Page 1

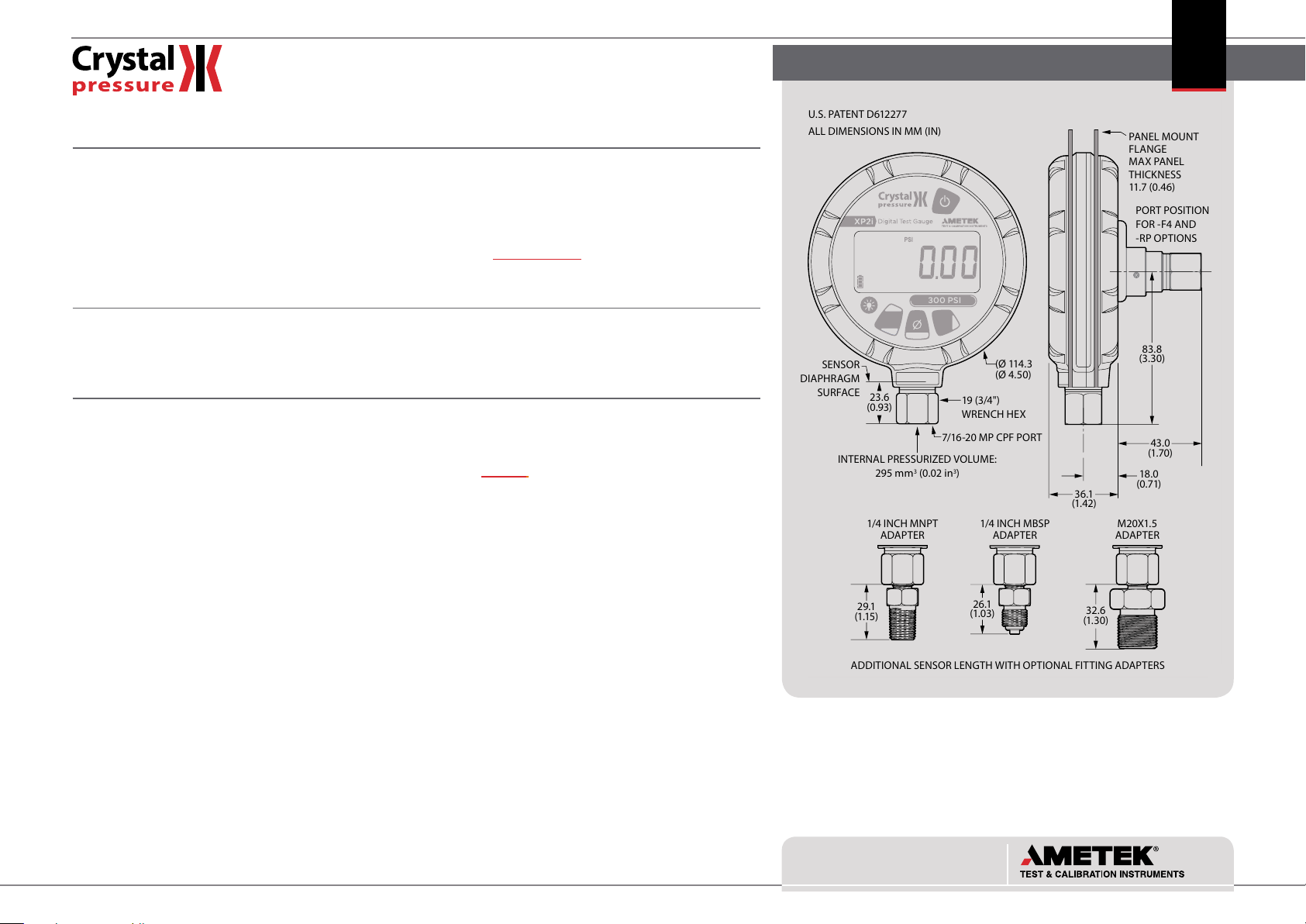

ACCURACY

300 PSI

PORT POSITION

FOR -F4 AND

-RP OPTIONS

INTERNAL PRESSURIZED VOLUME:

295 mm

3

(0.02 in3)

SENSOR

DIAPHRAGM

SUR FACE

36 .1

(1.42)

18.0

(0 .71)

43.0

(1.70)

(Ø 11 4. 3

(Ø 4.50)

7/16-20 MP CPF PORT

19 (3 /4")

WRENCH HEX

83.8

(3.30)

PANEL MOUNT

FLANGE

MA X PANE L

THICKNESS

11.7 (0.46)

