Page 1

EN - English

Installation and operating instructions

Intelligent paperless recorder

DS 500

DS 500 V1.55 Page 1 of 124

Page 2

Foreword

I. Foreword

Dear customer,

thank you very much for deciding in favour of the DS 500. Please read this installation

and operation manual carefully before mounting and initiating the device and follow

our advice. A riskless operation and a correct functioning of the DS 500 are only

guaranteed in case of careful observation of the described instructions and notes.

Sales Office South/Geschäftsstelle Süd

Zindelsteiner Str. 15

D-78052 VS-Tannheim

Tel.: +49 (0) 7705 978 99 0

Fax: +49 (0) 7705 978 99 20

Mail: info@cs-instruments.com

Web: http://www.cs-instruments.com

Sales Office North/Geschäftsstelle Nord

Am Oxer 28c

D-24955 Harrislee

Tel.: +49 (0) 461 700 20 25

Fax: +49 (0) 461 700 20 26

Mail: info@cs-instruments.com

Web: http://www.cs-instruments.com

DS 500 V1.55 Page 2 of 124

Page 3

Table of contents

II. Table of contents

I. Foreword ....................................................................................................................... 2

II. Table of contents ....................................................................................................... 3

1 Safety instructions ........................................................................................................ 7

1.1 General ..................................................................................................................................... 7

1.2 Installation ............................................................................................................................... 8

2 Application area ...........................................................................................................10

3 Intended use .................................................................................................................11

4 Technical data DS 500 .................................................................................................12

5 Input signal ...................................................................................................................13

6 Cable cross-section .....................................................................................................13

7 Package dimensions ...................................................................................................14

8 Assembly instructions .................................................................................................15

9 Panel and wall mounting .............................................................................................16

10 Connection diagrams DS 500 ..................................................................................17

10.1 DS 500 with 4 channels ..................................................................................................... 17

10.2 DS 500 with 8 channels ..................................................................................................... 17

10.3 DS 500 with 12 channels ................................................................................................... 18

10.4 Power supply DS 500 standard version 100 - 240 VAC ................................................. 18

10.5 X2.1 and X2.2 by standard version 100 - 240 VDC, wired ex works ............................. 18

10.6 Power supply by special version 24 VDC ....................................................................... 19

10.7 Connection 4 x alarm relay, max. 230 VAC, 6 A ............................................................. 19

10.8 Connection bus systems X4.1 and S4.1 ......................................................................... 19

10.9 Connector pin assignment for all sensors XA.1 – XA.4, XB.1 – XB.4, XC.1 – XC.4 .... 19

11 Connection diagrams of the different sensor types ...............................................20

11.1 Connection CS dew point sensors, series FA 415/FA 300 ............................................ 20

11.2 Connection for dew point- and consumption sensors, series FA/VA 4xx .................. 21

11.3 Connection for dew point- and consumption sensors, series FA/VA 5xx .................. 22

11.3 Connection pulse sensors ............................................................................................... 23

11.4 Analogue two-, three-, and four-wire current signal ...................................................... 24

11.5 Three- and four-wire power supply 0 - 1/10/30 VDC ...................................................... 27

11.6 Two-, three-, and four-wire connector pin assignments for PT100/PT1000/KTY81 .... 28

11.7 Connection with RS485 .................................................................................................... 28

DS 500 V1.55 Page 3 of 124

Page 4

Table of contents

12 Connect the DS 500 with a PC .................................................................................29

13 Operation DS 500 ......................................................................................................30

13.1 Main menu (Home) ............................................................................................................ 30

13.1.1 Initialization ...................................................................................................................... 30

13.1.2 Main menu after initialization ........................................................................................... 31

13.2 Shutdown ........................................................................................................................... 31

13.3 Settings .............................................................................................................................. 32

13.3.1 Password settings ............................................................................................................ 32

13.3.2 Sensor settings ................................................................................................................ 33

13.3.2.1 Choice of the sensor type (For example type CS-Digital sensor) ............................ 33

13.3.2.2 Label and setting the description fields .................................................................... 36

13.3.2.3 Name the measurement data and define the decimal places .................................. 36

13.3.2.4 Recording measurement data .................................................................................. 37

13.3.2.5 Alarm settings ........................................................................................................... 38

13.3.3 Dew point sensor with type CS-Digital (SDI Bus) ............................................................ 40

13.3.4 Flow sensor VA 400 / VA 420 of type CS-Digital (SDI Bus) ............................................ 41

13.3.4.1 More-Settings (scale analogue output) .................................................................... 42

13.3.5 Dew Point Sensor of type FA 5xx (RS 485 Modbus)....................................................... 45

13.3.5.1 Settings Dew point sensor FA 500 FA 510 .............................................................. 46

13.3.5.1.1 Unit selection for temperature and humidity ...................................................................... 46

13.3.5.1.2 Definition of the System pressure (relative pressure value) .............................................. 46

13.3.5.1.3 Definition of Reference pressure (absolute pressure value) .............................................. 47

13.3.5.1.4 Calibration ......................................................................................................................... 48

13.3.5.1.5 More Settings Analogue output 4-20mA ........................................................................... 48

13.3.6 Flow sensor of type VA 5xx (RS 485 Modbus) ................................................................ 49

13.3.6.1 Settings for Flow sensor VA 5xx .............................................................................. 50

13.3.6.1.1 Diameter settings .............................................................................................................. 50

13.3.6.1.2 Gas Constant settings ....................................................................................................... 51

13.3.6.1.3 Definition of the reference conditions ................................................................................ 52

13.3.6.1.4 Definition Unit of flow and velocity ..................................................................................... 52

13.3.6.1.5 Definition consumption counter value and consumption unit ............................................. 53

13.3.6.2 Settings analogue output 4-20mA of VA 5xx............................................................ 54

13.3.6.3 Settings Pulse / Alarm output of VA 5xx ................................................................... 55

13.3.6.4 Settings ZeroPoint or Low Flow Cut off for VA 5xx .................................................. 56

13.3.7 Configuration of analogue sensors .................................................................................. 57

13.3.7.1 Type 0 - 1/10/30 Volt and 0/4 - 20 mA ................................................................... 57

13.3.7.2 Type PT100x and KTY81 ......................................................................................... 58

13.3.7.3 Type Pulse (Pulse ration) ......................................................................................... 59

13.3.7.4 Type No Sensor ........................................................................................................ 61

13.3.8 Typ Modbus ..................................................................................................................... 62

13.3.8.1 Selection and activation of sensor type .................................................................... 62

13.3.8.2 Modbus settings ....................................................................................................... 62

13.3.9 Option Modbus extended channels ................................................................................. 66

13.3.9.1 Activation of the extended Modbus channels ........................................................... 66

13.3.9.2 Settings of the extended Modbus channels ............................................................. 66

13.3.9.3 Modbus Settings ....................................................................................................... 67

13.3.10 Sensor Settings storing/importing (Custom Sensor) .................................................... 68

13.3.10.1 Sensor Settings Storing ........................................................................................... 68

13.3.10.2 Sensor Settings import ............................................................................................ 69

DS 500 V1.55 Page 4 of 124

Page 5

Table of contents

13.4 Logger settings (data logger) ........................................................................................... 70

13.5 Device settings .................................................................................................................. 74

13.5.1 Set language .................................................................................................................... 74

13.5.2 Date & Time ..................................................................................................................... 74

13.5.3 Network settings .............................................................................................................. 75

13.5.4 ModBus settings (Slave) .................................................................................................. 76

13.5.5 Relay Settings .................................................................................................................. 76

13.5.6 SD-Card ........................................................................................................................... 77

13.5.7 Update System ................................................................................................................ 78

13.5.7.1 Saving System settings ............................................................................................ 78

13.5.7.2 Update FW (Main and channel ................................................................................. 79

13.5.8 Factory Reset................................................................................................................... 80

13.6 Report settings (optional) ................................................................................................. 81

13.7 Virtual Channels (optional) ............................................................................................... 82

13.7.1 Option „Virtual Channels“ activation ................................................................................ 82

13.7.2 Virtual Channels Settings ................................................................................................ 83

13.7.3 Selection of Sensor-type .................................................................................................. 83

13.7.4 Configuration of each single virtual value ........................................................................ 85

13.7.4.1 Activation of a single virtual value ............................................................................ 85

13.7.4.2 Definition of Operands .............................................................................................. 85

13.7.4.3 Definition of Operations ............................................................................................ 86

13.7.4.4 Definition of Unit ....................................................................................................... 87

13.7.4.5 Value name, resolution of decimal places and recording of values ......................... 88

13.7.4.6 Calculation Example „Specific Performance“ .......................................................... 89

13.8 Analog Total (optional) ..................................................................................................... 91

13.8.1 Option „Analog Total“ activation ...................................................................................... 91

13.8.2 Selection of sensor type .................................................................................................. 92

