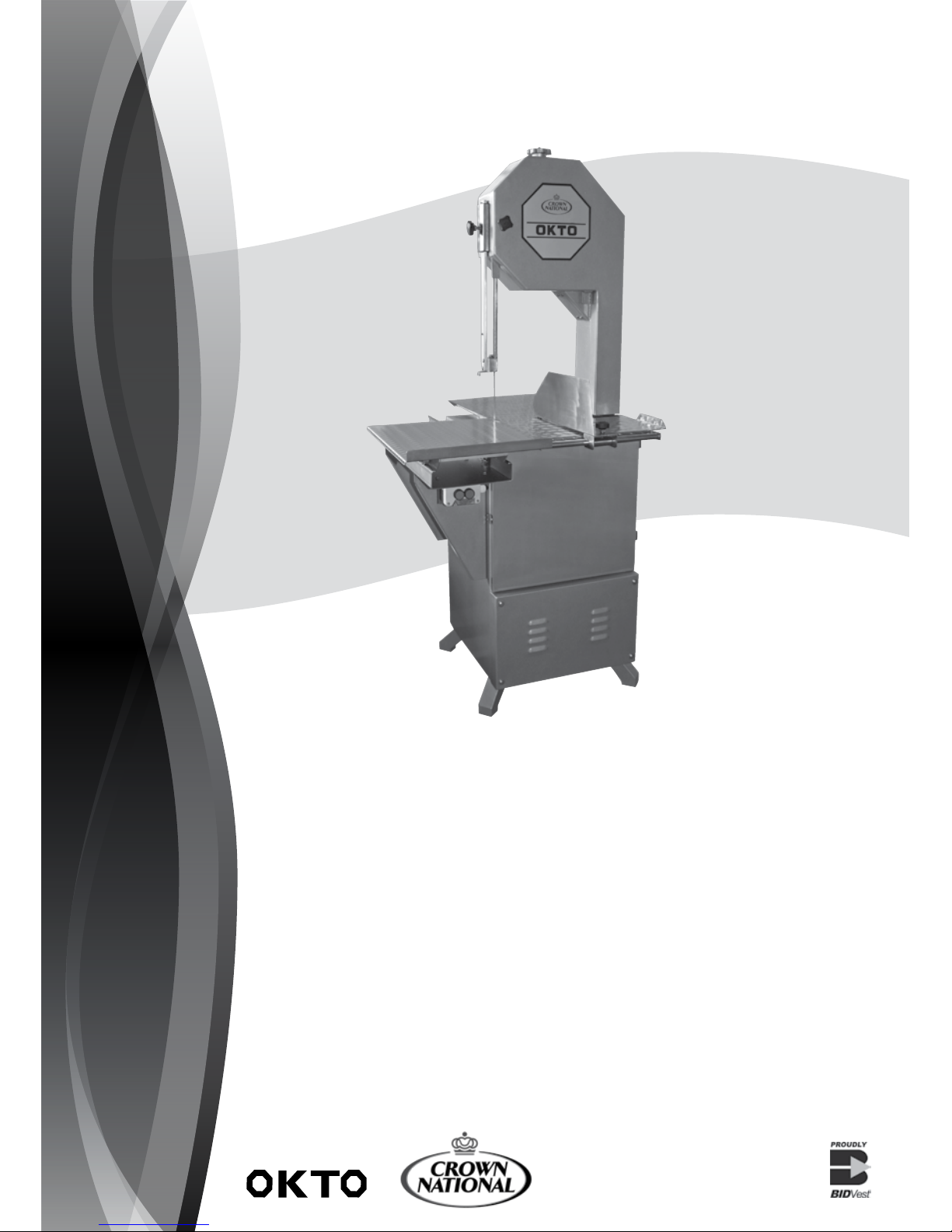

Crown National OKTO MK7 User Manual

Index:

General Data 2

Owner’s Responsibility 3

Authorised Crown National

Distributors 3

Parts Ordering / Service Information 4

Prior to Installation of Equipment 4

Cleaning Process 4

Trouble Shooting 5

Installation 6

Wiring Diagrams 7

Spares 8

Preventative Maintenance 11

Lubrication 12

Safety 12

OKTO BAND SAW

MODEL MK7

[ 2 ]

