Page 1

ATMi Series

Intrinsically Safe

Advanced Temperature

Module

Page 2

Expand

Your HPC50

Pressure Calibrator

Now Measure Temperature!

HE CRYSTAL ATMi intrinsically safe temperature modules, with

T

exible cable lengths, oer the functionality and exibility to read

up to 2 temperature inputs with a single HPC50 calibrator. In addition

to the two installed pressure modules in the HPC50 Series, two ATMi

temperature modules can be connected to the device. This provides

the exibility to read pressure with ambient and process temperature in

the same instrument.

The ATMi is engineered to deliver the same high level of accuracy

whether in the lab or in the eld. When combined with the ATMi tem-

perature module, the HPC50 is a powerful calibration tool.

Key Features

Accuracies to 0.015% of Reading.

Performance to meet almost any calibration and measurement task.

Supports Pt100 RTDs.

With readouts in °C, °F, K, R, and Ω.

When

“

combined

with the ATMi

temperature

module, the

Crystal ATMi oers

seamless integration

with the Crystal

HPC50 Series.

Rugged Construction.

–

Machined stainless steel housing. Engineered for rough eld use

almost unbreakable.

Self-Contained, Intelligent Module.

Calibration data is stored in the module, so any module can

be combined with any HPC50 calibrator. No need to “calibrate”

the module to an indicator.

HPC50 Series

Calibrator is

a powerful

calibration

tool.

”

Page 3

Lab Accuracy in the Field

Active Temperature Compensation

Count on the same accuracy at any temperature, between -20 and 50° C.

Calibrate with Condence Anywhere

Take measurements with up to 0.015% of reading accuracy.

Crystal Engineering calibration facilities are A2LA accredited, (# 2601.01)

which is internationally recognized by ILAC.

Combine with Our Ready To Go Pump Systems

Reference Sensors

The ATMi combines with JOFRA reference sensors to

provide high accuracy temperature measurement on the

HPC50 Series.

An intrinsically safe Pt100 temperature sensor with a spe-

cial non-conductive handle is available with or without

a calibration certicate. Other sensors sizes, temperature

ranges, and accuracies are available from JOFRA

.

*

Combine the ATMi temperature modules with the HPC50 pressure

calibrator and any of our pump systems for a complete pressure and

temperature calibration system. From small pneumatic hand pumps to a

precision, hydraulic pressure comparator we have the perfect kit for

your application.

Not all sensors are intrinsically safe.

*

Page 4

ATMi Specifications

ATEX

Temperature Measurement

Accuracy ................±(0.015% of rdg) + 0.02 Ohm

Range ..................................0 to 400 Ohms

Resolution ...........................0.01 on all scales

Units ......................................°C, K, °F, R, Ω

TCR .....................0.003850 Ω/Ω/°C (IEC 60751)

Wiring .................................4-wire support

Includes all eects of linearity, hysteresis, repeatability, temperature, and

stability for one year.

Output

Temperature Resolution ............................0.01

Display Update ...................up to 10 per second

Temperature resolution and Display Update are the maximum

values available.

The resolution of your Crystal device may be dierent.

The proper selection of the RTD sensing element is very important as the error associated with this device is the majority of the overall system measurement uncertainty. IEC 751 is the standard that denes the temperature versus resistance for 100Ω, 0.00385 Ω/Ω/°C platinum RTDs. IEC 751 denes two

classes of RTDs: Class A and B. Class A RTDs operate over the -200 to 630°C range versus -200 to 800°C for the Class B elements. For example, the Class A

uncertainty is about half that of the Class B elements as illustrated in the following table.

