Crown Steam SB-ST-E Service Manual

OWNER’S MANUAL

MARINE STEAM-IT

ELECTRIC COUNTER MODEL

MODEL: ● SB-ST-E

WARNINGS:

BE SURE TO GROUND THE COOKER CHASES FROM

THE GROUND TERMINAL BOX TO THE OUTSIDE

GROUND. REFER TO WIRING DIAGRAM C95-3914.

DO NOT OPEN THE DRAIN VALVE WHILE THE STEAM

COOKER IS OPERATING. PREMATURE OPENING MAY

RESULT IN SCALDING OF THE OPERATOR.

DO NOT LEAVE HAND ON HANDLE.

TO PREVENT SCALDING, THE OPERATOR SHOULD

KEEP HANDS OFF THE DOOR HANDLE WHILE EXCESS STEAM/VAPOR IS ESCAPING.

THE ELECTRIC POWER SUPPLY MUST BE DISCONNECTED PRIOR TO PERFORMING ANY MAINTENANCE/REPAIR WORK.

CAUTION:

HELP PREVENT PITTING OF THE ALUMINUM INTERIOR. DO NOT USE STRONG DETERGENT OR ABRASIVE CLEANERS.

NOTES:

TO ASSURE A PROPER PRESSURE SEAL, THE DOOR

DISTRIBUTION STATEMENT

THIS PUBLICATION IS REQUIRED FOR OFFICIAL USE FOR ADMINISTRATIVE OR OPERATING PURPOSES. DISTRIBUTION IS LIMITED

TO U.S. GOVERNMENT AGENTS ONLY. OTHER

REQUEST FOR THIS DOCUMENT MUST BE REFERRED TO COMMANDER, NAVAL SEA SYSTEMS COMMAND, SEA 09, WASHINGTON, DC

20362.

GASKET MUST BE FREE OF SOIL, SCALE AND

BREAKS.

SHOULD THE COOKING CYCLE BE STARTED WITH

INSUFFICIENT WATER IN THE COMPARTMENT, THE

SAFETY ACTION OF THE LOW WATER CUT-OFF WILL

SHUT THE UNIT DOWN. WHEN ADEQUATE WATER

(TOTAL: 6 QUARTS) IS ADDED TO THE CHAMBER,

THE COOKING CYCLE MAY BEGIN AGAIN.

FEDERAL SPEC S-C-1474B S6161-PA-FSE-010-/38379

TYPE SC1474-3106MA1 0910-LP-436-6200

Telephone: (802) 658-6600 Fax: (802)864-0183

www.marketforge.com PN 14-0299 Rev C (11/17)

© 2017 - Market Forge

S6161-PA-FSE-010-/38379

0910-LP-436-6200

DISTRIBUTION STATEMENT:

THIS PUBLICATION IS REQUIRED FOR OFFICIAL USE FOR ADMINISTRATIVE OR OPERATIONAL PURPOSES. DISTRIBUTION IS LIMITED TO U.S. GOVERNMENT AGENTS ONLY.

OTHER REQUEST FOR THIS DOCUMENT MUST BE REFERRED TO COMMANDER, NAVAL

SEA SYSTEMS COMMAND, SEA 09, WASHINGTON, DC 20362.

