Page 1

Service Manual

Domestic Series 5000 Compact Tractor

NOTE: These materials are prepared for use by trained technicians who are experienced in the service and repair of equipment of the

kind described in this publication, and are not intended for use by untrained or inexperienced individuals. Such individuals should seek

the assistance of an authorized service technician or dealer. Read, understand, and follow all directions when working on this equipment. This includes the contents of the Operators Manual, which came with your equipment. No liability can be accepted for any inaccuracies or omission in this publication, although every care has been take to make it as complete and accurate as possible. The right

is reserved to make changes at any time to this document without prior notice and without incurring an obligation to make such

changes to previously published documents. All information contained in this publication is based on product information available at

the time of publication. Photographs and illustrations used in this publication are for reference use only and may not depict actual

model and component parts.

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-01633

12/2004

Page 2

Page 3

TABLE OF CONTENTS

CHAPTER 1 - Hydraulics

Standard Hydraulic Systems on the Domestic Series 5000: Orientation ......................................1

Hydrostatic Drive: Basic Operation ...............................................................................................4

External Checks ............................................................................................................................6

Best Practices: Hydraulic Systems ................................................................................................8

Flow and Pressure Tests: Hydrostatic Drive .................................................................................8

Auxiliary Pump ............................................................................................................................12

Steering Pump and Cylinder .......................................................................................................14

Hydraulic Lift Cylinder and Control Valve ....................................................................................18

Loader Valve ...............................................................................................................................22

Component Breakdown: Auxiliary Pump .....................................................................................25

Component Breakdown: Steering Unit ........................................................................................26

CHAPTER 2 - MFD

About This Section: .....................................................................................................................31

Identifying the MFD: ....................................................................................................................31

Domestic Series 5000 MFD ........................................................................................................31

MFD Removal: Preparation .........................................................................................................33

Removal ......................................................................................................................................34

MFD Installation ..........................................................................................................................36

In-Frame Repairs: Drop Axle Service ..........................................................................................37

In Frame Repairs: Drop Axle Cover ............................................................................................38

In-Frame Repairs: Drop-Axle Removal .......................................................................................40

Bench Repairs: Drop Axle and Kingpin Housing Assemblies .....................................................42

Bench Repair: Axles and Differential. ..........................................................................................46

Torque Specifications ..................................................................................................................60

CHAPTER 3 - Rear Axle

Reason for Change: ....................................................................................................................61

Preparation: .................................................................................................................................61

Axle Assembly .............................................................................................................................63

Install the New Axle. ....................................................................................................................64

CHAPTER 4 - Deck Adapter Kit - 190-830-100 65

About This Section: ..................................................................................................................... 65

Preparation and Brackets: ...........................................................................................................65

Lift Shaft and Arms: .....................................................................................................................66

Hanger to Deck Connections ......................................................................................................67

Mating the Deck to the Tractor ....................................................................................................68

CHAPTER 5 - Dash and Steering Pump

About This Section: .....................................................................................................................71

Dash Panel Removal ...................................................................................................................71

The Dash Panel ...........................................................................................................................75

Steering Shaft and Pump: Sauer .................................................................................................77

Steering Shaft and Pump: Ross ..................................................................................................79

I

Page 4

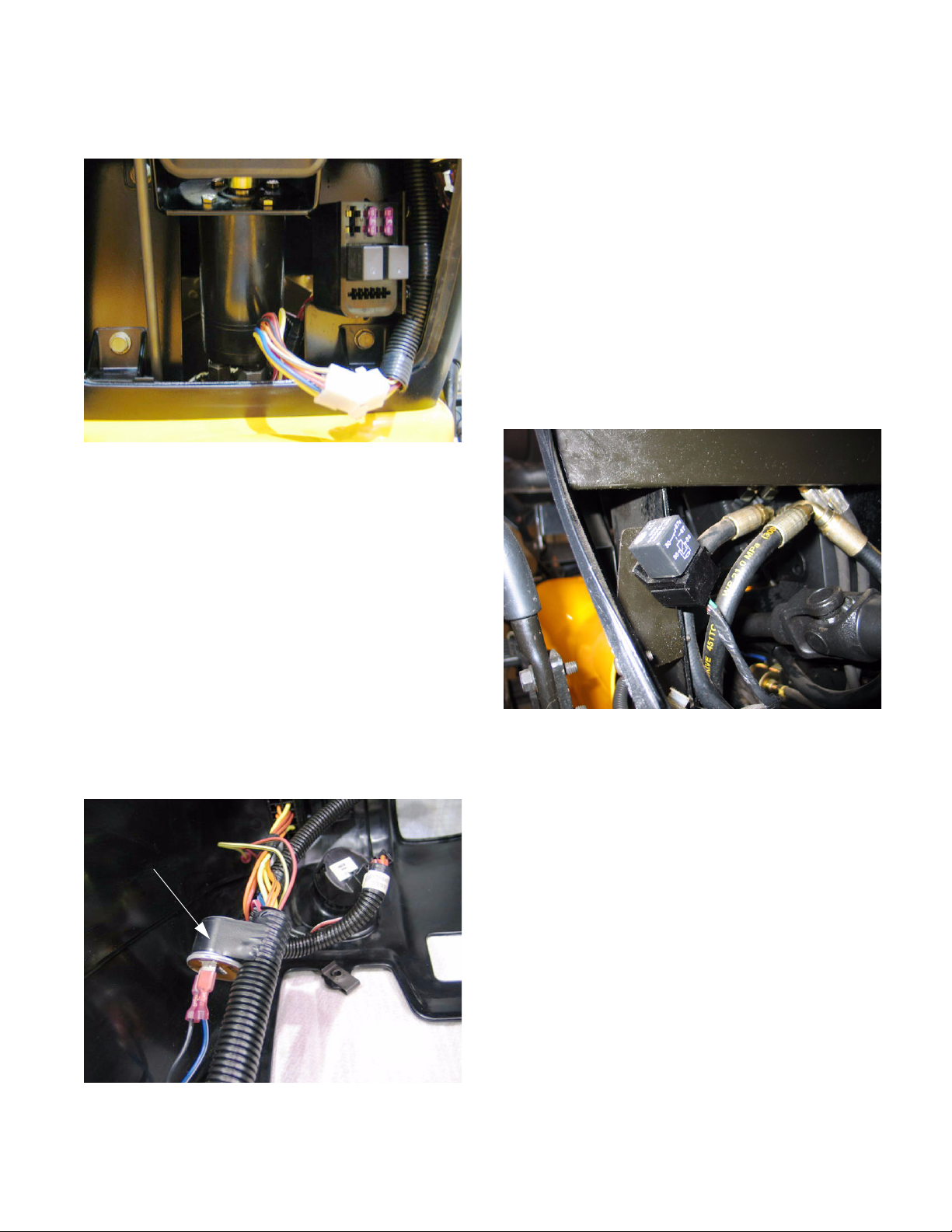

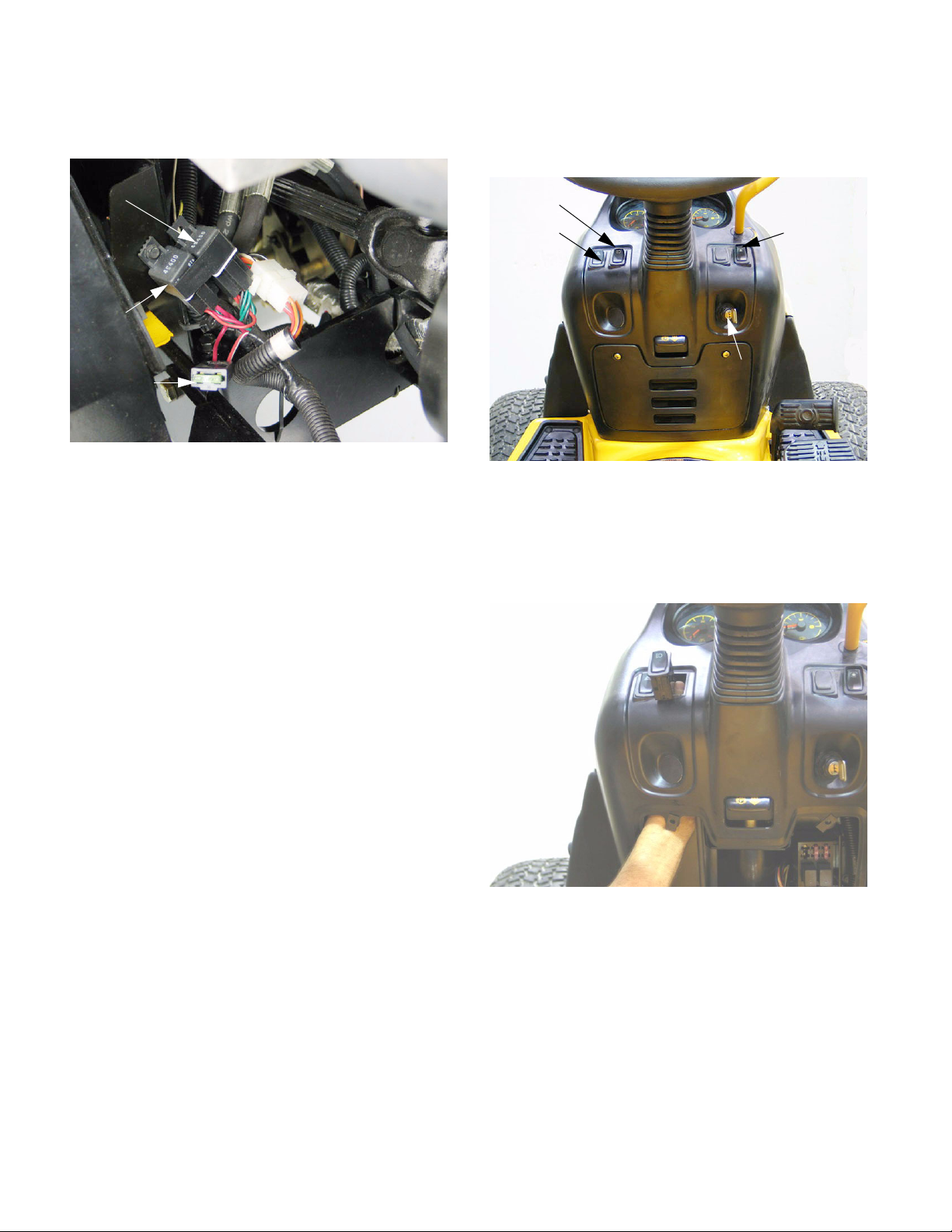

CHAPTER 6 - Electrical System

Similarities and Differences..........................................................................................................81

Components.................................................................................................................................82

Electric Clutch and Fuel Pump .....................................................................................................90

II

Page 5

Domestic Series 5000 Hydraulics

Domestic Series 5000 Hydraulics

1. STANDARD HYDRAULIC SYSTEMS ON THE DOMESTIC SERIES 5000: ORIENTATION

NOTE: Subsections 1 and 2 of the Domestic

Series 5000 Hydraulics portion of this manual

provide a basic orientation to the system. Subsection 3 and those that follow it contain specific

test procedures.

NOTE: Hydraulic diagrams are contained in an

appendix to this section.

1.1. The transmission housing acts as a reservoir for

all of the hydraulic systems on the tractor: hydrostatic drive pump, hydrostatic steering system,

lift cylinder, and accessories.

1.2. Fluid: the transmission and hydraulic system are

filled with 5.0 gallons (19.0 L) of Cub Cadet

Hydraulic Drive System Fluid Plus (P/N: 7373120 1Qt., 737-3121 1Gal.).

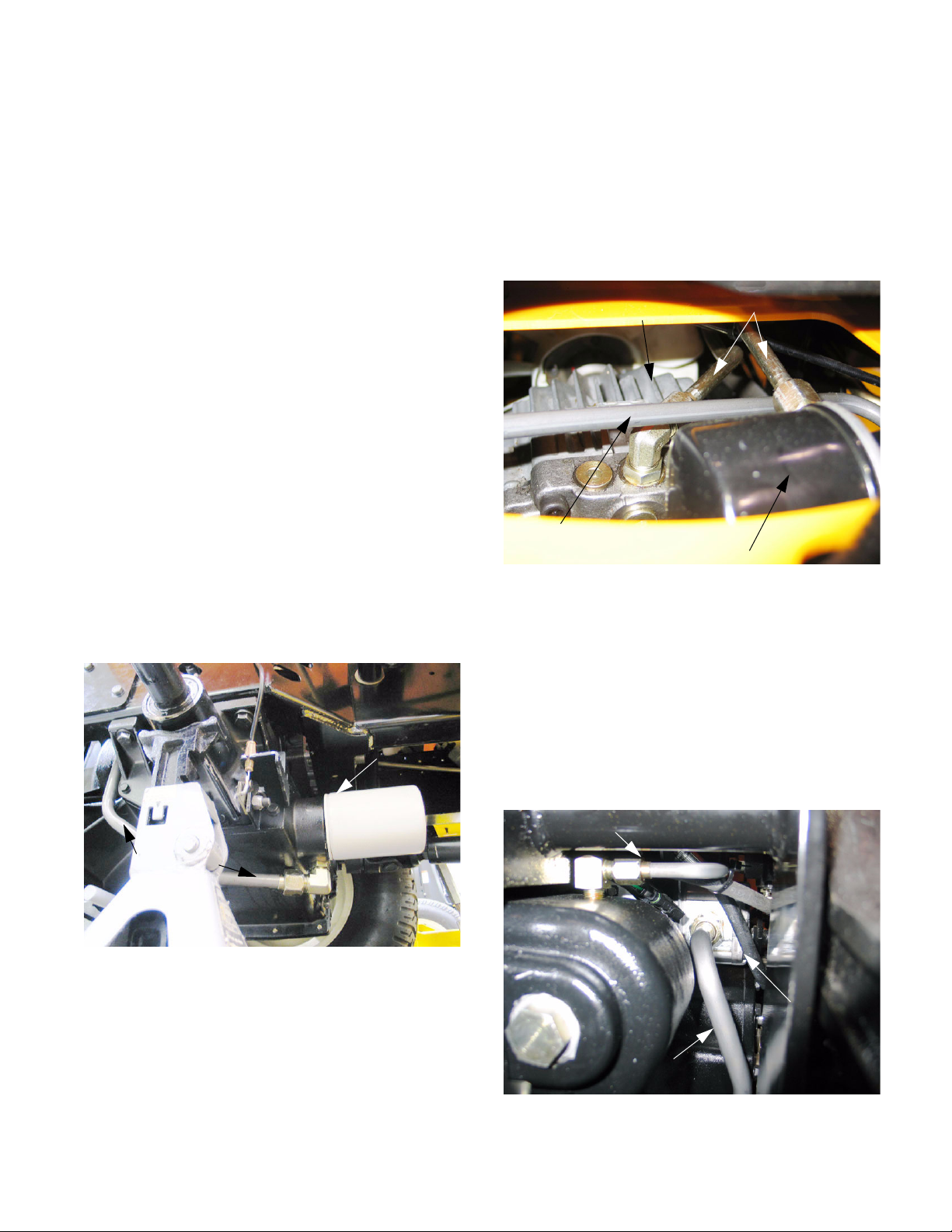

1.3. Filtration: The hydraulic system filter (P/N:723-

0405) is located on a boss on the front surface of

the transmission housing, adjacent to the midmount, 2000 R.P.M. P.T.O. shaft.

