Page 1

www.mymowerparts.com

Service Manual

4x2 Utility Vehicle

Poly Bed and Steel Bed

NOTE: These materials are prepared for use by trained technicians who are experienced in the service and repair of equipment of the

kind described in this publication, and are not intended for use by untrained or inexperienced individuals. Such individuals should seek

the assistance of an authorized service technician or dealer. Read, understand, and follow all directions when working on this equipment. This includes the contents of the Operators Manual, which came with your equipment. No liability can be accepted for any inaccuracies or omission in this publication, although every care has been take to make it as complete and accurate as possible. The right

is reserved to make changes at any time to this document without prior notice and without incurring an obligation to make such

changes to previously published documents. All information contained in this publication is based on product information available at

the time of publication. Photographs and illustrations used in this publication are for reference use only and may not depict actual

model and component parts.

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-01635

12/2004

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 2

www.mymowerparts.com

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 3

www.mymowerparts.com

TABLE OF CONTENTS

Poly Bed 4 X 2 Drive System

Customer Responsibilities ............................................................................................ 1

Gear Lube .....................................................................................................................1

Diagnosis: Confirming Transaxle Fault .........................................................................3

Transmission Linkages ................................................................................................. 3

Diagnosis and Service: Drive Belt and Clutches

(CVT or Continuously Variable Transmission) ...................................................11

Transaxle Removal and Replacement ........................................................................20

Transaxle Installation Notes: .......................................................................................24

Link Assembly .............................................................................................................25

Transaxle Repairs .......................................................................................................26

Poly Bed 4 X 2 Brake System

Maintnance and Description of the Brake System ...................................................... 39

Complete Inspection (Drum and Shoe Removal) ......................................................40

Brake Adjustment (under the hood) 43

4 X 2 Drive System - (Steel Bed)

Customer Responsibilities .......................................................................................... 47

Gear Lube ...................................................................................................................47

Diagnosis: Confirming Transaxle Fault .......................................................................48

Diagnosis and Service: Drive Belt and Clutches

(CVTor Continuously Variable Transmission) ......................................................49

CVT Removal: Driven Pulley ......................................................................................52

CVT Removal: Driving Pulley ......................................................................................53

Transaxle Removal and Replacement ........................................................................55

Transaxle Installation Notes: .......................................................................................59

Link Assembly .............................................................................................................60

Transaxle Orientation ..................................................................................................61

Transaxle Disassembly: Axle tube Removal and Case Separation ............................ 62

Transaxle Disassembly: Gear Set Removal and Disassembly ................................... 64

Transaxle Disassembly: Differential ............................................................................68

Transaxle: Axle Tubes ................................................................................................70

In-cradle Engine Service .............................................................................................74

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 4

www.mymowerparts.com

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 5

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

Poly Bed 4 X 2 Drive System

ABOUT THIS SECTION:

This section covers the drive system and transaxle

used in the Big Country utility vehicle model series 414

(37AN414J710). This model is distinguished from the

420 and 430 series by a polymer bed and the use of a

different drive system. The 420 and 430 series use a

Honda 18 hp. V-twin engine and a Dana transaxle.

The 414 uses a drive system manufactured by

Kawasaki.

1. CUSTOMER RESPONSIBILITIES

• Housing, axle, bearing, or axle tube damage

caused by impact or over-loading constitutes

customer abuse, and is not covered under the

warranty. The poly bed Big Country has a lower

load rating than the steel bed version: 900 Lb.

(410 KG) including bed load, operator, and passenger.

• Damaged caused by shock-loading the transmission is not covered under the warranty.

Shock-loading is primarily caused by shifting

between forward and reverse gears without

allowing the vehicle to come to a full stop. This is

possible if the vehicle is operated abusively

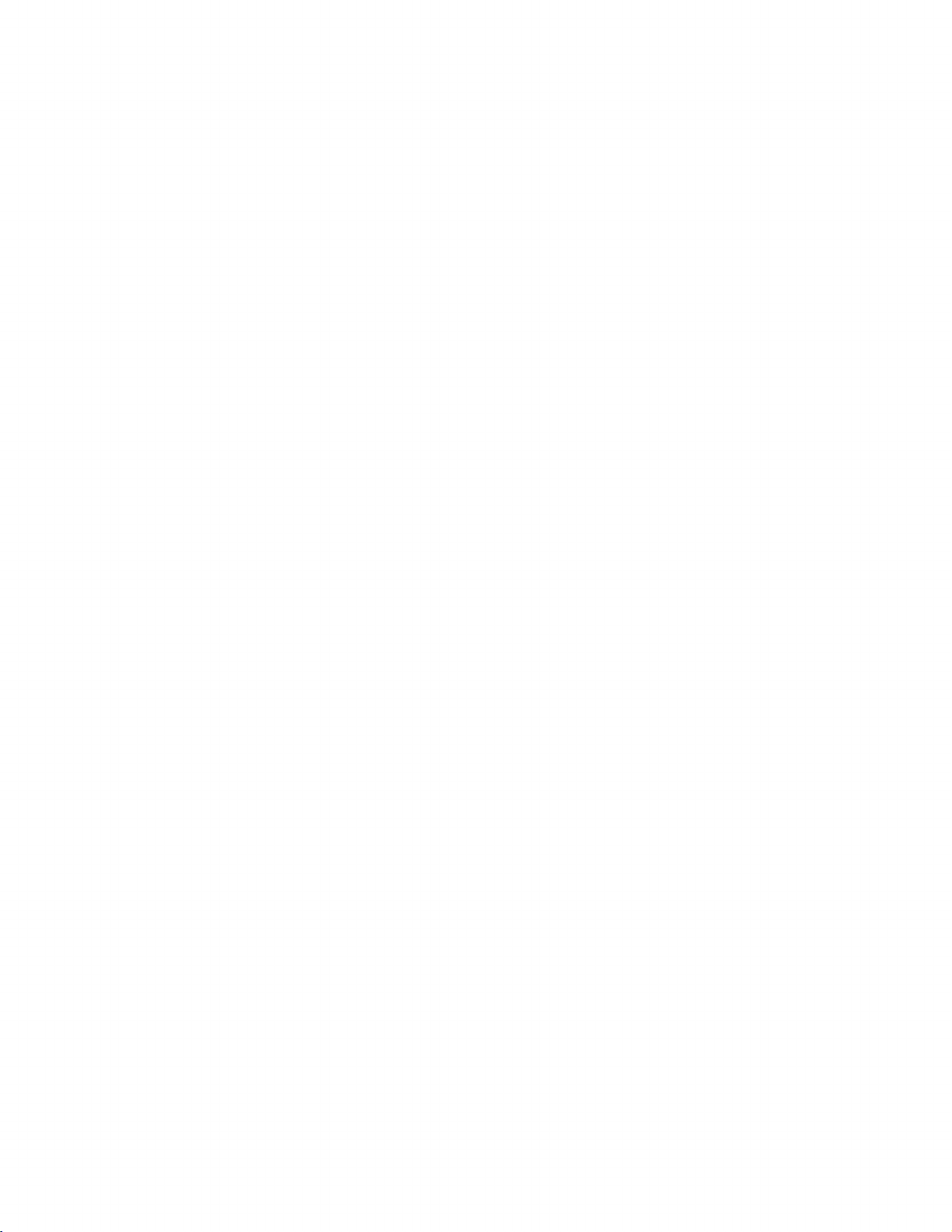

2. GEAR LUBE

2.1. Service intervals: Initial change: 50 hours

Subsequent changes: 500 hours of 2 years

Check level: every 100 hours.

2.2. The transaxle should contain 68 fluid ounces

(2.0 L) API “GL-5” hypoid gear lube.

• SAE 90 weight above 41deg. f. (5 deg. C.)

• SAE 80 weight below 41 deg. f. (5 deg. C.)

2.3. To check the gear lube level, park the vehicle

on a flat level surface.

2.4. Clean the area around the oil fill cap/dipstick

near the back of the transaxle housing and

remove the dipstick.

2.5. Wipe the dipstick clean, insert it back into the

threaded hole, but do not thread it in.

2.6. Withdraw the dipstick and check the oil level. It

should be between the upper and lower level

lines. The area between the lines is marked with

cross-hatch. See Figure 2.6.

• Damage caused by a lubrication failure is not

covered under the warranty.

• It is the customer’s responsibility to have any

leaks repaired in a timely fashion.

• The lug nuts should be inspected for looseness

after the first ten hours of operation. Lug nuts

should be tightened to a torque of 55-60 ft.-lbs.

• The brakes are not self-adjusting. It is the customer’s responsibility to maintain them in good

working order and proper adjustment, whether

directly or through an authorized Cub Cadet Servicing Dealer.

• It is the customer’s responsibility to maintain the

vehicle in accordance with the Operator’s Manual. This includes an initial gear lube change

after 50 hours of operation, and changes every

500 hours of operation (or 2 years) thereafter.

• The gear lube level should be checked every

100 hours of operation. At this time a visual

inspection should be made for leaks or damage.

Dipstick location

Figure 2.6

2.7. If additional lube is needed, confirm the current

contents of the transaxle, and add more of the

same to reach the specified level.

2.8. If additional fluid is needed, inspect the transaxle

for leaks or damage. If leakage is found, make

any necessary repairs before returning the vehicle to service.

1

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 6

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

2.9. A blocked vent can provoke oil leaks. The vent is

located at the top of the transaxle housing.

See Figure 2.9.

Vent line

Figure 2.9

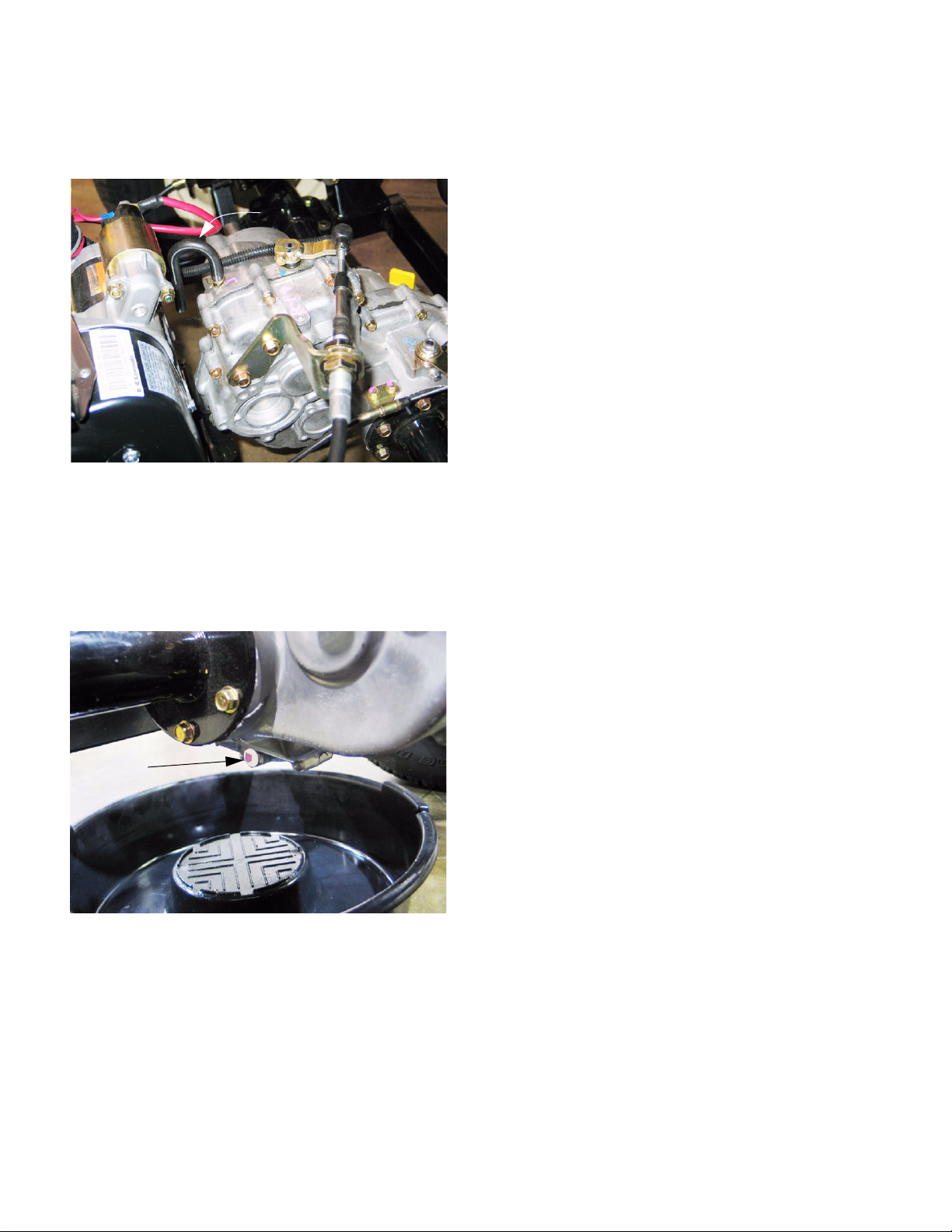

2.10. To change the gear lube: Clean the area

around the fill and drain plugs before removing

either.

