Page 1

Page 2

Page 3

(t) *C~~~E!!EJ

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply

with the instructions may result in personal injury.

SAFE OPERATION PRACTICES FOR RIDING VEHICLES

1. Read this owner's manual carefully in its en- 16. Disengage power to attachment(s) and stop

tirety before attempting to assemble or engine before making any repairs or adoperate this unit. Keep this manual in a safe justments. Disconnect the spark plug wire

place for future and regular reference and for and keep the wire away from the plug to preordering replacement parts. vent accidental starting.

2. This unit is a precision piece of power equip- 17. Before attempting to unclog the mower or

ment, not a plaything. Therefore exercise ex- discharge chute, stop the engine. The mower

treme caution at all times. blade(s) may continue to rotate for a few

3. Know the controls and how to stop quickly- seconds after the engine is shut off.

READ THIS OWNER'S MANUAL. Therefore, be sure the blade(s) have stopped

4. Do not allow children to operate vehicle. Do completely. Disconnect the spark plug wire

not allow adults to operate it without proper and keep the wire away from the plug to preinstruction. Only persons well acquainted vent accidental starting.

with these rules of safe operation should be 18. Disengage power to attachment(s) when

allowed to use your mower. transporting or not in use.

5. ~o one shO';Jld op.erate th.is u,nit whil~ int<?x- 19. Take all possible precautions when leaving

Icated or while takl~g medication that Impairs vehicle unattended such as disengaging

the senses or reactions. power-take-off, lowering attachments, shift-

6. Wear ~t~rdy, rough-soled yvork shoe~ and ing into neutral, setting parking brake, stopclose-fitting. slacks a.nd shirts to avoid en- ping engine and removing key.

tanglement In the moving parts. Never operate .

a unit in bare feet, sandals, or sneakers. 20. Do .not stop or. start suddenly when going

7. To prevent injury, do not carry passengers or uphill or dow.nhili. Mow up and down face of

give rides. Keep children, pets and by- steep slop~s, ~e~er. across the face. ~se exstanders out of the area while mowing. Only treme cautlo~ If .It IS necessary to drive the

the operator should ride on the unit and only trac.tor ~p an Incline or back the tractor down

ride in the seat an Incline because the front of the tractor

8. Check overhea'd clearance carefully before could lift and ra~idly !Iip over backward which

driving under power lines, guy wires, bridges could cause serious Injury.

or low hanging tree branches, before entering 21. Reduce speed on slopes and in sharp turns to

or leaving buildings, or in any other situation prevent tipping or loss of control. Always

where the operator may be struck or pulled keep the tractor in gear when going down

from the unit, which could result in serious in- steep hills to take advantage of engine brak-

jury. ing action.

9. To maintain control of the unit and reduce the 22. Stay alert for holes in terrain and other hidden

possibility of upset or collision, operate the hazards.

tractor .smoothly. Avoid erratic operation and 23. Use care when pulling loads or using heavy

excessive speed.. equipment.10.

Keep the ':lrea of operation .clear of all per- A. Use only approved drawbar hitch points.

sons, pa~tlcularly small ch~ldren a.n~ .pets. B. Limit loads to those you can safely control.

Stop engine when they are In the vIcinity. of C. Do not turn sharply. Use care when backyour mower. Although the area of oP.eratlon ing.

~hould be comple,tely cleared of foreign ob- D. Use counterweight(s) or wheel weights

jects, a small object ~ay have been over. when suggested in owner's manual.

looked and could be accidently thrown by the " .

mower in any direction and cause injury. 24. Watch out for traffic when crossing or near

11. Clear work area of objects which might be roadways.

picked up and thrown by the mower in any 25. When using any a~tachments, never direct dis-

direction and cause injury. charge of material toward bystanders nor

12. Stop the blade(s) when crossing gravel drives, allow anyone near vehicle while in operation.

walks or roads. 26. Handle gasoline with care. It is highly flam-13.

Disengage all attachment clutches and shift mable.

into neutral before attempting to start engine. A. Use approved gasoline container.

14. Disengage power to attachment(s) and stop B. Never remove cap or add gasoline to a runengine before leaving operating position. ning or hot engine or fill fuel tank indoors.

15. Do not put hands or feet near or under rotating Wipe up spilled gasoline.

parts. Keep clear of the discharge opening at C. Open doors if engine is run in garage. Ex-

all times as the rotating blade(s) can cause in- haust fumes are dangerous. Do not run

jury. engine indoors.

3

Page 4

(2) Never make a cutting height adjustment

while engine is running if operator must

dismount to do so.

(3) Shut the engine off and wait until the

blade comes to a complete stop before

removing the grass catcher.

(4) Check blade mounting bolts for proper

tightness at frequent intervals.

34. Check grass catcher bags frequently for wear

or deterioration. For safety protection, replace

only with new bag meeting original equipment

specifications.35.

Look behind to make sure the area is clear

before placing the transmission in reverse

and continue looking behind while backing

up. Disengage blades before shifting into

reverse and backing up.36.

This unit should not be driven up a ramp onto

a trailer or truck under power, because the

unit could tip over, causing serious personal

injury. The unit must be pushed manually to

load properly.

27. Keep the vehicle and attachments in good

operating condition, and keep safety devices

in place. Use guards as instructed in

operator's manual.

28. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working condi-

tion.

29. Never store the equipment with gasoline in

the tank inside a building where fumes may

reach an open flame or spark. Allow engine to

cool before storing in any enclosure.

30. To reduce fire hazard, keep engine free of

grass, leaves or excessive grease.

31. The vehicle and attachments should be

stopped and inspected for damage after striking a foreign object. The damage should be

repaired before restarting and operating the

equipment.

32. Do not change the engine governor settings

or overspeed the engine.33.

When using the vehicle with mower, proceed

as follows:

(1) Mow only in daylight or in good artificial

light.

4

Page 5

The Owner

recommended operation and maintenance pro.

cedures are followed.

To obtain top performance and assure economical

operation the tractor should be inspected,

depending on its use, periodically, or at least once

a year, by your authorized dealer.

When in need of parts, always specify the model,

chassis, and engine serial numbers, including the

prefix and suffix letters. Write these serial

numbers in the space provided on this page.

Should you have difficulties with the unit consult

your authorized dealer. UNDER NO CIRCUM.

STANCES SHOULD YOU AnEMPT TO SERVICE

THESE UNITS YOURSELF. Only your dealer is

authorized to repair or replace units on this drive

under the terms of the warranty. Should you

desire additional information not found in this

manual, contact your authorized Cub Cadetdealer.

Assembled in this manual are operation, lubrica-tion,

and maintenance instructions for the Cub

Cadet 1282, 682 and 782 Tractors. The material has

been prepared in detail to help you better understand the correct care and efficient operation of

your tractor. Before you operate the tractor, study

this manual carefully. Additional copies may be

ordered from your dealer at a nominal price.

