INSTRUCTIONMANUAL

VENEXIA 15-18-21-25

MURANO15-18

INGLESE

ENGLISH

You have just purchased a high quality product produced entirely in Italy.

Reading this manual is very important to guarantee correct functioning of the product in regards to

safety and servicing of the machine.

The correct installation and set up of initial parameters is vital and therefore reserved for technicians

that have been authorised by the manufacturer, the same is true for periodic maintenance.

Cleaning is fundamental for safeguarding safety and product operation, it must be carried out

periodically to guarantee long product life and for people and machine safety.

WARNING FOR THE CORRECT DISPOSAL OF PRODUCT WASTE

Waste disposal of electric and electronic appliances (RAEE) as per Legislative Decree 49/2014

implementation of the European Directive 2012/19/EU.

At the end of its working life, the product must not be disposed of with household waste

but be taken to a special differentiated waste collection center or to a dealer providing

this service.

To dispose of the device separately allows to avoid potential negative consequences for

the environment and human health deriving from inappropriate disposal and it promotes

recycling of the materials of which it is composed.

As a reminder of the need to dispose of appliances separately, the product is marked with a crossed

out wheeled bin.

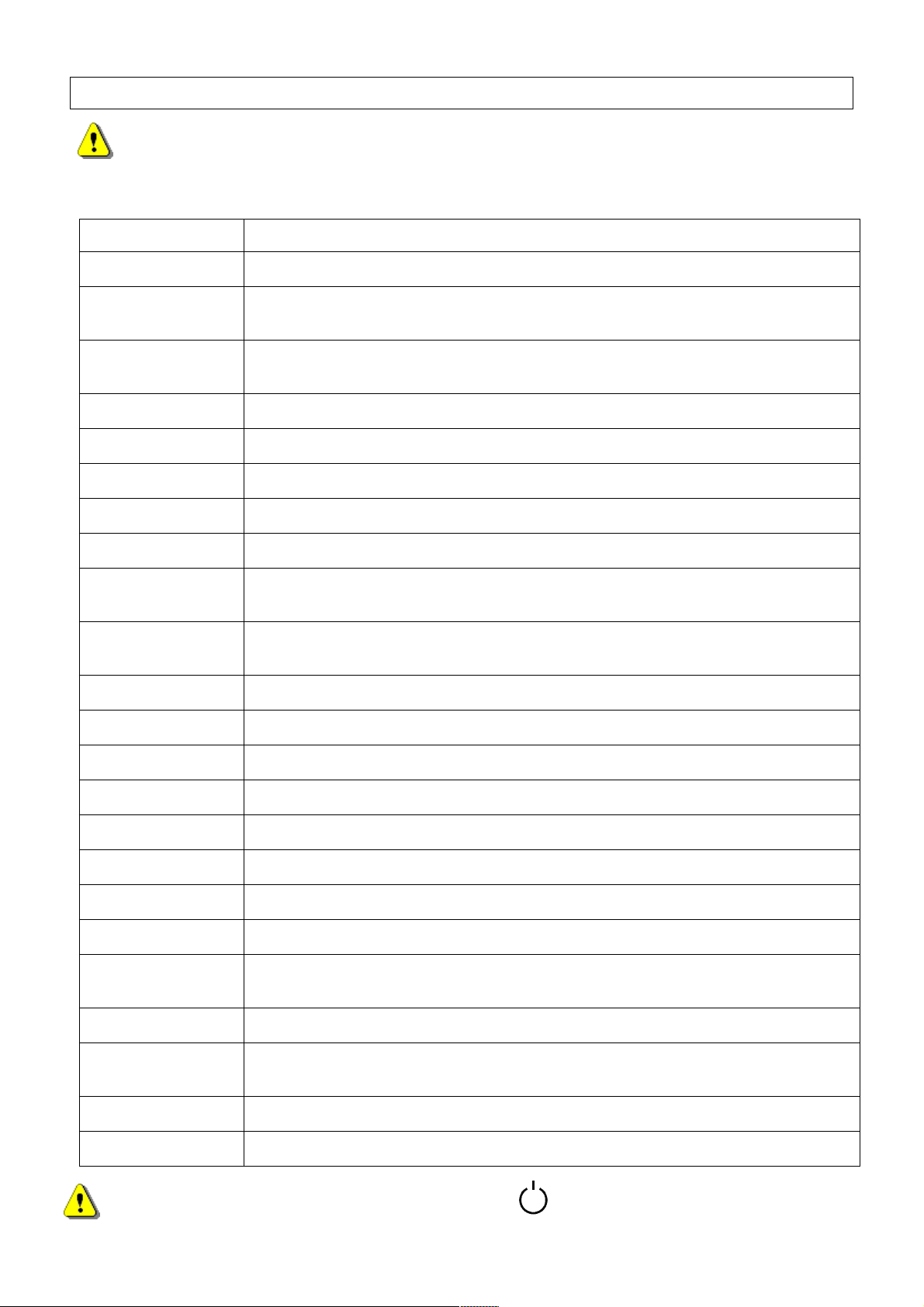

INDEX

1 Safety warnings ................................................................................................................... 2

2 Product description ........................................................................................................... 3

3 Pellet quality ........................................................................................................................ 3

4 Dimensions and hydraulic fittings ................................................................................... 4

5 Technical data ...................................................................................................................... 6

6 Hydraulic connection ......................................................................................................... 7

7 General rules for creating the flue ................................................................................ 10

8 Eliminating fumes discharge .......................................................................................... 11

9 Oxidising air intake .......................................................................................................... 12

10 Electrical connections ..................................................................................................... 13

11 Preliminary controls before the first start up ............................................................. 15

12 Control panel display ....................................................................................................... 16

13 Operational phases ........................................................................................................... 16

14 Programming ..................................................................................................................... 17

15 Alarm codes ........................................................................................................................ 19

16 Cleaning and maintenance ............................................................................................. 20

1

1. SAFETY WARNINGS

Do NOT use fuels that are different from those instructed by the manufacturer.

DO NOT use any flammable liquid to light the boiler.

DO NOT light boiler if glass is damaged and do not, for any reason, open the fire box door while

operating.

Only clean the glass and painted parts with boiler cold, using a specific cleaning detergent, NOT

abrasive or corrosive, with a cotton cloth.

