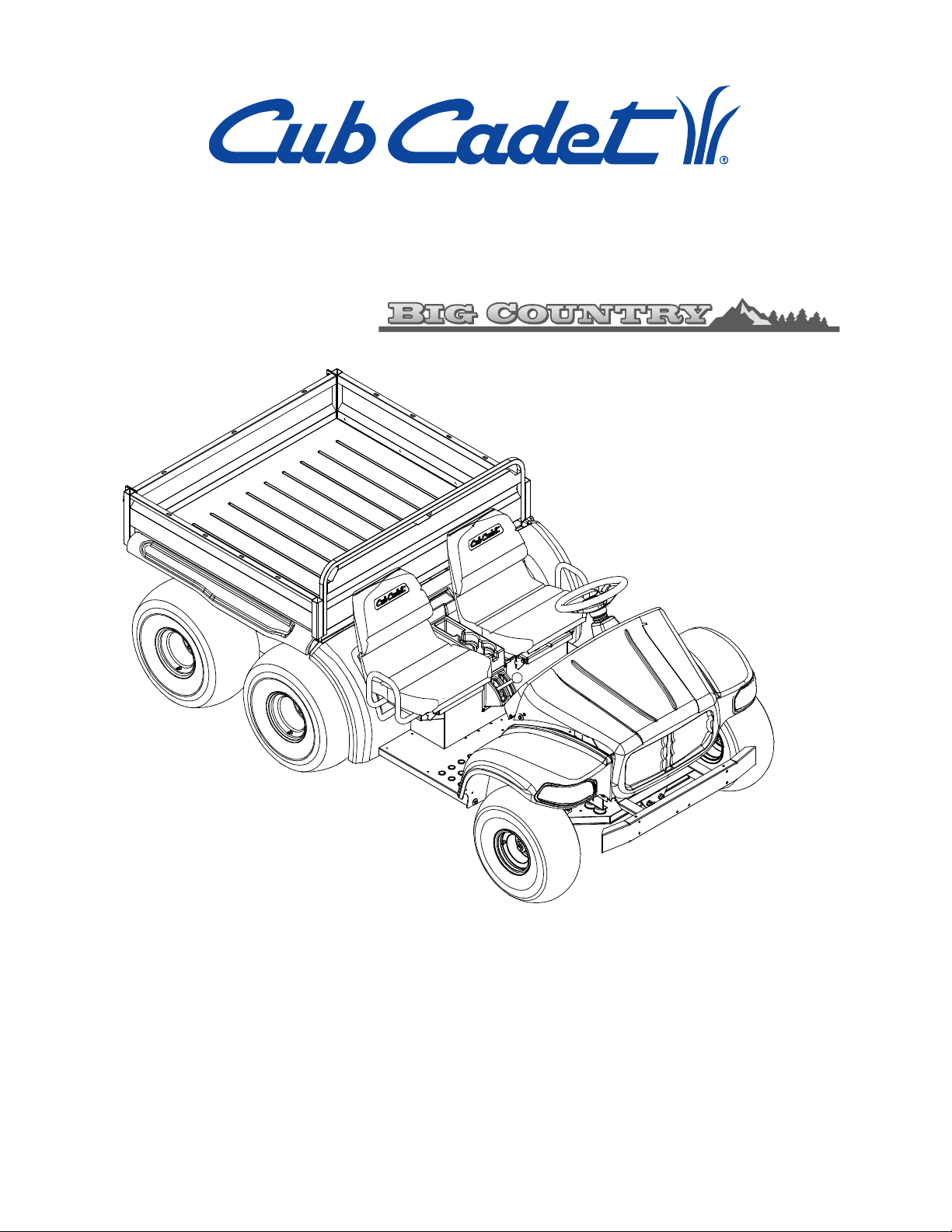

Page 1

OPERATOR’S MANUAL

6x4 Utility Vehicle

Model 640

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368023 Cleveland, Ohio 44136-9722.

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO.

769-00078C.fm

(9/02)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Know Your Utility Vehicle ...................................................................................7

Operating Your Utility Vehicle ............................................................................10

Servicing Your Utility Vehicle ............................................................................. 12

Service Chart ..................................................................................................... 17

Accessories ....................................................................................................... 18

Specifications ....................................................................................................18

Troubleshooting................................................................................................. 19

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new utility vehicle. It will help you assemble, prepare

and maintain the unit for best performance. Please read and understand what it says.

Before you use your new utility vehicle, please locate the model plate on the vehicle

under the left side of dash panel and copy the information from it in the space provided

below. The information on the model plate is very important if you need help from our

Customer Support Department or an authorized center.

• A sample model plate is explained below. For future reference, please copy the model number and

the serial number of the equipment in the space below.

Copy the model number here:

Copy the serial number here:

CUB CADET LLC

www.cubcadet.com

DEALER LOCATOR PHONE NUMBER:

P. O. BOX

CLEVELAND, OH 44136

361131

877-282-8684

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Dealer Referral Line.

Call 1-877-282-8684 to reach the Customer Dealer Referral Line. Please have your unit’s

model number and serial number ready when you call. See previous section to locate this

information. You may be asked to enter the serial number in order to process your call.

For more details about your unit, visit our website at www.cubcadet.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this

manual before attempting to operate or service this vehicle. When you see this symbol - heed its

warning.

WARNING:

Engine exhaust, some of its constituents, and certain vehicle components contain

or emit chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm

DANGER: This vehicle is designed to be operated according to the rules for safe operation in

this manual. As with any type of vehicle, carelessness or error on the part of the operator can

result in serious injury. Failure to observe the following safety instructions could result in

serious injury or death.

.

General Operation

1. Read, understand, and follow all instructions on the

vehicle and in the manual before attempting to

operate or service. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. This is an off-road utility vehicle and it should not be

operated on public highways. Know and comply

with all laws and regulations governing the use of

off-highway vehicles in your area.

3. This vehicle handles and maneuvers differently

than a normal passenger car. Sharp high speed

turns and abrupt maneuvers can cause vehicle to

roll over or go out of control. Slow down when

turning and avoid abrupt maneuvers.

4. Handling and maneuvering characteristics of

vehicle change depending upon cargo load. Heavy

loads affect steering, braking, stability, and overall

handling of vehicle.

5. Be familiar with all instructions and controls and

their proper operation before starting vehicle.

6. Never allow adults to operate this vehicle without

proper instruction.

