Page 1

Operator’s Manual

HYDRAULIC FRONT

ATTACHMENTHITCH

For Cub Cadet Series 3000 Tractors

(Optional Manual Angling Kit 190-171-100)

INSTALLATION

INSTRUCTIONS

Model Number

343

IMPORTANT:

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A. FORM NO. 770-0843C

(11/03)ECO 07686

Page 2

NOTES

2

Page 3

CONTENTS

Section Page

Safe Operation Practices ................................. ... ............................................. ... .......... 3

To The Owner ............................................................................................................... 3

l Front Hitch Components ............................................................................................... 4

Il Tractor Preparation ................................... .................................................................... 6

lll Installation .................................................................................................................... 9

IV Tractor Reassembly .................................... .... ............................................. ... ............. 19

V Removal and Maintenance ........................................................................................... 21

VI Optional Manual Angling Kit (190-171) ......................................................................... 22

Warranty .......................................................................................................................24

WARNING

The tractors which use this front hitch atta chment are equ ipped wit h an inter na l combu stion eng ine and sh ould

not be used on or near any unimproved forest-covered, brush-covered, or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a

spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California, the above is re quired by la w (Se cti on 4 442 of t he Califor nia Pub lic Reso ur ce s Code ).

Other States may have similar laws. Federal laws apply to federal lands. A spark arrester muffle r is available at

your nearest engine authorized service center.

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED,

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND

OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— HEED ITS WARNING.

SAFE OPERATION PRACTICES

TO THE OWNER

This manual contains instructions for installation of the Front Hitch System, Model Number 190-343, on the Cub

Cadet Series 3000 Tractors. Carefully read all sections and study the illustrations to ensure proper installation.

If the optional Hydraulic Angling Kit (190-288) is going to be installed on the Front Hitch System, its

installation procedures should be performed in conjunction with those of this attachment.

Read and observe all WARNING and CAUTION statements. They are included to provide for the protection of the

equipment installer and user, and to ensure the prolonged service life of the equipment.

NOTE

References to LEFT and RIGHT indicate th e left and right sides of the tractor when facing fo rward in the

operator’s position. Reference to the FRONT indicates the grille end; to the REAR the drawbar end.

CALLING FOR SERVICE

If you are having difficulty assembling this product or if you have any question regarding the operation or

maintenance of this equipment, contact your dealer. If you need help locating a dealer in your area, contact the

Customer Dealer Referral Line by calling:

1-877-282-8684

3

Page 4

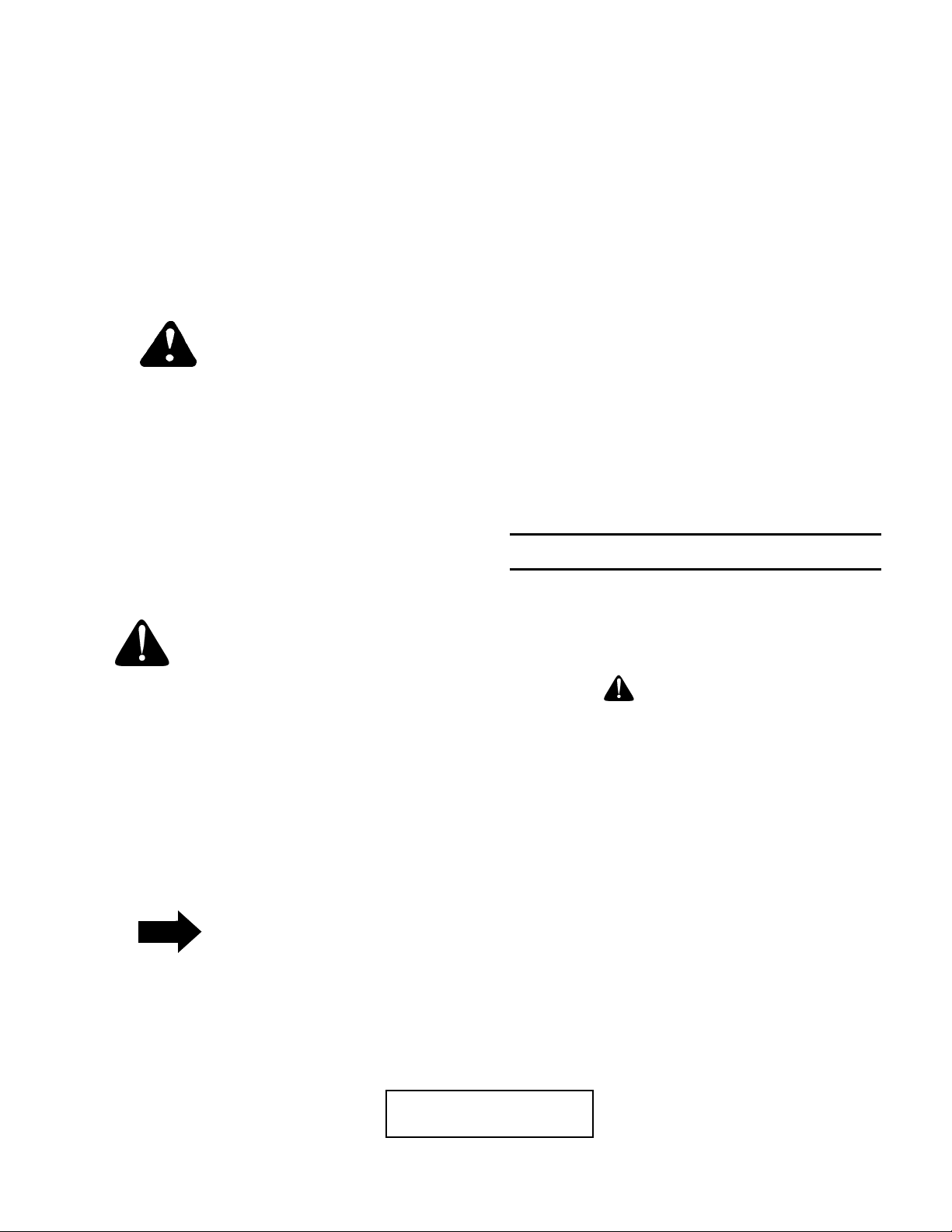

SECTION I. FRONT HITCH COMPONENTS

Before beginning installation of the Front Hitch

System, remove all parts from the shipping container.

Refer to Figures 1 and 2 to confirm that all parts are

present and to familiarize yourself with the part

descriptions.

22

6

8

10

11

7

5

1

Throughout the installation instructions in this manual,

the component part name is followed by the reference

letter or number in parentheses to aid in identification.

9

12

4

2

3

3

13

14

Figure 1

Ref.

No. Part No. Description Qty.

1 N/A Cylinder and Hose Assembly ....... 1

2 717-3456 Lift Cylinder .................................. 1

3 727-3012 90° Fitting w/O-Ring ..................... 2

4 N/A Hydraulic Hose Ass’y. ..................

(w/Female Coupling)

5 N/A Hydraulic Hose Ass’y. ..................

(w/ Male Coupling)

6 N/A Hydraulic Coupling Ass’y. - Male . 1

7 N/A Hydraulic Coupling Ass’y. - Female 1

8 703-3184 Fitting Bulkhead — For use with

tractors having welded running

board brackets.

9 727-3142 Hydraulic Lift Tube - Down ........... 1

10 727-3141 Hydraulic Lift Tube - Up ............... 1

1

1

1

19

15

18

17

16

21

Ref.

No. Part No. Description Qty.

11 747-3372 Hose Support Rod ........................ 1

12 N/A Front Hitch Ass’y. ......................... 1

13 741-0491 Nylon Flange Bearing ................... 2

14 747-3350 Handle, Aux. Valve #1 .................. 1

15 748-3081 Lift Link ......................................... 1

16 748-3082 Handle Clamp ............................... 1

17 703-3154 Lift Valve Bracket .......................... 1

18 727-3149 Hydro Return Tube, Aux. Valve #1 1

19 717-3452 Hydraulic Valve Assembly ............ 1

20 711-3294 Valve Adapter ............................... 1

21 703-1803 Double Valve Clamp ..................... 1

22 703-3442 Fitting Bulkhead — For use with

tractors having bolt up running

board brackets.

