Page 1

C

Specifications

WP 2300 Series

Walkie Pallet

Truck

WP 2300

Series

Page 2

17

BRAKE

DRIVE

BRAKE

OVERRIDE

BRAKE

5.1"

[

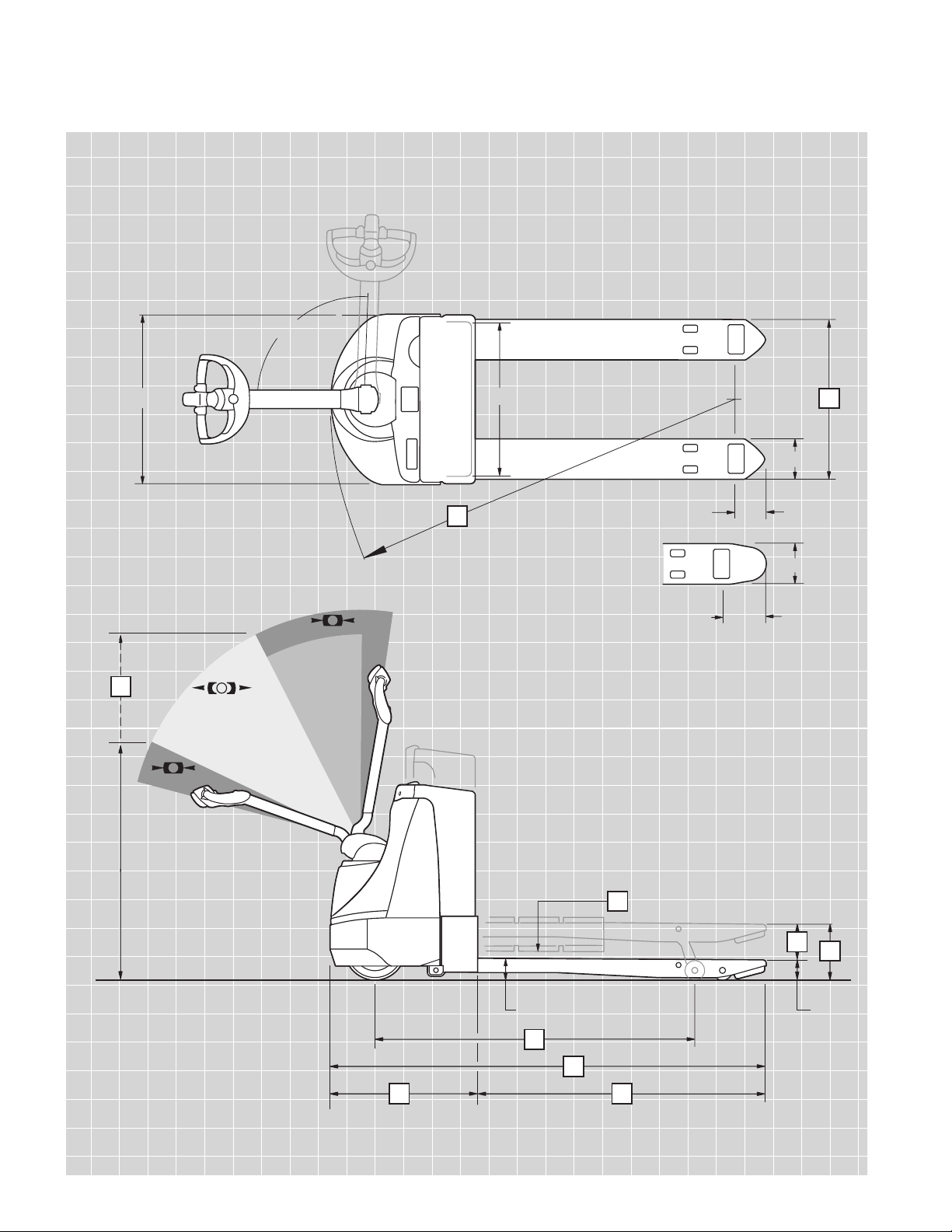

WP 2335 & WP 2345

]

11

12

13

10

3.5"

14

9

8

27.9"

16

93º

25.8"

6.7"

6.7"

7. 2 "

[

WP2330 & WP2340

]

15

3.25"