2.13. Remove the oil fill cap/dipstick. This will allow air

to enter the transaxle faster, which will allow the

gear lube to drain faster.

2.14. Install the drain plug and tighten it to a torque of

132 in.-lb. (15 N-m).

2.15. Add 68 fluid ounces (2.0 L) API “GL-5” hypoid

gear lube, and install the oil fill cap/dipstick.

• SAE 90 weight above 41deg. f. (5 deg. C.)

• SAE 80 weight below 41 deg. f. (5 deg. C.)

2.16. Confirm the correct fluid level by by inserting

(but not threading-in) the fill cap/dipstick, and

withdrawing it to read the level.

2.11. Place a drain pan under the transaxle.

See Figure 2.11.

Drain plug

Figure 2.11

2.12. Remove the drain plug at the lower left corner of

the transaxle using a 12mm wrench.

NOTE: 80 and 90 weight gear lubes are very

thick at low temperatures, and may take considerable time to drain if the ambient temperature is

below 41 deg. f. (5 deg. C.)

2

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 7

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

3. DIAGNOSIS: CONFIRMING TRANSAXLE FAULT

3.1. Get as much information as possible from the

customer regarding symptoms and circumstances.

3.1. Inspect the vehicle for physical damage and

clues regarding the nature and cause of failure.

3.2. Carefully operate the vehicle if possible, to confirm noises and symptoms.

3.3. Confirm whether the problem is internal, in the

shift linkage, brake system, or the belt drive system (CVT):

• If a drive gear (forward or reverse) or the differential lock fail to engage or disengage by manually overriding the shift mechanism.

• Shift mechanism issues can be isolated from

internal issues by disconnecting the cables at

the transaxle end, and operating the transaxle

directly.

• Performance problems such as failure to reach

full speed are likely to be caused by engine,

brake, or belt/clutch issues.

• Complaints of “lurchy” operation are an indication that the brakes may be dragging or adjusted

too tight.

• It is easy to check for dragging brakes by pushing the vehicle with the parking brake released,

or by jacking-up the back of the vehicle and

checking the wheels for ease-of rotation.

• Refer to the “Brake” section of this manual for

service and adjustment information.

• Gear clash can result from drive being applied to

the input shaft during shifting. Refer to the

“CVT” section of this manual for performance

information.

• Gear “spit-out” or gear clash when the gear

selector is in Neutral can result from a misadjusted shift linkage. Refer to the “Transmission Linkage” section of this manual.

4. TRANSMISSION LINKAGES

Shift Control Cable

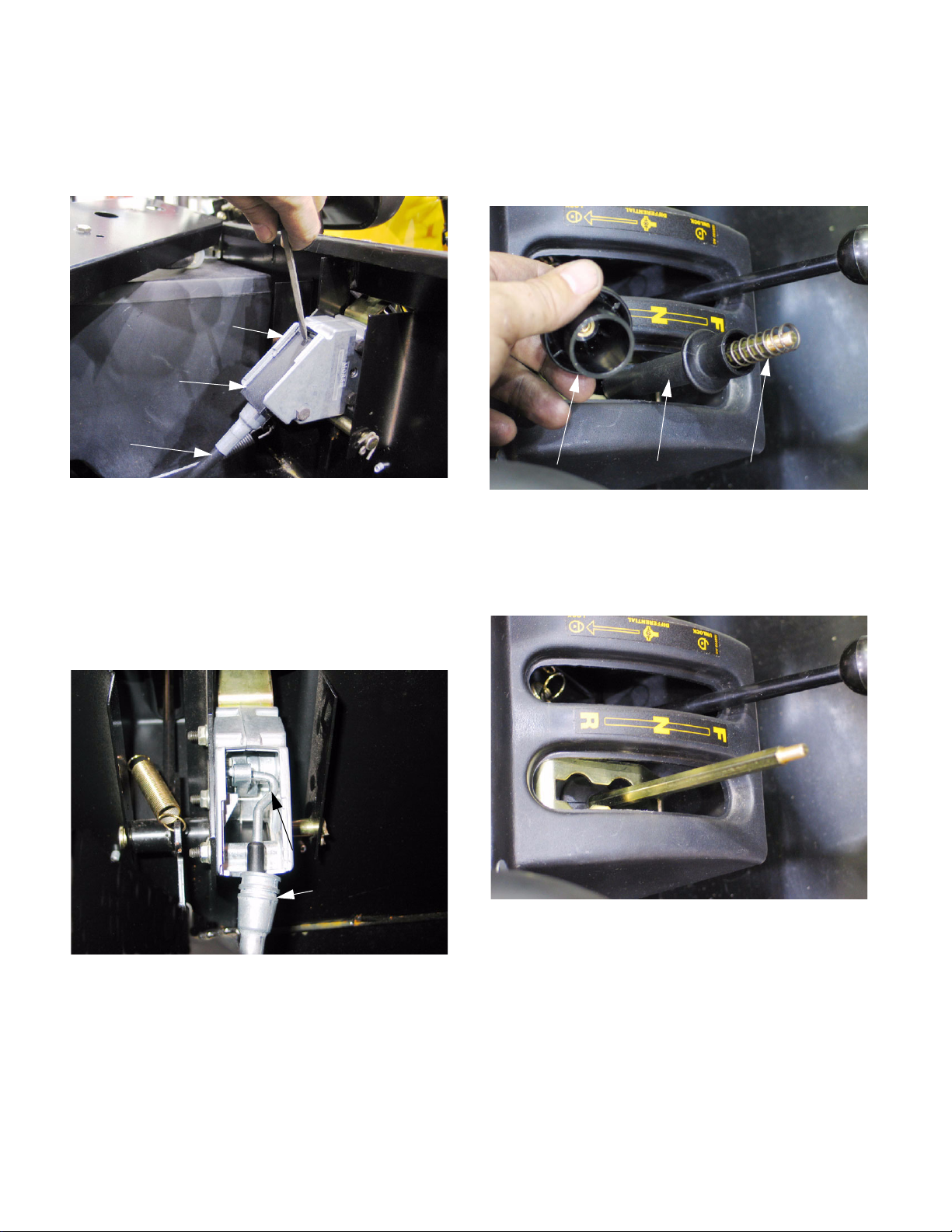

4.1. It is possible to remove the gear shift control

cable and gear shift control independently or

together.

4.2. To gain access to the gear shift control, tilt both

seats forward, and remove the console/cup

holder using a 7/16” wrench. See Figure 4.2.

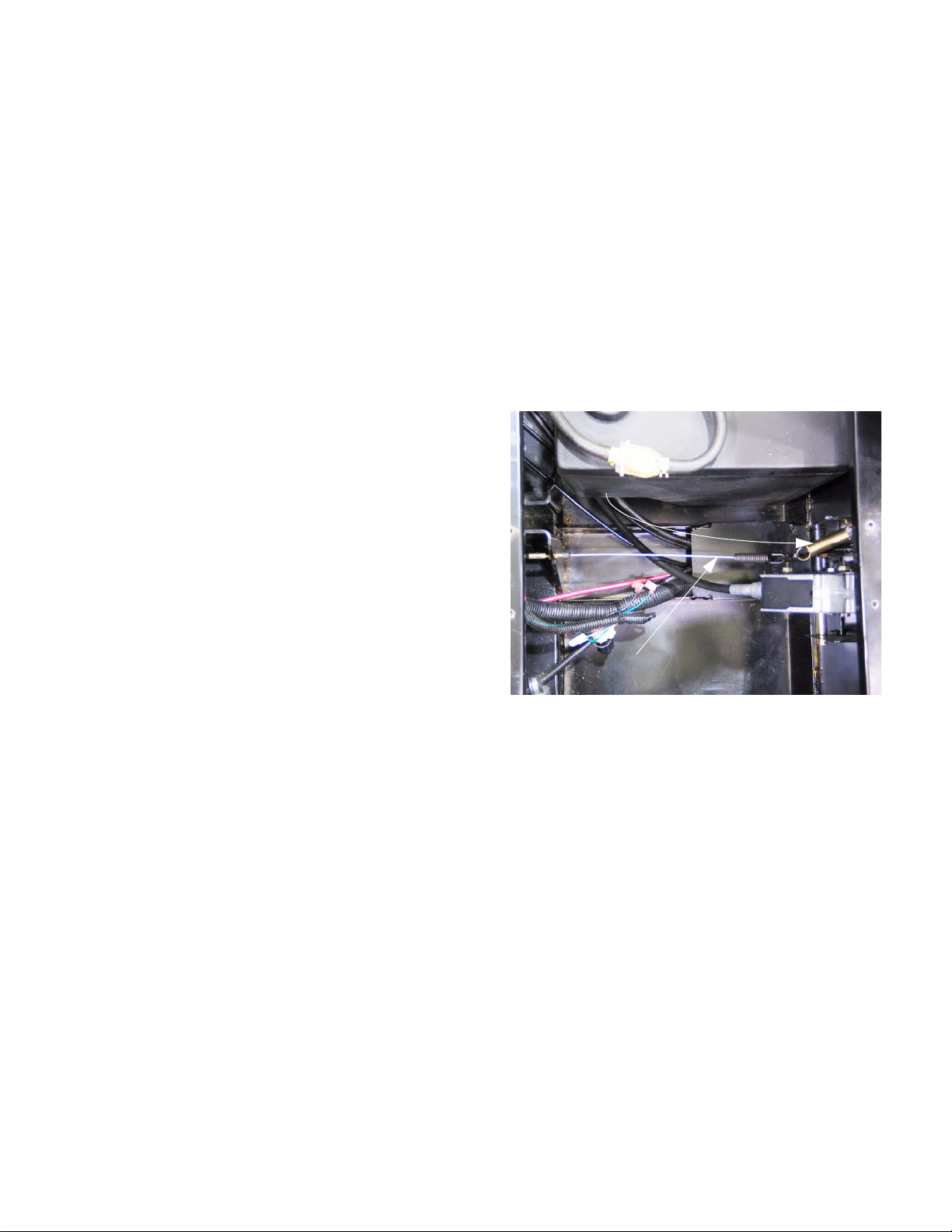

Differential

lock return spring

4.3. Unbolt the console support plate from the frame

using a 7/16” wrench.

NOTE: The vacuum driven fuel pump is

mounted to the bottom of the console support

plate. It may be unbolted from the plate using a

pair of 7/16” wrenches so that the plate may be

completely removed. It is not absolutely necessary to unbolt the fuel pump if the support plate

is only moved aside for access.

4.4. Un-hook the differential lock return spring from

the console support plate, and move (or remove)

the plate.

Console support plate

Fuel pump mounting bolts

Figure 4.2

• Under-steer (vehicle is less responsive to steering wheel in-puts) accompanied by rear wheel

squeal during turning maneuvers indicates that

the differential lock is engaged. If this condition

exists when the differential lock lever is

released, refer to the “Transmission Linkages”

section of this manual.

K&T Saw Shop 606-678-9623 or 606-561-4983

3

Page 8

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

4.5. There is a black plastic cover on the gearshift

control. Slide it rearward, then lift it away from

the gear shift control to expose the cable attachment. See Figure 4.5.

Gear shift control

Plastic cover

Gear shift cable

Figure 4.5

NOTE: There is a lip at the front edge of the

cover that will provide sufficient purchase to

slide the cover back.

4.6. With the cover removed, lift the shift control

cable housing end out of the recess that locates

it in the shift control housing. See Figure 4.6.

Shift Control

4.8. If the shift control is to be removed, the knob

must be taken-off the shift lever. It threads off.

See Figure 4.8.

Knob Lock collar Spring

Figure 4.8

4.9. The knob retains a spring and a lock collar. Both

can be removed after the knob is taken off.

See Figure 4.9.

Hook

Cable housing end

Figure 4.6

4.7. Disengage the hooked end of the cable from the

shift control and lift the cable out of the shift control housing.

K&T Saw Shop 606-678-9623 or 606-561-4983

Figure 4.9

4.10. Three nuts and bolts secure the shifter control to

the frame. The nuts may be removed with a pair

of 7/16” wrenches. The shifter control may then

be removed.

4.11. There are no internal replacement parts available through Cub Cadet for the shifter control. It

is to be replaced as an assembly.

4

Page 9

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

4.12. Within the housing for the shifter control there is

a torsion spring that returns the shift lever to the

center of its travel. There is not a detent mechanism in the shifter control. See Figure 4.12.

