Page 1

18(4VSHYGXW%OXMIRKIWIPPWGLEJX¤7EEVFVµGOIR¤+IVQER]

&

*36123

SERIES 7000

Page 2

English

Français

Deutsch

Page 3

3

TABLE OF CONTENTS

TO THE OWNER ..................................... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... .............. 3

CALLING SERVICE INFORMATION ...................................................................................... 3

RECORDING MODEL AND SERIAL NUMBER INFORMATION ........................................... 4

USING THE TRACTOR CORRECTLY..................................................................................... 5

IMPORTANT SAFE OPERATION PRACTICES ..................................................................... 6

SAFETY LABELS ................................................................................................................. 10

SECTION 1: CONTROLS AND FEATURES ........................................................................ 12

SECTION 2: OPERATION .................................................................................................... 18

SECTION 3: ADJUSTMENTS .............................................................................................. 27

SECTION 4: TRACTOR MAINTENANCE ............................................................................ 30

SECTION 5: ENGINE INFORMATION AND MAINTENANCE ............................................. 43

SECTION 6: SPECIFICATIONS ........................................................................................... 49

SECTION 7: OPTIONAL EQUIPMENT AND ACCESSORIES ............................................. 50

WARRANTY ........................ ...... ....... ...... ....... ...... ....... ...... ...... ....... ...................................... 51

TO THE OWNER

This Operator’s Manual is an important part of your new tractor. The information contained in this

manual has been prepared in detail to help you better understand the features, correct operation,

adjustments, and maintenanc e of your tractor. The per formance and dependa bility of this trac tor rely

greatly on the manner in which it is operated and maintained. Therefore, it i s recommended that all

operators of the tracto r carefully read this manua l and fully understand its operation. Also keep the

manual available for reference to ensure proper operation, and that maintenance procedures are

performed as scheduled to assure the tractor’s optimal mechanical condition.

NOTE:

All references to LEFT, RIGHT, FRONT, and REAR, unless specifically stated otherwise,

indicate that relative position on the tractor when facing forward while seated in the operator’s seat.

Your authorized

Cub Cadet

dealer is interested in the perfo rmance y ou re ceive fr om yo ur trac tor, and

with the maintenance needed to ensure the satisfactory operation of your tractor. The dealer has

trained service personnel familiar with the latest servicing information, is equipped with the latest

tools, and has a complete l ine of genuine

Cub Cadet

service parts whic h assure proper fit and high

quality.

CALLING SERVICE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance,

power-rating, and specifications.

If you have difficulties wit h the tractor and/or equip ment; have any ques tions regarding the ope ration

or maintenance of this equipment; or desire additio nal information not found in th is manual, contact

your dealer. If you need assistance in locating a deal er in your area, contact the Cust omer Dealer.

Before calling your deal er, make sure that you have you r model number(s) and manufa cturing date

available for the dealer.

Page 4

4

www.cubcadet.com

CUB CADET LLC

P. O. BOX

361131

CLEVELAND, OH 44136

DEALER LOCATOR PHONE NUMBER:

877-282-8684

Model Number Mfg. Date

XXXXXXXXXXX XXXXXXXXXX

RECORDING MODEL AND SERIAL NUMBER INFORMATION

Product identification plates are provided for major components of your tractor. The numbers on these

plates are importa nt if you r tractor sh ould re quire de aler serv ice, or i f you nee d additio nal informa tion

on your tractor. Prior to using y our tracto r for the firs t time, rec ord the numbe rs from th e identifi cation

plates in the appropriate spaces provided below.

• The tractor model plate is located on the right frame rail behind the right front tire.

• The engine model/ serial number plate and engin e information plate are locat ed on the right side

of the engine above and aside the injection pump (below the air cleaner).

• The transmission serial plate is located on right brake drum cover behind the right rear wheel.

• The ROPS information plate is located on the left vertical leg of the ROPS.

Tractor Model Plate:

Model Number Mfg. Date (Serial No.)

Engine Information:

Engine Model Serial Number

Transmission Serial Plate:

Serial Number

ROPS Information Plate:

ROPS Serial No.

TRACTOR MODEL PLATE

TRANSMISSION SERIAL PLATE

ROPS INFORMATION PLATE

Page 5

5

USING THE TRACTOR CORRECTLY

This tractor is intended for use

• As a tractor for usual employ ment in the land- and forestry, green areas- and plant car e as well as for

winter services.

• In accordance with the instructions and safety information contained in this guide.

Any other use is c onsidered to be co ntrary to the inten ded purpos e. The use r is lia ble for al l damage done to

third parties and to their property on the part of the manufacturer for damage resulting therefrom.

WARNING: This tractor is not licensed for use on public roads and public surfaces within its

standard configuration. When using public traffic roads and public surfaces the tractor

respective regulations of the country the is used in have to be considered.

Page 6

6

IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL,

HEED ITS WARNING.

WARNING: The engine exhaust, some of its constituents, and certain vehicle components

contain or emit chemic als known to the State of Ca lifornia to cause cancer, birth defects or other

reproductive harm.

DANGER: Your tractor was built to be operated according to the rule s for safe operation in this

manual. As with any ty pe of power equip ment, car elessn ess or error on th e part of the op erato r ca n

result in serious i njury. To help prevent accident s, read and take the foll owing precautions before

operating this tractor. Failure to observe the following safety instructions could result in serious

injury or death.

1. GENERAL OPERATION

• Read, understand , and follow all instructions in

the operator’s manual and on the machine

before starting. Keep this manual in a safe

place for future and regular reference.

• Only allow res ponsible individuals familiar wit h

the instructions to operate the machine. Know

controls and how to stop the machine quickly.

• Use the roll bar and seat belt for safe operation.

Overturning the tractor without a roll bar, or with

a roll bar and the seat belt unfastened, can

result in death or injury.

• Always use the seat belt, except if the roll bar

has been removed or , if applicable, the roll bar

is in the folded position.

• Use the handholds and running boards when

getting on and off the tractor to help prevent

accidental falls. Keep the running boards cl ear

of mud and debris.

• Wear sturdy, rough-soled work shoes. Never

operate the tractor in bare feet, sandals, or

sneakers.

• Do not wear loose fitting clothes or jewelry.

They can be caught in moving parts.

• Do not allow anyo ne but the o perator to r ide on

the tractor. There is no safe position on the

tractor for additional riders. Do not carry

passenger.

• Keep all safety decals clean and readable.

Replace any missing, illegible, or damaged

safety decals.

• Do not operate the machine while under the

influence of alcohol or drugs.

• Use only accessories approved for this

machine by the manufacturer. Read,

understand and follo w all instructions provided

with the approved accessory.

• Before starting the tractor, engage the parking

brake, place the PTO switch in the "OFF"

position, place the lift con trol lever in the down

position, and make certain any remote control

valve levers are in the neutral position.

• Always sit in the tractor seat when starting the

engine or operating controls. Do not start the

engine or operate controls while standing

beside the tractor.

• Never tamper with safety devices. Chec k their

proper operation regularly. Contact your Cub

Cadet dealer if safety devices malfunction.

• Avoid accidental contact with control pedals

while the engine is runni ng, as this can cause

unexpected movement of the tractor.

• Never leave a running machine unattended.

Always disengage the PTO, engage the

parking brake, and stop engine before

dismounting.

• Never park the tractor on a steep incline.

• Pull only from a dr awbar or the l ower hitc h links

in the down position. Mak e certain the drawbar

pin is locked in p lace. P ullin g fr om the rea r axl e

of the tractor or any point abov e the axle could

cause the tractor to overturn.

• Maintain the weight balance of the tractor.

Install front end weights to counterbalance

heavy implements attached to the three point

hitch. Do not operate the tractor with a light

front end.

Page 7

7

• Any towed vehicle wit h a tota l wei ght exc eed in g

that of the tractor should be equipped its own

braking system that is operational from the

tractor seat.

• Do not leave equipment in the raised position.

• Watch for traffic when operating near or

crossing roadways. If local laws permit road

travel, use the flashing hazard lights and SMV

signs when traveling on public roadways.

• Make certain all tractor lights are illuminated

when operating at night.

• Always watch where you are going, especi ally

at blind corners, trees, or ot her object s that can

obscure your vision.

• Check overhead clearance carefully before

driving under power line s, wires, bridges or low

hanging tree branches, before entering or

leaving buildings, or in any other situation

where the operator and/or roll bar may be

struck, which could result in serious injury.

• To avoid upsets, dr ive the tracto r with care an d

at a safe speed. Use extra caution when

operating over rough ground, when crossing

ditches or slopes, and when turning corners.

• If the tractor becomes stuck, use reverse to

free the tractor to prevent tractor upset.

2. SLOPE OPERATION

Slopes are a maj or factor related to loss of control

and tip-over accidents which can result in severe

injury or death. All slopes require extra caution. If

you cannot back up the slope or if you feel uneasy

on it, do not operate this unit on that area or serious

injury could result.

DO:

• Operate up and down slopes, not across.

• Remove obstacles such as rocks, limbs, etc.

• Watch for holes , ruts or bumps. U neven terrain

could overturn the mac hine. Tal l grass c an hid e

such obstacles.

• Place the transmis sion in the low range. when

climbing or descending slopes. Always keep

machine in gear when going down slopes to

take advantage of engine braking action.

• Follow the manufactu rers recommendations for

counterweights to improve stability.

• Keep all movement on the slopes slow and

gradual. Do not make sudden changes in

speed or direction. Rapid engagement or

braking could cause t he front of the mac hine to

lift and rapidly fli p over backwards which coul d

cause serious injury.

• Avoid starting or stopping on a slope. If tires

lose traction, disen gage the PTO and proceed

slowly straight down the slope.

DO NOT:

• Do not turn on slopes un less necessary; then,

turn slowly and gradually downhill, if possible.

