Page 1

XP2i

It’s not like other

pressure gauges

Page 2

Would you know if your gauge

was broken?

Stronger. Tougher. Better.

Dropped, Submerged, Over-Pressurized

and it still reads accurately!

Submersible:

Sealed against dust and water. IP67 certied for

30 minutes of full submersion under 1 meter (3 ft.)

of water.

Shock Resistant:

Survives falls with no aect on accuracy.

(Can your gauges do that?)

Marine-Grade Construction:

The patented XP2i's, nickel-plated housing

resists corrosion with the same low-copper,

aluminum alloy found on saltwater

outboard motors.

Some sensors and bourdon gauges read incorrectly

after deforming under pressure. You would never know your gauge is broken

until you compare it to a reference.

The XP2i's silicon sensors shatter at very high pressure, but never deform.

They always return to their original shape and accuracy, even after accidental

overpressure. Sensor self-diagnostics will not allow operation if the sensor

is damaged.

Page 3

Always

Accurate

The Same Accuracy at Any Temperature

Active Digital Temperature Compensation corrects sensor for changes in temperature.

We guarantee 0.1% of reading accuracy from -10 to 50° C.

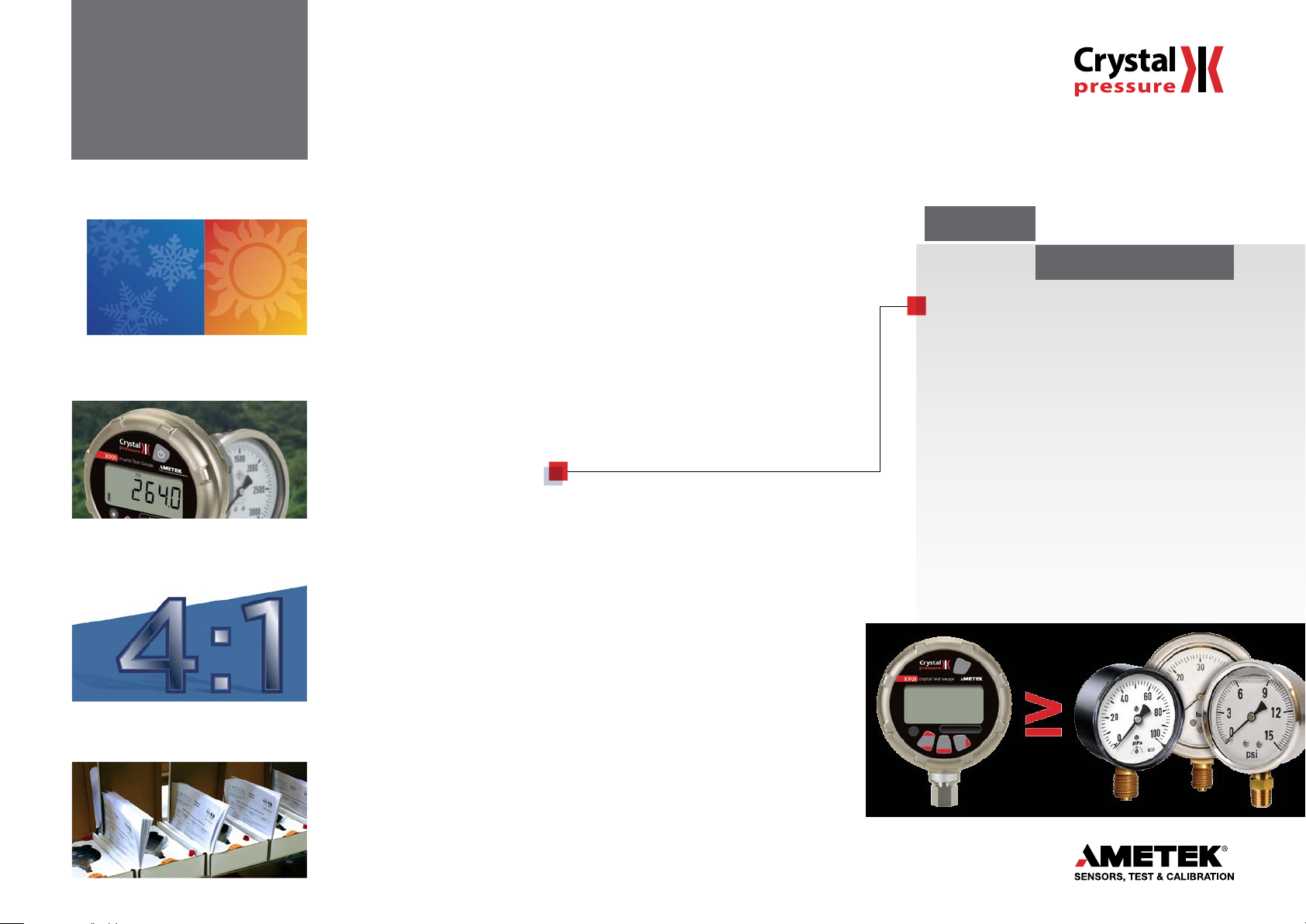

Higher Accuracy at Any Pressure

With the XP2i's "of reading" specs, your accuracy is always better than a 0.1% "of span"

gauge, at any pressure under full scale.

Plus, you can carry less gear.

Easy to Calculate 4:1 Calibration Ratios

Check the ne print in other test gauge specs–you will nd small uncertainty adders

that overwhelm the basic accuracy, even under conditions you work in every day.

With the XP2i's 0.1% of reading accuracy, your TUR is easy to calculate for devices rated

down to 20% of the XP2i's full scale.

CARRY

LESS

Save Money

One XP2i Replaces 3 (or More)

Test Gauges

Every XP2i maintains its accuracy across

a wide pressure and temperature range, so

using one XP2i is like carrying multiple

conventional gauges. PLUS: You save on next

–

year's calibration costs

an XP2i or a single test gauge, the costs are

about the same.

Now, you can save even more on calibration

costs with our new AMETEKCal program.

Prepay for three years of re-calibration for less

than the cost of two.

whether calibrating

Calibration Certicate Included (Free!)

Every XP2i comes with an ISO 17025 calibration report – NIST-traceable, A2LA

accredited, internationally recognized by ILAC

proving our gauges meet specications throughout their full temperature range.

Other manufacturers charge extra for a report with data only at room temperature.

