Page 1

Operator’s

Manual

45” Snowblower

Model 59A40051727

Cub Cadet Yanmar LLC

P.o. Box 368023

Cleveland, Ohio 44136-0019

PRINTED IN U.S.A.

76 9- 04 374A

(November 13, 2008)

Page 2

Table of Contents

Cub Cadet/YanmarLLC

CLEVELAND, OHIO 44136

Copy the model number here:

Copy the serial number here:

Model Number

Serial Number

xxxxxxxxxxxxx

xxxxxxxxxxxxx

P.O. Box 361052

www.cubcadetyanmar.com

Dealer Locator Phone Number: 877-282-5055

Content Page

Safe Operation Practices ................................................................................................................................ 3

Safety Labels found on the Snow Blower ....................................................................................................... 6

To the Dealer ................................................................................................................................................... 7

To the Owner ................................................................................................................................................... 7

Contents ......................................................................................................................................................... 8

Unpacking the Snow Blower ........................................................................................................................... 9

Installation ...................................................................................................................................................... 9

Maintenance .................................................................................................................................................... 13

Service............................................................................................................................................................. 15

Operation ........................................................................................................................................................ 15

Removing ........................................................................................................................................................ 16

Parts List .......................................................................................................................................................... 18

Finding Model Number

This Operator’s Manual is an important part of your new snow blower. It will help you assemble, prepare and maintain the unit for best

performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the information

from it in the space provided below. The information on the model plate is very important if you need help from our Customer

Support Department or an authorized dealer.

You can locate the model number by looking near the back right side of the auger housing. A sample model plate is shown below. For •

future reference, please copy the model number and the serial number of the equipment in the space below.

Calling Customer Support

If you have difficulty with this snow blower; have any questions regarding the controls, operation or maintenance of this equipment; or

desire additional information not found in this manual, contact your nearest authorized Cub Cadet Yanmar dealer. If you need assistance in

locating a dealer in your area, contact the Customer Dealer Referral Line.

Call 1-(877) 282-5055 to reach the Customer Dealer Referral Line. Please have your snow blower’s model number and serial number ready

when you call. See previous section to locate this information. For more details about your unit, visit our website at www.cubcadetyanmar.

com.

2

Page 3

Section 1: Safe operation practiceS

This symbol points out important safety instructions which, if not followed, could endanger the personal safety and /or property

of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury. When you see this symbol—HEED ITS WARNING.

This machine was built to be operated according to the rules for safe operation in this manual. As with any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This snow blower is capable of amputating

hands and feet and throwing objects. Failure to observe the following safety instructions could result in serious injury or death.

Training

Safety instructions are important! Read this manual and the 1.

tractor’s Operator’s Manual before operating this unit. Follow all

safety rules and safety label information. (Replacement labels

are available through your Cub Cadet Yanmar dealer.) Failure to

follow instructions or safety rules can result in serious injury or

death.

Never allow children to operate this equipment. Never allow 2.

adults to operate the equipment without the proper instruction

Know your controls and how to stop engine and attachment 3.

quickly in an emergency.

Operators must be instructed in and be capable of the safe 4.

operation of the equipment, its attachments and all controls.

Do not allow anyone to operate this equipment without proper

instructions.

Keep hands and body away from pressurized lines. Use paper 5.

or cardboard, not body parts to check for leaks. Wear safety

goggles. Hydraulic fluid under pressure can easily penetrate skin

and will cause serious injury or death.

Make sure that all operating and service personnel know that in 6.

the event hydraulic fluid penetrates skin, it must be surgically

removed as soon as possible by a doctor familiar with this

form of injury, or gangrene, serious injury or death will result.

CONTACT A PHYSICIAN IMMEDIATELY IF FLUID ENTERS SKIN OR

EYES. DO NOT DELAY.

Do not allow children or untrained persons to operate 7.

equipment.

Installation

During installation, the tractor engine should be off, the key 1.

removed and the parking brake engaged.

Do not disconnect hydraulic lines until attachments are 2.

removed or lowered to the ground and system pressure is

released by operating valve levers. Never operate any hydraulic

cylinders during any phase of the installation process.

After connecting hoses, check that all control lever positions 3.

function as instructed in this Operator’s Manual. Do not operate

until control lever and equipment movements are correct.

Preparation

Check that all hardware is tight and properly installed. Always 1.

tighten to torque specifications as instructed in this manual.

Air in hydraulic systems can cause erratic operation and allows 2.

loads or equipment components to drop unexpectedly.

Before operating or allowing anyone to approach the equipment, 3.

purge any air in the system by operating all hydraulic functions

several times after connecting equipment, connecting hoses, or

doing any hydraulic maintenance.

After connecting hoses, check that all control lever positions 4.

function as Instructed in this Operator’s Manual. Do not operate

until control lever and equipment movements are correct.

Protective sleeves must be over hydraulic hoses and securely 5.

fastened onto metal hose fittings as described in this manual.

Replace if damaged or if protective sleeve is not properly

positioned or secured.

Make sure all hydraulic hoses, fittings and valves are in good 6.

condition and not leaking before starting power unit or using

equipment. Check and route hoses carefully to prevent damage.

Hoses must not be twisted, bent sharply, kinked, frayed, pinched,

or come into contact with any moving parts. Operate moveable

components through full operational range to check clearances.

Replace any damaged hoses immediately.

Always wear relatively tight and belted clothing to avoid 7.

entanglement in moving parts. Wear sturdy, rough-soled work

shoes and protective equipment for eyes, hair, hands, hearing and

head.

Avoid injury or death. Never work under a raised attachment. 8.

Always lower attachment to the ground. Operate valve levers to

release any hydraulic pressure. If attachment obstructs tractor

maintenance, attachment must be removed from tractor.

Do not modify or alter or permit anyone else to modify or alter the 9.

equipment or any of its components in any way.

Your Cub Cadet Yanmar dealer can supply original equipment 10.

hydraulic accessories and repair parts. Substitute parts may not

meet original equipment specifications and may be dangerous.

Ensure implement is properly attached, adjusted and in good 11.

operating condition.

Power unit must be equipped with ROPS or ROPS CAB and seat 12.

belt. Keep seat belt securely fastened. Falling off power unit can

result in death from being run over or crushed. Keep foldable ROPS

systems in locked up position at all times.

Ensure all safety labels are installed. Replace if damaged. (See 13.

Safety Labels later in this section).

Ensure shields and guards are properly installed and in good 14.

condition. Replace if damaged.

Thrown objects can cause serious personal injury. Plan your snow 15.

throwing pattern to avoid discharge of material toward roads,

bystanders and the like.

3

Page 4

Keep bystanders, pets and children at least 75 feet from the 16.

machine while it is in operation. Stop machine if anyone enters the

area.

Exercise caution while operating tractor with this attachment, 17.

especially when traveling in reverse.

Thoroughly inspect the area where the equipment is to be used. 18.

Remove all door mats, sleds, boards, wires and any other foreign objects

which could be thrown by the auger/impeller.