See Figure 1.3.

1.4. The hydrostatic drive filter (P/N: BS-492932S) is

located on the return manifold, atop the transmission. It is accessible through the opening

ben e ath the sea t . See Fi gur e 1. 4 .

Charge pressure tube

BDU-21L-400

Charge pressure tube

from aux. pump

to filter

NOTE: Other than sharing a reservoir, the

hydrostatic drive operates independently of the

rest of the hydraulic system.

from filter to hydrostat

Hydrostatic

drive filter

Figure 1.4

Suction tube

(feeds auxiliary pump)

Figure 1.3

Hydraulic

system filter

1.5. The hydrostatic drive is a Hydrogear model

BDU-21L-400. It relies on the auxiliary pump to

produce charge pressure. The auxiliary pump

draws hydraulic fluid up the suction pipe from

the base of the transmission housing.

See Figure 1.5.

Return tube

Auxiliary

pump

Suction

tube

Figure 1.5

1

Page 6

Domestic Series 5000 Hydraulics

1.6. The steering and lift cylinder are also powered

by the a Sauer-Danfoss SNP 1/2.6 S auxiliary

pump.

1.7. The steering unit, located in the dash pedestal

contains it’s own back-up gerotor charge pump

that will enable steering control when the engine

is not running. See Figure 1.7.

Steering

unit

Figure 1.7

1.10. The control valve directs fluid pressure to a single-acting hydraulic cylinder that lifts the threepoint lift arms.

1.11. The hydraulic fluid flow is as follows:

1.12. Through the pick-up tube from the transmission

sump and filter, to the auxiliary pump.

1.13. Under pressure from the auxiliary pump the fluid

goes to the hydrostatic drive and to the “P” port

on the steering unit. See Figure 1.13.

L port

(pressure to

turn left)

P port

(pressure

from

pump)

T port

(returns fluid

to transmission)

R port

(pressure to

turn right)

E port

(pressure

lift valve)to

1.8. The steering unit directs fluid pressure to one

end of the double-acting differential steering cylinder while allowing it to return from the other

end of the cylinder in order to provide steering

action.

1.9. The lift cylinder is operated by a control valve

under the right rear fender. See Figure 1.9.

Lift control valve

Auxiliary pump

Figure 1.9

Figure 1.13

1.14. The steering unit distributes pressure to the

steering cylinder according to the position of the

steering wheel. Left turn input from the steering

wheel forces fluid out the port labeled “L” and

allows displaced fluid to return through the port

labeled “R”.

NOTE: The power steering unit is first in line,

and has priority over the rest of the system.

1.15. For left turns, the fluid flows from the L port to

the base end of the steering cylinder. This

causes the ram to extend, turning the wheels to

the left.

1.16. The steering cylinder is double-acting: As the

piston is forced down the length of the cylinder

by hydraulic pressure from the L port, fluid on

the ram side of the piston is displaced, returning

through the R port.

2

Page 7

Domestic Series 5000 Hydraulics

1.17. The process is reversed for right turns.

See Figure 1.17.

Pressure from L port

(left turn)

Pressure from R port

(right turn)

Steering cylinder

Figure 1.17

1.18. From the steering system, the fluid may follow

one of two return paths:

1.19. The fluid may pass through the T port, to the

return manifold. See Figure 1.19.

Fluid return from

lift valve

30 PSI

check

valve

Charge

pressure

(30 PSI)

1.22. From the E port, fluid will travel to the lift control

valve. See Figure 1.22.

Pressure from E port

Figure 1.22

1.23. The fluid pressure that comes out of the E port

goes to the outboard port of the lift control valve.

1.24. The lift control valve directs pressure to the single-acting lift cylinder through the elbow on the

bottom of the valve when operator control input

directs it to do so. See Figure 1.24.

Pressure to lift

control valve

Pressure to

lift cylinder

Lift

valve

Fluid return

from T port

Figure 1.19

1.20. From the return manifold, the fluid may be

directed through the hydrostatic drive filter, to

provide charge pressure to the hydrostatic drive.

1.21. Pressure is maintained to the filter and hydrostatic drive by a spring loaded check valve. The

check valve in this application acts to maintain at

least 30 PSI (2.07 Bars) of hydraulic pressure in

the system. Above 30 PSI, it allows fluid to

return to the reservoir (transmission housing).

Return via

return manifold

Direct return

(on down-stroke)

Figure 1.24

1.25. Fluid not required to power the lift cylinder will be

continuously directed back to the transmission

through the lower inboard port (forward facing

elbow) via the return manifold.

3

Page 8

Domestic Series 5000 Hydraulics

1.26. When the tractor operator moves the control

lever forward to lower the three point hitch, the

lift control valve allows fluid to escape from the

lift cylinder as the cylinder retracts under the

weight of any accessories supported by the

hitch.

1.27. Increased fluid volume beyond normal return

flow rate is generated when the lift arms are lowered. This flow is exhausted through the top

inboard port (rearward facing elbow) back into

the transmission housing via a separate return

tube. See Figure 1.27.

Direct return

from lift valve

2. HYDROSTATIC DRIVE: BASIC OPERATION

2.1. The input shaft to the BDU-21L-400 turns a shaft

that passes completely through the housing of

the hydro., driving an engine speed input shaft in

the transmission.

2.2. The input shaft drives the auxiliary hydraulic

pump and the P.T.O. They are driven at relatively constant engine speed, rather than in relation to ground speed. See Figure 2.2.

Pinion gears driving

auxiliary pump

Traction drive

pinion

PTO clutch

PTO shaft

Figure 1.27

Figure 2.2

2.3. The lower part of the pump contains a fixed displacement axial piston hydraulic motor. The

motor is driven by the output of the variable displacement pump.

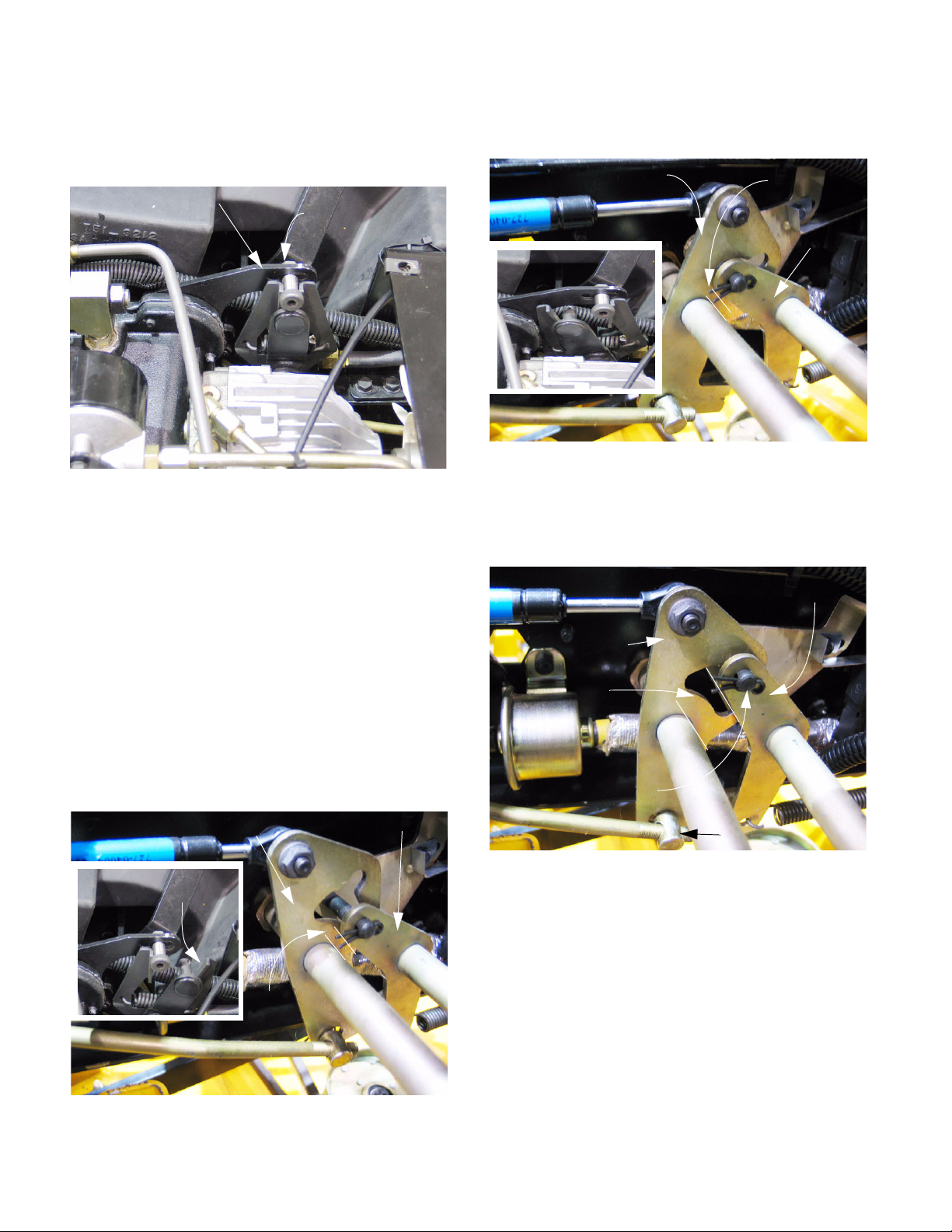

2.4. The hydro. control arm (scissors bracket) moves

a swash plate that controls the output of the

pump.

Hydro

control

arm

Set screw

Scissors bracket

4

Figure 2.4

Page 9

Domestic Series 5000 Hydraulics

S

2.5. : tilting the swash plate in one way causes the

variable displacement pump to drive fluid

through the fixed displacement pump in one

direction. See Figure 2.5.

Variable displacement pump

Input shaft

Fixed displacement

motor

Swash

plate

Pump

block

Motor block

Figure 2.5

NOTE: In figure 2.5, the pistons in the variable

displacement pump are alternately pressed into

the bores, and then released from bores of the

rotating pump block by the tilt of the swash plate.

Swash plate

angle

2.6. Tilting the swash plate the other way causes the

variable displacement pump to drive fluid

through the fixed displacement pump in the

opposite direction. See Figure 2.6.

Fixed displacement

motor

Pistons

Figure 2.6

2.7. When the swash plate is flat, the pump pistons

do not move up and down, no fluid is displaced

and no power is transmitted to the fixed displacement pump.

wash plate

angle

Pistons

• On the right side of the pump block in figure 2.5,

the pistons are down.

• The pistons are extended on the left side of the

pump block. They are forced up by springs contained in the pistons.

• This action causes the pistons to pump fluid in

one direction.

• The further the swash plate is tilted, the greater

the movement of the pistons as the pump block

rotates.

• As the travel of the pistons is increased, the displacement of the pump is increased, and more

fluid is pumped.

• The more fluid is pumped, the faster the fixed

displacement motor is driven.

2.8. The auxiliary pump maintains a supply of pressurized fluid (charge pressure) to the variable

displacement pump to feed and lubricate the

pump.

2.9. The charge check valves direct the flow of pressurized fluid to the ports that feed the pistons of

the variable displacement pump.

• When driving forward, fluid flows into the variable displacement pump through one set of

ports, and out through a second set.

• When driving backwards, the flow is reversed.

• One check valve opens and the other one

closes, depending on the direction of fluid flow.

• If the hydro. is in “neutral”, lubrication is provided

to this spinning (but not pumping) pump and

motor blocks through separate channels in the

housing.

2.10. If the hydrostatic drive is not performing correctly, begin diagnosing with simple things that

can be seen with minimal disassembly.

5

Page 10

Domestic Series 5000 Hydraulics

3. EXTERNAL CHECKS

3.1. If the transmission creeps, check the neutral

control adjustment. See Figure 3.1.

Neutral return bracket

Figure 3.1

NOTE: Complete neutral control adjustment pro-

cedures can be found in the 2004 Cub Cadet

Technical C.D.

3.2. If the tractor fails to achieve full ground speed,

check the adjustment of the linkages that control

the hydrostatic drive system.

NOTE: A d v e r t i s e d m a x i m u m g r o u n d s p e e d

High range forward:8 MPH (12.9 KPH)

Low range forward: 4 MPH (6.44 KPH)

High range reverse:4 MPH (6.44 KPH)

Low range reverse: 2 MPH (3.22 KPH)

Move shoulder bolt

in slot to establish

neutral

3.4. Confirm that full travel is achieved in the reverse

direction. See Figure 3.4.

Pedal linkage: Reverse

Hydro linkage:

Reverse

Figure 3.4

3.5. If the brake and drive pedals “fight” with each

other, the drive control rod is out of adjustment.

See Figure 3.5.

Pedal linkage:

Neutral

Note:

gap

Note: gap

Brake linkage:

brakes applied

Brake

linkage

3.3. Confirm that full travel is achieved in the forward

direction. See Figure 3.3.

Brake linkage

Pedal linkage Forward

Hydro linkage:

Forward

Note:

gap

Rod pulls hydro linkage

Figure 3.3

Pin locks linkage

Drive control rod

Figure 3.5

NOTE: Isolate the hydrostatic drive unit from the

linkage, and confirm the correct adjustment of

the neutral return before adjusting the linkage.

NOTE: After correct neutral return adjustment is

established, adjust the ferrule on the drive control rod so that it rests lightly against the front

edge of the slot that it fits into when the parking

brake is engaged.

6

Page 11

Domestic Series 5000 Hydraulics

3.6. If the tractor fails to achieve normal ground

speed, and the hydro pump emits an unusual

amount of noise, check for brake drag:

• Confirm that the neutral return and hydro control

linkages are correctly adjusted.

• With the tractor on a smooth, firm, level surface,

place the gear selector in neutral, release the

parking brake, and attempt to push the tractor.

• If the tractor does not roll with a reasonable

amount of effort, check the brakes for drag.

• The left and right brakes can be checked individually by jacking-up the rear of the tractor and

attempting to rotate the rear wheels. Leave the

transmission in neutral.

• If either or both brakes drag, confirm that the

linkage moves firmly and is properly adjusted.

• If the linkages are properly adjusted, and brake

drag is still present, check the pull-off springs on

the brake calipers.

• Bear in mind that both brake calipers act on a

common cross-shaft within the transmission.

With the rear wheels off the ground differential

action will still occur when the brakes are

applied, unless the differential lock is applied.

• Look for blueing on the brake rotors and freedom of movement when the brakes are

released.

3.8. Check the fluid at sight glass gauge on the back

of the transmission. Check the level, and compare the fluid to a sample of Cub Cadet Hydraulic Drive System Fluid Plus. Top-up or replace

the fluid as necessary. See Figure 3.8.

Sight glass

Suction line feeding

auxiliary pump

3.9. Replace the hydrostatic filter if there is any question of it’s condition.

3.10. Visually inspect the hydraulic system filter and

the suction tube that feeds fluid to the auxiliary

pump from the sump of the transmission. If it is

kinked or crushed, replace it. See Figure 3.10.

Fill plug

Figure 3.8

NOTE: Complete brake adjustment procedures

can be found in the 2004 Cub Cadet Technical

C.D.

