Page 1

DP Series

DC Load Reversing Solid State Contactors

Crydom’s advanced DC Switching Technology is now conveniently packaged in a High Power

“H-Bridge” configuration with optional Soft Start/Ramp Up, Soft Stop/Ramp Down & Brake

features for use in DC Load Reversing applications including motors, brakes, clutches, electro

magnets, solenoids, plating baths and electrolytic cells. The DP Series Solid State DC Reversers

are an all-solid-state design with 2.5 Kv Optical Isolation and incorporate low dissipation power

FETs for fast and efficient Load control.

FEATURES

Convenient FET switches in H-bridge configuration

Built-in protective Forward/Reverse interlock function

UL & IEC ratings for general use & Motor loads

LED Status indicators for Operating Modes

MOUNTING INSTRUCTIONS

Please read all installation instructions before using your DP Series Solid State Contactor (SSC).

Choose one of the two mounting options and follow the instructions.

Mounting on Heat Sink

Select adequate heat sink (see thermal derating

(B)

curves).

Be sure to use thermal pad or grease between the

SSC and the selected heat sink.

DP Series Contactor mounting slots have a diameter

of 0.2 in (5.0 mm). Four screws are needed (not

included) to mount the SSC onto heat sink (See Fig.

1). Choose screw length considering the mounting

surface and that DP Series baseplate thickness is

0.125 in (3.2 mm).

Before applying full torque tighten down all 4 screws until they contact the baseplate.

Then, tighten them to 20 in-lbs (2.2 Nm) starting with one immediately followed by the one

in the diagonally opposite corner. After the first 2 screws are completely tightened,

proceed tightening the remaining 2 screws.

For optimal thermal performance heat sink fins should be oriented vertically to natural

airflow.

Mounting on Panel

Locate the panel section on which the DP Series SSC will be mounted. Panel mount

surface must provide adequate heat sinking capability. (B)

Be sure to use thermal pad or grease between the SSC and the panel.

DP Series Contactor mounting slots have a diameter of 0.2 in (5.0 mm). Four screws are

needed (not included) to mount the SSC onto panel. Choose screw length considering the

mounting surface and that DP Series baseplate thickness is 0.125 in (3.2 mm).

Before applying full torque tighten down all 4 screws until they contact the baseplate.

Then, tighten them to 20 in-lbs (2.2 Nm) starting with one immediately followed by the one

in the diagonally opposite corner. After the first 2 screws are completely tightened,

proceed tightening the remaining 2 screws.

WIRING DIAGRAM

(C)

1 / -

4 / L2 3 / L1

(A)

DC Power Supply

DC POWER SUPPLY SIDE

LOAD SIDE

Thermal pad

fig. 1 DP Series SSC

mounted on HS053 heat sink

2 / +

(D)

5

6

7

8

+VCC

GND

+FWD

+REV

(A)

