1318 QUAKER CIRCLE P.O. BOX 589 SALEM, OHIO 44460

PHONE: 330-332-1800

FAX: 330-332-2144

www.ctmlabelingsystems.com

Designers and Manufacturers of Pressure Sensitive Labeling

Equipment and Custom Product Handling

360a LABEL APPLI CA TOR

CE VERSION

MAINTENANCE

&

SERVICE MANUAL

REVISION 360a-4a.1.X.XXX

EC DECLARATION OF CONFORMITY

Declaration: The listed product fulfils all the relevant provisions of the following Directive:

Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on

the approximation of the laws of the Member States relating to Machinery

Manufacturer: CTM LABELING SYSTEMS

1318 Quaker Circle, Salem, Ohio 44460 USA

Machine Name: 360a Series Label Applicator

Model Number: 360a

Serial Number: 360a-CE-0101-0809

Drawing Identification: ASS-200CE-0401, 1 Sheet, Rev. 6, Dated; 03-Mar-2008

Standards Used:

EN ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

reduction

EN ISO 14120:2015 Safety of machinery – Guards – General requirements for the design and construction

of fixed and movable guards

EN 1037:1995 +A1:2008 Safety of Machinery – Prevention of unexpected startup

EN ISO 13849-1:2015 Safety of machinery - Safety related parts of control systems – Part 1: General

principles for design

EN ISO 13850:2008 Safety of Machinery – Emergency stop equipment, functional aspects – Principles for

design

EN ISO 13857:2015 Safety of Machinery – Safety distances to prevent danger zones from being reached

by upper and lower limbs

EN ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles for

design and selection

EN 60204-1:2006 Safety of machinery – Electrical equipment of machines, Part 1: General requirements

+A1:2009

Means of Conformity: Technical File (TF): MS4581

Compiler of TF: Safenet Ltd., UK Notified Body Number 1674, Denford Garage, Denford, Kettering,

Northants.,

NN14 4EQ United Kingdom

Other Directives met: Directive 2014/30/EU of the European Parliament and of the Council of 26 February 2014

on the harmonisation of the laws of the Member States relating to electromagnetic

compatibility (recast)

Signature: ____________________________________ Date: __________________________

CTM LABELING SYSTEMS

1318 Quaker Circle, Salem, Ohio 44460 USA

Testing Procedures

Location

Level (dB)A

M1

81.9

M2

83.6

M3

79.8

The 360a-CE applicator was tested as a merge with the product detect sensor and display attached.

Because of the many configurations and options that are available for this model, there was no way to

test all configurations. The only issue with the different noses will be machine safety. The integration of

an applicator into a product line may cause pinch points or other dangerous situations that will need

guarded. The responsibility for guarding lies with the integrator.

Safety Related Issues to Ensure Compliance

• End user is responsible for meeting the final protective ground requirements.

• The power inlet on the back of the applicator is the AC power disconnect. The end user is

responsible for determining and providing a supply disconnect for the system.

• Voltages greater than 60 volts may be present inside the applicator after a discharge time of 5

seconds.

• The end user must provide protection concerning power interruptions/restoration, if needed.

• The end user must provide earth ground fault current protection, if required.

• The end user will provide any guarding needed after integration of the applicator.

Emergency Stop Actuators

EN/ISO 13850:2015 Clause 4.3.2 requires that an emergency stop device shall be located at each operator

control station, except where the risk assessment indicates that this is not necessary.

Upon reviewing the machine with the manufacture, it was agreed that the risks posed by the labeling

machine itself are not sufficient as to require a dedicated emergency stop pushbutton at the HMI console.

An entanglement test was preformed between the Nip and Drive rollers, and it was found that no

significant pull was exerted on fabric, and that only a mild pinch was exerted on the fingers.

The main machine into which this machine is incorporated should have an emergency stop system that

will remove power and air to the 360a system, thus removing all power to its actuators.

Acoustic Emissions Data

A weighted emission sound pressure levels at workstations do not exceed 70 dB(A).

Measurement Locations:

M1 –In front of label spindle

M2 –Operator’s position when using the HMI

M3 –Rear of machine frame

TABLE OF CONTENTS

i

TABLE OF CONTENTS

INTRODUCTION ......................................................................................................…...1

MACHINE TERMS ...................................................................................................…...2

DISPLAY PANEL ................................................................................................…….…3

KEY TYPES…………………………………………………………………… 3-1

ALARMS……………………………………………………………………… 3-2

CHANGING VALUES…………………………………………………….. …. 3-3

PASSWORD………………………………………………………………….… 3-4

MAIN MENU……………………………………………………………….…. 3-5

SETUP MENUS (main setup) …………………………………………….…. 3-5

LABEL SETUP………………………………………………………………... 3-6

Label Length…………….……………………………… 3-6

Label Stop…………………...…………………………… 3-6

Label Stop Compensation ...…………………………… 3-6

Label Sensor……………………………………………… 3-7

Label Formats……………..……………………………… 3-8

APPLICATOR SETUP……………………………………………………… … 3-10

Air Blast………….………..……………………………… 3-10

Tamp Times………….……..……………………………. 3-10

Extended Air Assist……….……………………………… 3-10

Web Speed……….………….…………………………… 3-10

Pre-Dispense……….…………………………………… 3-10

Over Speed………….……….…………………………… 3-11

Label Profile…………….……………………………… 3-11

Multi-Panel…………….…….…………………………… 3-15

PRODUCT SETUP.....................................................................................…… 3-17

Label Placement……….………………………………… 3-17

Detector Lockout…….………………………………….. 3-17

Encoder Option…….…………………………………… 3-17

CONFIGURATION..............................................................…………………… 3-20

Applicator Type………..…………………………………. 3-20

Applicator Options……….……………………………… 3-20

Loose Loop…….……………..………………………… 3-21

Imprinter……….………………………………………… 3-21

Crossover……….…………….………………………… 3-22

Multi-Label……….………….………………………… 3-24

Missing Label……….……………………………………

Powered Rewind……….…….………………………… 3-25

Tamp Home Mode……………………………………… 3-25

Skip Count……….……………………………………… 3-26

Foldover………………………………………………… 3-26

Label On Pad…………………………………………… 3-27

Vacuum Off…………………………………………….. 3-27

Product Detect Queuing…………………………………. 3-27

Max And S

I/O Diagnostic……….……………………………………

Reset Label Sensor……….………………………………

lew Speeds……….………………………… 3-28

3-24

3-29

3-29

TABLE OF CONTENTS

ii

SPECIAL OPTIONS........................................................................….............. 3-29

Drive Parameters ……….………………………………... 3-29

Customer Password……….……………………………… 3-30

No Labels Found Count……..…………………………… 3-30

Software Version.…………………………………….…

Placement To Time ……………………………………... 3-30

Missing Label Mode 2 ……………………………….…… 3-31

Auto Online Option………………………………………. 3-31

Product Detect Debounce Time…………………………… 3-31

Label Sensor Model……………………………………….. 3-32

FACTORY DEFAULT...................................................................................... 3-33

3-30

REAR PANEL ....................................................................................................……….. 4

SETUP PROCEDURES ........................................................................……………….. 5

MOVING THE APPLICATOR .............................................................……….. 5-2

JOB SETUP ........................ ..................................................................……….. 5-3

LABEL SENSOR SETUP ......................................................................……… 5-4

LABEL LENGTH SETUP ........................................................................…… 5-5

LABEL STOP SETUP..........................................................................……… 5-6

WEB SPEED SETUP ................................................................................…… 5-6

SLEW SPEED SETUP...........................................................................……… 5-6

LABEL STATIC TEST.........................................................................………… 5-7

LABELER TYPE SETUP ........................................................................................…… 6

MERGE APPLICATOR .................................................................................…. 6-1

AIR BLOW APPLICATOR ..........................................................................… 6-2

TAMP APPLICATOR ....................................................……………………… 6-5

DUAL ACTION TAMP (DAT) ......................................……………………… 6-9

PRODUCT SETUP ....................................................................................................….. 7

PRODUCT SENSOR ………………………………………………………… … 7-1

LABEL PLACEMENT ……………………………………………………… … 7-2

DETECTOR LOCKOUT……………………………………………………… 7-2

ENCODER……………………………………………………………………… 7-3

GENERAL MAINTENANCE ..................................................................................….8

DAILY ………………………………………………………………………… 8-2

WEEKLY ……………………………………………………………………… 8-2

MONTHLY …………………………………………………………………… 8-2

SEMI-ANNUAL ……………………………………………………… ……… 8-3

DANCER ARM ADJUSTMENT ……………………………………………… 8-3

REWIND SLIP CLUTCH …………………………………………………… … 8-4

DRIVE BELT ADJUSTMENT ………………………………………………… 8-5

TROUBLESHOOTING............................................................................................….. 9

DIAGNOSTIC CHART ……………………………………………………… … 9-1

DISPLAY FAULTS …………………………………………………………… 9-5

TABLE OF CONTENTS

iii

ACCESSORIES .........................................................................................................…. 10

RECOMMENDED SPARE PARTS.........................................................................…. 11

CHANGEOVER INSTRUCTIONS .....................................................................…… 12

APPLICATOR CHANGEOVER …………………………………………… … 12-1

BLOW BOX NOSE ASSEMBLY REMOVAL / INSTALLATION ………… 12-3

MERGE NOSE ASSEMBLY REMOVAL / INSTALLATION ……………… 12-4

TAMP NOSE ASSEMBLY REMOVAL / INSTALLATION ………………… 12-5

NOSE ASSEMBLY CHANGEOVER ………………………………………… 12-6

MERGE PEEL EDGE CHANGEOVER ……………………………………… 12-6

BLOW BOX PEEL EDGE / FAN / GRID CHANGEOVER ..………………… 12-7

TAMP PEEL EDGE / CYLINDER CHANGEOVER ………………………… 12-8

REWIND REMOVAL / INSTALLATION / CHANGEOVER ……………… 12-9

WIRING CHANGEOVER …………………………………………………… 12-9

APPLICATOR DRAWINGS ……….....................................................................… 13

INTRODUCTION

INTRODUCTION

The CTM Labeling Systems’ 360a Series Modular Labeling System is a high-speed Applicator used to

apply pressure sensitive labels to moving products on a production line. It is essentially a self-contained

Module that may be mounted in almost any position to apply labels to the top, bottom, or sides of packages

as they pass by on a production line.

The CTM Labeling Sys t ems’ 360a Series Modular Labeling Syste m is unique in that the M ain Module can

be adapted to three different types of Applicators: Air Blow, Merge, or Tamp by changing the Nose

Assembly. The symmetrical design of the Applicator allows labels to be dispensed to the right or left side

of the Applicator. The Applicator Type and configuration (either left or right -handed) will depend on the

type of product to be labeled and the arrangement of the production line.

If your application needs changed in the fut ure, a different Nose A ssembly may be purchas ed but the Main

Module would remain the same. There is no need to purchase a completely new Applicator. The CTM

Labeling Systems’ 360a Series Modular Labeling System can be easily changed over to a different apply

type by simply removing the existing No se from the module and replacing it with a different Nose.

You can also change the configuration (right-hand or left-hand) by simply moving the Appl icator Nose

from one side of the Applicator to the other. All the parts are interchangeable*. Everything you need is

already included with each Applicator Nose to make the change usin g your existing Module.

* Tamp Pad & Manifolds as well as some Options are hand specific.

The labels should be supplied on a liner web with a minimum label gap of 1/8”. The Applicator will accept

and dispense labels from rolls up to 20” O.D. Label accuracy is mostly dependant on product handling but

the Label Stop at the Peel Edge will be within +/- 1/32 inch when using labe ls constructed with a liner that

does not stretch.

For safe trouble free operation of the Applicator, carefully follow the instructions in this Manual durin g

setup, operation, label roll change s, cleaning, a nd maintenance. The Applicator is designed to operate

under the following environmental conditions:

ELECTRICAL SUPPLY: 207-253 Volts, 3 Amps, 50 - 60 Hertz, Single-Phase

108-132 Volts, 7 Amps, 50 - 60 Hertz, Single-Phase

AIR SUPPLY: The applicator requires clean and dry compressed air at pressures between 6.2 and

6.9 bar (90 - 100 P.S.I.) with a minimum flow rate of 113.3 L/min (4 S.C.F.M).

• Note: In the t amp applicator, an incr e ase in venturi vacuum

pressure may lead to higher SCFM requirements.

ENVIRONMENT: Operating temperature range is 10 to 35°C (50 to 95°F). Operating humidity

range is 20 to 85% RH, non-condensing.

NOTE: THE 360a SERIES MLS IS NOT INTENDED TO B E OPERATED IN AN

ENVIRONMENT WHERE FLAM MABLE OR EXPLOSIVE GASS ES ARE PRESENT. THE 360a

SERIES MLS IS N OT TO BE USED IN DIRECT CONTACT WITH FOOD PRODUCTS.

READ THE INSTRUCTIONS CAREFULLY AND COMPLETELY. This Manual includes all of the

information needed to setup the Applicator under normal operating conditions. The instruc tions include

important safety precautions that must not be ignored.

1-1

INTRODUCTION

READ THE INSTRUCTIONS IN O RD ER. The instructions are written as numbered steps that will take

you safely and efficiently through the setup process. Any steps performed out of sequence may result in a

hazard and the Applicator may not operate properly.

WORK CAREFULLY. Although set ting up the Ap plicator is not difficult, it does take ti me. Do not rush

through the process. Careful work will produce good results.

IF SOMETHING DOES NOT WORK PROPERLY, TRY SETTING IT UP AGAIN. Although an

Applicator malfunction is possible, most problems happen because the Applicator is not setup correctly. If

the Applicator doesn’t operate correctly, back up and start over.

FOLLOW ALL SAFETY INSTRUCTIONS. The CTM 360a Series MLS applicator has been provided

with a number of safety features. Observe all safety warnings and under no circumstances attempt to

remove or defeat safeguards or operate the Applicator in a manner contrary to the instructions.

1-2

MACHINE TERMS

DEFINITION OF MACHINE TERMS

AIR BLAST JETS:

The flexible Air Blast Jets pr ess-fit into the inside face of the B low Box Grid and can be re-arranged to

provide an air stream pattern that transfers labels of various sizes and shapes to the product. The Air Jets

are connected via a Manifold to the output of the “Air Blast” Solenoid Valve located in the Valve Bank.

The Regulat or Assembly on the Valve Bank controls the air pre ssure to this Solenoid Valve. The duration

of the Air Blast is controlled by the “Air Blast Time” function. Refer to the setup procedures for

instructions.

NOTE: Any unused Air Je t Tubes should be inserted into the Storage Block at the rear of the Blow Box.

