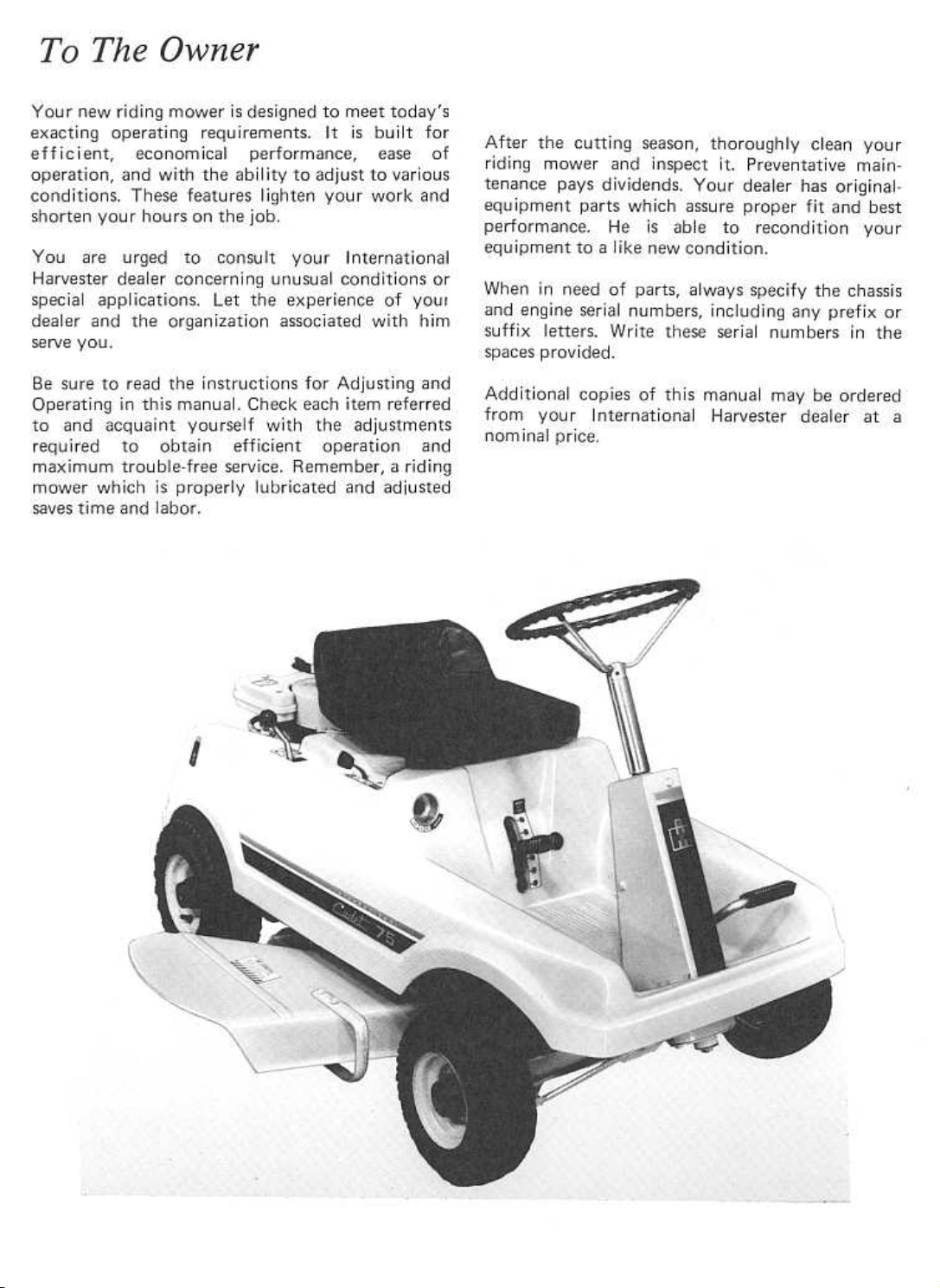

Page 1

Page 2

Page 3

Page 4

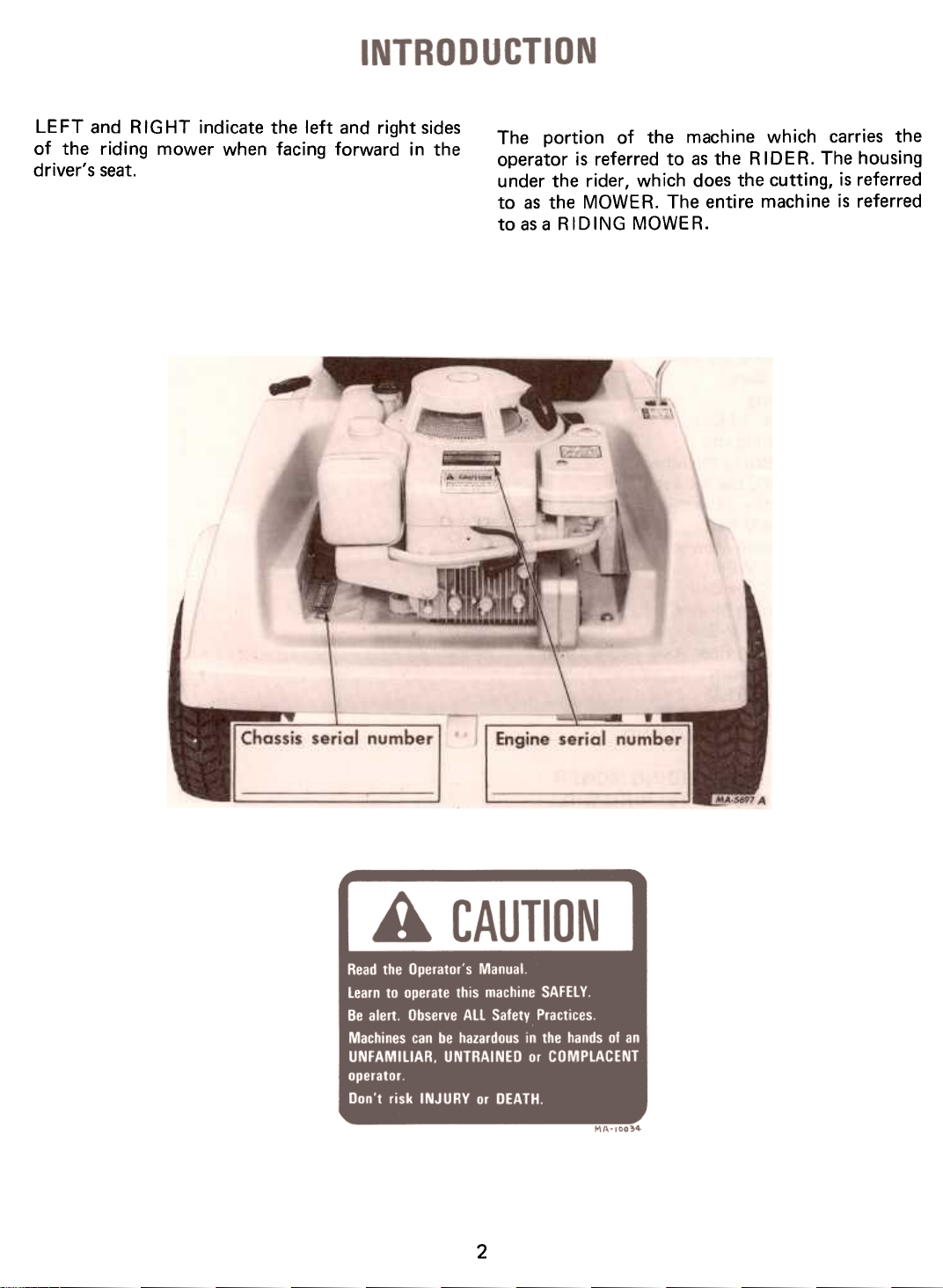

LE FT and RIG HT indicate the left and right sides

of the riding mower when facing forward in the

driver's seat.

The portion of the machine which carries the

operator is referred to as the RIDER. The housing

under the rider, which does the cutting, is referred

to as the MOWER. The entire machine is referred

to as a RIDING MOWER.

2

Page 5

This symbol is used to call your attention to

instructions concerning your personal safety. Be

sure to observe and follow these instructions.

Whenever the operator dismounts from the riding

mower or leaves the riding mower unattended,disengage

the mower and shut off the engine.

Know the controls and how to stop quickly.

READ THE OPERATOR'S MANUAL.

C.nly move the gear selector lever to shift into gear

or change gears with the clutch-brake pedal disengaged.

Never place hands or feet under the mower, in the

discharge chute, or near any moving parts while the

mower is running. Do not work on the mower with

the engine running, as the mower could acciden-

tally be engaged and cause injury.

Never leave the engine running unattended or

permit the riding mower to be operated by persons

not acquainted with its use and the rules for safe

operation.

Be sure all stones, branches, or other objects that

might be picked up and thrown by the mower

blades are removed before starting to mow.

Never look into the discharge opening while the

blades are in motion as serious accident and/or

injury could result.

has been supposedly cleared of foreign objects,

small objects may have been overlooked and may

be discharged by the mower causing serious injury.

Watch out for traffic when crossing or near

roadways.

When making any adjustments to your riding

mower, always disconnect the high tension wire to

the spark plug, otherwise the engine may start

