CSC SG250 Owner's And Service Manual

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

Contents

Foreword ....................................................................................................................................................... 4

Caution and Warning Symbols ...................................................................................................................... 4

Section 1: Owner’s Manual .......................................................................................................................... 5

General Motorcycle Safety Guidance ........................................................................................................... 5

Inspections Before Riding ............................................................................................................................. 6

Motorcycle Specifications ............................................................................................................................. 6

Motorcycle Description ................................................................................................................................. 8

Controls ......................................................................................................................................................... 9

Ignition Lock and Fork Lock ........................................................................................................................... 9

Fork Lock ....................................................................................................................................................... 9

Instruments ................................................................................................................................................... 9

Left and Right Handlebar Switchgear ........................................................................................................... 9

Fuel, Fuel Tank, Filler Cap, and Petcock ...................................................................................................... 10

Choke .......................................................................................................................................................... 11

Load Limits .................................................................................................................................................. 11

Tool Kit ........................................................................................................................................................ 12

Engine Break-In Procedure ......................................................................................................................... 12

Starting the Motorcycle .............................................................................................................................. 12

Operating the Motorcycle ........................................................................................................................... 13

Cleaning the Motorcycle ............................................................................................................................. 13

Storing the Motorcycle ............................................................................................................................... 14

Section 2: Service Manual ......................................................................................................................... 16

Maintenance Cautions and Warnings ......................................................................................................... 16

Component Cleaning................................................................................................................................... 16

Parts Inspection .......................................................................................................................................... 17

Maintenance Adjustments .......................................................................................................................... 17

Recommended Tools .................................................................................................................................. 17

Adjustment Specifications .......................................................................................................................... 17

Motorcycle Maintenance Schedule ............................................................................................................ 18

Torque Values ............................................................................................................................................. 18

Unpacking ................................................................................................................................................... 19

Inspection .................................................................................................................................................... 19

Frame and Body .......................................................................................................................................... 19

Brakes .......................................................................................................................................................... 20

Master Cylinder Location ............................................................................................................................ 20

Front Brake Pad Inspection and Replacement ............................................................................................ 21

Rear Brake Pad Inspection and Replacement ............................................................................................. 22

Front Brake Rotor Inspection ...................................................................................................................... 23

Flushing and Replacing the Brake Fluid ...................................................................................................... 24

Bleeding the Brakes .................................................................................................................................... 24

Brake Troubleshooting ................................................................................................................................ 24

Power Transmission .................................................................................................................................... 25

Chain Drive System ..................................................................................................................................... 25

1

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

Chain Lubrication ........................................................................................................................................ 25

Chain Adjustment ....................................................................................................................................... 25

Sprocket and Chain Inspection ................................................................................................................... 27

Chain Drive Troubleshooting ...................................................................................................................... 28

Clutch Maintenance .................................................................................................................................... 28

Clutch Cable Installation and Adjustment .................................................................................................. 29

Clutch Replacement .................................................................................................................................... 30

Clutch Troubleshooting ............................................................................................................................... 39

Suspension .................................................................................................................................................. 40

Forks ............................................................................................................................................................ 40

Changing Fork Oil and Replacing Fork Seal ................................................................................................. 40

Swingarm and Rear Suspension .................................................................................................................. 44

Swingarm and Rear Suspension Troubleshooting ...................................................................................... 47

Steering System .......................................................................................................................................... 48

Steering Stem Bearing Adjustment ............................................................................................................. 48

Steering System Troubleshooting ............................................................................................................... 50

Wheels and Tires ......................................................................................................................................... 50

Front Wheel Removal ................................................................................................................................. 51

Rear Wheel Removal ................................................................................................................................... 52

Wheel and Tire Inspection .......................................................................................................................... 55

Wheel and Tire Troubleshooting ................................................................................................................ 55

Fixing Flat Tires ........................................................................................................................................... 55

Engine.......................................................................................................................................................... 58

Oil Change ................................................................................................................................................... 58

Spark Plug Removal and Installation ........................................................................................................... 62

Valve Adjustment ........................................................................................................................................ 62

Carburetor ................................................................................................................................................... 69

Air Filter Replacement ................................................................................................................................ 80

Exhaust System ........................................................................................................................................... 81

Engine Troubleshooting .............................................................................................................................. 83

Fuel System ................................................................................................................................................. 84

Fuel System Troubleshooting...................................................................................................................... 87

Control Cables ............................................................................................................................................. 88

Clutch and Throttle Cable Troubleshooting ................................................................................................ 88

Electrical System ......................................................................................................................................... 88

Battery......................................................................................................................................................... 93

Lighting and Turn Signals ............................................................................................................................ 95

Charging System .......................................................................................................................................... 97

Starting System ......................................................................................................................................... 100

Electrical System Troubleshooting ............................................................................................................ 105

Electrical Schematic .................................................................................................................................. 107

Appendix A - Service Checklists ................................................................................................................ 108

2

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

A Word From Steve

Thank you for purchasing this CSC San Gabriel 250 motorcycle. The SG250 is a great motorcycle and we

are very proud of it. The SG250 is easy to maintain, it’s reliable, and it’s fun. You’ve made a wise

purchase decision.

I want you to know that we value the trust and confidence you have in CSC. Our guiding principle will

always be that our customers come first.

We wish you many miles of safe and enjoyable riding on your new SG250 motorcycle. If there’s

anything we can do to enhance your ownership experience, please let us know.

Thank you again,

Steve Seidner

Founder and CEO

CSC Motorcycles, LLC

1331 W. Foothill Boulevard

Azusa, California 91702

909 445 0900

www.CSCMotorycles.com

3

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

Foreword

The SG250 Owner’s and Service Manual provides information on operating and maintaining the CSC

SG250 motorcycle. It includes the motorcycle’s technical specifications, performance parameters, and

operating, maintenance, and adjustment data. This manual includes both the Owner’s Manual and the

Service Manual. The Owner’s Manual is included in the first section of this document; the Service

Manual in included in the second section of this document.

CSC Motorcycles stocks all SG250 motorcycle parts, and we recommend that you use only parts and

materials provided by us when servicing or maintaining your motorcycle.

The SG250 Owner’s and Service Manual is provided free to all who purchase a new CSC SG250

motorcycle.

Reproduction of the CSC SG250 Owner’s and Service Manual or posting it online without CSC’s

permission is expressly prohibited.

If you have any questions, please contact CSC Motorcycles by calling us at 909 445 0900 or via email at

info@CSCMotorcycles.com.

Caution and Warning Symbols

Caution and warning symbols in this manual are as follows:

The Caution! symbol indicates a condition that may lead to motorcycle damage.

The Warning! symbol indicates a condition that may lead to injury or death.

4

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

Section 1: Owner’s Manual

General Motorcycle Safety Guidance

Warning! Do not attempt to ride this motorcycle on public roads if you do not have a motorcycle

license.

Warning! Do not attempt to ride this motorcycle if you do not know how to ride a motorcycle.

Warning! Always wear appropriate motorcycle gear when riding your motorcycle. Never ride your

motorcycle without wearing an approved helmet, a motorcycle jacket, eye protection, gloves,

motorcycle pants, and boots.

Warning! Always remain alert while operating your motorcycle. Pay attention to traffic conditions and

the road surface. Adjust your speed and following distances taking these factors into consideration.

Warning! Never operate your motorcycle while under the influence of drugs or alcohol, or when sleep

deprived.

Warning! The motorcycle’s cylinder, cylinder head, and exhaust system are hot when the motorcycle is

running and after turning it off. Do not touch these items.

Warning! Always maintain appropriate tire pressure. Operating the motorcycle with low tire pressure

will adversely affect the motorcycle’s handling.

Warning! Replace worn tires promptly.

Warning! Never attempt to lubricate the chain by running the engine, putting the motorcycle in gear,

and lifting the rear of the motorcycle. Lubricate the chain with the engine off.

Warning! Make sure the choke is fully open when riding the motorcycle.

Warning! Do not attempt to reach under the tank to open or close the choke while riding the

motorcycle.

Warning! Do not overload the motorcycle or load it unevenly.

Warning! Do not attempt to carry more than one passenger (in addition to the rider).

Warning! Do not attempt to perform “wheelies.”

Caution! Don’t park your motorcycle facing downhill without leaving the motorcycle in gear, or it may

roll forward and fall down.

Caution! Never operate your motorcycle without the air filter, the muffler, and all emissions

components in place. Doing so will reduce performance, damage the engine, and void your warranty.

5

SG250 Owner’s and Service Manual

General

Type

Dual sport

Designation

CSC San Gabriel 250

Colors

Mocha, White, Black, Blue

Fuel

87 octane

Fuel Capacity

4.0 US gallons

Top Speed

Dependent on gearing and rider weight; approximately 70 mph with 15T

countershaft sprocket and 50T rear sprocket. Other gear ratios available

from CSC.

Powertrain

Engine Configuration

Single cylinder, air cooled, 2 valve, carbureted, counterbalanced, choke

www.CSCMotorcycles.com

Inspections Before Riding

Before riding your motorcycle, you should check the following:

Both tires are appropriately inflated.

Neither tire has nails nor other foreign objects embedded in the tread or the sidewall.

The fuel tank contains adequate fuel, and the fuel petcock is in the ON position. If the fuel

petcock is in the RESERVE position, fill the fuel tank at the next opportunity.

The crankcase has oil. You can check the oil level using either the dipstick or the crankcase

viewing port.

The turn signals, the front and rear brake lights, the horn, and the headlight all operate when

commanded to do so (the ignition switch must be in the ON position).

The front and rear brake levers have adequate free play.

The front and rear brakes operate.

The forks turn freely from side to side.

The rear-view mirrors are adjusted appropriately.

The engine kill switch is in the RUN position.

The chain has appropriate slack.

Major threaded fasteners are tight. We always hand check the axle nuts, the exhaust header

nuts and bolts, the muffler bolts and nuts (grab the muffler and check it for any side-to-side

play), the steering stem nut, and the front and rear caliper bolts.

