Page 1

Professional Shop Manual

33” Wide Area Mower

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accura te as possible at the time of publication. However, du e to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2007 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-03596

10/2007

Page 2

Page 3

Table of Contents

Chapter 1: Introduction ...........................................................................................1

Description of the Mower...................................................................................... 1

Fasteners ..............................................................................................................1

Assembly ..............................................................................................................2

Model and Serial Numbers ...................................................................................2

Chapter 2: Maintenance .......................................................................................... 3

Cleaning ...............................................................................................................3

Lubricants .............................................................................................................3

Axle shafts ............................................................................................................3

Front casters......................................................................................................... 4

Spindles ................................................................................................................4

Fasteners ..............................................................................................................5

Transmission ........................................................................................................5

Engine ..................................................................................................................5

Emissions .............................................................................................................5

Chapter 3: Drive system ..........................................................................................6

Transaxle ..............................................................................................................6

Drive Belt.............................................................................................................. 6

To remove/replace the drive belt.......................................................................... 6

Drive Cable ...........................................................................................................7

Brakes ..................................................................................................................8

Brake adjustment.................................................................................................. 9

Brake caliper .......................................................................................................10

Brake cables....................................................................................................... 12

Transmission Removal and replacement........................................................... 14

Chapter 4: Cutting Deck and lift shaft ..................................................................10

Deck removal ......................................................................................................10

Cleaning the deck............................................................................................... 11

Blades .................................................................................................................11

Blade removal..................................................................................................... 12

Spindles ..............................................................................................................13

PTO belt .............................................................................................................14

Deck Timing Belt ................................................................................................15

To service the deck timing belt........................................................................... 15

Deck engagement (PTO) cable ..........................................................................17

Leveling the deck ................................................................................................19

Deck lift shaft and lever ......................................................................................19

Page 4

CHAPTER 1: INTRODUCTION

33” Wide Area Mower

Description of the Mower

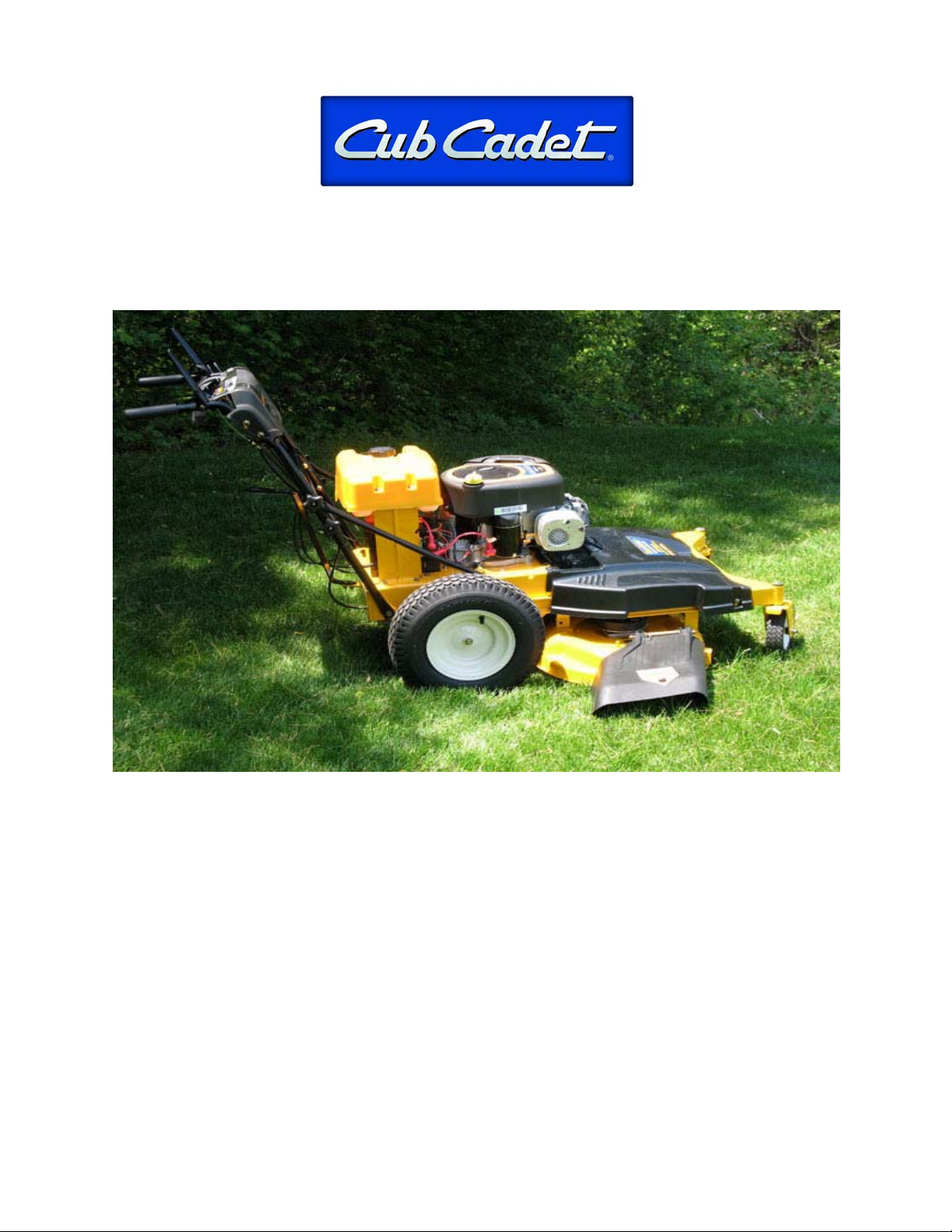

The Troy-Bilt 33” wide cut mower was discontinued in

2005. It has since been completely redesigned and

released as a Cub Cadet for the 2007 season.

See Figure 1.1.

Figure 1.1

Some changes and features included on this mower:

• Easier access to the belts.

• Improved blade timing.

• Control rods replaced with cables.

• Controls are more user friendly.

• The mower is 20 lbs lighter.

• Deck Height Control.

• 2 gallon fuel tank.

Disclaimer: The information contained in this Manual is

correct at the time of writing. Both the product and the

information about the product are subject to change

without notice.

Disclaimer: This handbook is intended for use by

trained, professional technicians.

• Common sense in operation and safety is

assumed.

• In no event shall MTD or Cub Cadet be liable for

for poor text interpretation, or poor execution of

the procedures described in the text.

