Page 1

- 1 -

SERVICE MANUAL

1. Main Functions:

-Audio Play/Video Recording

-Master /SLAVE GSM 900/1800MHz

-MMS/WAP

-Bluetooth 1.2

2. Main Selling Points

-BT communication

-FM supporting

-GPRS Class 12

-Support MP3, MP4

3. Other Functions

-Slide-Rotating

4. Spec

-SIZE 75X70X15mm

2.4" TFT 26K

Page 2

- 2 -

INTRODUCTION

The purpose of this document is to help service workshop technicians to service products. This service

TABLE OF CONTENTS

INTRODUCTION………………………………………………………………………………..3

Chapter 1 EXPLODED VIEW AND COMPONENT DISPOSAL………………………….4

EXPLODED DIAGRAM………………………………………………………………………….……...4

DISASSEMBL Y AND ASSEMBLY …………………………………………………………….………5

SERVICE TOOLS………………………………………………………………………………...5

DISASSEMBLE…………………………………………………………………………………...7

ASSEMBLY………………………………………………………………………………………..9

Chapter 2 SYSTEM BLOCK DIAGRAM……………………………………………………..11

Chapter 3 INSTRUCTION OF THE UNIT CIRCUIT………………………………………...12

Chapter 4 ACTUALL BOARD…………………………………………………………….….21

SIDE A (MASTER)…………………………………………..……………………………………….….21

SIDE B (SLAVE)……………………………………………………………………………………...….21

Chapter 5 TROUBLESHOOTING……………………………………………………………22

Chapter 6 SOFTWARE INSTRUCTION OF SW UPDATE………………………………..28

SW UPDATE OF MASTER……………………………………………………………..………………32

SW UPDATE OF SLAVE…………………………………………………………………………..……35

Chapter 7 FUNCTION TEST………………………………………………………………….39

Chapter 8 PARAMETER SETTING INSTRUCTION……………………………………….40

Chapter 9 CATCHER INSTRUCTION……………………………………………………….42

Page 3

- 3 -

manual must be used only by authorized service suppliers. The content of it is confidential. Please note that

provides other guidance documents for service suppliers. Follow these regularly and comply with the given

instructions. While every effort has been made to ensure the accuracy of this document, some errors may

exist. Please keep in mind also that this documentation is continuously being updated and modified, so

always watch out for the newest version.

CAUTIONS

Please refer to the phone’s user’s guide for instructions relating to operation, care, and maintenance,

which include important safety information.

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and that an anti-static wrist strap is worn.

3. Use only approved components as specified in the parts list.

4. Ensure all components, modules, screws, and insulators are correctly re-fitted after servicing and

alignment

5. Ensure all cables and wires are repositioned correctly

Electrostatic discharge can easily damage the sensitive components of electronic products. Therefore,

every service supplier must observe the precautions which mentioned above.

GENERAL REPAIR INFORMATION

1. Make sure your testing equipment is functioning properly before beginning repair work.

2. Before starting repairs you must observe ESD precautions such as being in your ESD

protected area and connecting your wristband.

3. Use gloves to avoid corrosion and fingerprints.

4. Cover windows and displays with a protective film to avoid dust and scratches.

5. Use a lint-free cloth to clean the LCD.

6. When cleaning the pads use a soft cloth\ ESD brush and isopropanol. Do not use a glass

fiber pencil: this scratches the surface and will corrosion.

7. Non-faulty mechanical parts(except shielding lids and bent parts or soldered components).

May be reused if they are not soldered.

8. When removing the shielding lids make sure to replace them with new ones, otherwise the

high-frequency leakage can affect the device.

9. Alw ays use the original spare parts.

10. Check the soldering joints of the parts concerned with regard to the fault symptom. And

resolder them if necessary.

11. Remove excess soldering flux after repair.

12. Observe the torque requirements when assembling the unit.

13. please aware that some malfunctions may be software related and solved by an update