Return spring

Figure 4.12

4.13. On installation of the shifter control:

4.16. Match-mark the shifter arm to the splined end of

the shift arm shaft, then remove the clamp bolt

using a 10 mm wrench.

NOTE: The clamp bolt engages a groove in the

shift shaft. It must be removed.

4.17. Use a pair of 7/8” wrenches to remove the end

jam nut on the threaded end of the cable housing. The cable core will pass through a slot in

the bracket. See Figure 4.17.

Jam nuts

• Position the bolts in the shifter control housing

prior to installation. There is insufficient lateral

clearance to instal them all in-situ.

• Tighten the nut to 96 in-lb. (10.848 Nm). If the

nuts are too tight, the housing will distort, and

operating effort will increase.

4.14. If the cable is to be replaced, the front end of the

cable can be disconnected as described in the

procedure for removal of the shifter control.

4.15. The back end of the cable is permanently

attached to the shifter arm. See Figure 4.15.

Index

mark

Clamp bolt

Figure 4.17

4.18. The cable can be withdrawn from the vehicle in

either direction. See Figure 4.18.

Note cable routing

Figure 4.18

NOTE: The correct routing of the cable: through

the recess in the lower front corner of the tank.

4.19. Confirm that the cable is correctly adjusted

Figure 4.15

5

before returning the vehicle to service.

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 10

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

Shift Control Adjustment

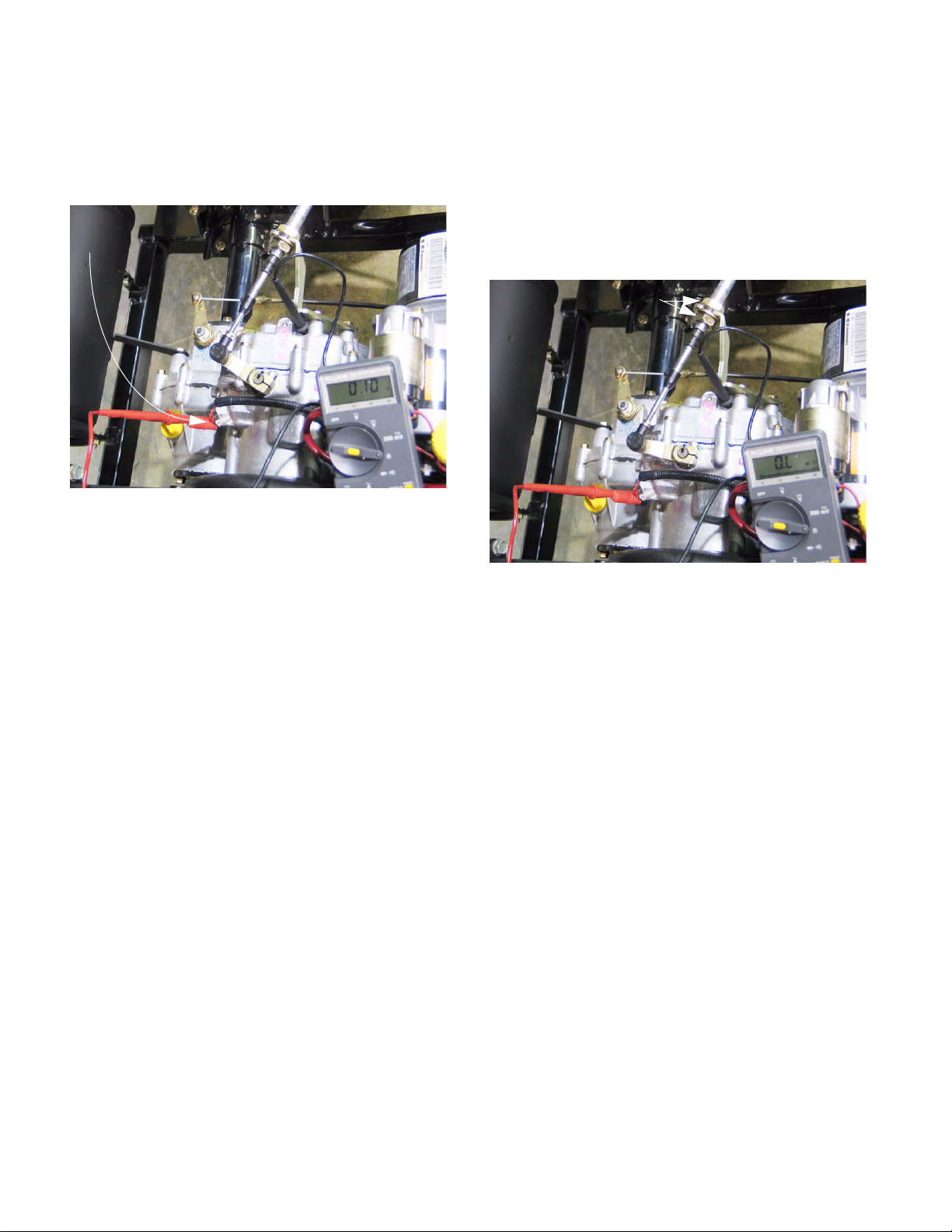

4.20. To adjust the shift cable, use the neutral safety

switch to confirm the neutral position.

See Figure 4.20.

Use safety switch

to find neutral

Figure 4.20

• Connect a powered continuity light or an Ohm

meter between the terminal on the neutral switch

and a good ground. This test works key-off.

4.21. With the transmission confirmed to be in neutral

by the meter or light connected to the switch,

move the gearshift lever to the neutral position.

4.22. Adjust the jam nuts as necessary so that the

contacts in the neutral switch open when the

gearshift lever is moved an equal distance in the

direction of forward and reverse gear positions.

See Figure 4.22.

Adjust cable here

Figure 4.22

• Otherwise, connect a test light in series between

the terminal on the neutral switch and the eyelet

on the wire that attaches to it. This test works

key-on, engine-off.

• When the continuity or test light bulb illuminates,

or the Ohm meter registers zero, the contacts

within the switch are closed.

• When the neutral switch is closed, the transmission is in neutral. Move the shifter through its

range of travel to confirm that the switch is working correctly.

• There is a significant range of travel around the

neutral position before the contacts in the neutral

switch open.

4.23. Tighten the jam nuts and test the operation of

the shift control before returning the unit to service.

4.24. Inspect the cable for wear or damage. Replace

it if there are any signs of fraying, binding, kinking or damage to the cable housing.

4.25. Lubricate the cable with light oil (penetrating oil

or cable lube) any time it is removed, and at 500

hr. intervals when the gear lube is changed.

4.26. Depending on the type of service being done,

the gear shift control cable may be removed

from it sprocket on the transaxle, or the bracket

may be removed from the transaxle housing

using a 10 mm wrench.

4.27. On installation, the gear shift control bracket

should be tightened to a torque of 78 in-lb. (8.8

N-m).

6

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 11

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

Differential Lock Control

In normal operation, a differential allows the two rear

wheels to rotate at different speeds. In a turning

maneuver, the wheels toward the outside of the turn

follow a path that describes a greater circumference

than the wheels toward the inside of the turn. Because

the outside wheels must turn faster than the inside

wheels, a differential is necessary.

Because it allows the rear wheels to rotate at different

speeds, a standard differential can only provide drive to

one wheel. One method of getting more traction is to

provide a manual device that over-rides the differential

feature by locking the two sides of the differential

together, providing drive to both rear wheels at the

same time.

It is not desirable to lock the differential together all the

time because it limits the turning radius of the vehicle:

• The two wheels driving at the same speed tend

to want to push the vehicle straight ahead.

• When the vehicle does turn, the two rear wheels

will fight against each-other for traction. In the

process they will apply exaggerated loads to the

drive train.

4.29. If the Big Country vehicle exhibits symptoms

indicating that the differential lock is not engaging or disengaging properly, investigation should

begin with the control cable.

4.30. The differential lock control lever pivots on a

large clevis pin. The clevis pin is secured to the

frame by a hairpin clip.

4.31. The spring on the end of the differential lock control cable connects to one arm of the differential

lock control lever, and a return spring connects

to the other arm. The other end of the return

spring hooks to the console support bracket.

4.32. To reach the differential lock control and cable:

See Figure 4.32.

Return spring, disconnected from

console support bracket

4.28. In normal use:

• The differential lock should engage when the differential lock lever is pulled-up.

• There are five engagement dogs on the differential. The rear wheels must rotate at most 72

degrees relative to one-another before the

engagement dogs align, allowing them to lock

together.

• Pulling-up on the differential lock lever extends

the spring at the front of the differential lock control cable. The spring applies force to the cable

and the differential lock lever on the transaxle.

When the engagement dogs align, the spring

force will push them into engagement.

• Once engaged, the lever may be released, and

the differential will remain locked until the drive

load on the left and right wheels is equalized.

• When the drive load between the rear wheels is

equalized, the load on the differential lock dogs

is relieved. When the load is relieved, torsion

spring on the differential lock lever will overcome the friction between the differential lock

dogs, and cause them to disengage.

Control cable

Figure 4.32

• Fold the seats forward.

• Remove the tool box from beneath the passenger seat, if so equipped.

• Remove the cup holder/console using a 7/16”

wrench.

• Unbolt the console support bracket using a 3/8”

wrench.

• Unhook the differential lock control return spring,

and move the console support bracket aside.

4.33. Operate the differential lock control lever, and

observe the movement of the cable and differential lock lever on the transaxle.

NOTE: It may be necessary to rotate one of the

rear wheels to align the differential lock dogs

before full engagement will occur. This is normal.

7

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 12

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

4.34. If the linkage binds, disconnect the cable to isolate the external portion of the linkage from internal transaxle components.

4.35. Disconnect the differential lock control cable

from the differential lock control lever: Pull the

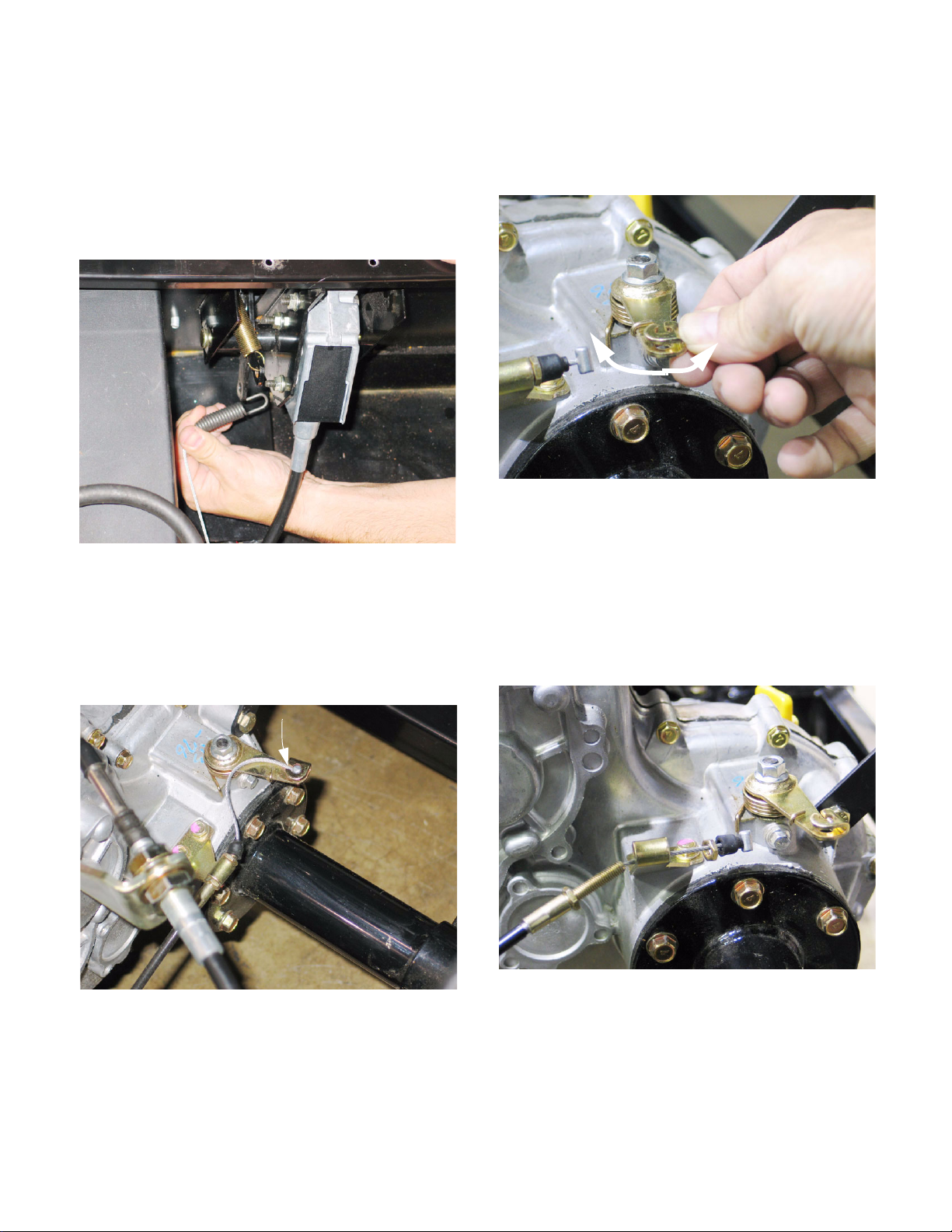

cable forward to get clearance to unhook the

spring at the end of the cable. See Figure 4.35.

