Page 1

EN- English

LD500 V1.00 Seite 1 von 68

Instruction manual

Leak meter with camera

LD 500 / LD 510

Page 2

Table of Content

LD500 V1.00 Seite 2 von 68

1 Table of Content

2 Foreword ............................................................................................................................................... 4

3 Safety instructions ................................................................................................................................ 5

3.1 About this document ........................................................................................................................................................................... 5

3.2 Ensuring safety .................................................................................................................................................................................... 5

3.3 Environmental protection .................................................................................................................................................................... 5

4 General function description ................................................................................................................ 6

5 Technical data LD500 ............................................................................................................................ 7

6 Device components and controls ......................................................................................................... 8

6.1 LD 500 ................................................................................................................................................................................................. 8

6.2 Pre Amplifier module ........................................................................................................................................................................... 9

6.3 Acoustic trumpet with camera ............................................................................................................................................................ 9

6.4 Focus tube with focus tip ................................................................................................................................................................... 10

6.5 Gooseneck (Optional) ........................................................................................................................................................................ 10

6.6 Assembly with acoustic trumpet ....................................................................................................................................................... 11

6.7 Assembly with focus tube with focus tip ........................................................................................................................................... 11

7 Commissioning / Applikation LD 500 or LD510 .................................................................................. 12

7.1 Switch on ........................................................................................................................................................................................... 12

7.2 Headphone Volume Loud / Volume Down ........................................................................................................................................ 12

7.3 Sensitivity level .................................................................................................................................................................................. 12

7.4 Procedure leak detection / measurement ......................................................................................................................................... 13

8 Operation ............................................................................................................................................ 14

8.1 Initialization ....................................................................................................................................................................................... 14

8.2 Screen Leckage .................................................................................................................................................................................. 15

8.3 The following picture shows and describes the display elements. .................................................................................................... 15

9 Settings ................................................................................................................................................ 16

9.1 Sensitivity settings ............................................................................................................................................................................. 16

9.2 Laser On/Off ...................................................................................................................................................................................... 16

9.3 Parameters for measurement ........................................................................................................................................................... 17

9.4 Storing oft he measurement .............................................................................................................................................................. 18

9.4.1 Measuring point designation / selection .............................................................................................................................. 19

9.4.2 Parameter of measurement (Re-Check) ............................................................................................................................... 19

9.4.3 Comment .............................................................................................................................................................................. 20

9.4.4 Storing measurement data to internal SD-card .................................................................................................................... 20

9.5 ZeroPoint adjustment ........................................................................................................................................................................ 21

10 Basic settings menu LD 500 ................................................................................................................ 22

10.1 Configuration ..................................................................................................................................................................................... 22

10.2 Export/Import .................................................................................................................................................................................... 23

10.2.1 Export „Journal Data“ ........................................................................................................................................................... 24

10.2.2 Export of System settings ..................................................................................................................................................... 25

10.2.3 Import of system settings ..................................................................................................................................................... 26

10.2.4 Export / import customer database ..................................................................................................................................... 27

Page 3

Table of Content

LD500 V1.00 Seite 3 von 68

10.3 View bitmaps ..................................................................................................................................................................................... 28

10.4 Device Settings .................................................................................................................................................................................. 29

10.4.1 Password settings ................................................................................................................................................................. 29

10.4.2 Device Settings ..................................................................................................................................................................... 30

10.4.3 Set backlight brightness ........................................................................................................................................................ 35

10.4.4 Cleaning ................................................................................................................................................................................ 36

10.4.5 System-Status ....................................................................................................................................................................... 36

10.4.6 About LD 500/LD510 ............................................................................................................................................................ 36

11 Charging the batteries ........................................................................................................................ 37

11.1 Protection of exhaustive discharge ................................................................................................................................................... 37

12 LD 510 ................................................................................................................................................. 38

12.1 Selection External sensor ................................................................................................................................................................... 38

12.2 Input signals ext. sensor LD510 ......................................................................................................................................................... 39

12.3 Cable cross section ............................................................................................................................................................................ 39

12.3.1 Sensor circuit points/Output signal: ..................................................................................................................................... 39

12.4 Connection diagrams of the different sensor types .......................................................................................................................... 40

12.4.1 Connector pin assignment for all sensors at PI 500 ............................................................................................................. 40

12.4.2 Connection for CS dew point- and consumption sensors, series FA/VA 5xx ........................................................................ 41

12.4.3 Connection with RS485 ........................................................................................................................................................ 41

12.4.4 Three- and four-wire power supply 0 - 1/10/30 VDC ........................................................................................................... 41

12.4.5 Analogue two-, three-, and four-wire current signal ............................................................................................................ 42

12.4.6 Two-, three- and four-wire connector pin assignments for PT100/PT1000/KTY81 ............................................................. 43

12.5 Dew Point Sensor FA 500 / FA 510 of type FA 5xx (RS 485 Modbus) ................................................................................................. 44

12.5.1 Settings Dew point sensor FA 500 FA 510 ............................................................................................................................ 45

12.6 Flow sensor of type VA 5xx (RS 485 Modbus) .................................................................................................................................... 48

12.6.1 Settings for Flow sensor VA 5xx ............................................................................................................................................ 49

12.7 Type Modbus ..................................................................................................................................................................................... 57

12.7.1 Selection and activation of Sensor-Type Modbus ................................................................................................................ 57

12.8 Data logger Settings ........................................................................................................................................................................... 61

13 Scope of delivery ................................................................................................................................. 65

Page 4

Foreword

LD500 V1.00 Seite 4 von 68

2 Foreword

Dear Customer,

thank you for purchasing our leak meter with camera LD 500.

The new leak meter LD 500 with integrated camera and leakage calculation are ideal measuring

instruments which help to find and document even smallest leakages (0.1 l/min corresponds to approx.

1 € p. a.) easily even in far distances.

The LD 510 is the worldwide first leak meter with an additional freely assignable sensor input for all CS

sensors. In addition to the leakage measurement and detection also all necessary measurements with

regards to dew point, flow, pressure, and temperature ... can be carried out

Main functions:

Tracking and location of leaks

compressed air, gas, steam and vacuum systems

condensate drain

seals

refrigeration systems

Documentation / storage of leaks with

Image of the leak position

Date / Time

Description of the leakage position with indication of company / department or hall /

machine

Size of the leak in liters / min (units adjustable)

Leakage costs per year in € (currency freely definable)

Remark: By means of the additional available CS leak Reporter (Order No .: 0554 0105)

detailed reports with summary totals, subtotals (departments / warehouses etc))

as well as history reports (for temporal / continuous improvements) could be created.

Page 5

Safety instructions

LD500 V1.00 Seite 5 von 68

3 Safety instructions

3.1 About this document

Read through carefully this documentation and familiarize yourself with the

product before putting it to use. Pay particular attention to the safety warnings to

prevent injury and product damage.

Keep this documentation to hand for easy reference when needed.

Pass on this documentation to any subsequent users of the product.

3.2 Ensuring safety

Only use the product as intended and within the parameters specified in the

technical data. Do not use force for operating..

Never measure with the device at or near live/energized parts!

During leak detection on electrical systems, please maintain a sufficient safety

distance to avoid dangerous electric shocks!

Avoid any direct contact with hot and/or rotating parts.

Always switch on the device before putting on the headphones! At high signal

levels (bar graph headphones in the red area), the volume can be correspondingly

large. The sensitivity setting can be used to reduce the volume.

Never point the laser directly into the eyes! Absolutely devoid a direct irradiation

of the eyes of humans and animals!

Laser module: corresponds to DIN EN 60825-1: 2015-07 Class 2 (<1mW)

Observe the prescribed storage and operating temperatures.

Improper handling or violence will void the warranty.

Any kind of interventions on the device, as far as they do not correspond to the

intended and described procedures, lead to the warranty expiration and to the

disclaimer.

The device is intended solely for the described purpose.

3.3 Environmental protection

Disposal of faulty rechargeable batteries / empty batteries in accordance with

applicable legal regulations

Lead back the product after the end of the period of use to the separate

collection for electric and electronic devices (observe local regulations) or

return the product to CS Instruments GmbH & Co.KG for disposal.

CS Instruments GmbH & Co.KG makes no warranty as to its suitability for any particular purpose and

assumes no liability for any errors contained in this manual. Nor for consequential damages in

connection with the delivery, performance or use of this device.

Page 6

General function description

LD500 V1.00 Seite 6 von 68

4 General function description

When gases escape from leaks in piping systems (leaking screw connections, corrosion, etc.), noises are

generated in the ultrasonic range. With the LD 500 even the smallest leaks, which are inaudible to the

human ear and not visible due to their size, can be located several meters away.