• Do not mow near drop-offs, ditches or

embankments. The mower could su ddenly turn

over if a wheel goes over the edge of a cliff or

ditch, or if an edge caves in.

3. CHILDREN

• Tragic accide nts can oc cur i f the oper ator is no t

alert to the presence of children. Children are

often attracted to the machine. Never assume

children will remain where you last saw them.

• Keep children out of the operating area and i n

watchful care of an adult other than the

operator.

• Be alert and turn machine off if children enter

the area.

• Before and when backing, look behind and

down for small children.

• Never carry children . They may fall off and be

seriously injured or interfere with safe machine

operation.

• Never allow children under 16 years old to

operate the machine. Bylaws may stipulate a

different minimum age. Children 16 years and

over should only op erate machine under close

parental supervision and proper instruction.

• Use extra care when approaching blind

corners, shrubs, tree s or other obje cts tha t may

obscure your vision of a child or other hazard.

• Remove key when machine is unattended to

prevent unauthorized operation.

4. OPERATING THE PTO

• When operating PTO driven equipment,

disengage the PT O, stop the engine, and wait

until the PTO stops before dismounting the

tractor and disconnecting the equipment.

• Do not wear loose fitting clothing when

operating the PTO or when near rotating

equipment.

Page 8

8

• To prevent injury, do no t adjust, unclog, clean,

or service PTO driven equipment while the

tractor engine is running.

• Make certain all PTO shields are always installed.

5. SAFETY FRAME (ROPS)

Your tractor is equipped with a rollover protective

structure (ROPS) which must be maintained in a

fully functional condition. Use care when driving

through doorways or spaces with a low overhead.

• Never modify the ROPS in any way.

• Never attempt to str aighten or reweld any part

of the main frame or retaining brackets that

have been damaged. Doing so may weaken

the structure and endanger your safety.

• Never secure any parts on the main frame or

attach the safety fr ame wi th a nyt hing other than

the special fasteners specified.

• Never attach ropes, chains, or cables to the

ROPS for pulling purposes.

• Although the ROPS provides you the maximum

protection possible, never take unnece ssary risks.

6. SERVICE

• Use extreme care in handling gasoline and

other fuels. They are extremel y flammable and

the vapors are explosive. Use onl y an app roved

container.

• Never remove fuel cap or add fuel with the

engine running.

• Replace fuel cap securely and wipe off any

spilled fuel before st arting the engine as i t may

cause a fire or explosion.

• Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

• Never refuel th e machine indoors becau se fuel

vapors will accumulate in the area.

• Never store the fuel container or machine

inside where there is an open flame or spark,

such as a gas hot wat er heater, space heater

or furnace.

• The cooling system is under pressure. Never

remove the radiator cap when the system is

hot. Slowly turn the cap the to the fi rst stop to

release pressure before removing the cap.

• Escaping hydraulic fluid under pressure can

penetrate the skin. If fluid is injected into the

skin, seek immedia te medical attention. Do no t

use your hand to check for lea ks. Use a piece

of cardboard or paper.

• Never run a machine inside a closed area.

• To reduce fire hazard, keep the tractor free of

any debris build-up. Clean up oil or fuel spillage.

• Before cleaning, repairing or inspecting, make

certain all moving parts have s topped. Keep all

nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

• Never tamper with safety devices. Chec k their

proper operation regularly.

• Check brake operation frequently. Adjust and

service as required.

• Engine components become hot during

operation and can cause a b urn. Allow to cool

down before touching.

• Do not change the engine governo r settings or

overspeed the engine. Excessive engine

speeds are dangerous.

• Observe proper disposal laws and regulations.

Improper disposal of fluids and materials can

harm the environment and the ecology.

• Prior to disposal, de termine the proper method

to dispose of waste from your local

Environmental Protection Agency. Recycling

centers are established to properly dispose of

materials in an environmentally safe fashion.

• Use proper co ntainers when dr aining fluids. D o

not use food or b everage containers that may

mislead someone into drinking from them.

Properly dispose of the conta iners immediately

following the draining of fluids.

• DO NOT pour oi l or oth er fl ui ds into the ground,

down a drain or into a stream, pond, lake or

other body of water. Observe Environmental

Protection Agency regulations when disposing

of oil, fuel, coolant, brake fl uid, filters, b atteries,

tires and other harmful waste.

• We do not recommend the use of a pressure

washer or garden hose to clean you r unit. They

may cause damage to electrical components;

spindles; pulleys; bear ings; or the engine. The

use of water will result in shortened life and

reduce serviceabi li ty.

WARNING:

- YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions in this manual and on the machine.

Page 9

9

Symbols on the appliance

On the appliance you will find various symbols on

adhesive labels. These symbols are explained in the

following:

Attention! Please read the operating

instructions before putting appliance into

operation!

Keep third parties away from the danger

area!

Before working on the cutting tools,

remove the spark plug connector! Keep

fingers and feet away from the cutting

tools! Switch off the appliance and

remove the spark plug connector before

adjusting, cleaning, or checking it.

Risk of injury from rotating cutting blades

or parts.

Injury hazard due to grass or solid

objects thrown out by mower.

Keep people, in particular children, and

animals away from the area in which the

appliance is being used.

Working on steep slopes can be

dangerous.

Warning!

Danger of explosion.

Battery acid/

risk of burns.

Before beginning any work on this

machine, remove the ignition key and

observe all information contained in this

guide.

Always keep these symbols on the appliance in

a legible state.

!

Page 10

10

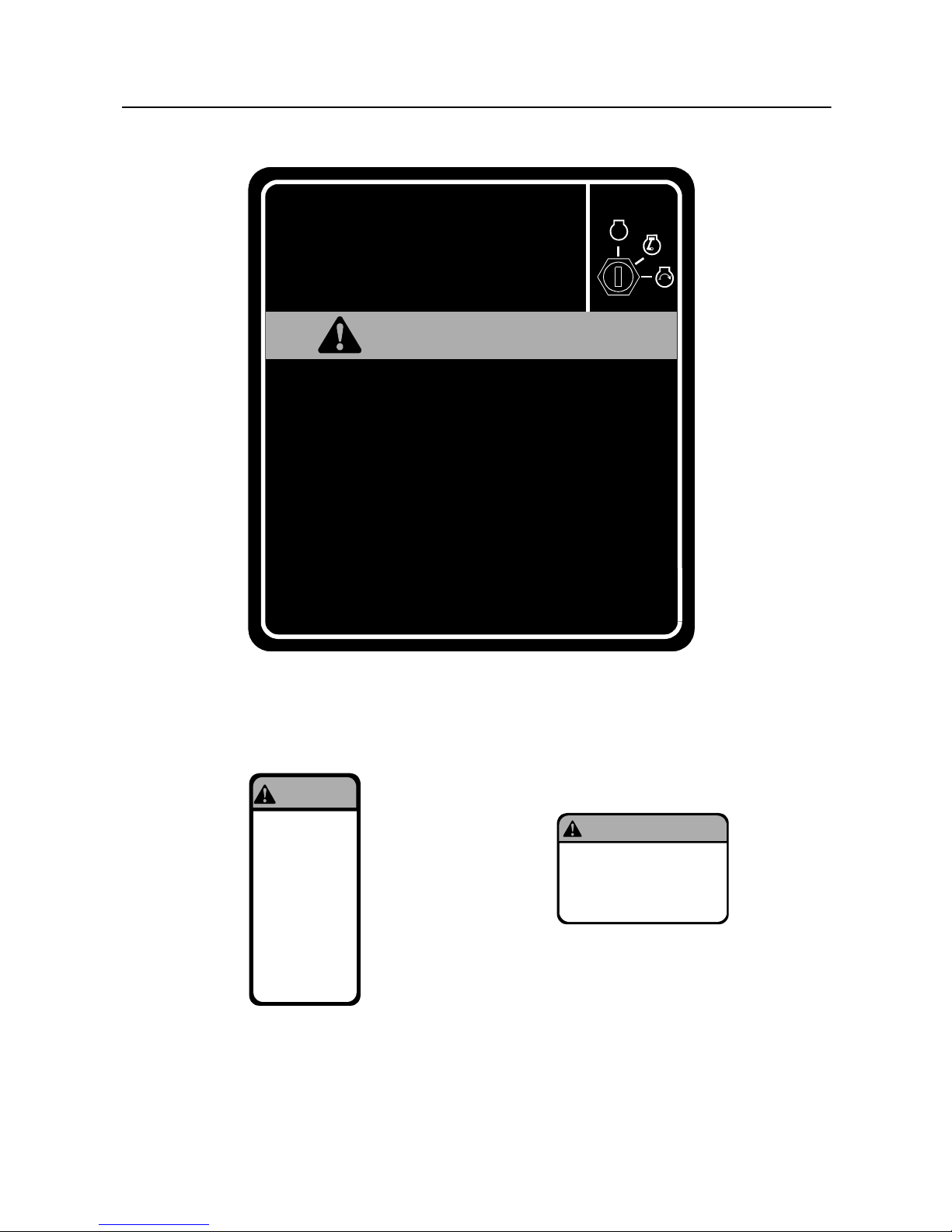

SAFETY LABELS

STARTING INSTRUCTIONS

1.

KNOW THE OPERATING AND SAFETY INSTRUCTIONS IN THE

OPERATORS’S MANUAL AN D O N THE T R ACTOR

.

2.

MOVE THROTTLE TO MID POSITION AND DEPRESS BRAKE PEDAL.

3.

TURN KEY TO THE START POSITION.

1.

DISENGAGE P TO AND SET PARKING BRAKE .

2.

MOVE THROTTLE CONTROL TO MID POSITION AND TURN KEY OFF.

•

GO UP AND DOW N S LOPES, NOT ACROSS.

•

AVOID SUDDEN T UR NS .

•

DO NOT OPERATE UNIT WHERE IT COULD SLIP OR TIP.