TABLE OF CONTENTS

INSTALLATION

SERVICE CONNECTIONS..................................1

ELECTRICALLY OPERATED ............................. 1

CERTIFICATIONS ..............................................1

UNPACKING & ASSEMBLY ...............................1

ELECTRICAL CONNECTIONS ..........................2

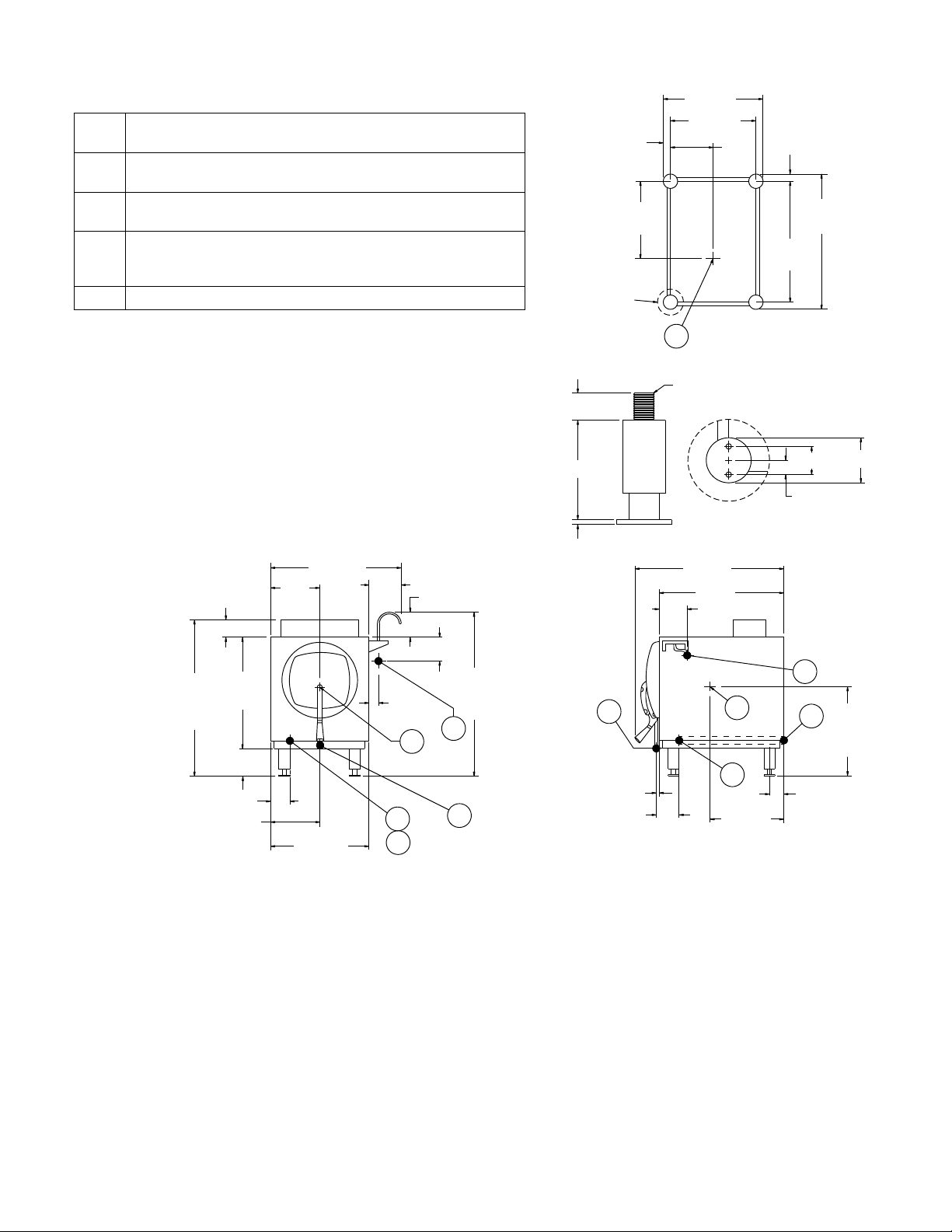

TERMINAL BOX LOCATION (FIG. 1) ................. 2

INSTALLATION CHECK-OUT ............................2

INITIAL CONTROL SETTINGS ..........................2

COOKER CHECK-OUT ...................................... 2

SHUTDOWN PROCEDURE ...............................2

PRINCIPLES OF OPERATION

GENERAL ........................................................... 3

OPERATION SEQUENCE .................................. 3

PRELIMINARY PROCEDURES .........................3

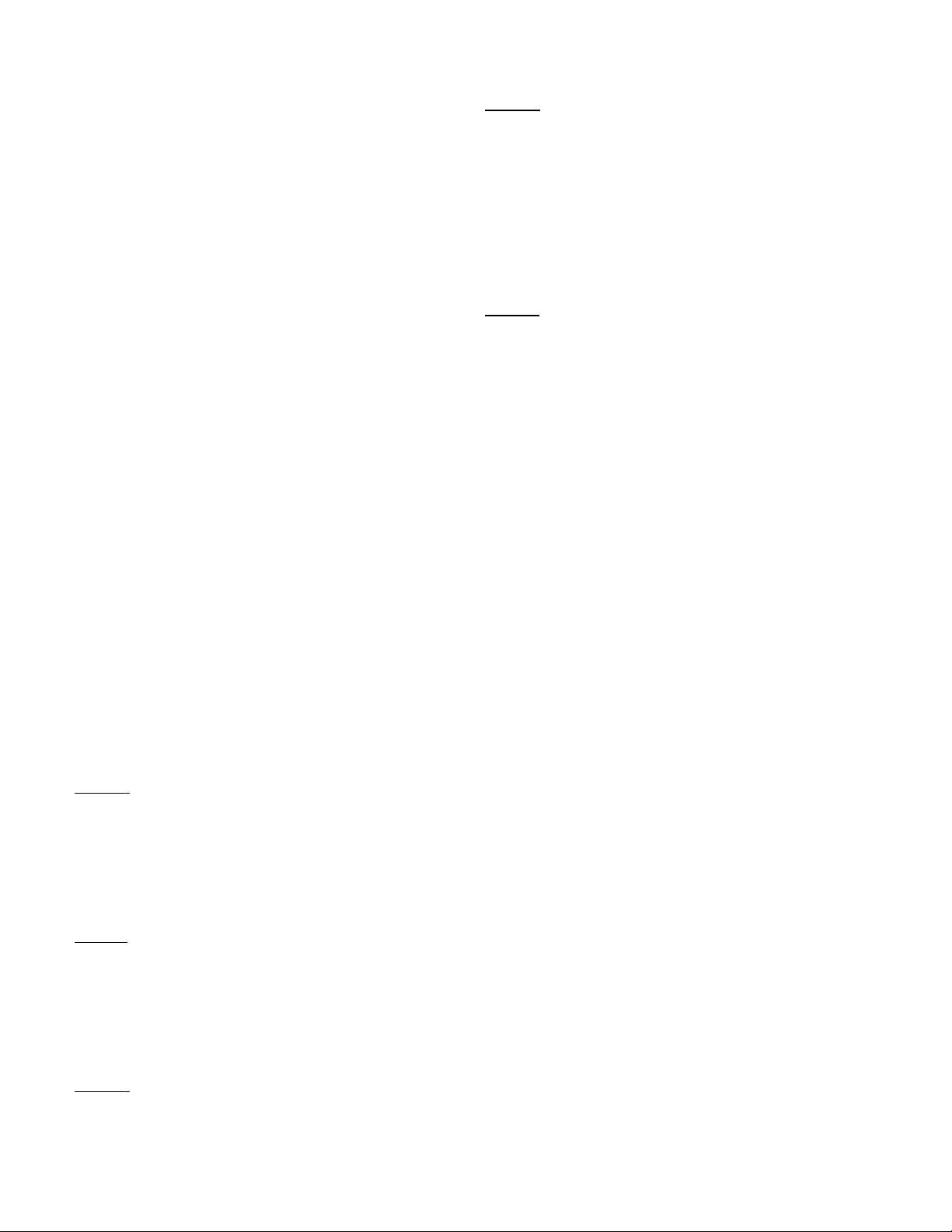

WIRING DIAGRAM (FIG. 2) ................................4

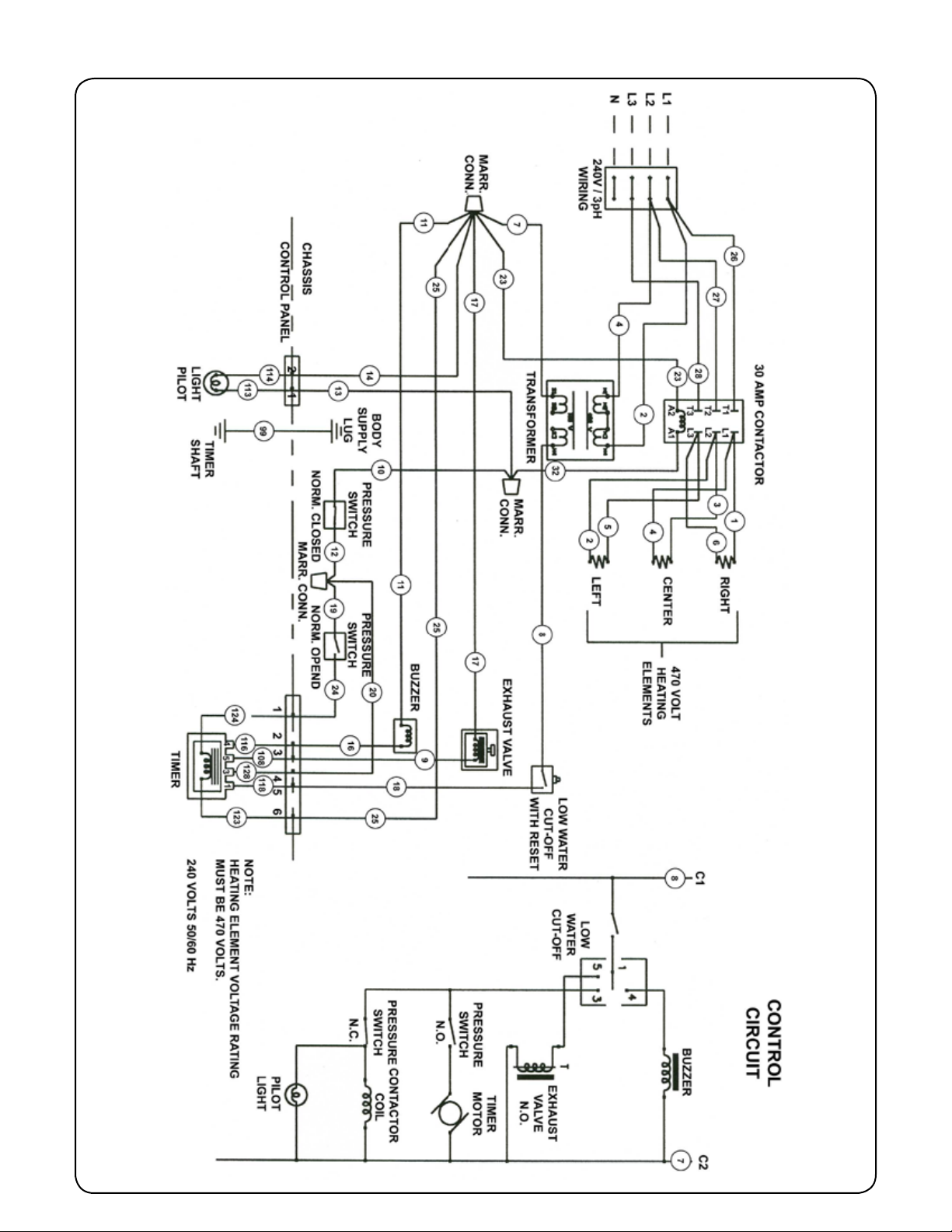

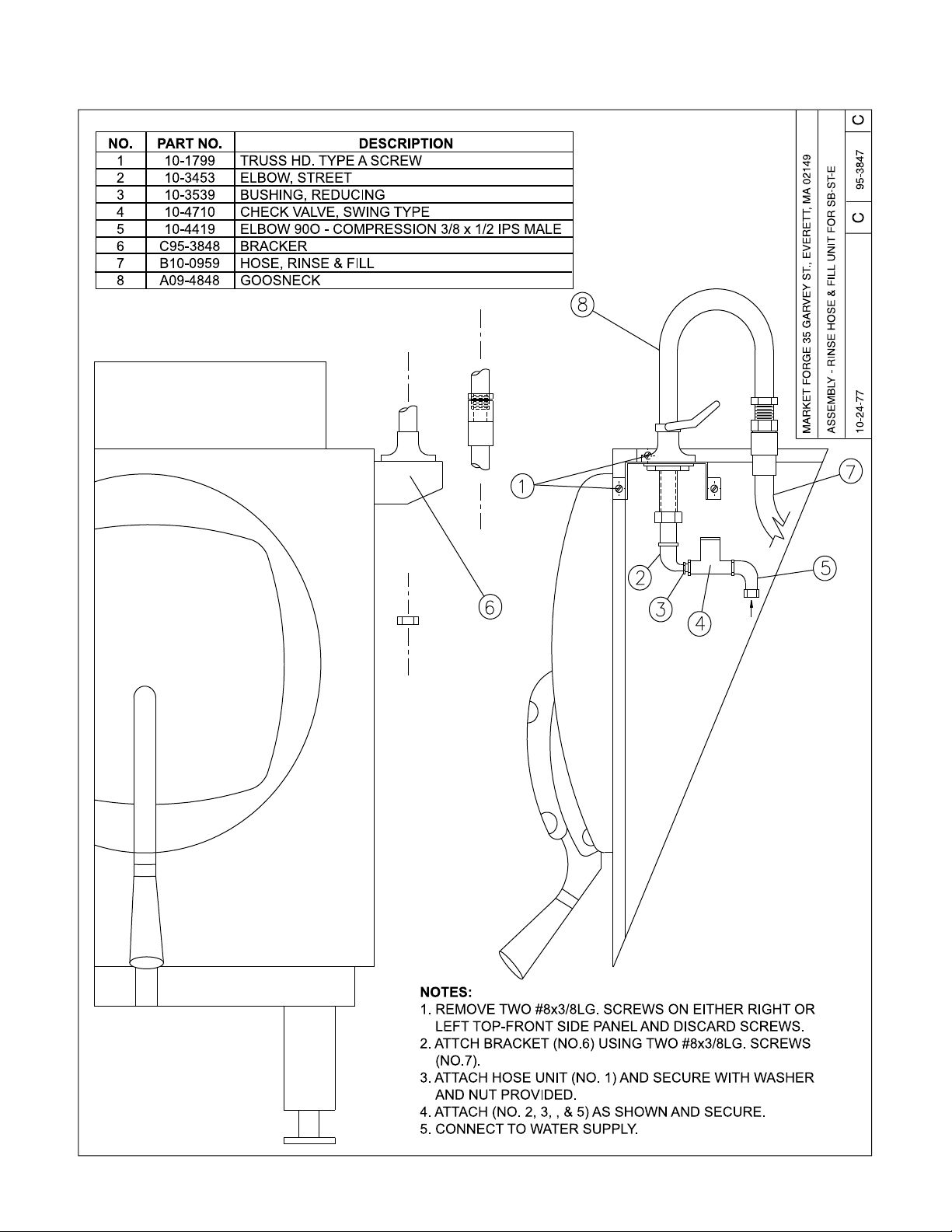

HOSE ASSEMBLY (FIG. 3) ................................ 5

PREHEATING ..................................................... 6

FACTS ON PARADE .......................................... 6

RECOMMENDED COOKING TIMES ................. 7

THE FLUE ..........................................................10

TO REMOVE THE FLUE .................................... 10

STEAM GAUGE .................................................10

STEAM TRAP ...................................................... 10

HOW IT WORKS ................................................10