The machine must ONLY be installed by qualified personnel, certified in conformity with current

rules and regulations.

DO NOT unplug the stove if there are flames in the fire pot.

Take care when the boiler is functioning: the hot parts (glass, handle, etc...) they may cause burns.

Keep out of reach of children.

Remove power from the machine before any kind of maintenance or cleaning.

DO NOT place hands inside the tank during functioning.

Never throw unburnt pellets into the tank: it is a fire hazard.

Never throw pellets manually into the fire pot, especially if there are flames or hot ashes.

Unpleasant smells during functioning may be caused by the type of pellets used.

ENGLISH

Possible noises during functioning are normal, caused by the settlement of assembled parts

Store bags of fuel at least 1 metre away from the boiler, in a dry and sheltered part of the home.

DO NOT EXCEED THE PERCENTAGE OF 60% OF CORN IN THE MIXTURE WITH WOOD PELLETS.

Other finely chopped fuels (for example: olive pits, shells, etc..) can be used alone, “not mixed”

with wood pellets, but they must have a minimum diameter of 4mm (to be used only in stoves with

biomass burner).

WARNING: (see UNI10683 standard)

One must always guarantee a natural force draught in the flue between 6 and 8 Pa, to avoid that, if the

electric power should go out unexpectedly or adverse environmental conditions should arise, the room may be

filled with smoke or electric components overheat.

SPECIAL WARNING

Improper flue draught, excessive humidity in the fuel, or an elevated ash residue in the

combustion chamber may cause THE STOVE TO NOT START AND IS NOT A RESULT OF A

DEFECTIVE PRODUCT.

In case of no switch-on, clean the crucible before restarting the boiler.

Check that the aeration of the machine installation is always correct

(UNI10683 and UNI7129 Standard)

2

ENGLISH

2. PRODUCT DESCRIPTION

This model of boiler is equipped with an innovative and patented biomass burner that is capable of burning

not only wood pellets, but also biomass (maze, grape seed, etc...).

An automatic cleaning system, controlled by an electronic control box, always keeps the burner clean and

obtains great efficiency and reliable use. The modulating operation varies according to the boiler temperature

that has been set and results in optimal environment heating. During initial start up phase (approximately 10

min.) the burner automatically fills with fuel, while the resistors, heating up, ignite the flame. Once flame has

been detected by the combustion fume sensors, normal operation begins and, thanks to the microprocessor,

fuel intake can be changed, obtaining flame modulation. The electronic box controls continually check

temperature sensors, electric motors, and safety devices, in case of anomalies, it will stop functioning and

signal it on the display (see alarm code paragraph). Room heating is guaranteed by a circulator mounted inside

the boiler that will start once the temperature reaches 55°C. Below this temperature the boiler activates the

anti-condensing function, therefore stopping the circulator.

Production of domestic hot water is guaranteed by a motorised deflector valve, also fitted inside the boiler, and

managed by the boiler probe that signals the position and ensures the hot domestic water boiler has priority.

3. PELLET QUALITY

There are various types and qualities of pellets on the market and it is important that the ones you use are not

of abysmal quality. A poor, cheap quality pellet could contain glues, resins or chemical substances that could

seriously jeopardise the functioning and the safety of the product, by inciting blockage of ashes and smoke

discharger, forming corrosive gas, reducing machine performance, release polluting substances into the

atmosphere and window incrustation. Regulations on this matter have established that products using this type

of fuel must be fed with good quality pellets, compact and not very powdery. We recommend that you ask your

retailer for a suitable type of pellet, that are in compliance with DIN51731 standards or M7135 standards

including any updates.

The characteristics of wood pellet that should be used are: of a 6÷8 mm diameter, approx. 5÷20 mm length,

have an 8% humidity and a heating potential of 18200 KJ/Kg.

The manufacturer does not assume any responsibility for the use of poor quality pellets and therefore

the is non responsible if the boiler malfunctions as a result.

Store pellets at least 1 metre away from the boiler in a dry and sheltered part of the home.

SETTING THE FUEL

Before switching the appliance on, select on the display the kind of fuel you are going to use:

- Select “fuel 1” to use certified wood pellets (DIN PLUS / ö-Norm M7135) or good quality wood pellets having

a low humidity value (<13%) and a low ash residual.

- Select “fuel 2” to use non-certified wood pellets (for example made with bark and branches) having a high

humidity value (>13%) and a high ash residual.

- Select “fuel 3” to use a corn (humidity max 15%) mixed with wood pellets.

- Select “fuel 4 ” to use a biomass fuel: corn mixed with wood pellets, finely chopped (∅4mm minimum) or

whole olive pits, almond/hazelnut/pine nut husks ( ∅4mm minimum), pelletized vine pruning, cherry pits

(∅4mm minimum), miscanthus pellets, agripellets.

- List “fuel 5” remains available for the technician/dealer to set particular fuels that are not mentioned in the

above list.

In order to obtain a correct functioning and a high efficiency of the stove, it is necessary to select

the most suitable fuel list.

In order to obtain a correct functioning and a high efficiency of the stove, it is necessary to select

the most suitable fuel list. All chopped fuels (olive pits, husks, etc..) must have a minimum

diameter of 4mm.