Page 4

- 4 -

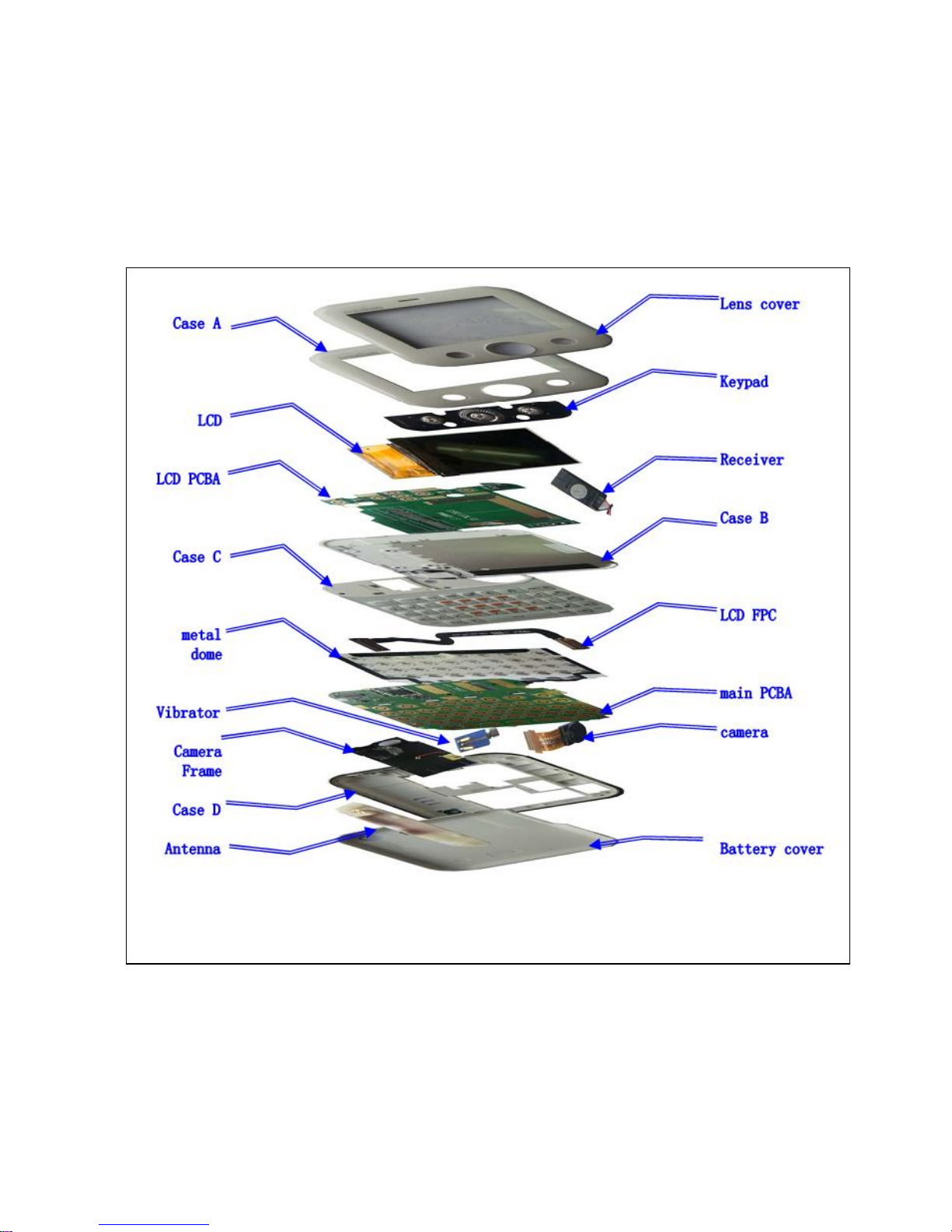

Chapter 1

EXPLODED VIEW AND COMPONENT DISPOSAL

EXPLODED DIAGRAM

Page 5

- 5 -

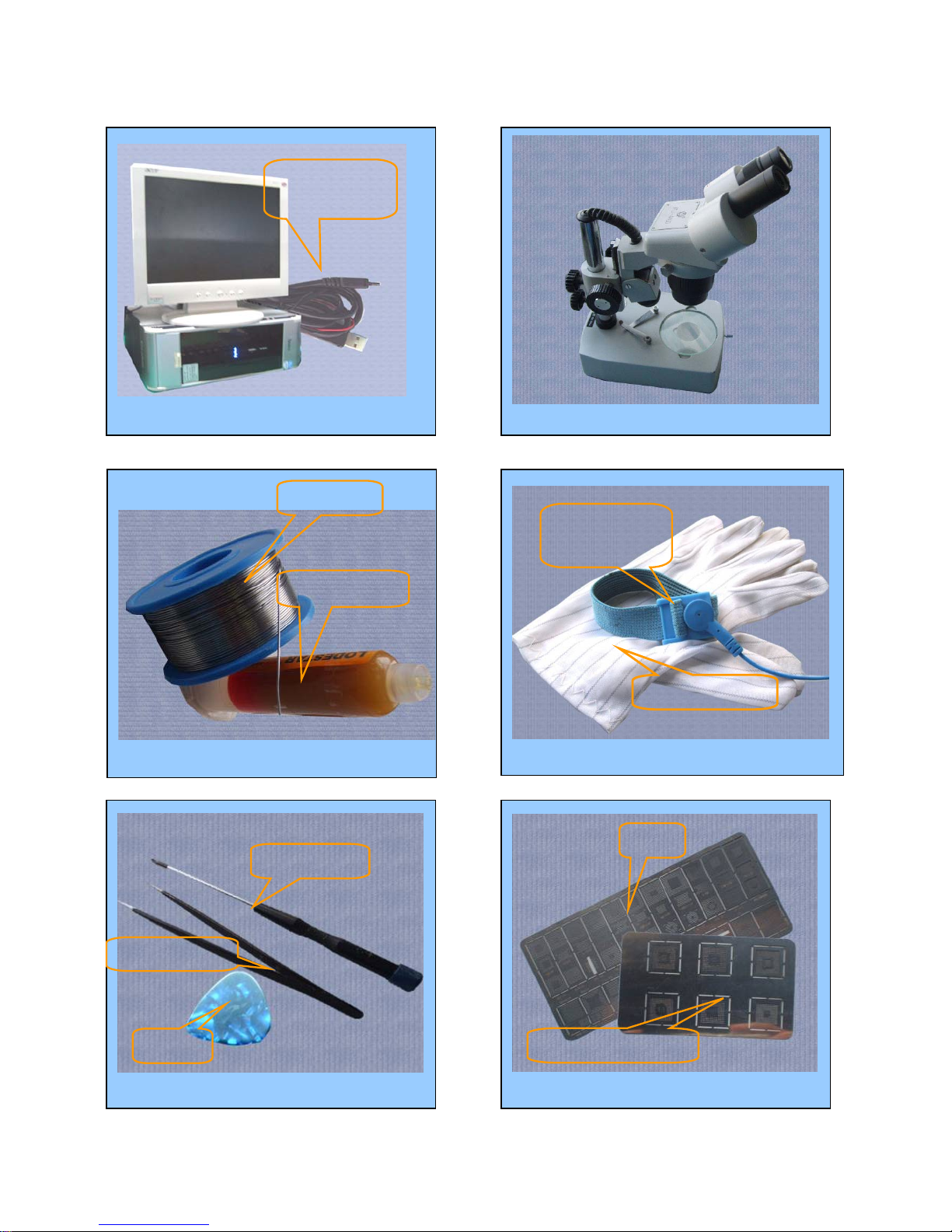

DISASSEMBLY AND ASSEMBLY

SERVICE TOOLS

Voltage regulator

Multimeter

Iron

850 heater

Constant temperature heater

Oscillograph

Page 6

- 6 -

Computer and software download cable

Wrist grounding strap, Antistatic gloves

Wrist