C

WP 2300 Series

Walkie Pallet Truck

Page 3

WP 2300 Series WP 2330 WP 2335 WP 2340 WP 2345

Nominal Fork Length in 36/42/48 48 36/42/48 48

11 Actual Fork Length in 35.6/41.7/47.6 45.5 35.6/41.7/47.6 45.5

12 Overall Length in 58.8/65.0/70.9 67.7 60.0/66.1/72.0 69.9

13 Wheelbase Lowered in 44.2/50.3/56.2 55.2 45.4/51.5/57.4 56.4

Raised in 39.7/45.8/51.7 52.1 40.8/46.9/52.8 53.3

14 Grade Clearance* % 52.7/44.5/38.7 31.6 50.9/43.2/37.8 30.6

Gradeability Loaded % 10 10 10 10

15 Turning Radius in 51.6/57.7/63.6 62.6 52.8/58.9/64.8 63.8

7 Truck Weight** Less Battery lb 712 712 712 712

WP 2300 Series

Specifications

1 Manufacturer Crown Equipment Corporation

2 Model WP 2330 WP 2335 WP 2340 WP 2345

3 Load Capacity lb 4500 4500 4500 4500

4 Power Electric 24 Volts 24 Volts 24 Volts 24 Volts

5 Operator Type Stand-up Walkie Walkie Walkie Walkie

8 Lift Height in 9.25 8.5 9.25 8.5

9 Lift in 6 5.2 6 5.2

Battery Compartment Length in 7.9 7.9 9.1 9.1

10 Head Length in 23.2 23.2 24.4 24.4

16 Outside Fork Spread in 21.3/26.4 21.3/26.4 21.3/26.4 21.3/26.4

17 Tiller Arm Height

in Drive Position

Min/Max in 31.1 / 47.5

18 Travel Speed Empty/Loaded mph 3.7 / 3.4

General Info

Dimensions

Forks

* Determined with forks raised

**With 48" forks

WP 2300 Series

Technical Information

Standard Equipment

1. 24-volt fused electrical system

2. MOSFET transistorized

traction control system

3. Separately excited drive motor

(SEM)

4. Electric brake

5. Brake override

6. Anti-roll down

7. Regenerative motor braking

8. Heavy-duty drive unit

9. Drive unit enclosed in high

ductile strength steel frame

10. Stamped steel power unit

cover

11. Safety reversing button

12. Roll formed forks with pull rod

height adjustment

13. 175 amp connector with

quick disconnect

14. Color-coded wiring

15. Two pre-programmed

performance levels

16. 10" x 4" wide rubber drive tire

17. 3.25" x 4.5" wide Vulkollan

load wheels with debris guard

18. Low overall height for fork and

load visibility

19. Paper retainer on battery

cover (WP 2330 and WP 2335)

20. Horn

21. Key switch

Optional Equipment

1. Casters

2. Hour meter

3. Discharge indicator

4. Curtis Unigage includes hour

meter, discharge indicator

with interrupt

5. Handset analyzer for calibration or fault analyzing

6. 30 amp fully automatic

charger

7. 48", 60" or 72" high load

backrest

8. Maintenance free or swingout battery package

9. Freezer/corrosion

conditioning

10. Polyurethane drive tire

11. Non-marking rubber tire

12. Siped rubber drive tire

13. Keyless on/off toggle switch

in lieu of key switch

14. Drive/tow switch

15. Battery straps

Battery and Charger

Two battery compartments are

available to suit your duty cycle.

The 7.9" battery compartment

(WP 2330/WP 2335) is designed

for the battery package. Battery

package options are as follows:

• Maintenance-free battery

pack, four 6-volt batteries

at 195 amp hour

• Wet-cell swing-out battery

pack, four 6-volt batteries

at 160 amp hour

• Dry-cell swing-out battery

pack, four 6-volt batteries

at 160 amp hour

The optional nylon battery straps

secure the batteries to the stand

to minimize vibration in rough

floor or over dock applications,

reducing potential damage to

the batteries or the stand.

The 9.1" battery compartment

(WP 2340/WP 2345) will accept

an industrial storage battery up

to 300 amp hour capacity.

A built-in 30 amp charger is

available as an option on all

models. This premium fan

cooled solid-state charger is

durable and efficient. It has an

advanced memory feature to

allow for opportunity charging.

The charger can be set for either

maintenance-free, wet-cell or

industrial batteries. An extension

cord is included with any truck

equipped with the built-in

battery charger.

Operator Controls

The WP’s robust X10™ control

handle is designed to allow for

an optimum turning radius with

low steer effort. All control buttons can be operated with either

hand and can be accessed with

minimum hand and wrist movement. The horn switches are

integrated in the hand grips.

An ergonomic forward/reverse

thumb wheel allows for precise

maneuvering. Depending on the

conditions, maximum travel

speed can be reduced via the

rabbit/turtle switch. The parking

brake is activated at the lower

and upper end of the tiller

position.

WP 2300 Brake Override

Function

For easy operation in tight areas

a brake override function is

incorporated which allows the

WP 2300 to be driven safely

and precisely at creep speed

with the handle in a near vertical

position. The control handle

remains within the profile of the

power unit at all times, even

when performing 90° turn.

When the forward/reverse

thumb wheel is in neutral the

parking brake is immediately

activated thus preventing

unexpected movement.