20

1

4

Page 5

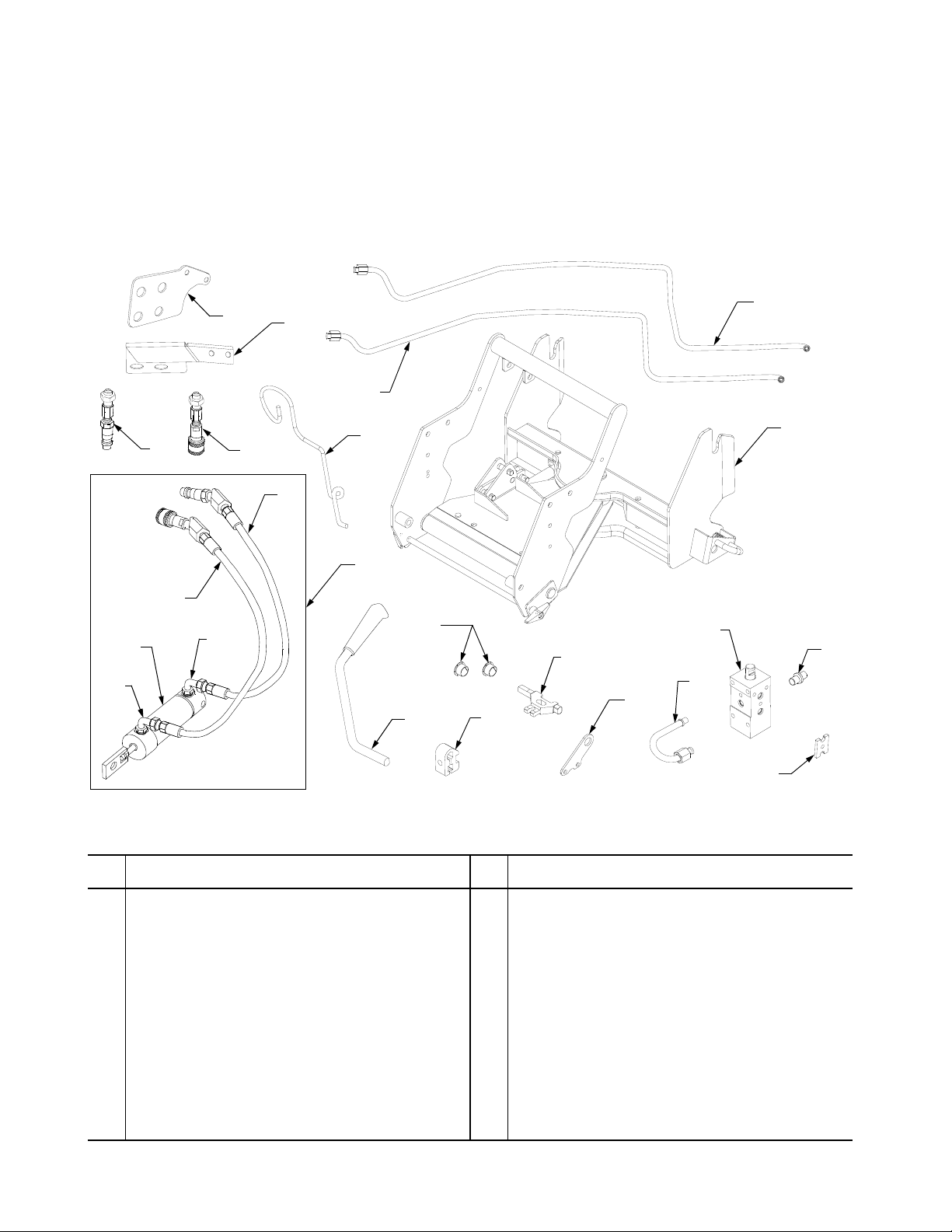

A

B

C

D

E

F

G

H

K

Ref.

No. Part No. Description Qty.

A 710-0805 Hex Cap Screw, 5/16-18 x .1.5 ..... 1

B 710-0528 Hex Cap Screw, 5/16-18 x 1.25 1

C 710-3025 Hex Cap Screw, 5/16-18 x.625 GR5 2

L

M

D 712-0429 Hex Insert Lock Nut, 5/16-18 ........ 4

E 710-3131 Hex Cap Screw, 1/2-13 x 1.0 GR5 4

F 712-3083 Hex Insert Lock Nut, 1/2-13 .......... 4

G 710-3104 Hex Cap Screw, 1/2-13 x 2.25 GR5 2

H 712-3083 Hex Insert Lock Nut, 1/2-13 .......... 2

I 710-1058 Hex Cap Screw, 1/4-20 x 4.0 ........ 4

J 712-0291 Hex Lock Nut, 1/4-20 .................... 2

K 710-3013 Hex Cap Screw, 1/4 -20 x 1/2 ....... 3

L 721-3021 O-Ring, .301 ID x .070 Dia ........... 5

M 711-0578 Clevis Pin ...................................... 1

N 714-0145 Internal Cotter Pin ......................... 1

0 736-0159 Flat Washer, .349 x .879 x .063 .... 1

P 721-0492 O-ring, Backup .............................. 8

I

J

N

O

P

Figure 2

MODEL 190-171-100

OPTIONAL MANUAL ANGLING KIT

Figure 3

5

Page 6

SECTION II. TRACTOR PREPARATION

This section contains instructions for preparing the

tractor for installation of the Front Hitch System.

WARNING

Place the tractor on a firm and level surface,

disengage the PTO, and turn the ignition switch

to the OFF position. Chock the front wheels to

prevent the tractor from rolling in either

direction.

WARNING

Allow the tractor to cool if it has been recently

operated.