grounding strap

Antistatic gloves

Software

download cable

Microscope

Solder wire, soldering paste

Metal tweezers, Screw driver, SRT-6 Plates

Metal tweezers

SRT-6

Screw driver

MTK series CPU plate

Plate

soldering paste

Solder wire

Page 7

- 7 -

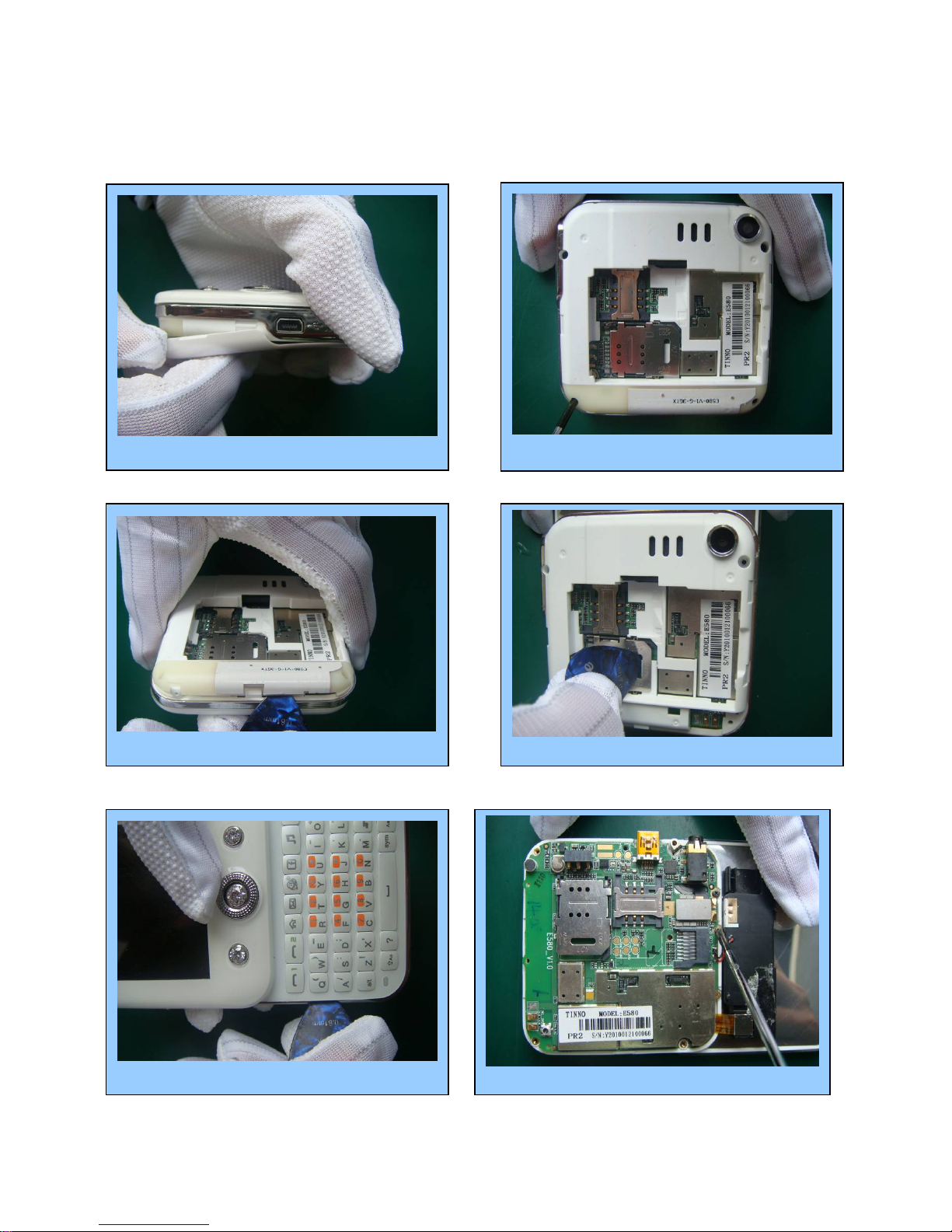

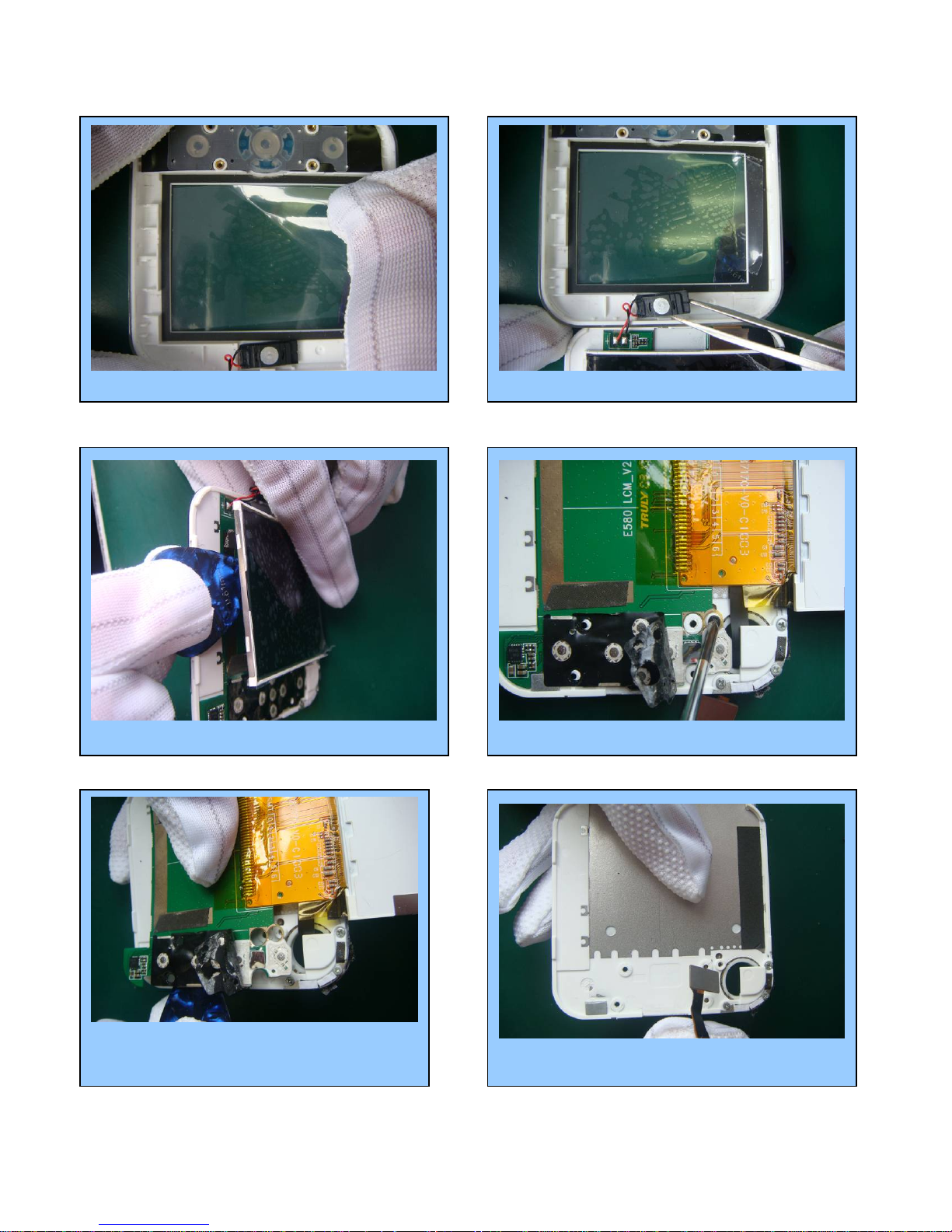

DISASSEMBLY

Take out the battery cover.

Remove 4 screws with screw driver.