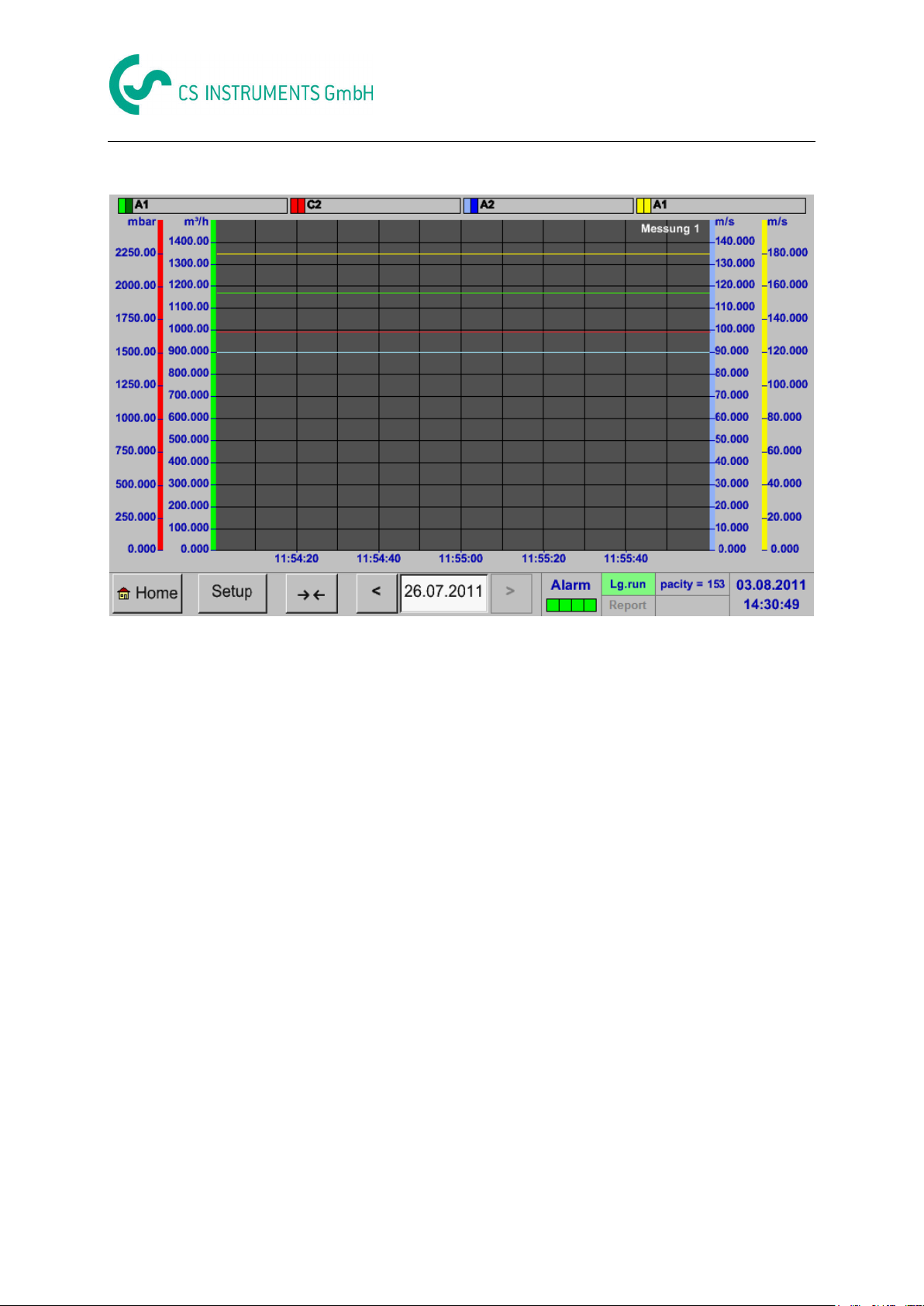

13.9 Chart ................................................................................................................................... 93

13.10 Chart/Real time values ...................................................................................................... 98

13.11 Channels .......................................................................................................................... 100

13.12 Real time values .............................................................................................................. 101

13.13 Alarm overview ................................................................................................................ 102

13.14 Further setting options ................................................................................................... 103

13.14.1 Set backlight ............................................................................................................... 103

13.14.2 Calibrate touch-screen ............................................................................................... 104

13.14.3 Cleaning ..................................................................................................................... 104

13.14.4 System Status ............................................................................................................ 104

13.14.5 About DS 500 ............................................................................................................. 105

13.15 Consumption report with cost settings, export data and webserver ........................ 106

13.15.1 Consumption report (optional).................................................................................... 106

13.15.2 Cost settings (optional) .............................................................................................. 108

13.16 Webserver (optional) ....................................................................................................... 109

13.16.1 Option „Webserver“ activation.................................................................................... 109

13.16.2 Setup the Webserver Admin Password ..................................................................... 109

13.16.3 Webserver start .......................................................................................................... 110

13.16.3.1 Webserver assignment of rights (Administrator) ................................................... 111

13.16.3.1.1 Accessrights Webserver ................................................................................................ 111

13.16.3.1.2 Webserver Login ........................................................................................................... 111

13.16.3.1.3 New users and password defintion ................................................................................ 112

13.16.3.2 Webserver E-Mail Configuration (Administrator) .................................................. 113

13.16.3.3 Webserver MailOnAlarm (Administrator & Operator) ............................................ 114

13.16.3.4 Webserver Chart (Administrator, Operator & User) .............................................. 115

13.16.3.5 Webserver Screen ................................................................................................. 116

13.16.3.6 Webserver Actuals ................................................................................................ 117

13.16.3.7 Webserver Status .................................................................................................. 117

DS 500 V1.55 Page 5 of 124

Page 6

Table of contents

13.17 Import / Export ................................................................................................................. 118

13.17.1 Export Logger data ..................................................................................................... 118

13.17.2 Screenshots export .................................................................................................... 119

13.17.3 Export System Settings .............................................................................................. 120

13.17.4 Export Report ............................................................................................................. 120

13.17.5 Import system settings ............................................................................................... 121

14 Screenshot function ............................................................................................... 122

14.1 Screenshot saving .......................................................................................................... 122

15 Cleaning .................................................................................................................. 123

DS 500 V1.55 Page 6 of 124

Page 7

Safety instruction

Warning!

Inadmissible operating parameters!

Undercutting and exceeding respectively of limit values may cause danger to persons

and material and may lead to functional and operational disturbances.

Attention!

Malfunctions at the DS 500!

Faulty installation and insufficient maintenance may lead to malfunctions of the DS 500

which may affect the measuring results and which may lead to misinterpretations.

Please check whether this manual corresponds with the device type.

Please attend to all notes indicated in this instruction manual. It contains essential information

which has to be followed during installation, operation and maintenance. Therefore, this

instruction manual has to be read categorically by the technician as well as by the responsible

user/qualified personnel before installation, initiation and maintenance.

This instruction manual has to be available at any time at the operation site of the DS 500.

Regional and national regulations respectively, have to be observed in addition to this instruction

manual if necessary.

In case of any obscurities or questions with regard to this manual or the instrument please contact

CS Instruments GmbH.

1 Safety instructions

1.1 General

Measures:

• Make sure that the DS 500 is only operated within the admissible limit values indicated on the

type label.

• Strict observance of the performance data of the DS 500 in connection with the application.

• Do not exceed the admissible storage and transportation temperature.

Further safety instructions:

• Attention should also be paid to the applicable national regulations and safety instructions during

installation and operation.

• The DS 500 is not allowed to be used in explosive areas.

Additional remarks:

• Do not overheat the instrument!

• Change of battery or SD-Card are only allowed to be carried out by authorized qualified personnel.

and in strainless state!

R

DS 500 V1.55 Page 7 of 124

Page 8

Safety instructions

Warning!

Supply voltage!

Contact with supply voltage carrying non-insulated parts may cause an electric shock

with injury and death.

Danger!

Missing earth connection!

When the earth connection (protective earth) is missing, there is the

risk in the event of malfunction, that contactable, conductive

components may carry supply voltage. Touching of such parts leads

to an electric shock with injuries and death.

It is imperative to connect the plant to earth or to connect the

protective conductor according to the regulations.

Do not use plug adapters at the power plug.

Have the power plug replaced by qualified skilled persons, if

required.

1.2 Installation

Measures:

• Note all applicable regulations for electrical installations (e.g. VDE 0100)!

• Carry out maintenance only in strain less state!

• All electric works are only allowed to be carried out by authorized qualified personnel.

DS 500 V1.55 Page 8 of 124

Page 9

Safety instructions

DANGER!

Supply voltage!

When wiring the connecting lead, it must be ensured that the double or

reinforced insulation be-tween the electric circuits that are dangerous in the

case of contact and the contactable secondary circuit remains maintained.

NOTE!

The additional insulation must be suitable for a test voltage of 1500 V

alternating current.

The thickness of the insulation must be at least 0.016 inch.

E.g. flexible insulating tubing, type BIS 85 (Bierther GmbH).

The plug of the power supply cord is used as a separator. This separator must be clearly recognizable

and easily accessible by the user. A plug connector with a CEE7/7 system is necessary.

All the electrical lines carrying supply voltage or another voltage that is dangerous in the case of contact (power supply cord, alarm and indicator relays), must additionally be equipped with double or

reinforced insulation (EN 61010-1). This can be ensured by using plastic-sheathed cables, a second

insulation (e.g. flexible insulating tubing), or correspondingly suitable lines with reinforced insulation.

The connecting cables can be equipped, for example, with flexible insulating tubing.

The additional flexible insulating tubing must withstand the electrical and mechanical stresses which

can occur during the intended use (see EN 61010-1, Clause 6.7.2.2.1).

The additional insulation of the connecting leads (mains connection, alarm and indicator relays) can

be implemented as follows:

3 2 1

(1) - Terminals (connectors)

(2) – Flexible insulating tubing for the connecting leads

(3) – Connecting cable

DS 500 V1.55 Page 9 of 124

Page 10

Application area

Versatile:

Up to 12 sensors, incl. all CS sensors

(consumption, dew point, pressure, current,

KTY, PT 100, PT 1000) are identified automatically by DS 500. Optional analogue

sensors (0/4 - 20 mA, 0 - 1/10/30 V, pulse)

can be configured easily and quickly.

Digital sensors can be connected via

RS 485, Modbus RTU and SDI.

Flexible:

Network-compatible and

worldwide remote data

transmission via

Ethernet, integrated web

server.

Alarm relay / fault

indication:

Up to 32 threshold

values can be

configured freely and

allocated to 4 different

alarm relay. Collective

alarms are possible.

