Page 1

MCN Monitoring and Control Network

Comparator Display System

Input/Output Interface Module

IIB

Hardware Reference Manual

S2-60400-115

68-10844-115

Page 2

FCC Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Warning: Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to operate the

equipment.

DOC Statement

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

This manual describes products which include copyrighted CTI Products, Inc. computer programs in semiconductor memory. CTI Products, Inc. reserves all

Computer Software Copyrights

rights for these programs, including the exclusive right to copy or reproduce the copyrighted computer programs in any form. No copyrighted computer program

contained in products described in this manual may be copied, reproduced, decompiled, disassembled, or reversed engineered in any manner without express

written permission of CTI Products, Inc. The purchase of products from CTI Products, Inc. shall not be deemed to grant either directly or by implication, estoppel,

or otherwise, any license under the copyrights, patents, or patent applications of CTI Products, Inc., except for the normal non-exclusive, royalty fee license to use

that arises by operation of law in the sale of the product.

Information contained in this document is subject to change without notice and does not represent a commitment on the part of CTI Products, Inc.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, for any

purpose without the written permission of CTI Products, Inc.

Copyright 1995, CTI Products, Inc. All rights reserved.

MCN is a trademark of CTI Products, Inc. ASTRO-TAC is a trademark of Motorola, Inc. Other trademarks referenced are properties of their respective owners.

68-10844-115

Page 3

IIB Hardware Reference

CTI Products, Inc.

Standard Limited Hardware Warranty

LIMITED WARRANTY. Equipment manufactured by CTI Products, Inc. is warranted to be free from defects in material and workmanship for a

period of ONE (1) YEAR from date of shipment to original purchaser. Under this warranty, our obligation is limited to repairing or replacing any

equipment proved to be defective by our inspection within one year of sale to the original purchaser. This warranty shall not apply to equipment which

has been repaired outside our plant in any way, so as to, in the judgment of CTI Products, Inc. affect its stability or reliability, nor which has been

operated in a manner exceeding its specifications, nor which has been altered, defaced, or damaged by lightning.

CUSTOMER REMEDIES. In the event of a defect, malfunction, or failure to conform to specifications established by the seller during the period

shown, the customer shall call CTI Products, Inc. to obtain a Return Authorization Number and return the product or module, shipping and insurance

prepaid. CTI Products, Inc., will then at its option, either repair or replace the product or module and return it, shipping prepaid, or refund the

purchase price thereof. On-site labor at the purchaser's location is not included in this warranty.

EQUIPMENT NOT MANUFACTURED BY CTI Products, Inc. Equipment not manufactured by CTI Products, Inc. is excluded from this

warranty, but is subject to the warranty provided by its manufacturer, a copy of which will be supplied to you upon specific written request.

NO OTHER WARRANTIES. The foregoing constitutes the sole and exclusive remedy of the buyer and exclusive liability of CTI Products, Inc.,

AND IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED OR STATUTORY AS TO MERCHANTABILITY,

FITNESS FOR PURPOSE SOLD, DESCRIPTION, QUALITY, PRODUCTIVENESS OR ANY OTHER MATTER.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES. WITHOUT LIMITING THE FOREGOING, IN NO EVENT SHALL CTI

PRODUCTS, INC. OR ITS SUPPLIERS BE LIABLE FOR ANY DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS

OF BUSINESS INFORMATION, OR OTHER PECUNIARY LOSS) ARISING OUT OF THE USE OF OR INABILITY TO USE CTI

PRODUCTS, INC. EQUIPMENT BY PURCHASER OR OTHER THIRD PARTY, WHETHER UNDER THEORY OF CONTRACT, TORT

(INCLUDING NEGLIGENCE), INDEMNITY, PRODUCT LIABILITY OR OTHERWISE, EVEN IF CTI PRODUCTS, INC. HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES OR LOSSES. IN NO EVENT SHALL CTI PRODUCTS, INC.’S, LIABILITY

EXCEED THE TOTAL AMOUNT PAID BY PURCHASER FOR THE EQUIPMENT GIVING RISE TO SUCH LIABILITY.

68-10844-115

i

Page 4

IIB Hardware Reference

CTI Products, Inc.

CTI Products, Inc.

1211 W. Sharon Rd.

Cincinnati, OH 45240

If you have questions about the MCN comparator display system, call us at:

(513) 595-5900. (8:30 to 5:00 Eastern)

68-10844-115

ii

Page 5

IIB Hardware Reference

CTI Products, Inc.

1. INTRODUCTION.....................................................................................................1

1.1 REFERENCE DOCUMENTS ...........................................................................................1

2. SPECIFICATIONS................................................................................................... 2

3. THEORY OF OPERATION ....................................................................................4

3.1 COMPARATOR STATUS ...............................................................................................4

3.2 CONTROLLING THE COMPARATOR ..............................................................................4

3.3 ASSOCIATING AN IIB WITH A COMPARATOR I/O MODULE...........................................4

3.4 SYSTEM EXAMPLE .....................................................................................................4

3.5 RECEIVER BANKS.......................................................................................................5

3.6 PARALLEL I/O SIGNALS..............................................................................................6

3.7 BI-DIRECTIONAL LINES ..............................................................................................6

3.8 EXAMPLE CONNECTIONS TO A CONSOLE.....................................................................7

4. OPTION SWITCHES...............................................................................................8

5. CONNECTORS ......................................................................................................10

6. SPECIAL INSTALLATION INSTRUCTIONS.....................................................14

6.1 UNIT ADDRESS SETTING...........................................................................................14

7. SPECIAL FEATURES............................................................................................ 17

7.1 LINK FAILURE REPORTING........................................................................................ 17

8. MOUNTING............................................................................................................18

9. CONNECTING AN IIB TO A CEB.......................................................................19

10. TROUBLESHOOTING........................................................................................21

iii

68-10844-115

Page 6

IIB Hardware Reference Introduction

CTI Products, Inc.