–

with test data at 5 temperatures,

Page 4

Intrinsically Safe Recorder

Now Record up to 32 000 Data Points

When you purchase DataLoggerXP, you transform your XP2i into a portable pressure data logger. Leave your

XP2i on location as it records and timestamps readings for months at a time. Start and stop recording with a

single button, record multiple data sets

XP2i logs pressure at intervals down to 1 reading per second

in a number of ways such as Actual Pressure, Average Pressure,

or Average Pressure with Peak Hi and Low values.

DataLoggerXP is Ideal For:

Pipeline leak testing

•

Wellhead monitoring

•

Chart recorder replacement

•

Diagnostics–capture intermittent or transient events

•

…and many more

,

or take individual readings.

Saves You Time:

Easy to use

•

Output to pre-formatted Microsoft® Excel spreadsheets

•

Change logging parameters directly from the keypad

•

Install on additional computers at no extra cost

•

Extended battery life for long-term recordings.

Record up to 1 YEAR with Ultra-Low Power mode

•

Now available on a Dual Line Display gauge

See the number of remaining datapoints and live pressure on the same display.

•

Try before you buy with a 100 data point free trial!

Download the DataLoggerXP software here.

Page 5

FunctionsSpecial

Pressure Safety Valve Test

No more guess work. Simply enable this feature to increase your

read rate to 8 times per second. XP2i captures and displays the relief

pressure even if you're not looking at the gauge when the valve

opens.

Leak Rate

On the Dual Line Display (-DD Model), view Leak Rate and Live

Pressure at the same time.

ONLY

e Features You Need

Simplify your XP2i with ConfigXP software by selecting only the

functions you use. (ConfigXP is free at ametekcalibration.com)

Store multiple configurations on your computer, or set all your

XP2i gauges to work the same way.

Using CongXP with your XP2i you can:

Enable only the units you use, or add custom units you need (for

•

example: feet of seawater)

Disable any button (except for Power and Backlight)

•

Custom Units

Dene custom pressure units with ConfigXP.

For example, you can dene feet of seawater, tank level,

or any torque (N-m or ft-lbs).

Build and load task-specific configurations from your PC

•

Copy a configuration to several gauges

•

Password-protect to prevent changes

•

And more…

•

Page 6

You Can Read This Display Anywhere

Easy to Use

No Menus. No Manual. No Problem.

Three buttons — that’s all you need

to operate the XP2i.

Understand every function

two minutes after

opening the box.