TROUBLE TEST AND REMEDIES .....................10

FLUE REMOVAL ITEMS (FIG. A) ....................... 10

MAINTENANCE

PREVENTIVE MAINTENANCE .......................... 11

DOOR ASSEMBLY ............................................. 11

GASKET REPLACEMENT .................................11

DOOR SEAL TENSION ADJUSTMENT .............. 12

DOOR LIFT SPRING REPLACEMENT .............. 12

STEAM EXHAUST VALVE & TRAP

REPLACEMENT ................................................. 12

DAILY CLEANING ..............................................12

WEEKLY CLEANING .......................................... 12

CLEANING EXHAUST SILENCER .....................13

CLEANING TROUBLE-SHOOTING GUIDE

(STAINLESS STEEL) ..........................................13

ILLUSTRATED PARTS LIST

COOKER COMPARTMENT (FIG. 7) .................. 14

DOOR HANDLE ASSEMBLY (FIG. 8) ................ 17

THE COOKER DOOR ASSEMBLY .................... 18

DOOR ASSEMBLY (FIG. 9) ................................ 18

FULCRUM & DRAIN ASSEMBLY ....................... 18

ROLLER ASSEMBLY .......................................... 18

OLD STYLE FULCRUM & DRAIN

ASSEMBLY (FIG. 10) .........................................19

NEW STYLE FULCRUM & DRAIN

ASSEMBLY (FIG. 11) .......................................... 19

SAFETY VALVE .................................................. 19

CHECKING SAFETY VALVE .............................. 19

EXHAUST VALVE (FIG. 12) ...............................20

NEW EXHAUST VALVE, BUILT AFTER

JULY 1983 (FIG. 13) ............................................ 21

TROUBLE-SHOOTING

OLD STYLE BUILT PRIOR TO

