Page 1

Page 2

Assembled in this manual are operation, lubrication, and maintenance instructions for the

International Cub Cadet 86, 108, 128, 129, 149,

and 169 Tractors. The material has been prepared

in detail to help you better understand the correct

care and efficient operation of your tractor. Before

you operate the tractor, study this manual care-fully.

New copies may be ordered from your dealer

at a nominal price.

have difficulties with the unit consult your

International Harvester dealer. UNDER NO CIR-

CUMSTANCES SHOULD YOU ATTEMPT TO

SERVICE THESE UNITS YOURSELF. Only your

dealer is authorized to repair or replace units on

this drive under the terms of the warranty. Should

you desire additional information not found in this

manual, contact your International Harvester

dealer.

Your local I nternational Harvester dealer is interested in the performance you receive from this

tractor. He has factory-trained servicemen, informed in the latest method of servicing tractors,

modern tools, and original-equ ipment I H service

parts which assure proper fit and good performance.

The International Cub Cadet 129, 149, and 169

Tractors have a hydrostatic drive. It is the best

hydraulic drive unit available and will require

minimum service if recommended operation and

maintenance procedures are followed. Should you

The I nternational Cub Cadet 86, 108, and 128

Tractors have a conventional clutch ana trans-

...

mission.

To obtain top performance and assure economical

operation the tractor should be inspected, depending on its use, periodically, or at least once a year,

by your International Harvester dealer.

When in need of parts, always specify the model,

chassis, and engine serial numbers, including the

prefix and suffix letters. Write these serial numbers

in the space provided on page 4.

Page 3

Page 4

Page 5

Page 6

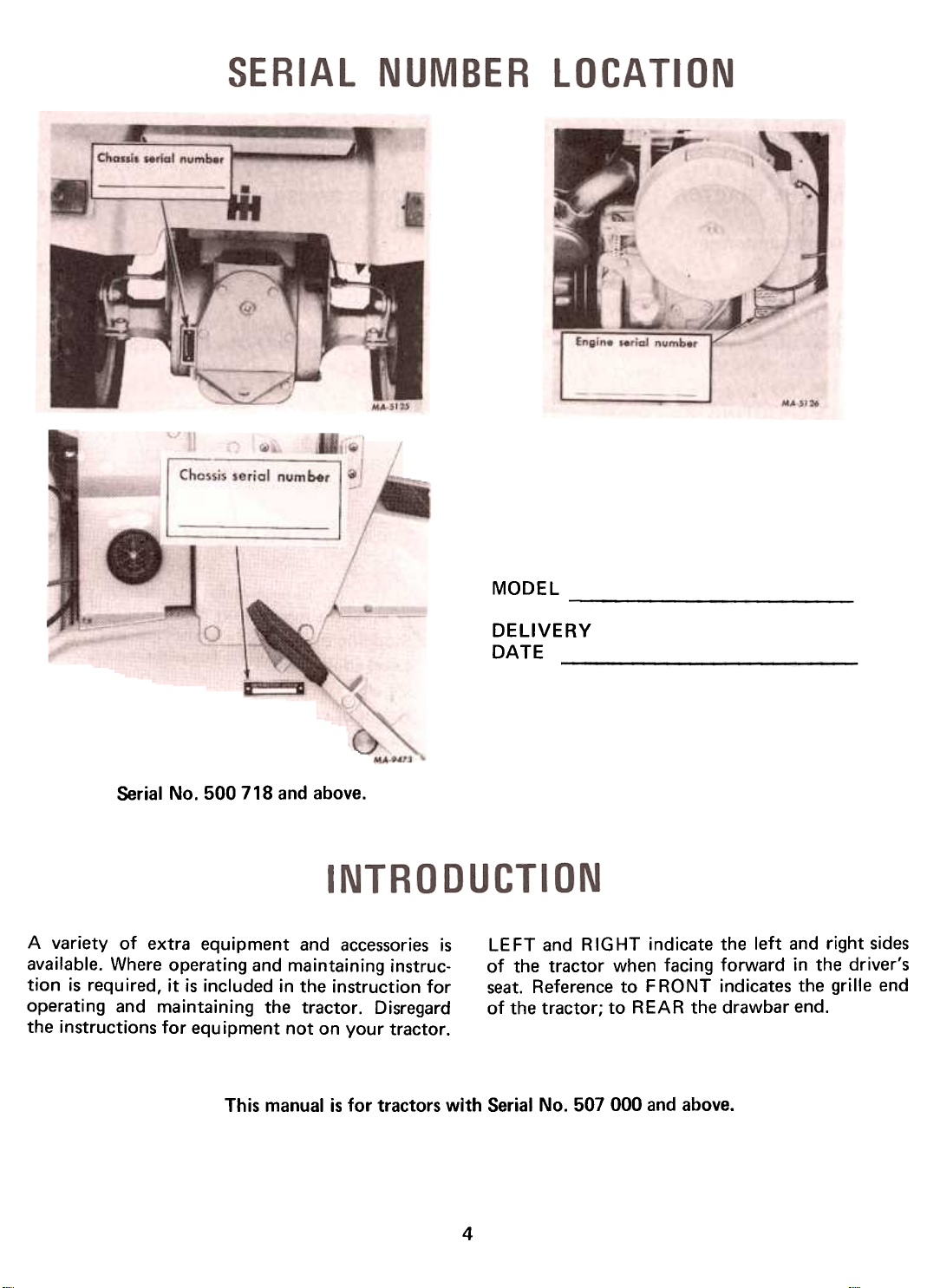

Serial No. 500718 and above.

MODEL

DELIVERY

DATE

A variety of extra equipment and accessories isavailable.

Where operating and maintaining instruc-

tion is required, it is included in the instruction for

operating and maintaining the tractor. Disregard

LEFT and RIGHT indicate the left and right sides

of the tractor when facing forward in the driver's

seat. Reference to F RaNT indicates the grille end

of the tractor; to REAR the drawbar end.

the instructions for equipment not on your tractor.

This manual is for tractors with Serial No. 507 000 and above.

4

Page 7

This symbol is used to call your attention to instructions

concerning your personal safety. Be sure to observe and

following these instructions.

Disengage all clutches and shift into neutral before

starting the engine.

Disengage power to any attachments and stop

engine before leaving operator's seat or making any

repairs or adjustments.

Know the controls and how to stop quickly -

READ THE OPERATOR'S MANUAL.

Do not allow children or adults to operate the

equ ipment without proper instruction.

Clear work area of objects which might be picked

up and thrown.

Disengage power to any attachment when trans-

porting or not in use.

Do not carry passengers of give rides. Keep children, pets, and by-standers a safe distance away.

Always disengage the power take-off, shift trans-

mission into neutral, set the parking brake, stop

the engine, and remove ignition key when leaving

the machine unattended.

Use care when pulling loads or using heavy

equipment: -A. Use only approved hitch points.

B. limit loads to those you can safety control.

C. Don't turn too sharp, and use care when

backing. D. Use counterweight or wheel weights

when suggested in Operator's Manual.

Watch out for traffic when crossing or near

roadways.

When using any attachments, never direct discharge

of material toward bystanders nor allow anyone

near the machine while in operation.

Handle gasoline with care -it is highly flammable:

-A. Use approved gasoline container. B. Never

remove the fuel tank cap or fill the fuel tank when

the engine is running, is hot, or indoors. Also, do

not smoke when working around inflammable fuel.

Wipe up spilled gasoline. C. Replace gasoline cap

securely. D. Open doors if engine is running in a

garage -exhaust gases are dangerous.

Keep machine in good operating condition and

keep safety devices in place. Use guards or shields

as instructed in Operator's Manual.

Reduce speed on slopes and in sharp turns to

prevent tipping or loss of control.

Stay alert for holes in terrain and other hidden

hazards.

Don't stop or start suddenly when going uphill ordownhill.

It is recommended that the machine be stopped

and inspected for damage after striking a foreign

object and that any damage be repaired before

restarting and operating the machine.

Always depress the brake pedal and set the brake

pedal lock before working on the machine. Dis-

engage all implements and shift the transmission

into neutral.

5

Page 8

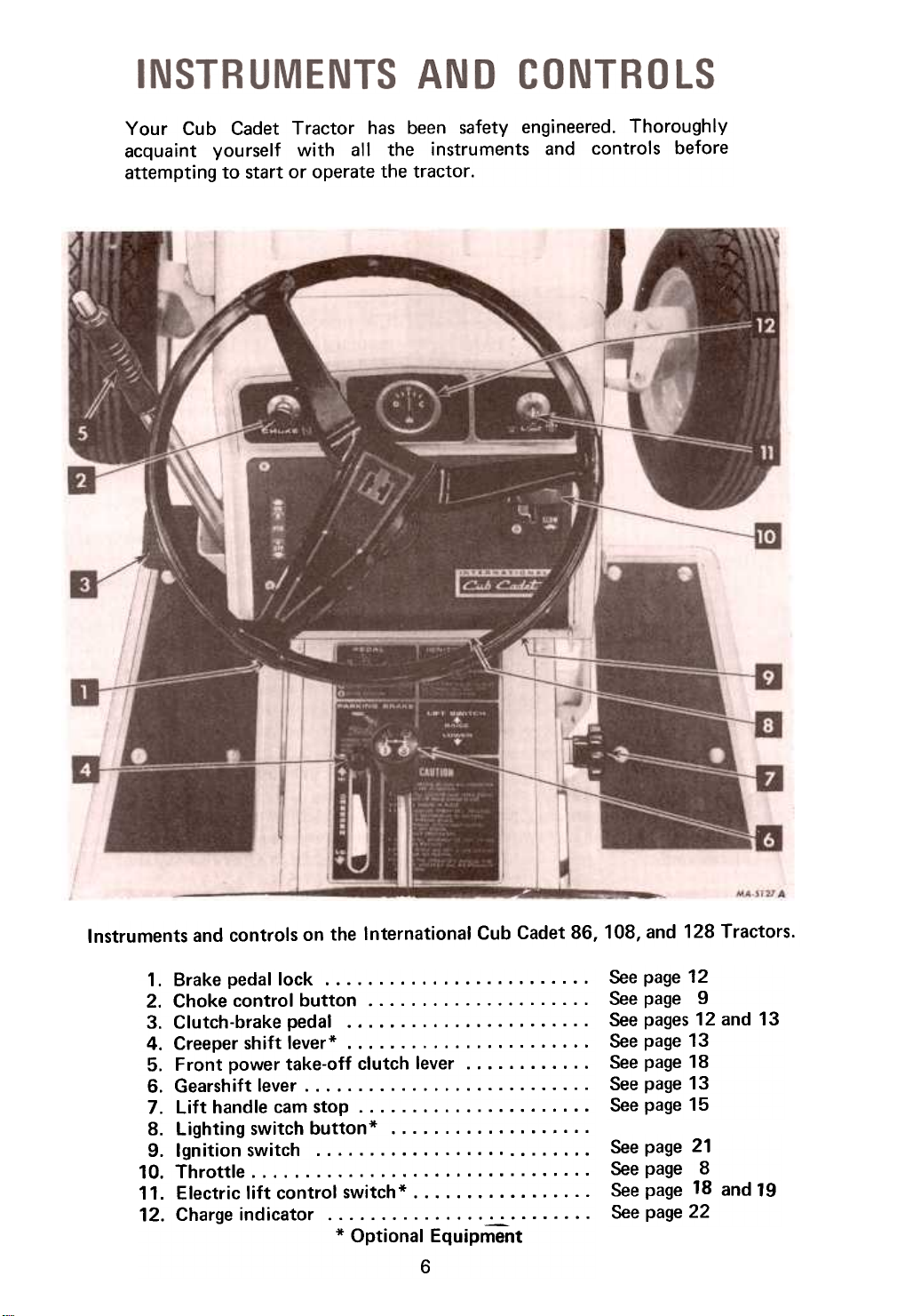

Your Cub Cadet Tractor has been safety engineered. Thoroughly

acquaint yourself with all the instruments and controls before

attempting to start or operate the tractor.

Instruments and controls on the International Cub Cadet 86, 108, and 128 Tractors.

1. Brake pedal lock 2. Choke control button. 3. Clutch-brake pedal 4. Creeper shift lever* 5. Front power take-off clutch lever. 6. Gearshiftlever 7. Lift handle cam stop 8. Lighting switch button* 9. Ignition switch """"""""" 10. Throttle 11. Electricliftcontrolswitch* 12. Charge indicator """""""'-:":'--""""