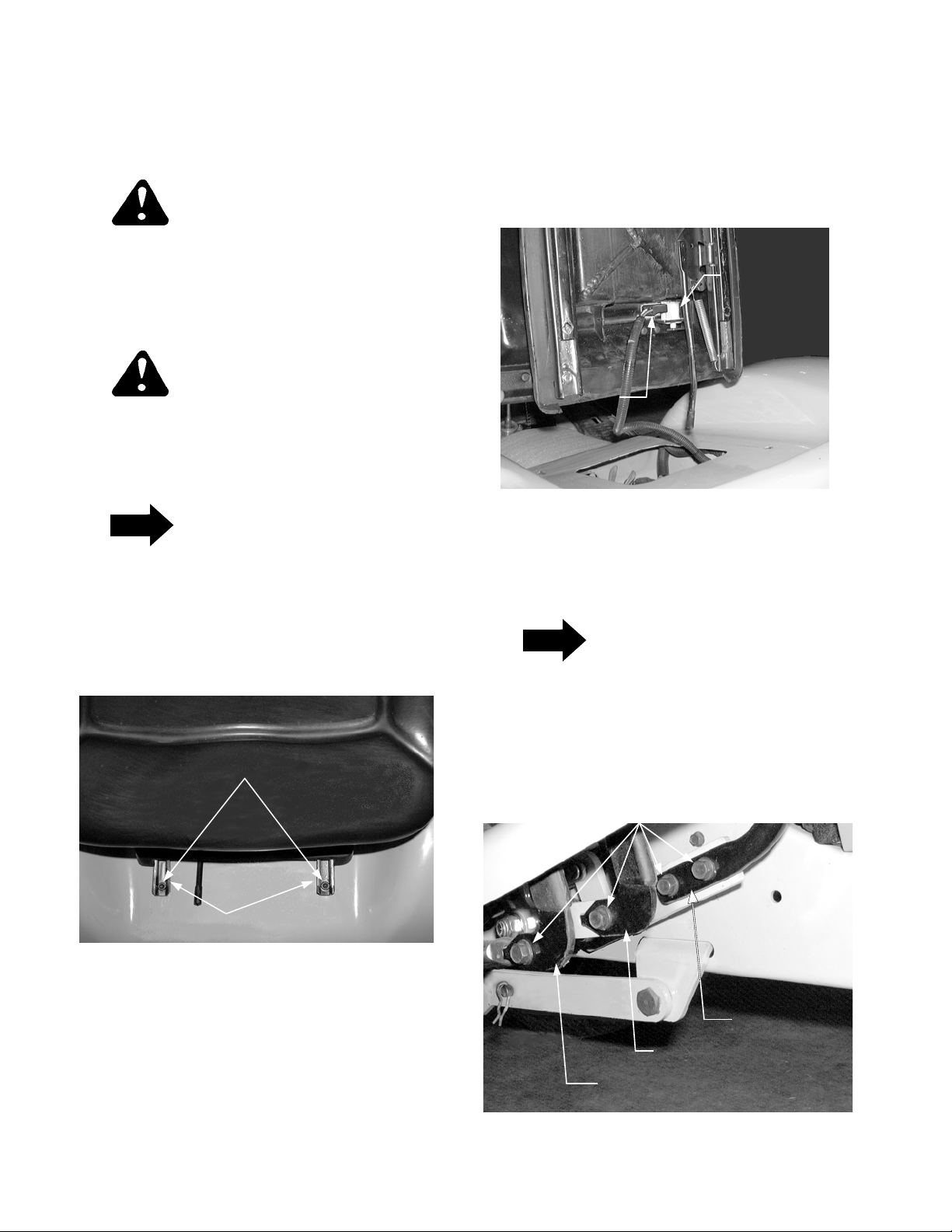

A. REMOVE THE TRACTOR SEAT.

NOTE

On some tractors, socket head screws were

used to secure the seat slide channels to the

tractor frame.

4. Lift the locking tab of the connector and unplug the

wire harness connector from the seat switch (See

Figure 5).

5. Place the seat assembly to the side.

SEAT

SWITCH

HARNESS

CONNECTOR

Figure 5

B. REMOVE THE FENDER AND RUNNING

BOARD ASSEMBLY

1. Slide the seat rearward and remove the two torx

head screws (or socket hd. s crews) from the seat

slide channels (See Figure 4).

TORX HEAD SCREWS

(OR SOCKET HD. SCREWS)

SLIDE CHANNELS

Figure 4

2. Slide the seat forward and remove the two rear

torx head screws ( or socket hd. screws) from the

slide channels.

3. Grasp the rear of seat base, then carefully lift and

tip the complete seat assembly so that it rests on

its side. Use care to avoid scratching the paint.

NOTE

The front hitch attachment can be installed

without removing the tractor fenders. However,

because of limited access and to ensure proper

installation, it is recommended that the fender

and running board assembly be removed from

the tractor.

HEX WASH. HD. TAPP SCREWS

BRAKE PEDAL

FORWARD PEDAL

REVERSE PEDAL

Figure 6

6

Page 7

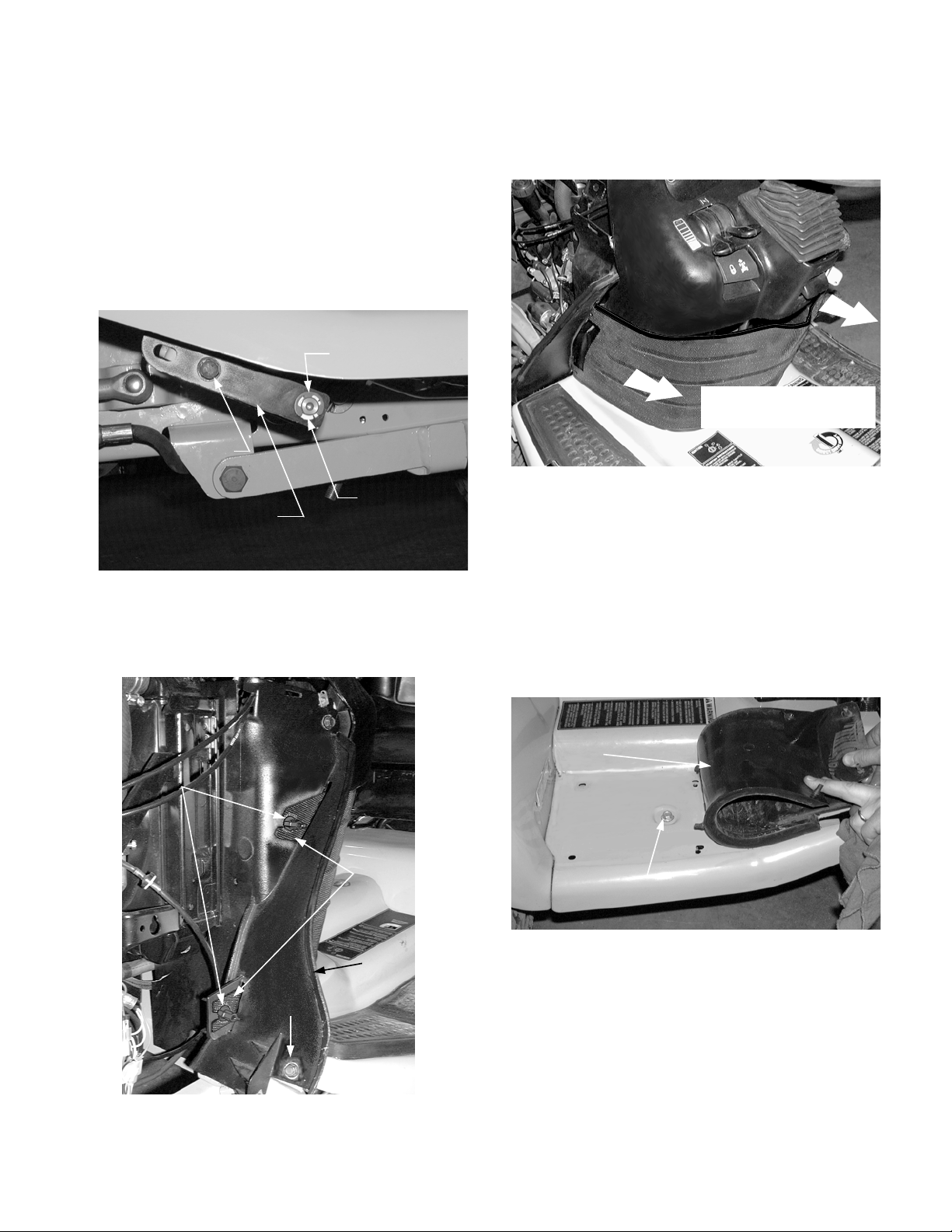

1. From beneath the right running board, remove the

hex wash. hd. tapp screws and remove in the

following order: the reverse control pedal, forward

control pedal, and the brake pedal (See Figure 6).

NOTE: The following step 2 app lies only to tractor s

equipped with the Diff-Lock feature.

2. From beneath the left running board, remove the

retaining ring and hex wash. hd. tapp screw to remove the diff-lock pedal. Use care to avoid losing

the nylon bearing in the pedal (See Figure 7).

RETAINING

RING

HEX WASH. HD.

TAPP SCREW

NYLON

DIFF - LOCK

PEDAL

BEARING

4. Loosen the four wing nuts securing the dash

screen to both sides of the bulkhead; then slide t he

screen rearward and out from below the dash

panel (See Figures 8 and 9)

SLIDE SCREEN FROM

BELOW DASH PANEL

Figure 9

Figure 7

3. Raise the hood and remove the side panels per the

instructions in the tractor Operator’s Manual.

WING

NUTS

SCREEN

TABS

BULKHEAD

HEX

SCREW

5. Remove the two hex screws securing the bottom

of the bulkhead and the front of the running board

to both sides of the frame (See Figure 8).

6. Carefully pull up the rear of the RH and LH foot

pads and remove the hex screws securing the

running board to the frame (See Figure 10).

RH FOOT

PAD

HEX SCREW

Figure 10

7. From underneath the rear fender, turn the four tail

light sockets counterclockwise (approximately 1/4

turn) until aligned with the notches of the reflector

housing and pull the sockets from housings. Be

careful to avoid pulling the bulbs from the sockets.

Figure 8

8. Remove the cap from the fuel tank.

7

Page 8

WARNING

Use care when handling the fender and running

board assembly. The edges could cause cuts to

the skin.

9. With the help of an assistant, lift the front of the

running board off the frame brackets, then raise

the rear fender over the neck of the fuel tank and

the lift handle to remove the fender assembly.

10. Reinstall the cap onto the fuel tank.

rearward as described in the following section D

to increase the space. If the o ptional Hydraulic

Angling Kit (190-288-100) is also being

installed, the tank must be moved rearward.