Always wear safety glasses or eye shields during operation and while 19.

performing an adjustment or repair to protect your eyes. Thrown

objects which ricochet can cause serious injury to the eyes.

Do not operate without wearing adequate winter outer garments. 20.

Do not wear jewelry, long scarves or other loose clothing which could

become entangled in moving parts. Wear footwear which will improve

footing on slippery surfaces.

To avoid personal injury or property damage use extreme care in 21.

handling gasoline. Gasoline is extremely flammable and the vapors are

explosive. Serious personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin and change

clothes immediately.

Use only an approved gasoline container.a.

Never fill containers inside a vehicle or on a truck or trailer bed b.

with a plastic liner. Always place containers on the ground, away

from your vehicle, before filling.

When practical, remove gas-powered equipment from the truck c.

or trailer and refuel it on the ground. If this is not possible, then

refuel such equipment on a trailer with a portable container,

rather than from a gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank or d.

container opening at all times, until refueling is complete. Do not

use a nozzle lock-open device.

Extinguish all cigarettes, cigars, pipes and other sources of e.

ignition.

Never fuel machine indoors. f.

Never remove gas cap or add fuel while the engine is hot or g.

running.

Allow engine to cool at least two minutes before refueling.h.

Never over fill fuel tank. Fill tank to no more than ½ inch below i.

bottom of filler neck to provide space for fuel expansion.

Replace gasoline cap and tighten securely.j.

If gasoline is spilled, wipe it off the engine and equipment. Move k.

machine to another area. Wait 5 minutes before starting the

engine.

Never store the machine or fuel container inside where there l.

is an open flame, spark or pilot light (e.g. furnace, water heater,

space heater, clothes dryer etc.).

Allow machine to cool at least 5 minutes before storing.m.

14.

Adjust collector housing height to clear gravel or crushed rock surfaces. 15 .

Disengage all clutches and shif t into neutral before starting the engine. 16.

Never attempt to make any adjustments while engine is running, except 17.

where specifically recommended in the operator’s manual(s).

Let tractor engine and attachment adjust to outdoor temperature 18.

before starting to clear snow.

Operational

Do not allow other people in the area when operating, 1.

attaching, removing, assembling or servicing equipment;

particularly small children.

Improper use of a snow thrower can cause injury or death.2.

Do not put hands or feet near or under rotating parts, in the 3.

auger/impeller housing or discharge chute. Keep clear of the

discharge opening at all times. Contact with the rotating parts

can amputate hands and feet.

Never operate with a missing or damaged discharge chute. Keep 4.

all safety devices in place and working.

When cleaning, repairing or inspecting the snow thrower, 5.

make certain the collector/impeller and all moving parts have

stopped. Disengage the power take-off, lower attachment,

set the parking brake and stop engine before you leave the

operating position. . Do not run the engine indoors, except

when starting the engine and for transporting the snow thrower

in or out of the building. Open the outside doors; exhaust fumes

are dangerous.

Do not operate machine while under the influence of alcohol or 6.

drugs.

Exercise extreme caution when operating on or crossing gravel 7.

surfaces. Stay alert for hidden hazards or traffic.

Exercise caution when changing direction and while operating 8.

on slopes.

Do not clear snow across the face of slopes; go up and down. 9.

Exercise extreme caution when operating on slopes. Do not

attempt to clear steep slopes.

Plan your snow throwing pattern to avoid discharge towards 10.

windows, walls, cars etc. To avoid property damage or personal

injury caused by a ricochet.

Never direct discharge at children, bystanders and pets or allow 11.

anyone in front of the machine.

Do not overload machine capacity by attempting to clear snow 12.

at too fast of a rate.

Never operate this machine without good visibility or light.13.

Disengage power to the auger/impeller when transporting or 14.

not in use.

Never operate machine at high transport speeds on slippery 15.

surfaces. Look down and behind and use care when in reverse.

If the machine should start to vibrate abnormally, stop the 16.

engine, disengage the power take-off, lower the attachment

and set the parking brake. Inspect thoroughly for damage.

Repair any damage before starting and operating.

After striking a foreign object, stop the engine, remove the 17.

wire from the spark plug, thoroughly inspect the snow thrower

for any damage, and repair the damage before restarting and

operating the snow thrower.

Disengage the power take-off, lower attachment, set the 18.

parking brake and stop engine before you leave the operating

position. Wait until the auger/impeller comes to a complete

stop before unclogging the discharge chute, making any

adjustments, or inspections. Remove the key if leaving the

machine unattended.

Do not carry passengers.19.

If situations occur which are not covered in this manual, use care 20.

and good judgment. Contact your dealer or telephone 1-(877)

282-5055 for assistance and the name of your nearest servicing

dealer.

4

Page 5

Allow for snow thrower length and width when making turns.21.

Use only attachments and accessories approved by the 22.

manufacturers of the snow blower (such as wheel weights,

counter weights or cabs.)

Clearing a clogged discharge chute. Hand contact with the 23.

rotating impeller inside the discharge chute is the most common

cause of injury associated with snow throwers. Never use your

hand to clean out the discharge chute.

SHUT THE ENGINE OFF!a.

Wait 10 seconds to be sure the impeller blades have b.

stopped rotating.

Never operate the snow thrower without good visibility c.

or light.

Avoid Injury or Death from Rollover Accidents:

Move and turn tractor at low speeds.•

Watch for hidden hazards such as holes, ditches, and other •

obstructions which may cause tractor and snow thrower to tip

ove r.

Be extra careful when operating on a slope.•

Do not operate on steep slopes.•

Do not stop, start or change directions suddenly on slopes.•

Tractor must be equipped with a Roll-Over Protective Structure •

(ROPS) and seat belt.

Keep seat belt securely fastened and keep foldable ROPS •

systems in “locked up” position at all times.

Avoid Injury or Death from Falling Objects:

Before dismounting tractor or performing any service or •

maintenance, disengage the power to the implement, lower the

3-point hitch and all raised components to the ground, operate

valve lever to release any hydraulic pressure, stop engine, set

parking brake, remove key, and unfasten seat belt.

Shut off tractor, set park brake and remove key. Operate •

valve levers to release any hydraulic pressure. If snow thrower

obstructs tractor maintenance, snow thrower must be removed

from tractor.

Maintenance

Before dismounting tractor or performing any service or 1.

maintenance, disengage power to implement, lower the 3-point

hitch and all raised components to the ground, operate valve

levers to release any hydraulic pressure, stop engine, set parking

brake, remove key, and unfasten seat belt.

Adjustment of system relief pressure should be done by a 2.

qualified, experienced Cub Cadet Yanmar dealer. Incorrect

adjustment can result in system failures and serious personal

injury.

Always wear relatively tight and belted clothing to avoid 3.

entanglement in moving parts. Wear sturdy, rough-soled work

shoes and protective equipment for eyes, hair, hands, hearing

and head.

Do not allow other people in the area when operating, 4.

attaching, removing, assembling or servicing equipment.