See page 12

See page 9

See pages 12 and 13

See page 13

See page 18

See page 13

See page 15

See page 21

See page 8

See page 18 and 19

See page 22

* Optional Equipment

6

Page 9

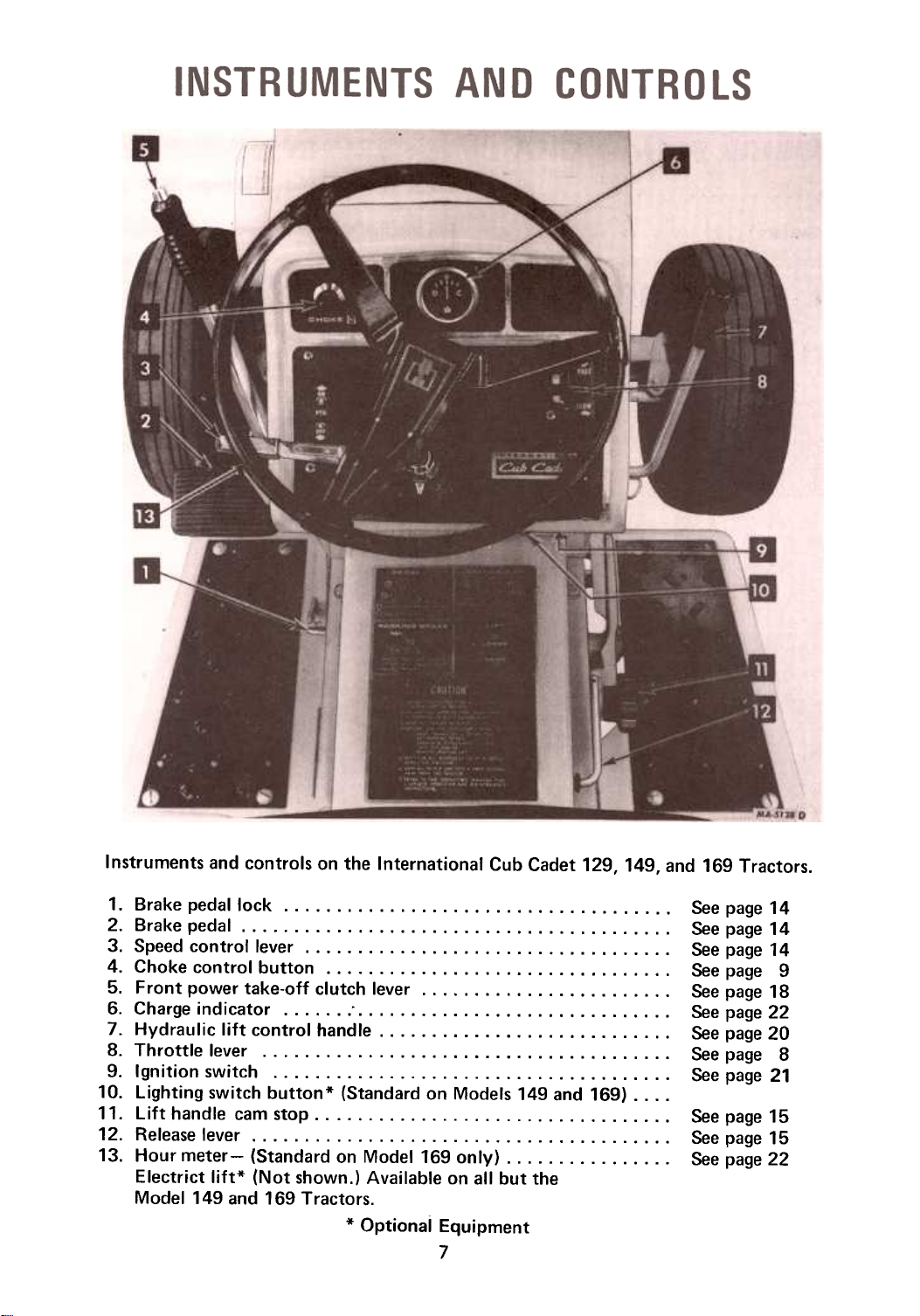

Instruments and controls on the International Cub Cadet 129, 149, and 169 Tractors.

1. Brake pedal lock 2. Brake pedal. 3. Speed control lever 4. Choke control button 5. Front power take-off clutch lever 6. Charge indicator : 7. Hydraulic lift control handle 8. Throttle lever 9. Ignition switch. 10. Lighting switch button* (Standard on Models 149 and 169) 11. Lifthandlecamstop 12. Release lever. 13. Hour meter- (Standard on Model 169 only) Electrict lift* (Not shown.) Available on all but the

Model 149 and 169 Tractors.

* Optional Equipment

7

See page 14

See page 14

See page 14

See page 9

See page 18

See page 22

See page 20

See page 8

See page 21

See page 15

See page 15

See page 22

Page 10

Lubrication

Lubricate the entire tractor. See pages 33 to 41

Tires.

Fuel System. Fill the fuel tank with gasoline. See pages 10 and 11.

Check the air pressure. See pages 24 to 26

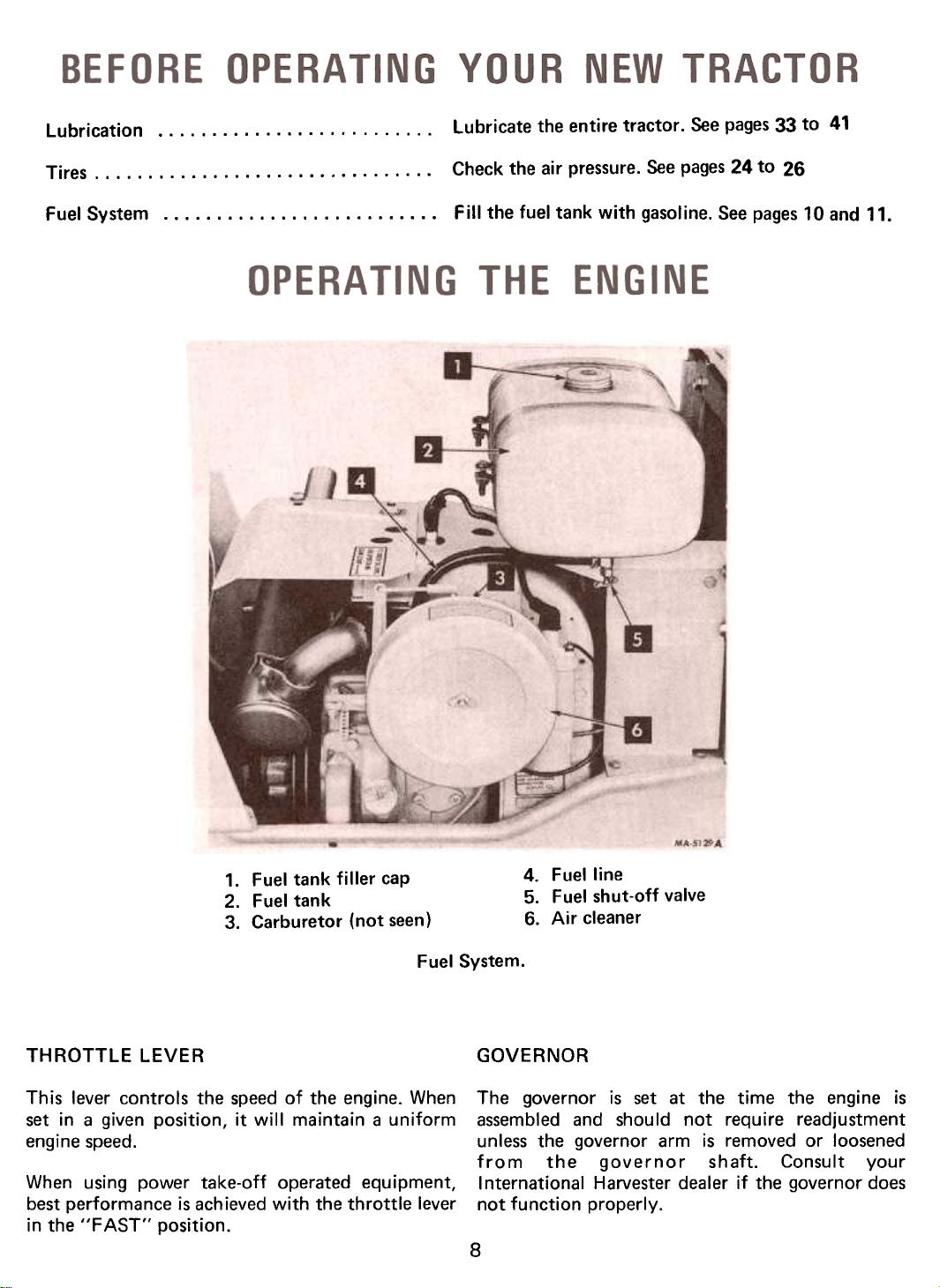

1. Fuel tank filler cap

2. Fuel tank

3. Carburetor (not seen)

THROTTLE LEVER

This lever controls the speed of the engine. When

set in a given position, it will maintain a uniform

engine speed.

When using power take-off operated equipment,

best performance is achieved with the throttle lever

in the "FAST" position.

4.

Fuel line

5. Fuel shut-off valve

6. Air cleaner

Fuel System.

GOVERNOR

The governor is set at the time the engine is

assembled and should not require readjustment

unless the governor arm is removed or loosened

from the governor shaft. Consult your

I nternational Harvester dealer if the governor does

not function properly.

8

Page 11

OPERATING THE ENGINE

LIFTING THE HOOD

The tractor hood is arranged to swing up and

forward to make the engine and fuel tank readily

accessible. To raise the hood take hold of the

spring latches on each side of the pedestal and lift

up and out to release the spring latches from the

hood crossmember.

Pull the choke control button all the way out.

More or less choking may be necessary due to

variations in temperature, grade of fuel, etc. Little

or no choking will be needed when the engine iswarm.

Place the throttle lever half-way between

"SLOW" and "FAST",

Place the throttle lever half-way between

"SLOW" and "FAST".

6. To start the engine the clutch-brake pedal must

be pressed all the way down and the power

take-off clutch handle must be in the disengaged

position to actuate the safety starting switches.

On the I nternational Cub Cadet 129, 149, and 169

Tractors the speed control lever will return to

neutral wher the clutch-brake pedal is pressed all

the way down.

International Cub Cadet 86, 108, and 128 Trac-

tors: Check to see that the gearshift lever is in the

neutral position.

STARTING THE ENGINE

Be sure there is an adequate supply of gasoline

in the fuel tank.

A CAUTION! Never remove the fuel tank

cap or fill the fuel tank when the engine

is running, is hot, or indoors. Also, do

not smoke when working around inflammable fuel.

Be sure the fuel shut-off valve is open.

All Models: Turn the ignition key clockwise to the

"ST ART" position and release it as soon as the

engine starts; however do not operate the motor

generator for more than 30 seconds at anyone

time. If the engine does not start within this time,

turn the key "OFF" and wait a few minutes, then

try again.

5. After the engine starts, slowly release the

clutch-brake pedal and gradually push the choke

control button all the way in. Do not use the

choke to enrich the fuel mixture, except when

necessary to start the engine.

STOPPING THE ENGINE

Move the throttle lever to the "SLOW" position

and allow the engine to idle for a short time before

stopping. Then turn the key to the "OFF"

position.

3.

4.

5.

1.

2.

9

Page 12

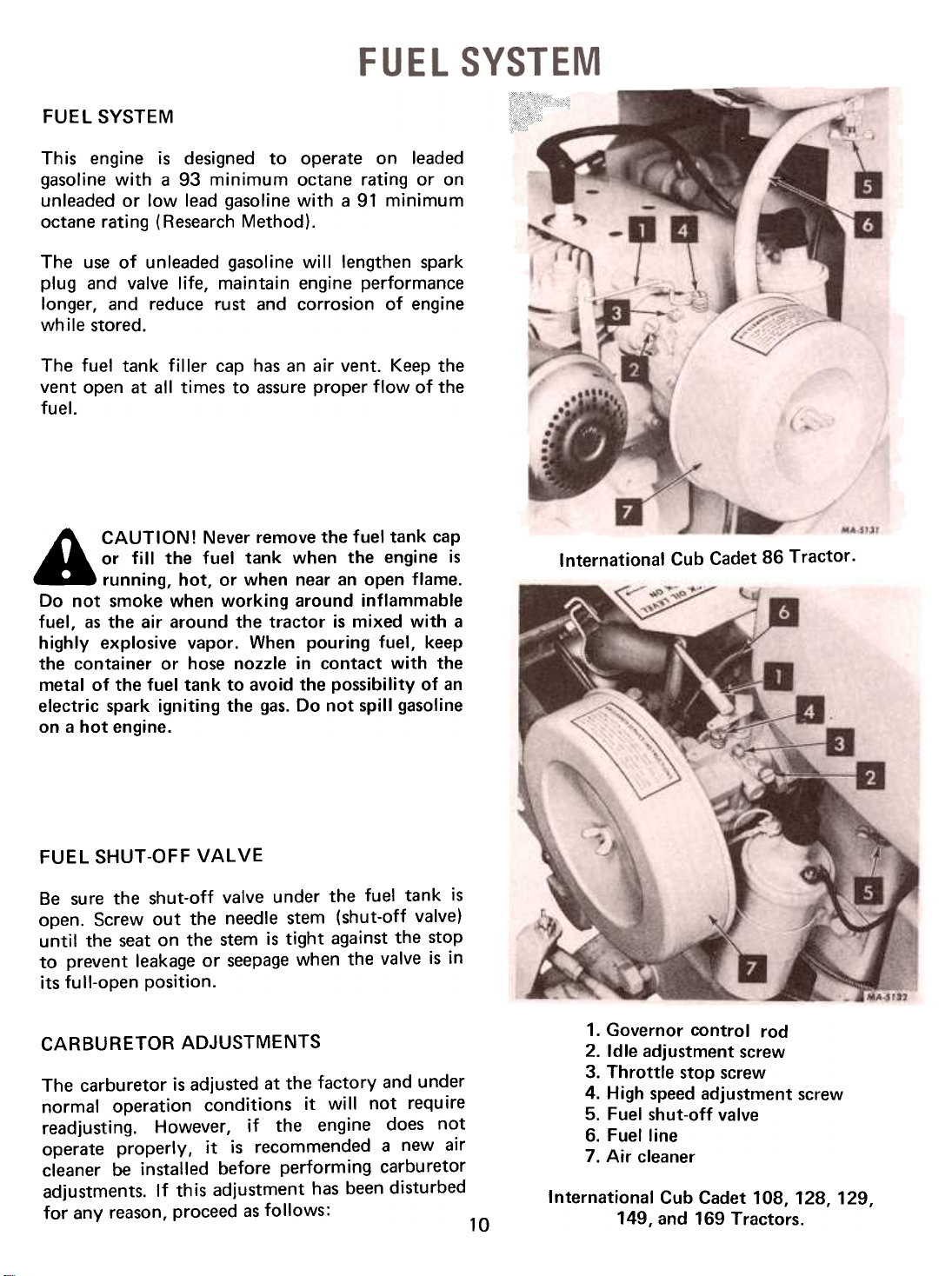

FUEL SYSTEM

This engine is designed to operate on leaded

gasoline with a 93 minimum octane rating or on

unleaded or low lead gasoline with a 91 minimum

octane rating (Research Method).

use of unleaded gasoline will lengthen spark

plug and valve life, maintain engine performance

longer, and reduce rust and corrosion of engine

wh ile stored.

The fuel tank filler cap has an air vent. Keep the

vent open at all times to assure proper flow of thefuel.

A CAUTION! Never remove the fuel tank cap

or fill the fuel tank when the engine is

running, hot, or when near an open flame.

Do not smoke when working around inflammable

fuel, as the air around the tractor is mixed with a

highly explosive vapor. When pouring fuel, keep

the container or hose nozzle in contact with the

metal of the fuel tank to avoid the possibility of an

electric spark igniting the gas. Do not spill gasoline

on a hot engine.