3

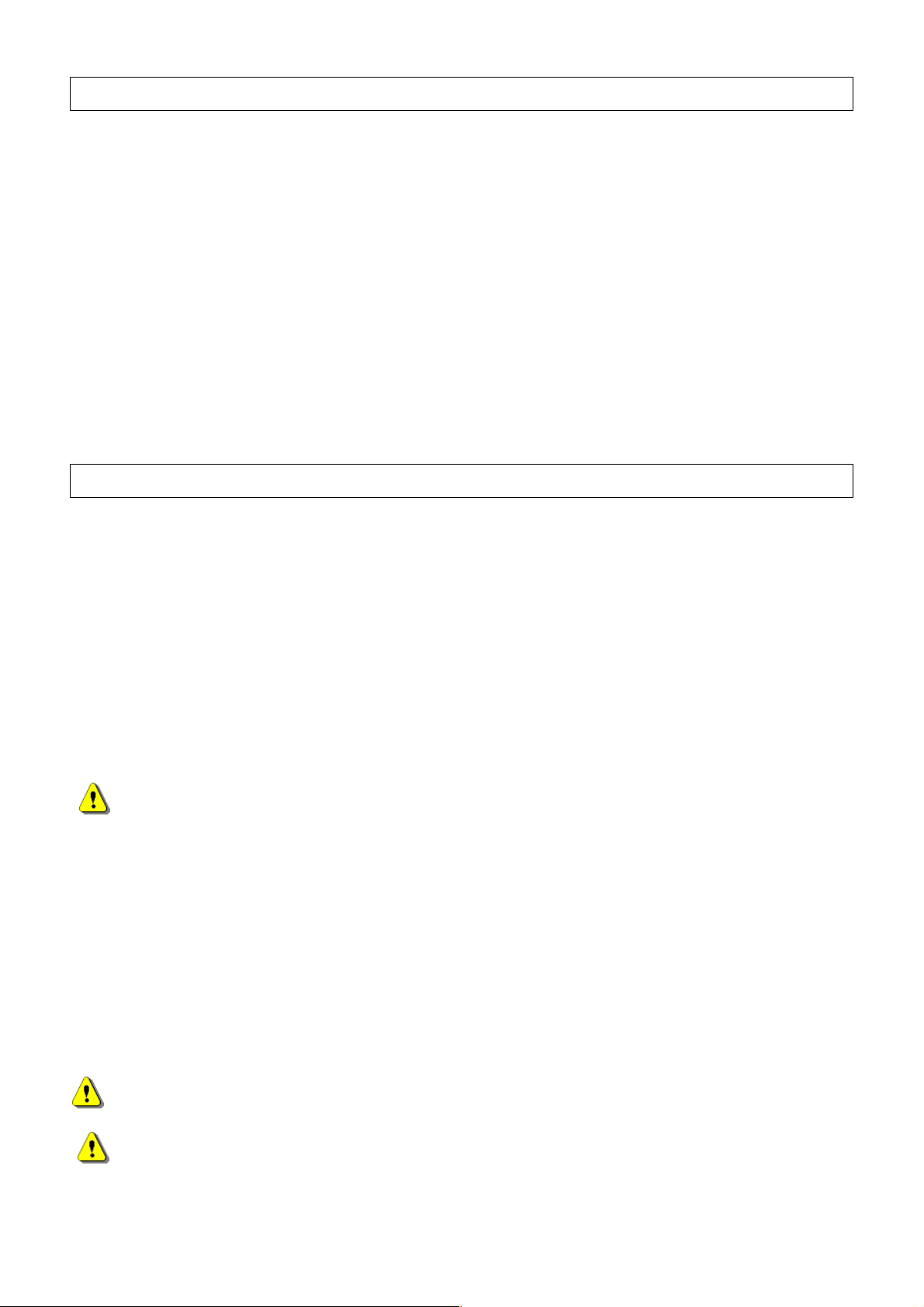

VENEXIA 21-25

4. DIMENSIONS AND HYDRAULIC FITTINGS

SIDE VIEW

1- Automatic air vent

2- Smoke discharge Ø 80mm

3- Safety pressure switch

4- System return 3/4"

5- Boiler return 3/4"

6- Circulator

7- Safety valve discharge 3Bar

8- Boiler discharge cock

9- Expansion tank

10- System flow 3/4"

REAR VIEW

VENEXIA / MURANO 15-18

ENGLISH

4

630

620

scarico fumi

sortie fumées

presa aria esterna

external air intake

prise d’air extérieur

620

scarico fumi

sortie fumées

presa aria esterna

external air intake

prise d’air extérieur

EXTERNAL DIMENSIONS

VENEXIA 21-25 Model

VENEXIA 15-18 Model

output tube

output tube

ENGLISH

D.80mm

D.80mm

550

5

560

680

scarico fumi

sortie fumées

external air intake

prise d’air extérieur

HEAT INPUT

NOMINAL HEAT OUTPUT

POWER OUTPUT TO WATER

COMBUSTION EFFICIENCY (EN303-5)

CONSUMPTION AT FULL POWER

MURANO 15-18 Model

5. TECHNICAL DATA

presa aria esterna

output tube

ENGLISH

D.80mm

MAXIMUM SMOKE TEMPERATURE °C

AVERAGE OPERATING ELECTRICAL POWER W

MAXIMUM BOILER TEMPERATURE °C

MAXIMUM HOT WATER TEMPERATURE °C

MAXIMUM OPERATING PRESSURE bar

ENVIRONMENTAL QUALITY CLASS

MODEL

(wood pellet fuel)

(wood pellet fuel)

(wood pellet fuel)

(wood pellet fuel)

CO (13% O2) RATED POWER g/Nm3

CO (13% O2) REDUCED POWER g/Nm3

PP 13% O2 mg/Nm3

FUEL

(pellet fuel)

PELLET TANK CAPACITY Kg

HEATED VOLUME m3

SMOKE OUTLET DIAMETER mm

ELECTRICAL POWER SUPPLY V

MAXIMUM ABSORPTION A

MAXIMUM ELECTRICAL POWER W

BOILER WATER CAPACITY lt

BOILER NET WEIGHT kg

LOW VACUUM Pa

* The fire box, nominal power and the performance are measured by means of laboratory test in optimal installation conditions.

** The data has been taken from laboratory test in optimal conditions. The hourly consumption can vary depending on the type of pellet used and installation made.

*** The heated volume is subject to variation depending on the installation conditions, the type of insulation of the home and the outdoor climatic conditions relating

to the geographical position

UNIT OF

MEASURE

kW

kW

kW

%

kg/h

VENEXIA - MURANO 15 VENEXIA - MURANO 18 VENEXIA 21 VENEXIA 25

16,5* 18,4* 20,8* 25,6*

15,4* 17,0* 19,8* 24,0*

13,6* 15,3* 18,0* 22,1*

93,3* 92,5* 95,0* 93,4*

0,16 0,21 0,07 0,08

0,27 0,27 0,32 0,32

12,2 11,8 12,1 11,4

wood pellet - biomass wood pellet - biomass wood pellet - biomass wood pellet - biomass

21 21 32 32

180-430*** 180-470*** 300-540*** 300-640***

80 80 80 80

160 160 160 160

V230~ / 50Hz V230~ / 50Hz V230~ / 50Hz V230~ / 50Hz

3 3 3 3

130 130 130 130

700 700 700 700

80 80 80 80

65 65 65 65

3 3 3 3

32 32 52 52

4 stars 4 stars 5 stars 4 stars

220-250 220-250 270 270

6 6 6 6

4,4 max** 5,2 max**3,4 max** 3,8max**

6

Pf = pressione di taraura della valvola di sicurezza

coefficient

ENGLISH

6. HYDRAULIC CONNECTION

In order for the boiler to work correctly it must be suitably connected to a heating system. It is reminded that

installation must be carried out by trained personnel or companies according to MD 37/90. The

manufacturer declines any responsibility for installations not carried out correctly or by unqualified

personnel. For installation please refer to UNI7129 and UNI10412 (and any relative updates) Standards.

