Crown Verity ZZ 500 201, ZZ 430 090, ZZ 440 090, ZZ 500 202, ZZ 500 205 User Manual

...

CopyDisc Duplicator Series

Automated CD & DVD Standalone Printer Series

OPERATING and MAINTENANCE

OPERATING and MAINTENANCE OPERATING and MAINTENANCE

OPERATING and MAINTENANCE

COMPLETE SOLUTIONS FOR ON-DEMAND CD and DVD PRODUCTION

MANUAL

MANUAL

MANUALMANUAL

1

CopyDisc Duplicator Series

Thank you for purchasing a Verity Systems

CopyDisc Series Duplicator

OPERATING and MAINTENANCE MANUAL

Document Reference No. TP 000 259 (Ver 1.02)

Production Standard

ZZ 540 090 + ZZ 500 301 CopyDisc AutoPrinter Platinum

ZZ 440 090 + ZZ 500 302 CopyDisc OptiPrinter Pro Platinum

ZZ 504 090 +ZZ 500 305 CopyDisc P-55 Platinum

ZZ 530 090 + ZZ 500 201 CopyDisc AutoPrinter XC Platinum

ZZ 430 090 + ZZ 500 202 CopyDisc OptiPrinter Pro XC Platinum

ZZ 530 090 + ZZ 500 205 CopyDisc P-55 XC Platinum

VERITY SYSTEMS LTD VERITY SYSTEMS, INC.

2 Eastern Road 5441 Merchant Circle, Unit A

Aldershot Placerville

Hampshire California

GU12 4TD 95667

United Kingdom United States

Tel: +44 (0) 1252 317000 Tel: (530) 626-9363

Fax: +44 (0) 1252 316555 Fax: (530) 626-9395

Email: sales@veritysystems.com Email: ussales@veritysystems.com

www.veritysystems.com

2

©

CopyDisc Duplicator Series

WARNING

To avoid electrical shock hazards, unit covers should only be removed by

authorised personnel.

COPYRIGHT

This document is the property of Verity Systems and it may not be

reproduced, copied or exhibited to a third party without the written

permission of Verity Systems.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be thrown away with household waste.

Please recycle where facilities exist.

Verity Systems reserves the right to amend or modify the specifications and design criteria

applying to these products.

Check with your local authority or retailer for recycling advice.

3

CopyDisc Duplicator Series

SOFTWARE WARRANTY (LIMITED)

If you discover physical defects in the media on which the software is

distributed or in the User’s Manual, Verity Systems will replace the media or

manual for a period of ninety (90) days after the purchase by the retail

customer. You must return the disk or manual to Verity Systems or an

authorized Verity Systems dealer within the warranty period accompanied by

proof of purchase.

VERITY SYSTEMS DISCLAIMS ALL IMPLIED WARRANTIES ON THE

PRODUCT, INCLUDING WITHOUT LIMITATION WARRANTIES OF

MERCHANTABILITY, PERFORMANCE AND FITNESS FOR A

PARTICULAR PURPOSE. Verity Systems WILL NOT BE LIABLE FOR ANY

BUG, ERROR, OMISSION, DEFECT, DEFICIENCY, OR NONCONFORMITY

IN ANY SOFTWARE. AS A RESULT, THE SOFTWARE IS SOLD “AS IS”,

AND THE PURCHASER ASSUMES THE ENTIRE RISK AS TO ITS

QUALITY AND PERFORMANCE.

VERITY SYSTEMS SHALL IN NO EVENT BE LIABLE FOR DIRECT,

INDIRECT, SPECIAL, INCIDENTAL, CONTINGENT OR CONSEQUENTIAL

DAMAGES RESULTING FROM ANY DEFECT IN THE SOFTWARE OR ITS

DOCUMENTATION INCLUDING DAMAGES FROM LOSS OF DATA, EVEN

IF VERITY SYSTEMS OR AN AUTHORIZED VERITY SYSTEMS DEALER

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. YOU

AGREE THAT VERITY SYSTEMS’ LIABILITY, ARISING OUT OF

CONTRACT, NEGLIGENCE, STRICT LIABILITY IN TORT OR WARRANTY

SHALL NOT EXCEED ANY AMOUNTS PAID BY YOU FOR THIS

PRODUCT.

