Page 1

INSTRUCTION MANUAL

CXL2 LOCATOR

DXL2 LOCATOR

MXL2 LOCATOR

SGA2 SIGNAL GENERATOR

SGV2 SIGNAL GENERATOR

MXT2 TRANSMITTER

Page 2

WARNINGS

ALWAYS

EXCAVATE

WITH CARE

C.Scope Locators detect services radiating a detectable signal.

There may be some services that do not radiate and cannot be located.

Do not use the equipment outside of the temperature range -10˚C to +50˚C

as the batteries may cease to function adequately.

Geographical conditions such as hills and mountains may effectively screen signals

and prevent a detectable Radio signal.

C.Scope Locators alone will not always locate every service.

Use a Generator or Transmitter wherever possible.

Do not touch the metal of the C.Scope Generator/ Transmitter Crocodile Clips or

of the Plastic Pipe Tracer terminals when in use.

The C.Scope Generator/ Transmitter leads MUST NOT be connected directly to

a live service.

Beware of multiple services. C.Scope Locators will not always indicate services

that are close together or one above the other.

Do not use the equipment in areas where hazardous gases may be present.

Check for underground services before using the Earth Stake.

Always make sure that the Locator and Generator/ Transmitter are set to the same

frequency when used together.

Performance may be impaired by unusually strong electromagnetic fields.

Do not hold the Locator earpiece close to the ear for extended periods.

It is recommended that the operation of the Locator and Generator/ Transmitter is regularly checked (see pages 52-55).

2

Page 3

Contents

Warnings 2

Features

CXL2, DXL2 and MXL2 4-5

SGA2, SGV2 and MXT2 6-7-8-9

Locator Operating Modes

Power 10

Radio 11

All

Scan 12-13

Generator/ Transmitter 14

Using the Locator

Batteries

Alkaline and Rechargeable 15

Automatic Daily Self Test 16-17

Holding the Locator 18

Searching 19

Pinpointing 20

Tracing 21

Using the Generator/ Transmitter

Output Power 22

Frequency 23

Batteries

Alkaline and Rechargeable 24

Direct Connection 25-26

Street Lighting/ Furniture 27-28

Signal Clamp/ Injector 29

Searching 30

Tracing 31

Induction 32

Searching 33-34

Multiple Services 35

Inductive Sweep 36

Pipe Tracing using a Sonde 37

Sonde Batteries 38-39

Tracing 40-41

Plastic Pipe Tracer 42-43

Depth Measurement

Line 44-45

Sonde/ Plastic Pipe Tracer 46

Signal Current Measurement 47-50

Data Logging 51

Function checks

Locators 52-53

Generator/ Transmitter 54

Depth 55

Maintenance/ General symbols 56

Specifications

Locators 57

Generators/ Transmitter 58

Support Services 59

3

Page 4

CXL2 DXL2 MXL2 Locator Features

The C.Scope CXL2, DXL2 and MXL2 Locators are Pipe and Cable Locators that

can provide precise information about the position and depth (DXL2 and MXL2 only)

of buried services. The combination of locating modes ensures buried services

are detected quickly and reliably.

AUTOMATIC DAILY SELF TEST

The CXL2, DXL2 and MXL2 Locators have an automatic

daily self test feature which is activated the first time that

the Locator is switched on each day. The display indicates

‘ ’ and a test countdown when performing the test.

(See pages 16-17 for more details).

DATA LOGGING

A data logging feature allows a record to be kept of all

Locator activity for analysis on a PC. The Bluetooth™

version also allows live map location and other functions.

(See page 51 for more details).

4

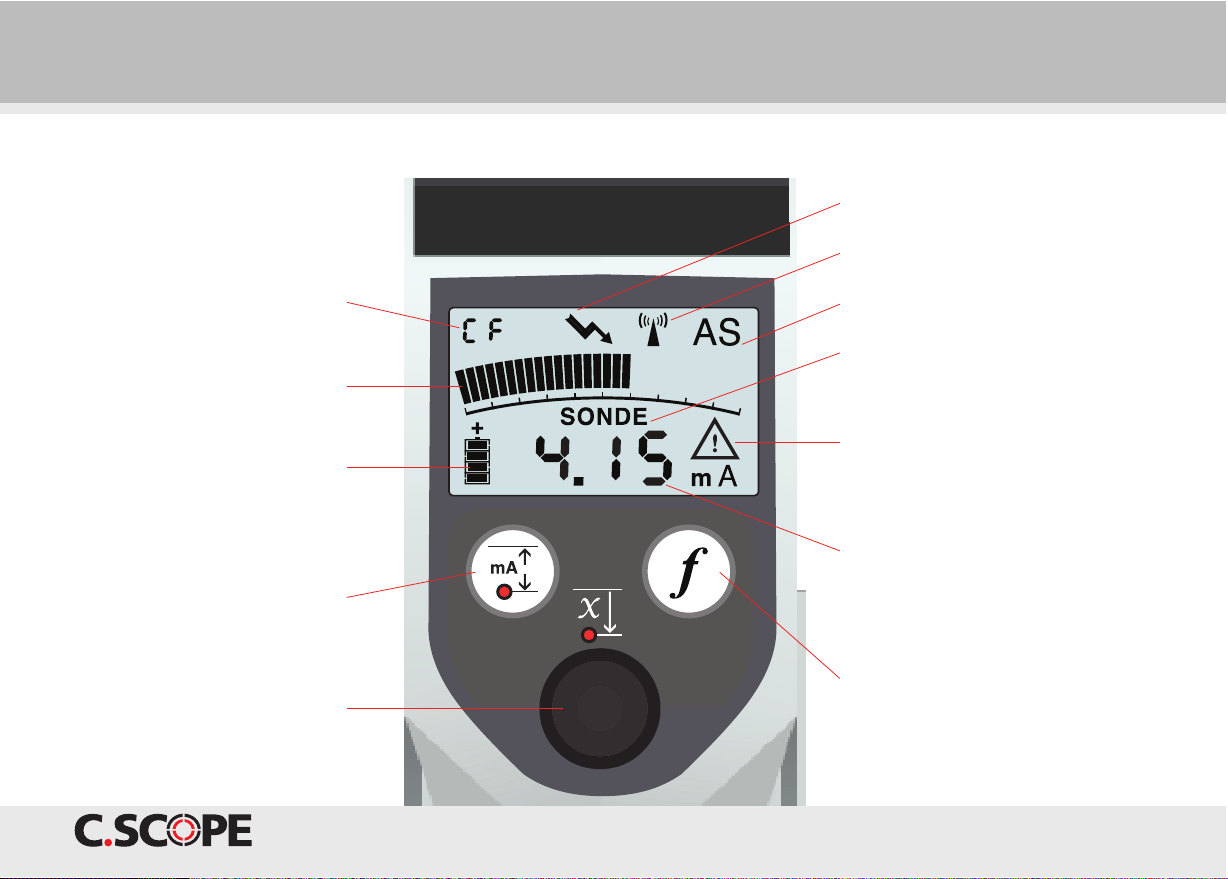

Digital Display

with automatic backlight

Detachable Loudspeaker

On/ Off Switch

Sensitivity Control

4 Position Mode Switch

P: Power

R: Radio

G/T: Generator/ Transmitter

A: All Scan

Battery Compartment and

Data Access Connection

Replaceable Wear Foot

Page 5

CXL2 DXL2 and MXL2 Locator Features

Generator/ Transmitter

Mode Indicator

Signal Strength Bar Graph

Battery Condition Indicator

Signal Current Button

(MXL2 only)

Power Mode Indicator

Radio Mode Indicator

All Scan Mode Indicator

Sonde Depth Mode Indicator

(DXL2 and MXL2 only)

Self Test Indicator

Depth (DXL2 and MXL2 only)

or Signal Current Measurement

(MXL2 only)

Depth Measurement Button

(DXL2 and MXL2 only)

Frequency Button (MXL2 only)

5

Page 6

SGA2/SGV2 Signal Generator and MXT2 Transmitter Features

The C.Scope SGA2 and SGV2 Signal Generators are an

ideal accompaniment to the CXL2 and DXL2 Locators.

The SGA2 has the facility of high and low output power and

can operate with a pulsed or continuous output signal.

The SGV2 additionally has a display showing the battery

condition and power output indication. The SGV2 has four

levels of output power that can be selected by the user.

Direct Connection Socket

Auxiliary 10m Earth Lead

Crocodile Clips

Connection Magnets

Auxiliary Earth Lead Socket

The C.Scope MXT2 Transmitter is an ideal accompaniment

to the MXL2 Locator.

The range of operating frequencies and adjustable

power output is designed to make the MXL2 and MXT2

combination an extremely versatile Pipe and Cable Locator

that is able to tackle many varied locating tasks.

Batteries

Accessory Tray

Accessory Tray Holding Clips

Earth Stake

6

Page 7

SGA2 Signal Generator Features

Output Power

Increase Control

Output Power

Decrease Control

Pulsed/ Continuous

Output Control

On/ Off

Control

Loud/ Mute

Control

7

Page 8

SGV2 Signal Generator Features

Output Frequency Indicator

Signal Strength

Indicator

Battery Condition

Indicator

Loud/ Mute Setting

Indicator

On/ Off Control

Output Power

Decrease Control

Connected Mode Indicator

Induced Mode Indicator

Output Power Level

Indicator

Loud/ Mute

Control

Pulsed/ Continuous

Output Control

Output Power

Increase Control

8

Page 9

MXT2 Transmitter Features

Output Frequency Indicator

Signal Strength

Indicator

Battery Condition

Indicator

Loud/ Mute Setting

Indicator

On/ Off Control

Output Power

Level Control

Connected Mode Indicator

Induced Mode Indicator

Output Power Level

Indicator

Loud/ Mute

Control

Pulsed/ Continuous

Output Control

Frequency Control

9

Page 10

Locator Operating Modes: Power Mode

In Power Mode the Locator detects power signals.

These power signals are present on all current carrying

electricity cables although not all are detectable. Power

signals may also flow along other conductors such as

metal gas and water pipes, telecom cables, metal fences

and railway tracks.

WARNING Locators can only detect services radiating a detectable electromagnetic signal.