Page 4

WP 2300 Series

Technical Information

The standard fork design has 6"

of lift with a conventional fork tip

and comes in 36", 42" and 48"

lengths. Fork spreads are 22"

or 27" wide.

The forks are roll-formed for

maximum strength and the pull

rods incorporate fork tip adjustment to aid in pallet entry/exit.

All pivot points have Teflonimpregnated, bronze, steelbacked bushings. In addition,

each pivot point is provided with

a grease fitting to flush out dirt

and moisture, reducing downtime and providing increased

service life.

Serviceability

One piece steel power unit

cover is removed easily for

access to all major components.

Fork adjustment is done easily

using the threaded pull rod.

Brake rotor and disc inspection

and replacement are easy.

Drive motor brush access is

excellent.

Color-coded wiring speeds

troubleshooting and the Crown

transistor uses visible LED

flashes

for fault communication.

Optional

plug-in analyzer for

servicing and programming

capability.

Control handle switch cap is

easily removed to expose

components.

InfoPoint™ allows your technician to troubleshoot without

complicated schematics, wiring

diagrams or cumbersome service manuals for over 95 percent

of your repairs. Simplicity is

complete with InfoPoint Quick

Reference Guide, color component maps and “Information

nuggets” located on the truck.

Wheels and Tires

Drive tire - solid rubber

10" dia x 4" wide x 6.5" hub

Load wheels - Vulkollan

3.25" dia x 4.5" wide

Optional casters are

3.5" dia x 2" wide

Pallet Planning Guide

On WP 2300 models the load

wheel will drop into the second

opening of the pallet. When “A”

dimension equals nominal fork

length, “C” dimension is 6" maximum and “B” is 14" minimum.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with audible

travel alarms and flashing lights

include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Other Options Available

Contact your local Crown dealer.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and the

conditions of the operating area.

Crown products and specifications are subject to change

without notice.

Performance

The WP 2300 benefits from

Crown’s design and engineering

excellence.

The transistor control module

works in conjunction with a new

separately excited (SEM) drive

motor to provide excellent

acceleration and top travel

speed loaded or empty. Good

acceleration enhances efficient

pallet entry and exit to increase

productivity. Transistor control is

programmable for specific tasks

or operator skill levels.

Smooth travel and lift combine

with excellent controls to reduce

product damage and increase

productivity.

Electrical System

A heavy-duty 24-volt fused

electrical system provides good

travel and lift speeds.

Separately excited motor control

eliminates directional contactors

reducing maintenance and

downtime.

The transistor control is sealed

from dirt, dust and moisture for

trouble-free operation. Transistor

control features include overtemperature protection, polarity

protection, self-test and visible

diagnostics.

Regenerative motor braking is

activated under a downhill condition, during plugging or when

the directional control is returned

to neutral. “Regen” reduces heat

build-up and extends motor

brush life.

An anti-roll down feature will

apply the brakes if the truck rolls

without a travel command.

175-amp battery connector with

standard disconnect handle

.

Hydraulic System

Heavy-duty 4" diameter hydraulic

motor with integral pump and

reservoir for maximum efficiency

and durability.

Twin, hard-chromed lift cylinders

provide improved load stability.

Additionally, smaller twin lift

cylinders reduce truck length,

improving maneuverability.

Hydraulic lines, fittings and elbow

connections are minimized to

reduce heat from hydraulic oil

flow and improve efficiency.

At full lift, a top of stroke cutout

switch shuts the lift motor off,

which saves energy and prevents

motor overheating.

The totally enclosed system is

protected by pressure, suction

and return line filtration. A convenient fill plug allows for easy fluid

level checks.

Drive Unit and Brakes

Heavy-duty gear box with spur

gears for low noise emission.

Drive unit is equipped with an

electromagnetic disc brake that

is spring applied and electrically

released. Brake is activated by

the control handle position.

Brake rotor and disc are easily

accessed for inspection and

replacement. Regenerative motor

braking assists brake effort and

improves component life.

Drive unit mounts in truck frame

with a permanently lubricated,

twin conical roller bearing that

disperses load forces evenly,

reducing maintenance and

downtime.

Forks

The WP 2300 has two fork styles

to suit the application.

The Crown “profiled fork” offers

tapered fork tips with shorter

lengths and wheelbase to

improve the turning radius

and facilitate load handling in

tighter areas.

C

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Te l 419-629-2311

Fax 419-629-3796

crown.com

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown, the Momentum symbol, InfoPoint and The X10

Handle are trademarks of Crown Equipment Corporation.

Copyright 2004 Crown Equipment Corporation

SF14424 6/04

Printed in U.S.A.

A

CC

BB

First

Opening

Second

Opening

Loading...

Loading...