Page 1

Page 2

Page 3

INTRODUCTION

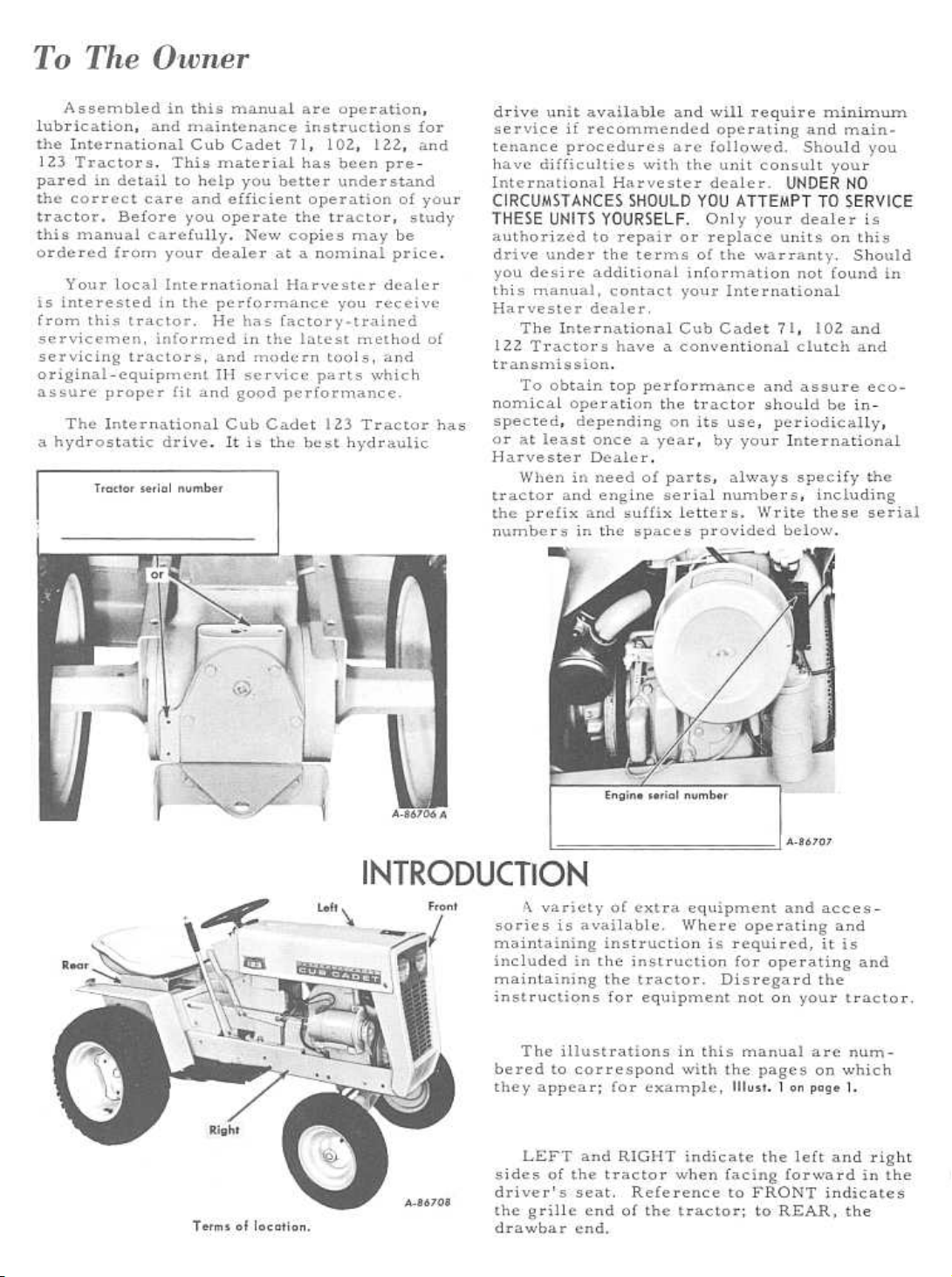

Illust. 1

Internatianal Cub Cadet 122 Tractor.

International Cub Cadet 102 Tractor.

1

Illust. 1A

Page 4

INTRODUCTION

International Cub Cadet 71 Tractor.

Illust.2

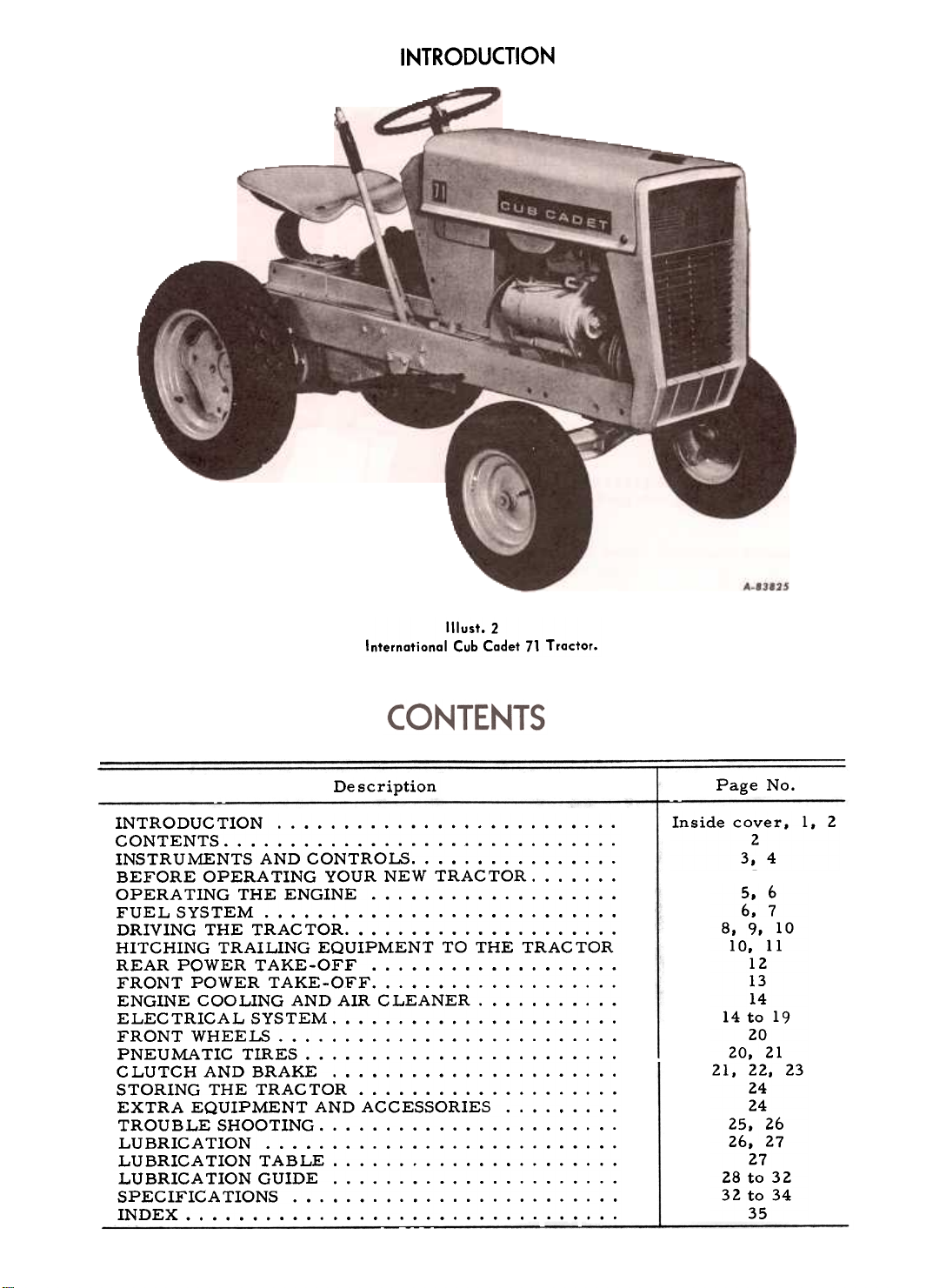

De scription

INTRODUCTION. CONTENTS. INSTRUMENTS AND CONTROLS. BEFORE OPERATING YOUR NEW TRACTOR .

OPERATING THE ENGINE FUEL SYSTEM. DRIVINGTHETRACTOR HITCHING TRAILING EQUIPMENT TO THE TRAC TOR

REARPQWERTAKE-OFF FRONT POWER TAKE-OFF ENGINE COOLING AND AIR CLEANER. ELECTRICALSYSTEM FRONT WHEELS. PNEUMATIC TIRES. CLUTCH AND BRAKE. STORING THE TRACTOR EXTRA EQUIPMENT AND ACCESSORIES TROUBLESHOOTING LUBRICATION. LUBRICATION TABLE. LUBRICATION GUIDE. SPECIFICATIONS. INDEX.

Page No.