1. Introduction

The Input/Output Interface Module (IIB) is a member of the Monitoring and

Control Network (MCN™) family of User Interface Modules. Hardware

specifications, special installation, and configuration information are described in

this manual.

The IIB module connects a parallel operator display device (such as a console) to

the MCN network. The IIB is used with the operator display device and a

Comparator I/O Module (such as a CIB or AIB) to create a comparator display

system. The comparator display system provides monitoring and control functions

for your communications system. Receiver states monitored by the IIB include

VOTE, RECEIVE, DISABLE and FAIL. Receiver functions that can be

controlled include FORCE VOTE and DISABLE.

PRODUCTS, INC.

IN

OUTNETWORK

DC IN

8

8

9

7

7

A

6

6

B

5

C

5

4

D

4

3

E

3

F

2

2

1

0

1

PWR ACT

MODULEGROUP

8

9

9

7

A

A

6

B

B

C

5

C

D

4

D

E

3

E

F

F

2

0

1

0

1 2 3 4

ON

OPTION

Figure 1 - IIB Front and Rear View

1.1 Reference Documents

1. Monitoring and Control Network System Manual

Part Number S2-60425

ERR

E1 A

RESET

J1

E1 B

CA-80023-100CA-80023-100

68-10844-115

1

Page 7

IIB Hardware Reference Specifications

CTI Products, Inc.

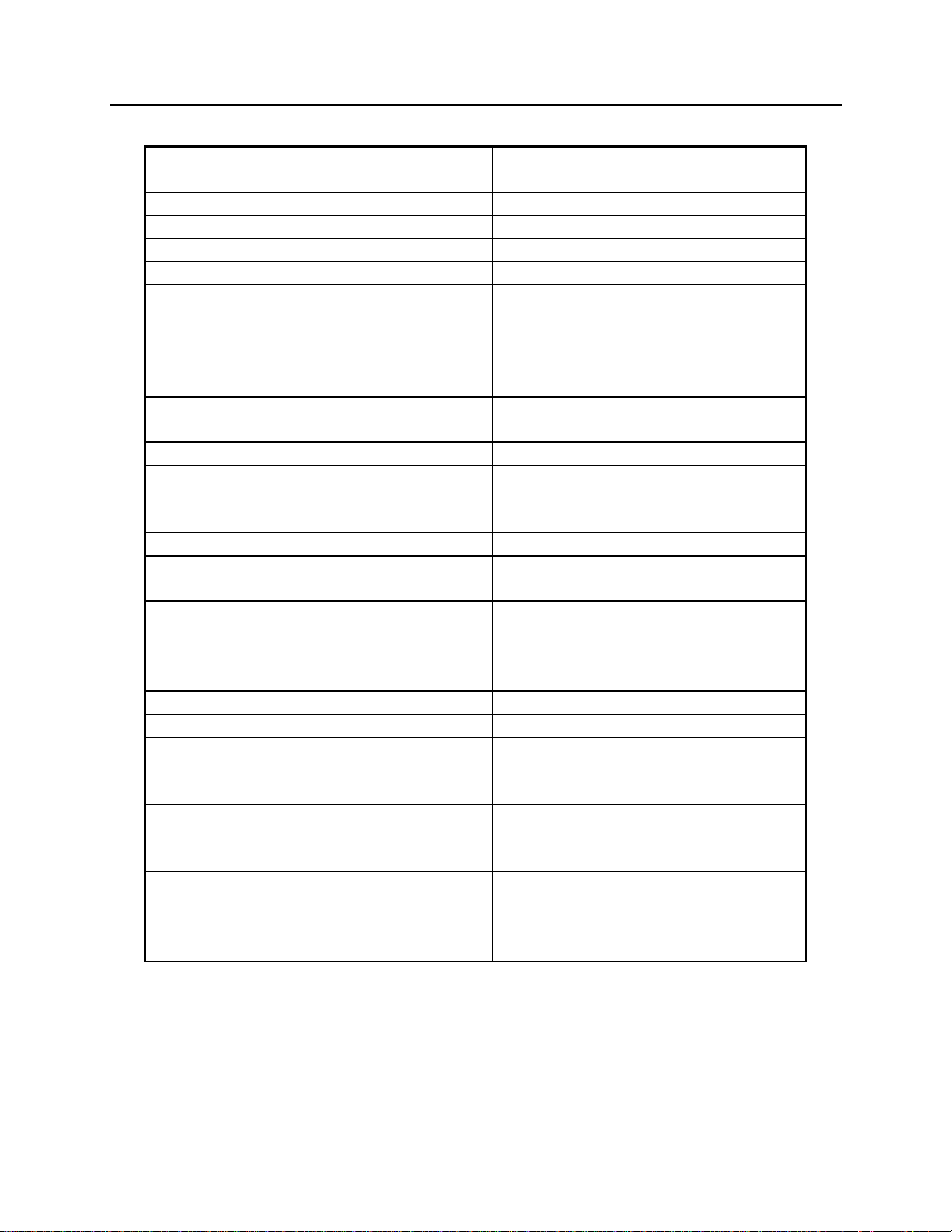

2. Specifications

Size 5.5” x 4.2” x 1.5” (140 x 107 x 38

mm)

Weight 16 oz (455 gm)

Temperature 0 - 50 ºC

Humidity 10 - 95% non-condensing

Module Power 10 - 32 Vdc / 2 Watts max.