Your local authorized dealer is interested in the

performance you receive from your tractor. He has

factory-trained servicemen, informed in the latest

method of servicing tractors, modern tools, and

original-equipment service parts which assure

proper fit and good performance.The

Cub Cadet 1282,682 and 782 Tractors have a

hydrostatic drive. It is the best hydrostatic drive

unit available and will require minimum service if

NUMBER LOCATION

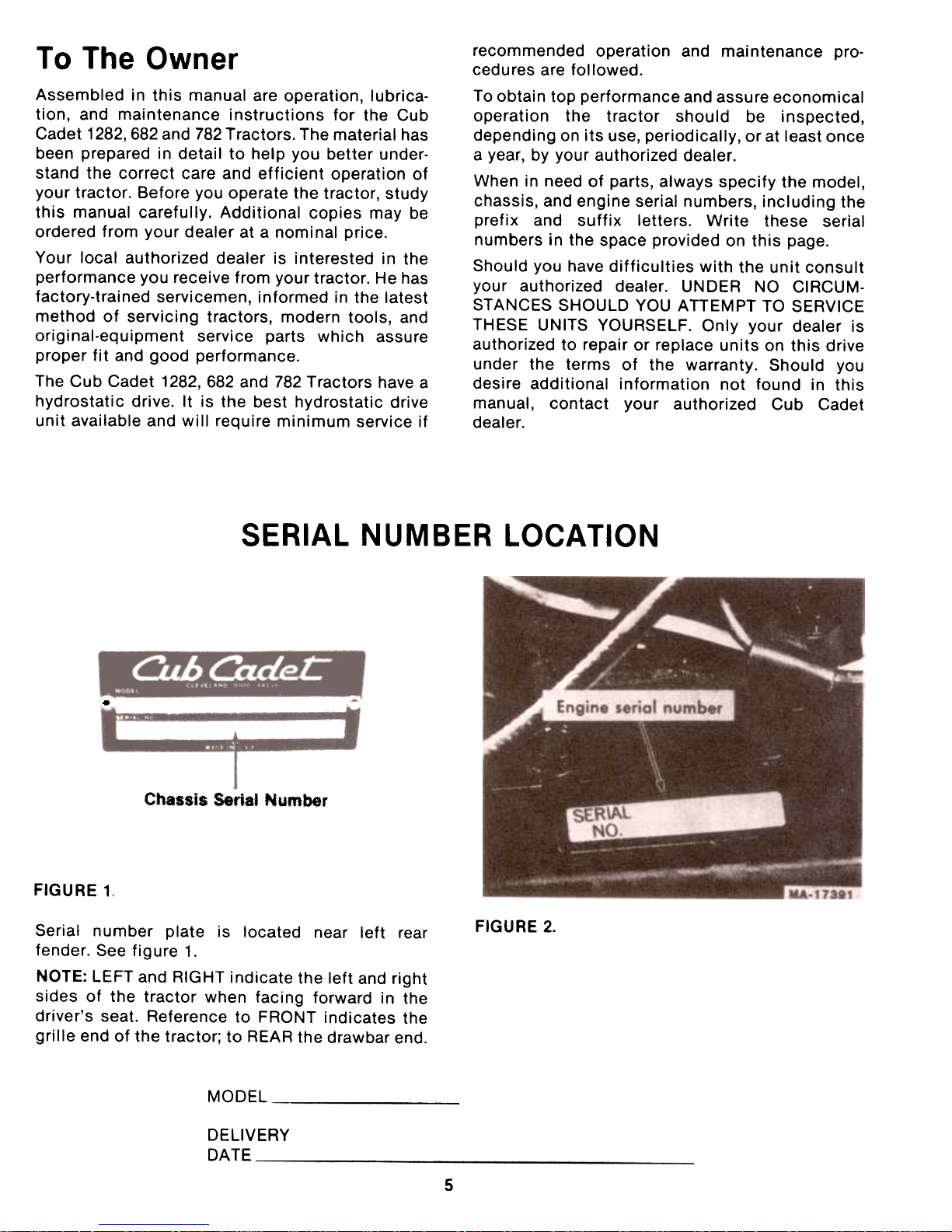

Chassis Serial Number

FIGURE 1,

FIGURE 2.

Serial number plate is located near left rearfender.

See figure 1.

NOTE: LEFT and RIGHT indicate the left and right

sides of the tractor when facing forward in the

driver's seat. Reference to FRONT indicates the

grille end of the tractor; to REAR the drawbar end.