Any written or oral information or advice given by Verity Systems

dealers, distributors, agents or employees will in no way increase the

scope of this warranty. Nor may you rely on such oral or written

communication. Some states do not allow the exclusion or limitation of

implied warranties or liability for incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights that

vary from state to state.

4

CopyDisc Duplicator Series

RECOMMENDED MEDIA

The type and quality of the blank media is one of the most important factors concerning the

duplication and printing quality. The better the quality of media you use the better the duplication

and printing results will be. Buying brand-name media will almost always result in more reliable and

consistent duplication and printing results.

For the best recording results in any CD/DVD recordable environment, be sure to use superior CDR or DVD-R media from Taiyo Yuden.

Taiyo Yuden is the leader in CD-R and DVD-R manufacturing. In today’s high volume CD/DVD

recordable environments, users need the assurance that their choice of media will provide high

performance, compatibility and long term data integrity. Taiyo Yuden’s long history of development

and manufacturing, combined with their zero tolerance for sub-standard products, makes their

media the best choice for your requirements.

Used by professionals for mastering around the world, Japanese-made Taiyo Yuden is made by

the inventor of the CD-R disc. All Taiyo Yuden media is manufactured in a single plant and on the

same machine, ensuring unparalleled consistency and quality like no other brand. Taiyo Yuden

has the widest play back compatibility, the lowest error rates in recording, and comes with a 100year data integrity guarantee. Taiyo Yuden media is available with lacquer, thermal printable, white

and silver inkjet-printable, and hub printable surfaces.

Verity Systems recommends Taiyo Yuden media for use in all of their DVD and CD duplicators and

printers.

Features:

• Certified grade A media, genuine Taiyo Yuden

• Compatibility with all CD/DVD recorders and duplicators

• Jitter and deviation levels are the lowest in the industry

• Proprietary printable surface media provides professional looking graphics and text on the

media surface

• 100 Year data integrity is guaranteed

5

CopyDisc Duplicator Series

……………………….……….

TABLE OF CONTENTS

Section 1 GENERAL DESCRIPTION……

1.1Introduction……………….……………………………………… 8

1.2Network Operation………………………………………………. 8-9

1.2CopyDisc Platinum XC Series..……………………………….. 9-11

8

Section 2 SET UP…………………………………………………………... 12-13

2.1Box Contents……………………………………………………. 12

2.2Operating Environment….………………………………….. 12

2.3Power On………………………………………………………. 13

Section 3 OPERATION………………………………………………….… 14-21

3.1Turning On………………………………………………………. 14

3.2Keyboard………………………………………………………… 14-15

3.2.1/\ \/ < > Key……………………………………………………. 14-15

3.2.5Stop/Start Key……………………………………………………. 15

3.3LCD Display…………………………………………………… 15

3.4Menu Structure…………………………………………………. 15-19

3.4.1Print Only Mode 15

3.4.2Image Manager 16-17

3.4.2.1 Load New Print Image…..………………………... 16

3.4.2.2 Show Print Images………………………………... 16

3.4.2.3 Delete Print Images….……………………………. 16

3.4.2.4 Rename Print Image………………………………. 16-17

3.4.3Setup……………………………………………………………… 17

3.4.3.1 Printer…………………………………………………. 17

3.4.3.2 Autoloader……………………………………………. 17

3.4.3.3 Licence Key…………………………………………… 17

3.4.3.4 Menu…………………………………………………… 17

3.4.4Utilities…………………………………………………………… 18-19

3.4.4.1 Hard Disc Utilities……………………………………. 18

3.4.4.2 Firmware Utilities….…………………………………. 18

3.4.4.3 Loader Utilities….…………………………………….

18

3.4.4.4 About Hardware……………………………………… 19

6

CopyDisc Duplicator Series

3.4.4.5 About Firmware……………………………………… 19

Section 4 PRINTING VIA DISCPILOT………………………………….… 19-28

Section APPENDICES………………………………………………….… 29-48

Appendix A Menu Structure………………………………………………... 29-31

Appendix B Technical Support……………………………………………… 32

Appendix C Routine Maintenance…………………………………………. 33

Appendix D CopyDisc OptiPrinter Pro Platinum…...………………… 34-39

Appendix E CopyDisc AutoPrinter Platinum…………………………....