Inside cover, I, 2

2

3, 4

5. 6

6. 7

8. 9. 10

10. 11

12

13

14

14 to 19

20

20. 21

21. 22. 23

24

24

25. 26

26. 27

27

28 to 32

32 to 34

35

Page 5

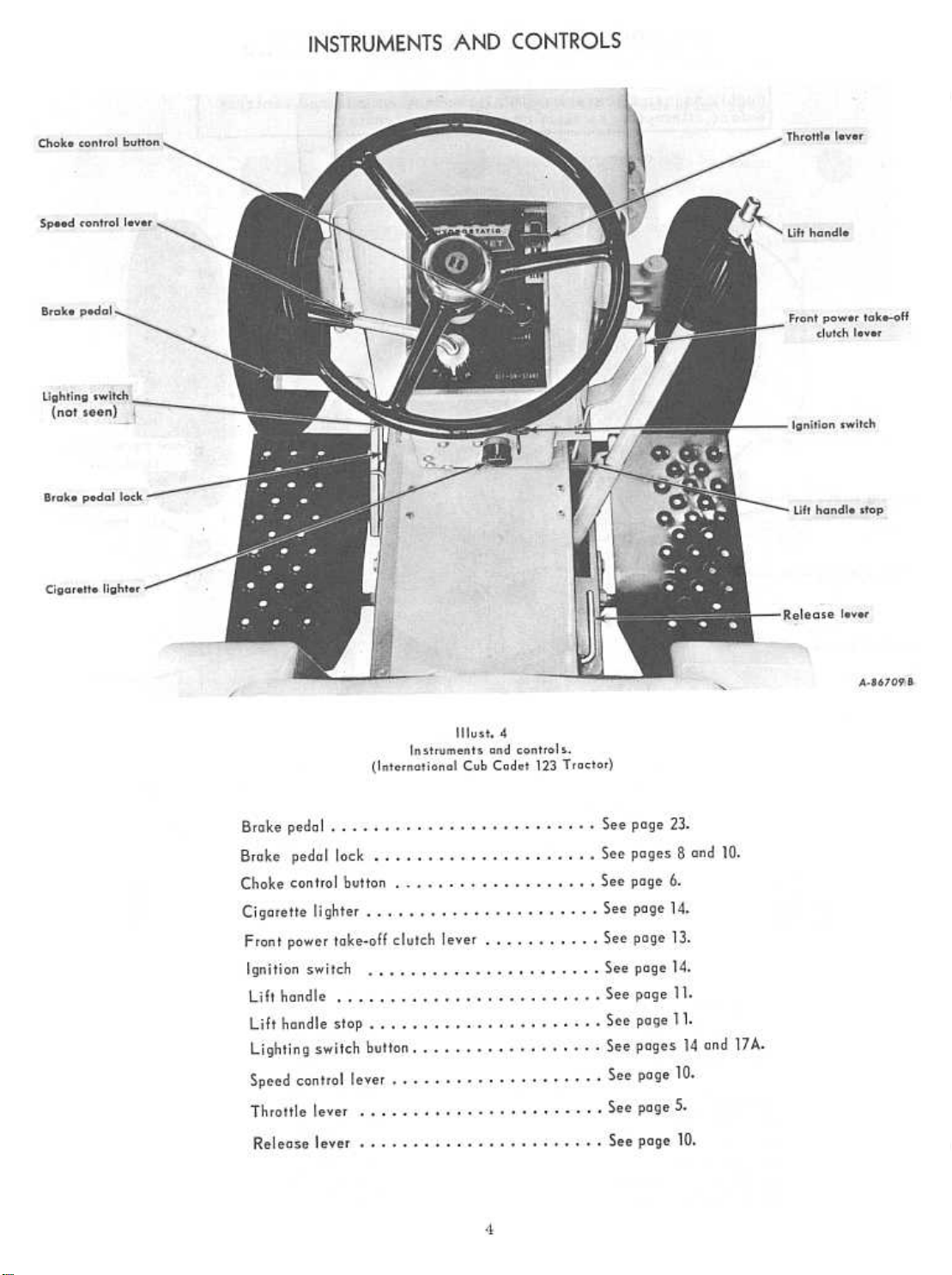

Instruments and contrals on the International Cub Cadet 71, 102, and 122 Tractors.

Brakepedallock See pages 8 and 9.

Choke control button .See page 6.

Clutch and broke pedal See pages 21 and 22.

Creeper shift lever. See page 9.

Front power toke-off clutch lever.. See page 13.

Gearshift lever See page 9.

Ignition switch Seepage 14.

lift handle Seepage 11.

Lifthandlestop Seepage 11.

Lighting switch button. See pages 14 and 17.

Throttle lever. See page 5.

Illust. 3

3

Page 6

Page 7

BEFORE OPERATING YOUR NEW TRACTOR

Lubrication. Lubricate the entire tractor. See pages 26 ta 32.

Check the air pressure. See pages 20 and 21.

Fuel system.

Fill the fuel tank with gasoline. See page 6.

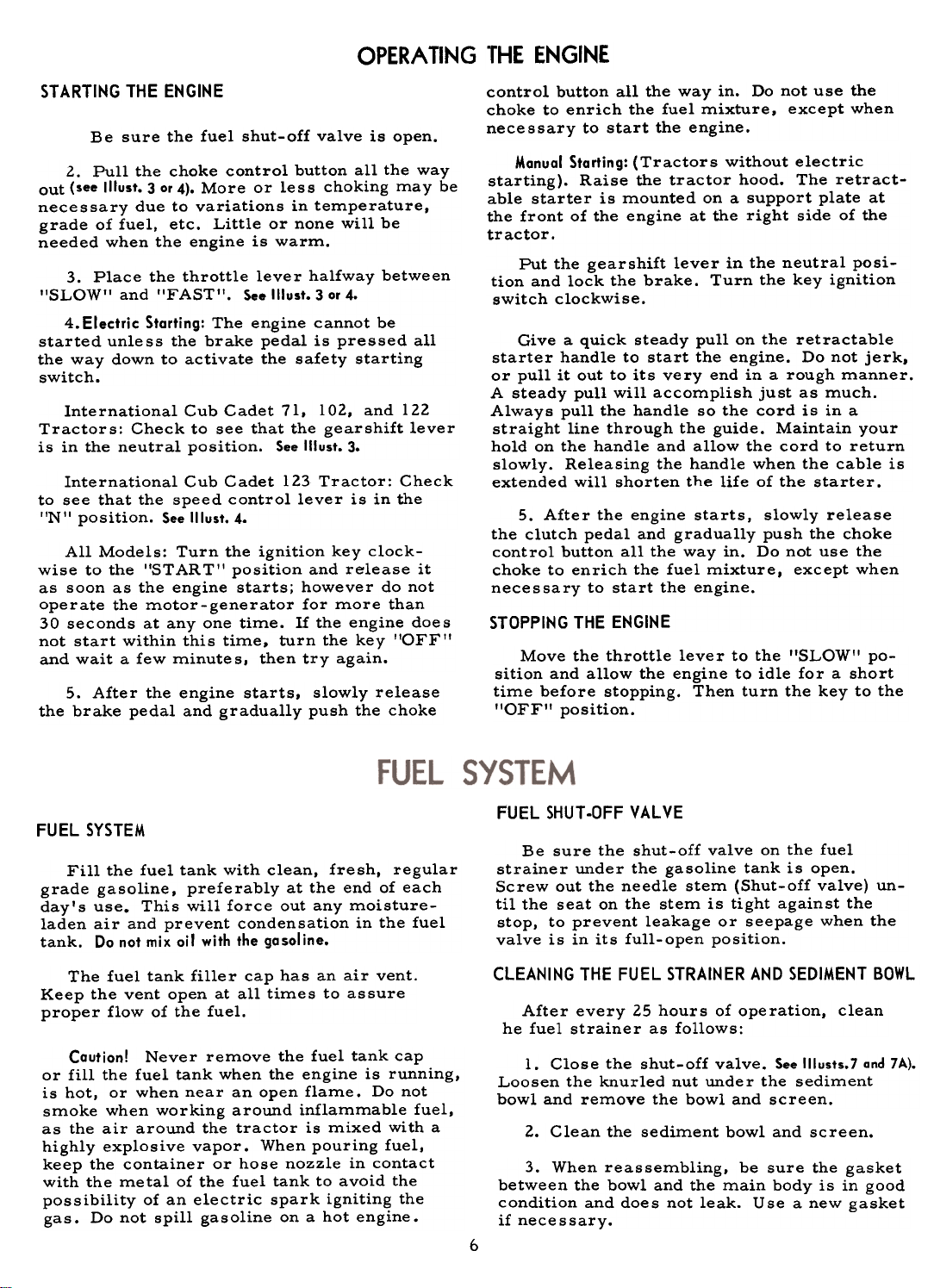

Fuel system and contrals on International Cub Cadet 123 Tractor.

(International Cub Cadet 71, 102 and 122 Tractars are similar.)

