INSTRUCTION MANUAL

Effective date:

30.09.2013

Digital Light Engraver DLE

ORIGINAL INSTRUC TION MAN UA L

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Telephone: +49 2151 1592260

Fax: +49 2151 520329

Email: support@c-s-t.de

office@c-s-t.de

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 1 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

0

Contents

Effective date

30.09.2013

0.

0. Contents ....................................................................................................... 2

1. General Information ..................................................................................... 4

1.1 Notes about the Technical Annex .................................................................. 4

1.2 Explanation of symbols .................................................................................. 5

2. Safety ............................................................................................................ 7

2.1 Appropriate use and improper modes of ope r ati on ........................................ 7

2.2 General information for operators and personnel........................................... 9

2.2.1 Requirements placed on personnel ............................................................... 9

2.2.2 Operator’s duties............................................................................................ 9

2.2.3 Important rules of conduct ........................................................................... 10

2.3 Protective equipment ................................................................................... 12

2.3.1 Existing protective equipment ...................................................................... 13

2.3.2 Inspection of the protecti ve equipment ........................................................ 14

2.4 Emissions (noise levels/sounds) .................................................................. 15

2.5 Fire protection .............................................................................................. 15

2.6 Pneumatics .................................................................................................. 16

2.7 Hydraulics .................................................................................................... 16

2.8 Electrical ...................................................................................................... 17

2.9 Spare parts .................................................................................................. 17

2.10 Personal protective equipment .................................................................... 18

2.11 EC DECLARATION OF CONFORMITY ...................................................... 19

3. Transportation, storage, installation, electrical connection .................. 20

3.1 Special safety instructions ........................................................................... 20

3.2 Transport ..................................................................................................... 21

3.3 Storage ........................................................................................................ 22

3.4 Installation .................................................................................................... 23

3.5 Electrical connection .................................................................................... 23

4. Machine description .................................................................................. 24

4.1 Machine housing .......................................................................................... 25

4.2 Screen frame clamping system .................................................................... 26

4.3 Bridge .......................................................................................................... 27

4.4 Operating control units ................................................................................. 28

5. Initial commissioning, decommissioning ................................................ 30

5.1 Special safety instructions ........................................................................... 30

5.2 Preparatory work for commissioning ............................................................ 32

5.3 Decommissioning ......................................................................................... 33

5.4 Instructions about disposal .......................................................................... 34

6. Operation and cleaning ............................................................................. 35

6.1 Special safety instructions ........................................................................... 35

6.2 Operation ..................................................................................................... 37

6.2.1 Starting the machine .................................................................................... 37

6.2.2 Start an imaging process ............................................................................. 38

6.2.3 Four colour printing ...................................................................................... 41

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 2 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

0

Contents

Effective date

30.09.2013

6.2.4 Checking the LEDs ...................................................................................... 42

6.2.5 Finishing work on the machine .................................................................... 43

6.2.6 EMERGENCY STOP ................................................................................... 44

6.2.7 Action to be taken after an EMERGENCY STOP ........................................ 44

6.2.8 DLE settings ................................................................................................ 45

6.3 Focus test for the DLE Engraver .................................................................. 49

6.4 Cleaning ....................................................................................................... 53

7. Dealing with faults ..................................................................................... 56

8. Service and Maintenance .......................................................................... 61

8.1 Special safety instructions ........................................................................... 61

8.2 General ........................................................................................................ 64

8.3 Weekly/monthly intervals ............................................................................. 65

8.4 Biannual/ annual interval .............................................................................. 65

8.5 Maintenance plan......................................................................................... 67

8.6 Maintenance Logbook .................................................................................. 68

9. Technical Annex ........................................................................................ 69

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 3 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

1

General Information

Effective date

30.09.2013

1. General Information

This instruction manual provides a wealth of safety and operating instructions

for the following product:

Vertical Digital Light Engraver (DLE)

1.1 Notes about the Technical Annex

The Technical Annex is an integral part of this instruction manual and includes all important technical details agreed upon

between the purchaser

and the manufacturer, including, for example:

• Project technical drawings/data sheets

• Spare parts list for parts subject to wear

• Relevant operating instructions

• Information pertaining to the necessary certification

• Miscellaneous

Apart from the basic model, we also offer optional extras and a variety of

configurations.

Options include:

• A semi-automatic unloading system for the machine in cooperation with

other vendors

• A fully automatic loading and unloading system in cooperation with other

vendors

• Customer-specific adaptation.

This instruction manual contains important information that needs to be taken

into account in all stages of the life cycle of the machine, including the transportation, installation, operation, maintenance and disposal.

Therefore, it is imperative that this instruction manual is read by the installation engineer and the responsible technical personnel/operator prior to installation and commissioning and must always be stored at the operating location of the machine.

Information pertaining to

specific hazards to persons, property or the envi-

ronment is highlighted in the relevant chapters of this instruction manual.

Apart from this instruction manual, it is important to take into account th e rel-

evant technical documentation provided by the vendors. This contains the

operational safety instructions which have to be observed.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 4 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

1

General Information

Effective date

30.09.2013

1.2 Explanation of symbols

Danger

Nature and source of hazard!

This symbol warns of an immediate danger to the life and health of people.

• Failure to observe such instructions could lead to severe adverse health

effects or even life-threatening injuries as well as substantial dam age to

property.

• Action that has to be avoided to prevent hazards from arising.

Warning

Nature and source of hazard!

This symbol warns of a possible dangerous situation to the lif e and health of

people as well as damage to the environment and property.

• Failure to observe such instructions could lead to severe adverse health

effects to lif e-threatening injuries as well as substantial damage the environment and property.

• Action that has to be avoided to prevent hazards from arising.

Caution

Nature and source of hazard!

This symbol warns of a possible dangerous situation to the life and health of

people as well as damage to the environment and property.

• Failure to observe such instructions could result in moderate

to slight

health effects or even injuries as well as damage to the environment and

property.

• Action that has to be avoided to prevent hazards from arising

Information

Nature and source of hazard to the machine and equipment!

This symbol warns of a hazardous situation and indicates important instructions on how to handle the machine and the equipment.

• Failure to observe such instructions can lead to extensive damage to

property.

• Action that has to be avoided to prevent

damage to the machine and

equipment.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 5 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

1

General Information

Effective date

30.09.2013

Warning symbol denoting

remotely started equipment

Warning symbol denoting

drawing-in hazard

Caution, warning symbol denoting a danger zone

Warning symbol denoting

bottleneck

Warning symbol denoting a

slip hazard

Warning symbol denoting

fork lift trucks in operation

Warning symbol denoting

hazardous voltage

Warning symbol denoting UV

radiation

Warning symbol denoting hot

surface

Warning symbol denoting

suspended load

Warning symbol denoting

hand injury

Always wear protective safety glasses against UV radiation

Please follow these instructions and act accordingly in all cases.

