Crown Steam ETP-10G Installation Manual

ECO-TECH® PLUS

GAS CONVECTION STEAMER

INSTALLATION - OPERATION - MAINTENANCE

MODEL

ETP-10G

Telephone: (802) 658-6600 Fax: (802)864-0183

www.marketforge.com PN 14-0270 Rev C (1/17)

© 2017 - Market Forge

Your Service Agency’s Address:

Model

Serial number

Steamer installed by

Installation checked by

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation, service or maintenance can cause property damage,

injury or death. Read the installation,

operation and maintenance instructions thoroughly before installing or

servicing this equipment.

INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT

LOCATION. This information may be obtained by contacting your local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other

ammable vapors or liquids in the vicinity of this or any other appliance.

Do not attempt to operate this unit in the

event of power failure.

Adequate clearances must be maintained

for safe and proper operation.

INSTALLATION

Service Connections ............................................. 2

Introduction ...................................................... 3

Installation....................................................... 4

Water Conditioning ............................................... 7

Filter Change Procedure .......................................... 8

Performance Check .............................................. 9

OPERATION

Operating Instructions ...........................................10

Lighting ....................................................10

Cooking ....................................................10

Cleaning ................................................... 11

Drainage ................................................... 11

Control Panel ................................................... 12

Test Kitchen Bulletin ............................................. 13

Cooking Guide .................................................. 15

MAINTENANCE

Cleaning & Preventative Maintenance.............................18

Cleaning ...................................................18

Deliming .................................................... 19

The appliance area must be kept free

and clear of combustibles.

Do not obstruct the ow of combustion

and ventilation air.

The information contained in this manual

is important for the proper installation,

use, and maintenance of this steamer.

Adherence to these procedures and instructions will result in years of troublefree service. Please read this manual

carefully and retain it for future reference.

ERRORS: Descriptive, typographic or

pictorial errors are subject to correction.

Specications are subject to change

without notice.