2 Application area

Our long-term hands-on experience in measurement and control technology was implemented in the

new DS 500.

From recording of the measured data, automatic sensor identification, indication on a big colour

screen, alerting, storage up to remote read-out via web server, all that is possible with DS 500. By

means of the CS-Soft, software alarms can be sent via SMS or e-mail.

On the big 7' colour screen with touch panel all information is available at a glance.

The operation is very easy. All measured values, measured curves and threshold exceeding’s are

indicated. The progression of the curve, since the beginning of the measurement, can be viewed by

an easy slide of the finger.

Daily, weekly and monthly reports, with costs in € and counter reading in m3, for each consumption

sensor are completing the sophisticated system concept.

The huge difference to ordinary paperless chart recorders reveals in the easy initiation as well as in

the evaluation of the measured data. All sensors are identified directly and powered by DS 500.

Everything is matched and tuned.

DS 500 V1.55 Page 10 of 124

Page 11

Intended use

3 Intended use

The DS 500 data logger serves for the stationary measured data acquisition and storage of analogue

and digital input signals.

The DS 500 data logger is exclusively designed and constructed for the proper application purpose that

is described herein and must only be used correspondingly.

A check in order to ascertain whether or not the device is suitable for the chosen employment must be

carried out by the user. It must be ensured that the medium is compatible with the components which

come into contact with it. The technical data listed in the data sheet are binding.

Improper handling or operation outside the technical specifications is impermissible. Claims of any kind

on the basis of improper use are excluded.

DS 500 V1.55 Page 11 of 124

Page 12

Technical data DS 500

Dimensions of housing

280 x 200 x 95 mm

Connections

18 x PG 12 for sensors and supply, alarm relay

1 x RJ 45 Ethernet connection

Version panel mounting

Cutout panel 250 x 156 mm

Weight

3,5 kg

Material

Die cast metal, front screen polyester

Protection level

IP65

Sensor inputs

4/8/12 sensor inputs for analogue and digital sensors

freely allocatable.

Digital CS sensors for dew point and consumption with SDI interface

FA/VA 400 Series.

Digital third-party sensors RS 485/Modbus RTU, other bus systems

realizable on request.

Analogue CS sensors for pressure, temperature, clamp-on

ammeters preconfigured.

Analogue third-party sensors 0/4 – 20 mA, 0 - 1/10/30 V, pulse,

Pt100/Pt1000, KTY.

Power supply for sensors

Output voltage: 24 VDC ± 10% galavanically isolated

Output current: 130 mA by continuous operation, peak 180mA

Maximum output current over all channels with

- one power supply: 400mA

- two power supplies: 1Ampere

Interfaces

USB stick, USB cable, Ethernet/RS 485 Modbus RTU/TCP,

SDI other bus systems on request, web server optionally

Outputs

Outputs 4 relay (max. switching voltage: 400 VAC / 300 VDC, Switching

current: min. 10mA, max. 6A) alarm management,

relay freely programmable, collective alarm.

Analogue output, pulse in case of sensors with own signal

output looped, like e. g. VA/FA Series.

Memory card

Memory size 2 GB SD memory card standard, optionally up to 4 GB

Power supply

100 - 240 VAC/50 - 60 Hz, 75VA , special version 24 VDC

Battery 1)

CR 2032

Colour screen

7" touch panel TFT transmissive, graphics, curves, statistics

Accuracy

See sensor specifications

Operating temperature

0 - 50 °C

Storage temperature

-20 - 70 °C

Optionally

Web server

Optionally

Quick measurement with 10 ms sampling rate for analogue sensors,

Max/Min indication per second.

Optionally

Option "consumption report” statistics, daily/weekly/monthly report.

4 Technical data DS 500

1)

Lithium manganese dioxide Battery, Panasonic CR2032 / 3 V / 225 mAh

DS 500 V1.55 Page 12 of 124

Page 13

Input signal

Current signal

(0 – 20 mA / 4 – 20 mA)

internal or external

power supply

Measuring range

0 – 20 mA / 4 – 20 mA

Resolution

0,0001 mA

Accuracy

0,03 mA 0,05 %

Input resistance

50

Voltage signal

(0 - 1V)

Measuring range

0 - 1 V

Resolution

0,05 mV

Accuracy

0,2 mV 0,05 %

Input resistance

100 k

Voltage signal

(0 - 10 V / 30 V)

Measuring range

0 - 10 V/30 V

Resolution

0,5 mV

Accuracy

2 mV 0,05 %

Input resistance

1 M

RTD

Pt100

Measuring range

-200 - 850 °C

Resolution

0,1 °C

Accuracy

0,2 °C at -100 - 400 °C

0,3 °C (further range)

RTD

Pt1000

Measuring range

-200 - 850 °C

Resolution

0,1 °C

Accuracy

0,2 °C at -100 - 400 °C

0,3 °C ( further range )

Pulse

Measuring range

Minimum pulse length 100 μs

frequency 0 - 1 kHz

max. 30 VDC

5 Input signal

Input signal/Cable cross-section

6 Cable cross-section

6.1 Power supply 100 - 240 VAC, 50 - 60 Hz, special version 24 VDC:

Cable cross section power supply: 0,75 mm²

6.2 Sensor circuit points/Output signal:

AWG16 – AWG28, cable cross-sections: 0,14 - 1,5 mm

Cable gland clamping Range: 4-8mm

DS 500 V1.55 Page 13 of 124

2

Page 14

7 Package dimensions

Package dimensions

Dimensions of holes for wall mounting (D = 6 mm):

DS 500 V1.55 Page 14 of 124

Page 15

8 Assembly instructions

Assembly instructions

DS 500 V1.55 Page 15 of 124

Page 16

Cut-out panel

Dimension of housing 270 x 170 x 90 mm

Dimension of holes for wall mounting D = 6 mm

9 Panel and wall mounting

Panel and wall mounting

DS 500 V1.55 Side 16 of 124

Page 17

Connection diagrams DS 500

1

2

3

123

12345

1 2 3 4 5 6 7 8

9

12345678

9

123

1

2

3

1

23

12345

12345

12345678

9

1 2 3 4 5 6 7 8

9

X3.4

X3.3

X3.2

X3.1

X2.2

X2.1

X1.1

X4.1

XA.4 XA.3

XA.1

XA.2

ON

1 2

3 4

5 6

7 8

S4.1

X1.1:

power supply

X2.1, X2.2:

for internal use

X3.1 - X3.4:

alarm relay 1 – 4

X4.1, S4.1:

for CAN, RS485,

R120 configuration

XA.1 - XA.4:

sensor channels 1 – 4

1

2

3

123

12345

1 2 3 4 5 6 7 8

9

12345678

9

123

1

2

3

1

23

12345

12345

12345678

9

12345678

9

12345678

9

12345678

9

12345678

9

1 2 3 4 5 6 7 8

9

X3.4

X3.3

X3.2

X3.1

X2.2

X2.1

X1.1

X4.1

XB.4 XB.3 XB.2 XB.1

XA.4 XA.3

XA.1

XA.2

X1.1:

power supply

X2.1, X2.2:

for internal use

X3.1 - X3.4:

alarm relay 1 – 4

X4.1:

for CAN, RS485,

R120

configuration

XA.1 - XA.4:

sensor channels

1 – 4

XB.1 - XB.4:

