Page 1

C

Specifications

WE 2300 Series

WS 2300 Series

Walkie Stackers

WE/WS 2300

Series

Page 2

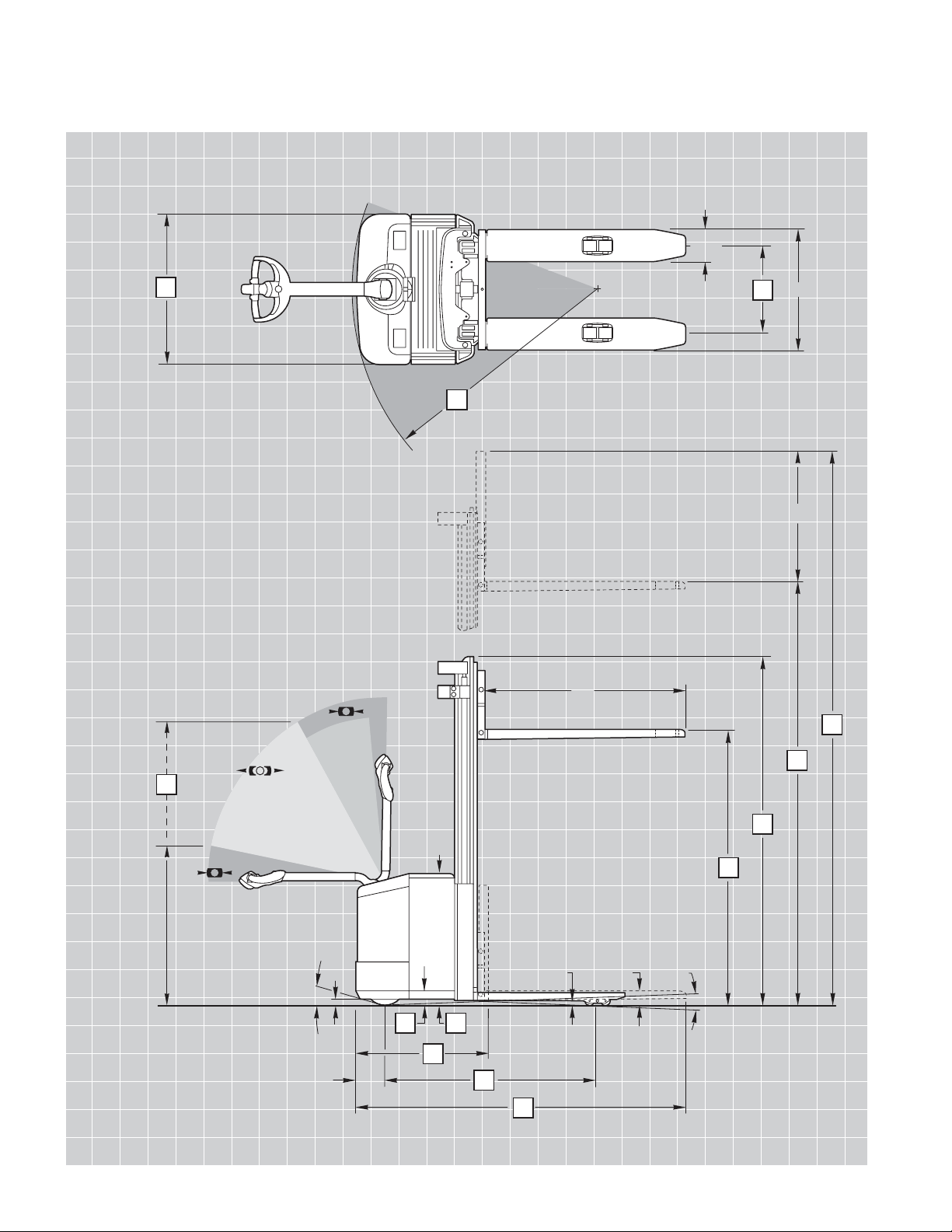

21

3.5"

1.2"

24

7

6.6"

18

20

19

28.7%

10.5%

1.4"

27"

7.5"

38

34

42"

32

27

31

23

17

47.3"