International Cub Cadet 86 Tractor.

FUEL SHUT-OFF VALVE

Be sure the shut-off valve under the fuel tank isopen.

Screw out the needle stem (shut-off valve)

until the seat on the stem is tight against the stop

to prevent leakage or seepage when the valve is in

its full-open position.

CARBURETOR ADJUSTMENTS

The carburetor is adjusted at the factory and under

normal operation conditions it will not require

readjusting. However, if the engine does not

operate properly, it is recommended a new air

cleaner be installed before performing carburetor

adjustments. If this adjustment has been disturbed

for any reason, proceed as follows:

The

~

10

1. Governor control rod2.

Idle adjustment screw3.

Throttle stop screw4.

High speed adjustment screw5.

Fuel shut-off valve6.

Fuel line7.

Air cleaner

International Cub Cadet 108, 128, 129,

149, and 169 Tractors.

Page 13

FUEL SYSTEM

CARBURETOR ADJUSTMENTS -Continued

A CAUTION! Be sure the brake pedal is in

the locked position, transmission is in

neutral, and the mower is disenga~d

before adjusting the carburetor.

Adjusting the High-Speed Adjustment Screw

Turn the high speed adjustment screw counterclockwise approximately two turns from the closed

position and start the engine.

Be sure the choke is fully open when adjusting.

After the engine has reached normal operating

temperature, place the throttle lever in the fast

position and turn the high speed adjustment screw

clockwise to the leanest mixture that will allow

sat i sf actory acceleration and steady governor

operation. Then, turn counterclockwise to the

richest mixture that allows satisfactory operation.

The difference between the rich and lean points is

about 1/2 turn. Set the mixture to the rich end of

this range.

If the engine shows a sooty exhaust and is sluggish

under load, the high speed mixture is too rich. The

high speed adjustment screw must be turned

clockwise 1/4 turn at a time until the condition is

corrected.

Adjusting the Idle Adjustment Screw

After the high speed adjustment screw is adjusted,

it may be necessary to readjust the idle adjustment

screw as each affects the other.

Close the idle adjustment screw to its seat by

turning it clockwise; then open it one turn. Start

the engine and operate it at fast idling speed

(without any load) until thoroughly warm.

While the engine is running at fast idle speed, it is

advisable to screw in the throttle stop screw a few

turns to keep the engine from stopping when the

throttle lever is moved to the fully retarded

"SLOW" position. The engine will then be idling at

a fairly high speed and the throttle stop screw can

be backed out a little at a time until the desired

idle speed is obtained.

If the engine misses and backfires under load, the

high speed mixture is too lean. The high speed

adjustment screw must be turned counter-clock-

wise 1/4 turn at a time until the condition is

corrected.

PREPARING THE TRACTOR FOR EACH DAY'S WORK

Check the crankcase oil level and add new oil if necessary. See pages 34 and 35.

Clean the air cleaner element if necessary. See page 21.

Inspect the tires for general condition. See page 26

If the engine misses or rolls while backing out the

throttle stop screw, the idle adjustment screw may

be adjusted in or out until the engine operates

smoothly. Speed up the engine for a few seconds;

then recheck the idle adjustment. A slight adjust-

ment in or out will give the smoothest idle.

11

Page 14

Retighten the cap screws after the seat is adjusted.

NOTE: The battery is located in a well under the

operator's seat for ease in servicing or replacement

when necessary.

CLUTCH AND BRAKE PEDAL

Adjusting the seat.

Before starting the tractor, adjust the seat to the

most comfortable driving position. Tile the seat

forward over the steering wheel, loosen the four

cap screws in the seat support, and slide the seat

assembly forward or rearward to the position

wh ich is most comfortable for the operator.

Brake pedal lock in the engaged position.

LOCKING THE BRAKE

Always lock the brake when the tractor is parked

on a grade. To lock the brake, press down on the

pedal; then place the brake pedal lock in the

engaged position. To disengage the lock, press

down on the pedal, lift the lock up and place it in

the disengaged position.

12

Page 15

International Cub Cadet 86, 108 and 128 Tractors

CLUTCH-BRAKE PEDAL

The combination clutch-brake pedal is used to

disengage the engine from the transmission when

shifting gears and to actuate the brake to stop the

tractor. The pedal must be pressed all the way

down to activate the safety starting switch when

starting the engine.

To disengage the clutch, and apply the brake, press

the pedal all the way down.

GEARSHIFT LEVER

lever is used to select various gear ratios

provided in the transmission. There are threeforward

speeds and one reverse speed. Refer to

"SPECIFICATIONS" on page 42.

STARTING THE TRACTOR

1, Advance the throttle lever slightly.

free the tractor by speeding up the engine and

suddenly engaging the clutch. Try backing out

instead of going forward.

STOPPING THE TRACTOR

Disengage the clutch by pressing the pedal all the

way down. Move the gearshift lever to the "N"

position. Before dismounting always lock the

pedal, disengage the power take-off, and turn the

ignition "OFF".

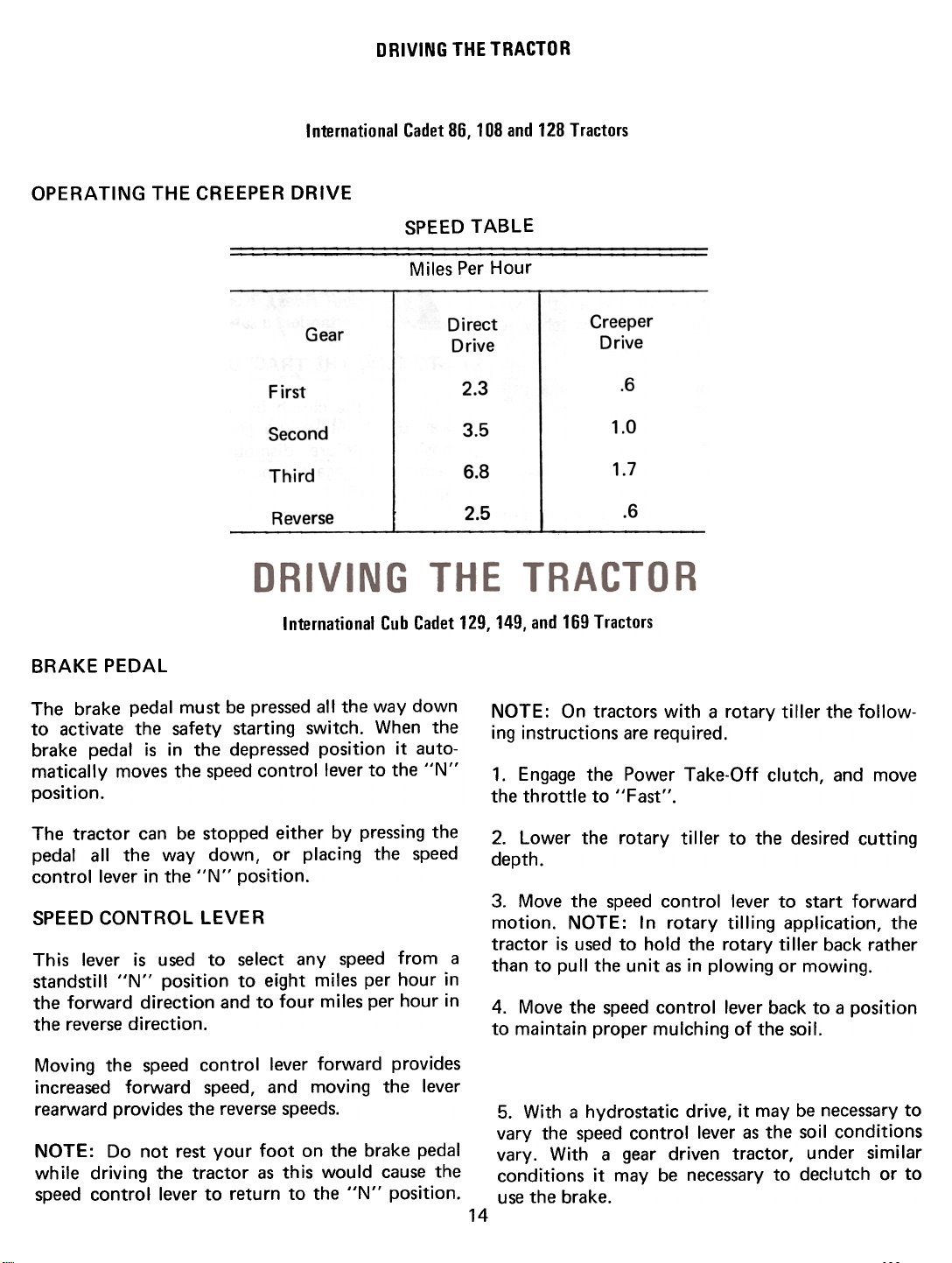

CREEPER SHIFT LEVER

The creeper drive (optional) provides a slower

speed in each respective gear, by a four-to-one

reduction in speed from direct drive. When the

creeper shift lever is all the way forward, it is in

direct drive, or all the way rearward, it is in creeperdrive.

Do not carry passengers or

give rides. Keep children, pets, and

bystanders a safe distance away.

Disengage the clutch by pressing the clutch

pedal all the way down, and release the brake lock.

Move the gearshift lever to the desired speed.

Start the tractor in motion by slowly releasing

the clutch pedal and moving the throttle lever to

the position where the engine operates best for the

load to be handled.

NOTE: When using power take-off operated

equipment, best performance is achieved with the

throttle lever in the "Fast" position.

NOTE: Do not shift gears while the engine clutch

is engaged or while the tractor is in motion.

NOTE: Do not rest your foot on the pedal while

driving the tractor, as this will result in excessive

clutch lining wear.

Always be sure the rear wheels are free to turn.

Under any adverse conditions, do not attempt to

OPERATING THE CREEPER DRIVE

To operate the tractor in creeper drive, depress the

pedal and move the creeper shift lever all the wayrearward.

Then select the transmission speed de-

sired and proceed as instructed under "Starting the

Tractor".

NOTE: Do not use a mid-point position on the

creeper drive as neutral. Neutral position must be

selected only with the standard transmission gear-

shift lever.

The following table shows the speeds available in

each of the three forward gears and the reversegear.

13

CAUTION!

This

2.

3.

Page 16

International Cadet 86, 108 and 128 Tractors

OPERATING THE CREEPER DRIVE

DRIVING THE TRACTDR

SPEED TABLE

Miles Per Hour

Gear

Second

Reverse

International Cub Cadet 129, 149, and 169 Tractors

BRAKE PEDAL

The brake pedal must be pressed all the way down

to activate the safety starting switch. When the

brake pedal is in the depressed position it auto-

matically moves the speed control lever to the "N"

position.

Direct

Drive

2.3

3.5

Creeper

Drive

.6

1.0

6.8

.6

NOTE: On tractors with a rotary tiller the following instructions are required.

1. Engage the Power Take-Off clutch, and move

the throttle to "Fast".

The tractor can be stopped either by pressing the

pedal all the way down, or placing the speed

control lever in the "N" position.

SPEED CONTROL LEVER

This lever is used to select any speed from a

standstill "N" position to eight miles per hour in

the forward direction and to four miles per hour in

the reverse direction.

Moving the speed control lever forward provides

increased forward speed, and moving the lever

rearward provides the reverse speeds.

NOTE: Do not rest your foot on the brake pedal

while driving the tractor as this would cause the

speed control lever to return to the "N" position.

1.7

2.5

2.

3.

4.

Lower the rotary tiller to the desired cutting

depth.

Move the speed control lever to start forward

motion. NOTE: In rotary tilling application, the

tractor is used to hold the rotary tiller back rather

than to pull the unit as in plowing or mowing.

Move the speed control lever back to a position

to maintain proper mulching of the soil.

5. With a hydrostatic drive, it may be necessary to

vary the speed control lever as the soil conditionsvary.

With a gear driven tractor, under similar

conditions it may be necessary to declutch or to

use the brake.

14

Page 17

DRIVING THE TRACTOR

International Cub Cadet 129, 149, and 169 Tractors

STARTING THE TRACTOR

1. Depress the brake pedal and release the brakelock.

Move the throttle lever to the position wherethe

engine operates best for the load to be handled.

2. Start the tractor in motion by moving the speed

control lever slowly forward or rearward as de-

scribed above.

RELEASE LEVER

To push or move the tractor for a short distance,the

release lever must be held in the (up) positionand

the speed control lever must be in the "N"

position.

CAUTION! Never operate engine with re-

lease lever in (up) position. Towing or

pushing the tractor for more than a few

feet may result in transmission damage.

STOPPING THE TRACTOR

Move the speed control lever to the "N" position

or use the brake. Before dismounting always lock

the brake pedal and turn the ignition "OF F", Also,

disengage the power take-off clutch lever.

Do not carry passengers or

give rides. Keep children, pets, and

bystanders a safe distance away.

The lift handle is used to lift or lower equipment

used with the tractor. The equipment can be set in

multiple positions by depressing the button on the

top of the handle and releasing it when the desired

position is reached.

HEIGHT ADJUSTMENT

If a single implement height is normally used, the

handle may be adjusted to locate the desired position by use of the cam stop.

With lift handle in desired implement height posi-

tion, release cam by turning locking knob counter-clockwise.

Turn cam until it contacts tang. Lock

cam into this position by turning knob clockwise.

15

CAUTION!

If free handle travel between cam stop and fully

raised position is desired (Float Position), depress

the release button on top of the handle, press in

the lock button located at the front of the handle

and release the top button.

NOTE: To disengage the lift handle from the float

position, pull lift handle back slightly and depress

top button.

NOTE: Refer to the equipment manual for proper

hitching instructions.

