Crown Verity CVPF2, CVPF1 User Manual

PRO SERIES GAS FRYERS

OWNER’S MANUAL

MODELS: PF-1 PRO-FRYER, PF2 DUAL PRO-FRYER

REVISED DECEMBER, 2014

*PLEASE RETAIN FOR FUTURE REFERENCE

ANSI Z83.11/CSA1.8 - 2009

This appliance has been tested according to ANSI Z83.11/CSA1.8 - 2009.

This outdoor cooking gas appliance is not intended to be installed in or on

recreational vehicles and/or boats.

Read the installation, operating and maintenance instructions thoroughly

before installing or servicing this equipment.

CROWN VERITY INC., 37 ADAMS BLVD., BRANTFORD, ON. CAN. N3S 7V8

TEL: (519) 751-1800 FAX: (519) 751-1802

www.crownverity.com

Email: info@crownverity.com

Printed January 2015

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ORDERING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CODES AND STANDARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GAS CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GAS PRESSURE.....................................................7

TEST GAS SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PROPANE CYLINDERS AND REGULATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TRANSPORTATION AND STORAGE OF LP CYLINDERS . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

LEVELING THE FRYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OVER-TEMPERATURE SHUTDOWN........................................ 9

BEFORE FIRST USE .................................................. 9

FILLING TANK WITH SHORTENING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LIGHTING THE PILOT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TURNING ON THE FRYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TURNING OFF THE FRYER.............................................12

EXTENDED SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

BASIC FRYING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fry Basket Guidelines.............................................12

EXTENDED SHORTENING LIFE ..........................................12

DRAINING THE TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FILTERING-ALL MODELS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BOIL OUT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2

IMPORTANT FOR YOUR SAFETY

WARNING Hot oil and parts can cause burns. Use care when operating, cleaning and servicing

the fryer.

WARNING Spilling hot frying compound can cause severe burns. Do not move the fryer without

draining all frying compound from the tank.

INSPECT HOSES BEFORE EACH USE.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT THE MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

NEVER CHECK FOR LEAKS WITH A MATCH OR OPEN FLAME.

AN LP CYLINDER NOT CONNECTED FOR USE SHALL NOT BE STORED IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

THIS APPLIANCE SHALL ONLY BE USED IN A WELL VENTILATED SPACE AND SHALL NOT BE USED IN

A BUILDING, GARAGE, OR ANY OTHER ENCLOSED AREA.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR TO THE FRYER.

DO NOT LEAVE YOUR FRYER UNATTENDED WHILE IN OPERATION.

DO NOT ALLOW CHILDREN TO PLAY ON OR NEAR YOUR FRYER.

DO NOT USE THIS FRYER UNTIL YOU HAVE READ AND UNDERSTOOD ALL OF THE INFORMATION IN

THIS MANUAL.

PROPER BURNER POSITIONING IS CRITICAL TO SAFE OPERATION. DO NOT ATTEMPT BURNER

ADJUSTMENT OR REPLACEMENT. CONTACT QUALIFIED PERSONNEL.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death.

FOR YOUR SAFETY

IF YOU SMELL GAS:

1) Shut off gas supply to appliance.

2) Extinguish any open flame.

3) If odor continues, immediately call your gas supplier.

CROWN VERITY INC., 37 ADAMS BLVD., BRANTFORD, ON. CAN. N3S 7V8

TEL: (519) 751-1800 FAX: (519) 751-1802

www.crownverity.com

Email: info@crownverity.com

3

INTRODUCTION

GENERAL

Crown Verity Inc. Fryers are produced with quality workmanship and material. Proper installation, usage

and maintenance will result in years of satisfactory performance.

Before using the fryer, thoroughly read this manual and carefully follow all instructions.

This manual is applicable to models listed on the cover page. Procedures in this manual will apply to all

models unless otherwise specified.

WARNING Hot oil and parts can cause burns. Use care when operating, cleaning and servicing

the fryer.

WARNING Spilling hot frying compound can cause severe burns. Do not move the fryer without

draining all frying compound from the tank.

ORDERING PARTS

Customers may order parts directly from Customer Service at 888-505-7240.

To speed up your order, provide the model number, serial number, gas type, part needed, item part

number (if known) and quantity needed.