Ensure implement is properly attached, adjusted and in 5.

good operating condition.

Keep all persons away from operator control area while 6.

performing adjustments, service or maintenance.

Tighten all bolts, nuts and screws securely. Check that all 7.

cotter pins are installed securely to ensure equipment is in

a safe condition before operating.

Ensure all safety labels are installed. Replace if damaged. 8.

(See Safety Labels later in this section)

Ensure shields and guards are properly installed and in 9.

good condition. Replace if damaged.

Do not disconnect hydraulic lines until all system pressure 10.

is relieved. Lower unit to ground, stop engine, and operate

all hydraulic control levers.

When servicing or replacing pins in cylinder ends, tines, 11.

etc., always use a brass drift and hammer. Failure to do so

could result in injury from flying metal fragments.

Check the shear bolts and other bolts at frequent intervals 12.

for proper tightness to be sure the equipment is in safe,

working condition.

Maintain and replace safety and instruction labels as 13.

necessar y.

Run the machine a few minutes after throwing snow to 14.

prevent freeze-up of the collector/impeller.

Storage

Block equipment securely for storage. Securely store

attachments to prevent falling. To help prevent injury caused by

a falling implement, always:

Detach on a hard, level surface.1.

Keep children and bystanders away2.

Engage the tractor’s parking brake before detaching from 3.

storage area.

Never store the machine with fuel in the fuel tank inside 4.

a building where ignition sources are present such as hot

water heaters, space heaters or clothes dryers. Allow the

engine to cool before storing in any enclosure.

Always refer to the operator’s manual for important details 5.

if the snow thrower is to be stored for an extended period

of time.

To provide necessary balance, frame must be equipped with

bucket or attachment before attaching or detaching from

tractor, or when snow blower is in stored position.

Do not loosen hydraulic fittings or hoses while snow 1.

blower is in stored position.

Do not climb or lean on equipment stored on stand.2.

WARNING! YOUR RESPONSIBILITY

Restrict the use of this attachment to persons who read, understand and follow the warnings and instructions in this manual, the tractor’s

Operator’s Manual and on the tractor and loader attachment. The safety labels found on the loader attachment are illustrated on the

following page.

5

Page 6

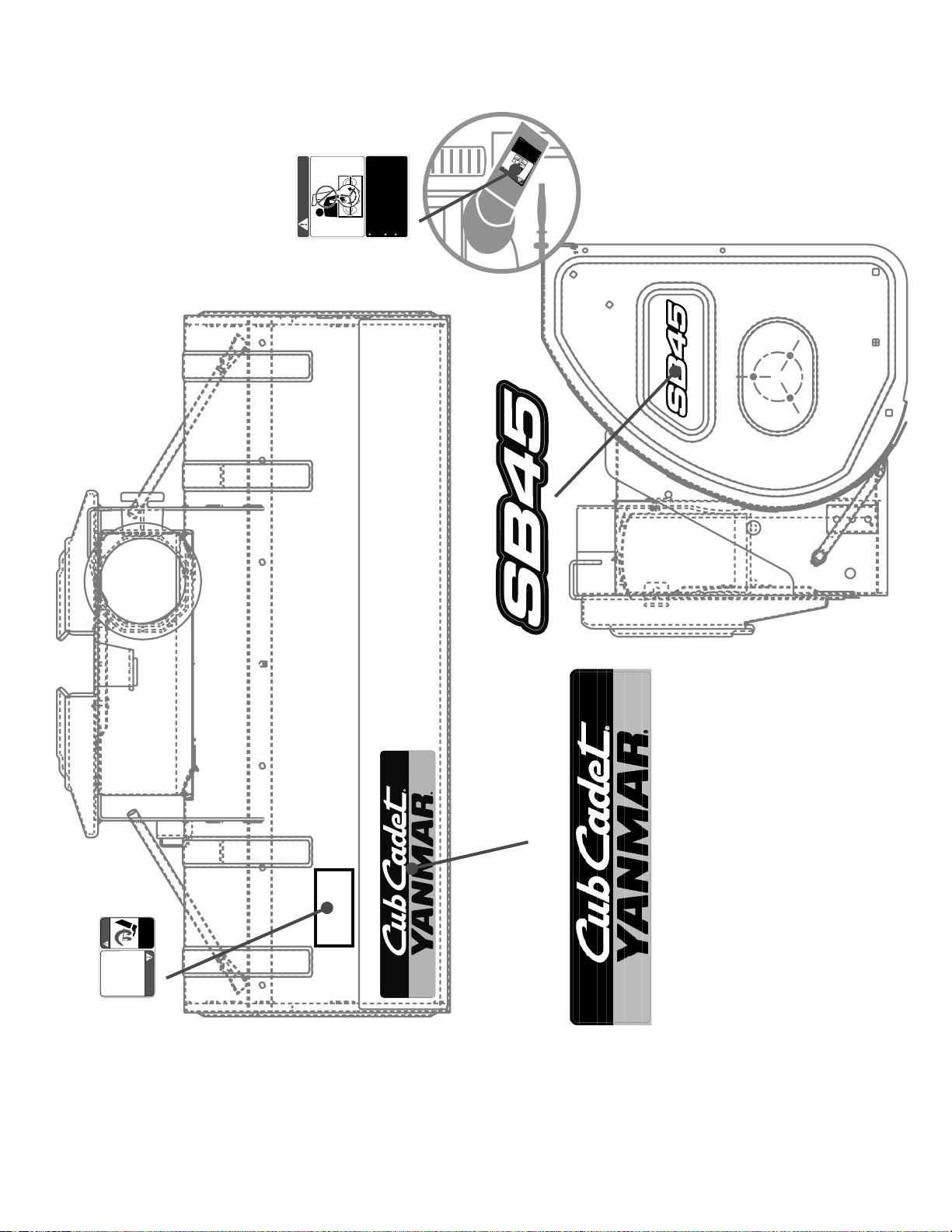

SECTION 2: LABELS FOUND ON SNOW BLOWER

DANGER

N

EVER

PUT

H

AN

D IN CHU

TE.

CO

NTAC

T WIT

H

ROTA

TING

P

ARTS

CAN AMPU

TAT

E FINGERS

AND

HA

NDS

.

DO

NOT

UN

CLOG DISCHARGE C

HUTE

WHILE

E

N

GINE IS R

UNNING

.

SHUT O

FF E

NGINE A N D R E M

AI

N ON

M

A

CHINE U NT IL

ALL MOVIN

G

PA

RTS

HAV

E

STOPPED BEFORE UNC

LOGGING.

777S30515

Cut Foot Pictorial Facing

Away From Operator

(QTY 2) 777D12773

DAN GER

DANGER

AVOID INJURY FROM

ROTATING AUGER - KEEP HANDS, FEET

AND CLOTHING AWAY.

KEEP AWAY FROM ROTATING IMPELLER AND AUGER. CONTACT WITH IMPELLE R

OR AUGER CAN AMPUTATE HANDS AND FEET.

