Crown Steam DMS-30 Installation Manual

INSTALLATION & OPERATION

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

MANUAL

Direct Steam 0RGXODUPower Tilting or Stationary Kettles

DMT-30 DMT-40 DMT-60

DMS-30 DMS-40 DMS-60

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read

the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

MANUAL 10074R2

WARNING

CROWN FOOD SERVICE EQUIPMENT

Division of Middleby Canada Company Inc.

70 Oakdale Road, Downsview (Toronto) Ontario, Canada, M3N 1V9

Telephone: 919-762-1000 www.crownsteamgroup.com

Printed in Canada

INSTALLATION AND OPERATION MANUAL,

DIRECT STEAM POWER TILTING OR STATIONARY KETTLES, MODELS DMT, DMS

INSTALLATION AND OPERATION

It is recommended that this manual be read thoroughly and that all instructions be followed

carefully.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

WARNING: Improper installation, operation, adjustment, alteration,

service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing, operating or servicing this equipment.

Intended for commercial use only. Not for household use.

This manual should be retained for future reference.

Part No. 10074R2 2 2019-01-21

INSTALLATION AND OPERATION MANUAL,

DIRECT STEAM POWER TILTING OR STATIONARY KETTLES, MODELS DMT, DMS

TABLE OF CONTENTS

DESCRIPTION PAGE

1.0 SERVICE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 INTRODUCTION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.0 BASIC FUNCTIONING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.0 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.0 MAINTENANCE.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.0 HYDRAULIC SYSTEM ADJUSTMENTS (DMT ONLY) .. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.0 CLEANING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

APPENDIX A, MATERIAL SAFETY DATA SHEET .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Part No. 10074R2 3 2019-01-21