NOTE: Hoses must be rated min. 140° F. Do not replace hoses, regulators, valves or burners with

other than original equipment. Do not attempt to replace or adjust burners. Contact qualified personnel.

UNPACKING

This fryer was carefully inspected and tested before leaving the factory. Upon acceptance of the

shipment, the transportation company assumes full responsibility for safe delivery.

Immediately after unpacking the fryer, check for possible shipping damage. If the fryer is damaged, save

the packaging material and contact the carrier immediately.

Check that the following have been included:

• Crumb Rack

• Basket Hanger

• Drain Pipe Extension

• Twin Fry Baskets (2)

• Manual and Warranty

Do not use the fr

yer’s door or its handles to lift the fryer at any time.

4

INSTALLATION

WARNING!

DO NOT OPERATE THIS OUTDOOR APPLIANCE UNDER OVERHEAD,

UNPROTECTED CONSTRUCTION.

THIS APPLIANCE SHALL BE USED ONLY IN A WELL VENTILATED SPACE AND SHALL

NOT BE USED IN A BUILDING, GARAGE, OR ANY OTHER ENCLOSED AREA.

Before installing the fryer, verify that the type of gas (natural or propane) agrees with the specifications

on the fryer data plate, which is located on the inside of the door panel.

Record your fryer model, device, and serial numbers for future reference in the space provided below.

This information can be found on the fryer data plate.

Fryer Model No: _____________________________

Fuel Type:____________________________________

Serial #(s): __________________________________

Clearances

• Minimum clearance from combustible construction:

6” (15 cm) from the sides of the fryer

6” (15 cm) from the back of the fryer

The fryer may be installed on combustible floors free of debris.

• Minimum clearance from non-combustible construction:

0” from the sides of the fryer

0” from the back of the fryer

• Between the fryer and any open-top flame units:

16” (41 cm)

Location

• Minimum ambient temperature for safe use is -25°C

• Install fryer outdoors only, on level ground, free of debris

• Do not obstruct the flow of combustion and ventilation air.

• Provide adequate clearance for air openings into the combustion chamber.

• Do not install near open windows and doors.

• CASTERS MUST BE LOCKED AT ALL TIMES DURING OPERATION.

5

CODES AND STANDARDS

The fryer must be installed in accordance with:

In the United States:

• State and local codes, or in the absence of local codes, with:

National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition).

In Canada:

• Local codes

• CAN/CSA-B149.1 Natural Gas and Propane Code (latest edition).

NATURAL GAS CONNECTIONS

NOTICE All gas supply connections and any pipe joint compound must be resistant to the action of

propane gases.

Codes require that a gas shutoff valve be installed in the gas line ahead of the fryer.

The NATURAL GAS supply line must be at least the equivalent of 1/2” (12.7 mm) iron pipe for single

units and 1-1/4” (31.75 mm) dual units. If using the optional quick-disconnect flex hose, 3/4” (19

mm) iron pipe for single units and 1-1/4” (31.75 cm) iron pipe for dual units.

Make sure the pipes are clean and free of obstructions, dirt, and piping compound. A dual unit requires

one or two connections of appropriate size for the gas requirement.

WARNING Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

After piping has been checked for leaks, fully purge gas pipes to remove air.

NOTICE Inspect hose(s) frequently. Replace with original manufacturer’s parts only.

CROWN VERITY INC., 37 ADAMS BLVD., BRANTFORD, ON. CAN. N3S 7V8

TEL: (519) 751-1800 FAX: (519) 751-1802

www.crownverity.com

Email: info@crownverity.com

6

GAS PRESSURES (ALL MODELS):

The gas pressure should be set at 4” W.C. (Water Column) (0.8 kPa) for natural gas and 11” W.C.

(2.75 kPa) for propane gas. If incoming pressure exceeds 1/2 PSI (3.45 kPa), an additional pressure

regulator may be required.

TESTING THE GAS SUPPLY PIPING SYSTEM:

When test pressures exceed 1/2 PSI (3.45 kPa), the fryer and its individual shutoff valve must be

disconnected from the gas supply piping system.

When test pressures are 1/2 PSI (3.45 kPa) or less, the fryer must be isolated from the gas supply

piping system by closing its individual shutoff valve.

PROPANE CYLINDERS AND REGULATORS

v Pressure regulators and hose assemblies supplied with this appliance must be used. Replacement

pressureregulators and/or hose assemblies must be original manufacturers parts.