causing serious injury.

Be sure the mower clutch control is "DISENGAGED" and the transmission is in neutral

before starting the engine.

It is recommended that the machine be stopped

and inspected for damage after striking a foreign

object and that any damage be repaired before

restarting and operating the machine, as broken

pieces could be thrown causing injury.

Until you become familiar with the riding mower it

is recommended that quick starts, stops, and rapid

engagement of the mower be avoided. .

Stay alert for holes in terrain and other hidden

hazards which could cause loss of control or upset.

Children should not be allowed to operate the

riding mower unless properly supervised, and are

physically and mentally capable of safe operation

or injury may occur.

Disengage power to the mower when transporting

or not in use.

Before backing the riding mower always look for

obstacles or bystanders in the area where the riding

mower will move.

No one should operate this machine while under

the influence of intoxicants or drugs that impair

the senses or reactions.

Do not allow anyone in the area parallel to the

discharge opening while moving. Although the area

Keep the machine in good operating condition and

keep safety devises in place. Use guards or shields

as instructed in Operator's Manual to avoid injury.

The discharge shield on the mower must be

attached at all times while operating the mower.

Avoid sudden stops or starts, especially on steep

slopes to avoid injury.

Do not carry passengers or give rides as serious

injury could result.

Handle gasoline with care it is highly flammable:

A. Use approved gasoline container. B. Never

remove the fuel tank cap or fill the fuel tank when

the engine is running, is hot, or indoors. Also, do

not smoke when working around inflammable fuel.

Wipe up spilled gasoline. C. Replace gasoline cap

secu rely.