3.7. If there is no drive at all, confirm whether the

problem lies in the hydro or elsewhere.

• With the engine running, confirm that the PTO

operates when it is turned-on. This confims that

the input shaft is turning.

• On smooth, firm, level ground, with the engine

turned-off and the parking brake released:

• Place the gear selector in high range and

attempt to push the tractor. It should not roll.

• Place the gear selector in low range and attempt

to push the tractor. It should not roll.

• If the tractor rolls, the problem is gear-related.

• Place the gear selector in neutral and attempt to

push the tractor. It should roll. If it does not, the

problem may be gear or brake related.

Hydraulic filter

Suction tube

to auxiliary

pump

Figure 3.10

NOTE: Drain the transmission fluid before

removing the suction tube.

3.11. Check that the set screw holding the control arm

to the hydro control shaft has not backed-out,

worn, or sheared.

7

Page 12

Domestic Series 5000 Hydraulics

4. BEST PRACTICES: HYDRAULIC SYSTEMS

NOTE: TESTS All hydraulic tests should be

done with the fluid at normal operating temperature, and the engine at normal operating speed.

In practical terms, normal operating temperature

means that the tractor should be operated (if not

disabled) for about 5 minutes before testing in

normal temperate climates. If the tractor has

been sitting outside for a week during February

in Green Bay, Wisconsin, it is advisable to store

the tractor in a heated shop for 12 hours before

testing. Normal operating speed is 3,000RPM.

NOTE: CLEANLINESS It is very important to

keep dirt out of hydraulic systems.

• Cleaning the areas around any joint to be disconnected, or component to be removed is

advisable.

• Contaminated fluid should be disposed of properly, not re-used.

• Tools and work benches used for work on

hydraulic systems should also be kept clean.

• Catch pans beneath work will ease clean-up.

5. FLOW AND PRESSURE TESTS: HYDROSTATIC DRIVE

NOTE: The fenders have been removed from

the tractor for the sake of photographic clarity.

The test procedure described in this section can

be performed without removing the fenders.

NOTE: It will be necessary to remove the seat.

NOTE: The hydrostatic drive can be removed

from the tractor from beneath without removing

the fenders.

5.1. If the problem is not revealed by any of the

external checks, check the charge pressure.

5.2. Clean the area surrounding the charge pressure

port immediately to the left of the feed tube from

the filter. The plug to the right is not easily

accessible.

5.3. Remove the plug using a 1/4” allen wrench.

5.4. Install a pressure gauge capable of reading 200

PSI (13.80 Bars) in the port that the plug was

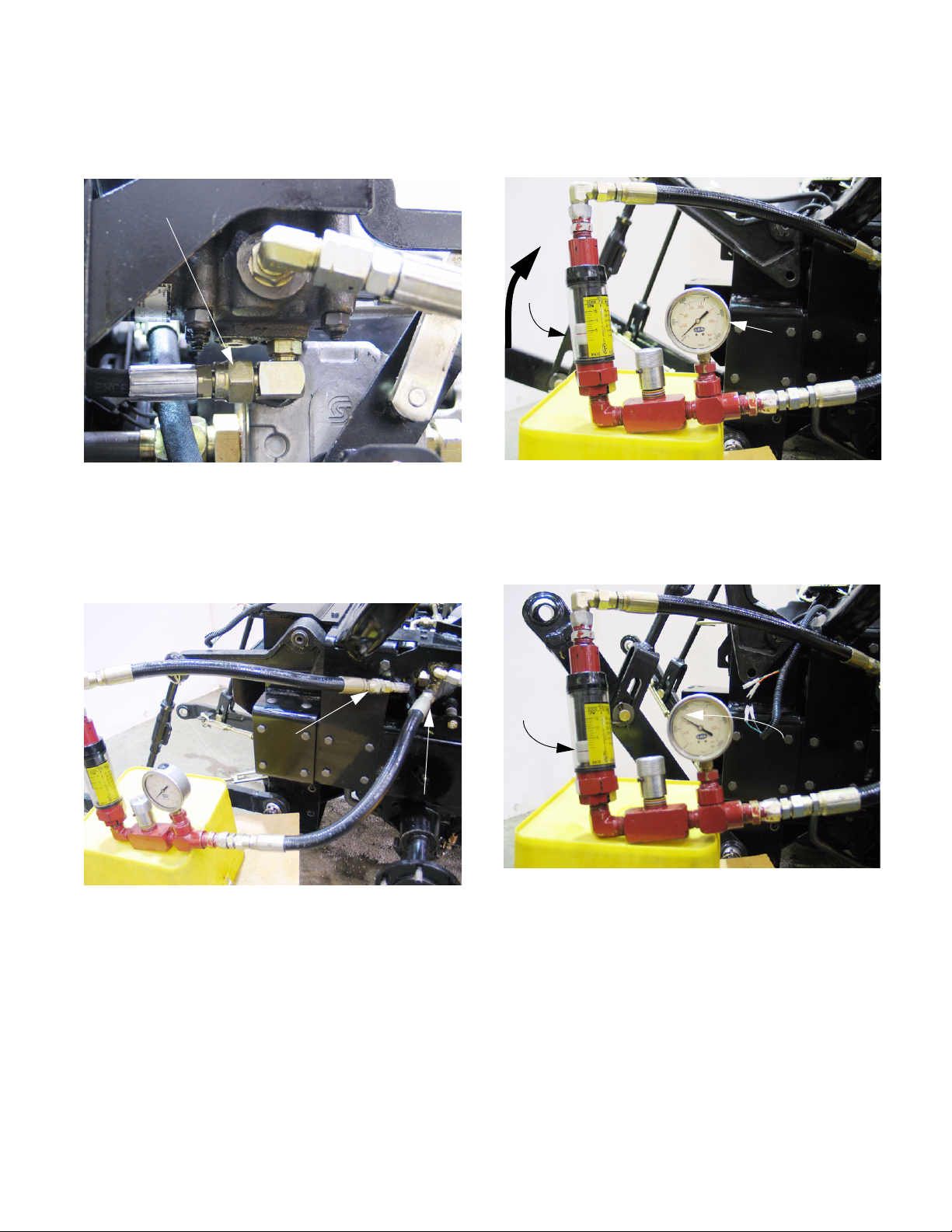

removed from. See Figure 5.4.

• CAUTION: High pressure hydraulic leaks can

be dangerous.

• Wear eye protection while performing tests.

• Do not operate any equipment with obvious

damage to parts such as hoses.

• Do not disconnect any fittings that may be under

pressure. Turn-off the engine and operate the

circuit to relieve pressure.

• Remember that anything (front-end loaders,

backhoe buckets, three-point hitches, etc....) that

is supported by hydraulic pressure will be subject to gravitational force when that pressure is

relieved.

NOTE: Sealants

• O-ring fittings require no sealant, though light

lubrication with the fluid used in the system is

sometimes helpful.

• Teflon tape is to be avoided. “Flash” from the

tape can dislodge, blocking valves and damaging pumps.

NOTE: Priming

• When a new hydrostatic drive is installed, turn

the input shaft at low speed until charge pressure builds to avoid immediate failure on initial

start-up.

200 PSI gauge

High

pressure

gauge

Charge pressure port

Figure 5.4

NOTE: Fitting size: 3/8” ORFS

5.5. Confirm that no unsafe conditions will be created

by starting the engine or operating the drive system before performing the test.

5.6. Place the High/Low/Neutral gear selector in neutral, and set the parking brake.

5.7. Start the engine and allow the fluid to warm up

briefly.

8

Page 13

Domestic Series 5000 Hydraulics

5.8. The charge pressure should read at least 30 PSI

(2.07 Bars) @ 1,200 RPM. See Figure 5.8.

200 PSI gauge

Figure 5.8

5.9. As the RPM is increased to the 3,000 RPM, the

pressure may increase somewhat. If pressure

goes down as engine speed increases, turn-off

the engine and determine the cause.

High pressure gauge

5.11. If the charge pressure is good, but drive has

been lost in one direction only, the corresponding charge check valve may not be working.

• There is a charge check valve located in each

circuit: one for forward, one for reverse.

• These check valves enable the charge pump to

provide charge oil to the side of the circuit that

has the lowest pressure, while sealing-off the

side that has higher pressure.

• The one on the left side maintains pressure in

the forward circuit, the one on the right side

maintains pressure in the reverse circuit.

5.12. The charge check valves can be removed using

a 5/8” wrench. See Figure 5.12.

5.10. After confirming that the supply to the pump is

good, low pressure or a complete lack of pressure at this port indicates:

• The auxiliary pump that is not working.

• Pressure from the auxiliary pump is not reaching

the charge port on the hydrostatic drive. The

steering unit may not be transferring pressure as

designed, or the return manifold check valve

may be failing to maintain 30 PSI (2.07 Bars).

• Pressure is being lost within the hydrostatic

drive, possibly because of a malfunctioning system relief valve.

O-ring seal

Charge check

valve cap

Figure 5.12

NOTE: The one on the right side (reverse) is

easy to reach. The one on the left side (forward)

can not be removed in the tractor. It may be

removed for inspection on the bench.

9

Page 14

Domestic Series 5000 Hydraulics

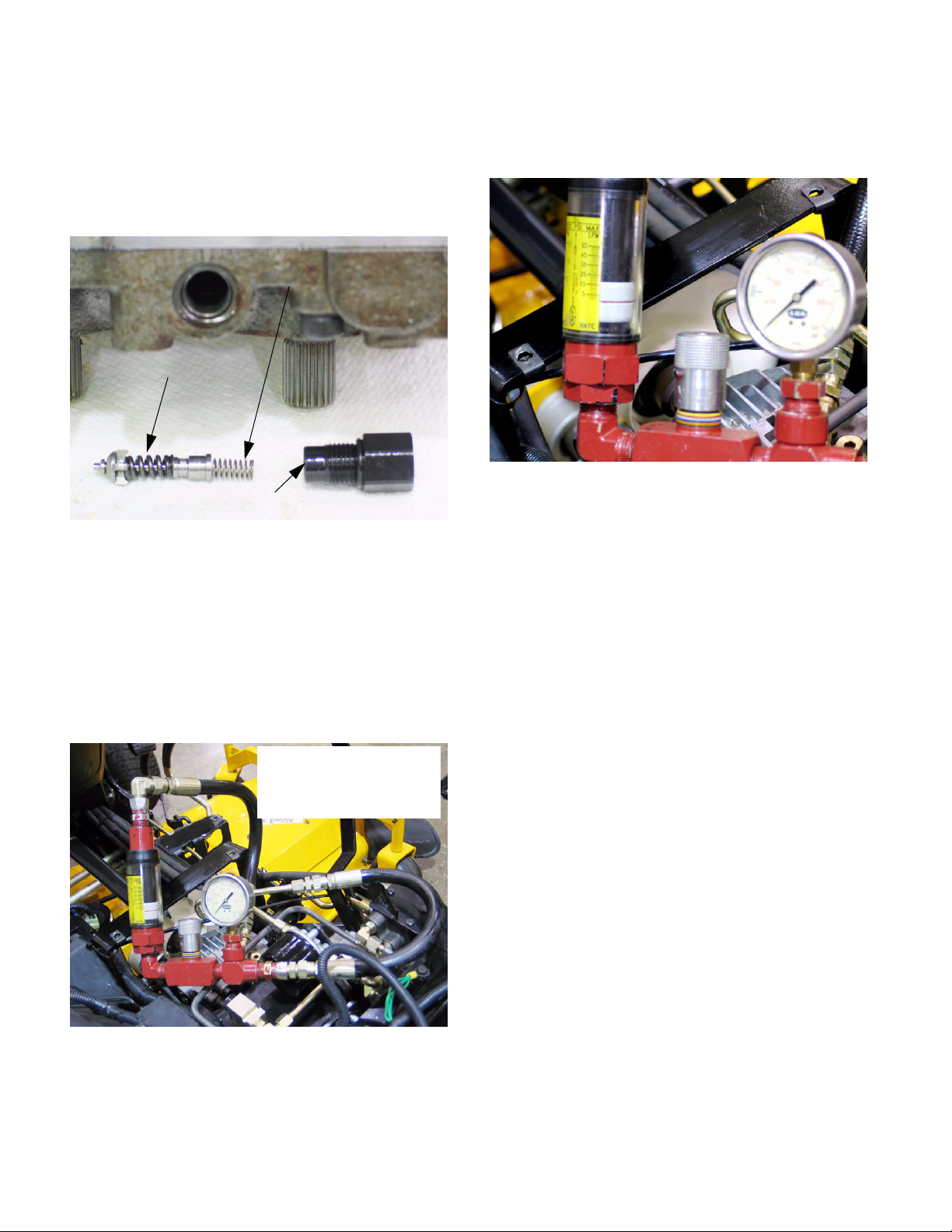

5.13. When removed, each charge relief valve comes

out as a cartridge. The light compression spring

provides the check valve function. The heavy

compression spring provides system relief. System relief comes into play in the event of a drive

system overload. See Figure 5.13.

Light compression spring

(check valve function)

Heavy compression

spring (relief function)

5.14. The output of the variable displacement pump is

dependent upon the performance of the check

valves.