There may be some services that do not radiate these signals and cannot be located.

WARNING Absence of a power signal does not mean the service is not live.

Limitations of Power Mode

Not all electricity cables can be found using the Power

Mode. Here are the most important examples of

electricity cables that may not be detectable in the

Power Mode:

Street lighting cables. When the lights are off, no

current flows and so no power signal is created.

Supplies to buildings or plant using very little or no

electricity may not have a detectable power signal.

Pot-ended or capped cables. These will never have any

current flowing through them but are possibly still live.

Disused or abandoned cables.

A few high voltage electricity cables. These can be

‘well balanced’, electrically and therefore radiate little

or no power signal.

Direct Current cables (such as those found on some

railway systems). These do not create their own

power signals.

Cables more than 3 metres deep.

10

NOTE Generally these services should be detectable using the Radio or Generator/ Transmitter Modes.

Page 11

Locator Operating Modes: Radio Mode

In Radio Mode, the Locator detects signals from various

radio transmitters. These signals flow through the

ground and will tend to follow the line of least resistance

such as a buried metallic service. When this happens

the service can often be detected by using the Locator

in Radio Mode.

WARNING Locators can only detect services radiating a detectable electromagnetic signal.

There may be some services that do not radiate these signals and cannot be located.

Limitations of Radio Mode

Not all services will be detectable in Radio Mode.

A strong radio signal present on one service may

be masking a weaker radio signal present on an

adjacent service.

It is not normally possible to determine what the

service is in Radio Mode, only it’s position.

Radio signals do not favour one utility over another.

The depth of the buried service CANNOT be judged

by the strength of the radio signal alone.

Normally it is only possible to detect radio signals

present on services up to 2 metres deep.

A short service may not have enough signal to

be detected.

NOTE Most buried metallic services not found in Radio Mode should be detectable by using Generator

Mode with the Generator or Transmitter Mode with the Transmitter.

11

Page 12

Locator Operating Modes:

In

All

Scan Mode, the Locator detects at ALL frequencies

in a wide band. Sometimes a signal that is outside of the

frequency range of the other search modes (Power, Radio,

and Generator/ Transmitter) will be present on a buried

metallic service.

search mode to employ as it may detect these ‘extra’

signals as well as the Power, Radio and Generator/

Transmitter signals.

All

Scan Mode is a useful additional

All

Scan Mode

12

Page 13

Locator Operating Modes:

All

Scan Mode

Limitations of

All

Scan Mode has exactly the same limitations as those

listed for the Power and Radio Modes:

Street lighting cables when the lights are switched off,

supply cables to buildings or plant using little or no

electricity, pot-ended or capped cables, well balanced

high voltage cables and direct current cables may all be

missed on the

A strong

a weaker

It is not normally possible to determine what the service

All

is in

All

Scan signals do not favour one utility over another.

The depth of the buried service CANNOT be judged by

the strength of the

Normally it is only possible to detect

present on services up to 2 metres deep.

A short service may not have enough signal to be detected.

All

Scan Mode

All

Scan Mode.

All

Scan signal present on one service may mask

All

Scan signal present on an adjacent service.

Scan Mode, only its position.

All

Scan signal alone.

All

Scan signals

WARNING Using the Power and Radio Modes may be more effective in areas where there are many services

All

radiating an

Scan signal.

13

Page 14

Locator Operating Modes: Generator/ Transmitter Mode

In Generator/ Transmitter Mode the Locator detects conductors

radiating a signal applied by the Generator/ Transmitter or detects

a signal radiated by a sonde.

The Generator/ Transmitter provides a means of applying a known

signal to buried metallic services which can then be detected using

the Locator. By detecting this signal it is possible to locate, trace

and identify the pipes or cables that may be carrying it.

There are a variety of methods by which the Generator/ Transmitter

signal can be applied to buried services:

Direct Connection using leads connected to the Generator/

Transmitter.

Induction without physically connecting to a service via the

Generator/ Transmitter radiated signal.

Signal Clamp connected to the Generator/ Transmitter.

Signal Injector connected to the Generator/ Transmitter.

Signal Hopping using the Direct Connection leads to couple onto

a service without physically connecting.

Direct Connection

Induction

14

WARNING Locators can only detect services radiating a detectable electromagnetic signal.

There may be some services that do not radiate these signals and cannot be located.

Page 15

Using the Locator: Batteries Alkaline and Rechargeable

C.Scope Locators can be powered by either eight standard alkaline

or by eight standard Nickel-Metal Hydride rechargeable (NiMH) AA (LR6) size batteries.

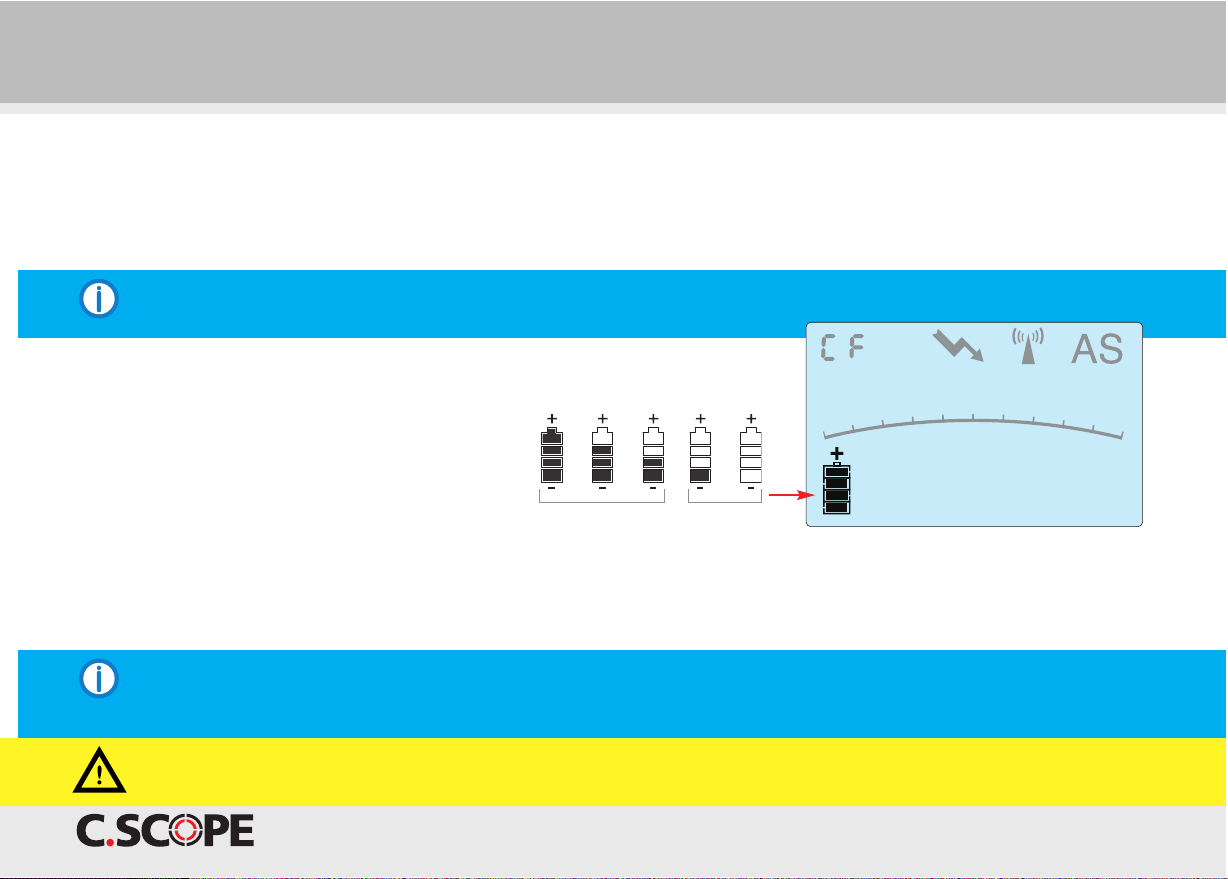

Locator Battery Check

Switch the Locator on by pulling up on the On/Off trigger positioned on the underside of the handle.

The Locator should emit a clear audible battery check tone for one second and the display should come on.

NOTE The Locator will carry out an automatic Self Test when it is

switched on for the first time each day (see pages 16-17 for full details)

Check the battery level indicator in the bottom

left hand corner of the display. If there is only

one segment or no segments of the indicator

filled in then the batteries will need to be

renewed or recharged before locating work

can begin.

Battery Levels OK

Changing Locator Batteries

Push the two clips back to release the battery compartment door. Remove ALL EIGHT used batteries and replace with

new ones. Be careful to insert the new batteries the correct way round in the holder. Replace the holder in the battery

compartment making sure that the two terminals on the holder make contact with the two terminals within the battery

compartment. Close the battery compartment door securely.

replace / recharge

batteries

NOTE A spare battery pack can be carried inside the battery compartment.

NOTE Only use alkaline or Nickel-Metal Hydride (NiMH) rechargeable AA (LR6) size batteries.

NOTE Dispose of the used batteries safely in accordance with local regulations.

WARNING Do not change batteries in confined spaces where gas may be present.

WARNING Do not mix old and new or different types of batteries.

15

Page 16

Using the Locator: Automatic Daily Self Test

The CXL2, DXL2 AND MXL2 Locators have an in-built automatic Daily Self Test function.

This tests the Locator’s circuits and receiving aerials for correct performance.

The Self Test is automatically performed the first time the Locator is switched on each day

and takes approximately four seconds. The Locator will then be ready for use.

NOTE When turning the Locator on for the first time it is important that no Signal Generators, Transmitters

or Sondes are operating within 5metres of the Locator.

NOTE Try not to switch the Locator on for the first time in an area with unusually high Power signals such

as next to an electricity transformer.

The Self Test process is indicated by ‘ ’ appearing on the display.

In the top left hand corner of the screen a countdown timer shows

the progress of the test.

