GaugeCalxp

Operator Instructions

™

PRESSURE COMPARATOR

10000 PSI–700bar

C R Y S T A L

engineering corporation

Page 2 • GaugeCalXP Operator Instructions

Introduction

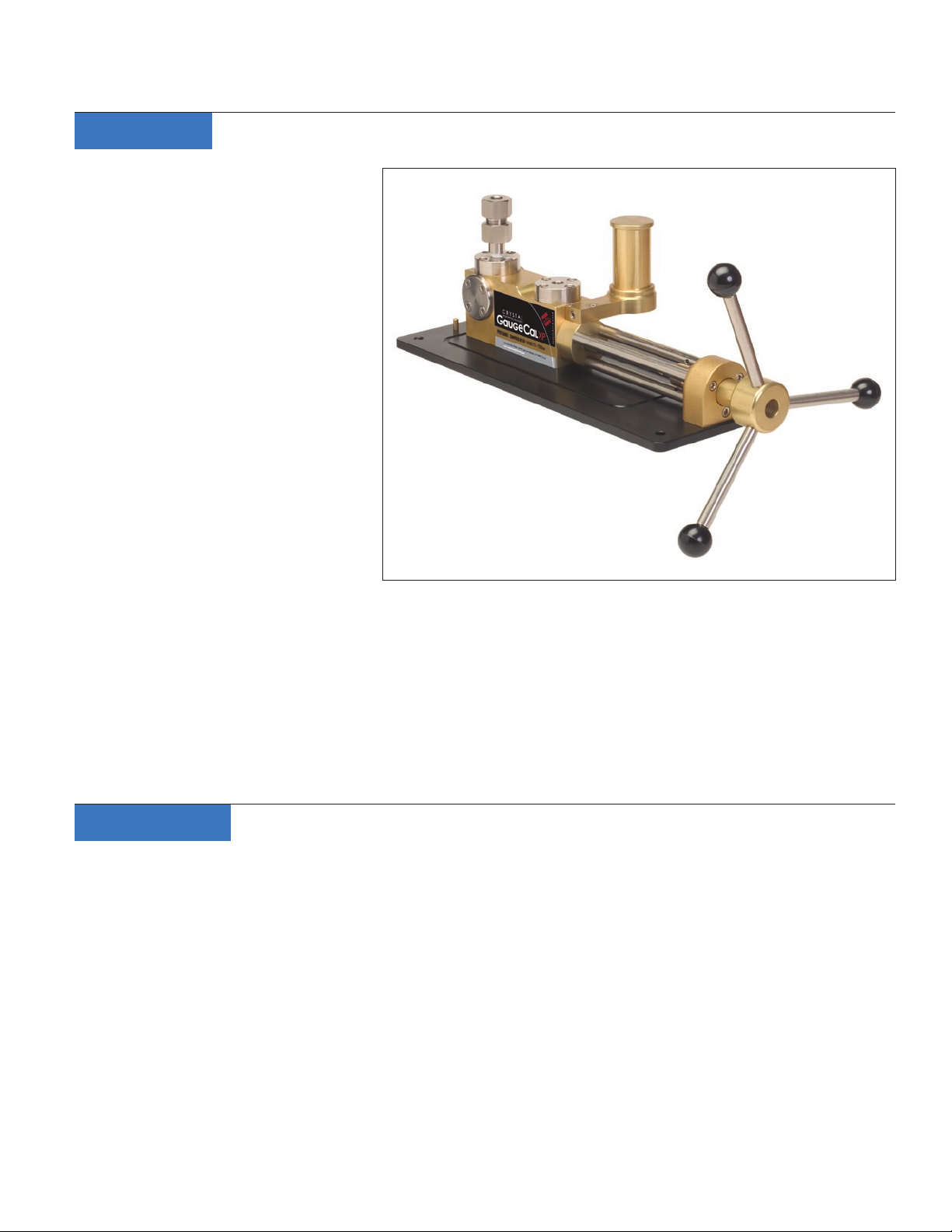

Thank you for purchasing a GaugeCalXP™

Pressure Calibrator from Crystal Engineer-

ing. The GaugeCalXP is a self contained,

precision hydraulic pressure generator

intended for the calibration of pressure

gauges rated up to 700 bar or 10,000 PSI.

Two pressure ports are provided. Connect

a reference grade gauge on one port (we

recommend an XP2i from Crystal Engineer-

ing) and the gauge to be tested on the

second port. Rotate the handle clockwise

until the desired pressure is generated.

Then, compare the displayed pressure val-

ues between the reference gauge and the

gauge under test.