Figure 4.35

4.36. There is sufficient slack in the cable to disconnect the barrel on the rear end of the cable from

the differential lock lever on the transaxle as

well: either end may be disconnected first.

See Figure 4.36.

4.37. With the cable disconnected, check the operation of the differential lock lever, and the torsion

spring that returns it to the unlocked position.

See Figure 4.37.

Figure 4.37

NOTE: Confirm that the torsion spring is prop-

erly positioned. Replacement of the torsion

spring with one that has a shorter leg was the

subject of Service Bulletin CC-456

4.38. The back of the cable is secured to the cable

holder by a pair of jam nuts: one on each side of

the cable holder. See Figure 4.38.

Disconnect barrel

from arm

Figure 4.36

Figure 4.38

4.39. Depending on the nature of the repair, the cable

holder can be unbolted from the transaxle housing, or the rear jam nut can be removed and the

cable withdrawn from the holder. A 10mm

wrench will fit the jam nuts and the cable holder

bolts.

8

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 13

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

4.40. Tighten the cable bracket mounting bolts to a

torque of 78 in-lb. (8.8 N-m) on installation.

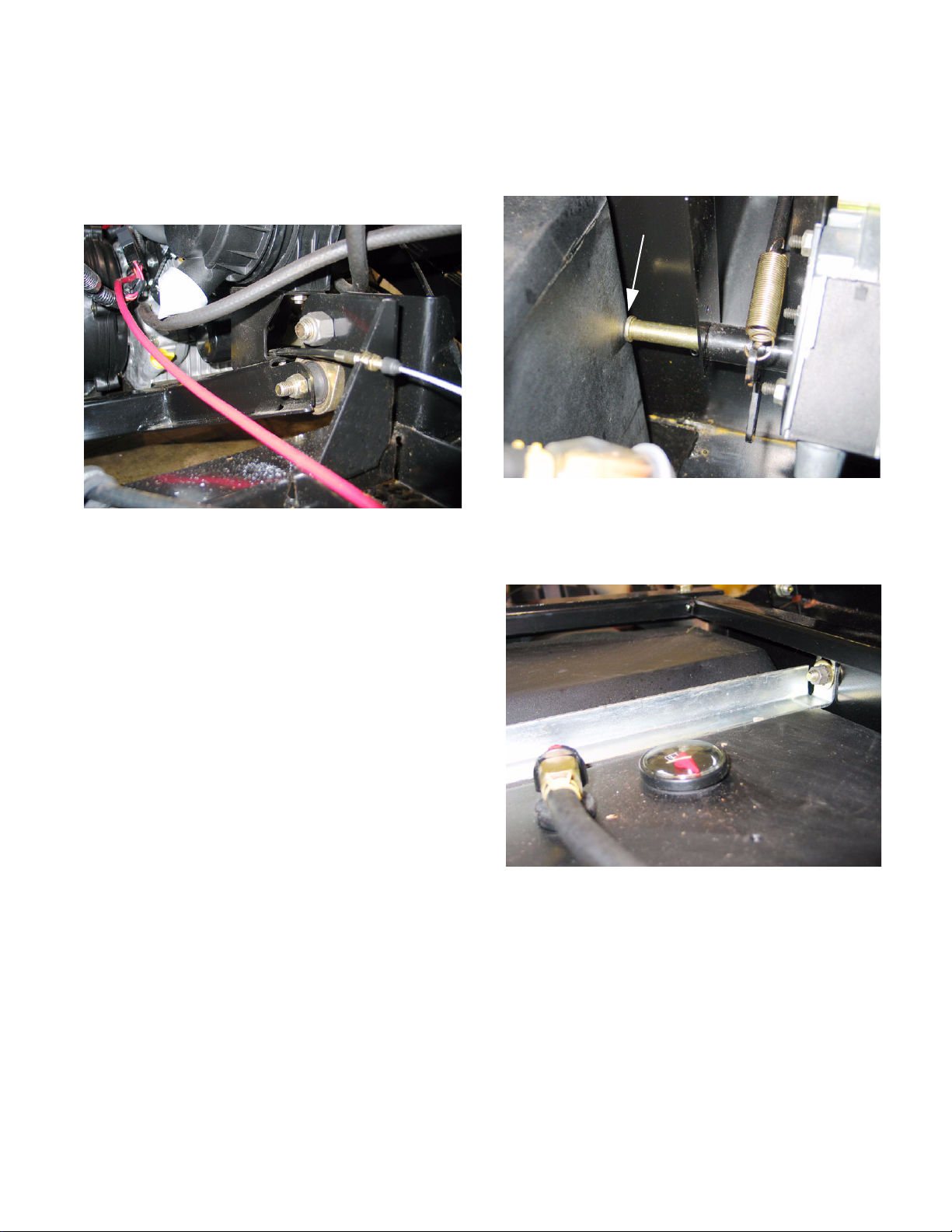

4.41. The cable is secured to a bracket near the front

mounting point of the engine and transaxle cradle. See Figure 4.41.

Note: cable routing

Figure 4.41

4.42. The cable is secured by two jam nuts that can be

removed using a 10 mm wrench.

4.46. The clevis pin that holds the differential lock control lever to the frame cannot be removed with

the fuel tank secured in position.

See Figure 4.46.

Move fuel tank

to remove pin

Figure 4.46

4.47. The fuel tank bracket assembly can be removed

using 7/16” wrench. See Figure 4.47.

4.43. Correct cable routing: cable mounted to right

side of bracket, then curved to the left to pass

beneath the air filter bracket.

4.44. Inspect the cable for wear or damage. Replace

it if there are any signs of fraying, binding, kinking or damage to the cable housing.

4.45. Lubricate the cable with light oil (penetrating oil

or cable lube) any time it is removed, and at 500

hr. intervals when the gear lube is changed.

Figure 4.47

9

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 14

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

4.48. With the bracket removed, the fuel tank can be

moved far enough back to allow the clevis pin to

be removed. See Figure 4.48.

Pin removal

Figure 4.48

4.49. Apply anti-seize compound or white lithium

grease to the portion of the pin that the differential lock control lever pivots on when it is reinstalled.

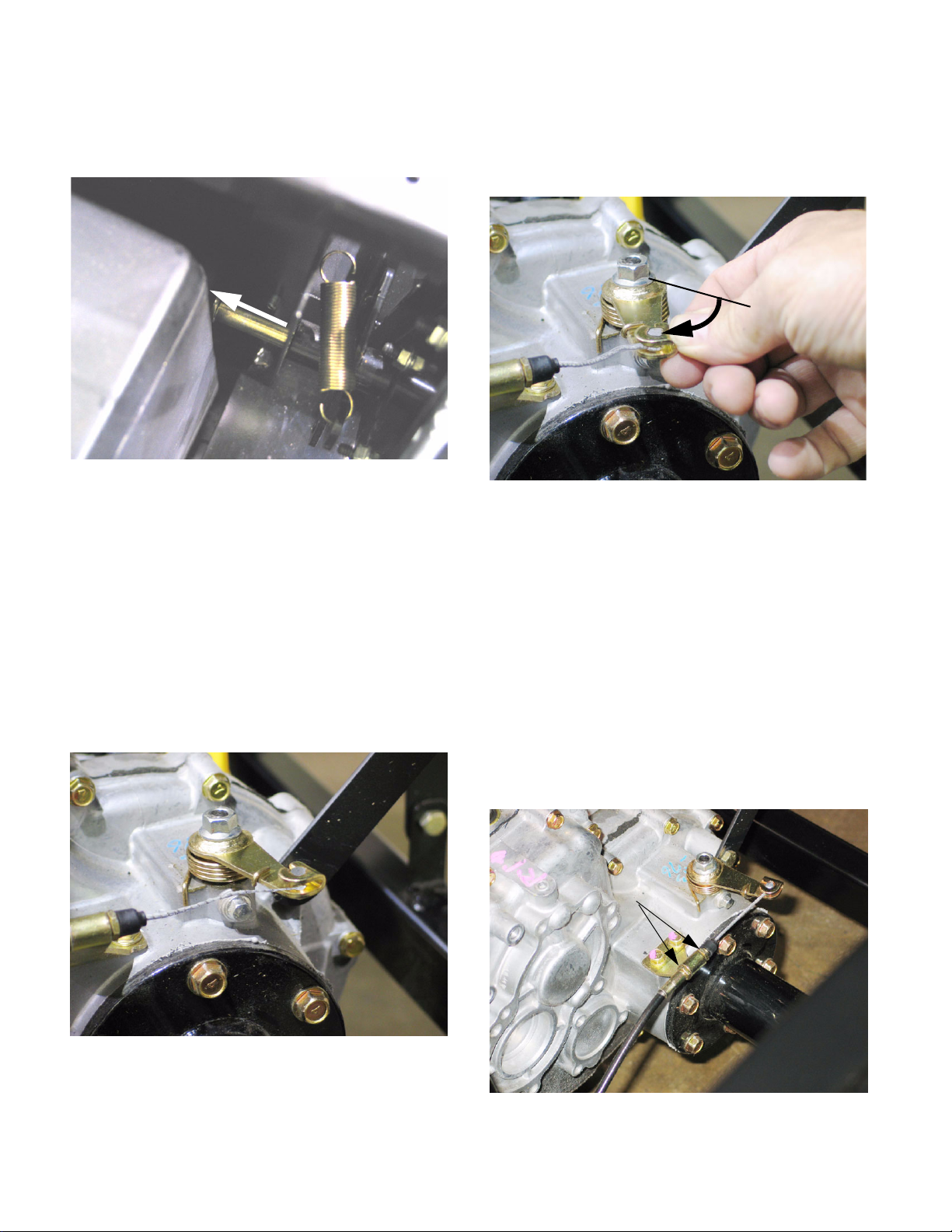

Differential Lock Control Cable Adjustment

4.50. When the differential lock is disengaged, the

spring at the front of the cable should be fully

retracted, there should be slight slack in the

cable, and the differential lock control arm

should be at the end of its rearward travel (all the

way back). See Figure 4.50.

4.51. When fully engaged, the differential lock arm

should pull forward about 7/8” (2.22 cm) as measured at the center of the barrel on the end of the

cable core. See Figure 4.51.

7/8”

Figure 4.51

4.52. There is much more travel available to the cable

than is necessary to fully engage the differential

lock. The spring at the front of the cable accommodates the over-travel.

4.53. As long as the arm on the transaxle hits the back

end of its travel when the differential lock is

released, and hits the front end of its travel when

the differential lock is engaged, the cable adjustment is correct.

4.54. If cable adjustment is necessary, it may be

accomplished with the jam nuts on either side of

the differential lock cable bracket.

See Figure 4.54.

Easiest point for

cable adjustment

Figure 4.50

Figure 4.54

10

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 15

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

5. DIAGNOSIS AND SERVICE: DRIVE BELT AND CLUTCHES (CVT OR CONTINUOUSLY VARIABLE TRANSMISSION)

5.1. Performance problems such as lack of power or

failure to reach full speed may be caused by:

engine performance issues, dragging brakes, or

belt/clutch issues.

5.2. Confirm whether the problem is internal to the

transaxle, in the brake system, or in the belt

drive and pulley system (CVT):

Transaxle

• If one drive gear (forward or reverse) or the differential lock fail to engage or disengage by

manually overriding the shift mechanism.

• Problems originating in the CVT will effect travel

in both forward and reverse: The belt and

clutches act on the input shaft of the transaxle.

• If forward or reverse gear is engaged, the

brakes released, and the vehicle is pushed, the

input shaft of the transaxle should rotate.

• The driven pulley is visible through an air

exhaust port in the back of the belt cover. It

should rotate with the input shaft of the transaxle.

• If the driven pulley does not rotate when the

vehicle is pushed in gear, the problem lies within

the transmission, the gear shift control/cable, or

the driven pulley has come loose from the input

shaft.

Brakes

• Complaints of “lurchy” operation are an indication that the brakes may be dragging or adjusted

too tight.

• It is easy to check for dragging brakes by pushing the vehicle with the parking brake released,

or by jacking-up the back of the vehicle and

checking the wheels for ease-of rotation.

• Refer to the “Brake” section of this manual for

service and adjustment information.