•

IF MACHINE ST O PS G OING UPHILL, STOP PTO AN D BACK DOWN HILL SLOWLY.

•

DO NOT MOW WHEN CHIL DR E N O R OT HE R S AR E AROUND.

•

DO NOT ALLOW P ASSENGERS ON THE TRACTOR AT ANY TIME.

•

LOOK DOWN AND BEHIND BEFORE AND WHILE BACKING.

•

KEEP SAFETY DEVICES [GUARDS, SHIELDS, AND SWITCHES] IN PLACE AND WORKING.

•

REMOVE OBJECTS THAT COULD BE THROWN BY THE BLADES.

•

KNOW LOCATION AND FUNCTION OF ALL CONTROLS.

•

BE SURE THE BLADES AND THE ENGINE ARE STOPPED BEFORE PL ACING HANDS

OR FEET NEAR BLADES.

•

BEFORE LEAVING OPERATOR’S POSITION, DISEN GAGE PT O, ENGA GE BRAKE LOCK,

SHUT OFF ENGINE AND REMOVE KEY.

•

SLOW DOWN FOR TURNS, ROUGH GROUND AND SLOPES TO AVOID UPSET.

•

ON PUBLIC ROADS USE SMV EMBLEM AND HAZARD LIGHTS.

AVOID SERIOUS INJURY OR DEATH

.

READ OPERATOR’S MANUAL

STOPPING INSTRUCTIONS

WARN

I

NG

IGNITION

S

T

O

P

WARNING

KEEP HANDS

AND CLOTHING

AWAY FROM

ROTATING FAN

AND BELTS TO

PREVENT

SERIOUS INJURY

WARNING

EXPLOSION AND INJURY CAN

RESULT FROM THE USE OF

STARTING AIDS WITH HOT GLOW

PLUGS, DO NOT I NJECT GASOLINE

OR ETHER IN AIR INTAKE

INSTRUCTION AND WARNING LABEL

LOCATED ON RUNNING BOARD TUNNEL COVER

FAN WARNING LABEL

LOCATED ON EACH

SIDE OF RADIATOR

STARTING AID

WARNING LABEL

LOCATED UNDER HOOD

Page 11

11

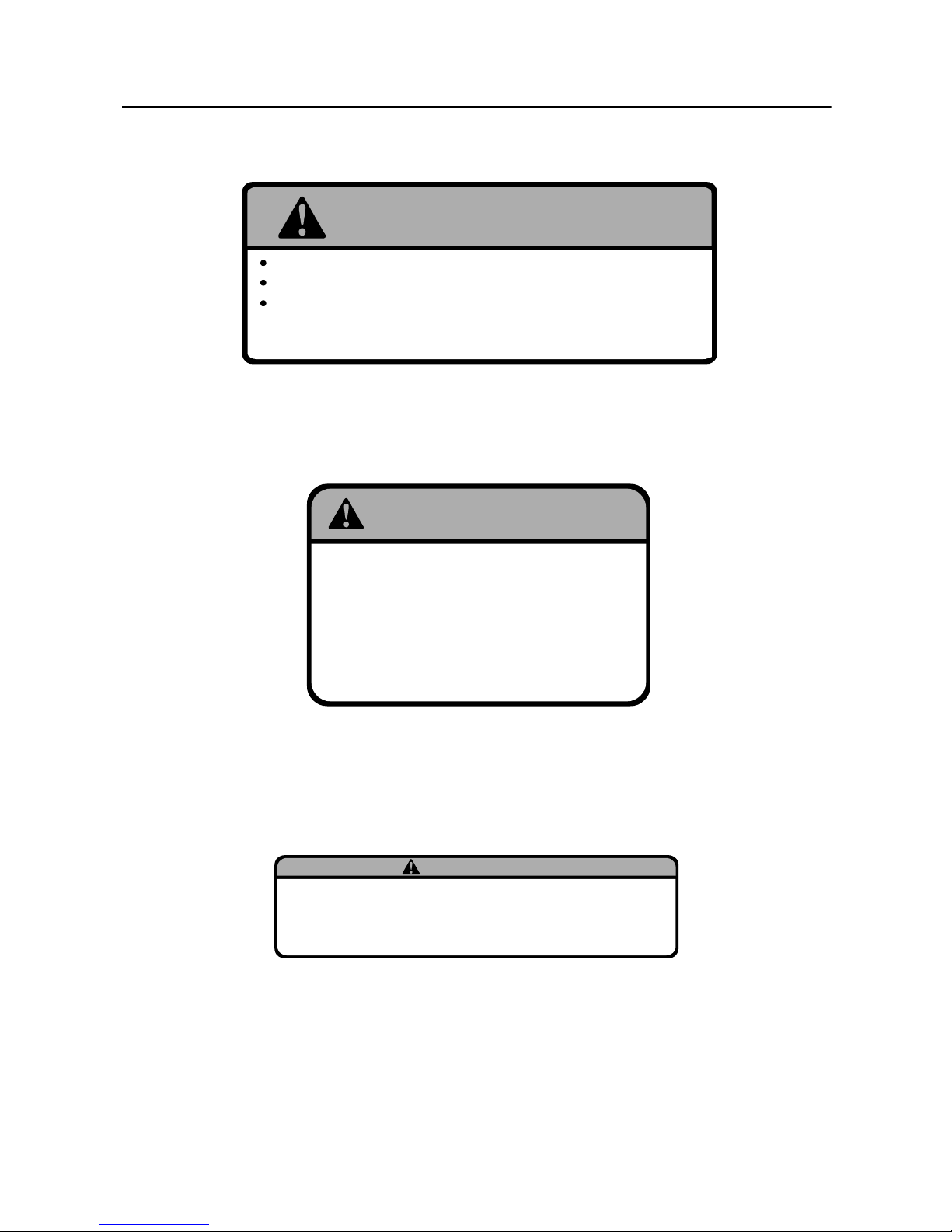

SAFETY LABELS (Cont.)

WARNING

FAILURE TO FOLLOW ANY OF THE INSTRUCTIONS ABOVE CAN CAUSE

SERIOUS INJURY TO THE OPERATOR, OR OTHER PERSONS.

To avoid personal injury, keep PTO shield in place.

Disengage PTO and stop engine before servicing tractor, or implements,

or attaching or detaching implements.

Pull only from draw bar. pulling from any other point can cause rear overturn.

WARNING

BATTERIES CON TAIN ACID AN D EXPLOSIVE GAS.

EX PL O S ION CAN R ESU LT FROM SPARKS, FLAM ES,

OR W RONG CABLE CONNECTIONS. TO CONNECT

JUM PER CABLES OR CHARGER SEE M ANUAL FOR

CORRECT PROCEDURE. FAILURE TO FOLLOW THE

ABOVE INSTRUCTIONS CAN CAUSE SERIOUS

PERS ON AL INJUR Y OR D EATH .

WARNING

When improperly operated this tractor can roll over or upset. Use of the ROPS and

sea t be lt mini mize the possibi li ty of inj ury or de at h if roll over or upset occu rs. For

low cl ear anc e use onl y, the ROPS can be low ere d. No prote ct ion i s provide d in t hi s

positi on and t he seat belt shoul d n ot be faste ned. For all othe r uses, secure the ROPS

in the upright position and fasten th e seat bel t.