The inaudible ultrasound is converted to audible frequencies in addition to the display emission level

shown in the display. With the convenient, sound-proof headphones, these sounds can be heard even in

noisy environments.

In addition, the new LD500 device calculates the costs associated with leaks, providing additional

transparency about the state of the system under test or the potential cost savings.

The loss is displayed in l / min as well as in a freely selectable currency. The cost per liter or per cubic

meter of compressed air can be stored in the device.

The professional measuring instrument LD500 finds typical application in leak detection in compressed

air systems and leak testing of pressure less systems.

With the help of an integrated laser pointer, which serves as a targeting, the leak can be pinpointed.

Depending on the leakage, the appropriate accessories may be used to increase the sensitivity of the

LD500 to use, available accessories are:

Acoustic trumpet

Focus tube with focus tip

Gooseneck

Parabolic mirrorarabol

Page 7

Technical data LD500

LD500 V1.00 Seite 7 von 68

5 Technical data LD500

Dimensions

263 x 96 x 280 mm (incl. Pre-Amp module and acoustic trumpet)

Weight

0,55 kg incl. Pre-Amp module and acoustic trumpet ,

complete set with transportation case ca.3,0 kg

Frequency range

40kHz (+/- 2kHz)

Power supply

Internal 7.4 V lithium-ion battery

Operating time

> 9 h (continuous operation)

Operating temperature

-5 °C to +40 °C

Charging

Ext. battery charger (included in the scope of delivery)

Charging time

approx. 1.5 h

Storage temperature

-20 °C to +50 °C

Laser

Wavelength 645-660nm, output < 1mW (Laser class 2)

Connections

3.5 mm jack for headphones,

power jack for connecting an external charger

USB Connection

Display

3.5“-Touchpanel TFT transmissiv

Interface

USB for data export / -import, SW update etc.

Datalogger

4 GB-Memory card (Micro SD Class 4)

Sensitivity

min: 0,1l/min at 6bar / 5m Distance

Page 8

Device components and controls

LD500 V1.00 Seite 8 von 68

6 Device components and controls

6.1 LD 500

Picture 1

Camera

Power on/off button

Loudness buttons (+/-)

USB connection

3,5“ TFT-Color Display

with Touchpanel

Foil keypad (4 buttons)

Battery charge socket

Acoustic trumpet

Pre Amplifier module

Release button for

preamplifier module

Store button

Page 9

Device components and controls

LD500 V1.00 Seite 9 von 68

Picture 2

6.2 Pre Amplifier module

Picture 3

6.3 Acoustic trumpet with camera

Picture 4

3.5mm jack for the

headphone

Opening of the

laser pointer

Ultrasonic microphone

Camera connection

Camera connection

Ultrasonic microphone

opening

Laser module

Page 10

Device components and controls

LD500 V1.00 Seite 10 von 68

6.4 Focus tube with focus tip

Picture 5

6.5 Gooseneck (Optional)

Picture 6

Page 11

Device components and controls

LD500 V1.00 Seite 11 von 68

6.6 Assembly with acoustic trumpet

The acoustic trumpet allows acoustic amplification by bundling the sound waves and specifies the

location of the leak. Due to the special construction of the integrated laser pointer is still usable. The

camera is integrated on the bottom of the acoustic trumpet and is electrically connected to the

preamplifier module via the jack plug.

Assembling is done by plugging the individual components until easy locking audible (plug in to the

stop).

The components are removed in the reverse order; for unlocking the preamplifier module, the release

button must also be pressed.

Picture 7

6.7 Assembly with focus tube with focus tip

The focus tube with focus tip is used to detect very small leaks, to accurately locate them.

Just like the acoustic trumpet, the tube can be plugged into the preamplifier with ultrasonic receiver.

The use of the camera is no longer possible.

The components are removed in the reverse order; for unlocking the preamplifier module, the release

button must also be pressed.

Picture 8

Page 12

Commissioning

LD500 V1.00 Seite 12 von 68

7 Commissioning / Applikation LD 500 or LD510

Please first observe the safety instructions in section 3

7.1 Switch on

Hold down the power button for about 1 second, the power will turn on, and a start-up sequence will

appear on the display. Pressing the button again switches the device off again.

On-Off button, see device components and controls

7.2 Headphone Volume Loud / Volume Down

The volume keys increase or decrease the volume in the headphone in 16 levels.

Continuously pressing the button automatically increases / decreases the value.

Volume up / down buttons for headphone volume, see device components and controls

Please make sure the headphone level is <50% before putting on the headphones.

7.3 Sensitivity level

When starting a leak detection or after switching on the sensitivity level "Auto" should be selected.

In the case of strong noise levels from the environment it can be switched to a manually adjustable gain

level, see chapter 9.1 „Setting of Sensitivity level“

Manual sensitivity level at measurement start: 30 – 90dB

Page 13

Procedure leak detection / measurement

LD500 V1.00 Seite 13 von 68

7.4 Procedure leak detection / measurement

LD 500

Switch on

Headphone level

< 50 %

Reduce

Headphone level

Sensivity slevel

„Auto“

Yes

No

strong noise levels

existing?

Sensivity level to

manual

30 – 90dB

leak detection

start

Leakage found ?

Continue leak search ?

LD 500

Switch off

Yes

No

Yes

Yes

Yes

Data export to USB Stick

Save measurement

Leaktag Issue/ attach

Picture 9

Page 14

Operation

LD500 V1.00 Seite 14 von 68

8 Operation

The operation is largely self-explanatory and menu-driven via the touch panel.

The selection of the respective menu items occur via short "tapping" with the finger or a soft round pen.

Attention: Please use no pens or other objects with sharp edges!

The foil can be damaged!

Inputs or changes can be made with all white deposit fields

8.1 Initialization

After switching on the LD 500, the

initialization takes place and then switch

to leakage display

Page 15

Operation

LD500 V1.00 Seite 15 von 68

8.2 Screen Leckage

8.3 The following picture shows and describes the display elements.

Date / Time:

Battery condtion indicator

Battery condition:

22%

Power supply connected and battery is charging:

Displayed values for:

Signal-Levell in dB

Leakage size

Leakage costs per year

Laser „On“ Icon

Date/ Time and battery

condition indicator

Bar graph of Signal level

LeakTag number

Actual picture from the

camera

Laser „On/Off“ button

Setting button

Store button for

Measurement

Zero point

adjustment

-button

Button Sensivity level

Home Menu

button

Page 16

Operation

LD500 V1.00 Seite 16 von 68

9 Settings

The operation is largely self-explanatory and menu-driven via the touch panel.

The selection of the respective menu items occur via short "tapping" with the finger or a soft round pen.

Attention: Please use no pens or other objects with sharp edges!

The foil can be damaged!

9.1 Sensitivity settings

In order to cover a measuring range from the smallest leaks (0.1 l / min) up to large leaks,

the LD 500 has different measuring sensitivity levels:

0 – 60dB for smallest leakages starting from 0.1 l/min

10 – 70dB

20 – 80dB

30 – 90dB

for bigger leakages up to max. 50 l/min

Remark: In case of high noise level to switch to next lower sensitivity level.

These steps can be selected manually by pressing the „ Sensitivity“ button.Levels are changed to the

next level each time they are pressed.

The„Auto“ setting allows you to automatically switch to the preferred sensitivity level for the

LD 500. However, this requires a min. measuring time of 2 seconds.

Auto(1) correspond to 0–60dB , Auto (2) to 10-70dB, Auto(3) to 20-80dB and Auto(4) to 30-90dB.

9.2 Laser On/Off

The laser pointer can only be switched on or off via the laser on / off button in the display (not via

the membrane keypad). When switched on, the display shows a laser warning symbol.

Please note the warnings for laser operation! V Avoid direct / indirect (via reflexion)

irradiation of the eyes in humans and animals!

Laser „On“ Icon

Page 17

Operation

LD500 V1.00 Seite 17 von 68

9.3 Parameters for measurement

To get correct readings, the parameters

• Existing pressure

• Distance to measuring point

are needed. By pressing the key „Parameter“ in the display, the parameter input window is

opened.

Note: Distance refers to distance from measuring point to acoustic trumpet or

focus tube with focus tip.

Appropriate input range is 1m to 6m for acoustic trumpet , for focus tube with focus tip fixed

to 20cm.

Pressure input range is 0.3bar to max. 10bar, for vacuum leakages -0.1bar to -1bar.

The pressure entry can be made by selecting one

of the 3 predefined values or via the text field.

Max. Permissible pressure value is 10bar.

In case of higher pressures, please insert 10bar)

For the distance input, there are 4 predefined

values or a text field for the measurementspecific distance entry.

Selection „20cm“ is reserved for the

measurement with the focus tube with focus tip.

