Page 1

Transmitter Steering Audio Matrix

Installation & Maintenance Manual

S2-60477-210

April 18, 2003

Information contained in this document is subject to change without notice and does not represent a commitment on

the part of CTI Products, Incorporated. The software described in this document is furnished under a license

agreement. The software may be used or copied only in accordance with the terms of the agreement.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying and recording, for any purpose without the written permission of CTI Products,

Incorporated.

Copyright CTI Products, Incorporated, 1994-2001. All rights reserved.

TSAM™, Smartswitch II and Smart-Steer are trademarks of CTI Products, Incorporated.

CENTRACOM Series II

and are used for reference only.

®

is a trademark of Motorola, Inc. Other trademarks are property of their respective owners

68-11097-210

Page 2

Page 3

TSAM Installation and Maintenance Revision 2.10

CTI Products, Inc.

Table of Contents

1. System Description ......................................................................................................1

1.1 TSAM Features ................................................................................................................... 1

1.2 Model Description ..............................................................................................................2

1.3 Feature Breakdown ............................................................................................................. 3

1.4 TSAM Audio Switching .....................................................................................................4

2. Main Channel Operation ............................................................................................5

2.1 Steering Algorithms ............................................................................................................5

2.1.1 Smart-Steer Intelligent Selection Algorithm...........................................................................5

2.1.2 First Receiver Voted Selection Algorithm ................................................................................. 5

2.2 Basic Transmit Site Update Modes & Controls..................................................................5

2.2.1 Instant Update Mode..................................................................................................................6

2.2.2 End of Receive (EOR) Update Mode / Ping-Pong Repeater Operation..................................... 6

2.2.3 Instant Update Input...................................................................................................................7

2.2.4 Fast Steer On Console 1 PTT.....................................................................................................7

2.3 Initial Transmitter Selection Options..................................................................................8

2.3.1 Home Transmitter / Transmit Revert Timer...............................................................................8

2.3.2 Dynamic Update Mode..............................................................................................................9

2.3.3 Dynamic Multicast Mode........................................................................................................... 9

2.3.4 Transmitter Revert and Dynamic Mode Timer Resets............................................................... 9

2.4 Simplex Operation ............................................................................................................10

2.5 Repeater Operation ...........................................................................................................10

2.5.1 Repeater Operation with various Steering Algorithms............................................................. 11

2.5.1.1 Repeater Keying with Instant Update Mode...................................................................... 11

2.5.1.2 Repeater Keying with EOR Update Mode.........................................................................11

2.5.2 Repeater Hang Time ................................................................................................................11

2.5.2.1 Repeater Hang Time with Instant Update Mode................................................................11

2.5.2.2 Repeater Hang Time with EOR Update Mode ..................................................................12

2.5.3 RPT Disable Input ...................................................................................................................12

2.5.4 RPT KEY Output..................................................................................................................... 12

2.5.5 Repeater Keying Programming Options ..................................................................................12

2.5.6 Console Priority with Repeater Systems..................................................................................13

2.6 Multicast Options..............................................................................................................14

2.6.1 Multicast Operation and Secondary Transmitters....................................................................14

2.6.2 Dynamic Mode with Multicast Operation................................................................................ 14

3. Secondary Channel Operation .................................................................................15

3.1 Secondary Site Selection...................................................................................................16

3.2 Secondary Site Select "Off"..............................................................................................17

3.3 Alert Tone Generation ......................................................................................................17

3.4 Secondary Channel PL Monitor Control ..........................................................................17

3.4.1 Momentary PL Monitor Control ..............................................................................................18

3.4.2 Sustained PL Monitor Control.................................................................................................18

4. Installation..................................................................................................................19

4.1 Power Supply Requirements.............................................................................................19

4.2 Expansion TSAMs for more than 8 Transmitters.............................................................19

i

Page 4

TSAM Installation and Maintenance Revision 2.10

CTI Products, Inc.

Table of Contents

4.2.1 Expansion Cables.....................................................................................................................19

4.2.2 Expansion TSAM Addressing & Jumpers ............................................................................... 20

4.2.3 Expansion Unit Programming.................................................................................................. 21

4.3 Physical installation of TSAM ......................................................................................... 21

4.4 P101 (TX) Cable Signals.................................................................................................. 22

4.4.1 P101 Main Channel Signal Definitions.................................................................................... 23

4.4.2 P101 Secondary Channel Signal Definitions ........................................................................... 23

4.5 P201 (RX) Cable signals .................................................................................................. 24

4.5.1 P201 Secondary Channel Signal Definitions ........................................................................... 25

4.5.2 P201 Main Channel Signal Definitions.................................................................................... 25

4.6 TX Select Console Wiring -- Diode Matrix Plug / Schematic ......................................... 26

4.7 TX Select Console Wiring with Diode Matrix Plug / Physical........................................ 27

4.8 Secondary Site & Frequency Control Wiring................................................................... 28

4.9 Receiver to Transmitter Mapping with Diode Matrix...................................................... 28

4.10 Secondary Frequency Tone Table .................................................................................... 30

4.11 Initial System Checkout.................................................................................................... 32

4.12 Front Panel Indicators....................................................................................................... 33

4.13 Main Channel Checks....................................................................................................... 34

4.14 Secondary Channel Checks .............................................................................................. 35

5. Setting Programmable Options................................................................................ 37

5.1 Terminal Connections & Settings..................................................................................... 37

5.2 Main Menu ....................................................................................................................... 37

5.3 Saving Changes ................................................................................................................ 38

5.4 High Level Guard Tone (HLGT) Options........................................................................ 38

5.5 Function Tone Options ..................................................................................................... 39

5.5.1 Function Tone Level................................................................................................................ 39

5.5.2 Coded (Encrypted) TX operation ............................................................................................40

5.5.2.1 Coded / Clear using Positive Mode Control Keying..........................................................41

5.5.2.2 Coded / Clear using Single Function Tone Keying ........................................................... 42

5.5.3 Keyup Function Tones............................................................................................................. 42

5.6 Repeater Options .............................................................................................................. 42

5.6.1 Multicast Menu........................................................................................................................ 43

5.6.2 L: Listing Enabled Multicast Transmitters.............................................................................. 44

5.6.3 EA Enabling All transmitters for multicast............................................................................. 45

5.6.4 EI: Enabling Individual transmitters for multicast.................................................................. 46

5.6.5 DA: Disabling All transmitters for multicast .......................................................................... 47

5.6.6 DI: Disabling individual transmitters for multicast................................................................. 48

5.6.7 Q: Quitting the Multicast Menu.............................................................................................. 49

5.7 Secondary Channel Options ............................................................................................. 50

5.7.1 Debounce Time........................................................................................................................ 50

5.7.2 PL Monitor Menu .................................................................................................................... 50

5.8 Transmitter Steering Options ........................................................................................... 51

5.8.1 Free Vote & Fade Hold Times................................................................................................. 51

5.8.2 Simplex and Duplex System Issues.......................................................................................... 52

5.8.3 Resteering During Console 1 PTT ........................................................................................... 52

5.8.4 Instant Update / End of Receive Update.................................................................................. 53

5.8.5 Fast Steer on C1PTT................................................................................................................ 53

5.8.6 Smart-Steer Steering Mode .................................................................................................. 53

5.8.6.1 Integration Time................................................................................................................ 53

ii

Page 5

TSAM Installation and Maintenance Revision 2.10

CTI Products, Inc.

Table of Contents

5.8.7 Simplex PTT Release Mask Timer Programming....................................................................53

5.9 Expansion and Home Transmitter Parameters..................................................................54

5.9.1 Expansion Units.......................................................................................................................54

5.9.2 Home Transmitter Selection .................................................................................................... 54

6. Level Setting ...............................................................................................................55

6.1 Tone Keying Generator Level setting............................................................................... 55

6.2 Console 1 & 2 TX Audio Input Adjustment..................................................................... 55

6.2.1 Motorola Centracom Series II Consoles ..................................................................................56

6.2.2 Level setting for other consoles ...............................................................................................56

6.2.3 Bridging Inputs ........................................................................................................................56

6.3 Transmitter 1-8 Line Output Adjustments........................................................................56

6.3.1 TX Output Level Settings ........................................................................................................56

6.3.2 Metering of TX outputs ...........................................................................................................56

6.3.3 Centracom Series II..................................................................................................................57

6.3.4 Other Consoles.........................................................................................................................57

6.4 Receive 1-8 Line Input Adjustment.................................................................................. 57

6.4.1 Generating a RX Peak Reference Tone....................................................................................57

6.4.2 Input range jumper selection....................................................................................................57

6.5 Console 1 RX Audio Output Adjustment ......................................................................... 58

6.6 Console 2 RX Audio Output Adjustment ......................................................................... 58

7. Tone Timing Diagrams..............................................................................................59

7.1 Transmit Tone Control Sequence .....................................................................................59

7.2 PL Monitor / Enable Tones (No TX)................................................................................60

7.3 PL Monitor / Enable Tones (With TX)............................................................................. 60

8. Maintenance Theory..................................................................................................61

8.1 Re-Initializing the TSAM-T1 Transmitter Board .............................................................61

8.2 Transmitter Board Electronics ..........................................................................................62

8.2.1 Power Supply...........................................................................................................................62

8.2.2 Audio circuitry power supply...................................................................................................63

8.2.3 Microcontroller Unit (MCU) ...................................................................................................63

8.2.4 Transmitter Audio Circuitry.....................................................................................................65

8.2.5 TSAM Expansion Bus .............................................................................................................66

8.3 Receiver Board Electronics...............................................................................................66

8.3.1 Receive Audio Line Inputs.......................................................................................................66

8.3.2 Receive Crosspoint Switch ......................................................................................................67

8.3.3 Receive Audio Expansion Bus................................................................................................. 68

8.4 Option Jumpers ................................................................................................................. 69

9. Hardware Specification.............................................................................................72

9.1 Audio Input/Output Electrical Specifications................................................................... 72

9.1.1 Power Requirements................................................................................................................ 72

9.1.2 Audio Inputs ............................................................................................................................72

9.1.3 Audio Outputs.......................................................................................................................... 72

9.1.4 Audio Quality...........................................................................................................................72

9.2 Control Signal Input/Output Electrical Specifications ..................................................... 72

iii

Page 6

TSAM Installation and Maintenance Revision 2.10

CTI Products, Inc.

Table of Contents

9.2.1 All Control Signals EXCEPT "Console 1,2 PTT Out"............................................................ 72

9.2.2 Console 1,2 PTT Out Control Signals ..................................................................................... 73

9.3 Physical and Environmental ............................................................................................. 73

10. Parts List Main Board (TSAM-T1) ......................................................................... 74

11. Parts List Secondary Board (TSAM-R1) ................................................................ 78

12. Schematics and Board Layout Diagrams................................................................ 80

12.1 TSAM-T1 Transmitter Board Schematic Diagram .......................................................... 81

12.2 TSAM-T1 Board Layout Diagram ................................................................................... 83

12.3 TSAM-R1 Receiver Board Schematic Diagram............................................................... 84

12.4 TSAM-R1 Board Layout Diagram ................................................................................... 85

13. TSAM Troubleshooting Charts ............................................................................... 86

Manual Revisions

S2-60477-210 Added gender of P101 and P102 connectors

iv

Page 7

TSAM Installation and Maintenance Revision 2.10

CTI Products, Inc.