PTO WARNING LABEL

LOCATED ON REAR PTO SHIELD

BATTERY WARNING LABEL

LOCATED UNDER HOOD

ROLL OVER WARNING LABEL

LOCATED ON RIGHT/REAR FENDER

Page 12

12

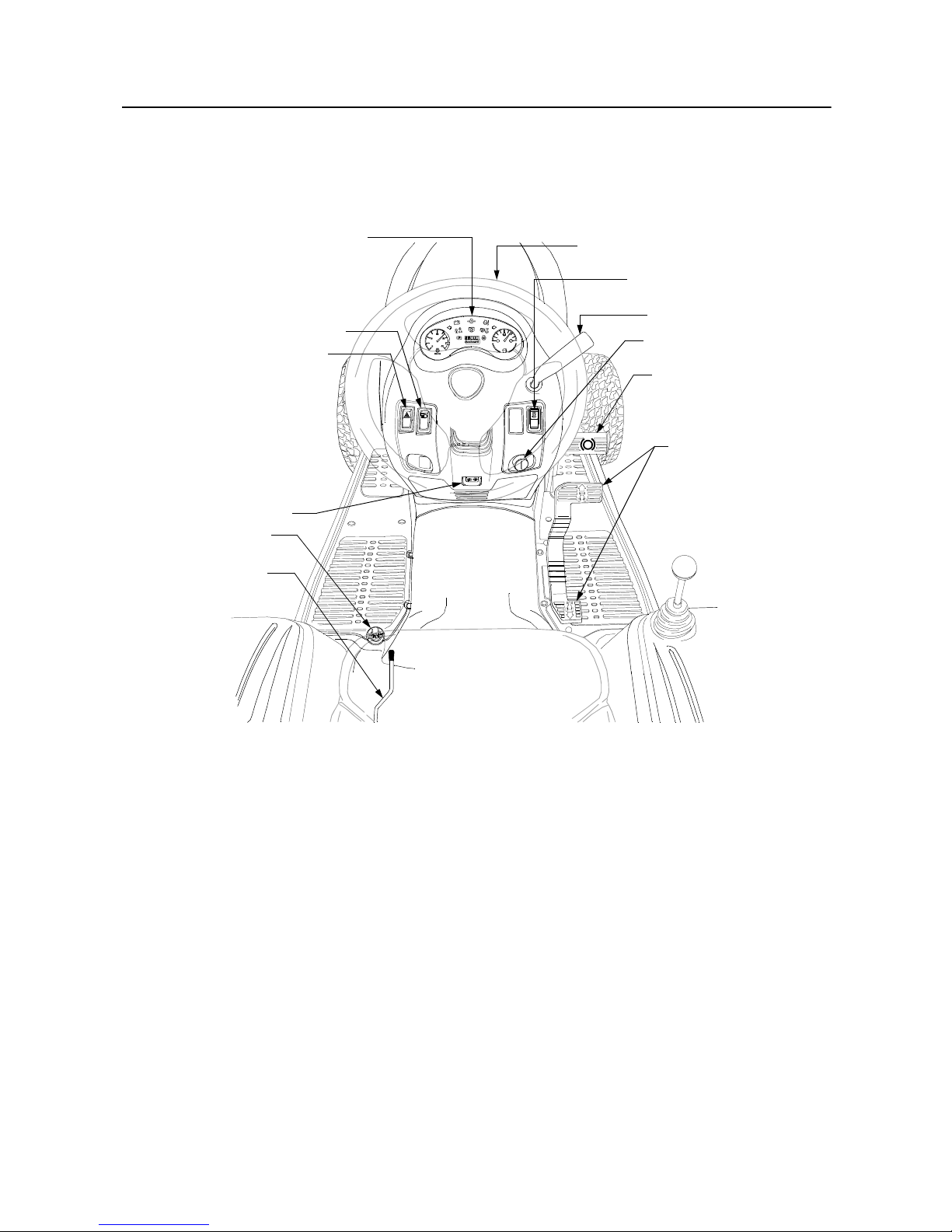

SECTION 1: CONTROLS AND FEATURES

FLOORBOARD AND DASH PANEL MOUNTED CONTROLS

Figure 1

B

C

D

E

F

G

H

J

K

L

M

A

A

B

C

D

E

F

G

H

J

K

L

M

Steering Wheel

PTO Switch

Throttle Handle

Ignition Switch

Brake Pedal

Forward/Reverse Pedal

Seat Adjustment Lever

Differential Lock Pedal

Parking Brake Lever

Hazard Light Switch

Headlight Switch

Instrument Panel

* Steering Wheel and Seat Phantomed For Clarity

Page 13

13

NOTE:

References to LEFT and RIGHT indicate

that side of the tractor when facing forward while

seated in the drivers seat. Reference to FRONT

indicates the grille end of the tractor; to REAR, the

drawbar end.

A. Steering Wheel

The steering wheel is centered on the dash panel. It

is used to change the d irection (left or right) of the

tractor while driving.

NOTE:

This tractor is equipped with hydraulic

power steering. With this feature, the cap and

spokes of the steering wheel may change position.

B. PTO Switch

Figure 2

The PTO switch is a rocker type switch located to

the right of the steering wheel on the dash panel.

Push the

top

of the PTO switch downward to

engage the PTO. Push the

bottom

of the switch

downward to disengage.

C. Throttle Handle

The throttle handle is located to the right of the

steering wheel on the dash panel. When set in a

given position, a uniform engine speed will be

maintained. Rotate t he handle rearward t o increase

the engine speed.

D. Ignition Switch

NOTE:

To prevent accidental starting and/or battery

discharge, remove the key from the ignition swi tch

when the tractor is not in use.

The ignition switch has three positions as follow:

Figure 3

OFF - The engine and electrical system is turned

off.

ON - The electrical system and glow plugs are

energized.

START- The starter motor will turn the engine.

Release the key immediately when the

engine starts

E. Brake Pedal

Figure 4

The brake pedal is locate d at the front of the right

floor board. Depress to engage the tractor brakes

and neutralize the hydrostatic transmission. Fully

depress the brake pedal to activate the safety

interlock switch when starting the tractor.

F. Forward/Reverse Pedal

The forward/reverse pedal is a self neutralizing

rocker style pedal lo ca te d al on g the r igh t flo or b oa rd.

Figure 5

Forward

Slowly press down on the front of the pedal to start

moving forward. The forward ground speed of the

tractor is directly affected by the distance th e front

of the pedal is depressed.

Reverse

WARNING:

Check behind the tractor to

be sure the area is clear of people, pets

or obstacles and use a slower speed to

maintain control of the tractor when

traveling in reverse.

Press down on the rear of the pedal to move in

reverse.

G. Seat Adjustment Lever

The seat adjustment lever is located beneath the

left side of the seat. This lev er is used to adjus t the

seat forward or backward.

PTO

Switch

Symbol

This symbol indicates the

This symbol indicates the

fast position.

slow position.

ON-PREHEAT

OFF

START

STOP

Brake Pedal

Symbol

Forward Reverse

Pedal Pedal

Symbol Symbol

Page 14

14

H. Differential Lock Pedal

Figure 6

Located at the rear of the left floor board, the

differential lock pedal engages the transmission

differential lock.

The differential lock is used to gain additional traction when operating th e tractor on wet or loo se soil .

When the pedal is dep r essed the rear wheels of the

tractor are prevented from r otatin g inde penden tly o f

one another.

WARNING: When operating with the

differential lock engaged, the tractor

will be difficult to steer. Do not drive

the tractor on roadways or at high

speeds with the differential lock

engaged.

NOTE:

Disengagement of the differential lock is

recommended prior to turning the tractor on grass

or other maintained surfaces — tire damage to the

turf could occur.

J. Parking Brake Lever

Figure 7

The parking brake lever is located below the

steering wheel in the dash panel. With the brake

pedal fully depresse d, push the park ing brake lever

downward and release the brake pedal to loc k the

parking brake.

K. Hazard Light Switch

Figure 8

The hazard light switch is a rocker type switch

located to the left of the steering wheel on the dash

panel. Push the

top

of the hazard light switch

downward to activate the flashing amber lights.

WARNING: Always activate the flashing hazard lights when operating the

tractor on, or near, roadways.

L. Headlight Switch

Figure 9

The headlight switc h is a roc ker ty pe sw itch locate d

to the left of the steering wh eel on the dash panel.

Push the

top

of the headlight switch downward to

turn on the headlights, in strument panel lights, and

tail lights.

Diff. Lock

Pedal

Symbol

Parking

Brake

Symbol

Page 15

15

M. Instrument Panel

Figure 10

1. Fuel Gauge

The fuel gauge monitors, at 20 second intervals,

the fuel level in the fuel tank. The needle pointing to

the right indicates a full tank. The ignition switch

must be in the ON position to read the fuel gauge.

2. Tachometer

The tachometer shows the engine speed in rev olutions per minute (RPM). Optimal engine operating

speed is approximately 2500-3600 RPM. When

operating PTO driven atta chments the RPM ind icator needle should b e within the green r ange on the

tachometer dial.

3. Battery Indicator Light

The bulb illuminates to indicate th e battery is be ing

discharged. If this warning lamp comes on during

operation, check the charging system for possible

causes and/or contact your Cub Cadet dealer.

4. Engine Oil Pressure Light

This warning lamp indicates low engine oil pressure. If the bulb comes on while the engine is

running, stop the engi ne immediately and check for

possible causes. NOTE:

The bulb may illuminate

when the ignition switch is in the ON position, but

should turn off when the engine is started

.

5. Engine Coolant Temperature Light

Illumination of this warning lamp indicates the

engine coolant temperature has risen above the

prescribed operating range. If the light comes on

while operating the trac tor, eliminate all loads and

try cooling the engine by run ning at mid throttle for

a few minutes. Stop the engine and allow to cool;

then check for possible causes (e.g. low coolant

level, plugged radiator sc reen).

6. Parking Brake Indicator Light

The bulb illuminates when the ignition switch is in

the ON position and the brak e pedal is depressed.

The light flashes if attempting to start the tractor

with the brake not engaged.

7. PTO Indicator Light

Light comes on in a fi xed mode wh enever the PTO

switch is in the ON position, with the following

exceptions.

• The light will illuminate in a flashing mode if

attempting to start the tractor with the PTO

switch in the ON position.

• The light will change to the flas hing mod e when

the PTO switch is on, but the re verse pedal has

been engaged and the reverse override has

NOT been engaged.

8. Hour Meter

The hour meter records th e hours and tenths of an

hour (

right

most digit) that the tractor has been

operated. The hourmeter is activ ate d w henev er th e

tractor engine is running. Keep a record of the

hours of operation and maintenance performed to

ensure all mainten ance procedures are completed

according to the schedule in this manual.

9. PTO Reverse Override Indicator

This warning lamp ill uminates to indicate the PTO

reverse override switch has been depressed and

the PTO reverse override is engaged. Use extra

caution when operating PTO driven attachments

while traveling in the reverse direction.

10. Hazard Light Indicator

Arrows will flash in conjunction with the amber hazard

lights when the hazard light switch is tu rned on.

11. Glow Plug Indicator Light

Illuminates when the ign ition switch is turne d to the

ON position. The ligh t remains lit for a preset time

while the glow plugs heat the precombustion

chambers of the diesel engine.