DISENGAGE PTO, STOP ENG INE, SET PARK

BRAKE, AND REMAIN ON MA CHINE UNTIL

ALL MOVING PARTS HAVE STOPPED BEFORE

UNCLOGGING OR SERVI CING.

TO AVOID THROWN OBJECTS I NJURIES,

NEVER DIRECT DISCHARGE AT BYSTANDERS.

USE EXTRA CAUTION WHEN OPERATING ON

GRAVEL SU RFACE S.

READ OPERATOR'S MANUAL

.

FOR BALLAST REQUIREMENTS REFER TO

YOUR ATTACHMENT MANUAL.

1.

2.3.4.

5.

777D12791

Place On To p Of Auger Housing 3.5” X 15.75”

777S30524

On Edge Of Chute Read

From Chute Position

DANGER

NEVER PUT HAND IN CHUTE. CONTACT WITH

ROTATING PARTS CAN AMPUTATE FINGERS

AND HANDS.

DO NOT UNCLOG DISCHARGE CHUTE WHILE

ENGINE I S RUNNI NG.

SHU T OF F E NGI NE AND RE MAI N O N

MACHI NE U NTIL ALL MOVI NG PA RTS

HAVE STOPPED BEFOR E UNCLOGGIN G.

6

Page 7

SECTION 3: TO THE DEALER

The initial assembly and proper installation of this attachment should be completed by the Cub Cadet Yanmar dealer. Read the instructions and safety precautions found in this manual carefully.

SECTION 4: TO THE OWNER

This Operator’s Manual is an important part of your new 45” Snow Blower assembly. Contained in this manual are instructions covering installation, safe operation, and maintenance of the Model 59A40051727 snow blower assembly. Please read and understand what it says.

The Model 59A40051727 45” Snow Blower assembly is designed for use ONLY with certain Cub Cadet Yanmar tractor models. It will NOT

fit nor operate safely or properly on or with any other tractor.

References to LEFT and RIGHT indicate the left and right sides of the tractor when facing forward in the operator’s position. Reference to

the FRONT indicates the grille end; to the REAR the drawbar end.

7

Page 8

SECTION 5: CONTENTS

10

11

12

13

15

18

17

16

14

19

20

5

6

7

8

1

2

3

4

9

The snow blower attachment components are listed below along with their part numbers. Assemblies are made up of more than one part

and do not have a part number. Before beginning installation, lay all components out on a flat surface to assure everything is present.

Figure 1

1. Snow Blower Assembly N/A 1 pc

2. Chute Crank N/A 1 pc

3/4. Drive Shaft & Front Hitch PTO 819-010225 2 pc

5. Link Connecting Chain 713-04069 1 pc

6. Link Connecting Chain 713-04072 1 pc

7. Cotter Pin 714-04040 2 pc

8. Shear Pin, .375 x .181 738-04155 2 pc

(5-8 packaged with manual)

9. Chute Assembly N/A 1 pc

10. Chute Clamp 703-4080 1 pc

11. Chute Clamp Spacer 703-4079 1 pc

12. Carriage Screw, 1/4-20 x 1.00 710-0932 2 pc

13. Hex Lock Nut, 1/4-20 712-0324 2 pc

14. Flange Lock Nut, 3/8-16 712-04065 2 pc

15. Flange lock Nut, 5/16-18 712-04063 4 pc

16. Hex Screw, 5/16-18 x 1.00 710-0376 2 pc

17. Carriage Bolt, 5/16-18 x .750 710-0451 2 pc

18. Hex Screw, 3/8-16 x 3.50 710-3085 2 pc

19. Spacer, 3/8 ID x 1.0 x 2.25 750-05176 2 pc

20. Bell Washer, .340 x .872 x .060 736-0242 2 pc

(10-20 packaged in screw pack)

8

Page 9

SECTION 6: UNPACKING

Stub Shaft

Hex Screw

Hex Lock Nut

Stub Shaft

Drive Shaft

Unpacking the Snow Blower

Move the tractor and snow blower to a firm flat area large enough

to accommodate both. Allow enough room to install the snow

blower on the front of the tractor.

Carefully open the shipping container. Cut any ties or bands •

securing the snow blower, chute assembly, drive shaft, chute

crank and front hitch PTO to the shipping pallet. Remove the

snowblower, chute assembly, drive shaft, chute crank and

front hitch PTO from the shipping container.

Remove the hardware from the manual bag. Check that the •

parts in the manual bag and the parts that came attached to

the crate are correct by referring to Figure 1 and the list on

page 3.

SECTION 7: INSTALLATION

Installing the Snow Blower

If your front hitch is equipped with the angle kit, the hitch angle

cylinders will need to be replaced. Follow the instructions below to

replace the cylinders.

WARNING! Do not disconnect hydraulic lines until

all system pressure is relieved. Lower the

attachment to ground, stop engine, and operate

all hydraulic control levers

Disconnect the angle kit hoses from the tractor hydraulic 1.

couplers, and slide the hoses out of the protective sleeve.

From either side of the tractor, remove the hex lock nuts, hex 2.

screws, washers, and spacers securing the cylinder to the

hitch ‘A’ frame and mounting bracket. Reassembly and Insert

the hardware in the appropriate cylinder ends and loosely

fasten with the hex lock nut to store the cylinder assembly.

Move to the other side the tractor and repeat the above step 3.

to remove the cylinder on that side of the tractor.

Remove the cotter pins and clevis pins from the fixed length 4.

hitch arms.

From either side of the tractor, align the shorter hub of the 5.

hitch arm with mounting bracket at the bottom of the hitch

bracket, and insert the shorter clevis pin. Secure with the

cotter pin.

Raise the longer hub end of the hitch arm up between the 6.

mounting brackets on the bottom of the ‘A’ frame. Insert the

longer clevis pin and secure with the cotter pin.

Move to the other side of the tractor and repeat the previous 7.

two steps to install the fixed length hitch arm on that side of

the tractor.

The front hitch assembly is required to mount the snow blower on

the tractor. If the front hitch is installed it has to be removed for

proper installation.

Remove the front hitch as follows:

Disconnect the hitch hydraulic hoses from the hydraulic 8.

outlets of the tractor. Install the protective caps on the hitch

hoses, and remove the hoses from hose support rods. Install

the protective plugs in the hydraulic outlets.

Remove the hex cap screws and hex lock nuts securing the 9.

hitch mounting brackets to the tractor frame, and carefully

lower the hitch assembly from the tractor.

Connect the stub shaft to the backside of the ‘A’ frame 10.

bracket as shown in Figure 2. Mount the stub shaft using

the hex screws and hex lock nuts shown in Figure 2. When

mounting the stub shaft be sure that the grease fitting is

facing downward.