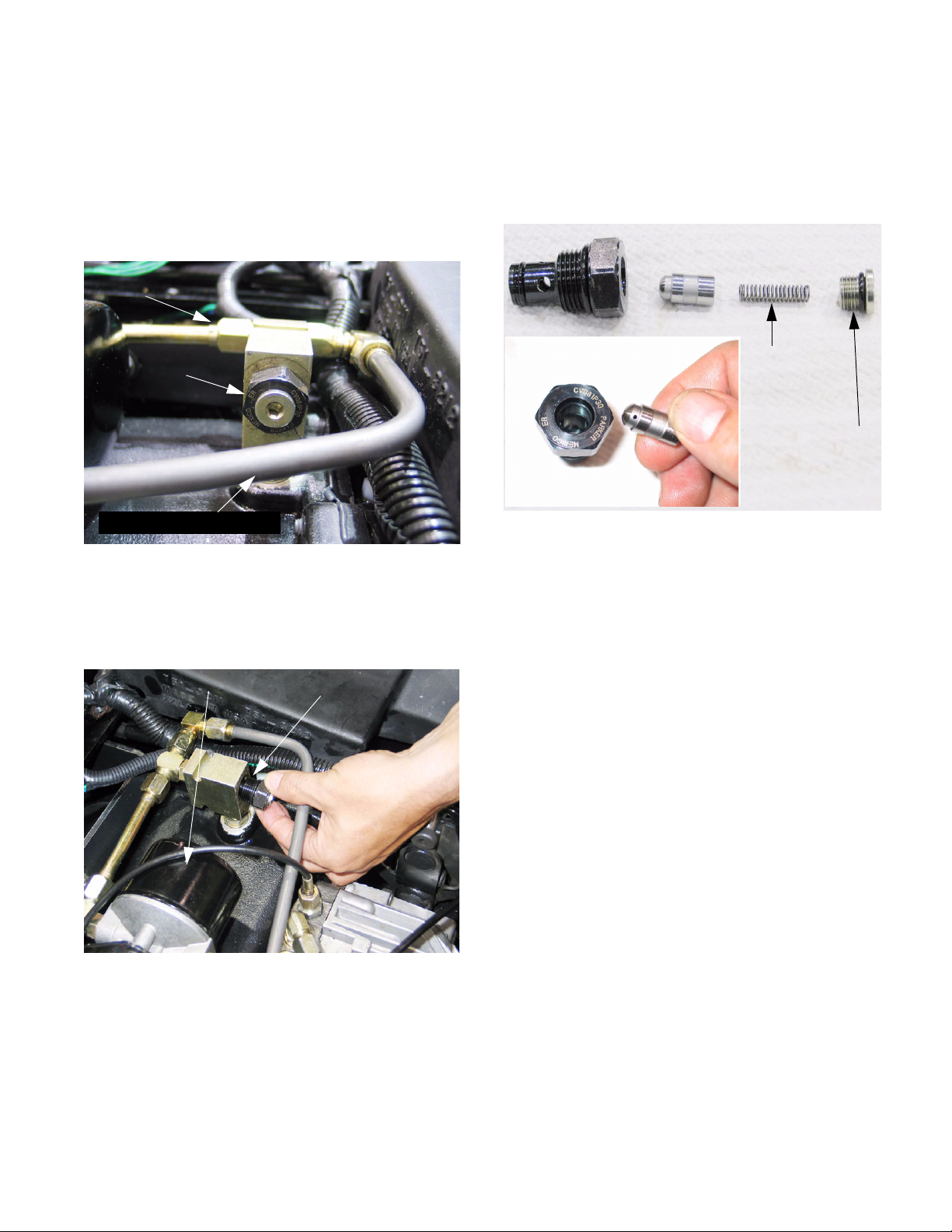

5.15. The presence of fluid flow from the auxiliary

pump, via the steering unit can be confirmed by

installing a flow meter in place of the tube

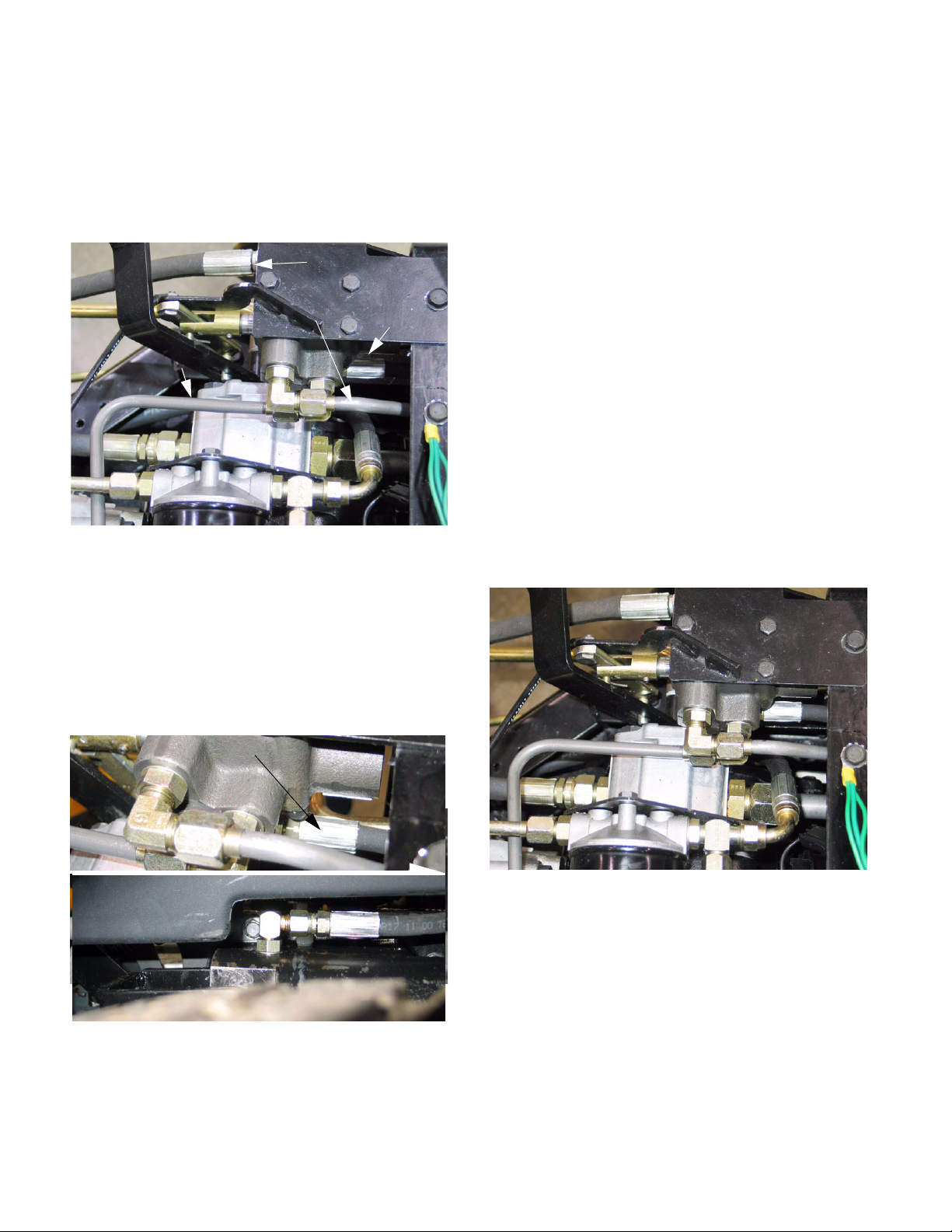

between the filter and the top port on the hydrostatic drive. See Figure 5.15.

Charge check valve cap

Figure 5.13

Flow and pressure test

kit in charge pressure line

between filter and hydrostatic drive unit

5.16. With the engine at a minimum speed of 1,200

RPM, fluid flow of roughly 2 GPM (7.60 LPM)

should register on the meter. See Figure 5.16.

Figure 5.16

NOTE: No hydraulically powered systems

should be in motion during this test. The steering and lift cylinder should be stationary. Confirm that the lift control valve is not in the down

position.

5.17. Conclusion: If flow is present, but there is no

pressure, as determined by the 200 PSI gauge,

then the auxiliary pump is producing flow, the

steering unit is passing that flow along to the

return manifold through the T port, but pressure

is being lost in the return circuit. The most likely

culprit is the return circuit check valve.

5.18. Conclusion: If there is neither flow nor pressure, either there is none reaching the return circuit, or it is being spilled-off through a path that

offers lower resistance.

Figure 5.15

• The lift control valve is the only other possible

outlet from the return circuit. Lift control valve

failure in this mode would be highly unusual. If

the lift control valve operates normally, this issue

can be eliminated from consideration.

• To discern if the auxiliary pump is functioning,

operate other hydraulic systems. If the steering

and the lift cylinder for the three point hitch fail to

operate, it is safe to assume that the auxiliary

pump is not producing pressure.

• The pressure that operates the lift cylinder

comes from one of two possible return paths

from the steering unit (E port). The charge pressure for the hydrostatic drive comes from the

10

Page 15

other (T port). If there is pressure to the steering

unit, at least one return path will have pressure.

5.19. The return circuit check valve maintains a minimum pressure given sufficient flow. It does not

control the maximum pressure in the system: it

is a check valve, not a relief valve.

See Figure 5.19.

Fluid return from

T port

30 PSI

Check valve

Domestic Series 5000 Hydraulics

5.21. If any mechanical problem is found with the

check valve, it is to be replaced as a unit. Individual service components are not available

through Cub Cadet. See Figure 5.21.

Light

compression

spring

Socket head

plug with

O-ring seal

Fluid return from lift valve

Figure 5.19

5.20. The core of the valve can be removed for

inspection. The nut and set screw are not a

means of adjusting pressure. See Figure 5.20.

Hydrostatic filter

Figure 5.20

Check valve core

Figure 5.21

11

Page 16

Domestic Series 5000 Hydraulics

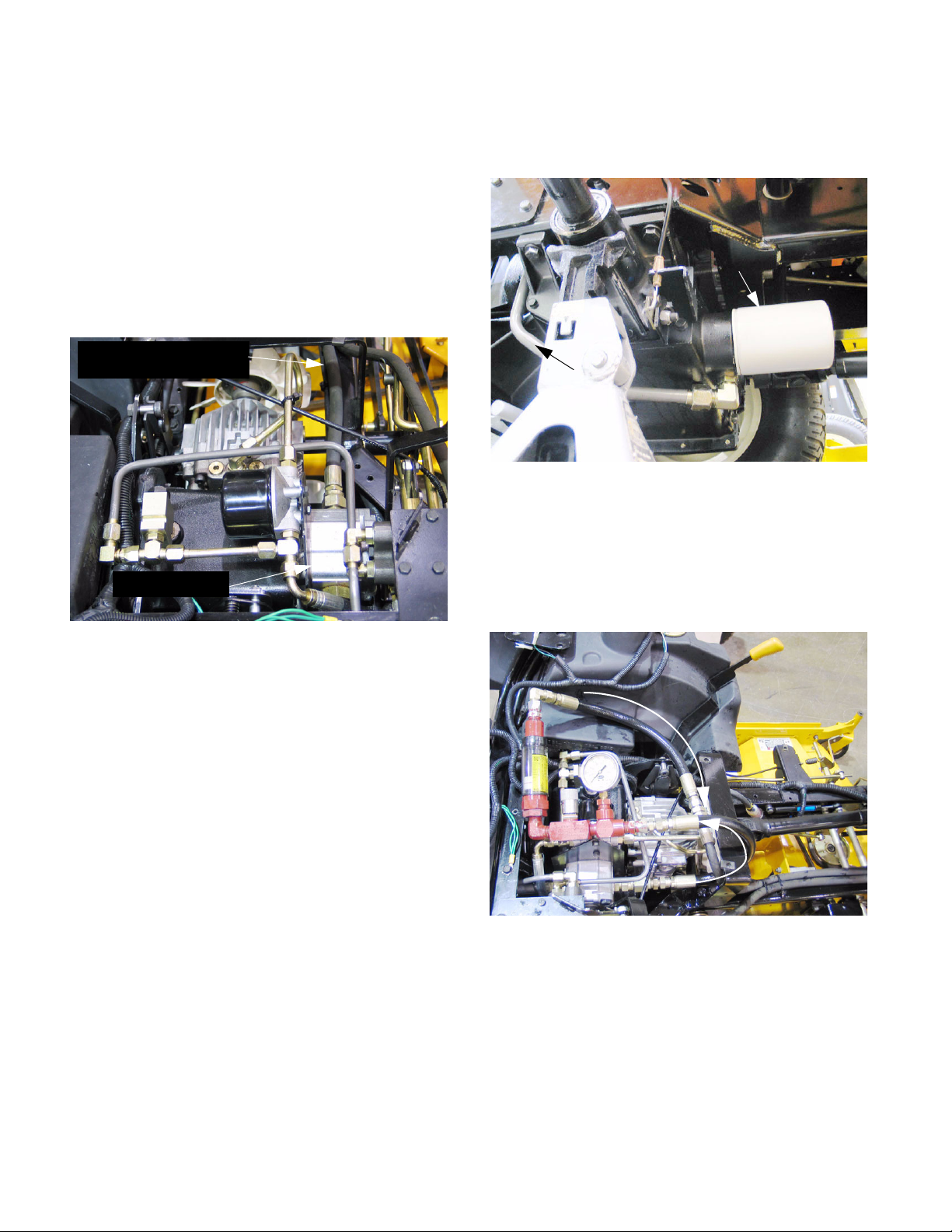

6. AUXILIARY PUMP

6.1. The auxiliary pump provides pressure for the

hydrostatic power steering unit, the lift cylinder

attached to the three-point hitch, and any

hydraulic-driven accessories that may be

installed on the tractor.

6.2. Series 5000 tractors come with a single auxiliary

pump mounted to the right side of the transmission. See Figure 6.2.

6.5. The filter and suction tubes are easily reached

for inspection with little or no disassembly.

See Figure 6.5.

Hydraulic filter

Pressure line to P port

on steering unit

Auxiliary pump

Figure 6.2

6.3. If performance of any of the tractors hydraulic

features or attachments is poor, it is necessary

to confirm that sufficient hydraulic power is being

supplied by the pump that drives it.

6.4. Begin with the basics: confirm that the pump

drive and supply are intact before drawing conclusions about the pump itself by making these

preliminary checks:

Suction tube

to auxiliary

pump

Figure 6.5

6.6. The rear fenders must be removed to access the

auxiliary pump itself. Fender removal is

detailed in the 2004 Cub Cadet Technical C.D.

6.7. To test the auxiliary pump, use a flow and pressure gauge set. See Figure 6.7.

To P port

• Check the fluid. If the fluid level is low, or the

fluid is not the correct type, both the hydrostat

and the auxiliary pump will perform poorly.

• Replace the hydraulic filter if there is any question of its condition.

• Confirm that the suction tube that provides fluid

to the auxiliary pump from the sump of the transmission is not crushed or kinked, and that the

connections are free of leaks.

From pump

Figure 6.7

NOTE: Equipment will vary from shop to shop,

but operating principles are similar.

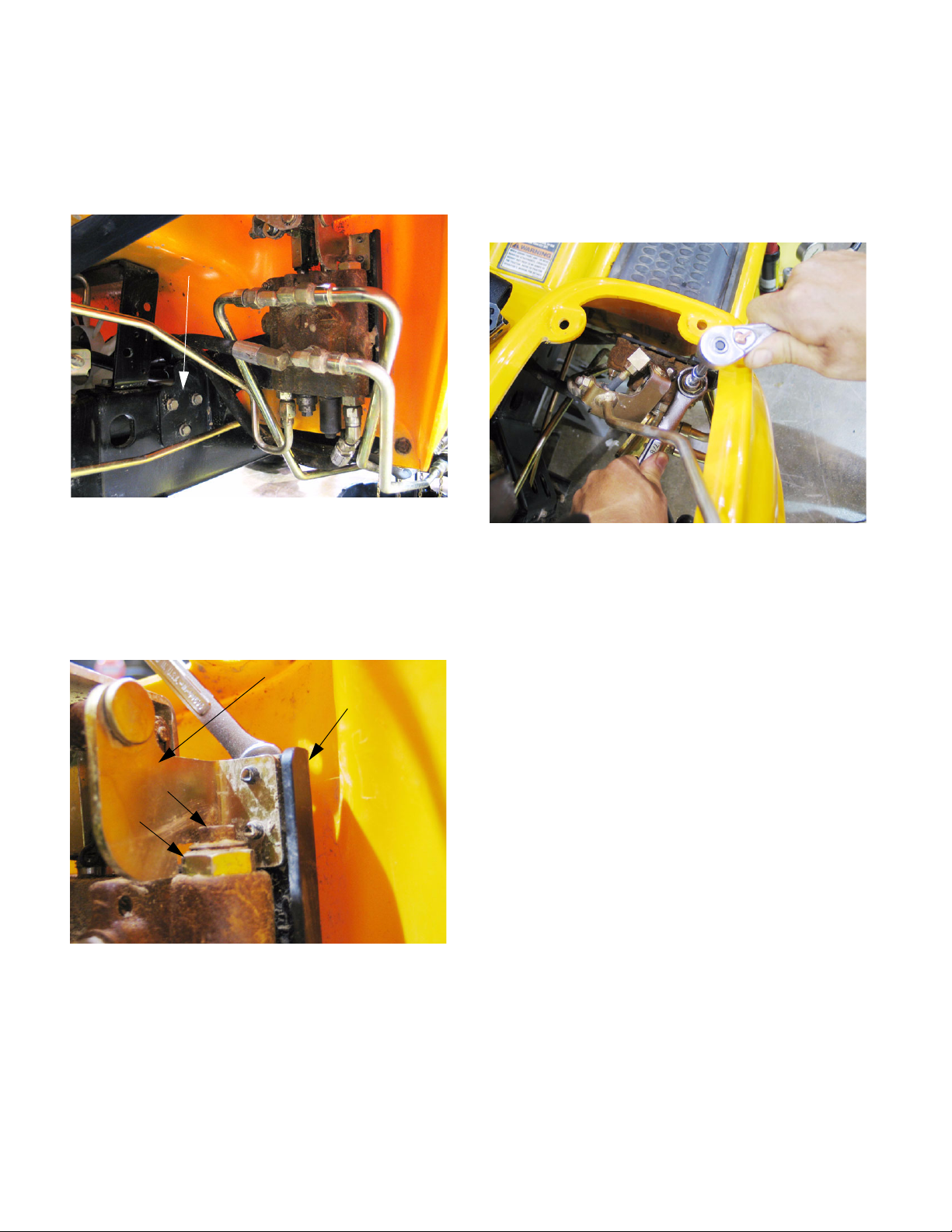

6.8. Disconnect the output line from the top of the

pump using a 3/4” wrench and a 9/16” wrench.