Table of Figures

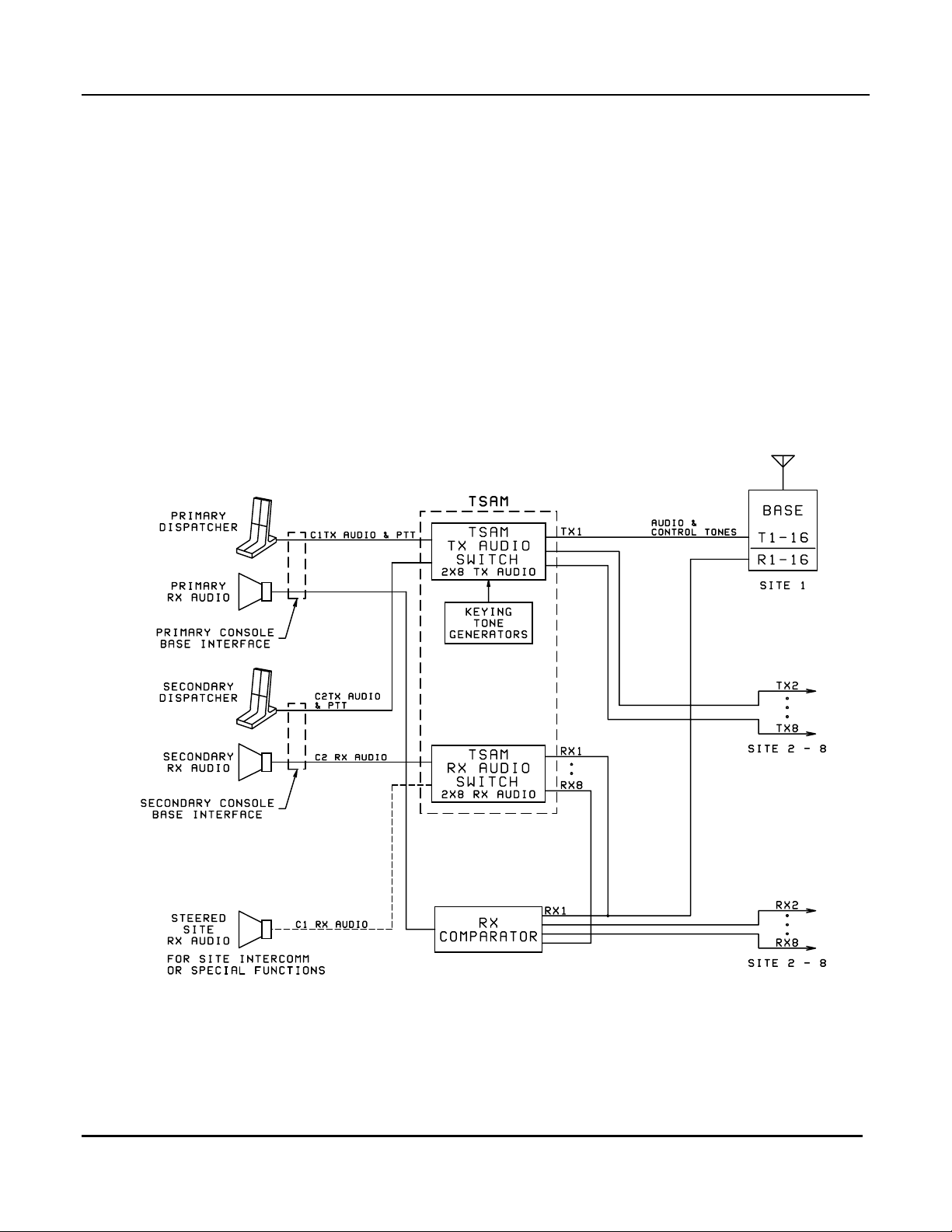

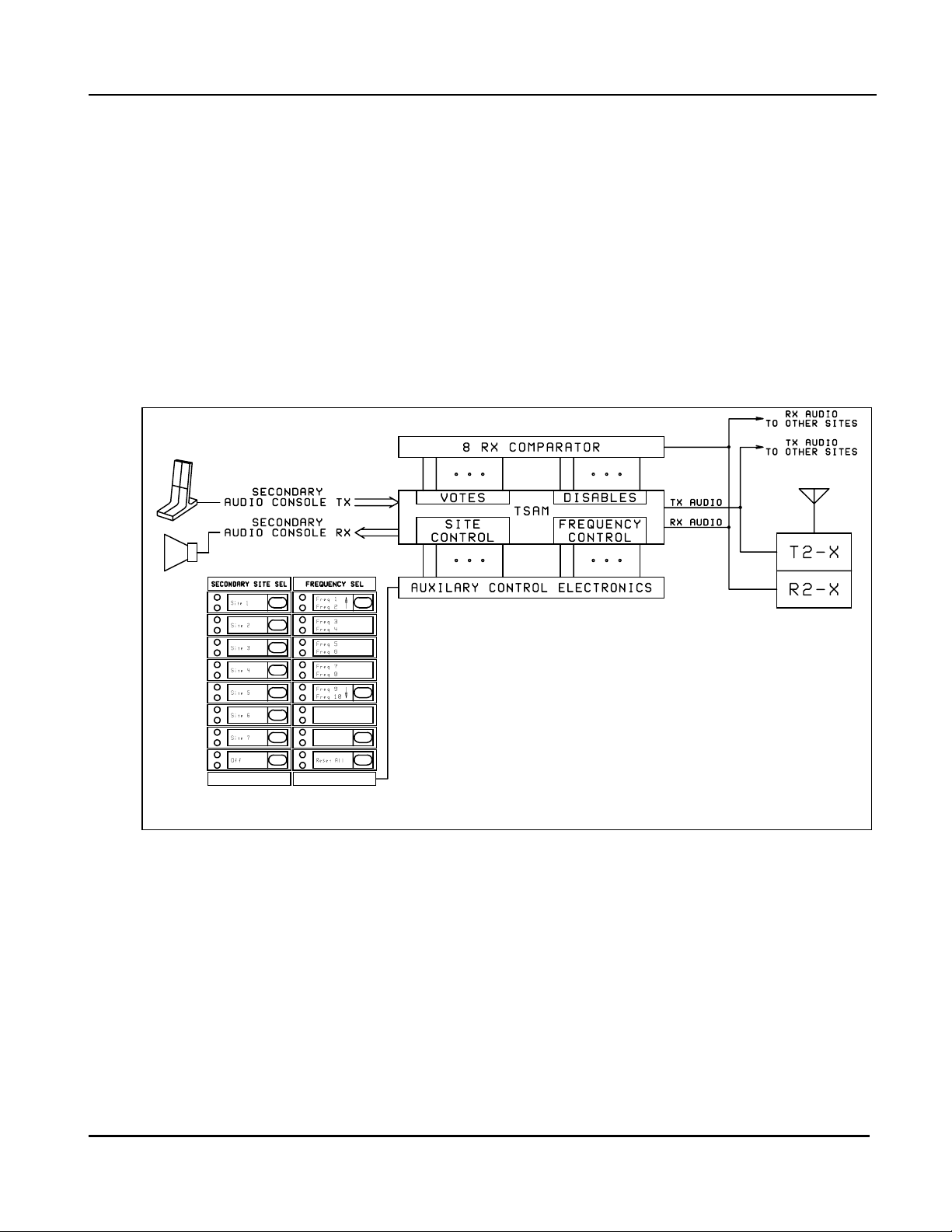

Figure 1 Typical System Diagram ................................................................................................................. 1

Figure 2 TSAM Audio Path Diagram............................................................................................................ 4

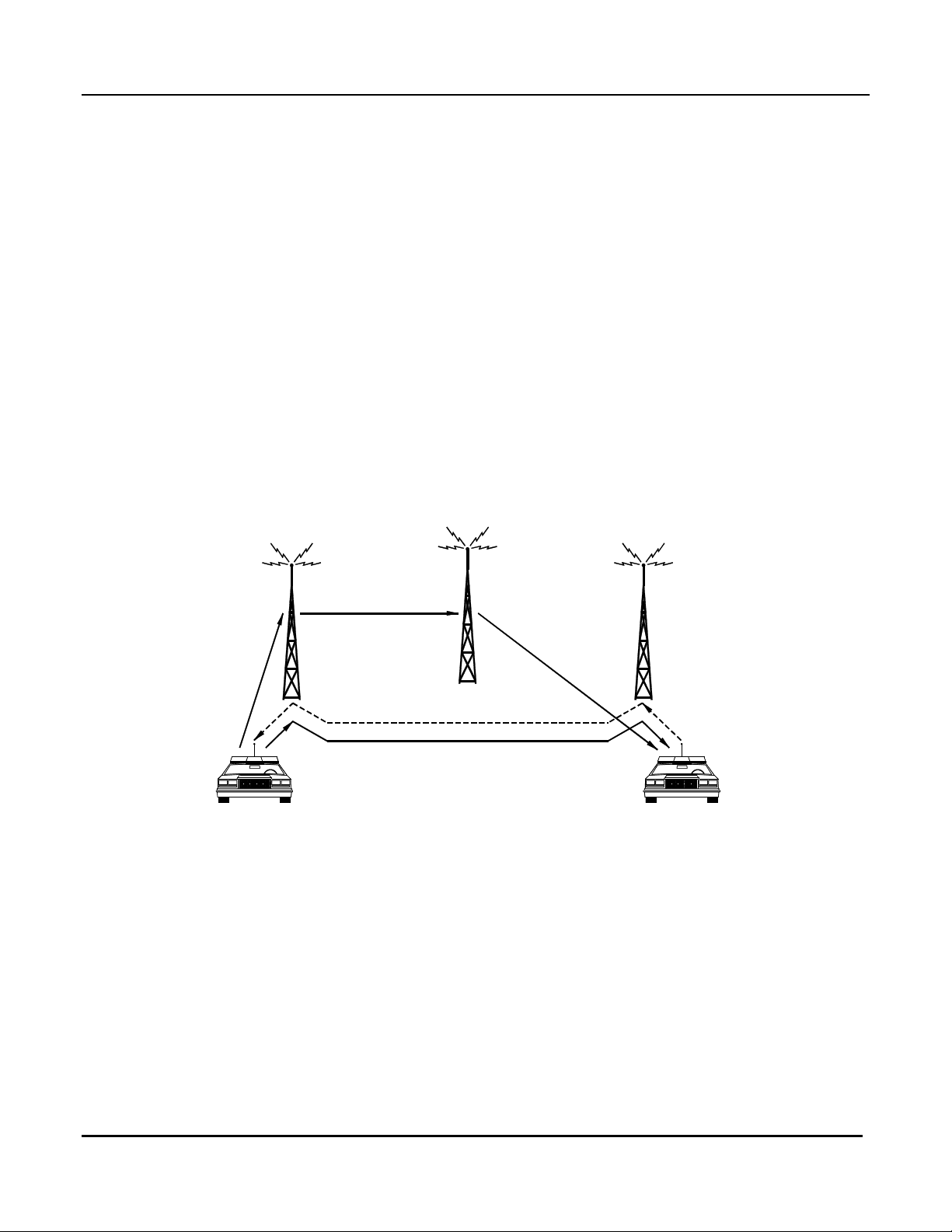

Figure 3 Repeater Ping-Pong Operation with End of Receive Mode ............................................................ 6

Figure 4 TSAM Console Priority Connections............................................................................................ 13