Motorcycle Specifications

6

SG250 Owner’s and Service Manual

Bore x Stroke

66.5mm x 66.2mm

Displacement

229.9 cc

Compression Ratio

9.6:1

Horsepower

16.1 @ 7000 rpm

Torque

13.5 ft-lb

Oil Type

10W 40, motorcycle type

Oil Capacity

1.3 quart

Starting

Electric and kick

Primary Type

Gear driven

Transmission

5 speed, constant mesh

Front/Rear Sprockets

15T/50T

Chain Type

428

Brakes

Type

Hydraulic disk front, drum rear

Front Disk Diameter

9.00 inches

Rear Drum Diameter

6.50 inches

Wheels and Tires

Wheels

Aluminum, spoked

Front Tire

90/70/17

Rear Tire

120/70/17

Front & Rear Tire Pressure

36 psi front, 40 psi rear

Switchgear/Controls

Instrumentation

Speedometer, tachometer, odometer, tripmeter, neutral indicator, turn

signal indicator, high beam indicator, fuel gage

Dash Cluster

Keyed ignition switch

Left Handlebar

High/low beam, horn, turn signals, high beam flash, choke

Right Handlebar

Engine kill switch, starter

Chassis and Suspension

Ground Clearance

6.3 inches

Seat Height

26.0 inches

Handlebar Height

35.0 inches

Footpeg Height (rider)

10.0 inches

Footpeg Height (passenger)

16.0 inches

Helmet Lock

Left rear frame

Tool kit

Right frame under battery

Wheelbase

52.0 inches

Weight

273 lbs

Gross Vehicle Weight Rating

573 lbs

Frame

Tubular steel

Rear Suspension Travel

2.3 inches

Front Suspension Type

Telescopic fork, upper fork diameter 32mm, lower fork diameter 43mm

Front Suspension Travel

4.0 inches

Rake

27 degrees

Rear Suspension

Twin nitrogen-charged shocks

www.CSCMotorcycles.com

7

SG250 Owner’s and Service Manual

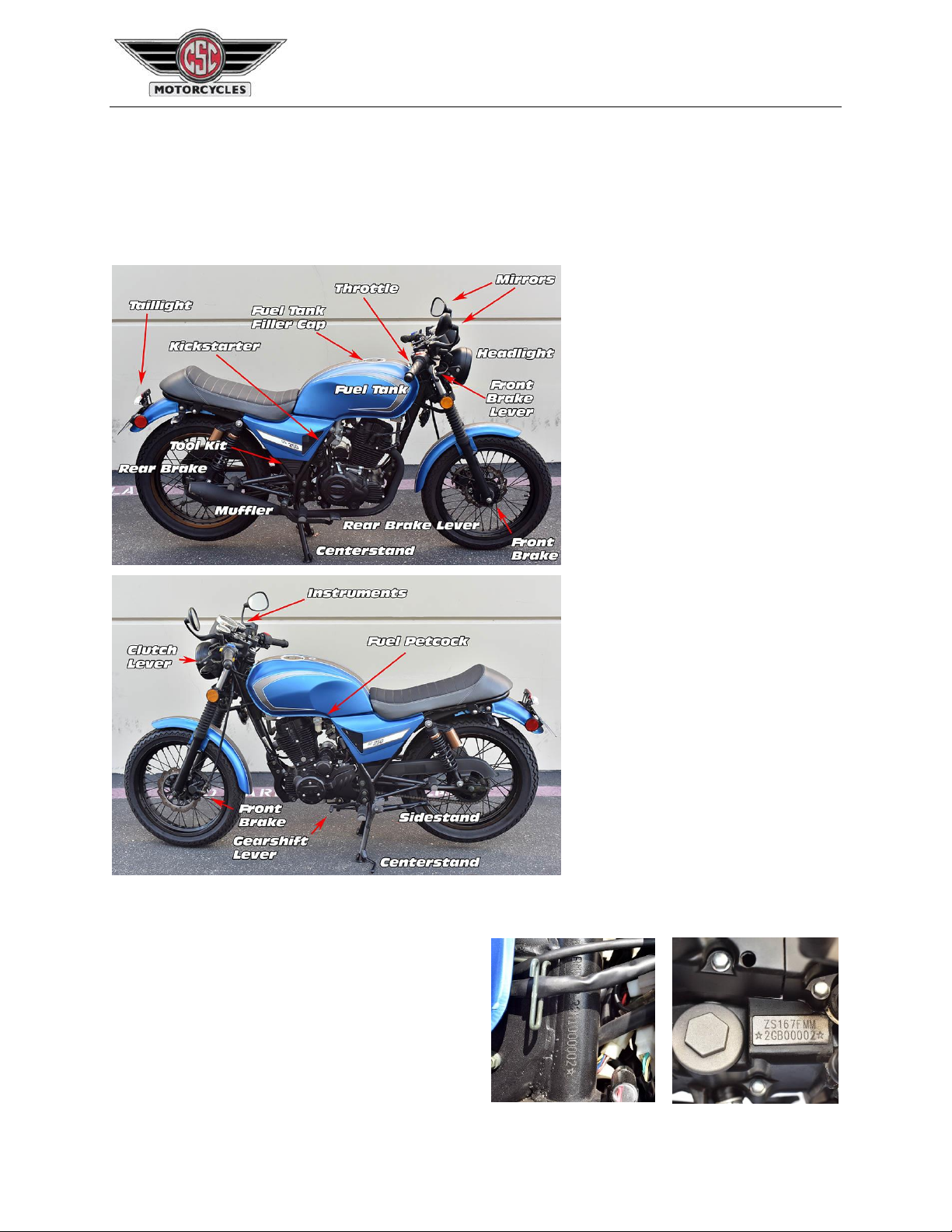

SG250 Right Side View

SG250 Left Side View

The vehicle identification number is located on the

right side of the steering stem, as shown in the

photo to the right.

The engine serial number is shown on the lower left

side of the engine crankcase (behind the shift

lever), as shown in the photo to the right.

www.CSCMotorcycles.com

Motorcycle Description

The CSC SG250 motorcycle is a 250cc street motorcycle. The motorcycle has a single-cylinder, 4-stroke,

air-cooled engine and a 5-speed transmission. Major components are identified in the photographs

below.

Vehicle Identification Number and Engine Number

8

SG250 Owner’s and Service Manual

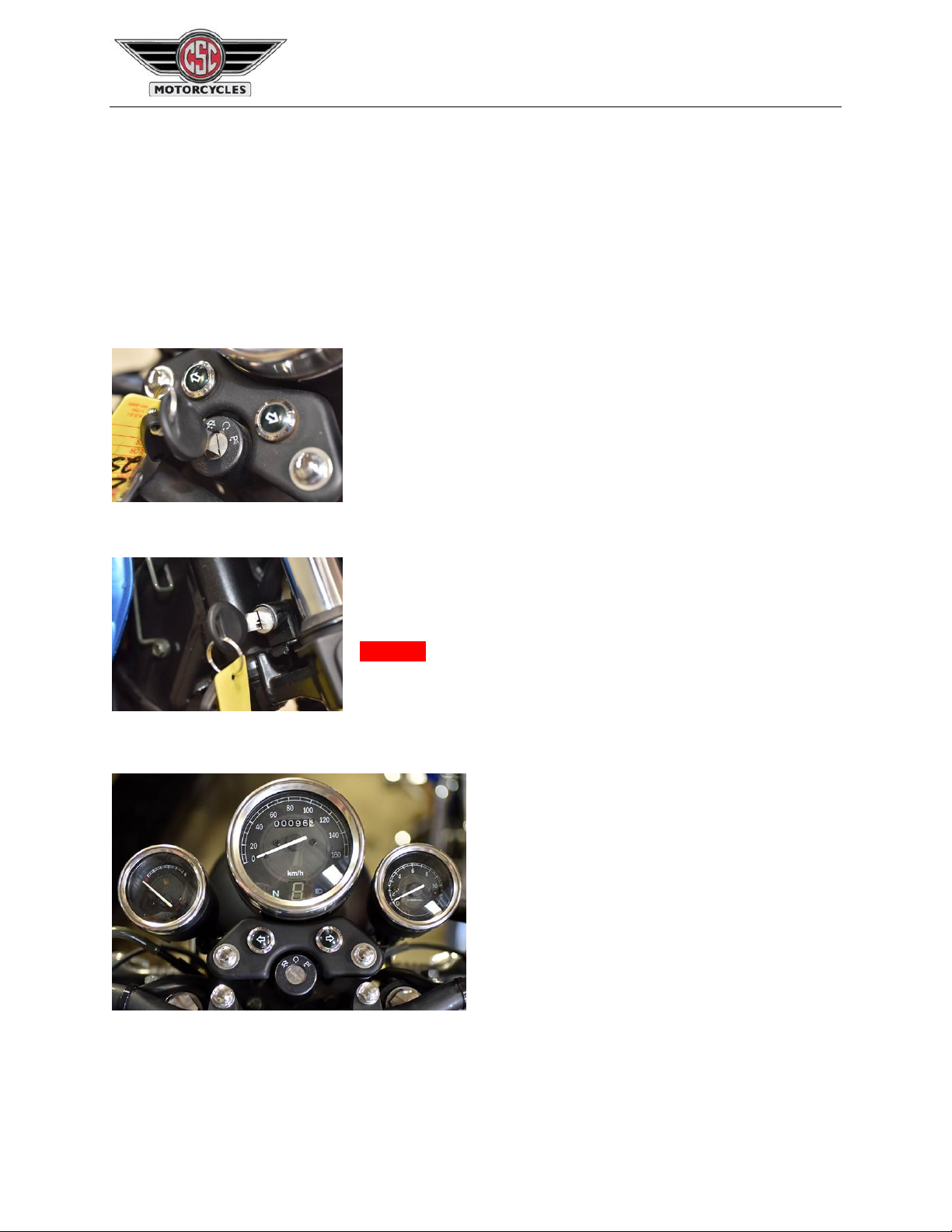

The motorcycle key operates the ignition lock. Insert the key and

turn it to the right to turn the ignition on. The ignition switch also

operates the parking light.

If you need additional keys, CSC stocks the key blanks for the SG250

motorcycle. Please call us at 909 445 0900 if you need to make

additional keys for your motorcycle.

The fork lock is located on the left side of the frame near the

steering yoke. To lock the forks, turn the forks all the way to the left.

Insert the ignition key, rotate it, and withdraw the key.

Warning! Do not attempt to ride the motorcycle with the forks in

the locked position.

SG250 instrumentation includes a speedometer, a

tachometer, an odometer, a fuel gage, turn signal

indicators, a high beam indicator, and a gear

indicator.

www.CSCMotorcycles.com

Controls

The motorcycle is operated with the ignition switch, the instruments, the throttle, the clutch, the front

brake lever, and the rear brake lever. You can start your motorcycle using either the kick starter or the

electric starter. Locations for these items are shown in the photos above and below. Operating the

motorcycle is explained below.

Ignition Lock and Fork Lock

Fork Lock

Instruments

Left and Right Handlebar Switchgear

Left handle switchgear includes the passing light, the high beam/low beam switch, the turn signals, and

the horn. The high beam/low beam flash switch momentarily activates the motorcycle’s high beam

9

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

when the low beam is on. You can use it to alert a vehicle you are about to pass. The high beam/low

beam switch is used to switch between the high beam and low beam. The turn signals are activated

when the turn signal is pushed either to the right or to the left. The turn signals are not self-cancelling;

you must depress the turn signal switch sharply in its center position to turn the turn signal off. The

horn button sounds the horn.

Right handlebar switchgear includes the engine kill switch and the starter switch. The kill switch is used

to shut all electrical power to the motorcycle. Do not routinely use the kill switch to stop the engine

(use the ignition switch instead). The starter switch is used to start the engine after the ignition switch is

turned on.