Currently the max. Measuring distance is 6.00 m.

Page 18

Operation

LD500 V1.00 Seite 18 von 68

9.4 Storing oft he measurement

To store the measurements please press either the button „Store“ on the foil keypad, see chapter

Device components and controls , or by button „Store“ in the display.

All data are stored on to the inetrnal SD card.

After pressing one of the two „Store“ keys, the corresponding information for the measuring point must

be completed. The measuring point information of the last stored storage (company, building and

location) is displayed, the numbering of the leaking day is increased by 1.

e.g .:

If necessary, fill out the

LeakTag-form and attach it to

the measuring location.

Please use correct LeakTagnumber.

Page 19

Operation

LD500 V1.00 Seite 19 von 68

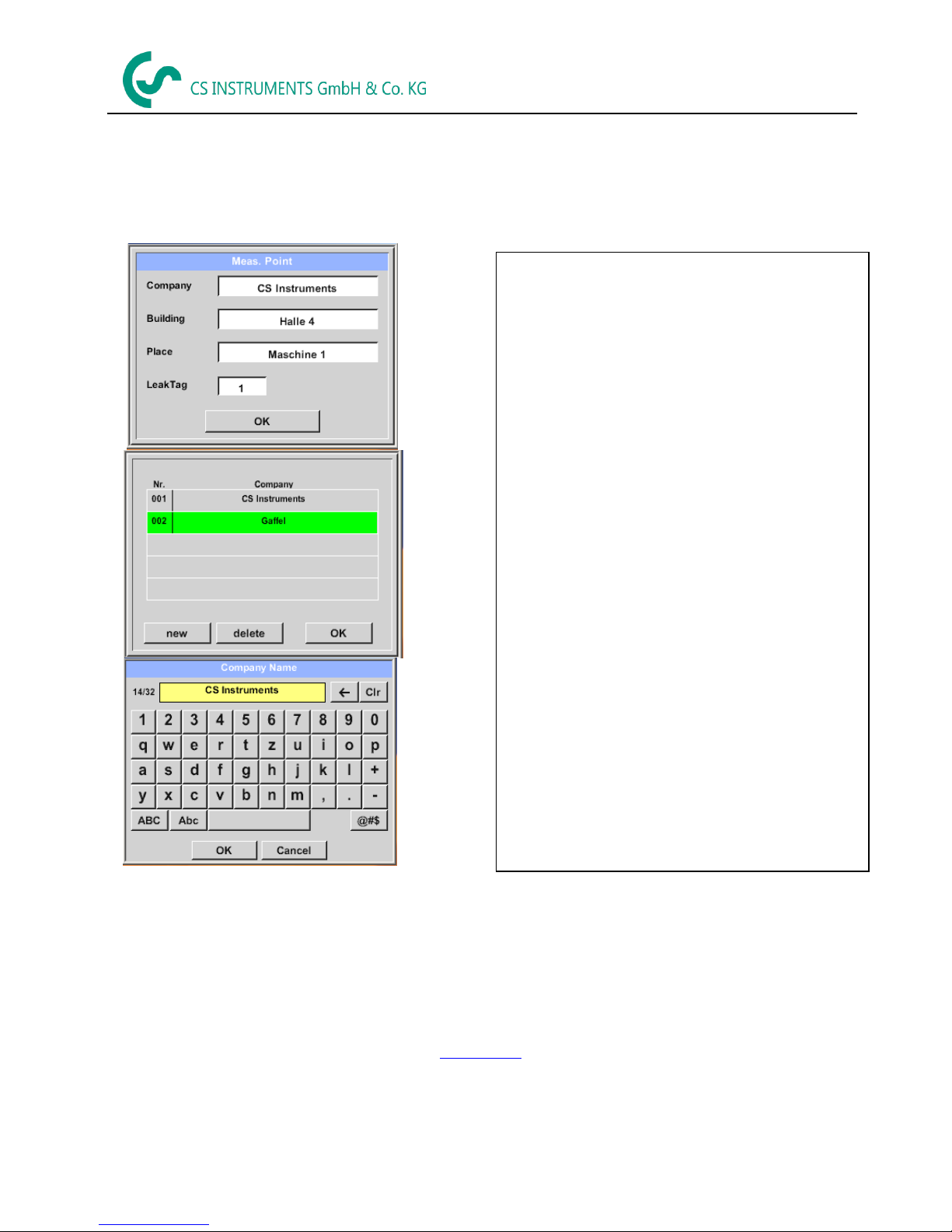

9.4.1 Measuring point designation / selection

Store Meas. Point

9.4.2 Parameter of measurement (Re-Check)

Store Parameter

At this point, it is again possible to check and correct the parameters „Pressure" and „Distance".

Changing the parameters gives new values for leakage and cost.

Execution of the corrections see description chapter 9.3

All information about the measuring point can

be changed by selecting the corresponding text

field or the stored measuring points can be

loaded from the internal database.

Then a menu opens with the available / saved

entries.

When selecting a saved value, select it

(highlighted in green) and then take over with

„OK“.

If a new entry is necessary, the input menu

opens after pressing the „new“ button.

Input is accepted via „OK“.

This procedure is analogous to enter the

information for company, building and location.

Using the „delete“ button, individual entries can

be deleted too.

Page 20

Operation

LD500 V1.00 Seite 20 von 68

9.4.3 Comment

Store Textfield Comment

9.4.4 Storing measurement data to internal SD-card

Speichern store

In addition to the details of the measuring point

with company, building and location, it is

possible to enter a comment (up to 32

characters).

To do this, select the text field „Comment“ and

enter the comment.

Before final storage of the measurement on the

internal SD card, a summary is created and the

correctness is queried once more for safety.

Storage is done with the „Yes“ key.

The „No“ key returns to the previous menu.

Page 21

Operation

LD500 V1.00 Seite 21 von 68

9.5 ZeroPoint adjustment

In high noise environments, an adjustment can be made to reduce it. This automatic process is carried

out by pressing the „Adj.“ key in the display.

Adj.

For this adjustment, the LD 500 should point to a

quiet point and the adjustment should be

started by pressing the „Automatic“ " button.

If a ZeroPoint adjustments was performed the

following icon is displayed.

To withdraw the ZeroPoint Adjustment e.g. for a

new measurement in a quieter location, please

press button „Default Value“.

Page 22

Operation

LD500 V1.00 Seite 22 von 68

10 Basic settings menu LD 500

Home

10.1 Configuration

Home Configuration

With the button „Home“ you access the basic

menu of the LD 500.

Return to measurement by pressing

„Leckage“ –button.

By selecting the national standard of „ISO“ or

„US“ you can store your production cost for

„1000 Nm³“ or. „1000 SCF“. These inputs are

used as the basis for the cost calculation.

The basic costs are entered via the text box

„Cost / 1000 Nm³“ for „ISO“ or „Cost / 1000

SCF“ for „US“.

The currency of the production costs can be

stored as text in the text field. „Currancy“.

The inputs „Parameter“ and „Meas. Point“

Follow the same procedure as described in

chapter 9.3.

Acceptance of the values and return to the basic

settings menu is done by pressing the „Home“.

Button.

20.00

0.54

Page 23

Operation

LD500 V1.00 Seite 23 von 68

10.2 Export/Import

With Export / Import, recorded "journal data" can be transferred to a USB stick,

system settings and measuring points can be exported as well as imported.

Page 24

Operation

LD500 V1.00 Seite 24 von 68

10.2.1 Export „Journal Data“

Export / Import Export Journal Data

Attention: With „ERASE Journal Data“ all journal data are deleted.

With the help of the „Change -button you

can set a period between „Start“ and „End“.

Stored measurement data that lies within

this period will be exported.

The selected date is always highlighted in

green and the dates of the Sundays are - as

in the calendar - red.

For days on which measurement data was

recorded, the date numbers are visually

exalted

If several measurements have been

recorded on a date, they will appear after

the date selection.

Now you can easily select the desired

recording.

With „OK“. the start or end time is taken

over.

Press the „Export“- button to transfer the

selected data to the USB stick

In the example given, 3 measurements are

exported.

With „ERASE Journal Data“ the Journal

Database is deleted.

For verification is still a security question.

With „Back“ you return to the main menu.

Page 25

Operation

LD500 V1.00 Seite 25 von 68

10.2.2 Export of System settings

This feature is especially relevant to the version LD 510, here for storing the external sensor settings as

well as e.g. display option for charts, sensor value etc.

Export / Import Export System settings

Here the definition of the storage location

takes place

.Selection for internal SD card with activation

of key „SdCard“ or on USB stick with key

„USB“.

The selection of the desired folder is made

by selecting and activating with „goto“

button.