PART NUMBER NOMENCLATURE

Start Mode

Blank: Start

SA: Soft Start/Ramp Up, 0.2 sec

Series

SB: Soft Start/Ramp Up, 0.5 sec

SC: Soft Start/Ramp Up, 1 sec

DP 4R SB 60 40

Function

4R: 4 Channel DC Reversing

Required for valid part number

For options only and not required for valid part number

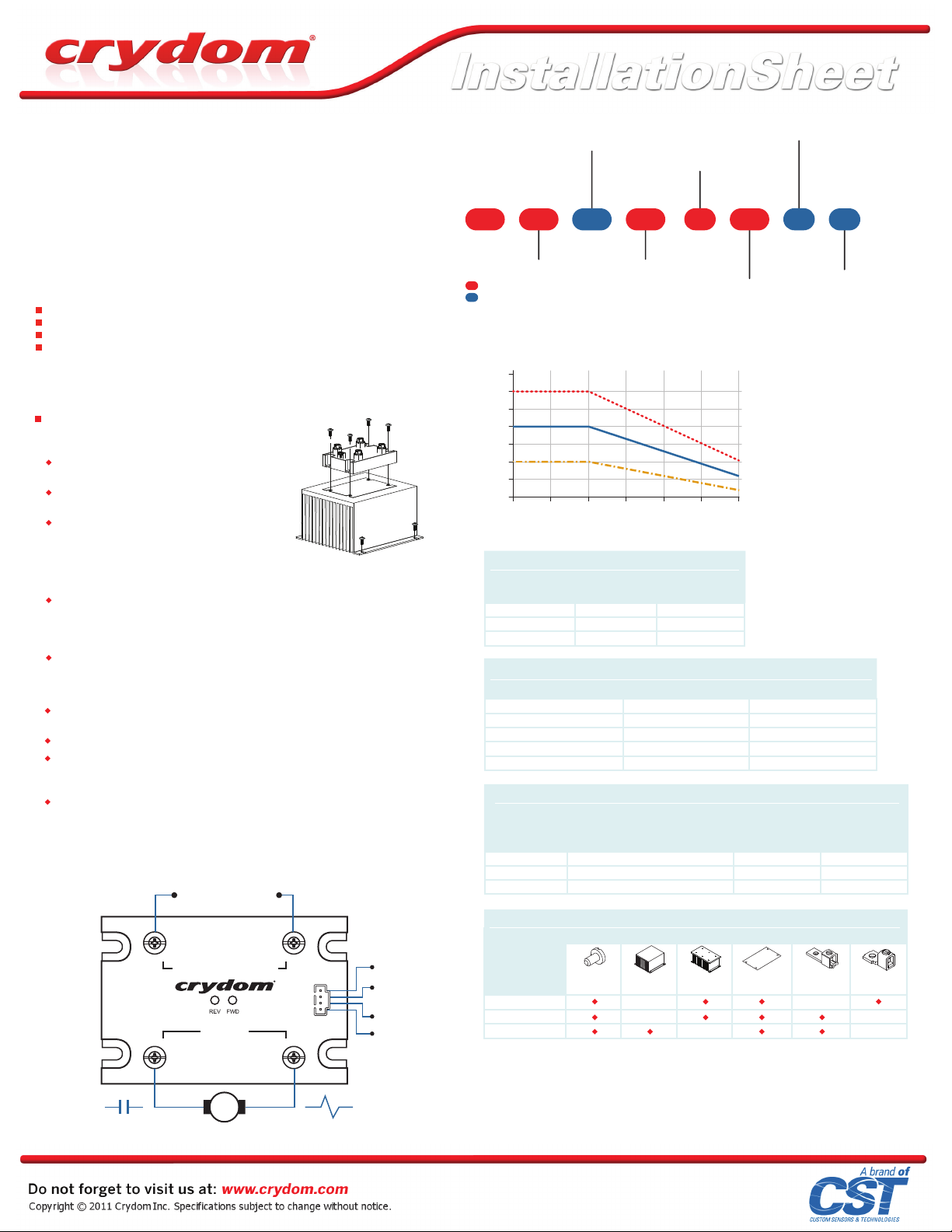

DERATING CURVES

70

DP4Rxx60x60xx

60

50

DP4Rxx60x40xx

40

30

DP4Rxx60x20xx

20

Load Current (Amps)

10

0

20 30 40 50 60 70 80

(B)

(E)

Control Voltage

D: 4.5-15 VDC

E: 18-32 VDC

D

Rated Operating Voltage

60: 48 VDC

Operational Current

20: 20 Amps

40: 40 Amps

60: 60 Amps

Ambient Temperature (ºC)

TABLE 1

DP Series

Part No.

DP4Rxx60x20xx HS103/HS103DR

DP4Rxx60x40xx

Required Heat Sink

[ºC/W]

1.5

1.0 HS103/HS103DR

0.5 HS053DP4Rxx60x60xx

Crydom Heat Sink

Part No.

TABLE 2

Status Functions Green LED (Forwa rd) Yellow LED (Reverse)

Initial Logic Supply Volt age On Flash Twice Flash Twice

Forward ON ON OFF

Reverse ON OFF ON

Dynamic Brake Flash Once Flash Once

Interlocking Flash 3x Intermittently Flash 3x Intermittently

TABLE 3

DP Series

Part No.

DP4Rxx60x20xx

DP4Rxx60x40xx

DP4Rxx60x60xx 25 (2.8)

Output Terminal

Screw / Clamp Combo Type 10-32 20 (2.2)

Hex Screw Type 1/4-20 with lock washers 25 (2.8)

Hex Screw Type 1/4-20 with lock washers

Maximum Torque

lbs in (N m)

TABLE 4

Accessories

DP Series

Part No.