Page 18

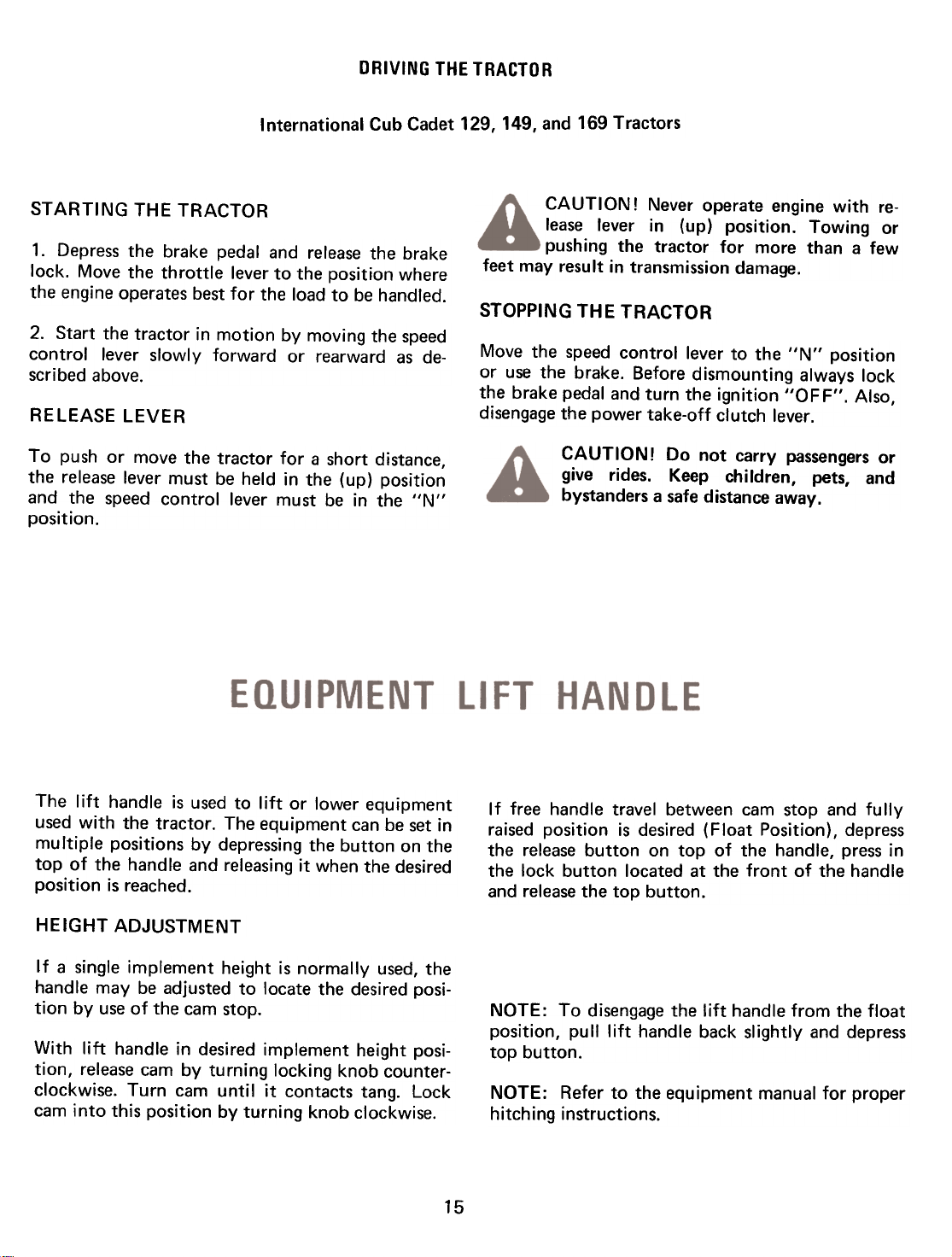

1. Lift lever

2. Draw bar

3. Three-point hitch

Orawbar and three-point hitch shown

on International Cub Cadet 86 Tractor.

DRAWBAR

Orawbar equipment must be hitched to the tractor

only at the hitch hole in the drawbar.

1. Release button2.

Lock button3.

Lift handle

4. Cam lock knob

5. Cam stop

6. Tang

THREE-POINT HITCH

When the tractor has a three-point hitch, equip-

ment adaptable to this hitch is raised and lowered

with the lift handle or power lift control. The lift

handle can be set to hold the equipment at various

positions by use of the notches in the lift handle

quadrant or cam stop. The lower mounting bracket

has three holes which are used for additional

adjustment.

Adjustable stop limiting handle travel.

A CAUTION! Disengage power to any

attachment when transporting or not in

use.

NOTE: Refer to the equipment manual for proper

hitching instructions.

16

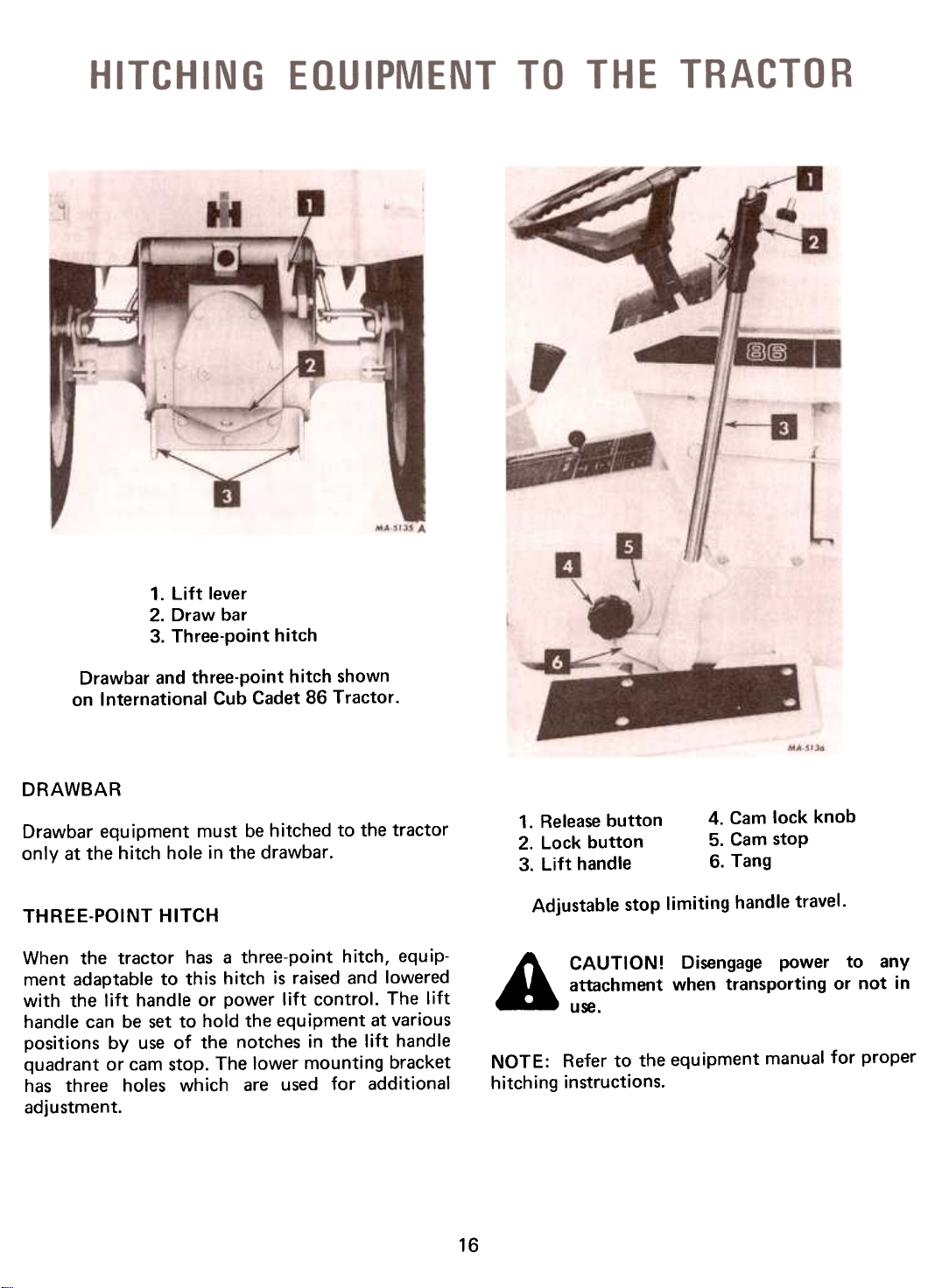

Page 19

International Cub Cadet 86, 108 and 128 Tractors

OPERATING THE REAR POWER TAKE-OFF

WITH THE TRACTOR STANDING STILL

1. Shifter lever

1. Power take-off guard

2. Grease fitting

If your tractor is equipped with a rear power

take-off, the following instructions should be

carefully studied and followed.

The rear power take-off is started and stopped by

the same engine clutch as the tractor. Be sure to

disengage the engine clutch before moving the

power take-off shifter lever.

A CAUTION! The shifter lever should always

be in the disengaged (rearward) position

when the power take-off is not in use.

Always cover the power take-off exposed shaft

with the guard when the power take-off is not

being used.

1. Move the throttle lever back to the "SLOW"

speed.

2. Depress the pedal and move the transmission

gearshift lever to the neutral position.

Move the shifter lever forward to the engaged

position.

4. Move the throttle lever forward to the "FAST"

position and slowly release the pedal.

OPERATING THE REAR POWER TAKE-OFF

WITH TRACTOR IN MOTION

Follow steps 1 thru 3 outlined above. Keep the

pedal depressed, move the transmission gearshift

lever to the speed desired and advance the throttle

lever. Slowly release the clutch pedal. This will

start the tractor in motion with the power take-off

in operation.

3.

17

Page 20

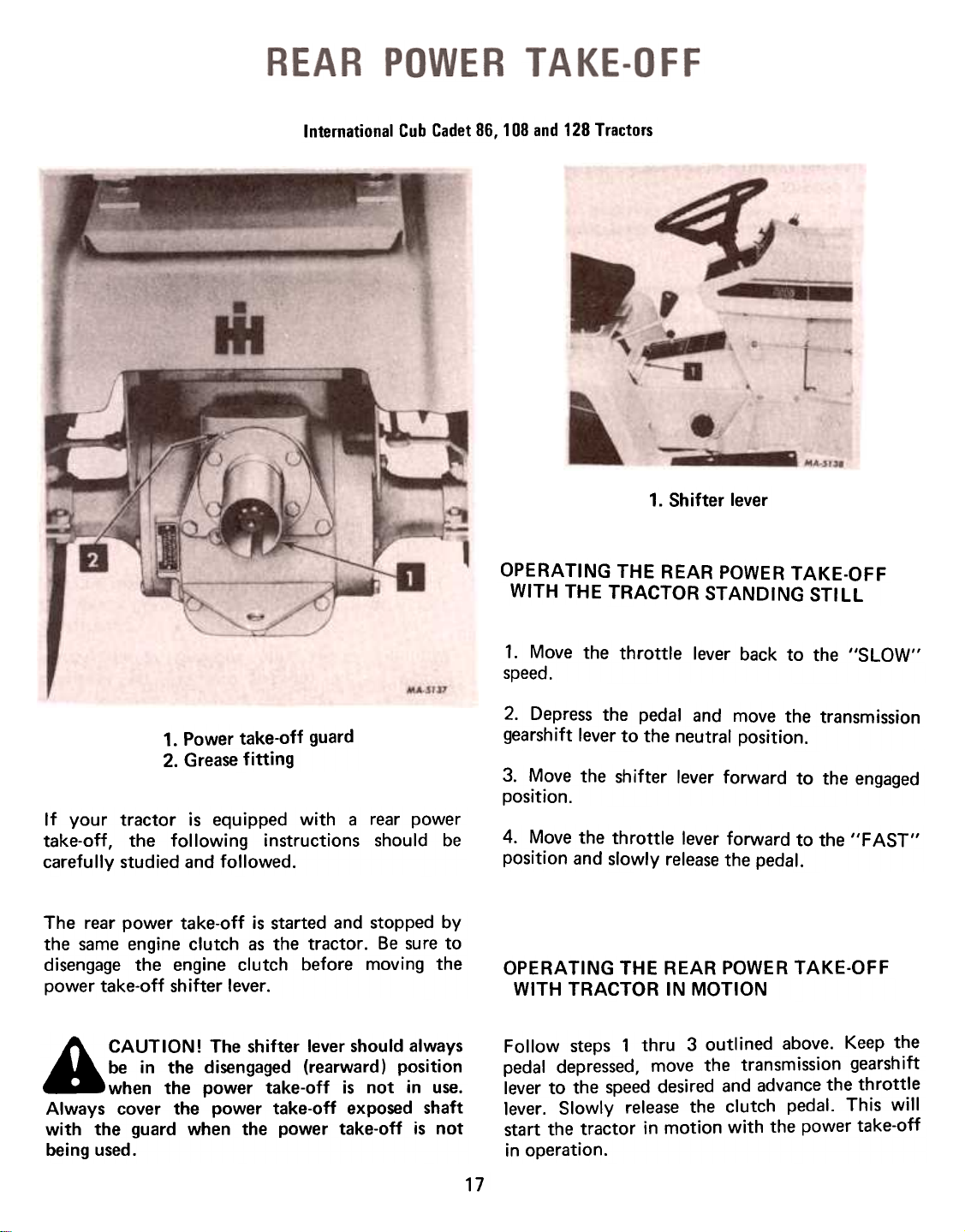

OPERATING THE FRONT POWER TAKE-OFF

CLUTCH

t. Move the throttle lever back to the medium or

"slow" position.

2. Move the control lever forward slowly to the

engaged position.

Advance throttle to operating speed.

ADJUSTING THE POWER TAKE-OFF CLUTCH

1. Clutch lever bracket

2. Quick attachable cotter pin

3. Clutch lever rod

4. Clutch control handle

5. Turnbuckle

The clutch is factory adjusted and should not

require further adjustment under normal operating

conditions. However, if clutch slips or fails to

disengage, see your International Harvester dealer.

After considerable use, it may be necessary to

readjust the clutch to secure proper clutch engagement.

A CAU!'ON! Do not adjust with engine

running.