Class A Class B

Temperature

°C

-200 0.02 0.05 0.24 0.55 0.24 0.55 0.56 1.30 0.56 1.30

-40 0.03 0.08 0.09 0.23 0.10 0.24 0.20 0.50 0.20 0.51

0 0.04 0.09 0.06 0.15 0.07 0.17 0.12 0.30 0.12 0.31

50 0.04 0.10 0.10 0.25 0.10 0.27 0.21 0.55 0.22 0.56

100 0.04 0.11 0.13 0.35 0.14 0.37 0.30 0.80 0.31 0.81

150 0.04 0.12 0.17 0.45 0.17 0.46 0.39 1.05 0.39 1.06

200 0.05 0.13 0.20 0.55 0.21 0.56 0.48 1.30 0.48 1.31

400 0.06 0.17 0.33 0.95 0.33 0.96 0.79 2.30 0.79 2.31

600 0.07 0.21 0.43 1.35 0.44 1.37 1.06 3.30 1.06 3.31

800 0.08 0.25 0.52 1.75 0.53 1.77 1.28 4.30 1.28 4.31

HPC50/ATMi

Uncertainty

±Ω ±°C ±Ω ±°C ±Ω ±°C ±Ω ±°C ±Ω ±°C

Class A

Uncertainty

HPC50/ATMi + Class A

Operating Temperature

Temperature Range ..........-20 to 50° C (-4 to 122° F)

< 95% RH, non-condensing. No change in accuracy over operating

temperature range. Gauge must be zeroed to achieve rated specication.

Applies to all modules.

Storage Temperature

Temperature Range ........ -40 to 75° C (-40 to 167° F)