D. MOVE THE FUEL TANK REARWARD.

1. Remove th e two hex cap screws and hex flange

lock nuts securing the top of the hitch plate to the

frame (See Figure 11).

2. Loosen, but do not remove, the two hex cap

screws and flange nuts at the bottom of the hitch

plate

C. REMOVE THE LEFT REAR WHEEL.

WARNING

Ensure the front wheels are chocked before

raising the rear of the tractor. Use jack stands to

support the tractor; do not work on the tractor

when supported only by the jack.

1. Use a jack placed under the rear hitch plate to

raise the rear end of the tractor.

2. Position jack stands under each side of the frame,

just forward of the rear wheels. Lower the tractor

onto the jack stands and remove the jack.

3. Remove the lug nuts to remove the left rear wheel

assembly.

NOTE

The position of the fuel tank limits the working

space available for installing the hydraulic valve

included in this kit. Although not required, it is

recommended that the fuel tank be moved

3. Tip the top of the hitch plate back as needed to

slide the fuel tank rearward. NOTE: The

transmission oil fill tube/dipstick may be pulled

from the transmission housing when the hitch plate

is tipped. If so, plug or cover the hole in the

transmission to prevent dirt or debris from

entering.

DIPSTICK

HITCH

PLATE

OIL FILL TUBE

FLANGE LOCK NUTS

(NOT SHOWN)

HEX CAP

SCREWS

(BOTH SIDES)

Figure 11

8

Page 9

SECTION III. INSTALLATION

This section contains instructions for installing the

Front Hitch System on the tractor. If the optional

Hydraulic Angling Kit (190-288-100) is also being

installed, refer to the installation instructions in its

Operator’s Manual as you complete each of the

following steps. Some of the instructions for

installation of the Angling Kit will supersede or

supplement instructions for the Front Hitch.

REAR VALVE

MTG. BRACKET

HEX SCREW

VALVE CLAMP

HYDRAULIC

VALVE

A. INSTALL THE HYDRAULIC VALVE.

WARNING

Allow the tractor to cool if recently operated.

CAUTION

Position a suitable container to catch any oil leakage that may occur when disconnecting the hydraullic lines. Obey all applicable laws for disposal

of oil.

NOTE

Early production tractors were built with a standard O-ring and a backup O-ri ng on the hydraulic lines at their connections to the hydraulic

valve. When disconnecting the hydraulic lin es,

make certain to note whether there are one or

two O-rings at each connection (O-rings may

stick in valve bores). Extra backup O-rings have

been provided with this kit for use if needed.

The backup rings can be used to ensure tight

connections at the hydraulic valves.

HEX SCREW

AND LOCK NUT

HYDRO

RETURN

TUBE

HEX LOCK

NUTS

HEX SCREW

AND LOCK NUT

‘T’ FITTING

COUPLING NUT

Figure 12

REAR VALVE

MTG. BRACKET

VALVE CLAMP

HEX SCREW

HYDRO

RETURN

HOSE

Figure 13

NOTE

Tractors built after Mfg. Code 1D178G20023

are equipped with a flexible hose instead of the

hard hydro return tube (See Figure 13). If

equipped with the flexible hose, skip step 1 and

refer to step 2

1. Mfg. Code 1D178G20022 and Before. Secure

the ‘T’ fitting to avoid damaging the hydraulic lines

and loosen the coupling nut; then remove the hex

screw and valve clamp to remove the standard

hydro return tube (See Figure 12) . Re move th e Oring and backup ring (if applicable) from the tube.

Retain the valve clamp, screw and backup ring.

2. Mfg. Code 1D178G20023 and After. Remove the

hex screw and valve clamp to disconnect the

hydro return hose from the valve (See Figure 13).

Use care to avoid losing the O-Ring and backup

ring (if applicable) from the end of the hose. Retain

the valve clamp and screw.

3. Remove the hex cap screw and lock nut fastening

the rear valve mtg. bracket to the tractor frame

(See Figure 12 or 13). Retain the fasteners.

4. Remove the two hex screws and lock nuts

securing the hydraulic valve between the front and

rear valve mtg. brackets (See Figure 13 and 14).

Remove and retain the rear mtg. brac ket and lock

nuts.

9

Page 10

NOTE

DOUBLE VALVE

CLAMP

Tractors built prior to Mfg. Code 1H018G have

the standard center lift hydraulic lin es ro uted to

the outside of the frame. The standard lines

should be moved to the inside of the frame to

provide space for routing the front hitch

hydraulic lines. The following step 5 applies

ONLY to these tractors.

5. Move the standard lift cylinder lines to the inside of

the frame as follows:

a. Remove the hex screw and valve clamp secur-

ing the hydraulic tube in the front of the valve

(See Figure 14). Use care to avoid losing the

O-Ring and backup ring (if applicable) from the

end of the tube.

b. Remove the two hex cap screws and slide the

lift valve bracket off the lift link (See Figure 14).

Use care to avoid losing the nylon bearing.

NYLON BEARING

HEX CAP

SCREW

LIFT VALVE BRACKET

LIFT LINK

HEX SCREW

HYDRAULIC

LINES

Figure 15

LIFT LINK SLOT

HYDRAULIC

TUBE

HEX

SCREW

VALVE

CLAMP

HEX SCREW

Figure 14

c. After first noting the position of the hydraulic

lines (top outlet port to front of cylinder) remove the hex screw and double valve clamp to

disconnect the hydraulic lines from the valve

(See Figure 15). Use care to avoid losing the

O-Rings and backup rings (if applicab le) from

the end of the hoses.

d. Slide the valve rearward off the hydraulic tube

and out of the slot in the lift link (See Figu re 16)

to remove from the tractor.

O-RING(S)

Figure 16

e. While holding the valve spool in place, rotate

the body of the valve assembly 180° so that

the outlet ports face inward and the valve

spool arrow points rearward(See Figure 17).

ARROW

VALVE

BODY

TOWARD

TRACTOR

FRAME

VALVE

SPOOL

OUTLET

PORTS

TOWARD

INSIDE OF

TRACTOR

Figure 17

10

Page 11

f. If not already installed, install a backup O-ring

(P) between the existing O-ring and the fl ange

of the front hydraulic tube.

g. With the out let ports facing inward, align the

valve assembly with the front hydraulic tube

and the slot ot the lift link, then slide the valve

into position in the tractor.

h. Slide the lift valve bracket w/nylon bearing

onto the lift link and secure with the two hex

cap screws (See Figure 18).

i. Secure the front hydraulic tube with the valve

clamp and hex screw (See Figure 18).

6. Slide a backup O-ring (P) and O-Ring (L) onto

each end of the valve adapter (20), and insert the

valve adapter into the rear port of the standard

center lift valve (See Figure 20).

NYLON

FLANGE

BEARING

O-RING

BACKUP RING

HEX CAP

SCREW

VALVE

CLAMP

LIFT VALVE BRACKET

NYLON BEARING

LIFT

LINK

HEX

SCREW

Figure 18

j. If not already installed, install a backup O-ring

(P) between the existing O-ring and the fl ange

on each of the hydraulic lines, then insert the

lines into their respective outlet ports as noted

previously. Secure with the double valve

clamp and hex screw (See Figure 19).

LIFT LINK

VALVE

ADAPTER

Figure 20

7. Slide a nylon flange bearing (13), flange first, onto

the longer arm of the lift link (15). Using care to

avoid damage to the bearing, insert the lift link and

bearing into the front most available hole of the

tractor frame (See Figure 20).

CAUTION

The spool of the hydraulic valve assembly (19)

must be correctly positioned in the valve body to

ensure proper operation of the valve. The arrow

on top of the spool must point in the d irection of

the hydraulic system oil flow.

8. Referring to Figure 21, check the position of the

spool in the hydraulic valve assembly (19). With

the outlet ports of the valve body facing outward,

the arrow should point toward the rear. If

necessary, rotate the spool.

DOUBLE

VALVE CLAMP

HEX SCREW

Figure 19

11

ARROW

VALVE

BODY

VALVE

SPOOL

OUTLET

PORTS

TOWARD

TRACTOR

FRAME

Figure 21

Page 12

9. Align the front port of the hydraulic valve (19) with

the valve adapter (20) and the notch of the valve

spool with the slot of the lift link (17); then slide the

hydraulic valve into position behind the installed

valve (See Figure 22). Hold the valve in position.