7. Never allow children under 16 years old to operate

this vehicle. Children 16 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent.

8. Watch for traffic when operating near or crossing

roadways. This vehicle is not intended for use on

any public roadway.

9. Do not operate this vehicle while under the

influence of alcohol or drugs.

10. Never carry more than one passenger. This vehicle

is designed to carry the driver and one passenger

only. No riders are allowed in cargo box or

anywhere else on vehicle.

11. Keep all body parts (i.e. head, arms, hands, legs,

feet) inside vehicle when vehicle is in motion.

12. Always remain seated and keep both hands on the

steering wheel when driving the vehicle.

13. Sit on the center of the seat and keep both feet

within the foot platform perimeter. Clean foot

platform if dirty and remove any debris from around

foot controls, e.g. brake pedal.

14. Do not misuse the utility vehicle. It is an utility

vehicle, not a recreation vehicle or toy.

Recreational riding can lead to accidents, severe

bodily injury or death.

15. Inspect area around vehicle before moving, especially in reverse. Back up slowly. Always look down

and behind before and while backing to avoid a

back-over accident. Keep bystanders out of area.

16. Avoid driving through water, since loss of control

may occur. Drive belt may slip if exposed to water

thus reducing vehicle pulling power and stopping

vehicle entirely.

17. Always use vehicle lights while operating in low

light situations.

18. Do not mount or leave vehicle while it is in motion or

in actual operation.

19. Avoid sudden starts, stops, or turns and always use

a level turn-around area.

20. Never leave vehicle unattended with the key in the

ignition. Always turn key to the “Stop” position, set

the parking brake and remove key.

21. Check overhead clearances carefully before driving

under low hanging tree branches, wires, etc.,

where the operator may be struck or pulled from the

unit, which could result in serious injury.

22. Improper use of the vehicle or failure to properly

maintain it could result in decreased vehicle

performance or personal injury.

23. Engine must be stopped when cleaning, servicing,

adjusting, repairing, or installing attachments on

utility vehicle.

24. After striking foreign objects, stop the unit and shut

off the engine. Inspect for damage and repair the

damage before restarting and operating

equipment.

25. Do not start or operate vehicle in an inside area,

unless it is adequately ventilated. Engine exhaust

3

Page 4

contains carbon monoxide fumes, which are very

poisonous and can be deadly.

26. Do not change engine governor setting or over

speed the engine. The governor is set at the factory

for safe operating speed.

27. Assure safety interlock switch is adjusted correctly

so engine cannot be started unless gearshift is in

the neutral position.

28. Do not touch engine or muffler while engine is

running or soon after it is stopped. They will be hot

and can cause a burn.

29. Always inspect your vehicle each time you use it to

make sure it is in safe operating condition. Always

follow the inspection and maintenance procedures

and schedules described in this manual.

30. If situations occur which are not covered in this

manual, use care and good judgement. Contact

your local service center or call toll free 1-877-2828684 for assistance and the name of your nearest

service center.

Slope Operation

Slopes are a major factor related to loss of control and

rollover accidents, which can result in severe injury or

death. If a slope is steeper than a 15° incline, do not

operate this unit on that area. Exercise extreme caution

while operating on slopes.

DO:

1. Travel straight up and down slopes, not across.

Exercise extreme caution when changing direction

on slopes.

2. Travel slowly while on a slope. Always keep the

forward speed limited when going down slopes to

take advantage of the motor braking action.

3. Keep all movement on the slopes slow and gradual.

Avoid starting or stopping on a slope.

4. Avoid slopes with slippery, loose, or bumpy

surfaces as they are especially hazardous.

5. Use extra care while carrying cargo. It may affect

the stability of the vehicle. Spread the load evenly

or tie down.

Do Not:

1. Do not travel near drop-offs, ditches or

embankments. The vehicle could suddenly turn

over if a wheel is over the edge of a cliff, ditch, or if

an edge caves in.

2. Do not stop or start suddenly when going uphill or

downhill. Be especially cautious when changing

direction on slopes.

3. Do not turn sideways to the hill. The vehicle may roll

over. If you must turn, go slow and do so carefully

and gradually.

4. Do not carry cargo on steep slopes or tow loads.

Children

1. Tragic accidents can occur if the operator is not

alert to the presence of children. Children are often

attracted to the vehicle. They do not understand the

dangers. Never assume that children will remain

where you last saw them. Avoid run over accidents.

a. Keep children out of the immediate area of

the vehicle and in watchful care of a

responsible adult other than the operator.

b. Be alert and turn the vehicle off if a child

enters the area.

c. Before and while backing, look behind and

down for small children.

d. Never carry children, they may fall off and be

seriously injured or interfere with safe vehicle

operation.

e. Use extreme care while approaching blind

corners, doorways, shrubs, trees or other

objects that may block your vision of a child

who may run into the path of the vehicle.

f. Remove key when vehicle is unattended to

prevent unauthorized operation.

2. Never allow children under 16 years old to operate

this vehicle. Children 16 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent.

3. Do not let children ride in the cargo box, in the

driver’s or passenger’s lap or anywhere other than

the passenger seat. Never give small children a

ride; not even in the passenger seat. They may fall

off.

Cargo Box Loading/Operation

1. Do not exceed vehicle’s Total Load Capacity rating

of 1,400 lb. This includes operator, passenger,

accessories, and cargo.

2. Do not exceed 1,000 lb. load in cargo box.

3. Spread load evenly and secure to prevent

movement.

4. Do not load above height of cargo box front panel.

Load could shift forward and injure driver or

passenger.

5. Avoid loads which exceed the physical dimensions

of cargo box.

6. Go slow. Heavy loads will affect steering, braking,

stability, and overall handling of the vehicle. Limit

loads to those that can be safely controlled.

7. Avoid sudden starts, stops, and turns which could

cause load to shift.

Cargo Box Lift

1. Stop vehicle on level ground and set Parking Brake

before raising cargo box.

2. On manual lift units, unload cargo box before

raising cargo box by hand.

3. When manually raising cargo box, make sure

Manual Support Lift Rod is securely locked before

leaning under raised cargo box.

4

Page 5

4. Do not operate vehicle with cargo box in raised

position.

5. Do not operate vehicle with cargo box latch

unlatched. Always re-latch upon manually lowering

cargo box.

6. When using optional electric lift:

• Stay in driver’s seat.

• Keep body parts away from cargo box and keep all

bystanders away.