Instruct all other users in regard to these safety guidelines.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 6 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2. Safety

2.1 Appropriate use and improper modes of operation

Information

Improper operation could lead to damage to the machine and equipment!

Improper operation can lead to damage to the machine and equipment.

• Make sure that all operations are carried out by qualified, authorized and

trained personnel.

• Follow the instructions given in the manufacturer’s instruction manual

carefully and comply with them accordingly.

• Make sure that the workplaces are clean when the machine and equip-

ment are in operation.

• Do not place any tools, appliances or the like on the machine and equip-

ment.

• Do not operate the machine and equipm ent without having prior adequate

training or without having first read the manufacturer’s instruction manual.

• Do not operate the machine and equipment with products that are not in-

tended to be used with the machine and equipment.

• Ensure that there is sufficient lightning when the machine and equipment

are in operation.

• Do not climb on or through the machine and equipment.

The CST Digital Lig ht Engraver is intended to be used in the print industry for

imaging screen stencils.

The machine is designed to be used only in the field of application listed in

the Technical Information section of the order confirmation or in this manual.

Any changes to the operating conditions shall necessitate a new contractual

agreement.

The machine shall be exclusively used in such a way as is desc ribed in the

order confirmation. Any other or additional operation, including, for example,

processing other products or operating with a mesh on the screen stencil that

is not intended for the process, shall be deemed improper usage.

The manufacturer/vendor shall not be held liable for any damage that results

from this. The risk is borne solely by the user.

The warranty and liability shall be in accordance with the contractual terms

and conditions.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 7 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

The machine and equipment shall only be operated with correctly installed

safety devices.

We would like to explicitly point out that no safety devices should be removed or disabled while the machine and equipment are in operation.

When maintenance work and cleaning as well as maintenance and repair

services are being performed, the machine and equipment shall be secured in such a way as to preclude unauthorized or inadvertent switching

on of the machine and equipment.

When t he maintenance and repair work as well as service work for overhauling and carrying out repairs are complete, all safety systems shall be

fully reinstalled and made operative again. An expert should check the

systems to make sure they function correctly.

When a member of staff recognises that there exists t he immediate risk of

danger to people at the machine and equipment

, the EMERGENCY

STOP device on the machine and equipment must be activated immediately.

In such cases of damage that would cause an immediate shutdown of the

machine and equipment, an EMERGENCY STOP device on the machine

and equipment can also be activated or automatically triggered.

The EMERGENCY STOP device should never be used to shut down the

machine and equipment under normal working conditions.

Special attention must be given to mounting and removing screen frames

and screens on the machine and equipment as it has to be carried out

carefully.

If work is carried out in an inattentive or careless manner, there exists the

hazard of limbs, items of clothing and objects being crushed, impacted

and sheared, which is due to moving parts. Therefore, particular attention

needs to be paid to the following points:

• Do not reach into the open gaps between the screen frame and bridge

• Extreme caution is needed when the bridge is in motion

• Apart from exceptional cases, screen frames are only to be inserted when

the machine and equipment are not in operation

• Tight fitting safety clothing and gloves should be worn

• Please exercise caution with lighting units and motors as they can be-

come very hot! Do not touch the lighting units and motors with exposed

limbs. Depending on the temperature of the lighting units, being in close

proximity to the lighting units can lead to burns

• Do not change the specific purpose of the machine

• During the manufacture of this product, the safety devices were specially

designed to wor k with this machine

• Please consult CST GmbH if you intend to change the intended use of the

machine

• Please make sure that the operators are familiar with the operation of the

machine and equipment

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 8 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.2 General information for operators and personnel

Prior to commencing work, the personnel designated to use

the machine

must be instructed on the hazards relating to their work and the m easures

used to prevent such hazards. Such instructions shall be derived from this

instruction manual.

The instruction manual and the applicable regulations should be stored in

such a way that they are accessible to operators and maintenance staff.

Disregarding the safety instructions can adversely affect the safety of both

the personnel and the environment as well as the machines. Disregarding

the safety instructions can also lead to the forfeiture of all c la im s a gainst war-

ranty.

In detail, disregarding the safety instructions could result in the following

hazards:

• Failure of important functions of the machine

• Failure of specified procedures of maintenance and repair

• Exposure of people to electrical, mechanical, physical and chemical

hazards

2.2.1 Obligation of the personnel

All work on/with the machine shall be carried out only by personnel who, by

virtue of their training and qualifications, are authorised to do so.

Responsibilities, competence and supervision of the personnel

must be

clearly defined by the operator.

Task

Qualification

Connection and installation operations Trained personnel

Qualified personnel from the

manufacturer

Repair, maintenance, inspection

Loading, supervision Trained personnel

Electrical work Qualified electrician

2.2.2 Operator’s duties

The operator is obliged to operate the machine onl y in perfect working condition.

The operating personnel must be ass igned by the operator to oper ate the m achine.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 9 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

In particular, the operator’s area of responsibility includes:

• Assigning trained and instructed personnel,

• Defining the responsibilities for operation, set up, maintenance, and re-

pairs,

• Making regular checks on

the operating personnel in regard to potential

hazards and making sure they work in a risk-aware manner in accordance

with this instructions manual

The operator is to safeguard against any possible danger zones which may

arise bet ween this machine and any upstream or downstream devices that

have been provided by the customer.

If the Digital Light Engraver is to be integrated into an

interlinked machine

line/machine, the provisions of the European Directives with regard to the

major modifications made to the mac hine have to be observed, if applicable.

The operator is legally obliged (irrespective of the operational state or asdelivered state of the machine) to assess the hazards that may arise out of

the employees work and to determine

any occupational safety measures that

may be required.

The operator is responsible for the observance of the relevant regulations.

2.2.3 Important rules of conduct

Danger

Increased risk of accidents as a result of moving masses!

The movement of masses can lead to serious/fatal injuries.

• People who operate power-driven machinery must make sure that they do

not endanger themselves or others through hazardous motions

• Access to the interior of the machine housing is only permitted when the

machine has been switched off and measures have been taken to pr event

it from being inadvertently switched back on

• Long hair, loose clothing, jewellery or the like can be drawn into moving

parts. This can lead to serious injury.

• Wear t ight-fitting clothing. Long hair can be protected by wearing a hair

net. Remove jewellery.

• It is not permitted to climb on the machine while it is in operation.

Danger

Increased risk of accidents as a result of partly intense/high levels of

ultraviolet radiation!

When monitoring/checking the ultraviolet light, there is always the risk of serious eye injuries and even permanent eye damage.