Prize up the antenna by pick Prize up SIM buckle

Prize up D cover with pick Remove 2 screws with tweezer

Page 8

- 8 -

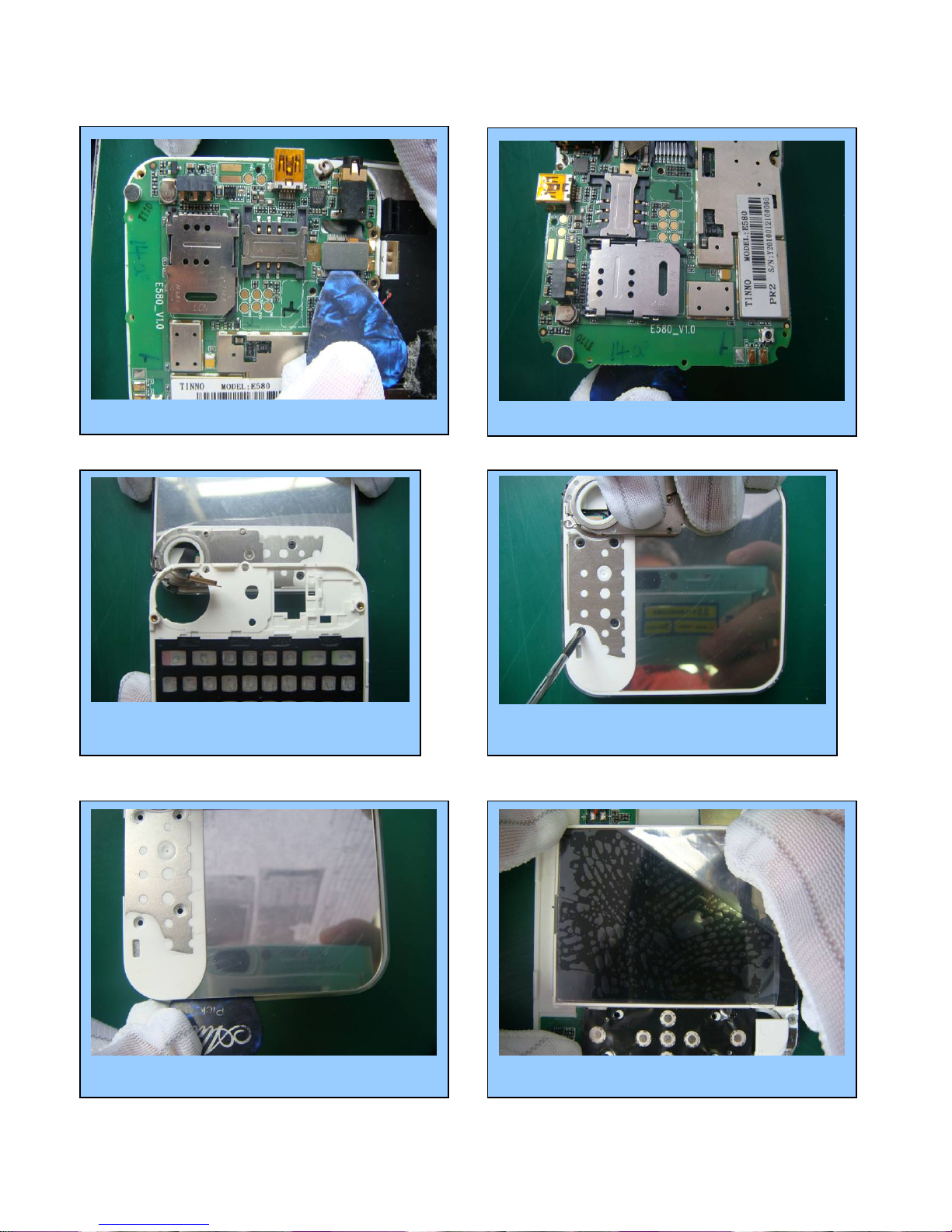

⑺ Take down FPC connector with pick

⑻ Take off PCBA by tweezer

⑼Take out C cover with hands

⑽ Take off 4 screws by tweezer

⑾ Prize up B cover with tweezer ⑿ Stick LCD film

Page 9

- 9 -

Finish

⒀ stick lens protection film ⒁ Take off receiver by tweezer

⒂ Separate LCD with pick

⒄ separate LCD PCBA with tweezer

⒃ Take off the screw with tweezer

⒅ Take off FPC

