Page 1

Application

CTX conveyor ovens are designed to

cook, bake or broil in high volume with

consistent quality results.

General Information

CTX heavy-duty, infrared, electric,

conveyor ovens are designed for

placement onto a countertop, doublestacked upon another, or on an

accessory stand. The legs may also be

removed for mounting on a bracket

above existing equipment for hanging

from a cantelivered shelf. U.L. requires

legs or open bottom.

The oven is equipped with a 16" wide

reversible stainless steel chain link belt,

which can be reversed by turning a key

switch on the control panel. The overall

dimensions are 51

3

⁄4"W by 26"D by 18"H

including 4" legs. The oven chamber is

26"W by 18

1

⁄2"D by 41⁄4"H. The installed

weight is 208 lbs.; shipping weight is

231 lbs. The oven is supplied with two

(2) crumb trays, adjustable heat curtains

and exit trays.

Construction

The outer body is constructed of 18gauge stainless steel. Oven chambers

are constructed of welded and

reinforced 16-gauge aluminized

steel.Patented infrared heat emitters are

enclosed in high-strength thermal

conductive steel plates that form the

upper and lower housing of the oven

chambers. Thermal conductive steel

plates are also mounted on the side

walls to provide even heating.

Insulation

The oven is fully insulated on all four

sides with at least 2" cerafelt type

insulation for cooler exterior touch.

Electrical

The ovens can be ordered for 208 VAC

or 240 VAC, 1-Phase electrical utilities

and 380 VAC, 3-Phase electrical

utilities. The total power input on 208,

240 and 380 VAC operation is 7.1 kW.

208 and 240VAC ovens are provided

with a 1-Phase, 5.5-foot (1537 mm)

electrical cord and plug.

Controls

The G-26, regulated by a solid state

controller, is equipped with an “ON/OFF”

rocker switch. The top and bottom

elements can be set independently from

200° to 900°F. Cook time can be

regulated from 1 minute to 30 minutes.

MenuSelect

®

The patented MenuSelect®feature

allows the operator to preset up to five

different times and temperatures into

the control that can be recalled by

pressing the appropriate preset key,

then the computer automatically

adjusts time (belt speed) and

temperatures. A ready light glows

when the desired temperatures are

reached.

Self-Cleaning

The G-26 can be self-cleaned by

pressing the clean button. The

temperature will rise to 900°F for 1 hour.

Energy Saving

Infrared design and electronic controls

allow the unit to operate at an average

operating usage of 2.9kW.

Agency Data

The G-26 is Underwriters’ Laboratories,

Inc. listed; NSF and Canadian

Standards Association certified; and

compliant with CE requirements.

GSA number is available - consult

factory.

Warranty

Warranted for one year covering parts

and labor under the “No Quibble

Warranty”. U.S.A. only.

Electrical Ordering Information*

❐ 208VAC, 1 Phase

❐ 240VAC, 1 Phase

❐ 380VAC, 3 Phase

❐ 380-400V, 3-Phase

*

Consult the electrical data on the rear

side of this specification sheet for

connected kW and amperage loading

representing your electrical utility.

Accessories

❐ ACXTG24L - Exit Tray, long (18")

❐ ACXTG24M - Exit Tray,medium

(13")

❐ ACXTG24S - Exit Tray, short (7")

❐ ACCTG24 - Crumb Tray, Extra

❐ ACST26 - Stand with 6" Casters

❐ G26STACK - Stacking Pins for

mounting one G-26 atop another

❐ ACRG26 Receptacle, 250V, 50a

(equipped with plug type NEMA

standard 6-50P)

Form 2201

Infrared Conveyor Ovens

Job_________

Item#_________

MenuSelect® Conveyor Oven

G-26

Foodservice Equipment

Model G-26

A MIDDLEBY COMPANY

1400 Toastmaster Drive

Elgin, Illinois 60120 USA

(847) 741-3300 Fax: (847) 741-0015

www.middleby.com

Middleby

Marshall

Page 2

We reserve the right to change specifications and product design

without notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions or replacements

for previously purchased equipment.