SEPTEMBER 1980 (FIG. 14) .............................22

ELEMENT CONTROL SWITCH .........................22

HOW IT WORKS ................................................22

DIAL ADJUSTMENT ........................................... 22

NEW STYLE BUILT AFTER

SEPTEMBER 1980 (FIG. 15) .............................22

RECALIBRATING ELEMENT CONTROL

SWITCH .............................................................. 22

PRESSURE CONTROL SWITCH

(BARKSDALE) .................................................... 22

OPERATING PRESSURE ADJUSTMENT

(BRAKSDALE) .................................................... 22

RECALIBRATING PRESSURE CONTROL

SWITCH .............................................................. 23

LOW WATER CUT-OFF .....................................23

HOW IT WORKS ................................................23

TIMER ................................................................. 23

TROUBLE TEST & REMEDIES .......................... 23

TIMER CONTROL SWITCH ................................ 23

HOW IT WORKS ................................................23

DIAL ADJUSTMENT ........................................... 23

RECALIBRATING TIMER CONTROL

SWITCH ...............................................................23

PILOT LIGHT ...................................................... 23

TROUBLE-SHOOTING GUIDE .......................... 24

i

INSTALLATION

SERVICE CONNECTIONS

EC Electrical Connection - Connection for incoming power supply

wires on terminal block

EP Power Supply - 1-1/4” threaded access hole for power supply wires.