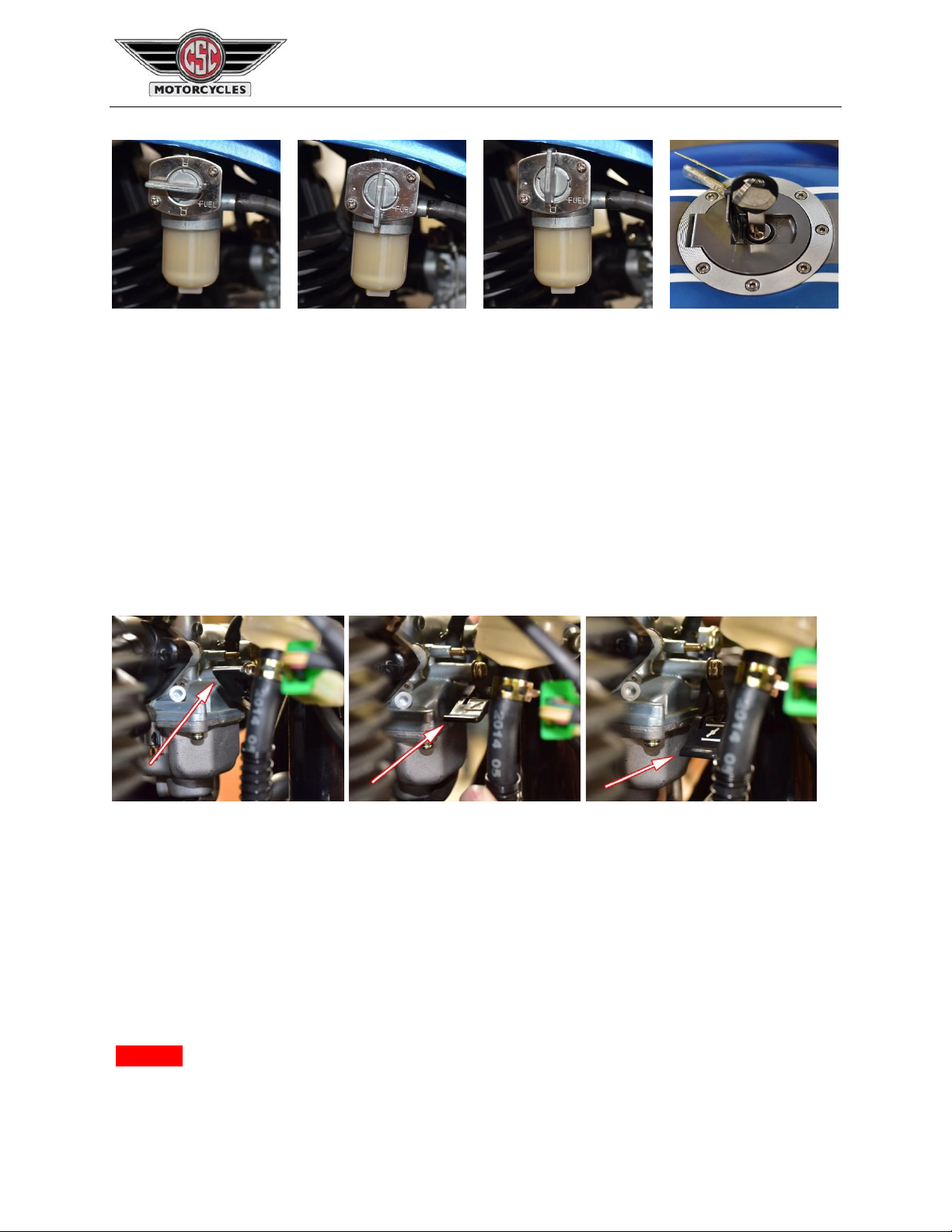

Fuel, Fuel Tank, Filler Cap, and Petcock

The SG250 fuel tank holds 4.0 gallons of fuel. Use 87 octane or higher fuel.

The fuel petcock is located on left side of the tank. Turn the petcock to the OFF position when you are

not riding the motorcycle. Turn the petcock to the RUN position prior to operating the motorcycle. If

the motorcycle runs out of fuel, turn the petcock to the RESERVE position. Find a fuel station and fill

the motorcycle as soon as possible after the fuel petcock switching to the RESERVE position.

The fuel tank filler cap is a locking cap. To open it, insert the ignition key in the fuel tank and turn it

clockwise. After filling the fuel tank, push down firmly on the filler cap to lock it.

10

SG250 Owner’s and Service Manual

Off

Normal Operation

Reserve Operation

Filler Cap

www.CSCMotorcycles.com

Choke

The choke is located on the left side of the carburetor underneath the fuel tank. When the choke lever

is all the way down, the choke is not engaged. When the choke is all the way up, the choke is fully on.

There is an intermediate position halfway between the choke open and fully‐choked position.

When starting the motorcycle with a cold engine, push the choke lever all the way up to the fully‐choked

position. After the engine has warmed slightly, push the choke to the intermediate position. After the

engine has warmed, open the choke fully by pushing the choke lever all the way down.

Choke Fully On Intermediate Choke Choke Fully Open

Do not ride the motorcycle until the engine is fully warmed and the choke lever is in the fully open (all

the way down) position.

Warning! Do not attempt to actuate the choke lever while riding the motorcycle.

Load Limits

The SG250 motorcycle weighs 273 lbs. The gross vehicle weight rating is 573 lbs.

Warning! Do not overload or unevenly load the motorcycle or the handling will be adversely affected.

11

SG250 Owner’s and Service Manual

The SG250 includes a tool kit stored in a container

on the right side of the motorcycle beneath the

battery. Pull up on the tab beneath the tool kit

cover and the cover will rotate up, providing access

to the tool kit.

www.CSCMotorcycles.com

Tool Kit

Engine Break-In Procedure

When an internal combustion engine is new, it should not be subjected to hard acceleration, lugging,

overheating, or running for long periods at a constant engine speed. You should avoid these situations

during the first 500 miles of service. Caution! Do not violate the guidance provided here, or you may

damage your motorcycle engine.

We recommend the first oil change when the motorcycle reaches between 200 and 500 miles. We

recommend a second oil change at 1,000 miles, and every 2,500 miles thereafter. We recommend

using only 10-40W motorcycle oil. Caution! Never use any oils intended for automotive use, or any oil

that contains friction reducing additives (use of these oils will induce clutch slippage not covered by the

CSC warranty).

Use only non-synthetic oils during the first 1000 miles of use. After that, you may wish to change to

synthetic motorcycle oil.

The oil change procedure is outlined in the Oil Change section of this Owner’s and Service Manual.

Starting the Motorcycle

After completing the pre-ride inspection, you can start the motorcycle using either the kickstarter or the

electric starter. Follow the steps listed below:

Put the fuel petcock in the RUN position.

In cold weather, close the choke.

Insert the ignition key and turn it to the ON position. Make sure the transmission is in the

neutral position. Make sure the engine kill switch is in the RUN position.

If using the kick starter, vigorously kick the engine through a compression cycle, while opening

the throttle slightly.

If using the electric starter, depress the start button while opening the throttle slightly. Do not

crank the engine with the electric starter for more than a few seconds.

12

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

After the engine starts, allow it to warm for at least one minute. As the engine warms, open

the choke an intermediate position and then after the engine has warmed to the fully open

position (the choke lever should be all the way forward).

Operating the Motorcycle

Operate the motorcycle as outlined below:

After completing the pre-ride inspection in the Inspections Before Riding section and putting on

your riding gear (helmet, gloves, jacket, eye protection, and other protective riding apparel),

mount the motorcycle. Warning! Do not attempt to hold the motorcycle upright while putting

on your riding gear. You could drop the motorcycle and injure yourself. Put all of your riding

gear on before you get on the motorcycle.

Straddle the motorcycle.

Start the motorcycle as outlined above.

If the motorcycle is on the centerstand, push it forward to take it off the centerstand. If the

motorcycle is on the sidestand, lift the sidestand to the retracted position. Warning! Do not

ride the motorcycle with the sidestand down.

Pull in the clutch and push the gearshift lever down to put the motorcycle in first gear.

Open the throttle slightly and engage the clutch.

As the motorcycle accelerates, pull in the clutch, pull up on the gearshift lever, and engage

second gear. Repeat the above process to engage third, fourth, and fifth gear.

When you need to stop, allow the throttle to close and apply both the front and rear brakes.

Warning! Do not apply the brakes too aggressively, as this can induce a skid. Be cognizant of

the road surface and adjust braking force appropriately.

As the motorcycle slows, pull in the clutch, depress the gear shift lever to shift to a lower gear,

and release the clutch. Match your speed as you decelerate to the gear you are downshifting

to. Warning! If you downshift too aggressively (i.e., you downshift to too low a gear for your

speed), you can induce a skid.

Repeat the above process, using engine braking and the front and rear brakes to slow the

motorcycle. Prior to coming to a complete stop, pull in the clutch. Shift the motorcycle to

neutral.

If you wish to park the motorcycle, turn off the ignition key. Caution! Do not use the kill switch

for routine stops and leave the ignition key in the ON position when the engine is not running.

This will run down the battery.

Deploy the sidestand and lean the motorcycle to the left. Make sure the sidestand is fully

forward prior to leaning the motorcycle to the left. Caution! Do not park the motorcycle with

the front end angled downward; it could roll forward (off the sidestand) and fall.

Lock the front forks. Caution! Do not leave the ignition key with the motorcycle.

Cleaning the Motorcycle

Clean your motorcycle when it becomes dirty as outlined below:

Wash the motorcycle with low pressure water to loosen and remove mud, insects, and other

debris.

13

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

Wash the motorcycle using soapy water. Rinse the motorcycle. Caution! Do not spray water

directly into the muffler.

Clean the chain using a suitable chain cleaner.

Dry the motorcycle with a towel or a chamois.

Lubricate the chain with a suitable chain lubricant. Caution! Do not spray lubricant directly into

the brakes.

Wax the motorcycle using a suitable wax.

Warning! When riding the motorcycle after cleaning it, actuate the brakes to make sure they

have not been degraded as a result of cleaning the motorcycle.

CSC stocks numerous cleaning and lubrication products; please call us at 909 445 0900 to order these

items.

Storing the Motorcycle

For storage longer than 60 days, store the motorcycle as outlined below:

Drain the fuel from the fuel tank, the fuel lines, and the carburetor. Close the fuel tank cap.

Remove the spark plug and add 5cc of motor oil into the cylinder. Reinstall the spark plug. With

the ignition switch in the OFF position, cycle the engine several times with the kick starter.

Remove the battery, charge it, and store it in a cool and dry environment.

Support the motorcycle on blocks to prevent tire damage.

Cover the motorcycle to protect it from dust, moisture, and other contaminants.

Add fuel stabilizer to the fuel to prevent gumming in the tank, the carburetor, or the fuel lines.

After storage, charge and reinstall the battery. Add fuel. Replace the engine oil if the

motorcycle has been in storage longer than 6 months.

For shorter storage intervals, we recommend attaching the motorcycle to a Battery Tender.

14

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

CSC stocks all the items described above. Please call us at 909 445 0900 to order any of the items

described above.

15

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

Section 2: Service Manual

Maintenance Cautions and Warnings

When you maintain or repair the motorcycle, please use original components and parts, accessories,

lubricating oil and other materials that are made or recognized by CSC Motorcycles. Caution! If you use

any parts or components other than those recommended by CSC, it may adversely affect the

performance, reliability, stability, or warranty of your motorcycle.

