Page 1

BRAKE TESTER EB30-2R

OPERATING INSTRUCTIONS

TES1447/D

Feb 2005

Page 2

EB30-2R OPERATING INSTRUCTIONS Page 2

IMPORTANT

Every reasonable effort has been made to ensure that information within these

Operating Instructions is correct at the time of release, but Crypton cannot acceptresponsibility for any errors that may occur.

The information in these Operating Instructions is subject to change without notice,

and does not represent a commitment on the part of Crypton.

Service & Warranty

The reliability of this equipment is fully supported by our service agent.

Please refer to the page at the end of this manual for full details.

Note:

Your attention is drawn to our Terms & Conditions of Sale. If a service engineer is

called out. under service warranty where, upon inspection and test the equipment is

found to be in full working order and no fault found, the user is liable to be charged

the cost incurred for this call out. Before calling out an engineer, ensure your

equipment is faulty by checking its operation, particularly mains supply and fault

codes/self test if applicable.

WARNING:

Do not attempt to operate this equipment unless you have read and

understood these

instructions.

Page 3

EB30-2R OPERATING INSTRUCTIONS Page 3

CONTENTS

Safety precautions 4

Hints and Tips 5

INTRODUCTION 6

Description of system components 6

Emergency switch 6

Pit unit 6

Control unit 8

Motor control 8

Printer 8

Remote control 9

Guide to testing 11

Test description 12

MOT Test Procedure 12

Enter car on PC 12

Reset system 12

First Axle 12

Foot brake 12

Centre 12

Left Foot brake test 12

Right Foot brake test 12

Bind, ovality and imbalance test 12

Secondary Brake 13

Left Secondary Rear Axle 13

Right Secondary brake test 13

Parking Brake Test Class IV and Class VII 14

Applied Parking Brake Test – Class V Only 14

Left Parking brake test 14

Right Parking brake test 14

Driving out 14

Next Axle 15

Printing results 15

Manual Testing 16

Calculations 17

Prompt sheet 18

Maintenance 19

Technical Specification 21

After Sales Service 22

Notes 23

Page 4

EB30-2R OPERATING INSTRUCTIONS Page 4

SAFETY PRECAUTIONS

Read these operating instructions carefully and thoroughly before attempting to

operate the equipment.

This operating manual should be available at the testing site at all times.

Always follow the procedures and actions defined in this manual, failure to do so

may result in personal injury or other damage. The manufacturer cannot be held

liable for personal injuries or vehicle damage that occur as a result of misuse of the

equipment.

All the national and international safety guidelines and legal regulations are to be

followed when operating testing equipment.

The operator is obliged to adhere to all the regulations applying to the workplace and

to ensure his knowledge of such regulations is up to date.

Do not allow other personnel near the test vehicle or rollers while a test is in

progress. Check that the area is clear before the rollers are started or the vehicle

moved EACH TIME this action is taken.

Testing often takes place with the engine running, to provide a vacuum supply to the

brake servo. Ensure exhaust extraction or adequate ventilation is used to clear the

poisonous exhaust gasses.

Do not modify the equipment or change any internal settings – this could result in a

very dangerous condition where the rollers could be started WITHOUT a vehicle in

the rollers!

TESTING STANDARD

When performing statutory MOT tests it is vital to follow the brake test

procedure detailed in the latest version of the relevant MOT Inspection Manual

Page 5

EB30-2R OPERATING INSTRUCTIONS Page 5

HINTS & TIPS

The brake tester must only be used for its intended purpose.

All the performance limits are to be followed, do not drive excessively heavy vehicles

over the pit unit or otherwise abuse the equipment as damage may occur and test

result accuracy may be affected.

Only authorised and well-trained personnel should perform the testing.

The work area should be kept clean and dry.

Always keep a safe distance from moving parts. The area must be marked so that

vehicle owners are aware of the danger associated with brake testing.

Note the location of the emergency stop switch before starting to use the equipment.

When driving off the brake tester, the roller motors should be switched on so that the

rollers are driven. This limits the speed of the rollers to a safe value. If the vehicle is

driven off the rollers without them being powered damage may occur.

Do NOT use the brake tester to start the engine of a vehicle as this may damage the

electric motors.