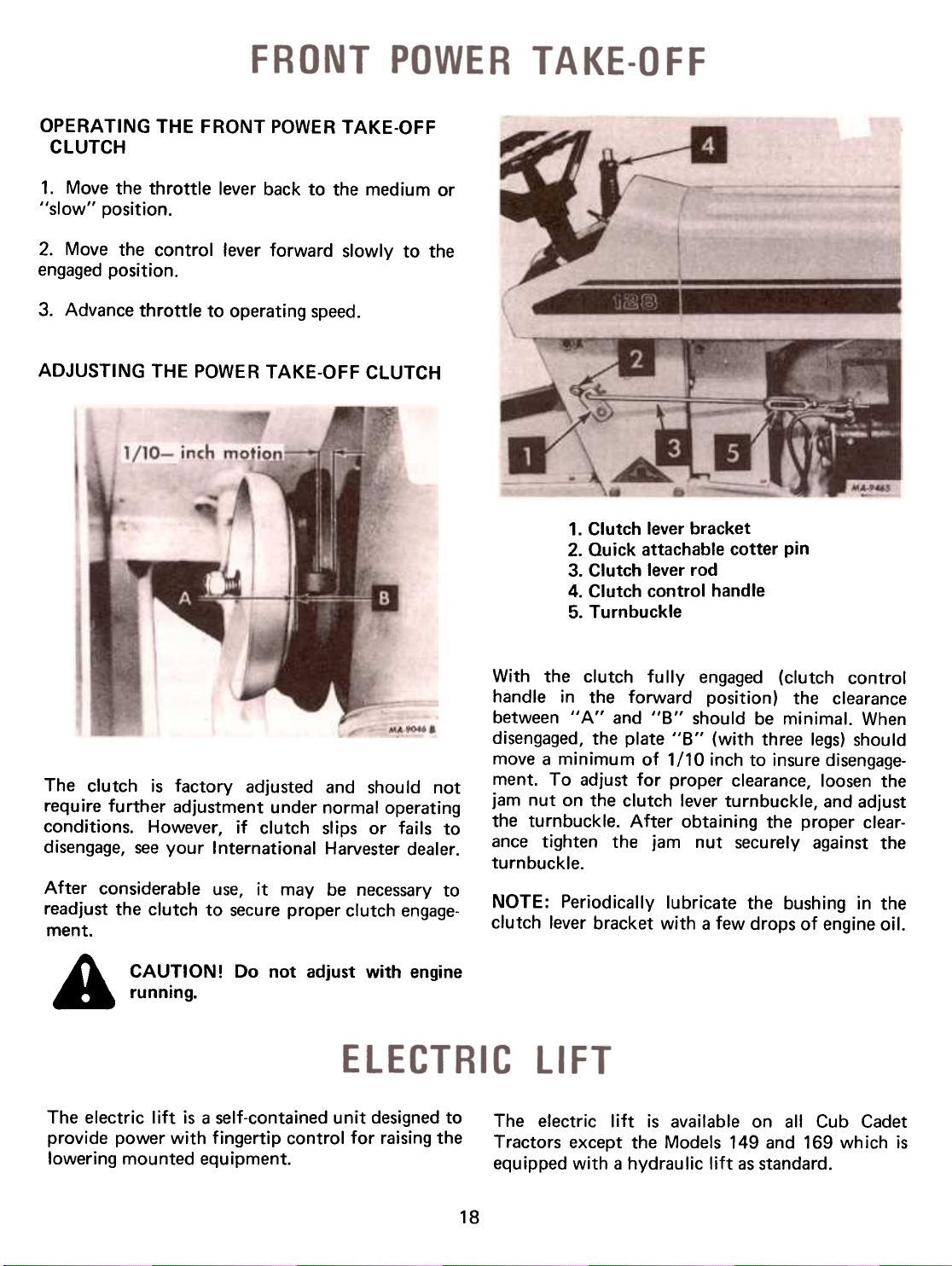

The electric lift is a self-contained unit designed to

provide power with fingertip control for raising the

lowering mounted equipment.

With the clutch fully engaged (clutch control

handle in the forward position) the clearance

between "A" and "B" should be minimal. When

disengaged, the plate "B" (with three legs) should

move a minimum of 1/10 inch to insure disengagement. To adjust for proper clearance, loosen the

jam nut on the clutch lever turnbuckle, and adjust

the turnbuckle. After obtaining the proper clearance tighten the jam nut securely against the

turnbuckle.

NOTE: Periodically lubricate the bushing in the

clutch lever bracket with a few drops of engine oil.

The electric lift is available on all Cub Cadet

Tractors except the Models 149 and 169 wh ich is

equipped with a hydraulic lift as standard.

3.

18

Page 21

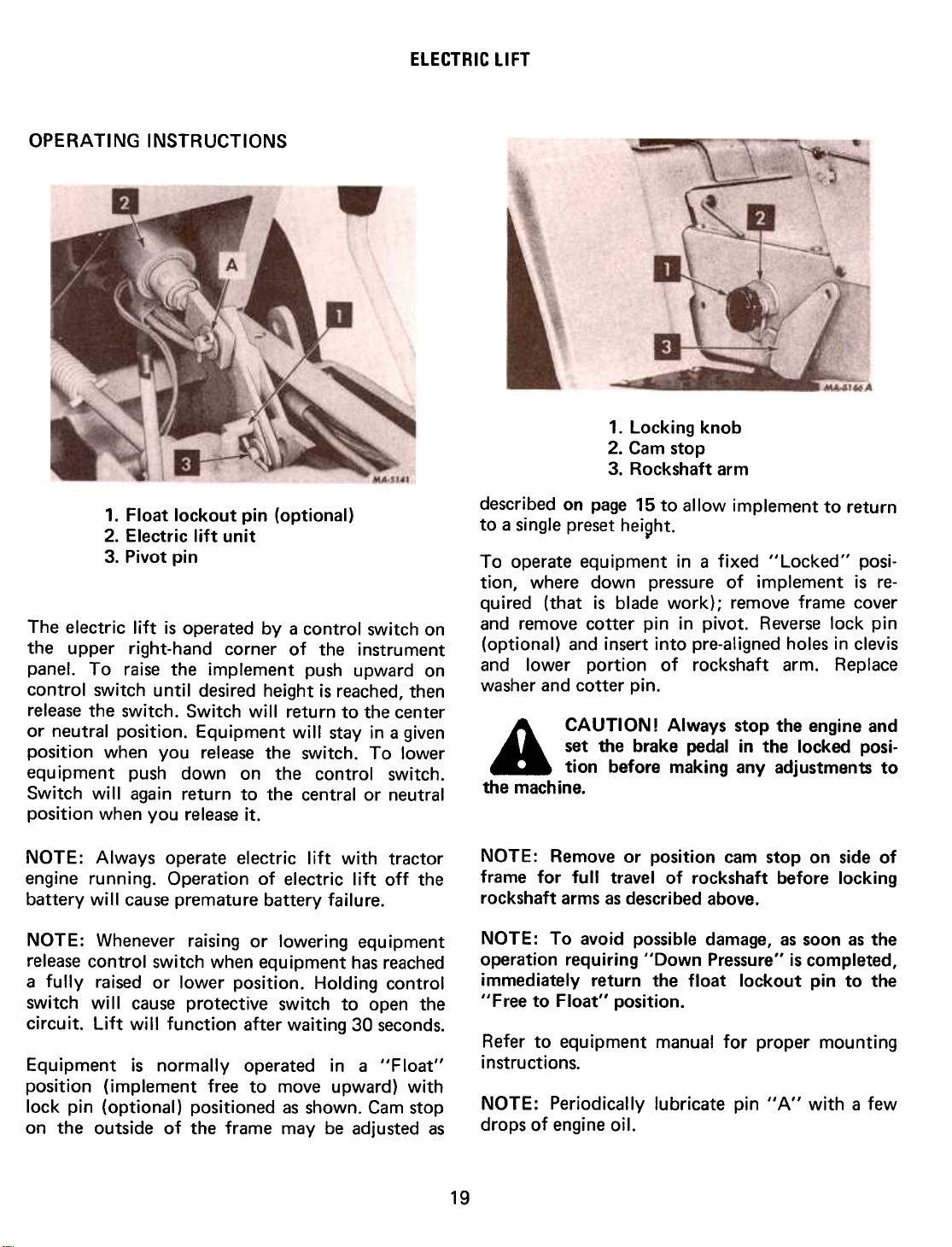

OPERATING INSTRUCTIONS

ELECTRIC LIFT

1. Locking knob2.

Cam stop3.

Rockshaft arm

1. Float lockout pin (optional)2.

Electric lift unit

3. Pivot pin

The electric lift is operated by a control switch on

the upper right-hand corner of the instrument

panel. To raise the implement push upward on

control switch until desired height is reached, then

release the switch. Switch will return to the center

or neutral position. Equipment will stay in a given

position when you release the switch. To lower

equipment push down on the control switch.

Switch will again return to the central or neutral

position when you release it.

NOTE: Always operate electric lift with tractor

engine running. Operation of electric lift off the

battery will cause premature battery failure.

NOTE: Whenever raising or lowering equipment

release control switch when equipment has reached

a fully raised or lower position. Holding control

switch will cause protective switch to open the

circuit. Lift will function after waiting 30 seconds.

Equipment is normally operated in a "Float"

position (implement free to move upward) with

lock pin (optional) positioned as shown. Cam stop

on the outside of the frame may be adjusted as

described on page 15 to allow implement to return

to a single preset hei~ht.

To operate equipment in a fixed "locked" position, where down pressure of implement is re-

quired (that is blade work); remove frame cover

and remove cotter pin in pivot. Reverse lock pin

(optional) and insert into pre-aligned holes in clevis

and lower portion of rockshaft arm. Replace

washer and cotter pin.

A CAUTION! Always stop the engine and

set the brake pedal in the locked posi-

tion before making any adjustments to

the machine.

NOTE: Remove or position cam stop on side of

frame for full travel of rockshaft before locking

rockshaft arms as described above.

NOTE: To avoid possible damage, as soon as the

operation requiring "Down Pressure" is completed,

immediately return the float lockout pin to the

"Free to Float" position.

Refer to equipment manual for proper mounting

instructions.

NOTE: Periodically lubricate pin "A" with a few

drops of engine oil.

19

Page 22

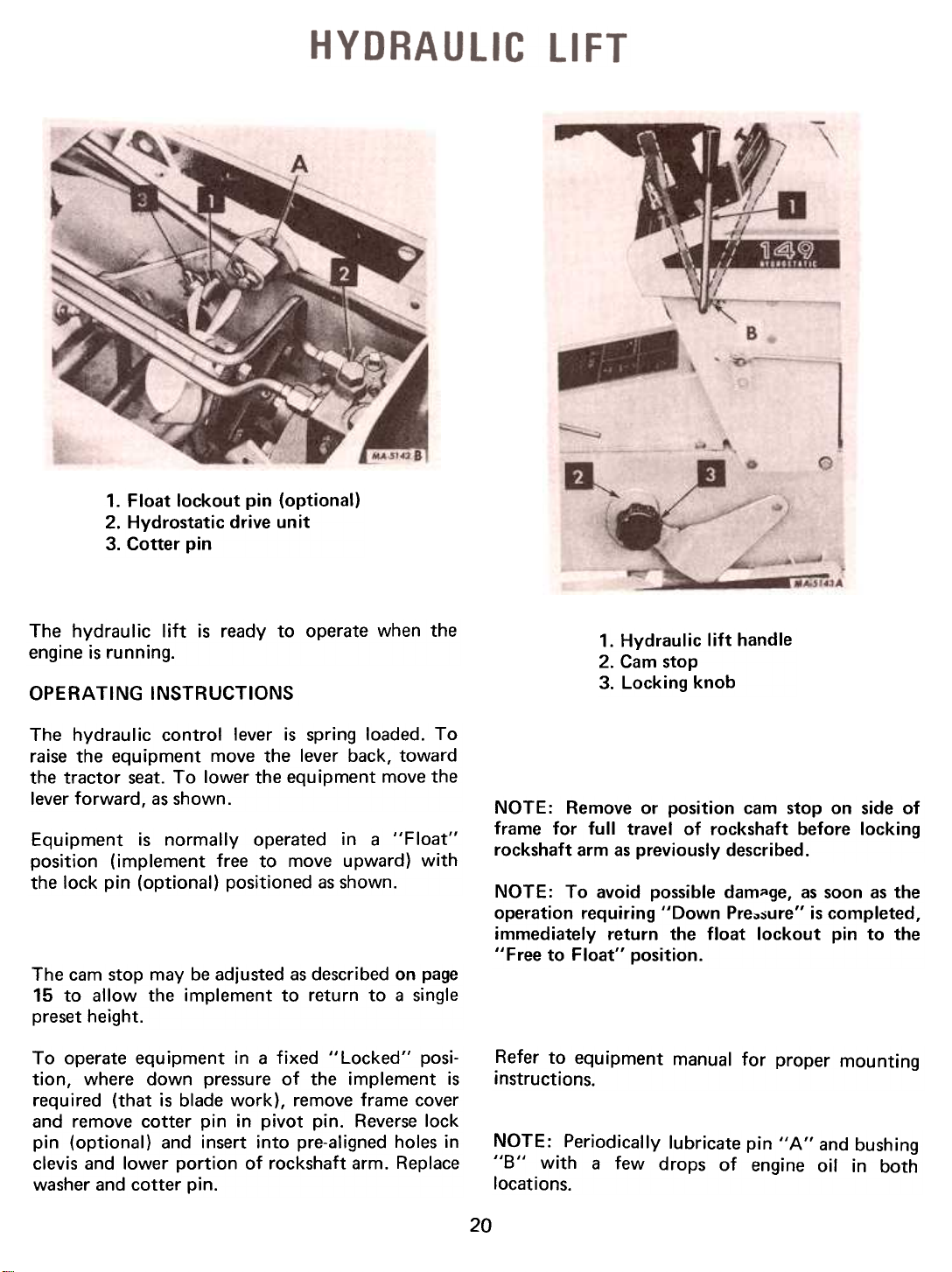

1. Float lockout pin (optional)2.

Hydrostatic drive unit3.

Cotter pin

The hydraulic lift is ready to operate when the

engine is running.

OPERATING INSTRUCTIONS

The hydraulic control lever is spring loaded. To

raise the equipment move the lever back, toward

the tractor seat. To lower the equipment move the

lever forward, as shown.

Equipment is normally operated in a "Float"

position (implement free to move upward) with

the lock pin (optional) positioned as shown.

The cam stop may be adjusted as described on page

15 to allow the implement to return to a single

preset height.

To operate equipment in a fixed "locked" posi-

tion, where down pressure of the implement is

required (that is blade work), remove frame cover

and remove cotter pin in pivot pin. Reverse lock

pin (optional) and insert into pre-aligned holes in

clevis and lower portion of rockshaft arm. Replace

washer and cotter pin.