OKTO BAND SAW MODEL MK7

GENERAL DATA:

MANUFACTURER: Reg No. 1954/002040/07

Vulcan Catering Equipment (Pty) Ltd

P O Box 60188 5 Newclare Road

Langlaagte 2102 Industria 2093

Johannesburg Johannesburg

South Africa South Africa

Web Site: www.vulcan.co.za

MODEL/SERIAL NUMBER: 302/11/0073 ONWARDS

ELECTRICAL LOAD: Three Phase

1.5kW

ELECTRICAL SUPPLY: 400 Volts

STARTER : Remote On/Off push button with O/L Relay

RELAYBLADE: 2870 X 15.875 X 2 Teeth per cm

(113” X 5/8 X 5 T.P.I)

PRODUCT DESCRIPTION:

The Band Saws are of a robust construction with heavy duty fabricated doors, heads and

bases. The base is provided with 4 levelling feet. Saw wheels are made of cast iron, running

on heavy duty bearings with scrapers on both wheels.

The machine has the following additional features:

Tensioned Scraper Assemblies

These are designed to keep the blade and wheels free of debris and support the blade while

cutting. These assemblies are easily removable for cleaning.

Easy slide table

This system ensures a smooth and precise moving table, reducing effort and increasing

productivity.

[ 3 ]

OKTO BAND SAW MODEL MK7

REV5-11-2011 / VFM28

Blade Tensioning System

The spring loaded tensioning system is incorporated into the top wheel assembly with an eye

level tension indicator. It assures proper blade tension for a clean cut and lasting blade life.

Accessories supplied

2 Band Saw blades

1 Bone dust box

Safety Feature

Doors must remain closed at all times while the Band Saw is in operation. The upper and

lower wheel door / covers are tted with Limit Switches. If the motor is running and either of

the doors are opened the motor will cut out as a safety precaution.

OWNERS RESPONSIBILITY:

It is the owners responsibility to:

• To ensure that the Band Saw unit is regularly and properly maintained.

• Ensure that all safety devices and warning signs are in their original location.

• The unit is not intended for use by persons (including children) with reduced physical

sensory or mental capabilities, or lack of experience and knowledge, unless overseen

and supervised by trained personnel.

• Replace warning signs or manuals when necessary.

Contact an authorised Crown National Distributor.

AUTHORISED CROWN NATIONAL DISTRIBUTORS:

J

ohannesburg Branch Ofce (011) 201 - 9100

Bloemfontein Branch Ofce (051) 430 - 0240

Cape Town Branch Ofce (021) 527 - 6100

Durban Branch Ofce (031) 263 - 0533

East London Branch Ofce (043) 722 - 9730

Nelspruit Branch Ofce (013) 752 - 2040

Pietersburg Branch Ofce (015) 293 - 1610

Port Elizabeth Branch Ofce (041) 484 - 3221

Pretoria Branch Ofce (012) 335 - 4821

[ 4 ]

OKTO BAND SAW MODEL MK7

PARTS ORDERING / SERVICE INFORMATION:

Parts/ spares orders must be placed directly with your local branch / distributor.

To help speed up your order, we require the following information:

1. Model / Serial Number

2. Voltage (400V)

3. Item Part Number

4. Quantity Required

The serial number data plate is situated at the back rear side of the unit.

Service information may be obtained by calling your local branch / distributor.

When calling, please have the following information available:

1. Model / Serial Number

2. Voltage (400V)

3. Nature of Service Problem

PRIOR TO THE INSTALLATION OF EQUIPMENT:

• Read the operating manual to make sure that the installation meets all the

requirements as specied within the Operating and Installation manual provided

with your unit.

BEFORE CLEANING THE MACHINE ISOLATE THE UNIT FROM

THE MAINS POWER SUPPLY.

CLEANING:

1. Use a soft sponge and warm soapy water when cleaning.

2. Care must be taken in cleaning not to damage machined surfaces.

3. Wipe surface with soapy damp cloth.

4. Never use soda, steel wool, green 3M scouring pad or any other harsh abrasive to

clean the unit.

5. Do not spray the unit with a high pressure hose or spray gun.

6. To ensure trouble free operation, the following parts must be cleaned.

Loading...

Loading...