THROTTLE LEVER

This lever controls the speed of the engine.

When set in a given position, it will maintaina

uniform engine speed.

GOVERNOR

The governor is set at the time the engine

is assembled and should not require readjustment unless the governor arm is removed or

loosened from the governor shaft. Consult

your International Harvester dealer if the

gove rnor does not function properly.

Tires.

Illust.5

LIFTING THE HOOD

The tractor hood is arranged to swing up

and forward to make the engine and fuel tank

readily accessible.

To raise the hood, take hold of each side of

the hood at the rear, pull outward, and raise

it upward and forward to its stop.

5

Page 8

THE ENGINE

STARTING THE ENGINE

Be sure the fuel shut-off valve is open.

2. Pull the choke control button all the way

out (see Illust. 3 or 4). More or less choking may be

necessary due to variations in temperature,

grade of fuel, etc. Little or none will beneeded

when the engine is warm.

3. Place the throttle lever halfway between

"SLOW" and "FAST". See Illust. 3 or 4.

4. Electric Starting: The engine cannot be

started unless the brake pedal is pressed all

the way down to activate the safety starting

switch.

International Cub Cadet 71, 102, and 122

Tractors: Check to see that the gearshift leveris

in the neutral position. See Illust. 3.

International Cub Cadet 123 Tractor: Check

to see that the speed control lever is in the

I'N'I position. See Illust. 4.

All Models: Turn the ignition key clock-wise

to the "START" position and release it

as soon as the engine starts; however do not

operate the motor-generator for more than

30 seconds at anyone time. If the engine does

not start within this time, turn the key !'OFF"

and wait a few minute s. then try again.

5. After the engine starts. slowly releasethe

brake pedal and gradually push the choke

control button all the way in. Do not use thechoke

to enrich the fuel mixture, except when

necessary to start the engine.

Manual Starting: (Tractors without electric

starting). Raise the tractor hood. The retract-

able starter is mounted on a support plate at

the front of the engine at the right side of thetractor.

Put the gearshift lever in the neutral posi-

tion and lock the brake. Turn the key ignition

switch clockwise.

Give a quick steady pull on the retractable

starter handle to start the engine. Do not jerk.

or pull it out to its very end in a rough manner.

A steady pull will accomplish just as much.

Always pull the handle so the cord is in a

straight line through the guide. Maintain your

hold on the handle and allow the cord to return

slowly. Releasing the handle when the cable is

extended will shorten the life of the starter.

5. After the engine starts, slowly release

the clutch pedal and gradually push the choke

control button all the way in. Do not use the

choke to enrich the fuel mixture, except when

nece s sa ry to start the engine.STOPPING

THE ENGINE

Move the throttle lever to the "SLOW" po-

sition and allow the engine to idle for a shorttime

before stopping. Then turn the key to the

"OFF" position.

SYSTEM

Fill the fuel tank with clean, fresh, regular

grade gasoline, preferably at the end of each

day's use. This will force out any moistureladen air and prevent condensation in the fueltank.

Do not mix oil with the gasoline.

The fuel tank filler cap has an air vent.

Keep the vent open at all times to assure

proper flow of the fuel.

Caution! Never remove the fuel tank cap

or fill the fuel tank when the engine is running,

is hot, or when near an open flame. Do not

smoke when working around inflammable fuel,as

the air around the tractor is mixed with a

highly explosive vapor. When pouring fuel,

keep the container or hose nozzle in contact

with the metal of the fuel tank to avoid the

possibility of an electric spark igniting the

gas. Do not spill gasoline on a hot engine.

OPERATING

FUEL

CLEANING

2.

FUEL SHUT.OFF VALVE

Be sure the shut-off valve on the fuel

strainer under the gasoline tank is open.

Screw out the needle stem (Shut-off valve) until the seat on the stem is tight against the

stop, to prevent leakage or seepage when the

valve is in its full-open position.

THE FUEL STRAINER AND SEDIMENT BOWL

After every 25 hours of operation, cleanhe

fuel strainer as follows:

1. Close the shut-off valve. See Illusts.7 and 7A).

Loosen the knurled nut under the sediment

bowl and remove the bowl and screen.

Clean the sediment bowl and screen.

3. When reassembling, be sure the gasket

between the bowl and the main body is in good

condition and does not leak. Use a new gasket

if necessary.

6

Page 9

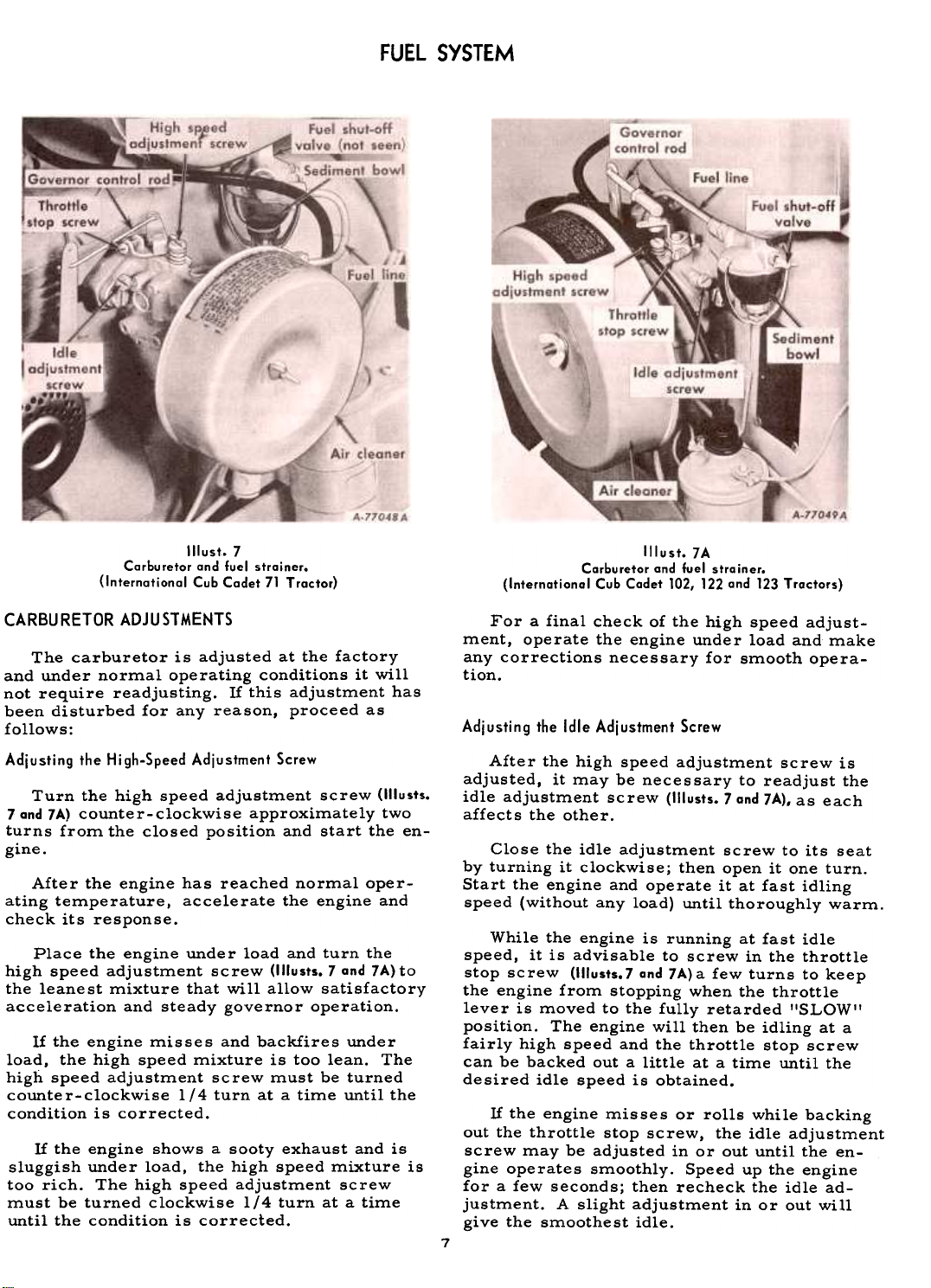

FUEL SYSTEM

Carburetor and fuel strainer.

Illust. 7

(International Cub Cadet 71 Tractor)

CARBURETOR ADJUSTMENTS

The carburetor is adjusted at the factory

and under normal operating conditions it will

not require readjusting. If this adjustment has

been disturbed for any reason, proceed as

follows:

Adjusting the High-Speed Adjustment Screw

Turn the high speed adjustment screw (1IIusts.

7 and 7A) counter-clockwise approximately two

turns from the closed position and start the en-gine.

After the engine has reached normal oper-

ating temperature, accelerate the engine and

check its response.

Place the engine under load and turn the

high speed adjustment screw (1IIusts. 7 and 7A) to

the leanest mixture that will allow satisfactory

acceleration and steady governor operation.