3

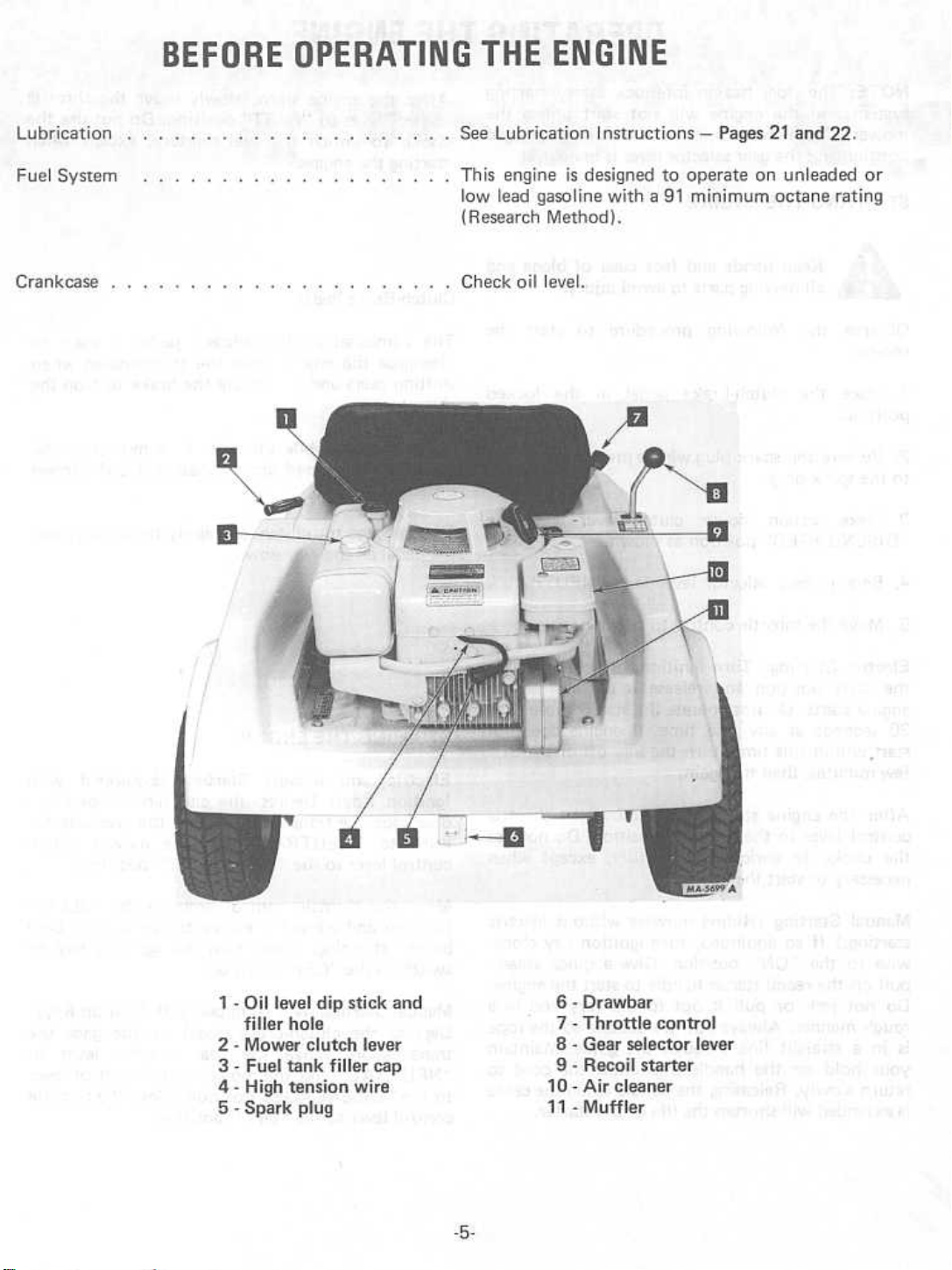

Page 6

Page 7

Page 8

NOTE: The rider has an interlock safety starting

system and the engine will not start unless the

mower clutch control is in the full disengaged

position and the gear selector lever is in neutral.

After the engine starts, slowly move the throttle

control lever to "FAST" position. Do not use the

choke to enrich the fuel mixture, except when

starting the engine.

STARTING THE ENGINE

Keep hands and feet clear of blade and

all moving parts to avoid injury.

Observe the following procedure to start theengine:

The combination clutch-brake pedal is used to

disengage the engine from the transmission when

1. Place the clutch-brake pedal in the lockedposition.

shifting gears and to actuate the brake to stop therider.

Pedal

Be sure the spark plug wire is properly attachedto

the spark plug.

To shift gears while the rider is in motion, pedal

should be depressed approximately 1/2 the travel

distance.

Make certain mower clutch lever is in the"DISENGAGED"

position as shown.

To disengage the clutch, and apply the brake, press

the pedal all the way down.

Be sure gear selector lever is in "NEUTRAL".

5. Move the throttle control to choke position.

Electric Starting: Turn ignition key clockwise to

the start position and release it as soon as the

engine starts. Do not operate the starter more than

30 seconds at anyone time. If engine does not

start within this time, turn the key off and wait a

few minutes, then try again.

After the engine starts, slowly move the throttle

control lever to the "FAST" position. Do not use

the choke to enrich fuel mixture, except when

necessary to start the engine.

Manual Starting (Riding mowers without electric

starting:) If so equipped, turn ignition key clockwise to the "ON" position. Give a quick steady

pull on the recoil starter handle to start the engine.

Do not jerk or pull it out to the very end in a

I:ough manner. Always pull the handle so the rope

is in a straight line through the guide. Maintain

your hold on the handle and allow the cord to

return slowly. Releasing the handle when the cable

is extended will shorten the life of the starter.

STOPPING THE ENGINE

Electric and Manual Starting (Equipped with

Ignition Key): Depress the clutch-brake pedal to

disengage the transmission. Move the gear selector

lever to "NEUTRAL" and the mower clutch

control lever to the "DISENGAGE" position.

Move the throttle control lever to the "SLOW"

position and allow the engine to idle a short time

before stopping. Then turn the ignition key or

switch to the "OFF" position.

Manual Starting (Not equipped with Ignition Key):

Depress the clutch-brake pedal to disengage the

transmission. Move the gear selector lever to

"NEUTRAL" and the mower clutch control lever

to the "DISENGAGE" position. Move the throttle

control lever to the "OFF" position.

Clutch-Brake

2.

3.

4.

6-

Page 9

Page 10

Page 11

ADJUSTING AND OPERATING

8e sure blade~ are assembled so the cutting edges

are in the direction of rotation with the wind wings

pointed toward the deck.

To detach the blade, place a large wood block

between cutting edge and housing to keep the

blade from rotating. Then remove the jam nut or

cap screws, depending on whether you have a side

discharge or a rear discharge mower.

When replacing blades use the reverse procedure,

lexcept put the wood block between the wing of

the blade and the deck.

HEIGHT OF CUT

Cutting height can be adjusted from approximately

1-1 /2-i nches to 4-i nches qu ick Iy and easi Iy. The

mower height control lever is located directly

under the operator's seat. When the lever is pulled

out it can be raised or lowered to the desired

cutting height.

Position the mower in the lowest position. Detach

front of mower from frame by removing the

retaining pins from the front mounting brackets.

The pins are held by two quick-attachable cotter

pins.

Slide the mower backward to remove V-belt from

mower center drive pulley and to disconnect rear

of mower from I ift frame.

Raise the mower lift handle to the highest position

and slide the mower out to the side.

The height of cut is approximate since operator

weight and tire inflation will effect the cutting

height.

The cutting blades are designed to create a suction

to I ift the grass for an even cut.

The mower extends beyond the driving wheels to

permit cutting close to walkways, fences, buildings,

trees, etc.

ATTACHING AND DETACHING THE MOWER

The facilitate changing the blades, sharpening the

blades, cleaning, etc., the mower may be detached

as follows:

CAUTION! Stop the engine and dis-

connect the high tension wire to the

spark plug. Lock the brake prior to

leveling the mower.