The standard, self-contained propane system fryer is designed for use with 13.6 kg. (30 lb.) propane

cylinders, equipped with a Type I cylinder valve.

v Do not store propane cylinders in or on the appliance, explosion, fire or injury may result.

The Type I (Q.C.C.1) cylinder valve is recognizable by the large external thread on the outlet part of the

valve. Standard valves do not have these exterior threads. Any attempt to fit the regulator(s) with

anything other than the mating Type I (Q.C.C.1) connector, (recognized by the large plastic coupling nut)

will negate the important safety features designed into the Type I (Q.C.C.1) system. Fitting a standard

#510 P.O.L connector, will not provide the flow control or temperature shut-off safety features built into

the complete Type I (Q.C.C.1) system.

When purchasing a cylinder for your PRO-FRYER, it must be constructed and marked in accordance

with the specifications of:

The U.S. Department of Transportation (DOT), or CAN/CSA B339.

The cylinder must also be equipped with:

a) A shut-off valve terminating in a proper cylinder valve outlet specified in current standards.

b) A safety relief valve having direct communication with the vapor space of the cylinder.

c) A collar to protect the cylinder shut-off valve.

d) An arrangement for vapor withdrawal only.

e) A bottom ring for securing to the cylinder support assembly.

v Protect regulator vent openings from the elements. Do not expose regulators to rain, snow or ice.

Store regulators in cabinet when not in use.

v Only install and operate cylinders in the retaining brackets on the appliance. Cylinders must be

secured against tip-over and from heat sources at all times.

7

FIRE EXTINGUISHERS

At least one UL/ULC approved, portable, dry chemical fire extinguisher must be

available to the operator(s) at all times while the fryer is in operation.

TRANSPORTATION AND STORAGE OF LP CYLINDERS

Handling, storage and transportation of propane cylinders must be in accordance with Storage and

Handling of Liquid Petroleum Gases, ANSI/NFPA 58 or Natural Gas and Propane Installation Code, CSA

B149.1.

THEREFORE:

Always use the protective cap provided with your cylinder whenever it is not connected to your fryer.

• Do not store in a building, garage or any other enclosed area. Store only in a well ventilated area.

• Do not store in the vicinity of any gas burning apparatus or in any high heat area such as a closed

car or trunk.

• Do not smoke while transporting a cylinder in your vehicle.

• Transport and store cylinder(s) in an upright position only.

• Store out of reach of children.

• Allow only qualified LP gas dealer to fill or repair cylinder(s).

• Do not allow the cylinder to be over filled.

• Make sure the LP gas dealer checks the cylinder for leaks after filling.

OPERATION

WARNING Hot oil and parts can cause burns. Use care when operating, cleaning and servicing

the fryer.

WARNING Spilling hot frying compound can cause severe burns. Do not move the fryer without

draining all frying compound from the tank.

CROWN VERITY INC., 37 ADAMS BLVD., BRANTFORD, ON. CAN. N3S 7V8

TEL: (519) 751-1800 FAX: (519) 751-1802

www.crownverity.com

Email: info@crownverity.com

8

LEVELING THE FRYER

Check the level of the fryer by placing a level on top of the fryer

Ensure that the fryer is level front-to-back and side-to-side in the installed position.

Lock the wheels after unit is level.

OVER-TEMPERATURE SHUTDOWN

If the shortening becomes overheated, a high-temperature shutoff device will turn the gas valve off and

extinguish the pilot.

If the fryer shuts down due to overheating, DO NOT re-light the pilot until the shortening temperature is

below 300° F (149° C).

If an overheating situation persists, contact Crown Verity Inc. service office at 1-888 505 7240.

BEFORE FIRST USE

Cleaning

New units are wiped down at the factory to remove any visible signs of dirt, oil, grease, etc. remaining

from the manufacturing process.

Before any food preparation, thoroughly wash the protective oil from all surface parts and the tank

interior with hot soapy water to remove any film residue and dust or debris.

NOTICE Do not use chlorine or sulfate/sulfide cleaners.

• Wash any accessories shipped with unit.

• Rinse fryer and accessories thoroughly and drain the fryer.

• Wipe tank completely dry with a soft, clean cloth.

WARNING Hot oil and parts can cause burns. Use care when operating, cleaning and servicing

the fryer.