Engine

• Engine performance issues will likely be accompanied by other engine-based symptoms: oil

smoke, black smoke from an overly rich condition, rough running, or poor idle quality.

CVT

• Gear clash can result from drive being applied to

the input shaft during shifting (at idle speed).

• Possible causes of drive force being applied at

idle speed include: high idle speed, misalignment between engine and transaxle, wrong belt,

damaged driving pulley or damaged driven pulley.

• Loss of drive (complete or slippage) may occur

because of a worn belt, wet belt / pulleys, damaged pulleys.

• Loss of top speed other than engine or brake

problems) may occur because of a worn belt,

wet belt / pulleys, damaged pulleys.

• Most CVT diagnosis is done through simple

observation and measurement.

• This is an enclosed drive system with an air filter

and a cooling fan. Loss of air-flow will cause the

CVT to over-heat, and will effect performance.

Maintenance

• The CVT system should be inspected at 250

hour or 1 year intervals. The air filter should be

removed and inspected, and the CVT cover

should be removed for belt measurement and

inspection.

• The air filter should be inspected every 50 hours

of operation.

• Air filter life will vary with operating conditions. A

dusty environment will necessitate more frequent maintenance of the engine and CVT air filters.

• Belt life will vary with operating conditions. High

load, high ambient temperatures, dusty conditions, operation on grades, and high number of

stop/start cycles are among factors that will tend

to shorten belt life.

• Any change in performance noted by the operator should prompt inspection.

• Any factors indicative of potential drive problems

should prompt inspection. eg.: evidence of

rodent nesting, or evidence of oil leakage from

engine or transaxle.

• Refer to the Engine” section of this manual for

diagnosis and repair of engine performance

issues.

K&T Saw Shop 606-678-9623 or 606-561-4983

11

Page 16

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

Inspection

5.3. Park the vehicle on a firm level surface, with the

ignition turned off, and lift the load bed to provide

access to the drive system.

5.4. Allow the exhaust system to cool before proceeding.

5.5. Inspect the CVT system air filter. The filter is

located in front of the outer cover for the CVT. It

is connected to the intake plenum by a molded

hose, and it is connected to the outer CVT cover

by a flexible hose. See Figure 5.5.

5.8. The CVT air filter has a foam wrap pre-filter over

the paper filter element. The foam wrap can be

washed in mild detergent, rinsed, dried, and reused. Do not oil the foam wrap. See Figure 5.8.

CVT pre-filter CVT air filter

Figure 5.8

5.9. The paper filter can be tapped-out. Do not blow

it clean with pressurized air. Replace it if it

shows significant dirt between the pleats.

CVT filter housing

Figure 5.5

5.6. Remove the two wing screws from the air filter

cover.

5.7. Lift the cover and remove the filter.

See Figure 5.7.

5.10. To remove the CVT drive cover, the air filter

assembly must be removed.

5.11. Loosen the hose clamp that secures the flexible

hose from the air filter to the CVT cover, and disconnect the hose from the cover.

See Figure 5.11.

Flexible hose from plenum

via filter, to CVT

Figure 5.11

Figure 5.7

12

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 17

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

5.12. Loosen the hose clamp that secures the molded

hose from the air filter to the plenum.

See Figure 5.12.

Figure 5.12

5.13. Remove the two bolts that hold the air filter

housing to the air filter bracket using a 1/2”

wrench, and remove the filter assembly.

5.14. The exhaust pipe interferes with the removal of

the CVT cover. It must be removed.

5.16. Disconnect the front flange of the exhaust pipe

from the cylinder head using a 12 mm wrench.

See Figure 5.16.

Flange mount to cylinder head

Exhaust pipe

Figure 5.16

5.17. Remove the exhaust pipe.

5.18. Remove the 9 screws holding the CVT cover to

the CVT housing using an 8 mm wrench, and

maneuver the cover out of the engine compartment. See Figure 5.18.

NOTE: For testing and diagnostic purposes,

existing exhaust flange gaskets may be re-used.

Any time the exhaust pipe is removed, it should

be reinstalled using new gaskets before returning the vehicle to service.

5.15. Disconnect the rear flange of the exhaust pipe

from the muffler using two 13 mm wrenches.

See Figure 5.15.

Flange mount to

muffler

Exhaust

pipe

CVT cover removed

Figure 5.18

Figure 5.15

13

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 18

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

5.19. Inspect the belt and clutches (pulleys) for obvious damage and wear: See Figure 5.19.

21 mm min.

Figure 5.19

• The belt should measure at least.827” (21 mm)

across the outside (wide) surface (service limit).

If it measures less than this it is worn, and

should be replaced.

• New belts should measure .906” (23 mm).

• Confirm that the correct belt is on the vehicle:

Cub Cadet Part # 754-04054.

• The arrow printed on the belt should point in the

direction of the belts rotation.

5.20. With the transaxle in neutral, it should be possible to rotate the driven pulley (on the transaxle)

without applying a force of more than 20 in-lbs.

(2.26 Nm) to the driving pulley (on the engine).

See Figure 5.20.

• A torque wrench with a 13 mm socket on it

should read less than 20 in.-lbs.(2.26 Nm) while

rotating the input shaft. The belt should slip easily on the driving pulley.

• If this figure is exceeded, remove the belt and

repeat the test. This will confirm if the bind is

internal or external.

• If the problem is internal, examine the transaxle,

if the problem is external, examine the CVT.

• If there is excessive drag, and the outer sheave

of the driving pulley is fully retracted, there may

be an alignment or spacing problem between the

crankshaft of the engine and the input shaft of

the transaxle. If there is an alignment problem,

it may be indicated by asymmetric wear on the

belt.

5.21. The distance between the centerline of the

crankshaft and the centerline of the input shaft

should be 9.41” (23.9 cm). The two shafts must

be parallel in vertical and horizontal axis.

NOTE: As a practical matter, this is a difficult

measurement to make without specialized fixtures. A combination of measurement, adjustment, and experimentation may be necessary in

the field.

5.22. To check the performance of the CVT, install the

exhaust pipe, but leave the CVT exposed for

observation.

5.23. Connect a tachometer to the engine.

5.24. With the vehicle in neutral, insure that no unsafe

conditions will arise from starting the engine.

NOTE: Perform the following procedure with all

due caution to ensure that no foreign objects,

including the technician, come into contact with

rotating components.

20 in-lbs to rotate here

Figure 5.20

K&T Saw Shop 606-678-9623 or 606-561-4983

14

Page 19

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

5.25. Confirm that the throttle cable, and the travel

stops on the throttle cable are adjusted to provide the full range of travel without straining the

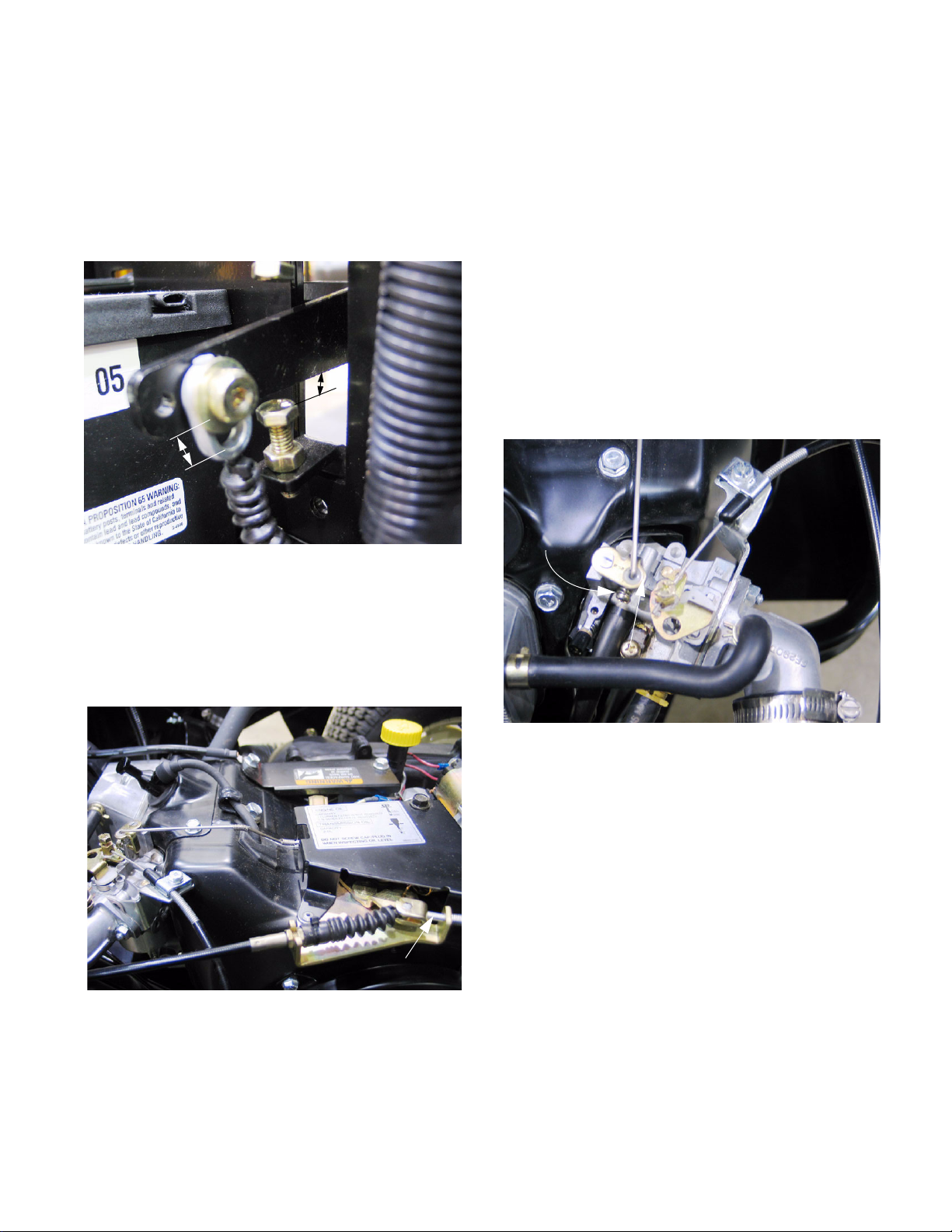

cable:

5.26. There should be roughly 3/16” (4.8 mm) of play

at the eyelet that connects the throttle cable to

the throttle pedal. See Figure 5.26.

3/16” free play

3/16” free play

Figure 5.26

• The adjustment can be made through a combination of stop bolt (1/2” wrench) and throttle

cable position (two 10 mm wrenches).

• Too little pedal travel in comparison to available

cable travel will result in sub-optimal engine performance.

• Too much pedal travel, in comparison to available cable travel will “load” the linkage, and may

damage components through bending or fatigue.

• Tension on the cable when the pedal is at rest,

or a cable that fails to return all the way to idle

position may cause an artificially high idle speed.

5.28. Start the engine and check the idle speed controlled by the stop-screw on the throttle arm of

the carburetor. See Figure 5.28.

Stop screw Set throttle stop

idle to 1100 RPM

5.27. The throttle pedal arm should reach the end of

its available travel, as set by the stop-bolt and

jam nut as the governor linkage reaches the end

of its travel at the engine end of the cable.

See Figure 5.27.

Governed idle stop

Figure 5.27

Throttle arm

Figure 5.28

NOTE: The engine should be fully warmed-up

prior to this adjustment. Engine temperature has

a significant effect on idle speed.

15

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 20

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

5.29. Hold the throttle arm against the stop screw.

Adjust the stop screw to set the engine speed to

1,100 RPM +

5.30. Release the throttle arm, then set the governed

idle speed to 1,200 RPM +

50.

50. See Figure 5.30.

Figure 5.30

NOTE: If the idle speed is set too low, the engine

will stall at idle. If warm idle speed has fallen

with time, check the condition of engine tune-up

factors (compression, valve lash, spark plug, air

filter) before making adjustment.

5.32. Gradually increase the speed of the engine

(manually, not through adjustment), and observe

the point where the outer sheave of the driving

pulley moves in to compress against the belt.

See Figure 5.32.

Driving clutch

at start of

travel

5.31. The idle speed is controlled by the phillips head

screw on the governor control panel.

See Figure 5.31.

Set governed idle here

Figure 5.31

NOTE: If the idle speed is set too high, the driv-

ing pulley will begin to apply force to the belt.

This will turn the input pulley of the transaxle

with enough force to cause gear clash when forward or reverse gear are engaged, and it may

cause difficulty in disengaging drive gears.

Figure 5.32

5.33. The belt should be squeezed between the

sheaves at 1,400 +

5.34. By 3,300 +

driving pulley should be fully extended.

See Figure 5.34.

100 RPM the outer sheave of the

100 RPM.

Driving clutch

fully engaged

Figure 5.34

16

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 21

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

5.35. As the driving pulley compresses the belt, it is

forced outward in the tapered sheave.