6.9. Install the gauge set in-line between the auxiliary

pump and the steering pump. The pressure

gauge should be near the auxiliary pump, and

the flow meter should be near the steering unit.

12

Page 17

Domestic Series 5000 Hydraulics

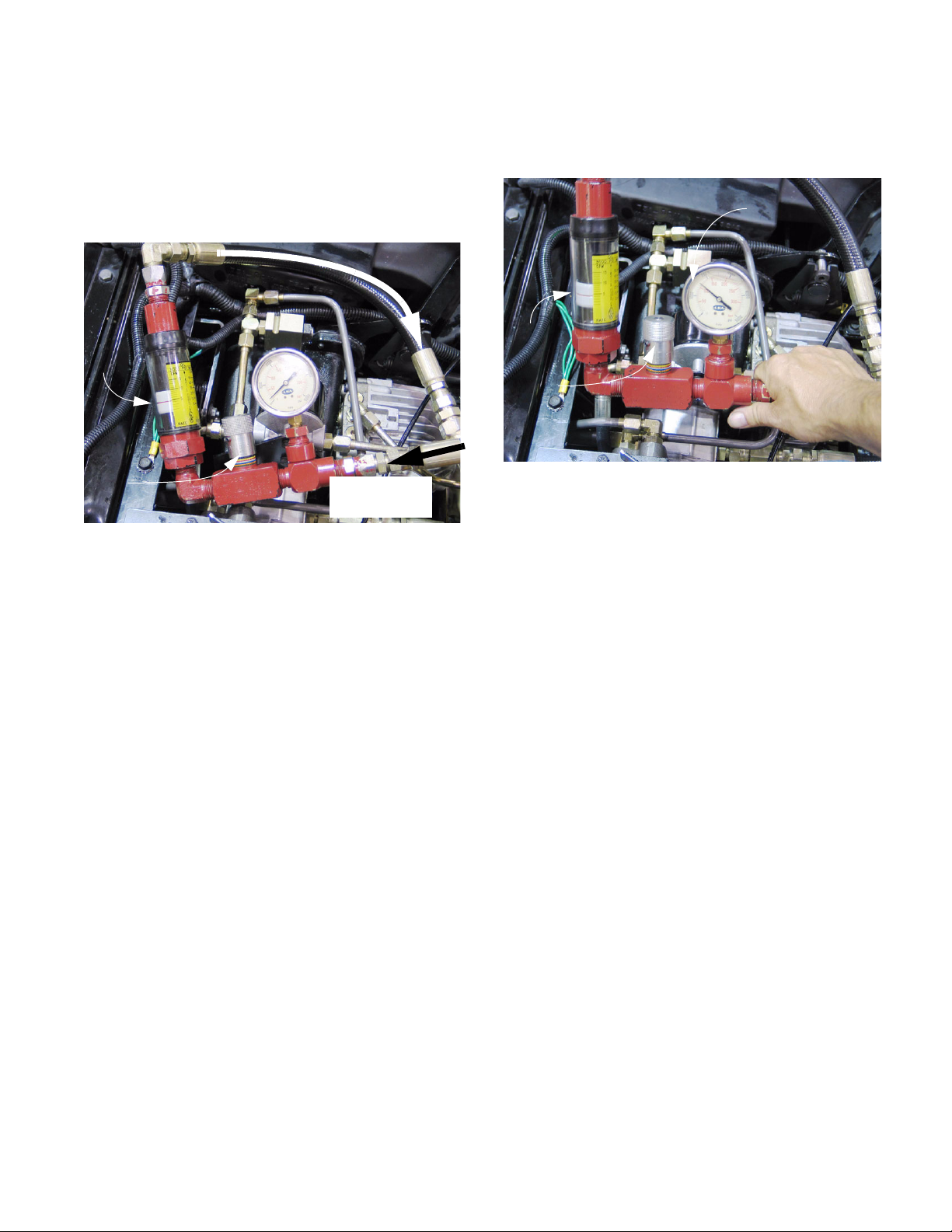

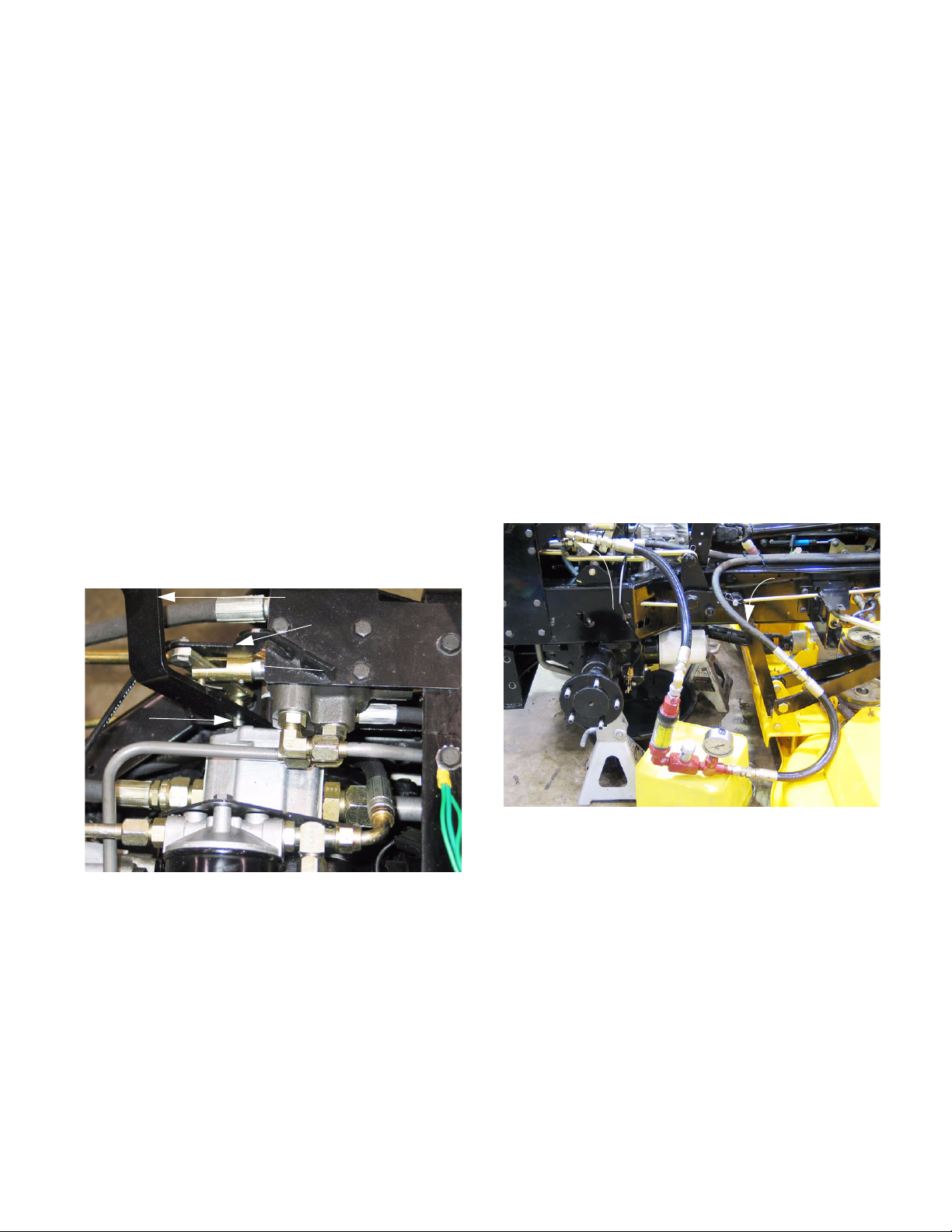

6.10. Set the parking brake, place the gear selector in

neutral, open the flow valve on the gauge set all

the way, and confirm that no unsafe conditions

will be created by starting the tractor engine.

6.11. Start the engine, allow the engine and hydraulic

system to warm-up. See Figure 6.11.

To P port on

steering unit

5 GPM

Valve

open

Figure 6.11

From auxiliary

pump

6.13. Close the flow valve until the pressure gauge

reads 1,500 PSI (103 Bar). Note the flow reading. See Figure 6.13.

1,500 PSI

5 GPM

Valve

partially

closed

Figure 6.13

6.14. As soon as the flow reading is noted, open the

the flow valve completely, relieving pressure

from the system. Turn -off the engine.

6.12. Performance:

• The SKP1/4.3 S auxiliary pump does not contain

a relief valve. It is capable of producing roughly

3,600 PSI (250 bars) at engine speeds beyond

1,200 RPM.

• This is far in excess of the needs of the rest of

the system, which is designed to operate at

1,500 PSI (103 Bars).

• For our purposes, it is not necessary to test the

pump to its full capacity, only to establish that it

produces enough flow and pressure to operate

the hydrostatic steering and hydraulic lift cylinder.

• The auxiliary pump was observed to move about

4.6 GPM (15 LPM) at an engine speed of 3,000

RPM, with no load applied.

• Flow will vary with engine speed, but pressure

tests can be done at lower engine speeds:

1,200-1,500 RPM.

• Set the throttle to maintain an engine speed in

this range, and note the reading on the flow

meter.

6.15. The flow readings noted at zero pressure and

1,500 PSI (103 Bars) should not vary significantly. Flow is more related to engine RPM than

to pressure.

13

Page 18

Domestic Series 5000 Hydraulics

7. STEERING PUMP AND CYLINDER

NOTE: It is normal for the spokes of the steering

wheel on an open-center hydrostatic power

steering system to change orientation with use.

There is no mechanical connection between the

steering wheel and the front wheels.

7.1. Identification: The Sauer OSPM 63 PB unit has

a round body. The ports are on the bottom of

the steering unit connecting to the hydraulic lines

with male straight thread O-ring seal fittings. See Figure 7.1.

7.5. The following set of symptoms, causes, and

solutions has been adapted from a list compiled

by Sauer-Danfoss to aid in the diagnosis of

hydrostatic steering issues. Internal steering

unit problems are described to aid technicians in

distinguishing internal steering unit problems

from problems that lie elsewhere in the system.

Internal problems dictate replacement of the

steering unit.

• High Effort Required to Turn Steering Wheel:

Cause 1: The auxiliary pump is not supplying suffi-

cient fluid to the steering unit. Confirm by testing auxiliary pump out-put.

Solution 1: Correct the problem with the auxiliary

pump.

Cause 2: The priority spool within the steering unit is

not moving, causing fluid to be directed to other parts

of the system when the steering system needs it.

Solution 2: Internal problem; priority spool.

Cause 3: The relief valve in the steering unit is stuck

open.

Figure 7.1

7.2. The ports are arranged as follows:

• P Pressure from the auxiliary pump.

• T Tank return of fluid pressure and volume not

required by the steering system.

• E Equipment power for accessories.

• R Right turn, pressure out when turning right.

• L Left turn, pressure out when turning left.

7.3. R&R: instructions for removal and replacement

of the steering units can be found in the DASH

PANEL AND STEERING PUMP section of this

manual.

7.4. If there is a warrantable problem with the power

steering unit, it is to be replaced as a complete

unit. Cub Cadet does not stock any internal

components for the steering units.

Solution 3: Internal problem; relief valve.

• “Motoring” Steering Wheel: rotates on its

own:

Cause 1: Bad leaf spring in steering unit.

Solution 1: Internal problem; leaf spring.

Cause 2: The relief valve is stuck open.

Solution 2: Internal problem: relief valve.

• Poor Straight Line Steering Characteristics:

Cause 1: There is a bind in the steering column.

Solution 1: Binds may be created by angular or radial

misalignment between the steering column and the

steering unit. Binds may also be created by a lack of

axial clearance between the steering column and the

steering unit. Correct any situation that may create

friction or binding in the steering column.

Cause 2: Bad leaf spring in steering unit.

Solution 2: Internal problem; leaf spring.

14

Page 19

Domestic Series 5000 Hydraulics

• Backlash

Cause 1: Wear or play between the steering column

and the cardan shaft.

Solution 1: If the wear is in the steering column,

replace the steering column (steering shaft per Cub

Cadet IPL). If the wear is in the cardan shaft, this is an

internal problem.

Cause 2: Bad leaf spring in steering unit.

Solution 2: Internal problem; leaf spring.

• Shimmy:

Cause 1: Air in steering system.

Solution 1: Repair any leaks in the hydraulic system.

Be aware that a leak on the suction side of the auxiliary

pump would entrain air into the hydraulic fluid, but may

not display significant fluid loss.

Cause 2: Worn mechanical connections.

Solution 2: Inspect the MFD and steering linkage for

sources of excessive play: worn wheel bearings, worn

tie rod ends, worn king pins, worn steering cylinder

mounting points, etc.... Replace the worn components.

• Slow Steering:

Cause 1: Insufficient fluid flow to the steering unit.

Confirm by testing the out-put of the auxiliary pump.

Solution 1: Repair of replace the auxiliary pump or

delivery line from the pump to the “P” port on the steering unit.

Cause 2: The priority valve in the steering unit is not

working properly. This valve normally maintains precedence of the steering system over all subsidiary systems (lift cylinder).

Solution 2: Internal problem; priority valve.

• The Steering Wheel Does Not Return to Center:

Cause 1: There is a mechanical bind in the steering

column.

Solution 1: Repair or adjust the steering column

(steering shaft) to eliminate the bind.

Cause 2: Bad leaf springs.

Solution 2: Internal problem; leaf springs.

Cause 3: The spool is pressing against the sleeve in

the steering unit.

• Steering Wheel Input Does Not Cause Steering cylinder to Move:

Cause 1: No fluid in the system.

Solution 1: Fill the system.

Cause 2: Worn steering cylinder / blow-by. Confirm

with flow test in line to cylinder.

Solution 2: Replace the steering cylinder.

