Crown Steam ELTM-80 Owner’s Manual

INSTALLATION & OPERATION

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

MANUAL

(OHFWULF6HOI*HQHUDWLQJ Single and Twin Mixer Kettles

(LTM-40-(2) (LTM-60-(2) (LTM-80-(2) (LTM-100-(2)

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read

the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

MANUAL 10041R4

WARNING

CROWN FOOD SERVICE EQUIPMENT

Division of Middleby Canada Company Inc.

70 Oakdale Road, Downsview (Toronto) Ontario, Canada, M3N 1V9

Telephone: 919-762-1000 www.crownsteamgroup.com

Printed in Canada

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

WARNING: Improper installation, operation, adjustment, alteration,

service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing, operating or servicing this equipment.

Adequate clearances must be maintained for safe and proper operation.

Intended for commercial use only. Not for household use.

This manual should be retained for future reference.

Part No. 10041R4 2 2018-08-08

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 3 2018-08-08

TABLE OF CONTENTS

DESCRIPTION PAGE

Important Notes for Installation and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.0 Service Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.0 Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.0 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.0 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Appendix A, Safety Data Sheet - Kettle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Appendix B, Safety Data Sheet - Hydraulic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 4 2018-08-08

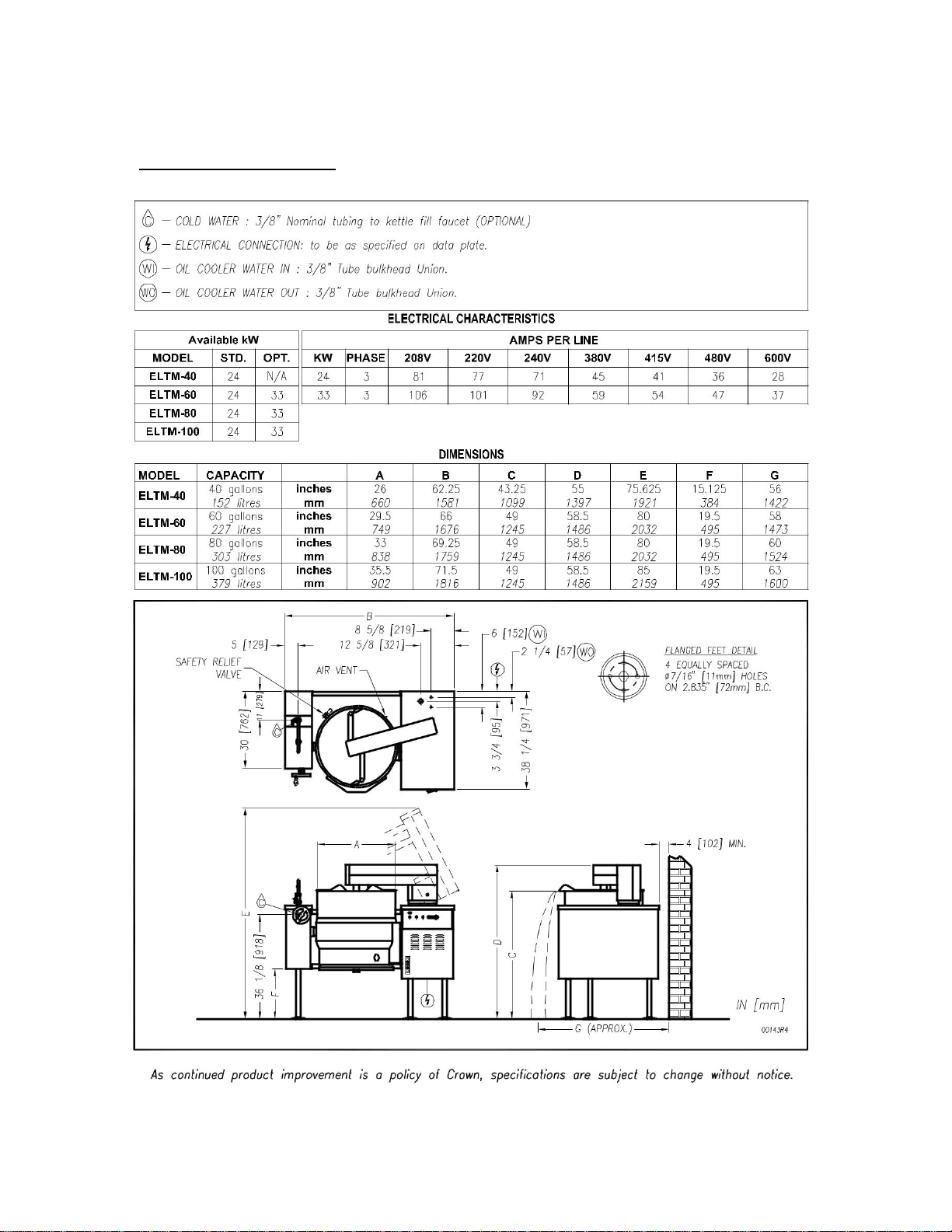

1.0 SERVICE CONNECTIONS

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 5 2018-08-08

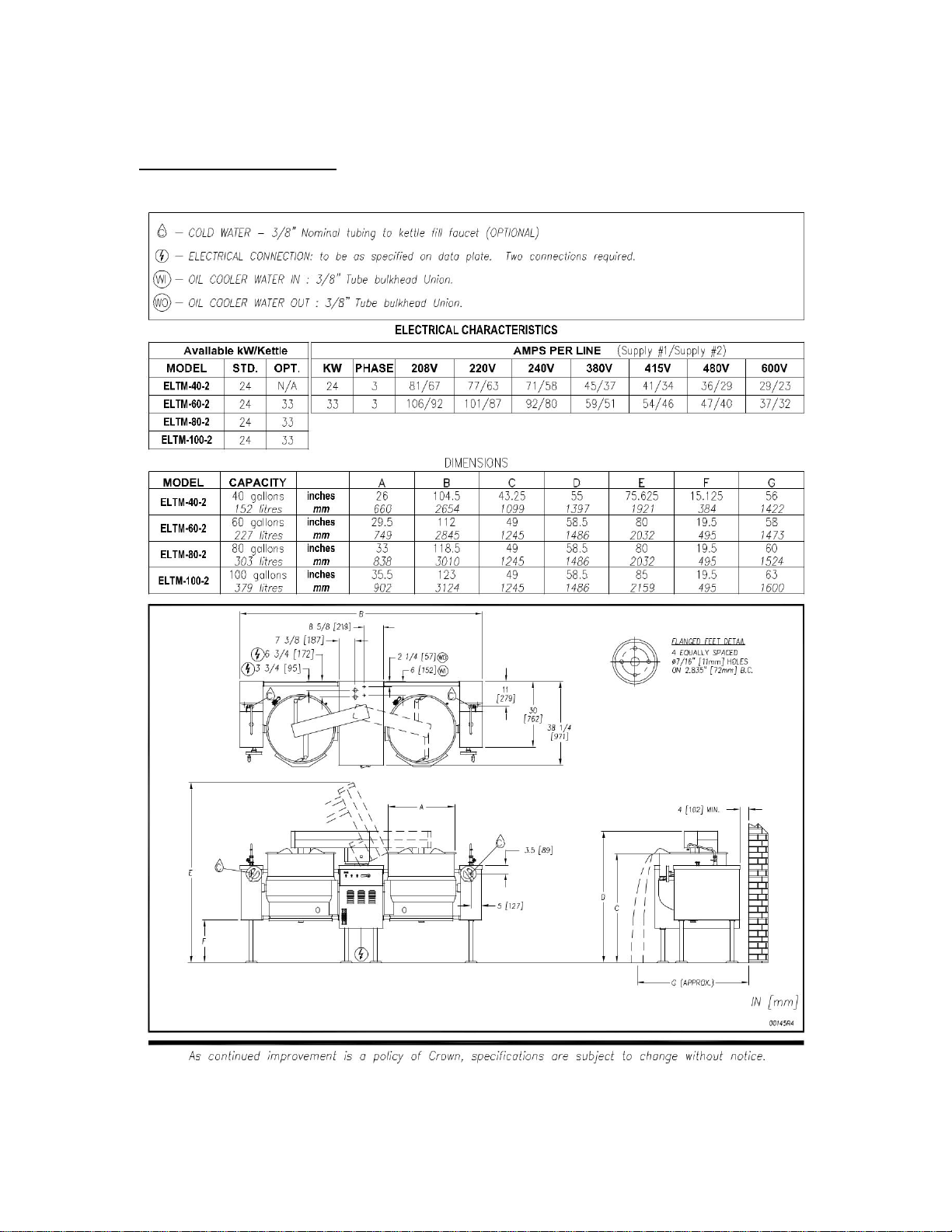

1.0 SERVICE CONNECTIONS (Continued)

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 6 2018-08-08

2.0 INTRODUCTION

DESCRIPTION

All electrically powered kettles described and referred to in this manual are pressure vessels

of a double-wall construction forming a sealed jacket (chamber) enveloping the lower two

thirds of the kettle bowl surface.

