Page 1

C

Specifications

Series TS

Turret

Sideloader

Series

TS

Page 2

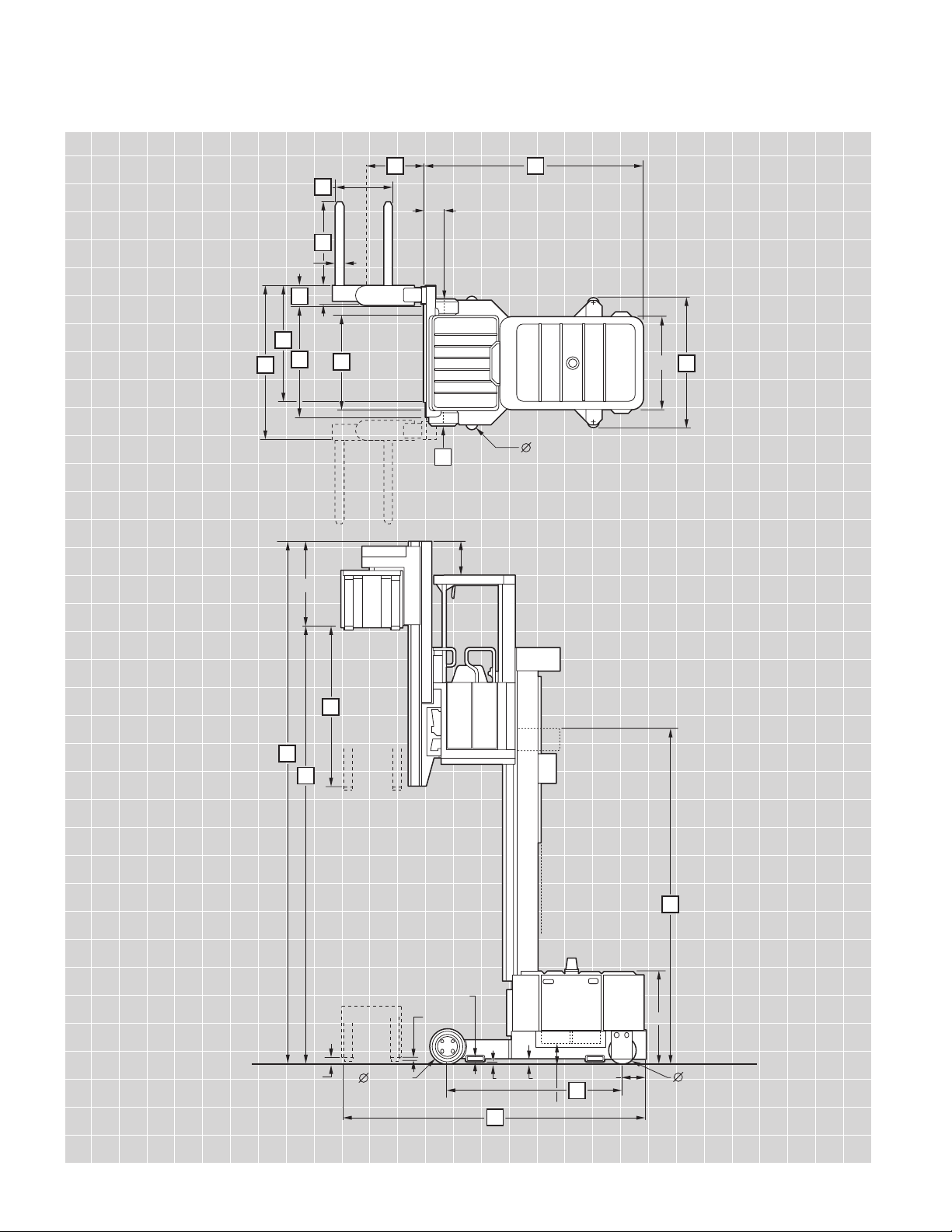

6"x 2"

48"

9"

4"

9.5"

42"

45.8"

3.6" Top of Guide

wheel to floor

2" Fork

3" 15"X 8"

2"

9.9" Battery to floor

11.6"

13"X 5.5"

17

16

16

18

19

21

20 23

25

14

12"

12

10

22

24

11

15

13

0.8"