Page 10

- 10 -

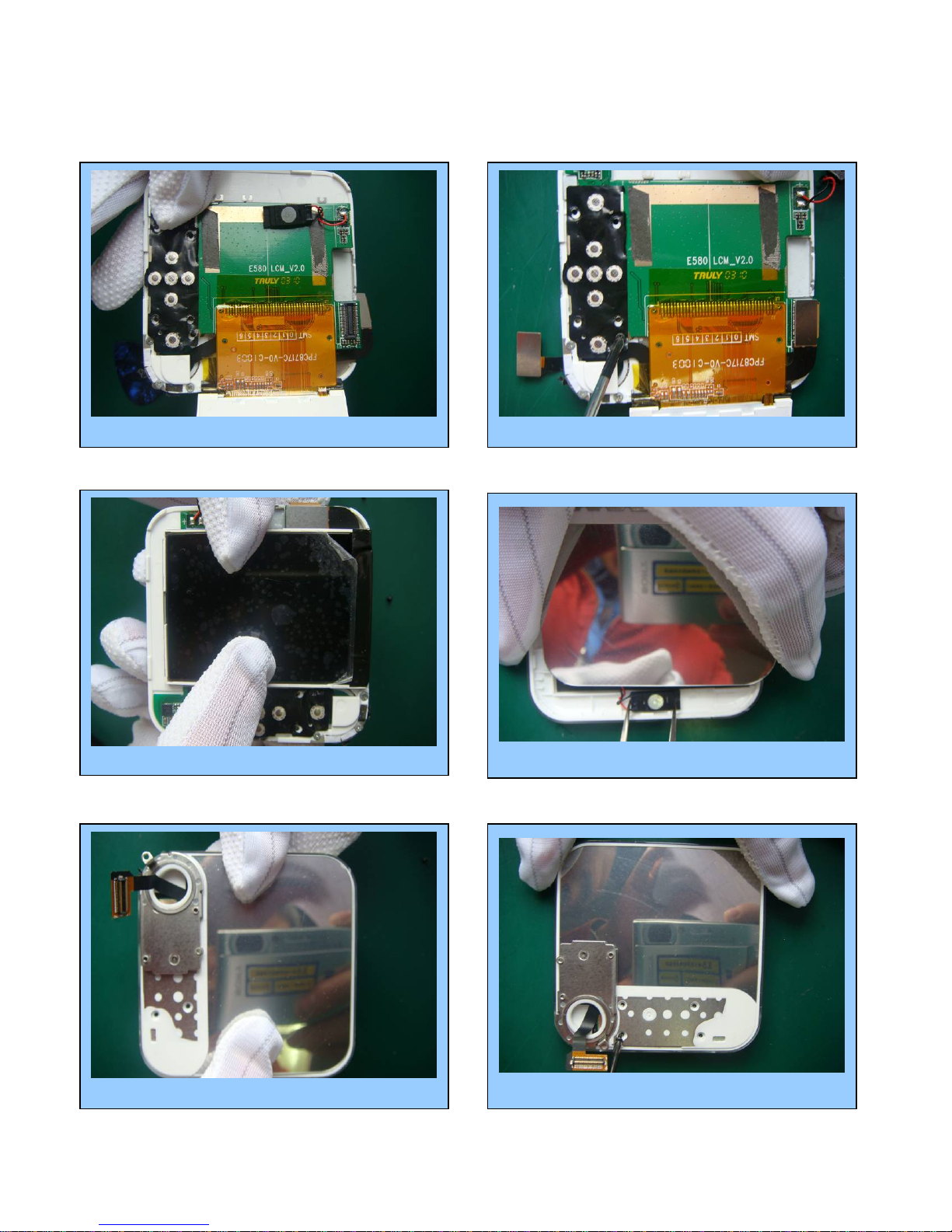

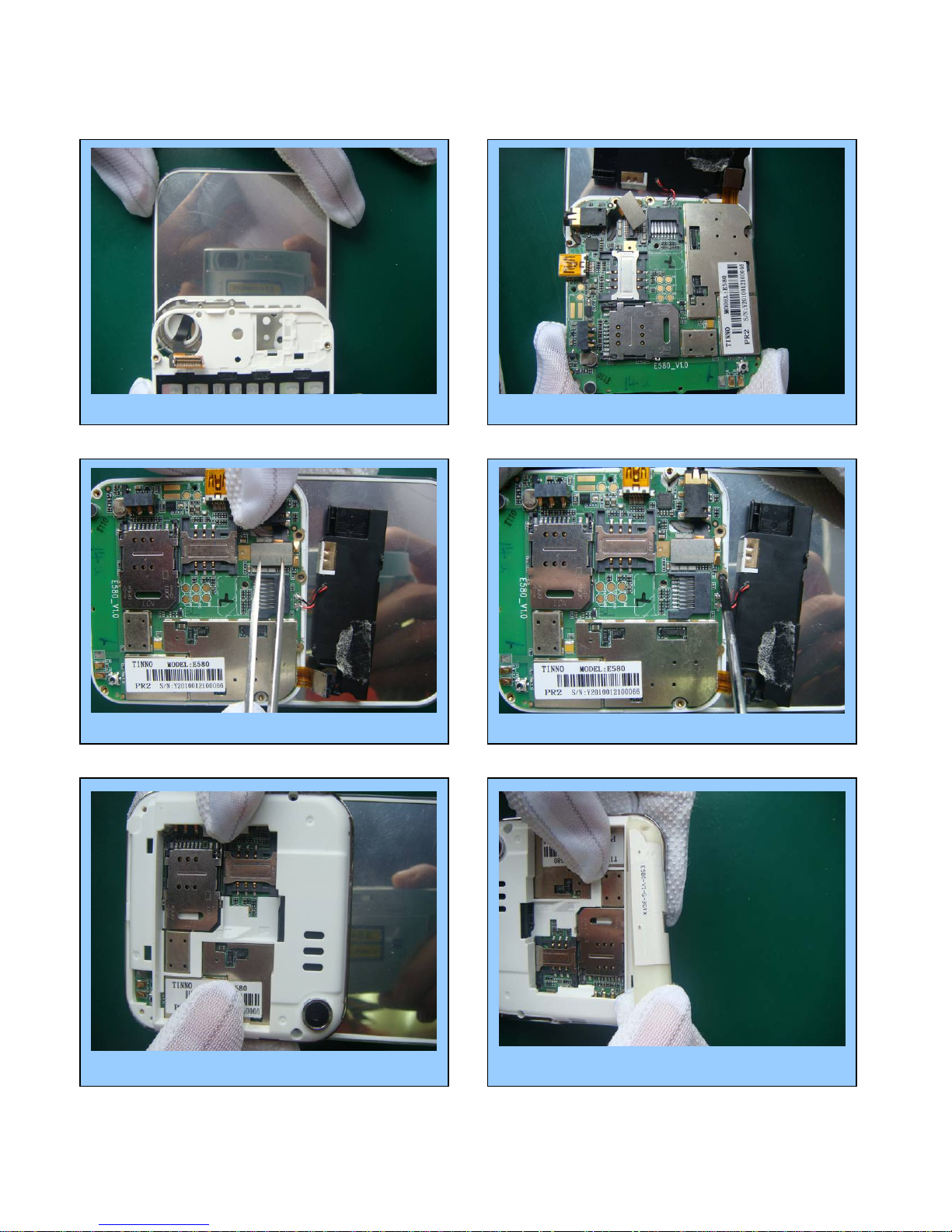

ASSEMBLY

⑴ Place LCD PCBA in A cover ⑵ Lock the screw

⑹ Lock the screws with tweezer ⑸ install B cover

⑷Install receiver with tweezer

⑶ Install LCD

Page 11

- 11 -

⑺ Install cover C

⑿ Install the antenna ⑾Connect FPC with PCBA board

⑽ Lock 3 screws with tweezer

⑻ Place main PCBA in C cover

⑼ Tighten the FPC connector

Page 12

- 12 -

Finish

⒀ Lock 4 screws

⒁ Button the battery cover

Page 13

- 13 -