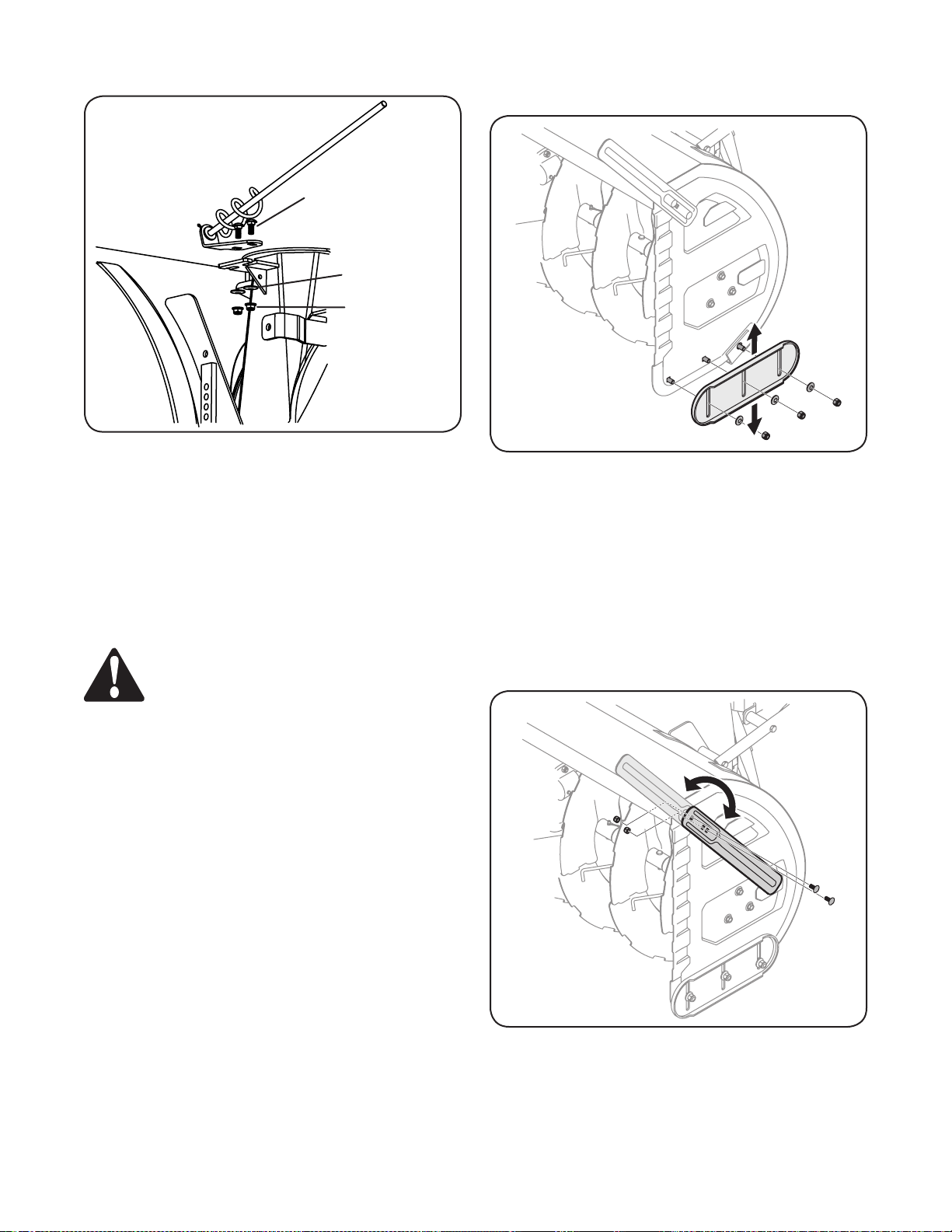

Figure 2

Re-install the front hitch with the stub shaft in place.11.

Mount the drive shaft the stub shaft as shown in Figure 3.12.

Figure 3

9

Page 10

Align the locking collar of the drive shaft with the Mid - PTO 13.

Front Hitch

“A” Bracket

Snow Blower

Mounting Frame

Jack Stand

Clevis Pin

Click Pin

Skid Shoe

Mid-PTO

Shaft

Locking Collar

Drive Shaft

shaft and slide the drive shaft fully onto the PTO shaft. If

necessary, compress the locking collar of the drive shaft to

ease connecting the shaft. See Figure 4. The intermediate

drive shaft must be securely connected to the Mid PTO shaft

at the lower/front of the tractor’s transmission housing.

Remove the clevis pin and click pin from the jack stand, move 17.

the jack into the third hole and replace the clevis pin and click

pin. Repeat on the other side. See Figure 6.

Figure 6

Figure 4

WARNING! Never position any part of your body

beneath tractor implements held in the raised

position only by the tractor’s hydraulic system. A

sudden loss of pressure could cause the implement to fall and could result in severe injury.

Pull the drive shaft to make sure it is locked onto the PTO 14.

shaft. The drive shaft must not pull off of the Mid PTO shaft.

NOTE: It may be necessary to turn the PTO slightly to align the

splines of the drive shaft with those of the PTO shaft.

Place the snow blower on a level surface.15.

Lower the skid shoes into the lowest operating position. See 16.

Figure 5. See the Adjustments section for how to adjust skid

shoes.

Figure 5

Start the tractor. Using the implement control lever, lower the 18.

front hitch ‘A’ frame.

Slowly driving the tractor forward, align the top of the front 19.

hitch ‘A’ frame with the side channels of the snow blower

mounting frame. Refer to Figure 7.

Figure 7

Using the implement control lever, slowly raise the front hitch 20.

while making sure the hitch ‘A’ frame engages the channels

of the snow blower mounting frame. Refer to Figure 7.

As you continue to raise the front hitch, the ramp at the top of 21.

the ‘A’ frame should push the snow blower hitch pin outward,

allowing the ‘A’ frame to fully engage the snow blower mounting frame and also aligning the hitch pin with the hole in the

front of the ‘A’ frame. The compression spring on the hitch pin

should push the pin through the ‘A’ frame hole to secure the

snow blower to the front hitch. See Figure 7.

10

Page 11

Raise the front hitch so that the snow blower is off the 22.

Stub Shaft

Drive Shaft

‘A’ Frame not show for clarity

Chute

Spacer

Clamp

Hex Screw

Chute Base

Hex Lock Nut

Mounting Holes

Bottom of Chute

Support Tube

Chute Crank

Hex Screws

Hex Bolts

ground; then stop the tractor engine and engage the parking

brake.

Check to verify that the snow blower pin is fully seated into 23.

the front hole of the ‘A’ frame. If not, push the pin rearward to

fully engage the ‘A’ frame.

Lower the blower to the ground then mount the snow blower 24.

drive shaft to the stub shaft by sliding the pulling the locking

collar back and sliding the PTO on to the stub shaft until the

PTO locks.. See Figure 8.

Mounting the Chute

NOTE: Grease the chute base before attaching. See Figure 9.

The chute was shipped with two of the chute clamps attached. To

attach the chute, place it onto the chute base and secure it with

the one remaining chute clamp using the clamp, spacer,

carriage screw and

1.0 0

See Figure 9.

1/4-20

hex lock nut from the screw pack.