AIR ASSIST TUBE:

The Air Assist Tube is a small stainle ss steel tube, with an anti-stick coating, t hat is mounted on the

underside o f the Peel Edge. It helps to separate the label from the liner as it is being dispensed onto the

Blow Box Grid or Tamp Label Pad for application.

APPLICATOR BLOW BOX NOSE:

The Blow Box Applicator Nose is used for dispensing labels via the Air Blow applicatio n. The Blow Box

creates a vacuum to hold the label to the Blow Box Grid until it is dispensed onto the product. The Nose

Assembly is easily converted from left-hand to right -hand and vice versa using the same parts. Al so, the

Blow Box Nose Assembly can be interchanged with the Merge, Tamp, or DAT Applicator Nose Assembly.

APPLICATOR MERGE NOSE:

The Merge Applicator Nose is used for dispensin g labels via the wipe on/merge applic a tion. A label is

dispensed from the Peel Edge and the brush wipes the label onto the product as it is traveling past the

Applicator. The Merge Applicator Nose is easily converted from left-hand to right-hand and vice versa

using the same parts. Also, the Merge Nose Assembly can be interchanged with the Air Blow, Tamp, or

DAT Applicator Nose Assembly.

APPLICATOR TAMP NOSE:

The Tamp Applicator Nose is used for dispensing labels via the air blast/tamping application. A labe l is

dispensed from the Peel Edge onto the Label Pad. The Air Cylinder extends the Tamp Assembly to the

product and the label is applied with an air blast. The Tamp Extend and Retract Times are configured

during Applicator Setup. The Tamp Applicator Nose is easily converted from left-hand to right-hand and

vice versa using the same parts*. Also, the Tamp Nose Assembly can be interchanged with the Air Blow,

Merge, or DAT Applicator Nose Assembly. *Tamp Pad & Manifold is hand specific.

2-1

MACHINE TERMS

APPLICATOR DAT NOSE:

The DAT (Dual Action Tamp) Applicator Nose is used for dispensing labels via an air blast to the side of

the produc t with a tamping action and the leading or trailing panel of the same product with a swing action.

SWING ONLY and SIDE ONLY operating modes are supported as well. A label is dispensed from the

Peel Edge onto the Label Pad. Air Cylinders extend the Tamp or Swing Arm Assemblies to the product

and the label is applied with an air blast. The Tamp/Swing Extend and Retrac t Times are configured during

Applicator Setup.

BLOW BOX / VACUUM GRID:

The Blow Box/ Vacuum Grid is the cube shaped assembly located next to the Peel Edge on a Blow Box

Applicator. Two (2) Axial Fa ns mounted above the Grid create the vacuum needed to hold the label in

place prior to application.

DANCER ARM:

The Dancer Arm is attached to the Unwind Block Assembly with a shoulder bolt, thrus t bearing and a

bushing. It appears immediately after the Unwind Mandrel in the web path. The Dancer Arm has a roller

at one end that rides against the label liner and is interconnected to the Mandrel Tension Disk with a spring.

The Dancer Arm maintains t ension on the liner loop as it operates the brake on the Unwind Mandrel when

labels are being dispensed. The spring tension should be large enough to properly tension the web but still

allow proper operation of the brake. Do not over tension the Dancer Arm.

DRIVE ROLLER:

The Drive Roller is coupled to a Stepper Motor that provides the motive force for advancing the label liner.

The Drive Ro lle r in conjunction with the spring loaded Nip Roller, pull the label liner around the Peel Edge

to dispense a label onto the product, Tamp Pad, or Blow Box Grid.

LABEL MANIFOLD:

The Label Manifold is the mounting blo ck that attaches the Label Pad to the bottom of the Tamp Cylinder

on the Applicator Nose. The Label Manifold is a custom part that is manufactured exactly to the label size

being applied. If at any time the label size changes, a new Label Manifold must be purchased along with

the Label Pad.

LABEL PAD:

The Label Pad is a white delrin material mounted onto the Label Manifold at the bottom of the Tamp

Cylinder of the Tamp Applicator Nose. The Label Pad is a custom part that is manufactured exactly to the

label size being applied. If at any time the label size changes, a new Label Pad must be purchased along

with the Label Manifold.

2-2

MACHINE TERMS

LABEL TENSION BRUSH ASSEMBLY:

This is an adjustable Brush to help create tension o n the label liner. The Brush can be released while

threading the label liner.

NIP ROLLER:

The spring-loaded Nip Roller provides positive pressure to the label liner that passes between the Drive and

Nip Roller Assemblies. These rollers ensure that the liner does not slip during the label dispense cycle.

The tension on the rollers may be released by turning the knob located on the top of the Nip Roller

Assembly.

PEEL EDGE:

The Peel Edge is the beveled plate located at the end of the Applicator’s Nose. When the label liner is

pulled around the Peel Edge, the label separates from the liner and is transferred to the Blow Box Grid,

Tamp Pad, or product depending on the Applicator Type.

PEEL EDGE LABEL TENSION SPRING:

This Tension Spring is attached to the bottom of the Spring Block Assembly. It is used to keep the label

liner flat on the Peel Edge surface and a ssist in controlling the dispensing o f the labe l onto the Blow Box

Grid, Tamp Pad, or product. The tension is adjustable to accommodate varying label thickness and release

properties.

REWIND MANDREL / SLIP CLUTCH:

The Rewind Mandrel is provided to store the label liner after labels have been removed. It is equipped with

a Slip Clutch and is driven by the Stepper Motor. The pressure exerted by the Slip Clutch is adjustable.

SINKING OUTPUT CONFIGURATION:

The 360a Applicator’s Alarm, I/O, and Valve Outputs are wired in the sinking configuration. The load

current for a sinking out put flows into the o utput terminal. The load

power supply terminal (+V). When the outp ut is active , current flows from the positive t erminal of the load

power supply through t he load into the output te rminal to ground. Io (max) = 80 mA

common connection is the positive

SOURCING INPUT CONFIGURATION:

The 360a Applicator’s Low Label, Web/Tamp, and Product Detect Inputs are optically-isolated. The

Sensors connected to these pins must be able to sink the opto-coupler’s input current. The Sensor

connectio n is the negative power supply ter minal (ground or -V). When the Sensor’s output is active,

current flows from the positive terminal of the load power supply through the op tic a l c oupler circuit

out of the input pin and through the sensor output (open collector /drain or SPST N.O relay) to ground.

and

Iin (max) = 15 mA.

common

2-3

MACHINE TERMS

UNWIND ASSEMBLY:

The roll of labels is placed on the Unwind Assembly for dispensing onto the product. The Unwind Block is

used to mount the Unwind Assembly to the Main Module. The Unwind Assembly can be removed and

remounted on the opposite side of the Module for easy conversion from a right-hand to a left-hand

Applicator or vice versa.

UNWIND ROLL MANDREL:

The Unwind Roll Mandrel is equipped with an adjustable Sp ring Tension Disk, a Br ake, and a quickchange Outer Disc. The Unwind Roll Mandrel and the Dancer Arm maintain proper web tension and

prevent excessive run-out of the label liner as labels are processed through the Applicator.

VALVE BANK:

The Valve Ba nk wil l consist of single (1) valve for a Merge Applicator with an Imprinter, two (2) valves

for a Blow Box Applicator, three (3) valves for a Tamp Applicator or four (4) valves for a Dual Action

Tamp Applicator. The Valve Bank has b uilt in Regulators and Gauges, it plugs into the Valve Connector

on the Rear Panel.

WEB PATH:

The web path is the path the label liner follows from th e Unwind Assembly through the vari ous rollers to

the Applicator Nose & onto the rewind assembly.

2-4

360a DISPLAY

3-1

360a TOUCH SCREEN DISPLAY

The following descript ion provides general information about the Display and will tell the op e rator how to

change values, explain the meaning of different screens, and describe the different options and how to set

them up.

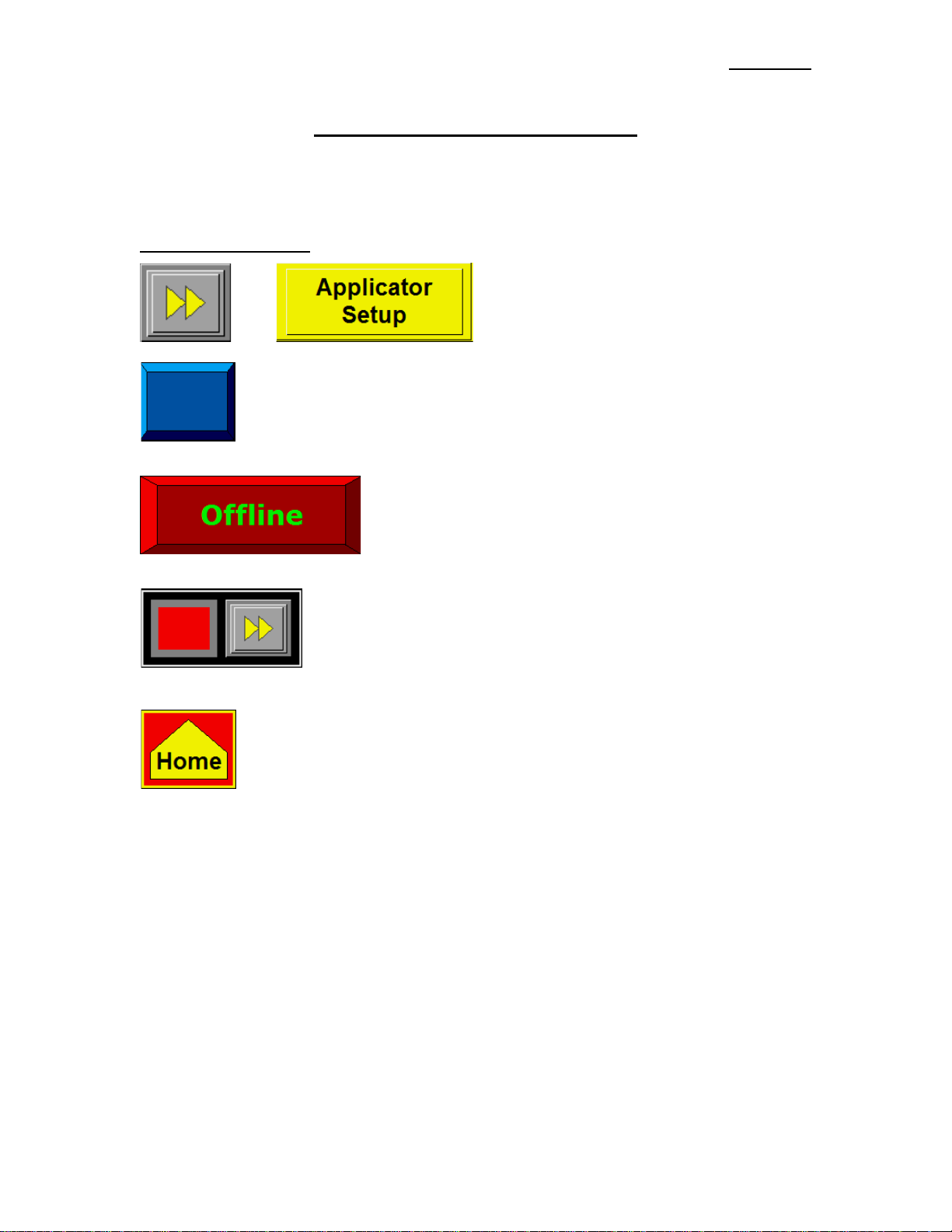

TYPES OF KEYS

Or are “go to” keys and will move the operator to

another screen.

This key is for setting something like an Applicato r Type, jog or us ed as an Alarm Reset

Key. The color of keys will vary depending on the application.

This key is for bringing the Applicator on and offline. When offli ne,

it will be as what is shown to the left, b ut when the App lic a tor is

online, it will be green with red le tte r s.

This block of keys usually turns something on or off. If the option is on, the

lamp to the left of the keys will be gre e n; o therwise it will be red.

This key will take you to the Main Menu even if you are in a setup screen.

360a DISPLAY

3-2

ALARMS

There are two types of alarms generated in the 360a Applicator:

Warning Alarm

Critical Alarm

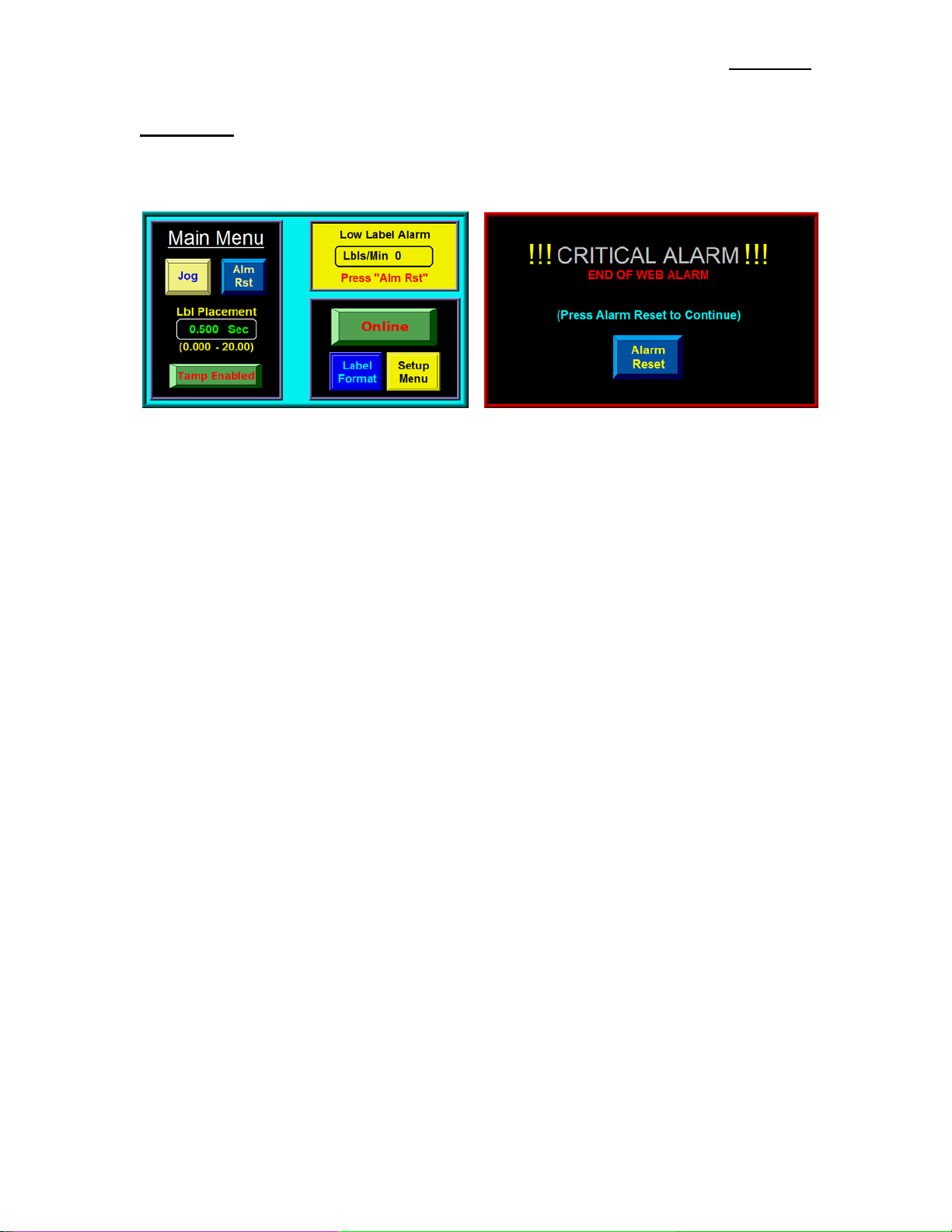

Warning Alarm Status Box Critical Alarm Screen

Warning Alarms will appear in the upper right hand corner of the Main Menu in the Status Box. Since

these alarms are not serious, the Applicator will not be stopped. During a Warning Alar m, the amber light

on the Light-Stack (if provided) will be turned on.