INSTALLATION AND OPERATION MANUAL,

DIRECT STEAM POWER TILTING OR STATIONARY KETTLES, MODELS DMT, DMS

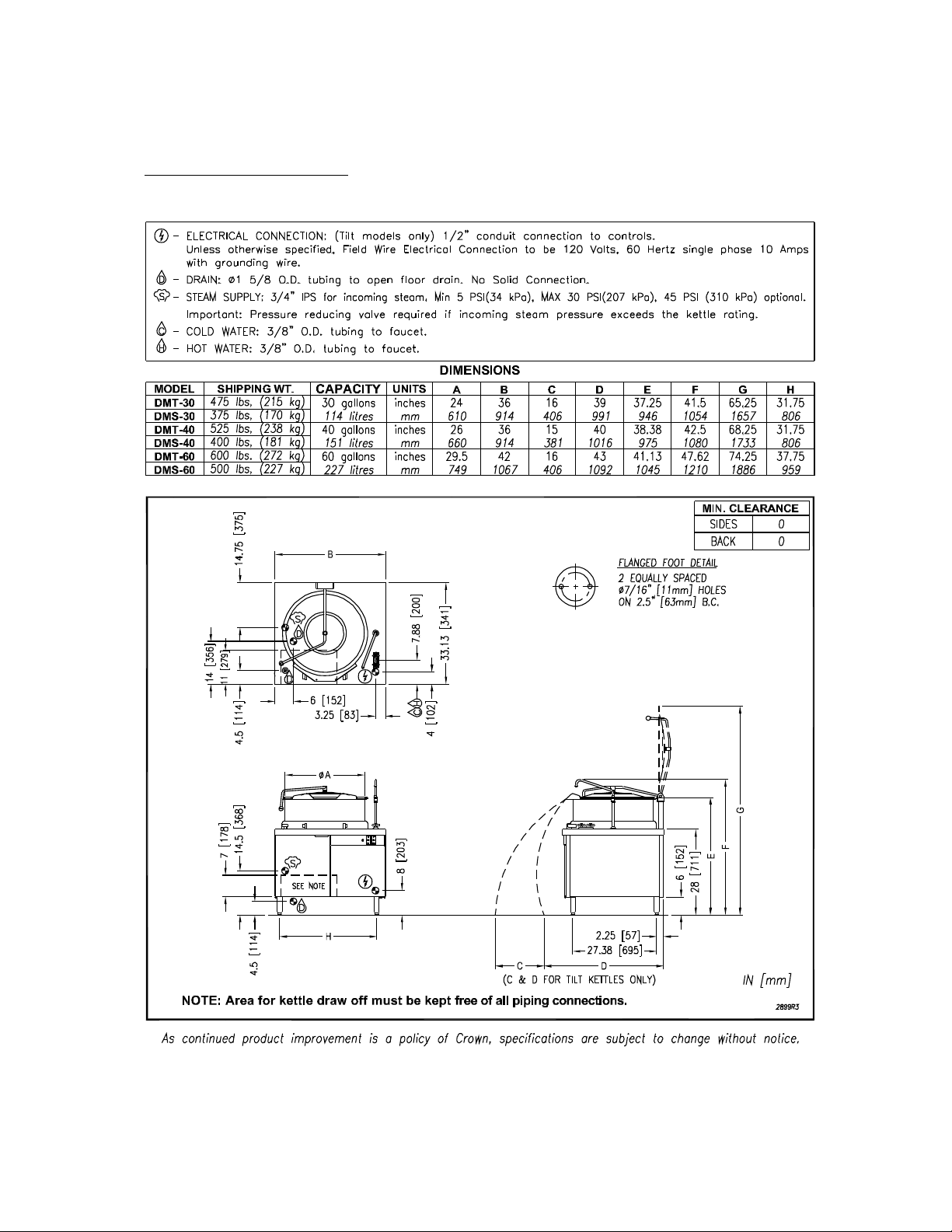

1.0 SERVICE CONNECTIONS

Part No. 10074R2 4 2019-01-21

INSTALLATION AND OPERATION MANUAL,

DIRECT STEAM POWER TILTING OR STATIONARY KETTLES, MODELS DMT, DMS

2.0 INSTALLATION INSTRUCTIONS

WARNING: Electrical and grounding connections must comply with

applicable portions of the National Electrical Codes.

WARNING: Plumbing connections must comply with applicable

health, safety and plumbing codes.

1. Select a location to provide drainage directly below the draw-off valve. Allow sufficient rear

clearance from the wall for the kettle cover to lift upright freely without obstructions. Allow

for clearance to side service panels.

2. Level the unit. Then mark anchoring hole locations through flanged adjustable feet.

3. With hole locations marked, drill holes and insert expansion plugs to accommodate 5/16"

size lag bolts.

4. Reposition the kettle. Check the level again.

5. Bolt the kettle down and seal with a high grade sealing compound. Sealant must be applied

not only to bolt heads but around the flanges and must be making contact with floor surface

to meet N.S.F. requirements. Wipe off excess sealant immediately.

6. Connect the steam line to the kettle (3/4" i.p.s., 5 psi minimum to 30 psi maximum, or 45 psi

with optional high pressure operation).

7. If the incoming steam pressure is greater than the kettle maximum operating pressure, then

a pressure reducing valve (supplied by others) must be installed in the line.

8. Connect hot and cold water supply to the faucet.

9. Connect the kettle condensate return line to a 2" open air gap drain or to a boiler return line.

Each kettle return line must have a suitable steam trap (supplied by others). Boiler return

lines must have a check valve (supplied by others).

Part No. 10074R2 5 2019-01-21

INSTALLATION AND OPERATION MANUAL,

DIRECT STEAM POWER TILTING OR STATIONARY KETTLES, MODELS DMT, DMS

2.0 INSTALLATION INSTRUCTIONS (Continued)

10. A control box with a power supply equivalent to electrical rating of the unit should be

located nearby. A waterproof electrical connection for the power supply to the unit must be

provided (for Power tilting models only).

11. The relief valve on the kettle must not be adjusted or closed off as it is set to relieve excess

pressure in the kettle.

12. If large amounts of water accumulate in the steam line, it will be necessary to install one or

more ball float traps (supplied by others) in the line to eliminate the water.

13. A steam line pressure gauge (supplied by others) is also recommended to determine the

actual amount of steam coming to the kettle.

14. Turn unit on when electrically connected, then check for proper operation.

Part No. 10074R2 6 2019-01-21

INSTALLATION AND OPERATION MANUAL,

DIRECT STEAM POWER TILTING OR STATIONARY KETTLES, MODELS DMT, DMS

3.0 INTRODUCTION

DESCRIPTION

The CROWN DMS and DMT kettles are direct steam models mounted in a modular cabinet

base. The DMS is a modular stationary model supplied with a tangent draw-off valve for food

product removal.

The DMT is a direct steam modular tilting model. It has a hydraulic pump and cylinder to tilt the

kettle to any angle between zero and ninety degrees for complete emptying of food products.

Tilting models include a pan carrier that holds a 12" x 20" pan. (Pan not supplied.)

Both of these units employ kettles which are direct steam operated pressure vessels with a

double wall stainless steel construction forming a steam chamber (jacket) around the lower two

thirds of the kettle. These kettles are furnished with a steam control valve and a hot and cold

water fill faucet mounted on the stainless steel counter top. Every kettle has a pressure relief

valve. Access to the inner cabinet area for installation or service is through the removable side

panels or the doors on the front of the unit.

The kettle bowl is the container for the food product which ideally should be a liquid or semiliquid for complete contact with the bowl surface to fully absorb the heat transmitted through the

surface from the steam in the kettle jacket.

These kettles are intended to be permanently floor mounted with adjustable flanged feet.

Part No. 10074R2 7 2019-01-21

Loading...

Loading...