1/4-20 x

Figure 8

WARNING! Do not attempt to connect the drive

shaft when the tractor engine is running. Stop the

tractor engine, disengage all PTO controls, engage the parking brake, and wait for all movement

to stop before connecting the snow blower drive

shaft.

Figure 9

Mounting the Chute Crank

To mount the chute crank you will need to two 3/8-16 x 3.50 Hex

Screws and two 5/16-18 x .1.00 hex bolts.

Mount the chute crank to the side of the chute base with the 1.

hex screws. See Figure 10.

Figure 10

Mount the support tube on the horizontal bracket below the 2.

chute base using the 5/16-18 x 1.00 bolts and flange nuts.

See Figure 10.

11

Page 12

Secure the crank assembly as shown in Figure 11 using two 3.

Flange Lock Nuts

Bell Washers

Carriage Bolts

5/16-18 x .750 carriage bolts, two .340 x .872 x .060 bell

washers and 5/16-18 flange lock nuts.

Figure 11

To adjust the skid shoes

Adjust skid shoes by loosening the six (three on each side) 1.

hex nuts, washers, and carriage bolts securing the skid

shoes to the auger housing. Refer to Figure 12.

Figure 12

Adjusting Chute Crank

It may be necessary to loosen or tighten the crank mounting

bracket prior to and after operation. To loosen the crank mounting

bracket, loosen the carriage bolts that secure the chute crank

mounting bracket to the snow blower. See Figure 11. To tighten the

clamps, tighten the carriage bolts.

Adjusting the skid shoes

Caution: It is not recommended that you

operate this snow blower on gravel as it

can easily pick up and throw loose gravel,

causing personal injury or damage to the

snow blower and surrounding property.

For close snow removal on a smooth surface, adjust the skid

shoes so that the shave plate on the bottom of the auger housing

is just off the ground.

Adjust the skid shoes to a lower position to raise the shave plate

off the ground when clearing uneven areas, such as a ribbon type

driveway or a gravel driveway

NOTE: If you choose to operate the snow blower

on a gravel surface, keep the skid shoes in position for maximum clearance between the ground

and the shave plate.

While observing the distance between the shave plate and 2.

the ground, adjust the skid shoes up or down to achieve the

desired shave plate height. See Figure 12.

Make certain the entire bottom surface of the skid shoes is 3.

against the ground to avoid uneven wear on the skid shoes;

then tighten nuts and bolts securely.

Drift Cutter

The drift cutter can be placed in the up or down position. See

Figure 13.

Figure 13

12

Page 13

SECTION 8: MAINTENANCE

Spacers

Grease Fitting

Shear Pins

Cotter Pins

Lube Chute Base

Roller Chain

Hex Nuts

Maintenance

WARNING! Before lubricating, repairing,

or inspecting, place tractor on a firm and

level surface. Place the PTO in the disengaged (OFF) position, set the parking

brake, shut engine off, and remove key to

prevent unintended starting.

Chute Directional Control

The base of the discharge chute should be lubed with lithium

grease or WD-40® once a season. See Figure 14. Spraying the

inside of the chute with lubricant is also recommended.

Auger Shaft

At least once a season, remove the shear pins and cotter pins on

the auger shaft. Oil or spray lubricant inside and on the plastic

bearings on the shaft, near the holes where the shear bolts were

removed before reattaching them and grease the fitting on the

auger gear assembly. See Figure 15.

Figure 14

PTO Lubrication

Lubricate all pivot points on the drive shaft, stub shaft and blower

drive shaft.

Figure 15

Roller Chain

The roller chain transfers power from the stub shaft to the auger

gear assembly and should be lubricated at least once a season.

To Lubricate the chain:

Remove the hex nuts that secure the chain cover. See Figure 1.

16.

Figure 16

Lubricate the chain with Cub Cadet Chain Lube.2.

Replace the cover and secure with the previously removed 3.

hex nuts.

13

Page 14

SECTION 9: SERVICE

Middle Hex Nut

Bottom Hex Nut

Top Hex Nut

Master Link

Hex Screw

Hex Bolt

Service

Shave Plate and Skid Shoes

The shave plate and skid shoes on the bottom of the snow blower

are subject to wear. They should be checked periodically and

replaced or flipped when necessary.

NOTE: The skid shoes on this machine have two wear edges.

When one side wears out, they can be rotated 180° to use the other

edge.

To Replace skid shoes:

Remove the six carriage bolts, hex nuts, and bell washers 1.

that secure the two skid shoes to the sides of the auger

housing. Refer to Figure 17.

Replacing or adjusting the chain

To adjust the tension on the roller chain, proceed as follows:

Loosen the three hex bolts on each side of the box. See 1.

Figure 18.

Figure 18

Figure 17

Position the new skid shoes and secure with the carriage 2.

bolts, bell washers, and hex nuts. Make certain the skid

shoes are adjusted to be level. Refer to Figure 17.

To replace shave plate:

Remove the hex nuts, bell washers, and carriage bolts that 1.

secure the shave plate to the bottom of the snow blower

housing. See Figure 17.

Remove the rear most hex nut, bell washer, and carriage 2.

bolt securing the back of each skid shoe to the sides of the

housing. Loosen the remaining hex nuts securing the skid

shoes.

Slide the shave plate out of the off-set slot at the bottom 3.

of the housing, and from between the skid shoes and side

panels of the housing.

With the mounting holes facing toward the back of the unit, 4.

slide the new shave plate into position and secure with the

fasteners removed previously.

To tighten the roller chain, loosen the top and middle hex 2.

nuts. Then while holding the bottom hex nut loosen the hex

screw. See Figure 18.

Once the desired tension is reached, re-tighten the top and 3.

middle hex nuts.

To loosen the roller chain, loosen the top and middle hex 4.

nuts. Then while holding the bottom hex nut tighten the hex

screw.

Once the desired tension is reached, re-tighten the top and 5.

middle hex nuts.

To replace the roller chain, master link or add links proceed as

follows:

Loosen the chain as instructed in step 3 above.1.

Insert a flat-head screwdriver into the master link and twist it 2.

to open up the link.

When the chain is off you can add new links or replace any 3.

damaged links.

NOTE: A replacement master link, and 1/2 link is packaged with

your manual.