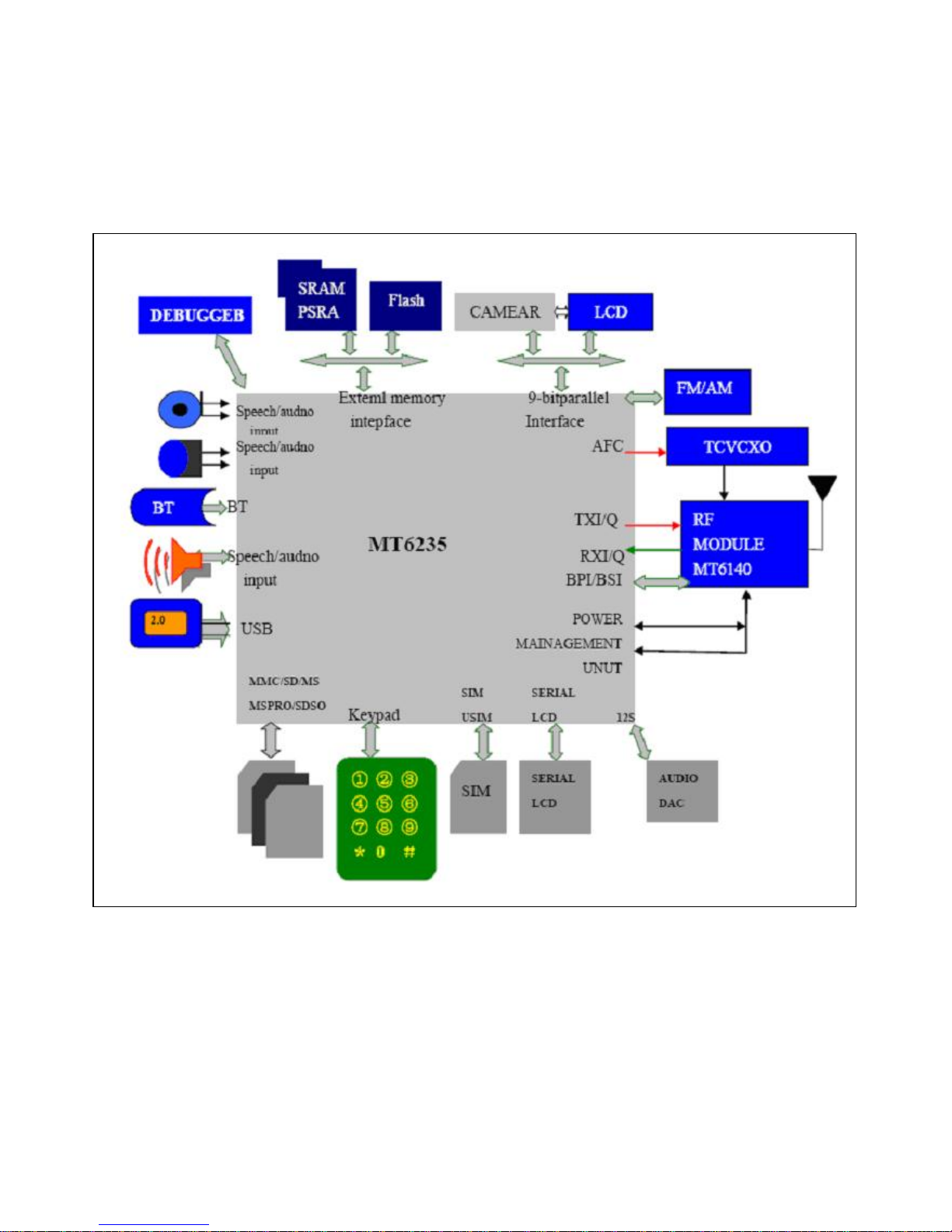

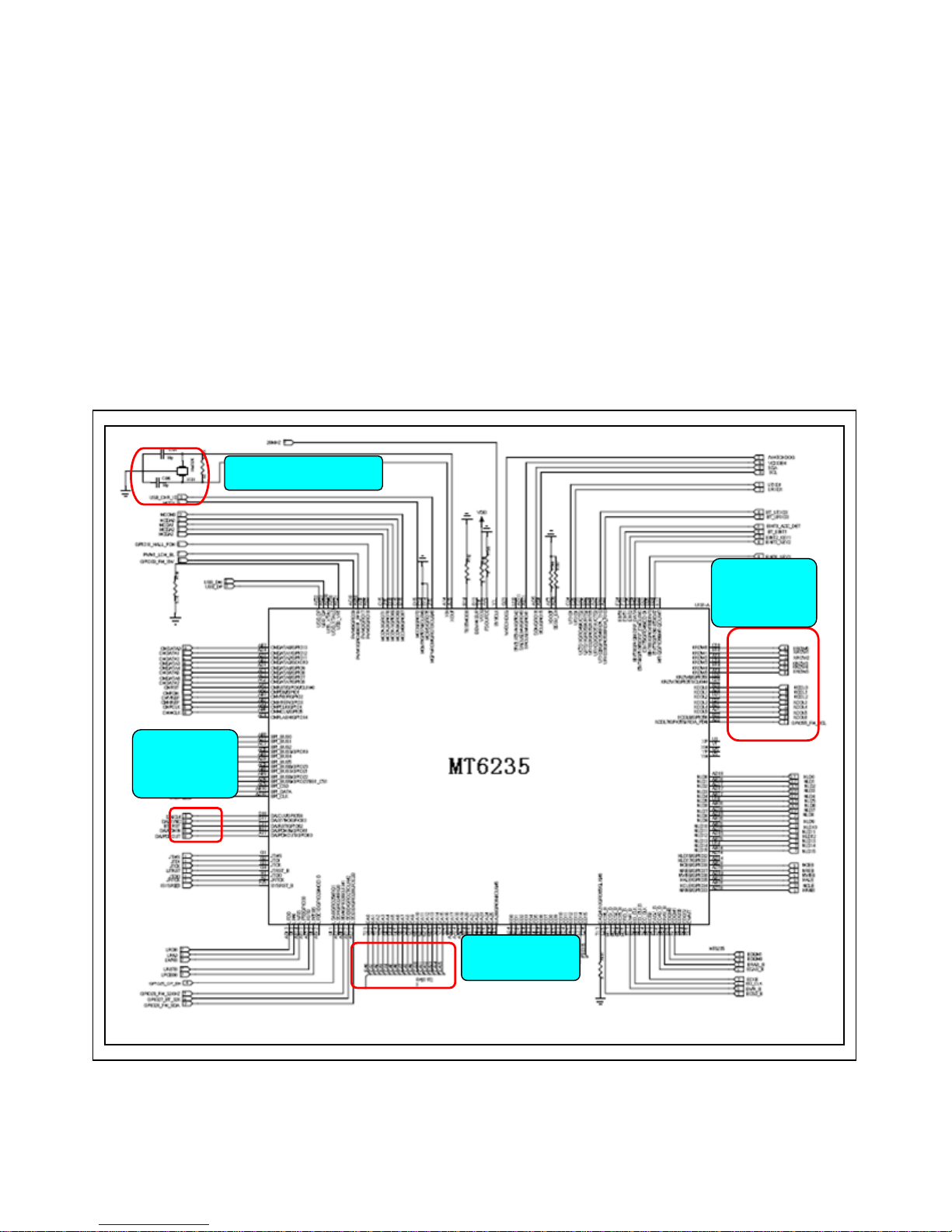

Chapter 2

SYSTEM BLOCK DIAGRAM

CPU (MT6235)

Page 14

- 14 -

Chapter 3

INSTRUCTION OF THE UNIT CIRCUIT

1. Instruction of the important ICs :

CPU is MT6235 which is the kernel IC of whole main circuit. It also integrates subsystems of channel coder and decoder, cross and

de-cross, encryption and decryption. It takes charge of process of voice and every parts of mobile, such as charge, liberation, LED

etc. And it includes WATCHDOG to improve system stability.