sensor channels

5 – 8

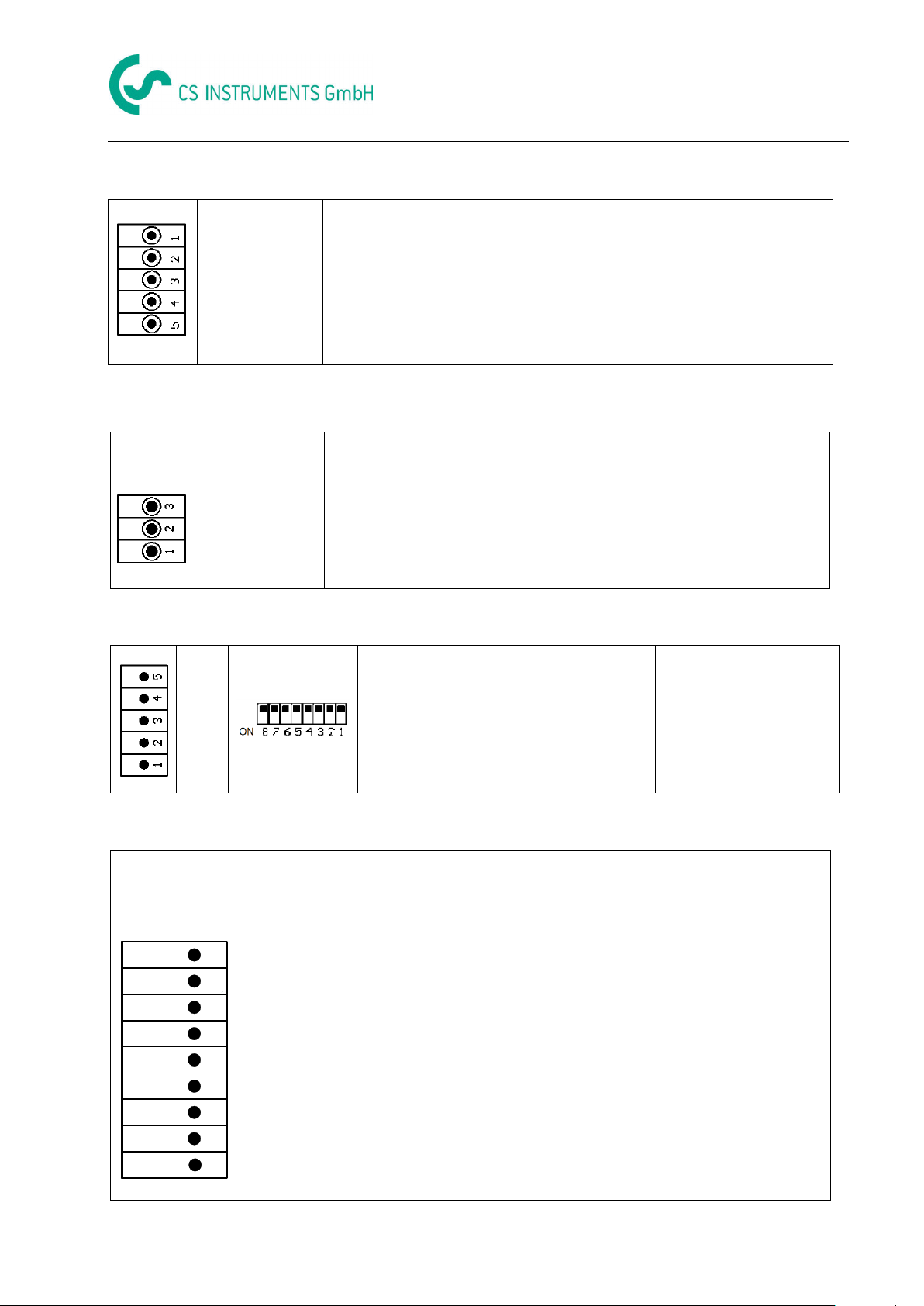

10 Connection diagrams DS 500

10.1 DS 500 with 4 channels

10.2 DS 500 with 8 channels

DS 500 V1.55 Side 17 of 124

Page 18

1

2

3

123

12345

1 2 3 4 5 6 7 8

9

12345678

9

123

1

2

3

1

23

12345

12345

12345678

9

12345678

9

12345678

9

12345678

9

12345678

9

12345678

9

12345678

9

12345678

9

12345678

9

1 2 3 4 5 6 7 8

9

X3.4

X3.3

X3.2

X3.1

X2.2

X2.1

X1.1

X4.1

XB.4 XB.3 XB.2 XB.1

XC.4 XC.3 XC.2 XC.1

XA.4 XA.3

XA.1

XA.2

X1.1:

power supply

X2.1, X2.2:

for internal use

X3.1 - X3.4:

alarm relay 1 – 4

X4.1:

for CAN, RS485, R120

configuration

XA.1 - XA.4:

sensor channels 1 – 4

XB.1 - XB.4:

sensor channels 5 – 8

XC.1 - XC.4:

sensor channels 9 – 12

X1.1

L1

N

PE

100 - 240 VAC, 50 - 60 Hz

X2.1, X2.2

L1´

N´

PE´

GND

U+ (24 VDC)

Only for internal use

10.3 DS 500 with 12 channels

Connection diagrams DS 500

10.4 Power supply DS 500 standard version 100 - 240 VAC

10.5 X2.1 and X2.2 by standard version 100 - 240 VDC, wired ex works

DS 500 V1.55 Side 18 of 124

Page 19

Connection diagrams of the different sensor types

X2.1

GND

U+ (24 VDC)

External supply 24 VDC (X 2. 2 not occupied)

Internal power supplies 100 - 240 VAC/24 VDC are not assembled.

The supply voltage 24 VDC connect directly into pin 4 and 5.

X3.1 – X3.4

NC

COM

NO

X3.1: alarm relay 1

X3.2: alarm relay 2

X3.3: alarm relay 3

X3.4: alarm relay 4

NC and COM are closed by: alarm, voltage breakdown, sensor

break

X4.1

A (+)

B (-)

GND

Y

Z

S4.1

RS485 Modbus S2, S3, S7 ON

TERMINATING 120R S1, S8 ON

DS 500 version with

4 channels

XA.1 – XA.4

XB.1 – XB.4

XC.1 – XC.4

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

RS485-A (+)

RS485-B (-)

SDI (CS-internal data transfer for all dew point and consumption sensors)

ANALOGUE IN + (current signal and voltage signal)

ANALOGUE IN – (current signal and voltage signal)

CURRENT SOURCE 500 µA

+VB, 24V DC sensor power supply

- VB-, GND sensor

- Support Pin for ext. use e.g. PLC/ZLT or Display

10.6 Power supply by special version 24 VDC

10.7 Connection 4 x alarm relay, max. 230 VAC, 6 A

10.8 Connection bus systems X4.1 and S4.1

10.9 Connector pin assignment for all sensors XA.1 – XA.4, XB.1 – XB.4, XC.1 – XC.4

DS 500 V1.55 Side 19 of 124

Page 20

Connection diagrams of the different sensor types

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Connector VA / FA 4xx

SDI

- VB

+ VB

+I 4…20mA

NC

Connector VA / FA 5xx

+ VB

Modbus A

- VB

Modbus B

+I 4…20mA

Connection cable

0553.0104 (5m)

0553.0105 (10m)

brown

white

blue

black

grey

1

3 2

SDI

+

-

Sensor

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

ß +4 ...20mA

DS 500

FA 300

FA 415

The digital data transmission between DS 500 and the dew point

sensors FA 415 and FA 300 occur via the SDI bus line.

.

à +4 ...20mA

3

SDI

1

2

Sensor

extern

SPS, ZLT

4 .. 20 mA

+

-

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

DS500 with ext. 4 -20mA routing

It´s possible to connect the FA 300/FA 425 alternatively as 4 – 20 mA

analogue sensor in 2-wire technology.

To route the current signal of 4 - 20 mA to an external display, PLC or

ZLT, please remove the bridge from Pin 4 (Analog IN) to support Pin

9 (ext. display) and then connect the external display according

schematic.

11 Connection diagrams of the different sensor types

By/With consumption sensors and dew point sensors from CS Instruments there is the possibility to provide

values as analogue current signal 4 – 20 mA for further working process.

The measurement/reading of the current signal for an external PLC/ZLT or external third-party display is

explained in the connection diagrams.

BY using of the CS Instruments connection cables 0553.0104 or 0553.0105 please follow pining:

The following connection diagrams in Chapter 10 apply to XA.1 to XC.4!

FA serial: dew point sensors from CS Instruments

VA serial: consumption sensors from CS Instruments

11.1 Connection CS dew point sensors, series FA 415/FA 300

DS 500 V1.55 Page 20 of 124

Page 21

Connection diagrams of the different sensor types

SDI

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

4

3

1

2

Sensor

+

-

ß +4 ...20mA

DS 500

FA 410

FA 400

VA 400

VA 420

The digital data transmission between DS 500 and the sensors FA

400/410 and VA 400/420 occurs via the SDI bus line.

à +4 ...20mA

SDI

extern

SPS, ZLT

4 .. 20 mA

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

ß +4 ...20mA

4

3

1

2

Sensor

+

-

DS500 with ext. 4 -20mA routing

To route the current signal of 4 - 20 mA to an external display, PLC

or ZLT, please remove the bridge from Pin 4 (Analog IN) to support

Pin 9 (ext. display) and then connect the external display according

schematic.

11.2 Connection for dew point- and consumption sensors, series FA/VA 4xx

DS 500 V1.55 Page 21 of 124

Page 22

Connection diagrams of the different sensor types

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

2

1

3

Sensor

+

-

Schwarz/Black

Weiss / White

Braun / Brown

Blau / Blue

4

DS500

FA 510

FA 500

VA 500

VA 520

The digital data transmission between DS 500 and the sensors

FA 500/ FA 510 and VA 500/520 occurs via RS 485 (Modbus).

à +4 ...20mA

extern

SPS, ZLT

4 .. 20 mA

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

ß +4 ...20mA

2

1

4

3

Sensor

+

-

5

Braun / Brown

Blau / Blue

Schwarz/Black

Weiss / White

Grau / Grey

DS500 with ext. 4 -20mA routing

To route the current signal of 4 - 20 mA to an external display,

PLC or ZLT, please remove the bridge from Pin 4 (Analog IN) to

support Pin 9 (ext. display) and then connect the external display

according schematic.

11.3 Connection for dew point- and consumption sensors, series FA/VA 5xx

DS 500 V1.55 Page 22 of 124

Page 23

Connection diagrams of the different sensor types

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

+

1 = 2.5V – 30V

0 = 0V – 0.7V

-

signal level 0:

low = 0 – 0,7 VDC

signal level 1:

high = 2,5 – 30 VDC

t = 400 µs

max. frequency

(duty cycle 1:1) = 1000 Hz

input resistance:

min. 100 kilo ohm

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

R

external essential

R = 4K7

Attention:

The DS 500 is counting a

consumption unit, by

switching „power on“.

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

R

external essential

R = 4K7

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

It won’t work!

11.3 Connection pulse sensors

DS 500 V1.55 Page 23 of 124

Page 24

Connection diagrams of the different sensor types

Sensors with 4 - 20 mA output in 2-wire technology

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

+

Sensor

ß 0 / 4 ...20mA

DS 500

à +4 ...20mA

+

ß 0 / 4 ...20mA

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

Sensor

extern

SPS, ZLT

4 .. 20 mA

DS500 with ext. 4 -20mA routing

To route the current signal of 4 - 20 mA to an external display, PLC,

ZLT, etc., please use support Pin 9.

Please make sure that the circuit is closed in any case.

(e.g. CS pressure sensors 1,6/16/40/100/250/400 bar or

temperature sensors with 4 - 20 mA)

11.4 Analogue two-, three-, and four-wire current signal

DS 500 V1.55 Side 24 of 124

Page 25

Connection diagrams of the different sensor types

Sensors with 4 - 20 mA output in 3-wire technology

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

+

-

Sensor

ß 0 / 4 ...20mA

DS500

à +4 ...20mA

+

-

ß 0 / 4 ...20mA

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

Sensor

extern

SPS, ZLT

4 .. 20 mA

DS500 with ext. 4 -20mA routing

To route the current signal of 4 - 20 mA to an external display, PLC,

ZLT etc. please use support Pin 9.