When working on your motorcycle, you should follow this guidance:

Warning! Whenever the motorcycle is to be reassembled after disassembly, washers, seals, and

cotter pins need to be replaced.

When you fasten a series of bolts or nuts, you should do so in a diagonal pattern.

Warning! Do not use flammable cleaning fluid to clean components and parts.

Caution! Before assembly operations, add lubricating oil or lubricating grease to lubricated

surfaces.

Warning! After assembly, make sure all parts are properly assembled and tightened.

Warning! Stop the engine when repairing the motorcycle.

Warning! If the maintenance operation needs to be done while the engine is working, make

sure the area is well-ventilated.

Warning! Gas is flammable and combustible, so do not smoke or provide ignition sources in the

work area.

Warning! The battery can liberate hydrogen, which is flammable. Do not smoke, ignite or make

sparks near the battery, especially when it is charging.

Warning! The electrolyte of the battery contains sulfuric acid. If your eyes, skin or clothes are

splashed with electrolyte, rinse them thoroughly with water and seek immediate medical

attention.

Warning! Disconnect the negative battery terminal when performing any maintenance on the

motorcycle engine, drive train, or fuel system.

Component Cleaning

After parts are disassembled, they may need to be cleaned. Cleaning methods vary according to the

characteristics of the parts.

To remove oil or grease contamination, CSC recommends using Simple Green or other similar

degreasing agents.

Warning! Never use gasoline as a cleaning agent.

To remove carbon deposits, use mechanical or chemical methods. The mechanical method uses

a wooden or plastic scraper or blade to clear the carbon deposit first, and then rinse the parts

with an appropriate cleaning agent. The chemical method is to soak the parts in the cleaning

agent first, then clean them with a brush, and then rinse them with hot water.

16

SG250 Owner’s and Service Manual

Item

Adjustment Limits

Clutch lever free play (at tip)

¼ to ½ inch

Throttle free travel

2-5 degrees

Drive chain

3/5 inch

Valve gap (at TDC)

0.04 to 0.08 mm

Tire pressure (front/rear)

40/36 psi

www.CSCMotorcycles.com

Parts Inspection

Parts should be inspected after they are cleaned. The purpose of inspection is to check if the parts need

to be repaired or replaced.

Maintenance Adjustments

The SG250 motorcycle requires adjustments in the following areas:

The clutch must be adjusted according to the maintenance instructions included in this manual.

The main adjustment feature is the clutch lever free travel (¼ to ½ inch), and the clutch cable

adjusting mechanism. This Service Manual presents the procedure for clutch adjustment.

The throttle cable adjustment is performed at the throttle. The throttle should have 2 to 5

degrees of free rotation. This adjustment is presented in this Service Manual.

The drive chain is adjusted by positioning and aligning the rear wheel. The drive chain should

have 3/5 inch of free play. The drive chain adjustment procedure is explained in this Service

Manual.

The valves should be adjusted to the specified gap. This Service Manual presents the procedure

for adjusting the motorcycle’s valve.

Tire pressure should be maintained at 40 psi for the front tire and 36 psi for the rear tire.

Recommended Tools

The CSC SG250 motorcycle includes a basic tool kit that is stored under the battery. These tools are

suitable for emergency repairs only. CSC sells custom tool kits with professional grade tools; please

contact us at 909 445 0900 to order tools.