MODEL

DELIVERY

DA TE -

5

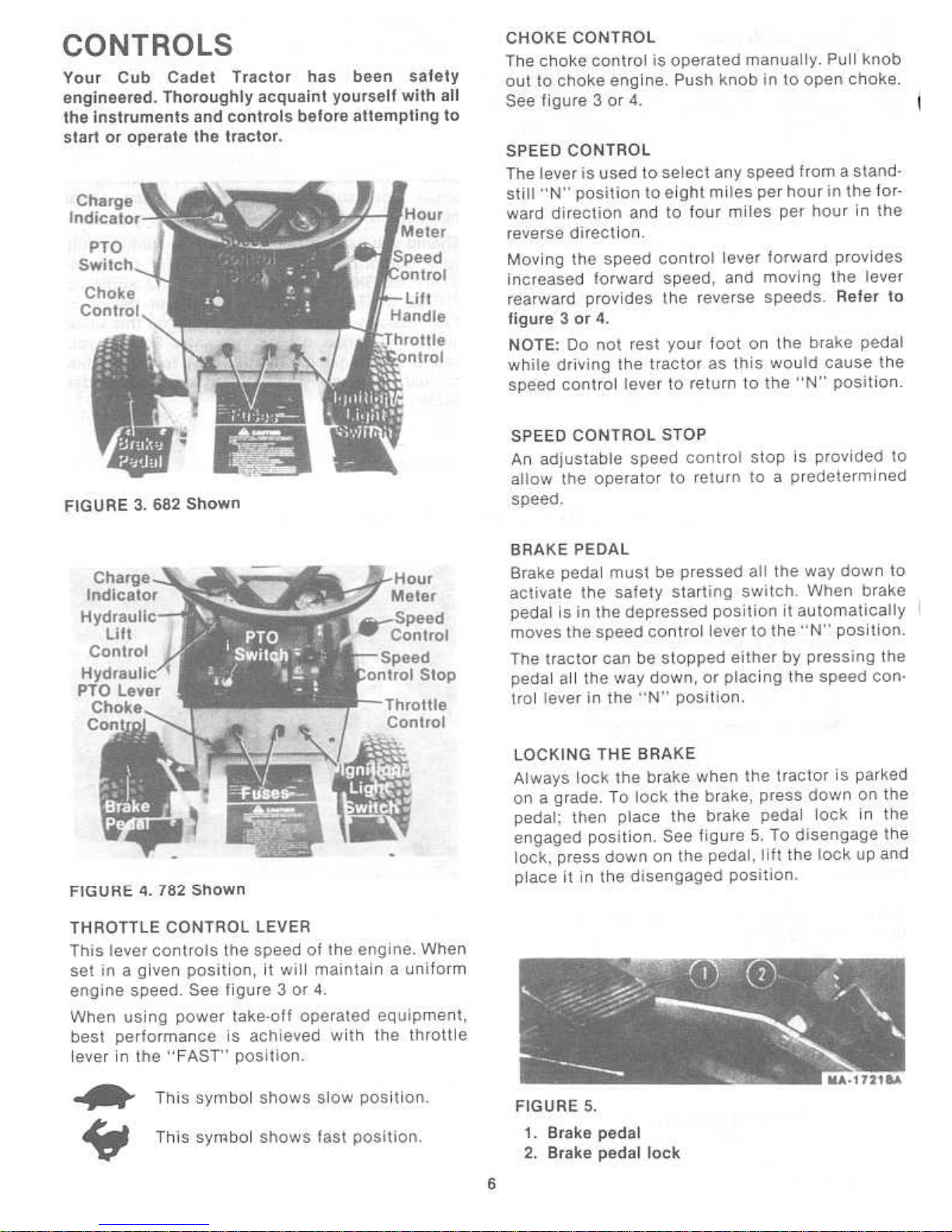

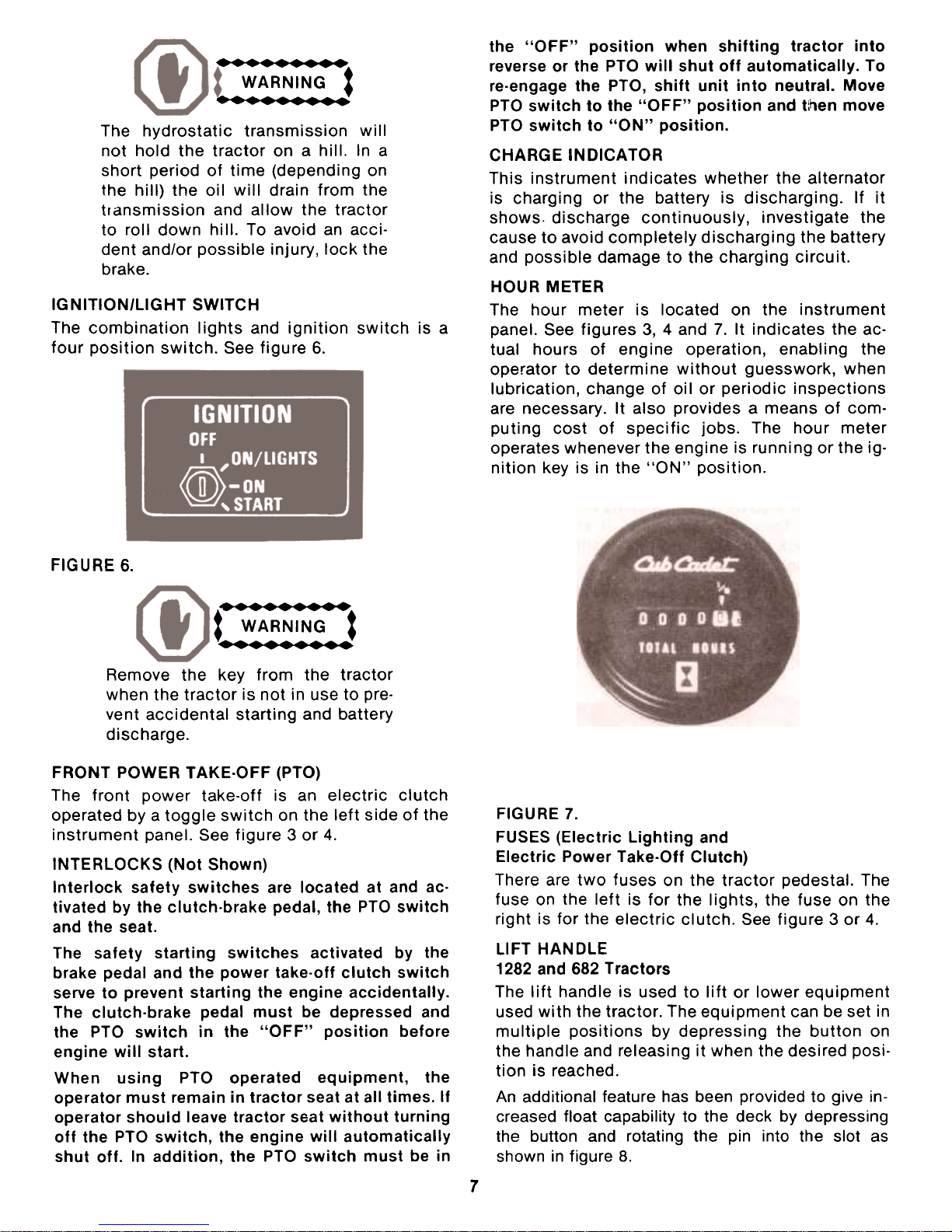

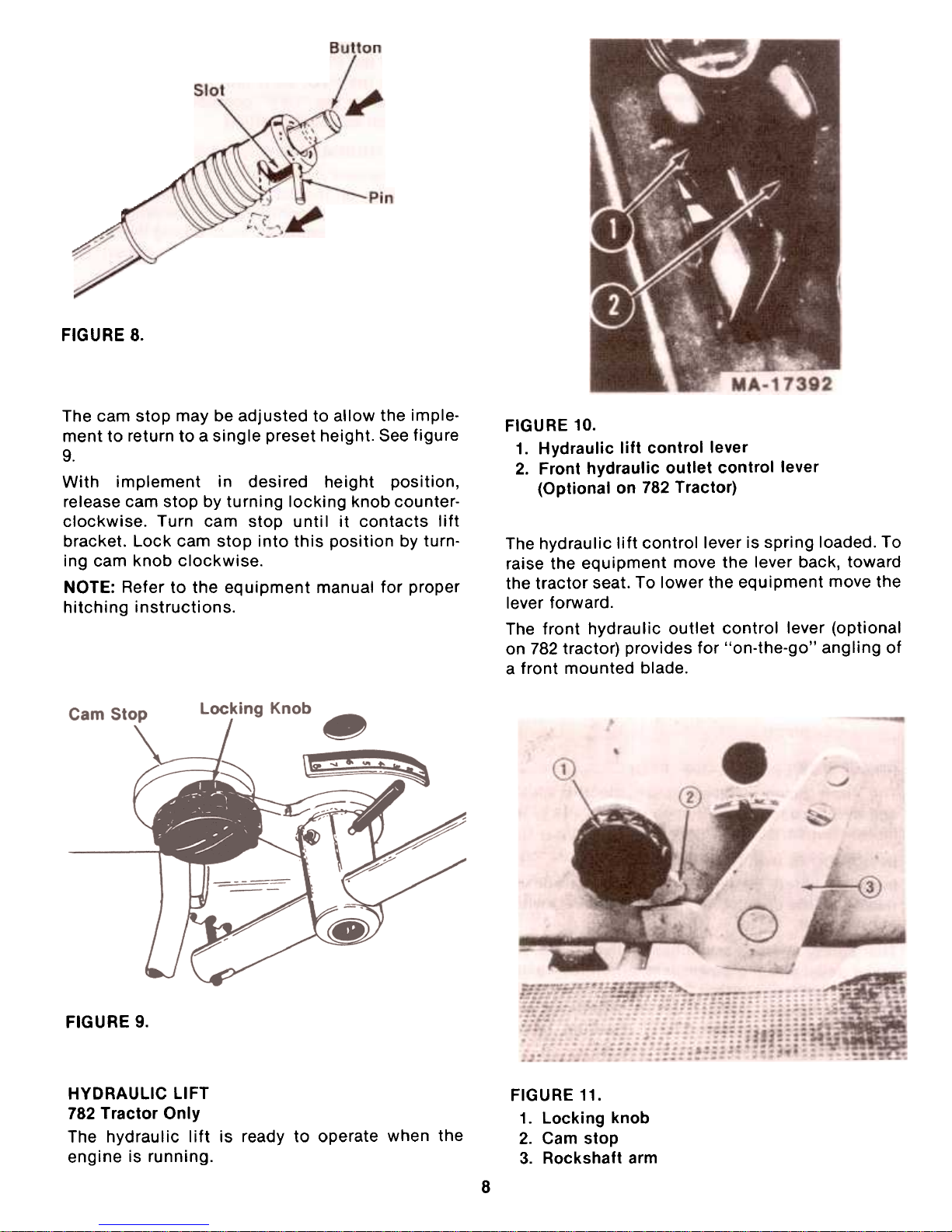

Page 6

Page 7

WARNING ~

The hydrostatic transmission will

not hold the tractor on a hill. In a

short period of time (depending on

the hill) the oil will drain from the

transmission and allow the tractor

to roll down hill. To avoid an acci-

dent and/or possible injury, lock the

brake.

the "OFF" position when shifting tractor into

reverse or the PTO will shut off automatically. To

re.engage the PTO, shift unit into neutral. Move

PTO switch to the "OFF" position and t:r,en move

PTO switch to "ON" position.

CHARGE INDICATORThis

instrument indicates whether the alternator

is charging or the battery is discharging. If it

shows- discharge continuously, investigate the

cause to avoid completely discharging the battery

and possible damage to the charging circuit.

HOUR METER

The hour meter is located on the instrument

panel. See figures 3, 4 and 7. It indicates the ac-

tual hours of engine operation, enabling the

operator to determine without guesswork, when

lubrication, change of oil or periodic inspections

are necessary. It also provides a means of computing cost of specific jobs. The hour meter

operates whenever the engine is running or the ig-

nition key is in the "ON" position.

IGNITION/LIGHT SWITCH

The combination lights and ignition switch is a

four position switch. See figure 6.

FIGURE 6.

~ WARNING:

Remove the key from the tractor

when the tractor is not in use to pre.

vent accidental starting and batterydischarge.

FRONT POWER TAKE.OFF (PTO)

The front power take-off is an electric clutch

operated by a toggle switch on the left side of the

instrument panel. See figure 3 or 4.

INTERLOCKS (Not Shown)

Interlock safety switches are located at and activated by the clutch-brake pedal, the PTO switch

and the seat.

The safety starting switches activated by the

brake pedal and the power take-off clutch switch

serve to prevent starting the engine accidentally.

The clutch-brake pedal must be depressed and

the PTO switch in the "OFF" position before

engine will start.

When using PTO operated equipment, the

operator must remain in tractor seat at all times. If

operator should leave tractor seat without turning

off the PTO switch, the engine will automatically

shut off. In addition, the PTO switch must be in

FIGURE 7.

FUSES (Electric Lighting and

Electric Power Take-Off Clutch)There

are two fuses on the tractor pedestal. The

fuse on the left is for the lights, the fuse on the

right is for the electric clutch. See figure 3 or 4.

LIFT HANDLE

1282 and 682 TractorsThe

lift handle is used to lift or lower equipment

used with the tractor. The equipment can be set in

multiple positions by depressing the button on

the handle and releasing it when the desired position is reached.

An additional feature has been provided to give increased float capability to the deck by depressing

the button and rotating the pin into the slot as

shown in figure 8.

7

Page 8

FIGURE 8.

FIGURE 10.

1. Hydraulic lift control lever

2. Front hydraulic outlet control lever

(Optional on 782 Tractor)

The cam stop may be adjusted to allow the imple-

ment to return to a single preset height. See figure9.

With implement in desired height position,

release cam stop by turning locking knob counterclockwise. Turn cam stop until it contacts lift

bracket. Lock cam stop into this position by turn-

ing cam knob clockwise.

NOTE: Refer to the equipment manual for proper

hitching instructions.

The hydraulic lift control lever is spring loaded. To

raise the equipment move the lever back, toward

the tractor seat. To lower the equipment move the

lever forward.

The front hydraulic outlet control lever (optional

on 782 tractor) provides for "on-the-go" angling of

a front mounted blade.

FIGURE 9.

HYDRAULIC liFT

782 Tractor Only

The hydraulic lift is ready to operate when the

engine is running.

FIGURE 11.

1. Locking knob

2. Cam stop

3. Rockshaft arm

8

Page 9

The cam stop may be adjusted to allow the imple-

ment to return to a single preset height. See figure

11.

With implement in desired height position,

release cam stop by turning locking knob counterclockwise. Turn cam stop until it contacts lift

bracket. Lock cam stop into this position by turn-

ing cam knob clockwise.

FUEL SHUT-OFF VALVE

The fuel shut-off valve is located below the

gasoline tank.

To turn the fuel on, turn the knob counterclockwise to the stop.

To turn the fuel off, turn the knob clockwise until

it is tight.