• Do not allow rear wheels to hang over the edge of a

drop-off when raising cargo box. Cargo box weight

may shift over center and cause vehicle to tip over

backwards.

Towing

• Always use an approved hitch and hitch point

provided on the utility vehicle.

• Do not tow more than 1200 lb. (545 kg) rolling

weight (i.e. trailer plus cargo).

• Never load more than 100 lb. (45.5 kg) tongue

weight on tow bracket provided.

• Go slow and use extra care when towing a trailer.

Allow for increased braking distance. Load trailer

properly.

• Do not tow heavy loads on slopes greater than 5°

incline. When going downhill or turning, the extra

weight tends to push the tow vehicle and may

cause you to loose control (i.e. braking and steering

ability are reduced, towed equipment may jackknife and cause utility vehicle to overturn).

Service

Safe Handling Of Gasoline:

1. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

c. When practical, remove gas-powered

equipment from the truck or trailer and refuel

it on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a

gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times

until fueling is complete. Do not use a nozzle

lock-open device.

e. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel while the

engine is hot or running. Allow engine to cool

at least two minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more

than ½ inch below bottom of filler neck to

allow space for fuel expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine

and equipment. Move unit to another area.

Wait 5 minutes before starting the engine.

k. To reduce fire hazards, keep machine free of

grass, leaves, or other debris build-up. Clean

up oil or fuel spillage and remove any fuel

soaked debris.

l. Never store the machine or fuel container

inside where there is an open flame, spark or

pilot light as on a water heater, space heater,

furnace, clothes dryer or other gas

appliances.

WARNING: Your Responsibility: Restrict the

use of this vehicle to persons who read,

understand and follow the warnings and

instructions in this manual and on the unit.

5

Page 6

6

Page 7

SECTION 2: KNOW YOUR UTILITY VEHICLE

NOTE: Reference to right or left hand side of the utility vehicle is observed from the operating position.

Figure 1

Read this operator’s manual, safety labels, and

operating instructions on the vehicle before operating.

Compare the illustrations in this manual with your unit

to familiarize yourself with the location of various

controls and adjustments. Reference to the right or left

hand side of unit is observed from the operating

position. Save this manual for future reference.

See Figure 1.

Read the Honda Engine operator’s manual before

operating this vehicle to familiarize yourself with the

engine controls and adjustments.

NOTE: Before operating your vehicle, follow the

starting instructions in the Operating Section and

check tire pressure per the recommendations in the

Maintenance Section.

Accelerator Pedal

The accelerator pedal is located on the right side of the

floor beneath the dash panel. Depressing the

accelerator pedal will move the vehicle in the direction

selected on the gearshift. As the pedal is depressed,

speed will increase to the maximum selected range.

Releasing the pedal reduces the speed, but does not

stop the vehicle. The brake must be applied to stop

vehicle. See Figure 2.

Brake Pedal

The brake pedal is located on the left side of the floor

beneath the dash panel. Remove foot from accelerator

pedal apply pressure to the brake pedal evenly until

vehicle slows down and stops. See Figure 2.

Brake Pedal

Accelerator Pedal

Figure 2

Parking Brake Latch

The parking brake latch is located on the right side of

the dash panel. It holds the brake in the engaged

position for parking. See Figure 3.

7

Page 8

• To engage the parking brake, push brake pedal

down firmly, pull out on the parking brake knob,

and release foot from brake pedal. Brake pedal will

stay down and parking brake light on dash will

come on to indicate parking brake is engaged.

• To release parking brake, push down on brake

pedal and parking brake latch will release.

Parking Brake

Latch

12V Power Outlet

The 12V power outlet is located on the right side of the

dash panel. It is used for the convenience of plugging in

accessories that require a power source with a

maximum load of 5 amps at 12 volts. See Figure 4.

Accessory Power Switch (Optional)

If equipped, the accessory power switch is located on

the right side of the dash panel. This switch turns power

on or off for optional accessories. See Figure 5.

Light Switch

The light switch is located on the right side of the dash

panel. Push in top/bottom of switch to activate or turn

off lights. See Figure 5.

Figure 3

Ignition Switch

WARNING: Never leave a running machine

unattended. Always set parking brake, stop

engine and remove key to prevent unintended

starting.

The ignition switch is located on the right side of the

dash panel. To start the engine, insert the key into the

ignition switch and turn clockwise to the START

position. Release the key into the Run position once

engine has fired. See Figure 4.

NOTE: The gearshift must be in the neutral position to

start engine.

Horn Plug

Ignition Switch

Figure 4

Refer to Starting The Engine in the Operation Section of

this manual for detailed starting instructions

12V Power

Outlet

Cargo Box Electric Lift Switch (Optional)

If equipped, the cargo box electric lift switch is located

on the right side of the dash panel. It activates lift to

raise and lower cargo box. See Figure 5.

Rear Power Outlet (Optional)

If equipped, the rear power outlet is located on the right

side of the dash panel. It turns power on and off for the

rear outlet. See Figure 5.

Accessory Power

Switch (Optional)

Light Switch

Cargo Box Electric

Lift Switch

Figure 5

(Optional)

Rear Power

Outlet (Optional)

Warning Light Cluster

The warning light cluster is located in the middle of the

dash panel. There are four warning lights: alternator

discharge light, parking brake light, engine oil pressure

light, and low fuel light. The alternator discharge light

will indicate that the alternator is not charging. The

parking brake light indicates when parking brake is

engaged. The engine oil pressure light activates when

engine has low oil pressure. The low fuel light activates

when fuel is low in tank. See Figure 6.

Horn Switch (Optional)

The horn switch is located on the right side of the dash

panel. Push button to activate horn. See Figure 4.

8

Page 9

Low Fuel

Light

Engine Oil

Pressure Light

Engaged

P

Alternator

Discharge Light

Figure 6

Parking

Brake

Choke

The choke lever is located on the left side of the dash

panel. The choke is used when starting a cold engine. It

richens the fuel mixture for cold weather starting.

See Figure 7.

Choke

Hour Meter

Figure 7

Hour Meter

The hour meter is located on the left side of the dash

panel. It reads the elapsed time engine has run.

See Figure 7.

Differential Lock

Gearshift Lever

Disengaged

Figure 8

Lever

Gas Gauge

The gas gauge is located under the seat on the left

side. It is mounted on top of the gas tank and it

indicates amount of fuel in tank. The fuel tank is 5.7

gallons. See Figure 9.