Use wire suitable for at least 90°C. Nominal amps per line.

D Drain - 1/2” 13mm O.D. tubing. Air break required for drain connec-

tion supplied by others

CW Cold Water - 3/8” 10mm O.D. tubing connection to fill hose. Cold

water line shall have a max of 50 PSI 3.5kg/cm2 and a min of 25 PSI

1.7kg/cm2 water pressure

CG Center of Gravity - with flanged feet

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality must be

within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment system

designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to federal, state or

local codes.

DIMENSIONS ARE IN INCHES [MM]

23.75 [603]

3.25

[83]

9.88

[251]

5

[127]

4.38 1[20]

5.25 [133]

1 [25]

6 [152]

0.38 [3]

1.5 [38]

SEE

DETAIL A

MARINE FOOT

12.8

[325]

17.88 [454]

14.88 [378]

CG

BOTTOM VIEW

1/3-13THD

31.5 [800]

25 [640]

6.25

[158]

7.94

[378]

DETAIL A

1.5

[38]

21.13

[536]

24.13

[612]

2.13 [54]

1.06 [27]

CW

3 [76]

23 [584]

31.75 [806]

6 [152]

3.25 [83]

9.38 [240]

18.75 [480]

1.25 [32]

CG

EP

EC

CW

D

UNPACKING AND ASSEMBLY:

The Steam-It cooker is shipped in a carton with protective

padding and mounted on a wooden pallet. Carefully remove the carton, padding and the bolts securing the unit

to the wooden pallet. Inspect assemblies as follows:

1. Inspect unit overall for dents or deformations in stainless steel cabinet enclosures.

2. Make sure visible attaching hardware for all assemblies are not missing or damaged.

3. Inspect timer, indicator light, RESET switch and pressure gauge to see they are not damaged.

4. Install pan supports so that the horizontal keyhole

is at the rear of the cooking chamber and so that

the ange and embossments face the middle of the

chamber.

32.25 [819]

D

0.75 [19]

3 [76]

CG

Conduit

EC

14.38 [375]

EP

16.88 [429]

2.5 [69]

5. Install the set (4 each) of Marine anged feet (3” di-

ameter anged plates) so the steam cooker can be

mounted on a counter top (refer to spec sheet S-

2160) for anged feet details.

6. Install the part number 95-3849 rinse and ll hose unit

on the shipboard steam cooker. Refer to the enclosed

drawing C95-3897 Rev A for installation details.

NOTE: The cooker is carefully inspected and packaged

before leaving the factory. If there are missing components or unit is damaged, notify the carrier immediately.

Should repairs be required, a network of authorized service agencies is available to assist with prompt service. If

necessary, please contact:

1

INSTALLATION

Product Service Department Market Forge

Toll Free: (866) 698-3188

Parts, Service and Availability Toll Free No.:

(888) 259-7076

custserv@marketforge.com, www.marketforge.com

The Model and serial numbers must be referenced when

corresponding with Market Forge. The data plate containing the serial number pertaining to the equipment is located on the front top of the cabinet.