For a correct installation, verify that the hydraulic system is not leaking, thus jeopardising the functioning of the

generator and its integrity. In this regard, the installing company must adopt the solutions it considers

necessary in order to avoid that the thermal exchange surfaces of the boiler can, in time, suffer

limestone type incrustation, sludge, iron residues from the system and anything else foreign to the

heating water. This will enable optimising the thermal yield and functioning safety of the generator and

of the system. We strongly recommend installing a softener on the cold water inlet for system load and a mesh

filter on the boiler piping to the filter larger impurities.

COMPLETELY BLEED THE HEATING SYSTEM AND THE BOILER AT EVERY FILLING.

FROM IMPURITIES AND FERROUS PARTICLES.

ALTERNATIVELY, WE RECOMMEND YOU TO USE A HEAT EXCHANGER TO SEPARATE THE BOILER’S

WATER FROM THE CIRCUIT’S WATER.

If the production of domestic hot water is envisioned, installer a domestic boiler holding at least 80

litres for good boiler functioning.

The boiler is provided with an 8 litres expansion tank that, should it also be insufficient for the system, another

of adequate measure must be installed. Below is the calculation to determine the necessary capacity of the

expansion tank:

CONNECT THE SAFETY VALVE DRAIN AND BRING IT OUTSIDE THE BOILER.

A DIRT SEPARATOR WITH MAGNET MUST BE INSTALLED ON THE RETURN CIRCUIT TO

PROTECT THE BOILER’S INTERNAL COMPONENTS, AS THE ELECTRONIC CIRCULATOR,

INSTALL AN ANTI-CONDENSATION VALVE, WITH SETTING AT 55°C, AS CLOSE AS POSSIBLE

TO THE BOILER.

Ve=

Ce (Vi+Vc)

Pi

(1- )

Pf

Ve = volume expansion

Ve = volume espansione

Ce = expansion coefficient

Ce = coefficiente espansione

Vi = liters of water plant

Vi = litri di contenuto acqua impianto

Vc = liters of water boiler

Vc = litri di contenuto acqua caldaia

Pi = precharge pressure

Pi = pressione di precarica del vaso

Pf = pressure relief valve

COEFFICIENTE DI

Should the existing expansion tank be insufficient

provide an additional tank.

TEMPERATURA MAX

Max temperature

40

50

60

70

80

90

99

Expansion

ESPANSIONE

0,0076

0,0118

0,0168

0,0224

0,0287

0,0357

0,0432

7

CIRCUITO

RISCALDAMENTO

CALDA SANITARIA

CIRCUITO

RISCALDAMENTO

ENGLISH

CONNECTION LAYOUT

Connection to a heating system layout

HEATING SYSTEM

PUMP

CIRCOLATORE

COLLETTORE

CARICO IMPIANTO

Connection to a heating system and domestic hot water production layout

HEATING SYSTEM

PUMP

CIRCOLATORE

COLLETTORE

USCITA ACQUA

HOT WATER

OUTLET

CARICO IMPIANTO

DOMESTIC HOT

WATER TANK

COLD WATER

ENTRATA

INLET

ACQUEDOTTO

8

LEGEND OF SYMBOLS

HOT WATER DELIVERY

VALVE

ANTI-CONDENSATE

CIRCUITO

RISCALDAMENTO

CARICO IMPIANTO

CALDA SANITARIA

HOT WATER

ENGLISH

PUMP

CIRCOLATORE

HEATING SYSTEM

COLD WATER

ENTRATA

INLET

ACQUEDOTTO

USCITA ACQUA

OUTLET

PUFFER

STORAGE

MIN 300LT

VALVE

CHECK VALVE

PRESSURE REDUCER

SAFETY VALVE

THERMOMETER

EXPANSION

TANK

FILTER Y

SEPARATOR

WITH MAGNET

PRESSURE GAUGE

AIR VENT

BOILER DELIVERY

RETURN DELIVERY

HOT WATER RETURN

WATER SOFTENER

INSTALL AN ANTI-CONDENSATION VALVE, WITH SETTING AT 55°C, AS CLOSE AS POSSIBLE

TO THE BOILER.

INSTALL A THERMOSTATIC MIXER AT THE HOT SANITARY WATER EXIT.

INSTALL A SAFETY VALVE CALIBRATED AT 6 BAR AT THE COLD WATER INLET TO AVOID

ANY STRAIN OF THE SANITARY WATER TANK.