If a new directory is required, this is done by

pressing „new File“, this can be created by

selecting „ new Directory“

Saving a system file with a new name takes

place analogously, then the key „new File“

must be pressed

Entries are to be confirmed with „OK“.

With „Cancel“ you return to the previous

menu.

Page 26

Operation

LD500 V1.00 Seite 26 von 68

10.2.3 Import of system settings

Export / Import Import System settings

Sequence of directory and file selection is

analogous to file export.

Selection of internal SD card with activation

of key „SdCard“ or on USB stick with key

„USB“.

The selection of the desired folder is made by

selecting and activating with the „goto“

button, then select corresponding system file.

Selection to be confirmed with „OK“.

Since system-relevant changes are made

here, a confirmation prompt is issued, which

must be confirmed with „OK“.

Page 27

Operation

LD500 V1.00 Seite 27 von 68

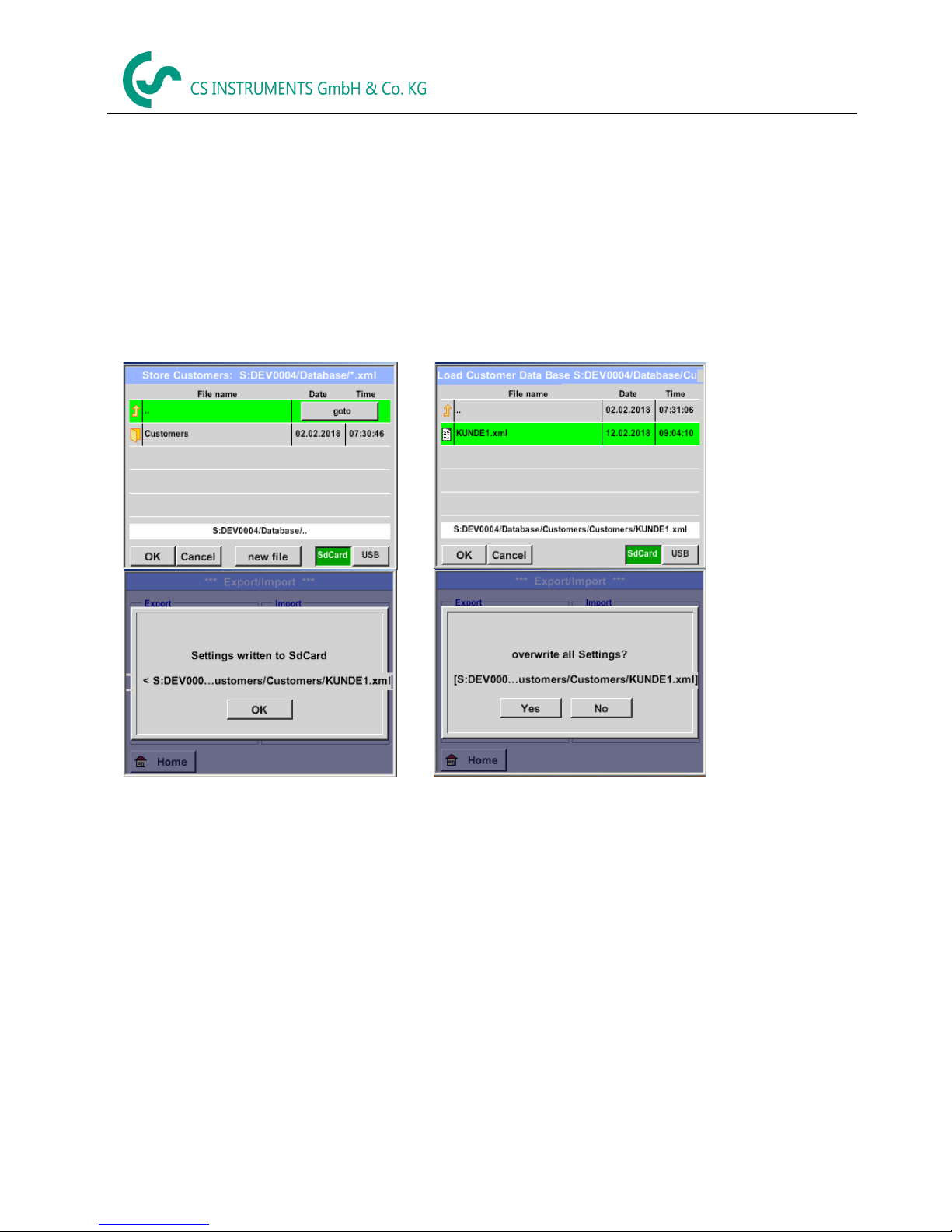

10.2.4 Export / Import Customer database

These functions allow the stored measuring point descriptions (companies, buildings and location) to be

exported as an XML file or to be imported from another LD 500 exported database.

That means it is also possible to create and import the database externally, but the prerequisite is the

correct format of the XML file.

Export / Import Export Customers Export / Import Import Customers

As data changes are made during importing, a confirmation

question needs to be confirmed with "„Yes“.

Page 28

Operation

LD500 V1.00 Seite 28 von 68

10.3 View bitmaps

View Bitmaps Select Screenshoot

This allows the stored pictures (measurement

pictures) on the SD-Card or USB Stick to load

and shown in the display again.

Please press button „Select Screenshot“

and select the required picture (bitmap).

The pictures are stored and organized in

different directories

The directory structure is year / calendar week

Designation: BMyyCWxx

yy = Year xx = calender week

The selection of the desired folder is made by

selecting and activating with the „goto“button.

Select the desired image and then display with

„OK“.

Page 29

Settings

LD500 V1.00 Seite 29 von 68

10.4 Device Settings

The settings are all protected by a password!

Settings or changes are generally confirmed with OK!

Remark:

If you go back to main menu and then again one of the setting menus is called, you must

enter the password again.

10.4.1 Password Settings

Settings Passwort Settings

Overview of the Settings

If an incorrect password is entered there appears

Enter password or New password repeat in red

font.

If you can’t remember the password, please use

Master password in order to enter a new

password.

Remark:

The master password is supplied together with

the instrument’s documentation.

Factory settings for password at the time of

delivery: 0000 (4 times zero).

If required, the password can be changed in the

Password settings.

The new password must be entered two times in

a row and in each case confirmed with OK

Page 30

Settings

LD500 V1.00 Seite 30 von 68

10.4.2 Device Settings

Settings Device settings

10.4.2.1 Language

Settings Device settings Set language

Overview of Device settings

Here you can select one of 11 languages for the

LD 500.

Page 31

Settings

LD500 V1.00 Seite 31 von 68

10.4.2.2 Date & Time

Settings Device settings Date & Time

10.4.2.3 SD-Card

Settings Device settings SD-Card Reset Logger Database

Settings Device settings SD-Card Erase SdCard

Settings Device settings SD-Card Test SdCard

By pushing the Time Zone description field and

enter the correct UTC, you can set the correct

time all over the world.

The summer and wintertime switchover is

realized by pushing the Daylight Saving button.

By pressing Reset Logger Database all actual

stored data on SD-Card will be blocked for use in

LD500 / LD510. Nevertheless all data are still

stored and available for external use only.

By pressing Erase SdCard all Data on the SD-Card

will be deleted.

With activation of Test SdCard data are written and

read to and from the SD-card.

The number of test cycles, as well as possible errors

and error codes are display in the status line.

Press the Back button to returns to the device

settings menu.

Page 32

Settings

LD500 V1.00 Seite 32 von 68

10.4.2.4 System update

Settings Device settings System-Update

P1: V033

C1

I1

Update Kanäle

10.4.2.4.1 Check for Updates

Settings Device settings System-Update check USB-Stick for new Updates

P1: V033

C1

I1

Update Kanäle

If it is required to install an older software version, you have press the button „Force all“

Overview of System-Update-Functions.

f after pressing the button “Check USB Stick

for new Software updates” the following

messages appear in the window, is the LD

500 is not properly connected to the USB

flash drive or there are no files available.

I If the LD 500 is correctly connected to the

USB stick and there are new versions of the

individual SW Parts, the new versions are

marked in red.

The update is started by pressing the „Update

Selection“. button.

Page 33

Settings

LD500 V1.00 Seite 33 von 68

10.4.2.4.2 Update Channels

Settings Device settings System-Update Update-Channels

If there is an update either for the internal and external channel (LD 510 only), it must be

started separately

Important:

If the Reboot system button appears after the update, it must be pushed to restart the LD

500!

10.4.2.5 Factory Reset

10.4.2.5.1 Standard Einstellungen wiederherstellen

Settings Device settings System Reset to Defaults

10.4.2.5.2 Unique USB ID

For connections with the PC, a status and therefore a unique USB ID can be defined here.