BRAKE

DRIVE

BRAKE

OVERRIDE

BRAKE

C

WE 2300 Series

Walkie Stackers

Page 3

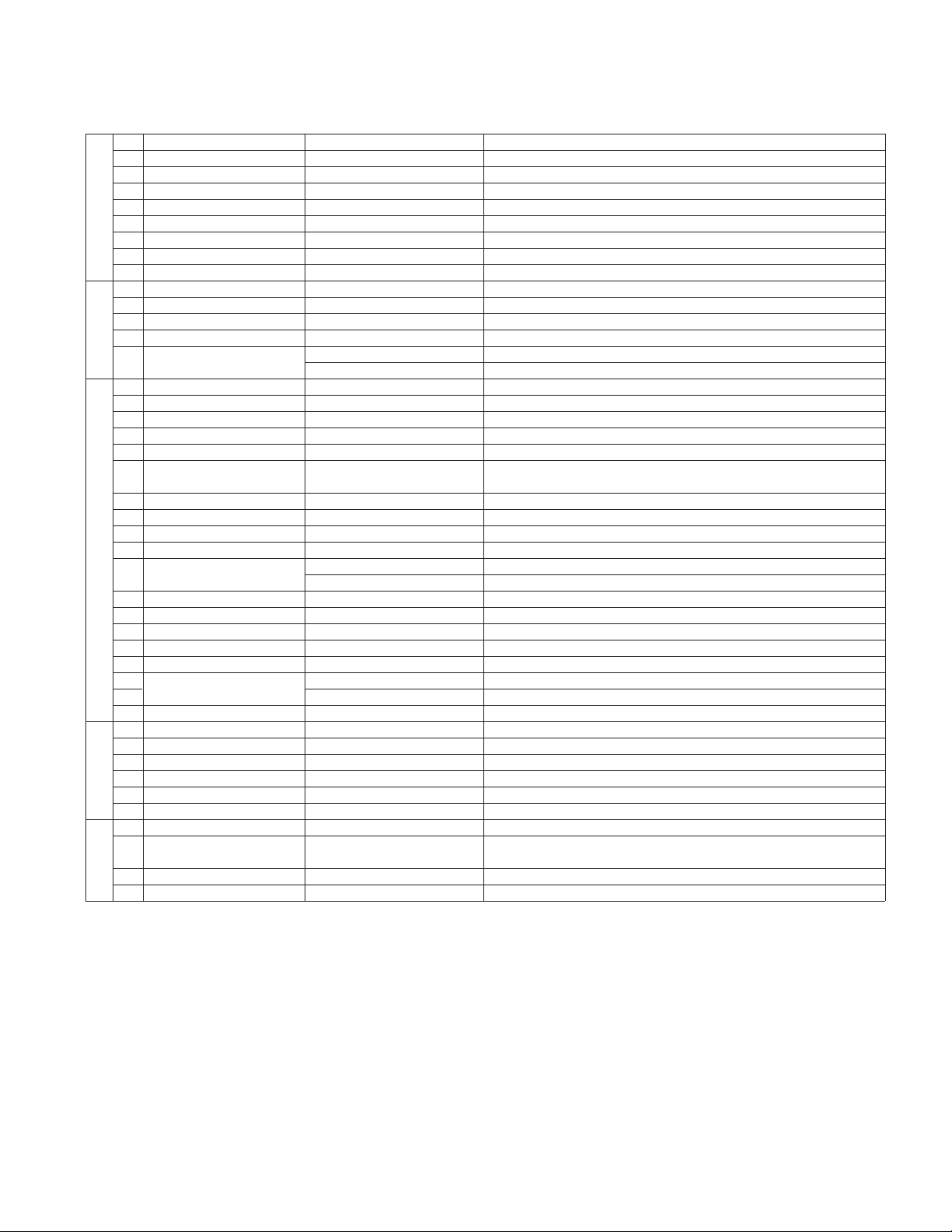

1 Manufacturer Crown Equipment Corporation

2 Model WE 2300-25 WE 2300-30

Mast Type TL TF

3 Power Electric

4 Operator Type Walkie

5 Load Capacity Max lb (kg) 2500 (1135) 3000** (1361**)

6 Load Center in (mm) 24 (600) 24 (600)

7 Wheelbase in (mm) 47 (1206) 50 (1280)

8 Weight Less Battery lb (kg) 1907 (865) 2072 (940)

13 Wheel Size Front (d x w) Vulkollan in (mm) 9.8 x 3 (250 x 75)

14 Wheel Size Rear (d x w) Vulkollan in (mm) 3.2 x 4 (82 x 100) 3.2 x 2.3 (82 x 60)

15 Additional Wheels Caster Wheel (d x w) in (mm) 5.9 x 2 (150 x 50)

16 Wheels (x=driven) Front/Rear 1x, 1/2 1x, 1/4

17 Track Width Front in (mm) 23 (587)

Rear in (mm) 15 (382)