Drive on and off the tester slowly and in a controlled manner.

Always check the ground clearance of the vehicle is adequate before performing the

test.

Page 6

EB30-2R OPERATING INSTRUCTIONS Page 6

INTRODUCTION

The EB30-2R is a roller brake tester designed to perform VOSA MOT tests on

Class IV, Class V and Class VII vehicles.

Control can be performed using the remote handset at the vehicle so one man

operation is possible and a printer in the console will produce a record of results.

Description of system components

The roller brake tester consists essentially two parts: one above ground, the control

and display console and one below ground, the road simulation rollers. A brief

description of the various features follows:

Emergency switch

The brake tester is equipped with an emergency stop switch. Note the location of the

emergency stop before starting to use the equipment. The emergency switch is not

necessary positioned in the same place at every installation, check the location

before using the equipment.

Pit unit

The rolling road consists of two sets of free roller pairs connected by a chain and

indirectly driven by two electric motors through gearboxes. The gearbox is joined to

the roller tester frame by a force transducer. During the motor operation when the

car is braking, the resultant force is transmitted from the rollers to the brake force

transducer. The outputs of the transducers are monitored by the internal circuits and

eventually shown on the display as brake effort.

A small third roller is fitted between each pair of main rollers. These perform two vital

functions. Firstly to monitor the presence of a wheel in the rollers so that motors can

only be energised when a vehicle is present and secondly to measure speed of the

wheel that is being braked. This ensures that the motors are automatically switched

off when the tyre starts to slip on the roller surface.

Page 7

EB30-2R OPERATING INSTRUCTIONS Page 7

EB30-2R MOT Class IV, V and VII Roller Brake Tester

Page 8

EB30-2R OPERATING INSTRUCTIONS Page 8

Control unit

The control unit contains front panel with:

Green indicator light : Car on rollers / Rollers drive direction / 4WD

(Arrows Lup, LDn, Rup, RDn)

Red indicator lights: Wheel locks (Lock left & Right)

Green indicator light : Ready for test (Ready)

Orange indicator lights: Show which scale range is being used

Pointers: Green for left, red for right

Digital display (DDsp): Imbalance, ovality, pressure, weight

Amber indicator lights: Showing type of information on digital display

(Oval, Pres, Wght)

Inside: Power supply board for control computer, front panel, amplifiers and

motor control

Motor control

Outside: Main switch, Emergency switch

Printer

The printer is an optional device that can be specified at the time of purchase or

fitted later. Follow the instructions in the printer handbook for loading paper and

fitting ink cartridges (if applicable).

An extension kit is available to allow the printer to be mounted some way from the

console.