• Heavy Impacts to Steering Wheel in Both

Directions:

Cause 1: The hydraulic hoses are incorrectly con-

nected; the hose that should connect to the “P” port is

connected to the “L” port or the “R” port.

Solution 1: Correct the hydraulic connections.

Cause 2: Incorrect setting of the cardan shaft to the

gear wheel (timing).

Solution 2: Internal problem; cardan shaft / gear wheel

timing.

Solution 3: Internal problem; relief valve causing too

much pressure to build, displacing the spool.

Cause 4: Binding between spool and sleeve caused by

fluid contamination.

Solution 4: Internal problem; contamination. If this is

a possibility, cleaning, fluid replacement, and filter

replacement will help prevent a repeat failure.

• Steering Action is Opposite of Input:

Cause 1: The “L” and “R” hoses are reversed at their

connections to the steering cylinder or steering unit.

Solution 1: Correct the connections of the hydraulic

lines from the steering unit to the steering cylinder.

Cause 2: Incorrect setting of cardan shaft to gear

wheel.

Solution 2: Internal problem; cardan shaft / gear wheel

timing.

15

Page 20

Domestic Series 5000 Hydraulics

• Steering Power Too Low:

Cause 1: The relief valve is set too low or malfunction-

ing.

Solution 1: Internal problem; relief valve.

• Fluid Leakage:

Cause 1: The seal around the cardan shaft is leaking.

Solution 1: Internal problem; cardan shaft seal.

Cause 2: The port fittings are leaking.

Solution 2: Replace port adaptors or O-rings. Tighten

the fittings to a maximum torque of 221 in-lbs. (25 NM)

on the “T”, “R”, and “L” ports. Tighten the fittings to a

maximum of 239 in-lbs. (27 Nm) on the “P”, and “E”

ports.

7.6. Engine-off test: With the engine turned-off so

that no pressure is supplied by the auxiliary

pump, the pump within the steering unit should

work well enough in manual mode to turn the

front wheels from one steering stop to the other

(full travel) with roughly 2.75 turns of the steering

wheel.

NOTE: The tractor was engineered to comply

with German TUV directive #38stVZo. It will provide steering action without pressure from the

auxiliary pump, maintaining steering wheel force

within a specified limit.

7.10. Install the hydraulic test kit in either one of the

two hydraulic lines leading from the steering

pump to the steering cylinder.

7.11. Disconnect the hydraulic line between the steering unit and the steering cylinder using a 5/8”

wrench and a 3/4” wrench. See Figure 7.11.

Hydraulic line

(pressurized

to turn right)

Hydraulic line

(pressurized

to turn left)

Steering cylinder

Figure 7.11

7.12. Connect the test kit so that the pressure gauge

side (as opposed to the flow meter side) is near

the source (steering unit). See Figure 7.12.

7.7. If there is air in the system, it will not perform to

design intent:

• If there are any leaks in the steering hydraulics,

air will be drawn into the system, degrading performance.

• If the system has been disassembled for any

reason, the engine must be started to provide

pressure from the auxiliary pump. With auxiliary

pump pressure to assist, turn the steering wheel

lock-to-lock three times, to purge air from the

steering system.

• After the air is purged, the engine-off test can be

performed with validity.

7.8. If the hydraulic steering lacks speed, test the

auxiliary pump as described in the previous section of this manual.

7.9. Once it has been established that the auxiliary

pump is developing enough flow and pressure,

then test the steering unit.

Pressure test kit

installed in right

turn hydraulic line

Figure 7.12

7.13. Confirm that the test kit valve is all the way open,

and that no unsafe conditions will arise from

starting the tractor engine.

7.14. Start the engine, warm-up the engine and

hydraulic system, then position the throttle to

1,200-1,500 RPM.

16

Page 21

Domestic Series 5000 Hydraulics

7.15. Have an assistant slowly turn the steering wheel

until the steering linkage hits the end of its travel.

Applying pressure to the steering wheel while

the linkage is at full lock will build pressure in the

system.

NOTE: The wheel can be turned in either direction to get a pressure reading.

NOTE: The steering pump is equipped with a

relief valve that will not permit the pressure to

rise above 1,087 to 1,160 PSI (75 to 80 Bars).

7.16. Observe the pressure reading on the test kit, at

full-lock. The pressure should be in the range of

1,087 to 1,160 PSI (75 to 80 Bars).

See Figure 7.16.

7.20. To check for blow-by, turn the steering wheel in

whichever direction causes the flow meter on the

test kit to rise:

• If the test kit is attached (as illustrated in figure

7.15) to the fitting at the base end of the cylinder,

turn the steering wheel to the right.

• If the flow meter is attached to the fitting at the

rod end of the steering cylinder, turn the wheel to

the left.

7.21. If the steering hits the end of its travel, builds terminal pressure, and the flow meter continues to

have a reading above zero, then fluid is blowingby the seals on the piston.

7.22. If the flow meter falls to zero and remains there

as pressure builds, then fluid is not blowing-by

the seals on the steering cylinder piston.

7.23. If blow-by exists, the steering cylinder is bad.

NOTE: A steering cylinder can get “blown-out”

by a steering pump with a relief valve that fails to

keep the pressure below 1,500 PSI (103 bars).

If this is the case, replacing the cylinder without

replacing the pump will result in rapid failure of

the replacement cylinder.

Figure 7.16

7.17. If steering pressure is low, and the auxiliary

pump has been confirmed to be functioning

properly, then the steering unit is the problem.

NOTE: Steering unit failure is a rare occurrence.

7.18. If the pressure is good between the steering unit

and the steering cylinder, but the steering system lacks power, then the steering cylinder is the

most likely hydraulic problem.

7.19. It is possible for the piston seals in the steering

cylinder to experience “blow-by” without creating

an externally visible leak.

7.24. If the hydraulic system (Auxiliary pump, steering

unit, cylinder, lines) is all in good order, then the

problem may be a mechanical bind in the steering linkage.

17

Page 22

Domestic Series 5000 Hydraulics

t

8. HYDRAULIC LIFT CYLINDER AND CONTROL VALVE

8.1. If the hydraulic lift cylinder does not work or is

low on power, begin by making a visual inspection of the valve, cylinder, linkage, and hydraulic

hose. See Figure 8.1.

Pressure line from E por

Direct return to

transmission

Return through

check valve

Figure 8.1

8.2. The outboard plumbing and linkage connections

to the control valve are visible beneath the

fender. More complete inspection, diagnosis,

and service require fender removal.

8.3. The lift cylinder and the hydraulic hose that connects it to the control valve are visible beneath

the left fender. See Figure 8.3.

Line to

cylinder

8.4. If the lift cylinder is operable, run it through the

full range of travel to confirm that the feedback

rod is working correctly. Normal operating characteristics include:

• The the lift arms move up when the control lever

is moved back. The lift arms move down when

the control lever is moved forward.

• In all positions, the lift cylinder will apply only

upward force to the lift arms. It is a single-acting

cylinder.

• Downward travel is not under hydraulic force,

and is only caused by the weight of the lift arms

and any accessories mounted to them.

• At any point in their travel, the lift arms may be

manually lifted beyond the point that the hydraulic system is holding them at. They will always

“float”.

• Because the steering system has priority over

the lift cylinder, it is normal for the lift cylinder to

have less power when the steering system is in

motion.

8.5. Orientation of the valve: See Figure 8.5.

Valve end of line

to cylinder

Cylinder end of line, behind left wheel

Figure 8.3

Figure 8.5

• The flexible line to the outboard side of the valve

provides pressure from the steering pump.

• A flexible line from the bottom of the valve connects it to the lift cylinder.

• The steel line leading rearward from the front

port on the valve carries fluid directly back to the

transmission housing (reservoir).

• The steel line leading forward from the rear port

on the valve directs fluid to the return manifold,

and back to the transmission housing.

18

Page 23

Domestic Series 5000 Hydraulics

8.6. Fluid movement:

• Fluid is constantly circulating from the auxiliary

pump, to the steering unit, through the valve,

then to the return manifold.

• When the valve is actuated to raise the lift arms,

it redirects fluid from this path to the lift cylinder.

• When the valve is actuated to lower the lift arms,

fluid is allowed to empty from the lift cylinder

through the valve, into the steel line leading from

the top of the valve to the transmission cover.

8.7. Control Linkage Description: The operator control handle pivots on a bracket bolted to the

frame. A pin on the valve link engages a slot in

the handle, above the handle pivot point. The

ratio of travel varies with the position of the handle, but when the pin is centered in the slot there

is a 10:1 ratio between the movement of the

handle and the movement of the pin. The top of

the valve link pivots on the valve mounting

bracket. Between the pin and the fulcrum is a

connection to the tubular link. There is a 3:1

ratio between the movement of the valve link

and the movement of the tubular link.

Control handle

Bracket

8.10. Confirm that the lift cylinder control valve is getting pressure from the steering pump:

• Remove any rear mounted attachments that are

supported by the lift arms or will interfere with

access to the lift cylinder and control valve.

• Remove the rear fenders.

• Lift and safely support the rear of the tractor.

• Remove the right rear wheel using a 21mm

wrench.

• Lower the lift arms to the bottom of their travel,

and confirm that the lift cylinder is fully retracted.

• Disconnect the flexible hydraulic line from the

bottom of the control valve using a 3/4” wrench

and a 5/8” wrench.

• Install the test kit with the flexible line connected

to the pressure gauge end of the kit, and the

control valve connected to the flow meter end of

the kit. See Figure 8.10.

From E port

To control valve

Tubular link

Pin

Figure 8.7

8.8. The effective movement ratio of 30:1between

the handle and the input to the control valve

allows precise movement of the three point lift

without the complexity of the shifting fulcrum

linkage used on the domestic Series 7000.

8.9. The category 1 three point hitch system on the

domestic Series 5000 tractor should be capable

of lifting 950 lbs. (430 Kg.), 24 in. (61 cm.)

behind the hitch. If it does not perform as

designed, use the following procedure to diagnose it.

Figure 8.10

8.11. Confirm that the test kit valve is all the way open,

and that no unsafe conditions will arise from

starting the tractor engine.

8.12. Start the engine, warm-up the engine and

hydraulic system, then position the throttle to

3,000 RPM.

19

Page 24

Domestic Series 5000 Hydraulics

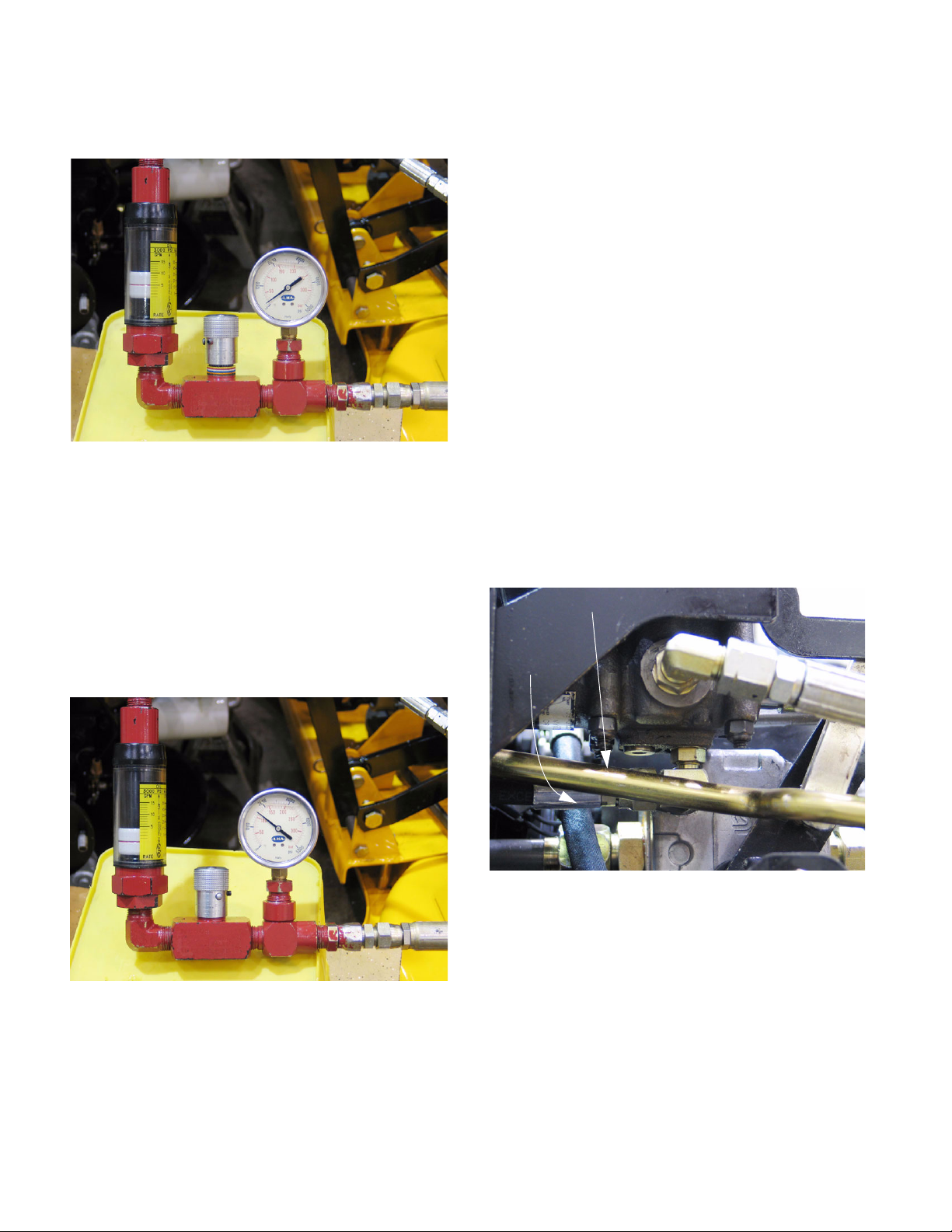

8.13. The flow meter should rise to 4 GPM (15 LPM)

and hold steady at that level. See Figure 8.13.

Figure 8.13

8.14. After the flow rate is established, lower the throttle setting to 1,200-1,500 RPM

8.15. Carefully close the valve on the test kit. It is not

necessary to move the lift cylinder to generate

pressure.

NOTE: Designed system pressure is 1,500 PSI

(103 Bars). Testing beyond this pressure subj ec t s t h e sy s te m t o n e ed l e ss o ve r - lo a d.

See Figure 8.15.

8.16. The flow should remain constant, while the pressure climbs to 1,500 PSI (103 Bars). Open the

valve a soon as the readings are confirmed.

NOTE: Remember, the flow varies with engine

RPM, but does not vary with pressure generated

unless the auxiliary pump is failing.

8.17. Turn off the engine. Retract the lift cylinder fully

to relieve pressure from the hydraulic system.

8.18. Remove the test kit from the line between the

steering unit and the lift control valve, and connect the hydraulic line to the control valve.

8.19. If the control valve is receiving full pressure from

the steering unit, but the lift cylinder lacks power,

perform a pressure test at the line between the

valve and the cylinder.

8.20. Install the test kit between the control valve and

the lift cylinder.

8.21. If the tractor is equipped with a mid-mount

mower deck, it will be necessary to disconnect

and remove the link that connects the three point

lift arm to the deck lift mechanism.