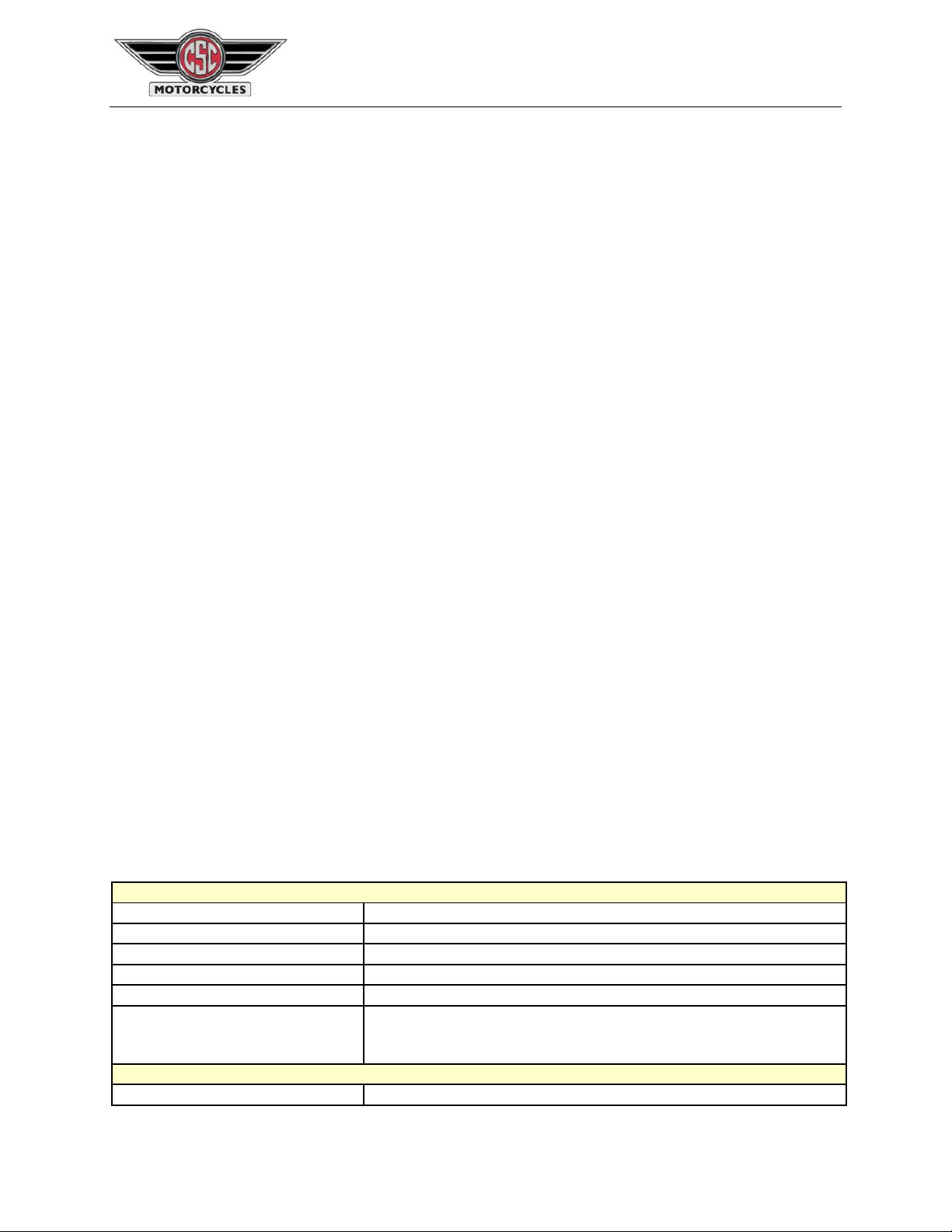

Adjustment Specifications

17

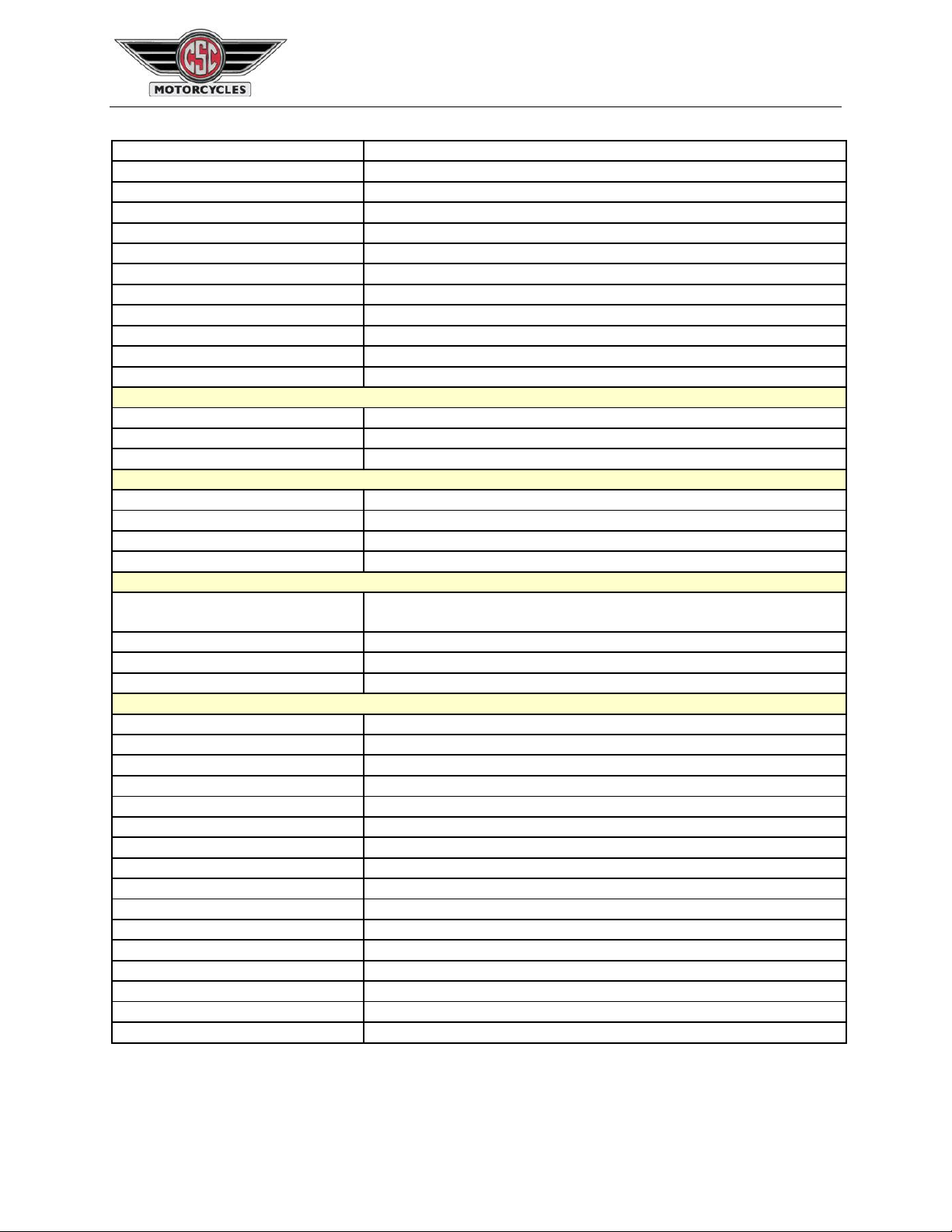

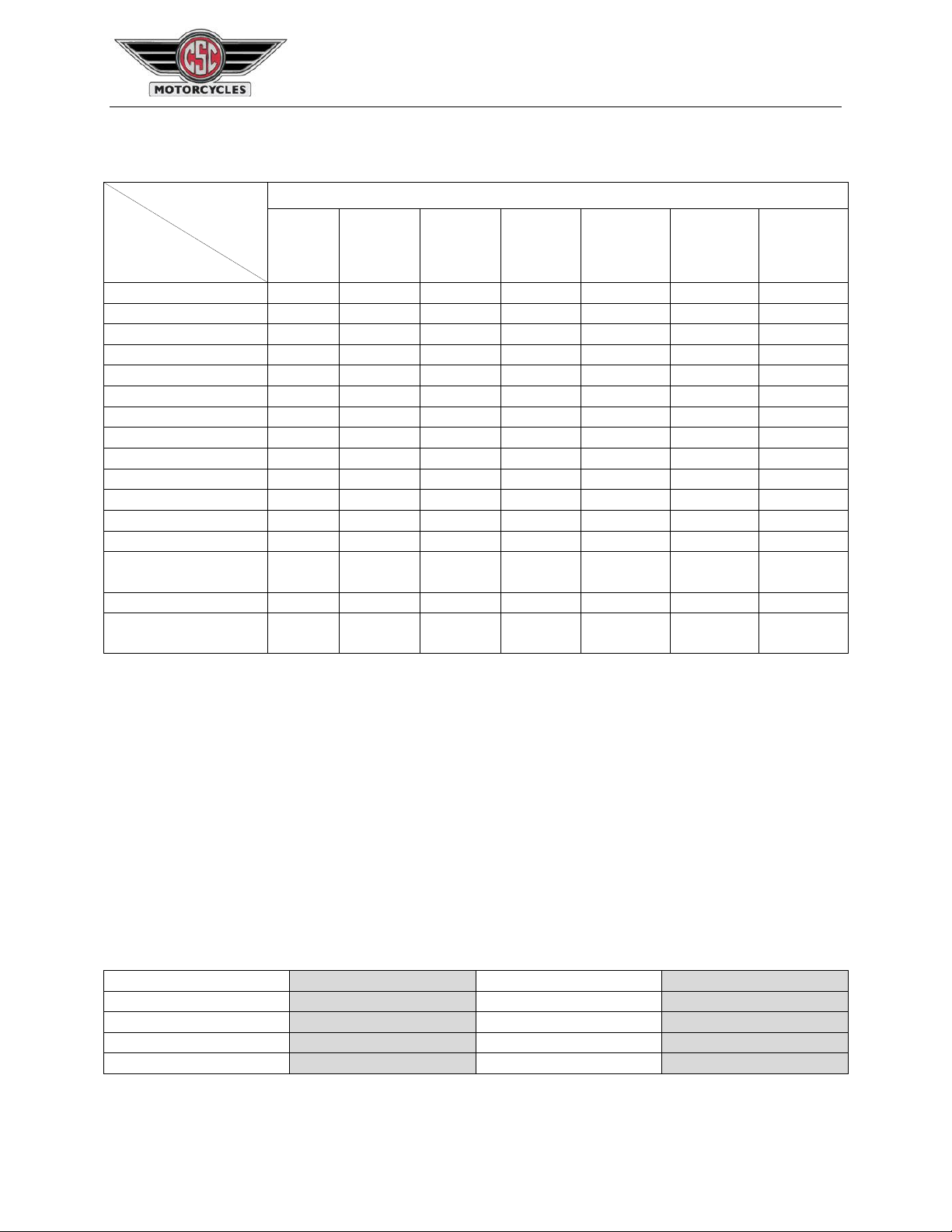

Motorcycle Maintenance Schedule

Maintenance

Times

Maintenance

Item

Odometer (miles)

500

miles

2,500

miles

5,000

miles

7,500

miles

10,000

miles

12,500

miles

15,000

miles

Fuel system

I I I

Fuel filter

I I I I I I I

Air cleaner element

I I I I I I I

Spark plug gap

l l l l l l l

Valve lash

l l l l l l l

Oil change

I/L

I/L

I/L

I/L

I/L

I/L

I/L

Rear chain

I/L

I/L

I/L

I/L

I/L

I/L

I/L

Battery l l l l l l

l

Brake pad wear

l l l l l l l

Braking system

l l l l l l l

Stop lamp switch

l l l l l l l

Headlamp

l l l l l l l

Sidestand

l l l l l l l

Front and rear

suspension

l l l l l l l

Nuts/bolts/ fasteners

l l l l l l l

Front/rear wheel

bearings

l l l l l l l

Bolt Size (mm)

Torque (ft-lbs)

Bolt Size (mm)

Torque (ft-lbs)

6

3-5

14

60

8

8-12

16

60-94

10

15-22

18

60-130

12

39

20

166-188

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

The motorcycle should be maintained according to the schedule above. The symbols are defined below:

R-rinsing

L-lubrication

l-inspection, cleaning, adjustment, lubrication or replacement

If you operate the motorcycle in dusty areas, the maintenance cycle should be shortened.

Torque Values

A table for general torque values follows. In various places in this Service Manual, specific torque values

may be provided, and you should use those where specified. In all other instances, use the values

provided below. The values provided throughout are for clean, dry threads.

18

SG250 Owner’s and Service Manual

Item

Cause

Symptom

Vehicle Effect

Maintenance Action

Frame

Frame is hit or falls

over

Frame is curved or

deformed

Drift

Correct or replace the

frame

Frame is hit or falls

over

Frame is cracked or

fractured

Motorcycle cannot drive

Weld or replace the

frame

Frame is impacted

and shocked by road

Frame welding

detachment

Shake or drift

Weld the frame

www.CSCMotorcycles.com

Unpacking

When the motorcycle is delivered, check the condition of the delivered crate. If there are any

anomalies, stop and call CSC at 909 445 0900. Check the VIN numbers on the exterior of the crate.

Compare these numbers to the documentation delivered to you prior to the motorcycle’s arrival. If the

numbers don’t match, stop and call CSC at 909 445 0900.

Inspection

Perform the following inspections when servicing the motorcycle.

Check to confirm all fasteners are properly tightened and all components are installed correctly

and in an operational state.

Swing the handlebars from side to side to make sure motion is uninhibited.

Check chain tension and rear wheel alignment in accordance with the requirements of this

Service Manual.

Insert the ignition key and turn it on.

Check horn function, turn signals, headlight high and low beam, brake lights for front and rear

brake activation, and instrument panel readout.

Check oil level and tire pressure.

Confirm the motorcycle is in neutral.

Place the clutch in, close the choke, and start motorcycle. Allow engine to warm.

Check brake and suspension function.

Test ride motorcycle to confirm operability.

Detailed inspection checklists are included in Appendix A of this Service Manual.

Frame and Body

The frame and body subsystem include the motorcycle’s steel frame, the seat, the body panels, the

sidestand, the Footpeg, the tool kit, and the fenders.

The tool kit is stored in a container under the battery.

The seat is held in place by two bolts. The rear seat can be removed to provide access to some of the

motorcycle’s electrical components.

Frame and body maintenance and troubleshooting guidelines are summarized below.

Frame and Body Maintenance and Troubleshooting

19

SG250 Owner’s and Service Manual

Item

Cause

Symptom

Vehicle Effect

Maintenance Action

Sidestand

Deformation or

fracture

Sidestand cannot

return

Noise and compromised

parking

Correct or replace the

side support

Left or right

rear panel

Impact

Panel damaged

Compromised

appearance

Replace or repair the

panel

Left or right

tank panel

Impact

Panel damaged

Compromised

appearance

Replace or repair the

panel

Front fender

Impact

Deformation or

breakage

Compromised

appearance

Replace the front

fender

Rear fender

Impact

Deformation or

breakage

Compromised

appearance

Replace the rear

fender

Seat cushion

Impact

Seat cushion

damaged

Riding comfort

decreases

Replace the seat

Front footpeg

Impact

Deformation or

breakage

Compromised driving

safety

Replace the footpeg

Rear footpeg

Impact

Deformation or

breakage

Compromised driving

safety

Replace the footpeg

Rearview

mirror

Impact

Deformation or

breakage

Compromised driving

safety

Replace the rearview

mirror

Rear rack

Impact

Deformation

Compromised

placement of items

Replace the rear rack

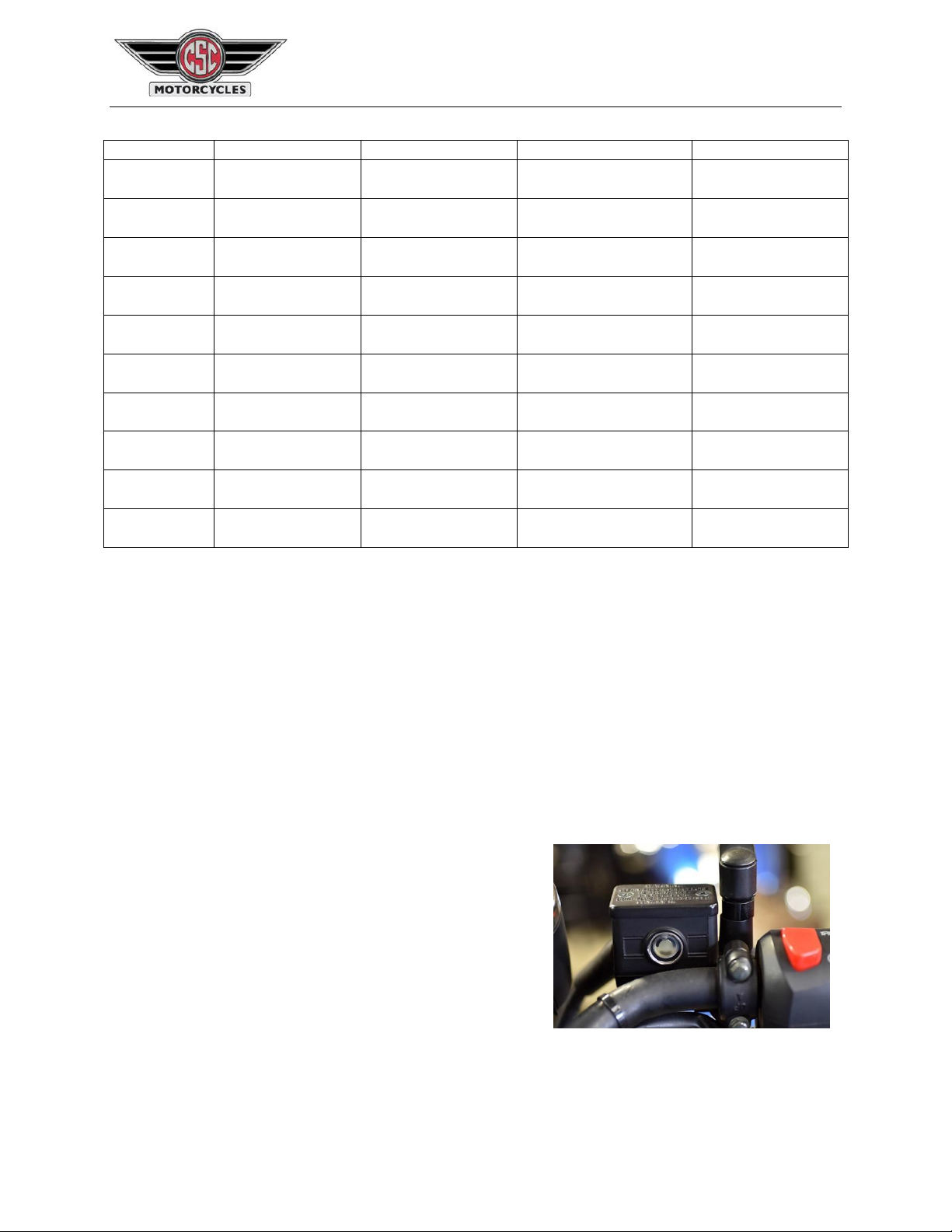

The front brake master cylinder is located on the right

handlebar. It has a fluid level indicator on the master

cylinder that shows the “low” level. When the front master

cylinder fluid level is at the low mark, it is an indication that

the front brake pads should be replaced. Do not rely only

on this indication; you should check the pad thickness

regularly and replace them when they are worn below

acceptable limits (to be described below).

www.CSCMotorcycles.com

Brakes

This section of the SG250 Owner’s and Service Manual covers the following topics:

Master cylinder locations

Inspecting and replacing the brake pads

Inspecting and replacing the brake disk

Flushing and replacing the brake fluid

Bleeding the brakes

Brake troubleshooting

Master Cylinder Location

20

SG250 Owner’s and Service Manual

The front brake caliper is located on the left side of the

motorcycle.