16

Page 17

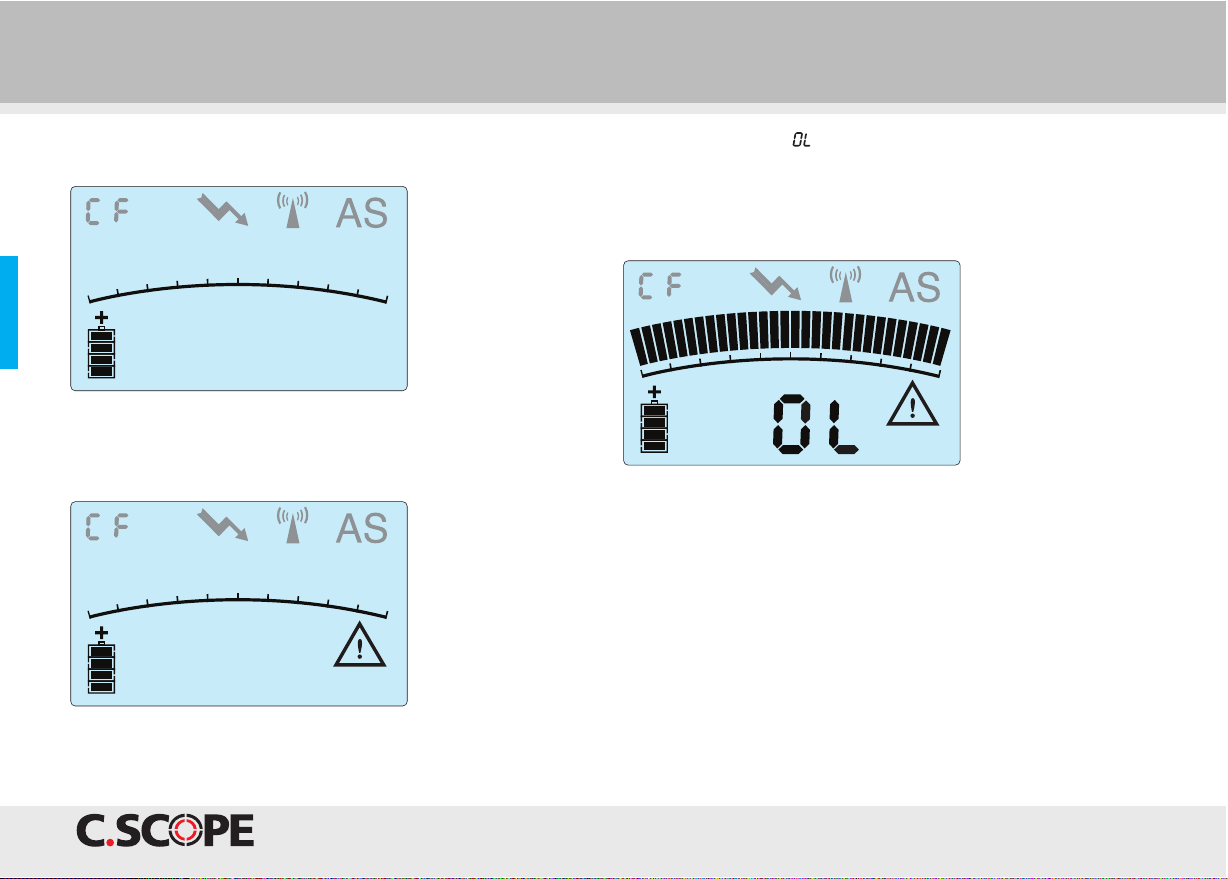

Using the Locator: Automatic Daily Self Test

After the Locator has successfully completed the

Self Test the Locator is ready for use as per normal.

If the Locator has failed the Self Test the Warning symbol

will appear in the bottom right hand corner of the screen.

If the error code: ‘ ’ is also displayed then this indicates

that there is either too much background interference

for the Self Test process to safely complete or there is

a Generator/Transmitter or Sonde transmitting nearby

which should be turned off.

In this situation, switch the Locator off and move to

a different area and the Locator will then automatically

repeat the Self Test when switched on. The Locator will

continue to repeat the Self Test process after every ‘fail’

and the Warning symbol will continue to stay on the

display until a successful test is carried out.

If the Locator continues to fail it’s Self Test then this

is indicating that there is a fault and the Locator should

be withdrawn from service. Contact C.Scope or a C.Scope

Authorised Service Centre for advice.

17

Page 18

Using the Locator: Holding the Locator

Your middle or little finger should be used to squeeze,

and hold on, the On/Off trigger.

Your index finger will then be free to adjust the

Sensitivity Control.

When in use the Locator should always be held upright.

NEVER swing the Locator such that it moves away from

the vertical. A single audible beep is sounded to indicate

if the Locator is being used incorrectly.

incorrect

correct

90

O

18

Page 19

Using the Locator: Searching

There are three stages to the locating process; searching,

pinpointing and tracing

1. Turn the Mode Switch to the appropriate mode.

2. Hold in the On/Off trigger. The Locator should emit the audible

battery test tone and the digital display should come on. Check

the battery level indicator to confirm the batteries are usable.

3. Rotate the Sensitivity Control fully clockwise to its maximum

setting as indicated by the arrow on the control.

4. Carry out the search using a grid pattern as shown in the

diagram. Walk slowly and keep the Locator upright at all times

and stationary by your side.

5. As you approach the area in which there is a signal the

Locator will emit an audible response and show a visual

response on the display.

6. Keep walking until the audible and visual responses disappear.

NOTE This search technique applies only to the

Power, Radio and

Generator/ Transmitter’ for the correct search pattern

when using Generator/ Transmitter Mode.

NOTE Sometimes the Locator will give an audible

response and strong (full scale) visual response across

the whole of the search area. In this case turn the sensitivity

down slightly and repeat the search using the same grid pattern.

All

Scan modes. See ‘Using the

Search Grid Pattern

19

Page 20

Using the Locator: Pinpointing

Having found a signal the next step is to pinpoint the source.

The closer the Locator is to the signal source the stronger

the response.

To Pinpoint a Signal

1. Keeping the Locator vertical, walk through the area of the

signal response. If the visual response goes up off the scale

then stop and reduce the sensitivity of the Locator slightly

before continuing.

2. The width of the signal response will shrink as the

sensitivity is reduced. Once it is reduced enough then a

clear peak response will be seen on the display as the

Locator traverses the service. The Locator is positioned

directly above the buried service when the display is at its

highest (peak) reading.

3. Carefully rotate the Locator over the peak reading until the

visual response falls to a minimum. The Locator will now be

roughly IN LINE with the direction of the buried service.

4. Mark the position of the buried service.

20

NOTE The amount of sensitivity adjustment needed to pinpoint a service can vary depending on the mode being

used, the signal strength and the service depth.

Page 21

Using the Locator: Tracing

Having pinpointed a service it should now be possible to trace its route.

1. Carefully follow the direction of the signal holding the Locator at right angles

to the line of the signal. It is necessary to constantly ‘slice’ the Locator from side

to side in order to be sure of still being over the peak signal response.

2. Stop and mark the position of the signal at regular intervals. As more marks

are recorded the precise direction of the service will become more apparent.

NOTE It may be necessary to readjust the sensitivity to maintain the

optimum response.

NOTE After tracing, return to the original search grid to search for

further buried services.

WARNING Never rush the tracing process. Small and unexpected changes in the service’s route will be

missed if care is not taken to follow the signal’s path every step of the way.

Lost Signals

This can be because of a curve, or bend in the route, change in depth of the

service, a T connection or the end of the service.

Finding Lost Signals

1. Locate in a circle at least 1 metre around the point where the signal was lost.

This should locate the service if it has simply changed direction sharply or T’d

into another service.

2. If you find nothing then increase the sensitivity and repeat the circle.

This should find the service if it has continued but at a greater depth.

21

Page 22

Using the Generator/ Transmitter: Output Power Level and Pulse/ Continuous Output

Output Power Level

The SGV2 Generator and the MXT2 Transmitter have four, selectable output

power levels. The SGA2 Generator has two selectable output power levels.

For long distance tracing or for detecting deep services it is always best to

use the highest power setting of the Generator/ Transmitter. Please note

that higher power settings will drain the batteries more quickly than lower

power settings.

For tracing work close to the signal application point, especially when using

Induction Mode, the lower power settings are better.

NOTE When using accessories such as Signal Clamps, Signal Injectors and Plastic Pipe Tracers it is normally

best to use the highest power setting.

Pulsed/ Continuous Output

For most locating work a Continuous signal output is best and MUST

be used for any Depth or Signal Current Measurements.

A Pulsed signal output can be useful when it has become difficult

to distinguish the Generator/ Transmitter signal from unwanted

interference, for example, when tracing services over long distances

or at greater depths.

22

NOTE The 640/512Hz signal can only be applied as a Continuous signal and by using the Direct Connection Leads

(MXT2 Transmitter only).

Page 23

Using the Transmitter: Which Frequency Signal to use (MXT2 Transmitter only)

Generally, Combined Frequency is the best frequency setting to use as it

performs well in all applications. The lower frequency signals (8kHz and

640/512Hz) should travel further along a metallic service than the higher

frequency signals although they may be more difficult to successfully apply

in the first place. There should also be less ‘coupling’ of these lower

frequency signals onto adjacent services.

There can be exceptions to this general rule and so the best option is to

try each frequency setting and then utilise the one that is giving the best

results for that particular service. This is irrespective of the method of

signal application; Direct Connection, Signal Clamp, Signal Injector or

Induction Mode, and of the service being traced.

NOTE The 640/512Hz frequency signal can only be applied using the Direct Connection Leads and with a

Continuous signal output.

WARNING The Locator frequency MUST always be set to the same frequency setting as the Transmitter.