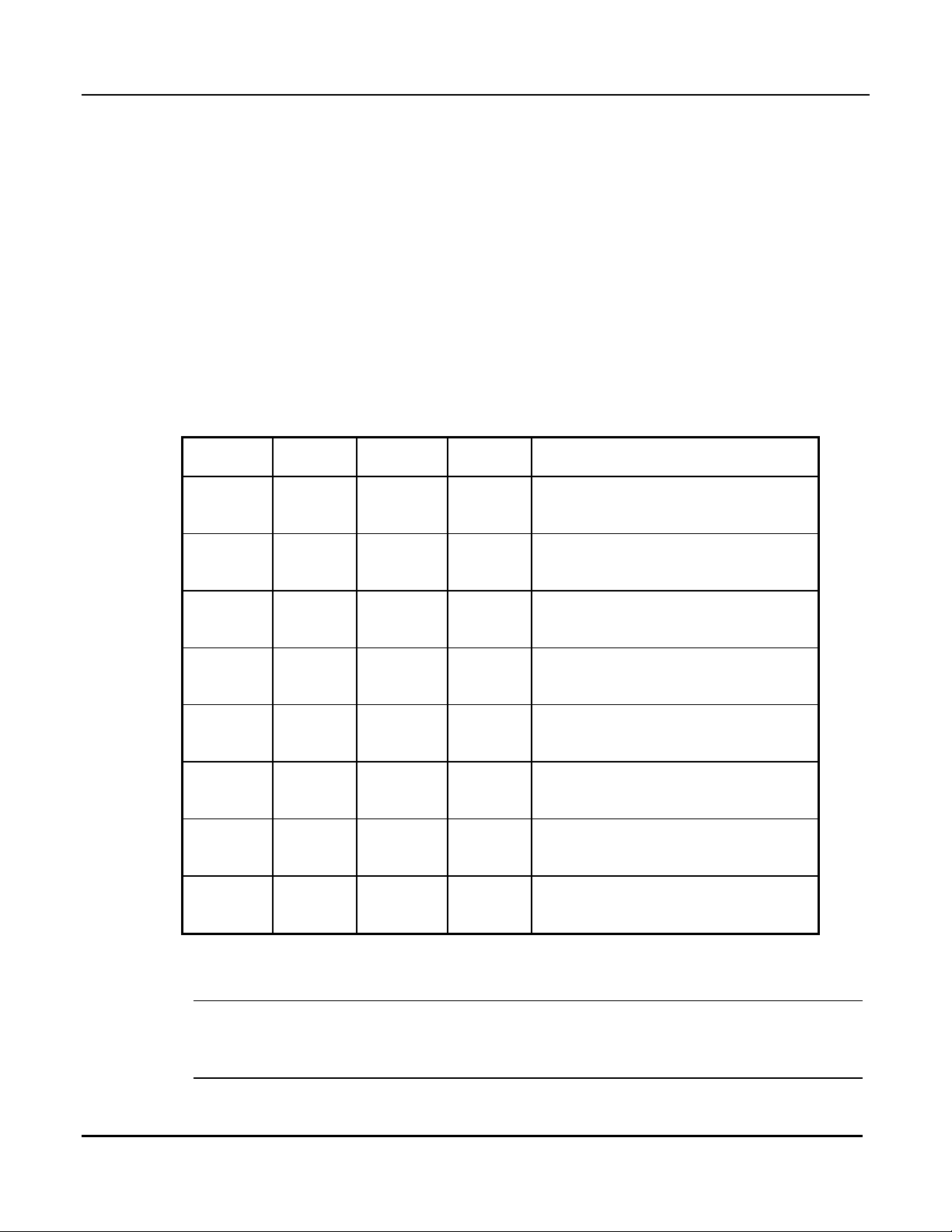

Figure 5 Typical secondary channel control................................................................................................ 15

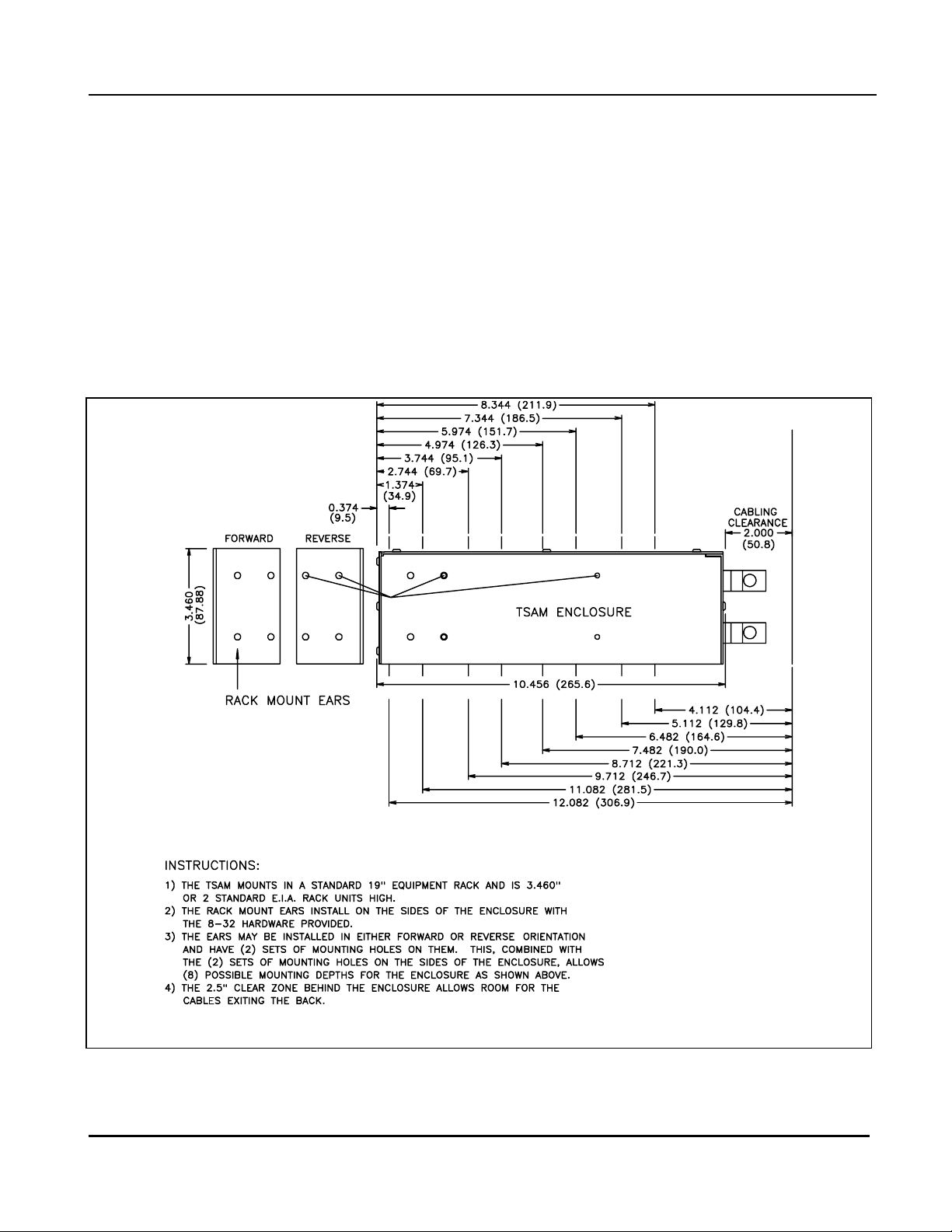

Figure 6 TSAM Mounting Positions ........................................................................................................... 21

Figure 7 TX Select Console Wiring -- Diode Matrix Plug Schematic........................................................ 26

Figure 8 TX Select Console Wiring with Diode Matrix Plug / Physical ..................................................... 27

Figure 9 Secondary Site & Frequency Control Wiring................................................................................ 29

Figure 10 Rx to TX Mapping Schematic..................................................................................................... 28

Figure 11 Rx to TX Mapping Diode Matrix Punch Block ..........................................................................28

Figure 12 System Block Diagram................................................................................................................ 32

Figure 13 Programming Screen ................................................................................................................... 37

Figure 14 Level Adjustment and Test Point Locations................................................................................ 55

Figure 15 Transmit tone Control Sequence ................................................................................................. 59

Figure 16 PL Monitor Tone Sequence -- Sustained Mode -- No TX........................................................... 60

Figure 17 PL Monitor Tone Sequence -- Sustained Mode -- With TX........................................................60

Figure 18 TX Board Audio Block Diagram ................................................................................................ 65

Figure 19 RX Board Audio and I/O Block Diagram ................................................................................... 67

Table of Tables

Table 1 TSAM Accessories........................................................................................................................... 2

Table 2 Expansion TSAM Switch and Jumper Settings.............................................................................. 20

Table 3 P101-TX Cable Connector Pinout and I/O Functions .................................................................... 22

Table 4 P201-RX Cable Connector Pinout and I/O Functions.................................................................... 24

Table 5 Secondary Site Select Inputs ........................................................................................................... 30

Table 6 Frequency Select Tone Table .......................................................................................................... 31

Table 7 Main Board (TSAM-T1) Jumpers.................................................................................................. 70

Table 8 Secondary Board (TSAM-R1) Jumpers..........................................................................................71

v

Page 8

TSAM Installation and Maintenance Revision 2.10

CTI Products, Inc.