See Figure 8.21.

Deck lift link

Pressure

line to lift

cylinder

Figure 8.15

Figure 8.21

20

Page 25

Domestic Series 5000 Hydraulics

8.22. Disconnect the flexible hydraulic line that leads

from the control valve to the lift cylinder using an

11/16” and a 3/4” wrench. See Figure 8.22.

Disconnect here

Figure 8.22

8.23. Connect the test kit to the 3/8” flare fittings. The

pressure gauge should be near the valve, and

the flow meter should be near the cylinder.

See Figure 8.23.

8.27. As the lift arms travel upward, note the reading

on the flow meter. It should be in the vicinity of 5

GPM (19 LPM). See Figure 8.27.

UP

4 GPM

No significant

pressure

Figure 8.27

8.28. Continue moving the arms up until they reach

the top end of their travel. Note the pressure

reading. See Figure 8.28.

To cylinder

To valve

Figure 8.23

8.24. Set the parking brake, place the gear selector in

neutral, open the flow valve on the gauge set all

the way, and confirm that no unsafe conditions

will be created by starting the tractor engine.

8.25. Start the engine, allow it to warm-up. Set the

throttle to maintain 3,000 RPM.

8.26. Move the hydraulic lift lever rearward to raise the

lift arms.

No flow

1,500 PSI

Figure 8.28

• The pressure should approach but not exceed

1,500 PSI (103 Bars).

• The flow will fall to zero as the pressure builds.

8.29. If the pressure delivered to the control valve is

low, the auxiliary pump has tested good, and the

hydraulic lines show no signs of physical damage or leakage, then the problem lies in the

steering unit.

21

Page 26

Domestic Series 5000 Hydraulics

8.30. If the pressure delivered to the control valve is

sufficient, but the pressure delivered to the cylinder is low, then the problem is likely to be in the

control valve.

8.31. If the pressure delivered to the cylinder is sufficient, yet the cylinder does not perform adequately, look for leakage from the cylinder.

8.32. If the pressures are O.K., no leakage exists, yet

the cylinder does not perform adequately, there

may be a mechanical bind, or the operator may

be overloading the equipment.

9. LOADER VALVE

9.1. The simplest way to check pressure to the

attachment is by connecting the test kit to the

Quick Disconnect ports. See Figure 9.1.

9.2. If the performance problem is isolated to the

movement of one set of cylinders (boom or

bucket), connect the test kit to the set of couplings that is associated with that movement

(1 & 3) or (2 & 4).

9.3. With the test kit installed to test the boom, the kit

loops fluid from one boom connector to the

other. They hydraulic lines that lead to the cylinders that operate the boom will be left disconnected. For this test, the kit is not connected inline with the cylinders, and the cylinders will not

be in motion during the test.

9.4. After the test kit is connected, confirm that no

unsafe conditions will result from starting the

engine or operating the hydraulic system.

9.5. Open the flow valve on the test kit completely,

then start the engine, and set the throttle to

maintain 3,000 RPM.

9.6. With the test kit installed so that the pressure

gauge is near the boom-down fitting (green band

3d one in), and the flow meter is near the boomup fitting (blue band, outboard coupler), pushing

the loader valve forward to the detent will generate a reading on the flow meter of about 5.0

GPM (19.0 LPM) when the test kit flow valve is

open. Pressure will be zero. See Figure 9.6.

Figure 9.1

• The hydraulic lines are arranged as follows, from

the outboard inward when connected to a frontend loader:

1. Outboard coupling, blue band, boom up.

2. Second coupling in, yellow band, bucket dump.

3. Third coupling in, green band, boom down.

4. Furthest inboard, red band, bucket roll up.

• One female quick disconnect and one male

quick disconnect will be required on the test kit.

• Connect to alternating couplers, eg.: 1 & 3 to

check boom operation, or 2 & 4 to check bucket

operation.

5 GPM

NOTE: Pushing the loader valve lever all the

way forward, past the detent, will put the valve

into “float” mode. This is reflected by a flow

meter reading that falls to zero, and a pressure

gauge reading falls to zero.

NOTE: Pushing the loader valve lever forward,

but not all the way to the detent will produce

readings with less flow, but increased pressure.

Zero pressure

Figure 9.6

22

Page 27

Domestic Series 5000 Hydraulics

9.7. Reducing throttle to the 1,200-1,500 RPM range,

observe the flow while pushing the loader valve

lever forward to the detent. The flow should be

around 5.0 GPM (19.0 LPM).

9.8. While holding the loader valve lever forward

gains the detent (but not into Float), slowly close

the flow valve on the test kit. See Figure 9.8.

Zero

flow

Valve closed

1,500 PSI

Figure 9.8

9.11. If the pressure varies slightly in above or below

1,500 PSI (103 Bars), the relief valve can be

adjusted. It is located on the top, outboard corner of the loader valve.

9.12. In order to adjust the relief valve, it is necessary

to remove the right side fender cover.

See Figure 9.12.

Fender

cover

Handles

Knob

Figure 9.12

NOTE: Because of the relief feature built into the

loader valve, as pressure approaches the relief

point of 1,500 PSI (103 Bars) more fluid will be

diverted to the return manifold. As more fluid is

diverted, the flow meter will show progressively

lesser readings while the pressure remains constant at 1,500 PSI (103 Bars). If the flow valve

on the test kit is closed completely, flow will stop

completely.

CAUTION: If pressure rises substantially above

1,500 PSI (103 Bars) discontinue the test immediately. Correct the pressure relief issue before

continuing.

9.9. The test described above will check the ability of

the hydraulic system to apply downward pressure to the boom. The test can be reversed, to

check lifting ability by reversing the connection

of the test kit and pulling the loader valve control

lever back instead of pushing forward.

9.10. The same procedures will work for testing the

controls for the roll operation of the bucket, but

the test kit will be connected to couplers 2 and 4

(second one in, red band and far inboard coupler, yellow band).

9.13. Remove the handles from the hydraulic lift control lever and the high-low range gear selector

lever by pulling them off.

9.14. Remove the knob and boot from the loader valve

control handle. The knob has normal right-hand

threads.

9.15. Remove the fender cover using a T-40 driver

from inside the fender. See Figure 9.15.

Figure 9.15

23

Page 28

Domestic Series 5000 Hydraulics

9.16. Unbolting the loader valve bracket from the

frame of the tractor will provide additional

wrench clearance between the pivot bracket and

the fender. This can be done with a 1/2” wrench.

See Figure 9.16.

Loader valve bracket

Figure 9.16

9.17. It is necessary to unbolt the pivot bracket

assembly from the loader valve in order to get a

wrench on the relief valve adjustment screw.

The pivot bracket can be unbolted using a 3/8”

wrench. See Figure 9.17.

9.18. Once access is gained to the adjustment screw,

index the screw, jam nut, and housing using a

marker.

9.19. Loosen the jam nut using a 7/8” wrench and turn

the adjuster screw using a 7/16” wrench.

See Figure 9.19.

Figure 9.19

9.20. Make adjustments to the relief valve in singlefacet increments:

• Loosen the jam nut.

Adjustment screw

Jam nut

Pivot bracket

Loader valve bracket

Figure 9.17

• Make adjustment: 1/6th turn or less.

• Tighten jam nut.

• Install pivot bracket.

• Test relief valve pressure.

• Repeat as necessary.

•DO NOT “crank-up” the pressure beyond 1,500

PSI (103 Bars).

• Install the fenders when adjustment is completed.

9.21. The pressure readings at both sets of ports

should respond equally to adjustments made to

the relief valve. If there is substantial difference

between the pressures found at the two sets of

ports, there is an internal problem with the

loader valve.

9.22. If the loader valve does not respond to adjustment, or does not perform as described in this

section:

• Confirm that the pressure delivered to the loader

valve is adequate, and if not, why not. -or-

• Replace the valve.

24

Page 29

Domestic Series 5000 Hydraulics

10. COMPONENT BREAKDOWN: AUXILIARY PUMP

NOTE: The auxiliary pump is to be replaced as a

unit if it fails. Disassembling it will VOID the

warranty. The pump has been disassembled

here to illustrate how it works.

NOTE: Individual pump components will not be

available through Cub Cadet.

10.1. The gear must be removed from the pump in

order to remove the pump from the transmission.

See Figure 10.1.

Auxiliary pump drive gear

Auxiliary pump

Nut

Lock tab

10.2. The back cover can be removed from the pump

by removing the four socket head cap screws.

See Figure 10.2.

Pump with back

Splined shaft

Figure 10.2

10.3. Removing the rear cover reveals an O-ring seal,

the splined shaft that transmits power to the tandem pump (when fitted), and four more socket

head cap screws.

cover removed

O-ring seal

Figure 10.1

• The gear is a taper-fit to the pump shaft, and it is

keyed to the shaft.

• The lock tab, key, and nut are included with the

pump.

• The nut and shaft have a non-standard metric

thread. They will not be commonly available.

• An O-ring seal and Ultra-black sealant are used

to seal the pump to the front of the transmission.

10.4. The second set of socket head cap screws holds

the two housing ends to the body of th e pu m p .

See Figure 10.4.

Housing end: back

Housing end:

mounting

Pump body

Figure 10.4

10.5. Both ends of the pump have O-ring type seals

where they meet the pump body.

10.6. The body contains a simple gear pump.

25

Page 30

Domestic Series 5000 Hydraulics

10.7. There is a cartridge that slides into the pump

body. See Figure 10.7.

Second

pump gear

Shaft with

pump gear

Bearing

cartridge

Figure 10.7

• The gears operate within, and are located by the

cartridge.

• The cartridge end is partially sealed. Lubrication

channels direct a metered amount of pressurized oil to the bearings and thrust surfaces.

11. COMPONENT BREAKDOWN: STEERING UNIT

NOTE: The steering unit is to be replaced as a

unit if it fails. Disassembling it will VOID the

warranty. The steering unit has been disas-

sembled here to illustrate how it works.

NOTE: Individual components of the steering

unit are not available through Cub Cadet.

11.1. The fittings on the end of the steering unit extend

through the first two sections of the body, into

the third and largest section. They hold all three

sections of the steering unit body together.

See Figure 11.1.

Figure 11.1

• O-rings seal the lines to the steering unit.

• O-rings also seal the fittings to the end of the

steering unit.

• There are two sizes of fitting: 9/16”-18 and 11/

16”-16

• If a 9/16”-18 fitting should come loose, tighten it

to a torque of 25 in-lbs. (221 Nm).

• If an 11/16”-16 fitting should come loose, tighten

it to a torque of 27 in-lbs (239 Nm).

26

Page 31

Domestic Series 5000 Hydraulics

11.2. With the fittings removed, the three sections of

the steering unit can be separated.

See Figure 11.2.

Figure 11.2

11.3. The first two sections comprise a gerotor pump

and end plate to pressures the system using

steering wheel motion. See Figure 11.3.

11.4. The cardan shaft transfers motion from the

steering wheel, through the body of the steering

unit, to the pump. See Figure 11.4.

Figure 11.4

11.5. The relief valve ball and retainer live in one of

the fitting bores. Carefully extract them with a

magnet while the steering unit is in the upright

position. See Figure 11.5.

Figure 11.3

Figure 11.5

27

Page 32

Domestic Series 5000 Hydraulics

11.6. The spool and sleeve can be easily tapped-out

of the housing. A thrust bearing assembly fits

between the spool and sleeve assembly and the

housing. See Figure 11.6.

Figure 11.6

11.7. A circular retainer holds the leaf springs in place.

See Figure 11.7.

11.8. A dowel pin connects the spool and sleeve axially, and transmits steering force to the sleeve

from the cardan shaft. See Figure 11.8.

Figure 11.8

11.9. Removing the dowel pin allows the spool to separate from the sleeve. See Figure 11.9.

Figure 11.7

• The leaf springs transmit steering force from the

sleeve to the spool.

• The effort it takes to deflect the leaf springs

determines the amount of force that must be

applied to the steering wheel before hydraulic

force is applied to the steering.

Figure 11.9

28

Page 33

11.10. There are two types of leaf spring: flat and

bowed. A pair of each goes together, back-toback. See Figure 11.10.

Figure 11.10

Domestic Series 5000 Hydraulics

29

Page 34

Domestic Series 5000 Hydraulics

30

Page 35

Domestic Series 5000 MFD

Domestic Series 5000 MFD

ABOUT THIS SECTION:

The Cub Cadet Series 5000 MFD (Mechanical Front

Drive) axle is visually similar to the MFDs used in the

Series 7000 Tractor. The MFDs used in the Series

5000 are functionally different from those used in the

Domestic Series 7000, and cannot be inter-changed.

The first part of this section describes the characteristics that will enable a technician to identify the three different units.

Early (2002 and 2003) production of the domestic

Series 7000 four wheel drive tractors used an MFD

(Mechanical Front Drive) sourced from another manufacturer. Beginning with serial number 1B014G20001

(February 1st, 2004) domestic Series 7000 tractors

were built using an MFD assembled in Cub Cadet’s

transmission plant in Leitchfield, KY.

Removal and replacement procedures for the MFDs in

the two tractors are not substantially different from oneanother. Service Policy on the Cub Cadet produced

MFDs will be to establish a pool of rotable exchange

units that can be ordered by dealers to replace damaged MFDs. This applies to the Cub Cadet produced

MFDs only, NOT to the outsourced MFDs that were

used in some early production domestic Series 7000

tractors.

For tractors with warrantable repairs required to a

Cub Cadet built MFD:

• The complete assembly is to be removed and

replaced.

1. TO IDENTIFY THEM MFD:

1.1. The Cub Cadet built MFD for the Series 5000 is

618-04028. The out-sourced Series 7000 MFD

is part number 618-3207. The Cub Cadet built

MFD for the Domestic Series 7000 is 618-0484.

1.2. The out-source MFD has numbers embossed on

most major components, the Cub Cadet Unit

does not. See Figure 1.2.

Casting numbers

= out-sourced MFD

Cub produced unit is blank

Figure 1.2

1.3. The Octagonal “pumpkin” is roughly 2” wide on

the out-sourced MFD. It is roughly 4” wide on

the Cub Cadet MFD. See Figure 1.3.

• The core shall be returned to Cub Cadet for

rebuilding. It is not to be disassembled in any

way.

• The determination as to whether a new or factory rebuilt MFD is to be installed under warranty

will be made on a case-by-case basis.

• Outside of warranty, the dealer is free to repair a

worn or damaged MFD, replace a worn or damaged MFD with a factory rebuilt unit, or to

replace a worn or damaged MFD with a new

one.

31

2”

4”

Figure 1.3

Page 36

Domestic Series 5000 MFD

1.4. The MFD manufactured by Cub Cadet is

mounted to two one-piece brackets.

See Figure 1.4.

Cub Cadet produced MFD mounts

with two 1-piece brackets

Figure 1.4

1.5. The out sourced MFD is mounted to a pair of

two-piece brackets. See Figure 1.5.

Out sourced MFD: mounts

with two 2-piece brackets

1.7. To visually distinguish the Series 5000 MFD

from the Series 7000 MFD: the Series 5000 unit

has four tapped holes or wheel studs on the axle

flanges, while the Series 7000 has five tapped

bolt holes on the axle flanges.