23

Page 24

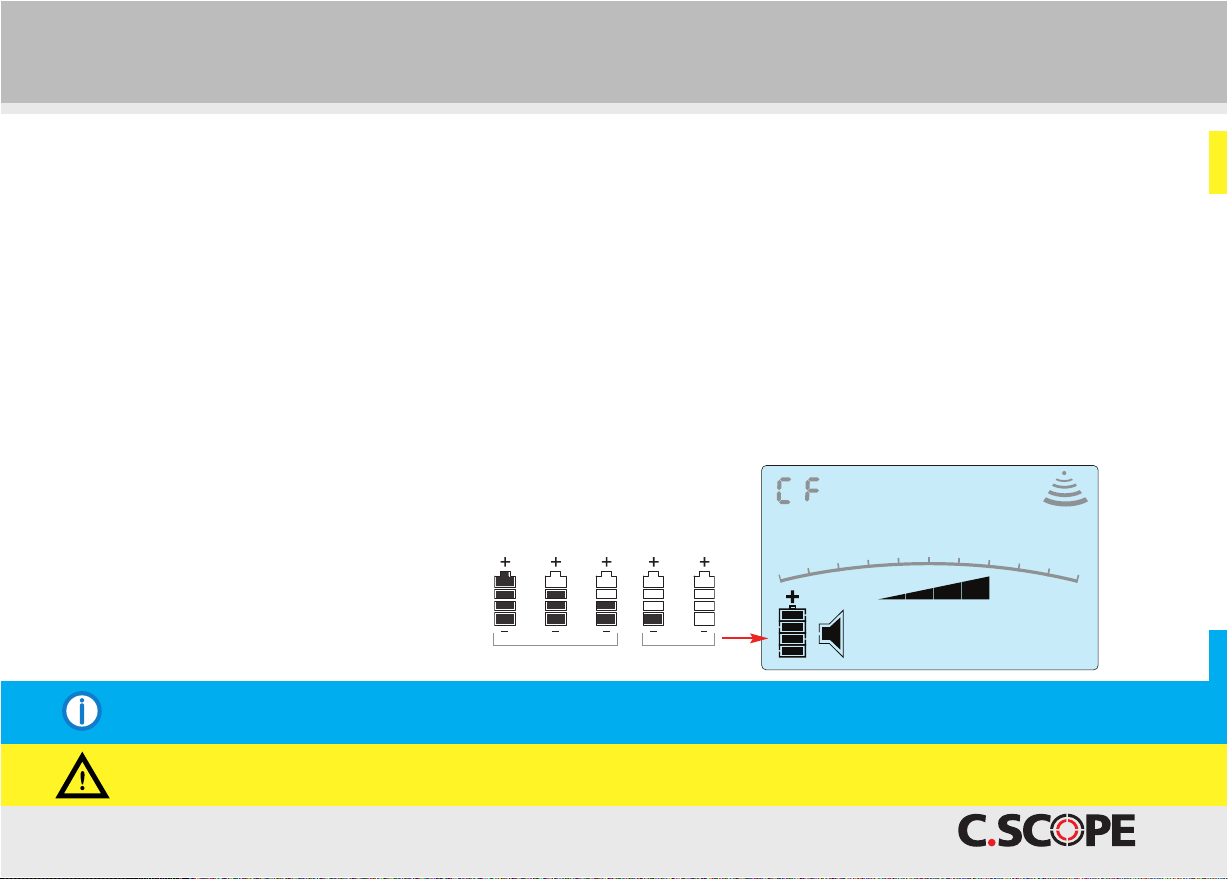

Using the Generator/ Transmitter: Batteries Alkaline and Rechargeable

C.Scope Generators/Transmitters can be powered

by either four standard alkaline or by four standard

rechargeable Nickel-Metal Hydride (NiMH) D (LR20)

size batteries.

Battery Check

Switch the Generator/ Transmitter on by pressing the

On/Off switch. The Generator/ Transmitter should emit

a loud continuous tone or a regular pulsed tone. If the

batteries need replacing or recharging an interrupted

tone will be heard.

During use, the Generator/ Transmitter will also warn the

Changing the Batteries

Remove the Accessory Tray.

Undo the two round, knurled retaining screws situated

on the underside of the Generator/ Transmitter holding

the Battery Cover.

Remove ALL FOUR used batteries and replace with

new ones.

Be careful to insert the new batteries the correct way

round in the compartment as indicated on the case.

Replace the Battery Cover being careful to not over

tighten the retaining screws.

Replace the Accessory Tray.

Locator user of low battery status by altering its normal

continuous or pulsed signal output to a distinct interrupted

signal output.

(SGV2 Generator and MXT2 Transmitter only:

Check the Battery Level Indicator in the

bottom left hand corner of the display.

If there is only one segment or no segments

of the indicator filled in then the batteries

will need to be renewed or recharged before

locating work can begin.)

Battery Levels OK

replace / recharge

batteries

NOTE Only use alkaline or Nickel-Metal Hydride (NiMH) rechargeable D (LR20) size batteries.

NOTE Dispose of the used batteries safely in accordance with local regulations.

24

WARNING Do not change batteries in confined spaces where gas may be present.

WARNING Do not mix old and new or different types of batteries.

Page 25

Using the Generator/ Transmitter: Direct Connection

WARNING Never connect directly to electrical services.

WARNING You may need to seek permission from the service owners before connecting on to some buried services.

The Direct Connection Leads and Earth Stake that are

supplied with the Generator/ Transmitter are used to apply

a signal to any metal pipe at a suitable access point such

as a valve, hydrant point, stop cock or exposed pipe length.

1. Plug the Direct Connection Leads into the Generator/

Transmitter connection socket.

2. Attach the red lead to the pipe at your point of access

using the Crocodile Clip. Ensure that you have a secure

and clean grip on the pipe with the Crocodile Clip.

3. Turn the Generator/ Transmitter on and set Output

Power Level to the lowest level.

(MXT2 Transmitter only: Select the frequency to be used;

CF, 8kHz or 640/512Hz).

NOTE The type of metal that the pipe is constructed from or it’s use will have little effect on its traceability.

NOTE If it is not possible to get the Crocodile Clip to grip the pipe then use the Magnet supplied.

NOTE MXT2 Transmitter only: When turning on, the Transmitter will return to the last Output Power, Frequency,

Pulsed/Continuous and Loud/Mute settings that were used.

WARNING Do not handle the bare Crocodile Clips when the Generator/ Transmitter is switched on.

1.

4. Place the Earth Stake in the ground (having first

searched the area for buried cables with the Locator).

The ideal position for the Earth Stake is at right angles to

the assumed line of the pipe and the full length of the

Direct Connection Leads away from the pipe access point.

2.

25

Page 26

Using the Generator/ Transmitter: Direct Connection

5. Connect the black Earth Lead to the Earth Stake (or the

alternative earth point). If your earth point is too far away from

the pipe access point for the black Earth Lead to reach then use

the yellow 10 metre Auxiliary Earth Lead instead.

6. As the Earth Lead is connected to the Earth Stake the audible

signal from the Generator/ Transmitter should change in pitch.

The lower the pitch, then the better the signal will be on the

metal pipe.

If there is no change of tone it may be that some dirt, rust

or paint on the pipe is preventing the Direct Connection Lead

from making a good contact with the pipe. Alternatively it may

be that your earth point is at fault. Change the position of the

Earth Stake or use an alternative earth point.

(SGV2 Generator and MXT2 Transmitter only:

There will also be a visual representation of the quality of the

connection in addition to the audible pitch change. The greater

the response on the display then the better the signal will be

on the pipe).

7. Adjust the Output Power Level to suit.

26

NOTE If it is not possible to use the Earth Stake use a nearby metal fence post, manhole cover or gully cover.

NOTE If the Earth Stake cannot be inserted into the ground then simply laying it flat on the ground can sometimes

provide a successful earth connection (especially if the ground is wet).

DO NOT use something that may have another metallic service attached to it, such as a metal street lighting column.

NOTE If the Generator/ Transmitter pitch does not change then there is no signal being transferred onto the service.

Page 27

Using the Generator/ Transmitter: Direct Connection

Direct Connection to a Street Lighting Column

or other street furniture

The best method to determine the position and route of street

lighting, car park lighting cables or any other item of street

furniture with a power supply is by using a Generator/

Transmitter and the pipe connection method.

Follow the same rules as for connecting the Generator/

Transmitter to a metal pipe except attach the red Direct

Connection Lead to a metal part of the OUTSIDE of the lamp

column/ street furniture.

WARNING NEVER open the lamp column door to gain access to the cables, this is potentially dangerous

and is not necessary.

NOTE Make sure that the Direct Connection Crocodile Clip is not insulated from the metal of the column by paint.

NOTE If the column is concrete attach the Crocodile Clip to the metal surround of the access door.

27

Page 28

Using the Generator/ Transmitter: Signal Hopping

Signal Hopping using Direct Connection Leads

If it is difficult or inconvenient to use the Direct Connection method

of signal application then an alternative technique

called Signal Hopping can be utilised to successfully energise

a street lighting or car park lighting cable with the Generator/

Transmitter signal.

Wrap the red Direct Connection lead around the street lighting

column (two or three times if possible). This is particularly

useful if it is difficult to get a good metal to metal connection

between the crocodile clip or magnet and the column.

The black Direct Connection lead is connected to the Earth Stake

positioned away from the column.

MXT2 Transmitter only: Ensure CF frequency setting is selected.

28

NOTE If the Earth Stake cannot be inserted into the ground then simply laying it flat on the ground

will often provide a successful earth connection when using the Signal Hopping technique.

Page 29

Using the Generator/ Transmitter: Signal Clamp/ Injector

Signal Clamp

1. Plug the Signal Clamp into the connection socket on the Generator/ Transmitter.

2. Turn the Generator/ Transmitter on (and select either CF or 8kHz on the Transmitter).

3. Check that the jaws of the Signal Clamp are clean. Place the Signal Clamp AROUND the cable

making sure that the jaws are able to fully close. The audible signal from the Generator/ Transmitter

should drop in pitch indicating that the clamp jaws have closed correctly and the response on the

display (if fitted) should increase.

WARNING NEVER attempt to place the Signal Clamp around electricity cables

that are deliberately suspended out of reach. They may be unsheathed or unprotected cables.

NOTE The Signal Clamp cannot apply a signal to a cable that is not earthed at both ends such as abandoned

cables that have been cut off where they appear above ground or cables supplying unearthed equipment.

Signal Injector

1. Plug the Signal Injector into the connection socket on the Generator/ Transmitter and an electric outlet.

2. Turn the Generator/ Transmitter on (and select either CF or 8kHz on the Transmitter).

3. Turn the socket on. The audible tone from the Generator/ Transmitter will drop in pitch to indicate a

successful connection and the visual response on the display (if fitted) should go to full scale.