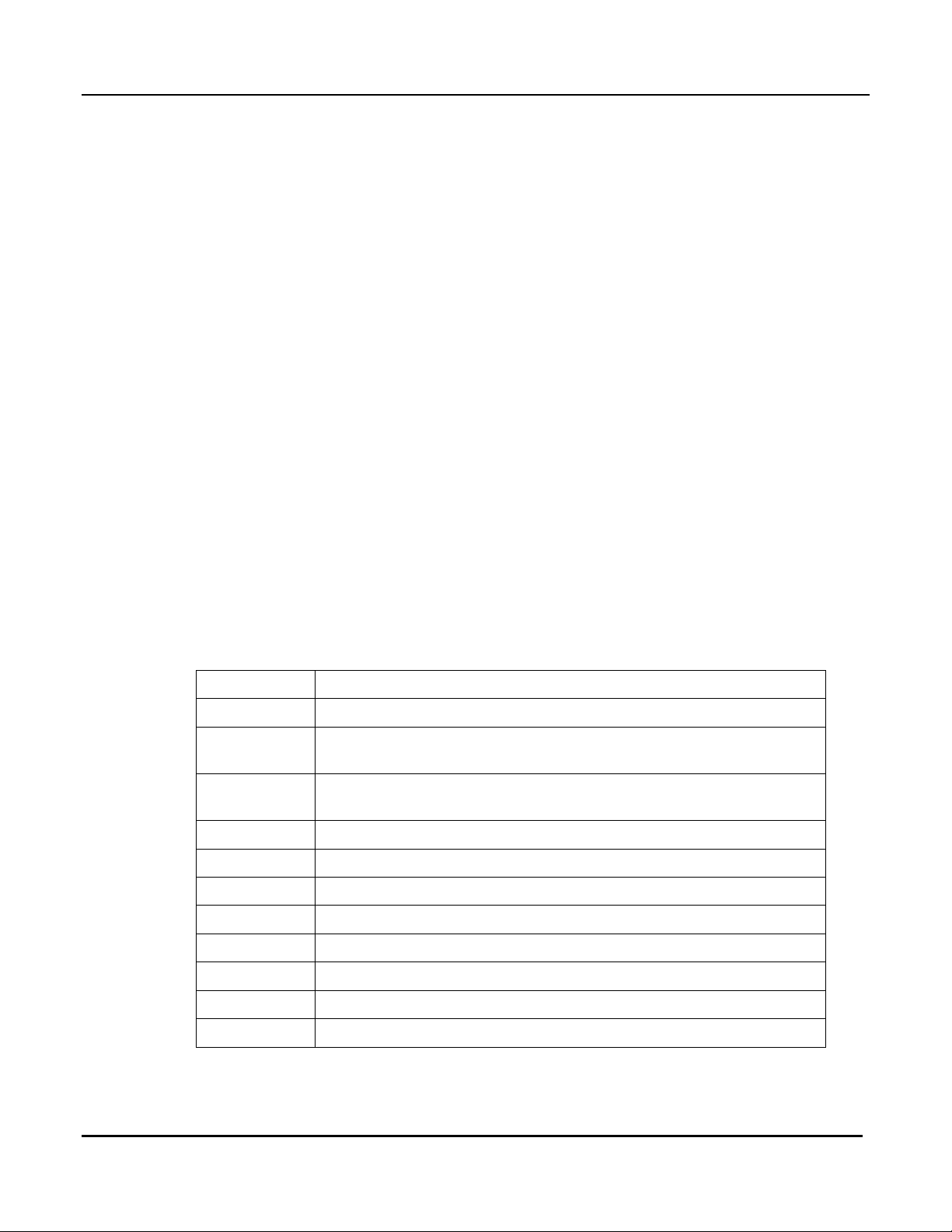

Default Programmable Options Changes Version 1.60

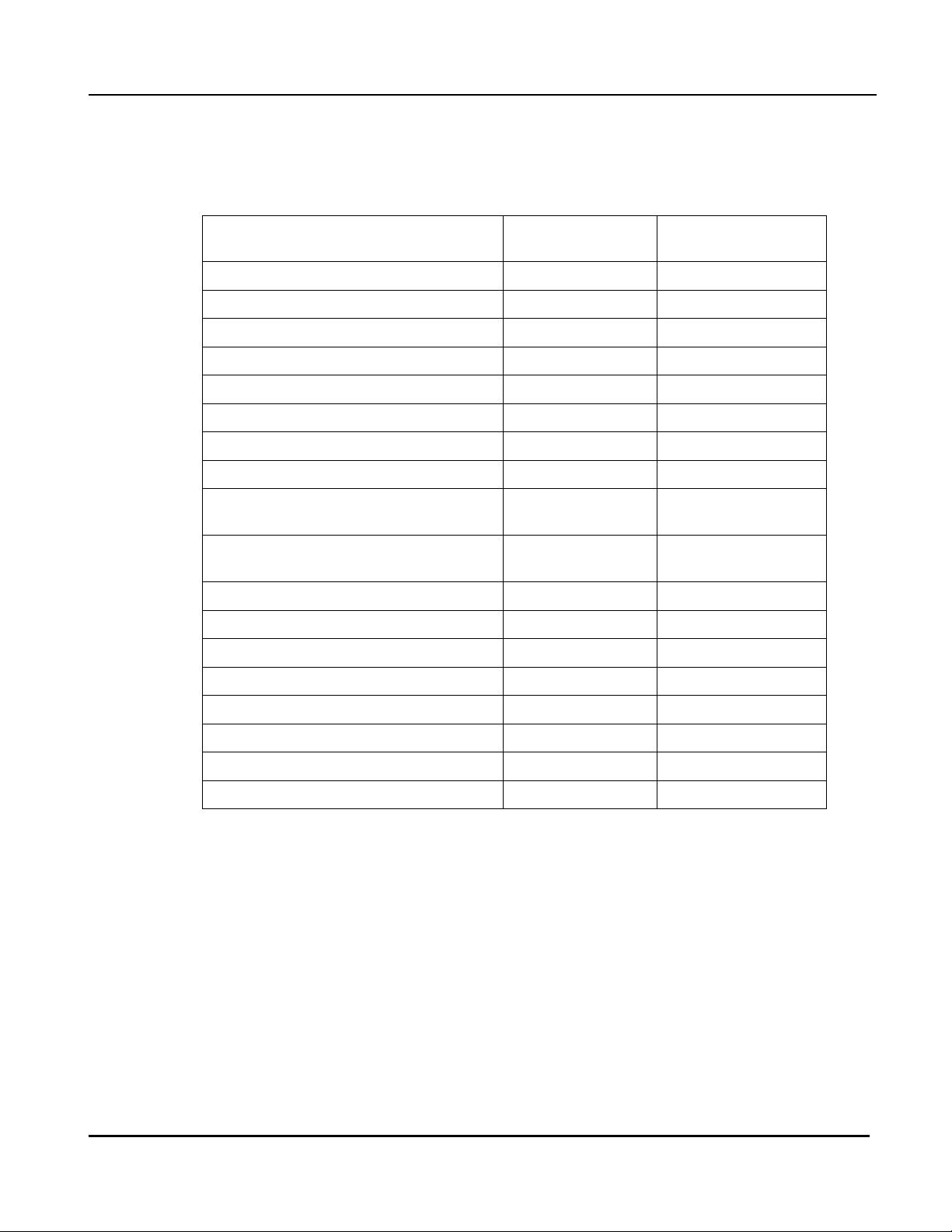

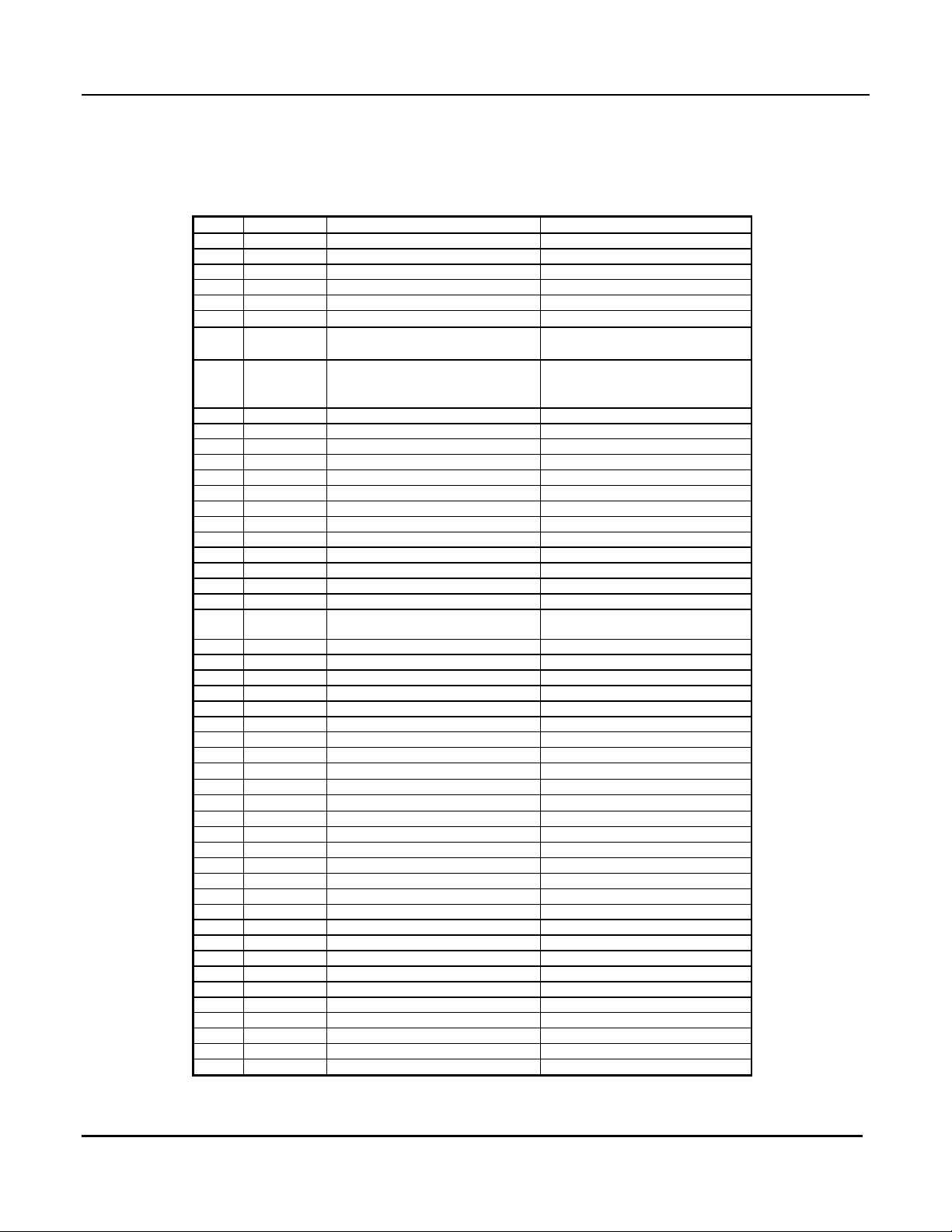

Programming Option Previous Default Value Rev 1.60 Default Value

High Level Guard Tone Duration 60 ms 120 ms

Steering Rules First RX Integrated Vote

Transmitter Revert Time Off 15 seconds

Default Programmable Options Changes in Version 1.70

Programming Option Previous Default Value Rev 1.60 Default Value

Free-Vote Time 230 ms 50 ms

Fade Hold Time 300 ms 50 ms

vi

Page 9

TSAM Installation and Maintenance Rev. 2.10 Chapter 1 CTI Products, Inc. System Description

1. System Description

Transmitter steering radio systems consist of multiple strategically located transmitters and receivers.

When a mobile or portable calls the dispatcher, the system comparator selects the receiver with the best

signal. The CTI Transmitter Steering Audio Matrix (TSAM) monitors this information to determine the

best site for the next transmission. After selecting the proper transmitter site, the TSAM routes the

transmit audio to the selected transmitter and provides a steered transmitter indication for display on the

radio control console.

The TSAM is a microprocessor-controlled unit that is field programmable and incorporates electronic

audio switching for high reliability. The TSAM generates all necessary transmitter keying and control

tones.

1.1 TSAM Features

The TSAM provides the following functions:

Routes audio between up to eight transmitters and eight receivers, with

•

expansion capabilities allowing up to eight TSAM units to be

interconnected. For a maximum capacity of 64 transmitters.

Provides several (selectable) steering decision algorithms.

•

Generates Positive Mode Control (PMC) keying tones.

•

Figure 1 Typical System Diagram

1

Page 10

TSAM Installation and Maintenance Rev. 2.10 Chapter 1

CTI Products, Inc. System Description

A transmitter may be manually selected via a "force" override.

•

Optional Secondary Mode operation, which removes a single base station

•

site from the voting scheme and locks it on an alternate frequency, using

internally generated frequency select tones. Audio is automatically routed

to a secondary base station interface.

Two tone generators, one for main and one for secondary mode operation.

•

A number of key operational parameters are field programmable.

•

PTT relay outputs for both Main and Secondary channels.

•

Repeater Operation

•

1.2 Model Description

Two basic model numbers exist for the TSAM units:

• S1-60165-xxx TSAM -- 8 Transmitters -- No Secondary

This unit has just the Transmit Control Board.

• S1-60006-xxx TSAM -- 8 Transmitters -- With Secondary

1.3 Accessories

The following accessories are available as separate line items for the TSAM unit:

Part Number Description

31-10354 Punch Block, Dual 25 Pair

S1-60216 Cable Assy Tel 50 Pin Female to Male 25FT

81-10397 POWER SUPPLY 120VAC TO 20 VAC TSAM

S2-60740 TSAM Diode Matrix Plug (50 pin - 25 diodes)

S1-60838 Expansion cable kit (2 TSAMs Total)

S1-60839 Expansion cable kit (3 TSAMs Total)

S1-60840 Expansion cable kit (4 TSAMs Total)

S1-60841 Expansion cable kit (5 TSAMs Total)

S1-60842 Expansion cable kit (6 TSAMs Total)

This unit has the Transmit Control Board

and the Receive (secondary) control board.