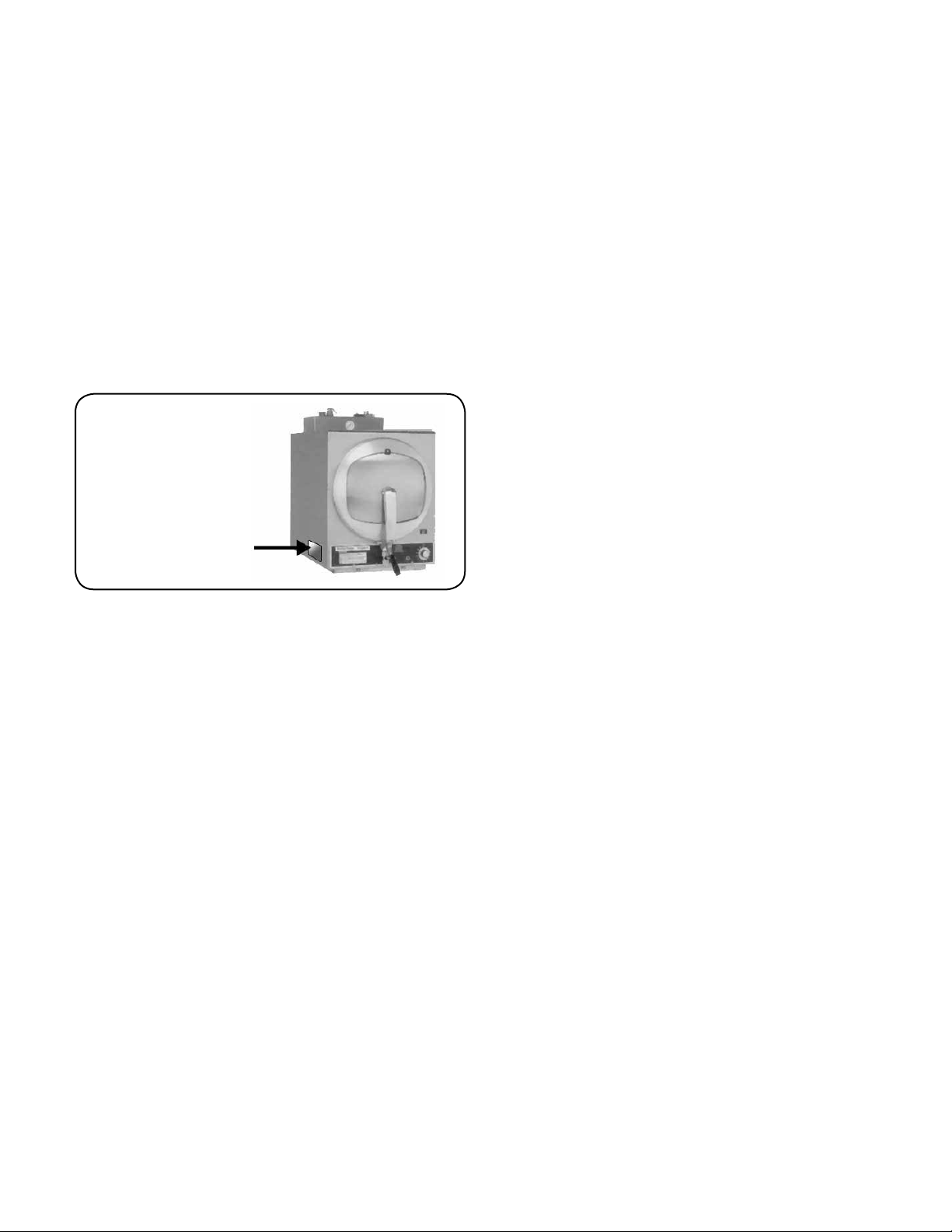

ELECTRICAL CONNECTION:

The electrical connection may be made at the terminal

box located at the lower left side of the Steam-It removing

the small covering panel (see gure 1 below, and service

connections on previous page).

FIG. 1

REMOVE THIS

PLATE TO ELECTRICAL

CONNECTION

Power input is 12 kW at 208, 236 or 440 Volt, 60 cycle

A.C. Equipment is adaptable for single ir three phase. Unit

must be grounded. Wires should be brought up through

conduit at bottom of cooker (see wiring diagram c95-3914

Rev A (440V/6pH/60Hz) for instructions on making connection. Unit must be fused separately.

NOTE: Refer to the spec sheet, side 2 on page 2 for the

complete list and location of the required service connection and electrical details.

WARNING: BE SURE TO GROUND THE COOKER

CHASES FROM GROUND TERMINAL BOX TO AN

OUTSIDE GROUND. REFER TO WIRING DIAGRAM

C95-3914 REV A ENCLOSED. ALL RECOMMENDED

SAFETY PRECAUTIONS SHOULD BE OBSERVED

WHEN CONNECTION THIS UNIT TO THE EXISTING

POWER SUPPLY.

INSTALLATION CHECK-OUT:

After the Steam-It cooker is completely assemblies and

properly located with electrical supply connected, the

cooker must be given a thorough checkout before being

put into cooking operation.

Before making this checkout the operator must be thoroughly familiar with the operating procedures in Section

3 and with the function of each control described in principles of operation in Section 3. Reference Figure 4 for

identication of controls required in the following procedures. If the unit fails to perform as described below, con-

sult the trouble shooting guide for corrective action.

INITIAL CONTROL SETTINGS:

Before beginning cooker checkout procedures, perform

the following steps:

1. Check to see that the timer is off.

2. Visually check interior of cooking compartment and

remove any materials, papers, etc. Check to see that

pan supports are properly installed (refer to principles

of operation in Section 3, step 5) and secured.

3. Check pressure gauge to see that it registers zero

pounds.

COOKER CHECK-OUT:

The cooker checkout procedures are as follows:

1. Secure the drain valve (refer to operating instruc-

tions S-202B gure No. 4 on page 7) then pour six

(6) quarts of water into the steam-it cooking compartment through the door opening.

WARNING: BE CERTAIN THE DRAIN VALVE IS

CLOSED AND DO NOT OPEN IT WHILE THE UNIT

IS OPERATING, PREMATURE OPENING MAY RESULT IN’ SCALDING OF’ THE OPERATOR.

2. Close the door and lock in position by placing the

tongue of the door lock under the roller on the drain

casting and pressing downward until door lock comes

to a rm stop. This lock makes the initial seal. (When

steam pressure builds up in the compartment it will

force the door to a tighter closed position.)

3. Turn the Steam-It en. by setting the timer to the desired cooking time. Observe pressure increase indicated by pressure gauge.

4. At the close of the preset cooking period, the timer

pointer will stop at the “0” position on the dial. This

will shut down the Steam-It and automatically open

the exhaust valve. The Buzzer will continue to sound

until the dial pointer is manually turned to the “OFF”

position.

5. Observe that the indicator light goes out when timer is

at the “O-minute” position. Check the pressure gauge

to see that the pressure reads zero. The door will not

open while there is steam pressure working against it

from wi thin the cooking compartment. The door must

be kept locked until the cooking cycle has completely

nished, then the door opened to allow vapor to clear.

Shut off gas supply by closing the gas shutoff valve.

SHUTDOWN PROCEDURE:

No special shutdown procedures are required with the exception that the door is left open, timer must be in the OFF

position and the gas supply valve closed, (consult local

codes for daily shut-off requirement.

NOTE: Before using the Steam-It for cooking, it is recommended that checkout operations be performed 2 or 3

times in order to determine that. it is working properly and

to insure cleanliness of the cooking compartment.

2

PRINCIPLES OF OPERATION

PLEASE READ CAREFULLY THE FOLLOWING INFORMATION AND THE OPERATING INSTRUCTIONS ON

THE FOLLOWING PAGES.

CAUTION: The model SB-ST-E Steam-It pressure

cooker cylinder is constructed of a corrosion resistant alclad aluminum alloy. The protective properties of this material afforded to the interior portion of, the cylinder which

is exposed to water may be destroyed by allowing a lm

to form. Such a lm can be caused by salt. or other con-

taminants in the water. If the water supply is known to be

hard or corrosive, a source of treated water should be

used. Corrosion may also occur if water is not drained

daily. Do not use distilled water.