NOTE On two wire Protective Multiple Earth (PME) systems it may be necessary to also

provide an external earth using the yellow 10 metre Auxiliary Earth Lead and Earth Stake.

NOTE Always check with the owners that it is acceptable to interrupt the supply before connecting the Signal Injector.

NOTE Using the Signal Injector may cause the system protection to trip.

WARNING DO NOT use the Signal Injector on systems with voltages in excess of 240 volts AC.

Domestic systems will normally be below this voltage.

29

Page 30

Generator/ Transmitter: Searching for the Direct Connected Signal

The search pattern used to find the Generator/ Transmitter signal

when applied by a direct connection method (Direct Connection

Leads, Signal Clamp or Signal Injector) is different to the normal

search pattern used on Power, Radio or

1. Move a few paces away from where the Generator/ Transmitter

has been connected to the service. Turn the Mode Switch to

Generator Mode or Transmitter Mode. Press the Frequency

Button (MXL2 Locator only) to select the same frequency as being

transmitted by the Transmitter. Hold the Locator so that the side of

the Locator is facing towards the Generator/ Transmitter.

2. Adjust the sensitivity so that the Locator is just showing a visual

response and just emitting an audible response.

3. If possible walk in a COMPLETE circle around the connection point

trying to keep the same distance from this point at all times. When a

signal is detected, ‘pinpoint’ that signal as shown in the ‘Using the

Locator’ section.

4. Having pinpointed the first signal, do NOT readjust the Sensitivity

Control but continue with the circle to see if any other signals are

detected. If more signals are detected compare the strength of each

signal by observing the bar display. The strongest signal will usually

be coming from the service that the Generator/ Transmitter is

connected to.

All

Scan Modes.

30

Page 31

Generator/ Transmitter: Tracing the Direct Connected Signal

The tracing technique used to follow the Generator/

Transmitter signal when applied by a direct connection

method (Direct Connection Leads, Signal Clamp or Signal

Injector) is almost exactly the same as the normal tracing

technique used on Power, Radio or

the following differences:

The signal that the Locator is detecting will get weaker

the further away from the Generator/ Transmitter that

you go. It will be necessary to regularly adjust (increase)

the Locator Sensitivity Control to compensate for this.

MXT2 Transmitter only:

Having traced the signal for a short distance it may be

worthwhile switching the MXT2 Transmitter to the

alternative frequencies to see if they give a stronger

response. Choose the frequency that gives the strongest

response and continue with the trace.

All

Scan Modes but with

NOTE It is not possible to search for the signal above any leads connecting the Generator/ Transmitter

to the service or above the Earth Lead connected to the Earth Stake.

31

Page 32

Generator/ Transmitter: Induction

This is the standard method for inducing signals onto

buried metallic services. It produces a strong signal

directly below the Generator/ Transmitter but the

signal strength drops off quite quickly either side

of the Generator/ Transmitter.

1. Check that there are no accessories plugged into

the Connection Socket. The Generator/ Transmitter

switches automatically to Induction Mode when the

socket is unused.

2. Place the Generator/ Transmitter UPRIGHT on the

ground where you suspect services may be buried and

IN LINE with the expected route of these services.

3. Turn the Generator/ Transmitter on (and with the MXT2

Transmitter select either CF or 8kHz) then check that the

batteries are OK.

4. The signal will be radiated into the ground immediately

below and for approximately 3 metres either side of the

Generator/ Transmitter.

32

NOTE The closer the Generator/ Transmitter is to the position of the buried service then the

stronger the signal will be on that service.

NOTE MXT2 Transmitter only: Normally the CF signal is more effective on Induction Mode,

particularly on short length or small diameter services.

NOTE MXT2 Transmitter only: It is not possible to apply a 640/512Hz signal by Induction Mode.

Page 33

Generator/ Transmitter: Searching for an Induced Signal

The search pattern used to find the Generator/ Transmitter

signal when applied by Induction Mode is slightly different

to the search pattern used on other modes.

1. Move AT LEAST 10 metres away from the Generator/

Transmitter position with your Locator. This is to avoid the

Locator picking up the airborne signal rather than the signal

induced onto the buried service.

2. Stand so that you are roughly in line with the end of

the Generator/ Transmitter and hold the Locator so that

the side of the Locator is facing towards the Generator/

Transmitter.

3. Select Generator Mode or Transmitter Mode.

(The MXL2 Locator must be set to the same frequency as the

MXT2 Transmitter).

4. Adjust the sensitivity so that the Locator is JUST showing

a visual response and emitting an audible response.

NOTE A Generator/ Transmitter will transmit a significant amount of signal into the air as well as into the ground.

Make sure you keep the Locator upright at all times to reduce the risk of picking up the airborne signal.

10m

33

Page 34

Generator/ Transmitter: Searching for an Induced Signal

5. Walk in a straight line across the end line of the

Generator/ Transmitter. When a signal is detected

‘pinpoint’ that signal as shown in the ‘Using the Locator’

section. If no signal is found move the Generator/

Transmitter 5 metres and try again. Continue this

procedure moving the Generator/ Transmitter in five metre

steps, following a grid pattern, until a signal can be found.

6. It may be possible to increase the strength of the

induced signal on the buried service by improving the

positioning of the Generator/ Transmitter. Once the buried

service has been pinpointed, moving the position of the

Generator/ Transmitter from side to side will give an

increase or decrease in the Locator response. Remember,

the closer the Generator/ Transmitter is to the position of

the buried service then the stronger the signal will be on

that service.

10m

34

NOTE The Generator/ Transmitter signal that the Locator is detecting will get weaker the further away

from the Generator/ Transmitter that you go. It will be necessary to regularly adjust (increase) the

sensitivity to compensate for this.

Page 35

Generator/ Transmitter: Induction; Multiple Services

It is important to check for the presence of adjacent services running

close, or parallel, to the service that you have already located.

1. Check that there are no accessories plugged into the Connection Socket.

2. Turn the Generator/ Transmitter on and check that the batteries are OK.

3. Place the Generator/ Transmitter on the ground ON ONE SIDE over the previously

located service so that you are no longer inducing a signal onto that service.

4. Re-scan the area looking for another peak signal close to where the original

signal was found. This operation should be repeated until you are satisfied that

no further services can be located.

NOTE This method can also be used to ‘mask’ one service so that another can be found.

NOTE The signal will be radiated up to 3 metres either side of the Generator/ Transmitter but NOT directly below

when the Generator/ Transmitter is on its side.

Limitations of Induction Method - There are limitations concerning what can be achieved when using a Generator/

Transmitter on the Induction Mode compared to the Connected Mode. It is not normally possible to identify what the

service is that has been detected with an induced signal. If the signal can be followed far enough, a visible feature such

as a valve cover or cable pit cover may be found that can indicate the

identity of the service.

0% 30%50%

1m 1m

Cables with a very small cross section may not have enough signal induced onto them to make them detectable. It is

often not possible to apply an induced signal onto just ONE specific buried service, in order to trace it alone, when other

services are positioned in a close proximity.

NOTE An induced signal cannot be applied to a buried service that lies beneath reinforced concrete. The reinforcing

bars will re-radiate the induced signal masking any signal that has been induced onto the buried service below.

35

Page 36

Generator/ Transmitter: Using an Inductive Sweep

If a large area needs to be searched for buried services

then an ‘Inductive Sweep’ could be used. It is an ideal

method for detecting the position of buried services as

they cross the boundary of a large site.

An Inductive Sweep requires two people; one to operate

the Locator and one to position the Generator/ Transmitter.

1. Stand about 10 metres apart.

2. The first person holds the Generator/ Transmitter,

switched on at the lowest Output Power Level, close to

the ground and ‘end on’ (see diagram) whilst you hold

the Locator switched to Generator Mode or Transmitter

Mode. (The MXL2 Locator must be set to the same

frequency as the MXT2 Transmitter).

3. Adjust the sensitivity so that the Locator is just showing

a visual response and emitting an audible response.

4. Together, slowly walk across the site, staying the same

distance apart and being careful to keep in line with each

other. When the Generator/ Transmitter gets close to a

buried metallic service the signal will be induced onto

it and you should see this in the increased response on

the Locator.

5. Immediately tell your colleague to stop and place the

Generator/ Transmitter on the ground at that point.

Now you can pinpoint the service and trace out it’s route.

Continue the sweep across the length and width of

search area.

36

NOTE It is important to maintain the same distance and between the Locator

and Generator/ Transmitter at all times.

Page 37

Pipe Tracing using a Sonde

Non-metallic pipes such as sewers or drains, service

ducts, plastic gas and water pipes are not electrically

conductive and so will not be detectable using a Locator

on the Power, Radio or

impossible to apply a detectable Generator/ Transmitter

signal to the non-metallic pipe or, for that matter, to the

water or gas within that pipe.

If access can be gained into these pipes then a C.Scope

Sonde or Plastic Pipe Tracer should make it possible to

determine their position and route.

Sondes

C.Scope Sondes are small, battery powered, waterproof,

33kHz, 8kHz OR 640/512Hz transmitters that can be

inserted into pipes such as a sewer, drain or cable duct.

Their position can be pinpointed (and therefore the location

of the pipe) by using the Locator switched to Generator

Mode/ Transmitter Mode.

The Sonde is inserted into and then moved along

the pipe to the point at which the pipe needs to be

located. This is normally done by fitting the Sonde

to drain rods. Alternatively, the Sonde can be attached

to a continuous fibreglass duct rodder, jetter hose or

camera inspection system.

All

Scan Modes. It is also

The 33kHz and 8kHz General Purpose Sondes can be

used in pipes as small as 50mm in diameter and up to

seven metres deep.

The 33kHz Duct Sonde can be used in pipes as small

as 30mm in diameter and up to five metres deep.

The 640/512Hz Metal Pipe Sondes can be used in Pipes

as small as 50mm in diameter and up to 2 metres deep.

C.Scope are continually developing Sondes for specific

applications. Keep abreast of our latest products via

our website www.cscopelocators.com or your local

distributor.

NOTE A 33kHz or 8kHz Sonde will NOT transmit a signal through a metal pipe.