C

Series TS

Turret

Sideloader

Page 3

Series TS

Specifications

1 Manufacturer Crown Equipment Corporation

2 Model 40TS

3 Load Capacity* 24" Load Center lb 4000

4 Power Electric 72-Volt (2 x 36 Volt)

5 Operator Type Sitdown Rider Turret Sideloader

6 Tire Type Load/Drive Poly/Poly

7 Wheels (x = driven) Load/Drive 2/2x

8 Truck Weight Less Battery lb 11,000 - 14,200

10 Lift Height Lift Height See Chart

11 Collapsed Height Overall See Chart

12 Extended Height Overall See Chart

13 Auxiliary Lift in 81

14 Load Wheel Overall Width (OAW) Available in 1" increments in 48 to 72

15 Operator Compartment Width With Any Carriage Width in 48

16 Carriage and Cab Width in 48 58

17 Clear Aisle - in 1" increments Carriage and Total Sideshift in 56 - 69 66 - 79

18 Sideshift Per Side Available in .5" increments in 4 to 10.5

19 Forks L x W x T in 30, 36, 37, 42, 45, 48, x 4 x 2

20 Load Handler Length Standard in 28.3

Available in 3" increments in From 30.3 to 54.3

21 Outside Fork Spread

For Load Handler from 28.3 to 54.3

in 15.3 to 29.3

For Load Handler from 36.3 to 54.3

in 15.3 to 43.3

For Load Handler from 48.3 to 54.3

in 15.3 to 53.8

22

Overall Length with 28.3" Load Handler

C Battery Compartment in 154

D Battery Compartment in 157.5

23 Headlength C Battery Compartment in 109.9

D Battery Compartment in 113.4

24 Wheelbase C Battery Compartment in 88.8

D Battery Compartment in 92.3

25 Width across Guide Roller Available in .25" increments in 1.25 - 8.75 greater than item 14

30 Speed Travel mph See Technical Information

31 Speed Lift Primary Mast Empty/Loaded fpm 80/64

Auxiliary Mast Empty/Loaded fpm 70/55

32 Speed Lower Primary Mast Empty/Loaded fpm 80/80

Auxiliary Mast Empty/Loaded fpm 40/70

33 Pivot Speed 180 degree rotation 7 seconds

34 Traverse Speed Inches per second 8

40 Battery (Two Required) C Compartment D Compartment

Max Battery Size in 15.88 x 38.38 x 31 high 18 x 38.69 x 31 high

Min Weight/Max Amp lb/Ah 1770/930 2085/1085

Number of Plates/Total Kwh 13/64.4 15/75.2

50 Brakes Number Load/Drive 2/2

Load Wheel Brakes Dual Disc

Drive Unit Brakes Dual Drum

General Info

Dimensions

Battery

*Contact factory. Capacity may be subject to derating.

Derating is dependent upon a combination of: load center, load wheel spread, 180° traverse/sideshift, battery compartment size,

lift height, travel speed and height of Auxiliary Mast.

Performance

Page 4

Series TS

Specifications

10 Lift Height in 219 231 243 255 267 279 291 303 315 327 339 351 363

Free Lift (TN)* in 84 84 84 84 84 84 84 84 84 84 84 84 84

Free Lift (TF)** in 83 89 95 101 107 113 119 125 131 137 143 149 155

11 Collapsed Height in 125 131 137 143 149 155 161 167 173 179 185 191 197

12 Extended Height in 261 273 285 297 309 321 333 345 357 369 381 393 405

Mast

10 Lift Height in 375 387 399 411 423 435 447 459 471 483 495 507

Free Lift (TN)* in 84 84 84 84 84 84 84 84 84 84 84 84

Free Lift (TF)** in 161 167 173 179 185 191 197 203 209 215 221 227

11 Collapsed Height in 203 209 215 221 227 233 239 245 251 257 263 269

12 Extended Height in 417 429 441 453 465 477 489 501 513 525 537 549

Mast

* Auxiliary lift only.

** Including auxiliary lift.

Note: Battery removal from left side.

Standard Equipment

1. 72-volt fused electrical system.

2. SCR controlled lift and drive

motors.

3. Electric power steering.

4. Microprocessor controlled.

5. 350-amp battery connector.

6. Emergency power disconnect.

7. Color-coded wiring.

8. Chain slack sensors.

9. Hour meters independently

recording key on, traction,

lift, steer and accessories.