14

Page 15

SECTION 10: OPERATION

Lower

Hitch

Raise

Hitch

Hitch

Float

Angle

Right

Angle

Left

Pull up Implement

Control Lock Lever

Snow Blower

Float

Right

Raise

Left

Lower

Operating the Snow Blower

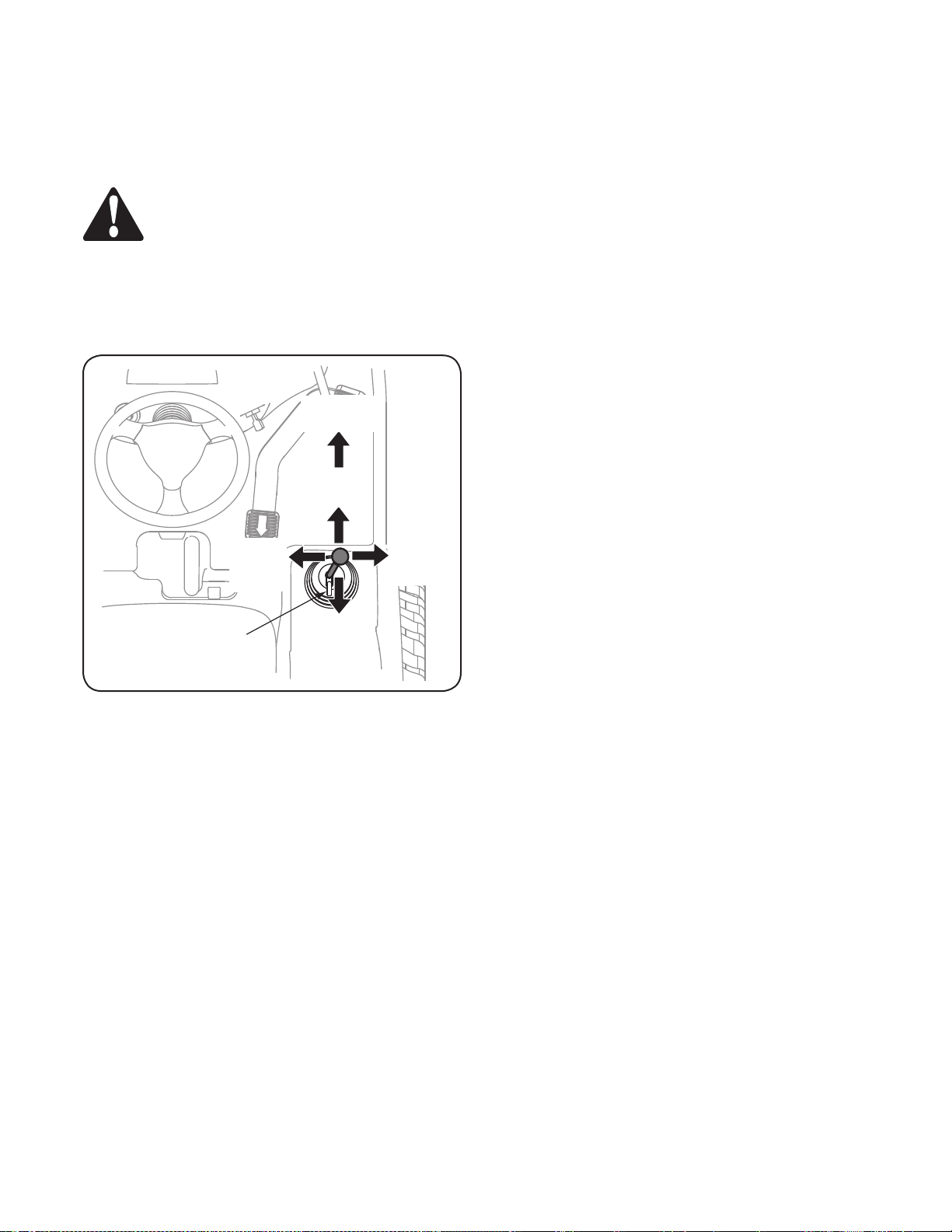

The tractor’s implement control lever is used to control the movements of the front hitch.

WARNING: Always comply with all Safety

Rules before starting the tractor.

Engaging the Snow Blower

Sit on the operator’s seat.1.

Lock the parking brake.2.

Move foot pedal to the neutral position.3.

Start the engine.4.

Adjust the engine speed to 1500 rpm or lower.5.

Position PTO selector into Mid PTO position. Pull up on the 6.

PTO switch to engage the PTO.

Adjust the throttle control lever to run the implement at an 7.

intended speed.

Start the tractor’s engine and operate at a low/safe RPM.

Pull the tractor’s implement control lock lever upward to •

the unlock position. See Figure 19 and refer to the tractor

Operator’s Manual.

Figure 19

Disengaging the Snow Blower

(When the operator is seated on the operator’s seat)

Run the engine at a low speed.1.

Push down on the PTO switch.2.

NOTE: Remember that while the operator is not seated on the

operator’s seat, the PTO will disengage. When the operator attempts to engage the PTO while not seated on the operator’s seat,

the safety interlock system will engage and the engine will stop: as

a result, all the moving components will stop moving.

Pull the lever rearward to raise the snow blower. Push •

the lever forward to lower the snow blower. If the optional

hydraulic chute rotation kit is installed, pull the lever to the left

to rotate the chute to the left and push the lever to the right to

rotate the chute to the right. Refer to Figure 19.

Push the lever fully forward until it locks in the detent position •

to place the snow blower in the float position. This position

relieves hydraulic pressure to the front hitch lift cylinder,

which lowers the snow blower to the ground and allows it to

follow the contour of the ground. Use the skid shoes to adjust

the snow blower height in this position.

NOTE: The blower should be operated in the float position to

prevent excessive wear to the skid shoes.

15

Page 16

Chute Crank

Chute Clean-Out Tool

To turn the chute to the right, rotate the chute crank clockwise. To

turn the chute to the left, rotate the chute crank counter-clockwise.

Chute Clean-Out Tool

WARNING! Never use your hands to clear a

clogged chute assembly. Shut off engine and

remain behind handles until all moving parts

have stopped before unclogging.

The chute clean-out tool is conveniently fastened to the rear of the

auger housing with a mounting clip. See Figure 20. Should snow

and ice become lodged in the chute assembly during operation,

proceed as follows to safely clean the chute assembly and chute

opening:

SECTION 11: REMOVING

Removing the Snow Blower

If necessary, adjust the skid shoes so that the snow blower 1.

will stand upright in its operating position.

Select a firm and level surface to store the snow blower. 2.

Using the implement control lever, lower the snow blower

until just contacting the ground. Stop the tractor engine and

engage the parking brake before dismounting.

Remove the clevis pin and click pin from the jack stand, move 3.

the jack into the appropriate hole that will make the snow

blower level then replace the clevis pin and click pin. See

Figure 3.

Pull the hitch pin forward to withdraw it from the hitch ‘A’ 4.

frame hole. Rotate the hitch pin so that does not align with

the hole in the hitch A frame. Refer to Figure 7.

Disconnect the snow blower shaft. 5.

Start the tractor and lower the front hitch ‘A’ frame so that 6.

it disengages the snow blower mounting frame. Back the

tractor away from the snow blower. Refer to Figure 7.

Reposition the hitch pin to engage the holes in the snow 7.

blower mounting frame.

Turn off the PTO.1.

Stop the tractor and engage the parking break.2.

Remove the clean-out tool from the clip which secures it to 3.

the rear of the auger housing.

Use the shovel-shaped end of the clean-out tool to dislodge 4.

and scoop any snow and ice which has formed in and near

the chute assembly.