1. Hydraulic lift handle2.

Cam stop3.

Locking knob

NOTE: Remove or position cam stop on side of

frame for full travel of rockshaft before locking

rockshaft arm as previously described.

NOTE: To avoid possible dam~ge, as soon as the

operation requiring "Down Pre,,~ure" is completed,

immediately return the float lockout pin to the

"Free to Float" position.

Refer to equipment manual for proper mounting

instructions.

NOTE: Periodically lubricate pin "A" and bushing

"B" with a few drops of engine oil in both

locations.

20

Page 23

ENGINE COOLING

This tractor has an air cooled engine. Air must be

able to circulate freely around the engine, through

the screen, shroud, and over the fins of the

cylinder head and cylinder block. Keep these areas

free of accumulated dirt and trash or engine will

overheat and result in damaged moving parts.

Periodic cleaning with compressed air will keep

area clear for adequate cooling.

DRY TYPE AIR CLEANER

Removing the air cleaner filter element.

Incoming air for combustion is filtered by a

dry-type air cleaner having a filter element inside

of the cover.

Clean or replace the element when loss of power is

noticeable. Replace at least once a year.

Cleaning the Element -To clean the element,

remove wing nut, air cleaner cover, then remove

element and tap it lightly on a flat surface to cause

loose dirt to falloff. Handle paper element with

care to avoid dents or crushing local areas. Do not

use compressed air to remove dirt as this can

repture the element. Do not wash or use a solvent.

Replacing the Element -Replace element with a

new one if dirt does not drop off easily, or if it is

bent or damaged. When replacing element be sure

the back plate is securely tightened to the carburetor. Replace the back plate if bent or cracked,

then be sure the element fits snugly around the

inside edge of the air cleaner base. The gasket

surfaces of the element must be flat against the

back plate and cover to seal effectively. Replace

cover and tighten wing nut finger tight.

The twelve-volt electrical system consists princi-

pally of a motor-generator, voltage regulator, and a

twelve-volt battery.

All connections must be clean and securely

fastened.

IGNITION SWITCH

Turn the key clockwise to turn on the ignition. A

further turn actuates the motor-generator. The key

cannot be removed when in the "ON" position.

21

NOTE: When the engine is not operating, the key

must be turned to the "OFF" position to prevent

battery discharge.

SAFETY STARTING SWITCH

The safety starting switches activated by the

clutch-brake pedal and the power take-off clutch

lever serve to prevent starting the engine acci-

dentally.

Page 24

ELECTRICAL SYSTEM

CHARGE INDICATOR

This instrument indicates whether the motor-

generator is charging or the battery is discharging.

If it shows discharge continuously, investigate the

cause to avoid completely discharging the battery

and possible damage to the motor-generator.

HOUR METER

The International Cub Cadet 169 is equipped with

an hour meter, which is located on the left side of

the tractor parallel to the air cleaner. It indicates

the actual hours of engine operation, enabling the

operator to determine without guesswork, when

lubrication, change of oil, or periodic inspections

are necessary. It also provides a means of computing cost of specific jobs. The hour meter

operates whenever the engine is running.

SPARK PLUG

Be sure the gasket is in good condition. Tighten the

plug 1/2 to 3/4 turns past tiger tight.

Replace a defective plug with a new plug. See your

I nternational Harvester dealer for the correct

replacement plug.

MOTOR GENERATOR

The motor-generator (12-volt negative ground) will

function as a cranking motor when the ignition key

is turned to the "START" position, driving the

engine by means of a belt.

When the engine is operating, the unit will function

as a generator.

MOTOR-GENERATOR BELT

Check the tension of the motor-generator belt after

the first 10 hours of operation and every 50 hours

of operation thereafter. The tension is correct

when the belt can be deflected a maximum of

1/4-inch by a ten pound force applied midway

between the two pulleys.

Checking the spark plug gap.

Set gap at .O25-inch.

NOTE: Remove all dirt from around the spark plug

before removing.

Remove the spark plug, always using a spark plug

wrench, after every 100 hours of operation to

check the gap.

A CAUTION! Be sure engine is off and

cool. before making any adjustments or

repairs. 22

A CAUTION! Check the belt with engine

off.

Also follow this procedure when a new belt is

installed.

Page 25

ELECTRICAL SYSTEM

MOTOR-GENERATOR BELT -Continued

Adjusting the Motor-Generator Belt

Loosen the motor-generator brace bolt and mount-

ing bolts.

Move the generator away from the engine until the

tension on the belt is correct.

NOTE: Under no circumstances should a pry bar

be used on the motor-generator to obtain belt

tension as damage to the bearings will result.

Tighten mounting bolts and brace bolt.

Removing and Replacing the Motor-Generator Belt

VOLTAGE REGULATOR

A satisfactory generator charging rate is maintained

by the voltage regulator. If the regulator fails to

operate correctly, see your I nternational Harvesterdealer.

NOTE: Never place a jumper lead between, or

accidentally bridge, the "BAT" terminal and the

"F" terminal on the regulator, as this will damage

the regu lator.

LIGHTS

Lights are optional on all models except the

Models 149 and 169.

The headlights are sealed-beam units. Refer to

"SPECIFICATIONS" when replacement is neces-

sary.

To replace the taillight lamp, remove the lens from

the taillight and r~place. Refer to "SPECIFICA-TIONS",

1. Mounting bolts2.

Motor generator brace bolt3.

Motor generator belt

Replace the motor-generator belt when it becomes

badly worn. To remove the old belt, loosen the

motor-generator brace bolt and mounting bolts.

Move the generator in toward the engine and slip

the old belt off the pulleys and over the crankshaft. I nstall the new belt in the reverse order of

removal and adjust the belt to the proper tension.

NOTE: If tractor is equil

drive belt must also be

generator belt.

with rotary mower I

removed when replacing

FUSE (Electric Lighting)

Always use the same capacity fuse for replacement.

Refer to "Specifications". If the lights fail, check

the fuse.

The fuse is located in a fuse housing in the line at

the back of the instrument panel.

To install a new fuse, press in on the fuse housing

cap and turn counterclockwise to remove it from

the fuse housing. Remove the old fuse and replace

it with a new one. Then reassemble the cap to the

housing. Remove the fuel tank if necessary to

reach the fuse.

Before working on any part of the electrical

system, disconnect the battery ground cable at the

battery negative (-) terminal. Do not reconnect

this cable until all work has been completed. This

will prevent shorting and damage to any of the

electrical units. Examine the electrical cables occa-

sionally to be sure they are not being frayed by

contact with adjacent parts.

pped

23

Page 26

ELECTRICAL SYSTEM

When replacing a battery, make certain the ground

cable is connected to the negative (-) terminal on

the battery. Be sure the rubber boot is properly

positioned over the positive (+) terminal on the

battery. NOTE: Both cables must be assembled

with the nuts to the inside of the terminals to

prevent shorting against fender well.

Cleaning and Servicing the Battery

Occasionally remove the battery cables and

brighten the terminal contact surfaces with wire

wool, and reassemble them. Apply a light coat of

vaseline or chassis lubricant. Be sure the terminals

are clamped tightly and that the battery is fastened

securely in the battery box. Replace unserviceable

cable. Keep the vent holes in the battery filler caps

open.

Keeping the battery fully charged not only adds to

its life but makes it available for instant use when

needed.

CAUTION! If the rider is to be tipped

up or on its side remove the batteries to

avoid spilling the electrolyte. Battery

electrolyte is poisonous and can be injurious to

eyes, skin, and clothing. If electrolyte is spilled,

flush immediately with a solution of one part

baking soda to four parts water.

Connecting Booster Batteries

When required, a booster 12-volt battery may be

connected in parallel with the 12-volt system on

International Cub Cadet Tractors.

CAUTION I Gas discharged by batteries isexplosive.

Avoid sparks near the batteries.

NOTE: All circuits must be turned "off". Electri-

cal system is NEGATIVE (-) grounded only.

Reversed polarity will result in permanent damage

to components of the electrical system.

Liquid Level

Check the battery at least once a month for water

level.

The electrolyte (acid and water) in each cell should

be at ring level at all times to prevent battery

failure. When the electrolyte is below this level,

add pure, distilled water.

Acid or electrolyte should never be added except

by a skilled battery man. Under no circumstances

add any special battery "dopes", solutions or

powders.

REAR TIRES

6-12 rear tires are standard equipment on the

International Cub Cadet 86 and 108 Tractors.

23 x 8.50-12 high floatation tires are standard

equ ipment on the I nternational Cub Cadet 128,

129, and 149 Tractors. They are also available as

optional equipment when ordered for the

International Cub Cadet 86 and 108 Tractors.

The first jumper cable must connect the positive

(+) terminal of the booster battery and the positive

terminal of the battery on the tractor.

The second jumper cable must first be connected

to the negative (-) terminal of the booster battery;

and then to a point on the frame of the tractor,

away from the battery, having a good ground, so

no spark occurs near the battery.

For dependable battery service,

I nternational Harvester dealer.

23 x 10.5-12 tires are standard on the International

Cub Cadet 169 Tractor.

The high floatation tires provide maximum mobil-

ity in sand, snow, and soft soil conditions. The

reduced ground pressure and low inflation provides

maximum protection for turf, soil and crops.

see

your

24

Page 27

PNEUMATIC TIRES

CARE OF TIRES

Avoid stumps, stones, deep ruts, curbs, and other

hazards. Cuts in tires should be repaired immediately as neglect decreases the tire life.

Keep tires free from oil and grease as both destroyrubber.

After using the tractor for spraying use water to

remove any chemicals that may be on the tires.

INFLATION

Keep the pneumatic tires properly inflated. Overinflation will cause operator discomfort. Underinflation will cause short tire life.

Always see that the tire valve caps are in place and

tightened securely to prevent loss of air and

protect the valve core and stem.

MOUNTING TIRES ON THE RIM

After mounting a new or old tire on the rim,

inflate it to 20 pounds pressure to seat the tire

bead on the rim flange. Then deflate the tire to the

correct operating pressure.

REAR WHEEL WEIGHTS

Rear wheel weights increase traction and reduce

w:'eel slippage. The weights weight approximately

26 pounds each.,They are attached to each rear

wheel with two bolts, lock washers, and hex. nuts.

If additional weight is desired, a second set of

weights can be attached to each first weight by

using two longer bolts.

OPERATING PRESSURE FOR TIRES

I nflate the front and rear tires for normal or heavyload

operations as shown in the following table.

Normal Heavy

Size

Front Tires4.80/4.00-8

Load Load

Pounds per square inch

12 12

16 x 6.50-8

Rear Tires 6-12

23 x 8.50-12

23 x 10.50-12

12 12

12 12

12 12

12 12

25

TIRE CHAINS

Tire chains will provide additional traction for wet

ground conditions, when plowing snow, or pulling

heavy loads. Rear wheel weights are recommended

when using chains.

OVERLOADING

Do not overload the tractor tires by mounting

equipment on the tractor which exceed the load

capacity of the size of the tires on the tractor.

Tire

Page 28

FRONT QUICK ATTACHING LATCH

This latch is used for front and center mounted

equipment. Refer to the equipment manual for

proper instructions.

FRONT WHEEL TOE-IN

Tie rod and drag link ball joints.

1. Front quick attaching latch

Front wheel adjustments.

1. Wheel hub

Front wheel adjustments.

The front wheel toe-in dimension is approximately

1/8-inch closer in front than in the rear. To

measure for proper toe-in, make a chalk mark on

the centerline of each tire the same height from the

ground as the front wheel hubs. Measure the

distance between the marks "A", then rotate the

tires so that the marks are toward the rear of the

tractor, the same height from the ground as they

were in front. The dimension should be approxi-

mately 1 18-inch larger at the rear. See "B."

To adjust the toe-in remove one ball joint, loosen

the lock nut "c" at the ball joint and turn the tie

rod ball joint in or out as required.

TURNING RADIUS

The front wheel should have an equal angle for left

and right turns. If adjustment is necessary, remove

ball joint and loosen lock nut "0", turn the drag

link ball joint clockwise or counterclockwise as

required.

A CAUTION! Be sure all parts are re-

assembled tight with cotter pins in place

and spread.

26

Page 29

International Cub Cadet 86, 108 and 128 Tractors

ADJUSTING THE CLUTCH

It is impoftant that a clearance of .O50-inch be

maintained between the clutch release lever and

the clutch release bearing. In order to maintain this

clearance, the pedal should have a free movement

of approximately 9/32-inch. This measurement is

taken at the point of contact of the pedal arm with

the front edge of the pedal return stop.

The clutch pedal adjustments are set at the factory

and should not require frequent attention unless

the linkage has been disturbed or when the pedal

movement becomes less than 9/32-inch. When it is

necessary to adjust the clutch, turn the adjusting

nut (No.3 on page 29) on the clutch release rod in

or out as required to get the proper measurements.

THE BRAKES

Adjust to 100 ft. Ibs. per wheel as shown in illus-

tration. If necessary tools are not available, adjust

as follows:

The disc brakes should start to engage when the

pedal is pressed down to a position where the

engine clutch starts to release.

Push the pedal down until the clutch just begins to

release. This can be checked by shifting the

transmission into third gear and rocking the tractor

back and forth. If the drive shaft turns free and

does not turn the engine, the clutch is disengaged.

Locate the pedal at this point with a "c" clamp

and adjust the jam nuts on both brake rods until

the brakes just begin to clamp the brake discs and

create some drag. Make sure the brakes completely

release when the pedal is up against the stop, and

then tighten the jam nuts.

The tractor transmission should shift easily when

the tractor is stopped and the clutch-brake pedal is

depressed.

NOTE: To check the equal ization of the brakes,

drive the tractor in third gear on a concrete or

blacktop surface. When making a sudden stop,

both wheels should start to slide simultaneously. If

one wheel stops before the other, make the proper

adjustment to obtain uniform braking of both

wheels.

ADJUSTING

27

Page 30

CLUTCH-BRAKE

ADJUSTING THE BRAKES -Continued

To adjust the brakes block the front wheels securely and raise the tractor so the rear wheels are

off the ground.