12. Cruise Control Indicator Light (Optional)

2

1

3

4

5

10

10

8

11

7

6

9

12

Page 16

16

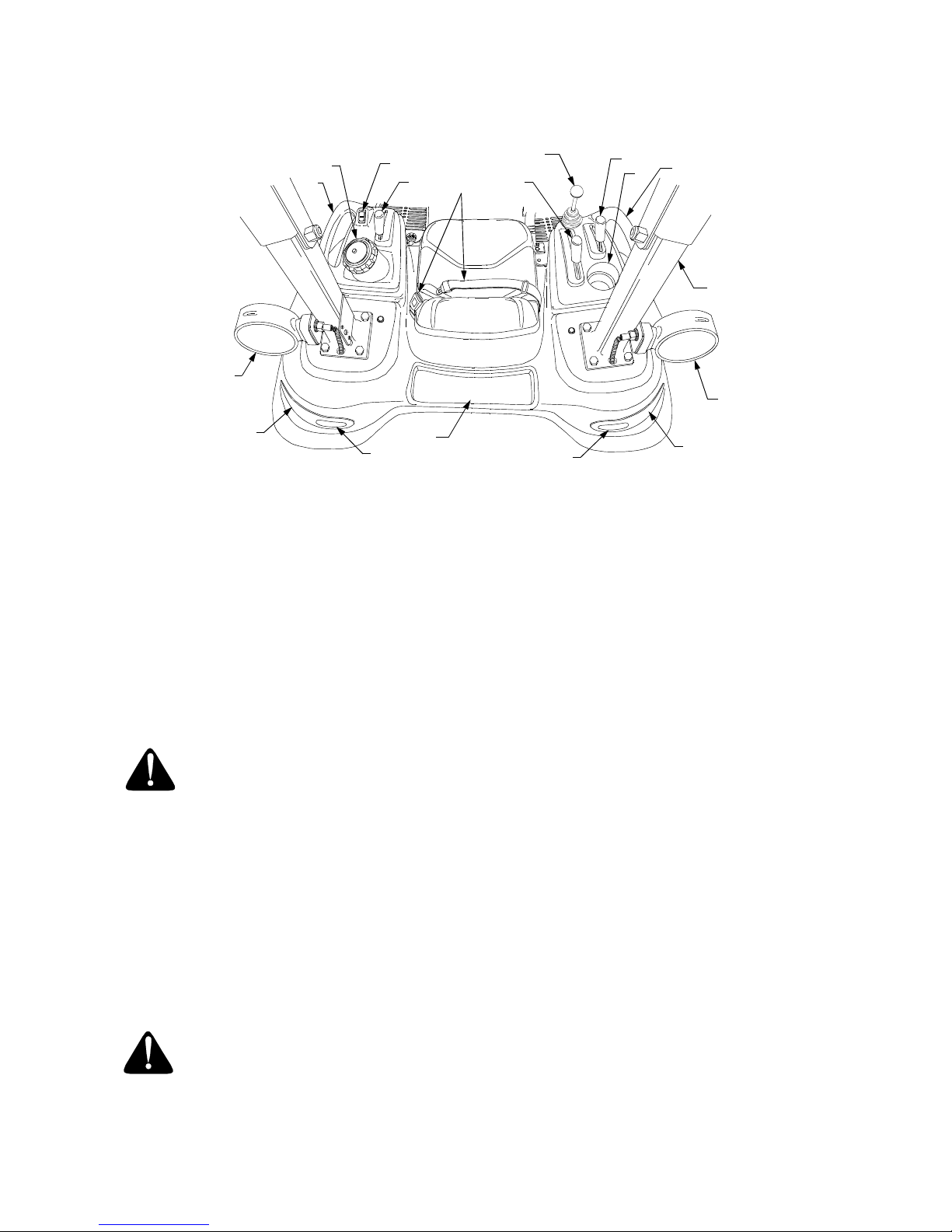

FENDER MOUNTED CONRTOLS AND FEATURES

Figure 11

A

B

N

D

E

F

G

H

K

J

H

J

K

L

G

C

M

O

A. Fuel Fill Cap

The fuel fill cap is located on the left fender beside

the operator’s seat.

WARNING: Never fill the fuel tank to

the top of the filler neck. Expansion

could result in overflow, allowing

highly flammable fuel to come in

contact with the operator.

B. PTO Reverse Override Switch

The PTO reverse overri de switch is located on the

left fender. Depress the front of the switch to

engage the override which allows the PTO to

operate while the tractor is traveling in the reverse

direction.

Once activated, this function remains

activated until the ignition switch is turned to

the OFF position,

regardless of the number of

times the PTO is turned off using the PTO switch.

WARNING: Use EXTREME caution

when operating PTO driven attachments while traveling in the reverse

direction.

C. PTO Selection Lever

The PTO selection lever is located on the left

fender.

• Push the lever forward to engage the mid PTO.

• Push the lever rearward to engage the rear

PTO.

• Move the lever to the center position to

simultaneously engage both the rear PTO and

mid PTO.

D. Hydraulic Lift Lever w/Position Control

The hydraulic lift lever is located on the right fender.

This lever controls the position of the three point

hitch lift arms. There is a direct relationship

between the position of the lever and the height

position of the installed equipment.

• To lower the lift arms, move the lift lever

forward until the desired height setting is

attained.

• To raise the lift arms, move the lift lever

rearward until the desired height setting is

attained.

A

B

C

D

E

F

G

H

J

K

L

M

N

Fuel Fill Cap

PTO Reverse Override Switch

PTO Selection Lever

Hydraulic Lift Lever

Trans. Hi/Lo Shift Lever

Cup Holder

Hand Holds

Amber Hazard Lights

Tail Lights (Red)

Reverse Lights (White)

Storage Tray

Foldable ROPS

Seat Belt

Auxiliary Hydraulic Control Ha ndleO

Page 17

17

E. Transmission Hi/Lo Range Shift Lever

The Hi/Lo range shift lever is located on the right

fender. The lever has two spe ed range s ettings an d

a neutral position. The lever must be shifted into

either the high or low range p rior to depressing the

forward/reverse pedal to drive the tractor.

• Push the lever forward to shift into the high

range.

• Push the lever rearward to shift into the low

range.

• Move the lever to the center position to shift

into the neutral position.

WARNING: Never attempt to shift the

range lever when the tractor is in

motion.

F. Cup Holder

The cup holder is located on the right fender.

G. Hand Holds

Hand holds are built into both the left and right hand

fender covers. The han dle s can be us ed t o as s ist i n

mounting and dismounting the tractor.

H. Amber Hazard Lights

The hazard lights ar e located on each side of the

ROPS bar. The lights illuminate in a flashing mode

when the hazard light s witch is turned on. Always

use the hazard lights when it is necessa ry to warn

others that the tractor is being operated in the area.

J. Tail Lights

The tail lights illuminate wh en the ignition switch is

in the ON position and the headlight switch is

turned on.

K. Reverse Lights

The reverse lights illuminate when the tractor is

being operated in the reverse direction.

L. Storage Tray

The storage tray is located behind the s eat. Us e th e

tray to carry small l oose artic les while ope rating the

tractor.

M. Foldable ROPS (Rollover Protective Structure)

ROPS is installed to prevent or reduce injuries to

the operator should the tractor accidentally overturn. The foldable feature allows the ROPS to be

lowered when operating in areas with low overhead clearance. The protection provided by the

ROPS is minimized if the se at belt is not used and

eliminated when in the folded position.

N. Seat Belt

The seat belt, properly adjusted and used in

conjunction with the Rollover Protective Structure

(ROPS), can greatly reduce the risk of serious

injury or death to the operator if an accidental

tractor overturn occurs.

WARNING: DO NOT use the seat belt if

the ROPS is in the folded position, or

the structure has been removed from

the tractor.

O. Auxiliary Hydraulic Control Handle

The auxiliary hydraulic control handle is loca ted on

the front of the right hand fender cover. Use this

handle to control the movement of attachments

connected to the auxiliary hydraulic system of the

tractor.

Page 18

18

SECTION 2: OPERATION

ROLLOVER PROTECTIVE STRUCTURE (ROPS)

This tractor is equipped with a foldable Rollover

Protection Structure (RO PS) and seat belts. When

used together they are effective in r educing inju ries

to the operator in the event of a n accidental tractor

rollover. The safety provided by the ROPS is

minimized if the seat belt is not properly adjusted

AND buckled. Refer to ADJUSTMENTS for seat

belt adjustment.

Figure 12

WARNING: Always wear the seat belt

when operating the tractor equipped

with a ROPS. However, if the ROPS is in

the folded position or has been removed, the seat belt must not be used.

Use the following guidelines when using a tractor

equipped with a ROPS:

• Be aware of o ve rhead c le aranc es in t he ar ea o f

operation. Check for cl earan ce of door (or gate)

openings and other overhead objects such as

utility lines and tree branches. Overhead

objects could catch the ROPS and upset the

tractor.

• Do not modify th e RO PS b y dr il li ng ho le s for, or

welding accessories to the structure.

• Do not use the ROPS to pull objects with the

tractor. Use ONLY the tractor drawbar for

pulling.

• In the event of an accident, have the ROPS

carefully inspected and, if necessary, replaced

by your

Cub Cadet

dealer. Do not attempt to

repair the ROPS.

FOLDING THE ROPS

The foldable ROPS feature allows the operator to

quickly lower the ROPS to opera te in areas where

there is low overhead clearance. However, the

ROPS should be used in the lowered position only

when absolutely necessary. Operate with the

ROPS in the ‘up’ position whenever possible.

WARNING: A folded ROPS does not

provide rollover protection. When the

ROPS is in the folded position, the seat

belt must NOT be used.

Reposition the ROPS as follows:

• Slightly loos en the two hex screw s on the front

of the ROPS to relieve their pressure on the

ROPS. See Figure 13.

• Remove the two i nternal cotter p ins, and, while

supporting the ROPS, withdraw the c levis pins.

See Figure 13. Carefully lower the ROPS.

• Reinstall the clevis pins and cotter pins for

storage.

Figure 13

To raise the ROPS:

• Remove internal cotter pin s and clevis pins and

lift the ROPS into position.

• Insert the clevis pins and secure with the

internal cotter pins.

• Tighten the hex screws against the ROPS.

ROPS

INTERNAL

COTTER PIN

HEX

SCREW

CLEVIS

PIN

CLEVIS

PIN

Page 19

19

SAFETY INTERLOCK SYSTEM

This tractor is equipped with a safety interlock

system for the protection of the operator. If the

interlock system should ever malfunction, do not

operate the tractor. Contact your authorized

Cub

Cadet

Dealer. The safety inter lock syst em prevents

the engine from cranking or starting unless the

brake pedal is fully depressed, and the PTO is

“OFF”.

• The safety interlock system will shut off the

engine if the operator leaves the seat before

engaging the parking brake.

• The safety interlock system will shut off the

engine if the opera tor leaves the seat with the

PTO “ON”, regardless of whether the brake

lock is engaged.