Loosen the front brake caliper’s two 5mm Allen pins.

Pull the caliper off the brake disk. You should not remove

the hydraulic, nor should you loosen it.

Completely remove the caliper’s two 5mm Allen pins, and

remove the two brake pads.

Note that one of the brake pads has a wear groove machined into the pad surface. When the pad is

worn such that the wear groove is no longer visible, replace both pads with new pads. CSC stocks

these pads, so call us at 909 445 0900 if you need to order a pair.

www.CSCMotorcycles.com

Front Brake Pad Inspection and Replacement

It is possible to check the thickness on the front brake pads without removing the caliper from the

motorcycle, but it is difficult to do so and get an accurate indication of brake pad thickness. It is better to

remove the caliper to better see the pads.

21

Assembly is the reverse of disassembly. Install new front pads, place the caliper over the rotor, and

install the two caliper mounting bolts.

Rear Brake Pad Inspection and Replacement

The SG250 uses a mechanically-actuated drum brake in the rear. It is mechanically linked to the rear brake

pedal with a steel rod. The amount of free play in the rear brake pedal before the rear brake starts to

engage is adjusted via a threaded nut on the rear of the steel rod.

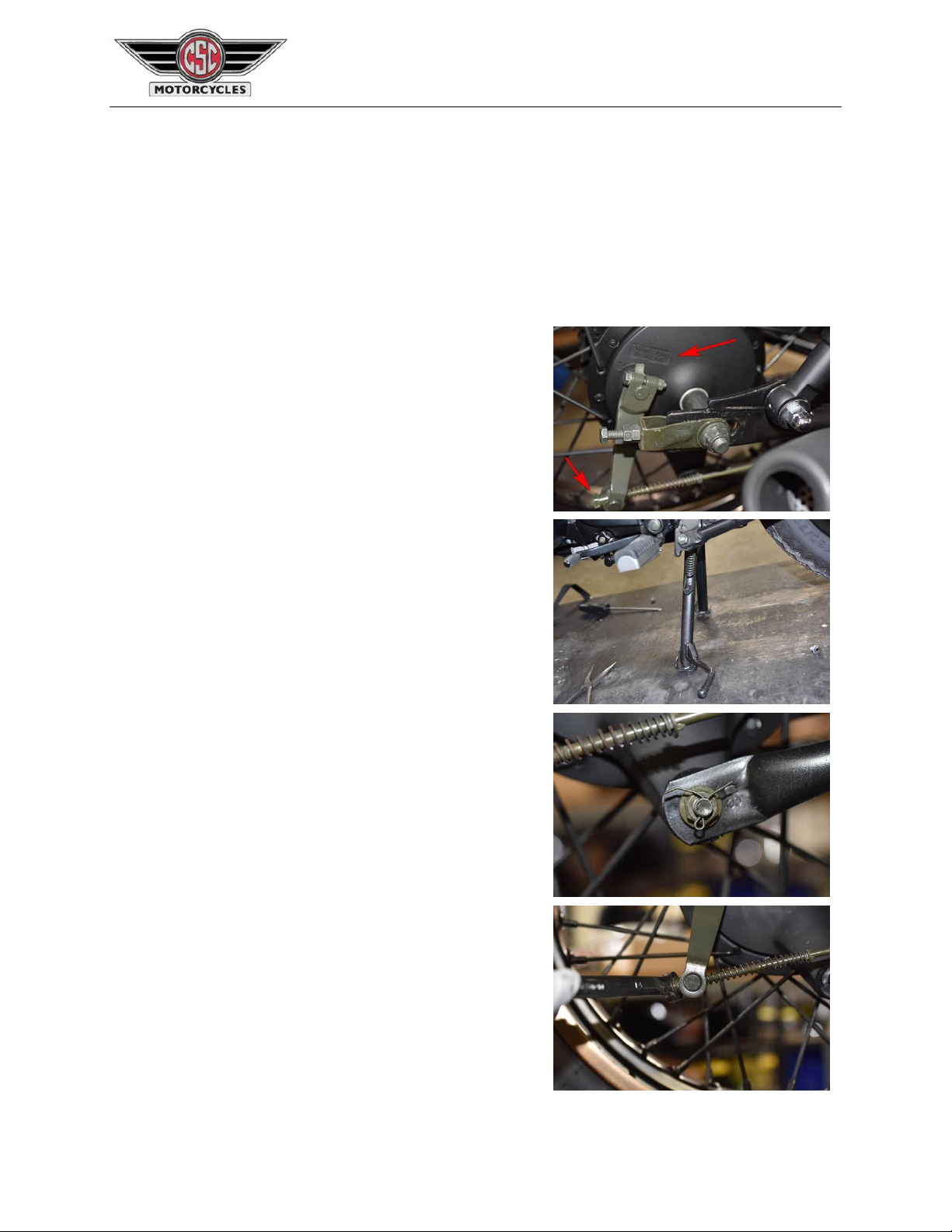

The rear brake caliper wear indicator is located on drum

(indicated by the upper arrow). As the rear brake wears,

free play is adjusted by turning the nut indicated by the

lower arrow. When the rear brake has reached the end of its

adjustment range, the brake shoes should be replaced. The

rear wheel must be removed to do this.

Place the motorcycle on the centerstand.

Remove the rear brake torque rod cotter pin and nut, and

disconnect the rear brake torque rod from the rear brake.

Remove the rear brake actuation rod nut and rotate the brake

actuator to disconnect the actuation rod from the rear brake.

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

22

SG250 Owner’s and Service Manual

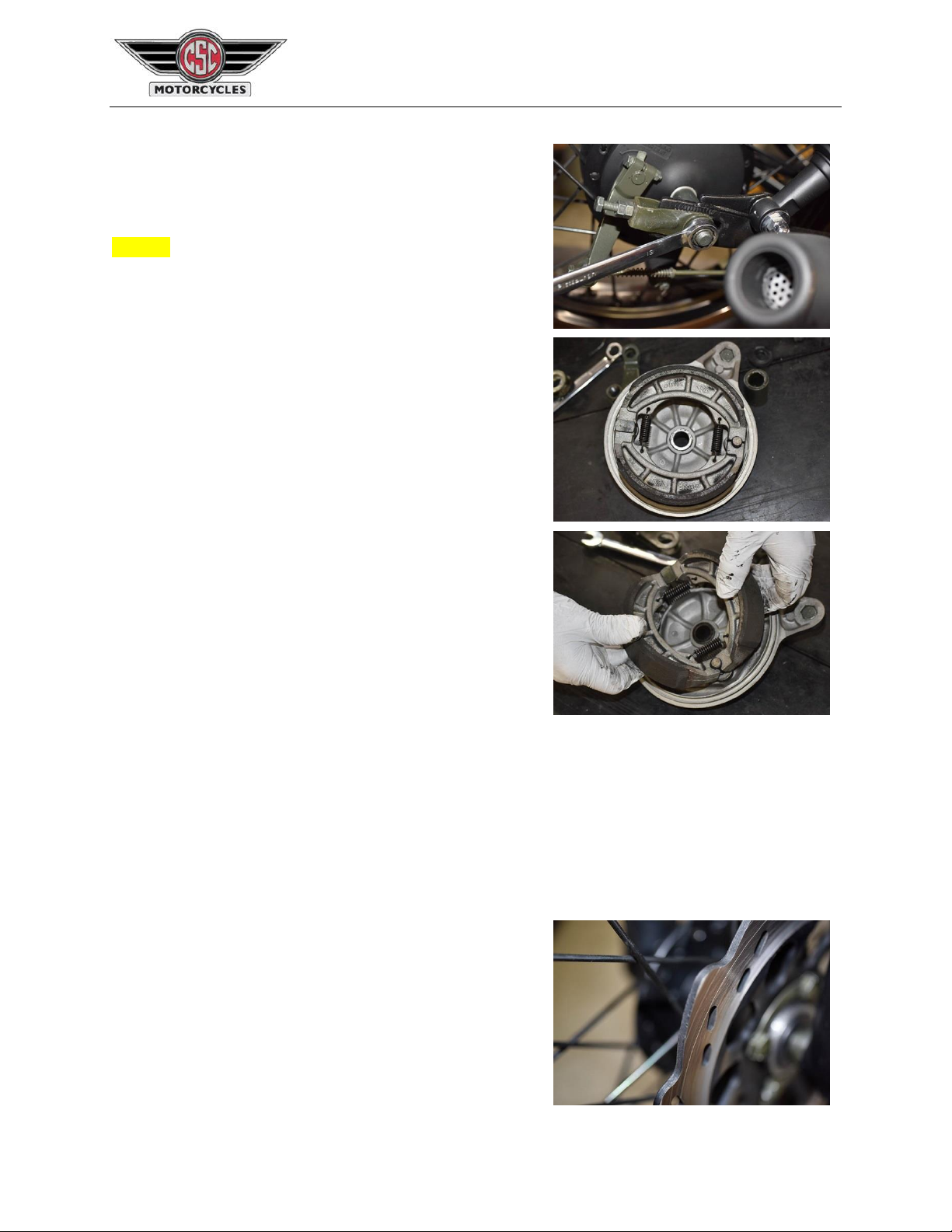

Remove the rear axle nut and remove the rear axle.

Caution! Support the rear wheel when removing the rear axle.

Remove the brake plate from the rear wheel to inspect the

brake shoes. When they are worn beyond the range allowed

for adjustability of the brake actuation rod (see above),

remove and replace both shoes.

The brake shoes are removed by rotating them away from

the brake plate, as shown here.

CSC stocks replacement brake shoes, so call us at 909 445 0900 if you need to order a pair.

Note that it is normal for the front brake pads to wear out much more quickly than the rear brake

shoes.

Assembly is the reverse of disassembly.