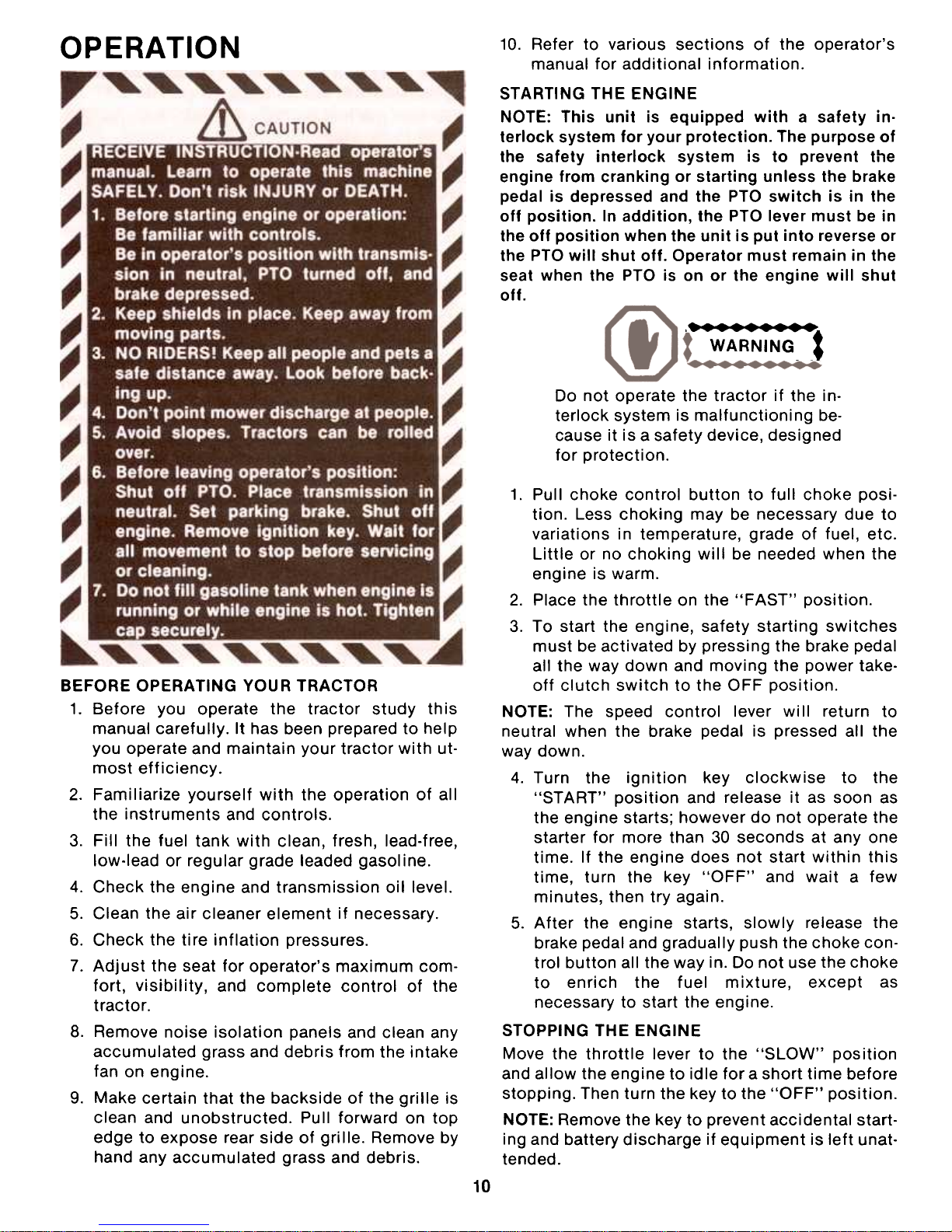

HOOD AND NOISE ISOLATION PANELS

The tractor hood is arranged to swing up and forward for easy access to the engine compartment.

The hood locks automatically when raised. To

lower hood, release latch on left side by gently

pushing hood up to release tension and pull latch

to left. See figure 13. Also, whenever engine

maintenance is required, the noise isolation

panels can be readily removed by removing the

two wing nuts and two washers (one on each side)

and disconnecting the panel spring.

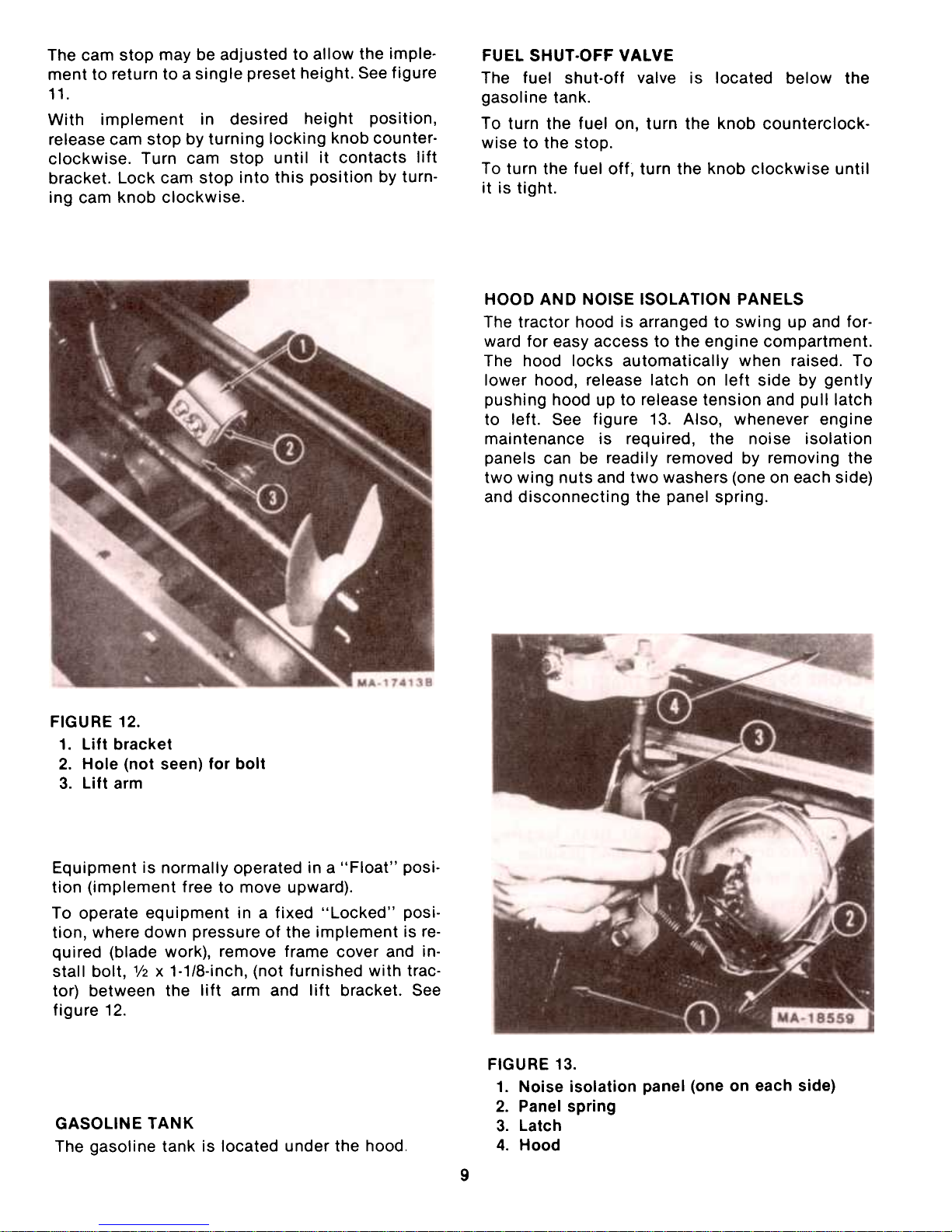

FIGURE 12.

1. Lift bracket

2. Hole (not seen) for bolt

3. Lift arm

Equipment is normally operated in a "Float" position (implement free to move upward).

To operate equipment in a fixed "Locked" position, where down pressure of the implement is required (blade work), remove frame cover and in-

stall bolt, 1/2 x 1-1/8-inch, (not furnished with trac-

tor) between the lift arm and lift bracket. See

figure 12.

FIGURE 13.

1. Noise isolation panel (one on each side)

2. Panel spring

3. Latch

4. Hood

GASOLINE TANK

The gasoline tank is located under the hood.

9

Page 10

OPERATION

10. Refer to various sections of the operator's

manual for additional information.

STARTING THE ENGINE

NOTE: This unit is equipped with a safety interlock system for your protection. The purpose of

the safety interlock system is to prevent the

engine from cranking or starting unless the brake

pedal is depressed and the PTO switch is in the

off position. In addition, the PTO lever must be in

the off position when the unit is put into reverse or

the PTO will shut off. Operator must remain in the

seat when the PTO is on or the engine will shut

off.

, :::::.

WARNING- -.

Do not operate the tractor if the interlock system is malfunctioning because it is a safety device, designed

for protection.

1. Pull choke control button to full choke position. Less choking may be necessary due to

variations in temperature, grade of fuel, etc.

Little or no choking will be needed when the

engine is warm.

2. Place the throttle on the "FAST" position.

3. To start the engine, safety starting switches

must be activated by pressing the brake pedal

all the way down and moving the power take-

off clutch switch to the OFF position.

NOTE: The speed control lever will return to

neutral when the brake pedal is pressed all the

way down.

4. Turn the ignition key clockwise to the

"START" position and release it as soon as

the engine starts; however do not operate the

starter for more than 30 seconds at anyone

time. If the engine does not start within this

time, turn the key "OFF" and wait a few

minutes, then try again.

5. After the engine starts, slowly release the

brake pedal and gradually push the choke control button all the way in. Do not use the choke

to enrich the fuel mixture, except as

necessary to start the engine.

STOPPING THE ENGINE

Move the throttle lever to the "SLOW" position

and allow the engine to idle for a short time before

stopping. Then turn the key to the "OFF" position.

NOTE: Remove the key to prevent accidental starting and battery discharge if equipment is left unat-

tended.

BEFORE OPERATING YOUR TRACTOR

1. Before you operate the tractor study this

manual carefully. It has been prepared to help

you operate and maintain your tractor with ut-

most efficiency.

2. Familiarize yourself with the operation of all

the instruments and controls.

3. Fill the fuel tank with clean, fresh, lead-free,

low-lead or regular grade leaded gasoline.

4. Check the engine and transmission oil level.

5. Clean the air cleaner element if necessary.

6. Check the tire inflation pressures.

7. Adjust the seat for operator's maximum comfort, visibility, and complete control of the

tractor.

8. Remove noise isolation panels and clean any

accumulated grass and debris from the intake

fan on engine.

9. Make certain that the backside of the grille is

clean and unobstructed. Pull forward on top

edge to expose rear side of grille. Remove by

hand any accumulated grass and debris.

10

Page 11

TRACTOR BREAK-IN PROCEDURE

Never operate a new engine immediately under

full load. Break it in carefully as shown in the tablebelow.

5. Leave the throttle in the slow position but

push the choke in all the way; then turn the ignition key to the start position and slowly pull

the choke out to the position which will cause

the engine to start and continue running. If

the engine falters after putting tractor into

motion, pull the choke out part way until the

engine runs smoothly, then gradually push

the choke back in as the engine warms.