If the engine misses and backfires under

load, the high speed mixture is too lean. The

high speed adjustment screw must be turned

counte r- clockwise 1 /4 turn at a time until the

condition is corrected.

If the engine shows a sooty exhaust and is

sluggish under load, the high speed mixture is

too rich. The high speed adjustment screw

must be turned clockwise 1 /4 turn at a time

until the condition is corrected.

7

Carburetor and fuel strainer.

Illust.7A

(Internationol Cub Cadet 102, 122 and 123 Tractors)

For a final check of the high speed adjustment, operate the engine under load and make

any corrections necessary for smooth opera-

tion.

Adjusting the Idle Adjustment Screw

After the high speed adjustment screw is

adjusted, it may be necessary to readjust the

idle adjustment screw (1IIusts. 7 and 7A), as each

affects the other.

Close the idle adjustment screw to its seat

by turning it clockwise; then open it one turn.

Start the engine and operate it at fast idling

speed (without any load) until thoroughly warm.

While the engine is running at fast idle

speed, it is advisable to screw in the throttle

stop sc rew (1IIusts.7 and 7 A) a few turns to keep

the engine from stopping when the throttle

lever is moved to the fully retarded "SLOW"

position. The engine will then be idling at a

fairly high speed and the throttle stop screw

can be backed out a little at a time until the

desired idle speed is obtained.

If the engine misses or rolls while backing

out the throttle stop screw. the idle adjustment

screw may be adjusted in or out until the en-

gine operates smoothly. Speed up the engine

for a few seconds; then recheck the idle ad-

justment. A slight adjustment in or out will

give the smoothest idle.

Page 10

PREPARING THE TRACTOR FOR EACH DAY'S WORK

Fill the fuel tank at the end of each day's

run. See page 6.

Check the crankcase oil level and add new

oil if necessary. Seepage 26.

Clean the air cleaner element if necessary.

See page 14.

Inspect the tires for general condition. See

pages 20 and 21.

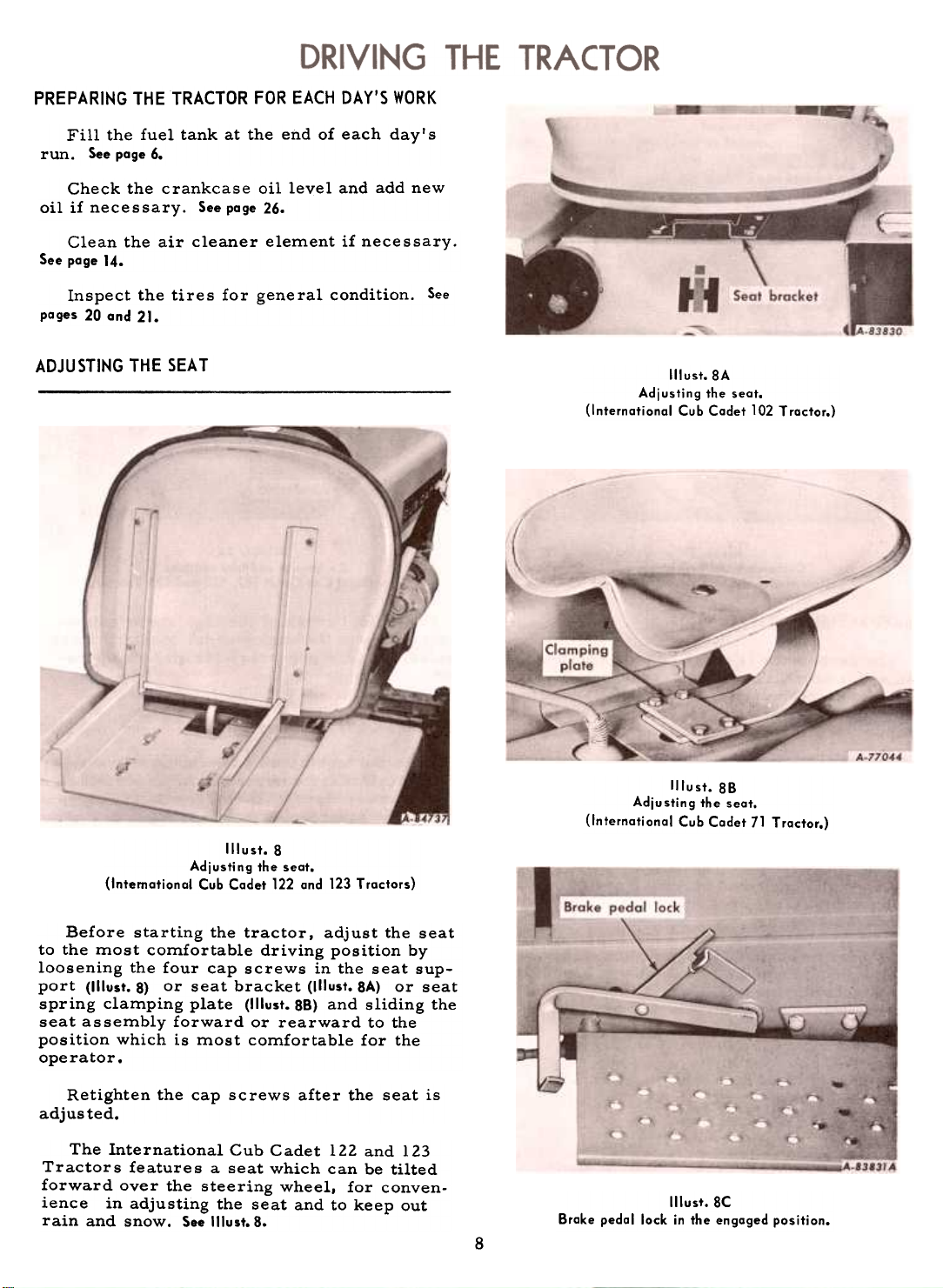

ADJU STING THE SEAT

Adjusting the seat.

(Intemational Cub Cadet 122 and 123 Tractors)

Illust. SA

Adjusting the seat.

(International Cub Cadet 102 Tractor.)

Illust. 88

Adju sting the seat.

(Internatianal Cub Cadet 71 Tractar.)

Illust. 8

Before starting the tractor, adjust the seat

to the most comfortable driving position by

loosening the four cap screws in the seat sup-

port (II lust. 8) or seat bracket (1IIust. 8A) or seat

spring clamping plate (1IIust.88) and sliding the

seat assembly forward or rearward to the

position which is most comfortable for theoperator.

Retighten the cap screws after the seat is

adjus ted.

The International Cub Cadet 122 and 123

Tractors features a seat which can be tilted

forward over the steering wheel, for convenience in adjusting the seat and to keep out

rain and snow. See Illust. 8.

Brake pedal lack in the engaged position.

Illust. 8C

8

Page 11

DRIVING THE TRACTOR

(International Cub Cadet 71, 102 and 122 Tractors)

CLUTCH AND BRAKE PEDAL

The combination clutch and brake pedal is

used to disengage the engine from the transmission when shifting gears and to actuate the

brake to stop the tractor. The pedal must be

pressed all the way down to activate the safety

starting switch when starting the engine.

To disengage the clutch, press the pedal

approximately half way down. To stop the tractor press the pedal all the way down.

LOCKING THE BRAKE

Always lock the brake when the tractor is

parked on a grade. To lock the brake, press

down on the brake pedal; ther. place the brake

pedal lock in the engaged position. To disen-

gage the lock, press down on the brake pedal

lift the lock up and place it in the disengagE:d

position behind the brake pedal as shown in

Illust. 17A.

Note: Do not rest your foot on the pedalwhile

driving the tractor, as this will result

in excessive clutch lining wear.

Always be sure the rear wheels are free

to turn. Under any adverse conditions, do not

attempt to free the tractor by speeding up the

engine and suddenly engaging the clutch. Try

backing out instead of going forward.

STOPPING THE TRACTOR

Disengage the clutch by pressing the pedal

all the way down. Move the gearshift lever to

the neutral position.

CREEPER SHIFT LEVER

The creeper drive provides a slower speed

in each respective gear, by a four-to-one re-

duction in speed from direct drive. When the

creeper shift lever is all the way forward, it

is in direct drive, or all the way rearward, it

is in creeper drive. See Illust. 3. Note: Do not

use a mid-point position on the creeper driveas

neutral. Neutral position must be selected

only with the standard transmission gearshift

lever.

GEARSHIFT LEVER

This lever is used to select various gear

ratios provided in the transmission. There

are three forward speeds and one reverse

speed. See Illust. 3. Refer to "SPECIFICA TlaNS't

on page 32.

STARTING THE TRACTOR

1. Advance the th rattle leve r s lightly. SeeIllust.

3.

2. Disengage the clutch by pressing the

clutch pedal all the way down, and move the

gearshift lever to the desired speed.

3. Start the tractor in motion by slowly

releasing the clutch pedal and moving thethrottle

lever to the pos it ion where the engine

operates best for the load to be handled.