The kettle bowl is the container for the food product which ideally should be a liquid or

semi-liquid consistency to achieve complete contact with the bowl surface. Food products

will fully absorb the heat transmitted through that surface from the pressurized steam

generated in the kettle jacket.

The jacket is intended to function as a self contained sealed chamber with a permanent solution

of water and antifreeze sufficient not only to immerse and thereby protect replaceable electric

heating elements, but also provide the steam source during the steam generating process.

The heating elements are thermostatically controlled to provide precise

temperatures throughout the range from slow simmer to rolling boil.

All tilting kettles are intended to be permanently floor mounted on legs with adjustable

flanged feet.

A sealed stainless steel tilt mechanism permits the kettle to tilt forward a full 90E for

complete emptying. The tilting mechanism is self locking for positive stop action.

MIXER FEATURES

The mixer is a variable speed unit powered by a 5 hp electric motor driving a hydraulic pump.

Two heavy duty hydraulic motors drive the primary scraper/agitator and secondary high speed

mixer. Both are removable without tools for cleaning. They are housed in a stainless steel

bridge that is power tilted and swings 140E out of the way for tilting the kettle(s).

CAPACITIES

All models are suffixed with either -40, -60, -80 or -100 to indicate the capacity of that kettle

in US gallons. Models with the suffix -2 indicate a twin model. Thus a unit with suffix -40-2

has two 40 gallon kettles, one on each side of the mixer console. An ELTM-40 indicates a

single 40 gallon kettle two thirds jacketed electrically powered steam kettle.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 7 2018-08-08

2.0 INTRODUCTION (Continued)

FUNCTIONING MODE

All electrically powered self steam generating kettles consist of a jacket containing a

permanent solution of water and antifreeze sufficient to completely immerse and protect

replaceable electric heating elements.

To minimize tampering, the Safety Valve is plumbed toward the rear of the kettle jacket.

Should any component malfunction and cause the pressure in the jacket to reach the

rated pressure of the kettle, this protective device will open automatically and release

excessive pressurized steam.

When the Power Switch is turned ON and the Temperature Control (Thermostat) Knob

dialed, the TEMPERATURE pilot light will ignite and contactors will close to allow power to

the elements. Steam generation will commence and continue until the preselected

temperature is reached, at which point the contactors open, cutting off power to heating

the elements. The TEMPERATURE pilot light will then extinguish. When the temperature

of the water in the jacket drops slightly, the cycle will repeat itself thus making it possible to

maintain any selected precise cooking mode temperature.

The temperature required for the cooking process to function adequately must be greater than

the boiling point of the liquid food product. Further, the higher the temperature, the greater the

steam pressure attained in the jacket and consequently the quicker the cooking process. For

example, steam pressurized at 30 p.s.i. attains a temperature of 274º Fahrenheit.

Since air is an unsuitable media through which heat may be transferred, it has been

removed from the kettle jacket during testing at the factory. The Pressure Gauge should

indicate vacuum in the jacket in green zone on the gauge (approximately 20 - 25 inches Hg)

when the kettle is cold or has been inoperative for some time. The kettle jacket is intended

to function at all times as a completely sealed self-contained chamber and it is especially

advisable not to trip the safety relief valve during inoperative periods since this will break the

vacuum seal and allow air to enter the kettle jacket.

The Temperature Controls (thermostats) used in these kettles have been calibrated to

prevent the heating elements from generating steam pressure that would exceed the rated

working pressure of the kettle. In the unlikely event that the Temperature Control fails and

the heating elements remain energized, the Safety Valve will blow and release the

excessive pressure and steam from the jacket, consequently lowering the water level in the

jacket. The Safety Probe sensing depletion of the water level in the kettle jacket will not

only activate the LOW WATER level indicator pilot light, but also signal the Liquid Level

Control to switch off power and de-energize the circuit to the heating elements (preventing

element burn outs) until the water level is adequately replenished.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 8 2018-08-08

2.0 INTRODUCTION (Continued)

FUNCTIONING MODE (Continued)

The mixer is a variable speed unit powered by a 5 hp electric motor driving a hydraulic pump.