OPERATING IN COLD WEATHER

(682 and 782 Tractors)

While operating tractors equipped with a 17 HP 2

cylinder engine, at light loads and usually in low

temperature conditions, it is possible to foul out a

spark plug. This will result in gasoline entering the

crankcase by way of the piston ri ngs on the

cylinder which is not firing.

Some symptoms are:

1. Oil level will rise due to gasoline in crankcase.

2. Air filter becomes oil and fuel soaked.

3. Engine leaks oil.

4. Mis-firing.

This condition does not necessarily mean that the

carburetor, piston rings, ignition coil-wires-points,

or gaskets are defective.

Correction:

1. Replace both spark plugs.

2. Check air filter element, replace if needed.

3. Change oil.

4. Adjust carburetor if needed.

5. Service spark plugs regularly when using trac-

tor under light duty or low temperature conditions.

COLD WEATHER STARTING

Engine starting is possible in cold weather pro-

viding the correct weight of engine oil is used, the

battery is fully charged, and the proper starting

procedure is followed. The best procedure for

starting at temperatures near or below freezing is

as follows:

1. Pull the choke all the way out into the full

choke position.

2. Move the throttle lever just off "FAST" posi-

tion.

3. Press the brake pedal all the way down and be

sure the power take-off switch is in the off

position. The safety interlocks will prevent

starting unless this is done.

4. Move the key switch into the start position

and hold until the engine starts; however, do

not operate the starter for more than 30

seconds at anyone time. As soon as the

engine starts, slowly push the choke in part

way.

DRIVING THE TRACTOR

1. Depress the standard brake pedal, release the

brake lock, and let the pedal up. Move the

throttle lever to the position where the engine

operates best for the load to be handled.

2. Start the tractor in motion by moving the

speed control lever slowly forward'or rearward

to desired speed.

~ CAUTION

During operation do not run the

engine in confined area such as

storage building any longer than is

necessary. Immediately move the

tractor outside into the air.

& CAUTION

Avoid sudden starts, excessivespeed,

sudden stops. Keep vehicle

in gear when going down hills.

NOTE: In cold weather the starting motor maydisengage

prematurely. This is caused by theengine

firing once but failing to continue running.

If this happens several times, the engine will be

flooded and it will be necessary to start as

described in step 5.

NOTE: When using power take-off operated equip-ment,

best performance is achieved with the throt-

tle lever in the "FAST" position.

Page 12

Advance throttle to operating speed (full

speed).4.

The operator must remain in tractor seat at all

times. If operator should leave tractor seat

without turning off the power take-off switch,

the engine will automatically shut off.5.

pro switch must be in the "OFF" position

when shifting the tractor into reverse or the

pro will shut off automatically. To re-engage

the pro, shift unit into neutral. Move pro

switch to "OFF" position and then move pro

switch to "ON" position.

Always be sure the rear wheels are free to turn.

Under any adverse conditions, do not attempt to

free the tractor by speeding up the engine and

suddenly engaging the clutch. Try backing out in-

stead of going forward.

~ CAUTION

Do not leave the seat of the tractor

without depressing the brake pedal

and setting the brake lock. If leaving

the tractor unattended, also turn the

ignition key off and remove the key.

ADJUSTMENTS

DRIVING ON SLOPES

Before operating the tractor on any slope, walk the

slope to look for possible hazards such as rocks,mounds,

ruts, stumps or other surface ir-

regularities which could cause an upset.

Back the tractor with implement up the steepest

portion of each slope you intend to work. If the

tractor cannot negotiate the slope in reverse, the

slope is too steep to be worked.

~ CAUTION

Always drive up or down the face of

a slope. Do not drive so that the

tractor may tip over sideways.

ADJUSTING THE SEAT

Before starting the tractor, adjust the seat to the

most comfortable driving position. Tilt the seat

forward over the steering wheel, loosen the four

cap screws in the seat support, and slide the seat

assembly forward or rearward to the position

which is most comfortable for the operator. See

figure 14.

Retighten the cap screws after the seat is ad-justed.

NOTE: The battery is located in a well under the

operator's seat for ease in servicing or replace-

ment when necessary.

Avoid turns when driving on a slope. If a turn must

be made, turn down the slope. Turning up a slope

greatly increases the chance of a rollover.

Avoid stopping when driving up a slope. If it is

necessary to stop while driving up a slope, start

up smoothly and carefully to reduce the possibility of flipping the tractor over backward.

STOPPING THE TRACTOR

Move the speed control lever to the "N" position

or use the standard brake pedal. Before dismounting always lock the brake pedal and turn the ignition "OFF." Also disengage the power take-off

control switch.

FIGURE 14.

ADJUSTING THE POWER

TAKE-OFF CLUTCH

The clutch is factory adjusted and should not require further adjustment under normal operatingconditions.

However, if the clutch fails to operate

properly check as follows:

OPERATING THE FRONT POWER

TAKE.OFF CLUTCH (PTO)

1. Move the throttle lever back to the medium or

"SLOW" position.

2. Flip the toggle switch to the "ON" position.

engage brake pedal lock,

lower equipment and shut off engine

before dismounting. Never start engine from ground.

Page 13

Check fuse on pedestal.

~ CAUTION

To avoid possible injury, always dis-

engage all clutches, move speed

control into neutral, depress the

brake, set the brake pedal lock and

turn the ignition "OFF" before working on the machine.

FIGURE 16.

Thread the clevis onto the brake rod one turn.

Reconnect the clevis to the jackshaft assembly.

There should be a minimum amount of clearance

(no drag) between the brake pads and the rotor.

See figure 17. If not, repeat adjustment .as

necessary.

Using a feeler gauge, check the air gap. See figure

15. Insert feeler gauge into one of three access

slots located around the outside of the brake

plate. The air gap should be .O10-.015-inches. Ad-

just the self-locking nuts to obtain the proper

clearance. Repeat the operation in all three access slots.

NOTE: If brake plate drags on clutch at

.O10-.015-inches air gap, increase air gap to

.O20-inches.

If the above procedure does not work, see your

authorized dealer.

FIGURE 17.

FIGURE 15.

1. Access slots

2. Brake plate

3. Self-locking nuts

ADJUSTING THE BRAKES

During normal operation of this machine, the

brakes are subject to wear and will require

periodic examination and adjustment.

With the brake pedal disengaged, remove the

clevis pinned end of one of the brake rod

assemblies from the jackshaft assembly by

removing the cotter pin from the clevis pin. See

figure 16.

NOTE: Figure 17 is shown with the wheel and

fender assembly removed for clarity.

Repeat the adjustment on the brake rod assembly

on the other side of the tractor.

Recheck brake adjustment and insure proper

brake operation before operating the tractor.

WHEEL ALIGNMENT

The front wheels should toe-in approximately 1/8".

Measure the distances A and B on the frontwheels.

See figure 18.

13

Page 14

NOTE: Dimension B should be approximately 1/8

inch less than dimension A.

18.

Front wheel adjustments.

To adjust the toe-in remove one ball joint, loosen

the lock nut "c" at the ball joint and turn the tie

rod ball joint in or out as required.

CARBURETOR ADJUSTMENTS

) ~C:~~:~~~ j

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage all

clutches and blades. Keep clear of

all moving parts and be careful of

heated surfaces and muffler.

~ CAUTION

To avoid injury or an accident, be

sure the brake pedal is in the locked:

position, transmission is in neutral,

and any equipment is disengaged

before starting engine to make car-

buretor adjustments.

The carburetor is adjusted at the factory and

under normal operating conditions it will not require readjusting. However, if the engine does not

operate properly, what may appear to be a faulty

carburetor adjustment is in many cases a clogged

air filter. This possibility should be ruled out

before attempting to readjust carburetor. Refer to

"MAINTENANCE."

NOTE: To prevent possible damage to the carburetor needles, be very careful closing the carburetor needles before basic adjustments are

made. Improper adjustment of the carburetor may

result in engine damage.

1282 Tractor Only

FIGURE 19.

Tie rod and drag link ball joints.

FIGURE 20.

1. Governor control rod 5. Fuel shut-off valve

2. Idle adjusting screw 6. Fuel line

3. Throttle stop screw

4. High speed adjustment screw

TURNING RADIUSThe

front wheels should have an equal angle for

left and right turns. If adjustment is necessary.

remove ball joint and loosen lock nut "D", turn the

drag link ball joint clockwise or counterclockwise

as required. See figure 19.

~ CAUTION

Be sure all parts are reassembled

tight with cotter pins in place and

spread.

14

Page 15

:

WARNING:

Carbon monoxide fumes can be

fatal! Do not make any adj ustments

to the carburetor in a confined area

such as a storage building. Move the

tractor outside into the air.

682 and 782 Tractors

NOTE: Air cleaner has been removed from illustrations in order to show carburetor.

Adjusting the High-Speed Adjustment Screw

Turn the high speed adjustment screw counterclockwise approximately two turns from the

closed position and start the engine. Refer to

figure 20.

Be sure the choke is fully open (knob fully in)

when adjusting.

After the engine has reached normal operatingtemperature,

place the throttle lever in the fast

position and turn the high speed adjustment

screw clockwise to the leanest mixture that will

allow satisfactory acceleration and steady governor operation. Then, turn counterclockwise to the

richest mixture that allows satisfactory operation.The

difference between the rich and lean points is

about V2 turn. Set the mixture to the rich end of

this range.