A CAUTION! Be careful and take neces-

sary precautions when raising tractor off

the ground.

With the rear wheels off the ground and the brake

pedal in the locked position, the brake settings

should be equalized as follows:

Disconnect the left brake rod at the pinned end,

rotate the right wheel by hand and adjust the jam

nuts on the brake rod until wheel brakes firmly.

Then, disconnect the right brake rod at the pinned

end and reconnect the left brake rod. Turn the left

wheel by hand and adjust the jam nuts until the

wheel brakes firmly. Reconnect the right rod.

NOTE: To check the equalization of the brakes

start the engine and shift the gears to third speed.

After the wheels are turning apply the brakes. Both

wheels should stop at the same time. If one wheel

stops and the other wheel continues to revolve

when the brakes are applied, stop the engine,

adjust the jam nuts on the brake rod of the wheel

that does not stop, enough so that both wheels

stop simultaneously.

1. Clutch release lever

2. Clutch release rod3.

Adjusting nut4.

Brake rods

5. Safety starting switch

28

Page 31

Speed control handle

centering zone when

brake pedal is used

"N" position.

Transmission is in

neutral

Braking zone.

Brake must be

engaging ~

With pedal lock in position as

shown brakes must withstand a

torque of 100 ft.lbs. per wheel ,..

~J FF :'~=~~::::.:;~-.:r:/ " "

Wear zone Pedal stop -I ! '-.L.-.4..

MA.5151

.:: -.t1 ..~-~

International Cub Cadet 129, 149 and 169 Tractors

""

""

""

"""

(-"-..

~.. r-l~

.~ ,

-r::;:::- =.==.:1 I I I

-.." ~"b-+-

L -~ ~ ~~..

Brake adjustments.

-- I' I

r-t-..

../1 "

I' "-r"--'-,,; -

r)

I I

I I

I I

ADJUSTING THE BRAKES

The disc brakes should engage when the pedal is

pressed down to within a maximum of 1-3/16inches and a minimum of 3/4-inch above the pedal

stop.

The brake is engaged when the pedal arm is at least

3/4-inch above the pedal stop.

To adjust the brakes block the front wheels

securely and raise the tractor so the rear wheels are

off the ground.

NOTE: The brakes must not engage before the

pedal is within the maximum distance of 1-3/16-

inches.

With the rear wheels off the ground and the brake

pedal in the locked position, the brake settings

should be equalized as follows:

Disconnect left brake rod at the pinned end, rotate

the right wheel by hand and adjust the jam nuts on

the brake rod until the wheel brakes firmly. Then,

disconnect the right brake rod at the pinned end

and reconnect the left brake rod. Turn the left

wheel by hand and adjust the jam nuts until the

wheel brakes firmly. Reconnect the right rod.

29

Page 32

When your tractor is not to be used for some time,

it should be stored in a dry and protected place.

Leaving your tractor out-doors, exposed to the

elements materially shortens its life.

Follow the procedure outlines below when storing

a tractor for an extended period of time.

1. Wash or clean and completely lubricate the

tractor. See the "lubrication Guide".

2. Store the tractor so the tires are p':.Jtected from

light. Before storing the tractor, clean the tires

thoroughly. Jack up the tractor so the load is off

the tires when it is to be out of service for a long

period. If not jacked up, inflate the tires at regular

intervals.

6. Clean the exterior of the engine.

7. Remove the battery and place it in a cool, dry

place above (+32°F.). Check battery at least once a

month for water level and amount of charge. See

pages 24 and 25.

On all gear driven International Cub Cadet

Tractors press clutch and brake pedal all the way

down and engage the brake pedal lock. This will

prevent clutch lining from sticking to pressure

plate.

Disengage P.T.G. clutch.

REMOVING FROM STORAGE

CAUTION! If tractor is jacked up or

placed on blocks, be sure it is done so it

cannot be tipped over or fall on

someone.

3. Run the engine long enough to thoroughly

warm the oil in the crankcase and then drain the

oil. Refill the crankcase with fresh oil as specified

in the "lubrication Table" and run the engine for

about five minutes.

Drain the fuel tank and run the engine until the

fuel is exhausted from the fuel system.

NOTE: Gum will eventually form in the fuel tank,

line, and carburetor if the unit is not drained.

5. After the engine has cooled, remove the spark

plug and pour two tablespoonsful of a rust

inhibited oil such as Hy- Tran@ or IH No. 1@

engine oil into the cylinder. Crank engine slowly

turning generator belt by hand to distribute the oil

over the cylinder walls. Then replace spark plug.

1. Fill the fuel tank and be sure the grade of oil in

the crankcase is according to the temperature range

in the "lubrication Table".

2. Install a fully charged battery and properly

connect.

3. Start the engine and let it run slowly. Do not

accelerate it rapidly or operate at high speed

immediately after starting.

A CAUTION J Keep doors wide open or re-

lease brake pedal lock and move the

machine outside the storage room before

engine is started to avoid the danger from exhaust

gas.

Check air pressure in tires.

8.

9.

4.

4.

30

Page 33

When you purchased your tractor, you probably

had it completely equipped for your particular

needs at the time. However, later you may wish to

obtain some of the equipment or accessories shownbelow.

These items and other allied equipment can

be purchased from, and installed by, your

The tractor is used for so many different types of

work, and because it is called on to operate under

so many different conditions, a variety of equip-

ment is available to adapt it to the requirements of

the user.

I nternational Harvester dealer.

Possible Cause

No gasoline in fuel tank or carburetor.

Fuel line or carburetor clogged.

in gasoline.

Choked improperly. Flooded engine. Defective ignition or loose wiring. Defective battery Spark plug dirty or improper gap.

Water

31

Possible Remedy

HARD TO START

Fill the tank with gasoline; open the fuel shut-off

valve. Check the fuel line, and carburetor.

Clean the fuel line and carburetor with acetone or

50-50 mixture of alcohol and benzol.

Drain the fuel tank and carburetor. Use new fuel

and dry the spark plug.

Follow the starting instructions.

Check the wiring, spark plug, or breaker.

Check and service; See page 24, or replace.

Clean, adjust the gap to .025 inch, or replace the

plug.

* See your I nternational Harvester dealer.

Page 34

TROUBLE SHOOTING

Possible Cause

ENGINE OPERATES IRREGULARLY OR KNOCKS

Engine incorrectly timed Spark plug dirty; wrong gap or wrong type. Poor or weak spark.

Carburetor setting incorrect. Poor grade fuel or water in fuel. Engine overheating ".'..'.'.'..' Engine valves at fault Enginesmokes

Otherengineproblems

Air cleaner clogged.

Engine overheated. Engine overloaded.

Poor fuel, too rich, or too lean a mixture. Fuel tank air vent clogged """"."..'.."

Air leakage between carburetor and engine.

Incorrect timing or faulty ignition. Clutch slipping (Models 86, 108, and 128) Brake drags

Possible Remedy

*

Clean, reset the gap to .025 inch, or replace.

Check the breaker points and breaker point open-

ing, spark plug, and wiring.*

Adjust; see "Carburetor" on pages 10 and 11.

Drain and use a good grade of clean fuel.

See "Engine Cooling" See page 21.

*

Adjust the carburetor. Check for worn piston and

rings.*

LACK OF POWER

Clean or replace the air cleaner element. See page

21.

Reduce the load.

Run the engine until it warms up before putting it

under load. See "Engine Overheats" below.*

See "Carburetor" on pages 10 and 11.

Open the vent in the cap.

Clean the air cleaner as instructed on page 21.

Tighten the carburetor and manifold mounting

nuts.

See "Spark Plug" on page 22.

Adjust the free travel of the pedal; see page 28.

Adjust the brake; see pages 29 or 30.

ENGINE OVERHEATS

Insufficient cool air, dirty air intake screen,

shroud, or cooling fins.

Speed control out of adjustment (Models

129, 149, and 169)

* See your International Harvester dealer.

Keep the air intake area and cooling fins clean; see

"Engine Cooling and Air Cleaner" on page 21.

CREEPING

Refer to Service Manual.*

32

Page 35

ENGINE OIL

The engine crankcase is filled with ship-away oil.

This oil may be used for the first 30 hours of

engine operation at temperatures between +90

degrees F. and 0 degrees F. If temperatures are not

within this range, drain the oil from the crankcase

and replace with new oil as specified in the

"lubrication Table". The engine oil must be

drained and replaced with new oil every 30 hours

of engine operation.

We recommend I.H. No. 1@ Engine Oil. If other

than I.H. No. 1@ Engine Oil is used, it must be

designated "For Service MS". In new API Code

these oils are usually designated as meeting either

SO or SE requirements.

Lubricate the entire tractor, using only high

quality lubricating oils and greases as specified in

the "Lubrication Table". For your own protection,

select only oils and greases of recognized manufac-

ture.

Regularly check the oil levels of the engine

crankcase and transmission to see that they are

filled to the correct levels. NOTE" Check the oil

level only while the engine is stopped.

NOTE: On the Cub Cadet 86 Tractor the oil filler

cap has the oil level gauge attached and is located

on the right side of the tractor.

NOTE: On all other models the oil filler cap and

gauge is located on the gear cover on the left side

of the tractor.

To aid starting, the selection of crankcase lubricating oils should be based on the lowest anticipated

temperature until the next drain period. See page36.

Always keep the oil level between the "FULL" and

the "LOW" marks on the gauge. When checkingthe

oil level the gauge must be withdrawn and

wiped clean, then inserted all the way and with-

drawn for a true reading.

33

Page 36

ENGINE OIL -Continued

lUBRICATION

Keep your supply of lubricating oil absolutely

clean and free from dust. Always use clean

containers. Keep the lubricator clean and wipe dirt

from the lubrication fittings before applying the

lubricator.

TRANSMISSION OIL FILTER

(International Cub Cadet 129, 149, and

169 Tractors)

Remove the throw-away can-type filter and replace

with a new filter after the first 10 hours and after

50 hours of operation, and every 100 hours of

operation thereafter.

1. Oil filler cap and oil level

gauge -Cub Cadet 86 Tractor

1. Oil filler cap and oil level

gauge -All models except the

Cub Cadet 86 Tractor

NOTE: Clean the outside area before removing the

filter to keep dirt from getting into the transmission case. If a mower is mounted on the tractor,

the mower must be lowered to facilitate removal of

the filter.

To remove the filter, turn the filter counterclockwise using an automotive type filter wrench

or an open end wrench.

Before installing the new filter I apply a coating of

oil on the filter gasket. Thread the filter on by

hand until tight enough to seat the gasket. Loosen

the filter. Then turn it until the gasket contacts the

base. Tighten the filter an additional one half turn.

Check for leaks and check oil level of transmission

case.

34

Page 37

Point of Lubrication

Check

at

Hours

Change

at

Hours

Capacity

Anticipated Air Temperature

Above +32°F.

to O"F.

Below QoF.

Engine Crankcase

Model 86 Tractor

Engine Crankcase

Models 108, 128,

129, 149, and

169 Tractors

Transmission

Models 129,149,

and 169 Tractors

Transmission

Models 86, 108,

and 128 Tractors

Creeper drive hous-

ing Models 86, 108

and 128 Tractors

Steering gear hous-

ing All models

Steering knuckles

All models

10

10

100

100

100

Yearly

10

30

30 3 pt.

Add as

needed

Add as

needed

Add as

needed

2-1/2 pt.

I.H. No. 1cB> Engine

Oil SAE-30

Note: Do not sub-

stitute 10W-30 or

10W-40

I.H. No. 1@

Engine Oil

SAE-10W

I.H. No. 1(8) Engine Oil

SAE-5W-20

or

SAE-5W Engine

Oil

14 pt. IH Hy-Tran@ Fluid

If fluid is used which does not meet requirements of

I H 8-6 Specification, International Harvester

7 pt.

Approx.

1/2 pt.

1/4 lb.

Use IH-251 IH EP grease or equivalent #2 multi-purpose

lithium grease and apply two or three strokes of the lubricator

or sufficient grease to flush out old grease and dirt.

Company will not be responsible for substandard

performance of transmission and hydraulic components. NOTE: Failures due to use of improper

fluid or filters are not covered by warranty.-FOR

MAXIMUM PROTECTION USE IH HY- TRAN@

FLUID AND FILTERS.

Two strokes of the lubricator using I H-251 H EP

grease or equivalent #2 multi-purpose lithium

grease.

+3~F.

35

Page 38

LUBRICATION GUIDE

International Cub Cadet 86, 108 and 128 Tractors

~

Q)

';

c

0

';:;

~

'~

..c

~

-J

36

Page 39

LUBRICATION GUIOE

International Cub Cadets 86, 108 and 128 Tractors

-After Every 10 Hours of Operation

1 -Oil filler cap and bayonet-type oil

level gauge. Cub Cadet 86.

1A -Oil filler cap and bayonet-type oil

level gauge for Cub Cadet 108

and 128.

2 -Steering knuckles (2),

3 -Front axle pivot pin.

4 -Engine crankcase.

5 -Power take-off shafting bearing.

Check the oil (with the engine stopped) and add sufficient

new oil to bring it to the "FU LL" mark on the gauge. Do

not overfill. Do not operate the engine if the oil level is

below the "LOW" mark on the gauge.

Use IH 251H EP grease or equivalent #2 multi-purpose

lithium grease and apply sufficient grease to flush out old

grease and dirt.

-After Every 30 Hours of Operation

While the oil is warm, remove the drain plug (4) and drain

all of the oil from the crankcase. Replace the drain plug.

Refill the crankcase with new oil up to the "FULL"

mark on the oil level gauge. Refer to the "Lubrication

Table" for the proper quantity and viscosity to use.

-After Every 150 Hours of Operation

Use IH 251H EP grease or equivalent #2 multi-purpose

lithium grease and apply two or three strokes of the

lubricator to the lubrication fittings.