37

Page 38

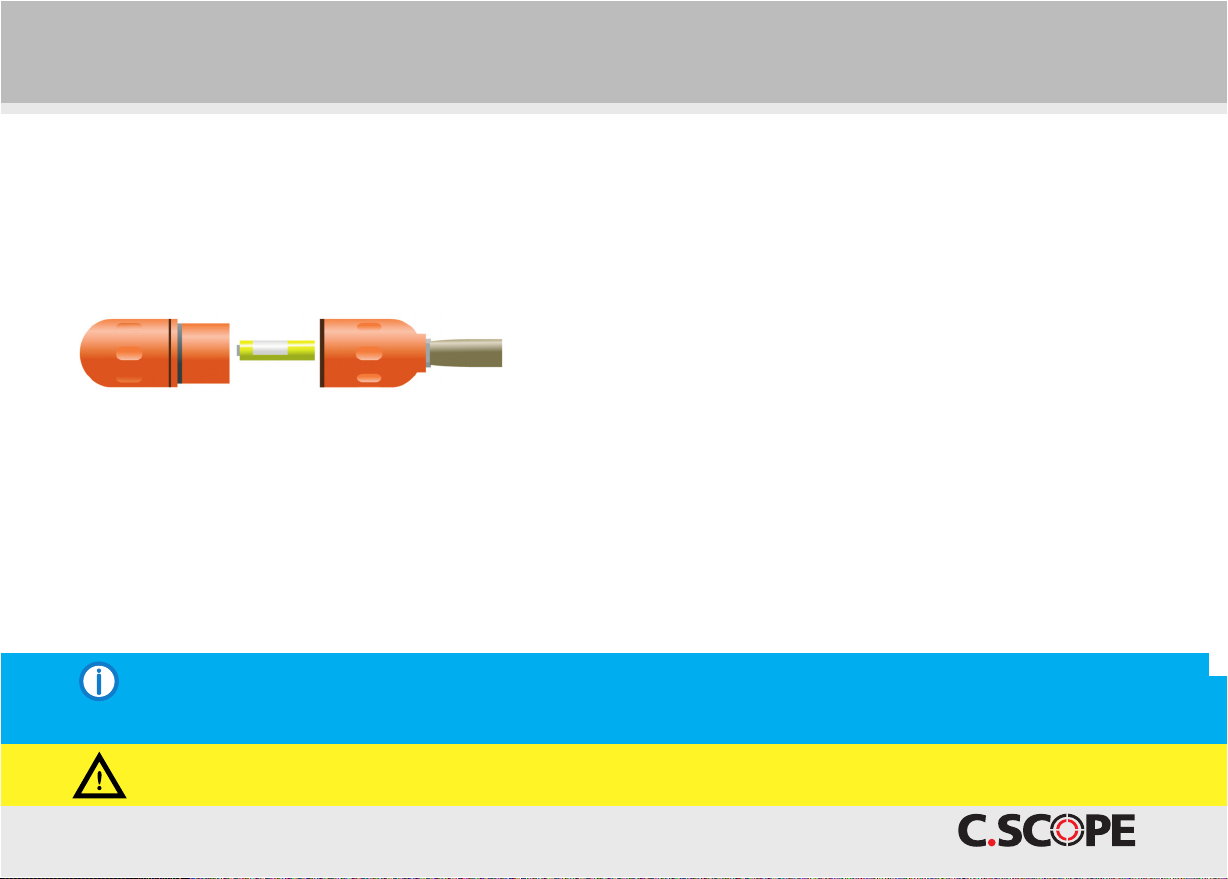

Pipe Tracing using a Sonde: Batteries Alkaline and Rechargeable

General Purpose Sonde

The General Purpose Sonde is supplied in two frequencies;

33kHz (orange casing) or 8kHz (green casing) and is

powered by a single AA (LR6) size alkaline or Nickel Metal

Hydride (NiMH) rechargeable battery. The 8kHz Sonde will

only function with the MXL2 Locator.

-----

+

1. To turn the Sonde on, separate the two halves of the

Sonde casing. Insert a new battery into the battery

compartment with the positive end down.

2. Screw the two halves of the Sonde together being

careful not to over tighten them. The Sonde is now

transmitting a signal.

3. To turn the Sonde off the battery must be removed

or reversed.

38

NOTE Only use alkaline or Nickel-Metal Hydride (NiMH) rechargeable AA (LR6) size batteries.

NOTE Dispose of the used batteries safely in accordance with local regulations.

NOTE Always use a new battery in a Sonde if you expect to take a long time to trace the pipe or duct route.

WARNING The Locator frequency MUST always be set to the same frequency as the Sonde.

Page 39

Pipe Tracing using a Sonde: Batteries

Duct Sonde

The Duct Sonde is supplied at 33kHz only (yellow casing)

and is powered by a single AAA (LR03) size alkaline battery.

Rechargeable batteries are not recommended for

this product.

1. To turn the Duct Sonde on, use a large flat bladed

screwdriver to unscrew the battery cover located within

the hollow end of the Sonde casing. Insert a new battery

into the battery compartment with the positive end down.

2. Replace the battery cover fully using the screwdriver to

secure. The Duct Sonde is now transmitting a signal.

3. To turn the Sonde off the battery must be removed.

+

-----

NOTE Only use alkaline batteries. Dispose of the used battery safely in accordance with local regulations.

NOTE Always use a new battery in a Sonde if you expect to take a long time to trace the pipe or duct route.

WARNING The Locator frequency MUST always be set to the same frequency as the Sonde.

39

Page 40

Pipe Tracing using a Sonde: Tracing a Sonde

The technique used to determine the position of a Sonde is always

the same irrespective of which Sonde is being used.

Before inserting the Sonde into the pipe it is best to set up the

Locator so that the sensitivity is correctly adjusted to suit the pipe

depth. This is easier to do when the Sonde is visible at the bottom

of the manhole rather than already in the pipe.

1. The blade of the Locator must be held IN LINE with the Sonde

at all times.

NOTE This is at 90degrees to the way in which the Locator is held for most other locating tasks.

2. Turn the Locator to Generator Mode/ Transmitter Mode, switch

on (and on the MXL2 select the correct frequency); ‘CF’ for 33kHz

Sondes, ‘8kHz’ for 8kHz Sondes and ‘LF’ for 640/512Hz Sondes).

Check the Battery Level Indicator to confirm the Locator batteries

are usable. Replace if necessary.

40

Page 41

Pipe Tracing using a Sonde: Tracing a Sonde

3. Keeping the blade of the Locator in line with the Sonde,

move the Locator backwards and forwards over the length

of the Sonde. Adjust the sensitivity until a clear peak

response is shown on the display as the Locator passes

directly over the position of the Sonde.

4. Move the Locator from side to side over the position of

the Sonde. A similar peak response should be seen on the

display as the Locator passes directly over the position of

the Sonde.

The Locator is now set up ready for tracing the Sonde.

5. Push the Sonde up the pipe.

6. With the Locator turned on, walk from the pipe access

point in the direction that the Sonde was pushed. A strong

peak signal directly over the Sonde should be detected with

two lesser “ghost” signals found either side of the Sonde’s

true position. These ghost signals are always weaker than

the main signal and should not be mistaken for the true

Sonde signal.

7. Pinpoint the Sonde position by moving the Locator back

and forth and from side to side to get the peak response.

8. Push the Sonde further up the pipe and repeat the

pinpointing process.

See page 46 for Depth Measurement using a Sonde.

3./ 4.

6.

41

Page 42

Non-Metallic Pipe Tracing: Plastic Pipe Tracer

Line Tracing

The Plastic Pipe Tracers can be used in services up to 3 metres deep (Locator dependent) on line

tracing mode but cannot transmit through metal pipes or ducts.

The Plastic Pipe Tracer needs to be inserted into the pipe before a signal from the Generator/

Transmitter is applied to the length of the Tracer.

The CF Generator/ Transmitter signal is applied using the ‘Direct Connection to a metal pipe’

method as shown on page 25-26 of this manual. Only one lead is connected to the Plastic Pipe

Tracer, the other is connected to an Earth Stake.

WARNING Authorisation may be required before using the Plastic Pipe Tracer on some services.

WARNING DO NOT touch the metal of the Crocodile Clips or the terminals of the Plastic Pipe Tracer

when using the Generator/ Transmitter.

42

NOTE It is important that a change of pitch is heard when making the connections to ensure that there is a

detectable signal present on the Tracer.

NOTE The Generator/ Transmitter signal is unlikely to travel the entire length of the Tracer within the pipe.

Never assume that you have located the end of the Tracer on Line Tracing Mode. Use End Tracing if required.

Page 43

Non-Metallic Pipe Tracing: Plastic Pipe Tracer

End Tracing

The very tip of the Plastic Pipe Tracer can be energised with the signal from a Generator/ Transmitter.

It is acting much like a Sonde and offers a very reliable way of pinpointing the position of the tip.

A CF Generator/ Transmitter signal is applied by connecting the red Direct Connection Lead to one of the

terminals on the Tracer and the black Earth Lead to the other terminal. As the second connection is made

a change of pitch should be heard from the Generator/ Transmitter signal indicating successful connection.

The tip of the Plastic Pipe Tracer is then pinpointed using the same technique as for Sonde tracing with the

Locator blade in line with the Tracer.

WARNING Authorisation may be required before using the Plastic Pipe Tracer on some services.

WARNING DO NOT touch the metal of the Crocodile Clips or the terminals of the Plastic Pipe Tracer

when using the Generator/ Transmitter.

NOTE It is important that a change of pitch is heard when making the connections to ensure that there is a

detectable signal present on the Tracer.

NOTE End tracing is the ideal method to use to determine where the end of the pipe is but does not give the

route of the pipe.

43

Page 44

Depth Measurement (DXL2 and MXL2 Locators only)

The DXL2 and MXL2 Locator can be used in conjunction with the Generator/ Transmitter or

Sonde to indicate the depth of a buried service.

Depth cannot be measured on the Power, Radio or

On the MXL2 Locator depth measurements can be taken from a CF, 8kHz

or 640/512Hz signal.