PRESSURE is Our BUSINESS

®

Pressure can be set very quickly and pre-

cisely. Gauges can be calibrated in less than ten minutes (5 to 10 test points, increasing and decreasing pressure) if you

follow the method outlined in this manual. The comparator can be lled with your choice of uid: water, oil or isopropyl

alcohol.

The GaugeCalXP is much, much faster to use than a deadweight tester, and it’s also faster than most automated pressure

controllers, but it costs much less than either. It’s so quick and easy to use, it’s ideal to calibrate those low cost gauges that

are often overlooked for ISO9000 compliance. Please spend a few minutes to read this manual, and learn how you can

get the most benet from your GaugeCalXP.

Specifications

Performance

Maximum Pressure . . . . . . . . . . . . . . .10,000 PSI / 700 BAR

Minimum Pressure . . . . . . . . . . . . . . . . . . . . . . 5 PSI / 0.5 BAR

Burst Pressure . . . . . . . . . . . . . . . . . >20,000 PSI / 1400 BAR

Materials

Ram/Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316SS

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Buna N (Nitrile)

Test Media. . . . . . . . . . . . . Water, Oil, or Isopropyl Alcohol

C R Y S T A L

engineering corporation

Dimensions

Width (of base) . . . . . . . . . . . . . . . . . . . . . . . . 175mm (6.88”)

Length (of base) . . . . . . . . . . . . . . . . . . . . . . 429mm (16.88”)

Length (overall) . . . . . . . . . . . . . . . . . . . . . . . 495mm (19.50”)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4kg (14.2 lbs)

Accessories (included)

Adapters . . . . . . . . . . . . . . . . . . . . . . . 1/4” and 1/2” NPT std.

Wrenches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping Information

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8.6kg (19 lbs)

Dimensions . . . . . . . . . . . . . . .559mm x 305mm x 229mm

(22.0” x 12.0” x 9.0”)

GaugeCalXP Operator Instructions • Page 3

Baseplate16.25mm

[0.64”]

19.4mm

[0.76”]

O/ 10mm [O/ 0.39”], 4 places

Maximum bolt size, 8mm or [5/16”]

174.9mm

[6.88”]

142mm

[5.60”]

390mm

[15.35”]

428.8mm

[16.88”]

Gauge

Adapter

Flange

Stem

Stem Nut

Flange

Base

Quick-

Connect

Gauge

Adapter

Stem

Adapter

Flange

Base

Operation

For safe and reliable operation of your

GaugeCalXP Pressure Comparator, please

spend a few minutes reading the follow-

ing instructions.

1 Mount the comparator to your bench

or table: At higher pressures the force

required to rotate the handle may

cause the base of the comparator to

lift. We recommend that the compara-

tor be bolted to your bench or table.

Refer to Figure 1 for the hole pattern

and suggested bolt sizes.

2 Install the ange stem or stem adapters:

There are two (2) stainless steel ange bases. Each base has a 1/4” female (tapered) NPT thread. These bases are in-

tended to have either a ange stem (Figure 2) or stem adapter (Figure 3) for quick connectors installed. It is possible

to install an XP2i reference gauge directly into the base, but this is practical if only one XP2i will be regularly used

with the comparator.

Figure 1. GaugeCalXP Pressure Comparator mounting hole pattern.

One ange stem is supplied with the

comparator, and installed into a base

ange. If testing is limited to 5000 PSI

(350 bar) or less, quick connect ttings

that eliminate wrenches, thread tape or

sealant, may be used. Use PTFE thread

tape when installing either the ange

stem(s) or the stem adapter(s) into the

ange base(s).

3 Fill the reservoir: The reservoir holds

Figure 2. Two stainless steel gauge adapters are supplied with

the GaugeCalXP Pressure Comparator.

Figure 3. O ptional quick-connect gauge adapters allow quick

interchange of gauges without the need for sealing tape or

wrenches.

the test uid that lls the system each

time you test a gauge. The test uid can be either water, lightweight hydraulic oil, or isopropyl alcohol. Wind the han-

dle fully counter-clockwise, then clockwise for at least 10 turns (this prevents uid ow through the comparator and

potential uid spillage). Then ll the reservoir with test uid to within 6mm (1/4”) of the top. Turn the handle counter-

clockwise until you see the uid level in the reservoir drop. This lls the system with uid and removes any trapped

air bubbles. The reservoir cap has an o-ring to allow the GaugeCalXP to be transported with the test uids in place.

Due to the sealing capabilities of the cap, it must be removed or ajar during testing to allow proper equalization of the

system.