NOTE:

The PTO switch must be moved to the

“OFF” position to restart the engine. If the

reverse override func tion had been a ctivated, it

will remain activated until the ignition switch is

turned to the "OFF" position.

• The safety interlock system will shut off the

PTO if the

reverse control pedal

is depressed,

unless the reverse override function is

activated.

FUELING THE TRACTOR

Fill the fuel tank with only clean, fresh , diesel fuel.

Fuel with a cetane number of 45 is recommended,

but fuel with a minimum cetane number of 40 is

acceptable. To ensure the freshness of the fuel,

purchase fuel in a quantity that can be us ed within

30 days.

NOTE:

DO NOT USE KEROSENE OR GASOLINE

in your diesel engine. Damage to the engine will

occur.

Generally a good grade Number Two Diesel Fuel

should be used in your diesel engin e. However, in

extremely cold temp eratures a qualit y Number One

Diesel Fuel, or a blend of Number One an d Num ber

Two Diesel fuels should be used. In most areas,

diesel fuel is prop erly blended for seasonal u se as

ambient temperatures change. Therefore, it is

important to monitor fuel purchases so that

seasonal grade fuels ar e not carried over after the

average ambient temperature has changed.

WARNING: Never fill the fuel tank to

the top of the filler neck. Expansion

could result in overflow through the

vents in the cap, allowing fuel to come

in contact with the operator.

• Do not smoke while refueling t he tractor.

• Do not fill the fuel tank when the engine is

running or while the engine is hot.

• The fuel fill cap is located on the fender to the

left of the seat. Unscrew the fuel cap and fill

tank from an approved c ontainer. Do not fill the

fuel tank to capacity. Allow room for expansion.

• Tighten the fuel c ap securely, and immediately

wipe up any spilled fuel.

• To minimize condensation, keep the fuel tank

as full as possible wi tho ut fi ll in g to capacity. It is

a good practice to fi ll the f uel tank at the en d of

the day to reduce overnight condensation.

• Do not allow the fuel ta nk to run dry. Running

out of fuel req uires bleeding air and reprimin g

the fuel system.

WARNING: Fuel in the engine injection

system is under high pressure. If not a

qualified mechanic, do not attempt to

service the fuel injection system. Do

not use your hand to check for leaks.

NEW TRACTOR BREAK-IN PROCEDURES

Proper care during the first hours of operation will

help to assure optimal performance from your new

tractor.

• Never operate a new en gine i mmedi ately under

full load. Allow the engine to warm up.

• Avoid operating the engine for prolonged

periods at either high or low speeds with no

load.

• Use the transmission’s low speed range for

heavy loads to avoid luggi ng of the engine due

to overload.

• Closely monitor the engine oil and coolant

levels, and keep filled to the recommended

levels.

• After the first ten hours of operation, check all

of the front and rear wheel bolts. If necessary,

retighten to the following torque:

Front Wheels — 74 Nm

Rear Wheels — 108 Nm

• Perform all break-in maintenance procedures

found in the MAINTENANCE section.

Page 20

20

STARTING THE ENGINE

WARNING: Always sit in the operator’s

seat when starting the tractor, Never

attempt to start the engine while

standing beside the tractor.

WARNING: Never use starting fluids,

such as ether, as a starting ai d. Severe

engine damage or fire could result.

• Check the engine oil and coolant levels.

• Operator must be sitting in the tractor seat.

• Move the throttle handle to the full (FAST)

throttle position. Refer to Figure 14.

• Make sure the PTO switch is in the “OFF”

position.

Note: The PTO light on instrument

panel will flash if switch is in ON position.

Figure 14

• Either fully depr ess and ho ld the brake pedal or

engage the parking brake.

Note: The parking

brake indicator o n instrument panel will flash if

pedal is not depressed

.

• Turn the ignition key clockwise to the "RUNPREHEAT" position, an d obse rve the gl ow plu g

indicator light on the instrument panel. Wait

until the glow plug indicator light turns off

before cranking the engine.

NOTE:

Preheating may no t be necess ary if the

engine has been running and is warm

.

• Turn the ignition key to the “START” position

and release it as soon as the engine starts;

however, do not crank the engine c ontinuously

for more than 20 seconds at a time. If the

engine does not start w ithin this time, turn the

key to “OFF” and wait at least one minute to

allow the engine’s starter motor to cool. Try

again after waiting.

• After the engine has started, slowly move the

throttle lever to the idle position. Allow the

engine to idle for approximately three to five

minutes before putting the engine under load.

• Observe the instrument panel. If the battery

indicator light, oil pressure light, or coolant

temperature light comes on, immediately stop

the engine. Have th e tractor inspected by your

Cub Cadet

dealer.

COLD WEATHER STARTING

Ensure that the correct viscosity grade of lubricating

oil is used for the ambient temperature range in

which the engine will run, as shown in the

lubrication table in the MAINTENANCE section of

this manual. Place the thro ttle co ntrol in the low idl e

(SLOW) position if the temperature is below 32°F

(0°C), then follow the normal engine starting

instructions above. Allow the eng ine additional time

to warm up.

USING JUMPER CABLES TO START ENGINE

WARNING: Batteries contain sulfuric

acid and produce explosive gasses.

Make certain the area is well ventilated,

wear gloves and eye protection, and

avoid sparks or flames near the battery.

If the battery loses power and is unable to

adequately crank the engin e to start it, the aid of a

booster battery may be necessary. Connect the

booster battery as follows:

• Connect the ends of one jumper cable to the

positive terminals of both the disabled tractor

battery and the booster battery.

• Connect one end of the other cable to the

booster battery’s negative terminal.

• Connect the other end of that cable to the

engine block or frame of the disabled tractor, as

far from the battery as possible.

• Start the disabled tractor following the normal

starting instructions previously provided; then

disconnect the jumper cables in the exact

reverse order of connection.

• Have the tractor’s electrical system checked

and repaired as soon as possible to eliminate

the need for jump starting.

STOPPING THE ENGINE

• Place the PTO switch in the “OFF” position.

• Place the throttle control as follows:

- If the engine has been operated at low loads ,

place the throttle control lever in the “SLOW”

position and allow th e engine to idl e for about

one minute.

- If the engine has b een operate d at high load ,

run the engine at approximately 1/2 throttle

for three to five minutes to reduce the en gine

coolant and oil temperatu res. Then move the

throttle control to the "SLOW" position.

THROTTLE

PTO SWITCH

IN ‘OFF’

POSITION

SLOW

FAST

HANDLE

Page 21

21

• Turn the ignitio n key to the “OFF” position and

remove the key from the ignition switch.

NOTE:

Always remove the key from the ignition

switch to prevent accidenta l starting or battery

discharge if the equipment is left unattended.

DRIVING THE TRACTOR

WARNING: Avoid sudden starts, excessive speed and sudden stops.

Do not leave the seat of the tractor

without disengaging the PTO and

engaging the parking brake. If leaving

the tractor unattended, turn the ignition key off and remove key.

• Adjust the operator’ s seat to the most comfortable position that allows you to operate all

controls and pedal s. Se e s ea t a dju stment in the

ADJUSTMENTS section.

WARNING: DO NOT use the seat belt if

the ROPS is in the folded position or

has been removed from the tractor.

• Adjust the seat belt to fit s nugly b ut com fortab ly

around your lap, then buckle the seat belt.

Refer to ADJUSTMENTS section.

• Shift the transmiss ion Hi/Lo r ange shift l ever on

the right fender to the desired speed setting.

Refer to USING THE HI/LO RANGE SHIFT

LEVER in paragraphs below.

• Use the tract or and /or the auxiliary hydraulic l ift

lever(s) to raise all tractor attachments from the

ground if transporting the tractor to a work site.

• Depress the brake pedal to release the parking

brake, then slowly release th e brake pedal.

• Move the throttle handle to the position where

the engine operates best for the load to be

handled (normally full throttle).

• Slowly depress either the front or rear of the

forward/rever se pedal to move the t ractor in the

desired direction. Refer to USING THE

FORWARD/REVERSE PEDAL.

DRIVING ON SLOPES

WARNING: Do not operate on inclines

with a slope in excess of 15 degrees

(a rise of approximately 25 cm every

1 Meter). The tractor could overturn

and cause serious injury.

IMPORTANT:

Always shift the transmission

into the LOW speed range BEFORE beginning

the climb or descent of any slop

e.

Operate the tractor up and down slopes, never

across slopes. Do not drive so that the tractor may

tip over sidewa ys.

Before operating the tractor on a slope, walk the

slope to look for possible hazards such as rocks,

mounds, stumps, or surface irregularities which

could cause the tractor to be upset.

Back the tractor with attachment up the steepest

portion of each slope you intend to work. If the

tractor cannot negotiate the slope in reverse, the

slope is too steep to be worked.

Avoid turns when driving on a s lope. If a turn must

be made, turn down the slope. Turning up a slope

greatly increases the chance of a roll over.

Avoid stopping when driving up a slope. If it is

necessary to stop while driving up a slo pe, start up

smoothly and carefully to reduce the possibility of

flipping the tractor over backward.

STOPPING THE TRACTOR

• Fully depress the brake pedal to bring the tractor to a complete stop. Push downward on the

parking brake lever and release the pedal to

engage the parking brake. Refer to Figure 15.

• Disengage the PTO using the PTO switch.

• Place the throttle control lever in the “SLOW”

position and allow the engin e to idle for about

one minute; then turn the ignition switch to

“OFF’” and remove the key from the switch.

• Depress the center button of the seat belt buckle

to release the seat belt before dismounting.

USING THE FORWARD/REVERSE PEDAL

The hydrostatic transmission provides constantly

variable ground speeds within the speed rating of

each transmission range. The tractor speed is

controlled by the forward/reverse rocker pedal on

the

right

floorboard.