WARNING Spilling hot frying compound can cause severe burns. Do not move the fryer without

draining all frying compound from the tank.

FIRE EXTINGUISHERS

At least one UL/ULC approved, portable, dry chemical fire extinguisher must be

available to the operator(s) at all times while the fryer is in operation.

9

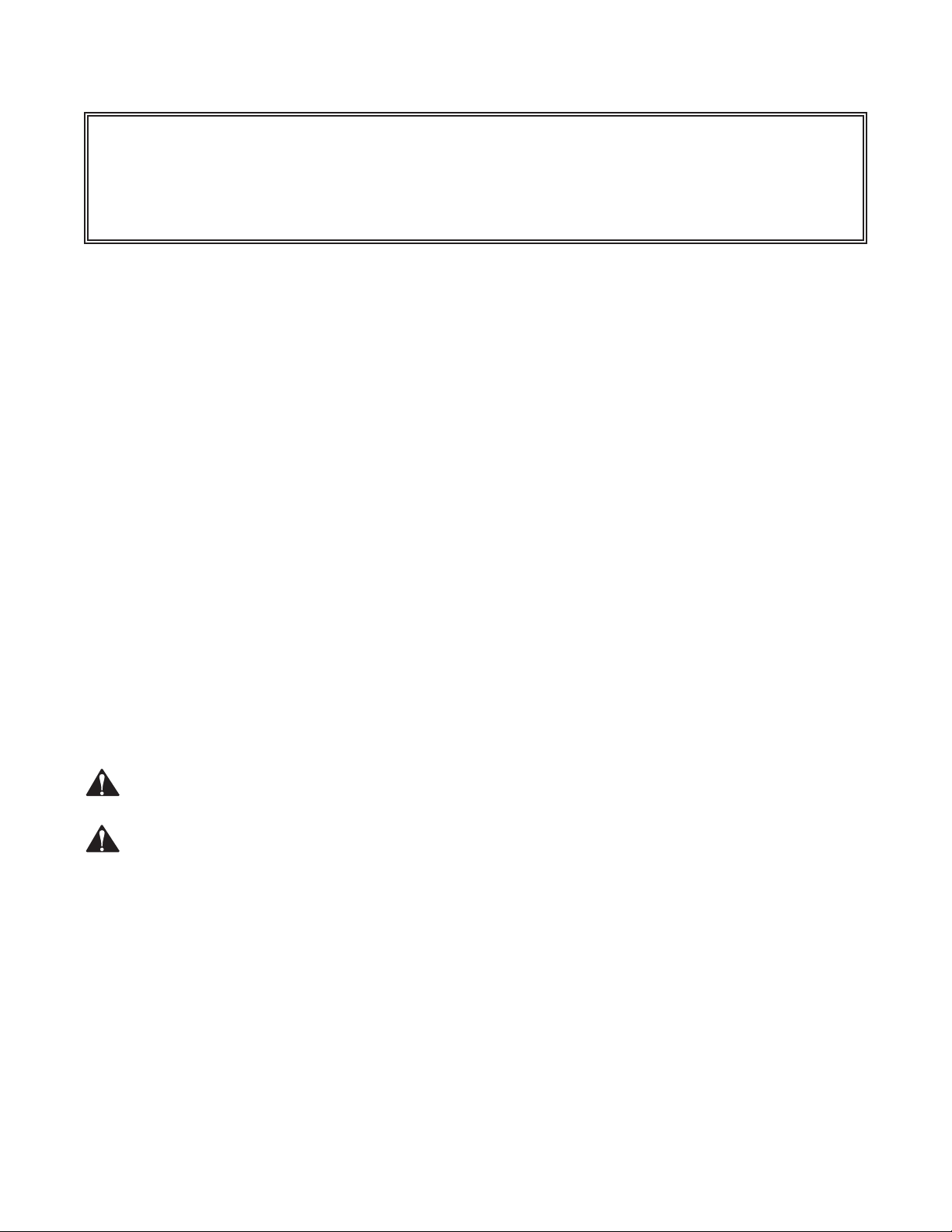

FILLING TANK WITH SHORTENING

NOTICE Solid shortening should NOT be used with PRO-FRYERS. Melting solid shortening will damage

the tank and void your warranty.

• Close the drain valve.