Critical Alarms will stop the Applica tor (take it offline) and turn a red light on in the Light-Stack (if

provided). The Alarm Screen will cover the current screen explaining the alarm type. An Alarm Reset

button appears at the bottom of the page to clear the alarm.

Warning Alarms

The following are Warning Alarms monitored by the Applicator:

Inhibit – This alar m occurs when an external device inhibits the Applicator from dispensing a label by

activating the Inhibit Input on I/O Connector C2-12.

Tight Loop - If the Loose Loop Option is on and t he Alarm Prox (upper Prox) turns on, this alarm occurs

causing the Applicator to stop applying lab e ls u ntil the Lower Prox turns on. There is no Reset Button

for this alarm since the Loose Loop Program controls whether the Applicator is functional or not.

Although the Applicator is stopped , this is still considered a Warning Alarm since the Applicator will

resume labeling as soon as the Printer catches up with the Applicator. The Tight Loop Status Bo x will

have a red background instead of yellow to signal the alarm condition.

Low Label – This alarm occurs when the Low Label Sensor detects that the unwind roll is nearly out of

labels.

Multi-Label C-C Distance Is Too Low – This alarm occurs when the Multi-Label Opt ion is on and the

Applicator cannot place labels at the desired Center-line Distance. If the application permits, increase

the Label C-C Distance to correct the problem. For Non-Merge Applicators, you can try increa s ing the

Web Speed value or decreasing the conveyor speed value. In Tamp Applicators, reduce the Tamp

Extend/Retract Ti mes to the minimum. In Air-Bl ow Applicators, reduce the Air Blast Time to the

minimum and increase the Pre-Dispense Time if possible. In Merge applications contact the factory

concerning appropriate Accel and Decel values for your application.

DAT Label Pla cements Are Too Close – If the Applicator Type is a Dual Ac tion Tamp and the Second

Label Placement is low enough that the second label is not out onto the Pad before it should be applied,

this alarm will occur. Increasing the Second Label Placement will correct the problem. This also

could be viewed as a rate alarm.

Conveyor Speed, Profile or OverSpeed % Too High Compared To MaxSpeed - This alarm occurs on

Merge Encoder-Based Applicators when the conveyor speed or the product of conveyor speed times

the Profile or Over Speed % yields a speed greater than MaxSpeed. If possible, decrease the conveyor

speed or increase the Applicator’s MaxSpeed value. In Over Speed or Profiling app lic a tions try

decreasing the Pre-Apply Speed % or WebRatio % values respectively.

360a DISPLAY

3-3

ALARMS (cont’d)

(WARNING ALARMS)

Label Placement is Too Low – This alarm occurs in Encoder-Based

distance is too small for encoder compensation to work correctly. During label placement a speed

dependent distance is subtracted from the label placement value to pr operly position the label. If this

alarm occurs, move the Product Detect Sensor upstream more, decrease the conveyor speed, or

increase the Label Placement value.

Profile Or OverSpeed % Too High Compared To MaxSpeed – This alarm occurs in Merge Time-Based

applications when the Profiling or Over Speed % times the Web Speed value yields a speed greater

than the MaxSpeed. If possible, decrease the conveyor speed or increase the Applicator’s MaxSpeed

value. If possible, decrease the Over Speed Pre-Apply Speed % or the profiling WebRatio % values.

Imprint Dwell Too High For Label Cycle – This alarm occurs if the Imprinter Valve is on when the

Applicator is ready to dispense a label to the product, Air-Blow Grid, or Tamp Pad. For Merge

applications, no label will be dispe nsed . Air-Blow and Tamp Applicators will wait for the Imprint

Dwell to timeout before dispensing a label to the Grid or Pad.

Critical Alarms

The following are the critical alarms monitored by the applicator:

End Of Web – This alarm occurs when the End Of Web sensor detects a break in the web.

No Labels Found – This alarm occurs if the number of consecutive missing labels on the liner exceeds the

Missing Label Count value. If a No Labels Found Alarm occurs when labels are present on the liner,

re-teach the label sensor sensitivity settings.

Printer Not Rea dy - This alarm occurs when the Printer is paused while the Applicator is controlling a

Printer in a Loose Loop format with the Printer Ready Input Signal active.

applications when the Label Placement

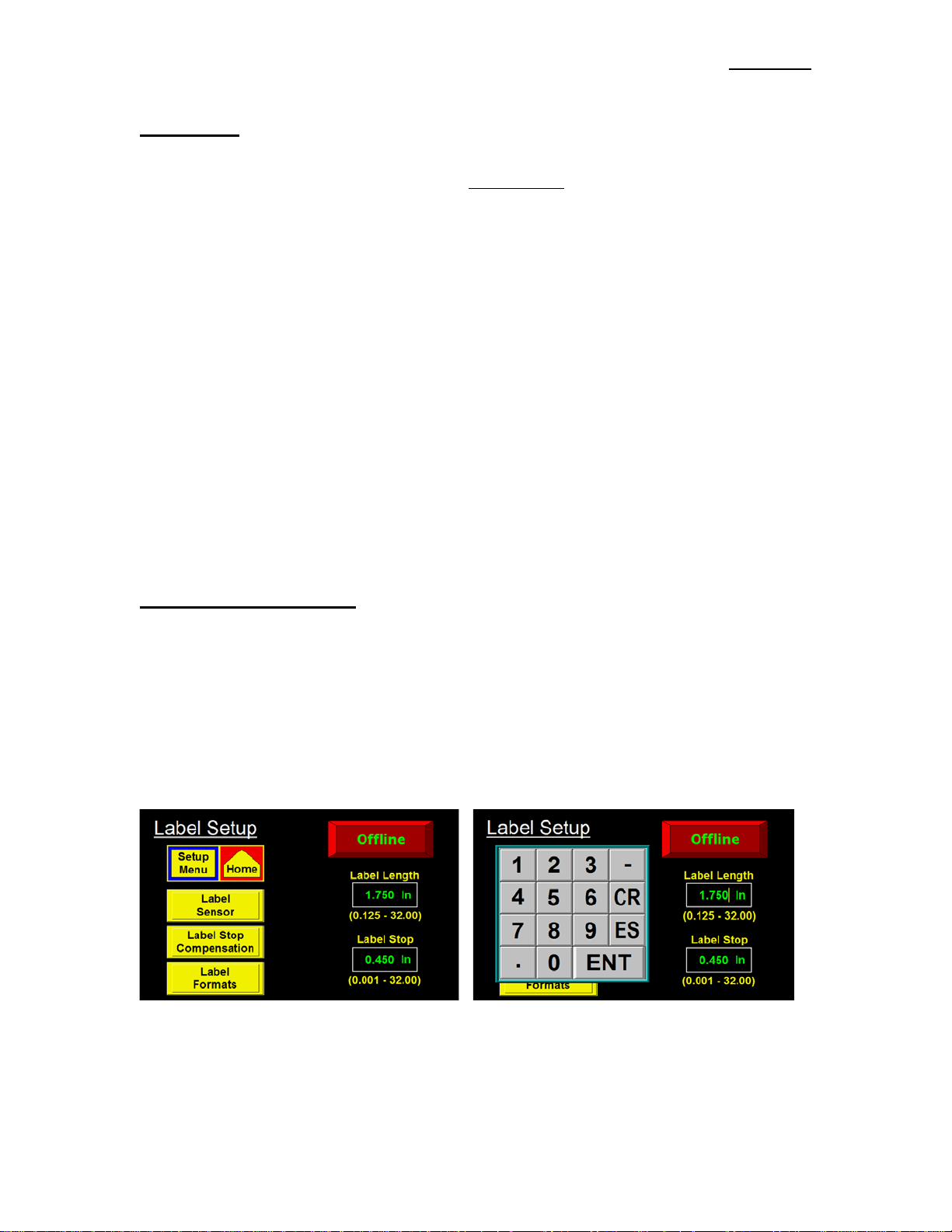

CHANGING VALUES

Values that may be changed are shown in boxes displaying the current value. In the example below, label

length is shown to have a value of 1.75”. To change this value, the operator will touch the screen in the

label length field and a keypad will appear to the side of the variable being changed. The figure to the right

shows wha t the Displa y should look like after t ouching the variable field. You can see a cursor has moved

over the rightmost digit. Also the numeric keypad has appeared to the left of the variable. As you touch

numbers on the keypad, the variable is zeroed and the new value is input to the variable box. Pressing

“ENT” will finish the process. Pressing “ES” will allow you to escape without changing the value and

“CR” will clear the value you’re changing. Note: In most cases, an out-of-range value w il l not produce

a warning message but the variable will return to the original value after pressing “ENT”.

3-4

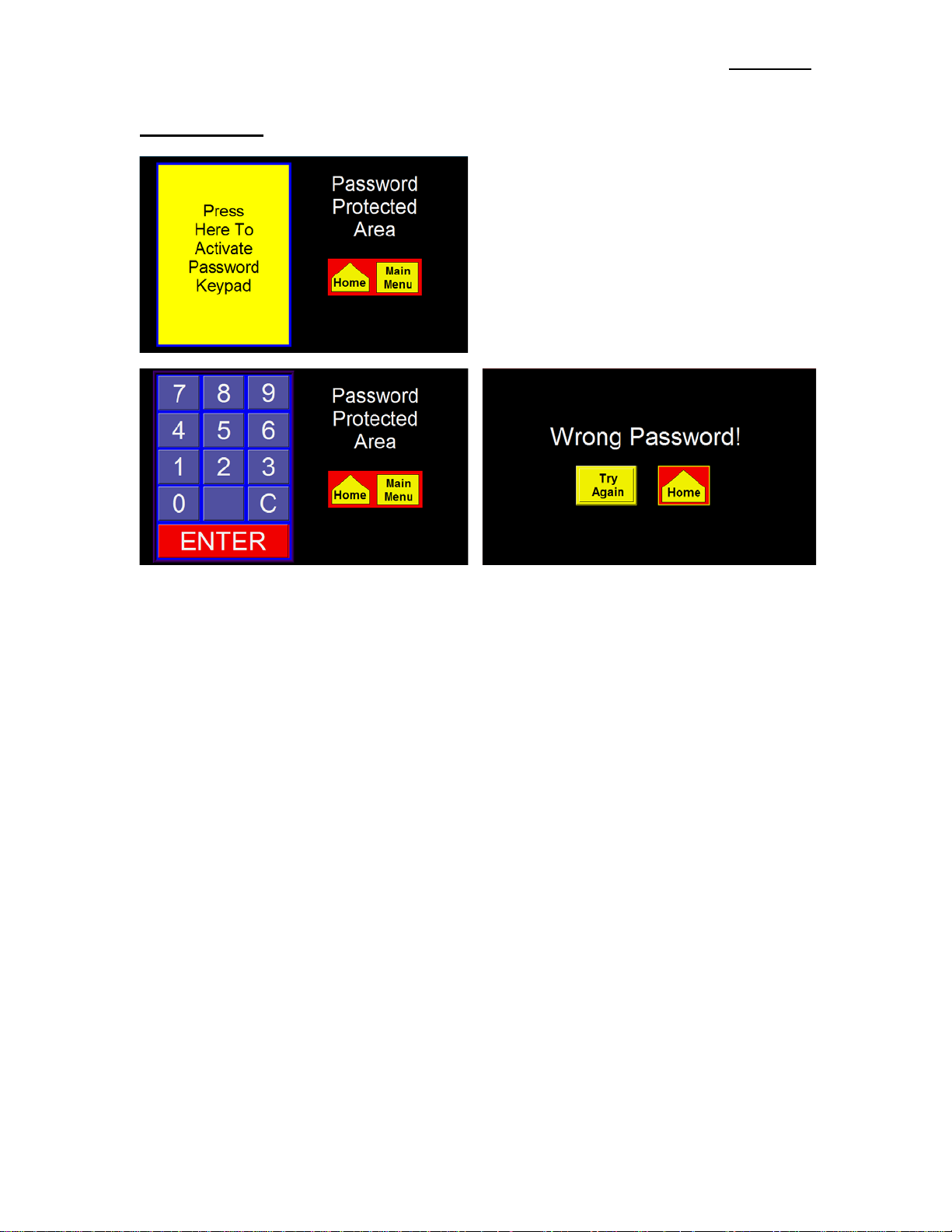

PASSWORD

360a DISPLAY

The Setup Section of the Display is password

protected. The Standard 360a password is “1800”.

When you get to a passwor d-protected area, a screen

similar to the one to the left will appe a r.

This screen notifies the operator that the area is

password protected. Here the operator can choose

to go back to the Main Menu or co nti nue wi th

password entry by touching within the box to the

left to activate the keypad

When you touch a number on the keypad, it will

highlight. This is the only indication that a key

was pressed since the password is not displayed.

If you know you’ve enter ed a wrong number,

press “C” to clear what you have and start again.

“ENTER” finishes the process.

If the wrong password was entered, the screen above

appears. If the operator wants to try again, press the

“Try Again” key. If you do not know the password,

press the other key to go to the Main Menu.