23.6

(0.93)

ADDITIONAL SENSOR LENGTH WITH OPTIONAL FITTING ADAPTERS

U.S. PATENT D612277

ALL DIMENSIONS IN MM (IN)

1/4 INCH MNPT

ADAPTER

29.1

(1.15)

1/4 INCH MBSP

ADAPTER

26.1

(1.03)

M20X1.5

ADAPTER

32.6

(1.30)

0 to 20% of Range: ±(0.02% of Full Scale)

20% to 110% of Range: ±(0.1% of Reading)

Vacuum:

* Full Scale = -14.5 psig

OPERATING TEMPERATURE

Temperature Range: -10 to 50° C (14 to 122° F)

DISPLAY

Screen: 5.5 digits

Single Line Display: 16.9 mm (0.67") high

Dual Line Display: Main Display: 13.9 mm (0.55")

Secondary Display: 5.3 mm (0.21")

Display Rate: 4 readings/second (standard)

8 readings/second (PSV mode)

±(0.25% of Full Scale*)

XP2i Pressure Gauge psi

Includes all eects of linearity, hysteresis, repeatability,

temperature, and stability for one year.

All models indicate vacuum, but vacuum specication applies

to 15 psi, 30 psi, 100 psi, and 300 psi models only.

Not recommended for continuous use below -14.5 psi.

Refer to XP2i-DP data sheet for gauges that are intended for

continuous high vacuum use.

Non-condensing. No change in accuracy over operating

temperature range. Gauge must be zeroed to achieve rated

specication.

LCD readable in sunlight with bright backlight.

PSV mode is intended for Pressure Safety Valve testing, and

requires software to enable. (CongXP is a free download

from XP2i.com.)