9-

Page 12

Page 13

Page 14

ADJUSTING AND OPERATING

ADJUSTING

MOWER

DRIVE

V-BEL T

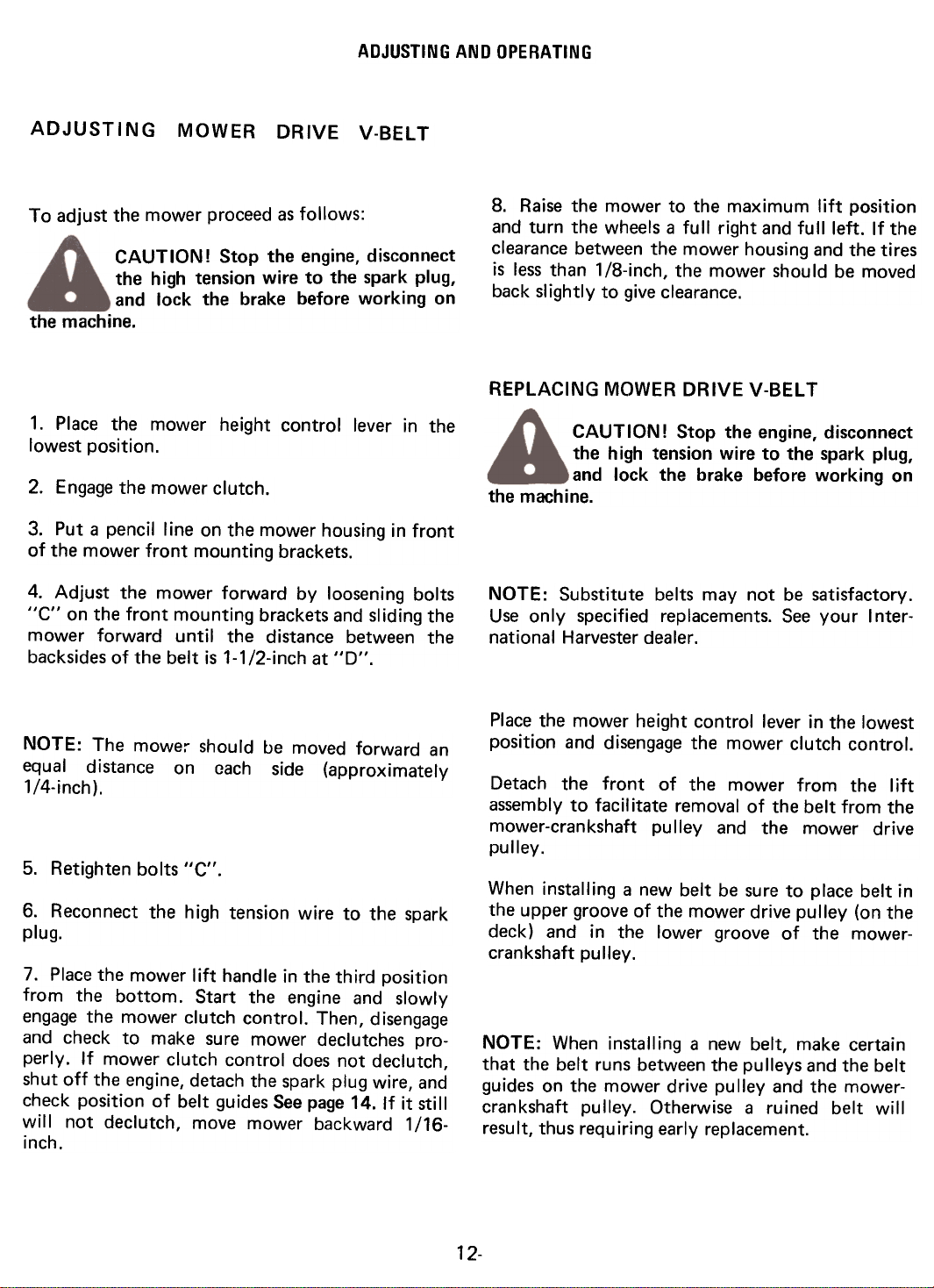

adjust the mower proceed as follows:

CAUTION! Stop the engine, disconnect

the high tension wire to the spark plug,

and lock the brake before working on

the machine.

1. Place the mower height control lever in the

lowest position.

Engage the mower clutch.

Put a pencil line on the mower housing in front

of the mower front mounting brackets.

Adjust the mower forward by loosening bolts

"c" on the front mounting brackets and sliding the

mower forward until the distance between the

backsides of the belt is 1-1/2-inch at "D".

Raise the mower to the maximum lift position

and turn the wheels a full right and full left. If theclearance

between the mower housing and the tires

is less than 1/8-inch, the mower shou Id be moved

back slightly to give clearance.

REPLACING MOWER DRIVE V-BELT

CAUTION! Stop the engine, disconnect

the high tension wire to the spark plug,

and lock the brake before working on

the machine.

NOTE: Substitute belts may not be satisfactory.

Use only specified replacements. See your International Harvester dealer.

NOTE: The mowe. should be moved forward an

equal distance on cach side (approximately

1/4-inch),

Retighten bolts "C".

Reconnect the high tension wire to the sparkplug.

7. Place the mower lift handle in the third position

from the bottom. Start the engine and slowly

engage the mower clutch control. Then, disengage

and check to make sure mower declutches pro-

perly. If mower clutch control does not declutch,

shut off the engine, detach the spark plug wire, and

check position of belt guides See page 14. If it still

will not declutch, move mower backward 1/16inch.

Place the mower height control lever in the lowest

position and disengage the mower clutch control.

Detach the front of the mower from the lift

assembly to facilitate removal of the belt from the

mower-crankshaft pulley and the mower drivepulley.

installing a new belt be sure to place belt in

the upper groove of the mower drive pulley (on the

deck) and in the lower groove of the mowercrankshaft pulley.

NOTE: When installing a new belt, make certain

that the belt runs between the pulleys and the belt

guides on the mower drive pulley and the mowercrankshaft pulley. Otherwise a ruined belt will

result, thus requiring early replacement.

8.

To

2.

3.

4.

5.

When

6.