(1) req'd for each Non-Secondary TSAM unit. (2) for each Secondary unit

(1 req'd for each TSAM unit).

S1-60843 Expansion cable kit (7 TSAMs Total)

S1-60844 Expansion cable kit (8 TSAMs Total)

Table 1 TSAM Accessories

2

Page 11

TSAM Installation and Maintenance Rev. 2.10 Chapter 1

CTI Products, Inc. System Description

1.4 Feature Breakdown

The "xxx" in the model number indicates the version number of the unit. Various features have been

added to the newer units as shown below:

S1-60165-xxx

Feature

First RX Steering Mode Y Y

Smart-Steer™ Steering Mode Y Y

Instant Update Mode Y Y

End of Receive Update Mode Y Y

Secondary Mode N Y

Expandable to 8 TSAMs Y Y

TX Select Indication Y Y

Force Select Y Y

Positive Mode Control (PMC) for

Coded/Clear

Home Transmitter &

TX Revert Timer

Dynamic Update Mode Rev 120 & up Rev 120 & up

Repeater Operation Rev 150 & up Rev 150 & up

Fast Steer on Console 1 PTT Rev 160 & up Rev 160 & up

No Secondary

YY

Rev 120 & up Rev 120 & up

S1-60006-xxx

With Secondary

Simplex PTT Release Mask timer Rev 162 & up Rev 162 & up

Multicast Mode N Rev 170 & up

Multicast Dynamic Mode N Rev 170 & up

PL Monitor (Secondary Channel) N Rev 170 & up

Single-Function Tone Encrypted Mode Rev 170 & up Rev 170 & up

3

Page 12

TSAM Installation and Maintenance Rev. 2.10 Chapter 1

CTI Products, Inc. System Description

1.5 TSAM Audio Switching

Transmit Audio from the radio control console microphone enters the TSAM through the Console 1

(Main--Steered Channel) and Console 2 (Secondary Channel) audio line inputs. A PTT signal for both

Console 1 and 2 is also connected to the TSAM.

When an operator keys the Main channel, transmit audio from the console is routed through the TSAM to

the steered transmitter line output. The proper keying tones are sent to the steered transmitter, thereby

keying the transmitter and passing console audio. The TSAM routes the console transmit audio to any one

of 8 audio line outputs. Audio is also routed out the expansion bus to other TSAMs, for systems with more

than 8 transmitters.

For Main channel operation, the comparator selects the best receive audio source and routes this audio to

the console Main channel RX audio port.

For TSAM units with Secondary Mode operation, receive audio also connects to the TSAM. The TSAM

routes secondary audio from the selected secondary site to the console secondary channel RX audio port.

Figure 2 TSAM Audio Path Diagram

4

Page 13

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2. Main Channel Operation

The Main radio channel is the steered radio channel. The TSAM has inputs to monitor the receiver Vote

or Select lines from the radio system comparator. The Vote indications are processed to determine the start

and end of transmissions from field radios. The TSAM then determines the best site for the next

dispatcher or repeater transmission, based on the criteria outlined in subsequent sections. Upon site

selection, audio from the C1 (Console 1) input line is switched to the steered site line driver.

2.1 Steering Algorithms

Steering algorithms determine how transmitter selection or "steering" occurs. An algorithm processes the

receiver vote information to determine the best transmitter site available. Once determined, the TSAM

activates the steered site. When a site is activated is different from how the site is selected. The Steering

Algorithm determines which site to select, and the Update Mode determines when that site becomes active.

2.1.1 First Receiver Voted Selection Algorithm

One mode for making the steering decision is to select a site based upon the first voted site during a

particular mobile/portable transmission. This mode has the advantage of being able to make a steering

decision before the mobile/portable transmission is complete. However, since the mobile or portable can

change between receive sites during a transmission, the First Received algorithm does not necessarily

reflect the best site to answer the unit at the end its transmission.

2.1.2 Smart-Steer

The Smart-Steer Algorithm watches the voting activity and choses the site that was voted the longest at the

end of the mobile or portable transmission. This gives the benefit of selecting the site closest to the field

unit towards the end of its transmission.

It is not sufficient to make the decision based on the last site voted. On receivers with dual level squelch

circuits, this causes problems. Dual squelch receivers lengthen the squelch tail on weak signals. A

receiver with a slow closing squelch circuit could be voted momentarily at the end of a reception. Picking

the last site voted actually picks a site with poorer reception.

The Smart-Steer selection mode eliminates these problems by picking the site voted for the longest total

time over a programmable period. The TSAM unit offers the benefits of a last-voted steering mode

without the problems caused by slow squelching and dual-level squelch receivers.

Intelligent Selection Algorithm

2.2 Basic Transmit Site Update Modes & Controls

Update Modes

algorithm. Two basic Update Modes are available:

1.

Instant Update Mode

complete.

2.

End of Receive Update Mode

transmission.

determine when the TSAM selects the transmitter based upon the results of the steering

allows the new transmit site to be activated as soon as the steering algorithm is

delays the update till the completion of a portable or mobile

The operation of these update modes can be changed by advanced options such as Home Site Revert and

Dynamic Update Mode.

5

Page 14

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2.2.1 Instant Update Mode

Instant Update Mode updates the steered transmitter as soon as the Free-vote timer has expired at the

beginning of a portable/mobile transmission. It is used only with the First Receiver Vote option enabled.

This mode mode is cannot be used with the Smart-Steer™ voting algorithm.

If you have a repeater system and the units will be talking between sites, the Instant update mode has

limitations. In this case, the unit will transmit from the transmitter closest to himself, not necessarily from

the transmitter closest to the person to whom he is talking.

2.2.2 End of Receive (EOR) Update Mode / Ping-Pong Repeater

Operation

As described above, instant update of the steered site may be undesirable for repeater systems. When a

portable/mobile is repeated, it would ideally be transmitted on the site closest to the person to whom he is

talking. The End of Receive Update Mode allows this. In this mode, the TSAM switches to a unit's

closest transmitter at the end of his transmission. Thus, the response to him will come over his transmitter.

This will allow a "ping-pong" selection of transmitters with two mobiles in different areas as shown in

Figure 3.

Home Site

Site A Site B

Car A Car B

Figure 3 Repeater Ping-Pong Operation with End of Receive Mode

In this example, the following happens:

1. Car A transmits and is received on Receiver A.

Car A is repeated over the Home Site (which has the best coverage).

(Home site Revert will be discussed in section 2.3, Initial Transmitter Selection Options.)

When Car A finishes his transmission, the TSAM unit steers to Transmitter A.

Transmission 1

Transmission 2

Transmission 3

CA-80437-100

2. Car B answers through Receiver B and is repeated over Transmitter A.

When Car B finishes his transmission, the TSAM unit steers to Transmitter B.

3. Car A answers. It is received through Receiver A and repeated through Transmitter B.

6

Page 15

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

Since the Smart-Steer algorithm does not complete vote processing until the end of current receiver

activity, it must use the End of Receive Update Mode.

2.2.3 Instant Update Input

This input can be used to switch between End of Receive Update Mode and Instant Update Mode from the

console. To do this, program the TSAM for End of Receive Update Mode. When the Instant Update

Input is active (low), the TSAM unit will use the First Receiver instant update steering mode on the next

reception. If the TSAM is already programmed for First Receive instant update steering, the input has no

effect.

2.2.4 Fast Steer On Console 1 PTT

TSAM firmware versions 1.60 and later provide a feature that allows the TSAM to steer when Console 1

PTT becomes active, even if receivers are active. This feature is functional only when the steering method

is programmed for Integrated Vote and the Fast Steer option is enabled. This feature allows faster console

transmit operation. The default setting for the Fast Steer option is enabled. It can be programmed in the

TX Steering Menu Integrated Vote section. It is recommended that this option be used whenever the

Smart-Steer™ Integrated Vote algorithm is used.

7

Page 16

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2.3 Initial Transmitter Selection Options

If you have made it this far in the manual, you're probably saying, "Okay, I understand how the Instant

Update and End of Receive Update Modes work, but what happens after the system has been quiet for a

while? Which transmitter is used?" (At least I thought I heard you say that.)

The Initial Transmitter Selection Update Options determine which transmitter is selected on an initial

transmission:

1. Home Transmitter

This is usually selected as the central transmitter or the transmitter with the best coverage.

2.

Dynamic Update Mode

Receive/Smart-Steer™ mode. It works well for repeater systems in which the mobiles units will be

talking primarily with units in the same area.

3.

Dynamic Multicast Mode

mode. This is only available with TSAM units that have Secondary capability. It can be used in very

wide-area systems, especially in repeater systems in which the mobiles will be talking with widely

dispersed mobiles. The first transmission (from the console or a mobile) is transmitted over many (or

all) transmitters. Normal steering will be done on subsequent transmissions.

4.

Force Selection:

manually force select a transmitter from the console. See section 4.6, TX Select Console Wiring -Diode Matrix Plug / Schematic for console connections.

selects a customer-programmed Home transmitter after a period of inactivity.

is a combination of Instant Update/First Receive Mode and End of

is a combination of Multicast Mode and End of Receive/Smart-Steer™

Although this is not a programmed mode in the TSAM, the dispatcher can always

2.3.1 Home Transmitter / Transmit Revert Timer

(TSAM Version 1.20 and up)

Using this mode, the first transmission (from a mobile or console) will be made over a customerprogrammed default "Home" transmitter. Subsequent transmissions are steered normally.

After a customer-programmed period of inactivity has passed, the system will again revert to the Home

transmitter. A period of inactivity is any period when there are no Voted signals, Forced Site Selections,

or Console/Repeater PTTs.

The Revert Timer starts to run at the end of the last detected activity. If any new activity occurs, the timer

is reset and held until the activity ceases. When the timer expires, the TSAM then steers the to the HOME

A transmitter. If secondary operation is used and the HOME A transmitter is being used in the secondary

mode, the TSAM reverts to the HOME B transmitter. After the end of activity, the revert timer starts

running again. On the next expiration of the revert timer, the TSAM checks for the availability of the

HOME A transmitter. If HOME A is available, the TSAM the reverts from HOME B to HOME A. If

HOME A is unavailable, the TSAM remains on HOME B. This cycle continues until HOME A becomes

available.

Transmit Revert Timer Programming

The revert timer is accessed through the TSAMs steering options menu. See section 4, Setting

Programmable Options of the TSAM Maintenance and Installation Manual, for information on accessing

the programming menus.

The Revert Timer can be programmed from 5 seconds to 32,767 seconds (9 hours 6 minutes and 7

seconds). Additionally, the timer can be programmed to revert off. With revert off, the TSAM remains on

the last steered site indefinitely. The TSAM is shipped with the revert timer set to 15 seconds. To

program the timer to off, enter any number between 32768 and 65535 into the timer. Any number in this

8

Page 17

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

range is interpreted as off and will display as revert off on the screen. Numbers outside the range of 5 to

65535 will produce an out of range error, and you will be prompted again to enter a value in the correct

range.

2.3.2 Dynamic Update Mode

(TSAM Version 1.20 and up)

Dynamic update mode is used in conjunction with the EOR (End of Receive Update Mode) and Integrated

Vote mode. Using this mode, the first transmission from a mobile will be made over his transmitter (First

Receive/Instant Update Mode). Subsequent transmissions are steered normally. The first transmission

from a console will be made from either the last transmitter selected or from the Home Transmitter (if it is

programmed and the Revert Timer has timed out).