SPOOL NOTCH

LIFT LINK SLOT

12. Align the rear mtg. bracket hole with the slot in the

lower/front corner of the frame opening and

loosely install the previously removed hex screw

and lock nut (See Figure 23).

13. In an alternating pattern, tighten the four hex cap

screws and lock nuts fastening the valves

together. Then tighten the hex screw and lock nut

to secure to the frame (See Figures 23).

14. Slide a nylon flange bearing (13), flange first, onto

the lift link (15).

15. Slide the lift valve bracket (17) onto the flange

bearing and lift link, and secure to the hydraulic

valve with two hex cap screws (K). See Figure 24.

Figure 22

10. Insert two of the hex cap screws (I) through the

inner holes of the valves and loosely fast en with

the two hex lock nuts (J). NOTE: the lower/inside

screw should be inserted from the rearward side

of the valve for ease of installation (See Figure 23).

11. Position the rear valve mtg. bracket and inser t the

remaining two hex cap screws (I) through the f ront

valve mtg. bracket, valves, and rear mtg. bracket

(See Figure 23). Loosely fasten with the pr eviously

removed hex lock nuts.

REAR VALVE

MTG. BRACKET

HEX LOCK NUTS

LIFT VALVE

BRACKET

HEX CAP SCREW

NYLON FLANGE

BEARING

Figure 24

NOTE

Steps 16 and 17 apply only to units built before

Mfg. Code 1D178G20023 that are equipped

with a hard hydro return tube. If equipped with a

flexible return hose, refer to step 18.

HEX

SCREW

FRAME SLOT

HEX LOCK NUT

Figure 23

LOWER/INSIDE

HEX CAP SCREW

16. Mfg. Code 1D178G20022 and Before. Slide a

backup O-ring (P) against the flange on the hydro

return tube (18) and install an O-Ring (L) onto the

tube. Insert the hydro return tube into the r ear po rt

of the new valve, while aligning the flanged end of

the tube with the tapered end of the hydraulic ‘T’

fitting (See Figure 25). Thread the return tube

coupling nut onto the ‘T’ fitting finger tight.

17. Install the previously removed valve clamp and

hex screw to secure the return tube in the hyd raulic

valve (See Figure 26). Support the return tube and

fully tighten the coupling nut .

12

Page 13

HYDRO RETURN TUBE

(AUX. VALVE #1)

B. INSTALL THE HYDRAULIC TUBES AND

COUPLING ASSEMBLIES.

BACKUP

RING

COUPLING NUT

O-RING

HYDRAULIC

‘T’ FITTING

Figure 25

18. Mfg. Code 1D178G20023 and After. If not

already installed, install a backup O-ring (P)

between the existing O-ring and the flange of the

hydro return hose. Insert the hydro return hose into

the rear port of the new valve an d secur e with the

previously removed valve clamp and hex screw.

NOTE

Early production tractors were built with

running board mounting brackets welded to the

frame, while later units have bolt up brackets.

Note which bracket is used on the tractor to

determine which fitting bulkhead will be used.

1. Tractors With Welded Frame Brackets. Install

the fitting bulkhead (8) on the LH frame mounting

bracket using the two hex cap screws (C) and hex

insert lock nuts (D) as shown in Figure 27.

WELDED FRAME

MOUNTING

BRACKET

FITTING

BULKHEAD

HEX CAP

SCREWS

HEX INSERT

LOCK NUTS

HEX SCREW

RETURN TUBE

OR HOSE

VALVE CLAMP

Figure 26

Figure 27

2. Tractors With Bolt Up Frame Brackets. Install

the fitting bulkhead (22) on the LH frame mounting

bracket using the two hex cap screws (C) and hex

insert lock nuts (D) as shown in Figure 28.

HEX LOCK NUTS

(NOT SEEN)

FITTING

BULKHEAD

BOLTED FRAME

MTG. BRACKET

HEX CAP

SCREW

Figure 28

13

Page 14

3. Remove the hex nuts from both the male and

female hydraulic coupling assemblies (6 and 7)

and install as follows (Refer to Figure 29):

a. From the front of the fitting bulkhead, insert the

male coupling assembly (6) into the top inside

hole of the bulkhead. Secure with the hex nut.

b. Insert the female coupling assembly (7) into

the bottom inside hole of the bulkhead and secure with the hex nut.

MALE COUPLING ASS’Y.

FITTING

BULKHEAD

FEMALE

COUPLING

ASS’Y.

HEX NUT

outlet port of the hydraulic valve. Align the flanged

front end of the tube with the tapered female

coupling assembly (7) and loosely fasten with the

tube coupling nut (See Figure 30).

CAUTION

The double valve clamp (21) has rounded

edges on one side and flat edges on the other.

Always place the flat edged side toward the

hydraulic valve when installing the clamp.

6. With its flat surface toward the valve, position the

double valve clamp (21) between the tubes,

squarely against the tube beads. Install a hex cap

screw (K) through the clamp and into the vlave.

Carefully tighten to secure the tubes in the valve

(See Figure 31).

DOUBLE

VALVE

CLAMP

Figure 29

4. Slide a backup O-ring (P) against the tube flange

and install an O-Ring (L) on the end of the ‘up’

hydraulic tube [10 (shorter bends)]. Insert the tube

into the lower outlet port of the hydraulic valve.

Align the flanged front end of the tube with the

tapered male coupling assembly (6) and loosely

fasten with the tube coupling nut (See Figure 30).

5. Slide a backup O-ring (P) against the tube flange

and install an O-Ring (L) on the end of the ‘down’

hydraulic tube (9). Insert the tube into the upper

FEMALE COUPLING

ASSEMBLY

MALE

COUPLING

ASSEMBLY

HEX CAP

SCREW

‘UP’ HYDRAULIC TUBE

‘DOWN’ HYDRAULIC TUBE

Figure 31

7. Fully tighten the coupling nuts on the front end of

the tubes.

‘DOWN’

HYDRAULIC TUBE

TUBE

COUPLING

NUT

‘UP’

HYDRAULIC TUBE

Figure 30

14

Page 15

C. INSTALL THE FRONT HITCH COMPONENTS.

WARNING

If the tractor has been recently operated, the

muffler, exhaust pipe, and surrounding areas

will be HOT. Allow the tractor to cool before

continuing installation.

NOTE

2. Install the hose support rod (11) onto the left side

of the mtg. plate assembly as follows (Refer to

Figure 33):

a. Align the small loop of the support rod with the

5/16” hole, and insert the short hook at the

bottom of the rod into the hole below.

b. Slide the flat washer (O) onto the hex cap

screw (A) and insert the screw through the rod

loop and mtg. plate. Secure with the hex insert

lock nut (D).

If a mower deck is installed on the tracto r, the

deck front hanger bracket will cause

interference during the initial installation of the

front hitch components. Lower the deck to the

ground and temporarily remove the front

hanger bracket from the tractor. Refer to the

mower deck Operator’s Manual if necessary.

NOTE

The front hitch assembly can remain on the

tractor while the mower deck is installed.

However, the mower deck drive shaft must be

disconnected from the PTO shaft whenever a

front attachment is being powered off the front

of the PTO shaft.

1. Remove the bumper from the front of the tractor by

removing the hex cap screw and lock nut from

each side of the frame (See Figure 32). Store the

bumper and hardware.

HOSE

SUPPORT

ROD (11)

HEX INSERT

LOCK NUT (D)

FLAT

WASHER (O)

HEX CAP

SCREW (A)

PIVOT PIN

ASSEMBLY

Figure 33

MTG. PLATE

ASSEMBLY

CLEVIS

PIN

INTERNAL

COTTER PIN

PIVOT

PLATE

ASSEMBLY

WINGNUT

KNOB

Figure 32

FRONT

BUMPER

HEX CAP

SCREW

(LOCK NUT

NOT SHOWN)

3. Position the hitch assembly at the front of the

tractor so that the mounting plate assembly aligns

with the frame.

NOTE

If desired to lessen the weight, the mounting

plate assembly can be separated from the pivot

plate assembly by removing the two wingnut

knobs and withdrawing the pivot pin from each

side of the mounting plate (See Figure 33).