Number of Receivers Supported 8 (Link Fail feature disabled)

7 (Link Fail feature enabled)

Open Circuit Voltage (all I/O pins)

jumper E1B removed

jumper E1B installed

Inputs per Receiver

active low, pull-up to +5 or +13.8 Vdc

Input Voltage (Input and In/Out pins) -0.6 to 30 Vdc (max)

Input Current (Input and In/Out pins):

jumper E1B removed (Vin = 0 Vdc)

jumper E1B installed (Vin = 0 Vdc)

Outputs per Receiver (active low) Vote, Receive, Disable, Fail

Output Saturation Voltage (Outputs and

In/Out pins) with Iout = 100 mA

Output Pin Current (Outputs and In/Out

pins)

Maximum Power Dissipation 2 Watts

Input/Output Connection 50 pin Telco style

Network Connector (2) RJ-45 (1 in, 1 out)

Safety Approvals UL 1950

Emissions Compliance FCC Part 15, Class A

Susceptibility Compliance IEC 801-2

+13.8 Vdc nominal

+5 Vdc nominal

Force Vote, Disable

-720 µA max (source)

-270 µA max (source)

550 mV

150 mA max per individual pin (sink)

100 mA max per pin if all outputs are

ON.

CSA 1950

EN 60950-1992

DOC Class A

EN55022

IEC 801-3

IEC 801-4

EN50082-1

Table 1 - Module Specifications

2

68-10844-115

Page 8

IIB Hardware Reference Specifications

Vp

CTI Products, Inc.

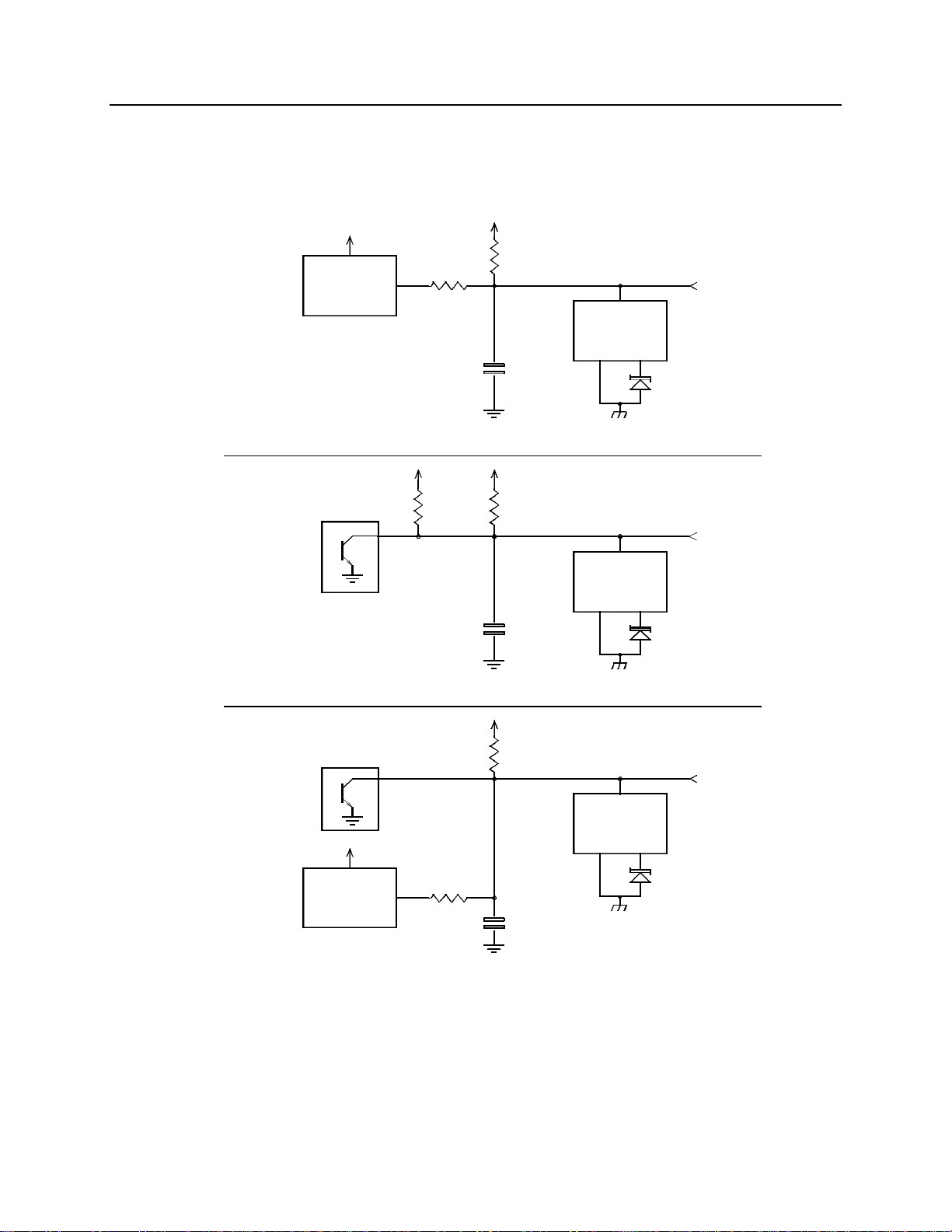

Figure 2 shows the equivalent circuits of the IIB I/O pins. The pull-up voltage Vp

by jumper E1B, located on the rear of the module.