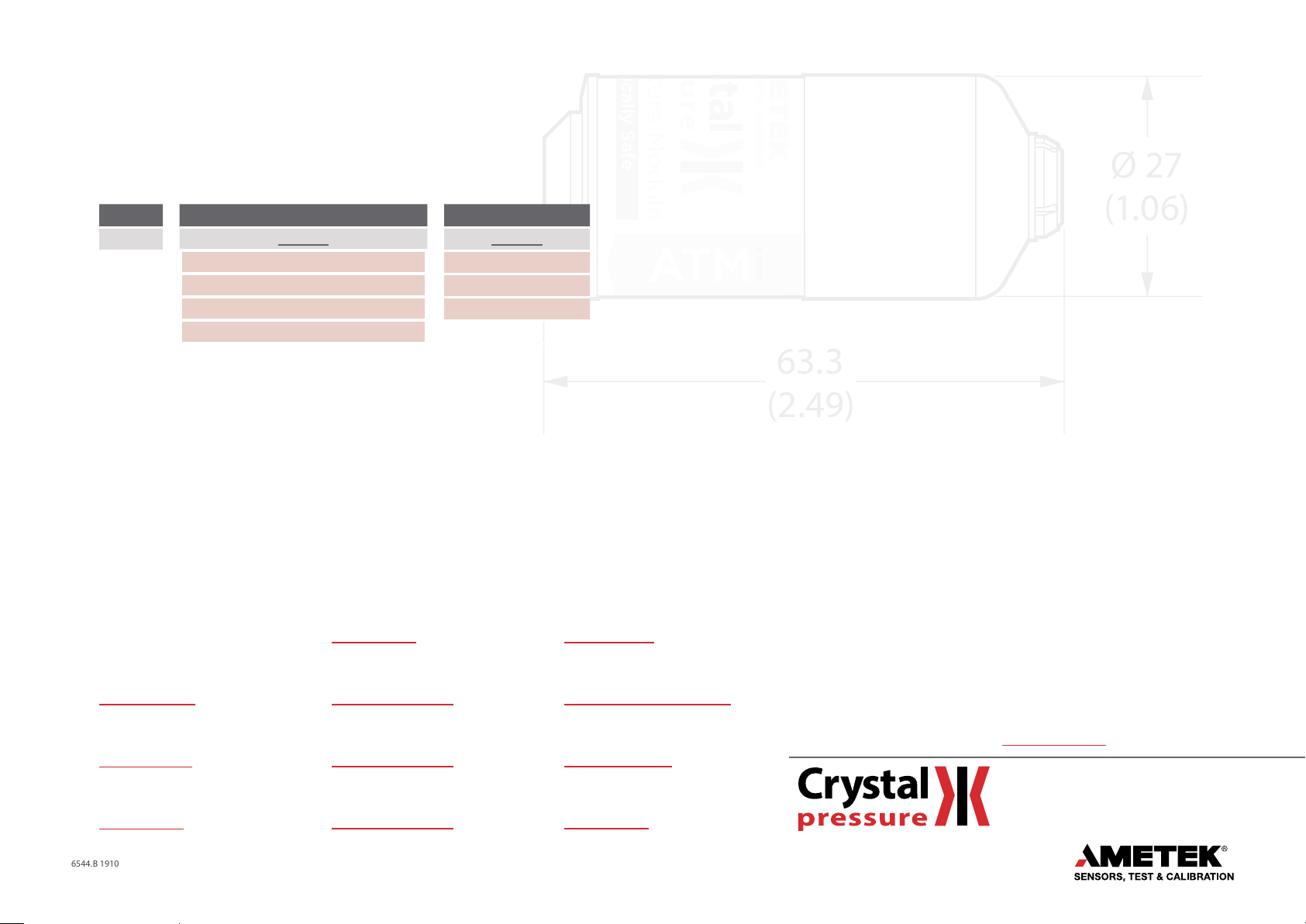

Enclosure

Dimensions ..............2.5 x 1.1 in (63.3 x 27.0 mm)

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.31 lbs (141.0 g)

Uncertainty

Class B

Uncertainty

HPC50/ATMi + Class B

Uncertainty

Intrinsic Safety Approvals

Ex ia IIC T4/T3 Ga

FTZU 18 ATEX 0043X

Ex ia IIC T4/T3 G

IECEx FTZU 18.0012X

Exia Intrinsically Safe and Non-Incendive for Hazardous

Locations: Class I, Division 1, Groups A, B, C, and D; Tem-

perature Code T4/T3. Class I, Zone 0, AEx ia IIC T4/T3 Ga.

a

Entity Parameters

Ui = 5.0 V

Ii = 740 mA

Pi = 880 mW

Ci = 8.8 µF

Li = 0

Certifications

We declare that the APMi is in accordance with

the Electromagnetic Compatibility Directive per

our declaration(s).

This HPC50 is approved for use as a portable test

instrument for Marine use and complies with DNV

GL Rules for Classication of Ships, High Speed & Light Craft,

and Oshore Units.

Page 5

PT100 Type T Specifications

JOFRA Reference Sensors

JOFRA PT100 probes are designed for fast and accurate, traceable calibration of temperature.

Dimensions

Reference A ................................200 mm (7.87 in)

Reference B ...................................4 mm (0.16 in)

Reference C ................................172 mm (6.77 in)

CA

B

Accuracy

Hysteresis

Long Term Stability

@ 0° C (32° F)

Repeatability

(1) When used in the range -50 to 400° C (-58 to 752° F).

(2) When exposed to 400° C (752° F) for 100 hours. Stability will depend on

(1)

@ 0° C (32° F) ....................0.01° C (0.02° F)

(2)

(1)

@ 0° C (32° F) .............. 0.005° C (0.009° F)

actual use of the sensor.

.............typical 0.014° C (0.025° F)

Temperature Range

All Sensors ......................-40 to 150° C (-58 to 302° F)

Sensing Element

Type ...................................................Pt100

Nominal Resistance @ 0° C (32° F) ......................100 Ω

Temperature Coecient ................α100 =0.00385 1/°C

Self-Heating Eect

0.06 °C /mW (0.108 °F/mW)

Response Time

τ0.5 (50%) ............................................7 seconds

τ0.9 (90%)

Liquid in motion v = 0.4 m/s.

.......................................... 17 seconds

Electrical Connections

Cable .....................................................4-wire

Connection

........................LEMO connector for HPC50

Insulation Resistance

@ 23° C (73° F) ......................................100 Gohm

@ 400° C (752° F)

..................................... 70 Mohm

Outer Tube

Inconel 600

Operating Conditions

Sensor, Connection, and Cable ............Max. 70° C (158° F)

Storage Temperature

Humidity

Protection Class

..........................................0 to 90% RH

...............-20 to 70° C (-4 to 158° F)

...............................DIN 40050 IP-50

Page 6

*

STS-050A Specifications

JOFRA Reference Sensors

JOFRA STS-050 A probes are designed for fast and accurate, traceable calibration of temperature.