The forward/reverse pedal i s self neutralizing. The

transmission and pedal return to neutral and the

tractor stops when the pedal is released.

• To move forward, slowly depress the front of

the forward/reverse pedal until the desired

speed is achieved. The speed of the tractor is

directly related to the distance the pedal is

depressed. Refer to Figure 15.

• To move in revers e, check that the area be hind

is clear then slowly depress the rear of the

forward/reverse peda l.

• When traveling short distances with frequent

changes in direction, th e fo rwa rd/r ever se rock er

pedal may be operated using the heel/toe

method. Place your foot on the center section

of the pedal and press downward with your

toes to move forward. Press downward with

your heel to move in reverse.

NOTE:

Slightly more effort is needed to depress the

forward/reverse pedal using the heel/toe method.

Page 22

22

Figure 15

WARNING: The forward/reverse pedal

will not operate when the parking brake

is engaged. Do not attempt to force the

pedal when the parking brake is

engaged; this could cause premature

wear or damage to the drive linkage.

USING THE HI/LO RANGE SHIFT LEVER

WARNING: The tractor must be

stopped before engaging or disengaging the transmission Hi/Lo range shift

lever. Shifting while the tractor is in

motion will cause damage to the

transmission.

WARNING: Always maintain a tractor

speed that allows for complete control

and stability of the machine. Be aware

of dangerous areas or conditions.

Push the lever to the righ t side of the slot to clear

the shift gate, then shift the lever as follows:

HI range — Shift the lever fully forward in slot. See

Figure 16.

Forward speed 0 to 17.7 km/h.

Reverse speed 0 to 8.8 km/h.

Hi range is normal ly used for transport and can be

used with some tractor attachments

Figure 16

LOW range — Shift the lever fully rearward in slot.

Forward speed 0 to 10.2 km/h.

Reverse speed 0 to 5.1 km/h.

Low range is recommende d for use with most PTO

driven tractor attachments. Low range must be

used when climbing or descending slopes.

NEUTRAL — Shift the lever to the center of slot.

Disengages the transmission drive.

Use ONLY for towing or moving the tractor when

not under power.

USING THE DIFFERENTIAL LOCK PEDAL

Depressing the differential lock pedal engages a

mechanism in the transmission that locks the

differential. This prevents the rear wheels from

rotating independently of each other and provides

constant power to bot h rear wheels wh en addi tional

traction is needed.

IMPORTANT:

Do not engage the differential

lock when one of the rear wheels is rotating.

Stop the wheel rotation and then engage the

differential lock.

WARNING: When operating with the differential lock engaged, the tractor will

be difficult to steer. Do not drive the

tractor on roadways or at high speeds

with the differential lock engaged.

• Fully depress and hold the differential lock

pedal to engage the transmission differential

lock. Release the pedal to disengage the

differential lock. See Figure 17.

Figure 17

NOTE:

Because of the drive load on the internal

engagement mechanism, releasing the differential

lock pedal may not always disengage the

differential lock. It may be necessary to slow the

tractor, or reverse the direction of travel, to

disengage the differential lock.

Forward

Reverse

BRAKE PEDAL

PARKING

BRAKE

LEVER

FORWARD/

REVERSE

PEDAL

Heel/Toe

Operation

HI/LO RANGE

SHIFT

LEVER

N

HI

LOW

SHIFT GATE

DIFFERENTIAL

LOCK PEDAL

(Depress and

Hold to Engage)

Page 23

23

USING THE HYDRAULIC LIFT LEVER

The hydraulic lift sys tem provides power fo r raising

and positioning three point hitch and belly mou nted

equipment. The system’s position control feature

maintains the selected height or depth of the

equipment. When the hydr aul ic li ft l ev er is mov ed to

a higher or lower setting, the system reposi tio ns th e

equipment and maintains that selected position.

• To raise an attachment using the hydraulic lift

system, the engine must be running.

• Generally, an attachment can be lowered with

the engine running or off.

• There is a direct relationship between the

height of the equipme nt and the positio n of the

lever in its slot. Operate the equipment to

determine your preferred height setting and,

consequently, the positio n of the lift lever in its

slot.

• Move the lift lever forward in the slot to the

position that lowers the equipment to the

desired height setting. See Figure 18.

Figure 18

• Move the lift lever rearward in the slot to raise

the equipment to a h igher height setting, or all

the way rearward to raise the eq uipment to the

transport position. See Figure 18.

USING THE PTO SELECTION LEVER

WARNING: NEVER shift the PTO selection lever while the PTO is engaged.

Damage to internal components will

occur.

The position of the P TO selection lever will determine whether the rear PTO, mid PTO, or both

PTO’s will be engaged whe n the P T O swi tch is act ivated.

Pull the lever to the rig ht side of the slo t to clea r the

shift gate, then shift the lever as follows:

• Shift the PTO selection le ver rearward to select

the rear PTO. The rear PTO is used to drive

equipment designed to operate at an input

speed of 540 RPM. See Figure 19.

Figure 19

• Shift the PTO lever forward to select the mid

PTO. The mid PTO is used to drive equipment

designed to operate at an input speed of 2000

RPM. Refer to Figure 19.

• Shift the PTO lever to the middle position to

select both the mid PTO and rear PTO. The

mid PTO and rear PTO will run simultaneous ly

when the PTO switch is activated. Refer to

Figure 19.

NOTE:

Occasionally you may not be able to shift

from one PTO selecti on to another due to a slight

misalignment between the internal shift collar and

the gears. In these insta nces if will be necessary to

‘jog’ the PTO while shifting the selection lever.

Momentarily engage the PTO while applying light

pressure on the shift lever to fully engage the

internal gears.

ENGAGING THE PT O

WARNING: The operator must be in the

seat at all times when the PTO in

engaged. If the operator should leave

the seat without turning off the PTO

switch, the tractor’s engine will shut

off.

• Move the throttle handle to the mid throttle

position. Refer to Figure 20.

• Push the

top

of the PTO switch downward to

engage the PTO (Refer to Figure 20). The PTO

light on the instrument panel will come on.

• Move the throttl e handle to the fu ll throttl e position. When operating PTO driven attachments,

observe the tachometer on the instrument

panel to ensure the RPM indicator needle is

within the green range on the tachometer dial.

HYDRAULIC

LIFT LEVER

Highest

Height

Position

Lowest

Height

Position

PTO

SELECTION

LEVER

PTO REVERSE

OVERRIDE

SWITCH

SHIFT GATE

Rear

PTO

Mid &

Rear

PTO

Mid

PTO

Page 24

24

Figure 20

• Push the

bottom

of the switch downward to

disengage the PTO.

IMPORTANT:

Normally the PTO will not

operate when the tractor is dri ven in t he rev ers e

direction. The PTO reverse override switch

must be activated to operate the PTO while

traveling in reverse.

USING THE PTO REVERSE OVERRIDE SWITCH

The PTO reverse override switch, located on the

left

fender, allows the PTO to operate while the

tractor is traveling i n the reverse direction. Refer to

Figure 19.

• The PTO must firs t be engaged using the PTO

switch on the dash panel.

• Depress the front of the override switch to

activate the reverse override system. The light

in the instrument panel will come on.

IMPORTANT:

Once activated, the reverse

override will remain activated until the ignition

switch is turned to the OFF position, regardless

of the number of times the PTO is engaged and

disengaged using the PTO switch. If the

override switch is illuminated, the system is

activated.

WARNING: Use EXTREME CAUTION

when operating PTO driven attachments while traveling in the reverse

direction.

LIGHTING

Headlights and Taillights

Always use the headlights and taillights for after

dusk and pre-dawn operation of the tractor. The

lights not only illuminate the work area, but also

increase the visibil ity of the tractor for anyone who

might enter the area of operation.

The headlights use two halo gen bul bs per si de. The

placement of the bulbs prov ide a broad light range

for safer operation of the tractor in low light

conditions.

• To turn on the headl ights and taill ights, depress

the top end of the headlight switch located to

the left of the steering wheel.

• To turn off the headl ights and taill ights, depress

the bottom of the light switch.

Use of headlights and taillights is also recommended when operating the tractor on or near roadways to increase visibility to traffic.

Hazard Lights

Always use the flashing a mber hazard lights along

with the SMV (Slow Moving Vehicle) emblem when

operating the tractor on, or near, roadways. Also

activate the haza rd lights when necessary to w arn

others that the tractor is being operated in the area.

• To turn on the flashing hazard lights, depress

the top end of th e hazar d li ght sw itch locate d to

the left of the headlight switch.

• To turn off the hazard lights, depress the

bottom of the light switch.

USING THE TOP LINK RETAINER HOOK

The top link hook is provided to retain the the top

link of the three point hitch when not in use.

To utilize the top link hook, proceed as follows:

• While holding the top link upward, raise the

hook rod and slide it fully to the

left

so that it

locks in the uprigh t position in the

right

slot of

the mounting bracket.

• Lower the top link into the hook of the rod.

• To release the top link , lift the to p link out of th e

retainer hook; then slide the hook rod fully to

the

right

and pivot it downward.

Figure 21

THROTTLE HANDLE

Mid Throttle

to Engage

PTO SWITCH

3500 RPM

to Run

MTG. BRACKET

HOOK ROD

LOCKED IN

BRKT. SLOT

TOP LINK

HOOK ROD

RELEASED

Page 25

25

USING THE THREE POINT HITCH

WARNING: Always disengage the PTO,

stop the engine, and set the parking

brake before dismounting the tractor

to connect, disconnect, or adjust three

point hitch mounted implements.

Use the rear three point hitch system to attach

three point mounted implements, which are

normally driven by the rear P TO. Us ing the pos ition

control feature of the t ractor’s hydraulic lift sys tem,

the three point hitch system provides for variable

positioning of the implemen t as well as allowin g the

implement to be fully raised for transport.

Read the ADJUSTMENTS section for instructions

on adjusting the RH a djustable lift link, upper hitch

link, and hitch chain. See Figure 22.