360a DISPLAY

3-5

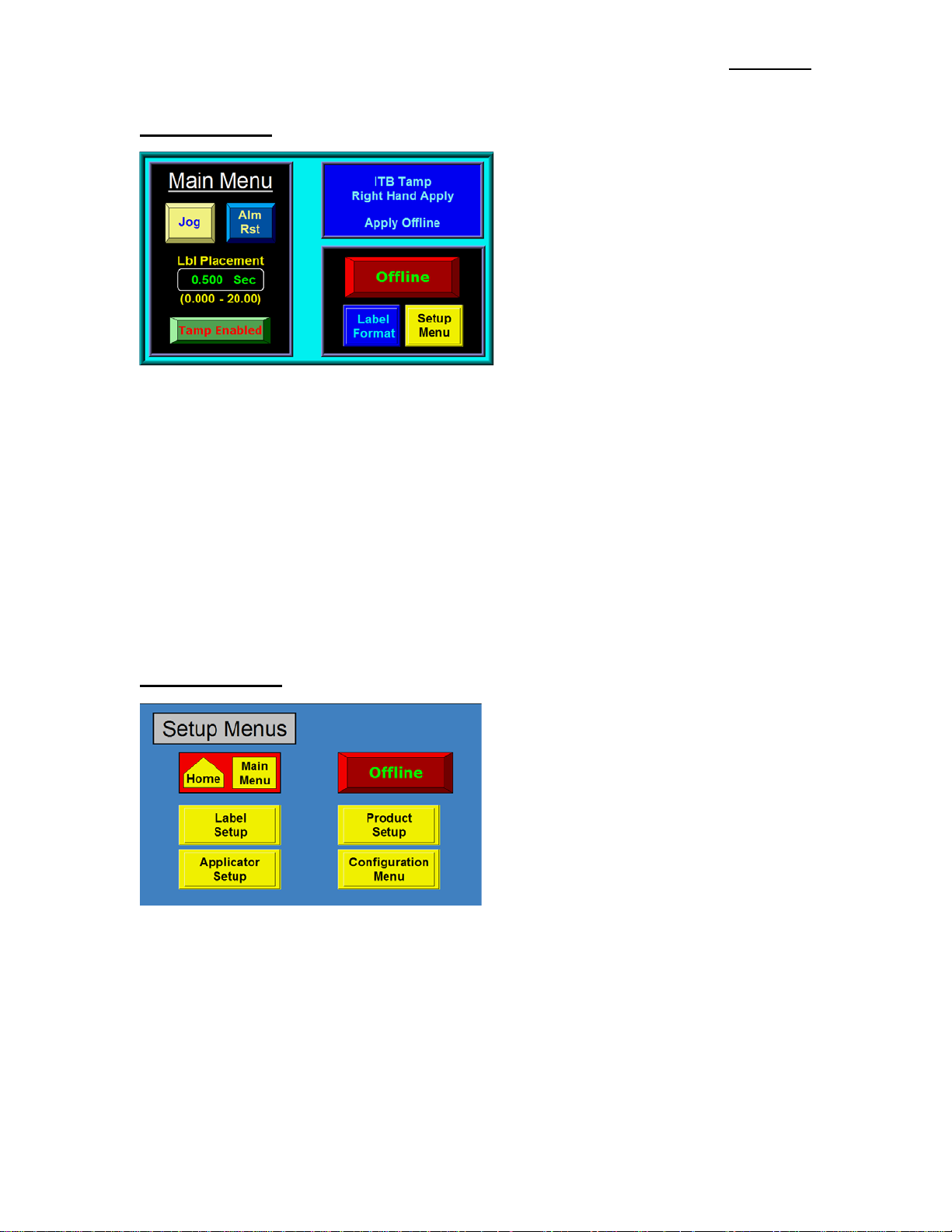

MAIN MENU

The Main Menu is divide d into three sections.

The upper right corner of the Display is a Status

Window. The purpose of this box is to inform

the operator of the status of the Applicator. The

display shown to the left appears immediately

after going offline. If the Applicator is online

with no alarms, the Status Windo w will have a

green background with the label rate displayed.

If a Warning Alarm occurs, the background

changes color and a message will appear

indicating the nature of the alarm. Specific

Warning Alarms were discussed previously.

The left side of the screen will change based on Applicator Type. There will always be Jog and Alarm

Reset keys and access to Label Placement.

The lower right corner has buttons to place the Applicator on and offline and keys to take you to the

Formats and Setup Menus. Plac ing the Applicator o nline applies power to the Drive Motor and arms the

Applicator for labeling. The Format Key gives access to the operator to load a saved Format. The operator

cannot change or erase Formats from here. The Setup Key takes the operator to a password-protected area

to make changes to the operation of the Applicator.

The Display is equipped with a backlight saver function that a utomatically turns off the backlight after 60

minutes of inactivity. Pressing a ny part of the Display will turn the backlight on again. Also, the

Applicator will initiate a backlight wake-up in response to any Critical Alarm condition. The later feature

insures that the operator has a visual indication of a Critical Alarm condition in systems without a LightStack Assembly.

SETUP MENU

Because the Setup Menus are password-protected,

pressing the Setup Key at the Main Menu wi l l

cause a password screen to appear. By entering the

correct password will cause the Setup Menu to

come up. From here the operator can go to the

different setup sections. The operator can also

bring the Applicator online while he changes the

setups. Once the Applicator is set up and the

operator exits the Setup Menu, the Applicator will

save the new s ettings. If power is cycled to the

Applicator before the Display is r e turned to the

Main Menu, the new settings will not be saved.

Note: You must be offline to enter the

Configuration Menu.

360a DISPLAY

3-6

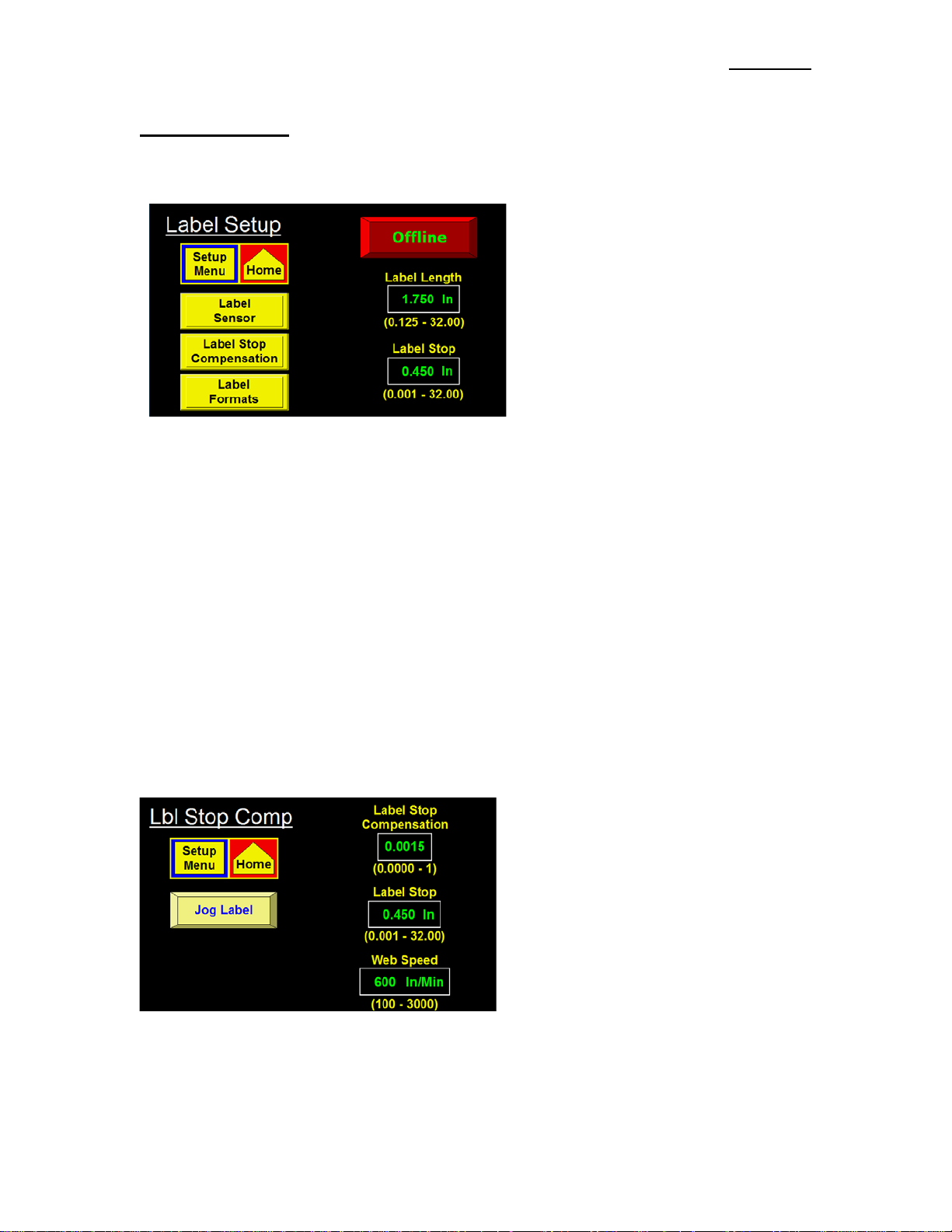

LABEL SETUP

The Label Setup menu is accessed from the Setup Menu by pressing the Label Setup Key. The label setup

section gives the operator access to variables on the Applicator that pertain to the label.

The following items may be changed in this

section:

Label Stop

Label Length

Label Sensor Setup

Label Stop Compensation

Label Formats

Label Length -The label length is defined as the feed length of the label plus the width of the gap between

labels. Stated another way, it is the distance from the leading edge of one label to the leading edge of the

next label. Since each application cycle moves the label length distance, it is important to enter the exact

label length value. Allowed values are between 0.125-32”.

Label Stop -The Label Stop b o x lets you enter the label stop distance value. The Label Stop value is the

distance from the label edge to the Label Sensor. Allowed values are between 0.03” and (label length –

0.06”). The Label Stop value may be changed while the Applicator is running.

Label Stop Comp –Although very rare, we have found the Label Stop would vary with Web Speed when

running certain types of labels. This seems to do more with narrow labels and the materials used to convert

them. Label Compensation is normally fixed but when Label Sop is moving with Web Speed, it was found

making changes to it can make the labe l stop position better. Label stop compensation is a number that

shortens the Label Stop value the higher the Web Speed. This corrects the problem of the label position

creeping out the faster the Web Speed.

Note: This option is only for Encoder-Based Merge Applicators

Label Stop Comp Setup

Before setting this up, make sure the Label Sensor, Label Length, Label Stop and Max Speed have all been

setup. It is also important the Encoder Variables are correctly setup.

The default value for Label Stop Comp is

0.0015. Set the Web Speed to the slowest speed

the product will be traveling (let’s say 500

in/min). Use the Jog Key on the Display or the

Jog Switch o n the Applicator to dispense a

couple of labels. Take note of where the label

stops. Now change the Web Speed to the

fastest the product will be traveling and jog a

couple more labels. If the Label Stop position

moved forward, increase the Label Stop

Compensation. If the Label Stop moved back,

decrease the Label Stop Compensation. It is

unlikely that the compensation value will be less than 0.0015. If you can change Web Speeds and the

Label Stop holds pretty well, you are finished. If needed, you can make adjustments to the label stop

position so the Label Stop is back where you want it. When you exit the Label Stop Compensation screen,

the Web Speed will return to the value set in the Applicator Setup Menu.

360a DISPLAY

3-7

LABEL SETUP (cont’d)

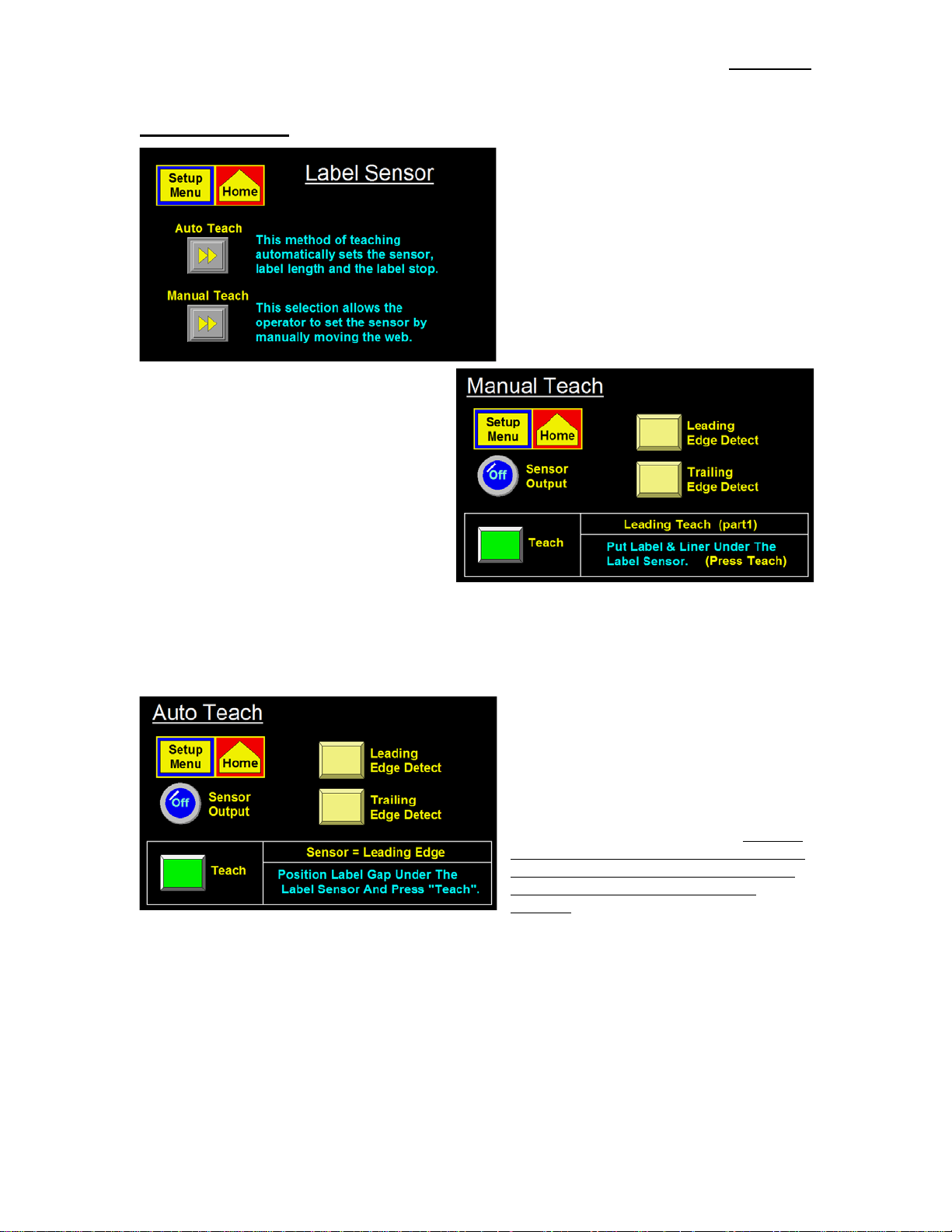

Label Sensor -Pressing this key will bri ng up

the Label Sensor Menu. This is where the

sensitivity of the Label Sensor is setup. The

operator will have two choices:

Auto Teach

Manual Teach

Manual Teach

In the Manual Teach Mode, the opera tor will

first choos e whether they want to trigger on the

leading or trailing edge of the labe l. The only

reason for c hanging edges occurs when the

Label Stop is either too small or too close to the

Label Length. After selecting an edge detection

mode, the Display will provide opera tor

instructions at the bottom of the scree n. For

example, if leading edge is selected, the Display

will prompt the user to move the label and liner

under the Label Se ns or and pre s s the Teach Key

on the screen. After a couple of seconds the user is prompted to move the liner under the sensor. Move the

label stock by turning the Drive Roller to place the label gap under the sensor or remove a label. Again the

operator will press the Teach Key. After a couple of seconds the process is finished. The operator can

return to the Label Setup Menu by pressing the “Prev Menu” Key.