Fuel Shut Off Valve

The fuel shut off valve is located under the seat and it is

strapped onto the fuel tank. It controls fuel to the

engine. To turn fuel off, turn knob so indicator is down.

To turn fuel on, turn knob to the up position.

See Figure 9.

Cup Holders

The cup holders are located between the seats. They

are designed for the use of non-alcoholic beverages.

WARNING: Never operate this vehicle while

under the influence of alcohol or drugs. Doing

so can result in serious personal injury or

death.

Gearshift Lever

The gearshift is located between the seats. It has the

larger ball knob and it controls neutral, forward, and

reverse of the vehicle. See Figure 8.

Differential Lock Lever

The differential lock lever is located between the seats.

It has the smaller ball knob and its activates the

differential locking mechanism. The differential lock is

used to lock the differential so all four drive wheels will

pull equally when rear wheels start to slip. See Figure 8

Fuel Shut

Off Valve

Gas Gauge

Figure 9

Adjustable Seat Lever

The adjustable seat lever is located beneath the

driver’s seat on the front side and it is used to move the

seat forward and backward. See Figure 10.

• Slide the lever to the left and push the seat forward

or back to the desired position.

• Release the lever so that it locks the seat in place.

9

Page 10

WARNING: Make sure seat is in locked

position prior to operation and do not try to

adjust the seat position while operating the

vehicle.

Seat Lever

Figure 10

Cargo Box

The cargo box is raised manually using the handle after

the cargo is emptied to gain access to the engine or if

equipped with a power lift, the cargo box can be raised

to dump cargo. If the cargo box has a manual lift, there

is a support rod to lock the box in place. See Figure 11.

WARNING: Do not exceed the vehicle’s

Total Load Capacity of 1,400 lb., which

includes driver, accessories, and cargo. Do

not exceed 1,000lb. in the cargo box.

Cargo Box

Figure 11

SECTION 3: OPERATING YOUR UTILITY VEHICLE

WARNING: This is an off-road utility vehicle

and it should not be operated on public

highways. Know and comply with all laws and

regulations governing the use of off-highway

vehicles in your area.

IMPORTANT:

and the Honda Engine manual thoroughly to

understand all instructions.

IMPORTANT:

inflation pressure in all tires to approximately 5 -6 psi.

Before staring the engine read this manual

WARNING: Do not run an engine in an

enclosed area. Move the vehicle to an

outside area before running the engine.

Tires are shipped over-inflated. Reduce

Check Safety Switch

• Sit in the operator’s seat and place key switch in

STOP position.

• Lock parking brake and move gearshift lever to the

forward position.

• Move key switch to START position. The engine

should NOT crank.

• Turn key switch to STOP and move gearshift lever

to the reverse position.

• Move key switch to START position. The engine

should NOT crank.

• Turn key switch to STOP.

• Keep engine compartment clean and be sure fan or

flywheel screens remains installed and clean.

Starting Engine

• Sit in the operator’s seat and place key switch in

STOP position.

• Move gearshift to the N (Neutral) position and lock

parking brake.

• Pull out the choke knob if engine is cold.

• Turn key to the START position.

• Release key to the RUN position when engine

starts.

• If engine does not start, wait a few seconds and

repeat procedures.

• After engine starts, push in choke knob.

NOTE: If engine surges after starting while idling or

driving at a low speed, apply choke as needed until

engine has warmed up.

IMPORTANT:

until engine has warmed up.

Do not operate the engine under full load

Stopping Engine

• To stop utility vehicle, release accelerator pedal

and depress brake pedal until vehicle comes to a

complete stop.

• Move gearshift lever to N (Neutral) position.

• Lock parking brake and turn key switch to STOP

position.

• Remove the key when not in use.

10

Page 11

Driving Utility Vehicle

• Make sure front wheels are turned to the desired

direction.

• Depress brake pedal to release parking brake.

• To avoid damaging transmission, depress brake

pedal fully and make sure vehicle is completely

stopped before shifting into Forward or Reverse.

WARNING: Do not stop or start suddenly

when going uphill or downhill. Be especially

cautious when changing direction on slopes.

Apply brakes when going down slopes to

maintain control of vehicle.

•Release brake pedal and apply pressure to

the accelerator pedal.

• Release accelerator and apply brake pedal evenly

and firmly to slow down or stop.

Engaging Differential Lock

• Stop or slow vehicle speed and pull up on lever to

lock differential. The differential will remain

engaged as long as lever is held in the up position.

IMPORTANT:

right side wheels are turning at slightly different speeds.

Do not attempt to turn when differential lock is engaged.

Engage the differential when the left and

WARNING: To avoid transaxle damage or

injury, go slow when operating vehicle with

differential lock engaged as steering

response is noticeably reduced.

Disengaging Differential Lock

• To disengage the differential lock, simply release

the lever, allowing it to return to the bottom position.

NOTE: Torque must be equal on both axles for

differential lock to release. It is best to slow down and

drive straight ahead at a constant speed when

disengaging the differential.

• Raise cargo box manually to upright position using

the handle on the drivers side of box.

See Figure 12.

• Place support rod into the slot when cargo box is

fully raised.

WARNING: Make sure support rod is

securely locked before leaning into engine

and transaxle area of vehicle. Do not operate

vehicle unless cargo box lift strap is latched

down.

• To lower support rod, raise cargo box slightly using

the box handle and release support rod from latch

slot.

• Slowly lower cargo box, while the support rod slides

along the slotted channel and re-latch the cargo

box latch.

Electric Lift

• Park the vehicle safely and turn key to the RUN

position.

• Raise cargo box by pressing and holding top of

electric lift switch. Release switch when box is at

desired dump height or when maximum height is

reached.

NOTE: A ratcheting noise will indicate cargo box is at

full extension. The same noise will also be heard when

cargo box is at the full down position. If lift capacity of

the power lift is exceeded, a ratcheting will also be

heard.

• To lower cargo box, push on bottom of electric lift

switch. Turn ignition switch to the STOP position.

Clip

Handle

Raising and Lowering Cargo Box

WARNING: To prevent the possibility of

bodily injury from unintentional lowering of

the cargo box, be sure vehicle is on a level

and stable surface and parking brake is

locked before raising cargo box.

Manual Lift

NOTE: The manual lift and lower procedures should

only be done after cargo box is emptied.

• Park the vehicle safely on level ground and set

parking brake.