Appendix F CopyDisc P-55 Platinum…...………………………………... 45-48

Standard Terms and Conditions…………………………………………….. 49-51

40-44

7

CopyDisc Duplicator Series

SECTION 1: GENERAL DESCRIPTION

1.1 Introduction

The Verity Systems CopyDisc Platinum printer series provide reliable, unattended inkjet and

thermal printing of optical discs.

There are three CopyDisc Platinum printer models:

• CopyDisc Platinum OptiPrinter Pro - inkjet printing

• CopyDisc Platinum AutoPrinter – thermal printing

• CopyDisc Platinum P-55 – thermal retransfer printing

All are similar in operation but offer a difference in print output.

Each model uses a pick and place mechanism to transfer the disc from the Input spindle or basket

to the printer and remove the disc from the printer subsequently and place it on the Output spindle.

Two different types of picker mechanism are available: the Vacuum picker and the Mechanical

picker. CopyDisc OptiPrinterPro models are fitted with the mechanical picker as standard. This

enables users to print right to the centre of full-face printable, inkjet discs. All CopyDisc thermal

printers are fitted with the vacuum picker as standard.

Note:

The mechanical picker is not compatible with the CopyDisc thermal printers.

Note:

Throughout this manual reference is made to CDs. The procedure for DVDs, CD Business

cards and mini discs is identical except where stated.