10. Start-up time and run time

diagnostics.

11. Diagnostic history with

optional service terminal.

12. Battery discharge indicator

with lift interrupt.

13. Maximum travel speed

programmed to meet the

application’s specs.

14. Gradual reduction in maximum travel speed as primary

lift is increased.

15. Swivel seat with height

adjustment.

16. Hinged cab door.

17. Key switch.

18. Horn.

19. Two-speed fan.

20. Cab light.

21. Work lights.

22. Rear view mirror.

23. Flashing light.

24. Storage pockets.

25. Infinite hydraulic control of

raise/lower, traverse and pivot.

26. Manual lowering valve

located in power unit.

27. Solid four-point suspension.

28. Rigid tubular mast.

29. Third mast chain.

30. 2-3/4" diameter battery

rollers.

31. Dual drive units.

32. Four-wheel braking automatically switched to two-wheel

at slower speeds.

Optional Equipment

1. Wire guidance.

2. Rail guidance.

3. End of aisle control system.

4. Extended load handler

lengths and carriage widths.

5. Extended Auxiliary Lifting

heights.

6. Programmable fork height

limits with overrides.

7. Non-marking tires.

8. Power source and mounting

brackets for CRT.

9. Fire extinguisher.

10. Cold conditioning.

11. Additional work lights.

12. Service Terminal.

Series TS

Technical Information

Page 5

Series TS

Technical Information

Travel Speeds

Maximum travel speed on guidance is: 6 mph (528 fpm) to 156"

fork elevation. Gradual speed

reduction to 1 mph at 372", 1

mph above 372" fork elevation.

Travel speed is limited to 1 mph

under any of the following

conditions:

1. Forks are elevated above

12" on the auxiliary mast.

2. Forks are not at full pivot.

3. Load handler traversesideshift are not at clear-aisle

travel position.

Travel speed is disabled under

any of the following conditions:

1. Forks are not at full pivot and

above 240".

2. Not on guidance and above

240".

3. Not on guidance, forks not at

clear-aisle travel position above

93" and steering turned greater

than 10°.

4. The TN travel speed is disabled, whenever out of guided

aisle and primary lift is raised,

unless otherwise specified.

Travel speeds not on guidance

are less than those on guidance

at elevated fork heights.

Wheels and Tires

Large, high-load capacity polyurethane press-on tires. Load

wheels - 15" diameter x 8" wide.

Drive Wheels - 13" diameter x

5.5" wide. Guide Wheels - 6" dia-

meter x 2" wide molded-on hub,

non-press-on.

Suspension

Four-point solid suspension with

long wheel base and wide spread

of load and drive wheels improve

truck capacity, reduce effect of

uneven floors, and improve floor

load distribution.

Forks--Fork Carriage--Turret

Carriage

Forks are incrementally adjustable.

Fork carriage pivots through 180º

permitting pickup and deposit

from either side or front. Cylinders

are equipped with hydraulic cushion stops to automatically reduce

speed at end of pivot. Cross-over

relief valves reduce excess pressure should forks be force-pivoted.

Pivot lock engages at full-rotated

position to prevent drift.

lights, palm switch light, open cab

door warning light, master servicerequired light, service calibration

light, wire guidance field strength

light (optional), wire guidance

switch and status lights (optional),

parking brake switch with status

light, fork height limit override

button with light, and discharge

indicator with low voltage lift interrupt to reduce truck and battery

maintenance.

Controls permitting emergency

fork movement are located below

the hinged arm rest pad. Horn

button, primary power emergency

disconnect and power key are

provided. All controls are located

convenient to the operator.

Storage pockets for work sheets

are provided. A two speed fan,

cab light and work lights front and

back, are located in the overhead

consoles.

Primary Mast

Elevated load sway due to mast

twisting, plus forward and side

bowing are minimized through

the use of closed cross-section

mast construction. Rolled “I”

beams continuously welded to a

flat and a formed plate create a

full length, deep cross-section

mast capable of resisting front

and side loading equally well. Lift

cylinders, hoses, cables and

chains within the mast are readily

accessible for service. Built-in

sensors detect slack chain and

shut down primary lower, auxiliary

lower, pivot and traverse functions.