Relevant for simultaneous connection of several USB devices to the PC.

Update for Channels LD 500.

If needed with „Reboot System“ the LD 500

could be started(reboot) here

Bevor the settings are changed to the

production default settings a safety prompt

is displayed and must be confirmed by

pressing the button „Yes“.

Page 34

Settings

LD500 V1.00 Seite 34 von 68

10.4.2.6 Calibration of touchpanel

Settings Device settings calibrate touchscreen

If necessary, the touch-screen calibration

can be changed here.

Push Calibrate and it appears, 1. left

above,2. bottom right, 3. bottom left, 4.right

above and 5. in the middle, a calibration

cross that must be pushed consecutively.

If the calibration finished positive a message

“Calibration successful” appears and have to

be confirmed with OK.

Is this not the case, so you can repeat the

calibration with the help of the Cancel and

Calibrate buttons.

Page 35

Settings

LD500 V1.00 Seite 35 von 68

10.4.3 Set backlight brightness

Settings Set backlight

Remark:

At the first touch, the Backlight in our example is reset to 39%, after that a "normal" function

operation is possible.

Important:

If the Backlight dimming after button is not activated, then the Backlight stays

permanently on, in the currently set brightness.

Here you adjust the desired Backlight

(15-100%) of the display directly.

E.g. Backlight to 39 %

With the help of the Backlight dimming after

button, after a definable time interval (here

after 15 minutes), the Backlight can be

reduced to the minimum.

As soon as the dimmed screen is operated

again, the Backlight is committed

automatically on the last set value before

dimming.

To reduce the energy consumption (device

runtime), you can switch off the display

backlight by setting "Backlight off after".

15

Page 36

Einstellungen

LD500 V1.00 Seite 36 von 68

10.4.4 Cleaning

Settings Cleaning

10.4.5 System-Status

E Settings System-Status

53.5 °C

11,74 V

5.01 V

53.5 °C

11,74 V

5.01 V

10.4.6 About LD 500/LD510

Settings about LD 500

05186002

Buy

Buy

Brief description of the Hardware and

Software Version, as well as the Serial

Number of the LD 500.

Under options, you can buy four

additional, different functions, if you have

not done this by ordering.

This function can be used for cleaning the

touch panel during running measurements.

If one minute is not enough time to clean,

the process can be repeated at any time.

Is the cleaning faster finished, then you can

push the to abort press long button (for

one or two seconds) to cancel.

The menu item “System status” provides

information about the power supply

voltages and an operating hour counter.

Page 37

Charging the batteries

LD500 V1.00 Seite 37 von 68

11 Charging the batteries

The battery is charged within the device. For this, the supplied plug-in power supply is connected to the

built-in charging socket of the LD 500 and the 230V socket.

The LD 500 checks the charging status of the battery and starts the charging process automatically if

necessary.

11.1 Protection of exhaustive discharge

Z To protect the Li-ION accumulator of exhaustive discharge the device is switching off automatically if a

cell voltage of 6,4V will be reached.

Connect external power

Symbol „CHG“ is

displayed during

charging.

Page 38

Scope of delivery

LD500 V1.00 Seite 38 von 68

12 LD 510

12.1 Selection External sensor

The use of an „external Sensors“ requires to switch to its mode.

Home Mode Externer Sensor

Home menu for external sensor connection

Page 39

Settings

LD500 V1.00 Seite 39 von 68

12.2 Input signals ext. sensor LD510

12.3 Cable cross section

12.3.1 Sensor circuit points/Output signal:

AWG26, cable cross-sections: 0,14 mm2

Input signals

Current signal

(0 – 20 mA / 4 – 20 mA)

internal or external

power supply

Measuring range

0 – 20 mA / 4 – 20 mA

Resolution

0,0001 mA

Accuracy

0,03 mA 0,05 %

Input resistance

50

Voltage signal

(0 - 1V)

Measuring range

0 - 1 V

Resolution

0,05 mV

Accuracy

0,2 mV 0,05 %

Input resistance

100 k

Voltage signal

(0 - 10 V / 30 V)

Measuring range

0 - 10 V/30 V

Resolution

0,5 mV

Accuracy

2 mV 0,05 %

Input resistance

1 M

RTD

Pt100

Measuring range

-200 - 850 °C

Resolution

0,1 °C

Accuracy

0,2 °C at -100 - 400 °C

0,3 °C (further range)

RTD

Pt1000

Measuring range

-200 - 850 °C

Resolution

0,1 °C

Accuracy

0,2 °C at -100 - 400 °C

0,3 °C ( further range )

Pulse

Measuring range

minimal pulse length 100 μs

frequency 0 - 1 kHz

max. 30 VDC

Page 40

Settings

LD500 V1.00 Seite 40 von 68

12.4 Connection diagrams of the different sensor types

12.4.1 Connector pin assignment for all sensors at PI 500

The interface connector to be used is a ODU Medi Snap 8 pin – Reference: K11M07-P08LFD0-6550

.

Available connection cables at CS-Instruments are:

ODU with Open ends: Order no 0553 0501, cable length: 5 m.

Order no 0553 0502, cable length: 10 m.

ODU with M12 Connector: Order no 0553 0503, cable length: 5 m.

Extension cable (ODU/ODU): Order no 0553 0504, cable length: 10 m.

Connection scheme:

Connector housing

Plug insert

Collet

Clamping nut

View on welding pins of Medi Snap Connector

C a b l e l e n g h t 5 m / 1 0 m

1

wei ss whi te

2

bra un b r ow n

3

grü n gre en

4

gel b y el l ow

5

gra u g re y

6

ros a p ink

7

bla u b l ue

8

rot red

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

+ RS485

- RS485

SDI (CS-internal data transmission for all Dew point and Flow sensor FA/ VA 400)

ANALOG IN +

ANALOG IN –)

STROMQUELLE 500 µA

+VB, 24V DC Power supply for sensor

-VB, GND Sensor

White

Brown

Green

Yellow

Grey

Pink

Blue

Page 41

Settings

LD500 V1.00 Seite 41 von 68

12.4.2 Connection for CS dew point- and consumption sensors, series FA/VA 5xx

2

1 3

+

-

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

4

Sensor

Weiss / White

Braun / Brown

Blau / Blue

Rot / Red

LD 510

FA 510

FA 500

VA 500

VA 520

The digital data transmission between LD 510 and the

sensors FA 500/ FA 510 and VA 500/520 occurs via RS 485

(Modbus).