Note: Do not shift gears while the engine

clutch is engaged or while the tractor is inmotion.

OPERATING THE CREEPER DRIVE

To operate the tractor in creeper drive,

move the creeper shift lever (1IIust.3) all the

way rearward. Then select the speed desired

and proceed as instructed under "Starting the

Tractor".

The following table shows the speeds avail-

able in each of the three forward gears and thereverse

gear.

Per Hour

Direct

First

Second

Drive

2.3

6.8

2.5

Drive

.6

1.0

1.7

.6

Miles

Creeper

Gear

3.9

Third

Reverse

a

Page 12

DRIVING THE TRACTOR

(International Cub Cadet 123 Tractor)

BRAKE PEDAL

The brake pedal must -be pressed all the

way down to activate the safety starting switch.

When the brake pedal is in the depressed position it automatically moves the speed control

lever to the "N" position.

The tractor can be stopped either by

pressing the pedal all the way down, or placing

the speed control lever in the "N" position.

THE BRAKE

Always lock the brake when dismounting

from the tractor. To lock the brake, press

down on the brake pedal; then place the brake

pedal lock in the engaged position. See Illust. 8C.

To disengage the lock, press down on the brak",

pedal, lift the lock up and place it in the disengaged position behind the brake pedal as

shown in Illust. 17A.

SPEED CONTROL LEVER

This lever is used to select any speeds

from a standstill "NI! position to eight miles

per hour in the forward direction and to fourmiles

per hour in the reverse direction.

Moving the speed control lever forward

provides increased forward speeds, and moving the lever rearward provides the reversedspeeds.

Hote: Do not rest your foot on the brake

pedal while driving the tractor as this wouldcause

the speed control lever to return to the

"N" position.

$T ARTING THE TRACTOR

1. Advance the throttle lever slightly.

1!lust.4.

2. Depress the brake pedal by pressing the

pedal all the way down, and move the towing

lever (lllust. 4) in drive (horizontal) position,

then move the throttle lever to the position

where the engine operates best for the load to

be handled.

See

3. Start the tractor in motion by moving

the speed control lever forward or rearward

as described above.

RELEASE LEVER

To push or move tractor for a short distance

or when working on the engine. the release le-

ver (1!lust.4) must be locked in the release

(down) position and the speed control lever must

be in the 'IN'I position. Caution: 12.2 tlQ.t;. ~.

STOPPING THE TRACTOR

Move the speed control lever to the I'NII

position or use the brake. Before dismounting

always depress the brake pedal.

TRAILING

Trailing -type equipment must be hitched to

the tractor only at the hitch hole in the draw-bar.

See Illusts. 11 and 11A.

When the tractor has a three-point hitch

(1IIusts. 11 and 11A) equipment adaptable to the

LOCKING

THE

EQUIPMENT TO

three-point hitch is raised and lowered with

the lift handle. The lift handle can be set tohold

the equipment at various positions by use

of the six notches in the lift handle quadrant.

The lower mounting bracket has three holes

which are used for additional adjustment.

10

Page 13

HITCHING TRAILING EQUIPMENT TO THE TRACTOR

Illust. 11

Drawbar and three-point hitch shown on

International Cub Cadet 71 Tractor.

LIFT HANDLE

This handle is used to lift or lower equip-

ment used with the tractor. Depress the

release button to move the handle.

When operating equipment in the "FLOAT"

position, depress the release button on top of

the handle and move the wire bail over the top

of the button. See Illust. 118.

When the equipment is allowed to float, the

position of the lift handle forward travel can

be limited by the adjustable stop. Loosen the

nut, slide the stop to the required position,

and tighten the nut. See Illust. 118.

Drawbar and three-paint hitch.

Illust. 11A

(International Cub Cadet 102. 122 and 123 Tractors)

Refer to the equipment manual for properhitching

instructions.

11

Illust. 118

Adjustable stop limiting handle travel.

Page 14

REAR POWER TAKE-OFF

(International Cub Cadet 71, 102 and 122 Tractors)

Illust. 12

Operating the Pawer T ake.aff.

Internatianal Cub Cadet 71 Tractar

If your tractor is equipped with a rear

power take-off, the following instructions and

precautions should be carefully studied and

followed.

The rear power take-off is started and

stopped by the same engine clutch as the

tractor. Be sure to disengage the engine

clutch before moving the power take-off shift -

er rod (1IIust. 12), or shifter lever (1IIust. 12A).

The shifter rod should always be in the disengaged (forward) position and the shifter

lever in the disengaged (rearward) position

when the power take-off is not in use.

Caution! Always cover the power take-off

exposed shaft with the guard when the power

take-off is not being used.

Operating the Pawer Take-off.

Itlust.12A

Internatianal Cub Cadet 102 and 122 Tractars

4. On the Inte rnational Cub Cadet 71

Tractor; Press down on the shifter rod

(1IIust. 12) and move it rearward to the engaged

position. Then release the shifter rod and

allow it to lock in place.

On the International Cub Cadet 102 and 122

Tractors; move the shifter lever (1IIust.12A)

forward to the engaged position.

Slowly release the clutch pedal.

OPERATING THE REAR POWER TAKE.OFF

WITH THE TRACTOR STANDING STILL

1. The transmission gearshift lever mustbe

in the neutral position.

2. Move the throttle lever back to low idlespeed.

3. Depress the clutch pedal to disengage

the engine clutch.

5.

OPERATING THE REAR POWER TAKE.OFF

WITH TRACTOR IN MOTION

Follow the first four steps outlined above;

then engage the power take-off shifter rod or

lever. Keep your foot pressed down on the

clutch pedal (in the dis engaged position),

advance the throttle lever and move the

transmission gear-shift lever to the speed

that is desired to run the tractor. Slowly

release the clutch pedal. This will start the

tractor in motion with the power take-off in

operation.

12

Page 15

OPERATING THE FRONT POWER TAKE.OFF CLUTCH

1. Move the throttle lever back to medium

or low idle speed.

After considerable clutch use, it may be

necessary to readjust the button clearance as

described below to assure proper clutch disengagement.

2. Move the front power take-off clutch

lever (forward) to the engaged position

(rearward) to the disengaged position. See

Illusts. 3 or 4 ond 13A.

Note: It is recommended that the clutch

lever be placed in the forward or engaged

position when the tractor is being used without front power take-off equipment.

ADJUSTING THE CLUTCH

The clutch is factory adjusted and should

not require further adjustment under normal

operating conditions. However, if clutch

slippage should occur. It is recommended

that you see your International Harvester

dealer for satisfactory servicing of the clutch,

as special equipment and instructions are

required.

With the clutch fully engaged (clutch lever

in the forward position) place a piece of thin

cardboard (match book cover) approximately

1/64 inch thick between the engaging lever

wear button IIAII and the pressure spring

thrust button IIBII (1IIust. 13), loosen the jam nut

on the turnbuckle lIC't (1IIust. 13A), and adjust the

turnbuckle until a light drag is felt on the

cardboard when it is removed from between

the buttons. Be sure all slack, except the

1/64 inch adjustment, is out of the linkage.

Then, tighten the jam nut securely against the

turnbuckle.

INSTALLING AND REMOVING DRIVE BELT

To install or remove the drive belt, loosen

the clutch lever bolt enough so the lever can

be moved forward to provide sufficient belt

clearance between the engaging lever wear

button "A" and the pressure spring thrust

button "B", s..lllust.13.

After installing a new belt, move the clutch

lever back onto the clutch lever latch and

tighten the bolt. See Illust. 13.

View with grille removed to show engoging

Illust. 13

lever weor button ond pressure spring

thrust button.

Note: It is not always necessary to place

the lever in the fully horizontal position as

shown in Illust. 13A.

Illust. 13 A

13

Page 16

ENGINE COOLING

This tractor has an air cooled engine. Air

must be able to circulate freely around the

engine, through the screen and shroud, and

over the fins of the cylinder head and cylinderblock.

Keep these areas free of accumulated

dirt and trash or the engine will overheat and

result in damaged moving parts.

DRY-TYPE AIR CLEANER

Incoming air for combustion is filtered by

a dry-type air cleaner having a filter element

inside of the cover.

Remove and clean or replace the element

with a new one when loss of power isnoticeable.

Cleaning the Element

To clean the element. remove the wing nut

and air cleaner cover (1IIust. 14) then remove the

element and tap it lightl y on a flat surface to

cause the loose dirt to falloff. Handle the

paper element with care to avoid perforations.Do

not use compressed air to remove the dirt

as this can rupture the element. Do not wash

or use a solvent.

The twelve-volt electrical system on a

tractor with electric starting consists princi-

pally of a motor-generator, voltage regulator,

and a twelve-volt battery.

Use the illustrations on poge 17 and wiringdiagrams

on poge 18, as a guide for identifyingthe

various electrical units and for tracing the

electrical cables and connections. Be sure all

connections are clean and securely fastened.