Page 9

EB30-2R OPERATING INSTRUCTIONS Page 9

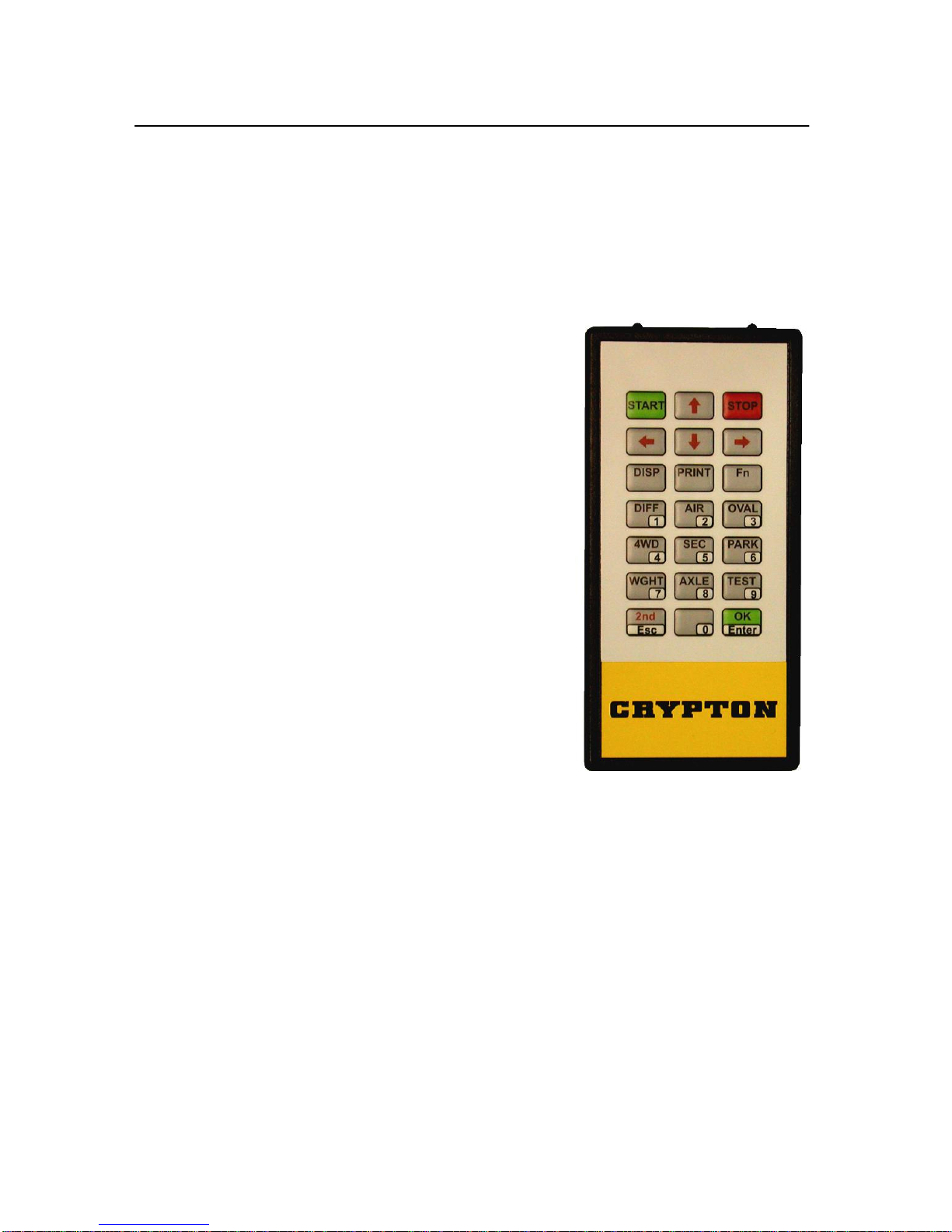

Remote control

Remote control consists of 16 keys, some of which have dual function which are

activated through the 2nd key.

START: Used to start the rollers

when the system is ready

for a test.

STOP: Used to stop the rollers,

any roller that is running

will stop. To stop the test

completely, press OK

while DDsp = STP

UP ARROW: Used for axle selection.

DOWN ARROW: Used for axle selection

OK: Press to save results

from the last test step.

LEFT ARROW: Used for wheel selection

RIGHT ARROW: Used for wheel selection

DIFF: Selects imbalance when

both wheels are running.

AIR: Selects air pressure

4WD: Used to switch test procedure into a special mode that rotates

wheels in opposite directions during all test steps so that prop

shaft does not rotate.

SEC: Used to initiate secondary brake test

PARK: Used to initiate parking brake test

OVAL: Used to initiate ovality measurement

WGHT: Used for weight input. With vehicle in rollers, press WGHT

Press STOP to cancel weighing or OK to confirm and save

axle weight.

AXLE: Used for axle selection

Page 10

EB30-2R OPERATING INSTRUCTIONS Page 10

PRINT: Used to print test results

TEST: Starts both rollers so that vehicle can be driven out.

2 nd: This key activates the second function of other keys

2 nd STOP: Will RESET the system and clear all previous results

so that a new vehicle test is activated.

When the system is RESET the DDsp = CL4

2 nd WGHT: This key sequence allows manual weight entry. DDsp = At

Respond by pressing AXLE for individual axle weight entry or

TEST for gross vehicle weight. Enter the weight in 100kg units

i.e. 100 = 10 Tonnes. Then press OK

2 nd OK: System internal test, DDsp = Tst

The Fn key is not currently used.

Page 11

EB30-2R OPERATING INSTRUCTIONS Page 11

GUIDE TO TESTING

General guide:

At first switch on all the LED indicators will be illuminated so that fuctionality can be

checked.