18 Lift Height in (mm) 130 (3300) 130 (3300)

19 Free Lift w/o Load Backrest lb (kg) 6 (150) 68 (1720)

20 Collapsed Height in (mm) 84 (2130) 84 (2130)

21 Extended Height* w/o Load Backrest in (mm) 147 (3730) 147 (3730)

22 Load Backrest Size in (mm) 47.3 (1202) H x 32.7 (832) W

23

Tiller Arm Height

in Drive Position

Min/Max in (mm) 31 (780) / 48 (1220)

24 Battery Comp’t Floor Ht in (mm) 3.4 (85)

25 Lowered Fork Height in (mm) 3.5 (90)

27 Power Unit Height in (mm) 29.75 (756)

28 Fork Lengths in (mm) 42 (1067)

29 Fork Dimensions Thickness in (mm) 2 (50)

Width in (mm) 7.5 (190)

30 Width Across Forks in (mm) 27 (686)

31 Headlength in (mm) 29 (730) 30 (753)

32 Overall Length at fork length 42" in (mm) 71 (1803) 72 (1829)

34 Overall Width in (mm) 33.5 (850)

35 Fork Carriage Width in (mm) 27 (680)

36 Ground Clearance w/Load Below Mast in (mm) 1.4 (35)

37 Center Wheelbase in (mm) 1.2 (30)

38 Turning Radius in (mm) 55 (1400) 58 (1475)

40 Travel Speed

w/wo Load

mph (km/h) 3.3 / 3.7 (5.3 / 6.0)

41 Lift Speed

w/wo Load

fpm (m/s) 31 / 51 (.16 / .26) 28 / 43 (.14 / .22)

42 Lowering Speed

w/wo Load

fpm (m/s) 71 / 43 (.36 / .22) 71 / 43 (.36 / .22)

43 Gradeability

w/wo Load, 30 min Rating

% 3 / 9 3 / 8

44 Maximum Gradeability

w/wo Load, 5 min Rating

% 9 / 17 8 / 17

45 Service Brake Electric

46 Maximum Battery Box L x W x H in (mm) 8.5 x 32.5 x 24.7 (216 x 827 x 627)

47 Battery Voltage (Nominal

Capacity 6 Hour Rating)

V/Ah 24 / 195

48 Type of Controller Drive Transistor

49 Battery Weight lb (kg) 644-712 (293-323)

WE 2300 Series

Specifications

General Information

Tires

Dimensions

PerformanceBattery

* Subtract 32" (810 mm) from free lift; add 32" (810 mm) to extended height if optional 47.3" (1202 mm) high load backrest is required.

** Up to 110" (2800 mm), 2910 lb up to 130" (3300 mm)

English conversions are approximations. Metric conversions should be done to find true values.

Page 4

WE 2300 Series

Technical Information

Standard Equipment

1. Four-point suspension with

centrally located handle

2. Traction speed control

(MOSFET)

3. Variable traction speed

forward and reverse

4. One-speed lift, two-speed

lower

5. Electric brake

6. Brake override

7. Key switch

8. Horn

9. Compound drive and lift

motor

10.

Emergency power

disconnect

11. Battery connector SB-175

12. Reversing button

13. Hour meter

14. Vulkollan tires

15. 27" x 42" fork configuration

Optional Equipment

1. Pivoting tandem load

wheels 3.2" x 2.3"

(WE 2300-25 only)

2. Battery compartment rollers

3. Battery discharge indicator

with low battery lift interrupt

and hour meter

4.

Freezer corrosion conditioning,

continuous -30° C / -22° F,

intermittent - 40° C / - 40° F

5. Load backrest

6. Maintenance-free battery

pack

Electrical System

24-volt electrical system

incorporating:

1. Transistor “MOSFET”

controller, microprocessor

controlled with on-board

service diagnostic capability.