12-

Page 15

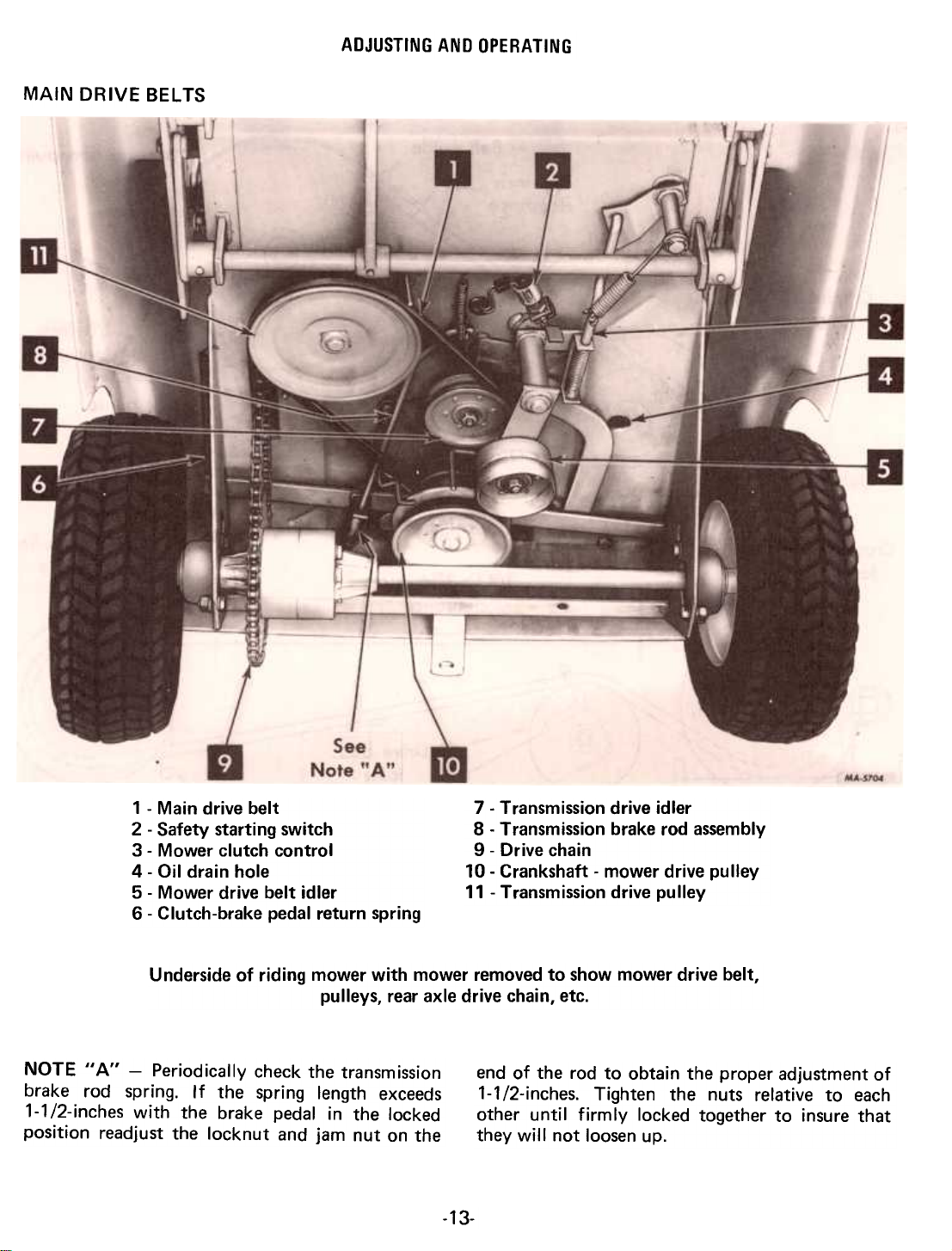

MAIN DRIVE BELTS

ADJUSTING AND OPERATING

1 -Main drive belt

2 -Safety starting switch

3 -Mower clutch control

4 -Oil drain hole

5 -Mower drive belt idler

6 -Clutch-brake pedal return spring

Underside of riding mower with mower removed to show mower drive belt,

pulleys, rear axle drive chain, etc.

NOTE II A II -Period ically check the transm ission

brake rod spring. If the spring length exceeds

1-1/2-inches with the brake pedal in the locked

position readjust the locknut and jam nut on the

7 -Transmission drive idler

8 -Transmission brake rod assembly

9 -Drive chain

10 -Crankshaft -mower drive pulley

11 -Transmission drive pulley

end of the rod to obtain the proper adjustment of

1-1/2-inches. Tighten the nuts relative to each

other until firmly locked together to insure that

they will not loosen up.