4533 . M XP2i psi Data Sheet

Page 1 of 5

Page 2

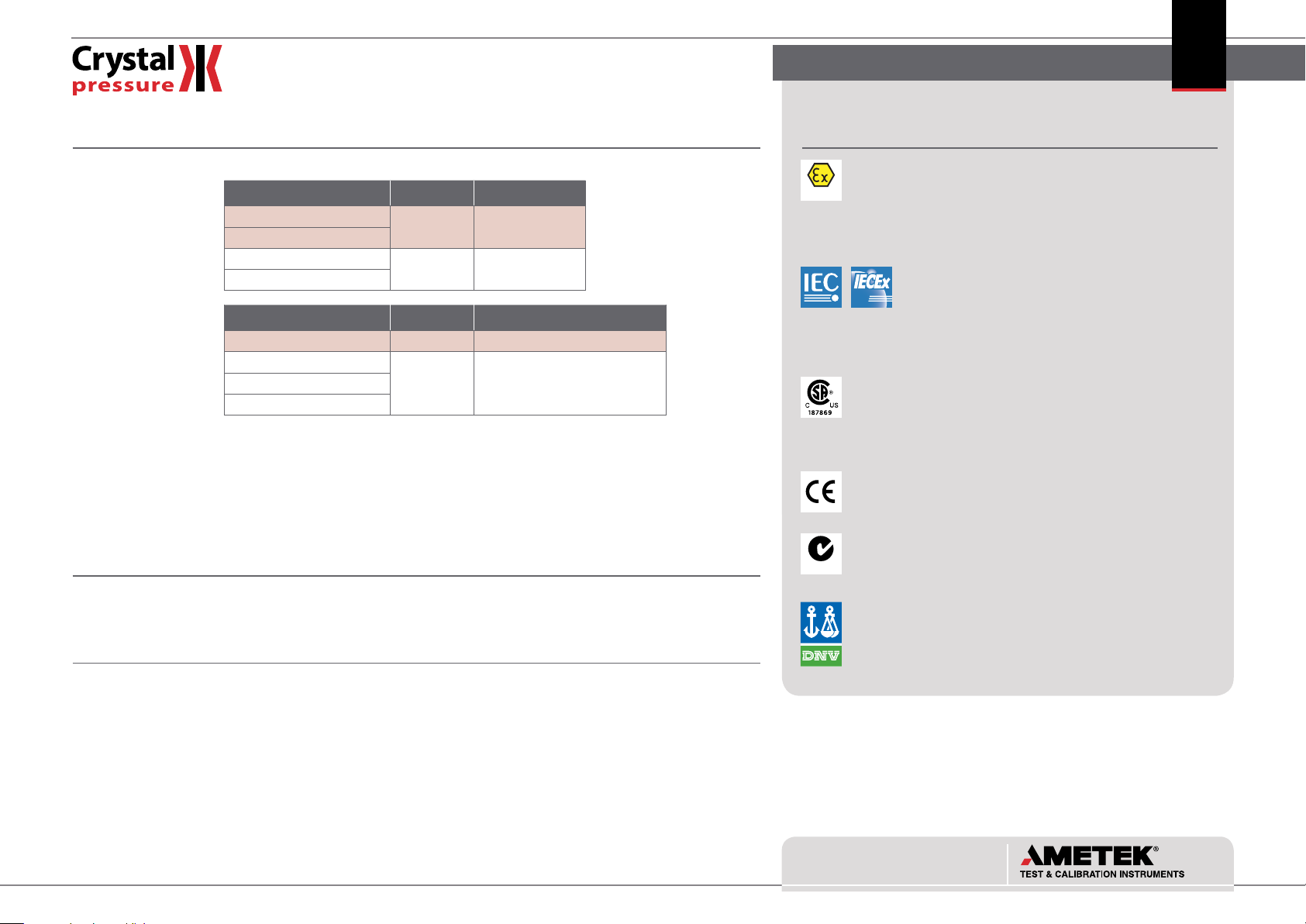

ATEX

C-tick

XP2i Pressure Gauge psi

POWER

The XP2i is Intrinsically Safe only if powered by one of the following battery types.

ATEX/IECEx:

3 x AA: 1500 hours, typical

Ultra Low Power: > 1 year, typical**

DATA/COMMUNICATION

Digital Interface: RS232, DB-9F

DATALOGGING

Capacity: 32 000 data points

Storage Type: Non-volatile ash memory

Minimum Interval: 1 second

Maximum Interval: 18 hours

Min. Event Duration: 250 mS***

Approved Battery Type Ta= Marking

Rayovac Max Plus 815

Energizer E91

Energizer EN91

Duracell MN1500

CSA:

Approved Battery Type Ta= Marking

Rayovac Max Plus 815 -20 to 45° C Class I, Division 1, A, B, C, D T4

Energizer E91

Energizer EN91

Rayovac Max Plus 815

-20 to 50 ° C Ex ia IIC T4 Ga

-20 to 50° C Ex ia IIC T3 Ga

-20 to 50° C Class I, Division 1, A, B, C, D T3C

Uses 3 alkaline AA (LR6) batteries. Use of backlight

and/or RS232 reduces operating time.

Optional AC power supply available.

For hazardous location product warnings, refer to the

operation manual.

**20 minute recording interval or greater in LT5 mode.

Free Labview® drivers and programming instructions are

available for download from website.

For hazardous location product warnings, refer to the

operation manual.

DataLoggerXP Firmware Update may be purchased at time of

order, or an Upgrade Package may be purchased afterward.

Software available for download from our website. Compatible

with 32 & 64 bit Windows 7, Vista, and XP (32 bit only). Produces

csv les, or uses Excel template les (samples included) to

automatically format and graph data.

*** Logging Type - Average with Peaks.

CERTIFICATIONS

II 1G Ex ia IIC T4/T3 Ga

FTZU 12 ATEX 0048X

This product conforms to:

EN 60079-0: 2009 | EN 60079-11: 2012 | EN 60079-26: 2007

Ex ia IIC T4/T3 Ga

IECEx FTZU 12.0009X

This product conforms to:

IEC 60079-0: 2011 | IEC 60079-11: 2011- 06 | IEC 60079-26: 2006

Exia Intrinsically Safe and Non-incendive for Hazardous

Locations: Class I, Division 1, Groups A, B, C and D, Temperature

Code T4 or T3C. For hazardous location product warnings, refer

to the operation manual.

XP2i complies with the Electromagnetic Compatibility and the

Pressure Equipment Directives.

The instrument was tested against AS/NZS 3584,

C-tick EMC/EMI requirements.

XP2i is approved for use as a portable test instrument for Marine

use and complies with Det Norsjke Veritas’ Rules for Classication

of Ships, High Speed & Light Craft and Oshore Standards.

4533 . M XP2i psi Data Sheet

Page 2 of 5

Page 3

ENCLOSURE

Weight: 562 g (19.8 oz)

Rating: IP67

Housing: Diecast aluminum

Keypad and Labels: UV Resistant Polyester

SENSOR

Wetted Materials: (wrench tight) 316 stainless steel

(

and Viton® (internal o-ring)

Diaphragm Seal Fluid: Silicone Oil

Connection: Crystal CPF Female

STORAGE TEMPERATURE

Temperature Range: -40 to 75° C (-40 to 167° F)

finger tight) 316 stainless steel

Weight includes batteries.