Wear appropriate protective equipment in the form of safety glasses that are

suitable for the particular light source.

• Never look directly at the ultraviolet beam or the image of the pattern on

the screen to be imaged without personal protective equipment (safety

glasses).

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 10 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

For the protection of the operators, warning and danger signs are placed on

the machine. Please observe these signs and act with extreme caution.

Additionally placed instructions must be strictly observed.

If warning and danger signs are damaged or illegible, they shall be replaced

immediately!

In addition to the instructions given in this manual, existing national accident

prevention rules as well as generally applicable legal and other mandatory

regulations relevant to accident prevention and environmental protection

must be observed!

Danger

Injuries and fatal accidents can occur as a result of hazardous voltage!

If there is a fault with electrical components or cables, the direct or indirect

contact with live parts could result in serious or fatal injury by electric shock.

• Replace faulty electrical cables and components immediately.

• Do not touch any components or cables that may be electrically live.

Warning

Adverse health effects due to the coolant used in machine!

The coolant contains 1.2-Ethanediol. The following precautions are recommended by the manufacturer/supplier of the heat transfer concentrate:

• R22: Harmful if swallowed.

• S2: Keep out of the reach of children.

• S24/25: Avoid contact with skin! In case of contact with skin, rinse imme-

diately with plenty of water.

• S46: If swallowed, seek medical advice immediately and show the con-

tainer or label.

• Not a hazardous material in compliance with GGVS

(ordinance on the

transport of dangerous goods by road) and GGVE

(ordinance on the

transport of dangerous goods by rail)

• Processing instructions of the manufacturer/vendor must be observed

Before working on electrical equipment, the entire machine must be disconnected from the mains. This is achieved by switching off t he main switch and,

if necessary, isolat ing it from the power supply (disconnect the power supply

plug).

Work on electrical installations shall only be undertaken by qualified electricians and in accordance with the applicable rules of electrical engineering.

Fuses may not be repaired or bypassed. Only u

se fuses specified by the

manufacturer.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 11 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.3 Protective equipment

Danger

Injuries and fatal accidents can occur as a result of missing protective

equipment!

If protective equipment is missing, damaged and/or modified there exists the

risk of injuries and fatal accidents.

• The machine and equipment may only be operated when all protective

equipment is in place and full working order.

• Do not remove or modify any protective equipment.

Operators and users are responsible for operating the machine in the correct

manner!

Danger zones that cannot be eliminated by constructional measures are fitted with protective equipment and, where appropriate, the machine is marked

with warning signs; moreover, relevant information relating to safe working

practice is specified in the instruction manual.

No alterations, additions or modifications that could affect safety are to be

made to the machine.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 12 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

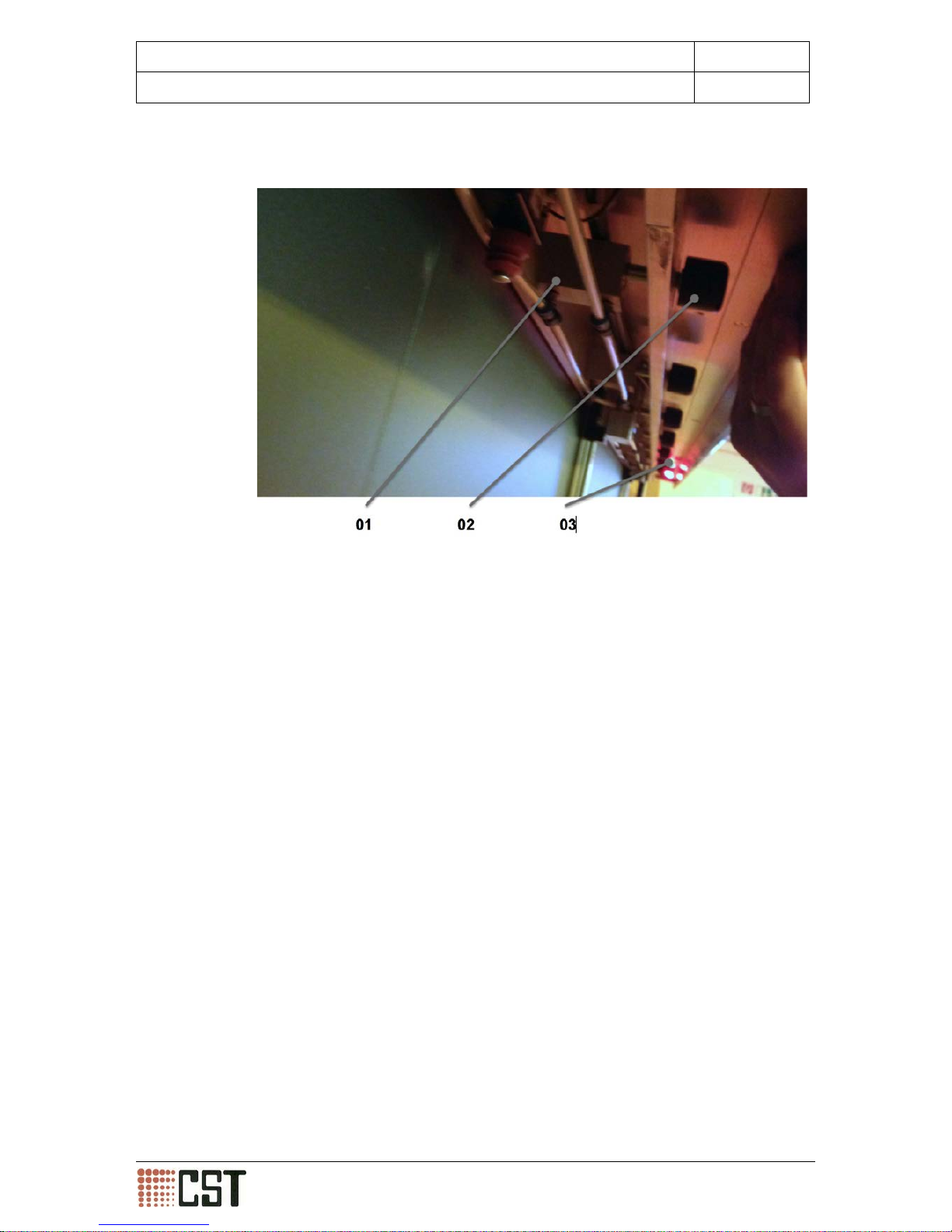

2.3.1 Existing protective equipment

The machine is equipped with the following safety devices:

• The lockable main switch is located on the main control panel (01).

• An EMERGENCY STOP button (02) is located on the vertical protect ive

cover (03) of the traversing head unit.

• A protective cover (03) covers the traversing head unit.