The front brake rotor is 4mm thick when new. When rotor

thickness drops below 3mm, the rotor should be replaced.

www.CSCMotorcycles.com

Front Brake Rotor Inspection

23

The front brake rotor is each retained by Allen head bolts. Take care when removing these for the first

time; they are Loctited in place at the factory and it is easy to strip the Allen drive socket (we

recommend heating the head of the bolt first to soften the adhesive). CSC stocks replacement rotors

and Allen bolts; if you need a new rotor please call us at 909 445 0900.

It is a good idea to bleed the front brake every year, and to

flush and replace the brake fluid every two years. Use only

DOT4 brake fluid. We sell brake fluid suitable for use in your

SG250 motorcycle; if you need brake fluid please call us at

909 445 0900. Caution! Brake fluid can damage painted

components. Promptly wipe up spilled brake fluid.

To drain the system, open the master cylinder. Attach a

hose to the caliper bleed port and route it to a suitable

container. Open the caliper bleed port with an 8mm wrench

and allow the brake fluid to drain. Note that the drain hose

is not shown in the photo to allow clarity in identifying the

caliper bleed port.

After draining the brake fluid, add fluid to the master cylinder and bleed the brakes as described below.

Caution! Brake fluid can damage painted components. Promptly wipe up spilled brake fluid.

To bleed the brakes, attach a hose to the brake caliper bleed port and route it to a suitable container.

Open the master cylinder, taking care not to spill any brake fluid.

Open the caliper bleed port while applying the brake lever, and before releasing the brake lever, close

the bleed port. It’s important not to allow the bleed port to remain open while releasing the brake

lever or you will suck air into the system. Repeat this open-the-bleed-port, apply-the-brake-lever,

close-the-bleed-port, add-brake-fluid process until the master cylinder is full. Reinstall the brake

master cylinder cover.

Prior to taking the motorcycle on the street, operate it slowly and apply the brakes several times.

Flushing and Replacing the Brake Fluid

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

Bleeding the Brakes

Brake Troubleshooting

Brake troubleshooting procedures are summarized below.

24

SG250 Owner’s and Service Manual

Item

Symptom

Cause

Vehicle Effect

Maintenance Action

Brake pad or brake

shoe

Reduced braking

force

Worn brake pads or

brake shoes

Longer stopping

distance, weaker

stopping

Replace brake pad

or brake shoe

Air in brake line

Reduced front

braking force

Air intrusion into

brake line

Longer stopping

distance

Bleed brake system

Pulsating brakes

Pulsating brake lever

Warped rotor disk

Pulsations; longer

stopping distance

Measure disk

runout, replace disk

rotor

www.CSCMotorcycles.com

Front and Rear Brake Troubleshooting and Maintenance

Power Transmission

The SG250 uses a manually-operated wet clutch and a chain drive system.

Chain Drive System

This system consists of the clutch, the countershaft sprocket, the rear sprocket, the rear wheel, and the

drive chain.

Chain Lubrication

The drive chain should be lubricated approximately every 500 miles or more often if riding in rainy or

dusty conditions. Use only a quality wax-based or petroleum-based motorcycle chain lubricant. Ride

the motorcycle for at least 15 minutes to warm the chain, and apply the lubricant immediately after

stopping. Warning! Take care not to spray lubricant onto the tire or the rear brake. Do not use the

motorcycle for the next 15 minutes to allow the lubricant to seep into the chain.

Chain Adjustment

This section of the Owner’s and Service Manual addresses adjusting the SG250 motorcycle’s chain and

aligning the rear wheel.

You don’t have to get the rear wheel off the ground to adjust the SG250’s chain.

Adjusting the chain on a motorcycle consists of two jobs: Adjusting chain tension and aligning the rear

wheel.

You can check this adjustment easily, and you should perform this check on a regular basis. A lubricated

chain will require adjustment every 500 to 1000 miles once the motorcycle is broken in.

Adjusting the chain involves loosening (but not removing) the rear axle, loosening the adjustor nuts and

locknuts, using a screwdriver between the chain and the rear sprocket to remove all kinks, aligning the

rear wheel, tightening the rear axle, and tightening the adjustor nuts and locknuts.

25

SG250 Owner’s and Service Manual

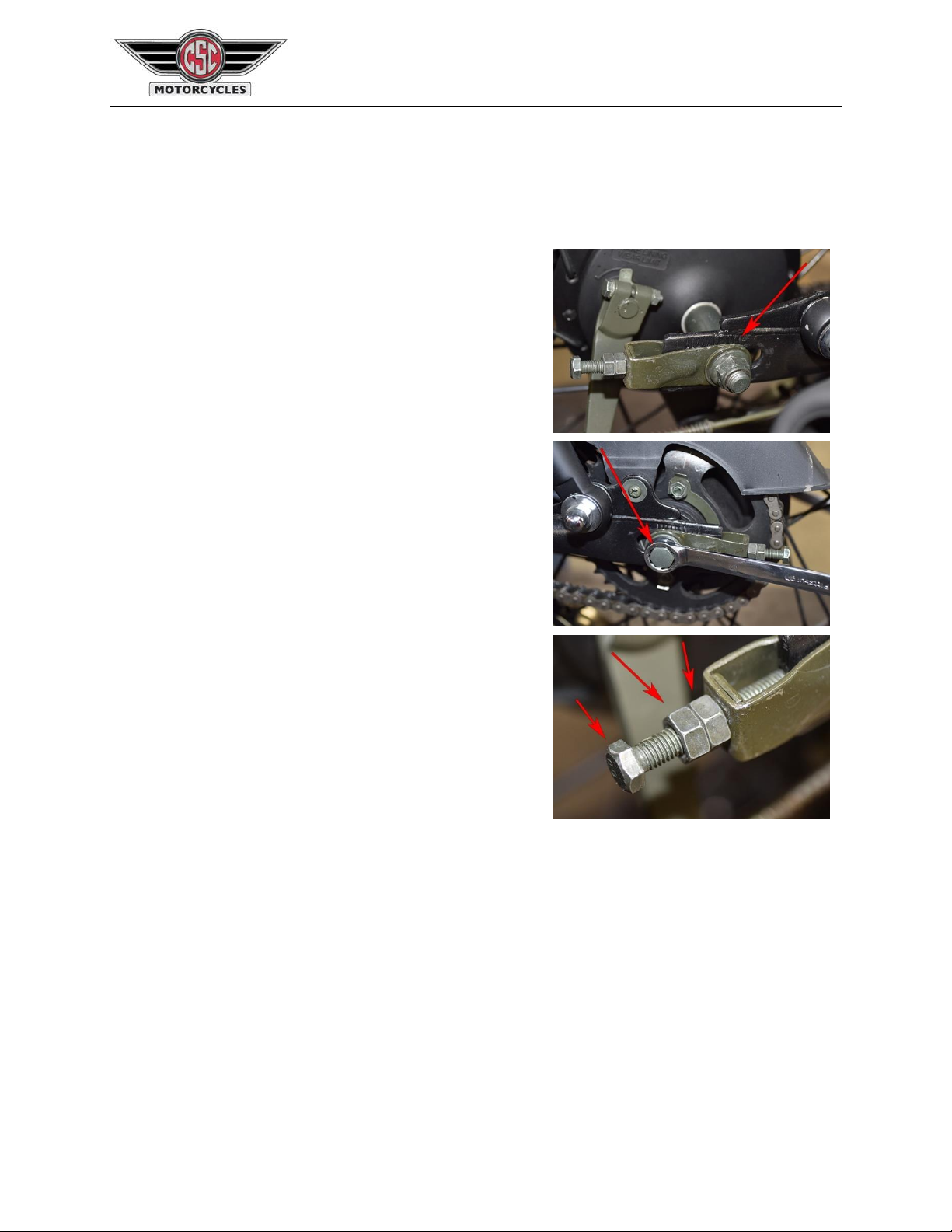

If your chain requires adjustment, loosen the rear axle. The

rear axle is loosed by loosening the rear axle bolt and

nut. This photo shows the axle nut on the right side of the

SG250 motorcycle.

The left rear axle bolt head.

The rear axle adjustor nuts and locknuts are located behind

the adjustor plate on both sides of the swingarm. Loosen

both nuts on both sides of the swingarm.

The intent is to position and align the rear wheel such that the chain has 3/5 of an inch slack at its

midpoint. This is the amount of slack the chain should have with the motorcycle on the ground and

the rider on the bike. If the bike is on a lift such that the rear wheel is off the ground, you should

increase the amount of slack when you adjust the chain such that when you are on the bike, the slack is

3/5 of an inch. If the rear wheel must move forward to increase chain slack, back off on the adjustor

nuts and locknuts and manually push the rear wheel forward. If the rear wheel must move rearward to

decrease chain slack, tighten the inner nuts as required on both sides of the swingarm to move the axle

to the rear.

www.CSCMotorcycles.com

You should check the chain adjustment during your motorcycle’s first scheduled maintenance and at

every scheduled maintenance thereafter. The biggest adjustment will occur at the first service interval,

because chains do most of their stretching in their first several hundred miles of use. When the chain is

properly adjusted, it should have about 15mm (or 3/5 of an inch) slack at its midpoint.

26

SG250 Owner’s and Service Manual

After moving the rear wheel, put a screwdriver between the

chain and the rear wheel sprocket (as shown below) and

sharply rotate the rear wheel. This will remove any kinks in

the chain. Note that this photo shows the TT250

motorcycle, but the procedure is the same for either the

TT250 or the SG250 motorcycle.

Check the alignment of the rear wheel by comparing the

scribe marks on the rear axle adjustors with the scribe marks

on the swingarm. This photo shows the right side of the

motorcycle and the scribe lines.

This photo shows the left side of the motorcycle and the

scribe lines.

You do not need to remove the rear axle to adjust the chain. Just loosen it and use the adjustor nuts to

move the wheel to its required location.

When the rear wheel is aligned and the chain slack is correct, tighten the rear axle to 35 ft-lb. Tighten

the rear axle adjustors’ positioning nuts, and then tighten the rear axle adjustors’ locknuts (the outer

nuts) to lock the adjustors in place.

Lube the chain every time it is adjusted. You can use either a wax-based or an oil-based chain lube; CSC

stocks both types. You can call us at 909 445 0900 if you need chain lube.

www.CSCMotorcycles.com

Sprocket and Chain Inspection

The SG250 has a 428 chain, a 17-tooth front sprocket, and a 50-tooth rear sprocket. If you keep your

chain properly adjusted and lubed, the chain and sprockets will last much longer than they would if you

don’t maintain these items, but they still won’t last forever. You can expect the chain and sprockets to

wear more quickly if you ride in dusty environments or off road, or if you don’t lube the chain regularly.

Chains and sprockets should be replaced as a set. Do not replace one sprocket without replacing the

other or rapid wear will result.