Two heavy duty hydraulic motors drive the primary scraper/agitator and secondary high speed

mixer. Both are removable without tools for cleaning. They are housed in a stainless steel bridge

that is power tilt and swings 140E out of the way for tilting the kettles(s). Once the bridge has

been lifted the agitators cannot be operated as a safety switch is activated. Bridge may now be

moved out of the way or if a twin mixer, moved to the other kettle. The speed control is located

on the front panel and may be set to the desired speed by turning. The maximum speed will not

exceed 54 RPM on the smallest kettle and 40 RPM on the largest.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 9 2018-08-08

3.0 INSTALLATION INSTRUCTIONS

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the kettle is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

INSTALLATION

Before installing, verify that the electrical service agrees with the specifications on the

rating plate located on the right side of the tilt console. If the supply and equipment

requirements do not agree, contact your dealer or Crown Food Service Equipment Ltd.

The kettle must be installed in accordance with State and/or local codes. In the USA,

the National Electrical Code, ANSI/NFPA-70 (latest edition). In Canada, the Canadian

Electrical Code, Part 1, CSA Standard C22.1 (latest edition).

1. Select a location to provide drainage for kettle pour path when tilted and for butterfly

valve if so equipped. Allow sufficient rear clearance from wall for access to rear service

panel on hydraulic console.

2. Level unit. With kettle in the upright position, place a carpenter’s level on top of the

kettle and turn the adjustable feet to level kettle side-to-side and front to back. Mark

hole locations on floor through anchoring holes provided in flanged adjustable feet.

3. Remove unit and drill holes where marked and insert expansion shields to

accommodate 5/16" size lag bolts.

4. Reposition unit. Re-level kettle by making necessary adjustments on flanged feet.

5. Bolt down unit and seal with Silastic or equivalent sealing compound. Sealant must be

applied not only to bolt heads but also around flanges making contact with the floor

surface to fulfil NSF requirements. Wipe off excess sealant immediately.

6. Connect water drain line from cooling system to drain or return line.

7. Connect cold water supply line for cooling system as indicated in bottom of

hydraulic console.

8. The relief valve on the kettles(s) must not be adjusted or closed off as they are set to

relieve excess pressure in the kettle(s).

9. Do not make any adjustments to the hydraulic system as it has been set at the factory.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 10 2018-08-08

3.0 INSTALLATION INSTRUCTIONS (Continued)

ELECTRICAL CONNECTIONS

A control box with a power supply equivalent to the electrical rating of the unit should be located

nearby. A waterproof electrical connection for the power supply to the unit must be provided.

Remove the back panel of the hydraulic console and make electrical connection per

wiring diagram located inside the console in plastic bag attached to tank. A waterproof

electrical connection from power supply to rear of hydraulic console must be provided.

Ground kettle to terminal provided in the hydraulic console.

Once proper connections are made, replace the back panel on hydraulic console, turn

power ON and check for proper operation.

SERVICE CONNECTIONS

All internal wiring for the kettle and hydraulic power unit is complete.

Connect water supply for cooling system as shown in Service Connections.

If faucet is provided connect water supply and check for proper operation.

INSTALLATION CODES AND STANDARDS

Your electric mixing kettle must be installed in accordance with:

1. Provincial and local codes, or in the absence of local codes, with C.S.A. C22.1

Canadian Electrical Code, Part 1, or in the U.S.A., the National Electrical Code

ANSI/NFPA-70 (latest edition).

2. ANSI NFPA Standard #96 “Vapour Removal from Cooking Equipment”, (latest

edition), available from the National Fire Protection Association, Batterymarch Park,

Quincy, MA, 02269.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 11 2018-08-08

4.0 OPERATION INSTRUCTIONS

WARNING: The kettle and its parts are hot. Use care when

operating, cleaning and servicing the kettle.

KETTLE

Ensure that the external electrical service to kettle is on.

Check pressure gauge for correct cold kettle reading. Reading should be in the green area

of the gauge indicating 25 - 30 In. Hg (630 - 730 mm Hg) of vacuum. If reading is not low

enough, follow VENTING procedure in Troubleshooting section prior to using kettle.

Place power switch to ON position.

Preheat kettle by placing thermostat knob at ‘10' and wait until TEMPERATURE light goes off.

NOTE: Preheating should not be used when cooking milk and egg food

products which adhere to hot cooking surfaces. These foods should be placed

into kettle before heating has begun.

Add food to be cooked into kettle.