• Warning and information signs (04) indicate possible danger zones.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 13 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.3.2 Inspection of the protective devices

Planning, execution and documentation pertaining to the inspection shall be

carried out by the operator and shall take into consideration the applicable

laws and regulations. The following information specifies some of the criteria

and proposals.

Main Power Switc h and EMERGENCY STOP button

Intervals

When the machine is switched on as well as every 4 years

in the scope of the electrical test in accordance with the r egulations of the Employer's

Liability Insurance Association

[BGV A3]

Scope

Functionality

Inspector

Operating personnel

Action to be

taken when

faults occur

• Do not switch on the machine

• Disconnect from the mains supply

• Arrange for qualified electrician to carry out maintenance

Protective cover

Intervals

When the machine is switched and before it is opened

Scope

Functionality (the machine must switch off when the protective cover is opened.)

Inspector

Operating personnel

Action to be

taken when

faults occur

• Do not switch on the machine

• Disconnect from the mains

• Arrange for qualified electrician to carry out maintenance

Protective guard (cover)

Intervals

During the commissioning and when the machine is

switched on

Scope

Visual inspection of the physical integrity

Inspector

Operating personnel

Action to be

taken when

faults occur

• Close off the danger zone

• Carry out repairs

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 14 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.4 Emissions (noise levels/sounds)

Sound emissions are inevitable with machines and equipment in operation.

These emissions are within the stipulated limits.

However, the on-site sound pressure level can vary. This depends upon the

operating conditions, such as the number of machines and equipment in the

room, external noise, and the design of the production area.

If this is the case, the operator of the machine or system must provide appropriate protection for the operating personnel. The noise protection devices

must not be removed from the machine or equipment.

All personnel who work on the machine or equipment must wear the specified personal hearing protection.

Advice for when to wear personal hearing protection:

• Up to 70 dB (A):

In this case, no special measures are required

. People’s sensitivity to

noise varies. Therefore, people who feel that they are bothered or even

harmed by such noise should wear hearing protection

• From 80 dB (A):

People constantly working in this particular area should wear hearing protection

• From 85 dB (A): Hazardous noise area

Such areas must be marked with warning signs. People working in these

areas must wear hearing protection

2.5 Fire protection

The local fire protection regulations are to be observed.

Avoid naked flames, extreme heat and sparks when using cleaning agents,

flammable or deformable parts in the vicinity of the machine. Failur e to comply could result in a fire; this may result in harmful gases or damage to the

insulation.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 15 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.6 Pneumatics

Any work to be carried out on the pneumatic systems of the machine or

equipment shall only be undertaken by a pneumatic system specialist.

Prior to working on pneumatic equipment, the moving parts of the pneumatic

system are to be placed in their home or park position.

Depressurise the

pneumatic system before performing any work on i t.

Caution is needed when looking for leaks in pneumatic lines that are under

pressure. Pressurized air can penetrate clothing and sk in, which can result in

injury or severe infections.

Caution is needed when loosening or replacing pneumatic lines; incorrectly

connected pneumatic lines can result in operations not functioning correctly.

The movement area of the actuator should not be blocked and acces s to the

area of movement of the actuator must be sufficiently secured.

2.7 Hydraulics

Any work

to be carried out on the hydraulic systems of the machine or

equipment shall only be undertaken by a hydraulic system specialist.

Prior to working on hydraulic equipment, the moving parts of t he pneumatic

system are to be placed in their home or park position. Depressurise t he hydraulic system before performing any work upon it.

Caution is needed when looking for leaks in hydraulic lines that are under

pressure. Pressurized hydraulic fluid can penetrate clothing and skin, which

can result in injury or severe infections.

Caution is needed when loosening or replacing hydraulic lines; incorrectly

connected hydraulic lines can result in operations not functioning correctly.

The movement area of the actuator should not be blocked and acces s to the

area of movement of the actuator must be sufficiently secured.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 16 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.8 Electrical

Before the machine and equipment is commissioned, all connections and

connected loads must be checked. The values that are measured must correspond to those specified on the electrical circuit diagram.

When the main switch is turned off the machine and equipment are isolated.

Nevertheless, inside the cabinets there could still be voltage-carrying parts,

such as power supplies for the interior lighting and service electrical sockets,

and these need to be switched off separately.

Before any work can be started on the electrical equipment, the m achine or

equipment have to be checked if the power is switched off, and, if necessary,

earthed and short circuited. Suitable insulated tools, safety equipment and

personal protective equipment must be used and tested every time before

being used.

Before disconnecting and connecting any electrical plug connections, make

sure they are isolated (this is with the exception of network connections, a s

long as they have non-hazardous voltages which satisfy the safety regulations).

Electrical parts (such as motors), which have been stored for a long time,

should not be used until they have undergone prior isolation tests.

When electrical equipment parts or components have become wet, some

parts, which would normally be voltage free in a dry condition, could be live.

Before touching a component that has become damp or wet, please check,

by means of a measurement, if exposed components have a voltage.

Faulty fuses must not be repaired or bypassed and are to be replaced by a

fuse of the same type.

2.9 Spare parts

You should only use genuine parts that are specified by us.

When you don’t use original components, or spare

parts that were neither

supplied by us nor were tested and approved by us, they could impair the

safety.

We will not be held liable for damage that is caused by such items.

For the erection, installation, integration as well as services for maintenance

and repair work, or alterations to machinery and equipment, our experienced

service technicians are available.

All details about contacting CST GmbH can be found on the cover of the operator handbook.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 17 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.10 Personal protective equipment

The type and extent of per sonal protective equipment required shall be defined by the operator in the scope of the risk assessment (see 2.2). The fol-

lowing information specifies some of the criteria and proposals.

Head

Not required in normal operation. Adjust appropriately to surroundings.

The minimum protection required are industrial hard hats conforming to DI N

en 812 which is recommended for maintenance work (ref er to Occupational

Health and Safety Regulations of the Trade A

ssociations regulation 193

[BGR 193])

Eyes

For exposure to hazardous

ultraviolet (UV) radiation: tight fitting protective

safety glasses with side protection (refer to Occupational Health and Safety

Regulations of the Trade Associations regulation 192 [BGR 192])

Body

Not required in normal operation. Adjust appropriately to surroundings.

Ears

Not required. Adjust appropriately to surroundings.

Hands

When there is the danger of a hot surface:

suitable protective gloves (e.g.

protective gloves in respect of mechanical hazards, in accordance with EN

388, category 1, also refer to Occupational Health and Safety Regulations of

the Trade Associations regulation 195 [BGR 195]).

Feet

Protective shoes classified S1 or P1 or professional shoes classified P1 are

required.

For maintenance work: safety boots

Please observe the hygiene rules when using personal protective equipment

and work clothes!