DS 500 V1.55 Page 25 of 124

Page 26

Connection diagrams of the different sensor types

Sensors with 4 - 20 mA output in 4-wire technology

à 0 / 4 ...20mA

ß 0 / 4 ...20mA

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

Sensor

+

-

.

DS500

à +4 ...20mA

+

-

ß 0 / 4 ...20mA

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

Sensor

extern

SPS, ZLT

4 .. 20 mA

DS500 with ext. 4 -20mA routing

To route the current signal of 4 - 20 mA to an external display, PLC,

ZLT etc. please use support Pin 9.

DS 500 V1.55 Page 26 of 124

Page 27

Connection diagrams of the different sensor

+

-

ß 0...1 / 10 / 30 Vdc

+

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

Sensor

Sensor with voltage output in 3-wire technology

+

-

ß 0...1 / 10 / 30 Vdc

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

Sensor

+

-

Sensor with voltage output in 4-wire technology

types

11.5 Three- and four-wire power supply 0 - 1/10/30 VDC

DS 500 V1.55 Side 27 of 124

Page 28

Connection diagrams of the different sensor types

Sensor

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

2-wire PT100/PT1000/KTY81

Sensor

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

3-wire PT100/PT1000/KTY81

Sensor

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

4-wire PT100/1000/KTY81

I (500µA)

12345678

+ RS485

- RS485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext.

Anzeige

+

-

RS485

Sensor

+

-

Sensor with RS485 interface

11.6 Two-, three-, and four-wire connector pin assignments for PT100/PT1000/KTY81

11.7 Connection with RS485

DS 500 Page 28 of 124

Page 29

Connect the DS 500 with a PC

Crossover-Adapter

12 Connect the DS 500 with a PC

Important:

The IP addresses of PC and DS 500 must be statically assigned (DHCP off) and have to be

in the same network.

If the IP-address of the DS 500 has changed, you have to reboot!

Remark:

IP-address of the DS 500: See chapter, 13.5.3 Network settings

Reboot the DS 500: See chapter, 13.5.8 Factory Reset

The DS 500 can be connected with the PC by a crossover cable, which has a RJ45 plug on each side,

or an Ethernet cable with a crossover adapter.

After connecting the DS 500 via a suitable cable to the PC, you can make graphical and tabular data

evaluations with the CS Soft Basic software.

Windows PC’s, network settings:

Windows 7:

Start Control Panel Network and Sharing Center adapter Networking Properties

Internet Protocol Version 4 (TCP/IPv4) Use the Following IP address enter IP address and

Subnet mask

After this: OK OK Close

Windows Vista:

Start Control Panel Network and Sharing Center

Network connection Networking Properties Internet Protocol Version 4 (TCP/IPv4) Use the

Following IP address enter IP address and Subnet mask

After this: OK OK Close

Windows XP:

Start Properties Control Panel Network connection Networking Properties Internet

Protocol Version 4 (TCP/IPv4) Use the Following IP address enter IP address and Subnet mask

After this: OK OK Close

Crossover cable with RJ45-plug

DS 500 V1.55 Side 29 of 124

Page 30

Operation DS 500/Main menu (Home)

After switching on the DS 500 all channels

are initialized and the main menu will appear.

Attention:

For the first initiation, there may be no

channels preset!

13 Operation DS 500

The operation is largely self-explanatory and menu-driven via the touch panel.

The selection of the respective menu items occur via short "tapping" with the finger or a soft round pen.

Attention: Please use no pens or other objects with sharp edges!

The foil can be damaged!

After sensors are connected, they also have to be configured.

Inputs or changes can be made with all white deposit fields.

The measured values can be represented as a curve or values.

Words in green font refer mainly to the pictures in the section of the chapter, but also on important menu

paths or menu items that are related to are in green font.

The menu navigation is generally in a green font!

The table of contents and chapter references in blue font contain links to the respective chapter title.

13.1 Main menu (Home)

From the main menu, you can reach every available item.

13.1.1 Initialization

Please see chapter 13.3.2 Sensor settings, then select appropriate configurations and set!

DS 500 V1.55 Side 30 of 124

Page 31

Main menu (Home)

hardware and

software version

alarm display

status

data logger

interval data logger and

remaining memory capacity

date & time

status

Report

13.1.2 Main menu after initialization

Important:

Before the first sensor setting is made, the language and time should be set!

Remark:

Chapter 13.5.1 Set language

(Main menu Settings Device Settings Set Language)

Chapter 13.5.2 Date & Time

(Main menu Settings Device Settings Date & Time)

13.2 Shutdown

Important: In case the DS500 has to be set into a strainless state,

it needs a defined termination / storage of the recorded data by a

proper shutdown

Main menu Shutdown

This process must always be confirmed by entering the password.

DS 500 V1.55 Side 31 of 124

Page 32

Settings/Password settings

If an incorrect password is entered, there

appears Enter password or New password repeat

in red font.

If you cannot remember the password, please

use Master password in order to enter a new

password.

Remark:

The master password is supplied together with

the instrument’s documentation.

Factory settings for password at the time of

delivery: 0000 (4 times zero).

If required, the password can be changed in the

Password settings.

The new password must be entered two times in

a row and in each case confirmed with OK.

Overview of the Settings

13.3 Settings

The settings are all protected by a password!

Settings or changes are generally confirmed with OK!

Remark:

If you go back to main menu and then again one of the setting menus is called, you must enter the

password again.

Main menu Settings

The optional Report settings and the appendant Cost settings, you will find in chapter 13.6 Report settings (optional)

and 13.15.2 Cost Settings (optional). The out of it resultant summary table, you can see in the Consumption report

in chapter 13.15.1 Consumption report (optional).

13.3.1 Password settings

Main menu Settings Password settings

DS 500 V1.55 Side 32 of 124

Page 33

Sensor settings/Choice of the sensor type

An overview of the available channels appears

after entering the password.

Depending on the version, 4, 8 or 12 channels.

Remark:

Usually no channels preset!

If still no sensor has been configured, the

Type No Sensor appears.

By pushing the description field Type No

Sensor the list of sensor types appears (see

next step).

13.3.2 Sensor settings

Important:

Sensors from CS Instruments are generally pre-configured and can be connected directly to a

free sensor channel!

Main menu Settings Sensor settings

Remark:

Depending on the DS 500: No extension board 4 channels/setups

One extension board 8 channels/setups

Two extension boards 12 channels/setups

13.3.2.1 Choice of the sensor type (For example type CS-Digital sensor)

Main menu Settings Sensor settings A1

DS 500 V1.55 Side 33 of 124

Page 34

Choice of the sensor type (e.g. type CS-Digital sensor)

Now the Type CS-Digital is selected for the

VA/FA 400 series.

Important:

The inner diameter of flow tube can be

entered here, if this was not automatically

correctly set.

Main menu Settings Sensor settings A1 Type description field CS-Digital

Main menu Settings Sensor settings A1 diameter description field

Important:

The inner diameter should be entered as precisely as possible, because otherwise the measurement

results are not correct!

There is no uniform standard for the tube inner diameter!

(Please, inquire at the manufacturer or measure by your own !)

DS 500 V1.55 Side 34 of 124

Page 35

Choice of the sensor type (e.g. type CS-Digital sensor)

After label and confirm with OK.

Now you can enter a Name and the counter

status of the old sensor, if the sensor was

changed.

This completes the configuration of the

sensor.

Main menu Settings Sensor settings A1

.

Remark:

After confirm with OK, the font is black again and the values and settings are accepted.

Attention:

Reference temperature and reference pressure (factory setting 20 °C, 1000 hPa):

All volume flow values (m³/h) and consumption values indicated in the display are

related to 20 °C, 1000 hPa (according to ISO 1217 intake condition)

0 °C and 1013 hPa (= standard cubic meter) can also be entered as a reference.

Do not enter the operation pressure or the operation temperature under reference

conditions!

DS 500 V1.55 Side 35 of 124

Page 36

Name and recording of measurement data

For the recorded Value there can be entered a

Name with 10 characters and later in menu

item Graphics/Real time values it is easier to

identify it.

Otherwise the Name is, for example, A1a.

The channel name is A1 and a is the first

measurement data at the channel,

the Second b and the Third c.

The Resolution of the decimal places is simply

adjustable by pushing right and left

(0 to 5 decimal places).

In the case of text description field, a menu

opens with the corresponding selection

a.) For name fields, a keyboard as you

can see left side.

b.) For value fields a keypad as you can

see left

c.) In case of a selection field a

corresponding menu with possible

entries will be displayed. See therefore

chapter Sensor settings.

For the sensor name it is possible to enter a

name with up to 24 characters.

For values names are max. 10 characters and

for the short name max. 3 characters possible.

13.3.2.2 Label and setting the description fields

Main menu Settings Sensor settings A1 Text filed Name

13.3.2.3 Name the measurement data and define the decimal places

Remark:

The Resolution of the decimal places, the Short Name and Value Name are found under the Tool

button!

Tool button:

Main menu Settings Sensor settings A1 Tool Button

See also chapter 13.3.2.2 Label and setting the description fields

Important:

In the menu items Main Settings Sensor settings and Main Real time values, the

Value Name displayed only by the DS 500 standard version with 4 channels!

The Short Name is used only in these two menu items, by the DS 500 versions with one or two

extension boards (8 or 12 channels).

DS 500 V1.55 Side 36 of 124

Page 37

Name and recording of measurement data)

.

Use the Record buttons to select the

measurement data that will be stored by

activated data logger.