This transistor controller

provides many benefits

such

as maximum energy

efficiency,

reduced

maintenance and infinite

speed control capability.

Fault Monitoring System:

Through a fault flash code

signaled by an LED, 17

detectable faults can be

recognized. Using an optional

hand set, faults can be displayed

digitally. Controller settings are

programmable. Functional

tests of components are also

possible. Incorporates storage

register for fault history that can

be interrogated by service

personnel.

2. Heavy-duty drive and lift

motors provide high reliability

and efficiency.

3. Electric panel with swing-out

feature, allows good accessibility and serviceability to

the distribution panel and all

other electrical components.

4. Emergency disconnect is

easily accessible from all

operating positions.

5.

Solid-state switching ensures

high component reliability.

6. Control and power circuits

are fused. Distribution panel

and controller are shortcircuit protected.

7. All wiring is color coded.

Hydraulic System

1. Heavy-duty compound

motor and gear pump

selected for optimum lift

performance and low noise.

2. Control block houses

proportional pressure

compensated flow control

valve, check valve, relief

valve and direction control

valve to select lower

function. The proportional

valve ensures smooth load

handling. Single speed lift

and two speed lowering is

available to the operator.

3. Cylinder rods are hard-plated

chrome with polyurethane

seals.

4. Relief valve tuned to capacity

protects all components in

the hydraulic system.

Drive Unit/Brake

Heavy-duty gear box with

helical spur input gear for low

noise emission. Drive unit is

equipped with an electromagnetic brake, spring applied,

electrically released. The brake

is activated by the control

handle position.

Frame/Pivoting Carriage

Frame and Articulated Truck

Suspension system (ATS) are

of a rugged design ensuring

minimum deflections during

operation. Modular pivoting

carriage design ensures excellent

traction, optimum truck stability

and minimum steering effort in

all load conditions. Easy serviceability

of all components in

power unit and simple adjustment to compensate for tire

wear is possible. Single swingout door design allows easy

access to all components.

Mast

High visibility two- and threestage mast design features

nested I-beams and canted

rollers. Lift cylinders are positioned in outer I-beam profile for

best visibility through mast and

clear view onto fork tips during

load handling. Standard

equipment includes full-free lift

for two- and three-stage mast.

Mast cushioning between

stages ensures smooth

operation. Heavy-duty mast

and chain rollers are sealed

and lubricated for life. Easy

access to carriage rollers.

Operator Controls

The robust X10™ control

handle is designed to allow for

an optimum turning radius with

low steer effort. All control

buttons can be operated with

either hand and can be

accessed with minimum hand

and wrist movement. The horn

buttons are integrated in the

hand grips. An ergonomic

forward/reverse thumb wheel

allows for precise maneuvering.

Depending on conditions and

operator experience, maximum

travel speed can be reduced

via the rabbit/turtle switch.

Exclusive brake override allows

slow speed travel with the

handle near vertical. This feature

improves maneuverability in

tight areas.

Battery

Removable side panels and top

hinged cover allow easy access

to battery, as well as battery

change in three directions,

either side or top lift out.

Compartment rollers are fitted

as an option.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with audible

travel alarms and flashing lights

include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and

the conditions of the operating

area. Crown products and

specifications are subject to

change without notice.

Page 5

19

20

18

21

4"

1.6"

6.6"

7

39

1.4"

17.6%

28.7%

32

17 343330

24

28

30

34

27

31

38

35

47.3"

23

BRAKE

DRIVE

BRAKE

OVERRIDE

BRAKE

C

WS 2300 Series

Walkie Stackers

Page 6

WS 2300 Series

Specifications

1 Manufacturer Crown Equipment Corporation

2 Model WS 2300-40 WS 2300-40

Mast Type TL/TF TT

3 Power Electric

4 Operator Type Walkie

5 Load Capacity Max lb (kg) 4000 (1815) 4000* (1815*)

6 Load Center in (mm) 24 (600) 24 (600)

7 Wheelbase in (mm) 51 (1300) 51 (1300)

8 Weight Less Battery lb (kg) 2072 (940) 2282 (1035)

13 Wheel Size Front (d x w) Vulkollan in (mm) 9.8 x 3 (250 x 75)

14 Wheel Size Rear (d x w) Vulkollan in (mm) 3.3 x 2.8 (85 x 70)

15 Additional Wheels Caster Wheel (d x w) in (mm) 5.9 x 2 (150 x 50)

16 Wheels (x=driven) Front/Rear 1x, 1/4

17 Track Width Front in (mm) 23 (587)

Rear in (mm) 46, 54 (1167, 1370)