• Empty cargo by hand and unhook cargo box latch

located in front of box. See Figure 12.

Latch

Figure 12

Manual Lift

Support Rod

Dumping Load From Cargo Box

• Back up the vehicle to the dump site and apply

parking brake.

• Unhook the tailgate from cargo box.

• On manual lift vehicles, unload cargo box by hand

before raising box.

11

Page 12

• If using an electric lift, raise cargo box to dump load

and lower box when empty.

WARNING: The center of gravity changes as

a loaded cargo box is raised. Do not allow

rear wheel to hang over the edge of a loading

dock or ravine. The cargo box weight may

shift over center and vehicle could tip over

backwards.

WARNING: A loaded cargo box can be very

heavy. Do not attempt to dump a loaded

cargo box unless vehicle is equipped with an

electric lift option.

IMPORTANT:

if actuator clutch slippage occurs. Lower cargo box

completely and remove excess load by hand before

dumping.

• Reconnect the tailgate to the cargo box. Do not

drive the vehicle with cargo box in the raised

position.

If dumping by electric lift, stop immediately

Loading the Cargo Box

WARNING: The utility vehicle may become

unstable if the cargo box is loaded

incorrectly. Avoid loose and shifting loads or

uneven loading of material.

•Verify cargo box is latched before loading.

• Securely anchor all loads in cargo box and do not

load beyond maximum capacity.

• The maximum box capacity is 1000 lbs (454.5 kg).

• When loading objects into vehicle, be sure load is

securely anchored and evenly distributed in cargo

box.

• Do not load above height of cargo box front panel.

Load could shift forward striking driver or

passenger or cause driver to loose control of

vehicle.

• Avoid loads which exceed physical dimensions of

cargo box.

• Avoid concentrated loads at rear or side of cargo

box. Be sure load is distributed evenly.

• Reduce load and ground speed when operating

over rough or hilly terrain. DO NOT overload

vehicle. Limit loads to those that can be safely

controlled.

Towing Loads

WARNING: To help prevent personal injury

due to loss of control or tipping, always tow a

load slowly enough to maintain control.

•Do not tow a load that exceeds 1200

lbs.(545.5 kg) rolling weight (i.e. trailer plus cargo)

and never exceed 100lbs (45.5kg) tongue weight.

• Go slow when towing a heavy load. Allow for

increased braking distance. Tow load at a speed

slow enough to maintain control.

• Do not tow on steep slopes.

• Be particularly cautious when towing down even a

gradual slope or turning. The extra weight tends to

push the tow vehicle and may cause you to lose

control (braking and steering ability are reduced;

towed equipment may jack-knife).

IMPORTANT:

crossings can place high bending loads on hitch

connection. If traversing terrain where these conditions

exist, use of a ball or pintle type hitch is recommended.

• Always use approved hitch and hitch point provided

for the utility vehicle. Do not modify the hitch in any

way.

Extreme angles such as high railroad

Transporting Vehicle

IMPORTANT:

will occur if vehicle is towed. Haul the vehicle on a

heavy-duty trailer or on a full-size truck.

• Drive utility vehicle onto the trailer or truck and

leave transaxle gearshift lever in forward or

reverse.

• Apply parking brake and turn fuel shut-off valve

to OFF position during transport.

• Fasten vehicle to trailer or truck with straps, chains,

or cables.

Never tow the vehicle. Transaxle damage

SECTION 4: SERVICING YOUR UTILITY VEHICLE

Lubrication

Chain & Roller Lubrication

• In dusty or dry conditions use a dry lubrication.

• Lubrication with a good grade of petroleum oil.

Lubrication between the chain links and the

bushings.

• Clean chains with soft wire brush to remove dirt and

then spray the chain and chain rollers with chain

lube every 20 - 40 hours.

• Grease applied to the chain should be avoided.

Front Axle Lubrication

• Lubricate one grease fitting on each axle with 2 or 3

shots of grease every 50 hours.

Axle Shaft U-Joint

12

Page 13

• Lubricate three grease fittings on each u-joint with 2

or 3 shots of grease 100 hours.

Rear & Center Arms

• Lubricate the eight grease fittings on the rear and

center arms every 50 hours.

Engine

Read the Honda Engine operator’s manual for any

service or maintenance information pertaining to the

engine.

Filling Fuel Tank

• Stop the vehicle on a level surface and apply

parking brake.

• Turn the ignition key to the STOP position and

remove the key.

• Allow engine to cool several minutes before you

add fuel.

• Clean area around fuel cap and remove cap.

See Figure 13.

• Fill tank with fresh, stabilized fuel only to bottom of

filler neck.

• Install fuel tank cap.

Fuel Cap

Figure 13

Battery

could change the polarity and cause damage to your

engine’s alternating system.

Clean Battery and Terminals

• Remove battery from vehicle. Always remove

negative cable first when disconnecting.

• Wash battery with solution of four tablespoons of

baking soda to one gallon of water.

• Rinse the battery with plain water and dry.

• Clean terminals and battery cable ends with wire

brush until bright.

• Apply petroleum jelly or silicone spray to terminals

to prevent corrosion.

• Install battery. Always install negative cable last

when connecting.

Jumping a Battery

WARNING: Do not attempt to jump start a

frozen battery. Warm to 16 degrees C (60

degrees F). Do not smoke near battery and

wear eye protection and gloves when

handling battery.

• Connect positive (+) jumper cable to booster

battery positive (+) post (A). See Figure 14.

• Connect the other end of positive (+) jumper cable

to the disabled vehicle battery positive (+) post (B).

• Connect negative (-) jumper cable to booster

battery negative (-) post (C).

• Connect the other end (D) of negative (-) jumper

cable to a metal part of the disabled machine frame

away from battery.

• Start the engine of the disabled machine and run

machine for several minutes.

• Carefully disconnect the jumper cables in the exact

reverse order: negative cable first and then the

positive cable.

Jumper Cables

D

WARNING: The battery produces a

flammable and explosive gas. Do not smoke

near battery. Wear eye protection and gloves

when handling the battery. Do not allow direct

metal contact across battery posts.

The battery is sealed and is maintenancefree. Acid levels cannot be checked and fluid can not be

added.

IMPORTANT:

disconnect the NEGATIVE (Black) wire from it’s

terminal first, followed by the POSITIVE (Red) wire.