27

SG250 Owner’s and Service Manual

Item

Symptom

Cause

Vehicle Effect

Maintenance Action

Rear

sprocket

Excessive wear

Inadequate lubrication,

misaligned rear wheel,

incorrect chain

adjustment

Chain skipping, chain

breakage

Replace chain and

both sprockets

Counter

shaft

sprocket

Excessive wear

Inadequate lubrication,

misaligned rear wheel,

incorrect chain

adjustment

Chain skipping, chain

breakage

Replace chain and

both sprockets

Drive chain

Excessive wear

Inadequate lubrication,

misaligned rear wheel,

incorrect chain

adjustment

Chain skipping, chain

breakage

Replace chain and

both sprockets

Excessive

tightness

Inadequate lubrication,

misaligned rear wheel,

incorrect chain

adjustment

Chain breakage, loss of

power, stiff rear

suspension

Adjust chain

Excessive

looseness

Improper adjustment of

chain’s tension

Chain skipping on

sprocket, excessive chain

slap

Adjust chain

www.CSCMotorcycles.com

Remove the countershaft sprocket cover by removing the bolts that attach it to the engine. You don’t

have to remove the gear shift lever to remove the countershaft sprocket cover.

If the sprocket teeth are hooked or otherwise excessively worn, replace both sprockets. If the chain has

excessive stretch or if it has kinks that you cannot work out by manually rotating the links with respect to

each other, it’s time for a new chain.

The SG250 motorcycle chain does not have a master link. When you need to replace the original

equipment chain on your motorcycle, you have to cut it off.

Please call us at 909 445 0900 to order replacement chains and sprockets.

Chain Drive Troubleshooting

Troubleshooting and maintenance activities for the chain drive system are summarized in the table

below.

Chain Drive Troubleshooting and Maintenance

Clutch Maintenance

This section of the SG250 Owner’s and Service Manual addresses clutch cable installation, clutch

adjustment, and clutch replacement. Note that some of the photos in this portion of the Service Manual

show the TT250 motorcycle. The engines in the SG250 and TT250 motorcycles are identical.

28

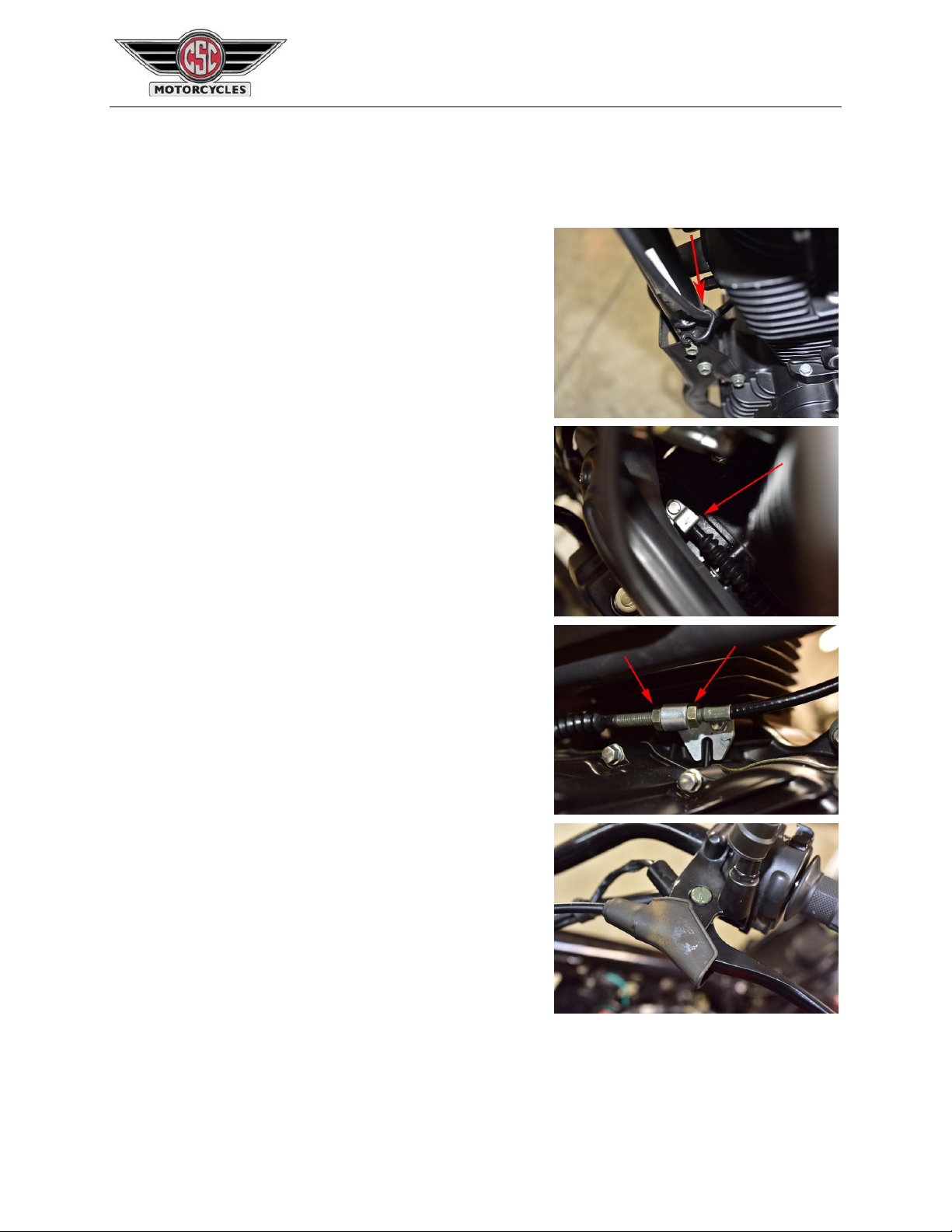

Route the cable from the handlebar (without attaching it yet)

to the engine. Note that there is a loop welded on the left

front frame downtube through which you should route the

clutch cable.

Apply a small amount of grease to the lower clutch cable

attachment point and attach the lower end of the clutch

cable to the engine clutch arm. This is what it will look like

looking down at the attach point between the engine and

the exhaust pipe.

Route the clutch cable through the adjustment mount on the

engine, and adjust the adjustor nuts to give the cable as

much slack as possible. The barrel should reach as far back

to the rear of the motorcycle as it can.

Pull back the handlebar clutch lever hood.

Clutch Cable Installation and Adjustment

SG250 Owner’s and Service Manual

www.CSCMotorcycles.com

29

SG250 Owner’s and Service Manual

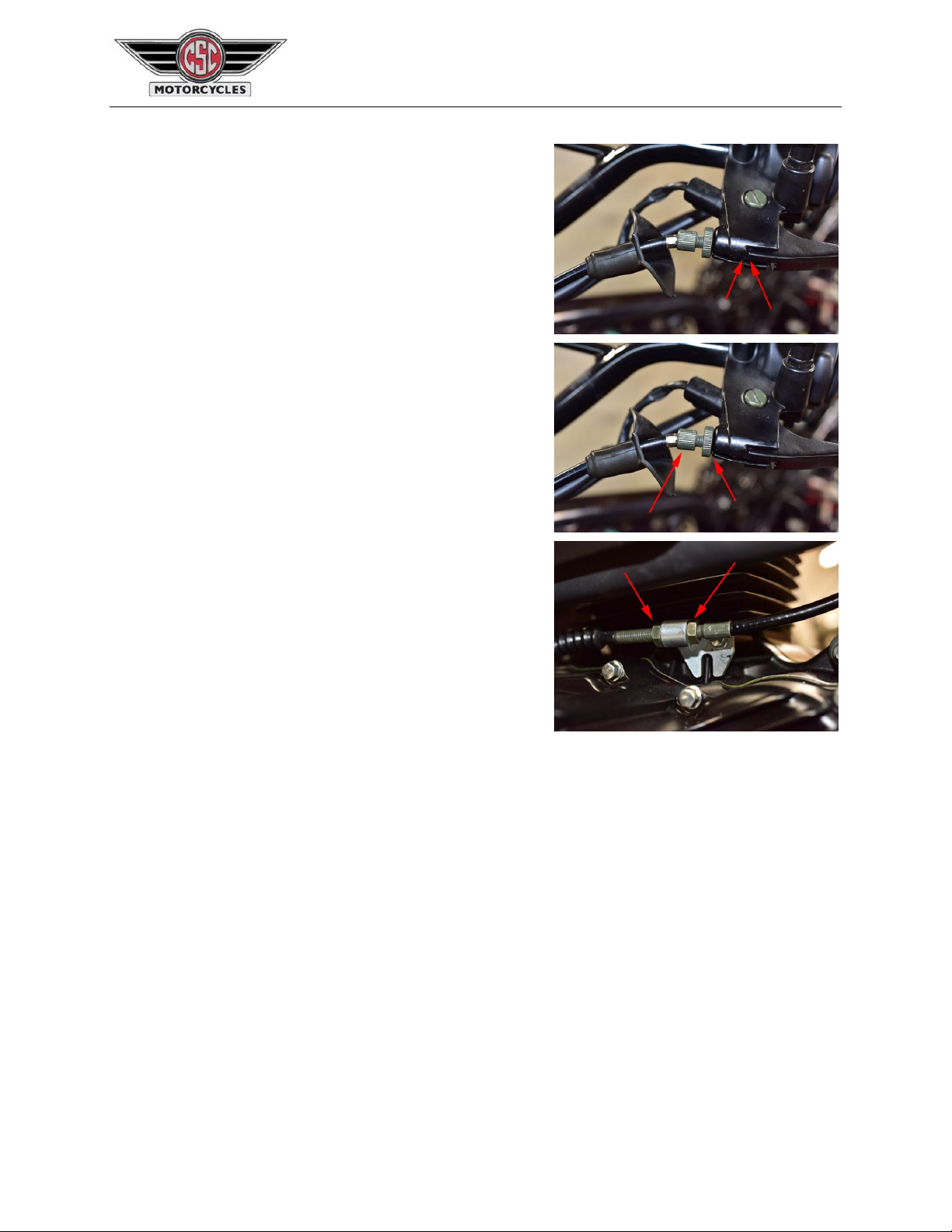

Screw the clutch lever adjustors into the clutch lever as far as

possible. After applying a small amount of grease to the

clutch cable barrel, route the clutch cable through the

adjustors and connect the clutch cable barrel.

After doing the above, position the handlebar clutch lever

adjustor so that the adjustor is in the middle of the

adjustment range. Note that there will still be considerable

slack in the clutch cable at this point.

Next, adjust the cable slack with the engine-mounted

adjustors. Use the adjustors shown here. Adjust these so

that there is approximately 3mm of slack on the handlebar

clutch lever.

Lock all the adjustor nuts (on the engine and on the handlebar clutch lever adjustor). Pull the rubber

adjustor hood over the adjustors at the handlebar clutch lever. All future clutch adjustments should be

made with the handlebar clutch lever adjustors. You should not lubricate the clutch cable; it has a

Teflon sheath and is self-lubricating.

www.CSCMotorcycles.com

Clutch Replacement

If you change your oil regularly, if you use the right kind of oil, and if you don’t abuse your bike, your

clutch will last a long time. If you abuse your clutch it will wear prematurely. If the clutch is grabby or if

it slips and you can’t fix it by changing the oil or by adjusting the clutch, you need a new clutch.

Note that the photos in this portion of the SG250 Service Manual show the TT250 engine. The TT250

and SG250 engines are identical.

30

Loading...

Loading...