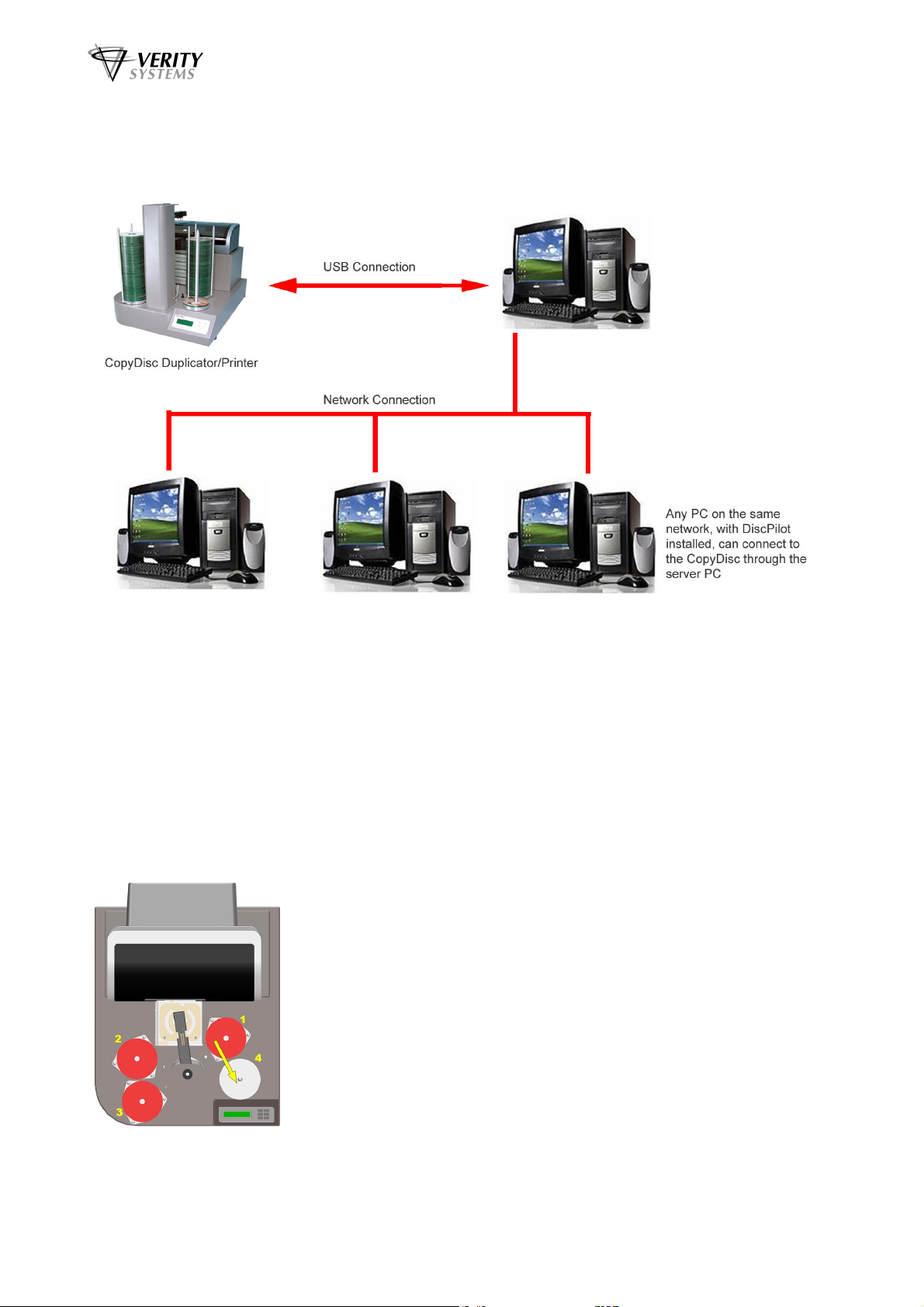

1.2 Network Operation

The CopyDisc Platinum printers are operated using DiscPilot advanced networking software.

There is no drive fitted so the system is run directly from a PC on a network.

This easy to use yet sophisticated and versatile CD and DVD printer management software

system, provides multiple users with access to one of Verity Systems range of automatic printers.

DiscPilot allows a CopyDisc to act as a peripheral device across a network.

DiscPilot is a completely new way of networking your CopyDisc. Instead of relying on a traditional

Cat5 cable network connection, uses a high speed USB connection for improved reliability and

data transmission rates.

Verity Systems PublisherNET forms the link between the CopyDisc and the host PC.

PublisherNET establishes a connection with the CopyDisc through the USB connection and

manages data transmission.

This Windows based software suite enables you to print a print file (PRN) stored on your file

server, and to request the required number of discs for your CopyDisc to print. CD/DVD print files

can also be selected from the CopyDisc’s hard drive itself.

8

CopyDisc Duplicator Series

DiscPilot has a fully integrated disc label creator. From within DiscPilot you can create your

labels, disc images, combine and send them as a ‘job’ and manage the files on your CopyDisc

hard drive.

Server PC with

PublisherNET installed.

This manages the USB

connection. The Server PC

can also have DiscPilot

installed.

For full instructions on how to set up the PublisherNET server and the DiscPilot client, please refer

to the DiscPilot User Manual which can be found on the DiscPilot Software CD.