NOTE: As the effective diameter of the driving

pulley increases, the belt is drawn deeper into

the sheave of the spring loaded driven pulley,

reducing its effective diameter. The combined

effect changes the drive ratio as speed goes up.

NOTE: Because the outer sheave of the driving

pulley is fully extended by around 3,300 RPM,

any vehicle speed increase beyond 3,300 RPM

engine speed is due directly to increases in

engine RPM, not to shifts in the effective drive

ratio.

5.36. If the vehicle fails to reach full speed (20 MPH)

or has lost performance, and the belt is good,

confirm that the engine still achieves it’s specified top-no-load speed and that the CVT

responds accordingly.

5.37. Top-no-load engine speed should be 4,000 +

RPM. Confirm this with a tachometer.

See Figure 5.37.

50

CVT Removal: Belt and Pulleys

5.39. Remove the exhaust pipe and CVT cover as

described previously in this section.

NOTE: If the belt is to be removed, but the pulleys are to be left in-place, it is not necessary to

remove the exhaust pipe. The CVT cover can

be moved aside, and the belt slipped-out. The

CVT cover does not need to be completely

removed to change a belt.

5.40. Disconnect and ground the spark plug H.T. lead.

5.41. If the pulleys are to be removed, loosen the bolts

that hold the pulleys to their respective shafts

before removing the belt.

NOTE: The bolts securing both CVT pulleys are

left hand thread. Turn them clockwise to

loosen them.

5.42. The driven pulley on the input shaft of the transaxle can be removed using a 12 mm wrench.

Use an adjustable face pin spanner with reach of

at least 3” (7.62 cm) and a 1/4” (6 cm) pin size

(Snap-On stock number AFS483 is suitable) to

keep the pulley from rotating. See Figure 5.42.

Figure 5.37

NOTE: The governor cover is riveted to the con-

trol plate. It is not adjustable.

5.38. If the engine fails to reach the specified top noload speed, or lacks performance under a light

load, check engine performance factors as

described in the Engine section of this manual:

• Ignition function and spark plug condition.

• Fuel system condition (fuel pump and lines, fuel

filter, air filter, carburetor, linkages).

• Engine mechanical condition (valve lash adjustment, cylinder compression, cylinder leakdown).

K&T Saw Shop 606-678-9623 or 606-561-4983

Figure 5.42

• Setting the parking brake will also help.

• If no other means are available, the pulley can

be held with a 2” (50 mm) wrench on the large

nut.

5.43. The bolt holding the driving pulley to the engine

crankshaft can be loosened using a 14 mm

wrench.

17

Page 22

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

5.44. If it is necessary to hold the crankshaft from turning: choose one of three methods.

See Figure 5.44.

• Remove the spark plug using a 13/16” (21 mm)

wrench. With the piston rising on the compression stroke pack the cylinder with starter rope to

act as a piston stop.

• Remove the flywheel cover using 10 mm

wrench, and hold the flywheel nut using a 22 mm

wrench.

• Use a strap wrench on the driving pulley.

5.46. Roll the belt off of the driven pulley on the transaxle. See Figure 5.46.

Figure 5.46

5.47. To remove the driven pulley, begin by removing

the bolt that holds it to the input shaft of the transaxle using a 3/4” wrench.

Remove screws to reach

flywheel nut

Figure 5.44

5.45. Tug upward on the top run of the belt. This will

spread the sheaves of the driven pulley, and create enough slack in the belt to allow easy

removal. See Figure 5.45.

NOTE: If an impact wrench is not available, it

may be necessary to manually place the transmission in Forward gear and set the parking

brake.

5.48. Carefully roll the drive belt off of the driven pulley, then remove it from the driving pulley.

See Figure 5.48.

Figure 5.48

5.49. Reverse the process for installation.

Figure 5.45

18

NOTE: The arrow on the belt points in the direc-

tion of travel.

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 23

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

5.50. After the belt is removed, the driven pulley can

be removed: See Figure 5.50.

• Take the bolt and washer that secure the pulley

onto the transaxle input shaft completely off

using a 12 mm wrench.

• Slide the pulley off of the input shaft. It may be

necessary to carefully pry on the pulley hub.

• There is a key between the pulley and the input

shaft, and a spacer between the pulley and the

shoulder on the input shaft.

Spacer

Key

Driven pulley

5.54. After the belt is removed, the driving pulley can

be removed: See Figure 5.54.

• Remove the bolt and washer securing the driving pulley to the engine crankshaft using a 14

mm wrench.

• Slide the driving pulley off of the crankshaft.

• There is a key between the pulley and the input

shaft, and a spacer between the pulley and the

shoulder on the crankshaft. The spacer is

notched to fit over the key.

Figure 5.50

5.51. If the driven pulley does not function properly,

replace it as a complete unit.

5.52. On installation:

• Apply a small amount of anti-seize compound to

the input shaft.

• Confirm that the spacer and key are properly

positioned. The chamfered side of the spacer

should face the shoulder on the crankshaft.

• Slip the driven pulley all the way onto the input

shaft, and seat it against the spacer.

• Apply a small amount of thread locking compound such as Loctite 242 (blue) to the threads

of the bolt.

• Secure the pulley to the input shaft with the bolt

and washer. Tighten the bolt to a torque of: 24 ftlb (32 N-m).

5.53. Key points to inspect on the driven pulley are the

ramp surfaces on the cams, and the polymer

buttons that ride against the ramps.

Figure 5.54

5.55. If the driven pulley does not function properly,

replace it as a complete unit.

5.56. On installation:

• Apply a small amount of anti-seize compound to

the crankshaft.

• Confirm that the spacer and key are properly

positioned. The chamfered side of the spacer

should face the shoulder on the crankshaft. The

key should fit through the notch in the spacer.

• Slip the driven pulley all the way onto the input

shaft, and seat it against the spacer.

• Apply a small amount of thread locking compound such as Loctite 242 (blue) to the threads

of the bolt.

• Secure the pulley to the input shaft with the bolt

and washer. Tighten the bolt to a torque of: 31 ftlb (42 N-m).

19

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 24

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

5.57. Beyond the warranty period, if a dealer chooses

to service a driven clutch, service information

and specialized tools are available from:

Hoffco/Comet Industries

358 NW F Street

Richmond, IN 47374

5.58. The CVT housing connects the engine to the

transaxle. It can be removed using a 12 mm

wrench. See Figure 5.58.

Spacers

Keys

6. TRANSAXLE REMOVAL AND REPLACEMENT

The transaxle is carried on the engine/transaxle cradle,

and the entire cradle moves up and down with the

travel of the suspension. It pivots on a dog-bone joint to

allow for some degree of axial twist in relation to the

rest of the chassis, as well as up and down travel. The

engine and transaxle cradle maintains correct alignment and spacing between the engine and the transaxle. The transaxle also mounts directly to the leaf

springs.

6.1. Park the utility vehicle on firm level ground

where there is sufficient room to work around the

sides and rear of the vehicle. Set the parking

brake.

6.2. Unlatch the hood and tilt it forward. It may be

removed completely at the technician’s discretion.

6.3. Disconnect the negative battery cable using a

7/16” wrench.

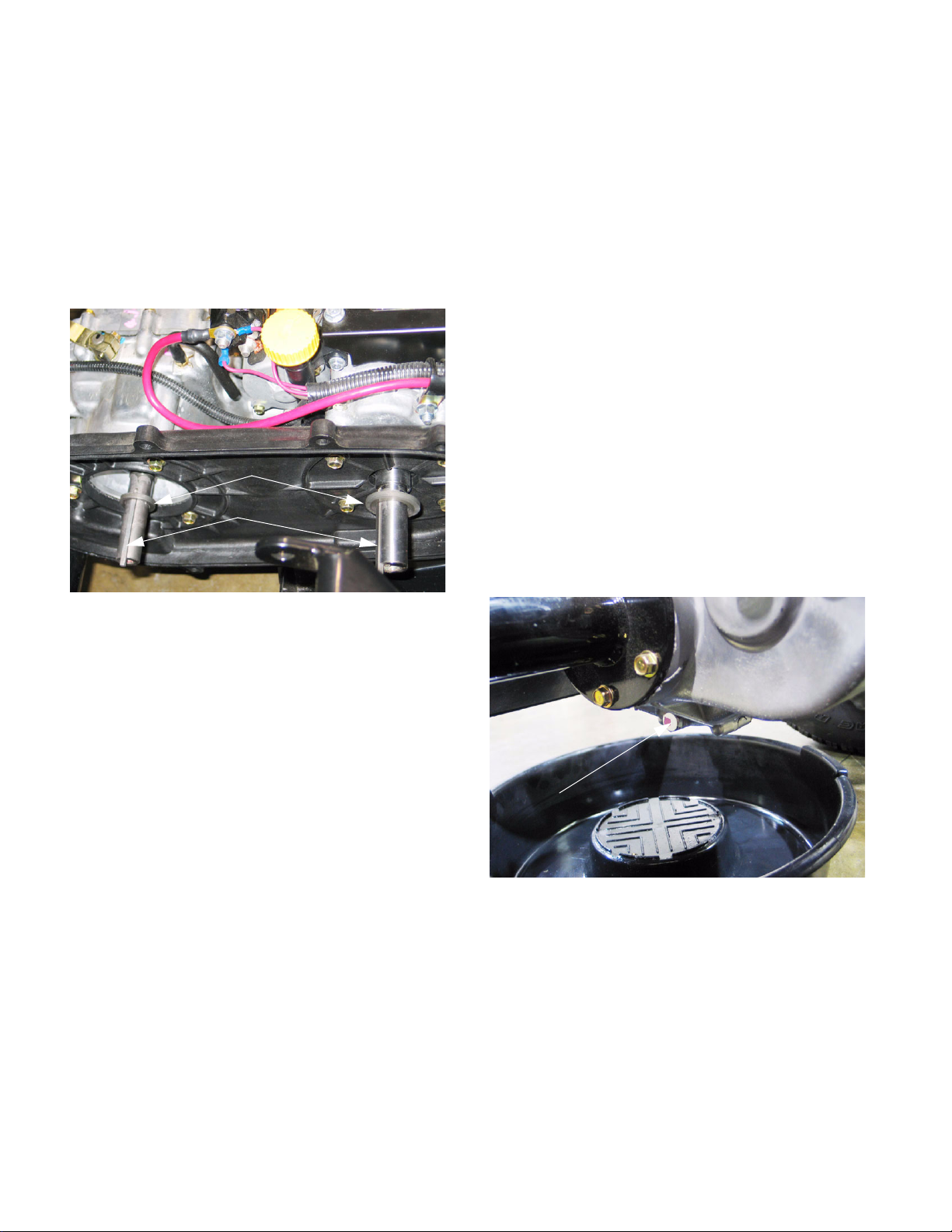

6.4. Place a drain pan beneath the transaxle, and

remove the drain plug using a 17 mm wrench.

See Figure 6.4.

Figure 5.58

5.59. If the engine or transmission has been removed,

the CVT housing can be used as a guide to align

them. An assembly jig (P/N: 57001-1341) is

available from Kawasaki.

5.60. Apply a small amount of thread locking compound such as Loctite 242 (blue) to the 7 bolts

that hold the CVT housing in place prior to installation. Tighten the bolts to a torque of 160 in-lb

(18 N-m).

5.61. Complete assembly, connect spark plug H.T.

lead, and thoroughly test operation in an area

that is clear of obstacles and hazards before

returning the vehicle to service.

Drain plug

Figure 6.4

NOTE: Removing the fill plug/dipstick will speed

the draining process.

6.5. If working without an impact wrench: loosen the

lug nuts on the rear wheels 1/2 turn each using a

19 mm wrench.