Place thermostat knob at required temperature setting from 1 to 10 coinciding with the

following table:

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 12 2018-08-08

4.0 OPERATION INSTRUCTIONS (Continued)

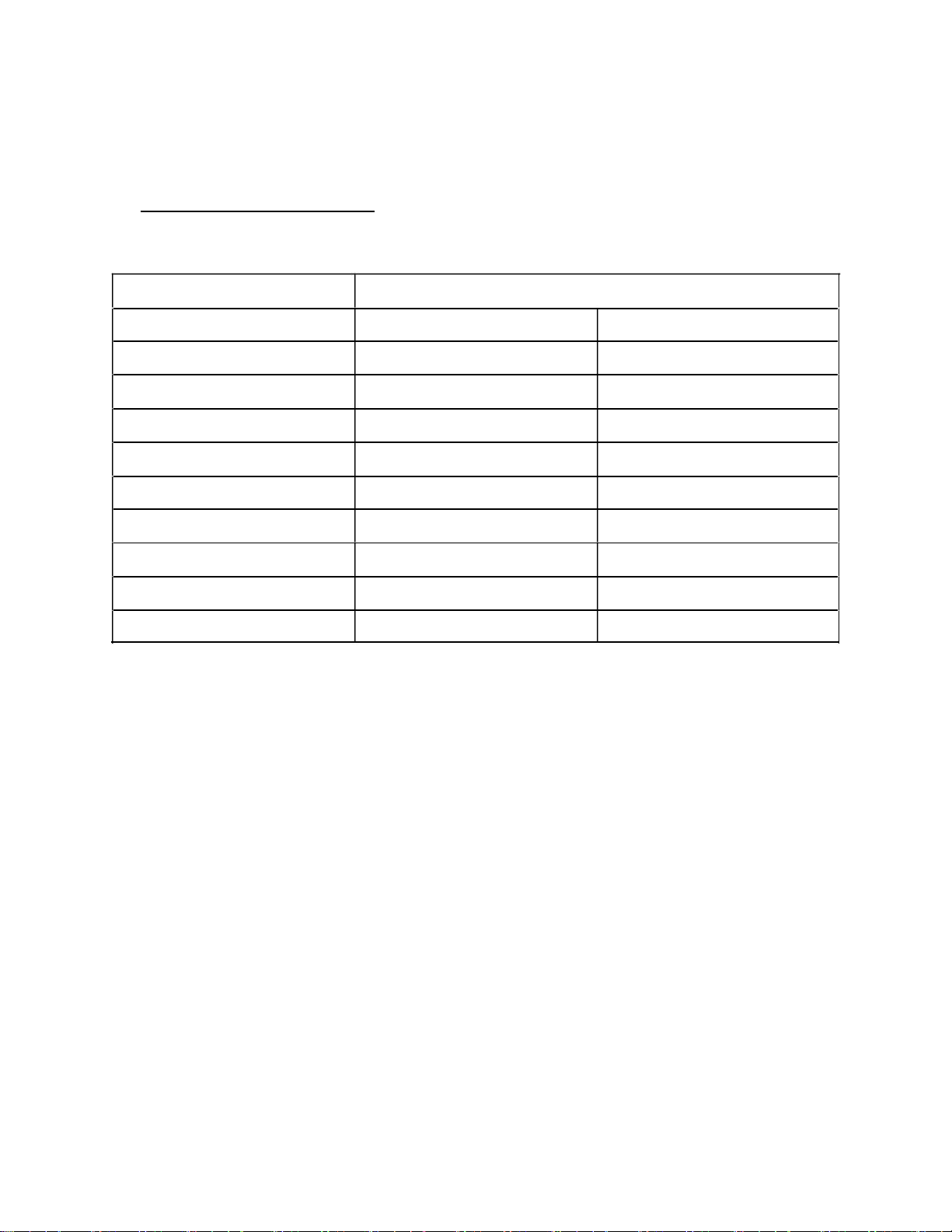

THERMOSTAT SETTING

APPROXIMATE (JACKET) TEMPERATURE

1

90° Fahrenheit

30° Celsius

2

118° Fahrenheit

42° Celsius

3

138° Fahrenheit

54° Celsius

4

158° Fahrenheit

64° Celsius

5

178° Fahrenheit

76° Celsius

6

200° Fahrenheit

88° Celsius

7

220° Fahrenheit

100° Celsius

8

240° Fahrenheit

111° Celsius

9

260° Fahrenheit

122° Celsius

10

280° Fahrenheit

134° Celsius

When cooking is finished set thermostat knob and power switch to OFF position.