12.4.3 Connection with RS485

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

+

-

Sensor

+

-

Sensor with RS485 Interface

12.4.4 Three- and four-wire power supply 0 - 1/10/30 VDC

+

-

ß 0...1 / 10 / 30 Vdc

+

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

Sensor

Sensor with voltage output in 3-wire technology

+

-

ß 0...1 / 10 / 30 Vdc

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

Sensor

+

-

Sensor with voltage output in 4-wire technology

red

blue

white

brown

Yellow

Yellow

grey

blue

blue

red

red

Page 42

Settings

LD500 V1.00 Seite 42 von 68

12.4.5 Analogue two-, three-, and four-wire current signal

Sensors with 4 - 20 mA-output in 2-wire technology

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

+

Sensor

ß 0 / 4 ...20mA

LD 510

Sensors with 4 - 20 mA output in 3-wire technology

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

+

-

Sensor

ß 0 / 4 ...20mA

LD 510

Sensors with 4 - 20 mA output in 4-wire technology

0 / 4 ...20mA

ß 0 / 4 ...20mA

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

Sensor

+

-

LD 510

Yellow

Yellow

Yellow

Grau

blue

blue

blue

red

red

Page 43

Settings

LD500 V1.00 Seite 43 von 68

12.4.6 Two-, three- and four-wire connector pin assignments for PT100/PT1000/KTY81

Yellow

rd

pink

Sensor

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

2-wire PT100/PT1000/KTY81

Sensor

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

3-wire PT100/PT1000/KTY81

Sensor

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

4-wire PT100/1000/KTY81

Yellow

Yellow

grey

grey

Pink

Pink

red

red

Page 44

Scope of delivery

LD500 V1.00 Seite 44 von 68

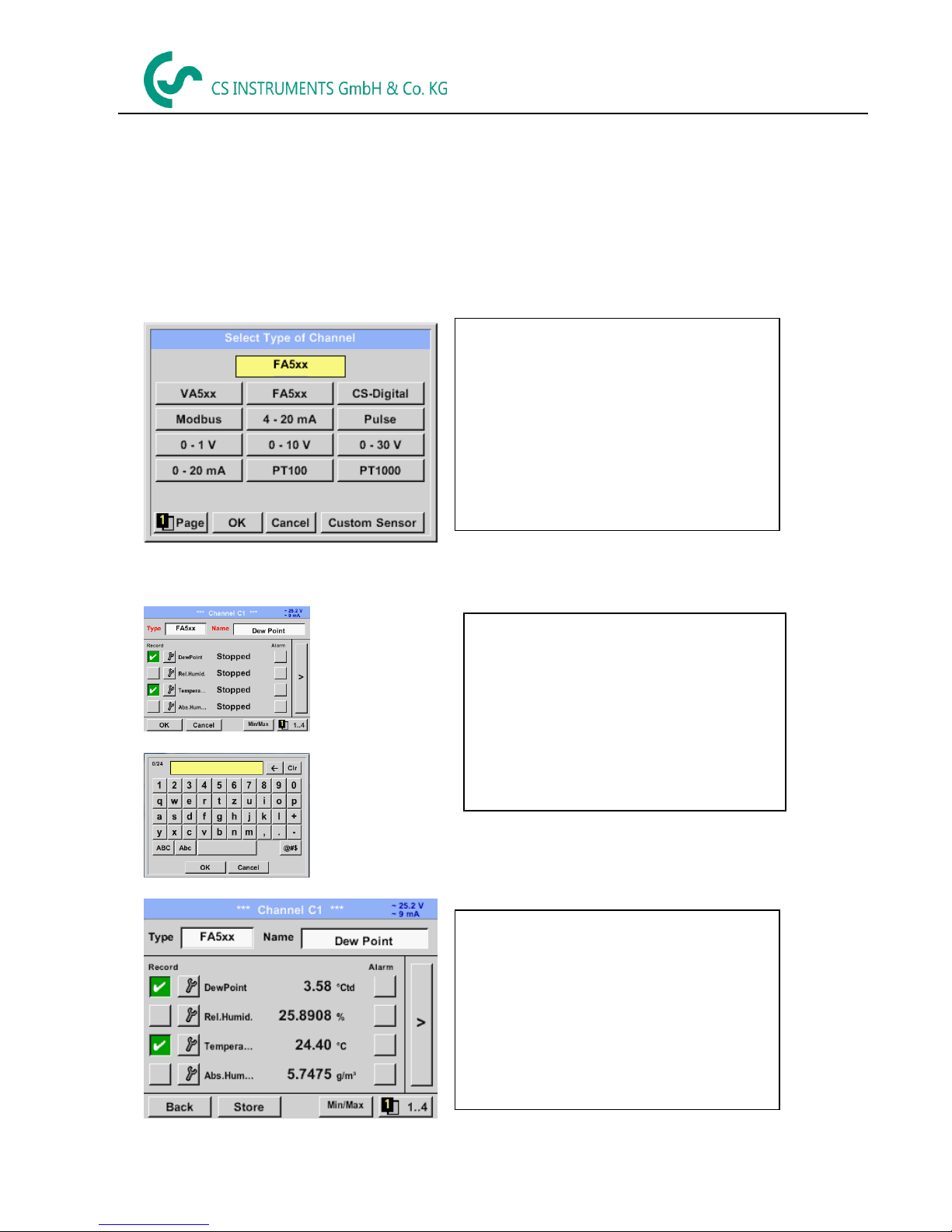

12.5 Dew Point Sensor FA 500 / FA 510 of type FA 5xx (RS 485 Modbus)

First step: choose an unused sensor digital channel

External sensor Settings Sensor settings C1

Second step: choose type FA 5xx

External sensor Settings Sensor settings C1 Type description field FA 5xx

External sensor Settings Sensor settings C1 text field “Name”

Now the Type FA 5xx is selected for the

FA 5xx series and confirmed by pressing

the OK button.

Input of a name, please enter the text

field „Name“.

It is possible to enter a name with max.

24 characters.

Confirmation by pressing the OK-button.

The connection with the FA 5xx sensor is

done after confirmation by pressing “OK”.

Page 45

Settings

LD500 V1.00 Seite 45 von 68

12.5.1 Settings Dew point sensor FA 500 FA 510

12.5.1.1 Unit selection for temperature and humidity

External sensor Settings Sensor settings C1 arrow right (2.page)

12.5.1.2 Definition of the System pressure (relative pressure value)

External sensor Settings Sensor settings C1 arrow right (2.page)Pressure Setting

The system pressure is inderted by entering

the values in the corresponding text field.

The unit can be freely selected, selection

menu is opened by pressing the

corresponding button units

Confirm the settings by pressing the OK

button.

Unit selection for temperature and

humidity by pressing the button °C, °F,

g/m³ or mg/m³.

Confirm the settings by pressing the OK

button.

Page 46

Settings

LD500 V1.00 Seite 46 von 68

12.5.1.3 Definition of Reference pressure (absolute pressure value)

External sensor Settings Sensor settings C1 arrow right (2.page)Pressure Setting

Text field Ref.Pressure

12.5.1.4 Calibration

External sensor Settings Sensor settings C1 arrow right (2.page) Calibration

26.45

Here, a one-point calibration can be

performed.

For that purpose, please enter in the text

box "Reference Value" the new correct

dew point value.

Then by pressing the "Calibration" button

taking over the inserted reference value.

Calibration can be put back to factory

Reference pressure is the pressure for that

the dew point in relaxation will be backcalculated.

Default- Value is 1013 mbar (Atm.

Pressure).

Confirm the settings by pressing the OK

button.

Page 47

Settings

LD500 V1.00 Seite 47 von 68

12.5.1.5 More Settings Analogue output 4-20mA

External sensor Settings Sensor settings C1 arrow right (2.page) More-Settings 4-20mA

22

<3.6

This menu allows the adjustment / assignment of the

measurement value and the scaling of the analogue

output.

Selection of the measurement value by selecting the

appropriate measured value key in this example, “DP °

C" for dew point ° Ctd.

In text fields "4mA" and "20mA" the appropriate

scaling values are entered, here from -80 ° Ctd (4mA) to

-20 ° Ctd

(20mA).

With "Error Val" is determined what is output in case of

error at the analog output.

<3.6 Sensor error / System error

22 Sensor error / System error

4..20 Output according Namur (3.8mA – 20.5 mA)

< 4mA to 3.8 mA Measuring range under range

>20mA to 20.5 mA Measuring range exceeding

Page 48

Scope of delivery

LD500 V1.00 Seite 48 von 68

12.6 Flow sensor of type VA 5xx (RS 485 Modbus)

First step: choose an unused sensor digital channel

External sensor Settings Sensor settings C1

Second step: choose type VA 5xx

External sensor Settings Sensor settings C1 Type description field VA 5xx

External sensor Settings Sensor settings C1 Name description field

The connection with the VA 5xx sensor is

done after confirmation by pressing “OK”.

Now the Type VA 5xx is selected for the

VA 5xx series and confirmed by pressing

the OK button.

Input of a name, please enter the text

field „Name“.

It is possible to enter a name with max.

24 characters.

Page 49

Settings

LD500 V1.00 Seite 49 von 68

12.6.1 Settings for Flow sensor VA 5xx

External senor Settings Sensor settings C1 arrow right (2.page)

12.6.1.1 Diameter settings (only for VA 500 or VA 550)

External senor Settings Sensor settings C1 arrow right (2.page) diameter description field

External senor Settings Sensor settings C1 arrow right (2.page) diameter unit description field

Important:

The inner diameter should be entered as precisely as possible, because otherwise the measurement

results are not correct!

There is no uniform standard for the tube inner diameter!

(Please, inquire at the manufacturer or measure by your own!)

For each text field could be the either a

value or a unit be set.

Settings by entering the text field and

then input a value or select the unit for

the appropriate field.

In case of VA 520 and VA 570 with

integrated measuring section the

diameter and diameter unit field are not

access able.

Important:

Only for VA 500 or VA 550 possible to

change the inner diameter

Here the “inner diameter” is set to

27.5mm.

Please confirm by pressing the OK button

and go back with arrow left (1.page).

After pressing the Unit Text fields

following units bare selectable.

Page 50

Settings

LD500 V1.00 Seite 50 von 68

12.6.1.2 Gas Constant settings

External senor Settings Sensor settings C1 arrow right (2.page) Gas Constant description field

Attention:

Reference temperature and reference pressure (factory setting 20 °C, 1000 hPa):

All volume flow values (m³/h) and consumption values indicated in the display are

related to 20 °C, 1000 hPa (according to ISO 1217 intake condition)

0 °C and 1013 hPa (= standard cubic meter) can also be entered as a reference.

Do not enter the operation pressure or the operation temperature under reference

conditions!

All gases marked in blue and with (real)

have

been a real gas calibration curve stored in

the sensor.

Select the gas you require and confirm

selection by pressing OK button.