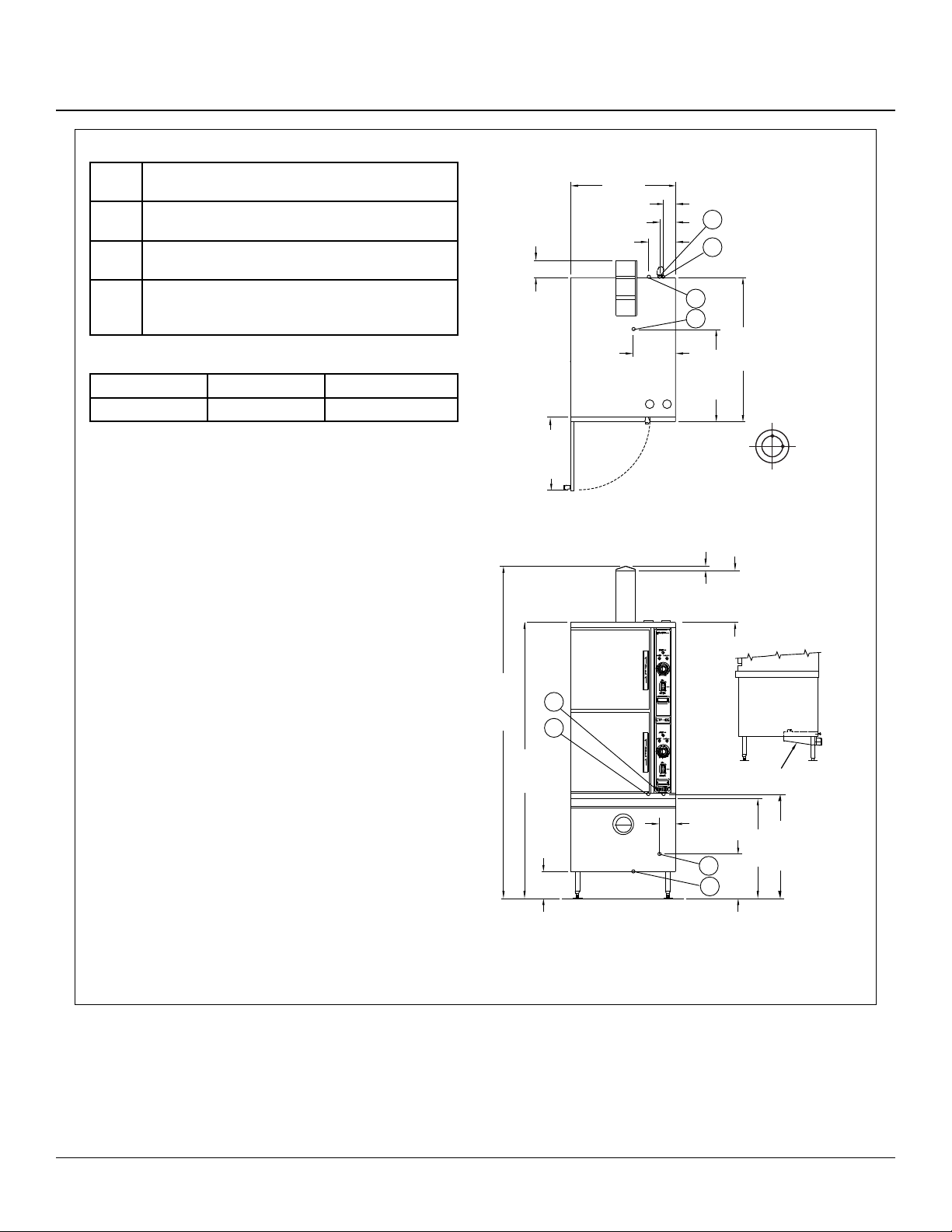

Service Connections

10 [254]

SERVICE CONNECTIONS

G Gas Connection - 3/4” (19mm) Male NPT. 84,000

BTU’s.

CW Cold Water - 3/8” (10mm) NPT, Maximum 50 PSI,

Minimum 25 PSI.

D Drain - 1-1/2” NPT male from the drain adapter (see

illustration)

EC Electrical Connection - 120 Volts AC, 60 Hz, single

phase, comes with 6 foot cord. NEMA 5-15. Total

Amps: 2

INSTALLATION CLEARANCE

Left Side Right Side Rear

3 6 6

GAS CONNECTION

3/4” NPT male

3 1/2” W.C. natural

10” W.C. propane

NOTES: If the equipment is to be installed where the elevation

exceeds 2,000 ft. (609.6 meters) above sea level, specify installation altitudes so that the proper gas orifices can be provided.

Rated Input: 42,000 BTU per compartment.

All service connections are made at the rear of the unit.

NOTES: PVC and CPVC pipe are not acceptable materials for

drains.

The drain piping must consist of temperature resistant material,

greater than 160°F, and be of adequate diameter not to cause

flow restriction. Improper materials may deform and cause restrictions, thus affecting performance.

DIMENSIONS ARE IN INCHES [MM]

24 [610]

2.75 [70]

4 [102]

6.25 [159]

4 [102]

16.75 [425]

cw

76.25 [1937]

EC

9.75

[248]

G

CW

EC

D

21.13 [537]

1 [25]

33 [838]

REAR FLANGED

FOOT DETAIL

2 EQUALLY SPACED

Ø7/16” [11] HOLES

ON 2.5 [63] B.C.

12 [305]

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water

quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to

federal, state or local codes.

INSTALLATION

Figure 1

2

64 [1626]

6 [152]

3.75 [95]

G

D

DRAIN ADAPTER

10 [254]

23.75 [603]

Introduction

DESCRIPTION

The ETP-10G is a gas red pressureless steam cooker.

The cooking compartments are equipped with a three-

piece door with inner gasket plate isolated from the exterior surface. Door latch operates by slam action for positive sealing of the door. Operating controls are displayed

on a front-mounted panel and include indicator lights for

ignition, ready and cooking modes, a timer to set cook

times and a selectable hold cycle to keep food warm once

cooked, a temperature display to monitor cavity temperature, and an illuminated ON/OFF/DELIME switch. Each

stainless steel steam generator operates “0” PSI (0 kg/

cm2) and is rated at 42,000 BTU.

BASIC FUNCTIONING

The cooker is ready for operation when the READY light

comes on.

At the end of the set interval, timer contacts switch to shut

off the cooking operation and sound a signal buzzer. The

buzzer is silenced by returning the timer dial to the OFF

position. In the ‘HOLD’ mode, the cooker will maintain a

safe food holding temperature at or above 150°F.

Steam and liquids from each cooking cavity pass through

a removable drain screen in the cavity and into the tempering tank. When the appliance is shut off, the steam

generators will also drain into the tempering tank. The

tempering tank condenses any residual steam and tempers the waste water to 140°F or less.

3

INSTALLATION

Installation

SETTING IN PLACE

The location of installation must be under an exhaust

hood, which will remove water vapour emitted when the

cooker door is opened, and exhaust combustion fumes.

Level the unit in nal location by turning the adjustable

feet. Using the cabinet top as a reference, obtain level

adjustment left-to-right and front-to-back.

MECHANICAL CONNECTIONS

All electrical and plumbing connections are located on the

rear panel of the unit. See ‘SERVICE CONNECTIONS

for location of mechanical connections.

INSTALLATION CODES AND STANDARDS

Installation must conform with local codes, or in absence

of local codes, with the National Fuel Gas Code - ANSI

Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1 as applicable.

1. The appliance and its individual shut off valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at pressures in excess of 1/2 PSI (0.035 kg/cm2).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or greater

than 1/2 PSI (0.035 kg/cm2).

Electrical grounding must be provided in accordance with

local codes, or in the absence of local codes, with the

National Electrical Code ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2 as applicable.