Removing the air cleaner filter element.

Illust. 14

Replacing the Element

Replace the element with a new one if dirt

does not drop off easily or if it is bent,crushed

or damaged. When replacing the ele-

ment be sure it fits snugly around the insideedge

of the air cleaner base. Then replace the

cover and tighten the wing nut finger tight.

engine has stalled and the operator leaves

the tractor, the key must be turned to the

"OFF" position to prevent battery discharge.

SAFETY STARTING SWITCH

The safety starting switch, activated by the

clutch or brake pedal, serves to prevent starting the engine accidentally.

IGNITION SWITCH

Turn the key clockwise to turn on the

ignition. With electric starting, a further turn

actuate s the motor -generator. The key cannot

be removed when in the IIONtl position.

Note: When the engine is not operating or

the

LIGHTING SWITCH BUTTON

Pull the button (1IIust. 17A) out to turn on thelights

and push it in to turn off the lights.

CIGARETTE LIGHTER

Push the lighter to make electrical contact.

When it pops back it is ready for use.

14

Page 17

ELECTRICAL SYSTEM

SPARK PLUG

Note: Remove all dirt from the base of the

spark plug before removing the spark plug.

Remove the spark plug after every 100

hours of operation for cleaning and checking

the gap. See Illust. 15. When making this adjustment, always bend the outer electrode. Never

bend the center electrode, as it may damag:!

the insulator. If the gap between the electrodes

is too great, the engine will misfire and be

hard to start.

Always use a spark plug wrench when removing or reinstalling the plug.

Be sure the gasket is in good condition,

and screw the plug in tightly. Do not tighten

more than enough to compress the gasket to

seal the plug and assure a good heat transfer

between the plug and the cylinder head. Tighten

the plug 1/2 to 3/4 turns past finger tight.

IGNITION TIMING

Illust.15A

Adjusting the breaker paints.

Set gap at .O20-inch.

Remove the breaker point cover after every

100 hours of operation for cleaning the points

and resetting the gap (1IIust.15A). Replace badly

pitted or burned points.

For more precise timing, a timing light

should be used. The engine has a timing sight

hole which is located in the right s ide of the

engine bearing plate on the International Cub

Cadet 71 Tractor or in the right side of the

blower housing in the International Cub Cadet

102, 122 and 123 Tractors. See Illust.15B.

Checking the spark plug gap.

(Ilust. 15

Set gap at .O25-inch.

Replace a defective plug with a new plug.

See your International Harvester dealer for a

correct replacement plug.

Cleaning the Spark Plug

Sandblasting is the recommended method of

cleaning the spark plug. Never scrape or clean

the insulator with anything which will scratch

the porcelain. Scratched porcelain allows

carbon and dirt to accumulate much faster.

With the engine running at 1/3 throttle. or

more, adjust the breaker points until the "SP"

mark on the flywheel is centered in the sight

hole. Note: The "Spl' mark will appear 20degrees

before top dead center. The other

mark is the top center mark and is stamped

with "DC'I below the mark.

Illust. 158

Location of timing sight hole.

(Motor-generotor has been removed to better

illustrate the location).

15

Page 18

ELECTRICAL SYSTEM

and Replacing the Motor-Generator Belt

The motor-generator (IZ-volt, negative

ground) will function as a cranking motor when

the ignition key is turned to the "START"

position, driving the engine by means of abelt.

When the engine is operating, the unit will

function as a generator.

MOTOR-GENERATOR BELT

Check the tension of the motor -generator

belt after the first 10 hours of operation and

every 50 hours of operation thereafter. The

tension is correct when the belt can be

deflected a maximum of 1/4-inch by a ten

pound force applied midway between the two

pulleys.

Replace the motor-generator belt when it

becomes badly worn. To remove the old belt,

loosen the motor-generator brace bolt I'A" and

mounting bolt.s lIB", Illust.17. Move the gener-

ator in toward the engine and slip the old belt

off the pulleys and over the crankshaft. Install

the new belt in the reverse order of removal

and adjust the belt to the proper tension.

VOL TAGE REGULATOR

A satisfactory generator charging rate is

maintained by the voltage regulator. If the

regulator fails to operate correctly, see your

International Harvester dealer.

Hote: Never place a jumper lead between,

or accidentally bridge, the I'BAT'I terminal

and the I'FI' terminal on the regulator, as this

will damage the regulator.

LIGHTS

The headlights are sealed-beam lights. The

parts are so constructed that the filament, re-

flector, and lens are all assembled in a unit

permanently sealed against dirt, moisture,

and corrosion. If a filament burns out or a

lens bxeaks, the complete unit must be replaced. Refer to I'SPECIFICA TIONS".

Also follow this procedure when a new beltis

installed.

Adjusting the Motor-Generator Belt

Loosen the motor-generator brace bolt I'A'I

and mounting bolts IIBI', Illust.17.

Move the generator away from the engine

until the tension on the belt is correct. See

Illust. 16.

Note: Under no circumstances should a pry

bar.be used on the motor-generator to obtain

belt tension as damage to the bearings will

re suIt.

Tighten mounting bolts IIB'I and brace bolt

IIA II

TAilliGHT

To replace the taillight lamp, remove thelens

from the taillight and replace the taillight

lamp with a 4 candle power lamp. Refer to

"SPECIFICATIONS".

FUSE (Electric Lighting)

It is important to use the same capacity

fuse for replacement. Refer to "Specifications". If the lights fail. check the fuse. If a

fuse continually burns out. check the electri-

cal wiring for short circuits.

The fuse is located in a fuse housing in theline

at the back of the instrument panel. See

Illust. 18.

To install a new fuse. pre ss in on the fusehousing

cap and turn counterclockwise to re-move

it from the fuse housing. Remove the oldfuse

and replace it with a new one. Then reassemble the cap to the housing. Remove the

battery if necessary to reach the fuse.

MOTOR-GENERATORRemoving

16

Page 19

ELECTRICAL SYSTEM

Electrical units an the right side of the tractor.

Illust. 17

Electrical units on the left side of the tractor.

Illust.17A

17

Page 20

Page 21

ELECTRICAL SYSTEM

Index to reference numbers shown in Illust. 18.

Ref.

No.

Key ignition switch.

Cable -ignition coil positive (+) terminal

to key ignition switch "IGN" terminal -

black.

3

Cable -magnetic switch to key ignition

4

5

6

7

8

9

STORAGE BATTERY

Battery and Cable$

switch "BAT" terminal -light green.

Safety starting switch.

Cable -safety starting switch to key

ignition switch "ST" terminal -

orange.

Cable -safety starting switch to

magnetic switch -orange w/black

tracer.

Magnetic switch.

Cable -generator "A" terminal to

magnetic switch -red.

Cable -regulator "BAT" terminal to

magnetic switch -gray.

---

Description

Ref.

No.

10

11

12

13

14

15

16

17

18

19

20

Voltage regulator.

Cable -regulator "GENtl terminal to

generator "All terminal -light blue.

Cable -regulator tIF" terminal to

generator t'F" terminal -yellow.

Cable -voltage regulator lower

mounting bolt to battery ground pink.

Cable harness.

Motor -generator.

Battery.

Cable -battery positive (+) terminal to

magnetic switch.

"';able -battery negative (-) terminal to

ground.

Battery terminal cover.

ignition coil.Ivondenser.

Description

21

Keeping the battery fully charged not only

adds to its life but makes it available for instant

use when needed.

Before working on any part of the electri-

cal system, disconnect the battery ground

cable at the battery negative (-) terminal. See

Illust. 17. Do not reconnect this cable until all

work has been completed. This will prevent

shorting and damage to any of the electrical

units. Examine the electrical cables occasion-

ally to be sure they are not being frayed by

contact with adjacent parts.

When replacing a battery, make certain the

ground cable is connected to the negative (-)

terminal on the battery. Be sure the rubber

boot is properly positioned over the positive

(+) terminal on the battery. Note: Both cables

must be assembled with the nuts to the inside

of the terminals to prevent shorting against

the pedestal.

Cleaning and Servicing the Battery

Occasionally remove the battery cables and

brighten the terminal contact surfaces with

wire wool, and reassemble them. Apply a

light coat of vaseline or chassis lubricant. Be

sure the terminals are clamped tightly and

that the battery is fastened securely in the battery box. Replace unserviceable cable. Keep

the vent holes in the battery filler caps open.

Liquid Level

Check the battery at least once a month for

water level.

The electrolyte (acid and water) in each

cell should be at ring level at all times to pre-

vent battery failure. When the electrolyte is

below this level, add pure, distilled water.

Acid or electrolyte should never be added

except by a skilled battery man. Under no

circumstances add any special battery !'dopes; 11

solutions or powders.

Caution! Electric storage batteries give off

highly inflammable hydrogen gas when charging and continue to do so for some time after

receiving a steady charge.