DP4Rxx60x20xx

DP4Rxx60x40xx

DP4Rxx60x60xx

HS103

HS103DR

HSP-5

Stop Mode

Blank: Stop Mode matches Start Mode

B2: Dynamic Brake, 0.2 sec

B5: Dynamic Brake, 0.5 sec

B8: Dynamic Brake, 0.8 sec

B: Dynamic Brake, Continuous

H

B

Thermal Pad

Blank: Not Included

H: Included

Wire Size

for Max. Ratings

TRM1 TRM6HS053HK1 HSP-3

AWG (mm

12 (3.3)

8 (8.4)

6 (13.3)

2

)

DC

MotorCell Resistance

(A) See compatible accessories in TABLE 4.

(B) For maximum ratings use heat sink ratings in TABLE 1.

(C) Terminal (3/L1) is (+) during Forward operation. Terminal (4/L2) is (+) during Reverse operation.

(D) Suggested Input Mating Connector/Plug : Crimp Housing, Positive Latch (Molex 050579404).

(E) For a complete description of available Operating Modes, see definitions on reverse side of this sheet.

Rev. 060211

Page 2

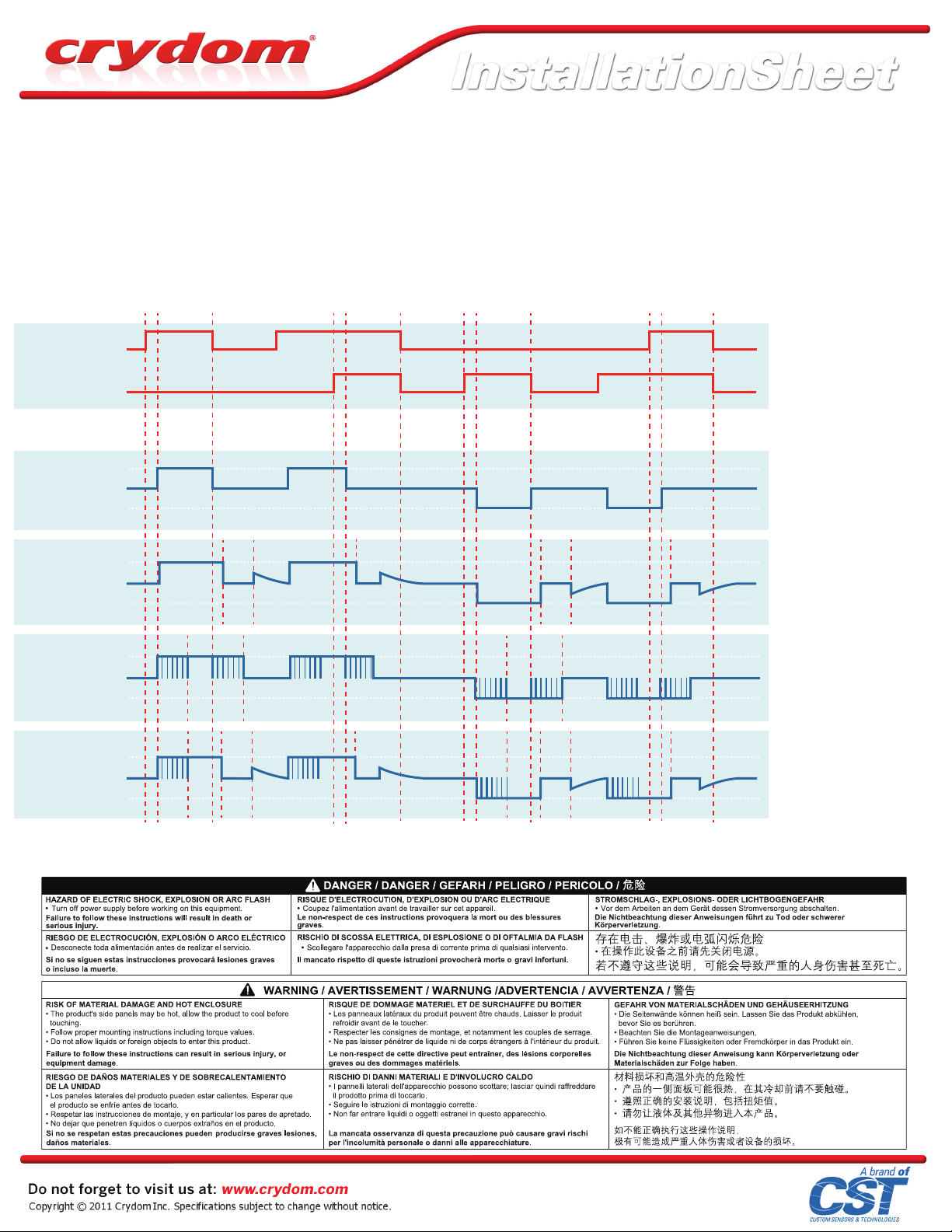

OPERATING MODES

Start: When either FWD or REV Control signal is applied, and after Control Signal Validation Delay, DC power

supply on terminals 1/- and 2/+ is directly connected to Load at terminals 3/L1 and 4/L2 with a polarity according

to the control signal. The start option can be combined with Stop and/or Dynamic Brake options.