C R Y S T A L

engineering corporation

Page 4 • GaugeCalXP Operator Instructions

XP2i Digital Test gauge

mounted with the supplied

NPT gauge adapter.

Analog gauge to be tested

mounted with a quick-connect

gauge adapter.

4 Install the digital gauge: Use a ¼” fe-

male NPT gauge adapter (Figure 4).

If you are using the ange stem, ap-

ply PTFE thread tape to the pressure

gauge threads, then screw the gauge

into the adapter (PN: 3116). Be sure to

use wrenches on both the tting AND

the gauge when tightening the tting.

CAUTION: Never use wrenches when

connecting the gauge adapter to the

stem adapter tting—hand tight is sucient to insure a leak free connection. The

wrenches are intended to help separate

the gauge adapter from the stem adapter

tting, if necessary.

PRESSURE is Our BUSINESS

®

If you are using the quick connect

adapter (PN 3126), just screw it onto

the gauge, nger tight, then onto the stem adapter, also nger tight. Although wrench ats are provided on the quick

connect adapter, these are intended only to help remove the adapter.

CAUTION: Never use a wrench to tighten a quick connect adapter.

5 Install the gauge to be tested: As with the digital gauge, choose the appropriate adapter, either the quick connect or

regular gauge adapter (Figure 4).

6 Remove any remaining air from the system: Each time you install a new gauge, air bubbles may be introduced

into the Comparator and cause problems with calibration. Check again that the reservoir is full, then turn the handle

counter-clockwise until it stops at the full out position. If air bubbles are present in the system, the test uid level in the

reservoir will drop as it ows into the Comparator. If necessary, repeat this step until all trapped air has been removed.

Another way to remove air bubbles is to tilt the comparator. Wind the handle fully counter-clockwise, then lift the back

of the comparator. Any remaining bubbles will come out the back ange adapter.

7 Set up the digital pressure gauge: Turn on the XP2i, and then select the pressure units required for the gauge to

be tested—kg/cm2, bar, kPa, or PSI. (Refer to the documentation you received with your Crystal Engineering XP2i for

detailed operating instructions.)

8 Start the test: We recommend that you exercise the gauges by applying the full scale pressure of the gauge being

tested, one or more times. To apply pressure to the gauges, wind the handle in a clockwise direction. (To decrease

pressure to the gauges, wind the handle in a counter-clockwise direction). After decreasing the pressure to zero, re-

check the uid level in the reservoir, and rezero the XP2i, if necessary. You will notice that the application of pressure is

non-linear, therefore pressure increases at a more rapid rate at higher pressures.

Figure 4. The GaugeCalXP Pressure Comparator can be congured with an XP2i digital test gauge and a gauge to be tested, in either

of the two ports.

C R Y S T A L

engineering corporation

GaugeCalXP Operator Instructions • Page 5

bar

4

2 8

6

0 10

C R Y S T A L

engineering corporation

300 PSI

Note: If you cannot generate the desired pressure it is because one of two reasons: Either the system has too much air

in it, or the volume being pressurized is too large. Repeat step 6 to bleed the system and start again. If this does not

solve the problem, the volume is too large, and an auxiliary hydraulic pump is required.

9 Compare pressure readings: Wind the handle clockwise on the comparator so that the needle on the gauge being

tested is centered on the rst major graduation mark (or rst calibration point). These major marks are usually placed

at 10% or 20% increments of the full scale of gauge being tested. Hold the pressure for 15 seconds, then compare the

pressure on the gauge to be tested to the pressure displayed on the XP2i digital gauge, and record the reading on the

XP2i (Figure 5).

Normally, pressure will drop at rst,

as each ascending pressure point is

reached. This is due to the residual,

trapped gas, rst heated by compres-

sion, then cooled, so that the com-

pressed gas is at the same temperature

as the ambient environment. An equal

and opposite eect happens when re-

ducing pressure—the pressure will rise

as each new lower pressure is achieved.

Waiting for these thermal eects to sta-

bilize can add a lot of time to the cali-

bration.

10 Quick test method: An alternative

method eliminates the time required

to wait for thermal pressure stability. Start by setting the XP2i into the Peak “Hi” mode and clearing any stored peak

value. As above, increase pressure to the rst major graduation on the gauge (or calibration point), but increase pres-

sure slowly, so that you don’t overshoot the mark (or point). The pressure recorded on the XP2i will be the pressure

that was applied when the gauge was on the mark—even if actual pressure drops. Just record the reading from the

XP2i and continue to the next test point or mark. If you are also checking the gauge for hysteresis, the procedure is the

same, except that you start at full scale and set the XP2i to indicate the Peak “Lo”, and then clear the peaks at full scale

pressure. The XP2i will record the descending points in the same way.