• Check the level of the fryer

• Fill the fryer tank with liquid shortening.

• Shortening level should be between the min and max

lines in the fryer tank.

• Shortening will expand when heated. Do not fill the

fryer tank past the MAX line.

• Add fresh shortening as needed to maintain oil level.

Before Start-Up • Inspect hose(s) for evidence of excessive wear, cuts or cracks. If evident, replace

only with manufacturer’s original parts before operation.

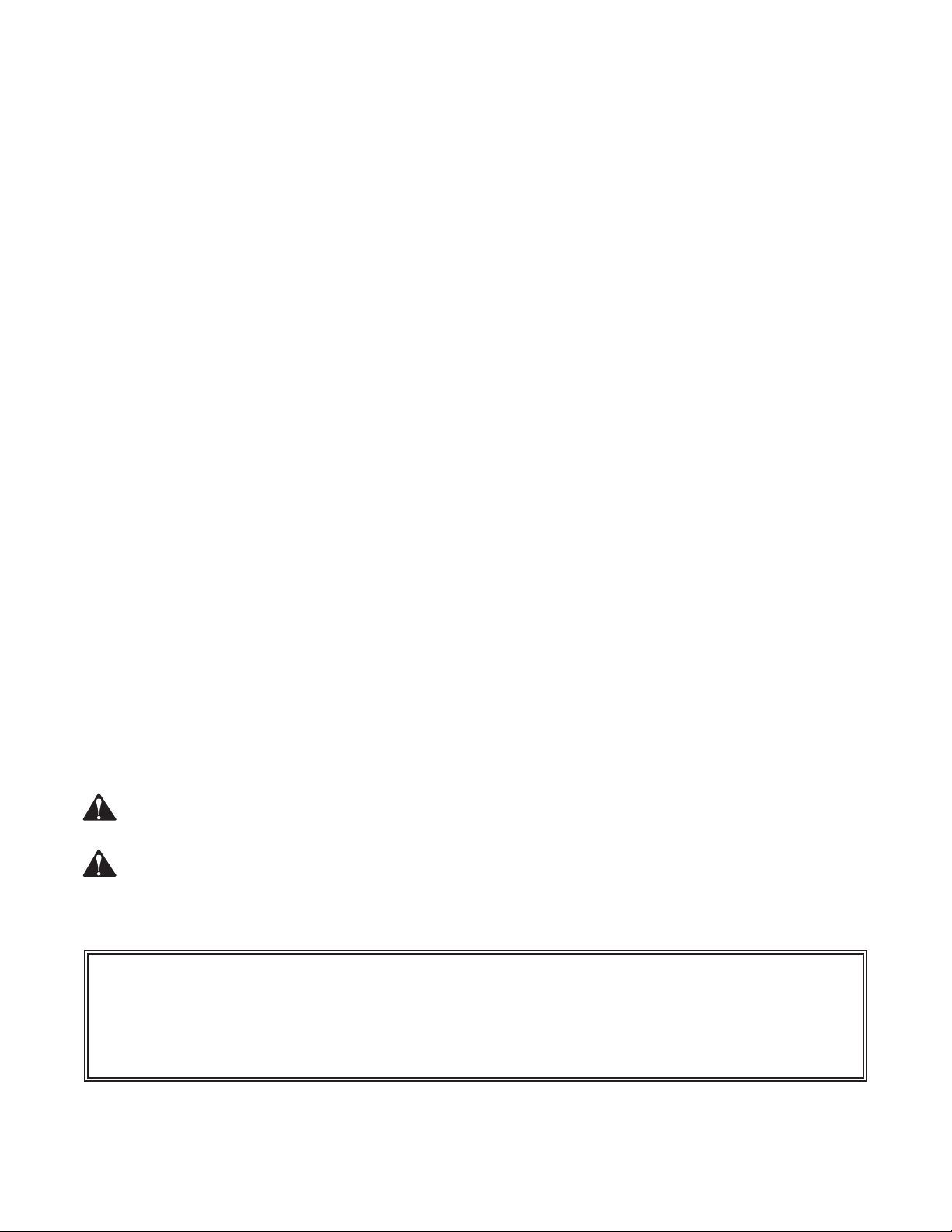

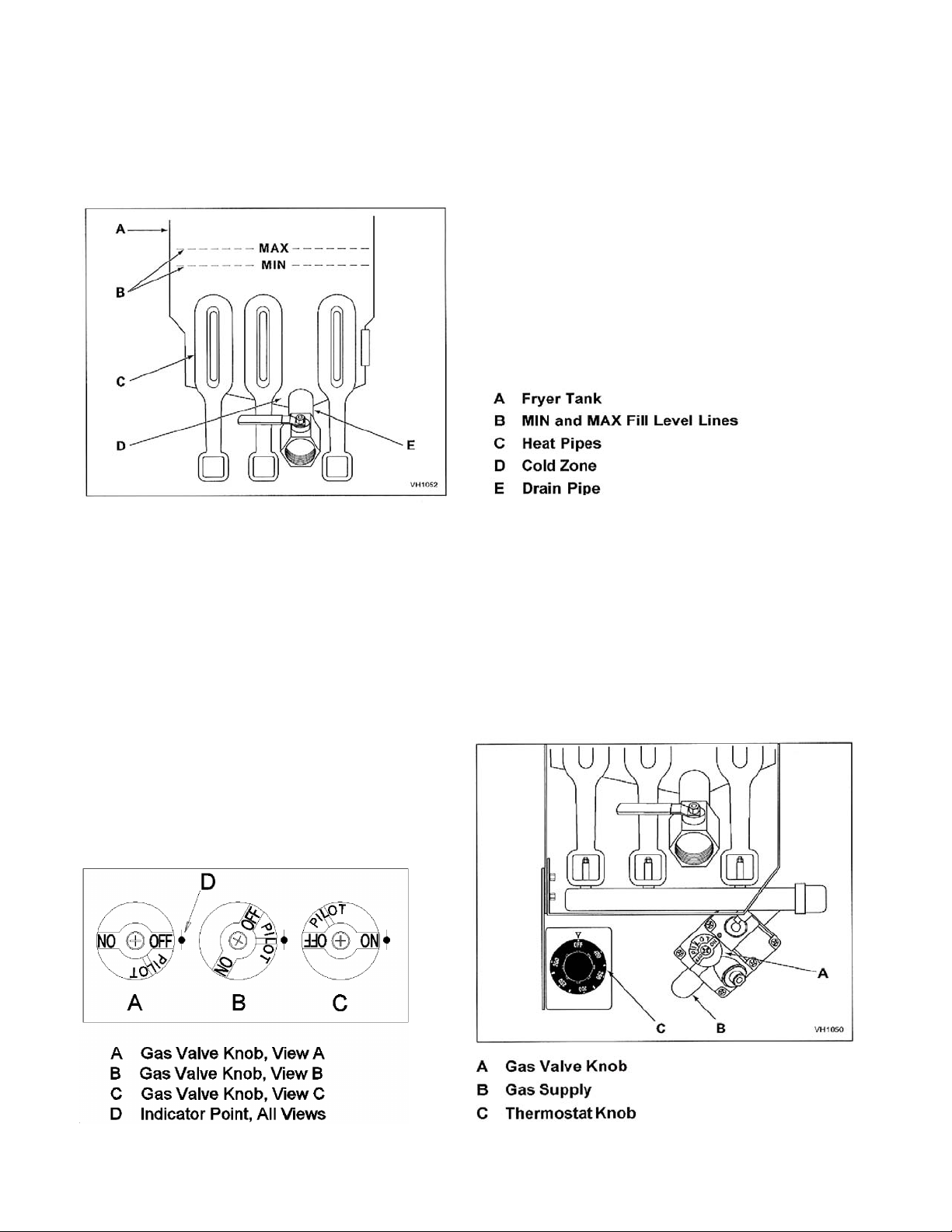

LIGHTING THE PILOT

1. Open the door

2 Turn the thermostat OFF (see figure below, view A). The thermostat is located behind the door.

3. Push the gas control valve knob and turn to OFF.Wait 5 minutes for unburned gas to vent.

4. Push and turn gas control valve knob to the “L” in PILOT (see figure below, view B).

5. While still holding the knob in, light the pilot with a lit flame. Continue to depress the knob until pilot

remains lit when knob is released. If the pilot

does not remain lit, repeat step 3 through 5.

6. Depress and turn gas control knob to ON (See

figure below, view C).

7. If gas supply is interrupted, repeat steps 2

through 6.

10

Loading...

Loading...