1.8. The Series 5000 MFD is wider than the Series

7000 MFD. The outside edge (measured at the

top) of the axle flanges on the 5000 are 3 1/2”

(8.9 cm) outboard of the seam where the axle

cover meets the drop axle housing. See Figure

1.8.

Series 5000

3 1/2”

4 studs on

drive flange

Figure 1.5

1.6. The Cub Cadet Series 5000 MFD (618-0428)

uses many of the same castings as the Cub

Cadet Series 7000 MFD (618-0484). The Series

5000 has a different ring and pinion gear orientation and the out-put to the wheels is in the opposite direction.

Figure 1.8

1.9. While the main castings are the same, the outside edge (measured at the top) of the axle

flanges on the 7000 are 2” (5 cm) outboard of

the seam where the axle cover meets the drop

axle housing See Figure 1.9.

Series 7000

Five tapped

lug-bolt holes

in drive flange

Figure 1.9

2”

32

Page 37

Domestic Series 5000 MFD

1.10. The difference in widths is accounted for by the

fact that axle flanges protrude visibly further out

of the housing on the 618-0428 (5000 MFD)

than they do on the 618-0484 (7000 MFD).

1.11. To mechanically distinguish between a Series

7000 MFD and a Series 5000 MFD, rotate the

input (pinion) shaft. Clockwise rotation (looking

at the end of the pinion shaft) will result in forward tractor motion on the Series 7000 (6180484 or 618-3207). Clockwise rotation will result

in reverse tractor motion on the Series 5000

(618-0428).

Tractor 7000 Cub 7000 Outsourced 5000 Cub

Part # 618-0484 618-3207 618-0428

Input Clockwise Clockwise C.C.W.

Axle Stubby Stubby Extended

Mounting 1 piece 2 piece 1 piece

Wheel 5 bolt 5 bolt 4 stud

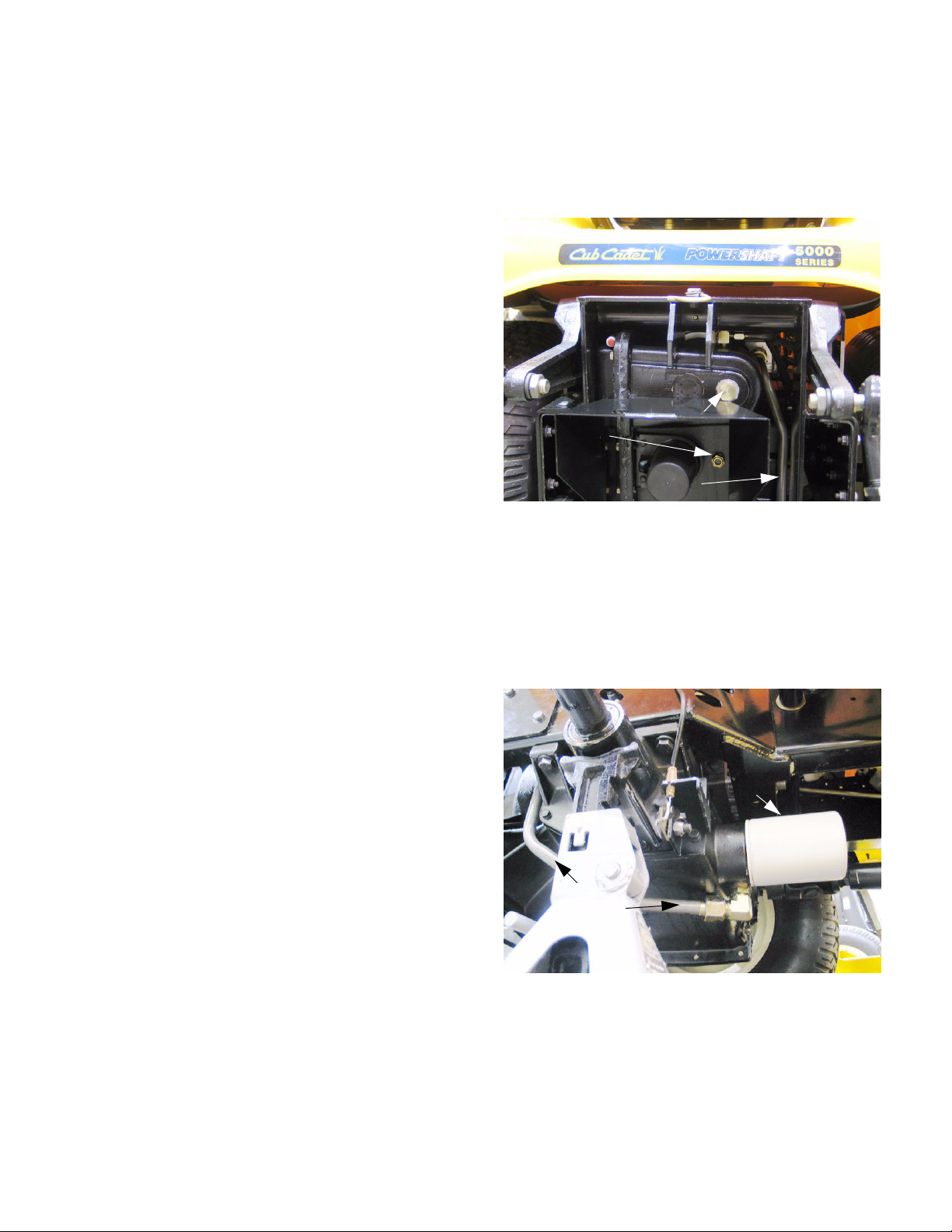

2. MFD REMOVAL: PREPARATION

NOTE: This procedure can be done on tractors

that are equipped with cutting decks, front-end

loaders, and other attachments. It is not necessary to remove the attachments in order to

remove and replace the MFD.

2.1. Park the tractor on a firm level surface. Lower

any attachments to the ground.

2.2. Place a drain pan under each final drive housing. Remove the drain plugs using an 11 mm

wrench. Remove the fill plugs using a 16 mm

wrench. See Figure 2.2.

Fill plug

Drain plug

Figure 2.2

2.3. Place a drain pan under the differential housing,

and remove the drain plug using a 16 mm

wrench. Remove the oil level gauge to allow

faster draining. See Figure 2.3.

Differential

drain plug

Oil level

gauge

33

Figure 2.3

Page 38

Domestic Series 5000 MFD

3. REMOVAL

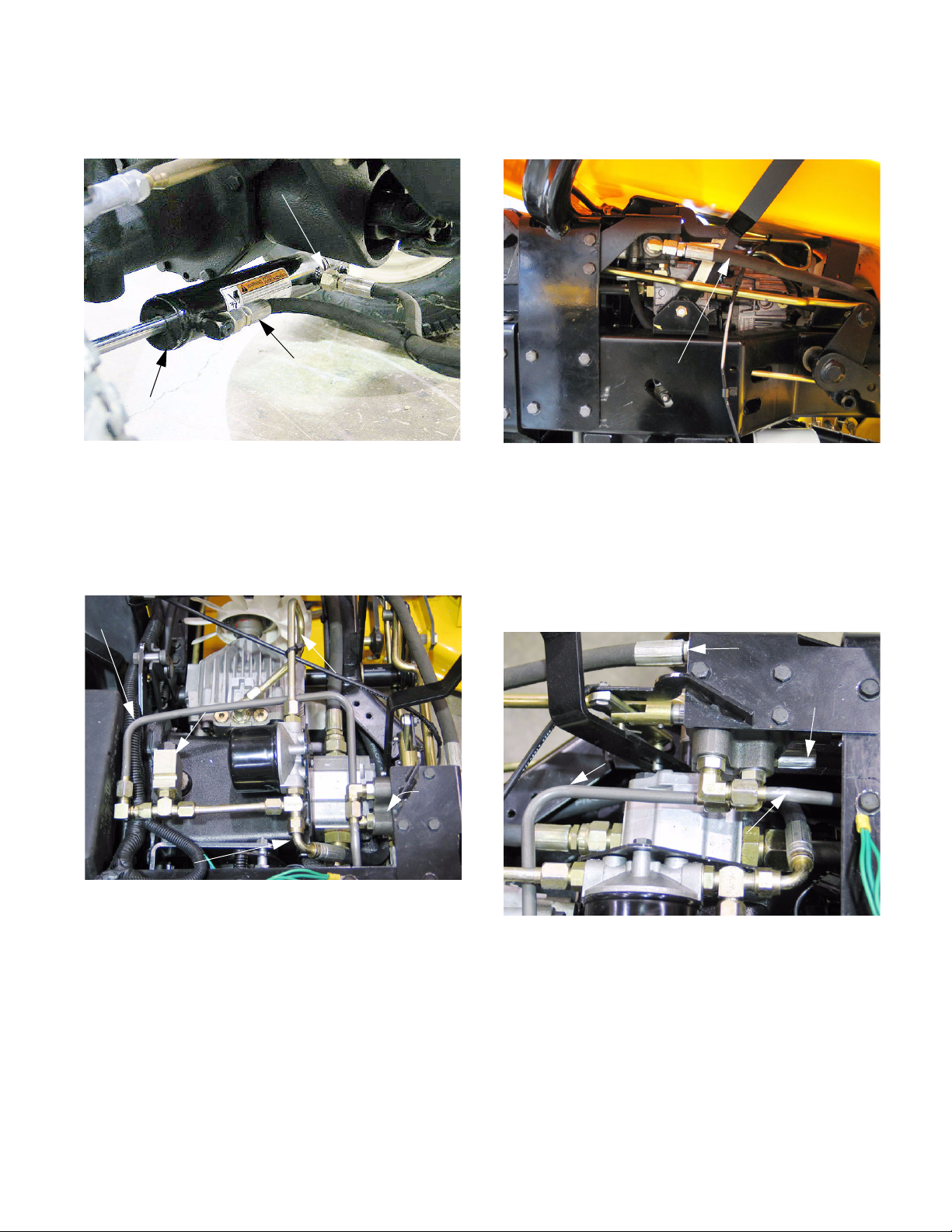

3.1. Loosen the set screw that secures the back end

of the 4 W.D. drive shaft to the splined output

shaft on the front of the transmission.

See Figure 3.1.

S

Figure 3.1

3.5. Remove the four bolts holding the steering cylinder bracket to the MFD housing using a 19 mm

wrench. See Figure 3.5.

Lock washers

Steering cylinder

mounting bracket

Figure 3.5

NOTE: Only the inner two bolts (closer to the

axle mounting bracket) have lock washers.

3.2. Slip the 4 W.D. drive shaft back to disengage it

from the MFD.

3.3. If the tractor is equipped with a cutting-deck,

loosen the two nuts on the front of the “U” bar

using a 3/4” wrench. Remove the “U” bar.

3.4. Remove the nut that secures the ram of the

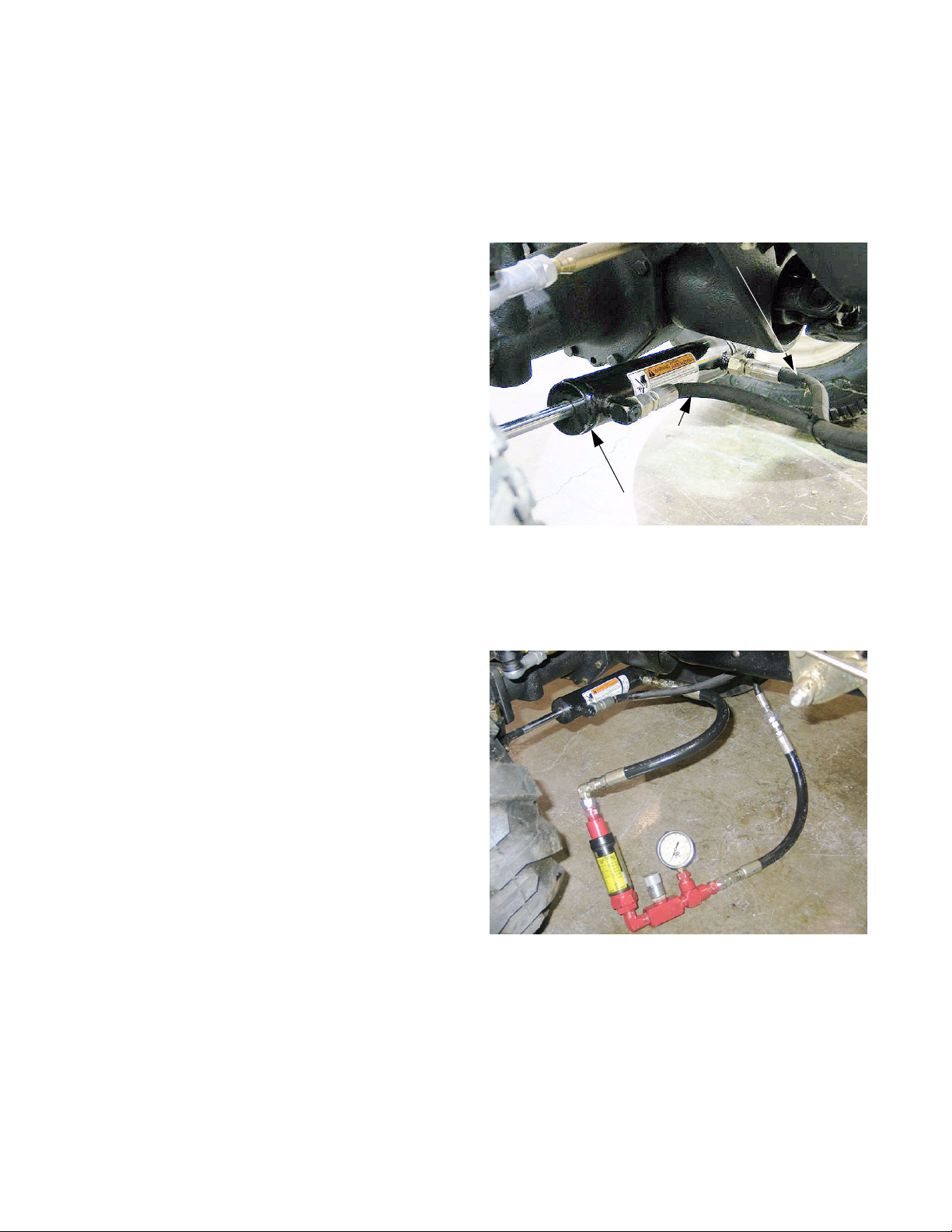

steering cylinder to the steering cylinder mounting stud using a 24 mm wrench. See Figure 3.4.

Stud

Steering

cylinder

Nut

3.6. Lower the steering cylinder carefully off of the

mounting stud, and position it safely out of the

way. See Figure 3.6.

Steering

Cylinder

Mounting

stud

Figure 3.6

NOTE: Do not allow the steering cylinder to

hang on the hydraulic hoses.

Figure 3.4

3.7. Remove the steering cylinder mounting stud

using a 1” wrench and a 1 1/16” wrench.

34

Page 39

Domestic Series 5000 MFD

3.8. Lift and support the front of the tractor by the differential housing. Leave the hydraulic jack in

place. See Figure 3.8.

Figure 3.8

NOTE: If the MFD is being replaced because the

housing is broken, an alternative jacking point

may need to be identified by the technician.

3.12. Remove the four nuts that secure the front axle

bracket to the frame using a pair of 3/4”