• If the person using this handbook is uncomfortable with any procedures they encounter, they

should seek the help of a qualified technician.

Fasteners

• Most of the fasteners used on the mower are

sized in fractional inches. Some are metric. For

this reason, wrench sizes are frequently identified in the text, and measurem ents are given in

U.S. and metric scales.

• If a fastener has a locking featu re th at has wo rn,

replace the fastener or apply a small amount of

releasable threadlocking compound such as

Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use

items that are not to be reused.

Other fasteners such as lock washers, retaining

rings, and internal cotter pins (hairpin clips) may

be reused if the do not show signs of wear or

damage. This manual leaves that decision to

the judgement of the technician.

• 10.5 horse power Briggs engine. (Horse power

as rated by Briggs and Stratton)

• 33” cutting width.

• 4 speed Peerless Transmission.

• Simplified gear selector.

• Single lever deck height adjustments.

• Timed dual blades.

• Front (grease able) caster wheels for better

maneuverability.

1

Page 5

Chapter 1: Introduction

Assembly

Torque specifications may be noted in the part of the

text that covers assembly, they may also be summarized in tables along with special instructions regarding

locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be

used so that the manual is handy as a quick-reference

guide as well as a step-by-step procedure guide that

does not require the user to hunt for information.

The level of assembly instructions provided will be

determined by the complexity and of reassembly, and

by the potential for unsafe conditions to arise from mistakes made in assembl y.

Some instructions may refer t o other parts of the manual for subsidiary procedures. This avoids repeating

the same procedure two or three times in the manual.

Model and Serial Numbers

The model and serial number tag can is located in the

back of the mower. See Figure 1.2.

Model Number

Serial Number

Figure 1.2

The model number is 12AE764N709.

The model number breaks down as follows:

12.........................self propelled

...A.......................sales level

......E....................type of starter (e = electric)

.........76................deck

.............4N...........engine

..................709.....customer number

The serial number is 11D107B20004.

The serial number breaks down as follows:

1...........................engineering level

.D.........................month of production (D = April)

.....10....................day of the month

.........7..................last digit of the year

...........B................plant it was built in

..............2.............assembly line number

.................0004.....number of unit built

2

Page 6

CHAPTER 2: MAINTENANCE

MAINTENANCE

Cleaning

Maintaining any piece of equipment begins with keeping it clean. Any spills such as fuel or oil should be

wiped off promptly. Use a mild detergent and water to

wash the mower.

NOTE: Do NOT use a pressure washer to clean

the mower. It may cause damage to the electrical components or remove lubrication that is

needed in critical areas.

NOTE: Using polishers like pledge on the plastic

components will affect their finish.

Use the Deck Wash System™ to rinse grass clippings

from the underside of the deck and prevent the build up

of corrosive chemicals caused by decaying vegetation

or fertilizers. It should only be done after the deck has

cooled down. Run the cutting deck for 15 minutes af terwards to dry the deck. After the deck is dry, inject one

squirt of grease in each spindle.

Lubricants

The grease used on this mower should be a high quality lithium based grease.

A high quality light weight oil such as WD 40 or 3-in-1

oil should be applied to all hinge and rotating points

that are not equipped with grease fittings.

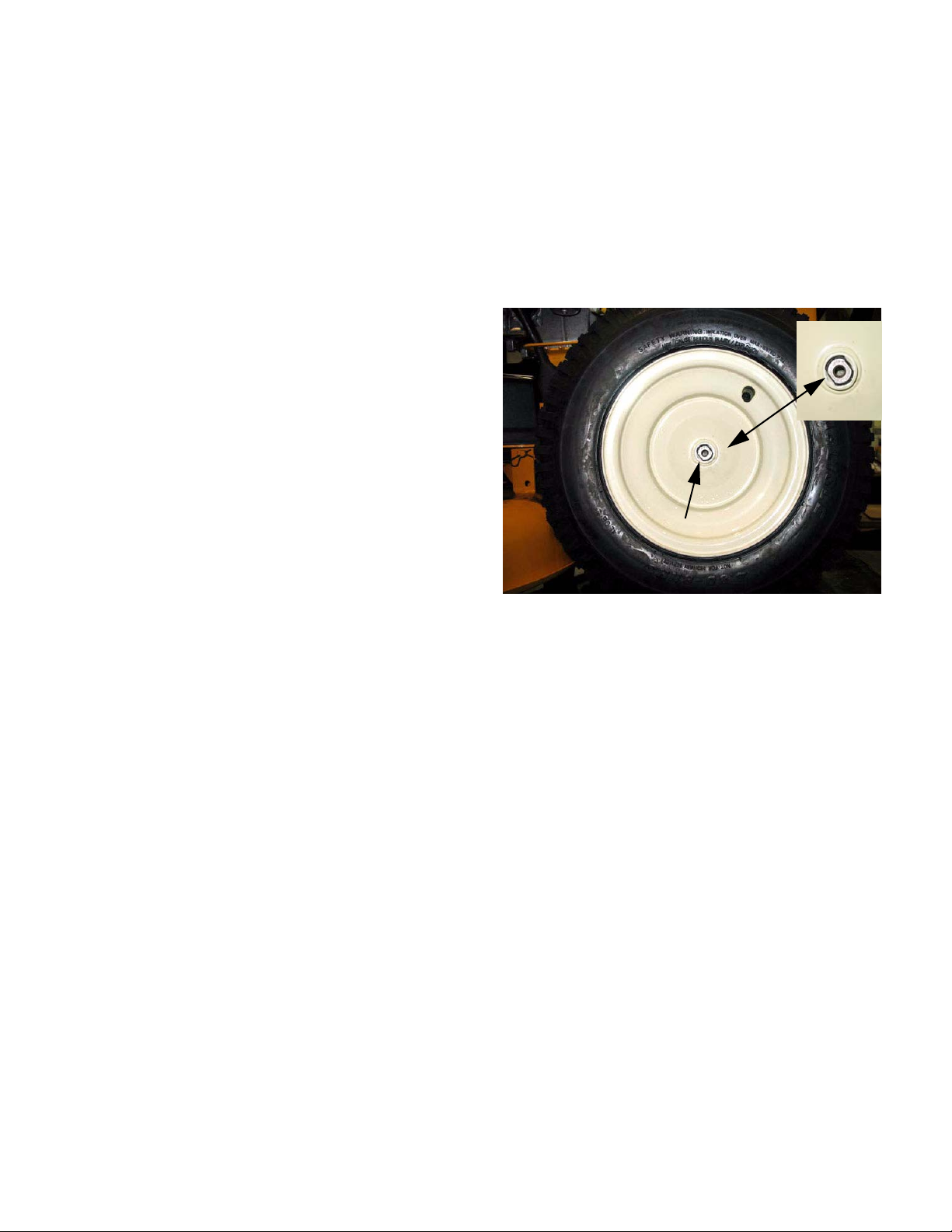

Axle shafts

The rear axle shaft coming from the transmission is a

double-D shaft. As required of all double-D axle shafts,

the wheels should be removed once a year and the

shafts coated with anti-seize. See Figure 2.1.