Removable CPF Adapter

Shifts everyday wear to a replaceable

NPT, M20, or BSP adapter (included).

For more information about CPF visit

ametekcalibration.com

U.S. Patent No. 8,794,677

Large Display: Read From a Distance

High Contrast Liquid Crystal: Read in Bright Sunlight

Bright Backlight: Read in the Dark

Page 7

Used Everywhere

Trust Every Reading

Consistent Performance in the Coldest Places on Earth Northern Canada

In northern Canada, our customers perform hydrostatic testing during winter, when pipelines become accessible by snowcat. They count on the XP2i to

be accurate and ready for work when they get there.

XP2i Proves Itself Middle East

Oil workers on Middle East pipelines operate every day in the blowing sand, under the hot desert sun. They need a reliable, Intrinsically Safe pressure

gauge that works as hard as they do. From pressure testing and equipment calibration to long-term recording, they choose the XP2i.

For Calibration Technicians with No Time to Waste Nuclear Power

Nuclear power technicians have limited time for testing, and no time for mistakes. They need an accurate,

simple measuring tool that can be congured to specic tasks. XP2i is trusted in more nuclear power

stations than any other similar product

When the Right Tool Matters North Sea

Equipment on North Sea platforms must endure harsh conditions. Not only do their gauges have

–

to withstand extreme weather and saltwater spray

choice.

they have to be accurate. XP2i is the obvious

Page 8

4535.F

Crystal Engineering Corporation

ATEX

708 Fiero Lane, Suite 9, San Luis Obispo, CA 93401, USA

Telephone: +1 805.595.5477 | Fax: +1 805.595. 5466

Safe & Reliable

in Hazardous Environments

Every XP2i is certied Intrinsically Safe.

Dear Pressure Gauge User,

Would you like to know exactly what makes such a signifi cant diff erence when you use an XP2i? Have a look,

and decide for yourself whether testing one in your operation is worth your time.

Typical Customer Experiences

A Quality Product

“We purchased three XP2i gauges, 18 months ago, because our mechanical test gauges kept breaking. We

have been using our XP2i gauges ever since they arrived, without any problems.”

A Broad Operating Range

“ e fi rst thing I noticed about the XP2i was the broad pressure range. I replaced 3 mechanical gauges. My

technicians really appreciated carrying just one gauge instead of the three they were accustomed to.”

Lower Cost of Ownership

“A few months ago, I was pleasantly surprised. e cost to recertify each XP2i was 1/3 of what I would pay

for the 3 mechanical gauges we used before. And these XP2i gauges are so sturdy they hardly show any

signs of wear. I expect them to last another 4-5 years, at least.”

Training Made Easy

“Last week, I hired a new technician. I confi gured his XP2i with only the functions he needed, so it took us

only 5 minutes to train him and he was ready to go.”

A Remarkable Diff erence

“ e time and money we saved with the XP2i is truly remarkable. Over the next year, I intend to replace

all our gauges with XP2i gauges. ey have made a tremendous diff erence for us.”

We want you to know this experience is typical for our customers. At every tradeshow we attend, customers

tell us about how the XP2i has improved the way they operate.

Try it For Yourself – FREE

You can try out an XP2i at your facility, for free. Simply ask one of our Crystal salespeople about your free

demonstration unit, today. We’re betting when your trial period ends, you won’t want to send it back.

II 1G Ex ia IIC T4/T3 Ga FTZU 12 ATEX 0048X

Ex ia IIC T4/T3 Ga IECEx FTZU 12.0009X

Intrinsically Safe and Non-incendive for Hazardous Locations:

Class I, Division 1, Groups A, B, C and D, Temperature Code T3C

or T4/T3C. Maximum working pressure 15 000 psi.

Crystal products include a factory calibration report

that proves it meets its specications over the operating

temperature range. The products described herein, are

calibrated in Crystal’s accredited Calibration Lab (A2LA,

Certicate #2601.01 ISO/IEC 17025) in an environmental

chamber using fully automated equipment. Inclusion of

the ILAC-MRA symbol does not imply certication or ap-

proval of the product itself, but rather refers to Crystal’s

accreditation as a calibration facility.

Sincerely,

e Crystal Team

For detailed specications

go to the Data Sheet at ametekcalibration.com

No part of this document may be reproduced or

modied in any form or by any means, electronic

or mechanical, without express written permission

from Crystal Engineering Corporation.

©2016 Crystal Engineering Corporation

Loading...

Loading...