9

YES

ENGLISH

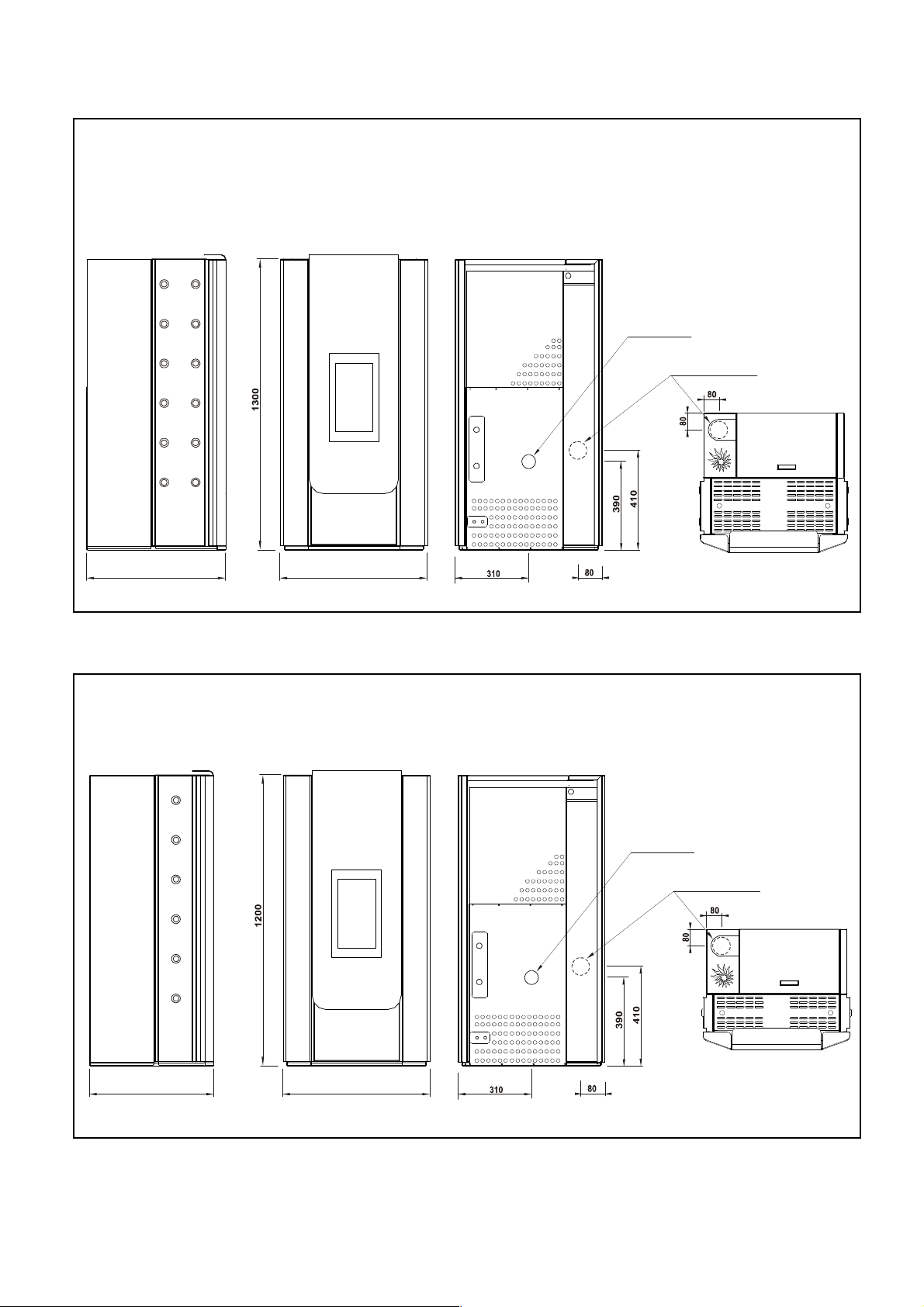

7. GENERAL RULES FOR CREATING THE FLUE

A few simple, yet important, rules to follow for safe constructing a flue are here explained (for further

information, please read the UNI 10683 regulation).

• Safe and correct pellet boiler operations depends on the connection to a single and independent flue. No

other fireplace, stove, boiler, aspiring hoods, etc., are to be connected to the same flue (see fig.3).

• This machine needs to expel products resulting from combustion via a vertical flue that has a suction

pressure between 6 and 8 Pa, in order to constantly guarantee the expulsion of smoke, even with the

absence of electric power or adverse conditions.

• The part of the flue that extrudes from the roof or remains in external contact must be covered with tiles or at

least well insulated.

• The stack must be wind resistant, with an internal section that is equal to that of the chimney, a useful

section at least twice the size of the chimney, and protect from any rain coming in.

• Any other building , plants or other obstacle that are higher than the roof must be positioned at least 3 m

away from the stack.(see fig.4).

• Whenever using two flues with parallel exits, raising the flue against the wind by one element is

recommended (see fig. 5).

The flue section must be uniform, with smooth walls that do not become more narrow, curves must be

regular and continuous.

It is advisable that the smoke conduct has a solid material and eventual condensation collecting box,

positioned under the smoke conduct intake, so that it is easily accessible and can be inspected from the

airtight door.

SI

NO

Fig.3

0,5 m

m in 2 m

m in 3 m

min 1,2m

Fig.4

YES

SI NO

Fig.5

10

ENGLISH

8. ELIMINATING FUMES DISCHARGE

Fumes discharge must comply with regulations in force and must therefore be brought above the roof. The

discharge tube must be made out of smooth steel with silicon washers and not be corrugated flexible type.

Furthermore it must be positioned externally and not in closed or semi-closed spaces. For example: garages,

narrow corridors, under closed roofs or any other place where fumes may collect in case of leaks. When

connecting the boiler to a flue, make sure, with a professional chimney sweep, that the flue is perfectly whole..

Oppositely it is absolutely obligatory to encase the existing flue with material which is suitable enough to ensure

correct functioning (see fig.7) The flue must not lean against the fan. It is necessary to assess the layout and

structure of the house once the flue has been installed via walls and the roof, to ensure that installation has

been done correctly and is in conformity with fire safety regulations. You should also check: the internal section

of the flue, that there are no obstructions or material used to build it, the height, the fittingness of the stack and

the possibility to realise vent holes.

TYPE OF TUBES USED FOR FLUES

Rigid painted steel tubes (at least 1.5 mm thick) , or stainless steel ones (at least 0.5 mm thick), can be used.

The male/female coupling collars must be superimposed by at least 40mm.

DIAMETER OF THE FLUE TUBE

The diameter of the tubes depends on the type of system. The boiler has been designed for tubes with an

80mm diameter, as shown in the table, however in some cases 100mm is advisable. If 100 mm diameter tubing

is necessary, connect it to the boiler using a "T" pipe connection using a ø 80 - ø 100 pipe fitting. (see fig. 8)

FLUE DIAMETER OPINION

Tube length less than 5 m 80 mm Correct

Tube length more than 5 m 100 mm (min) Mandatory

For installations at an altitude of more than

1200 m a.s.l.

Note: for each 90° curve add 1 m and for each 45° a dd ½ m. The lengths indicated on the table are only relevant for the vertical portion.

100 mm (min) Recommended

Horizontal parts must not exceed 2 m in length.