WARNING The depth indication MUST NOT be used to decide if mechanical

digging over the buried service is appropriate.

WARNING If the following procedure for Depth Measurement is not followed

then an inaccurate depth may be indicated. This is worse than having no depth

information at all.

1. The Generator/ Transmitter must be set to ‘Continuous’ signal output, NOT Pulsed output.

2. It is vital that the signal being measured is a GOOD QUALITY signal. This is best achieved

by using the Generator/ Transmitter in Connected Mode rather than Induced Mode.

3. Set the Locator to Generator Mode/ Transmitter Mode and pinpoint the position of the

buried service. Make sure the Locator is directly over the buried service and at right angles

to it’s route. Rest the Locator on the ground with the body vertical.

WARNING If the pinpointing of the service is inaccurate then the Depth Measurement will be inaccurate.

NOTE A poor quality signal is indicated by an unstable visual response on the Locator. Depth Measurement may

be inaccurate in these circumstances.

All

Scan Modes.

44

Page 45

Depth Measurement (DXL2 and MXL2 Locators only)

4. Press and hold down the depth button. The depth will be shown on the display,

measured in metres.

5. The depth can be verified by lifting up the Locator whilst keeping the depth button

depressed. The depth indication should increase by the same amount.

Limitations of Depth Measurement - There are some situations where it is not

possible to gain accurate depth information:

A curve or bend in the route of the service.

Close to where the service changes in depth.

Near to a ‘T’ junction in the service.

At the very end point of a service.

At any point where the signal has coupled onto an adjacent service.

Close to any large metallic objects such as metal fences or vehicles.

Within 25 metres of the position of the Generator/ Transmitter if used on Induction Mode.

Under reinforced concrete.

The signal is of poor quality.

Too close to the Generator/ Transmitter or leads if used in Connected Mode.

4.

(

Note: MXL2 pictured

)

NOTE The depth shown will be to the centre of the service and is not the depth of cover.

This is of greater significance on large diameter pipes.

45

Page 46

Depth Measurement using Sonde/Plastic Pipe Tracer (end tracing only)

(DXL2 and MXL2 Locators only)

3.

NOTE The following instructions apply equally to the Plastic Pipe Tracer in End Tracing

Mode, the Duct Sonde and the General Purpose Sondes.

1. Pinpoint the exact position of the Sonde as shown in the ‘Pipe Tracing using a Sonde’ section.

Take care to ensure that you are over the top of the Sonde and not over one of the two ‘ghost’

signals in front of and behind the true position.

2. Rest the Locator on the ground, keeping it vertical and IN LINE with the Sonde.

3. Push the depth button TWICE and hold, on the second push, to select Sonde Depth Mode.

The word ‘SONDE’ will flash on the display and the depth will then be displayed.

If the word ‘SONDE’ is not displayed then the depth reading will not be accurate.

NOTE The depth shown is that of the Sonde and NOT of the pipe.

Depth Measurement: Error Readings (DXL2 and MXL2 Locators only).

The Locator may show the following error codes when attempting a Depth Measurement:

1. 000 The service is too shallow (less than 0.20m deep) for the Locator to obtain an accurate depth. It should be possible

to calculate the depth by raising the Locator a set amount and then carrying out the Depth Measurement again.

2. 888 The service is too deep for the Locator to measure its depth or there is no signal at all present.

(

Note: MXL2 pictured

)

3. L0 The Generator/ Transmitter signal on the buried service is not strong enough for the Locator to give a reliable

Depth Measurement. Increasing the Generator/ Transmitter output or repositioning the Generator/ Transmitter

to give a stronger signal could solve the problem.

4. OL Overload. The signal is too strong for the Locator to give a reliable Depth Measurement.

Reducing the Generator/ Transmitter output to give a weaker signal could solve the problem.

46

Page 47

Signal Current Measurement (MXL2 Locator only)

MXL2 Locator only:

Signal Current Measurement is a feature by which it is

possible to measure the TRUE strength of the Generator/

Transmitter signal on a buried metal pipe or cable

irrespective of its depth. This is a useful aid for the

correct identification of specific pipes and cables and

may also help to determine the layout and condition of

a pipe or cable network.

When the Generator/ Transmitter has been connected to

a particular ‘target’ service, the Locator may not always

show the strongest response over that service. If the

target pipe or cable happens to be much deeper than

other services, which have picked up some of the

Generator/ Transmitter signal, these other services

may show similar responses. However, the Signal Current

reading will invariably be highest on the target pipe or

cable therefore aiding correct identification.

47

Page 48

Signal Current Measurement (MXL2 Locator only)

Signal Current Measurement can also help to identify the layout of pipe and cable networks

as the main line after a ‘T’ will have most of the Signal Current remaining on it whereas the

shorter connection will have correspondingly less.

The Signal Current reading should also reduce at a uniform rate as the distance from the

Generator/ Transmitter increases. A sudden drop in Signal Current, in a short distance,

indicates a change to that service such as an unknown connection, an insulated joint or

a break in the pipe or cable.

48

210

215

190

20

185

165

20

70

110

50

Page 49

Signal Current Measurement (MXL2 Locator only)

To ensure reliable Signal Current readings it is vital to

adhere to the same best practises as are used to give

accurate Depth Measurement readings.

1. Only apply the signal by a Connection method

(Direct Connection, Signal Clamp or Signal Injector)

to the target service.

2. The Generator/ Transmitter must be set to Continuous

signal output, NOT Pulsed output.

3. Set the Locator to Transmitter Mode, select the correct

frequency and pinpoint the position of the buried service.

Make sure the Locator is directly over the buried service and

at right angles to it’s route. Rest the Locator on the ground

with the body vertical.

4. Press and hold down the Signal Current button.

The Signal Current reading will be shown on the display,

measured in mA.

Allow the Signal Current reading to stabilise.

Signal Current Button

NOTE The Signal Current figure alone does not provide any useful information. It is how this figure compares

to other Signal Current readings taken on other services or at different points along our target service that can

indicate the layout and identity of the network.

49

Page 50

Signal Current Measurement

Limitations of Signal Current Measurement

There are some situations where it may not be possible to gain an

accurate Signal Current Measurement reading:

At a sharp curve or bend in the route of the service.

At a T junction in the service.

At the very end point of the service.

Close to any large metallic objects such as metal fences or vehicles.

Within 25 metres of the position of the Generator/ Transmitter.

If the signal is of poor quality.

50

Page 51

Data Logging

Data Logging

All CXL2, DXL2 and MXL2 Locators automatically record

data on how the product is being used. Over 12months

of data (in normal use) is stored before being overwritten.

A full audit trail is kept of all Locator activity so that it is

possible using the PC Toolkit (see below) to see Self Test

reports, which Modes have been used, when they have

been used, and for how long.

Data can be transferred at any time, via the onboard data

connection socket in the battery compartment, to a PC for

analysis using the PC Toolkit. A USB 2.0A male to mini B

cable is required. This can be purchased from C.Scope.

The CXL2-B, DXL2-B and MXL2-B Locators also have

additional Bluetooth™ technology which is indicated

on the product label. The Bluetooth™ technology allows

the data to be wirelessly transferred to a smart phone

or tablet and then emailed to a PC for analysis.

Data Analysis using PC Toolkit

C.Scope provide a PC Toolkit that allows manipulation

of stored data-logs into charts and graphs that illustrate

many aspects of the use of the Locator. The data can be

used to show correct usage in addition to assisting the

identification of any training requirements.

Android APP to transfer stored data or live link with GPS

For Users of CXL2-B, DXL2-B and MXL2-B Bluetooth™

Locators, the C.Scope RELAY Android APP enables

immediate on-site transfer of data from a Locator

via a smart phone or tablet to a PC.

In addition, the C.Scope RELAY Android APP allows global

positioning system (GPS) data from a smart phone or

tablet to be combined with the live Locator data so the

location of use can also be identified. It is also possible

to see the map location illustrated live on a smart phone

or tablet using Google™ Maps.

The C.Scope RELAY Android APP is free to download via

the C.Scope website: www.support.cscopelocators.com

The PC Toolkit is free for users to download from the

C.Scope website: www.support.cscopelocators.com

51

Page 52

C.Scope Locator: Function Checks

The CXL2, DXL2 AND MXL2 Locators have an in built Self Test feature that automatically tests the Locator’s circuits

and receiving aerials for correct performance each day (see pages 16–17).

The C.Scope Function Checker product allows further functionality checks to be made of any C.Scope Locators

at any time. It will also check the functionality of C.Scope Generators/Transmitters. If a Function Checker is not

available then the following procedures below can be used.

Locator:

Battery Condition

Check by depressing the On/Off Switch beneath the handle.

The display will show at least two solid segments if the batteries are OK.

Ensure power on tone is heard.

Power Mode

Select Power Mode. Set sensitivity fully clockwise and point the body of the Locator at a fluorescent light from

a distance of one metre. Switch the light on.

A loud tone should be heard and the display should read greater than 50% full scale. Reducing the sensitivity

should cause the displayed reading to reduce and the tone to cut out.

Radio Mode

Select Radio Mode. Set the sensitivity fully clockwise and, from a distance of less than 0.25 metres, point the unit at

a metal conductor of length greater than 100metres (for example a metal pipe or cable). A warbling tone should be

heard. The display should read greater than 50% full scale.

All

Scan Mode

All

Select

Scan Mode. Repeat the same tests that were used to function check the Power and Radio Modes.

52

Page 53

C.Scope Locator: Function Checks

Generator Mode/ Transmitter Mode

Locate an outdoor test area that is free from extraneous fields

resulting from overhead and underground cables. The area should

also not be near fences, steel framed buildings, or on reinforced

concrete. Place the Generator/ Transmitter on the ground in the

normal orientation and switch on - a tone should be heard. Set to

Continuous and ensure lowest output power is selected.

With the Locator in the orientation shown, select CF Generator Mode/

Transmitter Mode. Rotate sensitivity fully clockwise. At a

distance of 10 metres the audio should still be present and the

display indicate full scale. Reducing the sensitivity should cause the

displayed reading to reduce and the tone to cut out.

MXL2 Locator only:

Repeat with both Transmitter and Locator set to 8kHz.

The results should be the same.