Eliminating the time required to wait for thermal equilibrium, signicantly shortens the amount of time it takes to

calibrate a gauge.

Note: Below the rear gauge ange base of the Pressure Comparator are ports for an optional Fine Adjust accessory.

The Fine Adjust can be mounted on either side of the manifold block at the rear of the comparator. While the Fine

Adjust accessory is helpful for ne pressure adjustments, it is not necessary for general calibration. The Fine Adjust Kit

(P/N 3205) can be ordered directly from Crystal Engineering.

Figure 5. Checking the accuracy of an analog pressure gauge against the display of the XP2i digital pressure gauge.

C R Y S T A L

engineering corporation

Page 6 • GaugeCalXP Operator Instructions

Up to 10,000 PSI-700 bar

Kit p/n Individual Component p/n

GaugeCalXP Pressure Comparator

Fine Adjust Kit for GaugeCalXP

Rebuild Kit for GaugeCalXP

Rolling Carry Case Kit for GaugeCalXP

1

/8" Female NPT Gauge Adapter

1

/4" Female NPT Gauge Adapter (included)

1

/2" Female NPT Gauge Adapter (included)

1

/4" BSPP Gauge Adapter

1

/2" BSPP Gauge Adapter

3

/8" BSPP Gauge Adapter

NPT Quick-Connect Gauge Adapter Kit

Quick-Connect 1/8" Female NPT Gauge Adapter

Quick-Connect 1/4" Female NPT Gauge Adapter

Quick-Connect 1/2" Female NPT Gauge Adapter

1

/4" Male NPT Stem Adapter

BSPP Quick-Connect Gauge Adapter Kit

1

/4" Male NPT Stem Adapter

Quick-Connect 1/8" BSPP Gauge Adapter

Quick-Connect 1/4" BSPP Gauge Adapter

Quick-Connect 3/8" BSPP Gauge Adapter

Quick-Connect 1/2" BSPP Gauge Adapter

PTFE Thread Tape, 6mm (1/4") wide

3134

3116

3117

3137

3135

3136

3125

3126

3127

3254

3254

3184

3185

3186

3187

1810

3205

3143

3395

3183

3188

Up to 5,000 PSI-350 bar

Optional Accessories

PRESSURE is Our BUSINESS

®

C R Y S T A L

engineering corporation

GaugeCalXP Operator Instructions • Page 7

Warranty

Crystal Engineering Corporation warrants the GaugeCalXP Pressure Comparator to be free from defects in material and

workmanship under normal use and service for one (1) year from date of purchase to the original purchaser. It does not

apply when the product has been misused, altered, or damaged by accident, or abnormal conditions of operation.

For in (or out) of warranty service, we can be reached at:

Phone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (805) 595-5477

Email . . . . . . . . . . . . . . . . . service@crystalengineering.net

Web . . . . . . . . . . . . . . . . . . . . . www.crystalengineering.net

If calling, have ready the model number, serial number, date of purchase, and reason for return. You will receive instruc-

tions for returning the device to Crystal Engineering.

Crystal Engineering will, at our option, repair or replace the defective device free of charge, and the device will be re-

turned, transportation prepaid. However, if we determine the failure was caused by misuse, alteration, accident, or abnor-

mal condition of operation, you will be billed for the repair.

CRYSTAL ENGINEERING CORPORATION MAKES NO WARRANTY OTHER THAN THE LIMITED WAR-

RANTY STATED ABOVE. ALL WARRANTIES, INCLUDING IMPLIED WARRANTIES OF MERCHANT-

ABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, ARE LIMITED TO A PERIOD OF ONE (1) YEAR

FROM THE DATE OF PURCHASE. CRYSTAL ENGINEERING SHALL NOT BE LIABLE FOR ANY SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER IN CONTRACT, TORT, OR OTHERWISE.

Note (USA only): Some states do not allow limitations of implied warranties or the exclusion of incidental or consequen-

tial damages, so the above limitations or exclusions may not apply to you. This warranty gives you specic legal rights and

you may have other rights which vary from state to state.

Phone (Toll Free) . . . . . . . . . . . . . . . . . . . . . . . (800) 444-1850

FAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (805) 595-5466

C R Y S T A L

engineering corporation

C R Y S T A L

engineering corporation

© 2006 C rysta l Enginee ring Corpor at ion

708 Fiero Lane, Su ite 9, San Luis Ob ispo, Cali forn ia 9 34 01-8701

PN: 317 1—Re v C

Loading...

Loading...