18 Lift Height in (mm) 128 (3250) 160 (4050)

19 Free Lift ** TL lb (kg) 4 (100) na

w/o Load Backrest

TF/TT** lb (kg) 62 (1575) 51 (1305)

20 Collapsed Height in (mm) 84 (2130) 73 (1860)

21 Extended Height* w/o Load Backrest in (mm) 151 (3825) 182 (4625)

Outrigger Height in (mm) 4 (100)

22 Lowered Fork Height in (mm) 1.6 (40)

23

Tiller Arm Height

in Drive Position

Min/Max in (mm) 31 (780) / 48 (1220)

24 Battery Comp’t Floor Ht in (mm) 3.4 (85)

27 Power Unit Height in (mm) 29.75 (756)

28 Fork Lengths in (mm) 30, 36, 42, 45, 48 (760, 912, 1067, 1167, 1219)

29 Fork Dimensions Thickness in (mm) 1.6 (40)

Width in (mm) 4 (100)

30 Width Across Forks Adjustable Min/Max in (mm) 10 (253) / 31.1 (790)

31 Headlength in (mm) 31 (783) 32 (808)

32 Overall Length at fork length 42" in (mm) 73 (1850) 74 (1875)

33 Inside Straddle in (mm) 42, 50 (1067, 1270)

34 Overall Width Front in (mm) 33 (850)

Rear in (mm) 50, 58 (1267, 1470)

35 Fork Carriage Width in (mm) 32.5 (825)

36 Ground Clearance w/Load Below Mast in (mm) 1.4 (35)

37 Center Wheelbase in (mm) 1.6 (40)

38 Turning Radius in (mm) 59 (1490)

39 Length Over Outrigger in (mm) 60 (1535)

40 Travel Speed

w/wo Load

mph (km/h) 3.3 / 3.7 (5.3 / 6.0)

41 Lift Speed

w/wo Load

fpm (m/s) 26 / 43 (.13 / .22)

42 Lowering Speed

w/wo Load

fpm (m/s) 71 / 39 (.36 / .20)

43 Gradeability

w/wo Load, 30 min Rating

%2 / 8

44 Maximum Gradeability

w/wo Load, 5 min Rating

% 7 / 17

45 Service Brake Electric

46 Maximum Battery Box L x W x H in (mm) 8.5 x 32.5 x 24.7 (216 x 827 x 627)

47 Battery Voltage (Nominal

Capacity 6 Hour Rating)

V/Ah 24 / 195

48 Type of Controller Drive Transistor

49 Battery Weight lb (kg) 644-712 (293-323)

General Information

Tires

Dimensions

Performance

Battery

* Up to 144" (3658 mm), 3548 lb up to 160" (4050 mm)

** Subtract 26" (665 mm) (WS 2300-40 TF/TT) from free lift;

Add 26" (665 mm) (WS 2300-40 TL/TF/TT) to extended height if option 47.3" (1202 mm) high load backrest is required.

English conversions are approximations. Metric conversion should be done to find true values.

Page 7

WS 2300 Series

Technical Information

Standard Equipment

1. Four-point suspension with

centrally located handle

2. Traction speed control

(MOSFET)

3. Variable traction speed

forward and reverse

4. One-speed lift, two-speed

lower

5. Electric brake

6. Brake override

7. Key switch

8. Horn

9. Compound drive and

lift motor

10. Emergency power

disconnect

11. Battery connector SB-175

12. Reversing button

13. Hour meter

14. Vulkollan tires

Optional Equipment

1. Battery compartment rollers

2. Battery discharge indicator

with low battery lift interrupt

and hour meter

3.