20

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 25

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

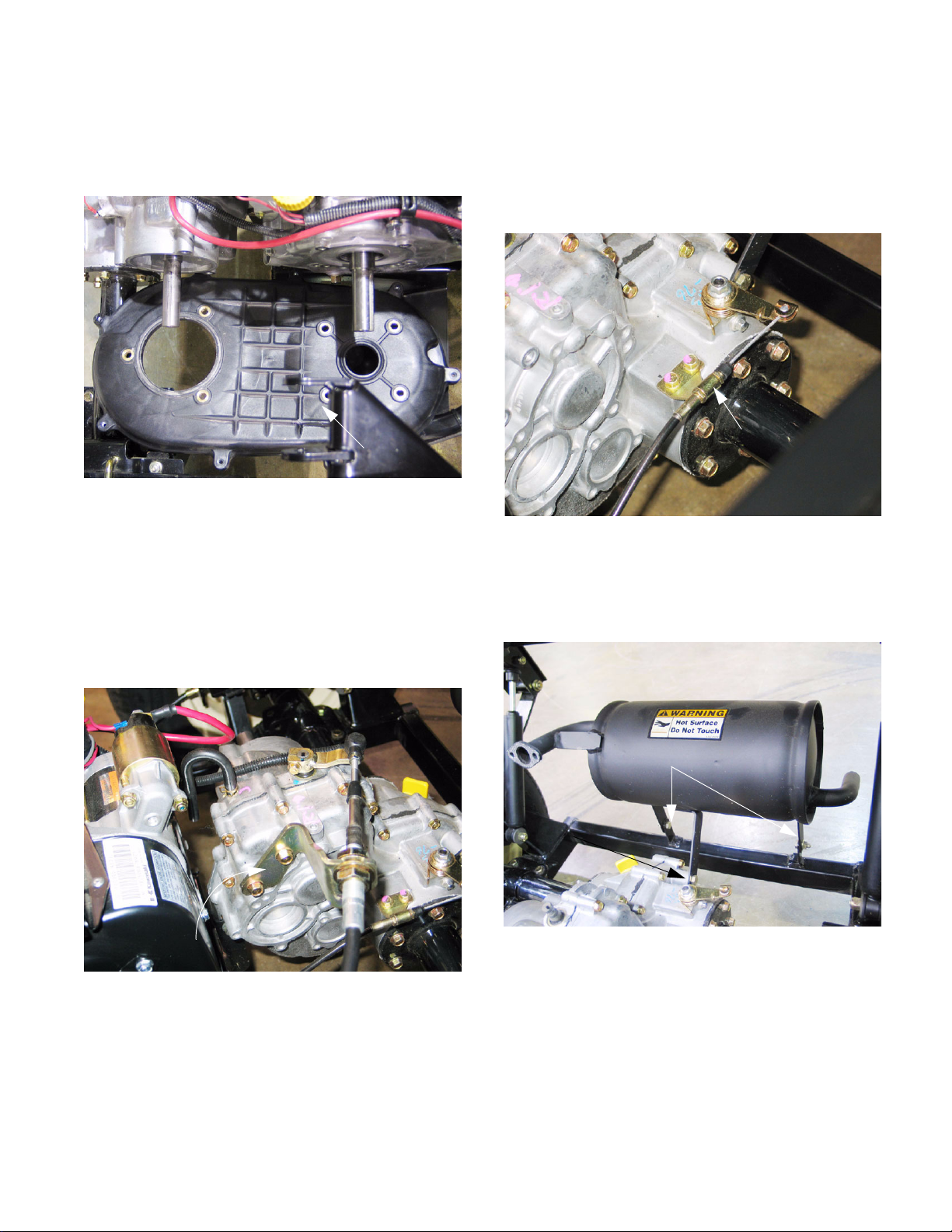

6.6. Lift the bed. Remove the exhaust pipe and the

CVT assembly, including the housing, as

described in the CVT section of this manual.

See Figure 6.6.

CVT housing

Figure 6.6

6.7. Index the forward-neutral-reverse shift arm on

the transaxle to the splined shaft that it mounts

to. Remove the clamp bolt that secures it using

a 10 mm wrench.

6.8. Remove the two bolts that hold the shift cable

bracket to the transaxle using a 12 mm wrench.

See Figure 6.8.

6.10. Remove the two bolts that hold the differential

lock cable bracket to the transaxle using a 10

mm wrench. There will be enough slack in the

cable to permit the barrel end to be disengaged

from the differential lock arm on the transaxle.

See Figure 6.10.

Differential lock

control cable

bracket

Figure 6.10

6.11. Unbolt the muffler from the frame using a pair of

1/2” wrenches. Unbolt the muffler from the transaxle using a 13 mm wrench. See Figure 6.11.

Shift cable bracket

Figure 6.8

6.9. Remove the shift arm from the shaft, and move

the cable out of the way.

Frame mounts

Transaxle mount

Figure 6.11

6.12. Release the parking brake.

21

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 26

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

6.13. Remove and discard the cotter pins securing the

clevis pins into each brake cable clevis/actuator

arm connection. Remove the clevis pins.

See Figure 6.13.

Cotter

pin

Figure 6.13

6.14. Disconnect the red wire with white trace from the

neutral switch, located on the rear surface of the

upper portion of the transaxle housing. The nut

that secures the eyelet to the stud can be

removed using a 7 mm wrench.

6.15. Remove the bolt holding the front of the transaxle to the torque bracket using two 9/16”

wrenches. See Figure 6.15.

Clevis pin

Clevis

6.16. Remove the bolts that fasten the spring mounts

to the engine and transaxle cradle using a pair of

1/2” combination wrenches. See Figure 6.16.

Spring mount

bolts and nuts

Figure 6.16

NOTE: On each side of the cradle there are two

pedestals: one in front of the axle tube, and one

behind. Two bolts fasten each pedestal to the

front or rear of a spring mount.

6.17. Install the drain and fill plugs, remove the drain

pan and lower the bed.

6.18. Lift and safely support the rear of the vehicle.

See Figure 6.18.

Torque bracket

Figure 6.15

NOTE: Lift the vehicle by the rear cross-member

of the engine and transaxle cradle.

22

Figure 6.18

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 27

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

6.19. Jackstands must be placed under the frame, not

the engine/transaxle cradle. See Figure 6.19.

(near C.G. of vehicle)

Jackstands under frame

Figure 6.19

NOTE: The cross member that the bracket for

the dog-bone joint is attached to provides a convenient place for jackstands. It is near the center

of gravity: the entire vehicle will usually balance

on two jackstands at this location. Because of

the teeter-totter effect, the rear wheels will be left

on until the transaxle is removed.

6.20. Remove the bolts that hold the axle tubes to the

engine/transaxle cradle using a pair of 9/16”

wrenches. See Figure 6.20.

6.21. Carefully lower the engine and transaxle cradle,

until the wheels touch the ground.

See Figure 6.21.

Figure 6.21

NOTE: While the transaxle is partially supported

by the cradle, it will remain up-right.

6.22. With a firm grip on the transaxle, lower the jack

completely, tip the front of the transaxle up so

that the housing clears the back of the cradle,

and roll the transaxle clear of the cradle on it’s

own two wheels. See Figure 6.22.

Axle mount bolts

Figure 6.22

Figure 6.20

6.23. With the transaxle completely removed, the Big

23

Country will be stable on the jackstands.

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 28

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

7. TRANSAXLE INSTALLATION NOTES:

7.1. Reverse the removal procedure to install the

transaxle. The following items are tips, reminders, and torque specifications.

7.2. When mounting the transaxle to the cradle:

• Roll the transaxle into position.

• Attach it loosely to the cradle using the eight

bolts through the brackets on the axle tubes.

• Lift the cradle into place against the spring

mounts, and attach it loosely with eight bolts

removed from these attachment points.

• Position the front of the transaxle in the torque

bracket and loosely install the bolt that secures

it.

• Fasten the CVT housing to the transaxle and the

engine.

• Confirm the correct span between the input shaft

and the crankshaft, and confirm that the two

shafts are parallel in vertical and horizontal

planes. The distance between the two shafts

should be 10.35” (26.28 cm).

NOTE: Two small magnetic squares and a

straight-edge can be used to check for parallelism.

• Once accurately in position, tighten all of the fasteners. (See torque table)

• After tightening, double-check poisoning, to confirm that the parts have not shifted.

7.6. Install the CVT:

• Apply a small amount of anti-seize compound to

the input shaft and the crankshaft.

• Install the appropriate spacers on the input shaft

and crankshaft, and install the appropriate keys

in the keyways on the shafts.

NOTE: The drive belt may be postponed on the

pulleys, and installed simultaneously, or it may

be rolled-on after the pulleys are installed.

• Install the driving and driven pulleys on the

crankshaft and input shaft, and secure them with

the washers and left-hand thread bolts.

• Install the belt.

• Install the CVT cover.

7.7. Confirm that the drain plug is tight.

7.8. Fill the transaxle with 68 fl.oz.(2 liters) of API

“GL5” Hypoid gear oil, or confirm the presence

of the correct amount of appropriate gear lube

using the dipstick:

• SAE 90 above 41 deg. f. (5 deg. c.)

• SAE 80 below 41 deg. f. (5 deg. c.)

7.9. Check the torque on the lug nuts.

7.10. In a safe area that is free of obstacles and hazards, check the drive system and brakes for correct operation before returning the vehicle to

service.

7.3. Connect the differential lock cable and attach the

differential lock bracket to the transaxle.

• Confirm correct operation of the differential lock

shift mechanism.

7.4. Connect the forward-neutral-reverse shift arm to

the splined shaft on the transaxle:

• Align the index marks made before removal.

• Secure the arm with the pinch bolt.

7.5. Connect the clevises on the ends of the brake

cable to the brake actuating arms using clevis

pins and new cotter pins.

• Lubricate the clevis pins lightly with anti-seize

compound or white lithium grease.

• Replace the clevis pins if they show signs of

wear.

24

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 29

www.mymowerparts.com

8. LINK ASSEMBLY

Poly Bed 4 X 2 Drive System

Table 1: Drive System Torque Values

Item Torque Note

cradle to axle tubes 17 ft-lb

21 N-m

cradle to spring

mounts

31 ft-lb

42 N-m

torque bracket 31 ft-lb

42 N-m

CVT cover 48 in-lb

5.5 N-m

CVT housing 160 in-lb

18 N-m

driving pulley 31 ft-lb

42 N-m

driven pulley 24 ft-lb

32 N-m

8.1. The link assembly (aka:dogbone joint) connects

the engine and transaxle cradle to the frame of

the Big Country. This joint locates the front of

the cradle, yet allows enough freedom of move-

1

ment that the cradle can swing up and down and

pivot to accommodate suspension travel.

See Figure 8.1.

2

2

3

Link assembly

3

Figure 8.1

diff. lock cable

bracket

78 in-lb

8.8 N-m

shifter cable bracket 18 ft-lb

25 N-m

shifter control arm 78 in-lb

8.8 N-m

lug nuts 25 ft-lb

34 N-m

drain plug 11 ft-lb

15 N-m

NOTE: 1 May be inaccessible with torque

wrench.

NOTE: 2If locking feature on nut is worn, replace

the nut or apply releasable thread-locking compound such as Loctite 242 (blue).

NOTE: 3 Left-hand threads

8.2. If the link assembly becomes worn or damaged,

the front of the engine and transaxle cradle may

shift and clunk, particularly when acceleration or

braking load is applied. To replace the link

assembly, use the following procedure:

8.3. Tilt the passenger seat forward, and lift out the

parcel bin. This will provide easy access to the

link assembly fasteners.

8.4. Open the hood, and disconnect the negative battery cable. Tools will be in close proximity to the

“hot” stud on the starter motor.

8.5. It is not absolutely necessary to support the front

of the engine and transaxle cradle with a jack,

but it may make it easier to relieve any bind on

the bolts that connect the cradle, link assembly,

and frame.

25

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 30

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

8.6. Remove the nut and bolt (top) that connect the

link assembly to the frame using a pair of 15/16”

wrenches. See Figure 8.6.

Figure 8.6

8.7. Remove the nut and bolt (bottom) that connect

the link assembly to the engine and transaxle

cradle using a pair of 19mm wrenches.

9. TRANSAXLE REPAIRS

Axle Assemblies:

NOTE: It is possible to replace axle bearings

and seals without removing the transaxle from

the vehicle. If this is done, inspect the axle

tubes carefully. If the axle tubes have been bent

by over-loading the suspension (static or shock)

then a mis-alignment of the bearings may have

occurred. This misalignment will cause the rapid

demise of the replacement bearings. Overloading constitutes abuse of the vehicle. The resultant damage is NOT warrantable.

NOTE: If the transaxle is being removed with the

anticipation of disassembly, steps can be saved

in the removal process by leaving the brake

drums and wheels attached to each other:

9.1. Remove and discard the cotter pins that secure

the castle nuts on the end of each axle shaft.

9.2. Set the parking brake, and remove the castle

nuts and washers using a 27 mm socket.

See Figure 9.2.

8.8. With the bolts removed, the link can be lifted out

and replaced. See Figure 8.8.

Figure 8.8

8.9. Installation notes:

• Apply anti-seize compound to the bolts so that

they may be easily removed in the future.

Castle nut

Washer

Cotter pin removed

Figure 9.2

9.3. Release the parking brake, and remove the transaxle assembly as described in the “Transaxle

Removal” portion of this manual.

9.4. Slide the brake drums off of the axle shafts without removing them from the wheels.

• Tighten the top nut and bolt to a torque of 100 +

10 ft.-lbs.

• Tighten the bottom nut and bolt to a torque of 40

+

5 ft.-lbs.

K&T Saw Shop 606-678-9623 or 606-561-4983

26

Page 31

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

9.5. After the wheels and brake drums are removed

from the axle shafts, remove the brake shoes as

described in the “Brakes” section of this manual.