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 18 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

2

Safety

Effective date

30.09.2013

2.11 EC DECLARATION OF CONFORMITY

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 19 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

3

Transportation, storage, installation, electrical

connection

Effective date

30.09.2013

3. Transportation, stora ge , installation, electrical connection

3.1 Special safety instructions

Danger

Serious or even fatal injury can occur during transportation, storage,

installation and electrical connection!

Disregarding the safety instructions can lead to injuries and fatal accidents.

• Please observe the safety information given in the chapter entitled

"Safety

" as well as the appropriate on-site applicable safety and accident

prevention regulations.

• All lifting and transportation work should be undertaken by qualified and

trained personnel and those who have been assigned to do such work.

• When permitted only use appropriate safety equipment, such as secure

ladders, lifting truck or the like to secure the means of transport (such as

transport crates).

• Do not climb on the means of

transport, unless it has been expressly

permitted.

Danger

Injuries and fatal accidents can occur as a result of the improper handling of loads!

The improper handling of loads can lead to injuries or fatal accidents as well

as the hazard of damage to the machine and equipment.

• Secure the load before any lifting and transport work is to be undertaken.

• Use cranes, hoists, lifting devices, slings and lifting tackle,

which are in

accordance with the applicable on-

site safety and accident prevention

regulations, and are designed for the weight of the machine and equipment.

• Use cranes, hoists, lifting devices, slings and lifting tackle which are speci-

fied by the manufacturer. Relevant approvals must be submitted (e.g.,

driving permits for cranes).

• All cranes, hoists, lifting devices, slings and lifting tackle m ust be regular ly

checked and keep a record of this in the inspection logbooks.

• Only use the designated lifting points for lifting the load.

•

Wear the appropriate protective equipment (e.g. gloves, safety boots,

hard hat, etc.).

• When undertaking any lifting or transportation work please exercise due

care and attention.

• Check that there are no personnel in the immediate lifting or transporta-

tion area and mak e sur e that the lifting or transportation area is cordoned

off

• Do not reach underneath or between suspended loads.

• Do not walk under suspended loads.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 20 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

3

Transportation, storage, installation, electrical

connection

Effective date

30.09.2013

3.2 Transport

Please refer to the order/delivery documentation f

or the exact scope of the

delivery. Following the delivery of the machine and all accessories, any damage caused by def ective packaging or transport shall be reported to the forwarder, the insurance company and the manufacturer

. Furthermore, we

would like to draw your attention to our Terms of Sale and Delivery.

Information

The improper handling of loads can lead to damage to the machine and

equipment!

The improper handling of loads can result in damage to the machine, equipment as well as parts and accessories!

• The factory packaging (transport crate) should be lifted only using the

specially designated lifting points. These are clearly marked on the external surface.

• Do not lift the packaging (transport crate) using any other point other than

those designated.

• The machine should always be transported and moved in an upright posi-

tion.

• Avoid any unnecessary sharp sudden movements, impacting and/or ex-

cessive vibrations during transportation, lifting and setting down.

Parts of the machine are delivered in a partially disassembled state.

The machine is packed differently, which depends upon the method of shipment and size. The packaging, unless specifically agreed, corresponds to our

general packaging guidelines.

For information about the weight of the machine including packaging, please

refer to the order/delivery documentation or the Technical Annex.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 21 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

3

Transportation, storage, installation, electrical

connection

Effective date

30.09.2013

3.3 Storage

The delivery shall remain in the factory packaging (transport crat e) until it is

ready to be installed.

Storage is to be carried out under the following conditions:

• A dry and well ventilated room

• The temperature has to remain between 20 to 26°C

• There should be no dramatic temperature fluctuations

• There should be no exposure to moisture

• No heat radiation

• No storage of chemicals in the area

Information

Machines and equipment can be damaged due to improper storage!

Improper storage can result in damage to the machine, equipment as well as

parts and accessories!

• Store the

machine, equipment as well as parts and accessories in the

original packaging.

• Take into account the maximum permissible floor loading limit.

• Please take special care when stacking wooden boxes and crates.

• Make sure that condensation does not form under the cover.

• Please observe the information provided by the manufactur ers for individ-

ual components.

• Do not store the delivery arbitrarily.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 22 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

3

Transportation, storage, installation, electrical

connection

Effective date

30.09.2013

3.4 Installation

The machine shall be installed in a vertical position and, using the adjustable

machine levelling feet, shall be balanced correctly. The floor must be level

and sufficiently stable.

Information

Machines and equipment can be damaged due to improper installation!

Improper installation can result in damage to the machine, equipment as well

as parts and accessories!

• Please make sure that there is sufficient space around the machine and

equipment during the installation/positioning of the machine and equipment.

It is recommended that the access areas around the Digital Light Engraver

should not go below a minimum width of 1m.

3.5 Electrical connection

For information about the electrical connection, please refer to the wiring dia-

grams.

Danger

Injuries and fatal accidents can occur as a result of hazardous voltage!

If there is a fault with an electrical component or cable, the direct or indirect

contact with live parts could result in serious or fatal injury through electric

shock.

• Replace faulty electrical cable and components immediately.

• Before connecting the machine or equipment, check the mains voltage.

• Do not touch any components or cables that may be electrically live.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 23 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

4

Machine description

Effective date

30.09.2013

4. Machine description

Direct imaging does away with the need for film, wax and ink for screen

masking, which means that consumable supplies are no longer required.

A DMD chip ( Digital Micro mirror Device) is an array of about 800,000 micromirrors that can be used for modulating an ultra-

high power UV light

source. The micromirrors making up the array can be individually controlled according to the data. As the DMD chip m oves o ver t he screen, the

data scrolls through the

chip so that a still image is projected onto the

screen. The image is created in strips and is executed in a continual and

scrolling motio n on the screen. The scrolling process has been patented

by CST-GmbH.

Each micromirror exposes one pixel. Therefore, given the high frequency

rate and the amount of mirrors, the imaging is not only executed very

quickly indeed but is also of an excellent quality.

Moreover, a range of lenses offer rapid speeds and the highest resolu-

tions.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 24 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

4

Machine description

Effective date

30.09.2013

4.1 Machine housing

• Linear guide elements (01), which are m

ounted on both the upper and

lower edges of the machine housing, run across the complete

width of

the machine housing.

• The vertically-mounted bridge (02) - where the head unit is located under

a protective cover - moves along the two linear guiding elements (01).

• The screen frame (04), which is to be imaged, is held in place by two hor-

izontally placed U-channels (03).

• The upper U-channel (05) can be vertically adjusted to accommodate dif-

ferent sizes of screen frames (04).