Freezer corrosion conditioning,

continuous -30° C / -22° F,

intermittent - 40° C / - 40° F

4. Load backrest

5. Maintenance-free battery

pack

6. Sideshift

Electrical System

24-volt electrical system

incorporating:

1. Transistor “MOSFET”

controller, microprocessor

controlled with on-board

service diagnostic capability.

This transistor controller

provides many benefits

such as maximum energy

efficiency, reduced

maintenance and infinite

speed control capability.

Fault Monitoring System

Through a fault flash code

signaled by an LED, 17

detectable faults can be

recognized. Using an optional

hand set, faults can be displayed

digitally. Controller settings are

programmable. Functional

tests of components are also

possible. Incorporates storage

register for fault history that can

be interrogated by service

personnel.

2. Heavy-duty drive and lift

motors provide high reliability

and efficiency.

3. Electric panel with swing-out

feature, allows good accessibility and serviceability to

the distribution panel and all

other electrical components.

4. Emergency disconnect is

easily accessible from all

operating positions.

5. Solid-state switching ensures

high component reliability.

6. Control and power circuits

are fused. Distribution panel

and controller are shortcircuit protected.

7. All wiring is color coded.

Hydraulic System

1. Heavy-duty compound

motor and gear pump

selected for optimum lift

performance and low noise.

2. Control block houses

proportional pressure

compensated flow control

valve, check valve, relief

valve and direction control

valve to select lower

function. The proportional

valve ensures smooth

load handling. Single speed

lift and two speed lowering

is available to the operator.

3. Cylinder rods are hard-plated

chrome with polyurethane

seals.

4. Relief valve tuned to capacity

protects all components in

the hydraulic system.

Drive Unit/Brake

Heavy-duty gear box with

helical spur input gear for low

noise emission. Drive unit is

equipped with an electromagnetic brake, spring applied,

electrically released. The brake

is activated by the control

handle position.

Frame/Pivoting Carriage

Frame and Articulated Truck

Suspension system (ATS) are

of a rugged design ensuring

minimum deflections during

operation. Modular pivoting

carriage design ensures excellent

traction, optimum truck stability

and minimum steering effort in

all load conditions. Easy serviceability of all components in

power unit and simple adjustment to compensate for tire

wear is possible. Single swingout door design allows easy

access to all components.

Mast

High visibility two- and threestage mast design features

nested I-beams and canted

rollers. Lift cylinders are positioned in outer I-beam profile

for best visibility through mast

and clear view onto fork tips

during load handling. Standard

equipment includes full-free lift

for two- and three-stage mast.

Mast cushioning between

stages ensures smooth

operation. Heavy-duty mast

and chain rollers are sealed

and lubricated for life. Easy

access to carriage rollers.

Fork Carriage

WS 2300 Series features a

standard 32" wide ITA Class II

fork carriage. Forks are

adjustable from 10" to 31".

Standard fork lengths are

30", 36", 42" 45" and 48".

Operator Controls

The robust X10™ control handle

is designed to allow for an

optimum turning radius with low

steer effort. All control buttons

can be operated with either

hand and can be accessed

with minimum hand and wrist

movement. The horn buttons

are integrated in the hand grips.

An ergonomic forward/reverse

thumb wheel allows for precise

maneuvering. Depending on

conditions and operator

experience, maximum travel

speed can be reduced via the

rabbit/turtle switch. Exclusive

brake override allows slow

speed travel with the handle

near vertical. This feature

improves maneuverability in

tight areas.

Battery

Removable side panels and top

hinged cover allow easy access

to battery, as well as battery

change in three directions,

either side or top lift out.

Compartment rollers are fitted

as an option.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with audible

travel alarms and flashing lights

include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and

the conditions of the operating

area. Crown products and

specifications are subject to

change without notice.

Page 8

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown, the Crown logo, the color beige, the

Momentum symbol and The X10 Handle are

trademarks of Crown Equipment Corporation.

Copyright 2004-2007 Crown Equipment Corporation

SF14404 Rev. 5/07

Printed in U.S.A.

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Tel 419-629-2311

Fax 419-629-3796

crown.com

You can count on Crown to build lift trucks

designed for safe operation, but that’s

only part of the safety equation. Crown

encourages safe operating practices through

ongoing operator training, safety-focused

supervision, maintenance and a safe working

environment. Go to crown.com and view our

safety section to learn more.

C

Loading...

Loading...