When re-installing the battery, always connect the

POSITIVE (Red) wire its terminal first, followed by the

NEGATIVE (Black) wire. Be certain that the wires are

connected to the correct terminals; reversing them

If removing the battery for any reason,

Charging

13

B

Disabled Battery

Figure 14

WARNING: Charge battery in a well

ventilated area and keep away from an open

flame or pilot light as on a water heater, space

heater, furnace, clothes dryer or other gas

appliances.

CA

Booster Battery

Page 14

If the vehicle has not been put into use for an extended

period of time, charge the battery with an automotive

type 12-volt charger for a minimum of one hour at six

amps.

Replacing Headlights

Headlights

• Remove the two screws from the each headlight

housing located behind each fender.

• Remove the headlight lens and housing from the

front. The lens and the housing are connected.

See Figure 15.

• Twist the plastic connector and pull out light

assembly.

• Disconnect light bulb assembly from wire connector

and replace with new bulb assembly.

• Reassembly in reverse order.

Wheel Replacement

WARNING: Using an unstable lifting device

and vehicle support may result in bodily injury.

Use a safe lifting device and supports to work

on raised vehicle.

Rear Wheels

• Stop the vehicle on a level surface and apply

parking brake.

• Turn the ignition key to the STOP position and

remove the key.

• Loosen but do not remove the five wheel bolts from

the axle hub. See Figure 16.

Wheel Bolts

Headlight Lens

& Housing

Figure 15

Replacing Warning Lights

• Raise hood to get access to under the dash panel.

• Remove the appropriate bulb socket and replace

bulb.

• Reattach socket and lower hood. Secure hood to

fender.

Fuses

• Raise hood to get access to under the dash panel.

• Remove the appropriate electrical fuse and replace

with proper amperage fuse.

• Reattach socket and lower hood. Secure hood to

dash.

Tire Pressure

WARNING: Explosive separation of tire and

rim parts is possible when they are serviced

incorrectly. Do not stand in front or over tire

assembly when inflating.

The recommended operating tire pressure is approximately 5-6 psi for both the front and rear tires.

Overinflating above recommended tire pressure can

reduce the life of the tire. Check tire pressure before

driving the vehicle.

Figure 16

• Raise rear of vehicle with a safe lifting device and

place support stands under vehicle.

• Remove the five wheel bolts and rear wheel. Place

new wheel on the axle hub and secure with bolts.

• Tighten wheel bolts diagonally until snug.

• Remove support stands and lower vehicle.

• Finish tightening the bolts to 55-60 lb-ft using a

torque wrench.

Front Wheels

• Stop the vehicle on a level surface and apply

parking brake.

• Turn the ignition key to the STOP position and

remove the key.

• Remove plastic hub cap and loosen 16 x 40 cap

screw.

• Raise front of vehicle with a safe lifting device and

place support stands under vehicle.

• Remove cap screw and front wheel. Place new

wheel on front axle hub and secure with cap screw.

• Remove support stands and lower vehicle.

• Finish tightening the 16 x 40 screw to 80-85 lb-ft

using a torque wrench.

IMPORTANT:

bearing damage.

Overtightening front wheel can result in

14

Page 15

Drive Chain Tension

WARNING: Do not rely on a lifting device

alone to support machine while servicing.

Always use jack stands or wooden blocks to

support vehicle while work is being performed

with machine raised.

NOTE: Drive chain is set taught at the factory, so it will

not reach normal stretch limits until vehicle has

experienced reasonable hours of operation (100 hrs).

• Stop vehicle on level surface, but do not apply

parking brake.

• Put transmission in neutral and differential in the

disengaged position.

• Turn the ignition key to the STOP position and

remove the key.

• Use a safe lifting device to raise all four rear wheels

off ground and place jack stands or wooden blocks

under vehicle.

• Raise and secure cargo box, if manual lift.

• Rotate wheels toward or away from each other and

check to see if there is any slack in the chain.

See Figure 17.

• If the chain adjusters are not keeping the chain

tight, a1/2 link will need to be removed.

• If chain is still loose after the 1/2 link is already

removed, the chain should be replaced using a 98

to 99 link chain. DO NOT USE a 97 link chain or

less.

• If chain is still loose after installing a new 98 pitch

chain, see your Cub Cadet dealer.

Chain Adjusters

Sag In Chain

• Remove dipstick located on the top of the transaxle

housing and wipe dipstick clean. See Figure 18.

• Check oil level by screwing dipstick fully into

transaxle case and then remove to check oil level.

• Add universal (Hydraulic) tractor transmission fluid

as needed until oil level reaches the full mark on

dipstick.

• Install and tighten dipstick.

• Lower cargo box.

Dipstick

Figure 18

Changing Transaxle Oil

WARNING: The fluid for your transmission

has been specially formulated to ensure the

safe and proper operation of your vehicle.

When changing the transmission fluid replace

it with Cub Cadet Drive System Fluid Plus

ONLY. Failure to use Cub Cadet Drive

System Fluid Plus may result in a failure of the

drive system which could result in property

damage or personal injury. Do not substitute.

Figure 17

Checking Transaxle Oil

IMPORTANT:

incorrect oil level. Check oil level when oil is cold and

with engine is not running.

• Park vehicle on level surface and apply parking

brake.

• Raise and secure cargo box, if manual lift.

IMPORTANT:

transaxle. Clean area around opening before removing

dipstick.

Hot hydraulic oil will expand and show

Dirt and debris in oil may cause damage to

IMPORTANT:

applied, change transaxle oil before waiting until the

service interval.

• Park vehicle on level surface and apply parking

brake.

• Raise and secure cargo box, if manual lift.

• Access drain plug through slot on underside of

machine and remove plug.

• Check O-ring on drain plug and replace if missing

or in poor condition.

• Install and tighten drain plug.

IMPORTANT:

transaxle. Clean area around opening before removing

dipstick.

• Remove dipstick located on top of transaxle

housing and wipe dipstick clean.

• Add approximately 189 oz (5.5 liters) of Shell TTF-

SB Oil (Cub Cadet Part No. 737-3120 or 737-3121).

• Check oil level by screwing dipstick fully into

transaxle and then remove to check level.

• Wait for two minutes and then check oil level again.

• Install dipstick and lower cargo box.

15

If brakes start to chatter or are noisy when

Dirt and debris in oil may cause damage to

Page 16

Drive Belt

WARNING: Fingers or loose clothing can get

caught in rotating parts. Stop engine and wait

for all moving parts to stop before servicing.

• Park vehicle on level surface and apply parking

brake.