37

Page 40

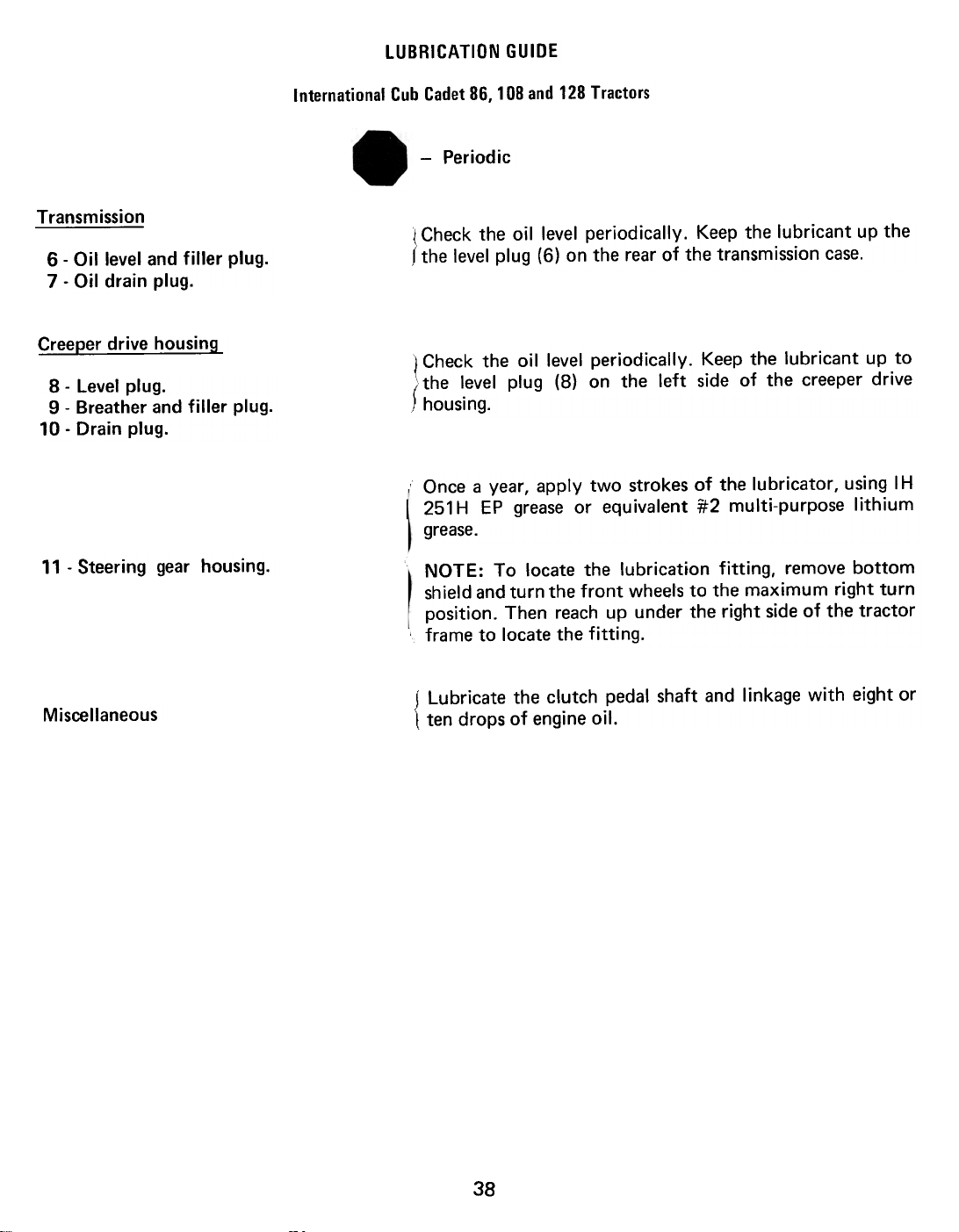

LUBRICATION GUIDE

International Cub Cadet 86, 108 and 128 Tractors

-Periodic

Transmission

6 -Oil level and filler plug.

7 -Oil drain plug.

Creeper drive housing

8 -Level plug.

9 -Breather and filler plug.

10 -Drain plug.

11 -Steering gear housing.

Miscellaneous

Check the oil level periodically. Keep the lubricant up the

the level plug (6) on the rear of the transmission case.

Check the oil level periodically. Keep the lubricant up to

the level plug (8) on the left side of the creeper drivehousing.

Once a year, apply two strokes of the lubricator, using I H251

H EP grease or equivalent #2 multi-purpose lithium

grease.

NOTE: To locate the lubrication fitting, remove bottom

shield and turn the front wheets to the maximum right turn

position. Then reach up under the right side of the tractor

frame to locate the fitting.

Lubricate the clutch pedal shaft and linkage with eight or

ten drops of engine oil.

38

Page 41

-1

~-

J~-~GI~".-O.~

39

I ~

I '-'

l """

I ,

I

)I I I

:~:r-

"; /'

i I

I

I

' J'"

".~

e'!'

~

~

e

LUBRICATION

~

Cub Cadet 129, 149, and 169 T

~)

: 0

~

~£~

>

~

.0

-=QI~

31~

."

~

."

.(

~

":

.c

..J

~

~

'S:

';;'

~

c

0

Page 42

International Cub Cadet 108, 149, and 169 Tractors

1. Oil filler cap and bayonet-type oil

level gauge.

LUBRICATION GUIDE

-After Every 10 Hours of Operation

Check the oil (with the engine stopped) and add sufficient

new oil to bring it to the "FU LL" mark on the gaugE:. Do

not overfill. Do not operate the engine if the oil level is

below the "LOW" mark on the gauge.

Steering knuckes (2).3.

Front axle pivot pin.

Transmission oil filter.

Engine crankcase.

Transmission oil filter.

Use IH 251 H EP grease or equivalent #2 multi-purpose

lithium grease and apply sufficient grease to flush out old

grease and dirt.

NOTE: After the first 10 hours only, remove the old filter

and replace with a new filter as instructed on page 35.

Change the oil filter after 50 hours and every 100 hours of

operation thereafter.

-After Every 30 Hours of Operation

While the oil is warm, remove the drain plug (5) and drain

all of the oil from the crankcase. Replace the drain plug.

Remove the crankcase oil filler cap (1). Refill the

crankcase with new oil up to the "FULL" mark on the oil

level gauge. Refer to the "Lubrication Table" for the

proper quantity and viscosity to use.

-After Every 50 Hours of Operation

NOTE: After the first 50 hours only, remove the old filter

and replace with a new filter as instructed on page 35.

Change the oil filter every 100 hours of operation

thereafter.

7. Transmission oil filter.

Transmission

Oil level and filler plug

2.

4.

5.

6.

8.

-After Every 100 Hours of Operation

Change the oil filter and replace with a new filter as

instructed on page 35.

-Periodic

Check the oil level periodically. Keep the lubricant up to

the level plug (8) on the rear of the transmission casecover.

40

Page 43

Steering gear housing.

LUBRICATION GUIDE

International Cub Cadet 129, 149, and 169 Tractors

-Periodic

Once a year, apply two strokes of the lubricator, using I H

251 H EP grease or equivalent #2 multi-purpose lithium

grease.

NOTE: To locate the lubrication fitting, turn the front

wheels to the maximum right turn position. Then reach up

under the right side of the tractor frame to locate the

fitting.

Speed Control Linkage

10. Speed control rod.

11. Cam plates

Miscellaneous

REAR POWER TAKE-OFF

Once a year, apply a few drops of oil (six or eight) around

the base of the control rod. When applying the lubricant

move the control rod from one extreme to the other for

more even distribution.

Once a year, apply a light amount of I H 251 H EP grease or

equivalent #2 multi-purpose lithium grease.

Lubricate the brake pedal shaft and linkage with eight or

ten drops of engine oil.

If the tractor is equipped with a Three-Point Hitch, once a

year the Lift Bar at the implement rockshaft should be

lubricated. Apply several strokes of I H 251 H EP grease or

equivalent #2 multi-purpose lithium grease.

The power take-off shaft connection is a 15/16-

inch pitch diameter, ten-tooth involute spline with

a 30 degree pressure angle, machined for outside

diameter fit. The dimensions are shown.

Rear Power take-off shaft spline dimensions

(International Cub Cadet 86, 108, and

128 Tractors).

9.

41

Power take-off shaft governed

speed 515r.p.m.

Direction of rotation (looking at rear

of tractor) counterclockwise

Center line of power take-off shaft

above rear axle center of 3-1 /4-in.

End of power take-off shaft to rear

of rear axle center line. 7-7/16-in.

Page 44

Page 45

SPECIFICATIONS

Model 86

Model 108 Model 128 Model 129 Model 149 Model 169

ENGINE -Continued

Ignition (electric

starting) Battery Battery Battery Battery Battery Battery

Spark plug gap

(14mm plug)

(Champion J-8 or

equivalent) 025 in. gap (Champion H-10 or

equivalent) 025 in. gap .025 in. gap .025 in. gap .025 in. gap .025 in. gap

Breaker points. 020 in. gap .020 in. gap .020 in. gap .020 in. gap .020 in. gap .020 in. gap

Timing. 20 degrees 20 degrees 20 degrees 20 degrees 20 degrees 20 degrees

before TOC before TOC before TOC before TOC before TOC before TOC

ELECTRICAL SYSTEM

System voltage.

12 volt neg. 12 volt neg. 12 volt neg. 12 volt neg. 12 volt neg. 12 volt neg.

ground ground ground ground ground ground

Battery Motor generator,

Delco- Remy Voltage regulator,

Delco- Remy Fuse (cartridge type) ..

9943X 9948X 9948X 9948X 9948X 9948X

15 amp.

2 unit

AGC-10

amp.

15 amp.

2 unit

AGC-10

amp.

15 amp.

2 unit

AGC-10

amp.

15 amp.

2 unit

AGC-10

amp.

15 amp.

2 unit

AGC-10

amp.

15 amp.

2 unit

AGC-10

amp.

Headlights -all glass, sealed beam units. Tailligh1

Lamp No. IH Part No.

4411

67

43

373662 R91

142 450

Page 46

Page 47

MOWERS

(38, 44, and 50-inch, 3 spindle)

with wide-oval runners

and

Quick-attachable mounting

45

Page 48

Your new rotary mower is designed to meet

today's exacting operating requirements. The ease

of operation and ability to adjust to field

conditions lighten your work and shorten your

hours on the job.

Be sure to read the instructions for Adjusting and

Operating in this manual. Check each item referred

to and acquaint yourself with the adjustments

required to obtain efficient operation and maxi-

mum trouble-free performance. Remember, a

machine which is properly lubricated and adjusted

saves time, labor, and fuel.

Your are urged to consult your International

Harvester dealer concerning unusual field condi-

tions or special applications. Let the experience of

your dealer and the organization associated with

him serve you.

After the operating season, thoroughly clean your

mower and inspect it. Preventive maintenance pays

dividends. Your dealer has original-equipment parts

which assure proper fit and best performance. He is

able to recondition your equipment to a like new

condition.

46

Page 49

The 3 spindle, center mounted, 38-, 44-, and 50-

inch rotary mowers are designed for use on

International Cub Cadet Tractors having serial

number 400,001 and higher, and are quick detachable by the use of two spring loaded handles and

two bayonet type hangers.

The mower extends beyond the tractor wheels to

permit cutting close to shrubbery, trees, fences,

buildings, drive and walkway edges, etc.

The mower is driven by a V-belt from the engine

mounted power take-off clutch. The clutch is

engaged and disengaged by means of a hand lever

mounted on the cowl pedestal.

A heavy-duty V-belt connects the three spindles

and permits independent turning of the blades

when an obstruction is struck by a blade. A springloaded belt tightener maintains proper belt tension.

Keep the machine in good operating condition and

keep safety devices in place. Use guards or shields

as instructed.

The blade spindle bearings are automotive type

double row ball bearings that can be relubricated

and are carefully enclosed and protected by seals.

The three cutting blades are designed to create a

suction to lift the grass and hold it for an even cut.

Raising and lowering of the mower is done by

means of the tractor lift handle or the power lift.

The lift linkage provides and maintains a true parallel lift for the mower. The cutting height ranges

from approximately 1 to 4-inches, depending on

tire and mower combinations.

Gauge wheels permit setting the cutting height to

allow the mower to follow the contour of the

ground and minimize ground scalping. The mower

front roller also aids in minimizing scalping.

The lift linkage with mounting brackets can be

quickly detached by removing the quick-attachable

cotter pins and releasing the tractor quick hitch.

The tapered discharge ch

protected opening for e

flow across the front of

terminates at a large,

fficient air and material

the mower to minimize

clogging.

ute

47

Page 50

CAUTIONI This symbol is used to call your attention to

instructions concerning your personal safety. Be sure to

observe and follow these precautionary instructions.

The discharge shield on the mower must be

attached at all times while operating the mower.

Keep the machine in good operating condition and

keep safety devices in place. Use guards or shields

as instructed in Operator's Manual.

Children should not be allowed to operate the

mower unless properly supervised, and are physi-

cally and mentally capable of safe operation.

Never place hands or feet under the mower, in the

discharge chute, or near any moving parts while the

tractor engine is running. Do not work on the

mower with the engine running.

Never leave the tractor engine running unattended

or permit it to be operated by persons not acquainted with its use and the rules for safe operation.

Stay alert for holes in terrain and other hiddenhazards.

Be sure all stones, branches, or other objects that

might be picked up and thrown by the mower

blades are removed before starting to mow.

Do not allow anyone in the area opposite the dis-

charge chute while mowing. Although the area has

been supposedly cleared of foreign objects, small

objects may have been overlooked and may be

discharged by the mower.

Disengage power to any attachment when transporting or not in use.

It is recommended that the machine be stopped

and inspected for damage after striking a foreign

object and that any damage be repaired before

restarting and operating the machine.

Watch out for traffic when crossing or near roadways.

not carry passengers or give rides.

Do

2.

3.

4.

Mower must be supported by the tractor.

Level the mower. See pages 7 and 8.

Engine Speed: Operate the engine at full

throttle.

Ground Speed: Choose a ground speed that will

satisfactorily handle the amount of material to be

cut.

48

Page 51

1. Power take-off clutch lever

2. Mower support brackets

3. Mower support clevises

4. Runners

5. Lift stop

6. Hydraulic lift handle

7. V-belt tension bolt

8. Extension spring measurement

38-inch mower.

9. Front hanger cover

10. Quick hitch

11. Power take-off clutch rod

12. Support pins (spring loaded)

13. Deflector shield

14. Extension spring

15. Gauge wheels

49

Page 52

~D OPERATING

1. Power take-off clutch lever2.