It is PROHIBITED to install air locks or valves that could obstruct the passage of smoke.

It is obligatory to use a "T" connection tube (see fig.8) with an inspection plug, as a connection between the

boiler and the flue, which will allow both the collection of soot that is deposited inside the tubes and periodical

cleaning of the flue, without the need to dismantle. Since the fumes are under light pressure, ensuring that the

plug for cleaning the flue is perfectly airtight is mandatory and it must be the same after each inspection. One

must remember put it back as it was originally and check the condition of the gasket. Verify that the various

tubes are connected properly, as instructed by the manufacturer.

It is strongly advised not to place tubes horizontally, but if absolutely necessary make sure they are placed with

an angle of at least 5%.

If a traditional flue is used it is possible to connect without the need for a "T" connection tube but you must

check that the flue has a bow for collecting ash.

It is advisable connect to the boiler with a horizontal track that is not more than 1m long.

If proper tube lengths are obeyed, the flue should have a draught between 6 and 8 Pa.

Do not change flue tube size in the middle of the route and especially after a bend or a horizontal portion. Verify

that there are no constrictions in the discharge conduit or in the flue.

11

Ø 100

DIREZIONE DI

ENGLISH

INSULATION AND DIAMETER OF HOLES IN WALLS OR ON THE ROOF

Once the position of the boiler is established and that you have checked that the place of installation is ideal, it

is then necessary to make the hole for passing tubes through the wall. This can vary according to the type of

installation, the diameter of the flue tube and the type of wall or roof that it must pass through.

N.B.: if the floor can not support the weight of the boiler, position a sheet platform of the correct size with

insulation applied on the floor (rock wool) and with a nominal density greater than 80kg/mc.

80-100 FITTING

Fig.7

END PART OF THE FLUE SYSTEM

The stack must not be installed in spaces that are closed, poorly ventilated or, in general, where fumes may

collect.

It is necessary to check that there are no flammable elements (plants, wood) or elements that could be visually

damaged (walls, windows) within 3m of the flue.

WARNING: Seeing that regulations regarding installation of pellet fuelled boilers are constantly being

updated, ask ones installer for eventual changes.

CLEANING

DIRECTION

Raccordo 80-100

Ø 80

“T” FITTING

Raccordo a "T"

PULIZIA

Fig.8

9. OXIDISING AIR INTAKE

Oxidising air can be taken from the atmosphere as long as there is sufficient ventilation, otherwise it is

necessary to take it from the outside: in this manner it is possible to guarantee an optimal combustion without

having to open air intakes in the room. For both cases please refer to the installation regulations in vigour (UNI

10683 and UNI7129) to avoid health risks of those who in the room where the machine has been installed.

Do not use flexible tubes and place a grid over the entrance (external) of the tube in order to stop alien

elements entering the system which could jeopardise the correct functioning.

12

MINIMUM DISTANCES FOR THE POSITIONING OF THE AIR INTAKE

For correct and safe positioning of the air intake (see

fig.9) where the minimum distances for any opening are

indicated. It is important to consider possible wall outlets

from other machines or kitchen aspiration hoods.

ENGLISH

Fig. 9

AIR INTAKE

10. ELECTRICAL CONNECTIONS

All machines are equipped with power cables, for which, in case of the need for replacing, an authorised

technician must be used.

Before connecting to the power supply, check that:

• the electric plant has been fitted with a 6A magnetothermal switch

• the characteristics of the plant are sufficient enough to satisfy what is indicated on the machine

characteristic plaque (electric power, nominal voltage etc...)

• that the plant has a sufficient earth connection according to nominal regulations in vigour (earth connection

is obligatory by law)

• the power cable should never. at any point, overheat 50°C above room temperature: If a direct connect ion is

desired, it is necessary to use an omnipolar switch, with a minimum opening between contacts of 3mm, that

has been designed for the electrical charge indicated on the plaque and must correspond to regulations in

vigour. the earth wire, brown/green, should not be interrupted by the switch. The plug or omnipolar switch

must be readily accessible once the machine has been installed

Disconnect the power supply when not using the machine for a prolonged period of time.

The manufacturer declines all responsibility if the above indicated anti-injury regulations are not

respected.

13

CIRCOL.

ELECTRONIC CONTROL BOX AND RELATIVE CONNECTIONS

IGNITION

POWER SUPPLY

230V - 50Hz~

RESISTOR

ACCEND.

N

L

FUSE

4 A

FUSE

0,8A

SMOKE FAN

ENCODER

CROG.

MISC.

COCLEA

CRUCIBLE

MOTOR

MIXING

AUGER

MOTOR

LOAD

AUGER

MOTOR

BOILER

SAFETY

THERMOSTAT

PORTA

P.H2OT.H2O

UNUSED

BOILER

PRESSURE

SWITCH

UNUSED

AUGER

SAFETY

THERMOSTAT

AIR PRESSURE

SWITCH

IF USING THE HOT DOMESTIC WATER BOILER CONNECT THE PROVIDED PROBE

CHECK THAT THE CONNECTION OF THE ROOM THERMOSTAT IS "CLEAN CONTACT" TO

AVOID DAMAGE TO ELECTRONIC CONTROL BOARD

DIVERTER

VALVE

N.C.

N.A.

ROOM

THERMOSTAT

BOILER

CIRCULATOR

DEV

PROGRAMMING

PORT

CALD.S.AMBT.AMBPRESST.SERT.COC

BOILER

PROBE

UNUSED

SANIT.

HOT WATER

PROBE

CLOCK

BATTERY

-T2+

UNUSED

-FUMI+

SMOKE

PROBE

CRUCIBLE

SENSOR MOTOR

COMBUSTION

FAN

FUMI

MSCCRG

MIXING AUGER

MOTOR SENSOR

ENGLISH

DISPLAY

14

ENGLISH

11. PRELIMINARY CONTROLS BEFORE THE FIRST START UP

N.B.: if the floor cannot support the weight of the boiler, position a correctly sized, at least 4mm thick,

sheet platform with insulation applied on the floor (rock wool) and with a nominal density greater than

80kg/mc.

MANDATORY GUIDE LINES FOR THE SAFETY OF PEOPLE; ANIMALS AND OBJECTS.

The following information is about a number of obligatory general regulations for a correct installation, and is

intended for the installer.