Double-D

Figure 2.1

NOTE: Failure to remove the wheels once a

year and lubricating the axle shaft will usually

result in the rim rust welding to the axle shaft.

A drop of oil on the steel braid of the cables, where the

enter the cable jacket, will prolong the life of the cables.

3

Page 7

MAINTENANCE

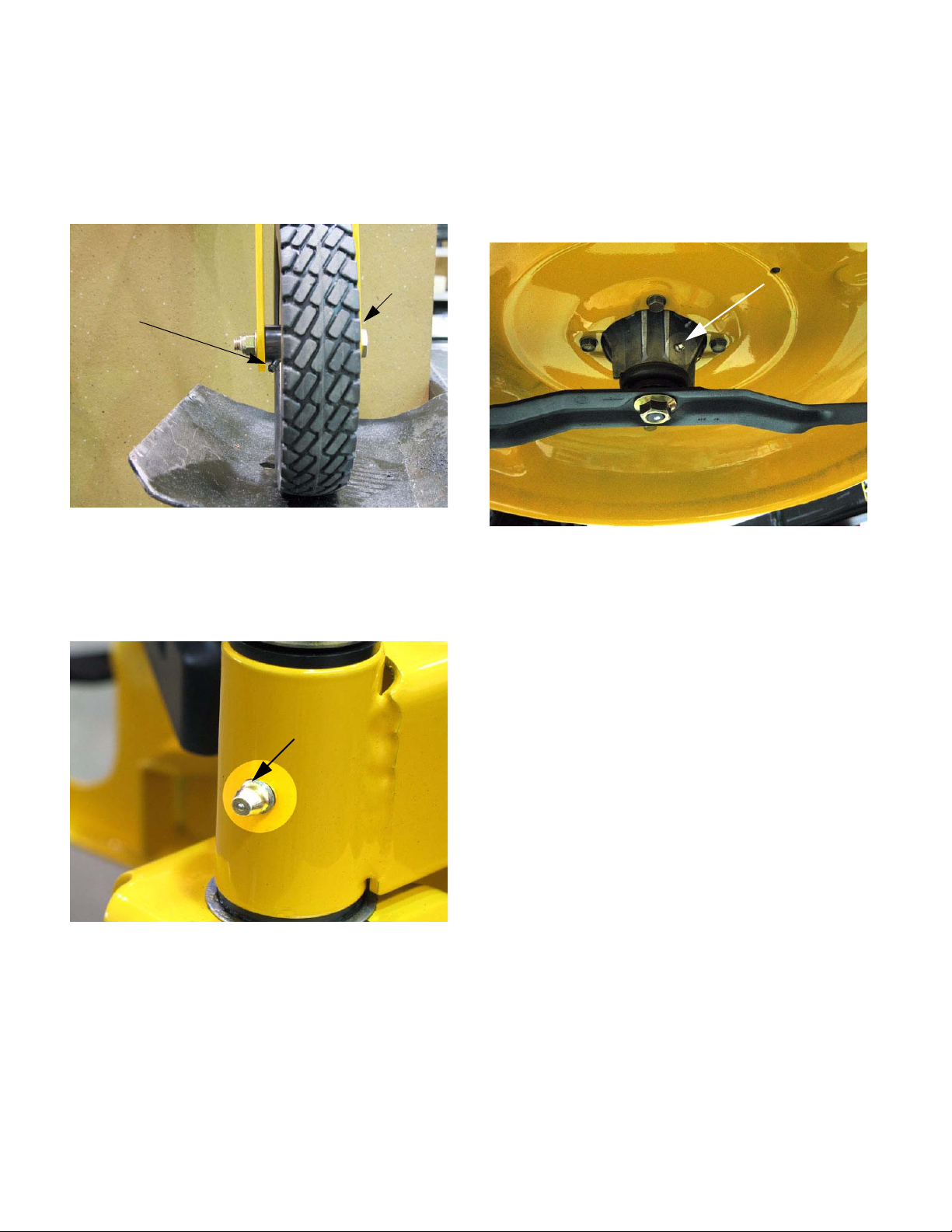

Front casters

The front caster wheels of the mower are equipped

with two grease fittings. Any grease injected into one

side of the wheel will migrate to the other side. A high

quality lithium grease is recommended. See Figure 2.2.

Grease

Grease fitting

Figure 2.2

The front wheel spindles are equipped with grease fittings and should be greased after each season of use

or every 50 hours what ever comes first.

See Figure 2.3.

fitting

Spindles

Both blade spindles are equipped with grease fittings.

The spindles should be greased every 50 hours or at

the end of the mowing season which ever comes first.

See Figure 2.4.

Grease fittings

Figure 2.4

CAUTION: Never put more that one squirt of

grease, per servicing, into a spindle. Putting

more that one squirt of grease into a spindle will

result in the bearings being pressed out of the

spindle housing.

Grease Fitting

Figure 2.3

NOTE: Failure to grease the front wheel spin-

dles could result in poor turning ability.

NOTE: Blades should be checked on a regular

basis for damage or dulling that has occurred

from regular use.

NOTE: Cutting with a dull or bent blade will

greatly reduce the quality of the cut.

NOTE: Replace any blade that is bent, damaged

or worn beyond the normal sharpening range.

CAUTION: If a blade is bent Do NOT try to bend

it back.

4

Page 8

MAINTENANCE

Fasteners

Check all fasteners annually for any signs of lo osening

or damage.

Excessive vIbration is a primary cause of fatigue failures. Vibration can loosen fasteners and fatigue met al.

Transmission

The 4 speed peerless transmission has 16 oz.(454 ml)

of 80w-90 gear lube.

The gear lube should not need to be changed unless it

has become contaminated.