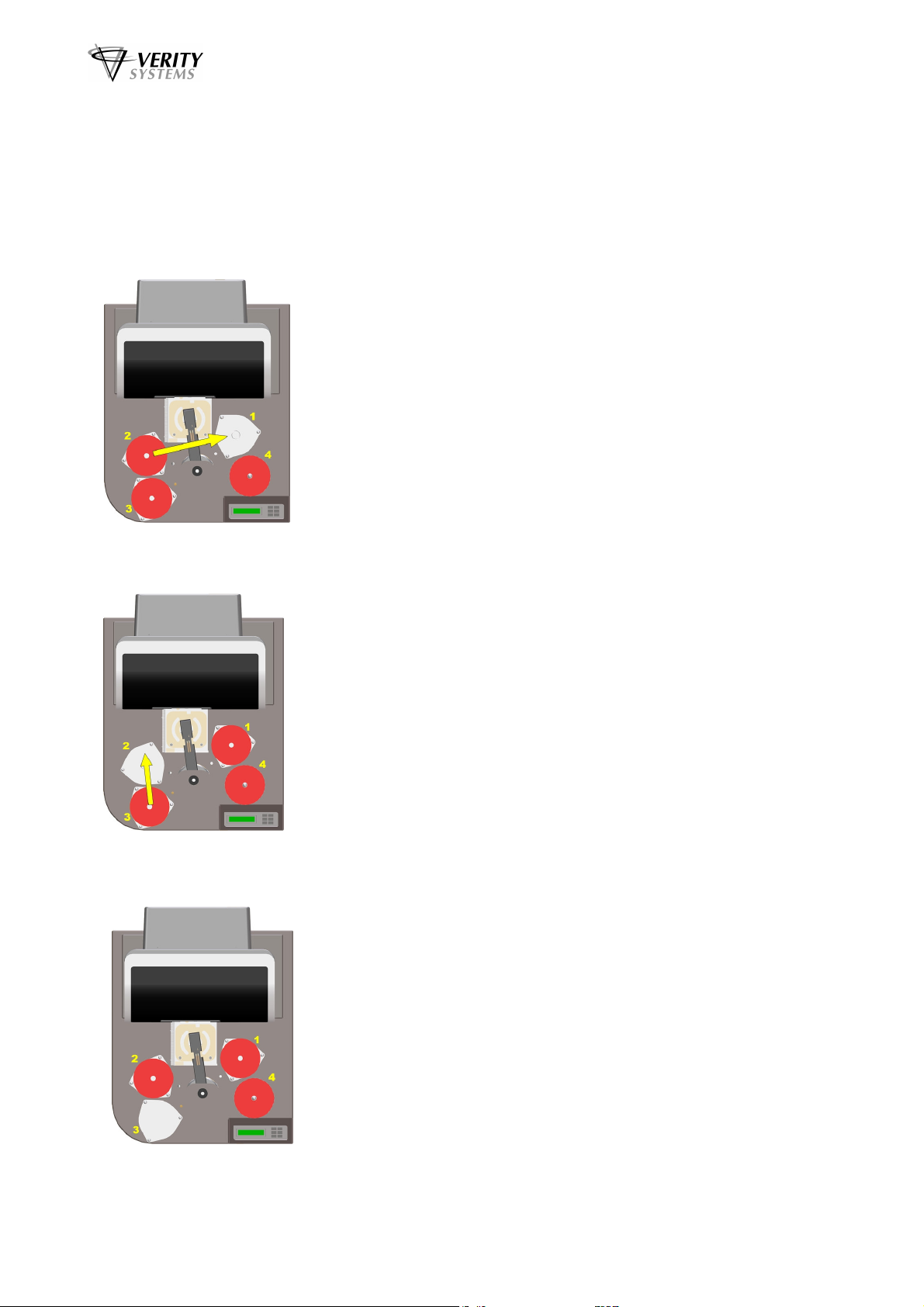

1.3 CopyDisc XC Systems (660 Capacity)

Not applicable to 220 disc capacity CopyDisc systems

The CopyDisc4 XC and the CopyDisc8 XC used 3 input baskets/spindles and 1 output spindle.

Baskets/Spindles No.1, No.2 and No.3 are used as input

baskets/spindles in the first instance. Each input basket/spindle

holds 220 blank discs, giving a total capacity of 660 discs.

Spindle No.4 is the initial output spindle.

Figure 1

9

CopyDisc Duplicator Series

When the printing process begins, blanks discs are transported one at a time from input

basket/spindle No.1 and placed into the waiting printer tray. Once printed, the discs are transported

from the tray onto output spindle No.4.

When all the blank discs from input basket/spindle No.1 have been exhausted, the CopyDisc XC

automatically moves onto the blank discs from input basket/spindle No.2

As the original output spindle (No.4) is full from printing all the discs

from input basket/spindle No.1, printed discs are now output into

empty basket/spindle No.1.