After a period of inactivity, the dynamic mode timer times out and switches the Update mode to First

receive for the next voted signal. After this, the update mode returns to the Smart-Steer™ Integrated Vote

/ EOR update mode.

Dynamic update allows an EOR update mode system to use a more appropriate steered site when a new

conversation starts. If EOR mode is used alone, a new conversation started on an idle channel would be

transmitted over the last used site. The dynamic update mode selects the site with the best coverage for the

new user. This assumes the new user desires best transmitter coverage in the area near him (as opposed to

across town). After the initial transmit site selection, subsequent sites are steered at the end of

portable/mobile transmissions (EOR update mode).

The Dynamic Mode Timer is programmable from 5 to 32,767 seconds. When programmed for 32,768 to

65,535 seconds the timer is turned off

2.3.3 Dynamic Multicast Mode

Dynamic Multicast Mode is available only on units with the Secondary Mode Option. It is similar to the

Dynamic Mode, but it uses Multicast Mode for the first mobile transmission after the Dynamic Mode

Timer has expired. On subsequent transmissions, the TSAM will use Smart-Steer™ Integrated Vote /

EOR update mode. This allows the first transmission (from the console or a mobile) to be transmitted over

many (or all) transmitters. Normal steering will be done on subsequent transmissions.

2.3.4 Transmitter Revert and Dynamic Mode Timer Resets

The Transmit Revert and Dynamic Mode timers run during periods of inactivity. When a timer is reset, it

is held in the reset state and not allowed to run until the activity has ended. The following types of activity

will reset the timer:

• Vote activity (or internally generated Repeater PTT)

• Console 1 PTT

• Force Select

9

Page 18

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2.4 Simplex Operation

In simplex systems, the voting receivers will hear the base station transmitters. If the comparator is active

during this time, the TSAM must be instructed to ignore any voting activity. This is done by programming

the

‘ Sense RX activity during Console 1 PTT’

Steering menu.

The receivers (and comparator Voted output) will still be active for a short time after the console PTT is

released. TSAM units with version 1.62 firmware and later include a

This tells the TSAM unit to ignore any Voted activity for a period after C1PTT is released.

option is set to

‘N’

Simplex PTT Release Mask Timer.

This is found under the TX

The

Simplex PTT Release Mask Timer

option is set to

PTT’

that it a repeater or split-frequency system.

The

‘ Sense RX activity during Console 1 PTT’

are programmed under the TX Steering menu.

. If this option is set to ‘Y’, this timer has no effect, since the TSAM assumes

‘N’

2.5 Repeater Operation

TSAM firmware versions 1.50 and later provide repeater operation for the TSAM unit. In a simplex

system, the TSAM only keys the steered transmitter when a console PTT is activated. In a repeater

system, the TSAM must also key the steered transmitter whenever a received signal is present and repeat

operation is enabled. The TSAM unit will generate its own internal Repeater PTT based upon activity on

the Voted inputs. Repeater transmitters normally remain keyed for a fixed amount of time after the

received signal drops. This time is the Repeater Hang Time.

Hang Time has several purposes, the main purpose is to minimize system access time. When using tone

keying and CTCSS or DCS, various system delays add up. This forces a repeater user to key for a

significant period of time before audio is repeated to receiving stations. By keeping the repeater

transmitter keyed after an initial transmission several of these access delays are eliminated. Hang time also

provides other benefits, such as eliminating some of the squelch bursts on carrier squelch systems and

providing an audible indication that a user accessed the system and keyed the repeater transmitter.

In a repeater system with transmitter steering, access time and hang time are far more complex than in a

single site repeater system. There are some access time tradeoffs to be considered in a steered system.

These are issues that must be addressed in the system design. The TSAM employs several steering

algorithms and is fully programmable which provides maximum flexibility when designing the steering

system.

is only enabled when the

option and the

‘ Sense RX activity during Console 1

Simplex PTT Release Mask Timer

10

Page 19

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2.5.1 Repeater Operation with various Steering Algorithms

The steering update mode used determines how repeater keying takes place in the TSAM. The TSAM

uses Instant and End of Receive Update modes. The Smart-Steer algorithm always uses the EOR update

mode. First RX steering uses either Instant update or EOR update modes. Repeater keying in each of

these modes is described in the following sections.

2.5.1.1 Repeater Keying with Instant Update Mode

For repeater mode operation, the TSAM will key the steered transmitter when the Free Vote time period

expires. The Free Vote time starts running the instant vote activity is detected on the TSAM inputs.

If the TSAM is in instant update mode, the proper site is steered just before the keying starts. Console 1

TX audio is then routed to the steered site. Repeat audio from the comparator must be routed to the C1

TX audio port. This is accomplished by taking the repeat audio output of a comparator with console

priority capability, or by means of an external relay which will switch between repeat and console audio.

One disadvantage of instant update keying is that the repeater transmitter is not keyed until after the Free

Vote timer expires. If Free Vote is set to a high value, to give the comparator time to make a better voting

decision, the initial part of a transmission will not be repeated. Care must be taken when setting Free Vote

to balance steering performance with system access time. Only repeat audio is effected by Free Vote.

Console audio is not cut off by Free Vote.

2.5.1.2 Repeater Keying with EOR Update Mode

In this mode, new vote activity is repeated over the last used transmitter site (a new site is not immediately

steered). Repeater keying is initiated at the time Free Vote expires. With EOR Update mode, Free Vote

can be set very short or to 0 msec with no degradation of steering performance. This is because the

steering decision is made at the end of vote activity (not at the beginning). After EOR, a steering decision

is made and the new TX site is steered. The next voted signal is then repeated on this site.

2.5.2 Repeater Hang Time

Repeater Hang Time is used on conventional repeater systems to improve system access time. During

hang time, the repeater transmitter remains keyed. Subsequent transmissions due not incur the delays

encountered when re-keying the repeater transmitter. These delays consist of 160ms typical tone keying

delay, and 200ms typical PL decode delay for the receiving field radio.

In a transmitter steering system, the repeater transmitter may change sites on each retransmission, requiring

that a new transmitter be keyed each time. This makes it more difficult to provide the same quick access

of a single transmitter repeater system.

To minimize system access the TSAM uses the following system hang time algorithm.

2.5.2.1 Repeater Hang Time with Instant Update Mode

In Instant Update Mode, when repeat traffic ends, the TSAM keeps the current system transmitter keyed.

When the next transmission begins, the TSAM steers to the site for that transmission. If no site change

occurred, the transmission can proceed over the current transmitter that is still keyed due to system hang

time. In this case, system access time is reduced. If a site change is required to repeat the next

transmission, then the TSAM unkeys the current site and keys the new site. In this case, additional system

access time is added for a new site key-up and PL decoding in the field radio.

11

Page 20

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2.5.2.2 Repeater Hang Time with EOR Update Mode

For EOR updated modes, the TSAM steers to the proper site for the next transmission when the current

transmission ends. If no site change occurs, the current site remains keyed for the duration of hang time.

If a site change does occur, the current site is unkeyed and the new site is keyed. It remains keyed for the

duration of hang time. When subsequent vote activity starts a repeater transmission, the proper site will

be already keyed. This improves system access time.

2.5.3 RPT Disable Input

When activated, the RPT DISABLE input knocks down any ongoing repeater transmission (including hang

time) and prevents any further repeater transmissions from taking place. When inactive, any vote activity

generates a repeater transmission and keys the steered site. If RPT DISABLE goes inactive after vote

activity ends but during the normal hang time period, hang time is not generated. If RPT DISABLE is

activated during hang time and deactivated before hang time expires, no further hang time is generated.

2.5.4 RPT KEY Output

The TSAM generates a RPT KEY signal for use in systems where transmitter keying is done with external

hardware. In these systems, the RPT KEY signal can be used as the PTT signal for the external transmitter

keying hardware. The TSAM generates this signal so that it has control of the hang time keying

generation.

2.5.5 Repeater Keying Programming Options

Enable Repeater Operation

When this option is enabled, the TSAM generates keying tones whenever vote activity is detected. The

TSAM also generates repeater hang time. If keying tones are disabled, then only the RPT KEY output

becomes active when repeater operation is enabled. Secondary channel operation is not supported with

Repeater Operation enabled.

Enable TSAM Internal Tone Keying

When internal keying tones are disabled, tones are not generated for any Main channel function.

Secondary channel functions still generate all required secondary channel control tones.

Repeater Hang Time

Repeater hang time can be programmed for 0 to 32767 milliseconds, and is normally set so the repeater

transmitter is not dropped during a conversation. For more detail on the operation of Repeater Hang Time,

see section 2.5.2 on page 11.

Resteer Key-up Delay Time

Resteer Key-up Delay forces a delay time between unkeying a base station and then resteering and keying

a new base station. It is programmable from 0-2000 milliseconds. The key-up delay is set long enough so

that the first base completes its unkey sequence. Typically, this delay is as long as 200 milliseconds. This

allows for LLGT detect time and the time for PL reverse burst to be transmitted from the base being

unkeyed. This time can be set to zero if key-up of the second transmitter takes around 200 milliseconds or

if the interference from having two transmitters keyed simultaneously is not objectionable.

12

Page 21

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2.5.6 Console Priority with Repeater Systems

In a typical transmitter steering repeater system, a transmitter is keyed from two different sources.

Detection of a received signal will key a transmitter so it can be "repeated", and the systems dispatcher will

key the transmitter from the dispatch console. In many systems, it is required for the dispatcher to have

priority access to the steered transmitter.