Engine

For maintenance and repair procedures, cont act the

engine manufacturer.

Emissions

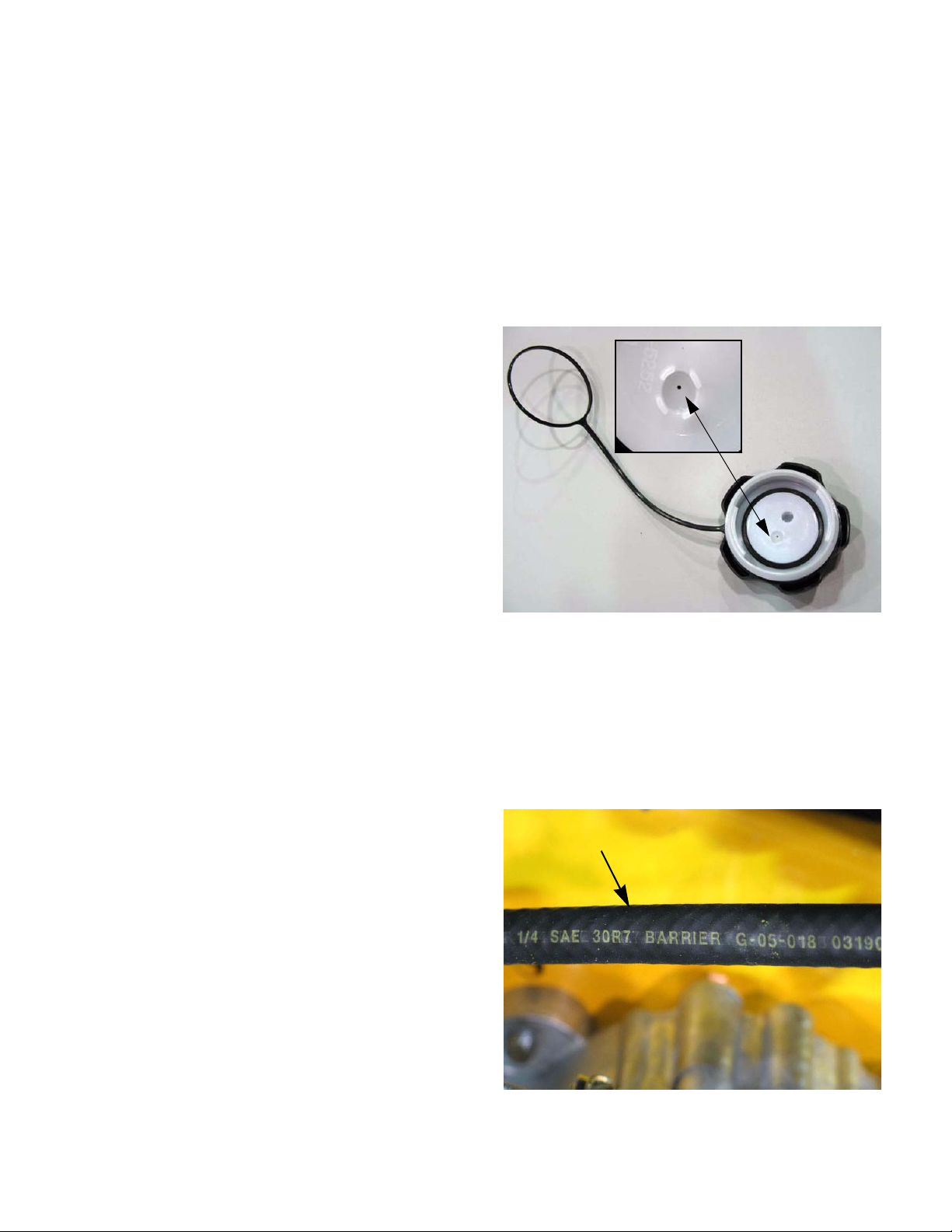

In order to meet the new EPA regulations, there has

been some changes to the fuel system. The fuel tank

is blow moulded and composed of a high density polymer. The fuel cap has a ratchet feature that will prevent

the end user from over tightening it.

The fuel cap is vented through a small hole located in

the top of the inner fuel cap. The air is drawn in thro ugh

the gap between the inner and outer fuel cap shells.

See Figure 2.5.

Vent

Figure 2.5

Fuel line

IMPORTANT: This mower uses the Green-bar

low permeation fuel line that is mandated by the

EP A. It min imizes the gasolin e fumes th at percolate into the atmosphere through the fuel line.

Use the same type of line when replacing the

fuel line. See Figure 2.6.

Fuel line

Figure 2.6

5

Page 9

CHAPTER 3: DRIVE SYSTEM

Drive system

A single belt is used to transfer power from the engine

crankshaft to the input shaft of the transaxle. The left

side control handle and cable operate a tensioner pulley that tightens the belt to engage the drive system

and loosens the belt to de-clutch the drive system.

Gear selection is done by a simple extension arm that

connects to the shift shaft of the transfer case.

Transaxle

The Transaxle is a peerless HMST-204-754, with 4 forward speeds, Neutral and 1 reverse.

The transaxle contains 16 fl oz (454 mL) of 80w90 gear

lube. It should not need to be changed, unless it

becomes contaminated or is drained to disassemble

the transaxle.

Complete service instructions can be found in the

Tecumseh/Peerless Motion Drive Systems handbook,

form #691218.