The START key starts the motor or motors as appropriate. This will only happen with

a car in the rollers as shown by the green Ready indicator lamp being illuminated.

After START is pressed and while the motor(s) is getting up to testing speed, the

digital display will show rotating icon(s) to confirm which wheel(s) is being started.

Once this icon disappears, test actions or brake force measurements can be taken.

Four actions will stop the rollers; if the STOP key is pressed, the car leaves (even

temporarily) one of rollers sets, wheel slip is detected or the safety mains switch is

activated.

With a car on the rollers and the rollers not running, one (or two) of the green

indicator lights LUp, LDn, RUp, RDn will flash to show the direction in which the

wheel(s) will be driven. Once the motor is started, the flashing light will be stay on.

As the brakes are applied and a wheel approaches the pre-set slip limit, the

respective red Lock indicator will flash.

The orange indicator lights will show which of the two scale ranges is in use for any

particular reading.

Any measured value will remain on the scale display (or DDsp) until the OK button is

pressed to accept the result. The pointer(s) will then be returned to zero.

If the brakes are cold or wet, take the opportunity to apply brake several times to

warm up and/or dry brakes while the wheels are being centred.

Individual sections of the MOT procedure can be repeated if unrepresentative

readings have been obtained or the process is interrupted for some reason. Simply

press the START key again and repeat the test section. Only the results taken

during the last sequence will be stored when the OK key is pressed.

The normal testing method follows the MOT tester’s manual sequence but the rollers

can be used in Manual mode – see later sections.

Once testing is complete, start the rollers to assist with driving the vehicle out of the

rollers.

Page 12

EB30-2R OPERATING INSTRUCTIONS Page 12

TEST DESCRIPTION :

Use the following section as a prompt list when performing MOT tests. The next

sections gives a more detailed description and should be studied by new users

before any attempt is made to follow this simple prompt list.

MOT BRAKE TEST PROCEDURE

Note: For Class IV and VII vehicles, use the secondary brake test when checking

the Parking Brake. DO NOT apply the locked parking brake test on these vehicles.

Enter the car details onto the PC (if connected) or press WGHT key to enter car

weight

If the vehicle braking system is fitted with a servo, ensure the engine is running at

idle throughout the test (use exhaust extraction or adequate ventilation).

Before Driving the Vehicle into the Rollers

RESET the system by pressing 2 nd and then STOP, DDsp shows A1 then Ctr

First Axle Drive the first axle into the rollers.

Foot Brake

CENTRE THE WHEELS: Press START key to start both roller sets, DDsp shows

both rotating icons then Ctr. Allow the wheels to centre and press STOP when

alignment is correct . DDsp shows A1.L

AXLE WEIGHT: If weighing is fitted, DDsp will show U U while weight is being

measure and then display the axle weight in Tonnes. Note this is necessary and

press OK to proceed.

LEFT FOOT BRAKE: Press START key to start only the left roller set. DDsp

shows left rotating icon then A.1L Apply footbrake smoothly until the wheel stops or

produces its maximum brake effort , then press STOP.

(This start, test, stop action can be repeated if necessary)

Once acceptable reading has been obtained press OK to store the result.

DDsp shows A1.r

Page 13

EB30-2R OPERATING INSTRUCTIONS Page 13

RIGHT FOOT BRAKE: Press START key to start only the right roller set. DDsp

shows right rotating icon then A.1r Apply footbrake smoothly until the wheel stops or

produces its maximum brake effort , then press STOP.

(This start, test, stop action can be repeated if necessary)

Once an acceptable reading has been obtained press OK to store the result.

DDsp shows A1

BIND, OVALITY and IMBALANCE TEST Press START key to start both roller

sets. Do not apply any brake force. DDsp shows both rotating icons then A1.b for a

few seconds. It will then show either the bind value or symbol “--” if bind is below

20kgf.

Apply a brake force of about 500 kgf and hold pedal steady

Press OVAL key to measure the ovality, DDsp shows to, wait 6 second approx.