Pour finished product from kettle using tilt handle. Be careful to avoid splashing.

Add water to kettle for cleaning purposes.

Wash kettle thoroughly. See CLEANING procedure, next section.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 13 2018-08-08

4.0 OPERATION INSTRUCTIONS (Continued)

OPERATION OF MIXER UNIT

Power to operate the mixer unit is controlled by the “Main Power” switch located on the left

side of the control panel. Ensure that mixer “speed” control is set to the “stop” position.

Place switch in the “ON” position. Set the mixer switch, located beside the main power

switch, to “ON” position. Note that the agitators should not be turning. The speed control

has four basic settings which are: stop, slow, medium and fast. Set the speed control to the

slow position and observe that the agitators begin to turn.

CAUTION: Never place hands inside kettle when agitators are

in motion.

Increasing the speed setting on the control will increase the speed at which the agitators turn.

NOTE: Always start agitators at the slow speed and then gradually increase

to the desired speed to avoid splashing or “throwing” the product over edge

of kettle.

TO RAISE MIXER BRIDGE

To tilt kettle for emptying or to clean agitators, the mixer bridge will tilt hydraulically upward

and manually swing clear of the kettle. To do this, first turn speed control to “STOP” and then

turn mixer switch to “OFF”.

NOTE: Mixer agitator arms must be stopped at 90 degrees to the

mixer bridge before raising the bridge. If the agitator arms do not

stop in this position when speed selector is set to stop, then “jog”

the selector on and off to achieve this position.

Push the “TILT” switch to the “RAISE” position and hold. Bridge will raise to maximum

height. Bridge will stop at any position if the tilt switch is released and will remain in that

position until switch is pushed to either raise or lower. When the bridge is fully raised it

can be manually turned to the side to be clear of the kettle.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 14 2018-08-08

4.0 OPERATION INSTRUCTIONS (Continued)

NOTE: The bridge is equipped with a safety switch which prevents turning

of the agitators, regardless of the mixer switch, or speed control settings.

Agitators will not engage unless the bridge is lowered so that the guide pin

rests fully in the guide pin bracket on the side of the kettle.

OPERATION OF MIXER UNIT

REMOVAL OF AGITATORS

For ease of cleaning, the agitators are removable without tools. To remove, raise bridge

as described above and swing clear of kettle. Grasp shaft of large agitator, push up and

turn to disengage lock pin. Pull straight down on agitator. Remove the small agitator in

the same manner. Soak and wash agitators in warm, soapy water. Never use abrasive

cleansers or scouring pads on the stainless steel surfaces as this will damage the finish

of the stainless steel.

If it is necessary to remove the scraper blades from the large agitator for cleaning purposes,

do so by removing the pin at the end of the mounting shaft and then slide the scraper blades

off of the shaft.

To clean the exterior stainless steel panels of your unit, use a damp soft cloth or soft cloth

and stainless steel cleaner. Never use abrasive cleansers or scouring pads on the

stainless steel surfaces as this will damage the finish of the stainless steel.

INSTALLATION AND OPERATION MANUAL, ELECTRIC SELF GENERATING SINGLE AND

TWIN STEAM MIXER KETTLE, MODELS ELTM-40 TO 100 AND ELTM 40-2 TO 100-2

Part No. 10041R4 15 2018-08-08

5.0 CLEANING INSTRUCTIONS

WARNING: Disconnect the power supply to the appliance before

cleaning or servicing.

WARNING: Never spray water into electric controls or components!

CAUTION: The appliance and its parts are hot. Use care when

operating, cleaning and servicing.

CAUTION: Do not use cleaning agents that are corrosive.

Your kettle should be cleaned immediately after each use or when cooking a different product.

Before cleaning, check that the kettle has cooled enough to touch it.

1. Ensure that power supply is OFF.

2. Pre-rinse inside of kettle thoroughly and drain to remove any food particles.

3. Using a nylon brush, clean kettle with a mild detergent and warm water rinse. Never

use steel wool or scouring powder as it will scratch stainless steel.

4. Tilt kettle fully or open the tangent draw-off valve if one is provided to allow soap and

water solution to drain. Rinse with clean water.

5. Wipe the exterior of kettle with a clean, damp cloth.

WARNING: If you are cleaning a valve that is assembled to a

kettle, be sure the kettle is completely empty of any product.

Loading...

Loading...