If the engine misses and backfires under load, the

high speed mixture is too lean. The high speed adjustment screw must be turned counterclockwise

1/8 turn at a time until the condition is corrected.

If the engine shows a sooty exhaust and is slug-

gish under load, the high speed mixture is toorich.

The high speed adjustment screw must be

turned clockwise 1/8 turn at a time until the condition is corrected.

Adjusting the Idle Adjustment Screw

After the high speed ajdustment screw is ad-justed,

it may be necessary to readjust the idle adjustment screw as each affects the other. Refer to

figure 20.

Close the idle adjustment screw to its seat by

turning it clockwise; then open it one turn. Start

the engine and operate it at fast idling speed

(without any load) until thoroughly warm.

While the engine is running at fast idle speed, it is

advisable to screw in the throttle stop screw a few

turns to keep the engine from stopping when the

throttle lever is moved to the fully retarded

"SLOW" position. The engine will then be idling at

a fairly high speed and the throttle stop screw can

be backed out a little at a time until the desired

idle speed is obtained (1800 RPM).

If the engine misses or rolls while backing out the

throttle stop screw, the idle adjustment screw

may be adjusted in or out until the engine

operates smoothly. Speed up the engine for a few

seconds; then recheck the idle adjustment. A

slight adjustment in or out will give the smoothest

idle.

FIGURE 21.

1. Main fuel screw

2. Idle fuel screw

3. Idle speed screw

If readjustment becomes necessary, stop the

engine, then turn the MAIN and IDLE fuel adjusting screws all the way in, until they bottom

lightly. Refer to figure 21.

Main Fuel Adjustment

Preliminary setting-turn screw out 2V2 turns.

Final setting-start engine and raise engine

speed to maximum governed, no load speed. Turn

screw in just until engine speed decreases and

note the position of the screw. Now turn the screw

out. The engine speed will first increase, but then

decrease as screw is turned out. Note the position

of screw when engine speed starts to decrease.

Set the screw midway between the t,wo points

noted above.

Idle Speed Adjustment

Run engine at maximum governed, no load speed

for a minimum of 30 seconds, then allow engine

speed to fall to idle or put throttle into idle posi-tion.

Set engine speed to 1200 (:t 75 RPM) by turn-

ing the idle speed screw in or out.

Idle Fuel Adjustment

Set the idle fuel mixture by turning the idle fuel

screw out, from the closed position, 3/4 to 1 fullturn.

15

Page 16

Page 17

Page 18

Properly cleaned and installed air cleaner

elements are the best guarantee to continued

long and satisfactory engine life.

CLEANING ENGINE

This tractor has an air-cooled engine. Air must be

able to circulate freely around the engine, through

the screen, shroud, and over the fins of the

cylinder head and cylinder block. Keep these

areas free of accumulated dirt and trash or engine

will overheat and result in damaged moving parts.

Periodically clean the inside of the side panels

and grille for adequate cooling.

NOTE: This machine is designed to cool properly

with the engine side panels in place. Operating

the machine without panels in place may result in

inadequate cooling.

SPARK PLUGS

Cleaning Spark Plug

Clean spark plugs with a penknife or wire brush

and solvent. If electrode is burned away or the

porcelain is cracked, replace with new plug.

NOTE: Do not sandblast or use any abrasive

machines to clean spark plugs; because any grit

introduced into the engine could cause severe

damage.

LIGHTS

The headlights are sealed-beam units. Refer to

"SPECIFICATIONS" when replacement is

necessary.

To replace the taillight lamp, remove socket and

bulb from the back of the taillight by rotating

socket 1/4 turn. Refer to "SPECIFICATIONS".

FUSES

Always use the same capacity fuse for replace-

ment. Refer to "SPECIFICATIONS." If the lights

fail or the electric clutch does not engage, check

the appropriate fuse.

To install a new fuse, press in on the fuse housing

cap and turn counterclockwise to remove it from

the fuse housing. Remove the old fuse and

replace it with a new one. Then reassemble the

cap to the housing.

NOTE: The fuse on the left is for the lights; the

fuse on the right is for the electric clutch.