Drive Units-Steering

Steerable dual drive units with

fixed mounted traction motors

minimize wear and maintenance

on electrical cables. Full electrical

power steering uses servomotors

for turning the drive wheels. Drive

wheels are automatically centered

on trucks equipped with aisleguide rollers.

Brakes

Two force levels of mechanical

braking provide smooth stopping.

This is achieved by the truck

automatically switching from four

wheel to two wheel braking at

slower travel speeds. Braking can

also be accomplished by proportional plugging which permits the

operator to control rate of deceleration when a greater stopping

distance is acceptable.

Electrical

Heavy duty 72 volt electrical

power system reduces current

requirements for improved efficiency. SCR controlled lift and

Auxiliary Mast

Turret carriage with forks can be

elevated on the auxiliary mast to

permit stacking close to the ceiling. Operator can view the load

from the underside at full auxiliary

lift to aid load placement. Lift

cylinder, hydraulic hoses and

electrical cables are protected

within the profile of the structure,

or behind removable covers. Vertical side alignment of the mast is

maintained by gear racks and

pinions. Lowering of auxiliary and

primary lift system will stop if

chains become slack.

Traverse and Sideshift

Traverse movement of the auxiliary mast and side movement of

the sideshift carriage are automatically sequenced, requiring

only one operator control. Full

sideshift travel with built-in limits

is brought to a smooth stop by

hydraulic cushions. Withdrawal of

forks from the side-extended position automatically stops at the

travel position.

Operator Cab and Controls

Adjustable operator’s seat pivots

35° from a full side position toward

a forward position to provide visibility to the front, rear or either side.

Lever controls permit all load

handling functions to be infinitely

controlled. Left hand control is

used for primary and auxiliary

raise and lower. Right hand pivot

and traverse controls can be

simultaneously operated for

pivoting the load in a minimum

amount of space. Movement of

the sideshift carriage is automatically sequenced to the traverse

control. Integrated palm-pressure

buttons in the control knobs

require the operator to keep his

hands within the compartment

during any load handling function.

Programmable fork height limits

are available for raise and lower.

Both lower and one raise limit can

be overridden by the operator.

Steer wheel position indicator is

located next to the steering arm.

Forward and reverse travel is controlled by a directional selector

and accelerator pedal. The truck

can be stopped by activation of

foot-operated brake, proportional

plugging, parking brake, emergency disconnect or power key.

A control and feed back display

include indicator lights for forward

and reverse travel direction, load

handler clear aisle travel position

drive motors. Each controller

provides current limiting motor

protection in addition to the fuses.

Two on-board micro-computers

are integrated into the truck to

provide maximum load handling

through-put and smooth truck

performance. Serial data link

communications between the

elevated cab and the lower power

unit minimizes the number of

electrical conductors through the

mast. Long life solid state encoders and LVDT are used in

place of potentiometers. Travel

speed is sensed and regulated to

precise rate. Height sensor provides input for a programmed

gradual reduction in maximum

allowable travel speed as the primary lift is elevated. Maximum lift

and lower speeds are reduced

near full lift and lower to provide a

soft stop. On-board software includes truck calibration, system

diagnostics and trouble isolation

capabilities accessible by an

optional plug-in terminal.

Hydraulics

Maximum lowering speed is limited by pressure-compensating

flow controls and velocity fuses.

Integrated hydraulic cylinder

cushions bottom stop when lowering. All lift cylinder rams are

plated. Primary mast emergency

lowering valve and load handler

emergency power switch are

located in the power unit.

Other Options

1. Audible Travel Alarm.

2. Contact factory for additional

options.

Safety considerations and dangers

associated with audible travel

alarms include:

• Multiple alarms can cause

confusion.

• Workers ignore the alarms

after day-in and day-out

exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Dimensions and performance

data given may vary due to manufacturing tolerances. Performance

is based on an average size vehicle

and is affected by weight, condition of truck, how it is equipped

and the conditions of the operating

area. Crown products and specifications are subject to change

without notice.

Page 6

SF12182 Rev. 4/03

The Momentum symbols are a trademark of

Crown Equipment Corporation.

C

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Tel 419-629-2311

Fax 419-629-3796

crown.com

Because Crown is continually improving its products,

specifications are subject to change without notice.

Copyright 1994 Crown Equipment Corporation

Printed in U.S.A.

Loading...

Loading...