Auto Teach

The Auto-Te ach function not only sets the

Label Sensor Sensitivity but also calculates the

Label Length and Label Stop values. When the

Auto-Teach function is selected, the operator is

prompted to move the label gap under the

sensor. Pressing the Teach Key causes the

Applicator to dispense 10 inches of labels while

setting the Label Sensor Sensitivity.

Key is provided to skip the sensitivi ty setup for

instances where the sensitivity is known to be

correct or when a Clear Label Sensor is

installed. Following the sensiti vity setup, the

operator is prompted to move the label to the Label Stop Position and press the Teach Key. Three labels

are dispensed while calculating the Label Length and Label Stop values. If the Multi-P anel Option was on,

an extra screen appears instructing the operator to move a label to the Peel Edge to allow the controller to

calculate the Short Feed Distance. This will be discussed in more detail in the Applicator Setup section.

NOTE: The Label Sensor output lamp will be a light blue when the sensor is on. If the sensor i s se t

to “Leading”, the light will be on when the la be l is unde r the sensor. If “Trailing ”, the light will be

on when the gap is under the sensor.

NOTE: See SPECIAL OPTIONS section for information regarding the Label Sensor Mode l setting if

the Applicator is not responding correctly to label teach routines.

A Bypass

360a DISPLAY

3-8

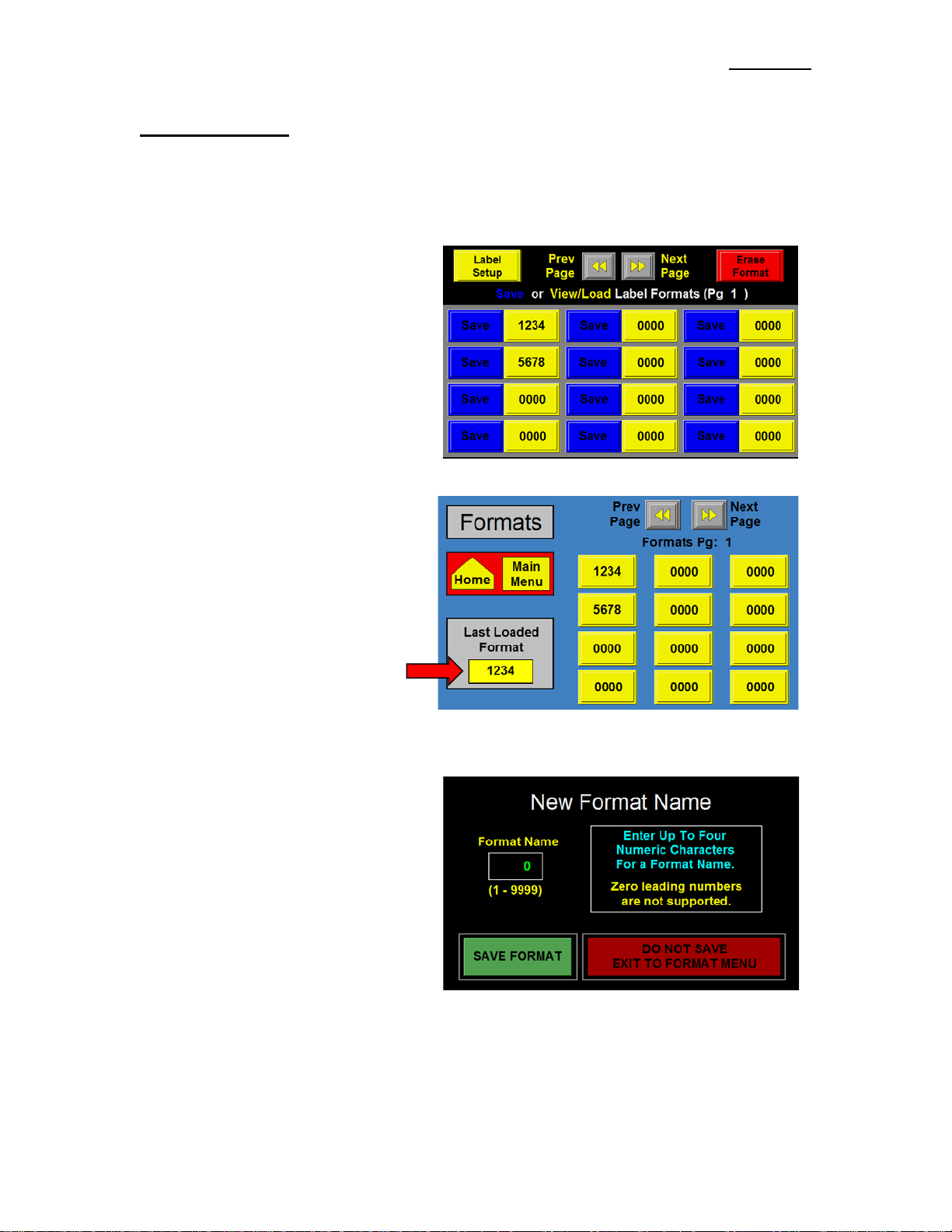

Main Menu Format Screen

Main Format Screen

LABEL SETUP (cont’d)

Label Formats

This section allows the operator to save and load configuration setups for up to (48) different products and

labels. This is useful if a customer is running several different products or labels over and over.

Note: The Label Format Key at the Main Menu only allows the operator to only load Formats.

A format saves the following parameters:

Label Placement Encoder Option

Label Length Pulse Length

Label Stop Compensation

Detector Lockout Air Blast Time

Web Speed Ext. Air Assist

Slew Speed Tamp Extend

Max Speed Tamp Retract

Accel Pre-Dispense

Decel

Options and Variables

Consult factory for a complete list of

Parameters saved.

This screen will show the last Format

loaded. If no Formats had been loaded,

the value in t he box would be “0000”.

Saving a Format

If the curre nt setup in the Applicator is

performing correctly and you wa nt to save it,

press “Label Formats” in the Label Setup

Menu. When a “Save” key is pressed, the

Applicator will check to see if a Format

already exists in the location selected. If it

does, the operator will be prompted whether

or not to overwrite its contents with the new

information. If the name is “0000”, the

operator will be asked to enter up to four

digits for the Format Name. Pressing the

green Save Format key, saves the Format to

the name shown in the Format Name box

provided the name is not already used for another Format. If it is, the system prompts the user to sele c t a

different na m e. Pressing the red Exit Key on the screen allows the operator to exit without saving the

Format.

360a DISPLAY

3-9

LABEL SETUP (cont’d)

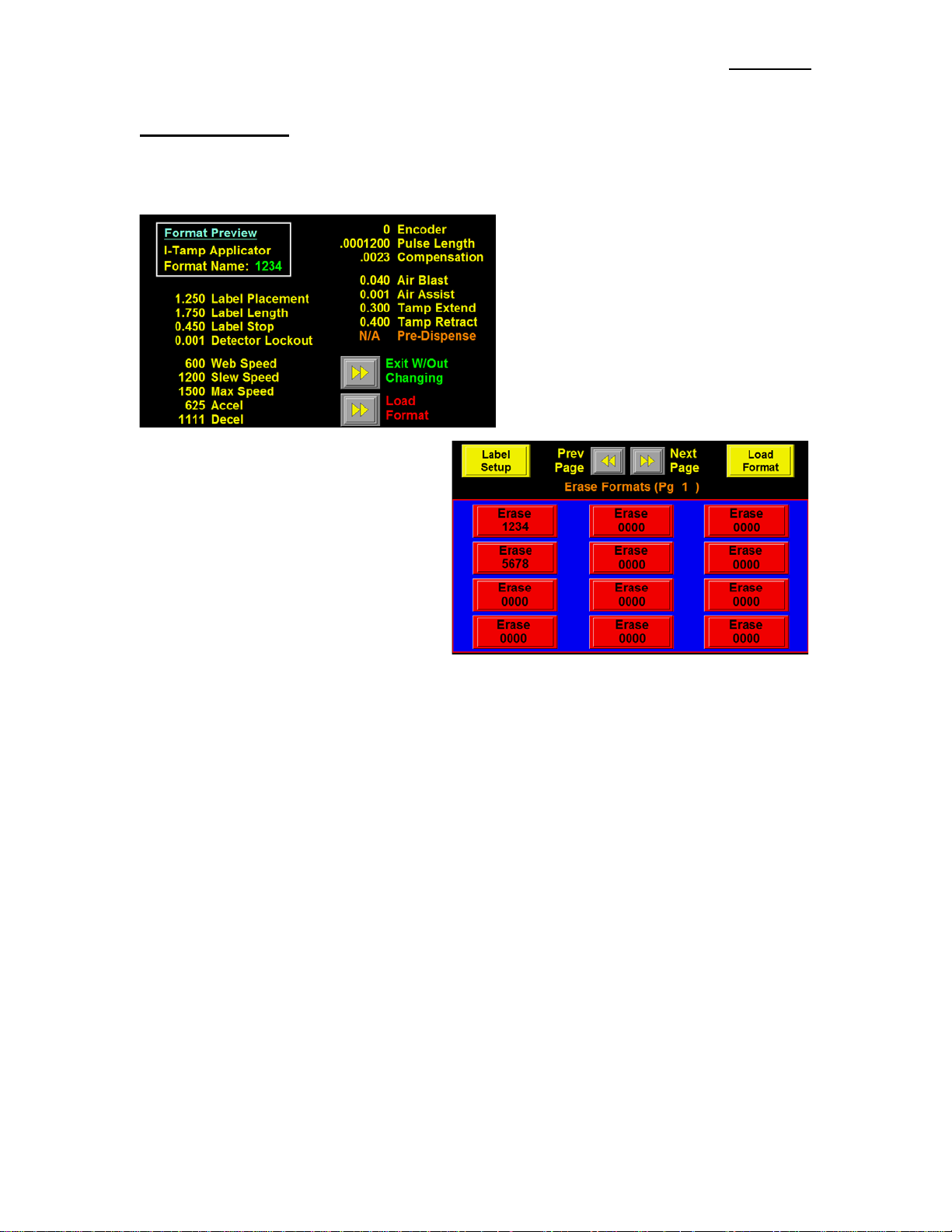

Viewing/Loading a Format

When the operator wants to view/load a Format File, they need to press the yellow portion of the key

associated with the desired Format name. If the number is “0000”, no Format is saved in that location.

Selecting a “0000” Format will cause a screen

to appear with a “No File Found” message.

Pressing the View/Load Ke y will not

immediately load the Format but will allow the

operator to view the values within that Format.

After reviewing the values, the operator may

press “Load Format” to load the Format. If th e

wrong format was selected, the operator can

press the “Exit W/ Out Cha n gi ng” key.

Deleting a Format

When the operator wants to delete a Format

that currently exists, pr ess the Erase Format

Key in the upper right hand corner o f the

Display. The screen to the right will appear.

Pressing any of the bo xe s with a name will

cause that Format to be erased.

Note: There is no second step to this

operation. Once you press the format box,

the Format will be erased.

360a DISPLAY

3-10

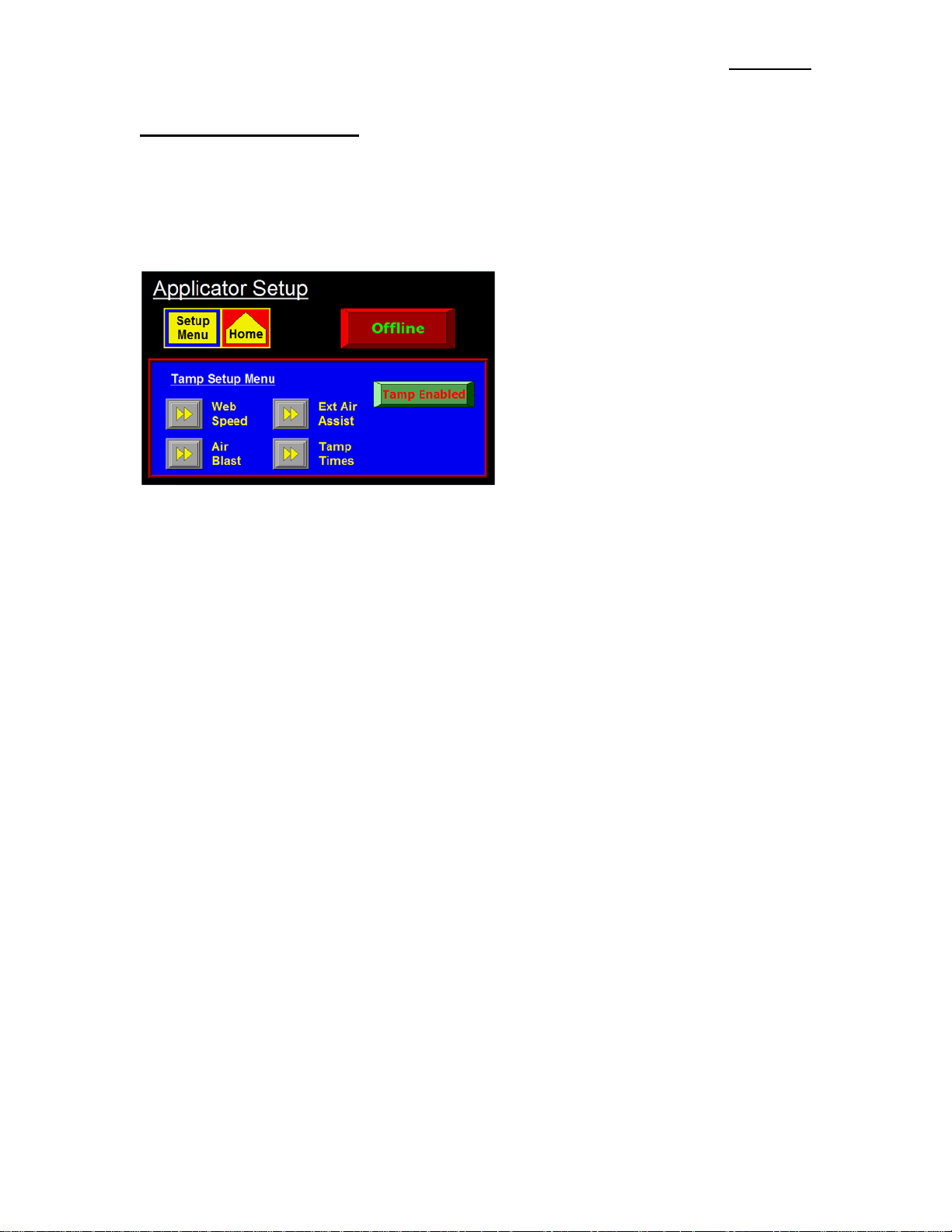

APPLICATOR SETUP

The Applicator Setup Menu is accessed from the Setup Menu by pressing the “Applicator Setup” Key. The

screen is split into upper and lower sections. The upper part does not change and allows the operator to

return to the Main or Setup Menus and place the Applicator on or offline. The lower section of the screen

changes based on the Applicator Type selected.