When DDsp shows BAL, the ovality measurement is complete, apply footbrake

smoothly up to about 90% of maximum force measured above and the imbalance

will be measured. Slowly release the pedal observing the force readings. Press the

STOP key to end the test. (This whole section can be repeated if necessary).

Press OK key to save the results.

If there is a Secondary brake on this axle, test it now before proceeding to next axle.

If the Parking brake is fitted to this axle, test it now before proceeding to next axle

Secondary Brake test

Press SEC key to select secondary brake test, the DDsp shows S1.L

LEFT SECONDARY BRAKE: Press START key to start only the left roller set.

DDsp shows left rotating icon then S1.L Apply Secondary brake smoothly until the

wheel stops or produces its maximum brake effort , then press STOP.

(This start, test, stop action can be repeated if necessary)

Once acceptable reading has been obtained press OK to store the result.

DDsp shows S1.r

RIGHT SECONDARY BRAKE: Press START key to start only the right roller set.

DDsp shows right rotating icon then S1.r Apply Secondary brake smoothly until the

wheel stops or produces its maximum brake effort , then press STOP.

(This start, test, stop action can be repeated if necessary)

Once an acceptable reading has been obtained press OK to store the result.

Page 14

EB30-2R OPERATING INSTRUCTIONS Page 14

Handbrake Test Class IV and VII.

Press the PARK key to start the test , DDsp = P1L indicating test of LEFT brake

With the handbrake released, press the START key to power up the left hand roller

set, DDsp will show rotating icon while motor starts then P1L

Apply the handbrake slowly to maximum until a lock is achieved or press the STOP

key if motor did not stop due to lock..

Repeat the test if required or press OK to accept the results

DDsp will now show P1R and the right handbrake should be tested using the same

procedure as the left.

Applied Parking Brake Test

This is a LOCKED BRAKE TEST and MUST NOT be applied to Class IV or Class

VII vehicles

Apply the Parking Brake

Press PARK key to start the test, DDsp = P1.L

LEFT PARKING BRAKE: Press START key to start only the left roller set. DDsp

shows left rotating icon then P.1L . Test will automatically stop after three seconds.

(This start, test, stop action can be repeated if necessary)

Once acceptable reading has been obtained press OK to store the result.

DDsp shows P1.r

RIGHT PARKING BRAKE: Press START key to start only the right roller set. DDsp

shows right rotating icon then P1.r . Test will automatically stop after three seconds.

(This start, test, stop action can be repeated if necessary)

Once acceptable reading has been obtained press OK to store the result.

Driving out: Not to be used for DP variants

It is safer to drive ‘driven’ axles out of the rollers with the brake tester motors

running. This eliminates any problems of over speeding the rollers and drive motors,

particularly when the vehicle under test has an automatic gearbox.

Select next axle by pressing AXLE and DOWN ARROW , then press START to

power both motors as if the wheels were being centralised and drive the wheels out

of the rollers. Brake tester motors will stop once the wheels leave the rollers.

Page 15

EB30-2R OPERATING INSTRUCTIONS Page 15

Next Axle: Press AXLE followed by DOWN ARROW key to switch to the

next axle, DDsp = A2 , A3, A4 etc.

Drive the next axle into the rollers and perform Footbrake, Secondary Brake and

Parking brake tests as applicable.

Repeat until all axles are tested.

Print results

When all axles have been tested, press PRINT key to print the test results.

Brake forces are printed if no vehicle weight has been entered.

If Gross Vehicle Weight has been manually entered or axles weighed during test,

the brake performance is calculated and printed.

Page 16

EB30-2R OPERATING INSTRUCTIONS Page 16

MANUAL TESTING

In this mode, the roller direction can be selected. This enables a 'quick check'

following a brake repair or testing of 4WD vehicles.

N.B. Not all 4WD vehicles are suitable for roller brake testing.

Check manufacturers' data before testing and if in doubt use a

decellerometer on a road test.

RESET the system in the normal way by pressing 2 nd then STOP keys and show

CL4 on the DDsp.

Drive the vehicle into the rollers.

Press 2 nd and then 4WD keys puts the unit into Manual Mode which is indicated by

DDsp showing MAn.

Select the roller direction by using the two rotary switches on the side of the motor

control box. The roller direction will be indicated by the green LEDs adjacent to the

direction arrows on the analogue display.