Submersible to 1 m for 30 minutes [IEC 60529].

Nickel plating over low copper, marine grade aluminum.

LCD protected from impact damage by 1.5 mm (0.06") thick

polycarbonate lens under polyester window.

Skydrol® compatible.

For hazardous location product warnings, refer to the

operation manual.

All welded, with a permanently lled diaphragm seal.

Metal to metal cone seal; O-ring can be removed if necessary.

Optional connection on back.

1/4" male NPT adapter included unless BSP, M20, or 15KPSI is

specied.

1/4" medium pressure tube system compatible with

HiP LM4 and LF4 Series, Autoclave Engr SF250CX Male

and Female Series.

U.S. Patent No. 8,794,677

Batteries should be removed if stored for more than one month.

XP2i Pressure Gauge psi

SPECIAL FEATURES

The following requires the use of our free CongXP software

User Dened Unit: Allows the user to dene and display any pressure units not included,

or to use the gauge to display force, level, or other pressure related parameters.

Reduce or increase displayed resolution.

PSV Mode: Intended for pressure safety valve / burst disk testing. 8 readings per second.

Captures point at which valve opens, as well as reseat pressure.

Averaging: Smooths unsteady readings (1 to 10 samples).

Remove: Unwanted pressure units from Units button.

Disable: Peak pressure button.

Limit or Disable: Zero button.

Password Protect: Changes to conguration or calibration factor(s).

Save: Conguration to a le.

Copy: Conguration can be copied to other gauges.

4533 . M XP2i psi Data Sheet

Page 3 of 5

Page 4

RANGE & RESOLUTION TABLE

Display Resolution

P/N

15PSI 15 6.5 x 0.001 0.01 0.001 0.01 1 0.0001 0.0001 0.1 0.01 0.00001

30PSI 30 3.0 x 0.001 0.01 0.001 0.1 1 0.0001 0.0001 0.1 0.01 0.00001

100PSI 100 2.0 x 0.01 0.1 0.01 0.1 1 0.0001 0.0001 0.1 0.01 0.00001

300PSI 300 2.0 x 0.01 0.1 0.01 1 0.001 0.001 1 0.1 0.0001

500PSI 500 2.0 x 0.01 1 0.1 1 0.001 0.001 1 0.1 0.0001

1KPSI 1000 2.0 x 0.1 0.1 0.001 0.001 0.1 0.0001

2KPSI 2000 2.0 x 0.1 0.1 0.01 0.01 1 0.001

3KPSI 3000 1.5 x 0.1 0.1 0.01 0.01 1 0.001

5KPSI 5000 1.5 x 0.1 1 0.01 0.01 1 0.001

10KPSI 10 000 1.5 x 1 0.01 0.01 1 0.001

15KPSI 15 000 1.3 x 1 0.01 0.01 1 0.001

ORDERING INFORMATION

P/N Model

Range

(psi)

XP2I

Standard:

Optional:

SAMPLE PART NUMBERS

300PSIXP2I ...........................300 psi standard gauge, with a 1/4” NPT pressure tting.

5KPSIXP2I-BSP-DL ...................5000 psi gauge, with a 1/4” BSP pressure tting and Data-logging.

10KPSIXP2i-DD-N-GWX-E-W .........10 000 psi Dual Display gauge with an NPT CPF tting kit; a System G

X

Ordering a Pump System Only

Any pump system, carrying case, and connection ttings for an XP2i pressure gauge may be ordered

separately from the gauge. Enter XP2I-NONE followed by the Pump System part number and the Carrying

Case option code.

Over-

pressure

Dual

Display

No ...(omit) NPT .......(omit) Bottom ..... (omit) No ......(omit) No .........(omit) No Pump. . . . . (omit)

Yes .... -DD G 1/4 B ....-BSP Back ..........-RP Ye s ........-DL NPT Kit (4013) ...-N System A (pneumatic) 0 to 30 psi .............................-AXX Full ......(omit) Aluminum ...(omit)

psi

Note: The 15KPSI gauge is available only with the CPF tting.

in

H

Adapter

Type

M20x1.5 ...-M20 Panel Mount ...-F4 BSP Kit (4015) ...-B System A (pneumatic) 0 to 580 psi ............................-AHX Drained ....... -E Waterproof ...... -W

pump system; no liquid; and a waterproof carrying case.