4. Lift the rear of the mounting plate to align its lower

hole (w/spacer) with the lower hole in the quick

latch bracket on either side of the frame (See

Figure 34). Insert a hex cap screw (G) and loosely

fasten with a hex insert lock nut (H).

15

Page 16

QUICK LATCH

BRACKET

HEX CAP

SCREW

MOUNTING

PLATE

Figure 34

5. Align the moun ting plate and latch bracket holes

on the other side of the tractor and loosely fasten

with the remaining hex cap screw (G) and insert

lock nut (H).

6. Pivot the top of the mounting plate upward and

align the upper two holes on each side of the plate

with those of the frame. Secure with the four hex

cap screws (E) and hex insert lock nuts (F). See

Figure 35.

and reassemble with the two pivot pin assemblies

and wingnut knobs (See Figure 33).

9. If the front hitch components were installed as

assembled and the mower deck is installed,

reinstall the deck front hanger bracket as follows:

a. Loosen the wingnut knob on the left side of the

front hitch assembly.

b. Remove the wingnut knob and pivot pin from

the right side of the hitch to lower the right side

of the pivot plate assembly (See Figure 36).

REMOVE

WINGNUT

KNOB

PIVOT PLATE

ASSEMBLY

REMOVE

PIVOT PIN

Figure 36

MOUNTING PLATE

HEX CAP SCREW

Figure 35

7. Fully tighten the lower hex cap screws (G) and

insert lock nuts (H) on both sides of the mounting

plate.

8. If the pivot plate assembly was separated from the

mounting plate and the mower deck is installed on

the tractor, reinstall the deck front hanger bracket

now. Align the pivot plate with the mounting plate

c. Maneuver the front hanger bracket under the

exhaust pipe to position in the frame. Pull the

quick latch rod downward and slide the front

hanger bracket into the latch receiver slots

(See Figure 37).

FRONT

HANGER

BRACKET

QUICK

LATCH

ROD

Figure 37

d. Align the right side of the pivot plate assembly;

install the right pivot pin; and tighten both

wingnut knobs.

16

Page 17

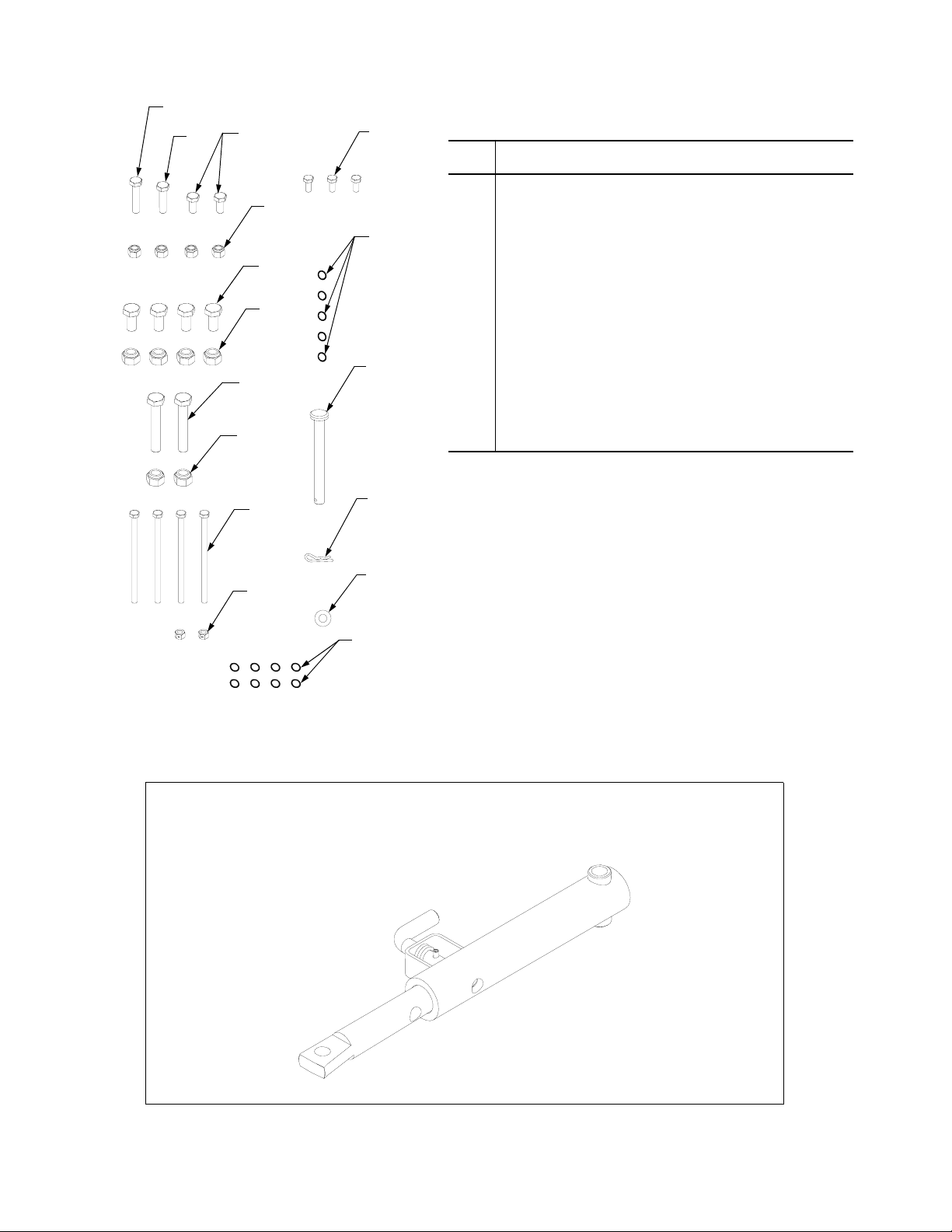

D. INSTALL THE LIFT CYLINDER AND HOSES.

NOTE

The lift cylinder, elbows, hydraulic hoses, and

coupler fittings were preassembled at the

factory to ensure proper sealing of the

connections and position of the hoses (angled

slighly upward). Refer to the assembly drawing

in Figure 1 (Page 4) to verify proper assembly.

1. Remove th e internal cotter pin an d clevis pin fr om

the front end of the float arms on the pivot plate

assembly (See Figure 38).

LIFT CYLINDER

ASSEMBLY

INTERNAL

COTTER PIN

FLOAT

ARMS

FLOAT

BRACKET

MOUNTING

BRACKETS

CLEVIS PIN

LIFT CYLINDER

Figure 39

5. Route the hydraulic hoses around the left side of

the tractor and up through the pigtail of the hose

support rod (See Figure 40).

CLEVIS PIN

(FLOAT SETTING)

CLEVIS PIN

Figure 38

2. Split the two float arms and position the piston of

the lift cylinder between them. Insert the clevis pin

through the arms and piston and secure with the

internal cotter pin (See Figure 38).

3. Remove the internal cotter pin and float setting

clevis pin from the float bracket (Refer to Figure

38).

4. Pivot the lift cylin der upward to position between

the mounting brackets of the m ounting plate. Insert

the clevis pin (M) through the mounting br ackets

and cylinder and secure with the intern al cotter pi n

(N). See Figure 39.

HOSE

SUPPORT

ROD

HYDRAULIC

HOSES

Figure 40

6. Remove the protective caps from both the male

and female coupling assemblies on the fitting

bulkhead. Snap the caps together to limit their

movement.

17

Page 18

LOCKING

COLLARS

45° FITTINGS

COUPLING

ASSEMBLY

PROTECTIVE

CAPS

LOCKING

COLLARS

a. To allow the front hitch to float, insert the clevis

pin in the upper hole of the float bracket and

secure with the internal cotter pin as shown in

Figure 42.

b. To set the front hitch in the fixed position, align

the holes in the float arms with the lower hole

in the float bracket and insert the clevis pin.

Secure with the internal cotter pin.

CLEVIS PIN

FLOAT

BRACKET

FLOAT POSITION

FIXED POSITION

Figure 41

7. Compress the locking collar o n the female fittings

and attach the hoses to their respective coupling

assemblies (See Figure 41). NOTE: the 45°

fittings on the hoses should angle outward and

upward to properly position the hoses.