• Vp = 13.8 Vdc with jumper E1B out

• Vp = 5.0 Vdc with jumper E1B in

HCMOS

IC

INPUT

+5V

+5V

150K

180K

22K

INPUT

Vp

22K

OUTPUT

0.1uF

0.1uF

ESD

PROTECTION

ESD

PROTECTION

30V

TRANSORB

30V

TRANSORB

Vp

22K

+5V

HCMOS

IC

INPUT

150K

0.1uF

INPUT/OUTPUT

Figure 2 - I/O Equivalent Circuit

3

ESD

PROTECTION

30V

TRANSORB

CA-80043-100CA-80043-100

68-10844-115

Page 9

IIB Hardware Reference Theory of Operation

CONSOLE

CTI Products, Inc.

3. Theory of Operation

This section describes the operation of the IIB module in an MCN comparator

display system.

3.1 Comparator Status

The Comparator I/O Module (such as an AIB or CIB) accepts the VOTE,

RECEIVE, DISABLE, and FAIL receiver status indicators from the comparator.

It sends status messages to the IIB module. The IIB module controls the VOTE,

RECEIVE, DISABLE, and FAIL parallel lines of the operator interface (such as a

console).

3.2 Controlling the Comparator

The IIB module monitors the VOTE and DISABLE lines from the console. When

the console activates a VOTE or DISABLE line, the IIB module will send a

FORCE VOTE or DISABLE command to the comparator. The Comparator I/O

Module will then generate the proper FORCE VOTE or DISABLE/ENABLE

signal to control the comparator.

3.3 Associating an IIB with a Comparator I/O Module

When an IIB is installed into a system, you need to configure the IIB with the

address of the Comparator I/O Module it will be operating with. Section 6.1

describes how to enter this extra address. By having the address of the

Comparator I/O Module, the IIB knows how to route its control messages for

FORCE VOTE and DISABLE over the MCN network.

3.4 System Example

Figure 3 shows an example comparator display system using the IIB module with a

console for the operator station.

CONSOLE

ELECTRONICS

IIB

MCN NETWORK

Figure 3 - IIB System Example

COMPARATOR

I/O

MODULE

COMPARATOR

CA-80034-100CA-80034-100

When the comparator detects that a receiver is active, it sends a RECEIVE

command followed by a VOTE command (if that receiver becomes voted). The

Comparator I/O Module processes these commands and sends them to the IIB.

The IIB then activates the VOTE and RX outputs for that receiver.

68-10844-115

4

Page 10

IIB Hardware Reference Theory of Operation

CONSOLE

CTI Products, Inc.

If the comparator detects that a receiver has failed, it sends a FAIL command to

the Comparator I/O Module. Again, the Comparator I/O Module sends this FAIL

command to the IIB so that the user can see that the receiver has failed.

From the console, the user can generate FORCE VOTE or DISABLE commands

for each receiver in the system. The IIB detects these active signals and sends

them to the Comparator I/O Module, which then controls the comparator.

3.5 Receiver Banks

The IIB module is designed to operate with a maximum of 8 receivers. This group

of 8 receivers is called a bank. If the Comparator I/O Module supports more than

8 receivers (more than 1 bank of receivers), then multiple IIBs are required to

monitor and control these additional banks. Section 4 describes how the IIB is

configured to select the bank of receivers being monitored.

For example, the system shown in Figure 4 shows an ASTRO-TAC™ Comparator

that supports a total of 13 receivers. The AIB Comparator I/O Module separates

the 13 receivers into two banks of 8 receivers.

IN

OUT

T

AIB

ASTRO-TAC

COMPARATOR

13 RECEIVERS

CA-80044-100CA-80044-100

CONSOLE

ELECTRONICS

IIB

BANK 0

IIB

BANK 1

P/S

OUT

IN

OUT

IN

T

Figure 4 - Multiple IIB System Example

Two IIBs provide support for the 13 receivers of the ASTRO-TAC™ Comparator.

The AIB module divides the 13 receivers into bank 0 (receivers 1 through 8) and

bank 1 (receivers 9 through 13). Each IIB has to be configured to operate with

one of the banks of the AIB. The first IIB would be configured to operate with

bank 0 of the AIB. The other IIB would be configured to operate bank 1 of the

AIB. This configuration is done using the option switches on the front of the IIB.

Refer to section 4 for details. With this configuration, the console will be able to

monitor and control receivers 1 through 13 of the comparator. The Link Fail

feature of the second IIB (configured for bank 1) can be enabled to monitor the

status of the AIB to ASTRO-TAC™ Comparator communication link as well as the

MCN network communications link. Refer to section 7.1. Because the second

IIB only monitors and controls receivers 9 through 13 (a total of 5 receivers) of

the ASTRO-TAC™ Comparator, its highest receiver is unused and therefore

available to display Link Fail status.