• It is recommended to place insulation between the floor and the touching points of the machine with a sheet

at least 2mm thick and a diameter at least 50mm greater than the area occupied by the machine, if the

boiler is installed on a wooden floor.

• The flue tubing must not have a diameter that is less than 80 mm.

• Leave a space of at least 50mm between the rear of the boiler and the rear wall, to ensure correct air intake

• Leave a space of at least 70cm around the sides of the boiler, to ensure easy maintenance.

• Should the machine be installed close to flammable or combustible walls, keep a safe distance of 30cm

from the rear and sides of the machine. Avoid leaving any type of flammable or combustible materials

within 1m of the heat waves from the glass window situated on the front of the machine.

• Check for a correct level of combustible load inside the crucible.

• Completely bleed the heating system before starting the boiler.

• Verify that the safety valve drain has been conveyed outside the boiler.

For the first few minutes that the machine operates (for the first time) it may be possible to smell

paint this is normal Aerate the room with the boiler operational.

MAKE A FLUE GAS OUTLET

Perform the following actions, as shown in the figures below:

- Connect an ash collector "T" tube to the exhaust motor (1)

- Install a 90 ° bend (2) to obtain the flue outlet on the rear side

- Install a straight tube (3), taking care to break the pre-cut on the top (4), to obtain the flue outlet on the upper side.

Flue gas outlet on the rear side Flue gas outlet on the upper side

4

3

2

1

15

1

Pause

Recorded boiler temperature

Recorded

domestic water

Operational power

ENGLISH

12. CONTROL PANEL DISPLAY

DESCRIPTION OF DISPLAY BUTTONS

SET

Set day and time

During operation

Key - turns the boiler on and off in manual mode (keep pressed for 2 sec.), eliminates alarms and exits

Lun 09:00 Tc 65°

OFF

Accesa 5 Ts 55°

programming.

Key SET - changes the screen and confirms set data

Key - key for increasing values being set

Key - key for decreasing values being set

MEANING OF LED LIGHTS

SUMMER

WINTER

The "permanently" on LED indicates the hot domestic water boiler is satisfied.

The "flashing" LED indicates the boiler is heating the hot domestic water boiler.

The "permanently" on LED indicates the heating system is not requesting heat.

The "flashing" LED indicates the heat request from the heating system.

13. OPERATIONAL PHASES

DISPLAY MEANING

Clean.

Charged

Pre-ventilation and safety controls phase, with fire pot cleaning before loading fuel.

Start-up phase with fuel load in the burner while supplying power to the resistors at the

same time.

Pause while awaiting flame.

St. fire

Stabil.

fire

Turn off

Off

Stand by

IN CASE OF AN ALARM, WAIT FOR THE END OF THE TURNING OFF PHASE

Waiting phase during which the start-up must take place.

Stabilisation phase, after the flame has started, with a medium size load of fuel.

Burner operational adjustment phase where power can varies from 1 to 6

Timed turn off phase associated to an interruption in the fuel for fire pot cleaning and

waiting for the flame to be totally extinguished.

Turned off status until there is an following request for heat

Switch-off for reached heating and domestic hot water temperature

16

combustible 1

ON00:00 OFF00:00

00:00

see specific

Load

Load

- _ _ _ 0 _ _ _ +

ENGLISH

14. PROGRAMMING

MAIN SETTINGS

Use the keys as instructed to access the desired setting

Lun 09:00 Tc 65°

OFF 5 Ts 55°

Season

ESC SET

Temp. boiler

ESC SET

Temp. hot water

ESC SET

Hours

ESC SET

Ignition

ESC SET

Combustible

ESC SET

ESC

ESC SET

Season

winter

Temperature H2O

boiler 70°

Temperature H2O

hot water 55°

Day of the

week Mon

Trigger

timer SI

Combustible

Using biomass fuels (maize, grape seed, other) it is important to mix them properly to ensure that the

boiler works correctly.

DO NOT EXCEED THE PERCENTAGE OF 60% OF CORN IN THE MIXTURE WITH WOOD PELLETS. Other

finely chopped fuels (for example: olive pits, shells, etc..) can be used alone, “not mixed” with wood

pellets, but they must have a minimum diameter of 4mm.

To correctly mix fuels it is recommended to weight them on scales with a precision of at least 100 g, and mix

them together in a single external container, not inside of the boiler, because that would not create an

homogenous mixture.

The menu “LOAD” allows to vary the quantity of combustible to be loaded and it is subdivided

into 3 levels of increase (+) and 3 levels of decrease (-): each level consists of 0,2 seconds,

therefore a total of +/- 0,6 seconds. Any variation made remains in permanent memory and it is

simultaneously programmed on all 6 power levels of the stove.

Before selecting on the display the type of fuel to be used make sure that it is the same as what is

already in the stove tank.

Hors

Timer01 mtwtfss

chapter

17

Timer02 mtwtfss

Timer02 mtwtfss

Timer02 mtwtfss

Timer02 MTWTFss

Timer02 MTWTFss

Timer02 MTWTFss

Timer02 MTWTFss

Timer02 MTWTFss

Timer02 MTWTFss

ON00:00 OFF00:00

ON00:00 OFF00:00

ON00:00 OFF00:00

ON00:00 OFF00:00

Press to modify

Press the key to confirm

Press the key to modify

Press the key to modify

ON08:30 OFF00:00

ON08:30 OFF00:00

AUTOMATIC START-UP PROGRAMMING

Turning off for each time slot must not terminate after 23:59 of that day

Activate

timer yes

Press to modify

Timer01 mtwtfss

ON00:00 OFF00:00

Press the key to confirm

Press to modify

ENGLISH

Press to modify

Press to modify

Press to modify

Press the key to confirm

ON00:00 OFF00:00

Press to modify

ON00:00 OFF00:00

Press the key to confirm

ON08:30 OFF00:00

Press the key to confirm

Press to modify

Press the key

18

Motor flue gas

ENGLISH

15. ALARM CODES

For your own safety do not tamper or modify any of the machine's components: the

manufacturer does not guarantee the normal operation, that as a result may be very dangerous.

In case of malfunctioning, difficulties, or whenever a safety device is activated, it is important to

contact authorised personnel. All operations must take place when the boiler is cold and disconnected

from the power supply.