Depending on the Applicator Type, the operator has access to the following variables:

Tamp/Swing Extend and Retract Times

Air Blast Time

Extended Air Assist Time

Web Speed

Pre-Dispense

Label Profile Configuration

Multi-Panel Option

Over Speed

The following serves as an explanation for each

section.

Air Blast -The Air Blast Time is the interval of ti me that the Air Blast Valve is turned o n. Allowed values

are .005 - 1 second.

Tamp Extend -The Tamp Extend Time is the interval of time allotted for the Tamp Slide to extend. After

the timer has timed out, the Air Blast will occur and the Tamp Slid e will return home. To keep labeling

speeds up, this value should be as low as possible. Allowed values are between .01 - 5 sec.

Tamp Retract -The Tamp Retract Time is the interval of time allotted for the Tamp Slide to return home

before feeding another label. If this value is too small, a label will feed into the Pad or Manifold. Allowed

values are between .01 - 5 seconds. Note: In a Tamp Applicator, the Tamp Slide action may be

disabled or enabled by pre ssing the “Tamp Enabled/Disabled” Keys.

Extended Air A ssist -The Extended Air Assist Time is the interval of time after the label feed until the Air

Assist is turned off. It is used in Air Blow and Tamp Applicators to help hold the label in place on the Grid

or Pad prior to being blown onto the product. Allowed values are between .000 - 1 sec.

Web Speed -The “Web Speed” Key allows the opera tor to enter the Applicator Web Speed value. Allowed

values are between 100 and 3000 ”/min with the upper limit depending on the Max Speed setti ng in the

Configurati on Menu. The specific limits are shown above the current Web Speed value. The Web Speed

value may be changed while the Applicator is running.

Pre-Dispense –This is the amount of time before the Air Blast turns-off that the Applicato r begins the label

dispense. This Option applies only to A ir Blow Applicators and will speed-up the application rate. If

the value is too high, the Applicator will start disp e ns ing a label into the Air Blast stream causing the label

to fall off the Grid. Ideally, the Pre-Dispense time allows th e Applicator to get past the label Accel curve

and place the label at the edge of the air stream when the Air Blast Valve turns off.

360a DISPLAY

3-11

APPLICATOR SETUP (cont’d)

Over Speed – The Over Speed Option allows a Merge Applicator to get up to Web Speed faster by

dispensing the “Pre-Apply Feed” distance at the (Pre-Apply Speed % x Web Speed). In Multi-Label mode,

this will help place the labels closer together. Not e: This Option is only for Merg e Applicators.

(Over Speed Screen)

(Over Speed Help Screen)

Note: The Help Screen will note what Functions are disabled when this Function is turned on.

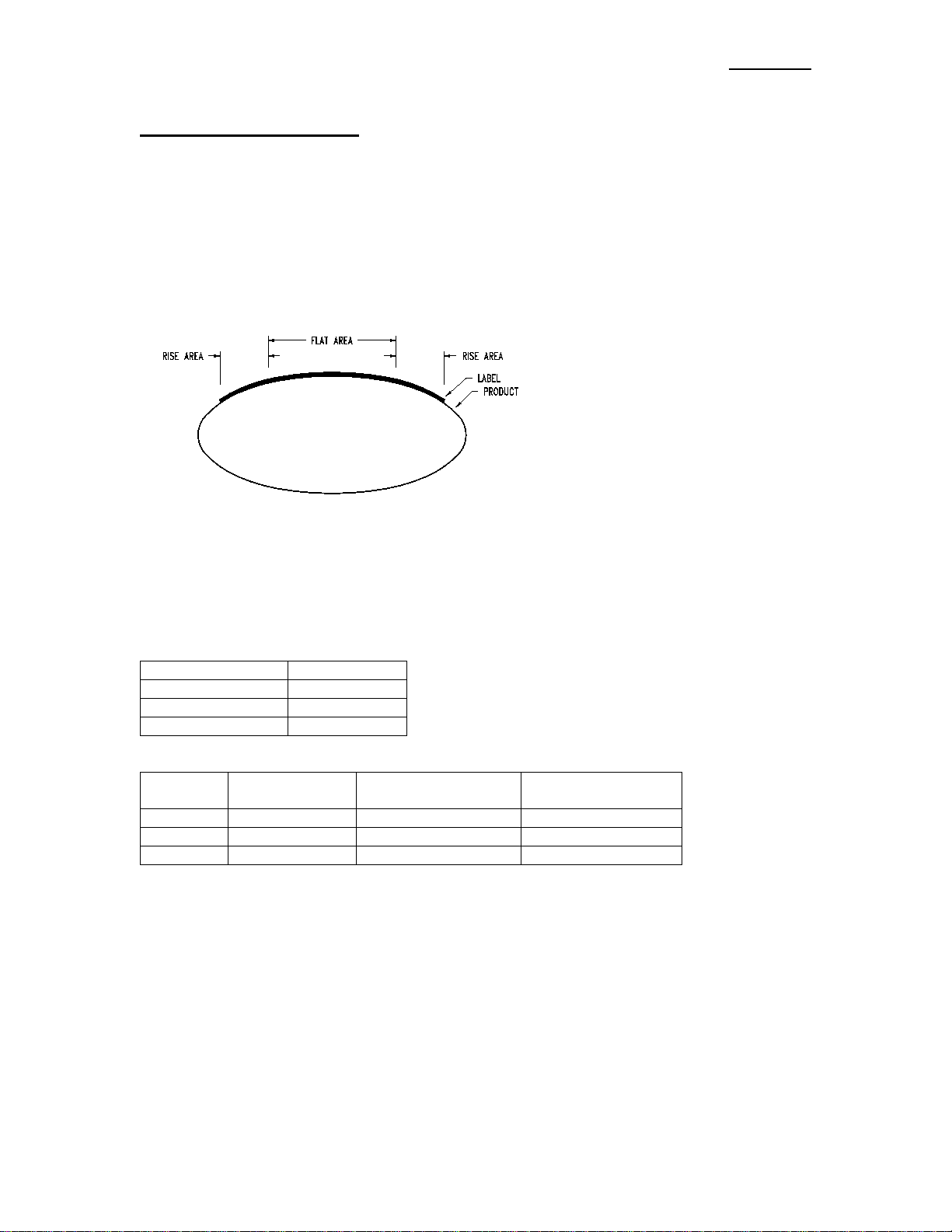

Label Profile -Profiling is a Merge only Option used to aid in labeling products that have a concave or

convex surface. If the surface of the product is convex and the web ratio is less than 100%, t he Applicator

will dispense a label at Web Speed during the “Rise Area” distance. After the “Rise area” distance, the

Web Speed changes to (web speed) x (web ratio) during the “flat area” distance. After traveling the

combined “rise” plus “flat” distances, the Applicator returns to Web Speed for the remainder of the move.

The reaso n for this action is that convex pro ducts start o ut farther away from the Peel Edge than it will be

by mid-product. The label is dispensed at normal speed at the beginni ng of the pr oduct. As the product

surface moves closer, the label must slow down so that the labels do not wrinkle. As the product surface

moves away, the label speeds-up. On concave products the label is dispensed at Web Speed initially. As

the surface of the product moves away, the label is dispensed faster to force the label into the product (Web

Ratio>100%). The label dispense speed is slowed as the product surface moves closer to the Peel Edge.

NOTE: 1) Label Profiling is a function of the Merge Applicator only.

2) Label Profiling is enabled when the “Web Ratio” is set to something different than

“100%”.

3) Max Speed for the Applicator is setup in the Configuration Menu and will range from 100

to 3000 in/min. If the Applicator exceeds the Max Speed “Conveyor Speed, Profile or

OverSpeed % Too High Compared To MaxSpeed” Warning Alarm will occur. The

Applicator will not exceed this speed even if the Web Ratio is set to a higher number.

360a DISPLAY

3-12

APPLICATOR SETUP (cont’d)

(LABEL PROFILE)

(Profile Screen)

(Profile Help Screen)

Note: The Help Screen will note Options that are incompatible with the Profiling

Option.

Profile Variables

Rise Area -This is the distance the label travels before chan ging to the mid-product labeling speed. Enter a

value between 0.1 and 20. The Applicator will be running at Web Speed during this distance.

Flat Area -This is the distance the label tr a vels while at the mid-product labeling speed. Enter a value

between .1 and 20. The Applicator will be running at a percentage (Web Ratio) of the Web Speed dur ing

this distance.

WebRatio -The Web Ratio is a scaling percentage applied to the Web Speed or conveyor speed value to

either slow-down or speed-up the Applicator during the Profile Flat Area. This nu mber will va ry

depending on product shape and is usually determined by trial and error. Enter a value between 50% and

150%.

360a DISPLAY

3-13

Condition

Product Shape

WEB RATIO < 100

Convex

WEB RATIO = 100

Flat Surface

WEB RATIO > 100

Concave

Web Ratio

Setting (%)

Speed during

0” to rise distance

Speed during

rise to flat distance

Speed during flat

to label length distance

< 100

web speed

(web speed) (web ratio)

web speed

= 100

web speed

web speed

web speed

> 100

web speed

(web speed) (web ratio)

web speed

APPLICATOR SETUP (cont’d)

(LABEL PROFILE)

Estimating Rise and Flat Areas

This process will give you a starting po int for setting Profile Variables. Some experimentation is necessary

for best results. The example shown is for a convex or oval product.

1. Apply a label by hand to the product. Measure the Rise Area by looking at the beginning of the

label to where it starts to flatten out. Also measure the length of the Flat Area. Use the diagram

below as an example.

2. Use these numbers when inputting values to the Display.

3. When using this type of product, Web Ratio is set less than 100%. This will slow the Web Speed

during the Flat Area.

PROFILING SUMMARY

360a DISPLAY

3-14

APPLICATOR SETUP (cont’d)

(LABEL PROFILE)

Rise Area and Flat Area Final Adjustment

The system will wor k best with the smallest Rise Area value and the largest Flat Area value that properly

applies the label. Use the instructions below to find these values.

1. With the Applicator online, send several products down the conveyor and observe the labels that

are applied.

2. If the leading edges of the labels were all applied at the same position on the products, go on to

step #3.

If the leading edges of the labels were placed at various positions on the products, the Rise Area

Length is too short.

Slightly increase the Rise Area Length and run some more products. Repeat until the leading edge

label placement is consistent.

3. If the leading edges of the label were applied at the required position on the product, go on to step

#4.

If the leading edge of the label is applied at the incorrect position, adjust the “LABEL

PLACEMENT”, or re-position the product detector. Run some more products. Repeat until the

leading edge of the label is applied a t the r e quired position on the product.

4. If there are no wrinkles or bubbles in the first half of the applied labels, go on to step #5.

If a wrinkle or bubbles appear from the top to the bottom of the first half of the label, the Rise

Area is too long.

Slightly decrease the Rise Area and run some more products. Repeat until the wrinkle in the first

half of the label is removed.

5. If there is no wrinkle in the center of the label, go on to step #7.

If a wrinkle appears from the top to the bottom at the center of the label, either the Web Ratio is

too high, or the Flat Area is too shor t.

The W e b Ratio will be adjusted first. Before adjusting, note the Web Ratio setting. Slightl y

decrease the Web Ratio and run some more products. Repeat until the wrinkle is removed. Go on

to step #7.

6. Increase the Flat Area slightly and run some more products. Repeat until the wrinkle is removed.

7. If the labels are applied wrinkle free from lead edge to trail edge, go on to step #8.

If small horizo ntal wrinkles appear on the trailing edge on the label, the Flat Area is too long.

Slightly decrease the Flat Area and run some more products. Repeat until wrinkles are eliminated.