Drive Belt

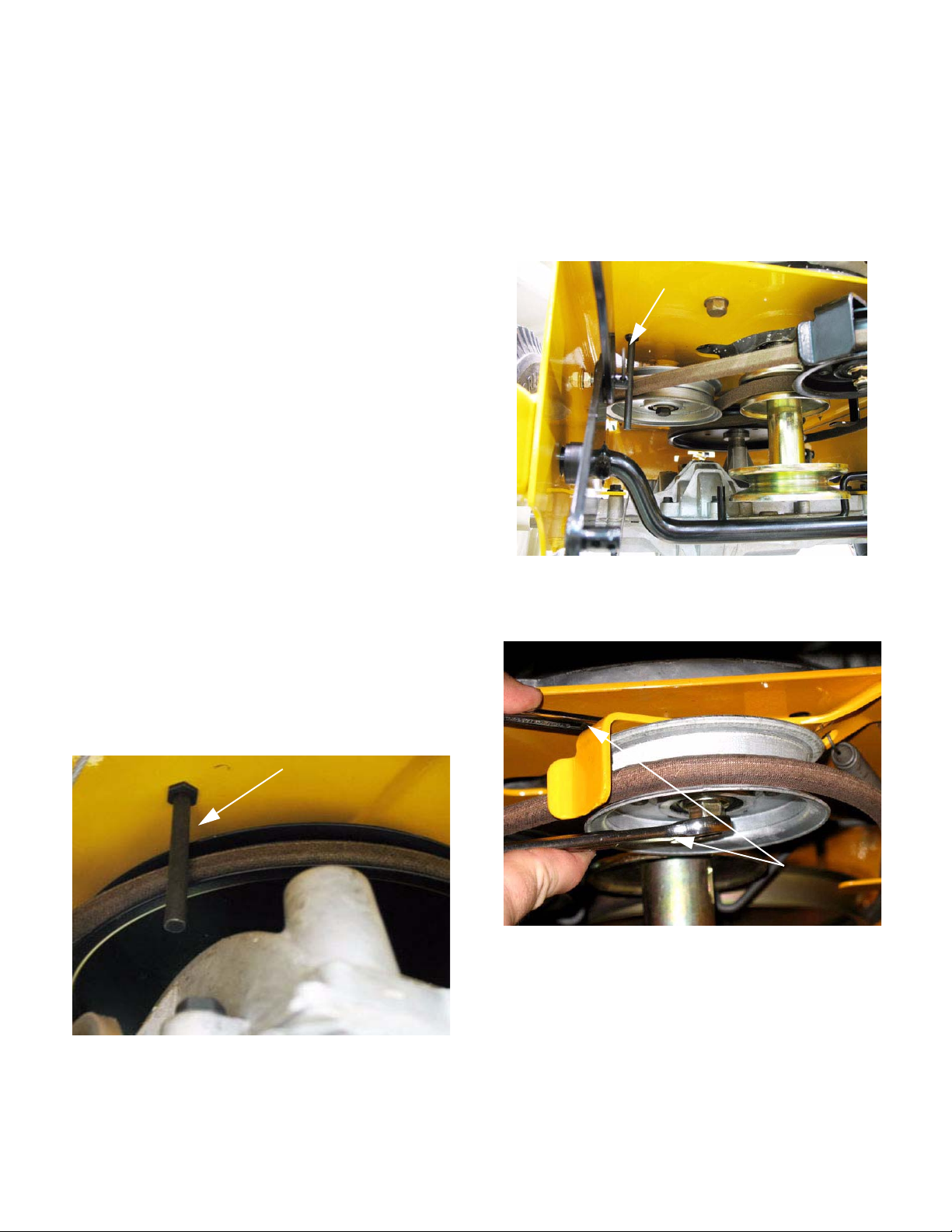

To remove/replace the drive belt:

1. Remove the deck as described in the section on

the Drive Engagement Cable.

3. Remove the belt guide that is near the idler pulley using a pair of 7/16” wrenches.

See Figure 3.2.

Belt guide

Figure 3.2

4. Loosen the drive belt tension pulley two 9/16”

wrenches. See Figure 3.3.

2. Remove the belt guide that is near t he transm ission pulley using two 7/16” wrenches.

See Figure 3.1.

Belt keeper guide

Figure 3.1

9/16 Wrench

Figure 3.3

6

Page 10

Drive system

T

5. Slip the belt past the belt guide and work the belt

off of the remaining pulleys.

IMPORTANT: Before installing a new belt, it

must be turned inside out to route the belt properly.

6. Install the belt following the above steps in

reverse order. For belt routing See Figure 3.4.

ransaxle

Pulley

Engine Pulley

Drive

belt

Figure 3.4

Drive Cable

A cable is used to pull the idler pulley to engage the

transmission driving the wheels. This puts tension on

the drive belt allowing it to turn the transmission pulley.

This cable is not adjustable.

To replace the drive cable:

1. Unhook the top Z-fitting from the drive engagement lever. See Figure 3.5.

Drive engagement cable

Drive cable

7. Install the drive cable by following the above

steps in reverse order.

8. Test run the mower before returning it to service.

Figure 3.5

2. Remove the cable from the cable bracket on the

handle bar using two 1/2” wrenches. Remove

the nut then slide the cable out through the slot

in the bracket. See Figure 3.6.

Drive cable

Figure 3.6

7

Page 11

Drive system

3. Remove the deck by following the steps

described in Chapter 4: Deck and lift shaft.

4. Unhook the drive cable from the idler bracket.

See Figure 3.7.

Drive cable

Figure 3.7

5. Remove the cable from the frame by using two

1/2” wrenches to loosen the jam nuts.

See Figure 3.8.

Brakes

The brake is released by squeezing either or both

levers. The handle on the left hand side will release the

brake when the drive control lever is engaged.

See Figure 3.9.

Figure 3.9

The handle on the right side is the deck engagement

lever. It will release the brake when it is pressed down,

allowing the mower to cut without the transmission

being engaged. See Figure 3.10.

Drive

cable

Figure 3.8

6. Install the drive cable by following the above

steps in reverse order.

7. Test run the mower in a safe area before returning to service.

Figure 3.10

As a safety feature, when both control levers are

released the brakes will be applied.

NOTE: Because the brake is on an intermed iate

shaft in the transaxle, there will still be differential action. The mower will pivot when the brakes

are applied, but it will not roll,

8

Page 12

Drive system

The two cable design allows the operator to mow without engaging the traction (wheel) drive. This is a handy

feature for mowing in tight areas where maneuverability is needed. The traction drive can also be engaged

independently of the deck. This is a handy feature for

transport.

The shift rod can be easily moved with a side to side

push from the users hand. To shift from one gear to

another the mower needs to be completely stopped. To

shift the mower into reverse the shifter has to be lift ed

and slid to the left. This prevents the mower from being

shifted into reverse accidently.

The brake system used in the Wide Area Mower is

engaged at rest. When either the deck or drive control

is squeezed the brake cable pulls back on the brake

lever on the transmission and disengages the brake.

The brake cables are the lower cables on the engagement handle or closest to the pivot point. See Figure

3.11.

Brake adjustment

1. Raise the rear of the mower at least 18” off the

ground.

2. Safely support mower with jack stands.

3. Squeeze either the deck or traction drive control

to release the brake.

4. Confirm that the caliper is properly assembled

and is in good working condition.

5. Use a spring clamp or rope to hold the handle

down. See Figure 3.12.