-13-

Page 16

Page 17

Page 18

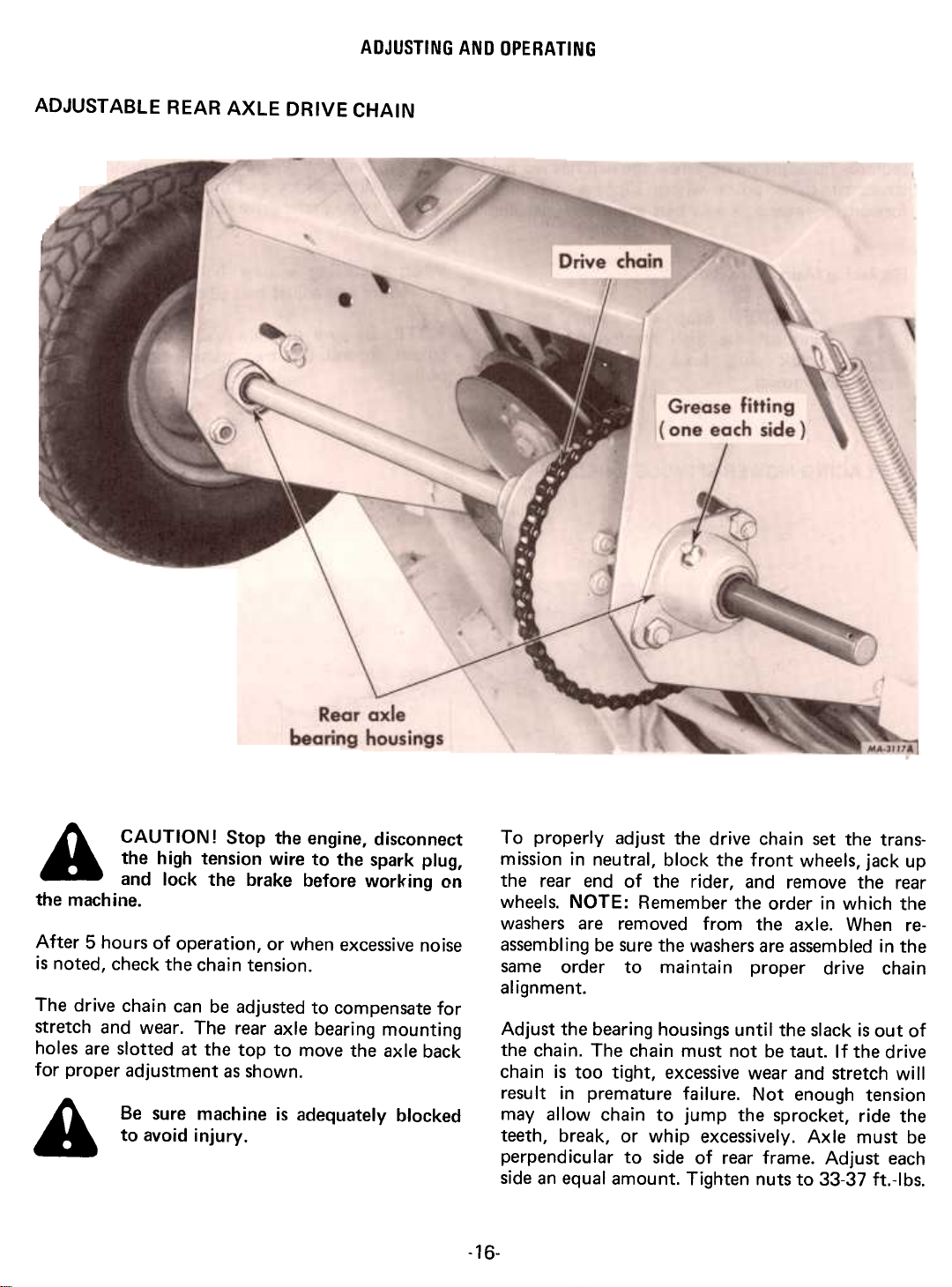

ADJUSTING AND OPERATING

ADJUSTABLE REAR AXLE DRIVE CHAIN

A CAUTION! Stop the engine, disconnect

the high tension wire to the spark plug,

and lock the brake before working on

the machine.

After 5 hours of operation, or when excessive noise

is noted, check the chain tension.

The drive chain can be adjusted to compensate for

stretch and wear. The rear axle bearing mounting

holes are slotted at the top to move the axle back

for proper adjustment as shown.

A Be sure machine is adequately blocked

to avoid injury.

To properly adjust the drive chain set the trans-

mission in neutral, block the front wheels, jack up

the rear end of the rider, and remove the rear

wheels. NOTE: Remember the order in which the

washers are removed from the axle. When reassembling be sure the washers are assembled in the

same order to maintain proper drive chainalignment.

Adjust the bearing housings until the slack is out of

the chain. The chain must not be taut. If the drive

chain is too tight, excessive wear and stretch will

result in premature failure. Not enough tension

may allow chain to jump the sprocket, ride the

teeth, break, or whip excessively. Axle must be

perpendicular to side of rear frame. Adjust each

side an equal amount. Tighten nuts to 33-37 ft.-lbs.

-16-

Page 19

This engine is designed to operate on unleaded or

low lead gasoline with a 91 minimum octane rating

(Research Method),

The use of unleaded gasoline will lengthen spark

plug and valve life, maintain engine performance

longer, and reduce rust and corrosion of engine

while stored.

A CAUTION! Handle gasoline with care, it

is highly flammable: A. Use approved

gasoline container. B. Never remove the

fuel tank cap or fill the fuel tank when the engine

is running, is hot, or indoors. Also, do not smoke

when working around flammable fuel. Wipe up

spilled gasoline. C. Replace fuel tank cap securely.

CARBURETOR ADJUSTMENTS

The carbu retor is adjusted at the factory. Do not

make adjustments unless absolutely necessary.

Factory settings are correct for normal operating

conditions. If adjustments are necessary proceed as

follows:

A CAUTION! During operating do not run

the engine in confined area such as

storage building any longer than is

necessary for immediate moving of the machine

ouside into the air. Exhaust gases are toxic.

Opening doors and windows may not provide

adequate ventilation.

Start the engine and allow it to warm up at 3000

RPM. Turn needle valve in until engine misses (lean

mixture) then turn it out past smooth operating

point until engine runs unevenly (rich mixture).

Turn needle valve to the mid-point between rich

and lean so engine runs smoothly. Hold throttle at

idle position and set idle speed, adjusting screw

until engine idle speed is 1800 RPM. Hold throttle

at idle position and turn idle valve in (lean) and out

(rich) until engine idles smoothly. If necessary,

correct idle speed. Release the throttle -engine

should accelerate without hesitation or sputtering.

If engine does not accelerate properly, the car-

buretor should be readjusted, usually to a slightly

richer mixture of needle valve.

1 -Carbu retor

2 -Fuel shut-off

1 -Needle valve

2 -Idle valve

3 -Idle speed adjusting screw

-17-

Page 20

The battery is located under the operator's seat. To

service or replace the battery remove the seat.

Remove the wing nut located under the center

backrest of the seat. Lift the back of the seat and

pull back to remove seat from front slot of seat

mounting bracket.

When reinstalling operator's seat reverse the above

procedu reo

A CAUTION! If the tractor is to be tipped

up or on its side remove the batteries to

avoid spilling the electrolyte. Battery

electrolyte is poisonous and can be injurious to

eyes, skin, and clothing. If electrolyte is spilled,

flush immediately with a solution of one part

baking soda to four parts water.

Occasionally remove the battery cables and brighten

the terminal contact surfaces with wire wool, and

reassemble. Apply a light coat of vaseline or chassis

lubricant. Be sure terminals are clamped tightly,

the rubber cover is slid over the positive terminal,

and that battery is fastened securely in the battery

box. Replace defective cable, and keep vent holes

in battery filler caps open.

The output of the built in charging circuit in the

engine rises from 2 amperes at 2400 RPM to 3

amperes at 3600 RPM and uses less than .2

horsepower.

Connecting Booster Batteries

When required, a booster 12-volt battery may be

connected in parallel with the 12-volt system on

the tractor.

NOTE: All circuits must be turned "off", Elec-

trical System is Negative (-) grounded only,

Reversed polarity will result in permanent damage

to components of the electrical system.

BATTERY

Liquid Level

For long battery life and trouble-free operation

check the battery at 15-day intervals for water

level. If the battery is in need of charging, it should

be given immediate attention. Keeping the battery

fully charged not only adds to its life but makes it

available for instant use when needed.

The electrolyte (acid and water) in each cell should

be at the proper level at all times to prevent

battery failure. When the electrolyte is below this

level, pure, distilled water should be added.

A CAUTION! Acid or electrolyte should

never be added except by a skilled

battery man. Under no circumstances

add any special battery "dopes", solutions, or

powders.