13.3.2.4 Recording measurement data

Main menu Settings Sensor settings A1 Record Button

Attention:

Before the selected measurement data are recorded, the data logger must be activated after the

settings(See chapter 12.4 Logger settings (data logger)).

DS 500 V1.55 Side 37 of 124

Page 38

Alarm settings

In the alarm settings, an Alarm 1 and

Alarm 2 incl. Hysteresis can be entered for

each channel.

In the menu Alarm overview (can be reached

from the main menu), the alarm settings are

clearly represented.

E.g. set the Alarm 1 to relay 2 and relay 4

and the Alarm 2 to relay 1 and relay 3.

It is possible to select from 5 different delays.

T0 is preset to no delay.

The delays (T1 to T4) are free definable but are

common valid for all relays.

13.3.2.5 Alarm settings

Main menu Settings Sensor settings A1 Alarm Button

By pushing an alarm button, the following window appears:

Main menu Settings Sensor settings A1 Alarm Button Alarm 1 and 2 Buttons Relay

Buttons

Remark: It can be set one of any relay as Alarm 1 or Alarm 2 thirty-two times.

Main menu Settings Sensor settings A1 Alarm-Button Relay-buttons

DS 500 V1.55 Side 38 of 124

Page 39

Alarm Settings

After the alarm activation at channel A1.

The delays (T1 to T4) are free definable but are

common valid for all relays.

By changing the text field values the new delay

time could be defined. Here for Delay T1.

Delay T0 is preset and cannot be changed and it

is an immediate alarm.

Confirmation by pressing the OK button.

Same procedure for the remaining delay times

T2-T4 is to apply.

Main menu Settings Sensor settings A1 Alarm-Button Setup Delay

Main menu Settings Sensor settings A1 Alarm-Button description field Delay T1

Main menu Settings Sensor settings A1

The settings finished by pushing the OK button!

DS 500 V1.55 Side 39 of 124

Page 40

Settings Dewpoint sensor type CS-Digital

The DS 500 detects, if the connected sensor

is a flow or dew point sensor of CS

Instruments and set the CS-Digital subtype

automatically correct.

Now the Type CS-Digital is selected for the

VA/FA 400 series and confirmed by pressing

the OK button.

It is possible to enter a name with 24

characters.

13.3.3 Dew point sensor with type CS-Digital (SDI Bus)

First step: choose an unused sensor channel

Main menu Settings Sensor settings B1

Second step: choose type CS-Digital

Main menu Settings Sensor settings B1 Type description field CS-Digital

Now, a Name (See chapter 13.3.2.3 Label and setting the description fields), the alarm settings (See

chapter 13.3.2.5 Alarm settings) and recording settings (See chapter 13.3.2.4 Recording

measurement data), and the Resolution of the decimal places (See chapter 13.3.2.3 Name

measurement data and define the decimal places) can be determined.

Third step: confirm with OK two times

DS 500 V1.55 Side 40 of 124

Page 41

Settings Flow sensor type CS-Digital

The DS 500 detects, if the connected sensor

is a flow or dew point sensor of CS

Instruments and set the CS-Digital subtype

automatically correct.

Now the Type CS-Digital is selected for the

VA/FA 400 series and confirmed by pressing

the OK button.

It is possible to enter a name with 24

characters.

13.3.4 Flow sensor VA 400 / VA 420 of type CS-Digital (SDI Bus)

First step: choose an unused sensor channel

Main menu Settings Sensor settings B1

Second step: choose type CS-Digital

Main menu Settings Sensor settings B1 Type description field CS-Digital

Now, a Name (See chapter 13.3.2.3 Label and setting the description fields), the alarm settings (See

chapter 13.3.2.5 Alarm settings) and recording settings (See chapter 13.3.2.4 Recording

measurement data), and the Resolution of the decimal places (See chapter 13.3.2.3 Name

measurement data and define the decimal places) can be determined.

Third step: confirm with OK two times

DS 500 V1.55 Side 41 of 124

Page 42

Settings Flow sensor type CS-Digital

In More-Settings, you can define whether the

4 - 20 mA analogue output of the sensor

based on the flow rate or velocity.

The green highlighted description field is

selected!

In addition, you can push the scale manual

button and set the measuring range.

After confirming with OK, the settings are

assumed.

Remark:

More-Settings only for type CS-Digital

available!

13.3.4.1 More-Settings (scale analogue output)

Main menu Settings Sensor settings A1 More-Settings

By pressing the OK button the settings are ready!

DS 500 V1.55 Side 42 of 124

Page 43

Settings Flow sensor type CS-Digital

If the data logger is activated, the following

window will appear and via pushing Yes it can

be disabled.

(Only activated, if already settings and recordings

are made)

Remark:

If sensor settings are defined or changed, the

data logger must be stopped.

Changes or entries can be made by

pressing the highlighted white fields.

Important:

The inner diameter of flow tube can be

entered here, if this was not automatically

correctly set.

Inner diameter is entered here for example

27.5 mm.

Main menu Settings Sensor settings A1

Main menu Settings Sensor settings A1 description field of numerical value

Important:

The inner diameter should be entered as precisely as possible, because otherwise the

measurement results are not correct!

There is no uniform standard for the tube inner diameter!

(Please, inquire at the manufacturer or measure by your own!)

DS 500 V1.55 Side 43 of 124

Page 44

Settings Flow sensor type CS-Digital

A preset selection of suitable Gas Constants.

The red labeled description fields indicates

that different values, such as the Diameter

and the Name, have been changed or

added.

The three parameters of flow, consumption

and velocity will be recorded (green hook)

after the data logger has been activated.

Main menu Settings Sensor settings A1 Gas Constant description field

In the same way as here in chapter 13.3.2.2 Label and set the description fields described,

the remaining description fields can be labelled.

Main menu Settings Sensor settings A1

See also chapter 13.3.2.1 Choice of the sensor types (For example type CS-Digital sensor)

Remark:

After confirming with OK, the font is black again and the values and settings are accepted.

Attention:

Reference temperature and reference pressure (factory setting 20 °C, 1000 hPa):

All volume flow values (m³/h) and consumption values indicated in the display are

related to 20 °C, 1000 hPa (according to ISO 1217 intake condition)

0 °C and 1013 hPa (= standard cubic meter) can also be entered as a reference.

Do not enter the operation pressure or the operation temperature under reference

conditions!

DS 500 V1.55 Side 44 of 124

Page 45

Settings Dew point sensor type FA 5xx

Now the Type FA 5xx is selected for the FA

5xx series and confirmed by pressing the OK

button.

For input of a name, please enter the text field

„Name“.

It is possible to set a name with max. 24

characters.

Confirmation by pressing the OK-button.

13.3.5 Dew Point Sensor of type FA 5xx (RS 485 Modbus)

First step: choose an unused sensor digital channel

Main menu Settings Sensor settings A1

Second step: choose type FA 5xx (inserted Digitalboard for A1/A2)

Main menu Settings Sensor settings A1 Type description field FA 5xx

Now, a Name (See chapter 13.3.2.3 Label and setting the description fields), the alarm settings (See

chapter 13.3.2.5 Alarm settings) and recording settings (See chapter 13.3.2.4 Recording

measurement data), and the Resolution of the decimal places (See chapter 13.3.2.3 Name

measurement data and define the decimal places) can be determined.

Main menu Settings Sensor settings A1 Name description field

DS 500 V1.55 Side 45 of 124

Page 46

Settings Dew point sensor type FA 5xx

The definition of the fixed value system pressure

value is done by activating the button "fixed", but

this is only required in case a ext. pressure

probe is connected.

The value is entered in the corresponding text

field. The unit can be freely selected, selection

menu is opened by pressing the corresponding

unit-button.

Confirm the settings by pressing the OK button.

Unit selection for temperature and humidity by

pressing the button °C, °F, g/m³ or mg/m³.

Confirm the settings by pressing the OK button.

13.3.5.1 Settings Dew point sensor FA 500 FA 510

13.3.5.1.1 Unit selection for temperature and humidity

Main menu Settings Sensor settings A1

13.3.5.1.2 Definition of the System pressure (relative pressure value)

Actual there are 2 possibilities to define system pressure (input as relative pressure value)

System pressure as a fixed value

System pressure taken over from an external pressure sensor

Main menu Settings Sensor settings A1Pressure Setting Fixed

DS 500 V1.55 Side 46 of 124

Page 47

Settings Dew point sensor type FA 5xx

Back

By using an ext. pressure sensor, which is

detected automatically e.g. here at input B1,

the button Sensor has to be activated.

With activation of the text field „Sys Pressure“

the corresponding channel with the required

measuring value could be selected

Only values with pressure units can be

selected.

Confirm the settings by pressing the OK button.

Reference pressure is the pressure for that the

dew point in relaxation will be back-calculated.

Default- Value is 1013 mbar (Atm. Pressure).

Confirm the settings by pressing the OK button.

Main menu Settings Sensor settings A1 Pressure Setting Sensor

13.3.5.1.3 Definition of Reference pressure (absolute pressure value)

Main menu Settings Sensor settings A1 arrow right (2.page)Pressure Setting Textfield

Ref.Pressure

DS 500 V1.55 Side 47 of 124

Page 48

Settings Dew point sensor type FA 5xx

3.33

23.313

25.85

5.6314

-55.927

55.055.927

55.927

-55.00

°Ctd

%

°C

g/m³

3.33

23.313

25.85

5.6314

Here, a one-point calibration can be performed.

For that purpose, please enter in the text box

"Reference Value" the new correct dew point

value.

Then by pressing the "Calibration" button taking

over the inserted reference value.

Calibration can be put back to factory setting by

pressing „Reset“.

For each performed calibration, the counter is

increased by 1.

This menu allows the adjustment / assignment of the

measurement value and the scaling of the analogue

output.