Re-fasten the clean-out tool to the mounting clip on the rear 5.

of the auger housing, reinsert the ignition key and start the

tractor engine.

Figure 20

16

Page 17

NOTES PAGE

17

Page 18

SECTION 12: PARTS LIST

Snow Blower

18

Page 19

Ref.

Part

No.

Number Description Qt y.

1. 05244B Bearing Housing 10

2. 603-04598 Housing Assembly 1

3. 603-04600 Chute Assembly 1

4. 603-04673 Bracket Assembly 1

5. 603-04689 Chain Cover 1

6. 618-04800 Auger Gear Assembly 1

7. 684-0090B Impeler Assembly 1

8. 684-04056 Chute Cleanout tool 1

9. 684-04329 Spiral Assembly, RH 3

10. 684-04330 Spiral Assembly, LH 3

11. 703-05048 Rubber Chute Bracket 1

12. 703-06972 Chute Deflector 1

13. 703-07066 Stand Bracket 2

14. 703-07168 Spacer Plate 2

15. 703-4079 Chute Clamp Spacer 3

16. 703-4080 Chute Clamp 3

17. 710 -0376 Hex Screw, 5/16-18 x 1.00 2

18. 710-0451 Carriage Bolt, 5/16-18 x .750 13

19. 710 -0514 Hex Screw, 3/8-16 x 1.00 6

20. 710-0726 Hx. Wshr. Screw, 5/16-20 x .750 1

21. 710 -093 2 Carriage Screw, 1/4-20 x 1.00 6

22. 710-0946 Machine Screw, 1/4-20 x .625 3

23. 710 -1207 Hex Screw, 5/16-18 x 3.50 2

24. 710-3008 Hex Screw, 5/16-18 x .75 1

25. 710- 3015 Hex Screw, 1/4-20 x .75 2

26. 710-3038 Hex Screw, 5/16-18 x .875 7

2 7. 710-3085 Hex Screw, 3/8-16 x 3.50 2

28. 710-3105 Carriage Bolt, 5/16-18 x .875 2

29. 710-316 8 Carriage Bolt, 3/8-16 x 1.00 2

30. 710 -317 8 Carriage Bolt, 3/8-16 x .75 4

31. 710 -3180 Hex Screw, 5/16-18 x 1.75 1

32. 710- 3251 Hex Screw, 5/16-18 x 1.75 1

33. 7 11- 017 3 Clevis Pin 2

34. 711- 0510 7 Input Shaft 1

35. 712- 0130 Hex Lock Nut, 3/8-16 6

36. 712-0298 Jam Nut, 1/4-20 2

37. 712-0 324 Hex Lock Nut, 1/4-20 6

38. 712-04063 Flange Lock Nut, 5/16-18 31

39. 712-04064 Flange Lock Nut, 1/4-20 7

40. 712- 04065 Flange Lock Nut, 3/8-16 2

41. 712-3010 Hex Nut, 5/16-18 8

42. 713- 04066 Sprocket 1

43. 713- 04067 Sprocket 1

44. 713-04068 Roller Chain 1

45. 713-040 69 Chain Connecting Link 2

46. 713- 04072 Chain Half Link 1

47. 714- 0126 Hi-Pro Key 1

48. 714- 0135 Woodruff Key 1

Ref.

Part

No.

Number Description Qt y.

49. 714 -0145 Click Pin 2

50. 714-04040 Bow-Tie Cotter Pin 8

51. 714 -04 059 Hi-Pro Key 1

52. 714-0507 Cotter Pin 1

53. 7 15 -0 118 Spirol Pin, 5/16-1.75 2

54. 715-0129 Spirol Pin, .125 x .812 4

55. 715-0138 Roll Pin, 1/8 x .63 1

56. 715-30 03 Spirol Pin 1

57. 716 -0102 Snap Ring 2

58. 717-04 641 Drive Shaft 1

59. 720-0201A Chute Crank Knob 1

60. 72 0 -0241 Wing Nut 2

61. 726- 0100 Push Cap 1

63. 731-05163 Spcer., 1.50 OD x 1.00 ID x 1.00 12

64. 732-3091 Compression Spring, .57 x 2.09 1

65. 735-04154 Rubber Deflector 1

66. 736 -0105 Washer, .401 x .870 x .063 6

6 7. 736 -0123 Flat Washer, .349 x 1.16 x .064 2

68. 736- 014 0 Flat Washer, .385 x .62 x .063 1

69. 736-0242 Bell Washer, .340 x .872 x .060 8

70. 736-0250 Flat Washer, 1.00 x 1.75 x .107 4

71. 736-0270 Bell Washer, .265 x .75 x .062 2

72. 736-0343 Flat Washer, .330 x 1.25 x .120 1

73. 736-0451 Saddle Wshr., .320 x.93 x .060 3

74. 736-3072 Flat Washer, .36 x .93 x .110 6

75. 738-0255 Shoulder Screw, .375 x .181 4

76. 738 -04155 Shear Pin, .25 x 1.75 8

7 7. 73 8- 04159 Spiral Axle 1

78. 741-04024 Self-Aligning Bearing 1

79. 741- 04132A Self-Aligning Bearing 2

80. 741- 0475 Plastic Bushing 3

81. 741- 04 94 Flnge. Bshg., 1.05 ID x 1.16 OD 12

82. 747-04188 Chute Crank Rod 1

83. 747-0481A Eye Bolt, 5/16-18 x 3.0 2

84. 747- 09 03 Chute Crank Rod, .375 x 36.75 1

85. 747- 3427 Front Hitch Pin 1

86. 749-04549 Crank Support Tube 1

87. 749-04552 Support Tube 1

88. 750-04020 Spacer, 1.004 x 1.375 x .25 2

89. 75 0- 05176 Spacer, 3/8 ID x 1.0 x 2.25 2

90. 784-5076 Gear Housing Support Bracket 1

91. 784-5123 Chute Crank Bracket 1

92. 784-5149 Bracket Assembly Joint 2

93. 784-5401 Chute Crank Assembly 1

94. 784-5696B Shave Plate 1

95. 784-5697 Skid Shoe 2

96. 784-5710 Support Plate 1

97. 790-00181 Blade Guide 2

19

Page 20

6

2

5

10

7

11

1

4

3

9

8

PTO/Drive System

Ref.

Part

No.

Number Description Qt y.

1. 710- 0376 Hex Screw, 5/16-18 x 1.00 2

2. 711 -16 23 Spline Shaft 1

3. 712-0429 Hex Lock Nut, 5/16-18 2

4. 716-0102 Shaft Snap Ring 2

5. 716-018 8 Retainer Ring 1

6. 717- 046 42 Drive Shaft 1

7. 719 -3172 Shaft 1

8. 721-0462 Grease Seal, 1.31 x 1.00 1

9. 737-3000 Lube Fitting 1

10. 741- 0131 Ball Bearing, 1.00 ID x 2.00 OD 1

11. 741-03 63 Bearing, 1.000 x 1.3125 x .7500 1

20

Loading...

Loading...