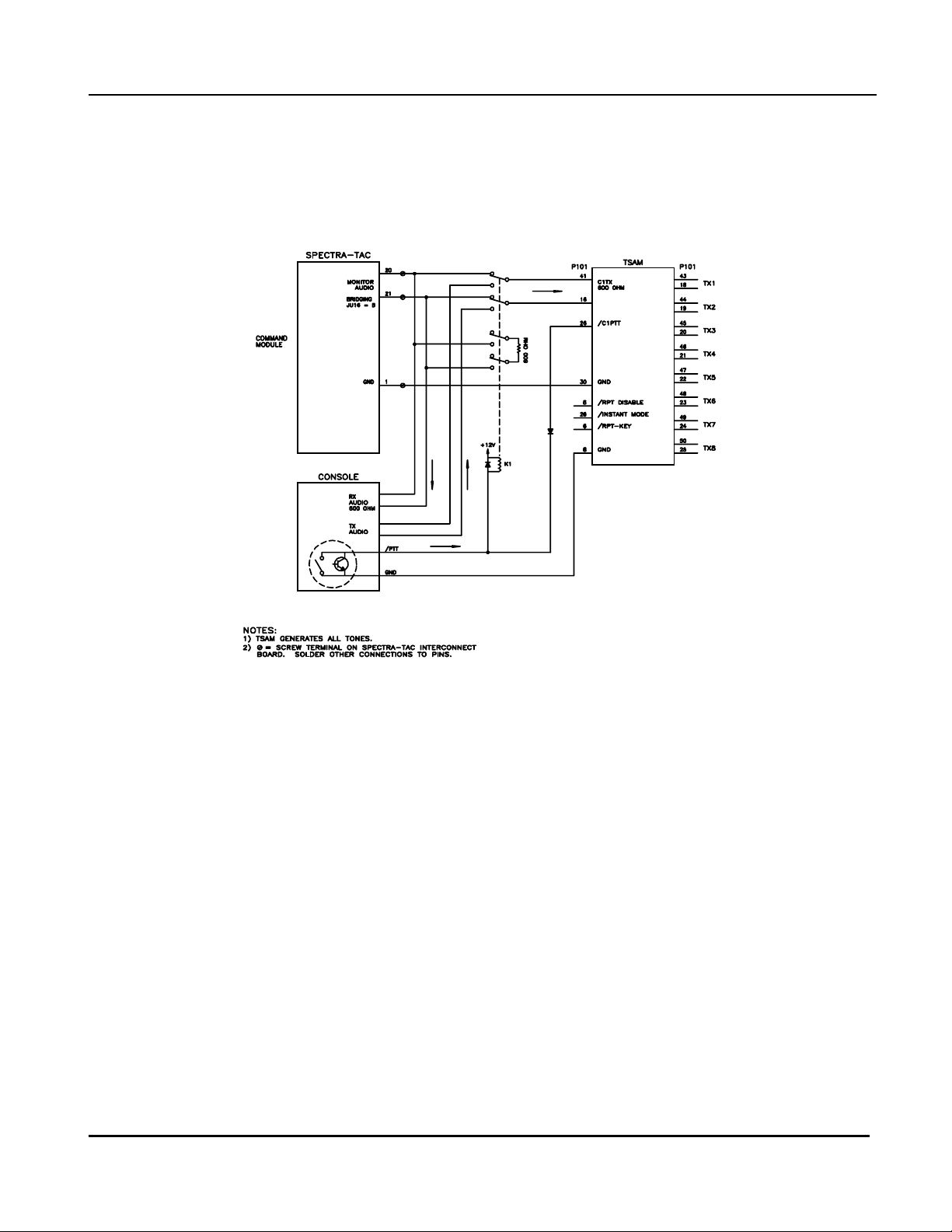

Figure 4 TSAM Console Priority Connections

To provide console priority, an external audio switching relay is added as shown in Figure 4. The console

PTT line is connected to the C1PTT input of the TSAM. Note there is no PTT connection from the

receiver comparator. This is because the TSAM monitors the comparators vote indicate lines and

generates an internal repeater PTT when vote activity is detected.

Since priority is given to console PTT, the TSAMs keying is different when a console keys than when a

repeater PTT keys. These differences are as follows:

• There is no hang time generated when the console unkeys.

• Force Site selects cannot be made while the console is keyed.

• Resteering during console PTT in normally disabled.

If a Force Site Select is activated during a repeater PTT, the current transmitter is immediately unkeyed

and the forced transmitter is keyed. Depending on the timing requirements of the system base stations, a

small portion of a transmission is lost while a station is unkeyed and a new station keyed. If a Force Site

Select is activated during console PTT, it is ignored.

Since resteering during console PTT is normally disabled, any receive activity that occurs while the

console is transmitting will not effect transmitter steering. With resteering enabled during console PTT,

receive activity that steers to a new site is remembered and the new site is updated when console PTT is

released.

Application Notes are available to describe Console Priority with a number of other comparators.

13

Page 22

TSAM Installation and Maintenance Rev. 2.10 Chapter 2

CTI Products, Inc. Main Channel Operation

2.6 Multicast Options

Unit Versions 1.70 and up / Units with Secondary System Capability Only

The Multicast feature allows the dispatcher to key a number of transmitters simultaneously on the main

channel for system-wide announcements. When the latched Multicast input is active and the console is

keyed, the Transmitter Steering System keys all transmitters that are programmed for Multicast operation.

If a transmitter (if any) is in Secondary mode, it will not be used in Multicast mode..

When the Multicast input goes inactive, the TSAM will return to the normal steered operation on the main

channel.

Caution:

The Multicast option is not intended to serve as a Simulcast controller.

There is no simulcast gain, phase, or delay optimization in the TSAM unit.

If the installed system does not have simulcast transmitters and appropriate

simulcast optimized control lines with controlled amplitude, delay and

phase, the system will experience (possibly severe) distortion in RF

coverage overlap areas.

The customer shall accept any and all responsibility and risks associated

with the operation of the system in multicast mode.

Depending upon your system coverage, you may want all or just some of the transmitters to be enabled for

Multicast Mode.

Example 1:

probably want to enable all transmitters for Multicast.

Example 2:

cover well enough for an initial call-up without causing too much distortion in the overlap area.

The transmitters are enabled through the Multicast menu.

If you have a very large system area with minimal overlap between transmitters, you would

If you have 8 relatively closely spaced transmitters, you may find that 3 or 4 of these will

2.6.1 Multicast Operation and Secondary Transmitters

If a transmitter is selected for Secondary operation and the Multicast input becomes active, that transmitter

will not be eligible for Multicast operation while it is selected as a Secondary Transmitter. When that

transmitter becomes de-selected, it will when then be used in Multicast operation on the next transmission

if it was enabled in the Multicast Menu.

If Multicast Mode is turned on and the operator tries to select one of the Multicast transmitters for

Secondary operation, he will hear a warning tone on the Secondary channel.

2.6.2 Dynamic Mode with Multicast Operation

Multicast Mode can be used on the first transmission in a conversation under Dynamic Mode. This

replaces the "First Receive" Dynamic Mode option. See the programming under Transmitter Steering /

Dynamic Mode section.

14

Page 23

TSAM Installation and Maintenance Rev. 2.10 Chapter 3

CTI Products, Inc. Secondary Channel Operation

3. Secondary Channel Operation

Only available on TSAM units with Secondary Option

One unique feature of the TSAM is that it allows a properly equipped steered base station

(receiver/transmitter pair) to be removed from the transmitter steering system and operate as an

independent base/repeater on a second channel. The secondary TSAM channel looks like and additional

channel to the system console. The TSAM supports the selection of up to 15 frequencies for the secondary

base.

Secondary Mode is useful for allowing a wide area coverage system to be used to handle a local incident

without tying up the main channel over the whole coverage area.

Figure 5 Typical secondary channel control

15

Page 24

TSAM Installation and Maintenance Rev. 2.10 Chapter 3

CTI Products, Inc. Secondary Channel Operation

3.1 Secondary Site Selection

The TSAM automatically completes the following steps when a dispatcher selects a secondary site.

Secondary Operation is initiated when the TSAM detects a non-zero secondary site on the binary active

low Site Select inputs. If the site is currently voted, the receiver is immediately disabled, forcing the

receive comparator to re-vote. If the site is currently keyed or steered, the transmitter is disabled and the

TSAM steers to the HOME A or the HOME B site. (If the HOME A site was selected for secondary

operation the TSAM steers to HOME B). Any interlocking required to prevent the TSAM from disabling

active sites is done externally.

The Secondary Site Select Sequence

1. TSAM C2 RX audio is normally muted and remains so. This prevents the secondary dispatcher from

hearing F1 comparator status tone.

2. The TSAM disables the secondary base RX at the receive comparator by forcing its Disable line low

and marking the transmitter as being unavailable for transmitter steering in internal memory.

3. The TSAM sends the currently selected secondary frequency select tones. The secondary frequency is

determined by 4 binary Secondary Frequency Inputs (SF1-SF8). These control lines are set by

dispatcher using the console Frequency Select control. The TSAM uses a programmable debounce

time to allow the inputs to settle before reading the final frequency value. The debounce time allows

the operator to scroll the frequency list without sending frequency select control tones for every

frequency. This time is programmable in 1 ms increments from 0 to 65.535 seconds (due to the 20 ms

scanning latency, the exact debounce is ± 20 ms).

4. If C2 PTT is detected before the debounce time expires, the transmitter is keyed immediately using the

most current frequency select input values. To allow for adequate debounce of the secondary site

select inputs, the inputs are scanned 20ms after the detection of C2 PTT.

5. Secondary Base RX audio outputs and TX audio inputs are routed to the secondary channel control

card in the dispatch console, and the audio paths are unmuted.

6. TSAM monitors Secondary PTT to initiate a secondary transmission.

7. Operator is free to use the Secondary channel or to change the frequency if required.

8. If interlocking of secondary site or frequency control is required, it must be done in the console.

16

Page 25

TSAM Installation and Maintenance Rev. 2.10 Chapter 3

CTI Products, Inc. Secondary Channel Operation

3.2 Secondary Site Select "Off"

1. This function terminates secondary operation and returns the secondary base to the Main steered

channel.

2. Secondary Operation is terminated when all secondary select inputs return high (active low

inputs).

3. The TSAM mutes C2 RX Audio.

4. The TSAM sends the F1 frequency change tone sequence to the secondary base.

5. The TSAM re-enables the receiver by releasing the Disable line to the receive comparator. The

TSAM marks the reverted transmitter as being available for transmitter steering in internal

memory.

3.3 Alert Tone Generation

If an attempt is made to transmit on the secondary channel when no secondary site is selected, a warning

tone is sent to the console. The warning tone is generated by the secondary keying tone generator and

routed through the cross-point audio switch to the secondary console RX audio line driver circuit.

3.4 Secondary Channel PL Monitor Control

Unit Versions 1.70 and up / Secondary System Only

The TSAM can control PL Monitor on the Secondary system. One of two modes may be selected,

Momentary Mode or Sustained Mode.

Momentary PL Monitor is used to check for activity on a Secondary channel before transmitting. It

functions much like a PL monitor on a typical remote control unit. The operator presses a momentary PL

Monitor button, and the base station remains in monitor mode until the next transmission.

Sustained PL Monitor is used to operate a Secondary station in a pseudo carrier squelch mode. This

allows the operator to hear traffic from mobile units that do not transmit the proper PL tones. It requires a

latched console output. The TSAM will generate a PL Monitor tone sequence after each transmission as

long as the PL Monitor input is active.

The PL Monitor function is sent out as two tones:

HLGT + PL Monitor Tone.

Some stations will not decode a new tone command immediately after a transmission or another tone

command. The PL Monitor Delay time is a dead time that allows the station tone decoder to reset before

the PL Monitor tone is sent.

When an operator de-selects a secondary station, the TSAM sends the F1 keying tone or F1 Revert tone to

the station. The station should go back into normal (guarded) PL mode when it changes back to F1.

Program the PL Monitor Control parameters from the Secondary menu:

PL Monitor Tone Timing is shown in sections 7.2 and 7.3.

17

Page 26

TSAM Installation and Maintenance Rev. 2.10 Chapter 3

CTI Products, Inc. Secondary Channel Operation

3.4.1 Momentary PL Monitor Control

When the Monitor input is momentarily activated, the TSAM sends a PL Monitor tone out the selected

Secondary site. The station re-enables the PL decoder on the next transmission.

3.4.2 Sustained PL Monitor Control

When the Monitor input is activated, the TSAM sends a PL Monitor tone out the selected Secondary site.

Since the station re-enables the PL decoder after a transmission, the TSAM will re-send the PL Monitor

tone after each transmission, as long as the PL Monitor input is active.

When the PL Monitor input goes inactive and a Secondary Site is still selected, the TSAM will generate

the appropriate Secondary Frequency tone sequence to that site.

If the PL Monitor input is active when a Secondary Site is first selected, the TSAM unit will do the

following:

1. Send the Secondary Frequency tone sequence

2. Wait for the PL Monitor Delay time

3. Send the PL Monitor tone sequence.

After the dispatcher releases the PTT, there will be a slight delay in receiving a mobile without the proper

PL, due to the time required to send and decode the PL Monitor tone sequence.

18

Page 27

TSAM Installation and Maintenance Rev. 2.10 Chapter 4 CTI Products, Inc. Installation

4. Installation

Installation of the TSAM consists of:

• Pre-setting jumper options

• Mounting the unit in a cabinet

• Routing the 25 pair control and audio cable(s) to the cross-connect panel

• Routing the power cable

• Programming the options

• Setting the system transmit and receive audio levels.

