast

B – Diameter of holes in top of

Implement mast

C – Diameter of hitch pins

D – Lower Hitch Pin

Inner Shoulder Spread

Cat I

Implement

44.5 mm (1-3/4 inch)

19.1 mm (3/4 inch)

22.2 mm (7/8 inch)

682.6 mm (26-7/8 inch)

57

Page 66

FIELD OPERATION

HITCH SYSTEM ADJUSTMENTS

UPPER

LINK

Lift Links

LIFT

LIFT

LINKS

LINKS

STABILIZERS

LOWER LINKS

LOCK NUT

TURN BUCKLE

The upper and lower links must be

adjusted correctly so the implement

can work at the needed depth and the

links are free to move up and down

with the shape of the ground.

1. Connect the lift links to the tractor

and to the lower links. Make sure

the lift links are installed on the

proper Sides as shown below.

2. The RH side lift link is adjustable

by turnbuckle to obtain the desired

RH LIFT LINK

position of the hitch point.

Turn the turnbuckle clockwise to

shorten the link or counterclockwise

LH LIFT LINK

to lengthen the link.

IMPORTANT: After the lift link is adjusted, make sure the locknut is

tightened against the turnbuckle.

58

Page 67

Upper Link

UPPER

UPPER

LINK

LINK

HOOK

HOOK

TURNBUCKLE

TURNBUCKLE

LOCK NUT

FIELD OPERATION

The length A of the upper link can be

adjusted from 470 to 750 mm (18.5 to

29.5 inches).

Turn the turnbuckle clockwise to

shorten the link or counterclockwise

to lengthen the link.

IMPORTANT: After the upper link is correctly adjusted, make sure the

lock nut is tightened against the turnbuckle.

Stabilizer

When side movement of the hitch is

undesirable or hazardous, the lateral

swing is adjusted by select hole on

the stabilizer.

LOCK PIN

SLIDER PLATE

Slide REAR STABILIZER and adjust

hole REAR and FRONT STABILIZER

set clevis pin the hole.

IMPORTANT: After making final

adjustments carefully raise the

implement to make sure that there is

proper clearance between the

implement and tractor components.

NOTE: Insert pin to hole in clevis pin

surely.

59

Page 68

FIELD OPERATION

HITCH OPERATION

Connecting Implement to Hitch

To connect an implement to the hitch, use the following procedure:

NOTE: Be sure the tractor and implement are on level ground.

1. Put the drawbar in the storage position.

2. Slowly move the tractor backwards to the implement.

3. When the hitch points on the tractor and implement are in the correct

position, stop the tractor.

4. Apply the park brake and stop the engine.

5. Connect the implement to the Upper and Lower Links.

6. Adjust the Upper and Lower Links as necessary. See Hitch System

Adjustments in this manual.

Disconnecting Implement from Hitch

To disconnect an implement from the hitch, use the following procedure:

NOTE: Be sure the tractor and implement are on level ground.

1. Stop the tractor completely and apply the park brake.

2. Disengage the PTO, lower the implement to the ground.

3. Gear Drive: Place the gear shift and range shift levers in Neutral.

Hydrostatic Drive: Release the speed lock lever, and place the range

shift lever in Neutral.

4. Stop the engine and remove the key from the key switch before leaving

the tractor.

5. Disconnect the implement from the hitch.

NOTE: Be sure the tractor and implement are stable and free from any

tendency to roll over.

60

Page 69

Hitch Control Lever

FIELD OPERATION

HITCH CONTROL LEVER

LOWER

STOP

RAISE

STOP

The hitch control lever is used to raise or lower the implement mounted to

the three point hitch. To raise the hitch, move the lever to the rear. To lower

the hitch, move the lever forward.

Adjustable stops are provided for use whenever it is desirable to return the

hitch control lever to the same operating position.

HITCH

CONTROL

LEVER

RAISE STOP

LOWER STOP

IMPORTANT: Position of the raise stop should not be set so rearward that

insufficient free play of the lift arms is available at the highest position

when hitch control lever is moved to the raise stop.

61

Page 70

FIELD OPERATION

FAST

Hitch Lowering Speed Adjustment

To adjust the hitch lowering speed, use the following procedure:

1. Move the hitch control lever forward

to lower the implements.

2. Turn the hydraulic flow control knob

to adjust the lowering speed. Turn

the knob counter clockwise to

increase the lowering speed. Turn

the knob clockwise to decrease

the speed or lock the hitch.

FAST

FAST

SLOW

SLOW

LOCK

LOCK