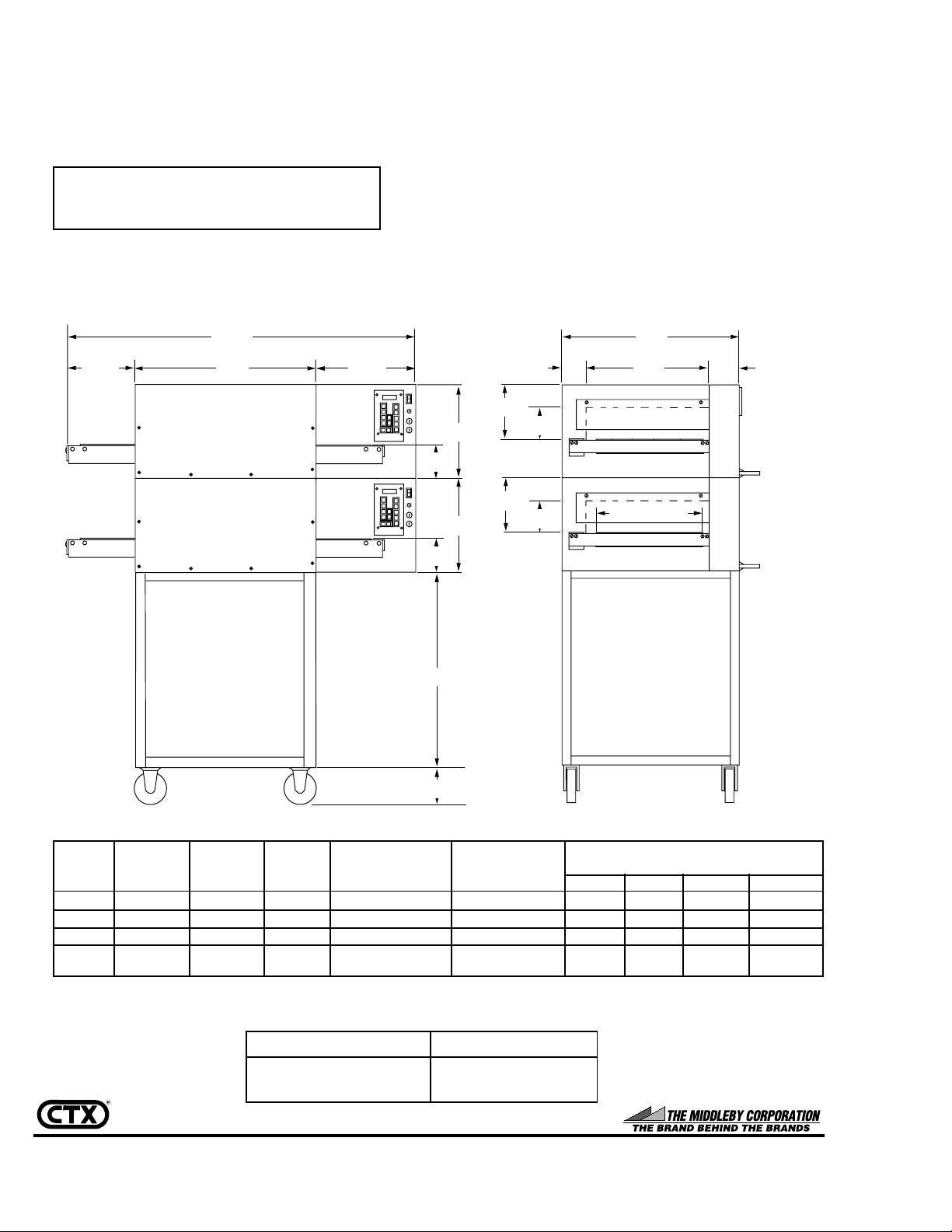

NOTE: ALL FIGURES IN PARENTHESES ARE IN MILLIMETERS.

Conveyor Oven

G-26 with MenuSelect

®

1400 Toastmaster Drive, Elgin, IL 60120-9272 USA • (847) 741-3300 • Fax: (847) 741-0015

www.middleby.com

TWO MODELS G-26, DOUBLE-STACKED

ELECTRICAL DATA

AVG

MODEL CONNECTED OPERATING CONNECTED LOAD

NO. VOLTS PHASE Hz kW kW L1 L2 L3 N

G-26 208 1 50/60 7.1 2.9 34.1 34.1 - - - G-26 240 1 50/60 7.1 2.9 30 30 - - - G-26 380 3 50 7.1 2.9 0.2 18 18 18

G-26 380-400 3 50 6.4 - - 0.1 14.0 13.8 13.9

(CE Listed)

9.75"

(247.65)

26"

(660.4)

51.75"

(1314.45)

16"

(406.4)

14"

(355.6)

5.5"

(139.7)

14"

(355.6)

5.5"

(139.7)

29.2031"

(741.7587)

6"

(152.4)

26"

(660.4)

18.5"

(469.9)

3"

(76.2)

4.5"

(114.3)

8.5"

(215.9)

4.25"

(107.95)

8.5"

(215.9)

4.25"

(107.95)

16" (406.4) BELT

NET WEIGHT OVEN SHIPPING WEIGHT

208 lbs. 237 lbs.

108 kg 94.5 kg

WEIGHTS

Printed in U.S.A. 5/99 Form 2201

Loading...

Loading...