Figure 2

Once input basket/spindle No.2 is empty and basket/spindle No.1

full, the CopyDisc XC will begin loading discs from input

basket/spindle No. 3. Printed discs will be output into basket/spindle

No. 2.

Figure 3

Once all 660 discs have been copied, your CopyDisc XC

baskets/spindles should look like figure 4.

Figure 4

10

CopyDisc Duplicator Series

IMPORTANT:

The CopyDisc XC uses three input baskets/spindles in order to accomplish the 660 disc capacity.

The media is moved from spindle to spindle via the printer in a specific cycle and it is therefore

essential that certain rules are followed in order to achieve perfect operation.

Normally the input baskets/spindles can only be replenished with new media at the end of a

spindle cycle and not at the end of or part way through a job.

The input spindles must not be replenished with new media part way through a spindle cycle

unless the power is removed from the CopyDisc XC thus re-setting the spindle cycle.

The CopyDisc XC will halt any job in the event of detecting an empty third input spindle. At this

point, if the job is finished, the processed media may be removed, the spindles replenished

with new media and the job re-started.

If the job is not complete and the requested number of copied discs has not yet been fulfilled,

the LCD display will display Input Hopper Empty. Select Cancel if you do not wish to

continue with the job. Otherwise by selecting Continue the CopyDisc XC will continue, first

looking to the first spindle for blank discs, then the second and finally the third. It is important

therefore to replenish the correct spindle(s) before continuing.

Not all input spindles need to be used but they should be used in sequence 1, and 2, and 3.

The input spindles do not have to be filled to capacity.

The initial output spindle should always be empty when starting a new job.

11

CopyDisc Duplicator Series

SECTION 2: SET UP

Your Verity systems CopyDisc Platinum printer series is designed to allow fast, easy, reliable and

unattended printing of CD-R discs. Following are some of the more important features of the Verity

Systems CopyDisc Platinum printer.

Print hundreds of discs per session

Unattended operation

Easy to read back lit LCD display

Network operation

2.1 Box Contents

Carefully remove your CopyDisc Platinum printer from its shipping carton and verify that all parts

are present. If there are missing or damaged parts contact Verity Systems or an authorised partner

immediately to correct any miss-packed or missing parts.

You should find the following:

Verity Systems CopyDisc Platinum robot

Inkjet or thermal printer

Printer Software CD (including driver and label design software)

Power Cord

Input and Output Spindles (Baskets)

Quick Start Guide

Manual CD

Networking CDs (including DiscPilot/CD Label Designer CD and PublisherNET CD)

Warranty Card

Note:

Please see appropriate appendix at the back for this manual for full details of contents.

Note:

If your Verity Systems CopyDisc Platinum printer is damaged during shipment, please

contact the freight carrier first, and then contact your partner or Verity Systems.

Note:

You should save your shipping materials so that if the need arises you can return your

CopyDisc Platinum printer for service. This packaging was designed specifically for

shipping your CopyDisc Platinum printer. Other packaging may not be as suitable.

2.2 Operating Environment

Your Verity Systems CopyDisc Platinum printer should be used in a climate controlled environment

free of dirt, dust, excess humidity, excessive heat or electro-magnetic interference.

Allow at least six (6) inches of clearance around the sides and back of the unit for ventilation. Try

and provide enough room around the machine to load and unload spindles, and other work of this

type.

12

CopyDisc Duplicator Series

2.3 Power On

Fit the printer to the CopyDisc Platinum robot. Please see the appropriate appendix the end of

this manual for full details on how to fit the relevant printer including fitting cartridges or

ribbons.

• Attach the power cord to your CopyDisc Platinum printer, plug it into the mains.

• Switch on the printer followed by the CopyDisc Platinum robot.

• After the power is turned on, the Verity Systems CopyDisc Platinum printer goes through a

series of self-tests (see section 3.1 for full details).

As all CopyDisc Platinum printers are operating via a network, the CopyDisc needs to be

connected to the server PC running PublisherNET. Please refer to the DiscPilot Networking

manual for full details.