NOTE: Market Forge will not be responsible for damage

resulting from the use of hard or corrosive water, from

failure to drain the unit daily, or from inadequate cleaning

procedures.

GENERAL:

The model SB-ST-E Marine Electric Steam-It pressure

cooker (15 PSI operation) consists of one (1) cooking compartment into which pans of food product are

loaded through an inwardly opening door. The self-con-

tained cooker is tted with electric heating elements for

440V/3PH/60HZ operation (16 amps) rated at 12KW impute

OPERATION SEQUENCE:

With water placed in the Steam-It to the recommended

six quart level and the door rmly locked to make a tight

seal, a cooking cycle will automatically be performed with

the act of setting the timer to the length of cooking time

desired. The automatic sequence of operation is:

STEP 1 Upon setting the timer, a current ows to: The

exhaust valve solenoid, activating it to close the exhaust

valve: The element pressure control switch, which relays

a current ow to the contactor coil causing the contactor to close and direct electricity to the heating elements:

The cooking cycle light, which remains in circuit while the

heating elements are on.

STEP 2 As steam is produced within the cooking cylinder,

trapped air escapes through the steam trap. The steam

trap is induced to close thermostatically when live steam

fully replaces the trapped air passing through it. Freeventing will automatically cease and cooking cylinder will

become steam-tight. A build-up of cooking cylinder steam

pressure will occur.

STEP 3 When the steam pressure build-up reaches 10

PSI, the timer control switch will activate the timer to start

its timing cycle.

STEP 4 When the steam pressure build-up reaches 14

PSI, the element control switch will cut off the current ow

to the contactor, causing it to open and cut off electricity

to the heating elements. When cooling causes the pressure to drop to 13 PSI, the element control switch will

again activate the contactor to close and restore the ow

of electricity to the heating elements. Thus, by controlling

the contactor to open and close intermittently, the element

control switch, in effect, maintains the cooking cylinder

steam pressures between 13 and 14 PSI.

STEP 5 (Timer reaches “Zero” position) When the timer

reaches “Zero” (the end of the cooking cycle), a circuit

is completed to the buzzer allowing it to sound while the

circuit t to the pilot light is broken. The steam exhaust

valve will open and the cooking chamber is automatically

exhausted of steam. The buzzer will continue to sound

until the timer knob is turned to the “Off” position. The

door will not open while there is steam pressure working

against it from within the cooking cylinder. The door must

be kept locked until the cooking cycle has completely nished, then open the door, allow a second or two for the

vapor to clear and remove the foods.

PRELIMINARY PROCEDURES:

1. Ensure that electric supply is connected and operating at until See Installation Instructions.

2. Close drain valve (g. 4, No. 3) by turning valve handle Clockwise.

3. Hang pan supports (g. 4, No. 2) on pan support

studs (cylinder side walls). The horizontal keyhole

on the support should be at rear or compartment and

vertical keyhole near front.

4. Pour approximately six quarts of water directly into

Steam-It cylinder.

NOTE: In geographical locations where a high amount

or lime and alkaline (salt-lime substance) deposits are

present in water Supply, add two tablespoons or vinegar

directly into six quarts of water in Steam-It compartment

prior to starting cooking cycle. It more water is added to

maintain required level, an occasional table Spoon of vinegar may be added as well, in order to compensate for

new mineral deposits fresh water.

CAUTION: A high degree or mineral salts in water can

cause pitting of cooking compartment unless above directions (See NOTE) are followed; the cooking compartment thoroughly cleaned and drained each night; and the

door left open. Also, go not scour cylinder With abrasive

cleanser.

WARNING: DO NOT OPEN DRAIN VALVE WHILE

UNIT IS OPERATING. PREMATURE OPENING MAY

RESULT IN SCALDING OF OPERATOR.

3

PRINCIPLES OF OPERATION

FIG. 2

4

PRINCIPLES OF OPERATION

FIG. 3

5

PRINCIPLES OF OPERATION

PREHEATING:

Before each Initial operation of cooker and at any time

when compartment is cold, a 5 to 8 minute preheating

period is required. To preheat cooking compartment. Proceed as follows:

1. Close door and lock in position by placing door handle tongue (Fig. 4 No. 4) under roller on drain casting

(Fig. 4 No. 5) press downward on door handle until

door is secured

2. Set minute timer (Fig. 4 No. 7) to 5 minutes by turning

past 10 and back to 5 to ensure proper setting. Indicator light will come on.

3. When preheating is ended (approximately 5 minutes)

and buzzer sounds. turn timer to OFF and allow pressure to return to 0 PSI on pressure gauge (Fig. 4 No.

8).

4. Open compartment door slightly by pulling up on latch

handle (g. 4. No. 6) to allow remaining vapor to escape before raising door to full open position.

WARNING: DO NOT LEAVE HAND ON HANDLE

WHILE EXCESS VAPOR IS ESCAPING. SCALDING OF

HAND MAY RESULT.

shut the unit down. When the required amount of water is added, the unit will be operational again after

the LOW WATER CUT-OFF BUTTON is pressed.

However, if the unit does not start after pressing the

reset button, more time will be needed before the reset button starts the unit. Should a cooking cycle be

interrupted by the low water cut off, the food in the

process of cooking will be affected. Proper compensation should be made for cooking already performed

and a new cook cycle determined. Clean the unit

thoroughly at the end of each day the cooker is used.

Ensure that the cylinder is left dry and the compartment door is left open.