Stop: Load is disconnected from DC power supply. All FET switches (S1, S2, S3 & S4) inside the DP Series SSC are

turned off. This simple Stop option is available only in combination with the simple Start option (suffix Blank).

Soft Start/Ramp Up: It is a modified Start where the DC power supply is connected to the load using a 200 Hz pulse

width modulation with a duty cycle going from 10% to 100%. Soft Start/Ramp Up time is defined by SA, SB and SC

suffixes. After Soft Start/Ramp Up time is elapsed, the Load will remain continuously energized for as long as FWD

or REV Control signal is applied. This option can be combined with Soft Stop/Ramp Down and Dynamic Braking

modes, but not with simple Stop.

Soft Stop/Ramp Down: It is a modified Stop where the DC power supply is disconnected from the Load using a 200

Hz pulse width modulation with a duty cycle going from 100% to 0%. After Soft Stop/Ramp Down time is elapsed,

Control Signals

+ V

FWD

Forward Control

Reverse Control

0

+ V

REV

0

the Load will remain continuously de-energized waiting for a new FWD or REV Control signal. Soft Stop/Ramp

Down time is tied to Soft Start/Ramp Up time selected by SA, SB and SC suffixes and can be combined with

Soft Start/Ramp Up only.

Dynamic Brake: It could be used as a modified Stop where the FET switches inside the DP Series SSC are

arranged in such a way that they provide a path for the Load Current to keep flowing after the DC power supply

has been disconnected. This mode allows for energy stored in some type of loads to be discharged. i.e. back

EMF on DC motors. Timing for Dynamic Brake is selected by suffixes B2, B5, B8 and B where the latest will

keep the braking or discharging path enabled for as long as FWD and REV Control signals are removed.

Interlock: It will shut down all FET switches inside the DP Series SSC within 0.2 sec after both control signals

FWD and REV are applied at the same time. An Interlock condition will trigger a modified Stop such as Soft

Stop/Ramp Down or Dynamic Brake whenever an option has been selected.

Load Voltage Signals

Start

Stop

DP4R60xxx

Start

Dynamic Brake

DP4R60xxxBx

(F)

+ V

DCS

- V

DCS

3 / L1 = + 4 / L2 = +

0

S1, S4 S3, S4

+ V

DCS

S1, S4

S1, S4 S2, S3 S2, S3

t

1

0

- V

DCS

t t t tInt Int

t

t

B

1

S1, S4 S1, S4 S2, S3 S3, S4

Soft Start/Ramp Up

Soft Stop/Ramp Down

DP4RSx60xxx

Soft Start/Ramp Up

Dynamic Brake

DP4RSx60xxxBx

+ V

DCS

0

- V

DCS

t

t

ST

S1, S4 S3, S4

+ V

DCS

t

SP

t t tInt Int

t

1

0

- V

DCS

t

t t t tInt Int

t

t

1

ST

B

(F) Load voltage signals shown are typical of a DC motor, behavior may change for other load types.

Int : Interlock

t : Control Signal Validation Delay

= 0.2 sec, except for

t Intt tt Int

t

1

Start / Stop (0.025 sec)

t

: 0.15 sec Break-before-make

1

delay

t

: Dynamic Brake time

B

B2: 0.2 sec

t

t

1

B

B5: 0.5 sec

B8: 0.8 sec

B: Continuous

t

: Soft Stop/Ramp Down time = t

SP

t

: Soft Start/Ramp Up time

ST

t

ST

t

ST

t

SP

t

1

t

t

1

B

SA: 0.2 sec

SB: 0.5 sec

SC: 1 sec

V

: VDC power supply

DCS

V

: Forward Control Signal

FWD

V

: Reverse Control Signal

REV

ST

Rev. 060211

Loading...

Loading...