68-10844-115

5

Page 11

IIB Hardware Reference Theory of Operation

CTI Products, Inc.

3.6 Parallel I/O Signals

The IIB provides two input/output lines per receiver (VOTE and DISABLE) that

allow both monitoring and control of the signal. Two output only lines per

receiver (FAIL and RECEIVE) are also provided. None of these I/O lines are

latched in the IIB. In the console, the VOTE switch or button should be

momentary, and the DISABLE switch or button should be latched.

Because the VOTE and DISABLE lines are input/output lines, when the VOTE or

DISABLE input is driven by the console, any device tied to that line will also be

driven (an LED for example).

3.7 Bi-directional Lines

Because the console VOTE and DISABLE lines are bi-directional, the console’s

LEDs will be lit if the console outputs are active. Because of this, the console

could still indicate a DISABLE or VOTE on a receiver even if there is a problem

in the network cabling or the Comparator I/O Module.

This is one reason for using the Link Failure Reporting of the IIB (see section 7.1,

Link Failure Reporting). Using this feature, the operator can be warned when the

comparator is not communicating with the Comparator I/O Module (provided the

Comparator I/O Module supports Link Fail reporting) or when the IIB is not

communicating with the Comparator I/O Module.

68-10844-115

6

Page 12

IIB Hardware Reference Theory of Operation

CONSOLE ELECTRONICS

IIB J1

CTI Products, Inc.

3.8 Example Connections to a Console

Figure 5 shows how an IIB may be connected to a console. Notice that the VOTE

and DISABLE lines between the IIB and the console are bi-directional.

+V

VOTE

MOMENTARY

+V

RX

+V

+V

DISABLE

LATCHING

FAIL

CA-80049-100CA-80049-100

Figure 5 - IIB Connections to a Console

68-10844-115

7

Page 13

IIB Hardware Reference Option Switches

CTI Products, Inc.

4. Option Switches

Three sets of option switches are provided for module configuration. The module

must be power cycled or reset after these switches are set so that the options will

take effect. Table 2 describes the option switches and shows the factory defaults.

SWITCH DESCRIPTION DEFAULT

GROUP unit address setting

refer to the MCN System Manual

MODULE unit address setting

refer to the MCN System Manual

OPTION

position 1 receiver bank selector 1 (see Table 3) DOWN

position 2 receiver bank selector 2 (see Table 3) DOWN

position 3 receiver bank selector 3 (see Table 3) DOWN

position 4 unit address selector DOWN

Table 2 - IIB Option Switches

00

0

The Group and Module selector switches are used to set the unit address during

module installation.

The unit address selector switch (OPTION switch position 4) is only used at

installation time. Refer to section 6, Special Installation Instructions, for a

description of this switch. For normal operation, this switch must be in the

DOWN position.

An IIB can monitor 8 receivers when the Link Fail feature is disabled or 7

receivers when the Link Fail feature is enabled (one receiver bank). Option

switches 1 through 3 allow the IIB to monitor any receiver bank supported by the

Comparator I/O Module. The settings for these switches is shown in Table 3. If

the Link Fail feature is enabled, the last receiver on an IIB is unusable. The IIB

will not provide monitoring and control functions for that receiver.

Bank Option Switch Position

1 2 3

0 DOWN DOWN DOWN 1 through 8

1 UP DOWN DOWN 9 through 16

2 DOWN UP DOWN 17 through 24

3 UP UP DOWN 25 through 32

4 DOWN DOWN UP 33 through 40

5 UP DOWN UP 41 through 48

6 DOWN UP UP 49 through 56

7 UP UP UP 57 through 64

Receiver

Numbers

Table 3 - Receiver Bank Selectors

8

68-10844-115

Page 14

IIB Hardware Reference Option Switches

E1 A

CTI Products, Inc.

When the IIB is used with a Comparator I/O Module that supports only 8

receivers, such as a CIB, bank 0 will always be used.

Figure 6 shows the configuration of the two jumper options available on the rear

of the IIB. These jumpers should be installed at system installation time with

power removed from the IIB.

E1 B

CA-80024-100CA-80024-100

Figure 6 - Jumper Options

Jumper E1A is located across the top 2 terminals of the 6 pin terminal block. This

jumper must normally be installed. It is only removed for factory test.

Jumper E1B is located across the left side middle and bottom terminals of the 6

pin terminal block. Set this jumper to match the needs of your operator interface

station.

The remaining 2 terminals of the block are unused.

Jumper Function Default

E1A In to enable output RX 7.

IN

Out to disable output RX 7.

E1B

Vp Set

In for inputs pulled up to +5 Vdc.

Out for inputs pulled up to +13.8 Vdc.

OUT

Figure 7 - Jumper Options Description

Because most installations require the pullup voltage to be +13.8 Vdc, no jumper

is provided with the unit for the E1B jumper terminals. If you have an application

that requires the pullup voltage to be set to +5 Vdc, you can order an additional

jumper by calling CTI Products Inc. and ordering part number 27-10351.

68-10844-115

9

Page 15

IIB Hardware Reference Connectors

CTI Products, Inc.

5. Connectors

The NETWORK IN/OUT ports on the front of the IIB are used to connect the

IIB with other MCN modules. These ports carry both the network data signals as

well as DC power for power distribution with other modules. . Table 4 gives the

pinout for these connectors. Figure 8 shows the location of pin 1 for each port.