Selection of the measurement value by selecting the

appropriate measured value key in this example, “DP ° C"

for dew point ° Ctd.

In text fields "4mA" and "20mA" the appropriate scaling

values are entered, here from -80 ° Ctd (4mA) to -20 ° Ctd

(20mA).

With "Error Val" is determined what is output in case of

error at the analog output.

<3.6 Sensor error / System error

22 Sensor error / System error

4..20 Output according Namur (3.8mA – 20.5 mA)

< 4mA to 3.8 mA Measuring range under range

>20mA to 20.5 mA Measuring range exceeding

Confirm the settings by pressing the OK button.

13.3.5.1.4 Calibration

Main menu Settings Sensor settings A1 Calibration

13.3.5.1.5 More Settings Analogue output 4-20mA

Main menu Settings Sensor settings A1 More-Settings 4-20mA

DS 500 V1.55 Side 48 of 124

Page 49

Settings Flow sensor type VA 5xx

m³/h

m³

m/s

°C

0.00

4589

0.00

25,70

Now the Type VA 5xx is selected for the VA

5xx series and confirmed by pressing the OK

button.

Input of a name, please enter the text field

„Name“.

It is possible to enter a name with max. 24

characters.

Confirmation by pressing the OK-button.

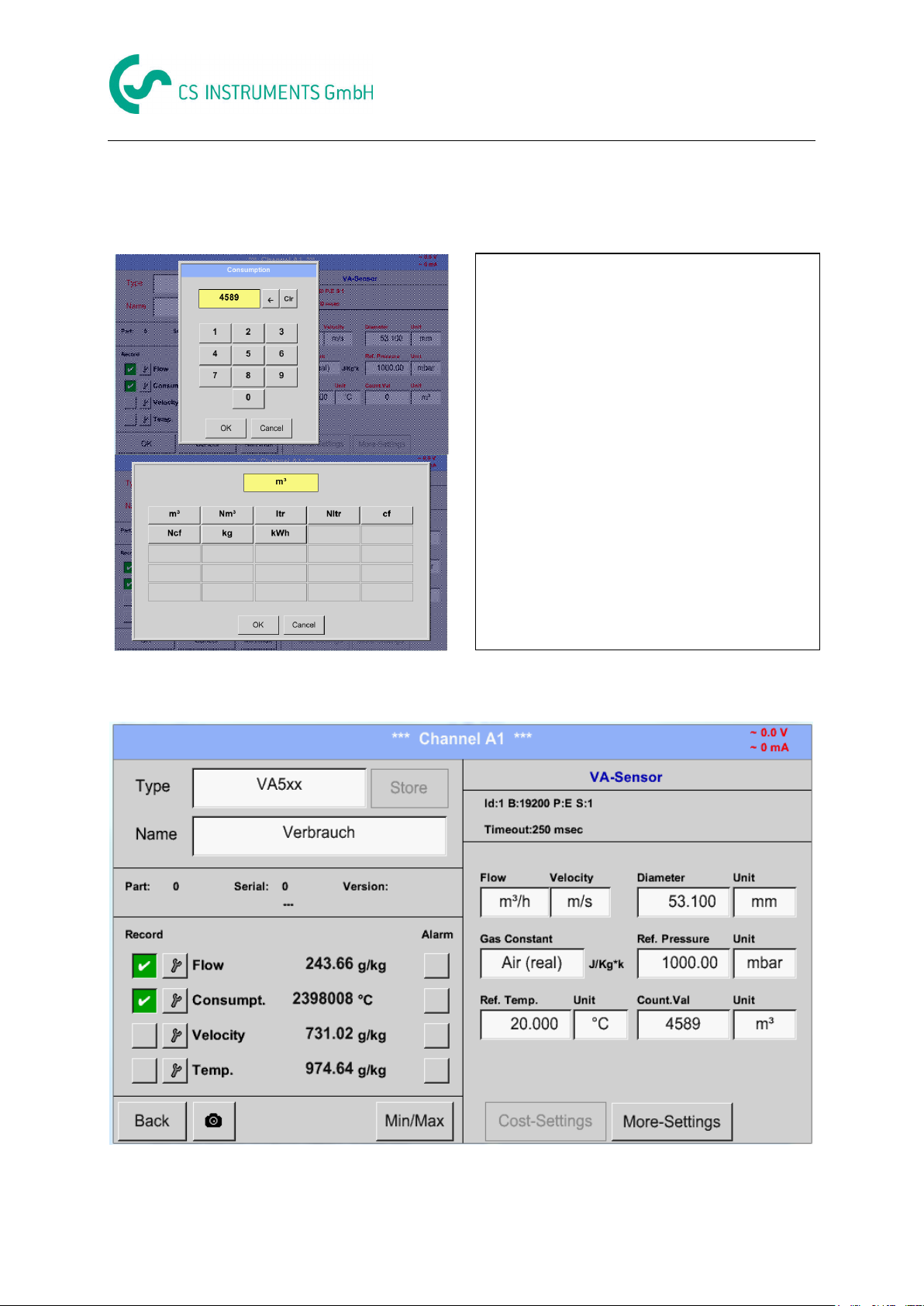

13.3.6 Flow sensor of type VA 5xx (RS 485 Modbus)

First step: choose an unused sensor digital channel

Main menu Settings Sensor settings A1

Second step: choose type VA 5xx

Main menu Settings Sensor settings A1 Type description field VA 5xx

Now, a Name (See chapter 13.3.2.3 Label and setting the description fields), the alarm settings (See chapter 13.3.2.5 Alarm

settings) and recording settings (See chapter 13.3.2.4 Recording measurement data), and the Resolution of the

decimal places (See chapter 133.2.3 Name measurement data and define the decimal places) can be determined.

Main menu Settings Sensor settings A1 Name description field

DS 500 V1.55 Side 49 of 124

Page 50

Settings Flow sensor type VA 5xx

m³/h

m³

m/s

°C

0.00

4589

0.00

25,70

For each text field could be the either a value

or a unit be set.

Settings by entering the text field and then

input a value or select the unit for the

appropriate field.

In case of VA 520 and VA 570 with integrated

measuring section the diameter and diameter

unit field are not access able.

Please confirm all changes /inputs by pressing

the OK button

Important:

The inner diameter of flow tube can be

entered here, if this was not automatically

correctly set.

In

Please confirm by pressing the OK button.

13.3.6.1 Settings for Flow sensor VA 5xx

Main menu Settings Sensor settings A1

13.3.6.1.1 Diameter settings

Main menu Settings Sensor settings A1 diameter description field

Important:

The inner diameter should be entered as precisely as possible, because otherwise the

measurement results are not correct!

There is no uniform standard for the tube inner diameter!

(Please, inquire at the manufacturer or measure by your own !)

Main menu Settings Sensor settings A1 diameter unit description field

DS 500 V1.55 Side 50 of 124

Page 51

Settings Flow sensor type VA 5xx

All gases marked in blue and with (real) have

been a real gas calibration curve stored in the

sensor.

Select the gas you require and confirm

selection by pressing OK button.

13.3.6.1.2 Gas Constant settings

Main menu Settings Sensor settings A1 Gas Constant description field

Attention:

Reference temperature and reference pressure (factory setting 20 °C, 1000 hPa):

All volume flow values (m³/h) and consumption values indicated in the display are

related to 20 °C, 1000 hPa (according to ISO 1217 intake condition)

0 °C and 1013 hPa (= standard cubic meter) can also be entered as a reference.

Do not enter the operation pressure or the operation temperature under reference

conditions!

DS 500 V1.55 Side 51 of 124

Page 52

Settings Flow sensor type VA 5xx

13.3.6.1.3 Definition of the reference conditions

Here, the desired measured media reference conditions for pressure and temperature can be defined

Main menu Settings Sensor settings A1 Ref. Pressure description field

Main menu Settings Sensor settings A1 Ref. Pressure Unit description field

Main menu Settings Sensor settings A1 Ref. Temp. description Field

Main menu Settings Sensor settings A1 Ref. Temp. Unit description Field

13.3.6.1.4 Definition Unit of flow and velocity

Main menu Settings Sensor settings A1 Flow description Field

Main menu Settings Sensor settings A1 Velocity description Field

DS 500 V1.55 Side 52 of 124

Page 53

Settings Flow sensor type VA 5xx

The sensor allows taking over a starting

counter value. Inserting the value by entering

the ”Count. Val.” text field.

In the Count. Val. Unit field different units

could be used. Selection by activation of the

“Count. Val. Unit” text field

In case the counter value unit will be changed

only the consumption counter value will be

recalculated to the appropriate unit.

Selection to confirm selection by pressing OK

button.

Important!

When the counter reach 100000000 m³ the

counter will be reset to zero.

13.3.6.1.5 Definition consumption counter value and consumption unit

Main menu Settings Sensor settings A1 Count Val. description Field

Main menu Settings Sensor settings A1 Count Val. Unit description Field

Remark:

After confirmation with OK, the font is black again and the values and settings are accepted

DS 500 V1.55 Side 53 of 124

Page 54

Settings Flow sensor type VA 5xx

This menu allows the adjustment / assignment of the

measurement value and the scaling of the analogue output

by pressing the”4-20mA Ch1” button.

Selection of the analogue output measurement value by

activating the appropriate measured value key in this

example, “Flow".

Possible outputs are flow, velocity and temperature.

In case of no use, please select “Off”.

The analogue output scaling have to possibilities,

automatic scaling (default) and a manual scaling by the

user. Auto scaling is based on the calibration settings,

means 4mA is set to zero and the 20mA value is based on

the max. settings here 900m³/h

A “manual scaling” needs an activation of the “scale

manual” button.

In text fields "4mA" and "20mA" the appropriate scaling

values are entered, here from zero m³h (4mA) to 300 m³/h

(20mA).