Brake Cable

Figure 3.11

Pivot

Point

Figure 3.12

6. Insert a .010” -.015” (.254mm -.381mm) feeler

gauge between the brake puck and the brake

disk. See Figure 3.13.

.010-.015

(.254mm.381mm)

1/2” wrench

Figure 3.13

9

Page 13

Drive system

7. If the brake needs to be adjusted, tighten or

loosen the adjustment nut with a 1/2” wrench,

See Figure 3.13.

NOTE: If the brake is set too tight the mower will

drag and not drive smoothly.

NOTE: If the mower doesn’t stop immediately

after both control levers are release d the adjust ment may be to loose.

Brake caliper

1. Raise the rear of the mower at least 18” off the

ground.

2. Safely support mower with jack stands.

3. Remove the spring that maintains tension on the

brake. It is attached to the brake engagement

lever and to a spring retainer rod.

See Figure 3.14.

Extension Spring

Brake

Lever

Spring Retaining Rod

Figure 3.14

4. Disconnect the brake cables by unhooking the

loop link coupler. See Figure 3.15.

Brake cables

Return spring

Figure 3.15

loop

link coupler

10

Page 14

Drive system

5. Remove the two caliper mounting bolts.

See Figure 3.16.

Figure 3.16

6. Remove the caliper and outboard brake puck.

7. Slide the brake disc off the splined shaft to

expose the inboard brake pad for inspection. See

Figure 3.17.

8. Inspect the brake yoke for signs of corrosion that

may prevent proper movement of pins through

the yoke. See Figure 3.18.

Actuator Pins

Brake Pad

Plate

Figure 3.18

NOTE: The two screws that fasten the brake

yoke have a patch of loctite. Replace them or

apply a small amount of releasable threadlocking compound such as Loctite® 242 (blue)

Adjustment

Screw

Brake Yoke

Front Brake

Pad

Brake Disk

Inboard Brake

Pad

Figure 3.17

NOTE: A small amount of good quality lithium

grease should be applied to the splines. Take

care not to get any grease on the brake pads or

the friction surfaces of the rotor.

.

11

Page 15

Drive system

Brake cables

To replace the cables:

NOTE: These cables are not adjustable.

1. Loosen the lock nuts located on the cable brackets and slide it up the cable. The bracket is

located on the handle bar beneath the dash

panel on both sides of the handle bars.

See Figure 3.19.

Figure 3.19

3. The cable will now be loose enough to slip the zfitting from the handle. See Figure 3.21.

Deck engagement cable

Brake

Cable

Figure 3.21

4. The brake cables are joined together on a loop

link coupler located under the frame on the left

hand side. See Figure 3.22.

Brake cable

Eyelets

2. Pull down slightly on the cable jacket. This will

allow the cable to slide out of the slotted bracket.

See Figure 3.20.

Figure 3.20

Loop Link

Coupler

Figure 3.22

12

Page 16

Drive system

5. Loosen the connecting nut of the loop link coupler with a 3/8” wrench to free the eyelets on the

brake cable. See Figure 3.23.

3/8”

wrench

Figure 3.23

6. Loosen the two lock nuts at the lower fram e to

free the cable from the frame. Use a pair of ½”

wrenches. See Figure 3.24.

7. Pull each cable out and down to free the cable

from the frame. The cables can be pulled 1 at a

time through the lowest hole in the punch out.

See Figure 3.25.

Figure 3.25

NOTE: To remove the upper cable, it is neces-

sary to remove the lower cable.

1/2” wrenches

Figure 3.24

8. Install the brake cables following the above

steps in reverse order.

9. Test run the mower in a safe area before returning to service.

13

Page 17

Drive system

Transmission Removal and replacement

1. Loosen wheel bolts using a 1/2” wrench.

2. LIft and safely support mower so that the wheels

are at least 18” off the ground.

3. Remove both rear wheels . See Figure 3.26.

1/2” hex bolt

Figure 3.26

6. Detach the lower shift rod from the upper shift

rod using a pair of 1/2” wrenches.

See Figure 3.28.

1/2” Wrenches

Figure 3.28

7. Detach the brake return spring from the spring

tension rod. Use a length of starter rope or spring

puller. See Figure 3.29.

4. Remove the traction drive belt as described on

the tractor drive belt section.

5. Detach the brake cables from the loop link coupler. See Figure 3.27.

3/8”

Wrench

Figure 3.27

Figure 3.29

14

Page 18

Drive system

8. Remove the hairpin clip that fastens the spring

tension rod to the transmission. See Figure 3.30.

Hairpin clip

Figure 3.30

9. Place a support under the transmission to prevent it from falling.

10. Remove the four transmission mounting bolts.

Using a pair of 1/2” wrenches. See Figure 3.31.

11. Lower the transmission and tilt it forward to

guide it out from under the frame.

12. When the transmission is out of the mower

remove the lower shift rod, spring retention rod,

and extension spring. Install them on the new

Transmission.

NOTE: Bench test the transmission prior to

replacing or shipping to the manufacturer for

warranty. To bench test a transmission with the

transmission out of the mower: move the gear

shifter to each speed position and rotate the

transmission pulley to verify that the transmission drives or fails to drive.

13. Remove the transmission pulley.

NOTE: When reinstalling the transmission pul-

ley, tighten to a torque of 300 to 400 in lbs (34 45 Nm). See Figure 3.32.

Figure 3.31

Figure 3.32

14. Install by following the above steps in reverse

order.

15. Test run the mower before returning it to service.

15

Page 19

CUTTING DECK AND LIFT SHAFT

CHAPTER 4: CUTTING DECK AND LIFT SHAFT

Deck removal

1. Take the deck cover off by removing the three

self tapping screws with a 3/8” wrench.

See Figure 4.1.

Self Tapping Screws

Figure 4.1

NOTE: Early 2007 production used nuts and

bolts to fasten the belt cover on.

5. Remove the four hairpin clips in the deck lif t links

and slide the deck to the left to clear the hanging

pins on the lift links. See Figure 4.3.

4 hairpin locations

Figure 4.3

6. Remove the belt guide with a pair of 5/16”

wrenches. See Figure 4.4.

2. Slide the cover off of the mower.

3. Lower the deck to the lowest cutting height.

4. Release the tension on the engagement pulley.

Disconnect the spring end of the deck engagement cable from the Idler bracket.

See Figure 4.2.