O

2

in Hgmm

Hg

Connection

Location

mm

O

H

2

Data-logging

kg/cm

2

bar mbar kPa MPa

CPF*

Fitting Kits

System B (pneumatic) -25 inHg to 30 psi. . . . . . . . . . . . . . . . . . . . . . . -BXX

System B (pneumatic) -25 inHg to 580 psi .....................-BHX

System C (oil) 0 to 3000 psi ..................................-CXX

System C (oil) 0 to 5000 psi ..................................-CHX

System D (oil) 0 to 5000 psi ..................................-DOX

System D (water) 0 to 5000 psi ...............................-DWX

System E (oil) 0 to 10 000 psi .................................-EOX

System F (oil) 0 to 15 000 psi .................................-FOV

System F (water) 0 to 15 000 psi ..............................-FWV

System G (oil) 0 to 15 000 psi ................................-GOX

System G (water) 0 to 15 000 psi .............................-GWX

System H (oil/pneumatic) -25 inHg to 580 psi and 0 to 5000 psi ...-HOX

SAMPLE PART NUMBER

XP2I-NONE-GWX-W ................System G pump system with a waterproof carrying case.

XP2i Pressure Gauge psi

Pump System**

4533 . M XP2i psi Data Sheet

Page 4 of 5

Liquid

(Systems C-H)

CPF Fitting Kits can only be ordered as part of a Pump System.

*

All ttings are rated to 10 000 psi, with the exception of

the MPF-1/2QTF rated to 5000 psi.

Refer to the following page for a more detailed description of

**

each Pump System.

~ The Waterproof Case is an option for Systems A, B, and C only.

The Waterproof Case is the only option for Systems G and H.

Carrying Case

~

Page 5

XP2i Pressure Gauge psi

900 Series

600 Series

P-018-CPF

P014

PUMP SYSTEMS

All pump systems for the XP2i include 1/4 NPT and BSP female ttings and a carrying case with

custom insert. Additional ttings and accessories included with individual systems are listed below.

X

Systems A… AXX (T-960), AHX (T-970)

MPH-1 hose, bonded seals, o-ring kit, and teon tape.

X

Systems B… BXX (T-965), BHX (T-975-CPF)

MPH-1 hose, bonded seals, o-ring kit, and teon tape.

X

Systems C… CXX (T-620), CHX (T-620H-CPF)

MPH-1 hose, MPF-CAP, MPM-PLUG, bonded seals, and teon tape.

X

Systems D… DOX and DWX (P-018-CPF)

Bonded seals and teon tape.

X

System E… EOX (P014)

Bonded seals and teon tape.

X

Systems F… FOV and FWV (T-1-CPF)

Bonded seals and teon tape.

X

Systems G … GOX and GWX (GaugeCalHP)

Carrying case hold-down straps.

X

System H… HOX (T-975-CPF and T-620H-CPF)

MPF-CAP, MPM-PLUG, bonded seals, o-ring kit, and teon tape.

ACCESSORIES

Protective Boot P/N 3696

Protect your XP2i even more from harsh environments

with our form tting chemical resistant thermoplastic

boot (Skydrol uid compatible).

AC Adapter Kit

For continous use applications without battery replacement concern.

Input voltage: 100 - 240V, 50-60 Hz. Includes all available international plugs.

For hazardous location product warnings, refer to the operation manual.

COMPLIMENTARY PRODUCTS

Crystal Engineering oers a wide range of products that

work with the XP2i:

Fittings that connect without tools, safely and without leaks

•

Lightweight, super exible high pressure hoses

•

Complete Calibration Kits

•

Pneumatic hand pumps

•

Hydraulic hand pumps

•

Portable pressure comparators

•

Software, for the quickest way to calibrate pressure transmitters

•

and gauges

P/N 2984

T-1-CPF

GaugeCalHP

CPF FITTING KITS

X

NPT Kit… -N (4013)

Includes MPF-1/8QTF, MPF-1/4QTF, and MPF-1/2QTF.

X

BSP Kit… -B (4015)

Includes MPF-1/8BSPF, MPF-1/4BSPF, MPF-3/8BSPF, and MPF-1/2BSPF.

crystalengineering.net

© 2014 Crystal Engineering Corporation 708 Fiero Lane, Suite 9, San Luis Obispo, California 93401-8701

Autoclave Engineers Fluid Components is a division of Snap-tite, Inc.

HiP is High Pressure Equipment Company.

Viton is a registered trademark of DuPont Performance Elastomers.

4533 . M XP2i psi Data Sheet

Page 5 of 5

Loading...

Loading...