• The screen frames (04) can be secured in both of the U-channels (03) by

means of pneumatically operated clamps.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 25 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

4

Machine description

Effective date

30.09.2013

4.2 Screen frame clamping system

• A number of pneumatic cylinders (01), which are positioned on the C-

channels, move rubberized clamps (02) mounted on piston rods.

• A light barrier (03), which is mounted on the upper C-channel, checks the

presence of the screen frame.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 26 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

4

Machine description

Effective date

30.09.2013

4.3 Bridge

•

The vertically traversing head unit (01) is located under the protective

cover of the bridge.

• The head unit includes two light units (05) which produce light in the ul-

traviolet wavelength range.

• This light units (05) are cooled by a closed loop cooling system (02) that

is also located in the head unit.

• The light beams that are generated by the two light units (05) are com-

bined in a prism unit (04) and then transmitted to the Digital Micromirror

Device (03).

• The micromirrors located in the Digital Micromirror Device (03) are elec-

tronically controlled to produce the image on the screen frame screen.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 27 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

4

Machine description

Effective date

30.09.2013

4.4 Operating control units

• The foot pedal unit pictured above (01) is used to close and reopen the

clamps in the upper C-channel vertical process.

Warning

Risk of crushing injury to the fingers, hands and feet when closing the

clamps!

There is the risk of crushing injury to the fingers, hands and feet when inserting

the screen in the upper and lower screen frame area and closing the

clamps.

•

Wear personal protective equipment in the form of safety shoes and

gloves when inserting the screen frame (screens) in the screen clamps.

• Ensure that nobody is in the danger zo

ne area when closing of the

clamps.

• Please instruct people to leave the danger zone.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 28 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

4

Machine description

Effective date

30.09.2013

Warning

Risk of crushing injury between the screen clamps and the cam limit

switches!

When operating of the upper screen clamp there is the risk of crushing injury

between the movable screen clamp and the cam limit switches on the screen

clamp which are mounted on the housing.

• Wear personal protective equipment in the form of safety shoes and

gloves when operating the screen clamps.

•

Ensure that nobody is in the danger zone when operating the upper

clamps.

• Please instruct people to leave the danger zone.

Information

When the screen clamp closes, the screen could drop out!

When the screen clamp is closing, there is the danger that the screen could

suddenly drop.

• Hold onto the screen frame when the screen clamp is closing.

• The operation and parameterization of the machine

can be carried out

using the PC unit (01) pictured above.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 29 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

5

Initial commissioning, decommissioning

Effective date

30.09.2013

5. Initial commissioning, decommissioning

5.1 Special safety instructions

Danger

Injuries and fatal accidents can occur during the initial commissioning!

Disregarding the safety instructions can lead to injuries and fatal accidents.

• Please observe the safety information given in the chapter entitled

"Safety“

" as well as the appropriate on-site applicable safety and accident

prevention regulations.

• The initial commissioning is to be carried out only by CST authorized qual-

ified personnel.

• All mechanical and electrical work is to be always performed with power

supply switched off (turn off the main switch and secure it with a padlock

or U-lock to prevent it from being inadvertently switched on).

• Before undertaking any work on the machine and equipment cordon off

the area with a temporary barrier (such as red and white saf ety chains)

and arrange for access to be restricted, if requ ired.

• When climbing onto the machine or equipment please use suitable safety

equipment, such as stepladders, pallet jack or the like.

• Do not remove or change any protection devices.

Danger

Injuries and fatal accidents can occur as a result of hazardous voltage!

If there is a fault with an electrical component or cable, the direct or indirect

contact with live parts could result in serious or fatal in-jury through electric

shock.

• Do not work on the machine and equipment when it is switched on.

• All mechanical and electrical work is to be always performed with power

supply switched off (turn off the main switch and secure it with a padlock

or U-lock to prevent it from being inadvertently switched on).

• After switching off the machine and equipment, check for the presence of

residual voltage.

• Wear appropriate protective equipment (e.g.

gloves, safety shoes, hard

hat, etc.), and especially tight fitting clothes.

• Access to the machine and equipment m ust only be via the approved ar-

eas.

• Do not carry out any work on voltage-carrying parts alone.

• Do not touch any components or cables that may be electrically live.

• Do not enter the danger zone.

• Do not leave the main switch unsecured.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 30 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

5

Initial commissioning, decommissioning

Effective date

30.09.2013

Danger

Injuries and fatal accidents can occur as a result of t he improper handling of loads!

The improper handling of loads can lead to injuries or f atal accidents as well

as hazard of damage to the machine and equipment.

• Please observe the safety information give

n in the chapter

tled ”Transport and Storage“.

• Make sure that the lifting and transportation work is carried out only by

qualified, authorized and trained personnel.

• When undertaking any lifting or transportation work please exercise due

care and attention.

• Check that there are no personnel in the immediate lifting or transporta-

tion area and make sure that the lifting or transportation area is cordoned

off.

• Do not reach underneath or between suspended loads.

• Do not walk under suspended loads.

Warning

Injuries and environmental damage can occur as a result of improper

handling of operating material and ancillary substances!

Improper use of equipment or ancillary substances could result in serious

health risks or fatal injuries. It could even lead to extensive environmental

and property damage.

• Read the rules applicable to the current materials material safety sheets

(MSDS) and the manufacturer’s instructions for the equipment and ancillary substances.

• Wear appropriate protective equipment (e.g. gloves, safety shoes, protec-

tive clothing, respirator, safety glasses, etc.).

• Make sure the area is sufficiently ventilated.

• Exercise extreme caution when handling hot equipment or ancillary sub-

stances. Contact can result in burns and scalds.

• When there is a leak from equipment or of ancillary substances use a

suitable bonding material to bind this and dispose of it in accordance with

on-site regulations

• Avoid skin contact with the equipment or ancillary substances.

• Do not breathe in any fumes from the equipment or ancillary substances.

• Do not use them near an open flame.

• Do not let any spills from equipment or of ancillary substances drain away

into the ground or into the drainage/sewer system.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 31 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

5

Initial commissioning, decommissioning

Effective date

30.09.2013

5.2 The preparatory work for the commissioning

Before the commissioning process can begin, the following work has to be

completed:

• The working area must be cleared and cleaned

• Protective equipment must be fitted and warning signs must be displayed

• Transport safety equipment must be removed

Check the following points on the machine and equipment before putt ing

them into operation:

• Accessories are fastened to the electrical and pneumatic components

• All screw connections are tight and

check the screw connection torque

levels, and correct if necessary

• Utilities such as electricity and compressed air are provided on site, e.g.

compliance with the working materials

• Power connections

• Terminals and protective fixtures

• Carry out, for example, the set up and then functional tests of the electr i-

cal and programmable logic controller (PLC)

• Carry out, for example, the set up and then functional tests of the pneu-

matics, lubrication

• Carry out, for example, the set up and then functional tests of t he control

systems

• Make sure that loose fittings are tightened and tensions are adjusted cor-

rectly

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 32 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

5

Initial commissioning, decommissioning

Effective date

30.09.2013

5.3 Decommissioning

Danger

Injuries and fatal accidents can occur during decommissioning!