Press the START key to start the selected wheel(s) and after the rotating icon

display a live reading of brake effort is shown on the pointer(s).

The test is stopped when the wheel slips, the wheel leaves the rollers, the STOP

button is pressed or the emergency switch is operated.

The pointer will then show the maximum brake effort recorded during the test.

If the PRINT key is pressed this maximum reading will be recorded on the printout.

To exit the manual mode, RESET the system by pressing 2 nd and then STOP keys

and the DDsp will show CL5 indicating a return to normal operation.

Page 17

EB30-2R OPERATING INSTRUCTIONS Page 17

CALCULATIONS

A rotary slide-rule type calculator is supplied with the unit and this should be used to

calculate the brake efficiency.

Alternatively a manual method can be used as follows:

Efficiency: Note the maximum brake force from each wheel in kgf, add

these numbers together and divide the result by the vehicle

weight in kg then multiply by 100.

This gives percentage brake efficiency.

Efficiency = A + B + C + D

(Vehicle weight)

Imbalance: If brake forces on a particular axle are A kgf and B kgf

Assuming A is greater than B then

Imbalance = A - B

A

X 100 %

X 100 %

Page 18

EB30-2R OPERATING INSTRUCTIONS Page 18

PROMPT SHEET – photocopy this page and use as a guide when testing.

Enter details onto the PC (if connected) or press WGHT to enter vehicle weight

RESET the system by pressing 2 nd and then STOP

First Axle Drive the first axle into the rollers.

Foot Brake: Press START key to start both roller sets. Allow the wheels to

centre and press STOP

Press START key to start only the left roller set. Apply footbrake smoothly until the

wheel stops. Once acceptable reading has been obtained press OK to store.

Press START key to start only the right roller set. Apply footbrake smoothly until the

wheel stops. Once an acceptable reading has been obtained press OK.

Press START key to start both roller sets. Do not apply any brake force. Wait for

display to show either the bind value or symbol “--” .

Apply a brake force of about 500 kgf and hold pedal steady. Press OVAL key, wait

6 second approx. When DDsp shows BAL, apply footbrake to about 90% of

maximum force measured above hold and slowly release. Press the STOP key.

Press OK key to save the results.

Secondary Brake test: Press SEC key

Press START key to start only the left roller set. Apply secondary brake smoothly

until the wheel stops. Once acceptable reading are obtained press OK to store.

Press START key to start only the right roller set. Apply secondary brake smoothly

until the wheel stops. Once an acceptable reading has been obtained press OK.

Parking brake - ONLY class V!

Apply the Parking Brake and press PARK key to start the test.

Press START key to start only the left roller set, wait 3 seconds, press OK.

Press START key to start only the right roller set, wait 3 seconds, press OK.

Next Axle: Press AXLE followed by DOWN ARROW key to switch to next.

Print results: Press PRINT key to print the test results.

Page 19

EB30-2R OPERATING INSTRUCTIONS Page 19

MAINTENANCE

Before all the repairs, service work and adjustments always lock the main switch of

the device.

The construction of the equipment is simple and thus does not require costly

maintenance. It is necessary to keep it clean, draw up loose bolts regularly control

the wear of the anti-skid surface of the rollers and in the case of larger wear to

replace this material or replace the set of rollers.

Lubrication

The oil in the gearboxes does not have to be replaced until after 10.000 hours of

service. The used gearbox lubricant is synthetic oil AGIP TELIUM VSF320. Flange

and ball bearings have to be refilled annually using a lubricant grease (for example

SKF LGMT2 or LKMT3).

If you are changing the lubricant, following instructions apply:

1. Remove the cover plates, chain tension assemblies and motors.

2. Lubricate the bearings of the rollers by pumping the grease through into the

bearings.

3. Lubricate bearings of the motors once a year. Lifting the rollers allows a better

access to the bearings.

4. Lubricate the chain with a suitable oil or a special grease at least once a year.

5. Check the oil level in the gearbox.

6. Bolt the cover plates on.

Warning: The lubricant greases and oils are oil base products and to preserve

the environment it is necessary to prevent their leakage into the

installation pit.