With "Error Val" it is determined what is the output in case

of an error at the analogue output.

2 mA Sensor error / System error

22 mA Sensor error / System error

4..20 Output according Namur (3.8mA – 20.5 mA)

< 4mA to 3.8 mA Measuring range under range

>20mA to 20.5 mA Measuring range exceeding

Inputs / changes to be confirmed with “OK” button. Return

to main menu with “Back”.

13.3.6.2 Settings analogue output 4-20mA of VA 5xx

Main menu Settings Sensor settings More-Settings 4-20mA Ch1

DS 500 V1.55 Side 54 of 124

Page 55

Settings Flow sensor type VA 5xx

The pulse output of the VA 5xx could be set

functionally as pulse output or alarm output.

Function to activate by pressing either the

“Pulse” or “Alarm” button.

In case of no use, please select “none”.

Inputs / changes to be confirmed with “OK”

button. Return to main menu with “Back”.

To set up the pulse first the unit and the

measurement value have to be defined.

Unit selection by pressing “unit” button and

choice one of the possible units “kg”, “cf”, “ltr”

or “m³”).

Pulse weight setting by entering the text field

“Value”.

Here with defined 1 pulse per m³ and with

positive polarity.

With „Polarity“ the switching state could be

defined.

Pos. = 0à 1 neg. 1à 0

pos

neg

open

closed

Inputs / changes to be confirmed with “OK”

In case of use the pulse output as alarm

following definitions needs to be set:

Unit selection by pressing “unit” button and

choice one of the possible units “cfm”, “ltr/s”,

“m³/h”, “m/s” ”, “°F ”, “°C” ”, “kg/s” or ”,

“kg/min”).

Alarm value setting by entering the text fields

“Value”.

The limits „High“ or „Low“ defines when the

alarm is activated, selecting by pressing the

appropriate button

High: Value over limit

Low: Value under limit

Inputs / changes to be confirmed with “OK”

button. Return to main menu with “Back”.

13.3.6.3 Settings Pulse / Alarm output of VA 5xx

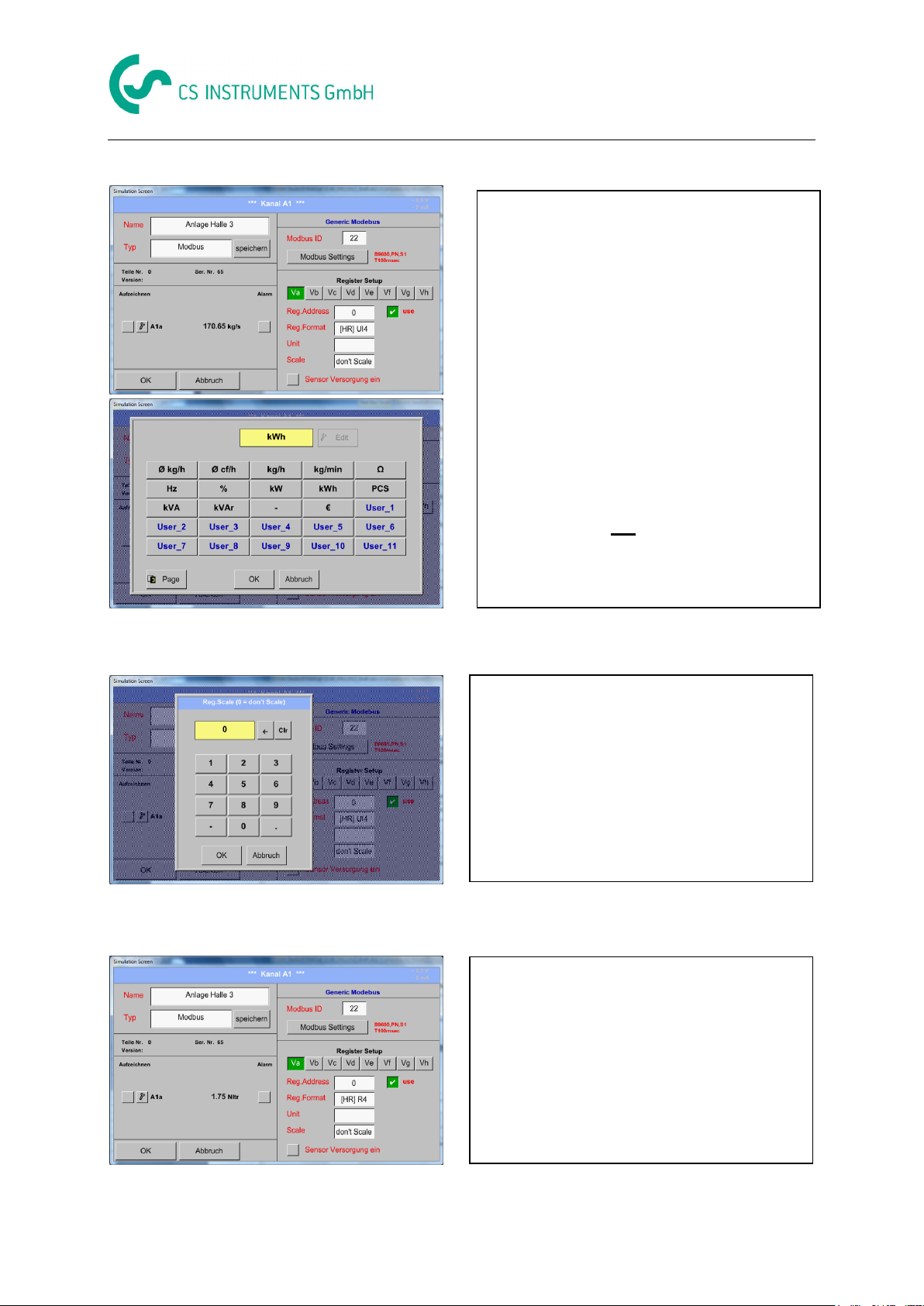

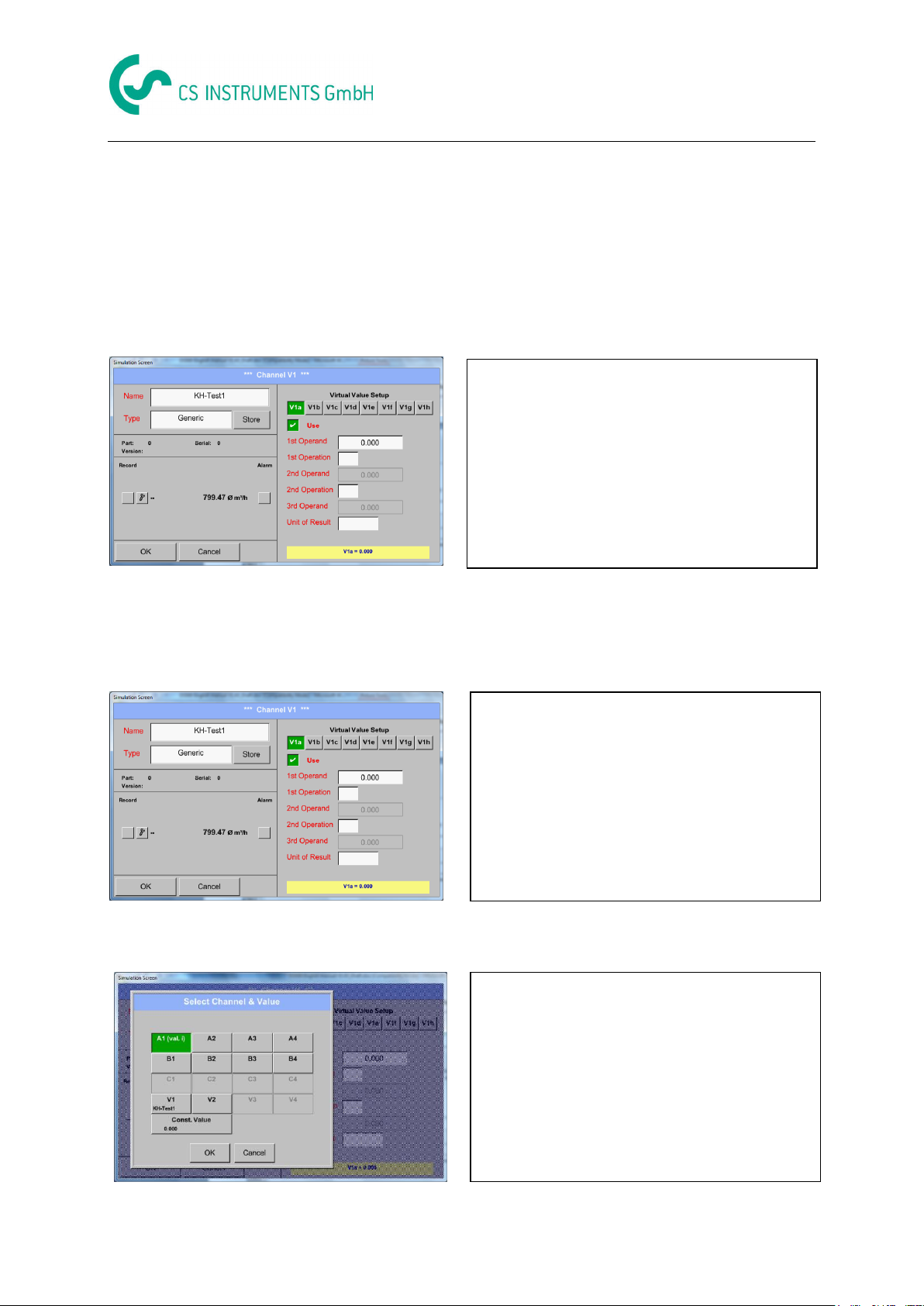

Main menu Settings Sensor settings More-Settings Pulse / Alarm