13

CopyDisc Duplicator Series

SECTION 3: OPERATION

This chapter provides detailed operating instructions for your Verity Systems CopyDisc Platinum

printer. Your CopyDisc Platinum printer has many options and features designed to make it more

productive and easier to use. Please read through this chapter carefully so that you can take full

advantage of all the features of your system.

3.1 Turning On

When the Verity Systems CopyDisc Platinum printer is turned on it goes through a series of selftests and displays several messages.

Following are all the messages displayed during a normal power-up:

Initializing System

Check IDE Port

Check Printer

Check Autoloader

And Finally:

-HOME MENU>Start Job

Image Manager

Utilities

Setup

If this series of messages are displayed then your CopyDisc Platinum printer is ready for use. If

this series of messages are not displayed or different messages are displayed see the Error

Messages section (section 4) of this manual.

3.2 Keyboard

Following is the function of each key on the keyboard:

Fig. 1

3.2.1 /\ Key (Up arrow)

If being prompted to enter a number or character this key increments the character at the

cursor to the next higher character or number. If a menu is being displayed this key moves

the cursor to the next menu selection up.

14

CopyDisc Duplicator Series

3.2.2 \/ Key (Down arrow)

If being prompted to enter a number or character this key decrements the character at the

cursor to the next lower character or number. If a menu is being displayed this key moves

the cursor to the next menu selection down

3.2.3 < Key (Left arrow)

Left arrow– If being prompted to enter a number or character this key moves the cursor 1

character to the left. If a menu is being displayed this key moves the cursor back a step.

3.2.4 > Key (Right arrow)

Right arrow– If being prompted to enter a number or character this key moves the cursor 1

character to the right. If a menu is being displayed this key moves one level deeper into the

menu structure or if the next step is executable it starts the process.

3.2.5 Stop Key

This key stops or aborts whatever is going on. When writing CD-R's the system is busy and

this key may be sluggish so press and hold it down until prompted to do something else.

The STOP key exits without saving your changes within each menu.

3.2.6 Start Key

If being prompted to enter a number or name this key accepts the currently displayed

selection. If the next item is executable it starts that process. The Start key also saves

options made within the menus.

3.3 LCD Display

The LCD display is used either to display menus or to show status. For instance while printing it

shows what it is doing, the number it has to do, how many it has done and the current mode.

15

CopyDisc Duplicator Series

3.4 Menus Structure

Use the up /\ and down \/ arrow keys to position the cursor (a > character on the left most column

of the display) to the desired menu item. Then use the > key to select it.

Following is a description of each menu selection.

3.4.1 Print Only Mode

This menu option will only be visible if you have a Printer attached to your CopyDisc

Platinum Series. Use this option if you only require discs to be printed, and not

duplicated.

The menu gives the user the option to either load a new PRN files from a CD-R, or

select an existing PRN file from the HD. You can also select the quantity required.

3.4.2 Image Manager

This menu option is used to maintain image files kept on the hard drive.

Print Manager

3.4.2.1 Load New Print Image

Allows you to load a new print image to the HD from a CD-R. You will be prompted

to enter a name for the image, then press START to begin loading.

3.4.2.2 Show Print Images

Show all print images currently stored on the hard drive.

3.4.2.3 Delete Print Images

Select a print image stored on the hard drive to be deleted by positioning the cursor

next to that image. Press the > key and you are prompted to confirm deletion by

selecting either Yes or No with the > cursor. Once selected press >.

3.4.2.4 Rename Print Image

Rename a print image currently stored on the hard drive. Select an image stored on

the hard drive to be renamed by positioning the cursor next to that image. Press the

> key and you are prompted to confirm renaming by selecting either Yes or No with

the > cursor. Select Yes and press the > key. You are now prompted to enter the

new name.

Since there are no letters on the keyboard text must be entered with the arrow keys.

When text needs to be entered all available character positions are displayed

between square brackets as follows:

[ _ _ _ _ _ _ _ _ _ _ _ _ _]

If the initial text is not defined all blanks will be displayed. Otherwise the starting text

will be displayed. Press the left /\ or right \/ arrow to move the cursor the desired

character location.

16

Loading...

Loading...