PRODUCTS, INC.

IN

PIN 1

NETWORK

OUT

DC IN

CA-80068-100

Figure 8 - Network IN/OUT Ports

Pin Function

1 DATA +

2 DATA 3 + POWER

4 No Connect

5 No Connect

6 - POWER

7 - POWER

8 + POWER

Table 4 - Network Connector Pinout

The DC IN port provides the primary power connection to the module. Power is

distributed through the NETWORK OUT connector to provide power to the

NETWORK IN connector of the MCN unit it is connected to. Each power

supply can power up to four units total. See reference 1 for complete details of

connections to the network and DC IN connectors.

Connector J1 provides the discrete I/O for the user interface signals. Table 5 gives

the pinout for this connector. Figure 9 describes the functions of the I/O signals.

All inputs and outputs are active low.

68-10844-115

10

Page 16

IIB Hardware Reference Connectors

CTI Products, Inc.

Signal Direction Description

VOTE Input/Output Output activated when comparator votes that receiver.

Ground input to force vote a receiver.

RX Output Activated when comparator detects a valid signal on

the receiver.

DIS Input/Output Output activated when receiver is disabled by

comparator.

Ground input to disable the receiver.

FAIL Output Activated when receiver failure is detected by the

comparator.

Figure 9 - I/O signal descriptions

11

68-10844-115

Page 17

IIB Hardware Reference Connectors

CTI Products, Inc.

IIB J1 Function Direction Wire Color

21 Vote 1 Input/Output Blu/Vio

19 Rx 1 Output Brn/Yel

20 Dis 1 Input/Output Slt/Yel

23 Fail 1 Output Grn/Vio

46 Vote 2 Input/Output Vio/Blu

44 Rx 2 Output Yel/Brn

45 Dis 2 Input/Output Yel/Slt

48 Fail 2 Output Vio/Grn

15 Vote 3 Input/Output Slt/Blk

12 Rx 3 Output Org/Blk

14 Dis 3 Input/Output Brn/Blk

17 Fail 3 Output Org/Yel

40 Vote 4 Input/Output Blk/Slt

37 Rx 4 Output Blk/Org

39 Dis 4 Input/Output Blk/Brn

42 Fail 4 Output Yel/Org

9 Vote 5 Input/Output Brn/Red

6 Rx 5 Output Blu/Red

8 Dis 5 Input/Output Grn/Red

11 Fail 5 Output Blu/Blk

34 Vote 6 Input/Output Red/Brn

31 Rx 6 Output Red/Blu

33 Dis 6 Input/Output Red/Grn

36 Fail 6 Output Blk/Blu

3 Vote 7 Input/Output Grn/Wht

18 Rx 7 Output Grn/Yel

2 Dis 7 Input/Output Org/Wht

5 Fail 7 Output Slt/Wht

28 Vote 8 Input/Output Wht/Grn

26 Rx 8 Output Wht/Blu

27 Dis 8 Input/Output Wht/Org

30 Fail 8 / Link Fail Output Wht/Slt

4 Link Fail Enable Input Brn/Wht

1 Ground Blu/Wht

10 unused Input Slt/Red

16 unused Input Blu/Yel

22 unused Input Org/Vio

29 unused Input Wht/Brn

35 unused Input Red/Slt

41 unused Input Yel/Blu

47 unused Input Vio/Org

7 unused No Connect Org/Red

13 unused No Connect Grn/Blk

24 unused No Connect Brn/Vio

25 unused No Connect Slt/Vio

32 unused No Connect Red/Org

38 unused No Connect Blk/Grn

43 unused No Connect Yel/Grn

49 unused No Connect Vio/Brn

50 unused No Connect Vio/Slt

Table 5 - IIB Connector J1 Pinout in ‘Logic’ Order

12

68-10844-115

Page 18

IIB Hardware Reference Connectors

CTI Products, Inc.