Disregarding the safety instructions can lead to injuries and fatal accidents.

•

Please observe the safety information given in the chapter

tled “Safety“ as well as the appropr iate on-site applicable safety and accident prevention regulations.

• Make sure that the decommissioning work is carried out only by qualified,

authorized and trained personnel.

• Do not climb on or through the machine and equipment.

Danger

Injuries and fatal accidents can occur as a result of hazardous voltage!

If there is a fault with an electrical component or cable, the direct or indirect

contact with live parts could result in ser ious or f atal injury through electric

shock. Injuries and fatal accidents can occur as a result of working on machine and equipment when it is switched on.

• Do not work on the machine or equipment when it is switched on.

• All electrical work is to be always performed with power supply switched

off (turn off the main switch and secure it with a padlock or U-lock to prevent it from being inadvertently switched on).

• After switching off the machine and equipment, check for the presence of

residual voltage.

• Wear appropriate protective equipment (e.g. gloves,

safety shoes, hard

hat, etc.), and especially tight fitting clothes.

• Access to the machine and equipment must only be via the approved ar-

eas.

• Before undertaking any work on the machine and equipment cordon off

the area with a temporary barrier (such as red and white saf ety chains)

and arrange for access to be restricted, if requ ired.

• Do not carry out any work on voltage-carrying parts alone.

• Do not touch any components or cables that may be electrically live.

• Do not enter the danger zone.

• Do not leave the main switch unsecured.

Remove the screens, which are still in the machine, and thoroughly clean the

machine/UV head both on the inside and outside.

Disconnect the machine from the electrical power supply.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 33 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

5

Initial commissioning, decommissioning

Effective date

30.09.2013

5.4 Instructions for disposal

Warning

Injuries and environmental damage can occur as a result of improper

handling of operating material and ancillary substances!

Improper use of equipment or ancillary substances could result in serious

health risks or fatal injuries. It could even lead to extensive environmental

and property damage.

• Read the rules applicable to the current materials material safety sheets

(MSDS) and the manufacturer’s instructions for the equipment and ancillary substances.

• Wear appropriate protective equipment (e.g. gloves, safety shoes, protec-

tive clothing, respirator, safety glasses, etc.).

• Make sure the area is sufficiently ventilated.

• Exercise caution when handling hot equipment or ancillary substances.

Contact can result in burns and scalds.

• When there is a leak from equipment or of ancillary substances use a suit-

able bonding material to bind this and dispose of it in accordance with onsite regulations.

• Avoid skin contact with the equipment or ancillary substances.

• Do not breathe in any fumes from the equipment or ancillary substances.

• Do not use them near an open flame.

• Do not let any spills from equipment or of ancillary substances drain away

into the ground or into the drainage/sewer system.

Applicable general precautions are to be taken during the dismantling and

disposal.

All components and parts, operating and auxiliary materials and other mate-

rials must be disposed of in compliance with the applicable regulations.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 34 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

6. Operation and cleaning

6.1 Special safety instructions

Danger

Injuries and environmental damage can occur during operation!

Disregarding the safety instructions can lead to injuries and fatal accidents.

•

Please observe the safety information given in the chapter

tled ”Safety“ as well as and to the appropriate on-

site applicable safety

and accident prevention regulations.

• Wear appropriate protective equipment (e.g. gloves, safety shoes, safety

glasses, etc.).

•

Make sure that the operation and cleaning work is carried out only by

qualified, authorized and trained personnel.

• Be aware of moving parts.

• When the machine is in operation, stay within the area of the control units

with the corresponding controls, since these are considered to be the

workplace of the machine and equipment

• Do not climb on or through the machine and equipment.

• Do not remove or change any protection devices.

• No cleaning work is permitted when the machine is in operation.

Danger

Increased risk of accidents can occur as a result of moving masses!

This symbol warns of an immediate danger to the life and health of people.

• People who operate power-driven machinery must make sure t hat t hey do

not endanger themselves or others through hazardous motions.

• Access to the interior of the machine housing in only permitted when the

machine has been switched off and measures have been taken to prevent

it from being inadvertently switched back on.

• Long hair, loose clothing, jewellery or the like can be drawn into moving

parts. This can lea d to very serious injuries.

• Wear tight-fitting clothing. Protect long hair by wearing a hair net. Remove

jewellery.

• It is not permitted to climb on the machine while it is in operation.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 35 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

Danger

Increased risk of accidents can occur as a result of intense/high levels

of ultraviolet radiation!

When monitoring/checking the ultraviolet light, there is always the risk of serious eye injuries and permanent eye damage.

• Wear appropriate protective equipment in the form of safety glasses that

are suitable for the particular light source.

• Never look directly at the ultraviolet beam or the image of t he pattern on

the screen without personal protective equipment (safety glasses).

Danger

Increased risk of accidents can occur as a result of hazardous voltage!

If there is a fault with an electrical component or cable, the direct or indirect

contact with live parts could result in ser ious or fatal in-jury through electric

shock!

• Replace faulty electrical cable and components immediately.

• Do not touch any components or cables that may be electrically live.

Information

Improper operation could lead to damage to the machine and equipment!

Improper operation can lead to serious damage to the machine and equipment.

• Make sure that all operations are carried out by qualified, authorized and

trained personnel.

• Follow the instructions given in the manufacturer’s instruction manual

carefully and comply with them accordingly.

• Make sure that the workplace is clean when the machine and equipment

are in operation.

• Do not place any tools, appliances or the like on the machine and equip-

ment.

• Carefully insert the imaged screen stencil into the machine.

• Do not operate the machine and equipment without having prior adequate

training or without first reading the manufacturer’s instruction manual.

• Do not climb on or through the machine and equipment.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 36 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

6.2 Operation

6.2.1 Starting the machine

• Turn the main switch to the "I" position

• Check the EMERGENCY STOP switch and turn on the machine at the main

switch.

• Press and hold the start button down for more than one second.

• Switch on the PC and turn on the monitor, and then wait until it has fully

booted up.

• Start the main program by double clicking on this desktop icon

Click on the "R” reference button on the software interface and wait until the

reference run is finished.

The LEDs on the light switch should now be switched on.

Now you will see that the LED status indicator has changed to the active

mode.