A CAUT ION! Electrical storage batteries

give off highly inflammable hydrogen gas

when charging and continue to do so for

some time after receiving a steady charge. Do not

under any circumstances allow an electric spark or

an open flame near the battery. Do not lay tools

across battery terminals as this may result in a

spark or short circuit which may cause an ex-

plosion. Be careful to avoid spilling any electrolyte

on hands or clothing.

For dependable battery service,

see

your

International Harvester dealer.

SPARK PLUG

NOTE: Remove all dirt from base of spark plug

before removing.

-18-

Page 21

ELECTRICAL SYSTEM

Remove the spark plug after every 100 hours of

operation for cleaning and checking the gap. When

adjusting the gap, always bend the outer electrode.

Never bend the insulator. If gap between the

electrodes is too great, the engine will misifre and

be hard to start.

Always use a spark plug wrench when removing or

reinstalling the plug.

Be sure the gasket is in good condition, and screw

plug in tightly. Do not tighten more than enough

to compress the gasket to seat the plug and assure a

good heat transfer between the plug and cylinder

head.

Replace defective plug with new plug. Use a

Champion CJ-8 spark plug or equivalent. See your

International Harvester dealer for a correct re-

placement plug.

Cleaning Spark Plug

Clean spark plug with a pen knife or wire brush

and solvent. If electrode is burned away or the

porcelain is cracked, replace with new plug.

NOTE: Do not use abrasive cleaning machine;

because any grit introduced into the engine could

cause severe damage.

Checking the spark plug gap.

Set gap at .O30-inch.

ENGINE COOLING

This is an air cooled engine. Air must circulate

freely around the engine. Keep the cooling fins and

housing area free of accumulated dirt and trash or

engine will overheat and result in damage to

moving parts.

OIL FOAM AIR CLEANER

Clean and re-oil the air cleaner element every 25

hours under normal operating conditions. Under

extremely dusty conditions, clean the element

every few hours.

To clean the element, proceed as follows:

Remove the cover screws, lift the air cleaner cover

and carefully remove the element to prevent dirt

from entering the carburetor.

Wash the foam element in kerosene or liquid

detergent and water to remove all dirt. Also clean

the air cleaner body and cover.

Wrap the foam element in a cloth and squeeze dry.

Then, saturate the element in engine oil (SAE-30).

Squeeze the element to remove excess oil and

reassemble and fasten to carburetor with screw.

NOTE: Replace air cleaner mounting gaskets that

are worn or damaged, to prevent dirt or dust

entering engine through improper sealing.

19-

Page 22

At the end of the mowing season or in the event

the riding mower is to be stored for any length of

time, (30 days or more) proceed as follows:

Drain the fuel tank and run the engine until the

fuel is exhausted from the fuel system.

Drain the fuel tank out-of-

doors and into a clean container.

CAUTION! Handle gasoline with care, it

is highly flammable. A. Use approved

gasoline container. B. Never remove the

fuel tank cap or fill the fuel tank when the engine

is running, is hot, or incloors. Also, do not smoke

when working around flammable fuel. Wipe up

spilled gasoline. C. Replace fuel tank cap securely.

CAUTION! If the tractor is to be tipped

up remove the battery to avoid spilling

the electrolyte. Battery electrolyte is

poisonous and can be injurious to eyes, skin, and

clothing. If electrolyte is spilled, flush immediately

with a solution of one part baking soda and four

parts water.

Remove spark plug and pour one ounce of I. H. No.

1@ Engine Oil through spark plug hole into thecylinder.

Crank engine several times to distribute

oil over cylinder walls. Replace the spark plug.

Wash or clean and completely lubricate the riding

mower. See "lubrication Guide" on pages 23 and

24. This is a fiberglass body. Use only a mild soap

or detergent. Do not use ammonia base or abrasive

cleansers.

A CAUTION! During operating do not run

the engine in confined area such as

storage building any longer than is

necessary for immediate moving of the machine

ouside into the air. Exhaust gases are toxic.

Opening doors and windows may not provide

adequate ventilation.

Remove the battery and place it in a cool, dry

place above freezing (+320 F.). Check the battery

at least once a month for water level and amount

of charge.

Store your riding mower in a dry and protectedplace.

to the elements, will result in materially shortening

its life.

automotive type steering wheel is detachable.

By removing the roll pin at the lower end of thesteering

shaft the steering wheel can be removedfrom

the housing. See "A" in illust.

This feature provides for easier storage or

transporting in areas where height is a factor.

Leaving the riding mower outdoors, exposed

CAUTION!

The

20-

Page 23

ENGINE Oil

NOTE: After checking the oil the oil dip stick

must be fully seated in the filler tube to avoid

excessive oil consumption and irregular engine

operation.

After the first five hours of operation, change the

oil as directed in Lubrication Table. The engine oil

must be drained and replaced with new oil every 25

hours of engine operation thereafter, or a

minimum of once a year, and sooner if the

equipment is operated under extremely dusty

conditions.

recommend I.H. No.1 Engine Oil. If other than

I.H. No.1 Engine Oil is used, it must be designated

"For Service MS". In new API code these oils are

usually designed as meeting either SO or SE

requ irements.

To aid starting, the selection of crankcase lubricating oils should be based on the lowest

anticipated temperature until the next drainperiod.

Check the oil level of the engine crankcase every

five hours to see that it is filled to the correct level.

Check the oil level only while the engine is

stopped.

The crankcase oil filler cap has the oil level gauge

attached to it. Always keep the oil level between

the "FULL" and "ADD" marks in the "SAFE"

range on the gauge. Do not over-fill. When

checking the oil level, the gauge must be

withdrawn and wiped clean, then inserted all the

way and withdrawn for a true reading.

After Every 5 Hours of Operation

Oil filter cap and

Bayonet-type Oil

Level Gauge

See Page 5.

Rear Axle Drive Chain

See Page 16.

Pedal Return Spring

See Page 13.

Mower Idler Pulley Arm

See Page 15.

Rear Axle Bearings (2)

See Page 16.

Check the oil (with the engine stopped) and add sufficient new

oil to bring it to the "FU LL" mark on the gauge. Do not

\ over-fil'. Do not operate the engine if the oil level is below the

"ADD" mark on the gauge. Dip stick must be fully seated

, before operating the engine.

After Every 10 Hours of Operation

f Apply a light coat of engine oil to the full length of the chain.

Apply a few drops of oil to the spring.

Apply a few drops of oil to the idler pulley arm.