• Raise and secure cargo box, if manual lift.

• Rotate and inspect belt for wear or damage.

• Measure width of belt on top surface. The width

should be a minimum of 1.1 (27 mm).

• Replace belt if worn beyond limit.

To replace belt:

• Remove hardware and belt shield. See Figure 19.

• Route belt over drive clutch pulley (front pulley).

• Route belt from drive pulley (rear pulley).

See Figure 19.

IMPORTANT:

arrow on belt points in the direction of belt rotation

(toward front of vehicle).

• Install new belt by routing over drive pulley (rear

pulley) and then over the drive clutch pulley (front

pulley). Install belt shield.

Belt Shield

Drive belt must be installed so indicator

Clutch Pulley

(Front)

Adjusting Brake

The wet brake system is an internal part of the

transmission and it is adjusted externally without

opening the transmission. There are two sets of brakes

that may require adjustment. Each set consists of two

rotating friction plates placed between three fixed steel

plates operating in oil. Each set of brakes is operated

by it’s respective lever arm. The brakes are properly

adjusted at the factory. To adjust the brakes:

• Stop the vehicle on a level surface.

• Turn the ignition key to the STOP position and

remove the key.

• Block the front wheels, position the shift lever into

neutral, and make sure parking brake in not

activated.

• Use a jack to raise the rear wheels at least one inch

off the ground. Then use blocks or stands to

support the machine.

• Disconnect brake arm return spring. See Figure 20.

• Loosen the front and rear jam nuts.

Brake Arm

Return Spring

Front Side

Jam Nut

Chain Adjuster

Drive Pulley

(Rear)

Rear Side

Jam Nut

Figure 20

• Push the brake lever arm forward until the internal

brake disc stop is detected.

• Run up the jam nut of the rear side until it touches

and then back off one turn.

• Tighten the front side jam nut.

• Check the brake pedal by hand. It should have 3/4”

free travel.

• Hook up the return spring.

• Rotate the rear wheels by hand with brake pedal

released. The wheels should rotate freely.

• Cautiously complete the testing on level ground by

operating the machine and applying brakes in a

normal manner.

• Repeat the adjustment procedure if necessary.

Cleaning

The body panels are scratch and impact resistant

automotive quality ABS plastic. The use of standard car

wash soap and non-abrasive car wax is acceptable for

cleaning the body panels. Avoid any abrasive cleaner

or rubbing compounds for these will damage the body

panels. Dry thoroughly to avoid water spots.

Figure 19

16

Page 17

WARNING: Damage may occur if direct hose

spray comes in contact with any other electrical components, i.e. at instrument cluster or

under dash.

Storage

• Stop the vehicle on a level surface and apply

parking brake.

• Allow vehicle to cool.

• Replace all worn, damaged, or missing parts and

tighten loose hardware as needed.

• Wash the vehicle and clean inside the engine

compartment and under the cargo box.

• Run engine for several minutes to dry belts,

pulleys, and other moving parts.

• Clean and polish metal and plastic surfaces.

• Apply light coat of oil to pivot and wear points to

prevent rust.

• Lubricate grease points.

• Replace fuel filter if needed. See engine manual.

• Change engine oil and filter. See engine manual.

• Drain all old fuel from tank.

• Prepare fuel system for storage.

If planning to store vehicle with fuel tank empty:

• Add a small quantity of fresh stabilized fuel to tank.

Run engine until it runs out of fuel. This will circulate

fuel mixture through engine.

If planning to store vehicle with fuel in the tank:

• Fill tank completely with fresh stabilized fuel to

prevent condensation build-up. Run engine for

several minutes to circulate fuel mixture through

engine.

• Turn the ignition key to the STOP position and

remove the key.

• Remove and clean battery. See Battery in Service

Section.

• Store battery in a cool, dry place. Fully charge

battery periodically during storage to maintain its

longevity.

• Support vehicle safely on blocks or stands to take

weight off tires. Reduce 1/3 air from tires.

• Cover vehicle with waterproof cover if stored

outside.

SECTION 5: SERVICE CHART

Before

Each Use

Check Transaxle Oil

Change Transaxle Oil

Tighten Wheel Bolts

Drive Chain Tension

Check Drive Belt

Grease Front Steering Spindle

Grease Axle Shaft U-Joints

Grease Rear & Center Arms

Grease Chain & Rollers

Check Interlock Switch System

First

10 Hours

Every

50 Hours

Every

100 Hours

Every

500 Hrs

or 2 years

Replace Interlock Switch

17

Page 18

SECTION 6: ACCESSORIES

Description Model Number

Electric Bed Lift 39A-100-100

Horn 39A-101-100

Rear Electric Outlet 39A-102-100

Rear Receiver Hitch 39A-103-100

Brush Guard 39A-104-100

Floor Mat 39A-105-100

Front Receiver Hitch 39A-106-100

Heavy Duty Tires 39A-107-100

SECTION 7: SPECIFICATIONS

Engine and Electrical

Make Honda

HP 20 HP

Type 4-Cycle Gas

Cylinders 2

Valves Overhead

Displacement 37.5 cu. in. (614cc)

Maximum Torque 32.5 lb-ft @ 2500 rpm

Ignition Transistor Controlled

Lubrication Full Pressure

Oil Filter Replaceable (standard)

RPM, idle (no load) 1350 - 1450

RPM, fast (no load) 3,850 - 4000

Cooling System Air

Air Cleaner Heavy Duty, Replaceable,

Dual Element

Battery 30-amp/hr, 365 cold cranking

amps

Alternator 12V-20amp Regulated

Headlights Two 37.5-watt Halogen

Wiring Automotive Style Fused Con-

trol System

Dimensions

Overall Length 110.4” (cm)

Overall Width 65.0” (cm)

Front-Tread Centers 50.0” (cm)

Rear-Tread Centers 52.0” (cm)

Overall Height 41” (cm)

Wheel Base 84.0” (cm)

Weight (including fuel/fluids) 1,552 lbs.

Ground Clearance

Under Transaxle 6.4” (cm)

Under Foot Platform 7.5”

Seating Capacity 2 persons

Seat Type High Back

Turn Clearance Circle 23.0 ft.

Towing Capacity 1,200 lb. (545.5 kg)

Payload Capacity* 1,400 lb. (636.4 kg)

*Includes 200 pound operator, 200 pound passenger, and

maximum bed capacity

NOTE: Some of these accessories may come already

equipped on your vehicle. If they are not equipped, they

may be ordered through your local Cub Cadet service

dealer.