Caution! Do not under any circumstances

allow an electric spark or an open flame near

the battery. Do not lay tools across battery

terminals as this may result in a spark or

short circuit which may cause an explosion.

Be careful to avoid spilling any electrolyte

on hands or clothing.

For dependable battery service, see your

International Harvester dealer.

19

Page 22

FRONT WHEEL TOE-IN

Front wheel adjustments.

Illust.20

Illust.20A

Tie rod and drog link boll joints.

The front wheel toe-in dimension is 1-32-

inch to 1/8-inch toe-in (1/32-inch to 1/8-inch

closer in front than in the rear). Measure the

distance between two points "A" and two points

"B" Illust. 20. Points "A" and "B" must be on the

inside of the wheels at the outer edges and at

the same height from the ground as the front

wheel hubs.

To adjust the toe-in, disconnect either

tie rod ball joint IIC" (1IIusts. 20 and 20A) loosen

REAR TIRES

6-12 rear tires are standard equipment on

the International Cub Cadet 71 and 102 Tractors.

23 x 8.50 -12 Terra-Tires are standard

equipment on the International Cub Cadet 122

and 123 Tractors. They are also available as

extra equipment when ordered for the

International Cub Cadet 71 and 102 Tractors.

the lock nut, and turn the tie rod ball joint

end in or out as required.

TURNING RADIUS

The front wheels should have an equal angle

for left and right turns. If adjustment is nec-

essary, disconnect the drag link ball joint I'D"

(II lusts. 20 and 20A) loosen the lock nuts and turn

the drag link ball joint in or out as required.

Keep tires free from oil and grease as both

destroy rubber.

After using the tractor for spraying-insect

control work-use water to remove any chemicals that may be on the tires.

The Terra-Tires provide maximum mobility

in sand, snow, and soft soil conditions. The

reduced ground pressure and low inflation

provides maximum protection for turf, soil,

and crops.

CARE OF TIRES

Avoid stumps, stones, deep ruts and other

hazards. Cuts in tires should be repaird

immediately as neglect decreases the tire life.

INFLATION

Keep the pnewnatic tires properly inflated.

Underinflation will damage the tire cord body

and may also cause the tire to slip on the rim,

thus tea'ring out the tube valve stem.

Always see that the tire valve caps are in

place and tightened securely to prevent the

loss of air and protect the valve core and stem.

20

Page 23

PNEUMA TIC TIRES

OPERATING PRESSURE FOR TIRES

Inflate the front and rear tires for normal

or heavy load operations as shown in the fol-

lowing table.

MOUNTING TIRES ON THE RIM

After mounting a new or old tire on the

rim, inflate it to 20 pounds pressure to seat

the tire bead on the rim flange and to prevent

the tire from creeping and shearing off thevalve.

Then deflate the tire to the correct

operating pressure.

REAR WHEEL WEIGHTS

Rear wheel weights increase traction and

reduce wheel slippage. The weights weigh

approximately 26 pounds each. They are

attached to each rear wheel with two bolts,

lock washers, and hex. nuts.

If additional weight is desired. a second set

of weights can be attached to each first weight

by using two longer bolts.

TIRE CHAINS

Tire chains will provide additional traction

for wet ground conditions, when plowing snow,

or pulling heavy loads. Rear wheel weights

are recommended when using chains.

(International Cub Cadet 71, 102 and 122 Tractors)

Clutch disengaged:

tractor must be

free to coast.

Neutral zone:

Both brake and clutch

are disengaged when.

pedal is in this zone.

Braking zone:

Brake must be engaged '"

when pedal is in this zone.

1-5/16-inch maximum

3/4 -inch minimum / --

clutching zone "

~~===~:::::

Brake must be fully engaged when/

pedal arm reaches this position.

CLUTCH AND BRAKE

Clutch engaged

Top surface of

pedal foot pad

f";;"~ "

/)(/

---~J ' "

"~~ " I

-~ 7 " "'-..

-"- "'-

-.;::".. "'-.. "

"/

!

Pedal stop

Illust. 21

Clutch and brake adjustments.

Foot support

(Model 71)

Peda.! return stop

Free movement

(3/16-inch)

Foot support

(Models 102 and 122)

\1'""') nIl

t ~.:==~ ]

A-84133

7~.

21

Page 24

CLUTCH AND BRA K E

(International Cub Cadet 71, 102 and 122 Tractors)

As the clutch and brake are both operated

by the same pedal, care must be taken to

maintain a neutral zone so the clutch is disengaged when the brake is applied.

ADJUSTING THE CLUTCH

It is important that a clearance of .050inch be maintained between the clutch release

lever and the clutch release bearing. In order

to maintain this clearance. the pedal should

have a free movement of approximately 3/16-

inch. See Illust. 21. This measurement is taken

at the point of contact of the pedal arm withthe

front edge of the pedal return stop.

The clutch pedal adjustments are set at the

factory and should not require frequent attention unless the linkage has been disturbed or

when the pedal movement becomes less than

3/16-inch. When it is necessary to adjust the

clutch, turn the adjusting nut "A" on the clutch

release rod (1IIust. 22) in or out as required to

get the proper measurements.

ADJUSTING THE BRAKE

The brake should engage when. the pedal

arm is pressed down to within a maximum of

l-5/l6-inches and a minimum of 3/4-inch distance above the top of the left foot support,

which serves as the pedal stop. See Illust. 21.

It may be possible to push the pedal all the

way down to the pedal stop, but this is of no

concern as long as the brake is engaged when

the pedal arm is at least 3/4-inch above the

pedal stop.

To adjust the brake, loosen the jam nut

"B" and turn the brake lever adjusting screw

"C" (1IIust. 22) in or out as required to get thismeasurement.

The brake must not engagebefore

the pedal arm is within the maximum

distance of 1-5/16-inches above the pedal stop.

Clutch and brake adjustments.

Illust.22

22

Page 25

Speed control lever centering ~

zone when brake pedal is used

BRAKE

(International Cub Cadet 123 Tractor)

Top surface of

pedal foot pad

Speed control lever is

in "N" position

Braking zone:

Brake must be engaged .'

when pedal is in this zone.

1-5/16-inch maximum

3/4 -inch minimum,

Brake must be fully engaged when,

pedal arm reaches this position.

Pedal stop

'--

~

!

Brake adjustments.

ADJUSTING THE BRAKE

The brake should engage when the pedal

arm is pressed down to within a maximum of

1-5/16-inches and a minimum of 3/4-inch dis-

tance above the top of the left foot support,

which serves as the pedal stop. See Illust. 23.

It may be possible to push the pedal all the

way down to the pedal stop, but this is of no

concern as long as the brake is engaged when

the pedal arm is at least 3/4-inch above the

pedal stop.

To adjust the brake, loosen the jam nut "B"

and turn the brake lever adjusting screw "G"

(1IIust. 23A) in or out as required to get this

measurement. The brake must not engage

before the pedal arm is within the maximum

distance of 1-5/16-inches above the pedal stop.

ADJUSTING THE SPEED CONTROL LEVER

Note: The brake pedal must be properly ad-

justed before beginning the speed control lever

adjustment. If the tractor "creeps" in the "N"

position or, if the speed control linkage has

been disassembled or removed for any reason,

the following adjustment must be made.

Block the tractor so the left rear wheel is

off the ground.

Start the engine at half throttle or faster.

Move the speed control lever to the forward

position. The rear wheel should rotate in the

forward direction. Depress the brake pedal all

the way down and release. The speed control

lever should return to the "N't position and the

rear wheel stop turning.

If the rear wheel turns in the forward direction, loosen jam nut "D" and turn the connecting rod "E" counterclockwise to lengthen it

until the wheel stops turning. (See Illust. 23A).

/)/(~--

"""'"

Pedal return stop

'-..J

Illust.23

If the wheel turns in the reverse direction

turn the c onnec ting rod lIE II clockwise.

Tighten the jam nut lID II.

If this adjustment does not stop "creeping"

see your International Harvester dealer.

Illust. 23A

Brake adjustments.

23

Foot s~pport~..

() I J

~~j

i

A-86719 A

'"

~

--j

Page 26

STORAGE

Store your tractor in a dry and protectedplace.

Leaving your tractor outdoors, ex-

posed to the elements. will result in materially shortening its life.

storing the tractor:

1. Wash or clean and completely lubricate

the tractor. See the "Lubrication Guide" on

poges 28 to 32.

2. Drain the fuel tank and run the engine

until the fuel is exhausted from the fuel system. Clean the fuel strainer screen and glass

bowl. See page 6.

Hote: Gum will eventually form in the fuel

tank, line, and carburetor if the unit is not

drained. Gum can be dissolved with acetone

or a 50-50 mixutre of alcohol and benzol.

3. After the engine has cooled, remove the

spark plug and pour one tablespoonful of lubricating oil of good quality into the cylinder.

Crank the engine slowly turning the generator

belt by hand to distribut~ the oil over the cyl-

inder walls. Then replace the spark plug.