IIB J1 Function Direction Wire Color

26 Rx 8 Output Wht/Blu

1 Ground Blu/Wht

27 Dis 8 Input/Output Wht/Org

2 Dis 7 Input/Output Org/Wht

28 Vote 8 Input/Output Wht/Grn

3 Vote 7 Input/Output Grn/Wht

29 unused Input Wht/Brn

4 Link Fail Enable Input Brn/Wht

30 Fail 8 / Link Fail Output Wht/Slt

5 Fail 7 Output Slt/Wht

31 Rx 6 Output Red/Blu

6 Rx 5 Output Blu/Red

32 unused No Connect Red/Org

7 unused No Connect Org/Red

33 Dis 6 Input/Output Red/Grn

8 Dis 5 Input/Output Grn/Red

34 Vote 6 Input/Output Red/Brn

9 Vote 5 Input/Output Brn/Red

35 unused Input Red/Slt

10 unused Input Slt/Red

36 Fail 6 Output Blk/Blu

11 Fail 5 Output Blu/Blk

37 Rx 4 Output Blk/Org

12 Rx 3 Output Org/Blk

38 unused No Connect Blk/Grn

13 unused No Connect Grn/Blk

39 Dis 4 Input/Output Blk/Brn

14 Dis 3 Input/Output Brn/Blk

40 Vote 4 Input/Output Blk/Slt

15 Vote 3 Input/Output Slt/Blk

41 unused Input Yel/Blu

16 unused Input Blu/Yel

42 Fail 4 Output Yel/Org

17 Fail 3 Output Org/Yel

43 unused No Connect Yel/Grn

18 Rx 7 Output Grn/Yel

44 Rx 2 Output Yel/Brn

19 Rx 1 Output Brn/Yel

45 Dis 2 Input/Output Yel/Slt

20 Dis 1 Input/Output Slt/Yel

46 Vote 2 Input/Output Vio/Blu

21 Vote 1 Input/Output Blu/Vio

47 unused Input Vio/Org

22 unused Input Org/Vio

48 Fail 2 Output Vio/Grn

23 Fail 1 Output Grn/Vio

49 unused No Connect Vio/Brn

24 unused No Connect Brn/Vio

50 unused No Connect Vio/Slt

25 unused No Connect Slt/Vio

Table 6 - IIB Connector J1 Pinout in ‘Punch Block’ Order

13

68-10844-115

Page 19

IIB Hardware Reference Special Installation Instructions

CTI Products, Inc.

6. Special Installation Instructions

6.1 Unit Address Setting

An IIB must be programmed with two unit addresses:

1. the address of the Comparator I/O Module it will operate with

2. the IIB’s own address

You only need to perform this programming once, at installation time. These

addresses are stored in non-volatile memory so the only reason that you would

have to repeat this step is if you changed the unit address of the Comparator I/O

Module or if you replaced the IIB module.

Before programming the address information into the IIB, determine the unit

addresses of all the MCN modules in the system, following the guidelines in the

Address Planning planning section of the Monitoring and Control Network

System Manual (reference 1).

Valid ranges for the Group and Module switches are:

• Group number = 00 through FE

• Module number = 0 through F

The steps for programming the unit address of the Comparator I/O Module are:

Step Action

1 Determine the unit addresses of all the MCN modules in the system.

2 Apply power to the IIB.

3 Place OPTION switch 4 in the UP position.

4 Set the Group and Module switches to the unit address of the

Comparator I/O Module (from step 1) that this IIB will operate with.

5 Press the RESET button on the IIB.

6 The ERR LED will turn on and remain on.

7 Place OPTION switch 4 in the DOWN position.

8 Set the Group and Module switches to the unit address of this IIB

(its own address from step 1).

9 Press the RESET button on the IIB.

10 The ERR LED will turn on momentarily and then turn off.

After you complete these steps, connect the IIB to the Comparator I/O Module.

Apply power to the Comparator I/O Module and within approximately three

seconds, the ACT LED of the IIB should turn on and the ACT LED of the

Comparator I/O Module should turn on or blink. If the ACT LEDs turn on, the

IIB has been correctly programmed with the unit address of the Comparator I/O

Module. If the ACT LEDs remain off, verify your unit switch settings and repeat

14

68-10844-115

Page 20

IIB Hardware Reference Special Installation Instructions

CTI Products, Inc.

the unit address programming steps.

15

68-10844-115

Page 21

IIB Hardware Reference Special Installation Instructions

CONSOLE

CTI Products, Inc.

For example, Figure 10 shows a system with a single IIB and Comparator I/O

Module. The following steps show how the system might be setup, using the

following address assignments:

• IIB address is Group 80, Module 0

• Comparator I/O Module is Group 00, Module 0

Step Action

1 Connect the network cable between the IIB NETWORK OUT port

and the Comparator I/O Module’s NETWORK IN port.

2 Power on both the Comparator I/O Module and the IIB.

3 On the Comparator I/O Module, set the Group switch to 00 and the

Module switch to 0.

4 Reset the Comparator I/O Module.

5 On the IIB, place OPTION switch 4 in the UP position.

6 On the IIB, set the Group switch to 00 and the Module switch to 0.

This is the address of the Comparator I/O Module it will work with.

7 On the IIB, set the receiver bank selector switches.

7 Press the RESET button on the IIB.

8 The IIB’s ERR LED will turn on and remain on.

9 On the IIB, place OPTION switch 4 in the DOWN position.

10 On the IIB, set the Group switch to 80 and the Module switch to 0.

This is the IIB’s own address.

11 Press the RESET button on the IIB.

12 The ERR LED will turn on momentarily and then turn off.

13 After a couple of seconds, the ACT LED on the IIB should turn ON

and the ACT LED of the Comparator I/O Module should turn ON

or begin blinking.

If this does not occur, repeat the process or consult the

troubleshooting guide in section 10.

CONSOLE

ELECTRONICS

IIB

MCN NETWORK

Figure 10 - Unit Address Programming Example

16

COMPARATOR

I/O

MODULE

COMPARATOR

CA-80034-100CA-80034-100

68-10844-115

Page 22

IIB Hardware Reference Special Features

CTI Products, Inc.

7. Special Features

7.1 Link Failure Reporting

The IIB has a selectable option to show communication link failures between the

IIB and its Comparator I/O Module (network link failures) or between the

Comparator I/O Module and the comparator (comparator link failures). With this

option enabled, the IIB will always report network link failures. Comparator link

failures will only be reported if the Comparator I/O Module implements Link

Failure Reporting. Refer to the hardware reference manual of the Comparator I/O

Module being used to see if it supports this feature (for example, Link Failure

Reporting is supported in the AIB module, but not in the CIB module).