MT6235 is a new generation high-end chip made by MEDIATEK, with a QFN 11.5mm*11.5mm, up to 261pins, 0.47pitch. MT6235

baseband chip has GSM/GPRS capability, also integrates audio and video function. MT6253 provides not only high-quality GPRS

Class 12 MODEM, high-rate data transmission service, but also multi-media applications, like 0.3M pixels camera, mp3, mp4 etc

32k clock signal

BT control

signal

Keypad

signal

Flash signal

MT6235 CPU

Page 15

- 15 -

FM circuit

U204 is FM receiving module. FM_ANT is used to receive the radio signal from the antenna, FM_VCC is the

2.8Vpower supply, FM32KHz is the reference clock, GPIO26 and GPIO31 is control signal from the baseband CPU.

FM ANT

FM output

Page 16

- 16 -

RF circuit

RF part generally means the analog RF and IF process system ,including Antenna system、TX path、RX path、Analog

modem and Frequency Synthesizer .

RF Circuit deals with the RX and TX of wireless signal, with responsibility for the bidirectional transmission of speech and data

between the MS and BS through the air interface. In detail RX part accomplishes the AGC amplifying, mix and demodulation

of RF weak signal received from BS, The final signal output from RX part is the analog baseband I/Q signal. The final RX I/Q

will be sent to Baseband Circuit for later disposal. On the other hand TX part deals with the signal modulation, up-conversion

mix and power amplifying of analog I/Q signal received from baseband, generating burst which meets the GSM specification.

And then the bursts are transmitted to Base station through the antenna. The signal interface between

RF Circuit and Baseband is analog baseband I/Q signal. The performance of RF Circuit can directly affects the signal

transmission quality of the mobile phone.

RF PA adopts RF7161 chip, RF7161 is a high-power dual-mode amplifier module with internal power control.

RPF88150B is used in the stage when GSM / GPRS dual-mode mobile phones amplify transmission array, the working

frequency is from 824MHz to 915MHz and 1710MHz to 1910MHz. There is a input pin to realize the selection of

frequency band. 6mm * 6mm chip package.

Rx path

Tx path

ANT

Page 17

- 17 -

BT circuit

Bluetooth IC processor is MT6612BN/A..

MT6612 is 5mm x 5mm 40-lead (0.5mm pitch) QFN, a high-integrated Bluetooth IC, including rich function and strong

disposal capability, and high performance transceiver.

BT ANT

32MHz clock

Page 18

- 18 -

Chapter4

ACTUALL BOARD

SIDE A

SIDE B

U101 CPU

U301 Flash

J201Battery

connecto

r

n

J302 I/O connector

J702 SIM slot

J501 RF connector

J202 T -flash connector

U501 RF IC

U702 FM IC

U503 antenna switch module

U502 RF PA IC

J303 Earphone

U801 BT IC

Camera

connector

Page 19

- 19 -

Chapter5

TROUBLE SHOOTING

NO

Test flowchart of SIM card

Replace SIM

card

Baseband IC U101may

have fault

Could not read

SIM card

Clean or replace

SIM socket

If points of

SIM are OK

NO NO

NO

YES

YES

YES

YES

OK

End

If SIM card is

invalidation

Connect to steady-voltage

power supply to see

if

Power may be damaged. Test if

voltage of J403 pin4/5 at exactly

power on is 3V. If pin 1/2/3 has

switch of pulse voltage

Replace U101

NO

Page 20

- 20 -

Test flowchart of can not power on (for master)

Replace

battery

May be MT6235 is fault

Could not power

on

Re-solder or replace

J103 of battery

If battery point

of J103 is OK

NO

NO

NO

NO

YES

YES

YES

OK

End

Connect to power

supply, if it can be

p

ower on

If current is 30-40Mx

Update software to

the latest version

Replace/resolder U101

NO

Page 21

- 21 -

The test flowchart of receiver

Replace

receiver

MT6235 defect

No sound in

receiver

Check if LS202 has

sundries or damaged

Handfree

OK?

NO

NO

NO

NO

YES

YES

YES

YES

Repulse LS202 or

clean it

If receiver is connect

OK or not

Remove receiver and test it by

multimeter’s beep function. If there is

sound like ‘sasa’ from receive

r

Replace

receiver

Replace U101

NO

NO

NO

Page 22

- 22 -

Test flowchart of incoming call with no ring.

Cancel

libration /mute

mode

Can test output sound signal

at B203/B204 by a

oscillograph when bell works

No sound of bell

Remove headphone

and test it by

multimeter’s beep

function. If there is

sound like ‘sasa’ from

headphone

NO

NO

NO

YES

YES

YES

YES

Replace bell

components

If it is libration /

mute mode.

If volume level

is lowest

Turn up the volume

Replace MT6235

NO

Use *#84666*# No.

7 to hear if bell has

sound

NO

Page 23

- 23 -

Test flowchart of no display or display abnormally.

Clean and

re-solder J603

Update software to

the latest version

No display or

display abnormal

Replace LCD

NO

NO

NO

OK

YES

YES

If display interface

connects OK

Replace LCD

End

Replace or re-solder

MT6235

Check LCD broken or

n

ot o

r leak

NO

OK

Page 24

- 24 -

Test flowchart of download failed

Replace or

re-solder J103

connector

Check if power management and LD0

have output voltage normally and

whether there is broken of

p

ower suppl

y

Can not download

Check conditions outside

the mobile, such as

configuration of software,

cable, power, PC etc.

If mobile is

power on

NO

NO

NO

NO

YES

YES

YES

YES

YES

OK

Replace or re-configure

Check if J103 connector

is false solder or

damaged

Connect download cable. Check

whether current is larger than

normal. (Normally is about 30mA)

Disconnect cable

immediately and touch

chip gently to check if

the chip is heat

Test VCORE, VDD, VADD,

VTCXO, VRTC, VMEM and clock

signal o

f 26MHZ

、

3

2KHZ.

Replace MT6235

NO

NO

Page 25

- 25 -

Chapter6

Instruction of SW update

1. Install the USB driver without the USB cable plugged into the computer.

2. After it is ok, plug the cable then check the device manager as the picture below:

Page 26

- 26 -

4. Select Format FAT (DISABLED).

3. Open SW updating platform FlashTool_v3.0848.00

Double click the icon FlashTool. Choose the port which the cable be connected to the

computer.