8. When the Web Ratio, Rise Area and the Flat Area are established, the setup is complete.

360a DISPLAY

3-15

A

B

E

D

C

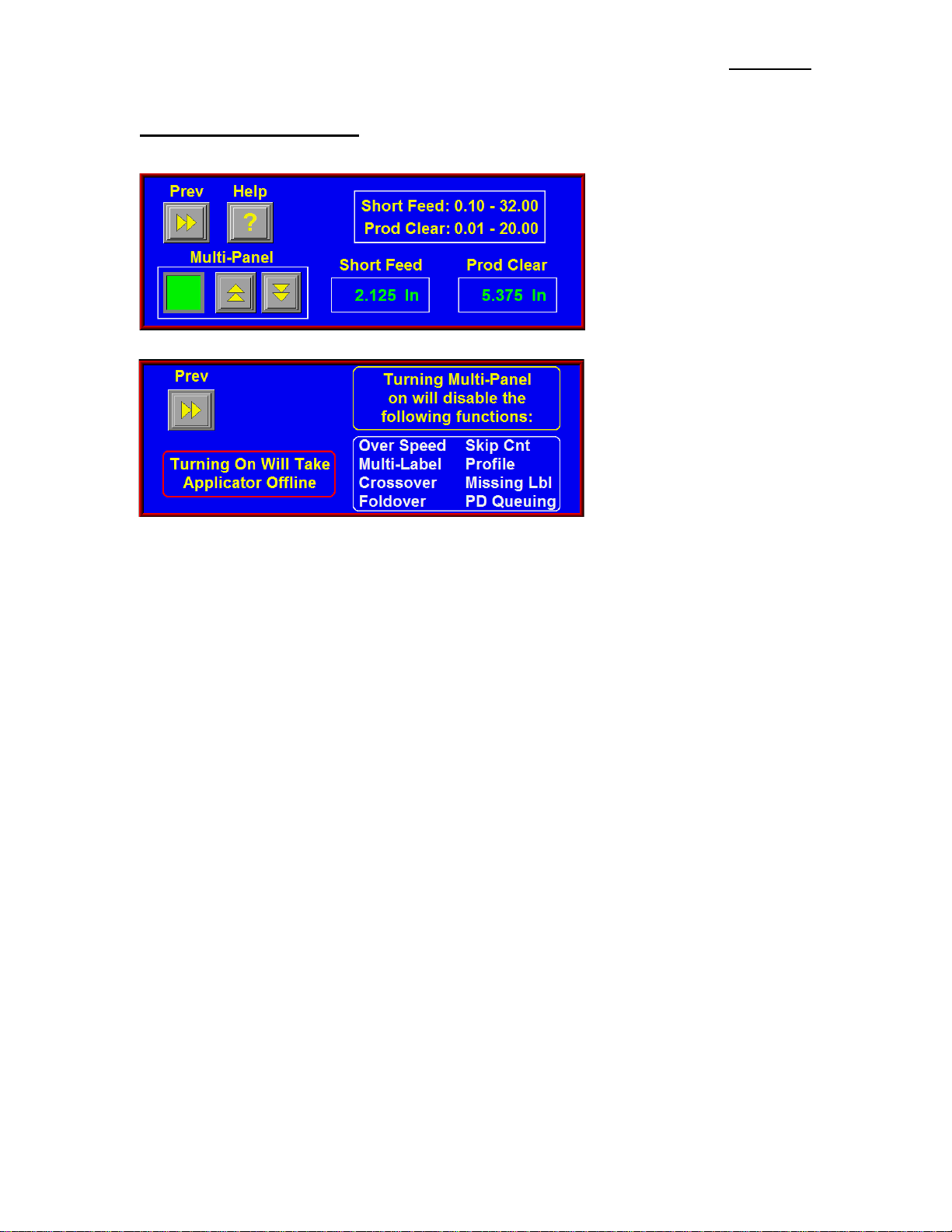

APPLICATOR SETUP (cont’d)

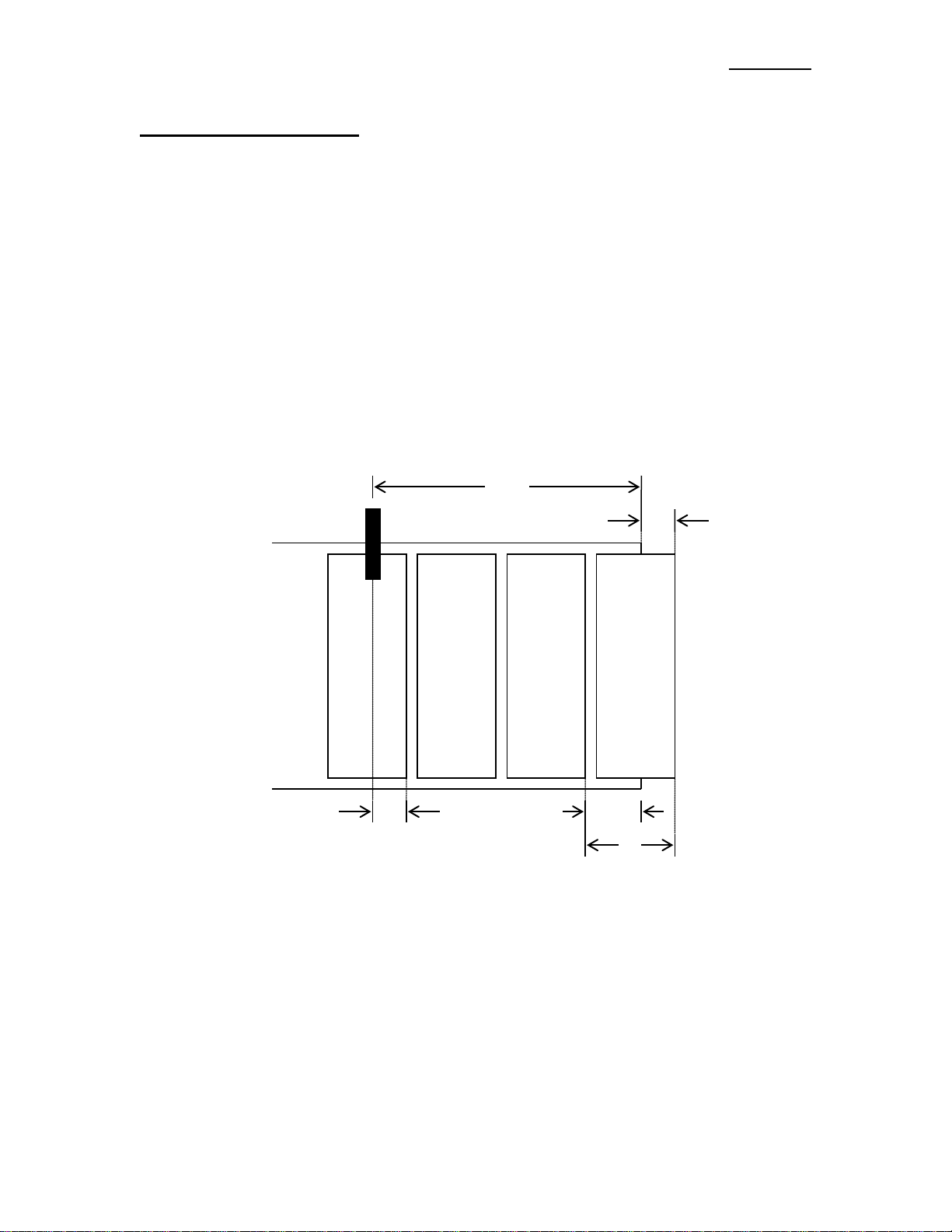

Multi-Panel Apply

The Multi-Panel Apply Option is used to merge a label onto two or three panels of a product. An example

might include the leading, top, and bottom panels of a clamshell container. The Applicator is initially setup

so that the label is flagged out in fro nt o f the product but is still supported on the liner. When a product

detect signal is received, the Ap plicator will wait for the Label Plac e ment distance. At Label Placement,

the Applicator will feed the “Short Feed Distance” at encoder speed. This will place the next label at the

Peel Edge. The Applicator will wait for the “Product Clearance” distance to allow the product to pass by

the Peel Edge before moving t he next label to the flagged out position (Label Stop ) a t Slew Speed. The

figure below illustrates an example se tup with four labels between the Peel Edge and the Label Sensor

along with the measurement definitions:

A: label sensor to peel edge distance

B: label length

C: label flag distance

D’: label stop distance with C = 0 ( no t shown)

D: label stop distance

E: short feed distance

When the Multi-Panel Option is turned on, the user is prompted to go to the Label Setup Menu and perform

a Label Sensor Auto Teach operation. The Auto Teach feature will calculate all of the dimensions shown

above if the option is enabled prior to running auto teach. The operator may override these settings by

measuring values B through E above and enteri ng them via the Display. Note: Since the Multi-Panel

Apply Option is distance based, the Encoder Option must be purchase d.

360a DISPLAY

3-16

APPLICATOR SETUP (cont’d)

(MULTI-PANEL OPTION)

(Multi-Panel Screen)

Note: The Help Screen will note Options that are disabled when this Option is turne d on.

Configuring Mult i -Panel Apply With Auto Setup

1. Make sure the Applicator is powered up and offline.

2. Perform the Encoder Setup procedure outlined in the Product Setup section.

3. Press “APPLICATOR SETUP” and select “MULTI-PANEL”

4. Toggle t he Option on.

5. Enter the distance after the label is dispensed to when the product clears the Peel Edge to the

6. Go back to the Main Menu and press “LABEL SETUP” then “LABEL SENSOR”

7. Select “AUTO SETUP” and follow the screen prompts (see: AUTO TEACH on page 3-7).

Configuring Mult i -Panel Manually

1. Make sure the Applicator is powered and offline.

2. Perform the Encoder setup procedure outlined in the Product Setup section.

3. Using the hand wheel, position the label in the flagged out position.

4. Under “LABEL SETUP”, enter the distance measured for dimension D shown above. Note: If the

(Multi-Panel Help Screen)

Product Clearance box. The distance should be approximately equal to the product length.

Label Sensor is set for trailing edge de te c tion, add the label gap distance to di mens ion D.

360a DISPLAY

3-17

APPLICATOR SETUP (cont’d)

(MULTI-PANEL OPTION)

5. While in “LABEL SETUP” enter the Label Length measured for dimension B.

6. Under “APPLICATOR SETUP”, press the “MULTI-PANEL” button and turn the Option on.

7. Set the Short Feed to the distance measured for dimension E.

8. Enter the distance after the label is dispensed to when the product clears the Peel Edge into the

Product Clearance box. The distance should be approximately equal to t he product l ength.

Note: During the last part of the di spen se cycle (after the product clears the Peel Edge), the label is

dispensed at Slew Speed . This is usually faster tha n the Web Speed and is set in the

Configuration Menu.

PRODUCT SETUP

The Product Setup Menu is accessed from the Setup Menu by pressing the “Product Setup” Key.

The following parameters may be changed or

monitored in this section:

Label Placement(s)

Detector Lockout

Encoder Speed (monitor)

Encoder Option

Label Placement -The Label Placement box lets you change the Label Placement value. Label Placement

is the time or distance from the Product Detect Sensor to where the label is dispensed onto the product. If

the value entered is out-of-range, the previous value will be restored after the “ENT” key is pressed. The

allowed range of values, in seconds if time based o r in inches if encoder based, are shown below the Label

Placement Box. The Label Placement value may be changed while the Applicator is running.

Note: This Label Placement parallels the Main Menu and is located here so that the operator

can do their setups wit hout exiting to the Main Menu.

Detector Lockout -The Detector Lockout functi on is used when more t han one product detect signal is

generated per product. If the Encoder is on, Detector Lockout is in inches; if there i s not an Encoder then i t

will be in seconds. The Lockout starts at the begin ning of a labeling sequence and the Applicator will

ignore Product Detect Signals until the lockout time or distance is finished. Allowed values are between

.001 – 200 inches or seconds.

Encoder Speed -Thi s box displays the conveyor velocity obtained from the Encoder Signal connected to

the Applicator’s Encoder Port. The value displayed is the number of (pulses/min from the encoder) x (the

pulse lengt h in inches/ pulse).

Encoder Option -The Encoder Option is useful when the product veloc ity varies during the applicatio n

cycle. An example of such an ap plication is a Merge Applicator on a Forms Table. With the Encoder

installed and enabled, the Applicator adjusts the label dispense speed to insure accurate label placement on

the product.

360a DISPLAY

3-18

PRODUCT SETUP (cont’d)

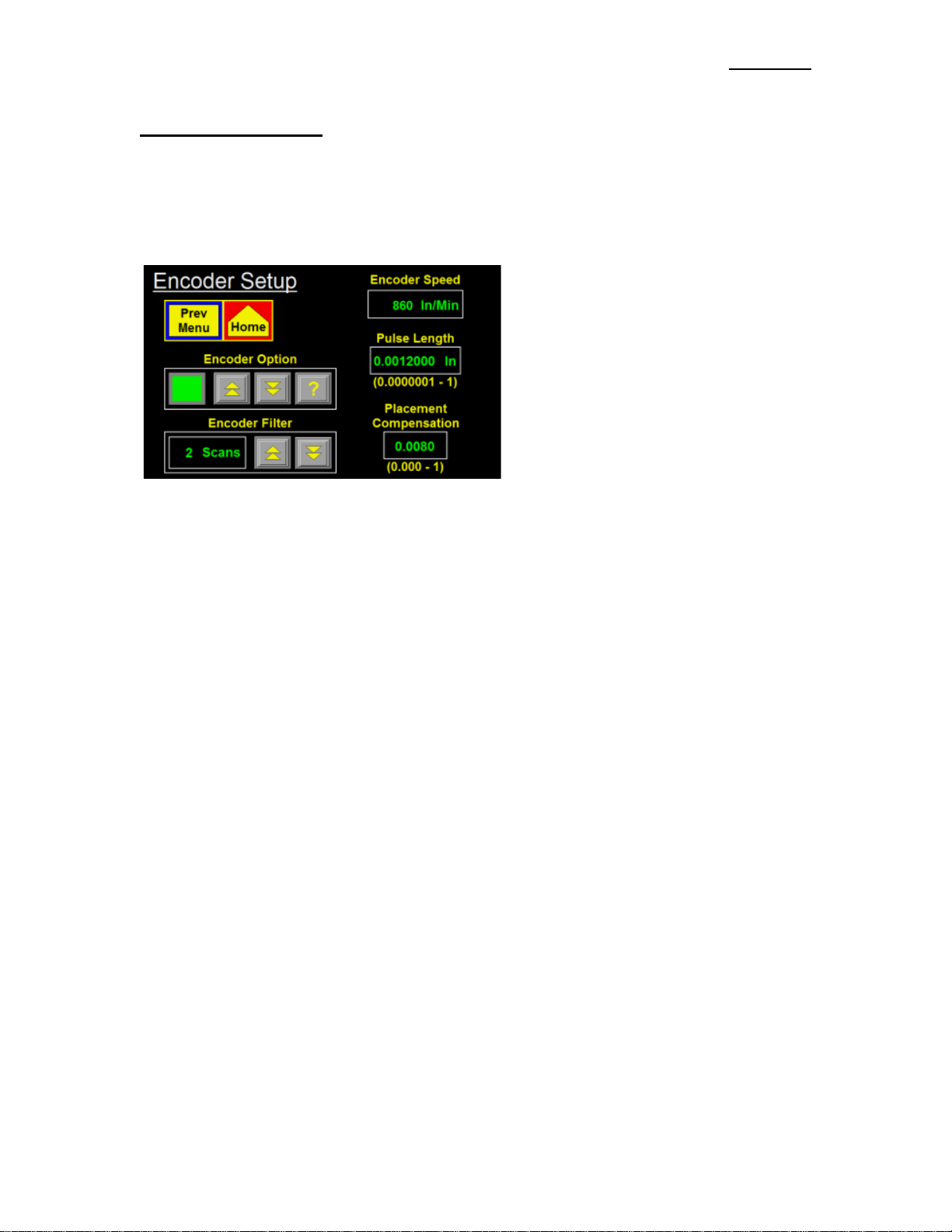

(ENCODER OPTION)

The Applicator has a differential quadrature incremental encoder interface with times four interpolation

built into the controller board. The Encoder Connector, located on the rear panel, has 5 VDC supply to

power the Encoder. The Encoder wiring diagram and pin-out information appear in the drawings section in

this manual and should be consulted for user supplied encoders. Factory encoders generate 2500 pulses per

revolution.