4. Clean the exterior of the engine.

5. Remove the battery and place it in a cool,

dry place above freezing (+32°F.). Check the

battery at least once a month for water level

and amount of charge. See page 19.

6. On the International Cub Cadet 71, 102

and 122 Tractors press the clutch and brake

pedal all the way down and engage the brake

pedal lock. This will prevent the clutch lining

from sticking to the pressure plate.

7. On the International Cub Cadet 123

Tractors. press the brake pedal all the way

down and engage the brake pedal lock.

REMOVING FROM STORAGE

1. Fill the fuel tank.

2. Install a fully charged battery and be

sure the proper connections are made. See

tltusts. 17 and 17A.

3. Start the engine and let it run slowly.

Do not accelerate the engine rapidly. or op-

erate it at high speed immediately after start-

ing.

Caution! Keep the doors wide open or move

the machine outside the storage room imme-

diately, to avoid danger from exhaust gas.

4. Inflate the tires to the correct operating

pressures. See "Pneumatic Tires" on pages 20

and 21.

5. Release the brake pedal lock.

AND

The tractor is used for so many different

type s of work and is called on top to operate

under so many different conditions that a va-

riety of equipment is available to adapt it to

the requirements of the user.

When you purchased your tractor, you

probably had it completely equipped for your

Type of Equipment

Cigarette Lighter ..

Charge Indicator. Creeper Drive (International Cub Cadet 71, 102 and 122 Tractors) DetachableSeatPad Dual Rear Wheels Electric Lighting. HydraulicLift Helper Spring. Rear Power Take-Off (International Cub Cadet 71, 102, and 122 Tractors). .

RearWheelFenders RearWheelWeights Three-Point Hitch Utility Box ~~

particular needs at the time. However, later

you may wish to obtain some of the equipment

or accessories shown below. These items and

other allied equipment can be purchased from,

and installed by, your International Harvester

dealer.

24

Models used on

1021122

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

123

x

x

x

x

x

x

x

x

x

When

71

Page 27

Page 28

TROUBLE SHOOTING

Possible Cause

Possible Remedy

LACK OF POWER -Continued

Incorrect timing or faulty ignition. Clutch slipping (Models 71,102 and 122)

See .'Breaker Points and Spark Plug" on poges

15 and 16.

Adjust the free travel of the pedal; see pages 21

and 22.

Brake drags.

Adjust the brake; see pages 21 ond 22.

ENGINE OVERHEATS

Insufficient cool air, dirty air intake screen, Keep the air intake area and cooling fins clean;

shroud, or cooling fins. See "Engine Cooling and Air Cleaner"

on poge 14.

CREEPING

Speed control lever out of adjustment (Model 123) See "Speed Control Lever Adjustment" on page 23.

':' See your International Harvester dealer.

ENGINE OIL

The tractor is shipped from the factory

with SAE-lOW engine oil in the crankcase. If

the engine is to be operated at temperatures

between +75 degrees F and 0 degrees F. this

oil can be used for the first five hours of

operation. If the temperatures are not within

this range, drain the oil from the crankcase

and replace it with new oil as specified in the

"Lubrication Table", The engine oil must be

drained and replaced with new oil every 30

hours of engine operation thereafter.

Oils designated "For Service MS" are

recommended for this engine.

To aid starting, the selection of crankcase

lubricating oils should be based on the lowest

anticipated temperature until the next drain

period.

Check the oil levels of the engine crankcase and transmission to see that they are

filled to the correct levels. Note: Check the

oil level only while the engine is stopped.

Illust.26

Oil level gauge.

26

Page 29

Page 30

Page 31

(International Cub Cadet 71, 102 and 122 Tractors)

1 -Oi I fi lief ca p and bayanet-type

oil level gauge.

2- Steering knuckles (2).

3- Front oxle pivot pin.

-Engine crankcase.

LUBRICATION GUIDE

--After Every 10 Hours of Operation

Check the oil (with the engine stopped) and add sufficient

new oil to bring it to the "FULL" mark on the gauge. Do

not overfill. Do not operate the engine if the oil level is

below the "LOW" mark on the gauge.

Use 1H-251 HEP grease or equivalent #2 multi-purpose

lithium grease and apply sufficient grease to flush out oldgrease

and dirt.

--After Every 30 Hours of Operation

While the oil is warm, remove the drain plug (4) and drain

all of the oil from the crankcase. Replace the drain plug.Remove

the crankcase oil filler cap (1). Refill the crank-

case with new oil up to the "FULL" mark on the oil levelgauge.

Refer to the "Lubrication Table" for the proper

quantity and viscosity to use.

--After Every 100 Hours of Operation

5- Power take-off shaft bearing

Transmission

6 -Oil level and filler plug.

7 -Oil drain plug.

Creeper drive housing

8. Level plug.

9. Breather and filler plug.

10. Drain plug.

11 -Steering gear housing.

Miscellaneous

Use IH-2.5l HEP grease or equivalent #2. multi-purpose

lithium grease and apply two or three strokes of the lubri-

{

cator to the lubrication fittings.

--Periodic

Check the oil level periodically. Keep the lubricant up tothe

level plug (6) on the rear of the transmission case.

Change the oil in the transmission case at least once a

year. Remove the drain plug (7) and remove the oil level

and filler plug (6) and allow all of the oil to drain out. Replace the drain plug. Refill with approved lubricant up to

the level plug opening and replace the plug.

Check the oil level periodically. Keep the lubricant up to

the level plug (8) on the left side of the creeper drive

housing. Drain and refill the housing each time the oil is

changed in the transmission case. To change the oil, remove the drain plug (I 0) at the bottom of the housing and

allow all the oil to drain. Then replace the drain plug.

Remove the breather and oil filler plug (9) at the right

of the creeper shift handle on top of the frame assembly,

and remove the oil level plug (8). Fill to the level plug

opening with approved lubricant and replace the plugs.

Once a year, apply two strokes of the lubricator, using

IH-251 HEP grease or equivalent #2 multi-purpose lithium

grease.

Note/: To locate the lubrication fitting, turn the front

wheels to the maximum right turn position: Then reach up

under the right side of the tractor frame to locate the

fitting.

Lubricate the clutch pedal shaft and linkage with eight or

ten drops of engine oil.

29

Page 32

Page 33

LUBRICATION GUIDE

(International Cub Cadet 123 Tractor)

--After Every 10 Hours of Operotion

1. Oil filler cap and bayonet-type

oj I level gauge.

Steering knuckles (2).

3. Front axle pivot pin.

4. Transmission oil filter,

Engine crankcase.

Check the oil (with the engine stopped) and add sufficient

new oil to bring it to the "FULL" mark on the gauge. Do

not overfill. Do not operate the engine if the oil level is

below the "LOW" mark on the gauge.

Use IH-251 HEP grease or equivalent #2 multi-purpose

lithium grease and apply sufficient grease to flush out oldgrease

and dirt.

Note: After the first 10 hours only, remove the old filter

and replace with a new filter as instructed on poge 27.

Change the oil filter after 50 hours and every 100 hours

of operation thereafter.

--After Every 30 Hours of Operation

While the oil is warm, remove the drain plug (5) and

drain all of the oil from the crankcase. RepLace the drain

plug. Remove the crankcase oil filler cap (I). Refill the

crankcase with new oil up to the "FULL" mark on the oil

level gauge. Refer to the "Lubrication Table" for the

proper quantity and viscosity to use.

--After Every 50 Hours of Operotion

6. Transmission oil filter.

Transmissian ail filter.

Transmission

Oi I level and fi Iler plug.

Note: After the first 50 hours only. remove the old filter

and replace with a new filter as instructed on page 21.

Change the oil filter every 100 hours of operation

thereafter.

--After Every 100 Hours of Operation

Change the oil filter and replace with a new filter as

instructed on poge 27.

--Periodic

Check the oil level periodically or once a year. Keep the

lubricant up to the level plug (8) on the rear of the trans-

mission case cover.

31

2.

5.

8.

Page 34

Page 35

Page 36

Page 37

Page 38

MEMORANDA

36

Page 39

with

No accident-prevention program can be suc-

cessful without the wholehearted co-operation

of the person who is directly responsible for the

operation of equipment.

To read accident reports from allover the

country is to be convinced that a large number

of accidents can be prevented only by the

operator anticipating the result before the

accident is caused and doing something about

it. No power-driven equipment, whether it be

transportation or processing, whether it be on

the highway, in the harvest field or in the

Accidentsbe

industrial plant, can be safer than the man who

is at the controls. If accidents are to be pre-vented

and they can be prevented-it will bedone

by the operators who accept a full measure

of their responsibility.

It is true that the designer, the manufacturer,

the safety engineer can help; and they will help,

but their combined efforts can be wiped out by

a single careless act of the operator.

It is said that' 'the best kind of a safety

device is a careful operator. '! We ask you

to be that kind of an operator.

Page 40

Loading...

Loading...