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply two or three strokes of the lubricator

to grease fittings.

We

1.

2.

3.

4.

5.

-21-

Page 24

Front Wheels

LUBRICATION GUIDE

Afer Every 10 Hours of Operation -Continued

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply one or two strokes of the lubricator to

the grease fittings (one fitting on each front wheel).

Mower Spindle

Bearings (3)

Rear Discharge

Mower

See Page 15.

Engine Crankcase

See Page 13.

Mower Spindle

Bearings (3)

Side Discharge

Mower

See Page 15.

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply one or two strokes of the lubricator to

the grease fittings (one fitting on each spindle). Center spindle

can be greased through lift handle slot.

After Every 25 Hours of Operation

While the engine is warm remove the drain plug and drain all the

oil from the crankcase. To drain completely, raise the right side

of the riding mower by placing a 4-inch to 6-inch block under the

right rear wheel. After draining, replace the drain plug. Remove

the crankcase oil filler cap and refill the crankcase with new oil

up to the "FU LL" mark on the oil level gauge. Refer to the

"Lubrication Table" for proper quantity and viscosity to use.

Use IH 251H EP grease or equivalent No.2 multi-purpose

, lithium grease and apply one or two strokes of the lubricator to

the grease fittings (one fitting on each spindle). Center spindle

, can be greased through lift handle slot.

Point of Lubrication

Crankcase

Transmission and

Differential

6.

7.

8.

9.

Above

Engine

1

Check

at

Hours

5

Change

at

Hours

25

32 oz.

qt.

22-

Anticipated Air Temperature

+320 F.

I. H. No.1 @

Engine Oil

SAE-30

+320 to 00 F. Below 00 F.

I.H. No.1 (!)

Engine Oil

SAE-10W

SAE-5Wor

SAE-5W-20

Factory sealed. See your ,. H. Dealer

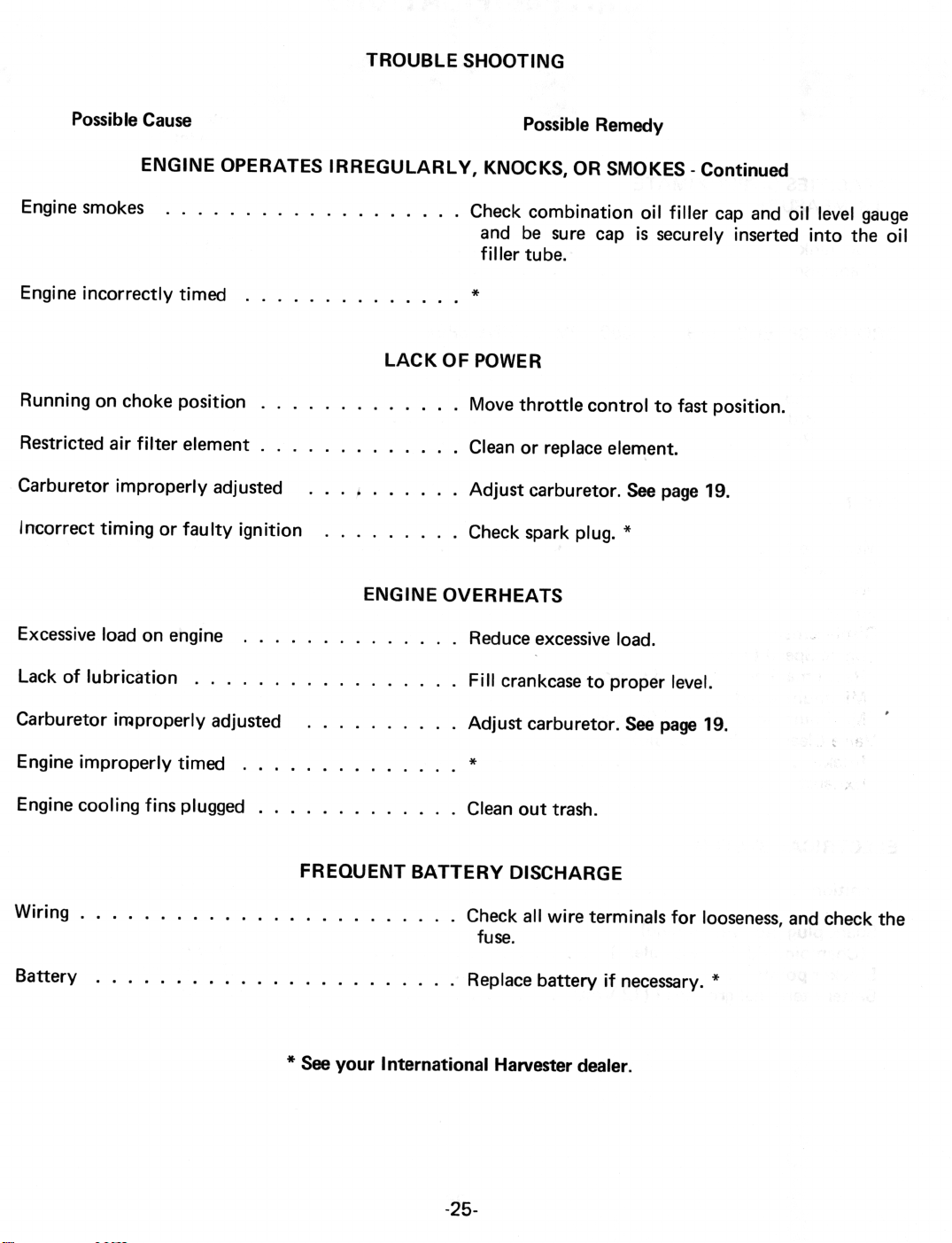

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

with

No accident-prevention program can be suc-

cessful without the wholehearted co-operation

of the person who is directly responsible for the

operation of equipment.

To read accident reports from allover the

country is to be convinced that a large number

of accidents can be prevented only by the

operator anticipating the result before the

accident is caused and doing something about

it. No power-driven equipment, whether it be

transportation or processing, whether it be on

the highway, in the harvest field or in the

industrial plant, can be safer than the man who

is at the controls. If accidents are to be prevented-and they can be prevented-it will be

done by the operators who accept a full measure

of their responsibility.

It is true that the designer, the manufacturer,

the safety engineer can help; and they will help,

but their combined efforts can be wiped out by

a single careless act of the operator.

It is said that' 'the best kind of a safety

device is a careful operator. II We ask you

to be that kind of an operator.

be

Page 31

Loading...

Loading...