10m

53

Page 54

C.Scope Generator/ Transmitter: Function Checks

Generator/ Transmitter:

Battery Condition

Select Continuous. Good batteries will be shown by a loud, clear

audio tone. Bad batteries give an interupted audio tone. The display

(if fitted) will show at least two solid segments if the batteries are OK.

Induced Mode

This can only be checked in conjunction with a Locator as described

on the previous page. If the unit does not meet the performance

expected, repeat the test with another Locator to determine whether

the Generator/ Transmitter is at fault.

Connected Mode

Set the minimum output level, insert the Direct Connection Lead

and the long Auxiliary Earth Lead and then connect the red lead

Crocodile Clip to the Auxiliary Earth Lead Crocodile Clip to create

a short circuit. The pitch should change to a low tone.

The leads should be arranged to create an open loop on the ground

of approximately 1 metre in diameter. Check that a signal can be

detected by the Locator in Generator Mode/ Transmitter Mode when

pointed closely at the loop.

54

NOTE These checks DO NOT guarantee full system performance. If a deterioration in performance

is suspected, the equipment should not be used. It should be returned to C.Scope or a C.Scope

Authorised Service Centre.

Page 55

C.Scope Locator: Depth Measurement Checks (DXL2 and MXL2 Locators only)

Depth Measurement

An area clear of services and metal structures should be chosen (beware

of reinforced concrete car parks). A search with the C.Scope Locator in

all 4 modes will help confirm the absence of other services. An insulated

cable or wire over twenty metres long (not supplied) is laid out on the

ground surface and the far end connected to a ground stake and earthed.

The near end is connected to the red Direct Connection Lead.

The black Earth Lead should be laid at right angles to the 20 metre cable

and earthed at the far end with the Earth Stake. The plug should be

inserted in the connector on the Generator/ Transmitter.

The Generator/ Transmitter is turned on to the lowest

Output Power Level, CF (MXT2 Transmitter only)

and Continuous Mode. The Locator should then

be held vertically above the longer cable,

approximately midway along it.

The depth can then be measured. It is best to make

a few readings at different depths.

Beware - metal step ladders affect the accuracy!

(MXL2 Locators only:

This procedure can then be repeated using 8kHz

and 640/512Hz).

NOTE These checks cannot be used to confirm the equipment is performing to the specifications

on page 57.

10m

10m

55

Page 56

Maintenance/General Symbols

Maintenance

Handling - C.Scope Locators and Generators/ Transmitters

are rugged instruments designed for the rigours of every

day use. However, to ensure that the specified accuracy

is maintained, it is essential to treat the instruments

with care by avoiding shocks, vibration and excesses

of temperature.

The construction of C.Scope Locators and Generators/

Transmitters incorporate weather proof seals, however,

they are not guaranteed to prevent water ingress if the

equipment is immersed.

Cleaning - The equipment can be cleaned with a sponge

dampened with warm water. A mild soap may be used if

required. The use of solvents should be avoided.

Do not allow moisture in the battery compartments or

near the connectors.

Storage - The equipment should be stored in a clean

and dry environment. The temperature should not exceed

the range -10˚C to +50˚C. If stored for long periods the

batteries should be removed.

General Symbols

Warning - Refer to manual.

Waste electrical products should not be disposed

of with household waste. Please recycle where

facilities exist. Check with your local authority

or retailer for recycling advice.

(In the UK visit www.recycle-more.co.uk)

Conforms to EEC safety requirements.

Tested to harmonised standards. There are

some restrictions on use in some EEC countries.

Contact Local Authorities.

Double Insulated.

56

Page 57

CXL2/DXL2/MXL2 Locators: Technical Specifications

Controls:

- On/Off Switch, spring loaded trigger switch under handle.

- Function Select Switch:

- 4 position:

P – Power Mode

R – Radio Mode

G - Generator Mode (or T – Transmitter Mode MXL2 only)

All

Scan Mode

A –

- Sensitivity Control.

- Depth Button. DXL2 MXL2 only

Pushbutton for live display of depth.

- Current Measurement Button. MXL2 only

Pushbutton for live display of Transmitter current.

- Frequency Select Button. MXL2 only

Pushbutton for Transmitter Mode frequency selection.

Indications:

Audio

- Removable and user replaceable loudspeaker module.

Visual:

Multi-segment Liquid Crystal Display with automatic backlight

gives indications of the following:

- Signal Strength

- Mode

- Battery Condition

- Self Test Indicator

When in Generator/ Transmitter Mode the following is also displayed:

- Frequency

- Depth (when selected) DXL2 MXL2 only

- Signal Current (when selected) MXL2 only

Data Logging:

Internal capacity for 12 months of data logged once per second.

Data logged includes Time/Date, Mode, Sensitivity Level, Received Signal Level,

Frequency, Depth, Self Test Result, Swing Indicator.

Data Connector:

Standard USB Mini B connector in battery compartment. USB 2.0 Compatible.

Self Test:

Built in Self Test cicuitry automatically triggered to run on first use of the day.

Swing Indicator:

Audio beep to indicate incorrect use of the Locator.

Generator Mode/ Transmitter Mode Frequencies:

Simultaneous 131,072Hz and 32,768Hz

Simultaneous 131,072Hz and 32,768Hz; 8,192Hz; and 640/512Hz MXL2 only

Performance:

Locate Accuracy:

better than ±5% of depth.

Depth Accuracy:

better than ±5% @ 10mA DXL2 MXL2 only

Depth Measurement Range:

Line 0.2m to 3m

Sonde 0.25m to 9.9m (depending on Sonde type)

Current Measurement:

0.01mA to 100mA MXL2 only

Construction:

- Case moulded from high impact plastic, sealed to IP65.

- Weight: 2.65kg (including batteries)

- Size: 720mm x 280mm x 65mm

- Designed to withstand 1m drop onto a hard surface.

Power Source:

- Internal 8 x ‘AA’ (LR6) cells (either alkaline non-rechargeable

or NiMH rechargeable)

- Battery Life: 40 hours intermittent use at 20ºC using alkaline cells.

Note:

Performance figures stated can be affected by site parameters such as ground

conditions, temperature, and strong electromagnetic fields.

All C.Scope Locators are in compliance with the essential requirements

and other relevant provisions of Council Directive 89/336/EEC. Compliance

has been demonstrated by testing representative samples to the relevant

harmonised standards.

All C.Scope Locators comply with the RoHS directive, 2002/95/EC.

57

Page 58

SGA2/SGV2 Generators and MXT2 Transmitter: Technical Specifications

Controls:

All operation is by push button control as follows:

- On/Off

- Power Level:

SGA2 2 available power levels via High and Low Power buttons

SGV2 4 available power levels via Increase and Decrease buttons

MXT2 cycles through 4 available power levels

- Frequency: (MXT2 only) cycles through 3 available output

frequencies using one push button

- Pulse/Continuous Output: toggles between pulse

or continuous output using one push button.

- Audio/Mute: toggles between high or low level audio output

using one push button

Indications:

Audio

- Audio Feedback on button push.

- Audio pitch drops with increasing load current in connected mode

- Audio pitch changes with power level in induced mode.

- Audio output pulses to indicate Pulsed Mode.

- Low battery indicated by interrupted Audio and output signal.

Visual (SGV2 and MXT2):

Multi-segment Liquid Crystal Display.

Gives indications of the following:

- Output Frequency

- Pulse Mode

- Continuous Mode

- Battery Condition

- Output level (bargraph)

- Speaker Mute

Output:

- Frequency (SGA2 and SGV2):

Induced = 32,768Hz.

Connected = 131,072Hz and 32,768Hz

- Frequency (MXT2 only):

Induced = 32,768Hz and 8,192Hz.

Connected = 131,072Hz and 32,768Hz, 8,192Hz and 640/512Hz.

- Carrier Pulse Frequency: 7.5Hz (pulsed mode)

- Audio pulse frequency: 3.75Hz (pulsed mode)

- MXT2 only: 640/512Hz is a factory set low frequency option.

Connected Mode:

Connection Mode automatically selected when lead is plugged into socket.

Maximum Output Voltage (open circuit): 28V rms

Maximum Output Current (short circuit): 65mA rms

Maximum Power: 1 Watt into 400Ω

Construction:

Case moulded from high impact plastic, sealed to IP65. Incorporates clip on

accessory storage compartment.

Weight: 3.4kg (including Batteries, Connection Leads and Earth Stake)

Size: 360mm x 180mm x 230mm with accessory compartment

Designed to withstand 1m drop onto a hard surface.

Power Source:

Internal 4 x ‘D’ (LR20) cells (either alkaline non-rechargeable

or NiMH rechargeable)

Battery Life (SGA2 and SGV2):

up to 40 hours intermittent use at 20ºC using alkaline cells.

Battery Life (MXT2 only):

up to 30 hours intermittent use at 20ºC using alkaline cells.

Note:

Performance figures stated can be affected by site parameters such as ground

conditions, temperature, and strong electromagnetic fields.

All C.Scope Generators/Transmitters are in compliance with the essential

requirements and other relevant provisions of Council Directive 1999/5/EC.

Compliance has been demonstrated by testing representative samples to the

harmonised standards EN300-330 and EN301-489.

The essential radio test suites have been carried out and the equipment

is in conformity with all applicable directives.

All C.Scope Generators/Transmitters comply with the RoHS directive, 2002/95/EC.

58

Page 59

Support Services: Training/Servicing/Repairs

Training - This manual is comprehensive but cannot

replace tuition. Excellent training is available directly

from C.Scope and via authorised C.Scope agents, cost

effectively, at your chosen location. We always

recommend that operators are trained before using

C.Scope Pipe and Cable Locators.

Calibration - These C.Scope Locators and Signal

Generators/Transmitters do not require periodic

re-calibration. However, where validation and

certification is a requirement this is available from

C.Scope and C.Scope Authorised Service Centres.

Servicing - Routine Servicing of your equipment

is available from C.Scope and C.Scope Authorised

Service Centres if required.

Repairs - Before returning equipment suspected of being

faulty, please check the machine carefully with a fresh set

of batteries. Check the battery connections and rotate the

batteries in the holder. Refer to the section in the manual