4.1 Power Supply Requirements

The TSAM requires either 24V DC or 20V AC at 1 amp maximum for proper operation. A 2-conductor

power connector and cord are supplied. Although the TSAM is polarity insensitive, observe proper color

coding conventions when connecting the TSAM to a DC supply.

4.2 Expansion TSAMs for more than 8 Transmitters

Multiple TSAMs can be linked together to control more than 8 transmitters or receivers on one channel.

As many as 8 TSAMs can be tied together. This allows control of up to 64 transmitters. If you have

expansion units, you will have to change some jumpers in the units before you mount them (unless the

units are marked as expansion units from the factory).

4.2.1 Expansion Cables

When multiple TSAMs are used together, they are linked through the expansion bus. The expansion bus is

made up of the necessary audio and control busses to allow TSAMs to share transmitter control hardware.

The master and slave units are connected via a daisy-chain ribbon cable that connects to P103 on all

TSAMs on the channel. Cables are available for systems with 2-8 TSAM units. See Table 1 TSAM

Accessories for part numbers.

When installing the expansion cables, install the supplied cable grounding clamps.

19

Page 28

TSAM Installation and Maintenance Rev. 2.10 Chapter 4

CTI Products, Inc. Installation

4.2.2 Expansion TSAM Addressing & Jumpers

Address switch SW102 on the front of the TSAM is used to set TSAM SPI bus addresses.

A Master TSAM always has address 0. Additionally, the Master TSAM drives the Main and Secondary

channel expansion transmit audio busses and receives audio on the Main and Secondary channel receive

audio expansion busses.

Slave TSAM units have addresses 1-7. The addresses must be sequential and no addresses may be

skipped.

The SW102 master/slave switch must be in the S position on all Slave TSAMs.

The Master TSAM controls the transmitter steering system. The MCU and control logic on the slave

TSAM operates only in a standby diagnostic mode. All of the Slaves I/O logic and audio switching are

controlled by the master TSAM MCU.

TSAM

Address

0 0,0,0 M

1 0,0,1 S

2 0,1,0 S

3 0,1,1 S

4 1,0,0 S

5 1,0,1 S

6 1,1,0 S

7 1,1,1 S

SW102

4,2,1

SW102

M/S

(Master

)

(Slave)

(Slave)

(Slave)

(Slave)

(Slave)

(Slave)

(Slave)

TX

Sites

1-8 E109-E112,E125 = In

9-16 E109-E112,E125 = See Note

17-24 E109-E112,E125 = See Note

25-32 E109-E112,E125 = See Note

33-40 E109-E112,E125 = See Note

41-48 E109-E112,E125 = See Note

49-56 E109-E112,E125 = See Note

57-64 E109-E112,E125 = In

Jumpers

E123,E127,E124,E128 = A

E217,E218,E219,E220 = Top

E123,E127,E124,E128 = B

E217,E218,E219,E220 = Bottom

E123,E127,E124,E128 = B

E217,E218,E219,E220 = Bottom

E123,E127,E124,E128 = B

E217,E218,E219,E220 = Bottom

E123,E127,E124,E128 = B

E217,E218,E219,E220 = Bottom

E123,E127,E124,E128 = B

E217,E218,E219,E220 = Bottom

E123,E127,E124,E128 = B

E217,E218,E219,E220 = Bottom

E123,E127,E124,E128 = B

E217,E218,E219,E220 = Bottom

Table 2 Expansion TSAM Switch and Jumper Settings

0 = down, 1= up

Note: RS-485 Terminators

Jumpers E109-E112, and E125 install RS-485 terminator resistors on the expansion bus. The terminators

are always required on the first and last TSAMs in a system. This means the Master TSAM and the last

Slave TSAM always have these jumpers installed. All other Slave TSAMs have these jumpers removed.

20

Page 29

TSAM Installation and Maintenance Rev. 2.10 Chapter 4

CTI Products, Inc. Installation

4.2.3 Expansion Unit Programming

When a system is programmed for a slave (expansion) TSAM and the slave unit is disconnected, the

system must be reprogrammed to insure proper operation. If you must run a system with an expansion unit

disconnected, re-program the master TSAM for one less expansion unit. Be sure that the expansion units

are addressed sequentially.

4.3 Physical installation of TSAM

A set of rack mount ears are furnished with the TSAM. There are two mounting locations on the TSAM

enclosure for the mounting ears. There are two sets of mounting holes in the ears. The ears may be

mounted with the mounting flange forward or reversed. These options allow the TSAM to be mounted in

any of 8 positions. This allows mounting in a variety of racks or cabinets.

Figure 6 TSAM Mounting Positions

21

Page 30

TSAM Installation and Maintenance Rev. 2.10 Chapter 4

CTI Products, Inc. Installation

4.4 P101 (TX) Cable Signals

This male connector is present on all units. The TX cable contains all of the transmit audio line outputs

and control signals.

Pins In/Out Name Notes

26 In Console 1 M Keying (/PTT) LOW=PTT

1 In Console 1 Coded/Clear LOW=Coded

27 In Console 2 M Keying (/PTT) LOW=PTT

2 In Console 2 Coded/Clear LOW=Coded

28 In FORCESEL LOW=Force Select Site

3In

29 In

4Out

30 Ground

5 Out Console 1 PTT Out COM Relay Closure=PTT

31 Out Console 1 PTT Out N.O. Relay Closure=PTT

6 Ground

32 In RX Voted 1 LOW=Voted

7 In RX Voted 2 LOW=Voted

33 In RX Voted 3 LOW=Voted

8 In RX Voted 4 LOW=Voted

34 In RX Voted 5 LOW=Voted

9 In RX Voted 6 LOW=Voted

35 In RX Voted 7 LOW=Voted

10 In RX Voted 8 LOW=Voted

36 Ground

11 In/Out TX Sel 1 /TXS1

37 In/Out TX Sel 2 /TXS2 LOW=Steered or Forced

12 In/Out TX Sel 3 /TXS3 LOW=Steered or Forced

38 In/Out TX Sel 4 /TXS4 LOW=Steered or Forced

13 In/Out TX Sel 5 /TXS5 LOW=Steered or Forced

39 In/Out TX Sel 6 /TXS6 LOW=Steered or Forced

14 In/Out TX Sel 7 /TXS7 LOW=Steered or Forced

40 In/Out TX Sel 8 /TXS8 LOW=Steered or Forced

15 Ground

41 In Console 1 TX Audio Tip

16 In Console 1 TX Audio Ring "

42 In Console 2 TX Audio Tip

17 In Console 2 TX Audio Ring "

43 Out TX 1 Audio Tip 600 Balanced Output

18 Out TX 1 Audio Ring "

44 Out TX 2 Audio Tip 600 Balanced Output

19 Out TX 2 Audio Ring "

45 Out TX 3 Audio Tip 600 Balanced Output

20 Out TX 3 Audio Ring "

46 Out TX 4 Audio Tip 600 Balanced Output

21 Out TX 4 Audio Ring "

47 Out TX 5 Audio Tip 600 Balanced Output

22 Out TX 5 Audio Ring "

48 Out TX 6 Audio Tip 600 Balanced Output

23 Out TX 6 Audio Ring "

49 Out TX 7 Audio Tip 600 Balanced Output

24 Out TX 7 Audio Ring "

50 Out TX 8 Audio Tip 600 Balanced Output

25 Out TX 8 Audio Ring "

RPT DISABLE LOW=Repeater TX Disabled

Instant Mode LOW=force Instant Update

Steering

RPT KEY LOW=Repeater PTT for

external transmitter

hardware

LOW=Steered or Forced

Force In/Selected Out

600 or 10KΩ balanced Input

600 or 10KΩ balanced Input

Table 3 P101-TX Cable Connector Pinout and I/O Functions

22

Page 31

TSAM Installation and Maintenance Rev. 2.10 Chapter 4

CTI Products, Inc. Installation

4.4.1 P101 Main Channel Signal Definitions

Console 1 M Keying (/PTT) (C1PTT) Logic signal from Console

Low = PTT on Main Channel

Console 1 Coded/Clear Logic signal from Console

Low = Coded TX Main Channel

High = Clear TX Main Channel

Console 1 TX Audio Tip & Ring 600 Ohm (Or Bridging) TX Audio from Console (Main

Channel)

RX Voted 1-8 Logic signals from comparator

Low = Voted

Instant Mode Logic signal from Console

Low = Instant TX Update Mode

RPT DISABLE Logic signal from Console

Low = Disable Repeater Operation

High = Enable Repeater Operation

(if programmed)

RPT KEY Logic Output from TSAM (Not normally used)

Low = PTT during Repeat operation

Console 1 PTT Out COM & N.O Relay contacts active when C1PTT is active.

FORCESEL Logic signal from Console (used with /TXS1-8)

Low to Force Select.

This tells the TSAM to use the /TXS1-8 lines as inputs.

Holding this line low also disables automatic steering.

TX Sel 1-8 /TXS1-8 Bi-directional logic signals

To/from Console (Main Channel)

Outputs from TSAM (when FORCESEL is High):

Low = Selected TX

Inputs to TSAM (Read on low-going FORCESEL):

Low = TX to force select

TX 1 - 8 Audio Tip & Ring 600 Ohm TX Audio Outputs to Transmitters

(Main Channel)

Gnd Negative Ground (common for all logic signals)

4.4.2 P101 Secondary Channel Signal Definitions

Console 2 M Keying (/PTT) (C2PTT) Logic signal from Console

Low = PTT on Secondary channel

Console 2 Coded/Clear Logic signal from Console

Low = Coded TX Secondary Channel

High = Clear TX Secondary Channel

Console 2 TX Audio Tip & Ring 600 Ohm (Or Bridging) TX Audio from Console (Secondary

Channel)

Gnd Negative Ground (common for all logic signals)

23

Page 32

TSAM Installation and Maintenance Rev. 2.10 Chapter 4

CTI Products, Inc. Installation

4.5 P201 (RX) Cable signals

This male connector is present only on units with Secondary Mode. It contains all receive audio line

inputs, control inputs for secondary operation, and a few other functions.

Pins In/Out Function Notes

26 Out Disable RX 1 LOW=Disable Site Receiver

1 Out Disable RX 2 LOW=Disable Site Receiver

27 Out Disable RX 3 LOW=Disable Site Receiver

2 Out Disable RX 4 LOW=Disable Site Receiver

28 Out Disable RX 5 LOW=Disable Site Receiver

3 Out Disable RX 6 LOW=Disable Site Receiver

29 Out Disable RX 7 LOW=Disable Site Receiver

4 Out Disable RX 8 LOW=Disable Site Receiver

30 Ground

5 Out Console 2 PTT Out COM Relay Closure=PTT

31 Out Console 2 PTT Out N.O. Relay Closure=PTT

6 Ground

32 In Sec Site Sel 1 /SS1 Active Low Binary Site Data

7 In Sec Site Sel 2 /SS2 "

33 In Sec Site Sel 4 /SS4 "

8 In Sec Site Sel 8 /SS8 "

34 In Sec Site Sel 16 /SS16 "

9 In Sec Site Sel 32 /SS32 "

35 In Multicast Enable (Main Channel) LOW = Enable Multicast (if pgm)

10 In PL Monitor Secondary Channel LOW = PL Monitor

36 Ground

11 In Sec Freq Sel 1 /SF1 Active Low Binary Freq Data

37 In Sec Freq Sel 2 /SF2 "

12 In Sec Freq Sel 4 /SF4 "