Fuel System

Capacity 5.7 U.S. gal.

Fuel Gauge Located Under Seat

Low Fuel Indicator Dash Indicator Light

Cargo Box

Material 14-Gauge Steel

Attachment Rubber Isolated

Capacity

Volume 13.3 cu. ft.

Weight 1,000 lb.

Steering

Suspension

Brakes

Parking Brake

Rack & Pinion w/ AckermanType Geometry

6 Wheel Fully Independent w/

Coil Over Shocks

Wet Disk in Transaxle

Foot Operated

Transmission

Type Continuously Variable (CVT)

Lubricant Shell TTF-SB Oil

Capacity 189 oz (5.5 liters)

Differential Lock Standard, Hand Operated

Drive Chain No. 60 Industrial Roller Chain

Ground Speed 0-19 mph

Transaxle Fully enclosed, Oil Bath

Gear Selection Forward, Neutral, Reverse

Rear Axle Housing Welded Steel

18

Page 19

SECTION 8: TROUBLESHOOTING

Trouble Possible Cause(s)

Engine will not start Battery has low voltage.

Loose or corroded battery connections.

Fusible link is melted.

Spark plug wire is loose or disconnected.

Faulty spark plug or coil.

Fuel shut-off valve turned off.

No Fuel or improper fuel.

Plugged fuel filter.

Defective starter solenoid.

Open-circuit in wiring.

Engine is hard to

start

Engine misses under

load

Engine vapor locks Poor quality fuel or methanol.

Engine runs

unevenly

Engine overheats Air cleaner element missing or plugged.

Engine is cold.

Plugged fuel filter.

Carburetor not adjusted properly or

dirty.

Engine oil viscosity too heavy.

Spark plug is fouled.

Faulty spark plug or wire.

Loose or corroded electrical connec-

tions.

Stale or improper fuel.

Choke not being used or adjusted incor-

rectly.

Faulty spark plug.

Stale or dirty fuel.

Plugged fuel filter.

Faulty coil or wire.

Very hot weather conditions.

Fuel tank vent plugged.

Dirt in fuel filter.

Loose electrical connections.

Choke or throttle cable sticking.

Fuel line or fuel filter plugged.

Stale or dirty fuel.

Improper fuel.

Air cleaner element plugged.

Carburetor not adjusted correctly.

Spark plug is fouled.

Carburetor air intake tube plugged.

Engine oil low.

Engine operated too long at slow

engine speed.

Trouble Possible Cause(s)

Engine loses power Engine overheating.

Too much oil in engine.

Faulty spark plug.

Fuel supply being restricted.

Fuel filter plugged.

Fuel line pinched or kinked.

Fuel pump output not adjusted to specification.

Improper fuel.

Air cleaner element plugged.

Engine knocks Low engine speed.

Stale or low octane fuel.

Engine overloaded.

Drive chain jumps

change tooth;

repeated popping

noise.

Starter does not work Loose or corroded connections.

Starter cranks slowly Low battery output.

Entire electrical system does not work

Dead battery Shorted starter solenoid.

Battery light comes

on when engine is

running

Indicator lights do not

come on when key

switch is in START

position

Battery will not take a

charge

Insufficient Chain Tension (Too Loose)

Remove 1/2 link; if still loose, check for

suspension damage.

Contact authorized service dealer.

Low battery output.

Sulfated or worn out battery.

Faulty starter.

Sulfated or worn out battery.

Engine oil too heavy.

Loose or corroded connections.

Blown fuse.

Loose or corroded connections.

Sulfated or worn-out battery.

Key switch not turned to STOP position.

Sulfated or worn out battery.

Low engine speed.

Faulty voltage regulator.

Faulty battery.

Faulty alternator.

Grounded wire in circuit.

Fault bulb.

Faulty wiring.

Faulty sensor.

Dead battery.

Loose or corroded connections.

Sulfated or worn out battery.

Fluid level low.

NOTE: For repairs beyond minor adjustments or corrections, contact your nearest Cub Cadet service dealer or call

1-877-282-8684.

19

Page 20

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Cub Cadet

LLC with respect to new merchandise purchased and used in

the United States, its possessions and territories.

Cub Cadet LLC warrants this product against defects for a

period of two (2) years commencing on the date of original

purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or

workmanship. This limited warranty shall only apply if this

product has been operated and maintained in accordance

with the Operator’s Manual furnished with the product, and

has not been subject to misuse, abuse, commercial use,

neglect, accident, improper maintenance, alteration,

vandalism, theft, fire, water, or damage because of other peril

or natural disaster. Damage resulting from the installation or

use of any accessory or attachment not approved by Cub

Cadet LLC for use with the product(s) covered by this manual

will void your warranty as to any resulting damage.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear parts or

component failures will be covered on the product for a period

of 90 days regardless of cause. After 90 days, but within the

two year period, normal wear part failures will be covered

ONLY IF caused by defects in materials or workmanship of

OTHER component parts. Normal wear parts and

components include, but are not limited to: batteries, belts,

seats, and tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate the dealer in your area, check your

Yellow Pages, or contact Cub Cadet LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-877-282-8684, or log

on to our Web site at www.cubcadet.com.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

carry a separate manufacturer’s warranty. Refer to

applicable manufacturer’s warranty for terms and

conditions.

b. Routine maintenance items such as lubricants, filters,

tune-ups, brake adjustments, clutch adjustments, and

normal deterioration of the exterior finish due to use or

exposure.

c. Cub Cadet LLC does not extend any warranty for

products sold or exported outside of the United States,

its possessions and territories, except those sold

through Cub Cadet LLC’s authorized channels of

export distribution.

d. Parts that are not genuine Cub Cadet parts are not

covered by this warranty.

e. Service completed by someone other than an

authorized service dealer is not covered by this

warranty.

f. Transportation charges and service calls are not

covered.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, except as

mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product,

shall bind Cub Cadet LLC. During the period of the

warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. Cub

Cadet LLC shall not be liable for incidental or

consequential loss or damage including, without

limitation, expenses incurred for substitute or

replacement lawn care services or for rental expenses to

temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, or limitations on how

long an implied warranty lasts, so the above exclusions or

limitations may not apply to you.

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of safety features of the product shall void this warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser or to the person for whom it was

purchased as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Cub Cadet LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-877-282-8684

Loading...

Loading...