Page 51

Settings

LD500 V1.00 Seite 51 von 68

12.6.1.3 Definition of the reference conditions

Here, the desired measured media reference conditions for pressure and temperature can be defined

External senor Settings Sensor settings C1 arrow right (2.page) Ref. Pressure description field

External senor Settings Sensor settings C1 arrow right (2.page) Ref. Pressure Unit description field

External senor Settings Sensor settings C1 arrow right (2.page) Ref. Temp. description Field

External senor Settings Sensor settings C1 arrow right (2.page) Ref. Temp. Unit description Field

12.6.1.4 Definition Unit of flow and velocity

External senor Settings Sensor settings C1 arrow right (2.page) Flow description Field

External senor Settings Sensor settings C1 arrow right (2.page) Velocity description Field

Page 52

Settings

LD500 V1.00 Seite 52 von 68

12.6.1.5 Definition consumption counter value and consumption unit

External senor Settings Sensor settings C1 arrow right (2.page) Count Val. description Field

External senor Settings Sensor settings C1 arrow right (2.page) Count Val. Unit description Field

Remark:

After confirmation with OK, the font is black again and the values and settings are accepted

The sensor allows taking over a starting

counter value. Inserting the value by

entering the ”Count. Val.” text field.

In the Count. Val. Unit field different units

could be used. Selection by activation of

the “Count. Val. Unit” text field

In case the counter value unit will be

changed only the consumption counter

value will be recalculated to the

appropriate unit.

Selection to confirm selection by pressing

OK button.

Page 53

Settings

LD500 V1.00 Seite 53 von 68

12.6.1.6 Settings analogue output 4-20mA of VA 5xx

External senor Settings Sensor settings C1 More-Settings 4-20mA Ch1

This menu allows the adjustment / assignment of the

measurement value and the scaling of the analogue output

by pressing the”4-20mA Ch1” button.

Selection of the analogue output measurement value by

activating the appropriate measured value key in this

example, “Flow".

Possible outputs are flow, velocity and temperature.

In case of no use, please select “Off”.

The analogue output scaling have to possibilities,

automatic scaling (default) and a manual scaling by the

user. Auto scaling is based on the calibration settings,

means 4mA is set to zero and the 20mA value is based on

the max. settings here 900m³/h

A “manual scaling” needs an activation of the “scale

manual” button.

In text fields "4mA" and "20mA" the appropriate scaling

values are entered, here from zero m³h (4mA) to 300 m³/h

(20mA).

With "Error Val" it is determined what is the output in case

of an error at the analogue output.

2 mA Sensor error / System error

22 mA Sensor error / System error

4..20 Output according Namur (3.8mA – 20.5 mA)

< 4mA to 3.8 mA Measuring range under range

>20mA to 20.5 mA Measuring range exceeding

Inputs / changes to be confirmed with “OK” button. Return

to main menu with “Back”.

Page 54

Settings

LD500 V1.00 Seite 54 von 68

12.6.1.7 Settings Pulse / Alarm output of VA 5xx

External senor Settings Sensor settings C1 More-Settings Pulse / Alarm

External senor Settings Sensor settings C1 More-Settings Pulse

The pulse output of the VA 5xx could be

set functionally as pulse output or alarm

output.

Function to activate by pressing either the

“Pulse” or “Alarm” button.

In case of no use, please select “none”.

To set up the pulse first the unit and the

measurement value have to be defined.

Unit selection by pressing “unit” button

and choice one of the possible units “kg”,

“cf”, “ltr” or “m³”).

Pulse weight setting by entering the text

field “Value”.

Here with defined 1 pulse per m³ and with

positive polarity.

With „Polarity“ the switching state could

be defined.

Pos. = 0 1 neg. 1 0

pos

neg

open

closed

Page 55

Settings

LD500 V1.00 Seite 55 von 68

External senor Settings Sensor settings C1 More-Settings Alarm

In case of use the pulse output as alarm

following definitions needs to be set:

Unit selection by pressing “unit” button

and choice one of the possible units

“cfm”, “ltr/s”, “m³/h”, “m/s” ”, “°F ”, “°C”

”, “kg/s” or ”, “kg/min”).

Alarm value setting by entering the text

fields “Value”.

The limits „High“ or „Low“ defines when

the alarm is activated, selecting by

pressing the appropriate button

High: Value over limit

Page 56

Settings

LD500 V1.00 Seite 56 von 68

12.6.1.8 Settings ZeroPoint or Low Flow Cut off for VA 5xx

External senor Settings Sensor settings C1 More-Settings Zeropoint

2.045

2.045

With these function following

adjustments for the sensor VA 5xx could

be done:

Zeropoint:

When, without flow, the installed sensor

shows already a flow value of > 0 m³/h

herewith the zero point of the

characteristic could be reset

Cutoff:

With the low-flow cut off activated, the

flow below the defined "LowFlow Cut off"

value will be displayed as 0 m³/h and not

added to the consumption counter.

For Zero Point the text field “ ZeroPoint”

to enter and insert the displayed actual

flow, here 2.045

Page 57

Sensor Type Modbus

LD500 V1.00 Seite 57 von 68

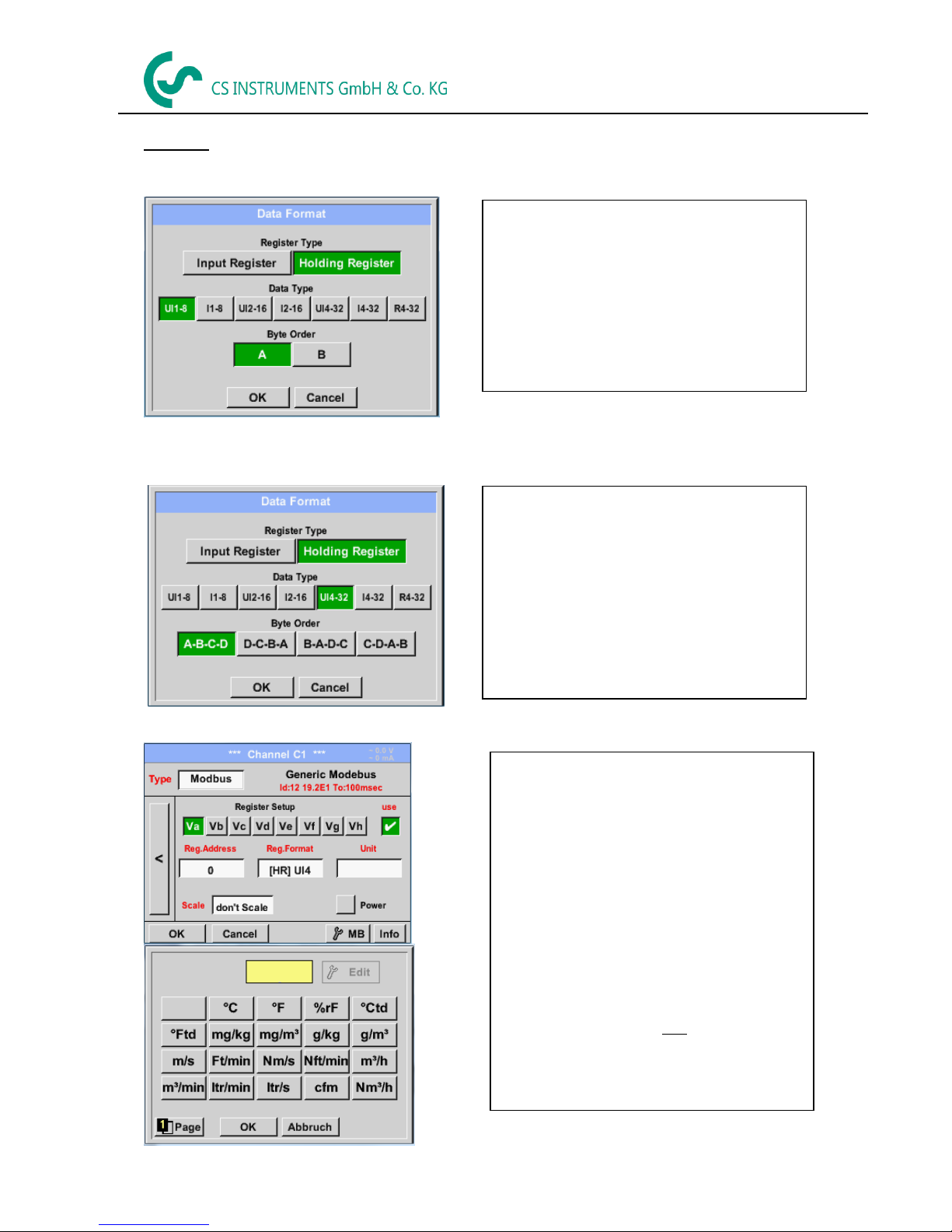

12.7 Type Modbus

12.7.1 Selection and activation of Sensor-Type Modbus

First Step: First step: choose an unused sensor channel

External sensor Settings Sensor settings C1

Second step: choose type Modbus

External sensor Settings Sensor settings C1 Type description field Modbus

Third step: confirm with OK.