NOTE

It may be necessary to extend or contract the lift

cylinder piston by applying pressure to the front

hitch yoke when performing the fo llowing step

8.

8. Reinstall the float setting clevis pin as follows

(Refer to Figure 42):

FLOAT ARMS

Figure 42

NOTE

To ease installation of the fender/running board

assembly, do not install the new valve handle

(14) until after the fender has been installed.

18

Page 19

SECTION IV. TRACTOR REASSEMBLY

A. REPOSITION FUEL TANK AND HITCH PLATE.

1. Slide the fuel tank fully forward in the frame slots.

2. If used, remove any plug or covering from the

dipstick hole of the transmission housing.

3. While guiding the dipstick tube into the

transmission opening, pivot the hitch plate up into

position on the frame. Install the two hex cap

screws in the upper holes of the hitch plate and

secure with the hex flange lock nuts.

4. Tighten the lower hex cap screws and flange lock

nuts of the hitch plate.

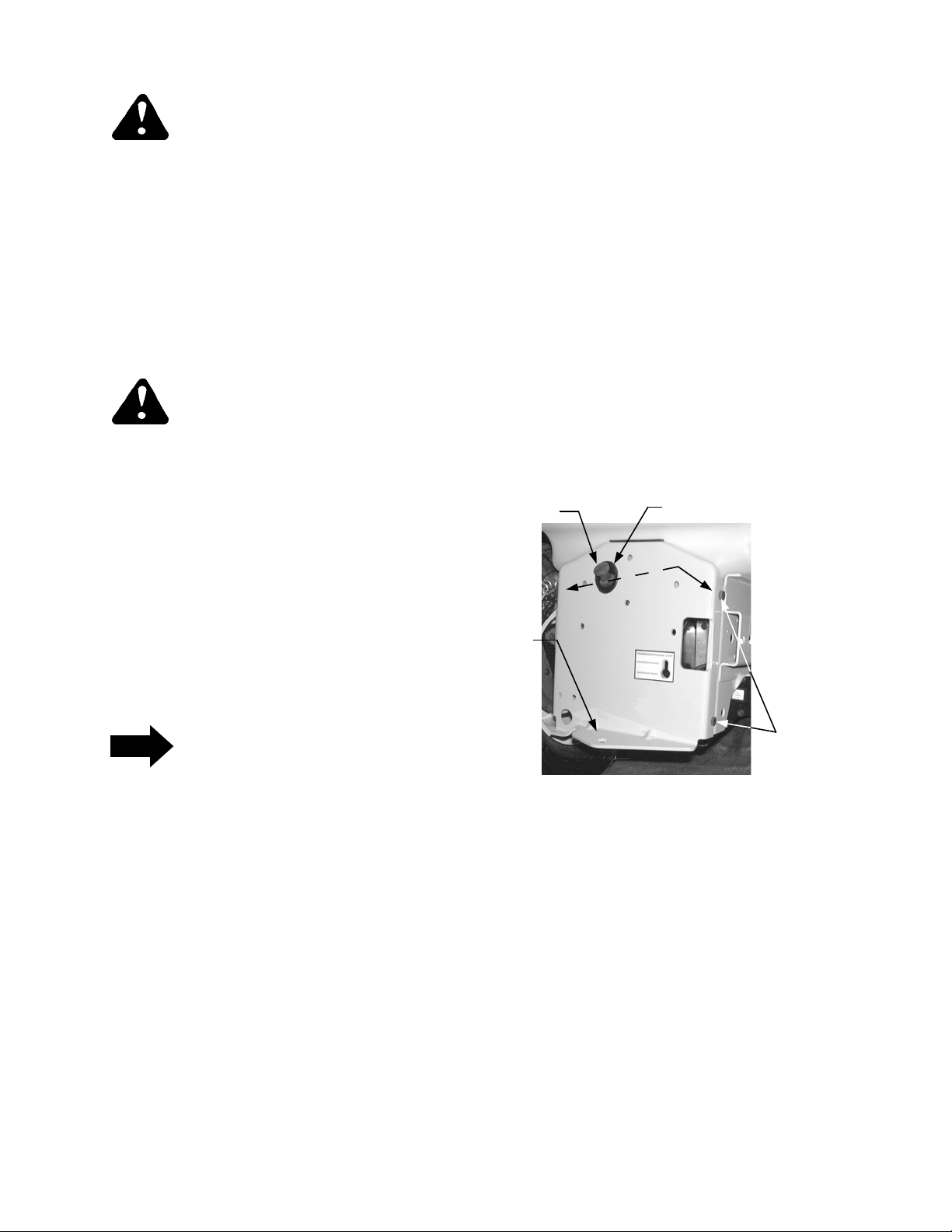

B. REINSTALL THE FENDER AND RUNNING

BOARD ASSEMBLY.

1. Remove th e cap from the fuel tank. Make certain

the tail lights and wires are draped over the top of

the fuel tank, and the seat switch wire lead is inside

the tractor frame (See Figure 43).

TAIL LIGHT

WIRES

• Press the front of the running board onto the

mounting brackets on each side of the frame.

3. Using care to avoid dislodging the bulbs from the

sockets, install the tail light sockets in the reflector

housings as follows:

• Reverse Lights - Install the light sockets having

a WHITE wire in the inner hole of the housing

• Tail Lights - Install the remaining two light sock-

ets in the outer holes of the housing.

4. Fasten the middle of the running boards to the

frame brackets with the two hex screws. Reinstall

the RH and LH foot pads by pulling the locking

projections through the running board and fender.

Refer to Figure 10.

5. Align the bulkhead and running board with the

frame mounting brackets and secure with the two

hex screws removed earlier. Refer to Figure 8.

6. Align the four tabs of the dash screen with the slots

in the bulkhead, then slide the screen forward

beneath the dash panel while guiding the tabs

under the four wing nuts. Tighten the wing nuts to

secure the screen. Refer to Figure 8.

NOTE: The following step 7 applies only to tractors

equipped with the Diff-Lock feature.

SEAT SWITCH

WIRE LEAD

Figure 43

2. With the help of an assistant, install the fender/

running board assembly as follows:

• Lower the front of the running board into posi-

tion above the frame.

• Guide the lift handle through the slot as you

lower the rear fender.

• Route the tail light wires along the upper /rear of

the fuel tank and position the rear fender so the

tail light reflector housings clea r the fuel tank,

then lower the fender over the fill neck of the

fuel tank. Do not damage the reflector housings

by forcing the fenders into place. Replace the

fuel cap.

7. Insert the diff-lock pedal down through the left

running board. Slide the pedal w/bearing onto the

pivot shaft and install the previously removed

retaining ring. Align the pedal with the engagement

bracket and secure with the hex wash. hd. tapp

screw. Refer to Figure 7.

8. Install the pedals in the right running board as

follows (Refer to Figure 6):

a. Insert the brake pedal through the running

board and align with the brake lever beneath

the right running board. Secure with the two

longer hex wash. hd. tapp screws.

b. Slide the forward control pedal (arrow on pedal

points forward) through the running board. Insert the pedal tab in the slot of the control lever

and secure with the hex wash. hd. tapp screw.

c. Slide the reverse control pedal (arrow on pedal

points rearward) through the running board.

Insert the pedal tab in the sl ot of the reverse

shaft and secure with the hex wash. hd. tapp

screw.

19

Page 20

C. REINSTALL THE SEAT ASSEMBLY.

1. Lay the seat assembly on its side on top of the

fender and plug the wire harness connector onto

the seat switch. Refer to Figure 5.

2. Carefully position the seat assembly on the fender.

Align the rear slide channel holes and fender holes

with the mounting holes of the frame. Fasten with

two torx head (or socket hd.) screws.

3. Slide the seat rearward, align the front holes and

fasten with the remaining two torx head (or socket

hd.) screws.

D. INSTALL THE NEW LIFT HANDLE.

1. From under the left fender, note the direction of the

hex cap screw and lock nut in the existing handle

clamp (See Figure 44).

NOTCH IN

CLAMP

HEX CAP SCREW

LIFT LINK

HANDLE SLOT

(AUX. VALVE #1)

COVER PLATE

LIFT

HANDLE

FLAP

LIFT

LEVER

COVER

Figure 45

5. Maneuver the new lift handle up through the inner

slot of the lift lever cover and slide the clamp onto

the arm of the lift link.