Once the preheating cycle is completed, the cooker compartment may be loaded. The following procedures should

be followed:

1. Insert the pans of food into the pan support located

on the right and left side of the cylinder.

2. Close the door and lock in position by placing the

door handle tongue under the roller on the drain cast-

ing (refer to gure 4). Press downward on the door

handle until the door is secured.

3. Set the timer for the desired cooking time (refer to

Facts on Parade) by timing the timer past the desired

setting and then back. NOTE: The timer will not start’

until the unit is at a minimum of 9 PSI as indicated on

the pressure gauge.

4. At the completion of the required cooking cycle,

steam will automatically exhaust. When the pressure

reaches zero PSI on the pressure gauge, the cooker

compartment door can be released by pulling on the

door latch handle. The operator should allow a few

seconds for the remaining vapor to leave the cylinder before completely opening the door. To stop the

buzzer, turn the timer to the OFF position.

5. The next step is to remove the cooked food, add

any desired seasoning and transfer it to - the serving area. If perforated pans are used, they should be

underlined with a solid pan.

6. Check the’ water level in the cooker before starting

‘another cooking cycle. The water should be at the

six quart level. NOTE: If the unit is operated with an

insufcient amount of water the low water cut-off will

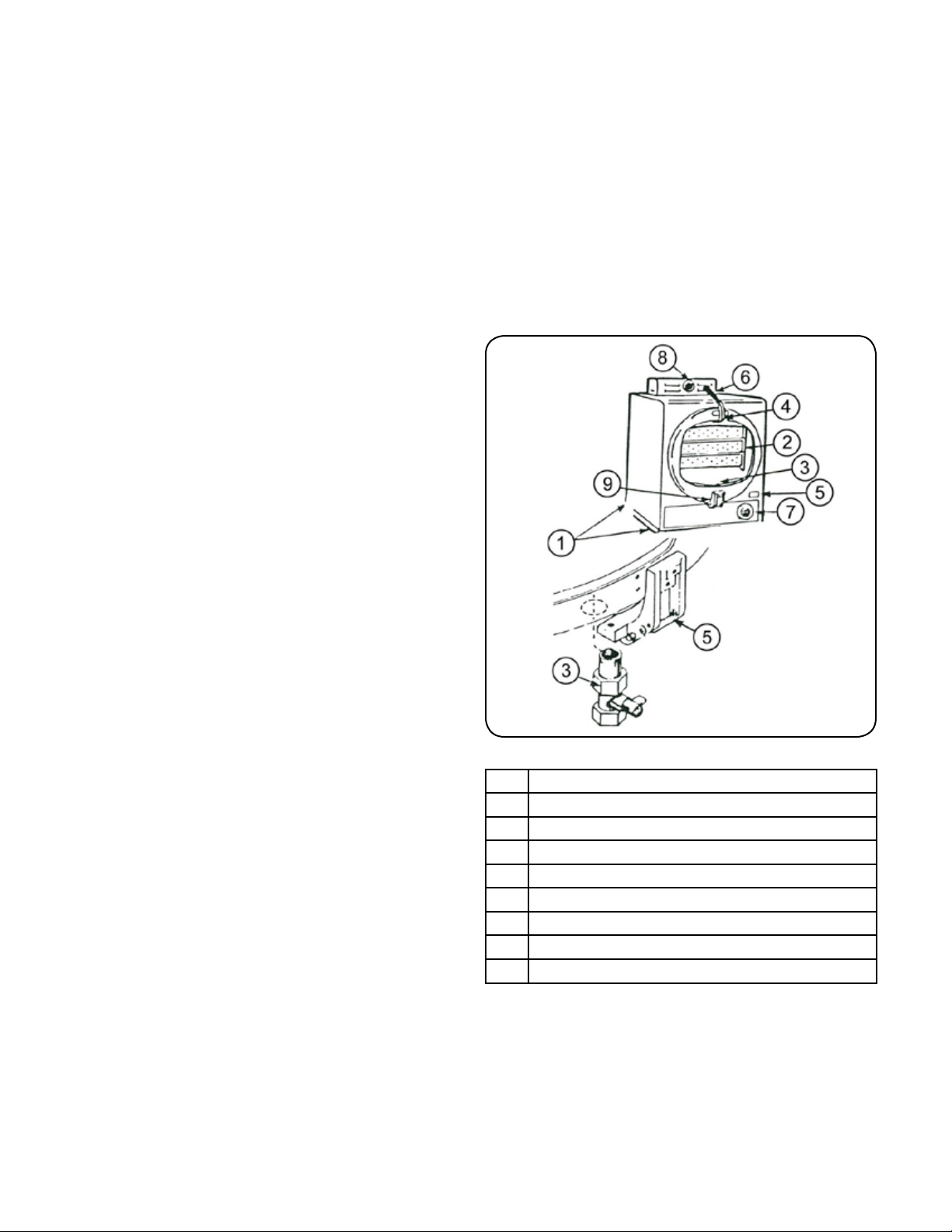

FIG.4

NOTE:

WATER RETAINER & SPRAY HOSE NOT SHOWN.

1 Electrical Connection Box

2 Pan Supports

3 Drain Valve

4 Door Handle Tongue

5 Roller on Drain Casting

6 Door Handle

7 Timer

8 Pressure Gauge

9 Low Water Cut-off Reset Button

FACTS ON PARADE:

1. All foods, except cakes and pastry, can be cooked in

a steam cooking unit.

2. Steam cooked meals have greater nutritional value

since they retain most of their vitamins and minerals.

3. Because foods are cooked faster by the higher temperatures of steam cooking, they can be prepared

closer to serving time, insuring maximum freshness.

6

Loading...

Loading...