Figure 22

USING THE HITCH PLATE

Use only the hitch plate and drawbar (Refer to Figure 22), for towing pull-behind equipment (carts,

trailers, etc.) or dragging loads.

Raise the lower links o f the three po int h itch to their

highest position to prevent interference with the

towed equipment.

IMPORTANT:

When transporting pull-behind

equipment, always use a safety chain to supplement the connection between the tractor and

towed equipment. The safety chain must have

a strength rating equal to or greater than the

gross weight of the equipment being towed.

USING THE AUXILIARY HYDRAULIC VALVE

Some tractors may be equipped with an auxiliary

hydraulic valve package. This package provides

two hydraulic circuits for operating optional

equipment that can be installed on the tractor.

The male and female hydraulic couplers, located

beneath the right running board, are marked with

color coded washers that should match the color

coded hydraulic lines of

Cub Cadet

equipment. See

Figure 23.

IMPORTANT: If color coding is not present, note

that the inner hydraulic couplers represent one

hydraulic circuit and the outer couplers the

other. Do not cross connect circuits when

connecting hydraulic lines of optional

equipment.

Figure 23

Using the Auxiliary Hydraulic Control Handle

Use the auxiliary hydraulic control handle located

on the right fender as follows:

• Pull the handle rearward to raise the front

hitch or front loader boom. See Figure 24.

• Push the handle forward to lo wer front hitch

or front loader boom. Refer to Figure 24.

• Push the handle fully forward until it locks in

the detent position to place the front hitch or

front loader boom in the float position.

• Push the handle to the right to angle (if

equipped) the front hi tch to the right or dump

the loader bucket. Refer to Figure 24.

• Pull the handle to the left to angle (if

equipped) the front hitch to the left or roll

back the loader bucket.

FIXED

LIFT

HITCH

CHAIN

HITCH

PLATE

LOWER HITCH LINK

LINK

DRAW

BAR

ADJUSTABLE

LIFT LINK

UPPER

HITCH LINK

INNER

COUPLERS

OUTER

FEMALE

COUPLER

OUTER

MALE

COUPLER

Page 26

26

Figure 24

“ON DEMAND” FOUR WHEEL DRIVE

The “On Demand” Four Wheel Drive system

automatically delivers power to the front axle

whenever the need for additi onal traction is sen sed

by the transmission. No action from t he operator is

required for engagement.

TRACTOR WEIGHTING

When implements are installed on either the front or

rear of the tractor, the normal balance of the trac tor

is altered.

• As a rear mounted implement is raised to the

transport position, the balance point of the

tractor shifts rearward, which may result in a

loss of steering control and tractor stability.

• When a front mounted imple ment is raised, the

balance point shif ts forward an d may res ult in a

loss of traction and stability.

To counterbalance these weight shifts, weight

should be added to the tractor in the form of either

cast iron weights or liquid ballast. However, only

enough weight should be added to obtain good

traction, control, and stability. Excess ive weight will

unnecessarily load down the tractor’s engine and

transmission.

NOTE:

When adding weight to the tractor, it may be

necessary to increase the inflation pressure in the

tires.

Front Weights

To counterbalance three point hitch mounted

equipment, a weight bracket/bumper kit and cast

iron weights are available from your

Cub Cadet

dealer.

When mounting optional

Cub Cadet

equipment on

the rear of the tractor, such as a rotary tiller, rotary

cutting deck, or a rear finish mower, the weight

bracket and a minimum of four suitcase weights

should be used.

For all other rear mounted equipment, follow the

guidelines provided in the implement’s Operator’s

Manual to determine ho w m uc h w eig ht is ne ede d t o

counterbalance the equipment.

If guidelines are not avai lable, ballast th e tractor so

that a minimum of approximately 40% of the

machine weight is on the front wheels.

Weighting the Rear of the Tractor

Adding weight to the rear of the tractor is not

required for most

Cub Cadet

front mounted

equipment currently available for this tractor.

However, if installing only the optional front end

loader (without the back hoe), weight must be

added to the rear of the tractor. The most common

methods of adding weight are fi lling the rear wheels

with liquid ballast (usually a calcium chloride and

water solution) or mounting a rear weight box.

Liquid Ballast

Properly filling the rear tires with liquid ballast

increases the weight of each rear wheel to

approximately 90 kg, which should provide

adequate counterbalance.

Because special equipment and a familiarity with

the practice is required, only a qualified tire

technician should perform this procedure. Consult

with your

Cub Cadet

dealer about having liquid

ballast added to your tires, and for any special

maintenance instructions after the procedure is

performed.

Rear Weight Box

A weight box will provide adequat e counterbalance

if the following criteria is met:

• The weight box and contents must total a

minimum of 90 kg.

• The weight b ox must be posi tioned a minimum

of approximately 5.8 cm rearward of the rear

axle, and be carried n o mo re tha n 30 .4 c m fro m

the ground.

If the weight box is positioned closer to the rear

axle or carried higher, additional weight must be

added to effectively counterbalance the front

loader.

ANGLE RIGHT

ANGLE LEFT

RH FENDER

COVER

DUMP BUCKET

ROLLBACK

LOWER HITCH

FLOAT HITCH

RAISE HITCH

RAISE BOOM

BUCKET

LOWER BOOM

FLOAT BOOM

Page 27

27

SECTION 3: ADJUSTMENTS

ADJUSTING THE SEAT

For the comfort of the operator, a single lever

adjustable seat is provided to set the fore to aft

position of the seat. Adjust the seat to the most

comfortable position that allows you to operate all

controls and pedals.

WARNING: Do not adjust the seat when

the tractor is moving, as this could

cause the operator to lose momentary

control of the tractor and result in an

accident.

• To adjust the seat, pivot the seat adjustment

lever to the left and hold while rep ositioning the

seat to the desired position.

• After repositioni ng th e se at, r elease the l ever t o

lock the seat in position. Slide the seat either

slightly forward or rearward to assure it is

locked or until engagement of the lock is felt.

See Figure 25.

Figure 25

ADJUSTING THE SEAT BELT

WARNING: Always wear the seat belt

when operating the tractor equipped

with a ROPS. However, if the ROPS

has been removed, the seat belt

should not be used.

NOTE:

If the belt is too long or too short to be properly adjusted using the upper belt webbing, the

adjustment clip should be repositioned. To do so,

firmly grasp the adj ustment clip and pull the lower

webbing though the cli p. Move the clip toward the

anchor point at the seat to shorten the belt, or

toward the buckle link the lengthen the belt.

Adjust the final length of the seat belt using the

adjuster clip, buckle li nk, and u ppe r be lt we bbi ng o n

the

right

half of the belt.

• To lengthen the belt, hold the ends of the

adjuster clip and tip upward the side of the clip

toward the buckle link. See Figure 26.

• While holding the clip, pull the upper webbing

of the belt through the clip toward the buckle

link. See Figure 26.

• Hold the belt and pull the buc kle link to the

left

to remove the sl ac k in t he upp er we bbi ng of th e

belt between the adjuster clip and the link.

Figure 26

• To shorten the belt, tip the other si de of the clip

upward, pull the free end of the belt webb ing to

the

right

, and pull the buckle link to the

left

to

remove the slack.

THREE POINT HITCH ADJUSTMENTS

• Adjust the RH adjustable lift link to

level

the

lower hitch links. L oosen the jam nut and turn

the adjustment tube as shown in Figure 27 to

shorten or lengthen the l ift link. Tighten the jam

nut against the adjustment tube after adjusting.

Figure 27

SEAT

ADJUSTMENT

LEVER

Pivot Lever

to Left

Pull Belt to

Shorten

Pull Belt to

Lengthen

BUCKLE

LINK

ADJUSTER

CLIP

LOWER

WEBBING

BUCKLE

RELEASE

BUTTON

Tip Sides of Clip

UPPER

WEBBING

JAM

Lengthen

Shorten

NUT

Loosen

Jam Nut

ADJUSTM ENT

TUBE

Page 28

28

• The length of the upper hitch link is normally

determined by the design of each implement.

To adjust the upper hitch link, loo sen the locking lever and turn the adjustment tube as

shown in Figure 28. After the appropriate length

is attained, tighten the lo cking lever. If correctly

adjusted, the upper hitch link will be parallel or

nearly parallel to the lower hitch links.

Figure 28

• The length of the hitch chai ns, atta ched to each

lower hitch link, limit the side-to-side movement of the lower link s. Loos en the jam nu t and

turn the chain’s hex shaft as shown in Figure

29 to adjust the length of the hitch chain.

Tighten the jam nut after adjusting.

Figure 29

ADJUSTING FRONT WHEEL TOE-IN

The front wheel toe-in is set at the factory and

should maintain the proper setting. However, the

toe-in should be checked periodically and

readjusted if necessary.

CHECK THE TOE-IN AS FOLLOWS:

• Place the tractor on a level surface with the

wheels in the straight ahead position.

• Place an easily visible mark on the cen ter lines

of both front tires at the horizontal c enter line of

the wheel.

• Measure and record the distance ‘A’ between

the two marks. See Figure 30.

• Roll the tractor forward or rearward until the

marks are at the horizontal center line at the

rear of the wheels. Measure and record the

distance ‘B’ between the marks. See Figure 30.

• Distance ‘A’ should be 0–0.5 cm less than

distance ‘B’ if the toe-in is correct. If it is not,

readjust the toe-in.

Figure 30

READJUST THE TOE-IN AS FOLLOWS:

NOTE:

The left ball joint and jam nut are left hand

threaded.

• Loosen the jam nu ts a t both the LH and RH ball

joints. See Figure 31.

• Slide an open-end wrench onto the flat area at

either end of the tie rod and turn the tie rod as

follows:

Rearward to shorten the tie rod and decrease

the toe-in. See Figure 31.

Forward to lengthen the tie rod and increase