The following parameters may be changed

or monitored in this section:

Encoder Filter

Encoder Option On/Off

Encoder Speed (monitor)

Pulse Length

Compensation

Encoder Filter – In some applications, the Encoder speed varies significantly around some average value.

This is especially problematic with Merge applicators, low-resolution Encoders and low conveyor speeds

where fewer encoder pulses are captured during the velocity calculation interval. The Encoder Filter

function allows the operator to average the Encoder Speed over a range of 1 to 10 scans to produce a

smoother label dispense. As with all filters, the response of the App lic a tor to the change in Encoder Speed

is proportional to the number of Scans. The lower scan numbers are more responsive to speed changes

while the higher number produces a smoother/quieter application with more power in the Merge

Applicator. In applications suc h as Forms Tables, where the conveyor performs start/stop moves, a lower

scan number is appropriate. In constant conveyor speed applications, a scan number closer to 8 may be

more suitable. In all instances, the performance of the system should be verified under a variety of

conditions.

Encoder Option –The Encoder Option Ke ys are for turning this Option on and off. If the Option is on, the

lamp to the left of the keys will be gre en. When the Encoder is on, Label Placement is in inches and not

seconds.

Pulse Length -The distance the product travels per pulse of the Encoder. T he pulse length may be

calculated using the following formula:

Pulse Length = (Distance Product Moves / Rev) /

((Encoder Pulses / Rev) x 4)

EXAMPLE: An Encoder is mounted to a conveyor drive pulley and the circumference of that pulley is

18.75”. Therefore, with one revolut i on of the E ncoder, the product on the conveyor w ill travel 18.75”. The

Encoder is a factory-installed encoder generating 2500 pulses per revolution.

Pulse length = 18.75” / (2500 x 4)

Pulse length = 18.75” / 10000

Pulse length = 0.001875 in/pulse

360a DISPLAY

3-19

PRODUCT SETUP (cont’d)

(ENCODER OPT I ON)

Compensation - Compensation is a number that functions within a formula to reduce the Label Placement

value based on the encoder velocity. When products move faster on the conveyor, the label dispense must

begin sooner to compensate for the acceleration time of the label to the product. The following expla ins

how to setup compensation for the different applicators.

Air Blow and Tamp Compensation Setup

When selecting a value for rate compensation, start at 0.017. Apply labels to the product at a slower speed.

Then run the product at production speeds or faster. If the labels are applied in the same place, the

compensation is correct. If the labels move back at higher speeds, INCREASE THE COMPENSATION.

If the labels move forward, DECREASE THE COMPENSATION. Whenever the rate compensation

value is adjusted, it is advisable to re-run the product at various speeds to make sure that the labels are

applied in the same position.

Merge Compensation Setup

When selecting a value for rate compensation, start at 0.008. Apply labels to the product at a slower speed.

Then run the product at production speeds or faster. If the labels are applied in the same place, the

compensation is correct. If the labels move back at higher speeds, INCREASE THE RATE

COMPENSATION. If the labels move forward, DECREASE THE R ATE COMPENSATION.

Whenever the rate compensation value is adjusted, you should re-run the produc t at slower and faster

speeds to make sure that the labels are a pplied in the same position.

Notes: 1) Label Placement units with the Encode r Option on are in inche s, not seconds.

2) The Encoder Option will not be accurate with a Normal Tamp Applicator.

3) It’s important to make sure that the Applicator is setup pro perly so labels are dispensed

consistently.

4) If product speeds are too fast causing the compensated Label Placement to lag behind the

current Label Placement, a warning will be give n to raise the label place ment value.

5) If the Encoder Option i s t urned off, all of the Enc oder-Based Options will also turn off

automatically. This is sho wn on the Display whe n the Help Key is pressed.

360a DISPLAY

3-20

CONFIGURATION SETUP

The Configuration Setup Menu is accessed from the Setup Menu by pressing the “Confi g Menu” key with

the Applicator offline

Applicator Type -The Applicator Type

function allows the operator to choose the

type of application (Air blow, M erge, Tamp,

or DAT) and whet her it will be in a Left-Hand

or Right-Hand configura tion.

NOTE: If the Apply Hand (Right or Left)

is changed, the user will be forced to cycle

power to the Applicator

There is a Status Box on the right hand sid e of

the screen that displays the current settings.

.

The Configuration Menu provides access to

Applicator: Type Setup, Options, Motion

Parameters, Diagnostics, and the Label Sensor

reset function. The Applicator Setup may be

monitored or changed by accessing the various

submenus.

Applicator Options –It is here that an operator can look to see if an Option is turned on or not. Pressing

the key will take you into the Option’s Sub-menu so that the operator ca n toggle it on/off or set specific

parameters pertaining to the Option. At each Option Sub-menu, there is a Help Key that will direct the user

to a Help Screen that will explain the c urrent Option’s compatibility with other Options and Applicator

Types. The Help Screen will also notify the user if turning the current Option on will change the state of

any other Option or Function.

360a DISPLAY

3-21

CONFIGURATION SETUP (cont’d)

(APPLICATOR OPTIONS)

Loose Loop - The Loose Loop Option allows

labels to be printed and applied from one

system by integratin g a thermal printer into the

web path of the Applicator. As the labe ls exit

the printer, they go around a dancer arm to

maintain web tension. Three (3) Proximity

Switches monitor the dancer arm position. The

loose loop dancer arm assembly should be free

to travel from the “Loose” Loop Prox, past the

“Tight” Loop Prox, up to the “Alarm” Loop

Prox posit ion. In the “at -rest” position, the

lower “Loose” Prox switch is active and the

printer is off. When the dancer arm assembly

reaches the “tight” Loop Prox, the printer begins printing labels. If the upper “Alarm” Prox switch is

active, the Applicator enters a Tight Loop Alarm condition and a “TIGHT LOOP ” message is displayed in

the Status Box on the Main Menu. T he Applicator is inhibited from applying labels until the dancer arm

returns to the lower “Loose” Loop position. When the Applicator is properly set-up under normal

operating conditions, the arm wil l not

360a Applicator is dispensing f aster than what the printer can print. To correct this issue, decrease

the product rate or increase the printer speed. Due to the variety of loop arrangements, the Loose Loop

assembly is a factory-installed item.

This option has not been CE approved.

Imprinter - The Imprinter Option allows a hot

stamp printer to be installed into the web path

of the Applicato r. It is useful in instances

where one line printing or date coding is

required.

There are two modes for the Imprinter. Mode 1

is the original sequence and is used if the

Applicator is controlling the Imprint Valve. The

Dwell Time in this ca s e is how long the Imprint

Valve is turned on. Mode 2 is used when the

Imprinter has its own controller. The Dwell

Value is now the delay the Applicator will wait before looking fo r the Sequence Complete Signal from the

Imprinter. This delay should be close to matching the Imprinter’s Dwell Time. The Help Key will also

explain each Mode at the Display.

This option has not been CE approved.

reach the “Alarm” Prox position. If the “Alarm” Prox is active, the

360a DISPLAY

3-22

CONFIGURATION SETUP

(APPLICATOR OPTIONS)

Crossover – The Crossover Optio n allows for “zero downtime” operation by interconnecting two (2)

Applicators. Both Applicators are placed on the conveyor system one (1) upstream of the other. The

upst r eam Applicator is the “Primary” labeler while the downstream applicator is the “Secondary” labeler.

The Crossover routine has changed after 360a-2c.0.031 progr am version. In the new Crossover routine, the

Secondary still functions the same in that when it gets a signal from the Primary to turn on or off, it will

track the On or Off Distance and change active state. The Primary now will wait for the next Product

Detect signal after it stopped labeling to s t art the Changeover Sequence. The same is true of the

Secondary. If the conditions are set for a “transfer to the primary”, it will wait for an apply cycle before

signaling the Primary to start. This will insure the transitions occur in the same place every time. Also

changed is the Secondary will start labeling if the Primary goes into a Critical Fault or goes offline and will

continue labeling, even if the Primary is brought back online.

Primary To Secondary Example

With the Primary labeling and the Secondary ready to label, if the operator either takes the Primary offline

or it goes into a Critical Alarm, the P r imary will stop labeling and waits for the next Product Detect Signal.

When the Product Dete ct Input turns on, the Primary sends a signal to the Secondary to start the “transfer

sequence.” When the product has traveled the “On Distance”, the Secondary will start la beling. The

operator can now correct the problem with the Primary and bring it back online.

Secondary To Primary Example

If the Secondary is labe ling when the Primary i s brought online, the Primary will not automatically star t

labeling. In the new sequence, the Secondary continues labeling until it is taken offline, Critical or Low

Label Alarm occurs, or the “Transfer” Key is pressed. Taking the Secondary offline or a Critical Alarm

will cause products not to be labeled but if a Low Label Alarm occurs or the Transfer Key is pressed , the

Secondary sends a signal to the Primary to start labeling while it continues to label. The signal o ccurs at

the first apply cycle of the Secondary after the transfer is initiated. The Primary will then look for the next

Product Detect Signal to start labeling again. When it gets the signal, the primary sends a signal to the

Secondary to start the “Off Sequence.” Doing this give s the Secondary a consistent starting point for either

transition s equence.

Main Menu Changes

When the Crossover Option is on, the left side of the Main Menu will c hange. Depending whether it is

setup as the Primary or the Secondary, it will look similar to the screens below.

(cont’d)

The Primary has two lamps that show which

Applicator is labeling. The reason is if the line

stops and both Applicators were online,

without this new setup, it would be impossible

to know whi c h was the active Applicator.

360a DISPLAY

3-23

CONFIGURATION SETUP

(CROSSOVER OPTION)

Crossover Setup

4) If the Applicator is going to be the Secondary, meas u re the distance between the two application points,

subtract ½ inch and enter this as the “On and Off Distances”.

5) Bring both Applicators online and begin labeling products. Take the Primary offline the Secondary

should label the first unlabeled product. If it started labeling too soon, increase the ‘On Distance”. If

labeling started too late and a pr oduct was missed, decrease the “On Distance”.

6) With the Secondary labeling and the P rimary online, press th e “Transfer” Key on the Se condary

Display. The Primar y should start labeling while the Secondary continues to label products between

the two Applicators. When the first labeled product from the Primary reaches the Secondary, the

Secondary should stop lab e ling. If the Secondary continues to label, lower the “Off Distance” value.

If it stopped too soon, increase the value.

(cont’d)

The Secondary has a new button that if this

Applicator is active, you can transfer the

labeling back to the Primary with less chance

of missing products. Pressing this button will

start the Primary labeling (if it is o nline) and

after the Off Distance, the Secondary stops.

1) Turn on the Encoder Option in the

Product Setup Menu.

2) With the Option turned off on both

Applicators, label some products to

make sure the Applicators are setup

properly and Label Placement is

correct. When finished, turn the

Option on in both Applicators.

3) Select the each Applicator to be either

the Primary or the Secondary

Applicator. The green lamp indicates

the current setup.

360a DISPLAY

3-24

CONFIGURATION SETUP (cont’d)

(APPLICATOR OPTIONS)

Multi-Label – The Applicator has the ability to apply multiple labels per Product Detect Signal. The

Number of Labels and the Center-to-Center Distance between the labels are configured in the Multi-Label

Submenu. When the Applicator is online and a product moves in front of it, the Applicator receives a

Product Detect Signal from the Sensor. The Applicator will wait the Label Placement value and apply a

label. An internal counter is incremented and the Applicator waits the Centerline Distance before applying

another label. This sequenc e continues until the Number of Labels has been satisfied. If the label rate is

faster than what the Applicator can dispense, a warning will occur in the Status Box at the Main Menu.

1) To setup, go t o the Multi-Label Option

Menu and turn the Option on.

2) Next, set the Number of Labels you

want to apply to the product.

3) Set the Centerline Distance of the

labels. If the Encoder is turned on the

units will be in inches, otherwise it

will be in seconds.

Note: The Minimum Value for the Centerline Distance is only a suggestion based on variables of the

Applicator Setup. The act ual Minimum Value could be considerably lo wer than the suggested value

in some Applicator configurations. One of these configurations would be a Time-Based Inverted

Tamp Applicator w i th both, Tamp Home and Tamp Re turn Sensors.

Missing Label – The Applicator has the ability to track missing labels between the Peel Edge and the

Label Sensor. When a missing label is detected on the label liner, the Applicator will feed a new label to

the Peel Edge at Slew Speed. After 3 missing labels in a row, a “No Labels Found” message will appear on

the Display (see Note 3 below).

1) To setup thi s Option, go to the

Missing Label Option Menu and turn

the Option on.

2) Count the number of labels from the

Peel Edge (include any that are

hanging out past the edge) to the

Label Sensor (co unt the one under the

Sensor) and enter that number into the

Lbls Between Sensor and Peel Edge

box.

Note: 1) If the Applicator is taken offline with a missing label on the line r between the Sensor and

the Peel Edge, the Applicator will quit trac king t he bl ank spot. Unlike previous software

versions, there is no Alarm Screen to notify the operator of this condition.

2) If the Label Length is changed, the Missing Label Option do e s not turn off as in previ ous

software versions. Therefore, the number of Labels Between Sensor and Peel Edge may be

incorrect.

3) The number of missing labels in a row before an alarm occurs is adjustable. Refer to the

Special Options Section of the Manual on page 3-27.

360a DISPLAY

3-25

CONFIGURATION SETUP

(MISSING LABEL OPTION)

Missing Label Mode 2

The Missing Label Option has two (2) Modes of Operation. If the Applicator Type is set to either Air Blow

or Tamp (N o r I) and the M issing Label Option is turned ON i n the Missing Label Submenu, the operator

can enter the Special Options Menu, see page 3-29, where they can select Mode 2. Missing Label Mode 2

was created to increase the cycle rate of the Applicator by moving the “liner only” condition at the Peel

Edge during the Air Blast and/or the Tamp Retract Time. In previous software versions, this move was

done after the apply sequence was complete. With Mode 2 selected, the Applicator moves the liner while it

is waiting for the Air Blast Time and/or the Tamp Retract Time to finish. This should create faster cycle

rates during missing label cond itions because the Applicator Drive Roller is not sitting idle while the label

is being applied.

NOTE: Since the “liner o nly” condition is going to be moved during the Air Blast Time