6. Holding the clamp on the lift link, slide the handle

into, or out of, the clamp as necessary to align with

the center of the slot. Tighten the hex cap screw

(B) and insert lock nut (D).

HANDLE CLAMP

STANDARD LIFT HANDLE

Figure 44

2. In the sa m e dir e ctio n as the existing clamp, install

the hex cap screw (B) and hex insert lock nut (D)

in the handle clamp (16). Do not tighten the

fasteners completely.

3. With the notch of the clamp facing forward, insert

the new handle (14) into the upper hole from the

left side of the clamp (Refer to Figure 44).

4. Remove t he cover plate fr om the inner slot of the

lift lever cover on the left fender (See Figure 45).

NOTE: It may be necessary to cut the connecting

edges of the cover plate. If so, use caut ion to avoid

cutting the lift handle flap underneath the plate.

7. Install the left rear wheel on the axle. In an

alternating pattern, torque the lug nuts to 60 ft. lbs.

8. Jack the rear of the tractor up to remove the jack

stands, then lower to the ground.

9. Install the side panels and close the hood per the

instructions in the tractor Operator’s Manual.

10. Engage the parking brake and start the tractor.

11. By actuating the newly installed lift handle fully in

both directions, completely cycle the hydraulic lift

system several times. This will prime the system

and force any air from it.

12. Stop the engine.

13. Remove the dipstick and check the transmission

oil level. Add sufficient oil to the transmission to

bring the oil level to the full mark on the dipstick.

DO NOT OVERFILL. USE ONLY THE SPECIFIED

OIL

20

Page 21

E. CHECK OPERATION.

If all previous installation procedures were correctly

performed, the front hitch should raise when the lift

handle is pulled upward (rearward) and lower when

pushed downward (forward). If the opposite actions

occur, switching the hose connections at the cylinder

will correct the problem. Proceed a follows:

CAUTION

HOSE FITTING

ELBOWS

Position a suitable container to catch any oil

leakage. Obey all applicable laws for disposal of

oil.

1. Lower the front hitch to its lowest position and stop

the tractor engine.

2. Because the oil may be under pressure, carefully

loosen the upper hose fitting from the cylinder

elbow to relieve pressure (See Figure 46).

Disconnect the hose.

3. Disconnect the lower hose and reconnect to the

upper elbow. Connect the other hose to the lower

elbow.

SECTION V. REMOVAL AND MAINTENANCE

A. REMOVAL. It is not necessary to completely

remove the front hitch assembly when not in use.

Remove as follows:

1. Compress the locking collar of the female fittings

and disconnect the hoses from the coupling

assemblies (See Figure 47). Snap the protective

caps onto the coupling assemblies.

2. Remove the hoses from the hose support rod.

HOSE FITTING

Figure 46

4. Start the tractor and completely cycle the hydraulic

lift system several times to prime the system.

5. Recheck the oil level in the transmission and fill to

the full mark on the dipstick.

Refer to the Operator’s Manual of the specific

attachment for hitching and operating instructions.

3. Remove the internal cotter pin and clevis pin

fastening the top of the lift cylinder to the mo unting

plate (Refer to Figure 39).

4. Remove the wingnut knobs; then pull the pivot pins

from the mounting and pivot plate assemblies to

disconnect the front hitch assembly (See Figure

48).

LOCKING

COLLARS

Figure 47

COUPLING

ASSEMBLY

21

MTG. PLATE

ASSEMBLY

WINGNUT

KNOB

PIVOT PIN

ASSEMBLY

HITCH YOKE

ASSEMBLY

PIVOT

PLATE

ASSEMBLY

WINGNUT

KNOB

Figure 48

Page 22

5. Reinstall the wingnut knobs to protect the threads

of mounting plate studs.

6. The mounting plate can remain installed on the

tractor.

B. MAINTENANCE.

Whenever the pivot pins are rem oved or once a year

apply a light coating of high grade lubricating oil to the

pins.

Once a year lubricate the front angling pivot shaft with

Cub Cadet 251H EP grease. Use a grease gun to

apply through the front lube fitting (See Figure 49).

SECTION VI. OPTIONAL MANUAL ANGLING KIT (190-171)

LUBE

FITTING

Figure 49

The Mechanical Angling Assembly provides five

positions for angling front hitch mo unted atta chments,

such as the front blade or rotary sweeper.

A. INSTALLATION.

1. Remove the fixed shaft from the left side of the

front hitch by removing the two internal cotter pins

and clevis pins (See Figure 50).

2. With the adjustment handle facing outward,

position the mechanical angling ass’y. between

the pivot plate and hitch yoke. Insert the clevis pins

and secure with the internal cotter pins.

MECHANICAL

ANGLING ASS’Y.

FIXED SHAFT

CLEVIS

PIN

INTERNAL

COTTER PIN

B. ADJUSTMENT.

WARNING

Always disengage the PTO, engage the parking

brake, turn the ignition switch to “OFF” and

remove the key before dismounting the tractor

to adjust the front hitch angle.

1. Raise the attachment slightly off the ground.

2. Pull the adjustment handle outward and pivot the

front hitch yoke left or right to the approximate

position desired (See Figure 51). NOTE: the index

holes are 1.25 inches apart.

3. Release the adjustment handle and pivot the hitc h

yoke slightly left and right until the handle snaps

into the desired index hole.

HITCH

YOKE

INTERNAL

COTTER PIN

CLEVIS

PIN

Figure 50

PIVOT

PLATE

ASSEMBLY

22

P

I

V

O

T

INDEX

HOLES

ADJUSTMENT

HANDLE

Figure 51

Page 23

23

Page 24

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Cub Cadet

LLC with respect to new merchandise purchased and used in

the United States, its possessions and territories.

“Cub Cadet” warrants this product against defects in material

and workmanship for a period of two (2) years commencing

on the date of original purchase and will, at its option, repair or

replace, free of charge, any part found to be defective in

materials or workmanship. This limited warranty shall only

apply if this product has been operated and maintained in

accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse,

commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water, or damage because of

other peril or natural disaster. Damage resulting from the

installation or use of any part, accessory or attachment not

approved by Cub Cadet for use with the product(s) covered

by this manual will void your warranty as to any resulting

damage.

Normal wear parts are warranted to be free from defects in

material and workmanship for a period of thirty (30) days from

the date of purchase. Normal wear parts include, but not

limited to items such as: batteries, belts, blades, blade

adapters, grass bags, rider deck wheels, seats, snow thrower

skid shoes, shave plates, auger spiral rubber and tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate the dealer in your area, check your

Yellow Pages, or contact Cub Cadet LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-877-282-8684, or log

on to our Web site at www.cubcadet.com.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

may carry a separate manufacturer’s warranty. Refer

to applicable manufacturer’s warranty for terms and

conditions.

b. Log splitter pumps, valves, and cylinders have a sepa

rate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening, tune-ups, brake adjustments, clutch

adjustments, deck adjustments, and normal

deterioration of the exterior finish due to use or

exposure.

d. Cub Cadet does not extend any warranty for products

sold or exported outside of the United States, its

possesions and territories, except those sold through

Cub Cadet’s authorized channels of export

distribution.

e. Replacement parts that are not genuine Cub Cadet

parts.

f. Service completed by someone other than an

authorized service dealer.

g. Transportation charges and service calls.

No implied warranty, including any implied w arranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, except as

mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product,

shall bind Cub Cadet. During the period of the w arranty,

the exclusive remedy is repair or replacement of the

product as set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. Cub

Cadet shall not be liable for incidental or consequential

loss or damage including, without limitation, expenses

incurred for substitute or replacement lawn care services

or for rental expenses to temporarily replace a warranted

product.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, or limitations on how

long an implied warranty lasts, so the above exclusions or

limitations may not apply to you.

In no event shall recovery of any kind be gre ater than the

amount of the purchase price of the product sold. Alteration

of safety features of the product shall void this warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased

as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

IMPORTANT:

Owner must present Original Proof of

Purchase to obtain warranty coverage.

Cub Cadet LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-877-282-8684

Loading...

Loading...