Figure 4.2

5/16” nuts

Figure 4.4

7. Remove the deck belt from the engine pulley.

8. Slide the deck out from under the mower.

9. Install the deck by following the above steps in

reverse order.

10

Page 20

CUTTING DECK AND LIFT SHAFT

Cleaning the deck

Clean debris off of the deck every time the deck cover

is removed. It is routine maintenance that will make the

deck easier to work on and prolong the life of the deck

and spindles.

DANGER: Debris build up on the mower deck is

an unsafe condition. The debris traps heat in the

spindles causing damage to the spindle bearings. Debris around the belt can over-heat.

To clean the deck while it is removed:

1. Blow all the debris off of the top of the deck

using compressed air regulated to about 35psi

(2.5 bar).

2. Scrape off the debris build up from the under

side of the deck using a plastic scraper.

NOTE: Applying a light coating of oil to the

underside of the deck after scraping it clean will

help prevent rusting of the deck and help keep

the debris from building up on the underside of

the deck.

Blades

The condition of the blades will greatly effect the quality

of the cut.

The blades should be sharpened and balanced after

every five acres, depending on local conditions. A dull

blade tears the grass instead of cutting it. Torn grass

blades leaves a rough look and makes the grass vulnerable to diseases.

Blades need to be examined for damage before sharpening. Blades must be balanced after sharpening to

reduce the vibrations felt from the deck.

Bent blades are a sign of a blade impact. The blades

must be replaced and the spindles inspected for damaged timing belt, pulley, bent shafts and cracked housings if a bent blade is found.

Synchronized blades and a high vacuum deck shell

design give an exceptionally good cut using OEM

blades.

The cutting deck on this mower is mounted with a slight

rake, meaning that the front of the deck is a 1/4” - 3/8”

lower than the rear of the de ck. This is very important

to get the proper air flow in the deck so that the blades

can make the grass blades stand up to get cut.

Air flow in the cutting deck is generated by the spin ning

blades. If the blades are mounted upside down, the air

flow will be reversed pushing the grass down instead of

standing up.

NOTE: Blades have the part number and the

word patent stamped on the bottom of the blade.

Blades that are mounted upside down, increase

the risk of impacting an object. See Figure 4.5.

Stampings

11

Figure 4.5

Page 21

CUTTING DECK AND LIFT SHAFT

Blade removal

1. Remove the deck as described in the previous

section of this chapter or lift the tractor using a

professional grade lift.

2. Remove the blade nuts using an impact wrench

and a 15/16” socket. See Figure 4.6.

Blade nut

Figure 4.6

5. Install the blade by following the above steps in

reverse order. Tighten the blade nut to a torque

of 70 - 90 ft-lbs ( 95 - 122 Nm).

NOTE: The blades have a star center. The star

must seat on the raised star on the bottom of the

spindle shaft with the fins of the blade pointing to

the deck. If there is damage to the raised star of

the spindle shaft, the spindle must be replaced.

See Figure 4.7.

Star center

CAUTION: Use care around the blade while

removing or tightening the nut. The blade can

spin and cause an injury to the technician.

3. Remove the blade.

4. When sharpening the blades:

• To properly sharpen the cutting blades, remove

equal amounts of metal from both ends of the

blades along the cutting edges, parallel to the

trailing edge, at a 25° to 30° angle. Sharpen the

top edge only.

IMPORTANT: If the cutting edge of the blade

has already been sharpened to within 1 5/8”

from the edge, or if any metal separation is

present, replace the blades with new ones.

• It is important that each end of the cutting blade

edge be ground equally to maintain proper blade

balance.

CAUTION: A poorly balanced blade will cause

excessive vibration and may cause damage to

the mower and result in personal injury.

Figure 4.7

• The blade can be tested by using a blade balancer. Grind metal from the heavy side until it

balances evenly.

12

Page 22

CUTTING DECK AND LIFT SHAFT

Spindles

The spindles are a complete unit. The only replaceable

parts are the pulleys. The spindles are equipped with a

grease fitting that should get one squirt of grease after

every use of the deck wash system or every 10 hours

of use.

NOTE: Never put more than one squirt of grease

in a spindle. Putting more grease in the spin dle

will push the bearing out of the spindle housing,

ruining the spindle.

To replace a pulley:

1. Remove the deck as described at the beginning

of this chapter.

2. Remove the belts by following the steps

described later in this chapter. See Figure 4.8.

Pulley nuts

To replace a spindle:

1. Remove the deck as described at the beginning

of this chapter.

2. Remove the blade following the steps described

in the previous section of this chapter.

3. Remove the belts by following the steps

described later in this chapter.

4. Remove the four screws fastening the spindle to

the deck. See Figure 4.9.

Remove these

screws

PTO belt

Timing belt

Figure 4.8

3. Remove the blade following the steps described

in the previous section of this chapter.

4. Remove the pulley nut using an impact wrench

with a 15/16” socket. See Figure 4.8.

5. Install the spindle pulleys by following the above

steps in reverse order.

6. Test run the tractor before returning to service.

Figure 4.9

5. Lift the spindle out of the deck shell.

6. Install the spindle by following the above steps in

reverse order.

NOTE: The four spindle bolts are self tapping

bolts. The new spindle housing will not have

threads in it.

NOTE: Tighten the spindle bolts to a torque of

200 - 300 in-lbs (23 - 34 Nm).

13

Page 23

CUTTING DECK AND LIFT SHAFT

PTO belt

The function of the PTO belt is to transfer the mechanical force from the engine to the blades. The belt faces

a lot of different forces.

• Clutching and de-clutching

• Heat from bending or deformation.

• The friction of the belt against the pulleys creates heat. This heat softens the belt which weakens it.

• When a blade impacts an object like a rock or a

tree root, the belt is subjected to an shock load.

• The belt has rubber in it. as the rubber ages, it

becomes brittle making it weaker.

NOTE: A damaged belt can cause the deck to

vibrate when the deck is engaged. The vibration

can be bad enough to simulate an engine or

blade issue.

NOTE: Not all belt damage is visible. Broken

cords inside the belt are not visible to the naked

eye, but can cause vibration issues and greatly

reduce the life of the belt.

CAUTION: Cub Cadet belts are design to fit our

equipment and are not standard lengths. Use of

a non-OEM belt may prevent the mowing deck

from working properly.

2. Slide the cover off of the mower.

3. Release the tension on the engagement pulley.

Disconnect the spring end of the deck engagement cable from the Idler bracket.