External sensor Settings Sensor settings C1 arrow right (2.page) Va use

12.7.1.1 Modbus Settings

External sensor Settings Sensor settings C1 arrow right (2.page) Modbus

Settings ID -text field

Via Modbus, it is possible to read out up to 8

Register-Values (from Input or Holding Register) of

the sensor.

Selection by the Register Tabs Va –Vh and

activation by pressing of the corresponding Use

button.

Please insert here the specified Modbus ID of the

sensor, allowed values are 1 -247, (e.g. here Modbus

ID = 12)

For setting the Modbus ID on the sensor, please see

sensor-datasheet.

In addition in the menu are the serial transmission

settings Baudrate, Stopbit, Paritybit and Timeout time

to define.

.

In case that the LD 510 is the end of the RS485 bus

system with activating Term- & Bias- button the

required termination and biasing could be activated.

Confirmation by pressing OK button.

For resetting to the default values please press Set to

Default.

Page 58

Sensor Type Modbus

LD500 V1.00 Seite 58 von 68

External sensor Settings Sensor settings C1 Reg. Address description field

Important:

Required is the correct register-address.

It should be noted that the register-number could be different to the register-address

(Offset). For this, please consult the sensor data sheet.

External sensor Settings Sensor settings C1 Reg. Format description field

Supported Data types:

Data Type: UI1(8b) = unsigned Integer => 0 - 255

I1 (8b) = signed integer => -128 - 127

UI2 (16b) = unsigned Integer => 0 - 65535

I2 (16b) = signed integer => -32768 - 32767

UI4 (32b) = unsigned Integer => 0 - 4294967295

I4 (32b) = signed integer => -2147483648 - 2147483647

R4 (32b) = floating point number

Byte Order:

The size of each Modbus-register is 2 Byte. For a 32 bit value two Modbusregister will be read out by

the DS500. Accordingly for a 16bit Value only one register is read.

In the Modbus Specification, the sequence of the transmitted bytes is not defined clearly. To cover all

possible cases, the byte sequence in the DS500 is adjustable and must adapted to the respective

sensor. Please consult here for the sensor datasheet.

e.g.: High byte before Low Byte, High Word before Low Word etc.

Therefore the settings have to be made in accordance to the sensor data sheet.

The measurement values are kept in the

registers of the sensor and can be

addressed via Modbus and read by the

PI 500

This requires setting the desired register

addresses in the PI 500

Entering the register / data address is

With the buttons Input Register and

Holding Register the corresponding

Modbus-register type will be selected.

The number format and transmission

order of each value needs to be defined

by Data Type and Byte Order. Both have

to be applied in correct combination.

Page 59

Sensor Type Modbus

LD500 V1.00 Seite 59 von 68

Example:

Holding Register - UI1(8b) - Value: 18

Holding Register – UI4(32) - Value: 29235175522 AE41 5652

External sensor Settings Sensor settings C1 Unit- description field

Selection Register Type Holding Register,

Data Type U1(8b) und Byte Order A / B

HByte LByte

18 => 00 12

Data Order 1. Byte 2. Byte

A 00 12

Selection Register Type Holding Register,

Data Type U1(32b) und Byte Order A-B-C-

D

HWord LWord

HByte LByte HByte

LByte

29235175522 => AE 41 56

52

By pressing the description field Unit

the list with the available units appear

Please select the unit by pressing the

respective button e.g. m³/h.

For validation of the unit, please push the

button OK

To move through the list please press the

button Page.

In case the unit is not available it is

possible to create a user defined unit.

Therefore, please select one of the

User_X buttons.

Page 60

Sensor Type Modbus

LD500 V1.00 Seite 60 von 68

External sensor Settings Sensor settings C1 Scale- description field

External sensor Settings Sensor settings C1 OK

The use of this factor allows adapting the

output value by the same.

By default or value = 0 no scaling is applied

and displayed in the field is don’t scale

By pressing the OK button, the inputs are

confirmed and stored.

Page 61

Data logger settings

LD500 V1.00 Seite 61 von 68

12.8 Data logger Settings

External sensor Settings Logger settings

Remark:

If more than 12 measurement data are recorded at the same time, the smallest possible

time interval of the data logger is 2 seconds.

In addition, if more than 25 measurement data are recorded at the same time, the

smallest possible time interval of the data logger is 5 seconds.

In the top row you can select the

predefined Time intervals 1, 2, 5, 10, 15,

30, 60 and 120 seconds for recording.

A different, individual Time interval can

be entered in the highlighted white

description field right at the head, where

the currently set Time interval is always

displayed.

Remark:

The largest possible Time interval is 300

seconds.

Page 62

Sensor Type Modbus

LD500 V1.00 Seite 62 von 68

External sensor Settings Logger settings force new Record File button

or

External sensor Settings Logger settings force new Record File button Comment

description field

Main menu Settings Logger settings timed Start button

A new recording file will be created by

pushing the force new record file button

and a name or comment can be entered

by the choice of the Comment

description field.

Important:

If a new recording file should be

created, the force new record file button

By pushing the timed Start button and

then the date/time description field

below, the date and the start time can

be set for a data logger recording.

Remark:

If the start time is activated, it will

automatically be set at the current time

plus a minute.

Page 63

Sensor Type Modbus

LD500 V1.00 Seite 63 von 68

External senor Settings Logger settings timed Stop button

External senor Settings Logger settings timed Start button/timed Stop button

Date/Time description field

By pushing the timed Stop button and

then the date/time description field

below, the date and the stop time can

be set for a data logger recording.

Remark:

If the stop time activated, it will

automatically be set to the current time

plus an hour.

After pushing the date/time description

field a window will appear where the

yellow marked area of the time or date

can always be set and changed.

Page 64

Sensor Type Modbus

LD500 V1.00 Seite 64 von 68

External senor Settings Logger settings timed Start button/timed Stop button

Date/Time description field Cal button

External senor Settings Logger settings Start button

External senor Settings Logger settings Start button/Stop button

Important:

If a new recording file should be created, the force new record file button must be

activated.

Otherwise, the last applied recording file is used.

After the start and stop time

activation and the created settings,

the Start button will be pushed and

the data logger is armed.

The data logger starts the recording at

the set time!

The data logger can be started without

activated time settings, use the Start

and Stop buttons for activate and

disable.

Left below there will be shown how

many values are recorded and how

long there still can be recorded.

Remark:

With the Cal button the desired date

can be easily select from the calendar.

Page 65

Data logger settings

LD500 V1.00 Seite 65 von 68

13 Scope of delivery

The LD 500 is available either as a single unit or in a set. The set contains all the components and

accessories that are protected in a a rugged and shock-resistant transport case.

.

In der nachfolgenden Tabelle sind die Komponenten mit ihren Bestellnummern aufgelistet.

Description

Order no.r

Set LD 500 consisting of:

0601 0105

LD 500 leak detector with acoustic trumpet, and integrated camera,

100 leak tags for marking the leakages on site

0560 0105

Sound-proof headset

0554 0104

Focus tube with focus tip

0530 0104

Battery charger(AC adapter plug)

0554 0009

Transportation case

0554 0106

Helix cable for connecting the ultrasonic sound sensor

0200 01402

Focus tube with

focus tip

(0530 0104)

Soundproof

headset

(0554 0104)

Ext. Power supply

(0554 0009)

LD500 Leak meter

(0560 0105)

Transport case

(0554 0106)

Page 66

Data logger settings

LD500 V1.00 Seite 66 von 68

Diese Erklärung beinhaltet keine Zusicherung von Eigenschaften.

Die Sicherheitshinweise der mitgelieferten Produktdokumentation sind zu beachten.

Page 67

Appendix

LD500 V1.00 Seite 67 von 68

Page 68

Contact

LD500 V1.00 Seite 68 von 68

SALES OFFICE NORD

Am Oxer 28c

D-24955 Harrislee

DEUTSCHLAND

Tel.: +49 (0) 461 80 71 50 - 0

Fax: +49 (0) 461 80 71 50 - 15

info@cs-instruments.com

www.cs-instruments.de

SALES OFFICE SOUTH

Zindelsteiner Straße 15

D-78052 VS-Tannheim

DEUTSCHLAND

Tel.: +49 (0) 7705 978 99-0

Fax: +49 (0) 7705 978 99-20

info@cs-instruments.com

www.cs-instruments.de

Loading...

Loading...