DISPLAY MEANING

Non working fumes motor: contact an authorised technician

Auger motor 1

Crucible

1 heat.elem.KO One of the resistors is not working: contact an authorised technician

2 heat.elem.KO Both resistors are not working: contact an authorised technician

heat.element KO The resistors are continually supplied with power: contact an authorised technician

gas probe The fumes temperature probe is interrupted or disconnected: contact an authorised technician

room probe The room temperature probe is interrupted or disconnected: contact an authorised technician

Thermost. boiler

Thermostat auger

Pressure switch Air pressure regulator is not working: contact an authorised technician

system error Internal error of the electronic control box: turn stove off and restart it

The horizontal fuel loading auger is not turning: verify if the fuel tube is clogged or contact an

authorised technician

The burner fire pot does not rotate: clean the burner and restart or contact the authorised

technician

Intervention of the boiler safety thermostat: clean the inside of the stove, reset the thermostat

and restart the stove

Intervention on the part of the fuel auger safety thermostat: clean the inside of the stove, reset

the thermostat and restart the stove

black out Loss of electric power: clean the burner and restart

Failed ignition Failed start-up: clean the burner and restart

f. turn-off Flame turns off while operating: clean the burner and restart

Over heating gas Overheating of combustion fumes: clean the stove completely and restart.

Cont. operation Malfunctioning of pellet loading motor: contact an authorised technician.

Boiler probe Boiler temperature probe interrupted or disconnected: contact an authorised technician.

Hot water probe

H2O Pressure Hot water pressure below 0.5 bar: fill the system with water or call the authorised technician.

Filling

Pellet sensor One of the fuel level sensor does not work: call the technician.

service Stove maintenance warning: contact an authorised technician

Domestic hot water temperature probe interrupted or disconnected: contact an authorised

technician.

The filling of the fuel tank has not occurred within the pre-set time: check loading auger and fuel

availability. Call the authorised technician.

TO RESTORE BOILER FUNCTIONING KEEP THE KEY PRESSED FOR 3 SECONDS

19

ENGLISH

16. CLEANING AND MAINTENANCE

To ensure correct functioning and maximum efficiency of the boiler, carry out the following cleaning and

maintenance operations.

THE FOLLOWING OPERATIONS MUST BE PERFORMED WHEN THE BOILER IS COLD, AT LEAST ONCE A

WEEK AND WITHOUT ELECTRICAL POWER

BIOMASS BURNER

In order for the stove to work correctly it is important to keep the burner as clean as possible and free of any

combustion residue. At least once a week extract the flow nozzle by loosening the locking screw with the

supplied hex wrench (fig. A) and remove all of the ash and unburned residue inside the burner (fig. B) using the

flexible pipe supplied (fig. E) to connect to your vacuum cleaner. To remove any encrustation, scrape the inside

of the wheel holes (fig. C) with the tip of the supplied accessory (fig. F), remove and empty as well the

collecting container placed underneath the cast-iron wheel. Finally vacuum the air combustion duct (fig. D)

behind the burner. Having performed the cleaning, make sure to replace the front panel of the burner correctly,

screwing the locking screw until it’s limit stop.

Fig. A

Fig. D

ALWAYS KEEP THE HOLES OF THE ROTATING WHEEL CLEAN AND FREE OF ANY

COMBUSTION RESIDUE. THE CLEANING FREQUENCY HAS TO BE APPROPIATE TAKING

CARE TO THE WORKING HOUR OF THE MACHINE AND TO THE CHARACTERISTICS OF THE

COMBUSTIONS RESIDUE (HIGH PERCENTAGE OF ASHES OR PRESENCE OF DEPOSITS).

Fig. B

Fig. C

Fig. E

Fig. F

20

ENGLISH

ASHES DRAWER

Weekly switch-off the boiler and proceed as follows:

- Open the door under the hearth, unscrew the nut and remove the ashes drawer with care. Empty out all the

ash taking care that there are no hot ashes (fig. A).

- Carefully remove all ash from the bottom to avoid malfunctionings (fig. B).

- Place the ash drawer back into its place an tighten the wingnut until the gasket is fully in place.

FLUE GAS TUBE

At least once a week, remove the protection top panel and lift a few times the two cleaning levers on the sides

of the boiler (Fig. A), in such a way as to drop all the ash in the ash drawer below.

At this point remove the ash drawer, taking care to remove as well all of the ash on the bottom of the boiler and

above the cavity of the exhaust motor (Fig. B): to do this, connect the supplied flexible hose to your vacuum

cleaner.

Fig. A

N.B .: for the model Murano use the appropriate tool supplied.

HEARTH DOOR SEAL

Frequently check the conditions of the seal fastened along the internal border of the hearth door to ensure air

tight closing.

Note: verify seal hold by placing a sheet of paper between the closed door and the frame: when trying to

remove it, make sure that it is possible but difficult. If this is not the case, contact an authorised Service Centre

to have the seal replaced.

Fig. B Fig. A

Fig. B

21

ENGLISH

HEARTH DOOR GLASS

The glass mounted in the hearth door is ceramic, and therefore resistant to high temperatures. To clean, use a

non abrasive dry cloth with specific liquid for glass cleaning.

Should it be damaged (e.g. chipped) it is recommended to have it replaced immediately by an authorised

technician before starting up the machine

DO NOT attempt to repair damaged glass: as there is a risk of explosion during functioning!

FLUE

To ensure that the machine works well, at least once a week, open, and when needed, clean the "T" at the

base of the fumes conduit and the horizontal portion of tube, if there is one.

The vertical fumes conduit and the entire flue must be checked and cleaned at least once a year. We

recommend the use of a specialised technician for a thorough and professional cleaning.

COMBUSTION AIR INTAKE

Monthly inspect the air intake tube positioned under the start-up resistors to ensure it is not blocked by any

foreign material. If required, remove or suck out the dirt.

GENERAL END OF SEASON CLEANING

Every two months empty the pellet tank and clean out all accumulated saw dust.

After use, at the end of the season, clean and check all the parts indicated above, remembering to disconnect

the power supply of the boiler for increased safety.

It is advisable to check and clean the machine at least once per year by an authorised technician to ensure

correct functioning.

It is recommended, when required, to check lubrication of the fuel loading auger bronze bearings.

22

Loading...

Loading...