See Figure 4.11.

Figure 4.11

4. Loosen both idler pulleys enough to slip the belt

out between the idler pulleys and the belt guides

using a pair of 9/16” wrenches See Figure 4.12.

To service the deck belt:

1. Take the deck cover off by removing the three

self tapping screws with a 3/8” wrench.

See Figure 4.10.

self tapping screws

Figure 4.10

NOTE: Earlier 2007 production may have nuts

and bolts securing the belt cover to the frame.

Belt Guides

Idler Pulley

Figure 4.12

.

14

Page 24

CUTTING DECK AND LIFT SHAFT

5. Remove the belt guide by the engine pulley with

a pair of 3/8 wrenches. See Figure 4.13.

Remove this

nut

Figure 4.13

6. Slide the belt off of the pulleys.

7. Discard the old belt.

8. Install a new deck belt by following the steps

above in reverse order.

Deck Timing Belt

To service the deck timing belt:

1. Take the deck cover off by removing the three

self tapping screws. See Figure 4.14.

three self tapping screws

Figure 4.14

NOTE: Nuts and bolts were used in early 2007

production to fasten the belt cover.

9. Test run the mowe r be fo re retur nin g to serv ice .

2. Slide the cover off of the mower.

3. Loosen both idler pulleys enough to slip the belt

out between the idler pulleys and the belt guides

using a pair of 9/16” wrenches. See Figure 4.15.

Figure 4.15

15

Page 25

CUTTING DECK AND LIFT SHAFT

4. Slide the belt off of the left side spindle.

5. Back the jam nut on the idler stop bolt to the

head of the bolt. See Figure 4.16.

Idler Stop Bolt

Figure 4.16

6. Insert a 3/8” ratchet or breaker bar into the

square hole in the idler bracket. Swing the idler

pulley away from the timing belt, pushing in the

idler stop bolt, using the ratchet for leverage.

See Figure 4.17.

7. With the tension relieved slip the timing belt off

of the pulleys.

8. To install the timing belt turn the blades 90

apart. See Figure 4.18.

o

90

Figure 4.18

NOTE: Failure to time the blades will result in

the blades hitting each other.

9. The timing marks will line up with the blades and

would need to be 90

o

apart. See Figure 4.19.

o

3/8” breaker bar

Figure 4.17

Blade

Timing Marks

Figure 4.19

NOTE: The timing marks on the blade pulleys

have been shown in white for clarity.

16

Page 26

CUTTING DECK AND LIFT SHAFT

10. Slide the timing belt over the spindles.

11 . Swing the idler pulley away from the belt using a

3/8” ratchet for leverage.

12. Slip the timing belt behind the idler pulley.

See Figure 4.20.

Idler Stop

Bolt

Figure 4.20

Test run the mower befo re ret urnin g to ser vice .

Deck engagement (PTO) cable

To service the PTO cable:

1. Unhook the top Z-fitting from the blade engagement lever. See Figure 4.22.

PTO cable

Figure 4.22

NOTE: The spring is applying enough force to

hold tension on the idler. The idler stop bolt is

there to prevent the idler from springing back

during a blade impact. This prevents the blades

from jumping time.

13. Tighten the jam nut on the idler stop bolt until

there is a .040” (1 mm) maximum gap between

the idler stop bolt and the idler bracket.

See Figure 4.21.

9/16”

Nuts

Maximum gap

.040

2. Remove the cable from the cable bracket on the

handle bar using two 1/2” wrenches to remove

the nut then slide the cable out through the slot

in the bracket. See Figure 4.23.

PTO cable

Figure 4.23

Figure 4.21

14. Reinstall the PTO belt.

15. Install the deck cover.

17

Page 27

CUTTING DECK AND LIFT SHAFT

3. Take the deck cover off by removing the three

nuts and bolts. See Figure 4.24.

NOTE: depending on production date the nuts

and bolts may have been replaced by self tapping screws.

Remove these

bolts or screws

Figure 4.24

4. Slide the cover off of the mower.

6. Remove the cable from the frame using two 1/2”

wrenches. See Figure 4.26.

Blade cable

Figure 4.26

7. Install the PTO cable by following the above

steps in reverse order.

8. Test run the mower before returning to service.

5. Unhook the blade cable from the idler bracket.

See Figure 4.25.

PTO

cable

Figure 4.25

18

Page 28

CUTTING DECK AND LIFT SHAFT

Leveling the deck

For the best quality cut, the deck must be level side to

side and the front of the deck should be 1/4” - 3/8”

lower than the rear of the deck.

Side to Side Leveling

1. With the mower parked on a firm, level surface,

move the deck to the mid height position using

the deck lift lever. Rotate one blade so that it is

perpendicular with the mower frame.

2. Measure the distance from the blade tip to the

ground.

3. Repeat steps 1 and 2 on the other side

4. Both measurements taken should be equal. If

they are not, note whether the left side of the

deck is lower or higher and proceed to the next

step.

NOTE: U se of Cub Cadet deck lev eling gauge,

part number 490-900-0041, will make measuring

the blade tip height easier. See Figure 4.27.

Deck lift shaft and lever

To remove the deck lift shaft:

1. Remove belt cover and deck by following the

steps previously described..

2. Remove the hairpin clips from the bracket that

links the front and rear lift rods. See Figure 4.28.

Hair Pin

Clips

Figure 4.27

5. There are no adjustments for leveling the deck

on this mower. Minor adjustments to level the

deck can be made by altering th e air p ress ure in

the tires. If the adjustment requires more than a

5psi difference between tires, something on the

mower is bent.

Figure 4.28

3. Remove the deck height lever with a 1/2”

wrench. See Figure 4.29.

1/2”

wrench

Figure 4.29

19

Page 29

NOTE: The deck adjustment lever is divided into

three (3) parts, the adjustment handle and two

(2) lever pivot brackets. See Figure 4.30.

Adjustment handle

Lever Pivot

Brackets

Figure 4.30

CUTTING DECK AND LIFT SHAFT

4. Remove the split bushing from the rear lift shaft.

See Figure 4.31.

Split bushing

Figure 4.31

5. Work the shaft out of the frame.

6. Repeat steps 4 and 5 on the front lift shaft.

7. Reinstall the lift shaft and lift lever by following

the above steps in reverse order.

Lift shaft

8. Test run the mowe r be fo re retur nin g to serv ice .

20

Loading...

Loading...