This option is enabled by grounding connector J1 pin 4, the Link Fail Enable

input, and then resetting the IIB. When this input is grounded, the IIB no longer

provides monitor and control of its receiver 8 I/O lines (J1 pins 26, 27, 28 and 30).

Instead, the Link Fail output (connector J1 pin 30) is used to show the status of

communication links. If this output is HIGH, all communications are OK between

the IIB and its Comparator I/O Module and between the Comparator I/O Module

and the comparator. If either of these communication links break (a cable is

disconnected or a module is turned off), then this output will be driven LOW by

the IIB to indicate the link failure.

17

68-10844-115

Page 23

IIB Hardware Reference Mounting

CTI Products, Inc.

8. Mounting

Refer the reference 1, section Mounting Options, for details about mounting the

IIB module.

CAUTION

Make sure that any mounting screws used to secure unit to a bracket do not

protrude into the unit’s enclosure more than 1/8 inches from the bottom surface of

the unit.

Using a larger screw that touches the pc board inside the unit may damage the unit

when it is powered. Doing so will void the unit’s warranty.

18

68-10844-115

Page 24

IIB Hardware Reference Connecting an IIB to a CEB

CTI Products, Inc.

9. Connecting an IIB to a CEB

The following example shows how you would connect an IIB to Motorola’s CEB

(Central Electronics Bank) in a comparator display system. Figure 11 shows what

this system looks like.

CEB

16 I/O

A

16 I/O

B

RX1-4

RX5-8

IIB

T

OUT

IN

T

IN

COMPARATOR

OUT

MCN

I/O

MODULE

P/S

COMPARATOR

CA-80029-100CA-80029-100

Figure 11 - IIB / CEB Connection Example

The IIB connects to the CEB through two 16 I/O cards (cards A and B) Each 16

I/O card can handle only 4 receivers. The CEB must be configured so that the 16

I/O cards operate as comparator display boards. Table 7 shows the cross

connections needed between the IIB and the 16 I/O cards. Once these

connections are made, you need to install jumper JU6 through JU33 on each 16

I/O card.

1

19

68-10844-115

Page 25

IIB Hardware Reference Connecting an IIB to a CEB

CTI Products, Inc.

IIBJ1Function Connect to

16 I/O Bd (A or B) - Pin

21 Vote 1 A - 26

19 Rx 1 A - 27

20 Dis 1 A - 28

23 Fail 1 A - 29

46 Vote 2 A - 30

44 Rx 2 A - 31

45 Dis 2 A - 32

48 Fail 2 A - 33

15 Vote 3 A - 34

12 Rx 3 A - 35

14 Dis 3 A - 36

17 Fail 3 A - 37

40 Vote 4 A - 38

37 Rx 4 A - 39

39 Dis 4 A - 40

42 Fail 4 A - 41

9 Vote 5 B - 26

6 Rx 5 B - 27

8 Dis 5 B - 28

11 Fail 5 B - 29

34 Vote 6 B - 30

31 Rx 6 B - 31

33 Dis 6 B - 32

36 Fail 6 B - 33

3 Vote 7 B - 34

18 Rx 7 B - 35

2 Dis 7 B - 36

5 Fail 7 B - 37

28 Vote 8 B - 38 *

26 Rx 8 B - 39 *

27 Dis 8 B - 40 *

30 Fail 8 / Link Fail B - 41 *

4 Link Fail Enable tie to IIB J1 pin 1 to enable

1 Ground A & B 1 through 16

the Link Fail feature

Table 7 - IIB to CEB Connections

* Signals for receiver 8 are active only if the Link Fail Enable (J1 pin 4) is open

(Link Fail feature is disabled). If J1 pin 4 is grounded, J1 pin 30 becomes a Link

Fail output and J1 pins 26, 27 and 28 become unused pins.

68-10844-115

20

Page 26

IIB Hardware Reference Troubleshooting

CTI Products, Inc.

10. Troubleshooting

This table is a list of troubleshooting tips specific to the IIB module. For

additional troubleshooting tips, refer to the troubleshooting section found in the

Monitoring and Control Network System Manual, reference 1.

Due to the high percentage of surface-mount components the IIB is treated as a

field replaceable unit. If any system problems are the result of a malfunctioning

IIB unit, the entire unit must be replaced and returned for repair.

PROBLEM CAUSE

ERR LED is ON Verify that the module’s Group and Module numbers are valid.

Reprogram the unit address of the Comparator I/O Module that the IIB is

connected to. Also, verify that this is a valid unit address. Refer to section

6.1 for a description of this procedure.

Receiver 8 is not

working properly

Link Failure

Reporting is not

working properly

Link Fail Enable

(J1 pin 4) is

grounded and the

Link Fail output

(J1 pin 30) is

active.

Verify that option switch 4 is in the DOWN position.

Verify that the Link Fail Enable pin (J1, pin 4) is not tied to ground when the

module is reset.

Verify that the Link Fail Enable pin (J1, pin 4) is tied to ground when the

module is reset.

If comparator link failures are not being reported, verify that the Comparator

I/O Module supports the Link Fail reporting feature.

Verify that the network cable between the IIB and the Comparator I/O

module is properly connected and that both modules are communicating

(their ACT LEDs are on).

Verify that the cable between the Comparator I/O Module and the

comparator is properly installed and that the Comparator I/O Module is

communicating with the comparator (refer to the troubleshooting section of

the Comparator I/O Module).

21

68-10844-115

Loading...

Loading...