Page 27

- 27 -

5. Choose “Auto Format FAT”, and don’t select “Validation”.

6. Click “Download Agent” to transfer “MTK_AllInOne_DA.bin” file.

Double click

Page 28

- 28 -

7. Update with the update cable. (The actually file name please refer to your software)

(1) As showed bellow, click “Scatter-loading” to transfer “****.txt” file in the folder of the new software.

Double click

Double click

Page 29

- 29 -

(2) Here, ROM/Boot files can be selected automatically. Don’t need to choose.

(3) Making sure the phone is powered off and the battery is taken out. Click “download”, then link the cable for the

master to the phone, insert the battery and keep pressing the power-on button for a while, soon the red progressing

bar will occur. Blue progressing bar appears after the blue one. Then an icon occurs to show the finish of

downloading.

Page 30

- 30 -

(4) As showed the phone is checked.

(5) As showed the software is written in.

Page 31

- 31 -

(6) This icon shows the finish of the downloading.

Page 32

- 32 -

Chapter7

FUNCTION TEST

Press “#84666*#” to check these items in stand by mode:

1. Version: to check the version of the software

2. Echo Loop: blow to the mic, the receiver will have a sound

3. Key: press relevant keys appear in the screen

5. Libration: The cellphone will librate

6. Lond SPK: there will be a sound from the speaker

7. Ring: press start there will be some music from the speaker

8. LED: press confirm button to check if LED is normal

9. LCD: LCD will Auto Display

11. Receiver: there will be a sound from the receiver

Camera ->Menu -> Camera-> to test if the camera is available or not

Page 33

- 33 -

Chapter8

PARAMETER SETTING INSTRUCTION

China mobile as an example, other countries please inquire the local operator

1. WAP parameter setting instruction

1) Data Account Process: Menu→Services→Data Account

GSM Data: Account Name: (default)

Number: 17266

User Name: WAP

Password: WAP

Line Type: ISDN

Speed: 9.6 Kbps

DNS: 010.000.000.172

GPRS: Account Name: (default)

APN: cnwap

User Name: WAP

Password: WAP

Auth. Type: (default)

2) WAP setting process: Menu→Services→WAP→Settings→Edit Profile

Edit Profile: Rename Profile: Optional

Homepage: http://monternet.com

Data Account: GSM/GPRS

Connection Type: HTTP (Proxy Address: 010.000.000.172)

Username: Optional

Password: Optional

After setting as above, the WAP is ready.

2. MMS parameter setting instruction (Premise is WAP is valid)

Setting process: Menu→Messages→MMS→Message Settings→Server Profile→Edit profile

Edit Profile: Rename Profile: Same as WAP Profile name

Homepage: http://mmsc.monternet.com

Data Account: Same as WAP Data Account

Connection Type: Same as WAP Data Account

Username: Optional

Password: Optional

After setting as above, the MMS is ready.

3. Email parameter setting instruction (Premise is WAP is valid)

1) GPRS setting process: Menu→Services→Data Account→GPRS

Edit Profile: Account Name: Optional

APN: cmnet

2) Email Profile setting process: Menu→Messages→Email→Email Profile

A. Outgoing server: stmp.126.com (depend on the user’s Email website )

Page 34

- 34 -

E-Mail Address: Full E-Mail Address of the user’s

Password: Password of the use’s E-Mail

B. Incoming server: pop3.126.com (depend on the user’s Email website )

E-Mail Address: Full E-Mail Address of the user’s

Password: Password of the use’s E-Mail

After setting as above, the MMS is ready.

Page 35

- 35 -

Chapter9

CATCHER INSTRUCTION

General: The figures in this document help to understanding, and they may not be exactly the same as

showed in your computer. Contact us please when you have any queries.

1 Install the USB driver if not yet.

1.1 Run the USB driver without the upgrade cable plugged into the computer.

Figure 1

1.2 After the installation is completed, plug the upgrade cable into the computer’s USB connector, and then check

the device manager as in figure 2:

Figure 2

Page 36

- 36 -

2 set the phone to prepare for using Catcher.

Open the phone and input “*#84666364*#” to enter the setting screen. In sequence enter DEVICE, UART, and

TST config. Choose UART1 and Clink done, and then the phone restarts. After the phone restarts, power it off.

3 choose the Database of the phone’s software.

3.1 run “Catcher.exe”, choose Config →.Set Database Path. The figures (figure 3, figure 4, and figure 5) occur in

sequence as below.

Figure 3

Figure 4

Page 37

- 37 -

Figure 5

3.2 Clink the button “...” in figure 5 to choose the Database file of the master phone or slave phone (for example

“BPLGUInfoCustomSrcP_MT6226M_S01_X6+_FLP_06_12_V3_2-TN-MP-5B-QN” file ). Refer to figure 6

showed as below:

Figure 6

When you examine the master phone’s problems, choose the master phone software’s database file, and when

the slave phone’s problems, the slave phone’s database file.

The database in the phone must be exactly the same as the chose database for Catcher, or the figure 14 will

occur when the Catcher work.

4 enter Logging mode and choose the right COM

4.1 clink the “Logging code” button in the red note in figure 7. Then figure 8 occurs.

Figure 7

Page 38

- 38 -

Figure 8

4.2 clink button “Configure RS232” in figure 9, then figure 10 occurs, choose the right COM in Port option, and

clink OK.

Figure 9

Page 39

- 39 -

Figure 10

5 use the Catcher to record debug information

5.1 clink the button “connect” in figure 11, clink the button “Default Filter” in figure12, select “Field Trial” button in

figure 13, and then clink “set” in Figure13.

Figure 11

Page 40

- 40 -

Figure 12

Figure 13

5.2 Clink “Filter” in figure 14, choose some items in figure 15, and then clink ok in figure 15. (Please query us if

you need to choose the filter settings)

Page 41

- 41 -

Figure 14

Figure 15

5.2 connect the upgrade cable to the phone and power on the phone. If the database in the phone is not exactly

the same as the chose database in Catcher, figure 16 occurs (for example, different software versions and wrong

cable connectors lead to the difference between the databases). You have to clink “EXIT” and make the

databases the same.

Page 42

- 42 -

Figure 16

5.3 The catcher records primitive information as showed in figure 17. Clink the button “clear” in figure 18 to clear

the useful primitive information. Then the phone user carries on some operations to the phone to make the

failures recur. After the wanted failures occur wholly, clink the button “disconnect” in figure 19. You can save the

“.clg” file now as showed in figure 20, and name it. The “.clg” file is that needed for analyzing the failures of

phone.

Figure 17

Page 43

- 43 -

Figure 18

Figure 19

Page 44

- 44 -

Figure 20

Page 45

Loading...

Loading...