A skin reaction to most of the lubricants is health unobjectionable

according to the manufacturers. However, during their use the

chemical ingredients increase their concentration. We recommend

using devices for skin protection and the right preventive preparations.

The companies specialized in skin protection will give you more

information about it.

Chain tension adjustment

It is necessary to watch the wear of the chain and after its elongation to replace it for

a new one before the chain wheels are damaged. The chains are pre-stretched and

need very little adjustment. They are adjusted by moving the front or rear roller or

the motor.

1. Remove both cover plates of the roller units.

2. Check the chain tension, it should not deflect by more than 5 mm.

3. Tighten the chain by moving one of the rollers away from the other. Loosen

the bolts holding the bearing. Tighten the chain by turning the adjustment

bolts, and re-tighten the bolts.

4. Bolt the cover plates back on.

Page 20

EB30-2R OPERATING INSTRUCTIONS Page 20

Other periodical maintenance

Due to a small number of movable parts it is not necessary, except for tensioning the

chain and inductive switch triggering control, to do any adjustments on the

equipment.

Daily:

Clean the cover plates of the roller units

Inspect and clean the rollers

Weekly:

Check the proximity of the middle metal rollers one at the time. The display

will show the respective Lup and Rup green indicating lights on when this

roller is pressed down. The roller brake tester cannot start unless the middle

metal roller is triggered pressed down.

Twice per year:

Remove all cover plates from the roller units.

Clean the pits from oil and dirt.

Check that the adjustment bolts support the main bearings properly.

Check the motors for oil leakage.

Check that the chain deflection does not exceed 10 mm when pressing by

hand.

Replace the battery in the remote control.

Clean the surfaces of the remote control and the control unit.

Bolt the cover plates back in place.

Perform a full check of all functions.

Yearly:

At least once per year the service organisation should perform the transducer

and amplifier calibration adjustment.

Page 21

EB30-2R OPERATING INSTRUCTIONS Page 21

TECHNICAL SPECIFICATION - EB30-2R

Maximum axle load 20 tonne

Maximum brake force 4,000 kgf

Maximum pedal force 1,000 N

Maximum brake pressure 10 bar

Weighing – maximum 20 tonne

Roller surface speed 2.4 kph

Roller Diameter 254 mm

Roller length 1000 mm

Distance between roller centres 475 mm

Roller project by 50 mm

Minimum wheel diameter 450 mm

Maximum wheel diameter 1,500 mm

Measuring system Strain Gauge Transducers

Dimensions:

Roller assembly Width 3,272 mm

Depth 833 mm

Height 590 mm

Control Unit Width 710 mm

Depth 565 mm

Height 2,400 mm

Weights

Roller assembly 1,400 kg

Control Unit 120 kg

Electrical supply:

Total load 26 kVA

Electrical connection 3NPE~50Hz 400V / TN-S

Page 22

EB30-2R OPERATING INSTRUCTIONS Page 22

AFTER SALES SERVICE

Apart from the routine maintenance and adjustments stipulated in this manual the equipment must not be

tampered with in any way. All further servicing must be carried out only by an engineer from our Authorised

Agents. Failure to observe these conditions will invalidate the Guarantee.

On-Site Service / Overhaul / Spare Parts

If you require a Service Engineer to attend ON SITE, either due to an equipment fault, or for machine calibration,

or if the equipment covered by this manual requires to be sent back for factory overhaul, or if you need spare

parts, please contact our Product Support Helpline at the following number.

Tel: 01278 436225 Fax: 01278 436238

Overseas

Service abroad is provided by the agent from whom your equipment was purchased.

Crypton provide information and contracts covering:

Car Data, Fault Code Information, Diagnostic Information, Technical Topics, Software Support

Contracts, Software Updates & Accessories

Helplines

Crypton run an Equipment Helpline during normal office hours.

Tel: 01278 436225 Fax: 01278 436238

email: support@CryptonTechnology.com

A fully comprehensive Product Support Contract is also available which provides additional assistance

with equipment / technical support. Please contact Product Support on the above Helpline no. for

further details.

Page 23

EB30-2R OPERATING INSTRUCTIONS Page 23

NOTES :

Loading...

Loading...