See Figure 9.5.

Brake backing plate

with shoes removed

Mounting bolts

Fixed post

Figure 9.5

9.6. Remove the Brake backing plate assembly from

the transaxle using a 17 mm wrench.

See Figure 9.6.

Actuating cam

9.7. Though it is not likely to require disassembly

during brake or transaxle service, it is worth noting that the backing plate is an assembly.

See Figure 9.7.

Dust cover

Structural backing plate

Figure 9.7

9.8. The cam can be removed from the backing

plate. See Figure 9.8.

Backing

plate removed

Figure 9.6

NOTE: This step is not strictly necessary,

depending on the repairs that are to be performed, but makes the transaxle easier to

maneuver on the bench.

K&T Saw Shop 606-678-9623 or 606-561-4983

Figure 9.8

27

Page 32

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

9.9. When placed on the bench, take note of the orientation of the transaxle components. Match

marks will ease the assembly process but the

following relationships are correct:

• The brake backing plates attach with the lever

and cam to the rear of the transaxle.

• The shock absorber mounts on the axle tubes

go toward the front of the transaxle.

• The spring perches are off-set toward the bottom

of the axle tubes.

• The mounting surfaces of the spring perches

should be parallel to the flat mounting surface for

the shift cable bracket.

• The left hand side (differential lock side) axle

tube is shorter than the right hand side (input

shaft side) axle tube.

9.10. Remove the vent tube from the transaxle housing.

9.11. Remove the screw that locates the differential

lock lever in the transaxle housing using an 8mm

wrench. See Figure 9.11.

Pilot on end of screw

seats in groove in

differential lock lever

9.12. Remove the six bolts that secure the flange of

each axle tube to the transaxle housing using a

12mm wrench. See Figure 9.12.

Six bolts on

axle flange

Shock mounts

to front

Figure 9.12

NOTE: Remove the axle tubes one at a time.

9.13. Shock the axle tube with a soft hammer, if necessary to break the sealant bond that may hold

the axle tube to the housing, and separate the

tube from the housing.

NOTE: The axle shaft may or may not come out

with the tube. Neither situation presents a problem.

Parallel

Figure 9.11

9.14. The left side axle shaft passes through the differential lock collar. The dogs on the collar are

driven by dogs on the differential when the differential lock is engaged. See Figure 9.14.

Differential lock

lever

Dogs

Differential

lock collar

Figure 9.14

28

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 33

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

9.15. The axle shaft will slip out of the collar. The

groove on the collar engages the pin on the shift

arm

9.16. The axle shafts should slip-out through the end

of the axle tube that was connected to the transaxle housing. See Figure 9.16.

Seal surface

Shoulder

Figure 9.16

9.17. To take apart the axle assemblies, remove the

circled that holds the sealed bearing in the end

of each axle tube. See Figure 9.17.

9.18. If the axle shaft is stuck in the inner race of the

bearing, the right side shaft can be removed with

the bearing. See Figure 9.18.

Figure 9.18

9.19. The left side axle shaft is thicker in cross section

to the inside of the seal surface than the right

side axle is. The right side axle will not fit

through the seal that is behind the bearing.

See Figure 9.19.

Right side axle shaft

Bearing

Circlip holds bearing

Left side axle shaft

Figure 9.19

Figure 9.17

NOTE: If the bearing in the right side axle shaft

is stubborn, the left side axle can be used to

force it out. Use caution not to damage the ends

of the axle.

29

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 34

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

9.20. Remove the seal from the axle tube.

See Figure 9.20.

Shoulder for bearing

Figure 9.20

NOTE: The oil seal seats against a shoulder in

the tube. Hook the seal removal tool under the

lip of the seal to avoid scratching the bore that

the seal fits in.

9.21. Technical Info. for the Curious:

See Figure 9.21.

Shoulder for seal

Seal

• The necked-down axle shaft spreads the force

over a wider area, allowing the shaft to twist over

a greater portion of its length when torque is

applied to it. This reduces the load on the weakest part of the shaft: the root of the spline.

9.22. Clean the axle tubes, and inspect them for:

• Bends, cracks, or crushes.

• Scratches or damage to mating surfaces.

9.23. Check the bearings for damage: looseness and

coarseness. Check the shafts for damage to the

splines, threads, bearing seat, and seal surface.

9.24. To remove the differential lock arm from the transaxle housing, simply push it down into the bore.

See Figure 9.24.

O-ring

Differential

lock arm

seal

Figure 9.21

• The weakest part of a splined shaft is at the root

of the spline. That is the smallest cross-section

of the shaft and the root of the spline creates

stress risers.

• The right side axle is necked-down in the middle,

to a size that is smaller than the root of the

spline.

Figure 9.24

9.25. Remove and discard the O-ring seal in the upper

groove on the differential lock arm.

NOTE: If the differential lock failed to disengage

under the pressure of the torsion return spring,

and the linkage moves freely, check the fit

between the shaft of the arm and the bore.

NOTE: Symptoms of a differential lock stuck in

the engaged position include squealing tires

when making turns at even modest speeds on

pavement, and complaints that the front end

“plows” or the ability to turn the vehicle in tight

quarters has diminished.

NOTE: Wear limits for differential lock shift

mechanism:

• Maximum groove width is 9.2mm (.36”)

• Minimum shift pin diameter: 8.3mm (.33”)

• Dogs should not have rounded or broken teeth.

30

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 35

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

Transaxle housing and internals:

9.26. Prepare to separate the case: Clean any rust or

burrs from the input shaft with emery cloth, and

remove the spacer if it was not taken off previously. See Figure 9.26.

Input shaft

Spacer

Figure 9.26

9.29. Use the pry-point recesses that are cast into the

housings to separate the the two halves of the

transmission case. See Figure 9.29.

Pry point

Figure 9.29

NOTE: Small pry-bars or brake adjustment

spoons are handy for case separation.

Brake adjuster spoon

9.27. Position the case so that it rests securely with

the input shaft down, and the perimeter bolts that

hold the case halves together facing up.

NOTE: Supports are easily improvised from 4X4

dimensional lumber, or similar items.

9.28. Remove the 16 perimeter bolts using a 10 mm

wrench. See Figure 9.28.

Perimeter bolts

IInput shaft

4X4s

Figure 9.28

9.30. Carefully lift away the right side half of the transmission housing. See Figure 9.30.

Figure 9.30

NOTE: Do not gouge the mating surface

between the two halves of the housing.

NOTE: do not lose or damage the dowel pins

that help align the two halves of the housing.

31

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 36

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

9.31. Clean the left half of the housing, and inspect the

three bearings that reside in it. See Figure 9.31.

Sealed bearing for input hsaft, blind

Ball bearing for red.shaft, blind

Differential

bearing

Figure 9.31

• The largest bearing supports the differential. It

may be driven out of the housing from the outside-in.

9.32. Be certain to remove all of the cleaning solvent

before heating the housing or reassembling the

transaxle. See Figure 9.32.

Clean any solvent

from behind

sealed bearing

Figure 9.32

• The solvent may be present hazards when

heated.

• The nose of the input shaft rides in a sealed

bearing in a blind hole.

• The reduction shaft is supported by an open ball

bearing in a blind hole.

• A blind bearing puller may be necessary to

remove the input shaft bearing and the reduction

shaft bearing.

• Heating the housing evenly to 200 degrees f.

(93 deg. c.) will cause it to expand, making bearing removal and replacement easier. This

should be done in an oven or by immersion in

hot oil. Do NOT heat the housing with a torch.

The un-even application of heat will cause it to

distort.

• The solvent will severely contaminate the gear

lube on assembly, causing a lubrication related

transaxle failure.

• The solvent tends to get trapped behind the

sealed bearing.

9.33. Remove the 25 mm circlip that secures the 51tooth reverse sprocket to the reduction shaft

using a pair of retaining ring pliers.

See Figure 9.33.

Thrust

washer

Reverse

sprocket

Circlip

Figure 9.33

9.34. Remove the thrust washer (17.3mm I.D.X 30mm

O.D.X 1.4mm thick) from the input shaft.

32

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 37

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

9.35. Lift the 51-tooth sprocket off of the reduction

shaft along with the 19-tooth sprocket from the

input shaft and the link-belt reverse chain.

See Figure 9.35.

19-tooth reverse

sprocket

9.36. Remove the washers that are behind the sprockets on the input shaft and reduction shaft.

See Figure 9.36.

51-tooth reverse sprocket

Figure 9.35

9.37. The shift collar is trapped onto the input shaft by

the shift lever. To remove the shift lever, it is

easiest to remove the detent assembly and

safety switch. See Figure 9.37.

Shift collar

Shift lever

Detent

Safety switch

Figure 9.37

9.38. Remove the detent bolt using a 14 mm wrench.

See Figure 9.38.

Input shaft

Reduction shaft

Thick washer

Thin washer Circlip

Figure 9.36

• A very thin washer (28.3mm I.D.X 34mm O.D.X

0.3mm thick) rides between the 51 tooth

sprocket and the circlip on the reduction shaft.

• A thick washer (22.3mm I.D.X 35mm O.D. X

2mm thick) rides between the dogs on the 19tooth sprocket and the shift collar.

Detent ball

Detent spring

(within bolt)

Detent bolt

Sealing washer

Figure 9.38

NOTE: The detent ball and spring will come out

when the bolt is removed. Discard the sealing

washer and replace it with a fresh one on reassembly if it shows any signs of leakage.

9.39. Remove the safety switch using a 14 mm

wrench. Discard the sealing washer and replace

it with a fresh one on reassembly if it shows any

signs of leakage.

33

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 38

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

9.40. Use a magnet to remove the pin that retains the

shift lever. See Figure 9.40.

Retaining pin

Shift lever

Figure 9.40

9.41. After the pin is removed, slide the shift arm into

its bore to retract the pin from the groove in the

shift collar.

9.42. When the pin is clear of the groove, lift the shift

collar off of the input shaft. See Figure 9.42.

9.43. The differential can be easily lifted out of the

transaxle as an assembly, at this point.

See Figure 9.43.

Differential

Figure 9.43

9.44. With the differential removed, the reduction shaft

and 55-tooth gear can be lifted out of the transaxle together. See Figure 9.44.

Reduction shaft

Remove

shift collar

Retract shift arm

Figure 9.42

NOTE: Wear limits for shift mechanism:

• Width of groove in shift collar: 14.30mm (.563”)

maximum.

• Roller on shift arm pin: 13.8mm (.54”) minimum

O.D. 8.2mm (.32”) maximum I.D.

• Pin on shift arm: 7.8mm (.31”) minimum O.D.

55-tooth reduction gear

(forward)

Figure 9.44

9.45. The input shaft can be removed from the case in

a similar manner. It may be necessary to drive it

out with a soft hammer.

34

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 39

www.mymowerparts.com

Poly Bed 4 X 2 Drive System

9.46. Like the input shaft, it will be necessary to clean

any rust from the exterior part of the shift lever

before it is removed. See Figure 9.46.

Figure 9.46

9.47. The shift lever can be removed through the

inside of the housing. there is a roller on the pin

that engages the shift collar. See Figure 9.47.

Shift lever

9.49. Remove and discard the input shaft seal and the

shift lever seal. Replace them with new seals.

See Figure 9.49.

Input shaft seal

Vent

barb

Shift lever seal

Figure 9.49

9.50. Clean and inspect the reduction shaft and 55tooth gear. 28mm circlips are used as positive

stops to position the gears on the shaft. If they

are suspect, replace them. Otherwise they are

best left undisturbed. See Figure 9.50.

28 mm Circlips used for positive stops

Roller

Figure 9.47

9.48. Clean the left side transaxle housing and inspect

the bearings.

• The reduction shaft bearing is in a blind hole,

and will require a blind bearing removal tool to

withdraw from the housing.

• The differential bearing and the input shaft bearing can be driven out.

• As with the right side housing, the even heat of a

200 deg. f.(93 deg c.) oven will loosen the bearings and ease removal. Do NOT us a torch.

Figure 9.50

35

K&T Saw Shop 606-678-9623 or 606-561-4983

Page 40

Poly Bed 4 X 2 Drive System

www.mymowerparts.com

9.51. A 28mm circlip holds the 55-tooth forward gear

to the reduction shaft. If either component

shows wear or damage, remove this clip to separate them. See Figure 9.51.

28 mm Circlip securing gear

Figure 9.51

NOTE: The gear is reversible, but should be

maintained in its original orientation once the

transaxle is broken-in.

9.52. Clean and inspect the input shaft.

9.53. The 24-tooth forward gear, along with a washer

(25.3mm I.D.X 33mm O.D.X 1mm width) is held

on by a 25mm circlip. See Figure 9.53.

9.54. Inspect the bearing surfaces on the input shaft

and 24-tooth forward gear. See Figure 9.54.

Bearing surface

Figure 9.54