BATTERY INFORMATION

~~~~R:~~G~J

FIGURE 24.

NOTE: Remove all dirt from around the spark

plugs before removing.To

remove spark plugs, always use a spark plugwrench.

Check gap after every 100 hours of opera-tion.

~ CAUTION

To avoid possible injury, be sure

engine is off and cool before making

any adjustments or repairs.

Replace a defective plug with a new plug. Set gap

at .O25-inch. See figure 24. Tighten plug to 7-15 ft-

Ibs. See your authorized dealer for the correct

replacement plug.

Battery acid must be handled with great care

as contact with it can burn and blister the skin.

It is also advisable to wear protective clothing

(goggles, rubber gloves and apron) when work-

ing with it..

B. Should battery acid accidentally splatter into

the eyes or onto the face, rinse the affected

area immediately with clean cold water. If

there is any further discomfort, seek prompt

medical attention.

C. If acid spills on clothing, first dilute it with

clean water, then neutralize with a solution of

ammonia/water or baking soda/water.

D. Since battery acid is corrosive, do not pour it

into any sink or drain. Before discarding empty

electrolyte containers, rinse them with a

neutralizing solution.

E. NEVER connect or disconnect charger clips to

battery while charger is turned on as it can

cause sparks.

18

Page 19

F. Keep all lighted materials (cigarettes,

matches, lighters) away from the battery as the

hydrogen gas generated during charging can

be combustible.

G. As a further precaution, only charge the battery

in a well-ventilated area.

.Always shield eyes, protect skin and clothing

when working near batteries.

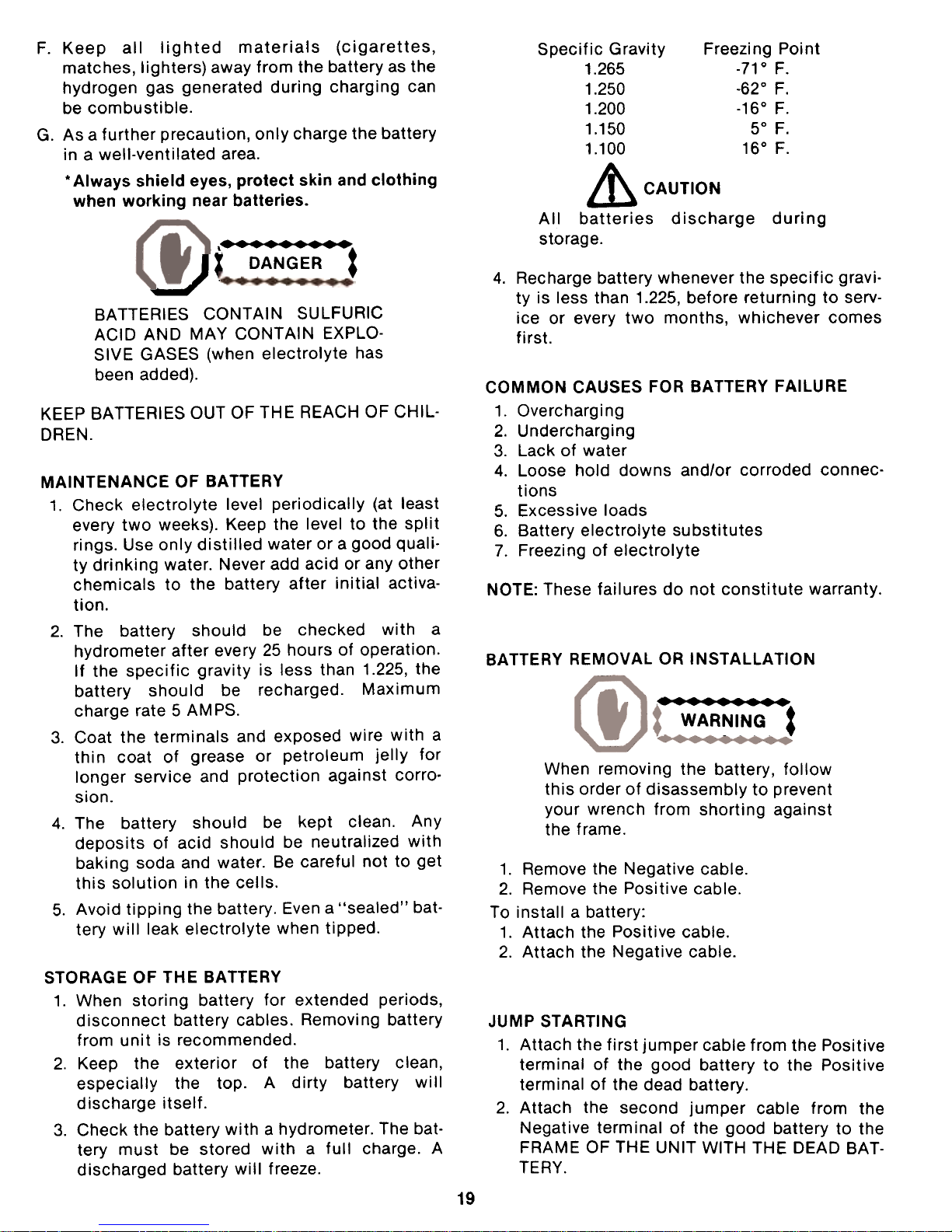

Specific Gravity Freezing Point

1.265 -710 F.

1 .250 -620 F.

1.200 -160 F.

1.150 50 F.

1.100 160 F.

~ CAUTION

All batteries discharge during

storage.

4. Recharge battery whenever the specific gravity is less than 1.225, before returning to service or every two months, whichever comes

first.

,' ), DANGER:

BATTERIES CONTAIN SULFURIC

ACID AND MAY CONTAIN EXPLOSIVE GASES (when electrolyte has

been added).

KEEP BATTERIES OUT OF THE REACH OF CHIl-DREN.

COMMON CAUSES FOR BATTERY FAILURE

1. Overcharging

2. Undercharging

3. Lack of water

4. Loose hold downs and/or corroded connec-

tions

5. Excessive loads

6. Battery electrolyte substitutes

7. Freezing of electrolyte

NOTE: These failures do not constitute warranty.

BATTERY REMOVAL OR INSTAllATION

'~;:R~~N~G~;::;'*

When removing the battery, follow

this order of disassembly to prevent

your wrench from shorting against

the frame.

MAINTENANCE OF BATTERY

1. Check electrolyte level periodically (at least

every two weeks). Keep the level to the split

rings. Use only distilled water or a good quali-

ty drinking water. Never add acid or any other

chemicals to the battery after initial activa-

tion.

2. The battery should be checked with a

hydrometer after every 25 hours of operation.

If the specific gravity is less than 1.225, the

battery should be recharged. Maximum

charge rate 5 AM PS.

3. Coat the terminals and exposed wire with a

thin coat of grease or petroleum jelly for

longer service and protection against corro-

sion.

4. The battery should be kept clean. Any

deposits of acid should be neutralized with

baking soda and water. Be careful not to get

this solution in the cells.

5. Avoid tipping the battery. Even a "sealed" battery will leak electrolyte when tipped.

1. Remove the Negative cable.

2. Remove the Positive cable.

To install a battery:

1. Attach the Positive cable.

2. Attach the Negative cable.

JUMP STARTING

1. Attach the first jumper cable from the Positive

terminal of the good battery to the Positive

terminal of the dead battery.

2. Attach the second jumper cable from the

Negative terminal of the good battery to the

FRAME OF THE UNIT WITH THE DEAD BAT-

TERY.

STORAGE OF THE BATTERY

1. When storing battery for extended periods,

disconnect battery cables. Removing battery

from unit is recommended.

2. Keep the exterior of the battery clean,

especially the top. A dirty battery will

discharge itself.

3. Check the battery with a hydrometer. The battery must be stored with a full charge. A

discharged battery will freeze.

19

Page 20

*

WARNING:

Failure to use this starting procedure could cause sparking, and

the gases in either battery could ex-plode.

TIRES

Keep the pneumatic tires properly inflated. Overinflation will cause operator discomfort. Underinflation will cause short tire life.

Inflate the front and rear tires for normal or heavy

load operations as shown in the following table.

Tire Size

Front Tires

16 x 6.50-8

Rear Tires

23 x 10.50-12

Pounds per square inch

12

10

1. Working outdoors, drain all fuel from the fuel

tank. Use a clean dry cloth to absorb the small

amount of fuel remaining in the tank, then run

the engine until all fuel in the carburetor is ex-

hausted.

2. Drain all the oil from the crankcase (this

should be done after the engine has been

operated and is still warm) and refill the crankcase with clean new oil.3.

Disconnect the spark plug wires and remove

the spark plugs from the cylinders. Pour about

2 or 3 tablespoons of engine oil into each

cylinder, and then turn the engine over several

times to spread out the oil. Replace the spark

plugs but do not connect the wires.4.

Clean the engine and the entire tractor

thoroughly.5.

Lubricate all lubrication points and wipe the

entire machine with an oiled rag in order to

protect the surfaces.6.

Follow battery storage instructions on page

19.7.

Protect tires and seat from sunlight. Inflate

tires at regular intervals.

Always see that the tire valve caps are in place

and tightened securely to prevent loss of air and

protect the valve core and stem.

Do not overload the tractor tires by mounting

equipment on the tractor which exceeds the load

capacity of the size of the tires on the tractor.

OPTIONAL

EQUIPMENTAND

ACCESSORIES

Mounting Tires On The RimAfter

mounting a new or old tire on the rim, inflate

it to 20 pounds pressure to seat the tire bead onthe

rim flange. Then deflate the tire to the correctoperating

pressure.

NOTE: After the first 10 hours of operation, check

and retorque the wheel lug nuts (both sides) to 35Ibf.

ft. to make sure they have seated properly.

When you purchased your tractor, you probably

had it completely equipped for your particular

needs at the time. However, later you may wish to

obtain optional equipment or accessories. These

items and other allied equipment can be purchased from, and installed by, your authorizeddealer.

The tractor is used for so many different types ofwork,

and because it is called on to operate under

so many different conditions, a variety of equip-

ment is available to adapt it to the requirements of

the user. Refer to equipment catalog.

If the machine is to be inoperative for a periodlonger

than 30 days, the following procedures arerecommended:

20

Page 21

Page 22

Page 23

TROUBLE SHOOTING

Possible Cause

Possible Remedy

ENGINE OVERHEATS

Insufficient cool air, dirty air intake screen,

shroud, cooling fins, or dirty grille.

Lean carburetor adjustment.

Oil level incorrect.

Keep the air intake area and cooling fins clean;

Refer to "MAINTENANCE".

Readjust; Refer to "ADJUSTMENTS".

Engine oil level must not be over the "FULL" mark

or below the "LOW" mark. Refer to "MAIN-

TENANCE".

* See your authorized dealer.

LUBRICATION

TABLE

Check

at

Hours

Change

at

Hours

Anticipated Air Temperature

Point of Lubrication

Capacit~

Above + 32°F.

+ 32°F. to OaF.

Below O°F.

Engine crankcase

3 pt.

(1282)

3 pt.

(682

and

782)

I.H. Low Ash En-

gine Oil SAE-30

Note: Do not

substitute 10W-30

or 10W-40

I.H. No. 1@

Engine Oil

SAE-5W-20

or

SAE-5W-30

Check

before

each

use

H. Low Ash

Engine Oil

SAE.10W

25

IH Hy .Tran@ Fluid

If fluid is used which does not meet requirements

of IH 8-6 Specifications, Cub Cadet will not be

responsible for substandard performance.

Failures due to use of improper fluid is not

covered by warranty. For maximum protection,

use IH Hy .Tran@ Fluid.

Hydro-drive unit

mounted on

transmission case

with filter

30 Add as

lneeded

14 pt.

Approx.

100

or

Yearly

Two strokes of the lubricator using IH-251 H EP

grease or equivalent No.2 multi-purpose

lithium grease.

1/4 lb.

Steering gear

housing

Use IH-251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply two or three strokes of the lubrica-

tor or sufficient grease to flush out old grease and dirt.

Steering knuckles &

front axle pivot bolt

10

100

or

Yearly

Remove front wheels and pack bearings with

IH-251 H EP grease or equivalent No.2 multi-

purpose lithium grease and reinstall wheels.

Front wheel

bearings

;t,~

Page 24

Be certain that all lubrication fittings are assembled in place, using the lubrication illustrations asa

guide.

lubricate the tractor thoroughly before tak-

ing it to the field. Use a pressure lubricating gun.

Be sure all fittings are free from dirt and paint so

the lubricant is certain to enter the bearing.

Always force the lubricant through the full length

of each bearing until it emerges at the end, carrying with it the worn lubricant and any dirt that may

have entered the bearing.

Miscellaneous working parts not provided with

lubrication fittings should be oiled daily with a

good grade of lubricating oil.

Lubricant is cheap. Use plenty of it. Worn parts

can be expensive to replace.

Keep your supply of lubricating oil and grease stored in clean containers,

and covered to protect from dust and dirt.

Keep the lubricating gun nozzle clean and wipe dirt from grease fittings

before lubricating.

symbols in the illustration indicate the

method of application and the hourly intervals to

apply the lubricant.

_.r:-~ Use a pressure lubricating gun and ap-

\ j ply IH 251 H EP grease (or equivalent No.

-2 multi-purpose lithium grease) sufficient to flush out the old grease and dirt.

Lubricate at hourly intervals indicated on sym-

bols.

use to check engine oil before

each use.

24

Page 25

Page 26

Engine filler cap

and dipstick.

1.

LUBRICATION GUIDE

-Before Each Use

Check the oil (with the engine stopped) and add sufficient

new oil to bring it to the "FULL" mark on the dipstick. Do

not overfill. Do not operate the engine if the oil level is

below the "LOW" mark on the dipstick.

-After Every 10 Hours of Operation

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply sufficient grease to flush out old

grease and dirt.

2-

Steering knuckles (2).

(Both sides)

NOTE: After the first 10 hours only, remove the oil filterand