Dimensions

Reference A ................................250 mm (9.84 in)

350 mm (13.78 in)

Reference B ...................................4 mm (0.16 in)

Reference C ................................140 mm (5.51 in)

CA

B

Accuracy

Hysteresis

Long Term Stability

@ 0° C (32° F)

Repeatability

(1) When used in the range -50 to 400° C (-58 to 752° F).

(2) When exposed to 400° C (752° F) for 100 hours. Stability will depend on

(1)

@ 0° C (32° F) ....................0.01° C (0.02° F)

(2)

(1)

@ 0° C (32° F) .............. 0.005° C (0.009° F)

actual use of the sensor.

.............typical 0.014° C (0.025° F)

Temperature Range

All Sensors ......................-50 to 400° C (-58 to 752° F)

Sensing Element

Type ...................................................Pt100

Nominal Resistance @ 0° C (32° F) ......................100 Ω

Temperature Coecient ................α100 =0.00385 1/°C

Self-Heating Eect

0.06 °C /mW (0.11 °F/mW)

Response Time

STS-050 A – 4 mm (0.16 in): τ0.5 (50%) ...............8 seconds

STS-050 A – 4 mm (0.16 in): τ0.9 (90%)

Liquid in motion v = 0.4 m/s.

............. 26 seconds

Electrical Connections

Cable .....................................................4-wire

Connection

...........................See "Cable Length and

Termination" options below

Insulation Resistance

@ 23° C (73° F) ......................................100 Gohm

@ 400° C (752° F)

..................................... 70 Mohm

Outer Tube

Inconel 600

Operating Conditions

Sensor, Connection, and Cable ............Max. 70° C (158° F)

Storage Temperature

Humidity

Protection Class

STS-050A probes are not intrinsically safe.

*

..........................................0 to 90% RH

...............-20 to 70° C (-4 to 158° F)

...............................DIN 40050 IP-50

Page 7

6544.B 1910

63.3

(2.49)

Ø 27

(1.06)

Ordering Information

Model

ATMi

–

*

Note: Options T / T4 / T5 include a large padded soft carrying

USA, Florida

Tel +1 (800) 527 9999

cal.info@ametek.com

Temperature Sensor Interface Cable Length

No Probe

.............................

PT100 Probe, IS certied, -40 to 150° C w/o cert

PT100 Probe, IS certied, -40 to 150° C w cert

STS050 Probe*, -45 to 400° C w/ cert

STS-050A probes are not intrinsically safe.

.....T

.....T4

............T5

case with shoulder strap (p/n SPK-HHC-003).

Singapore

Tel +65 6484 2388

jofra@ametek.com

China, Shanghai

Tel +86 21 5868 5111

jofra.sales@ametek.com.cn

(omit)

–

1 m / 3.3 ft ......(omit)

3 m / 10 ft ..........3M

10 m / 33 ft ........10M

SAMPLE PART NUMBERS

ATMi-T .......................ATMi with a PT100 probe and 1 meter cable.

ATMi-T4-10M ...............ATMi with a PT100 probe (with calibration certicate) and 10 meter cable.

ATMi-T5-3M ................ATMi with a STS050 probe (with calibration certicate) and 3 meter cable.

United Kingdom

Tel +44 (0) 1243 833 302

stc.uk@ametek.com

France

Tel +33 (0) 30 68 89 40

general.lloyd-instruments@ametek.fr

USA, California

Tel +1 (800) 444 1850

crystal@ametek.com

India

Tel +91 22 2836 4750

jofra@ametek.com

*

China, Beijing

Tel +86 10 8526 2111

jofra.sales@ametek.com.cn

China, Guangzhou

Tel +86 20 8363 4768

jofra.sales@ametek.com.cn

ISO 17025 accredited calibration lab, (A2LA #2601.01).

*

Germany

Tel +49 (0) 2159 9136 510

info.mct-de@ametek.de

Denmark

Tel +45 4816 8000

jofra@ametek.com

ametekcalibration.com

No part of this document may be reproduced or

modied in any form or by any means, electronic

or mechanical, without express written permission

from Crystal Engineering Corporation.

©2019 Crystal Engineering Corporation

Loading...

Loading...