LED OFF

LED ON

These displays indicate the

LED’s current power consumption when the LEDs are

in imaging mode

These displays indicate the LED status, showing

whether they are

on or off

These displays show

the LED’S current

temperature

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 37 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

Nach dem Anklicken

dieses Dreiecks erhal-

ten Sie eine

Dropdownliste mit Be-

musterungsgrößen

6.2.2 Starting a screen imaging process

• Load the design image: Edit/Add bilevel design image

• Choosing the c orrect image size as well as the correct design

After clicking on the arrow, a drop down list of the im age sizes will appear (bitte in Grafik einfugen!)

Once you have made your selection, confirm the selection by clicking "OK"

• The image will be shown in the imaging area at a sca le of 1:1

•

To display the entire image area, select the "Fit" option

• To start the imaging process, select "Expose/Expose ..." from the menu

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 38 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

• Entering the X and Y values f or the start position. The start position will de-

pend upon the imaging area that has been chosen.

• Enter the speed values in cm/sec.

The speed is based on the particular screen being used (yellow/white/150/90...), the type of emulsion as well as the coating thickness.

The maximum speed (5 to 55cm/sec) also depends upon the chip frequency

in combination with the exposure head resolution.

• Enter the values for the imaging rows. The values entered here specify how

many rows will be imaged by the chip. In the example below, the chip will

cover 640 rows. The maximum number of rows is stored in the DLE settings.

To reduce the imaging intensity, you need to reduce the number of rows.

CST recommends doing this gradually using increments of 50 in relation to

the final value (140-730/140 – 680...).

• Setting the slider to a value between Speed/Quality

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 39 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

This value determines the chip width that will be used. The maximum width

is 1,024 rows. You can use the slider to determine the overlap. In this case,

the progr am switches of f 40 micromirros on both sides of the chip and uses

944 micromirrors per row.

• Select a value for the shift function for four colour printing jobs.

This function is recommended for four colour print jobs, especially to avoid

banding of the individual colours on the same position. The value to be entered depends upon the colour. CST recommends working in increments of

222 (K = 0/C = 222/M = 444/Y = 666). When large Speed/Quality values are

to be used, you must reduce the start shift function value (200).

• Select which final motion should occur upon completing the imaging se-

quence.

You can choose between “Park after jet” and “Screen change after jet”.

When no option is selected, the head will stop in the f inal position where the

previous imaging was completed.

• Click on the "Move" button in order to move the head to the start position.

From here you can check the start position before imaging commences.

When you have entered and checked the values, start the imaging process

by clicking on the "OK" button. You can stop the imaging process by clicking

on t he “cancel” button with the mouse cursor or pressing the “space bar” on

the keyboard.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 40 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

6.2.3 Four colour Printing

After you have performed the imaging for the first colour of a four colour

print, you can use the "X-change image" function to keep the parameter settings.

• Opening the "X-change image" function

• You will see the file name of the last completed imaging. (Old image)

• Click on the “Browse” button and select the next image.

You will see both the old as well as the newly selected file names.

By clicking on the "OK" button, the program will replace the imaging without

changing the previously used parameter settings.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 41 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

6.2.4 Checking the LED’s

• You should always check the light values at the same time of day in order to

be able to compare the measurement values. Prior to this, please observe

points 1 to 7 on page two of this instruction manual.

• Turn on the camera.

• Press the "T" button at the top to move the head to the camera position.

• Start the “DLE calibration” pr ogramme.

The program will prompt you to enter a password. Enter "cst". The main

program will close and the calibration process will commence.

• Click on the "Lightvalue" button to perform the photometry

Machine activities

- The head moves towards the camera.

- The system adjusts the focus to the camera

- The head turns on all selected mirrors and carries out a t est run with the

camera.

You can see a live image and the light value.

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 42 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

The live image shows you the current state of the light distribution with the

currently loaded light-

curve correction (calibration curve). The file name

and the file path of the loaded curve (.bmp file) are displayed at the bottom

of the screen.

• The “calibration” button is used for carrying out a completely new calibra-

tion of the system. Please use this only if you are sure that this is necessary. Experience has shown that LEDs can remain stable for a period of

up to 500 hours.

When a recalibration is carried out, the current correction curve is

deleted. The system calculates a new curve from several measurements. Improper use of this function can lead to a loss of quality in

the production and may cause banding.

6.2.5 Finishing work

• Move the head close to the reference position, park or screen change po-

sition. (Click R, S or P in the software)

• Close the program "CST LED“

• Close the "Lexium mover"

• Shut down the PC

• Turn off the light unit

• Switch off the machine by turning the main switch to the "0" position

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 43 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

6.2.6 EMERGENCY STOP

The machine and equipment are equipped with an EMERGENCY STOP

switches so that the machine and equipment can be shut down quickly to

prevent any danger to people, machine and equipment.

The controller is designed in such a way that when an EMERGENCY

STOP is made all rotating or linear movements are shut down.

6.2.7 Action to be taken after an EMERGENCY STOP

Danger

Serious or even fatal injury can occur due to hot parts and hazardous

voltage!

Serious or even fatal injury can occur when continuing to work on the machine and equipment after an EMERGENCY STOP!

• Do not work on the machine or equipment when it is switched on

• All mechanical and electrical work is to be always performed with power

supply switched off (turn off the main switch and secure it with a padlock

or U-lock)

• After an EMERGENCY STOP, check the machine and equipment for the

presence of residual voltage. The machine and equipment are not necessarily isolated.

• Wear appropriate protective equipment (e.g. gloves, safety shoes, hard

hat, etc.), and especially tight fitting clothes

• Access to the machine and equipment must only be via the approved ar-

eas.

• Before undertaking any work on the machine and equipment cordon off

the area with a temporary barrier (such as red and white saf ety chains)

and arrange for access to be restricted, if requ ired.

• Do not stand close to hot parts following an EMERGENCY STOP with t he

machine and equipment.

• Do not carry out any work alone on voltage-carrying parts

and do not

leave the main switch unsecured after it has been turned off.

Resolve the cause that led to the EMERGENCY STOP and carry out the

following action:

• Unlock the EMERGENCY STOP devices.

•

For example, to unlock EMERGENCY STOP button, simply pull out the

“mushroom head” button and let it go back in again

• Return the protective devices to their original state

• Use the control system to acknowledge the alarm message ( error) that is

displayed

CST GmbH

Königsberger Straße 117

47809 Krefeld - Germany

Page 44 of 69

Betriebsanleitung DLE-AF 01.0 engl.docx

INSTRUCTION MANUAL Digital Light Engraver

6

Operation and Cleaning

Effective date

30.09.2013

6.2.8 DLE settings

In the "Settings" part of the DLE program, you will find various settings for

the operation of the machine, as well as the ways to control t he chip and

LED system.

Here, you can find the “DLE settings” under the “Utilities” tab

The program will prompt you to enter a password cst