Ventilation must be provided in accordance with local

codes, or in the absence of local codes, with ANSI/NFPA

96 Standard for Ventilation and Fire Protection of Commercial Cooking Operations.

EXHAUST FANS AND CANOPIES

Canopies are set over ranges, ovens, kettles, etc., for

ventilation purposes. It is recommended that a canopy

extend 6” past the appliance and be located 6’ 6” from the

oor. Filters should be installed at an angle of 45 degrees

or more with the horizontal. This position prevents dripping of grease and facilitates collecting the run-off grease

in a drip pan, usually installed with the lter. A strong

exhaust fan tends to create a vacuum in the room and

may interfere with burner performance or may extinguish

pilot ames. Makeup air openings approximately equal to

the fan area will relieve such vacuum. In case of unsatisfactory performance on any appliance, check with the

exhaust fan in the “OFF” position.

WALL EXHAUST FAN

Exhaust fans should be installed at least two feet above

the vent opening at the top of the unit.

CLEARANCES

Adequate clearance must be provided in aisle and at the

side and back. Adequate clearances for air openings into

the combustion chamber must be provided, as well as for

serviceability. Minimum clearance from combustible and

noncombustible construction, 3” on left side, 8” on right

side and 6” from back.

WARNING

These procedures must be followed by quali-

ed personnel or warranty will be voided. An

open gap oor drain is required immediately

below the appliance drain.

WARNING

Electrical grounding instructions - Units come

equipped with a three-prong (grounding) plug

for your protection against shock hazard and

should be plugged directly into a properly

grounded three-prong receptacle. Do not cut

or remove the grounding prong from this plug.

(120 VOLT UNITS ONLY)

WIRING DIAGRAM FOR APPLIANCE IS LOCATED ON

RIGHT HAND SIDE PANEL OF THE COOKER CABINET.

INSTALLATION

4

Installation

To Install

1. Uncrate carefully. Report any freight damage to the

freight company immediately.

2. Set the unit in place. Be certain to maintain the minimum clearances from combustibles and non-combustibles.

3. For an appliance supplied with legs, level the ap-

pliance using a spirit level. Four anged adjustable

feet are provided for permanent anchoring to the

oor. With the unit in location, mark hole locations

on the oor through the anchoring holes. Remove

the steamer and drill holes at marked locations on the

oor. Insert proper anchoring devices.

4. Set steamer back in proper position.

5. Install bolts through anchoring holes and into anchors

to secure the steamer to the oor. Seal bolts and

anged feet with Silastic™ or equivalent silicone seal-

ant.

6. After the drain is connected, check for level by pour-

ing water onto the oor of the compartment. All water

should drain through the opening at the back of the

compartment cavity.

WARNING

For an appliance equipped with casters, the

installation shall be made with a connector

that complies with the Standard for Connectors for Moveable Gas Appliances, ANSI

Z21.69/CSA 6.16 and a quick-disconnect

device that complies with the Standard for

Quick-Disconnect Devices for use with Gas

Fuel, ANSI Z21.41/CSA 6.9; adequate means

must be provided to limit the movement of the

appliance without depending on the connector

and the quick-disconnect device or its associated piping to limit the appliance movement:

the location where restraining means may be

attached is directly above the gas supply inlet

pipe on the rear of the appliance.

The water inlet connections must also be

installed with a exible water supply line, a

quick disconnect and strain relief.

GAS CONNECTION

1. The Serial and Rating Plate on the unit indicates the

type of gas your unit is equipped to burn. DO NOT

connect to any other gas type.

2. A 3/4” NPT line is provided at rear for the connection.

Each compartment is equipped with an internal pressure regulator which is set at 3.5” W.C. manifold pressure for natural gas and 10” W.C. for propane gas.

Use C” pipe tap on the burner manifold for checking

pressure.

An adequate gas supply is imperative. Undersized or low

pressure lines will restrict the volume of gas required for

satisfactory performance. A steady supply pressure, between 6” W.C. and 14” W.C. for natural gas and 11” W.C.

and 14” W.C. for propane gas is recommended. With all

units operating simultaneously, the manifold pressure on

all units should not show any appreciable drop. Fluctuations of more that 25% on natural gas and 10% on propane gas will create problems, affecting burner operation.

Contact your gas company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt or other

foreign matter before connecting the line to the unit. Use

pipe joint compound which is suitable for use with LP on

all threaded connections.

Test pipe connections thoroughly for gas leaks.

WARNING

Never use an open ame to check for gas

leaks. Check all connections for leaks using

soapy water before use.

NOTICE

If this equipment is being installed at over

2,000 feet altitude and was not so specied on

order, contact service department. Failure to

install with proper orice sizing may void the

warranty.

ELECTRICAL CONNECTION

120 VAC-60 Hz - Single Phase

Units with this electrical rating are factory supplied with a

three-wire cord and three-prong plug which ts any standard 120V, three-prong grounded receptacle. A separate

15 amp supply is needed for each unit.

5

INSTALLATION

Loading...

Loading...