replace with a new filter. Refer to "MAINTENANCE."Change

the oil filter after 50 hours and every 100 hours of

operation thereafter.

3-

Transmission oil filter.

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply sufficient grease to flush out old

grease and dirt. NOTE: It may be necessary to rotate the

front axle to reach the grease fitting.

After Every 25 Hours of Operation

4.

Front Axle pivot bolt.

(Right side)

While the oil is warm, remove the drain plug (5) and drain

all of the oil from the crankcase. Replace the drain plug.

Refill the crankcase with new oil up to the "FULL" mark

on the dipstick. Refer to the "LUBRICATION TABLE" for

the proper quantity and viscosity to use.

5-

Engine

oil drain plug.

6-

Transmission

oil leveland

fill tube.

Check the oil with the engine stopped. Keep the lubricant

up to "FULL" mark on dipstick (6).

-After Every 50 Hours of Operation

7.Transmission

oil filter.

8-

Transmission oil filter.

NOTE: After the first 50 hours only, remove the oil filter

and replace with a new filter. Refer to "MAINTENANCE."

Change the oil filter every 100 hours of operation

thereafter.

Every 100 Hours of Operation

Change the oil filter and replace with a new filter. Refer to

"MAINTENANCE."

9-Steering gear housing.

(Center bottom)

Once a year, apply two strokes of the lubricator, using IH

251 H EP grease or equivalent No.2 multi-purpose lithium

grease.

NOTE: To locate the lubrication fitting, turn the front

wheels to the maximum right turn position. Then reach up

under the right side of the tractor frame to locate the fit-ting.

Once a year, apply a small amount of IH 251H EP grease

or equivalent No.2 multi-purpose lithium grease in theslots.

Speed Control Linkage

10-Cam plates.

Miscellaneous

Brake pedal shaft

Lubricate the brake pedal shaft and linkage with eight or

ten drops of engine oil.

26

Page 27

Page 28

Page 29

The cam stop may be adjusted to allow the imple-

ment to return to a single preset-height. See figure

11

With implement in desired height position,

release cam stop by turning locking knob counter-

clockwise. Turn cam stop until it contacts lift

bracket. Lock cam stop into this position by turn-

ing cam knob clockwise.

The fuel tank filler cap has an air vent. Keep

the vent open at all times to assure proper

flow of the fuel.

NOTE: Gasohol is not approved for use

by the engine manufacturer and

should not be used. The use of

gasohol may damage the engine.

FUEL SHUT-OFF VALVE

The fuel shut-off valve is located below the

gasoline tank.

To turn the fuel on, turn the knob counterclock-

wise to the stop.

To turn the fuel off, turn the knob clockwise until

it is tight.

HOOD AND NOISE ISOLATION PANELS

The tractor hood is arranged to swing up and for-

ward for easy access to the engine compartment.

The hood locks automatically when raised. To

lower hood, release latch on left side by gently

pushing hood up to release tension and pull latch

to left. See figure 13. Also, whenever engine

maintenance is required, the noise isolation

panels can be readily removed by removing the

two wing nuts and two washers (one on each side)

and disconnecting the panel spring.

FIGURE 12.

1. Lift bracket

2. Hole (not seen) for bolt

3. Lift arm

Equipment is normally operated in a "Float" posi-

tion (implement free to move upward).To

operate equipment in a fixed "Locked" posi-tion,

where down pressure of the implement is required (blade work), remove frame cover and install bolt, 1/2 x 1-1/8-inch, (not furnished with trac-

tor) between the lift arm and lift bracket. See

figure 12.

GASOLINE TANK

The gasoline tank is located under the hood.

FUEL SYSTEM

This engine is designed to operate on

unleaded or leaded gasoline with a 91

minimum octane rating (Research Method), or

a minimum Antiknock Index (RON + MON)/2

of 87. Antiknock Index is posted on dispensing pumps.

The use of unleaded gasoline will increase

spark plug and valve life, maintain engine

performance longer, and reduce rust and corrosion of the engine while stored.

FIGURE 13.

1. Noise isolation panel (one on each side)

2. Panel spring

3. Latch

4. Hood

1 096 822 R1 4-83

PRINTED IN UNITED STATES OF AMERICA

31

Page 30

MAINTENANCE

To aid starting, the selection of crankcase

lubricating oils should be based on the lowest an.

ticipated temperatures until the next drain period.

Refer to "lUBRICATION TABLE".

We recommend IH Low Ash Engine Oil for

gasoline engines. IH Low Ash Engine Oil

exceeds API Service Classification SE. It is

specifically designed for heavy duty service

in gasoline engines, and is formulated to

minimize metallic deposits, lengthen spark

plug and valve life. IH Low Ash Oil used with

unleaded gasoline is the ideal combination to

maintain performance and extend engine life.

the "FULL" mark. For oil capacity refer to the

"SPECIFICATIONS" and "LUBRICATION TABLE"

section.

Remove the cap and dipstick and fill to the full

mark on the dipstick. POUR SLOWLY.

Capacity 3 pints. When checking the oil level,

push the dipstick assembly firmly but slowly

until cap bottoms on tube. DO NOT OVERFill. Dipstick assembly must be pushed fully

into tube at all times when engine is operat-

ing.

HYDROSTATIC DRIVE HYDRAULIC FLUID

FIL TER

Remove the throw-away can-type filter and replace

with a new filter after the first 10 hours and 50

hours of operation, and every 100 hours of opera-

tion thereafter.

NOTE: Clean the outside area before removing the

filter to keep dirt from getting into the transmission case. If a mower is mounted on the tractor,

the mower must be lowered to facilitate removal

of the filter.

To remove the filter, turn the filter counterclock-

wise using an automotive type filter wrench.

Before installing the new filter, apply a coating of

oil on the filter gasket. Thread the filter on by hand

until tight enough to seat the gasket. Loosen the

filter. Then turn it until the gasket contacts the

base. Tighten the filter an additional one half turn.

Start engine and allow it to run for a few minutes.

Shut engine off and check for leaks, check oil

level in transmission case.

AIR CLEANER

Dry Type (1282 Tractor Only)

If other than IH Low Ash Engine Oil is used it

must meet API Service Classification SE. For

maximum engine life select API SE oils with

lowest levels of barium, calcium, or magnesium additives and minimum ash content

(approximately 0.5%). Lubricant suppliers will

normally furnish this information on their

engine oils.

Multi-viscosity numbered oils such as SAE

10W-30 or SAE 10W-40 must not be used above 32

degrees Fahrenheit.

Regularly check the oil level of the engine crankcase to see that it is filled to the correct level.

NOTE: Check the oil level only while the engine is

stopped.

Always keep the oil level between the "FULL" and

the "LOW" marks on the dipstick. When checking

the oil level the dipstick must be withdrawn and

wiped clean, then inserted all the way and

withdrawn for a true reading.

Filling the Crankcase

To fill the crankcase with oil, place the tractor on a

level surface. Clean the area around oil fill before

removing combination oil filler cap and dipstick.

NOTE: Never overfill the engine crankcase.

Engine may overheat and/or damage may result if

the crankcase is below the "LOW" mark or over

.~-- ~

All engine air used for combustion is filtered by a

dry type air cleaner to assure long engine life.

NOTE: Left engine side panel must be removed to

have access to the air cleaner.

Service the air cleaner element when a loss of

power is noticeable. Discard used element and

replace with a new one at least once a year.

1 096 822 R1 4-83

PRINTED IN UNITED STATES OF AMERICA

32

ENGINE OIL

The engine crankcase is filled with ship-away

oil. This oil may be used for the first 5 hours of

engine operation at temperatures between

+90 degrees F. and 0 degrees F. If temperatures are not within this range, drain the

oil from the crankcase and replace with new

oil as specified in the "LUBRICATION

TABLE". The engine oil must be drained and

replaced with new oil every 25 hours of

engine operation.

Page 31

Page 32

Page 33

Page 34

1-Engine filler cap

and dipstick.

LUBRICATION GUIDE

-Before Each Use

Check the oil (with the engine stopped) and add sufficient

new oil to bring it to the "FULL" mark on the dipstick. Do

not overfill. Do not operate the engine if the oil level is

below the "LOW" mark on the dipstick.

-After Every 10 Hours of Operation

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply sufficient grease to flush out old

grease and dirt.

2-Steering knuckles (2).

(Both sides)

NOTE: After the first 10 hours only, remove the oil filter

and replace with a new filter. Refer to "MAINTENANCE."

Change the oil filter after 50 hours and every 100 hours of

operation thereafter.

3- Transmission oil filter.

4-Front Axle pivot bolt.

(Right side)

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply sufficient grease to flush out old

grease and dirt. NOTE: It may be necessary to rotate the

front axle to reach the grease fitting.

-After Every 25 Hours of Operation

While the oil is warm, remove the drain plug (5) and drain

all of the oil from the crankcase. Replace the drain plug.

Refill the crankcase with new oil up to the "FULL" mark

on the dipstick. Refer to the "LUBRICATION TABLE" for

the proper quantity and viscosity to use.

5-Engine oil drain plug.

6- Transmission oil level

and fill tube.

Check the oil with the engine stopped. Keep the lubricant

up to "FULL" mark on dipstick (6).

-After Every 50 Hours of Operation

7- Transmission oil filter.

8- Transmission oil filter.

NOTE: After the first 50 hours only, remove the oil filter

and replace with a new filter. Refer to "MAINTENANCE."

Change the oil filter every 100 hours of operation

thereafter.

-Every 100 Hours of Operation

Change the oil filter and replace with a new filter. Refer to

"MAINTENANCE."

9-Steering gear housing.

(Center bottom)

Once a year, apply two strokes of the lubricator, using IH

251 H EP grease or equivalent No.2 multi-purpose lithium

grease.

NOTE: To locate the lubrication fitting, turn the front

wheels to the maximum right turn position. Then reach up

under the right side of the tractor frame to locate the fit-

ting.

Once a year, apply a small amount of IH 251 H EP grease

or equivalent No.2 multi-purpose lithium grease in the

slots.

Speed Control linkage

10-Cam plates.

Miscellaneous

Brake pedal shaft

Lubricate the brake pedal shaft and linkage with eight or

ten drops of engine oil.

36

1 096822 R1 4-83

PRINTED IN UNITED STATES OF AMERICA

Page 35

Page 36

Loading...

Loading...